Device and method for cleaning middle shell cavity of automotive turbine supercharger

A technology for turbochargers and cleaning devices, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as bearing and shaft damage, low efficiency, and large fluctuations in dynamic values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

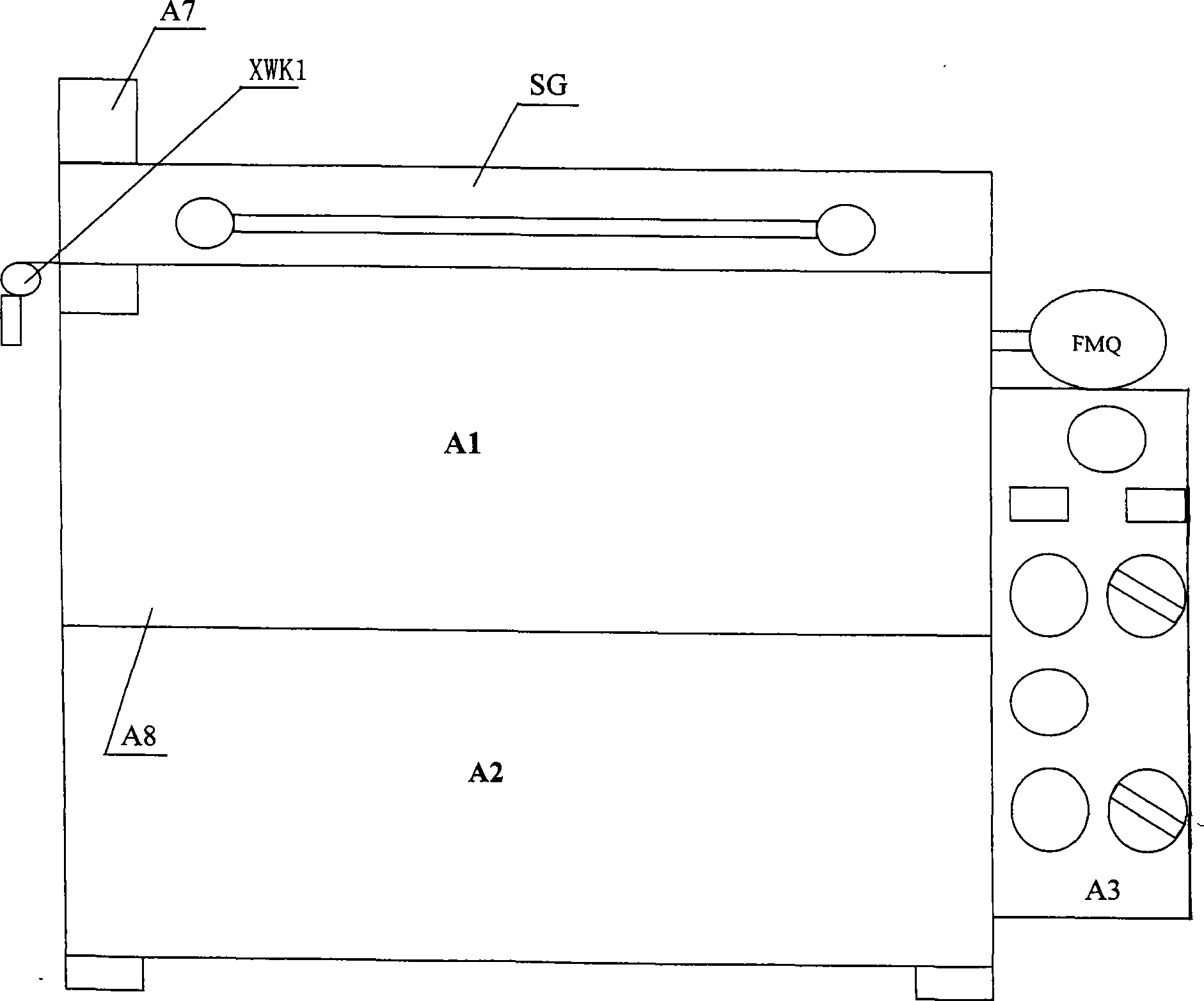

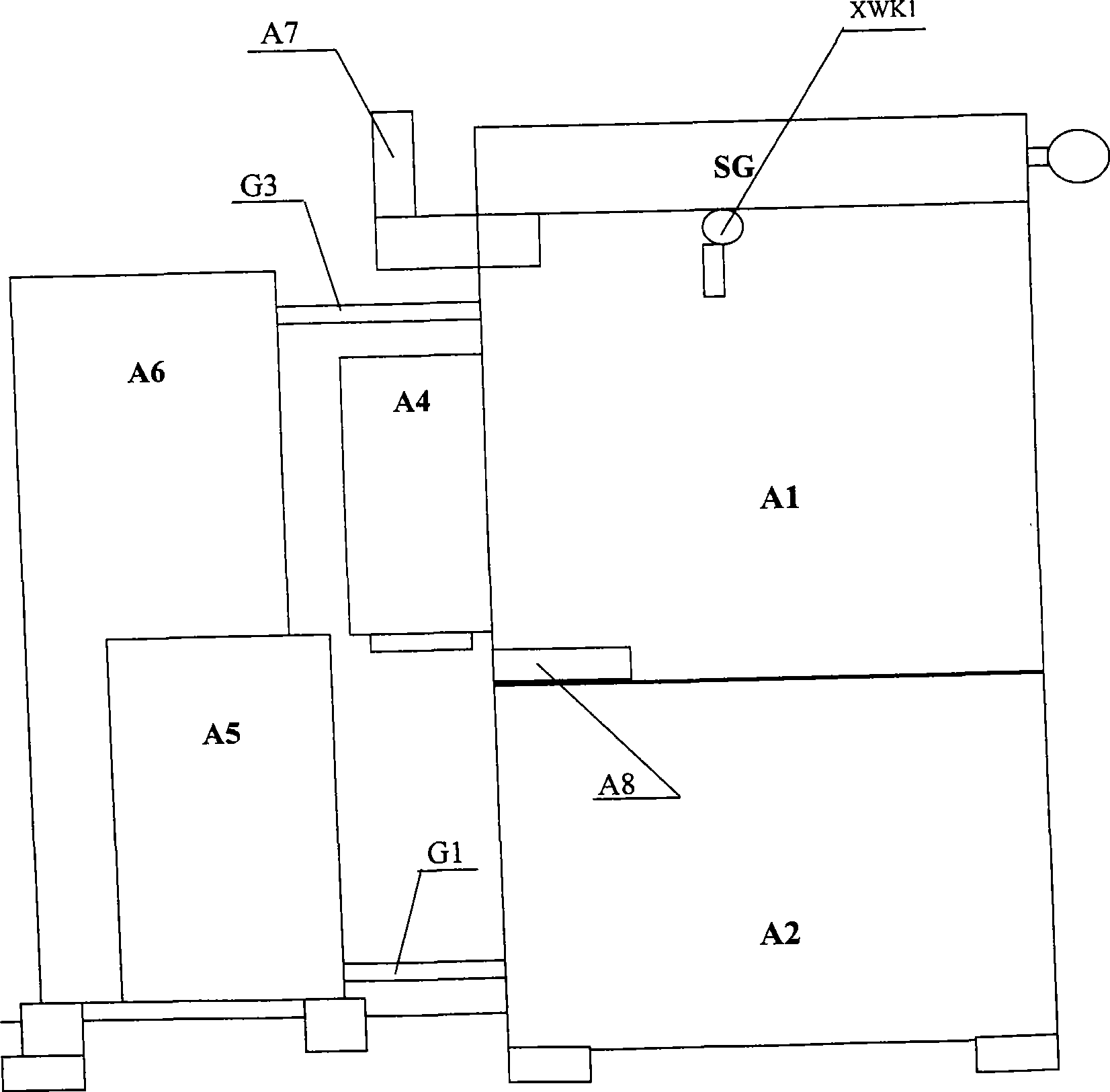

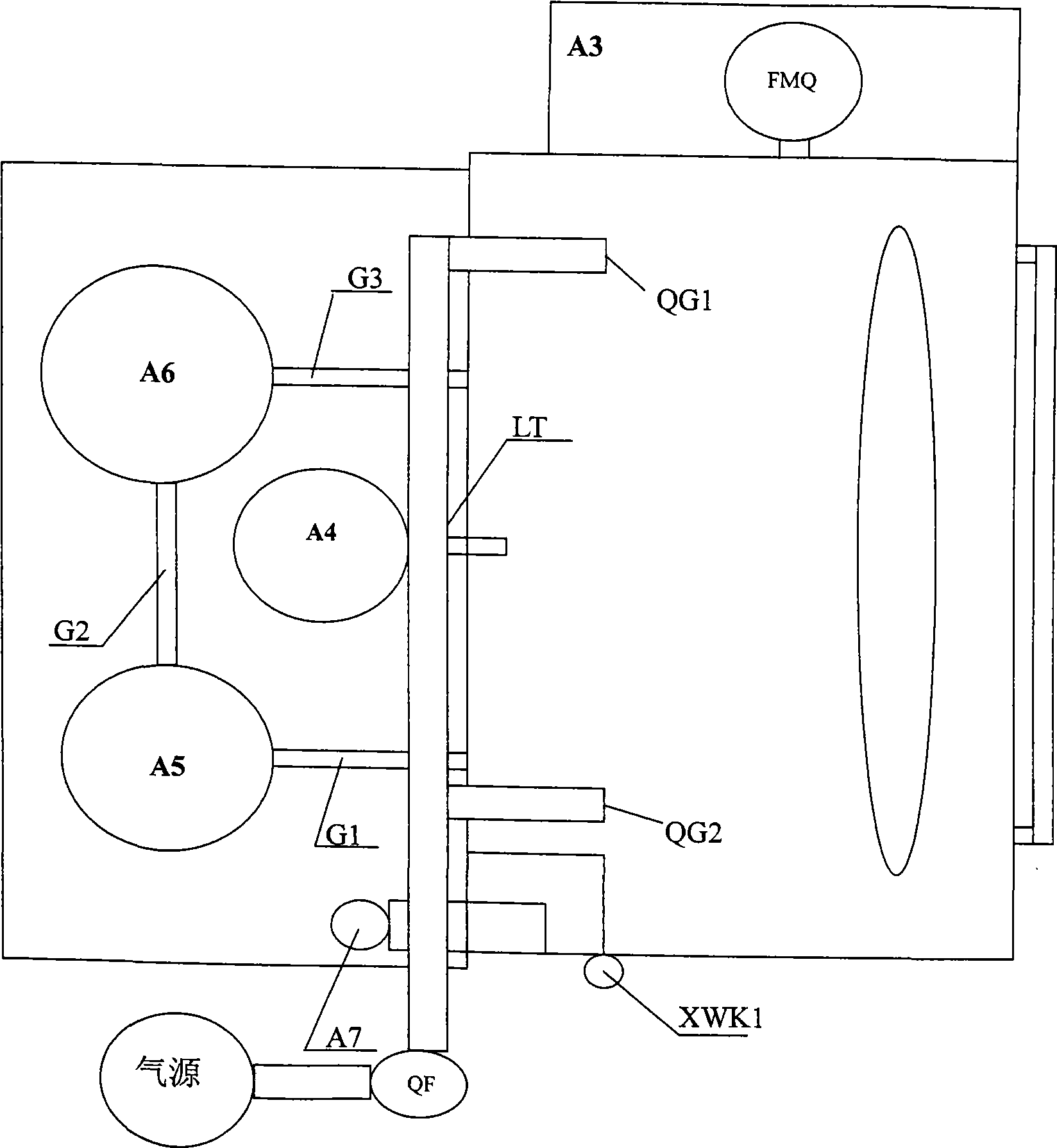

[0023] Such as Figure 1 to Figure 3 As shown, it is a kind of automobile turbocharger intermediate housing cavity cleaning device provided by the present invention, the exhaust port A7 is arranged on the side of the cleaning chamber A1, the end of the exhaust port A7 is placed outside the cleaning chamber A1, and the cleaning The upper end of the chamber A1 is the chamber cover SG, the left and right pressure springs are connected between the cleaning chamber A1 and the chamber cover SG, a limit switch XWK1 is set on the left side, the automatic mode control box A3 is parallel to the upper right side of the cleaning chamber A1, a vertical multi-stage high-pressure pump A5 is placed on the left rear side of the cleaning room A1, the rotating motor A4 is installed at the rear center of the cleaning room A1, the filter A6 is installed on the right rear side of the cleaning room A1, and the rotary disc motor A4 is connected to the mesh turntable WZP in the cleaning room through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com