Patents

Literature

78results about How to "Control cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

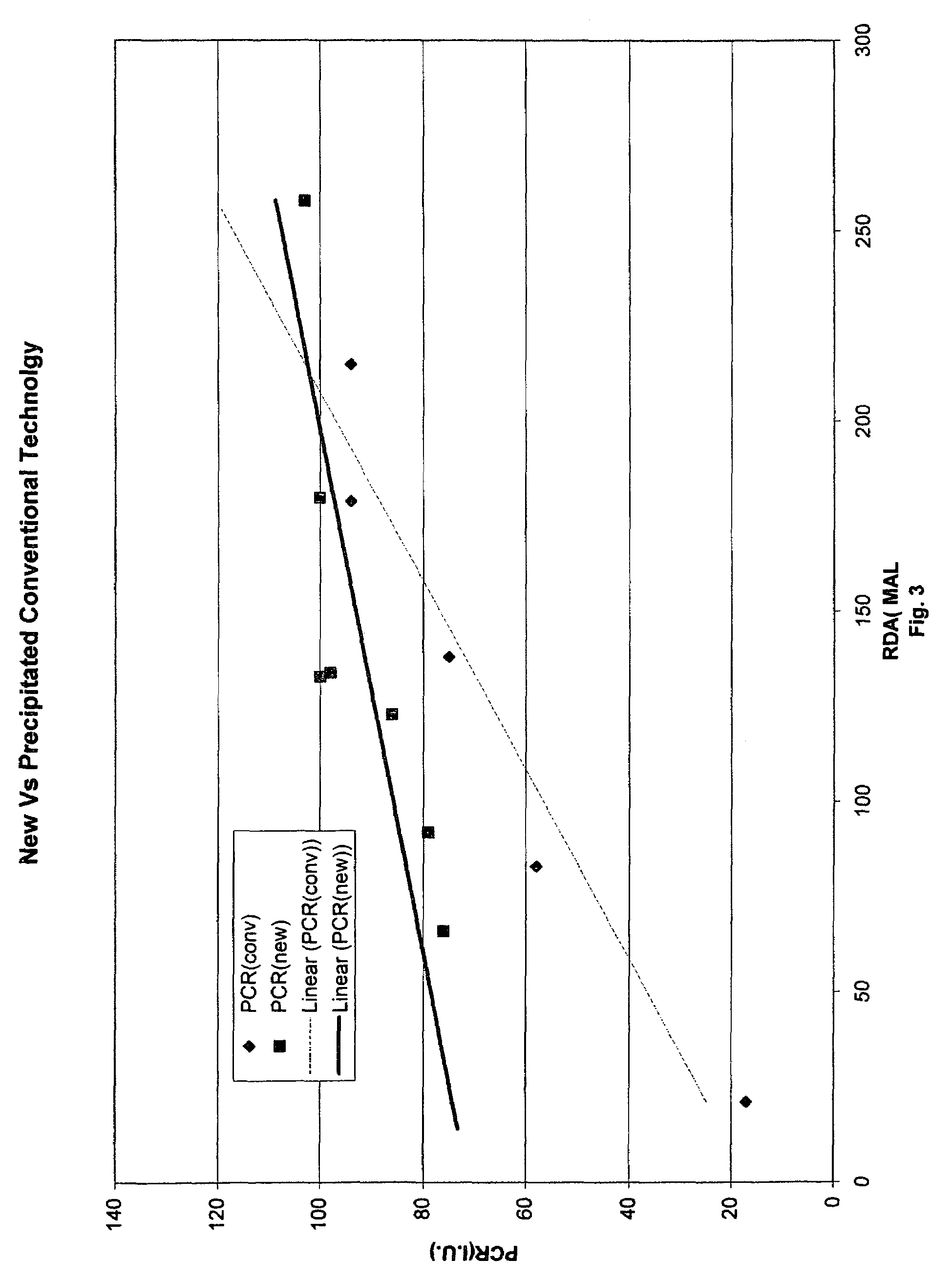

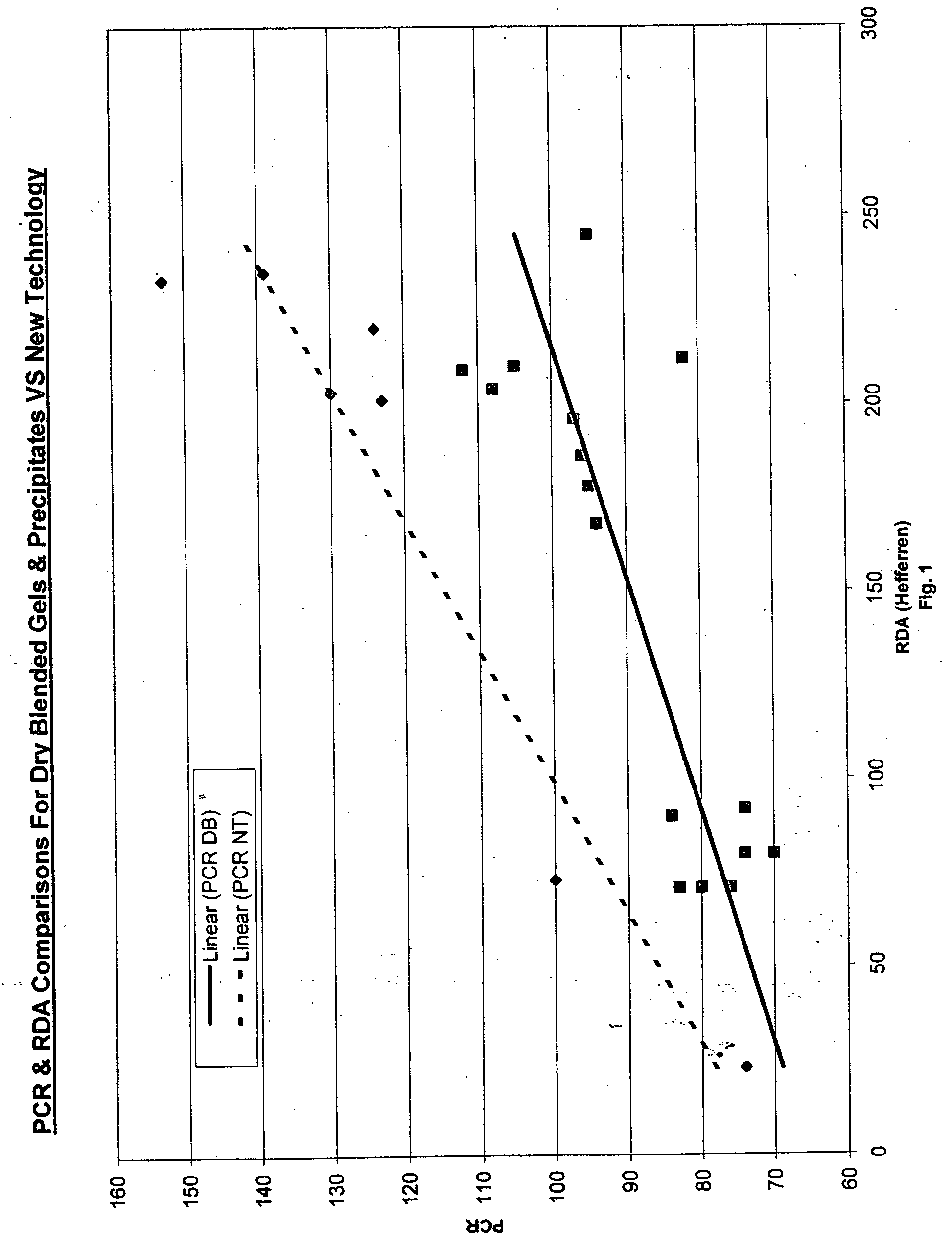

High-cleaning silica materials made via product morphology control and dentifrice containing such

InactiveUS20060110307A1Excellent thickening propertyDesirable abrasivePigmenting treatmentCosmetic preparationsClean teethViscosity

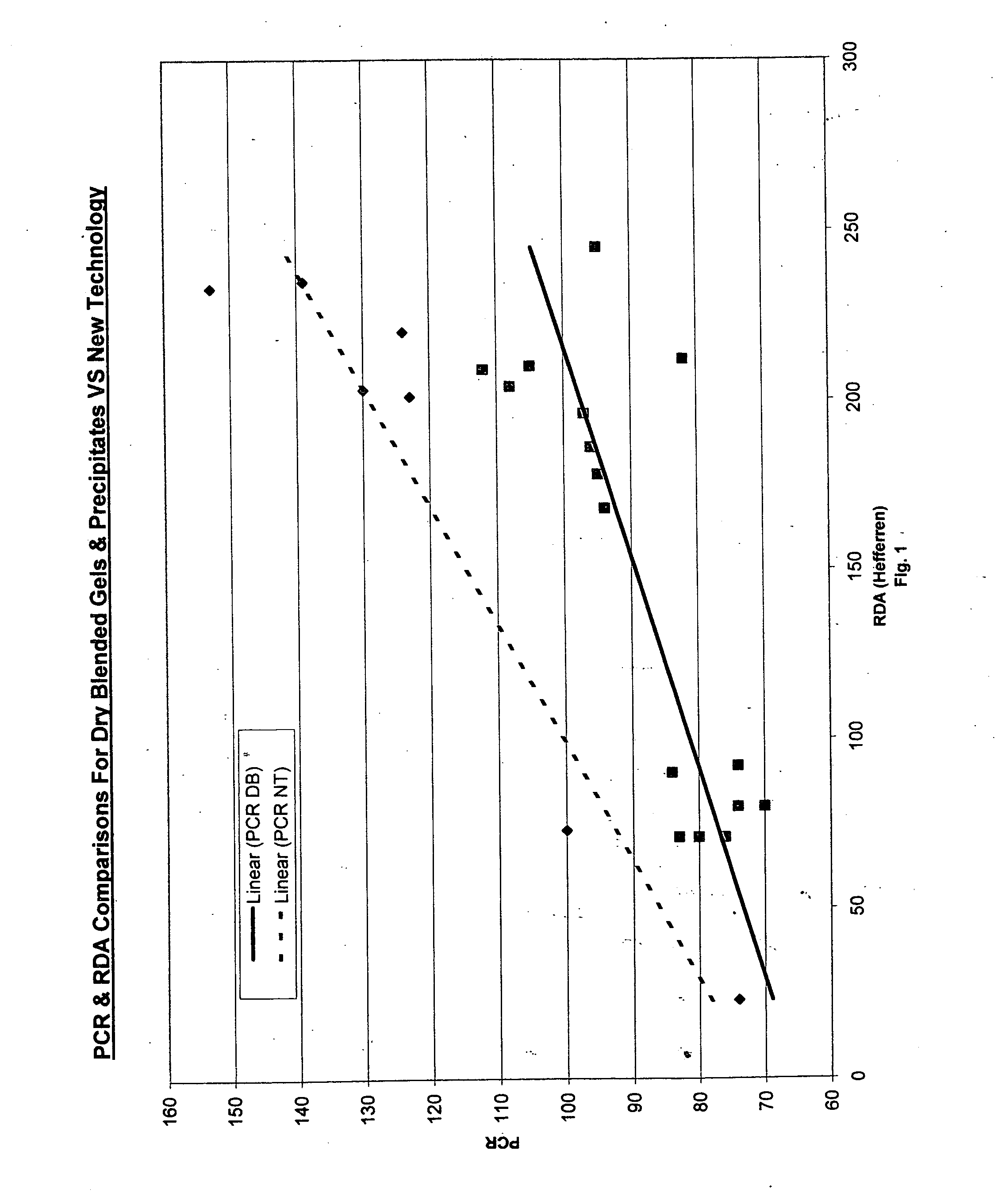

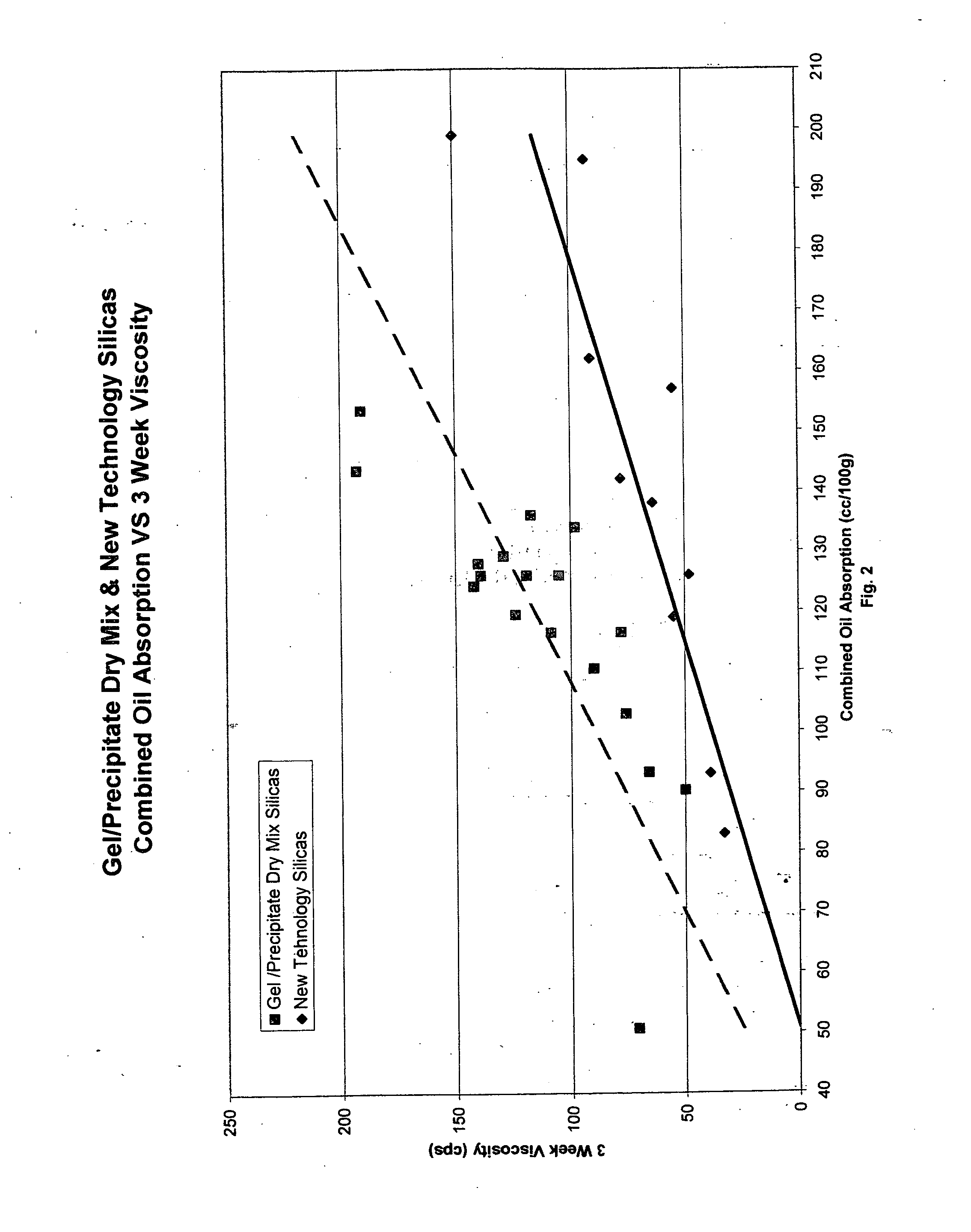

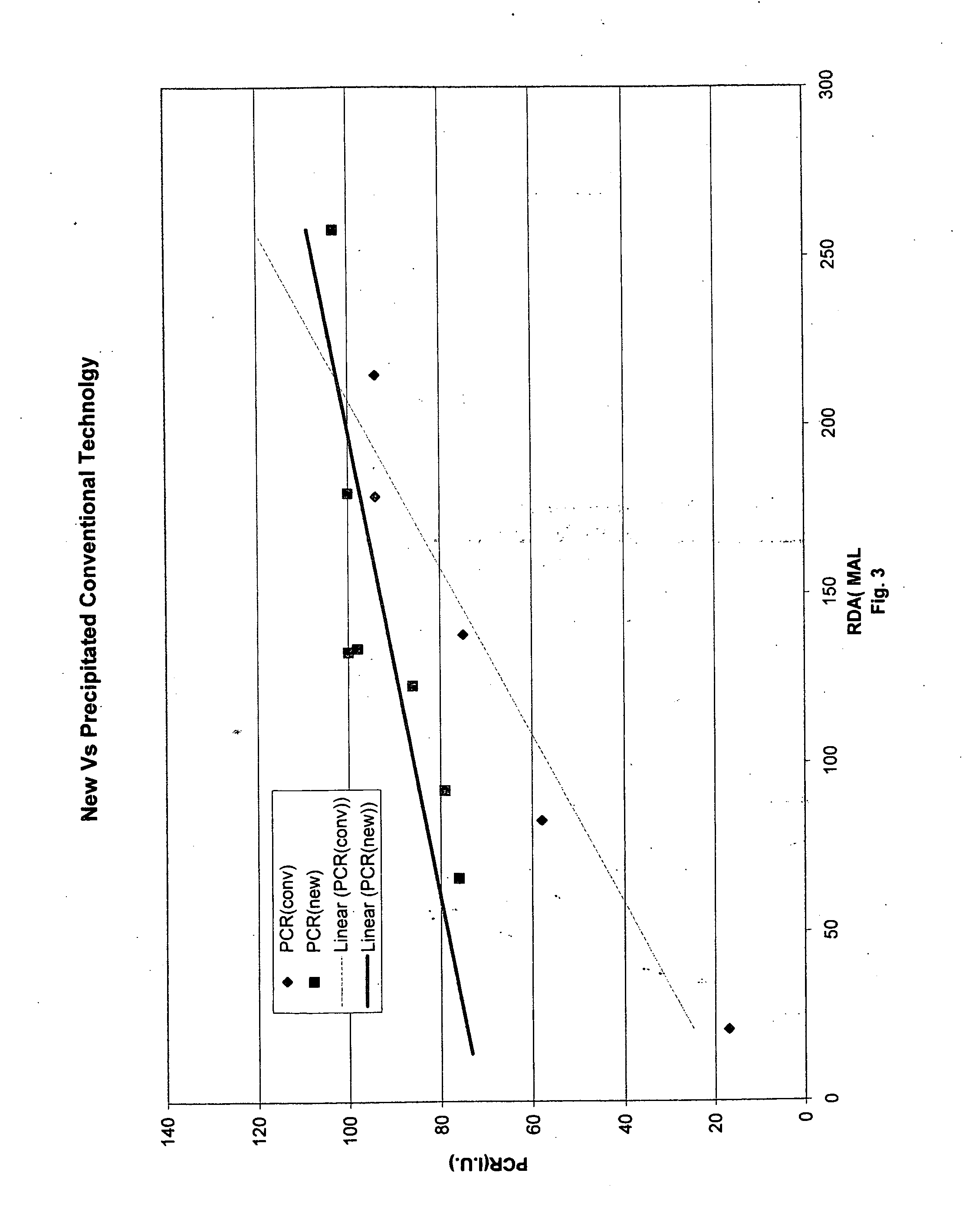

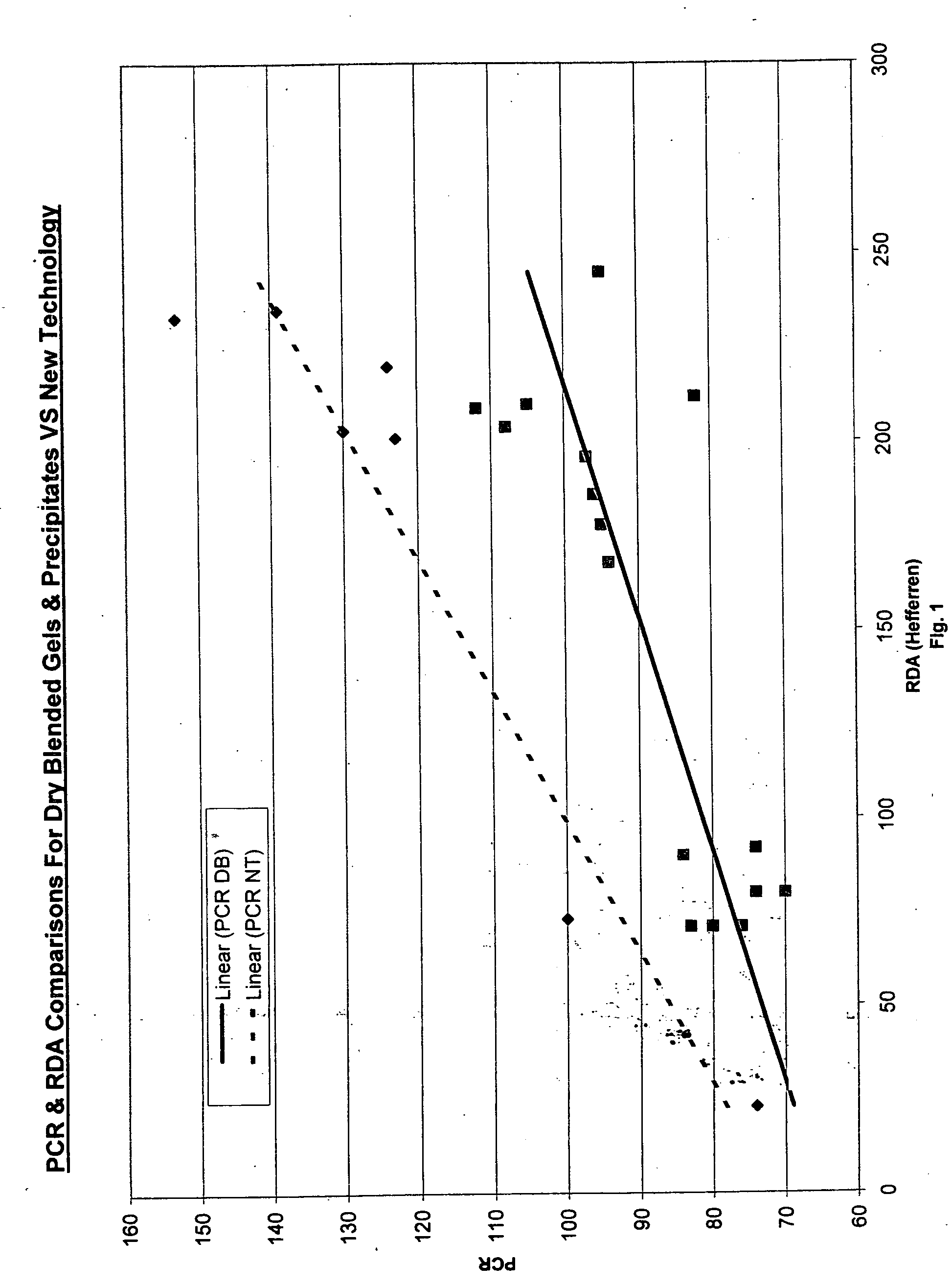

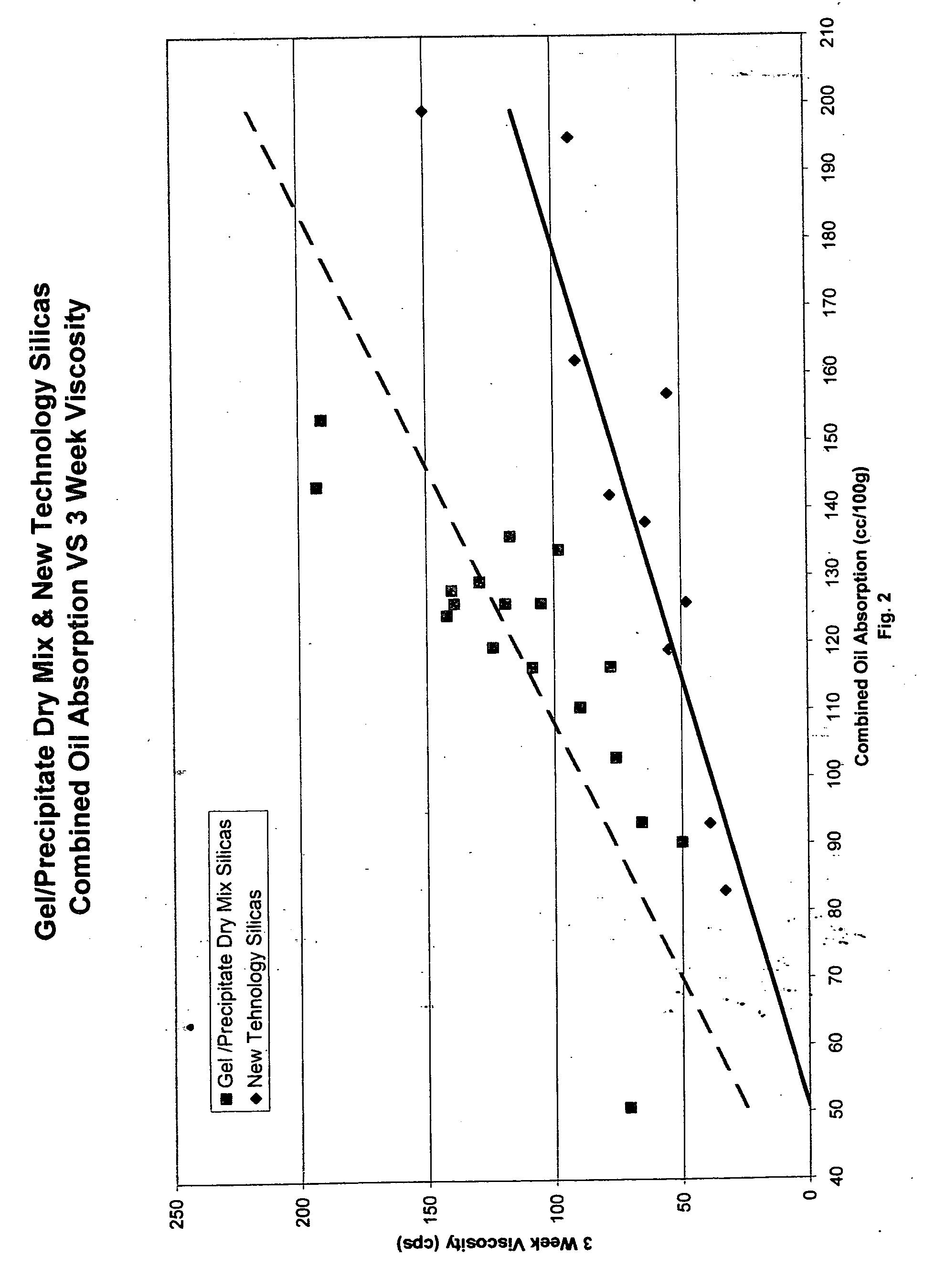

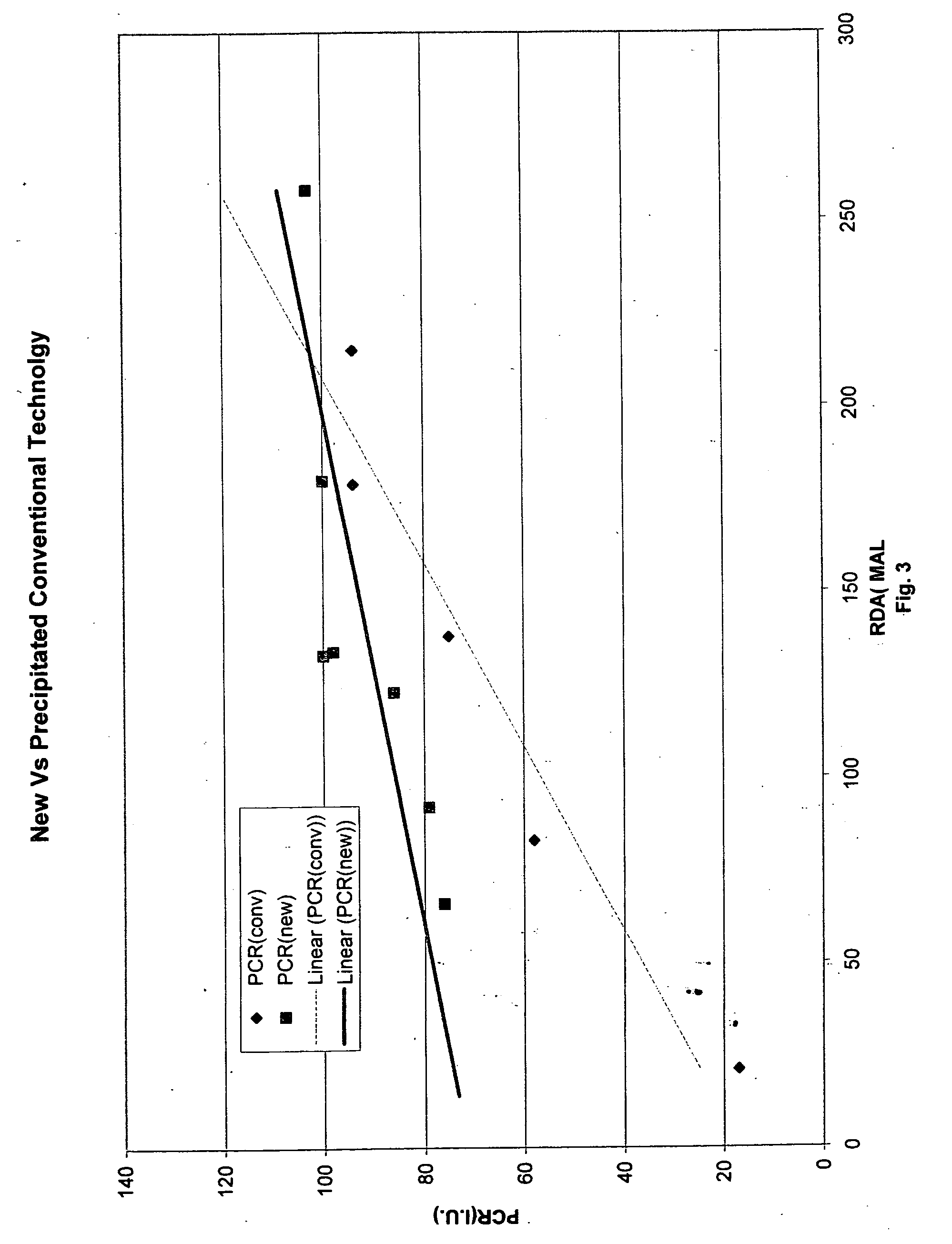

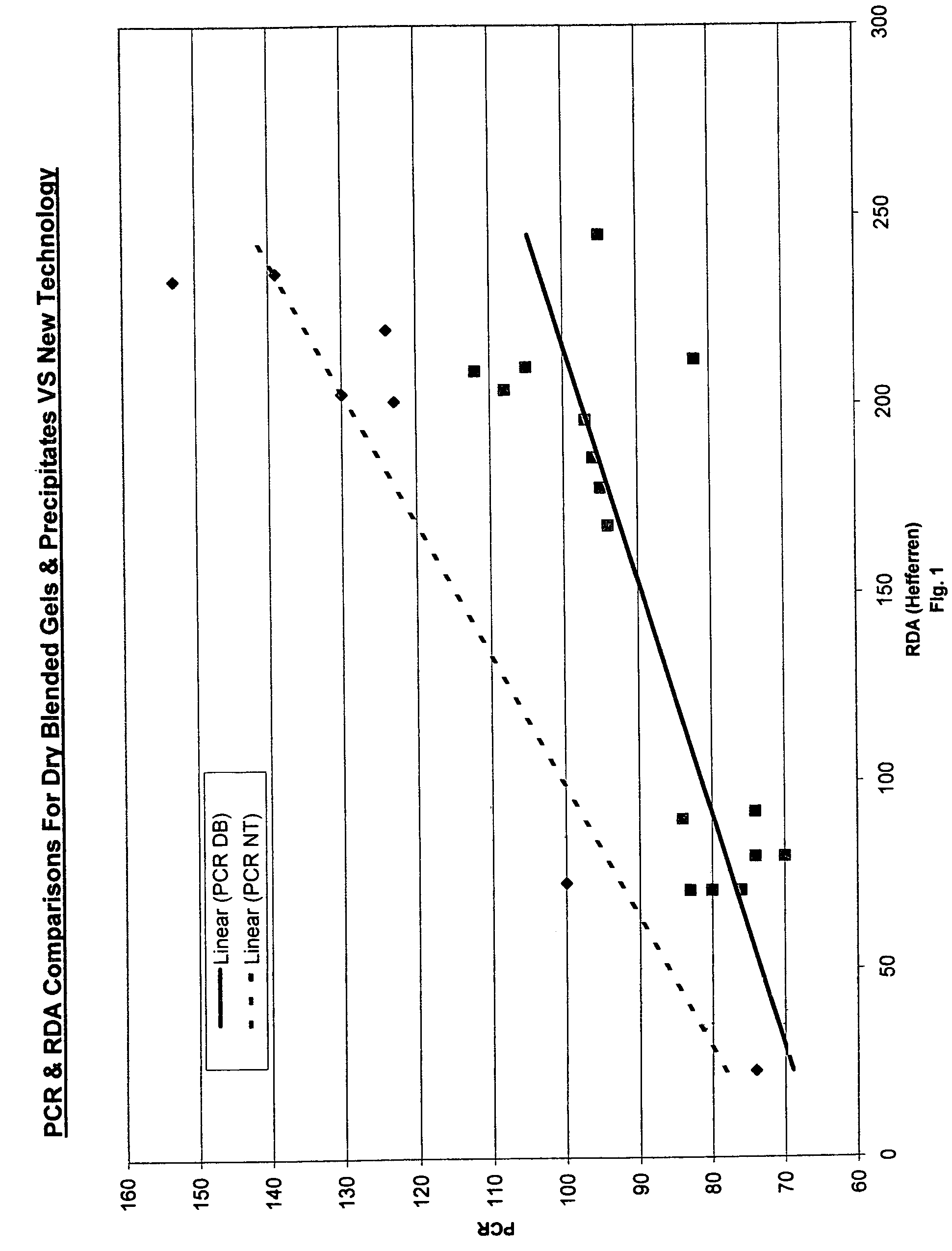

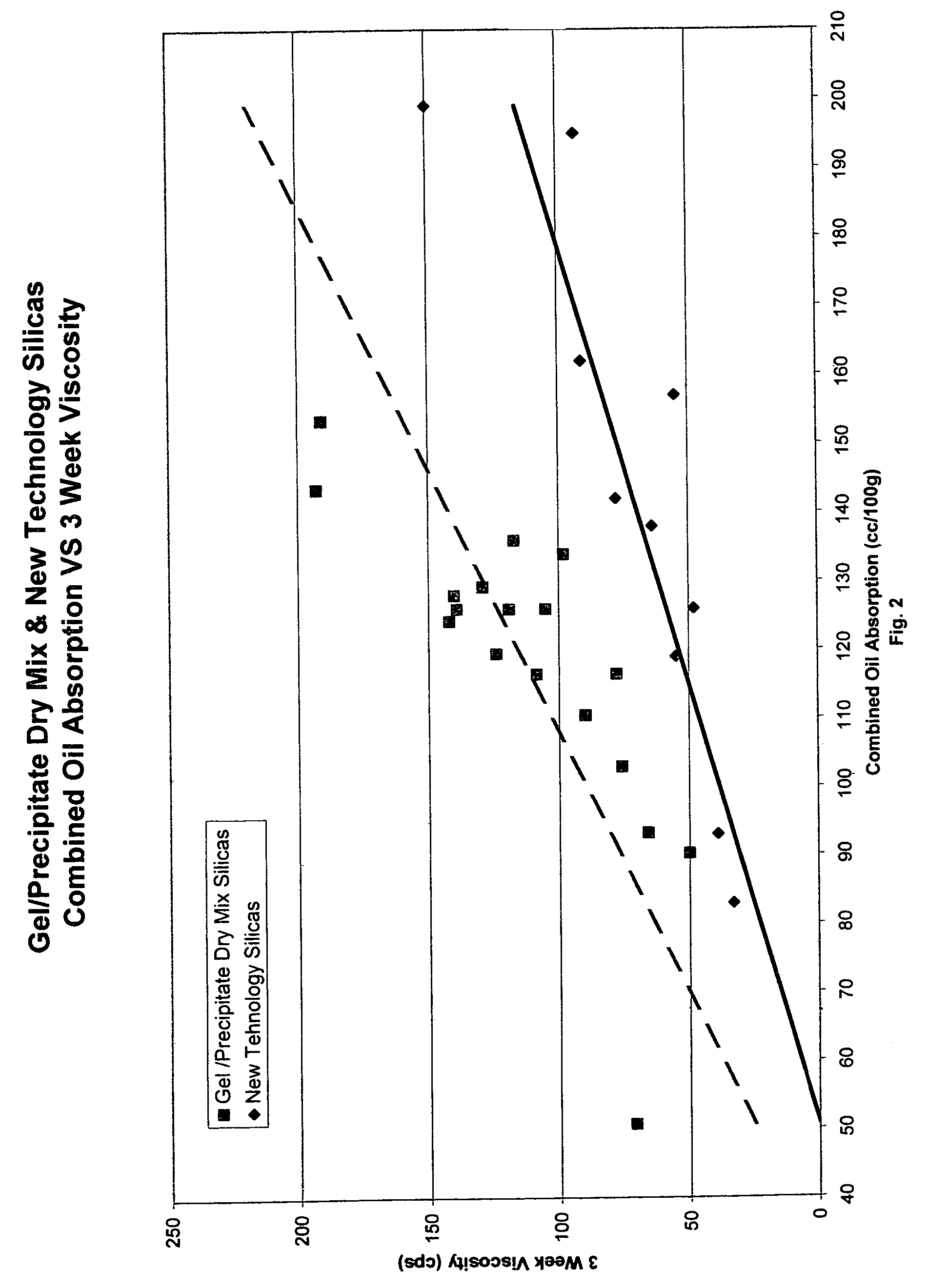

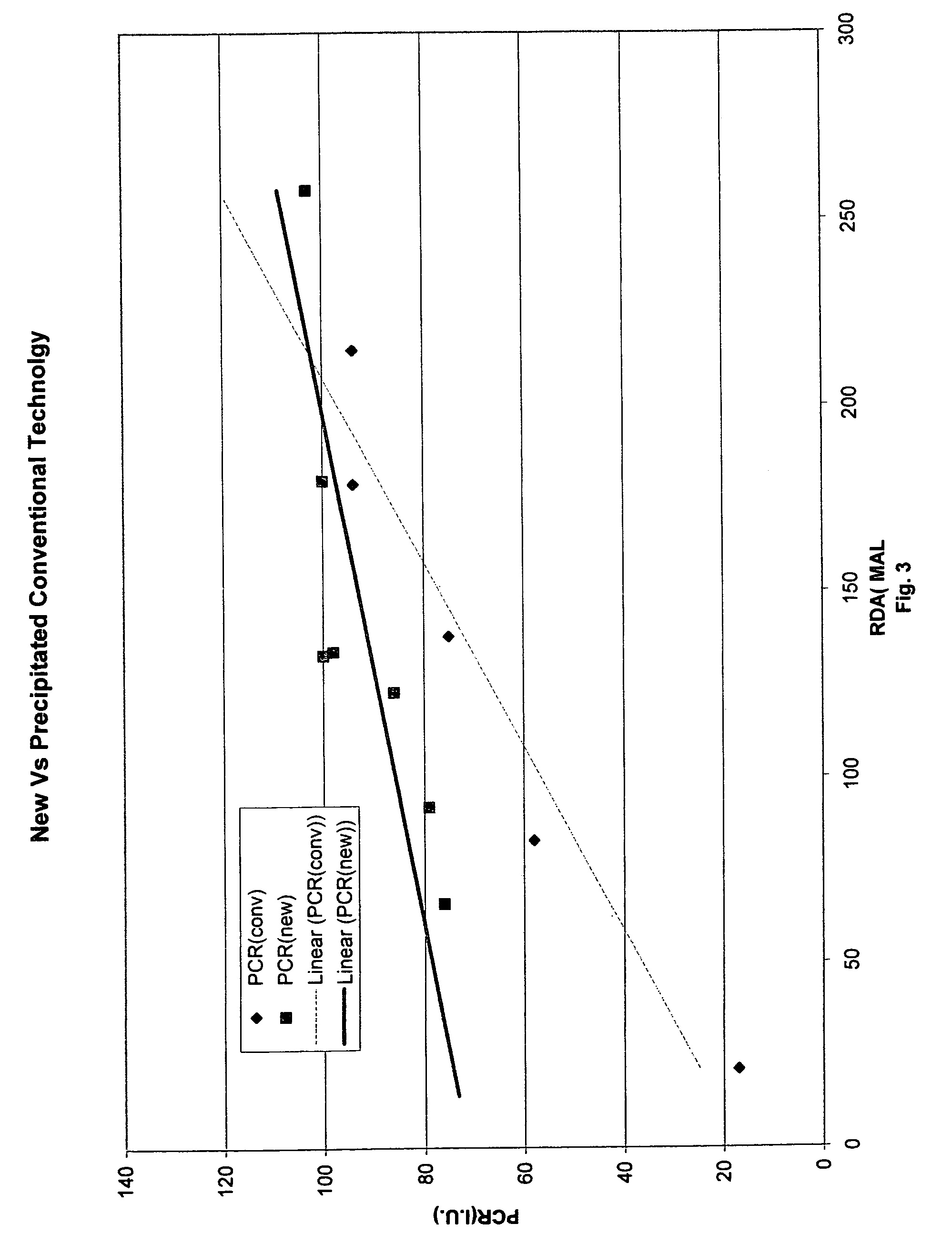

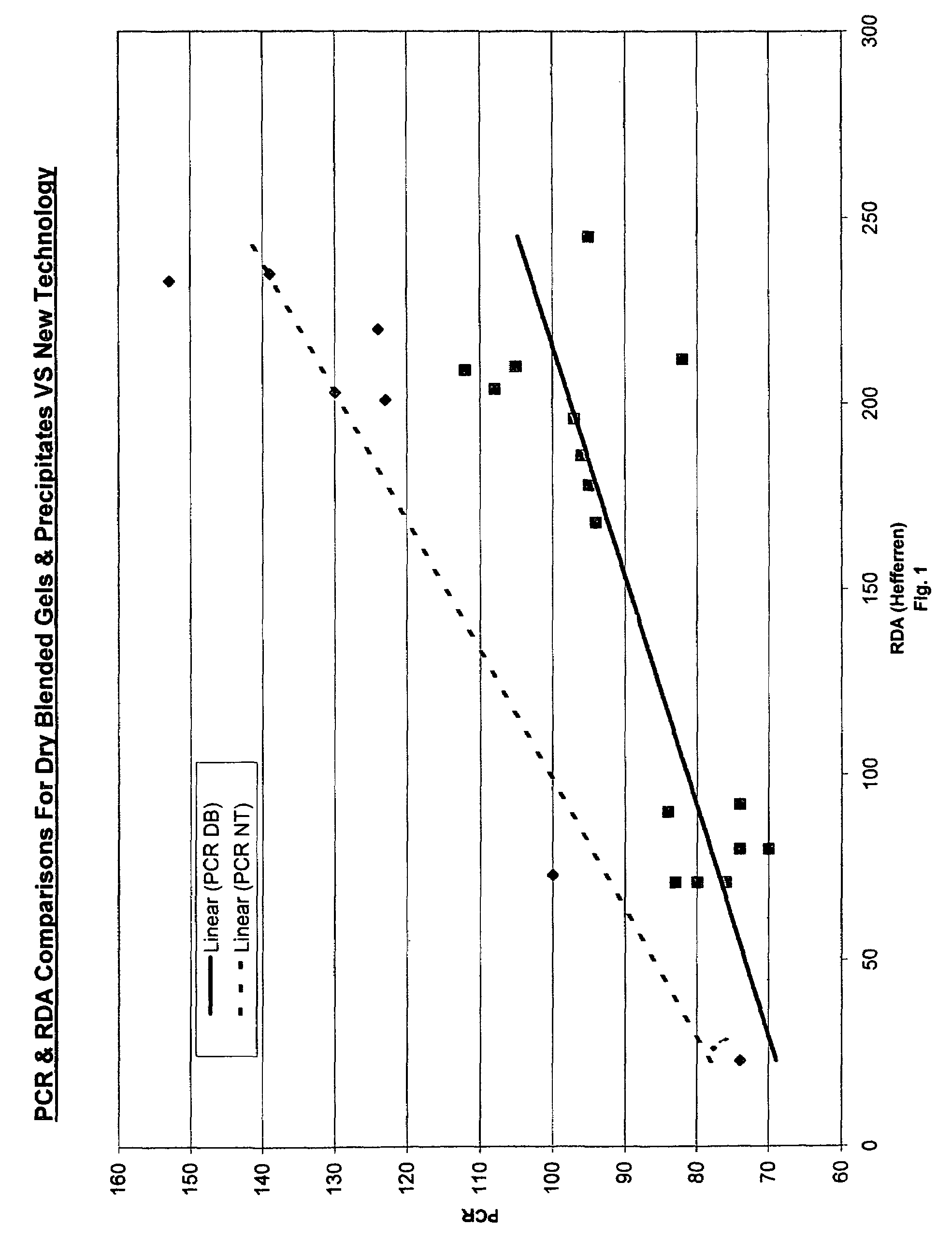

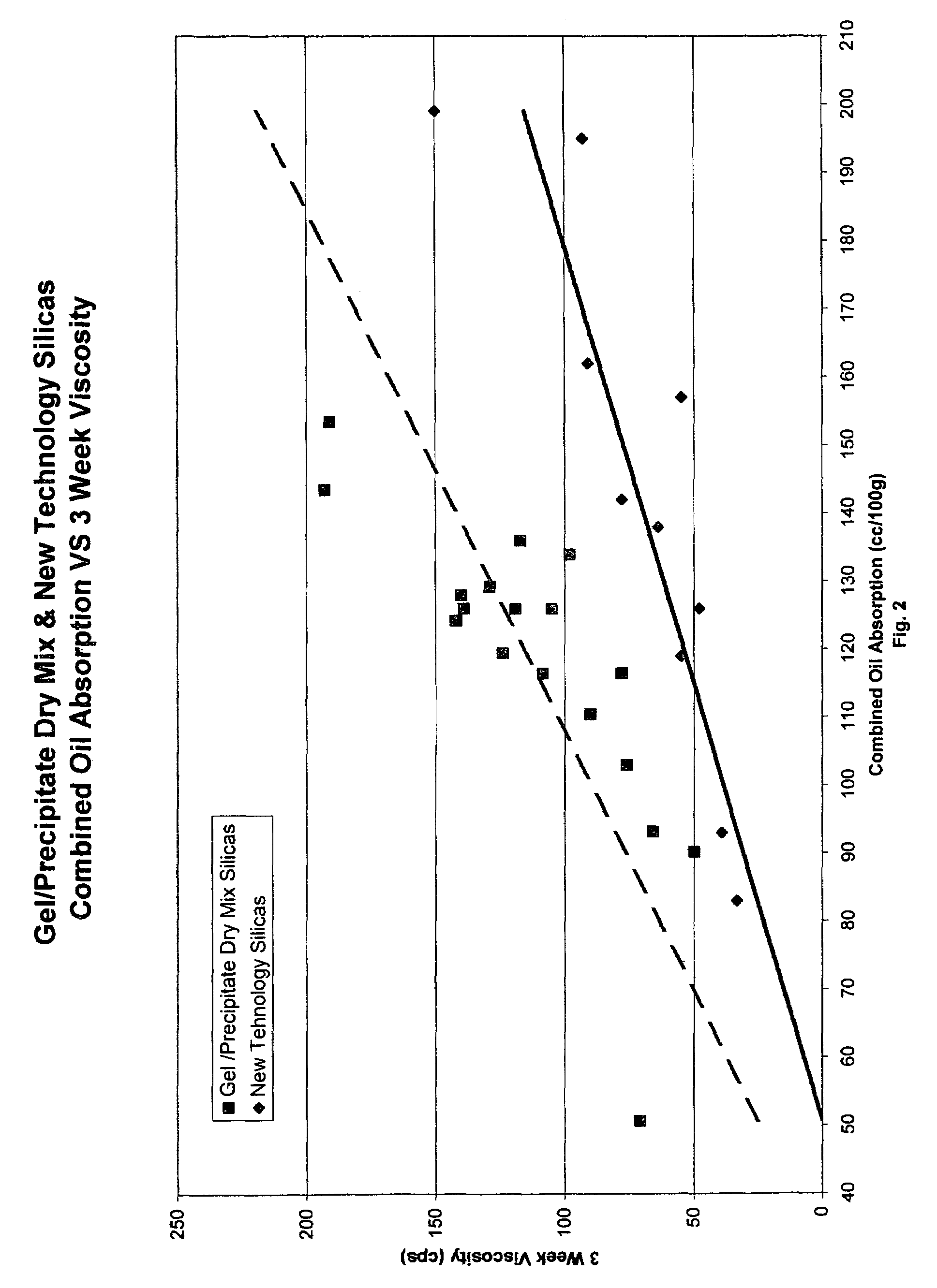

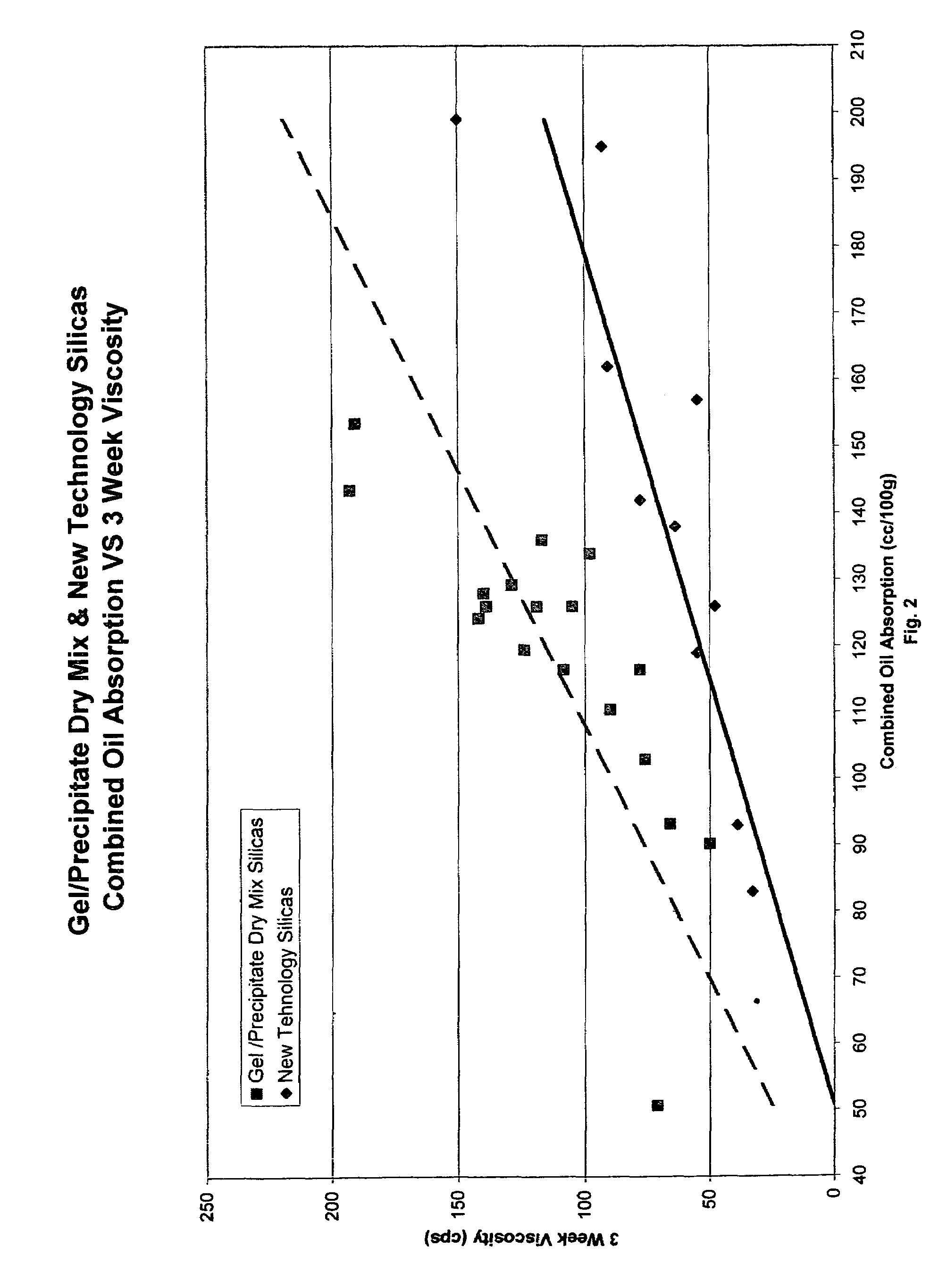

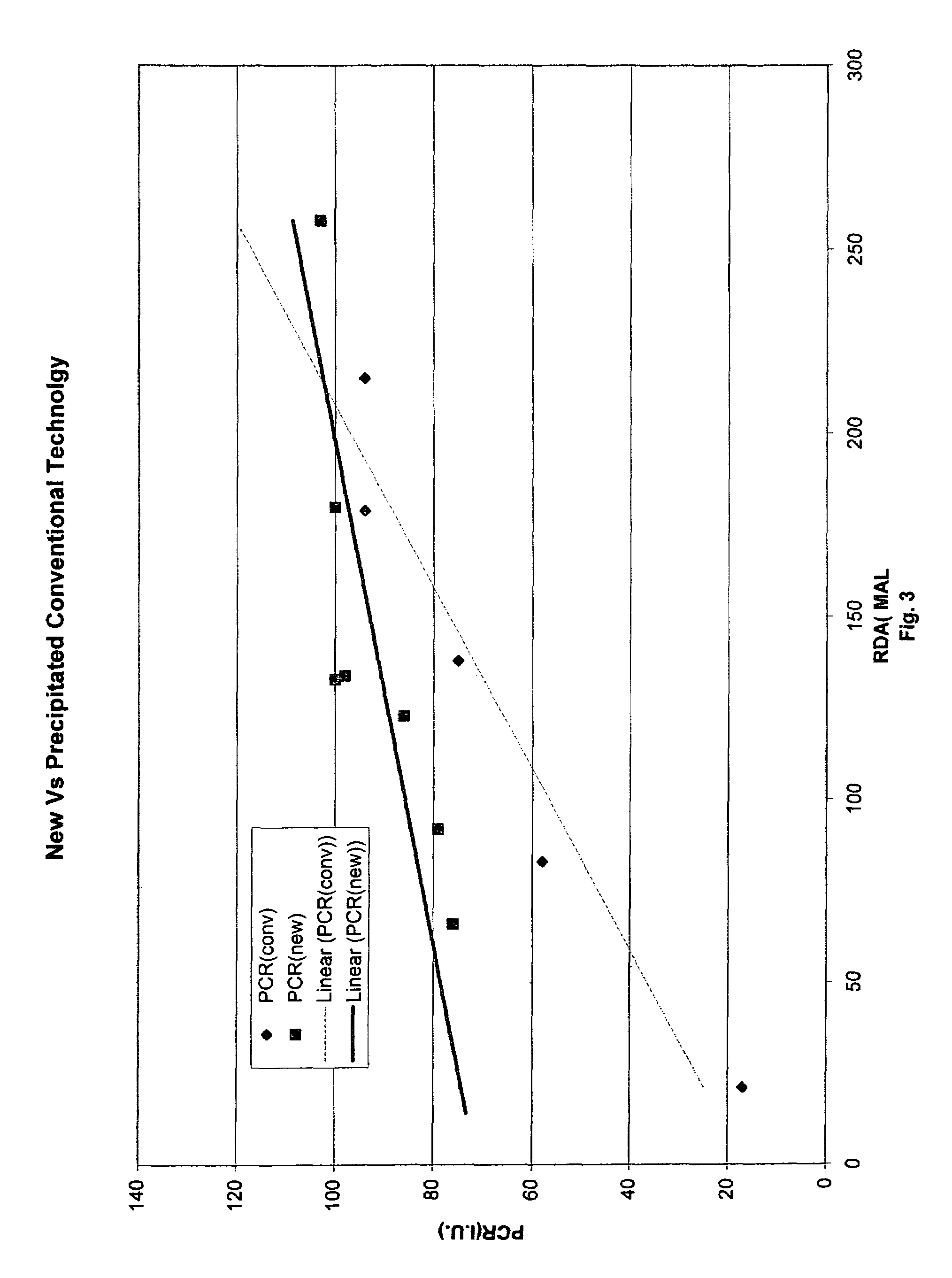

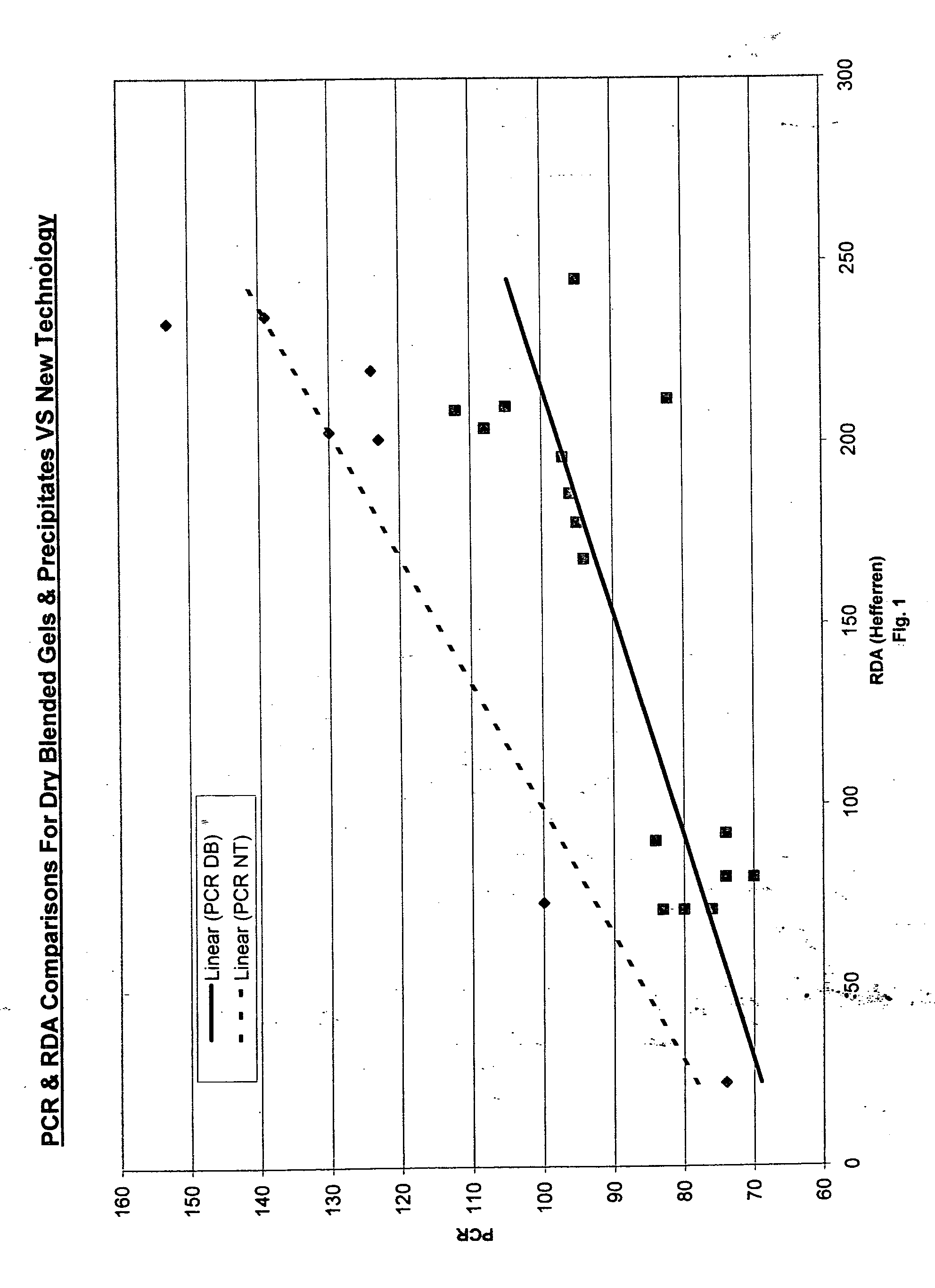

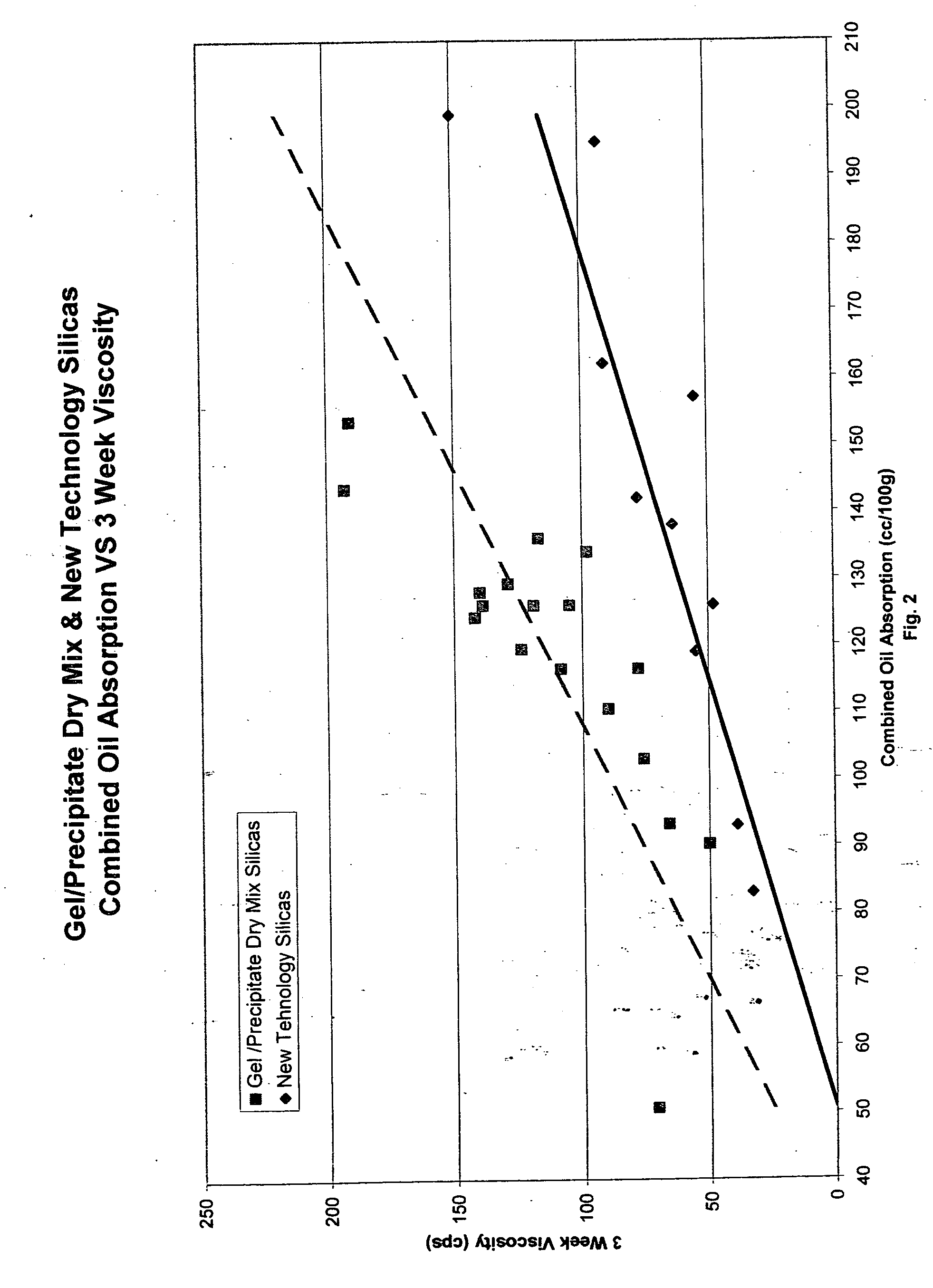

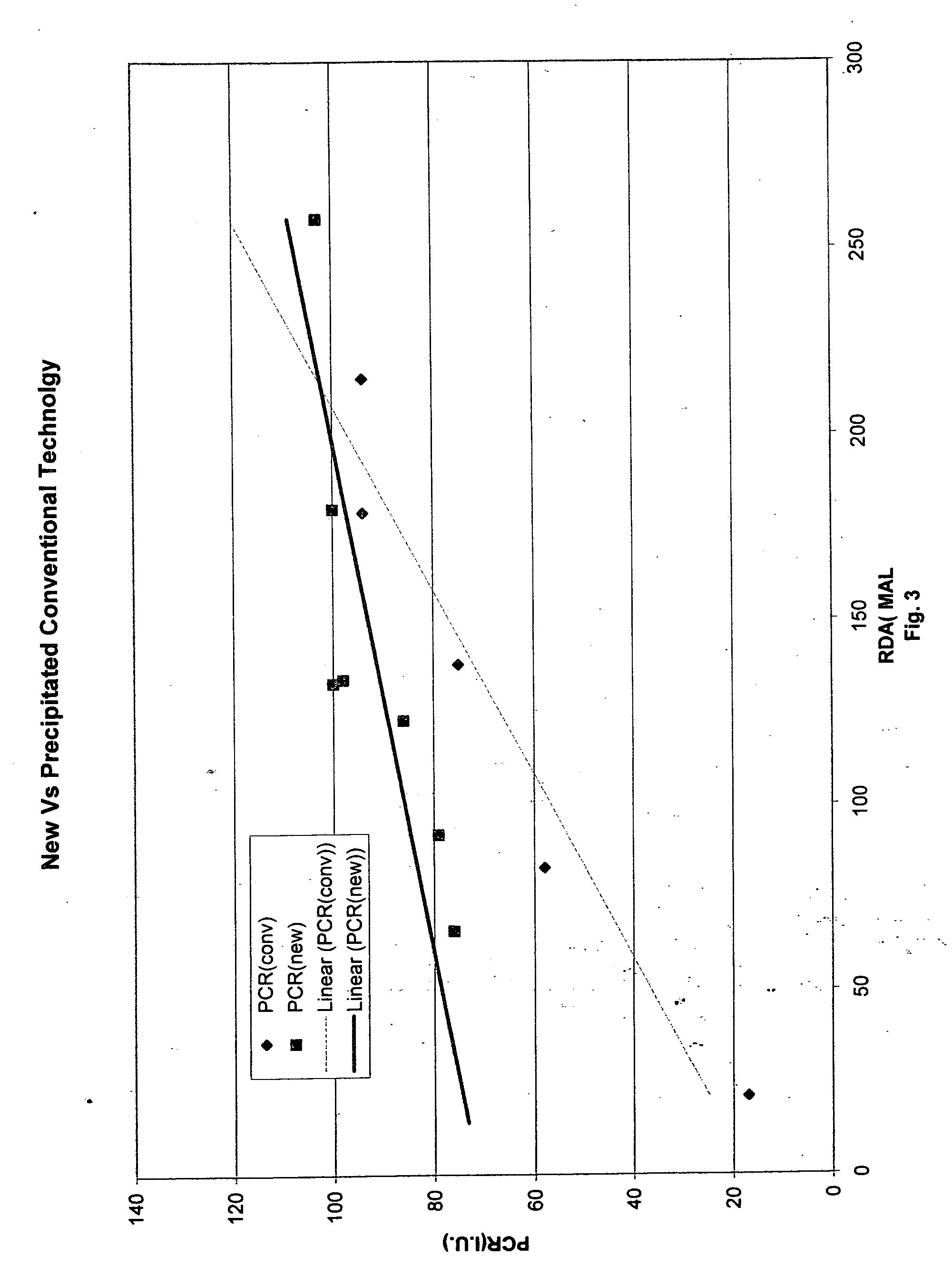

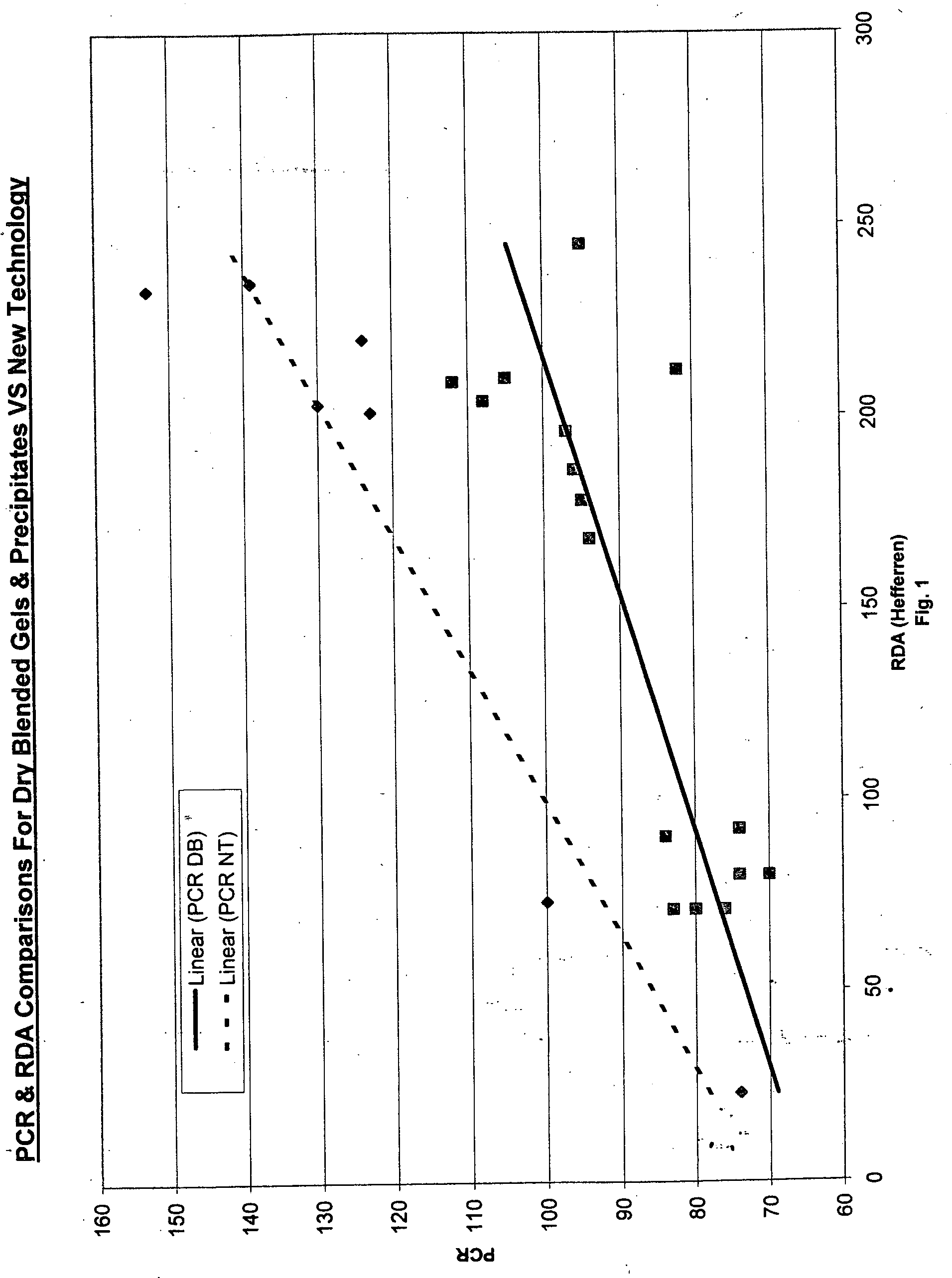

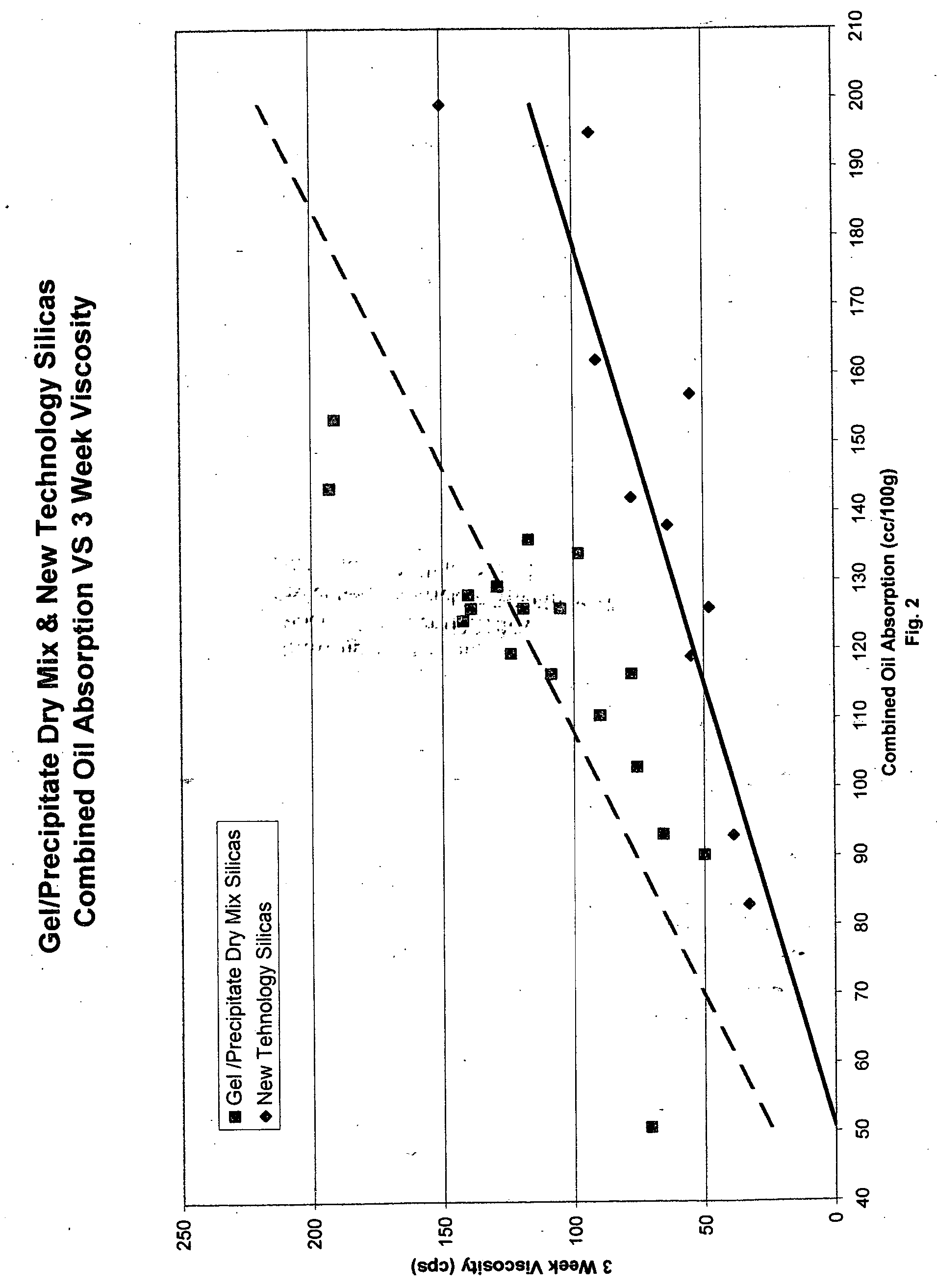

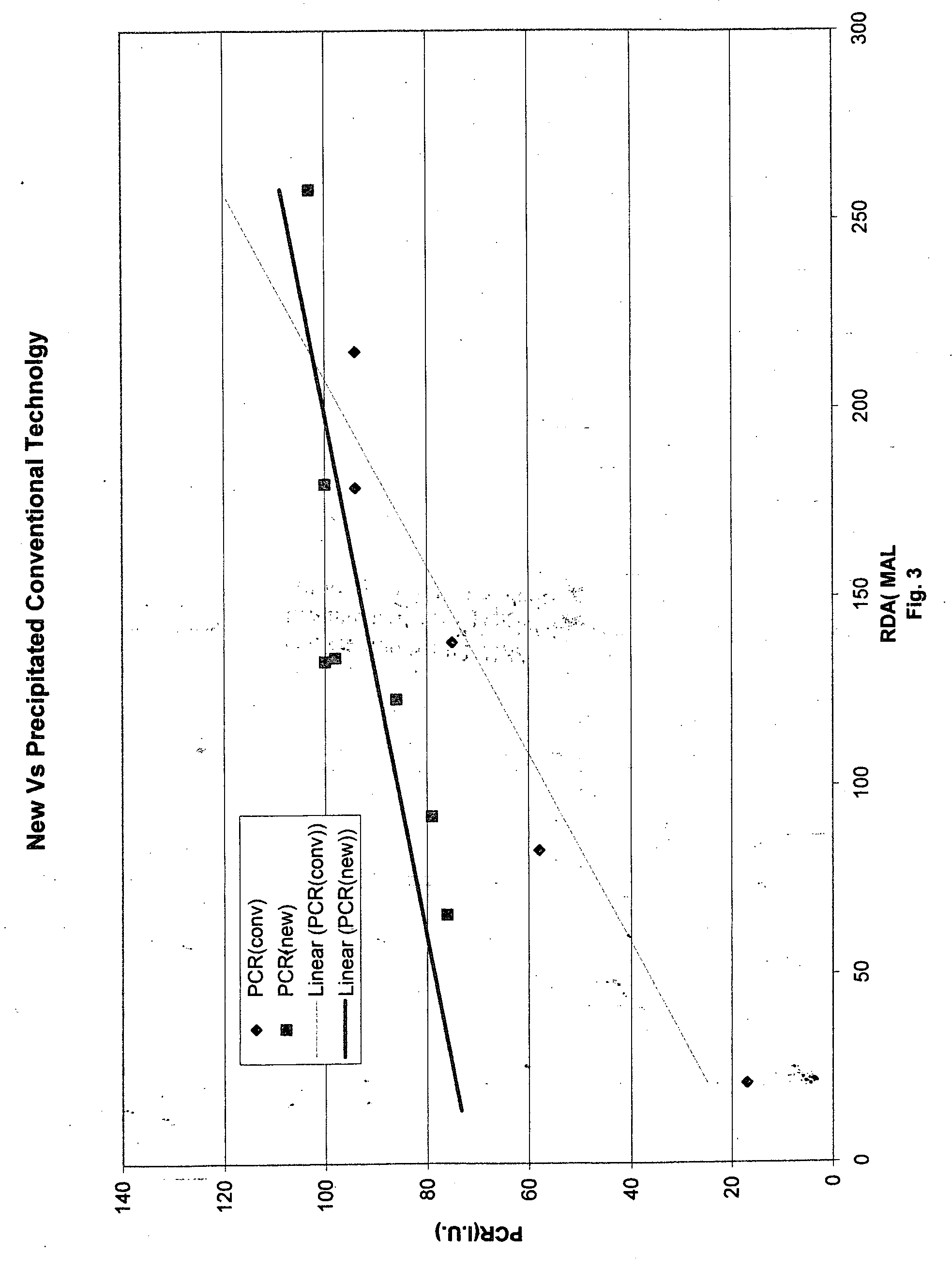

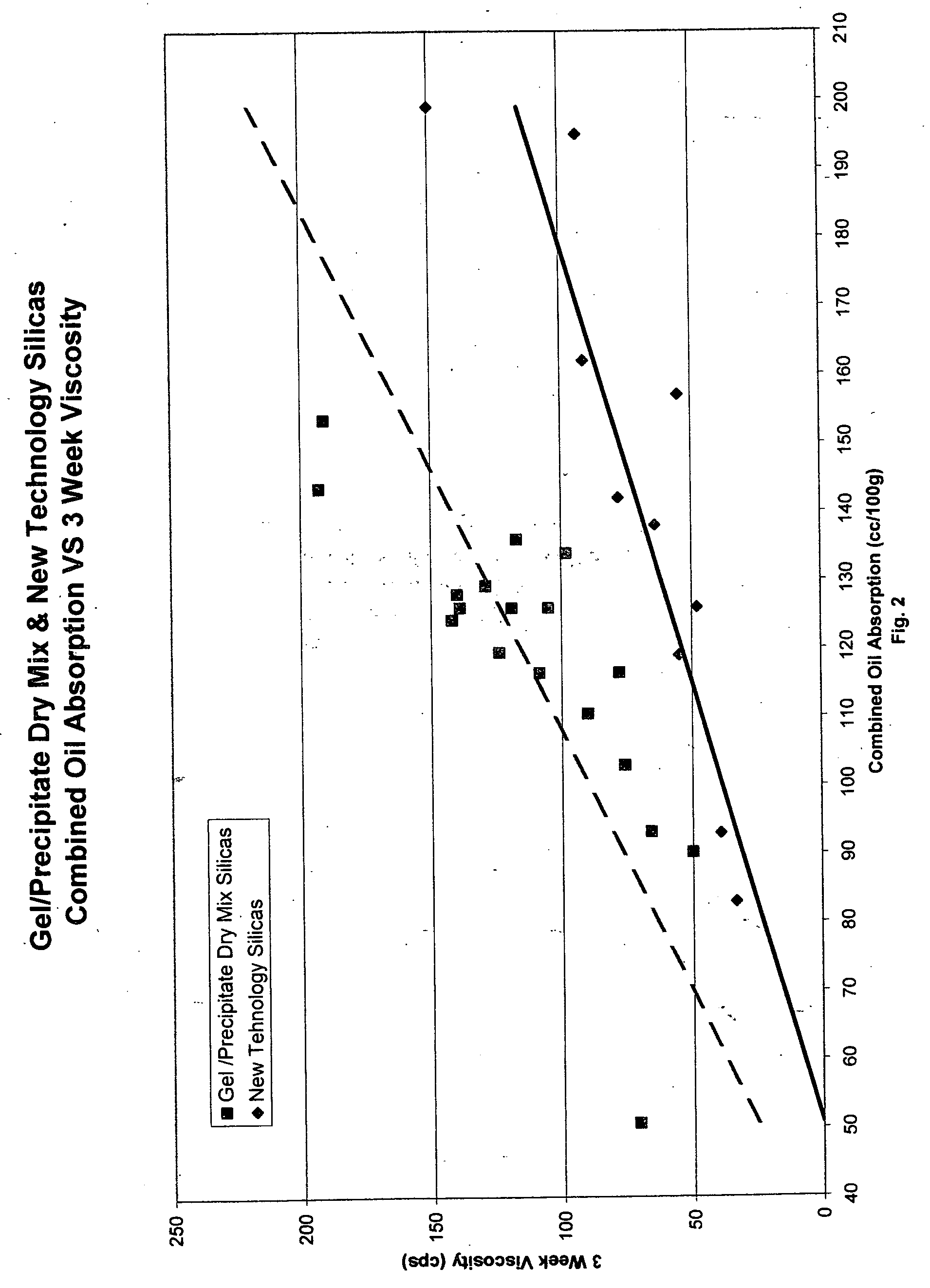

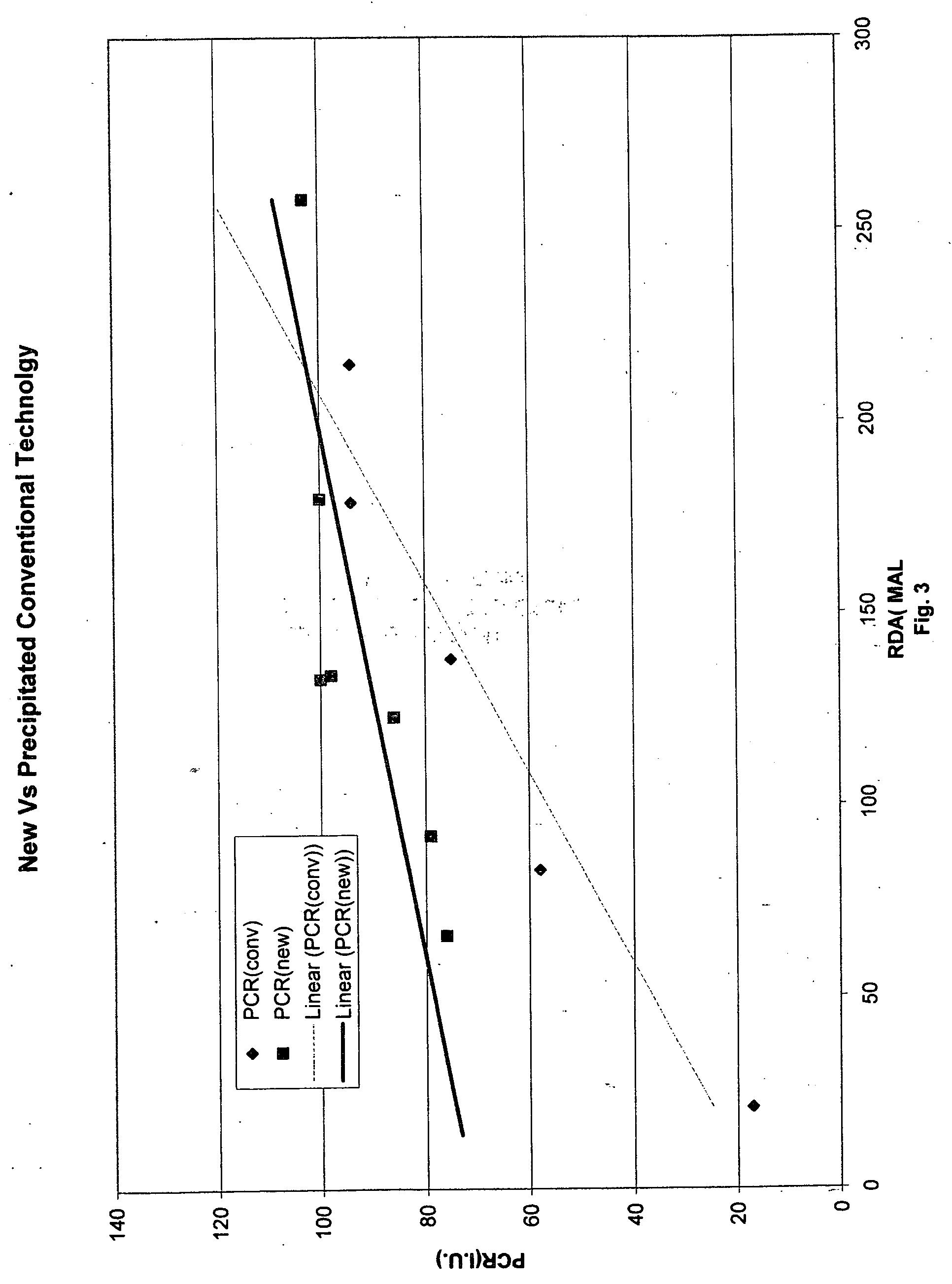

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

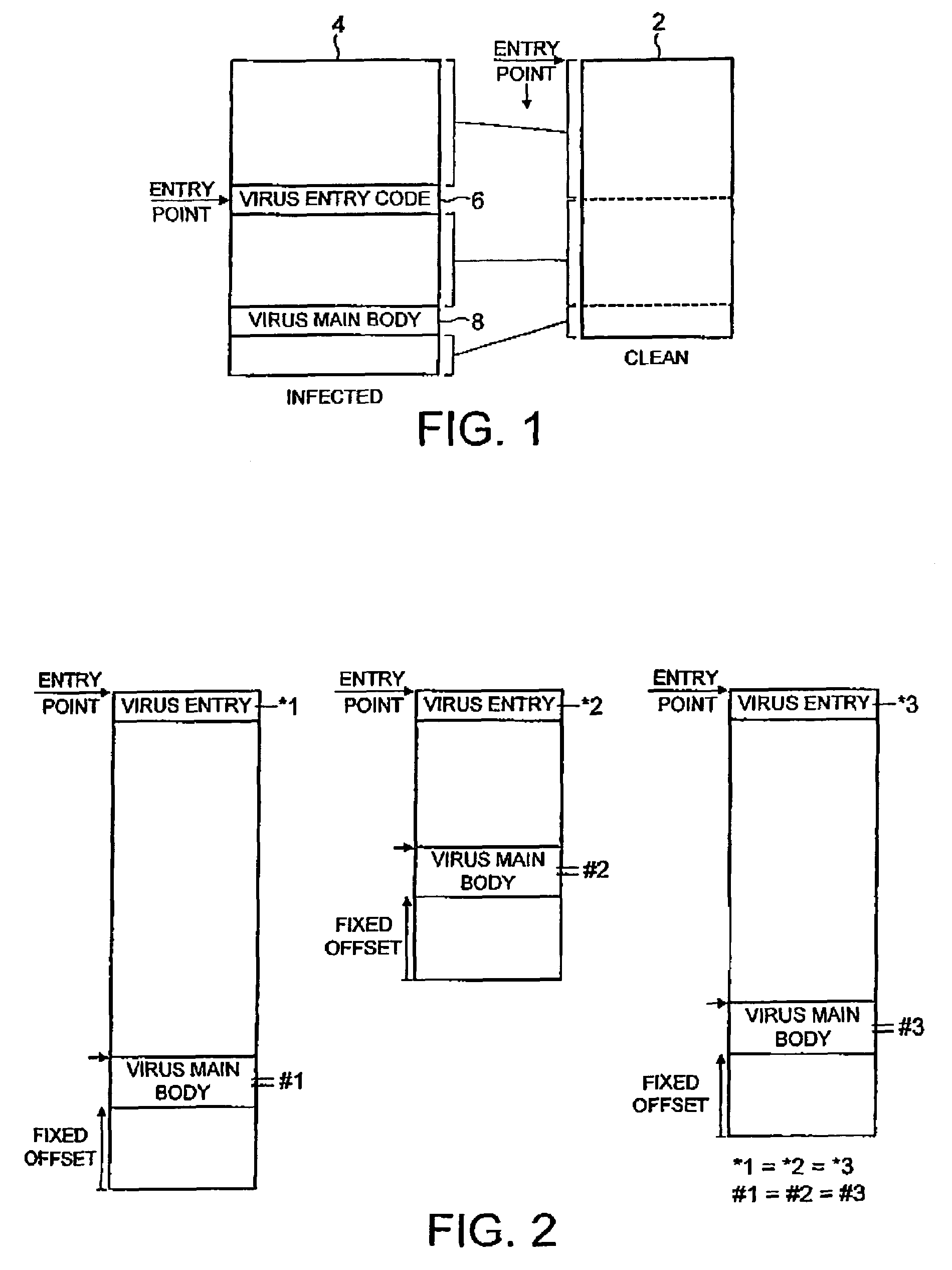

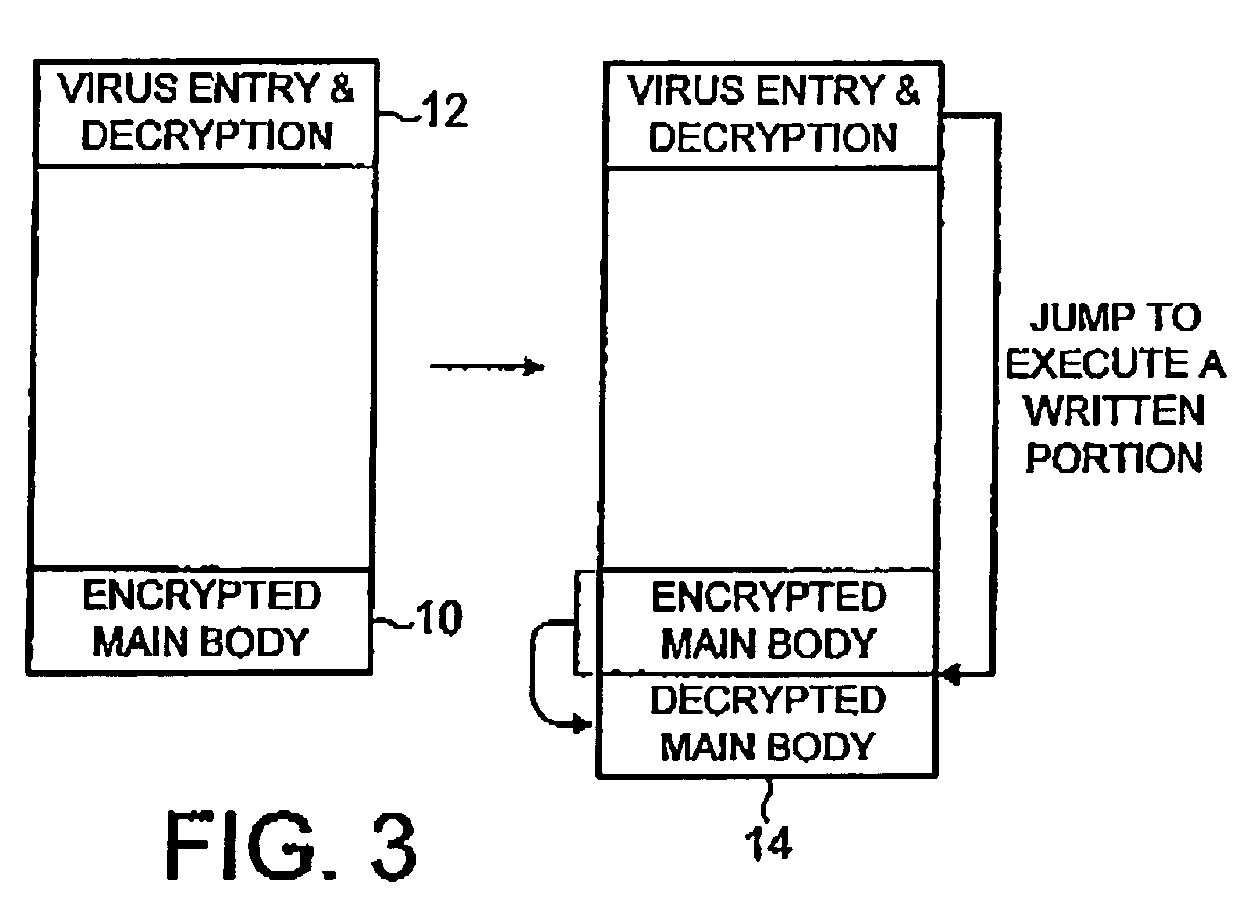

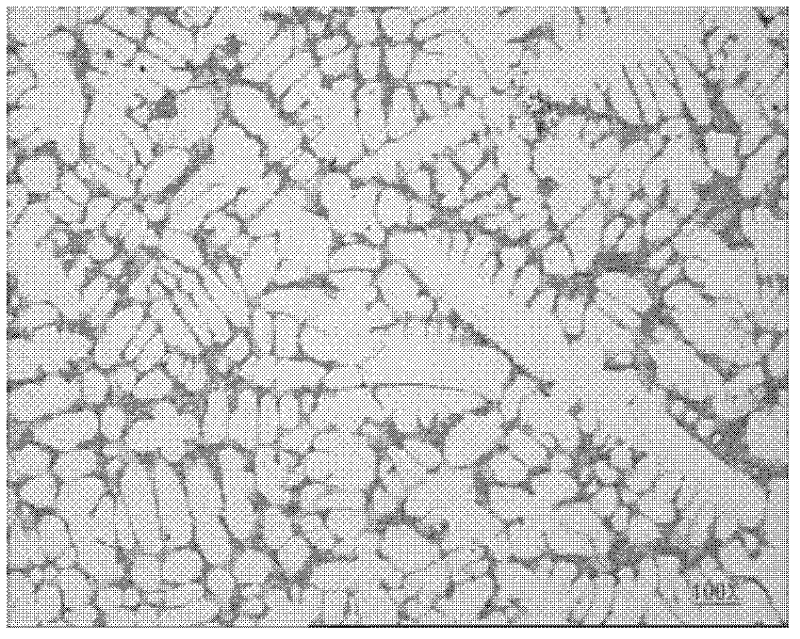

Automatic builder of detection and cleaning routines for computer viruses

InactiveUS7234167B2Limited abilityControl cleanlinessMemory loss protectionDigital data processing detailsFingerprintComputer virus

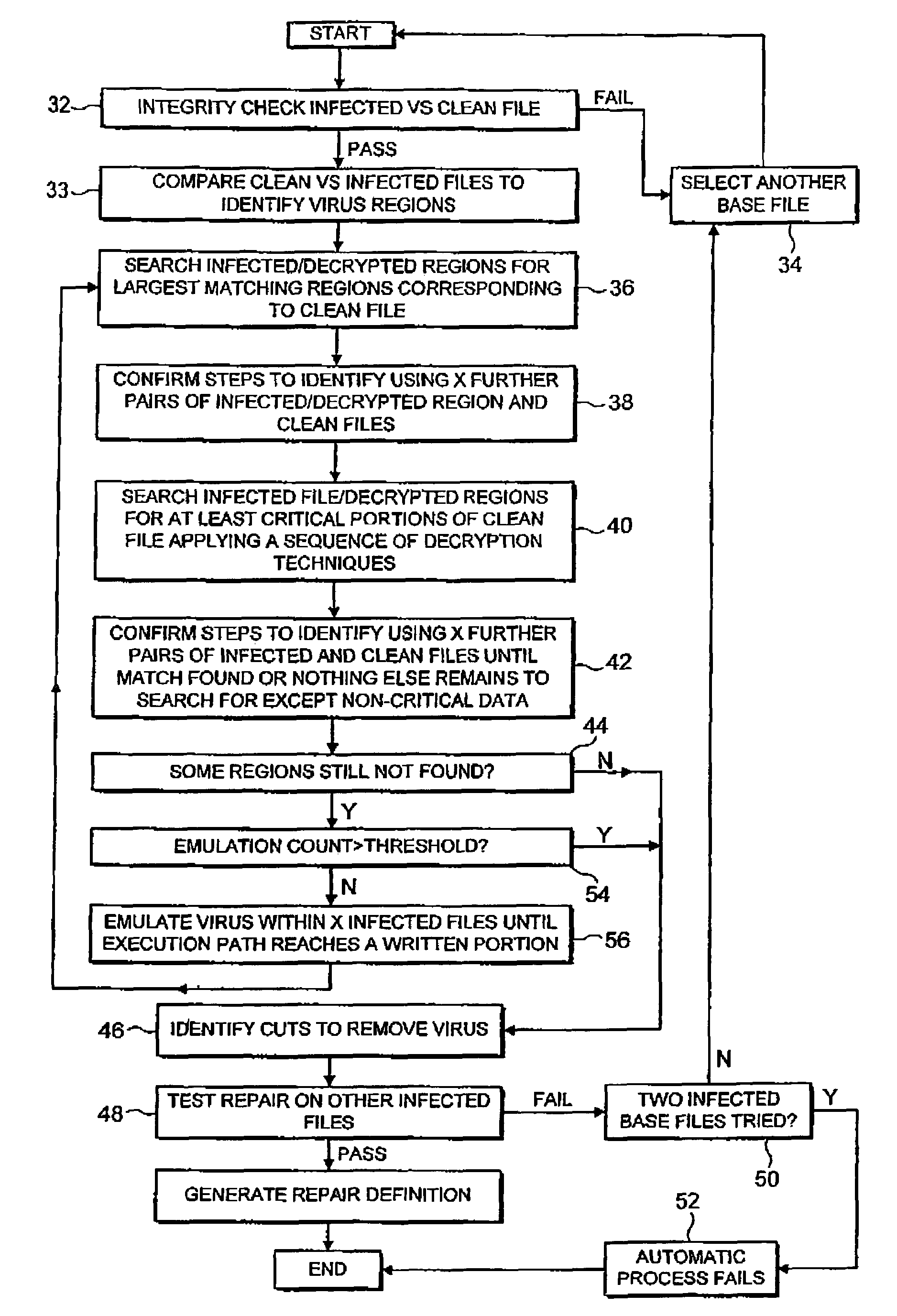

Virus fingerprint data is automatically generated for use in detecting computer viruses and virus removal data for use in removing computer viruses from infected files. The fingerprint generation technique serves to identify the infected virus carrying portions of a computer file and then search within those portions for matching blocks of bytes in excess of a certain size that are consistently located at a predetermined position within the infected computer file such that they may be used to reliably detect that computer virus when it is infecting different host computer files. The removal data generation mechanism serves to search the infected computer file against a clean version of that computer file to identify matching blocks. Critical data missing within the infected computer file may be found within the virus carrying portions by the application of various decryption techniques. Cutting points to remove the virus carrying portions are identified. The fingerprint data and the removal data are tested on pairs of clean and infected computer files to verify that they operate correctly.

Owner:MCAFEE LLC

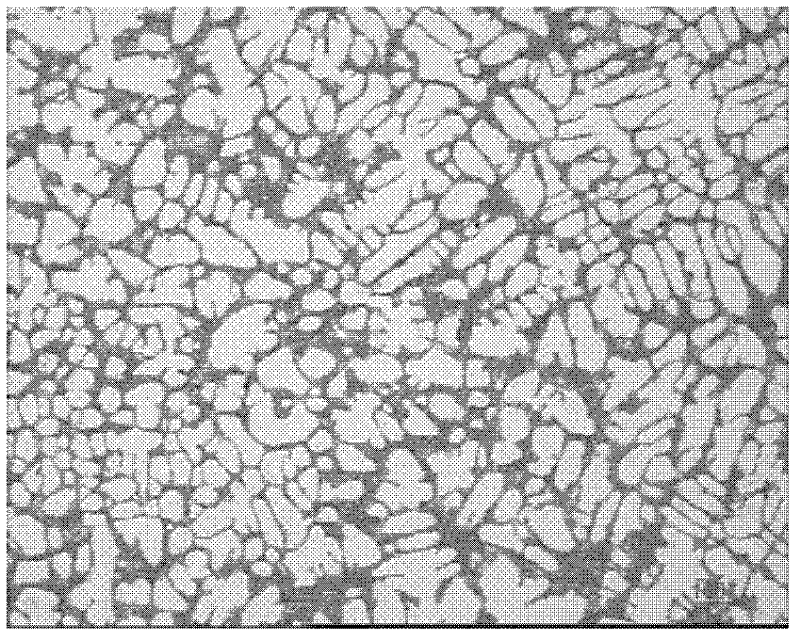

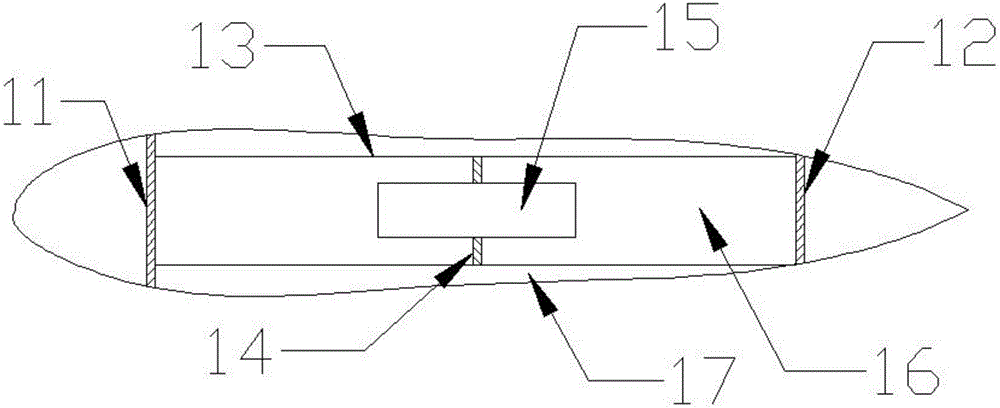

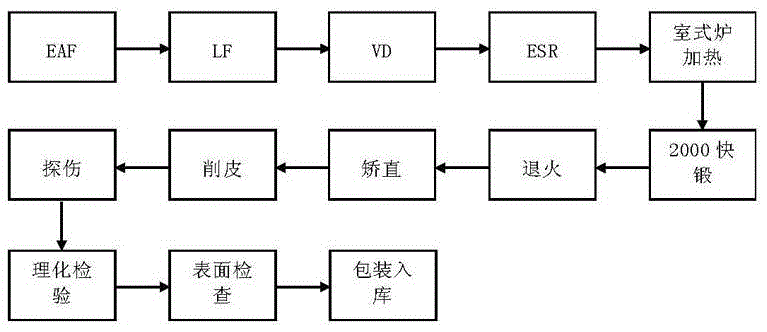

Novel manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel

ActiveCN102418042AImprove cleanlinessImprove segregationMetal-working apparatusProcess efficiency improvementCarbideHot working

The invention discloses a manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel, and the purpose is to solve the problems of quite severe ununiformity of large-section forging material eutectic carbides and the increase of defects of internal cracks and surface cracks during the forging process caused by segregation deterioration of cast structure carbides of large steel ingots. By using steel-making technical measures such as LF refining, VD degassing, aluminium wire feeding, and the like, the invention improves the molten steel cleanliness, the control of electroslag remelting output power, and the homogenization treatment before forging, and improves the segregation of eutectic carbides and the hot-working plasticity of steel; by controlling the forging heating numbers and various deformation amounts of large high-carbon high-chromium steel ingots, large granular carbides are crushed; the ununiformity of eutectic carbides is improved; crack defects during the forging process are prevented; and the produced high-carbon high-chromium steel large-section forging materials has ununiformity of eutectic carbides of up to grade 4-grade 6; the results of ultrasonic inspection are at good levels of E / e grade, D / d grade.

Owner:FUSHUN SPECIAL STEEL SHARES

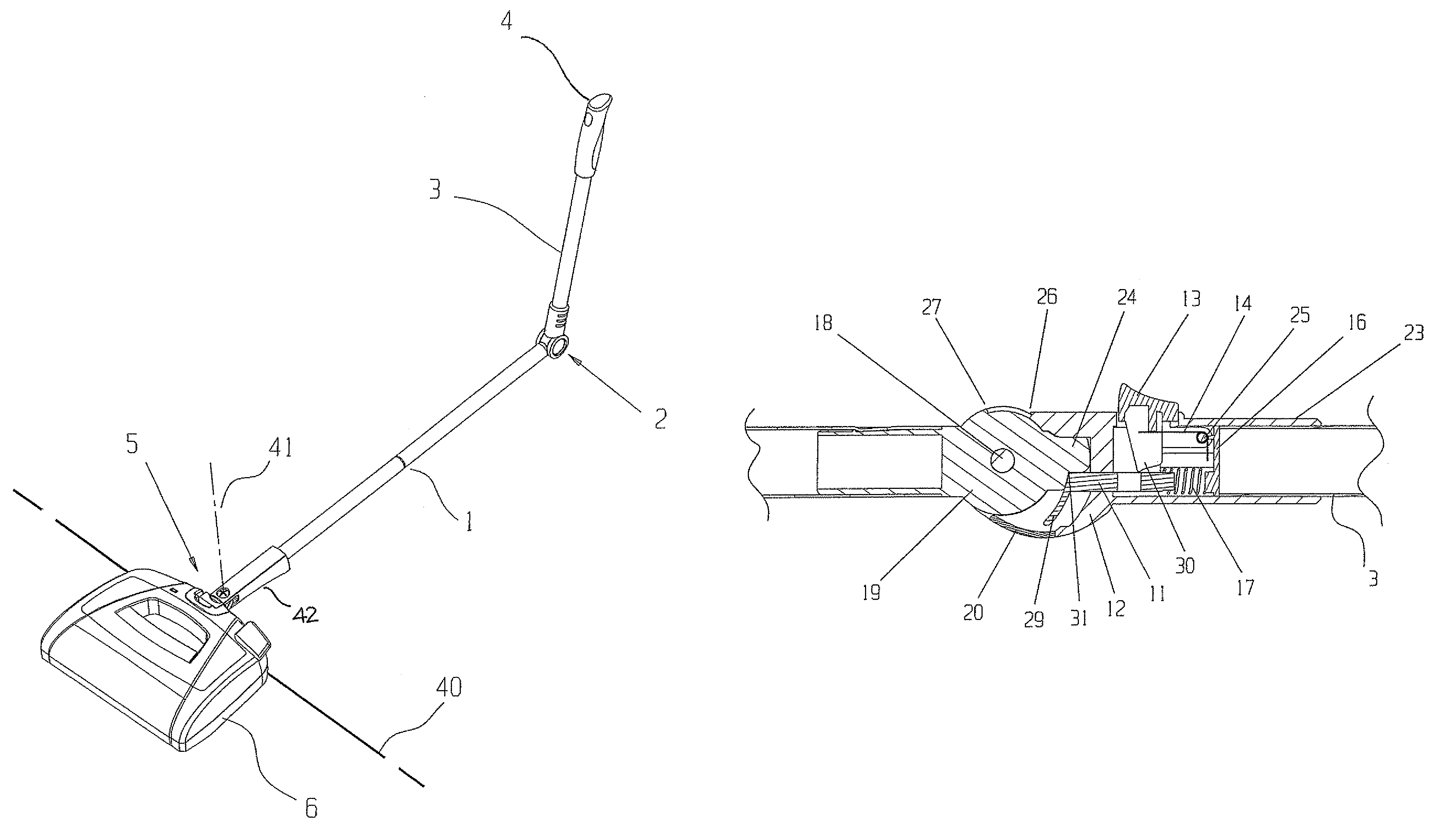

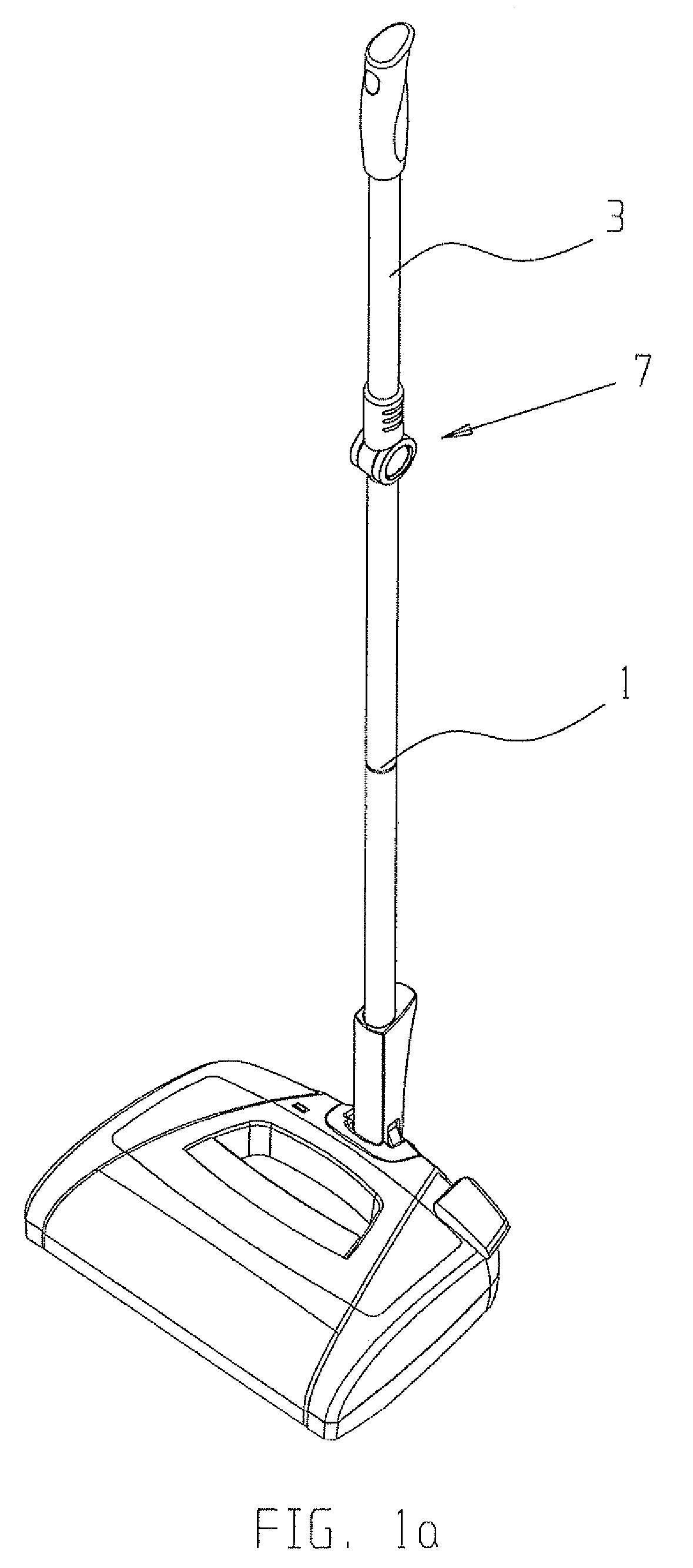

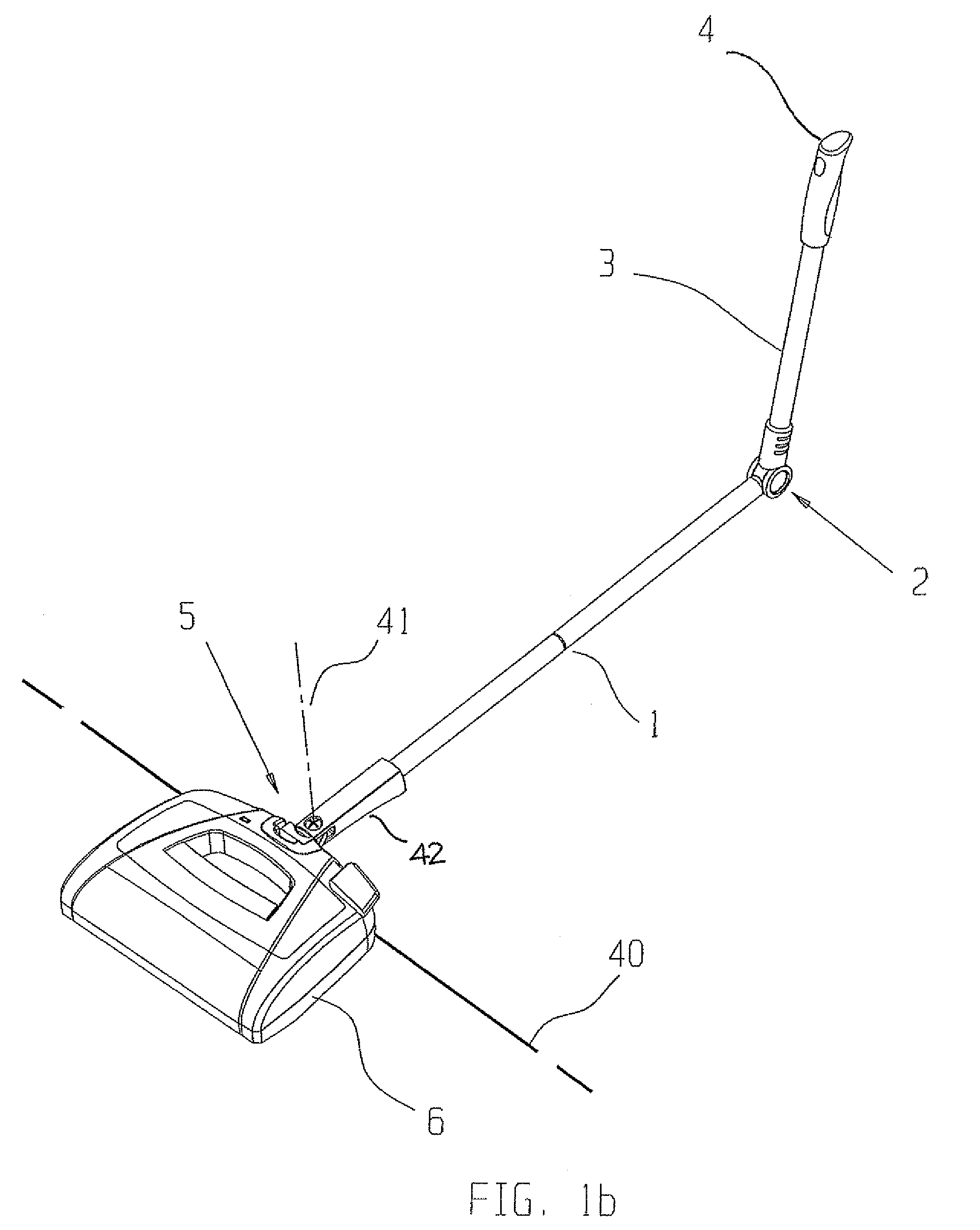

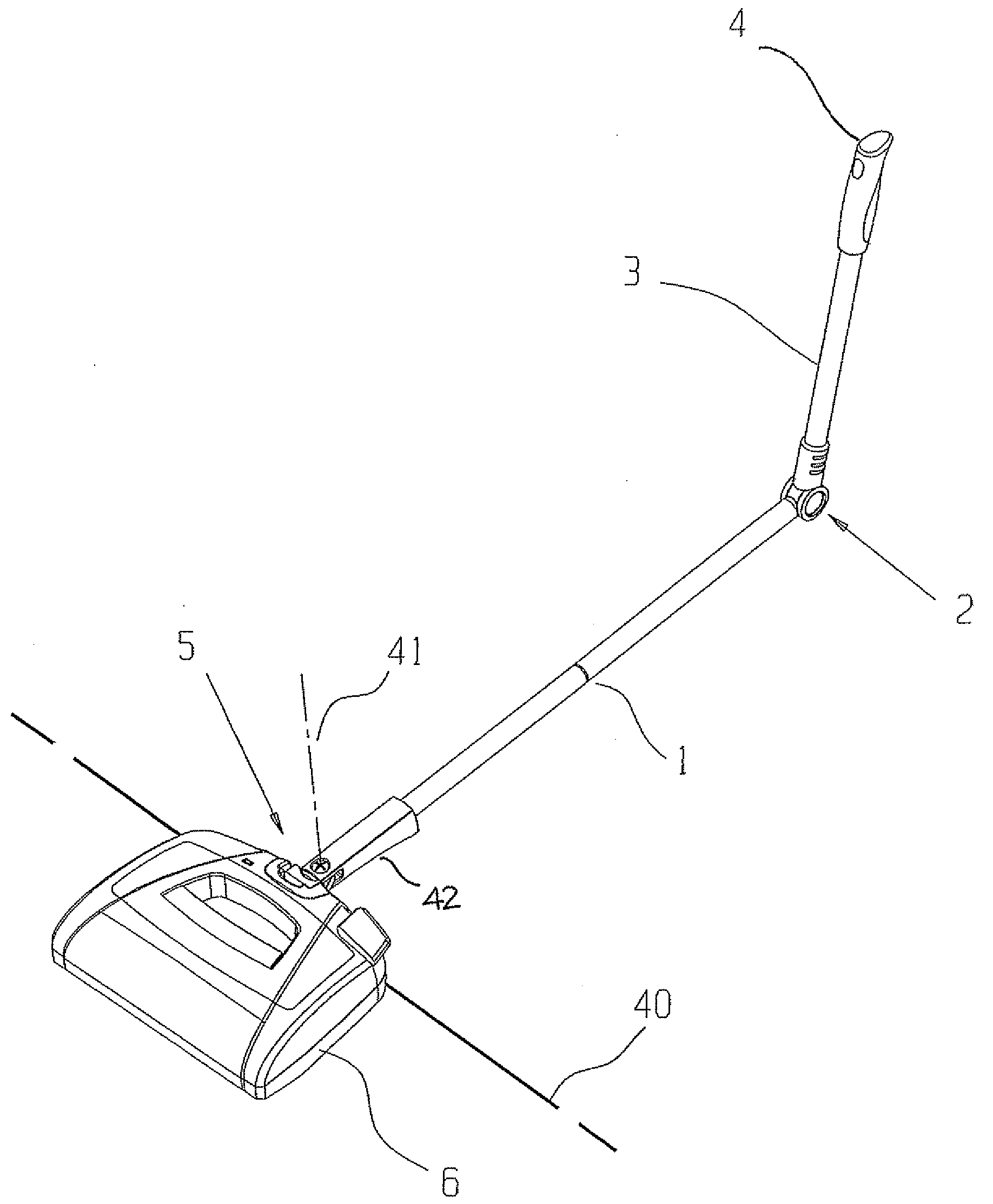

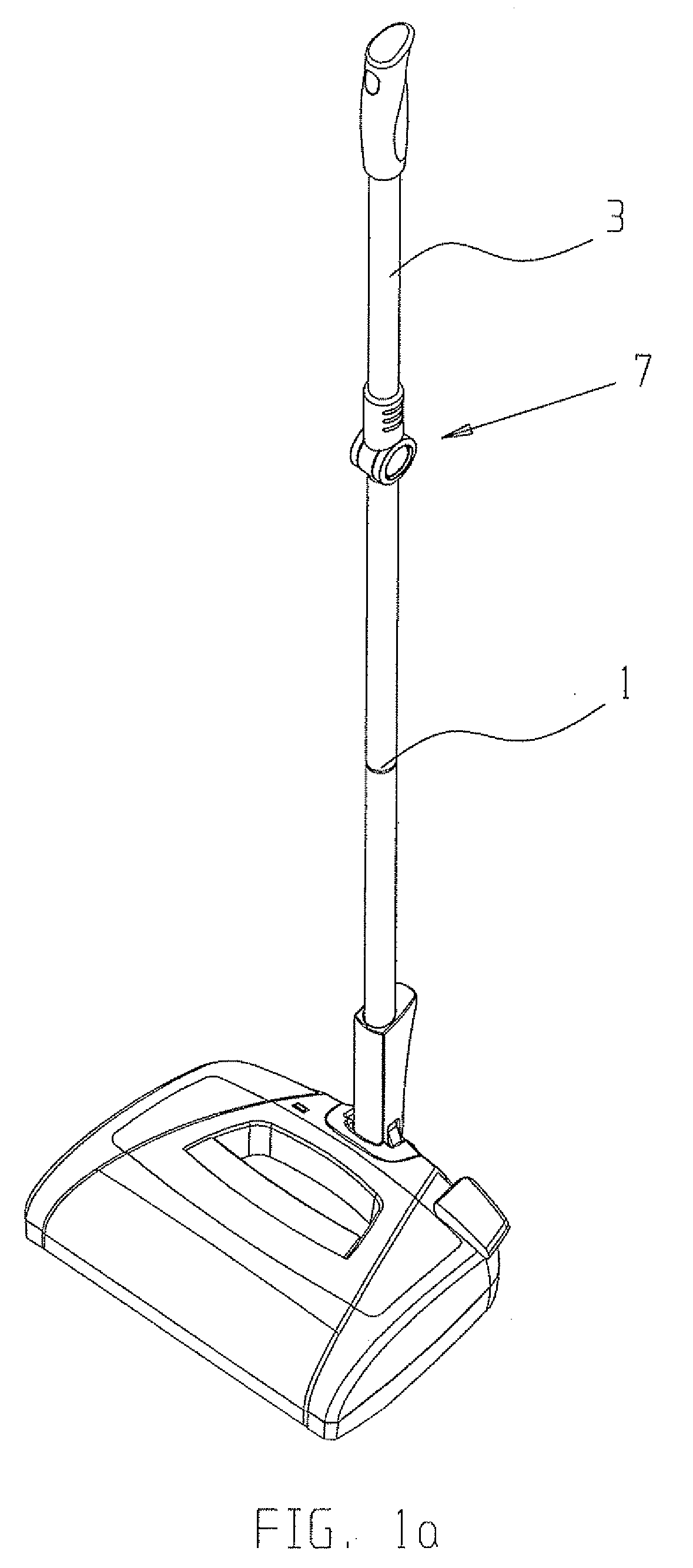

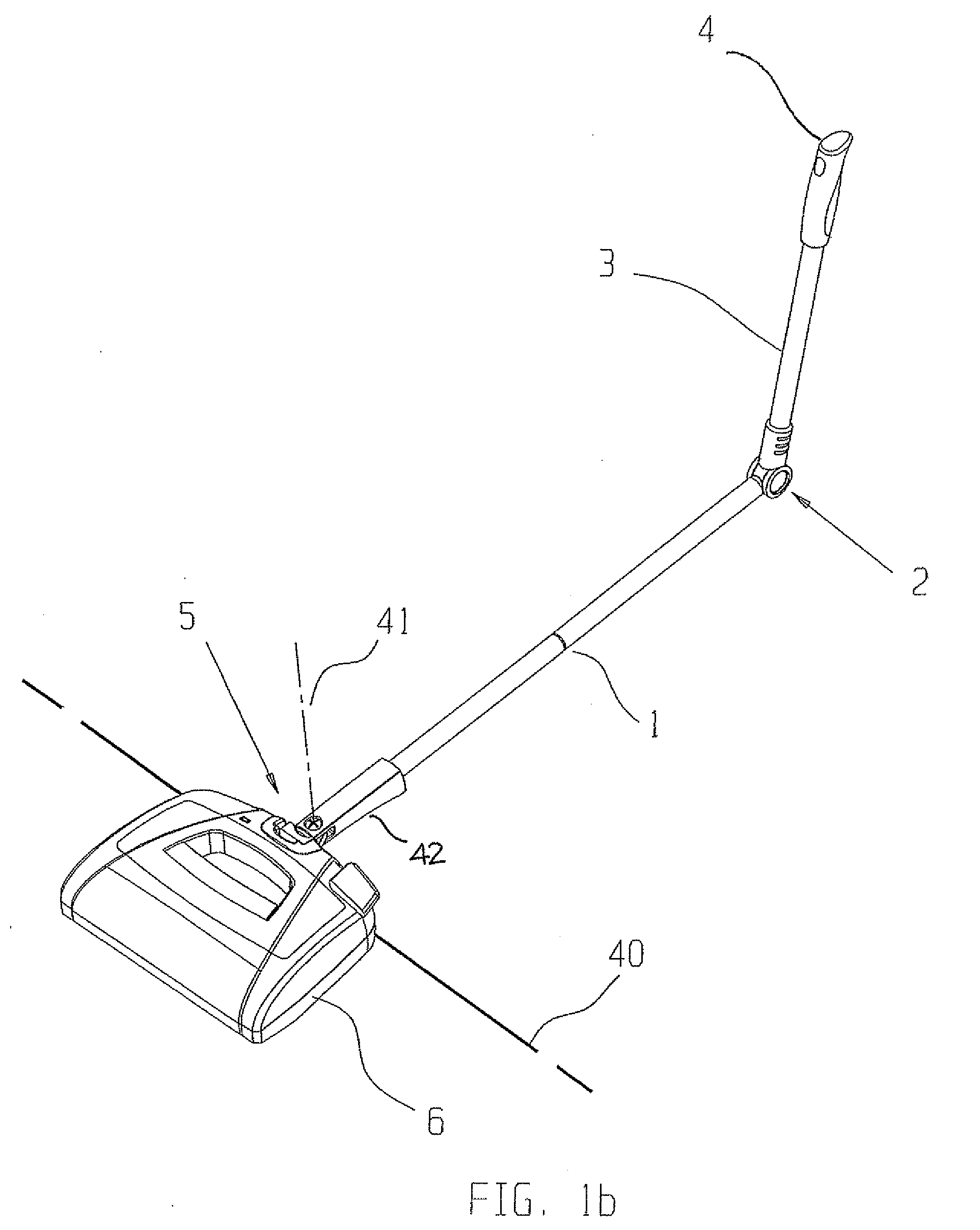

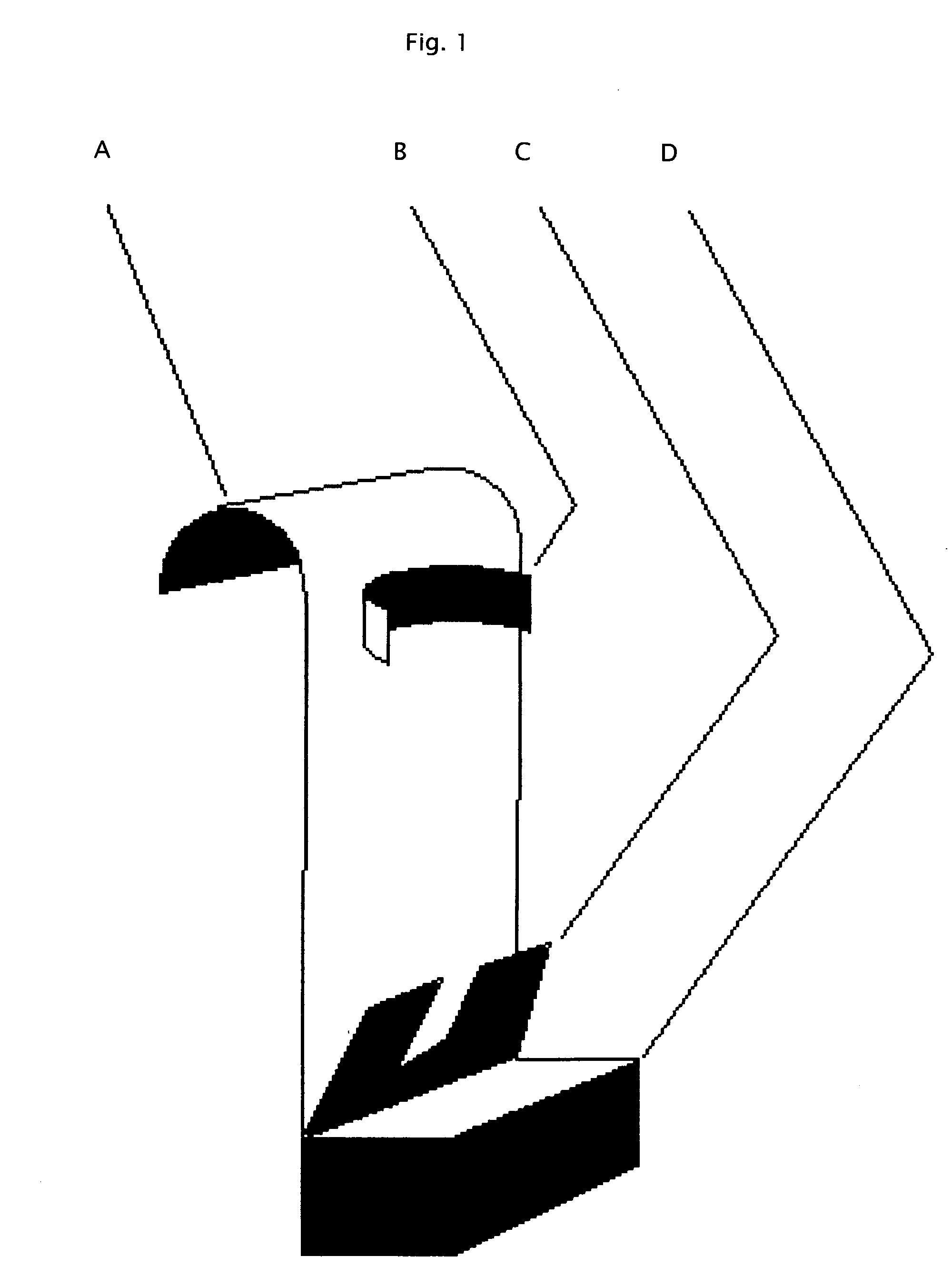

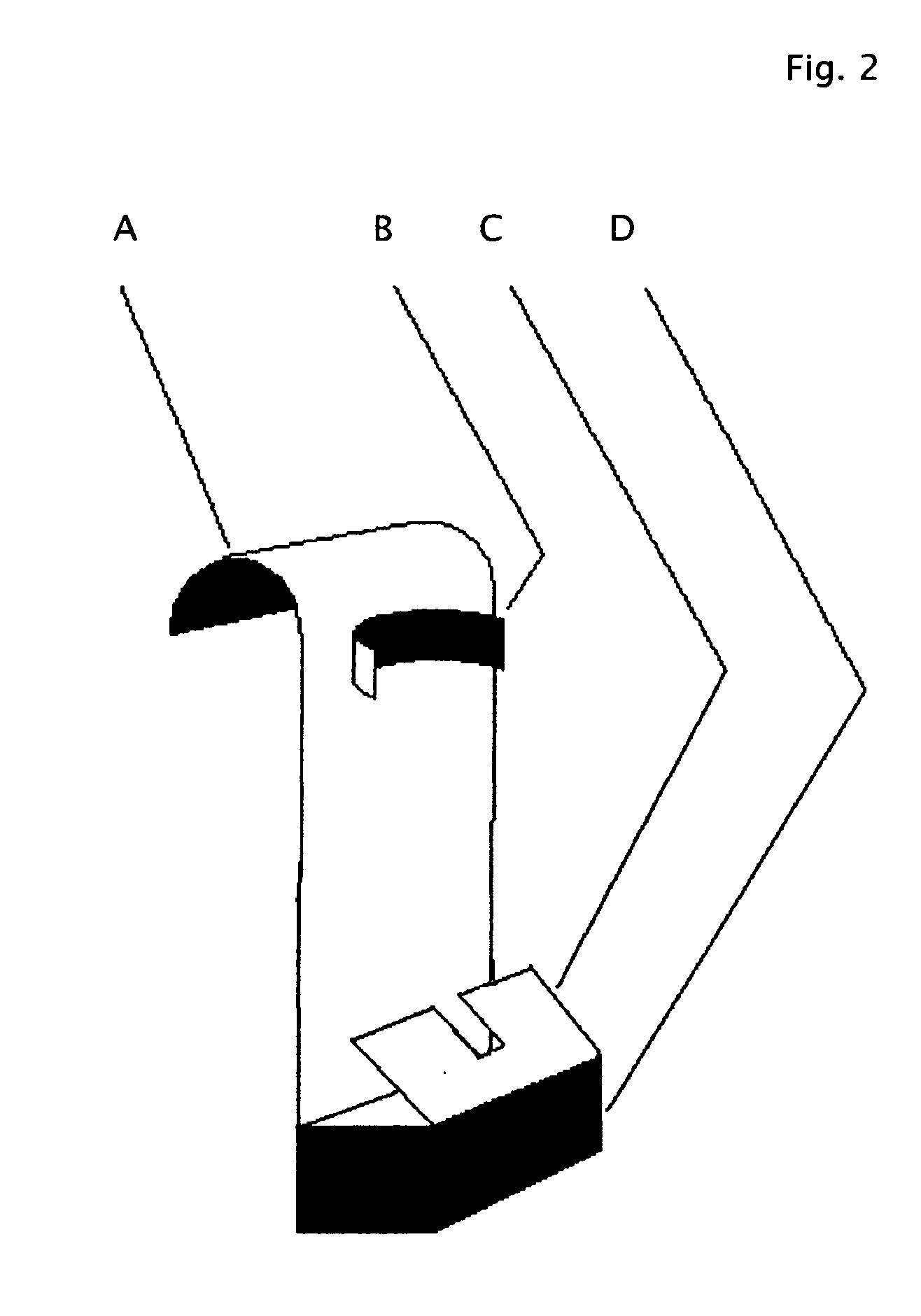

Floor cleaning apparatus with elongate handle and handle extension

InactiveUS7496984B2Quickly and easily can cleanAbility to clean beneath furnitureCarpet cleanersBrush bodiesLocking mechanismEngineering

A floor sweeping apparatus comprises a cleaning head with an elongate handle fixed at an inner end by a pivoting joint to the cleaning head, and at an outer end by a hinge to an elongate handle extension. A locking mechanism allows the handle extension to be locked in different angular positions relative to the handle and can be remotely controlled from the handle extension.

Owner:KWONNIE ELECTRICAL PRODS

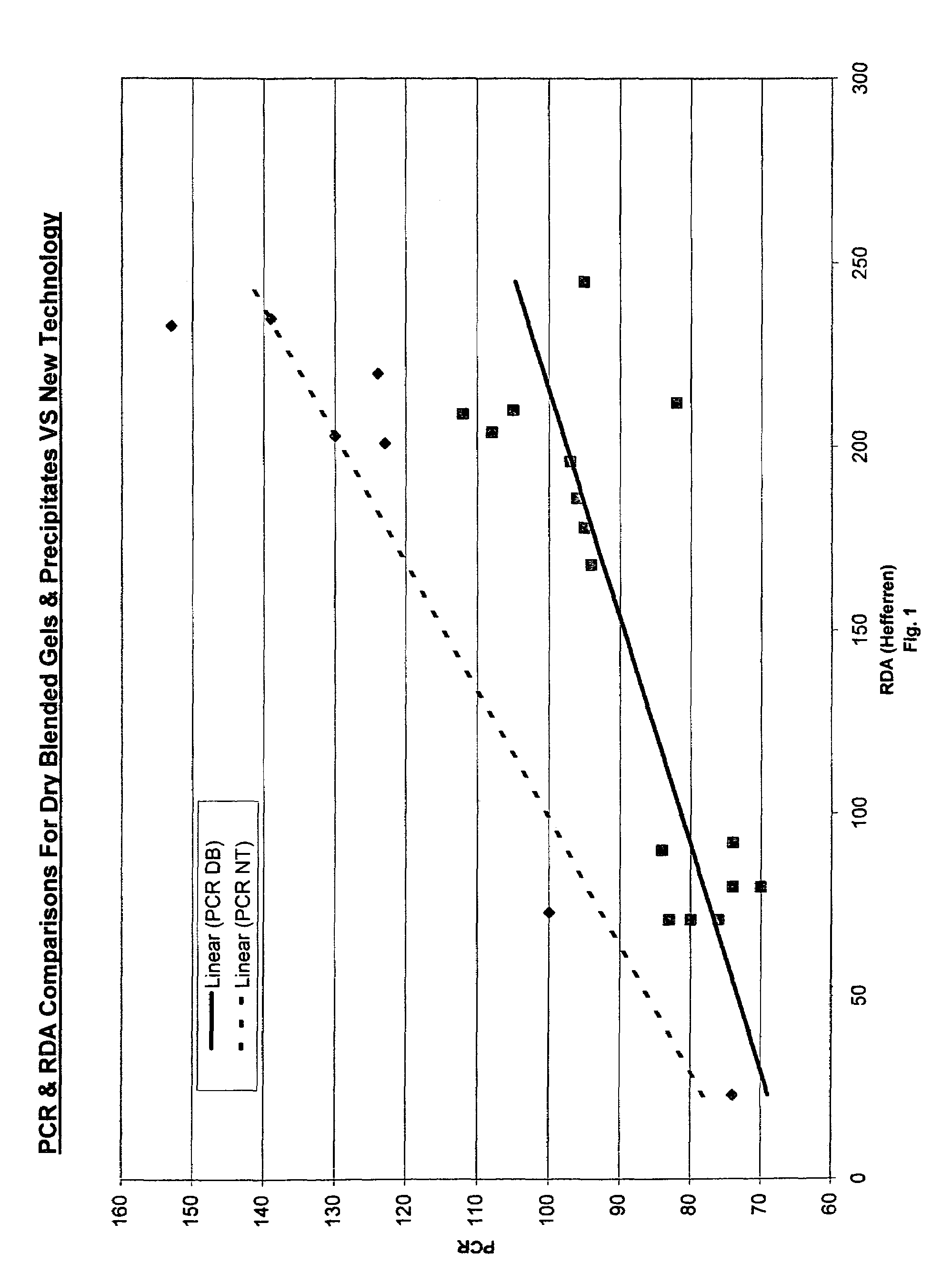

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS20060110338A1Desirable abrasiveGood thickening effectPigmenting treatmentCosmetic preparationsSilica gelSilicon dioxide

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS7267814B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High-cleaning/moderate abrasive silica materials and dentifrice containing such materials

InactiveUS7306788B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsSilicaLinseed oilSilica gel

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Floor cleaning apparatus with elongate handle and handle extension

InactiveUS20080155774A1Quickly and easily can cleanAbility to clean beneath furnitureCarpet cleanersBrush bodiesLocking mechanismEngineering

A floor sweeping apparatus comprises a cleaning head with an elongate handle fixed at an inner end by a pivoting joint to the cleaning head, and at an outer end by a hinge to an elongate handle extension. A locking mechanism allows the handle extension to be locked in different angular positions relative to the handle and can be remotely controlled from the handle extension.

Owner:KWONNIE ELECTRICAL PRODS

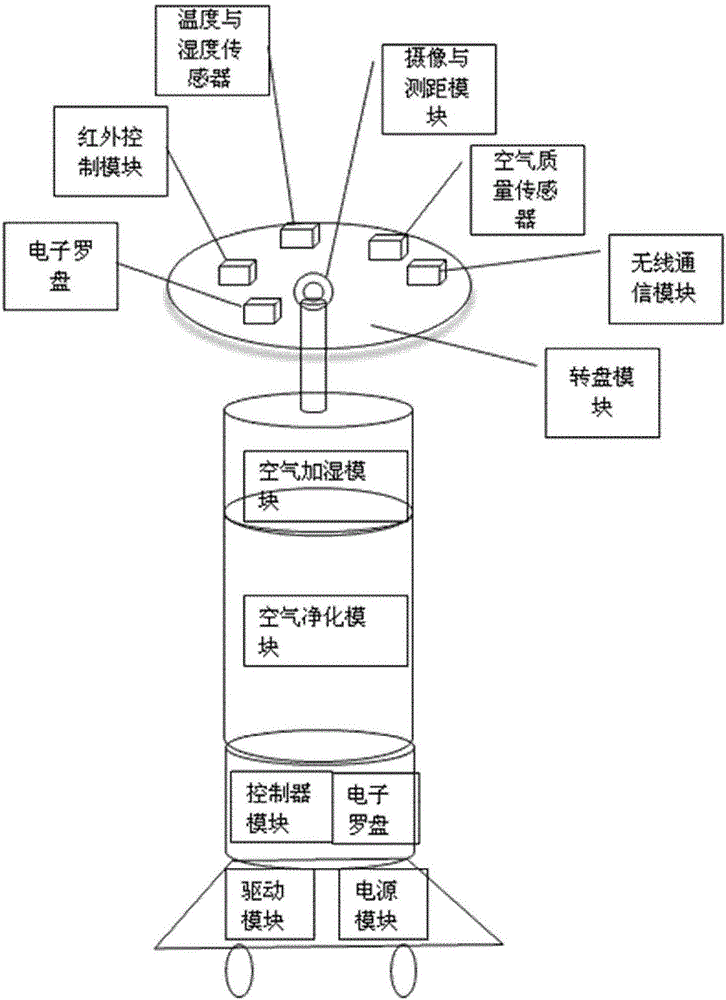

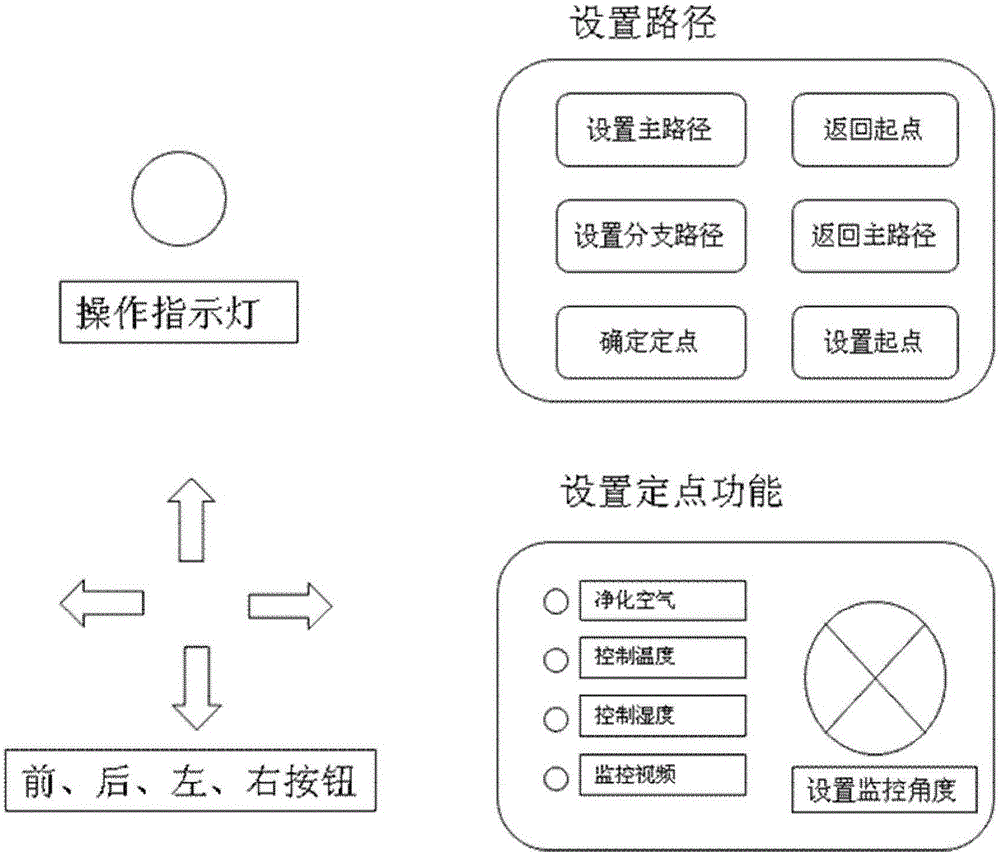

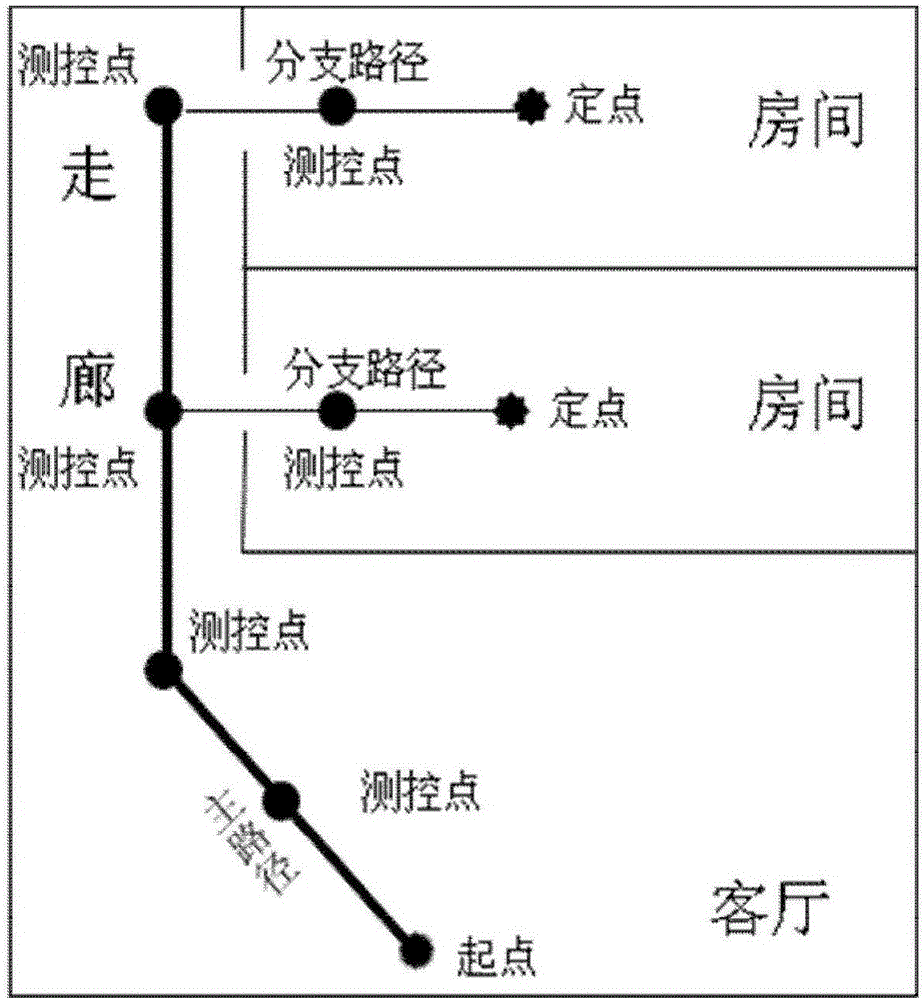

Indoor air conditioning device and method

InactiveCN105928061AReduce technical complexityTemperature controlMechanical apparatusSpace heating and ventilation safety systemsIndoor airEngineering

The invention discloses an indoor air conditioning device and method. The conditioning device comprises a controller module, an air quality sensor, a temperature and humidity sensor, an air humidification module, an air purification module and a power module. The controller module is used for controlling and receiving a set instruction for setting a motion path, and the motion path of the conditioning device is set according to the set instruction. The air quality sensor, the temperature and humidity sensor, the air humidification module, an infrared control module and the air purification module are controlled to adjust the indoor air quality, the indoor temperature and / or the indoor humidity, the temperature, the humidity and the cleanliness degree of air in each of multiple rooms of a house can be controlled, and the function of security and protection can be achieved.

Owner:深圳市智能体科技有限公司

Viscosity-modifying silica materials that exhibit low cleaning and abrasive levels and dentifrices thereof

InactiveUS7303742B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsSilicaCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Viscosity-modifying silica materials that exhibit low cleaning and abrasive levels and dentifrices thereof

InactiveUS20060110339A1Desirable abrasiveGood thickening effectCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High-cleaning silica materials and dentifrice containing such

InactiveUS20060110336A1Excellent abrasionImprove rendering capabilitiesCosmetic preparationsToilet preparationsCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

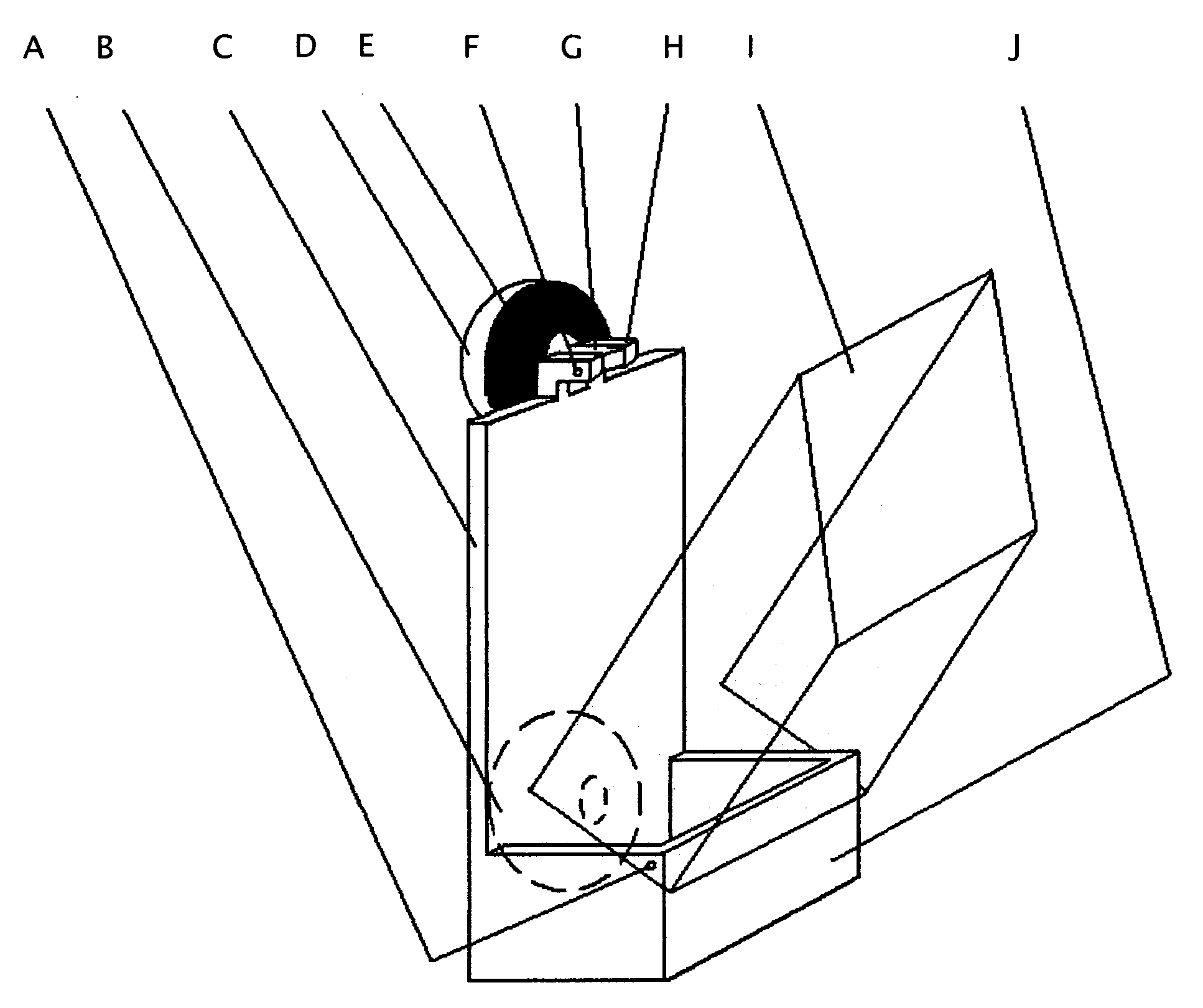

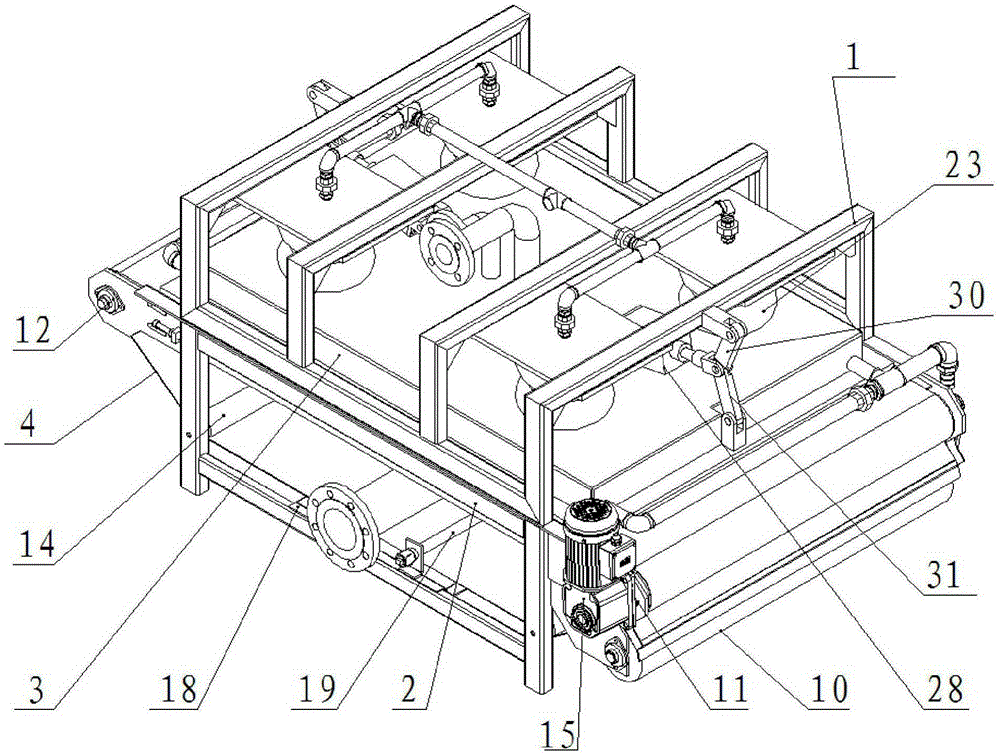

Wet electric precipitation system mounting method

ActiveCN104941805AControl installation qualityControl cleanlinessExternal electric electrostatic seperatorElectrostatic separation detailsThermodynamicsEngineering

The invention provides a thermal power generation wet electric precipitation system mounting method, which is characterized in that a thermal power generation wet electric precipitation system device is divided into several parts, and a step-by-step combined hoisting method and a mounting and anti-corrosion cross-operation method are adopted; in construction sequence, a framework is first mounted, and then a body is mounted, parts are mounted from outside to inside, and the construction principle that the mounting is in cooperation with anti-corrosion, and the mounting and the anti-corrosion are alternately carried out is followed; and the mounting is carried out according to the following operation sequences of mounting of the body and the framework, mounting of a shell, mounting of an insulation barrel, anti-corrosion, mounting of a cathode suspending lower girder (comprising a cathode wire lower framework), mounting of an anode module (comprising anode grounding and anode module upper and lower part sealing), mounting of a cathode suspending upper girder (comprising a cathode wire upper framework), mounting of a cathode wire, mounting of a top spraying system, adjusting of the cathode wire and mounting of a secondary atomizing system.

Owner:HUNAN THERMAL POWER CONSTR CO LTD OF CHINA ENERGY ENG GRP

Self cleaning blade razor holder

InactiveUS20090183379A1Easy to storeControl cleanlinessMetal working apparatusShaving accessoriesClassical mechanicsBlades razor

Owner:JOHNSON RYAN LAWRENCE

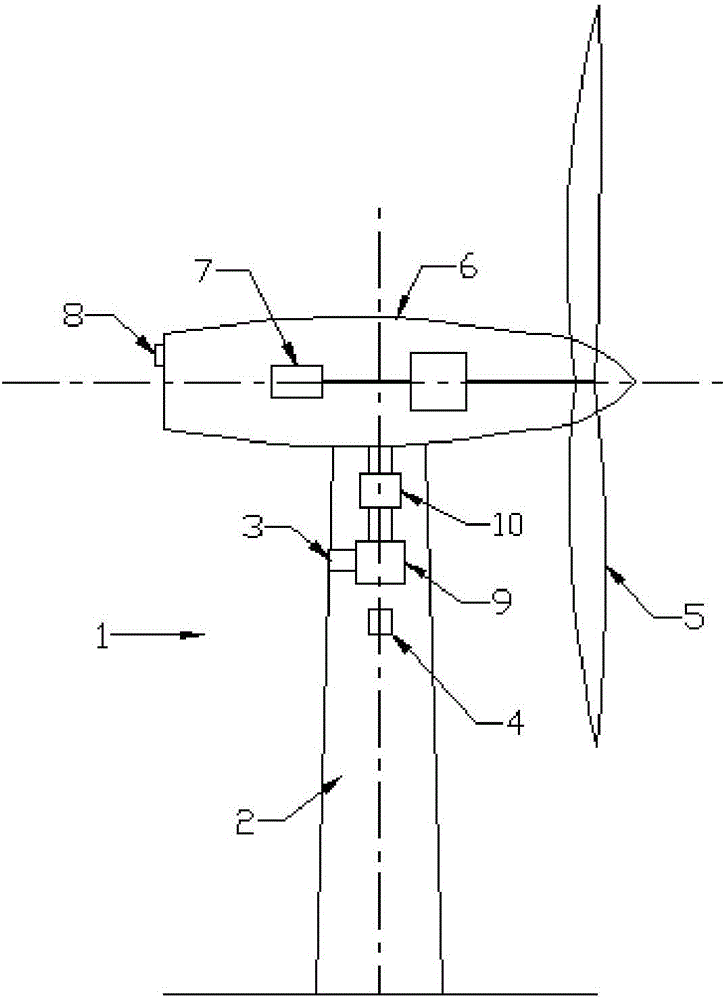

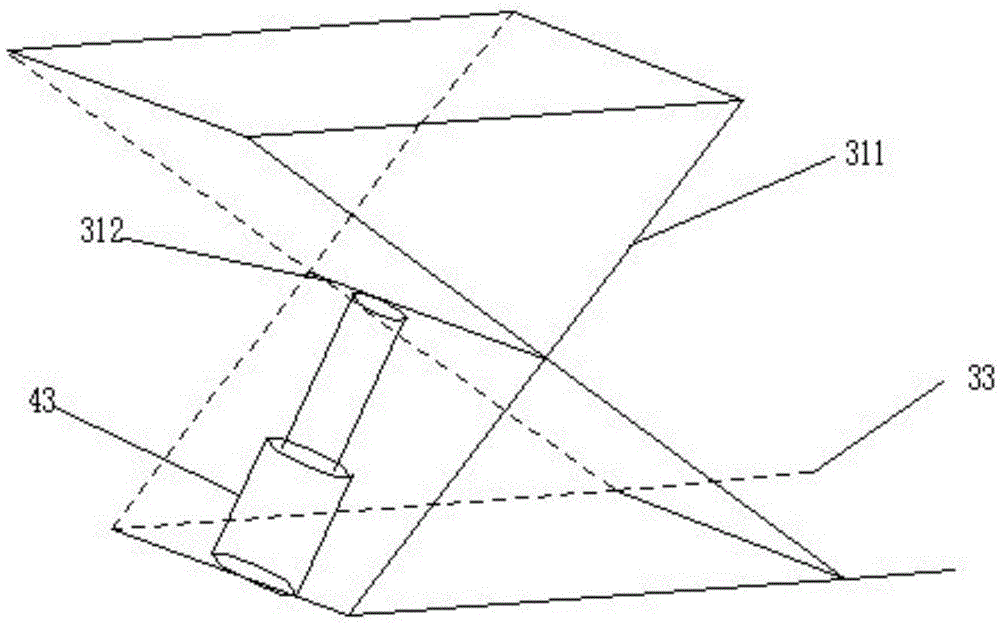

Wind driven generator

ActiveCN106224181ATemperature controlControl cleanlinessWind motor combinationsMachines/enginesWind drivenWind force

The invention discloses a wind driven generator. The wind driven generator comprises a tower drum fixed to the ground, a cabin located on a tower frame, a power generator arranged in the cabin, a rotor which rotates relative to the cabin and comprises a plurality of rotor blades, and an air circulation system used for deicing the blades and enabling the blades, the cabins and the tower drum to communicate. The air circulation system comprises a controllable air inlet formed in the position, away from the cabin by a certain distance, of the tower drum, an air filter arranged on the upper portion of the air inlet, a heater arranged on the upper portion of the air filter, and an internal heat exchanger used for heat exchange with the power generator in the cabin. Airflow circulation passages are arranged in the blades. Through the airflow circulation passages, airflow entering the blades flow through blade tips firstly and then flow through roots, and the airflow is exhausted out through small holes in the roots. By the adoption of the deicing system, the temperature, cleanliness and flow of air entering the cabin are controlled more effectively, the system does not occupy any space of the cabin, and the overall deicing effective is better.

Owner:DONGGUAN UNIV OF TECH

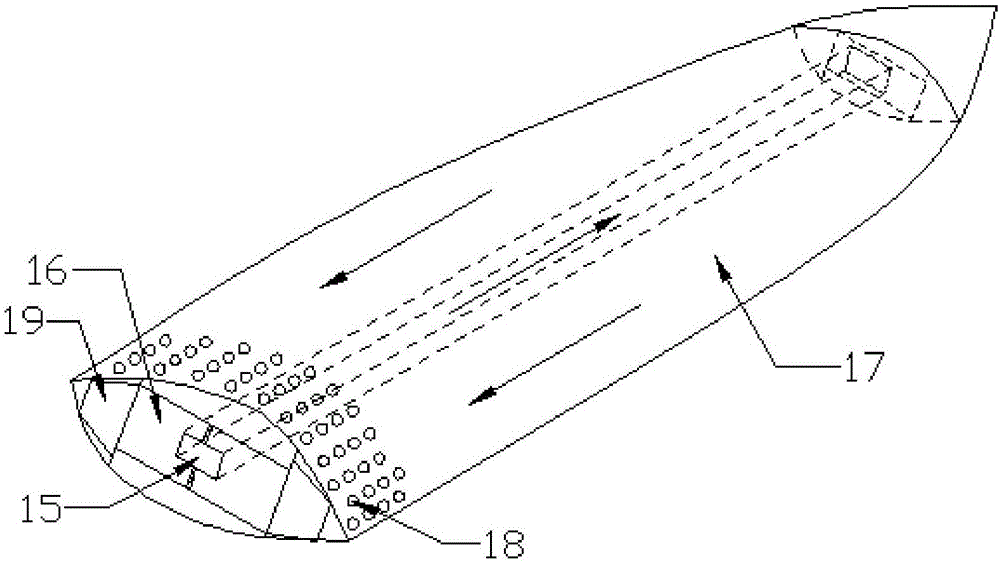

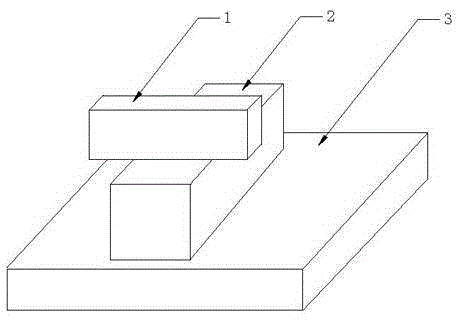

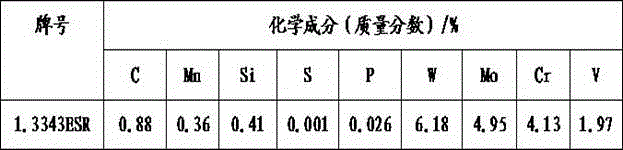

Manufacturing method for large section forgings of high-speed tool steel

InactiveCN105522085AReduce tissue segregationExcellent ingredient controlMetal-working apparatusProcess efficiency improvementTool steelForging

The invention discloses a manufacturing method for large section forgings of high-speed tool steel, and aims to solve the problem that internal cracks and surface cracks in the forgings are increased. According to the technical scheme adopted by the invention, the cleanliness of the molten steel is improved by steel-making processes such as LF refining, VD degassing, aluminum wire feeding and the like, and eutectic carbide segregation and steel hot-working plasticity are improved by controlling electroslag remelting output power and carrying out homogenization treatment before forging; large-particle carbides are crushed and unevenness of the eutectic carbides is improved by controlling forging times and different deformation amount of steel ingots of large high-speed tool steel; according to ASTMA388 standards, the ultrasonic flaw detection does not reach the level of a flat-bottom hole not greater than phi 3. The manufacturing method has the following advantages: carbon saturation is reasonably controlled, cleanliness of molten steel is controlled, segregation of components and carbides is reduced, the inner part of steel is sufficiently deformed, and the carbides of the steel internal structure are guaranteed to be crushed.

Owner:FUSHUN SPECIAL STEEL SHARES

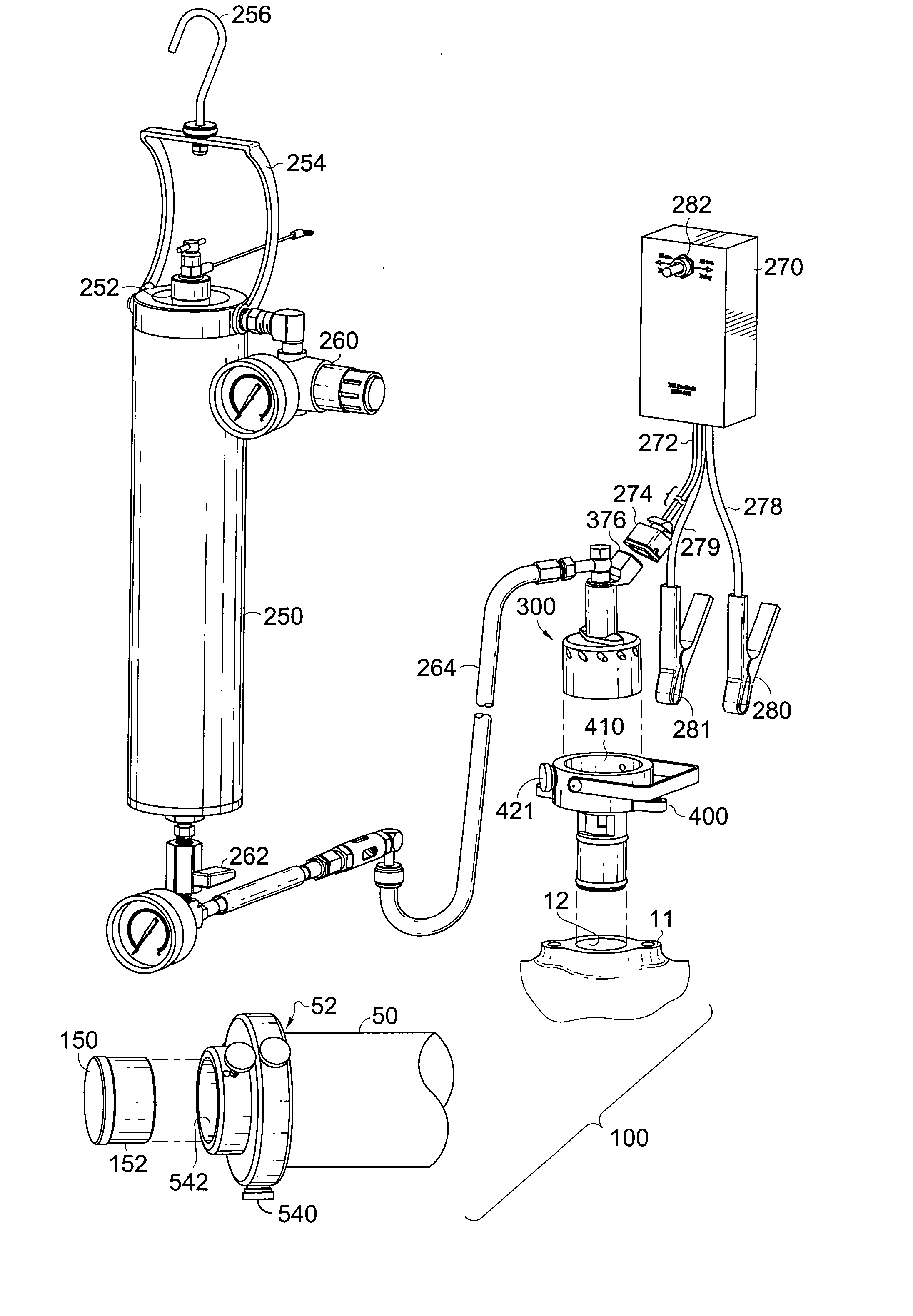

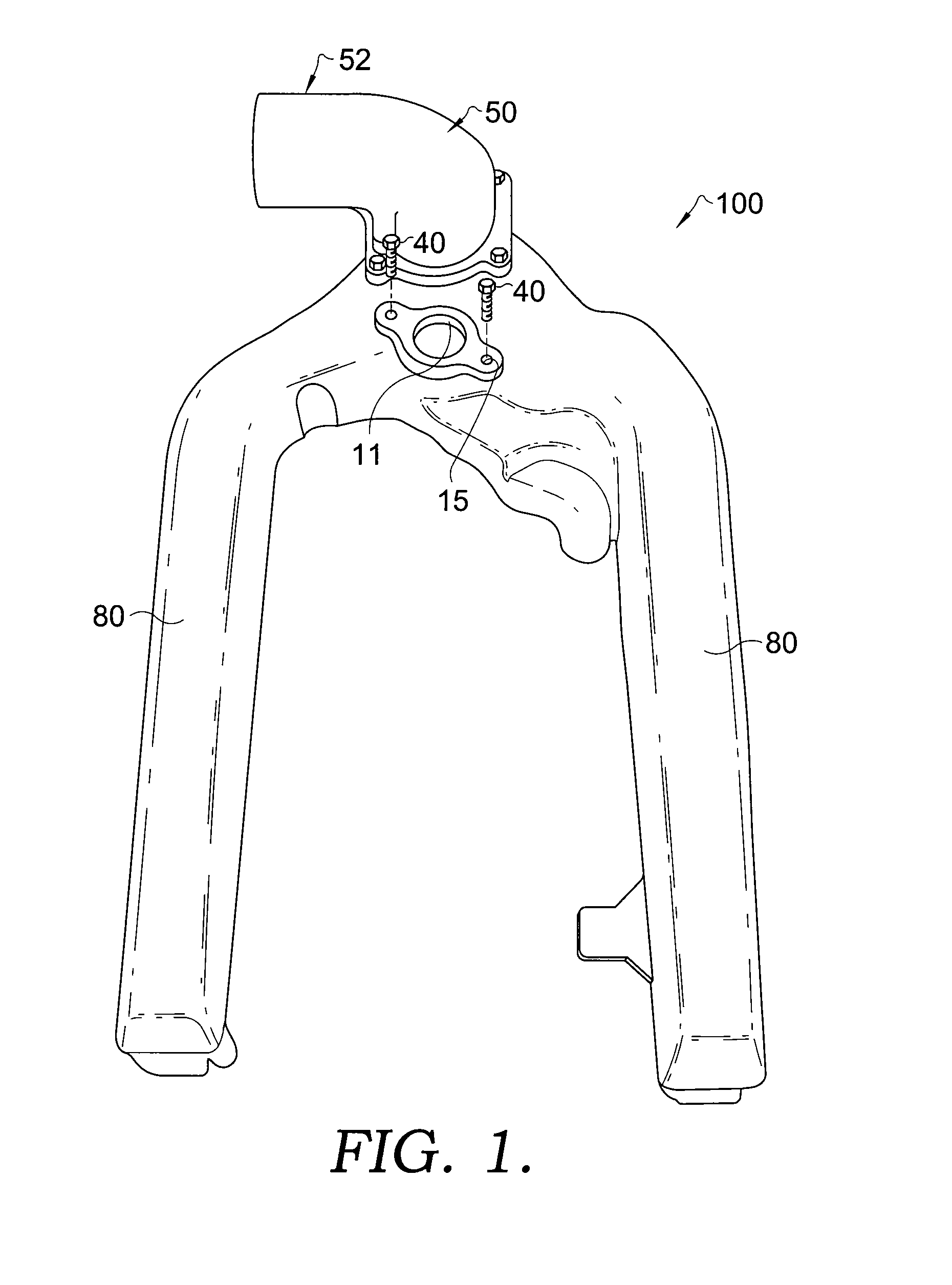

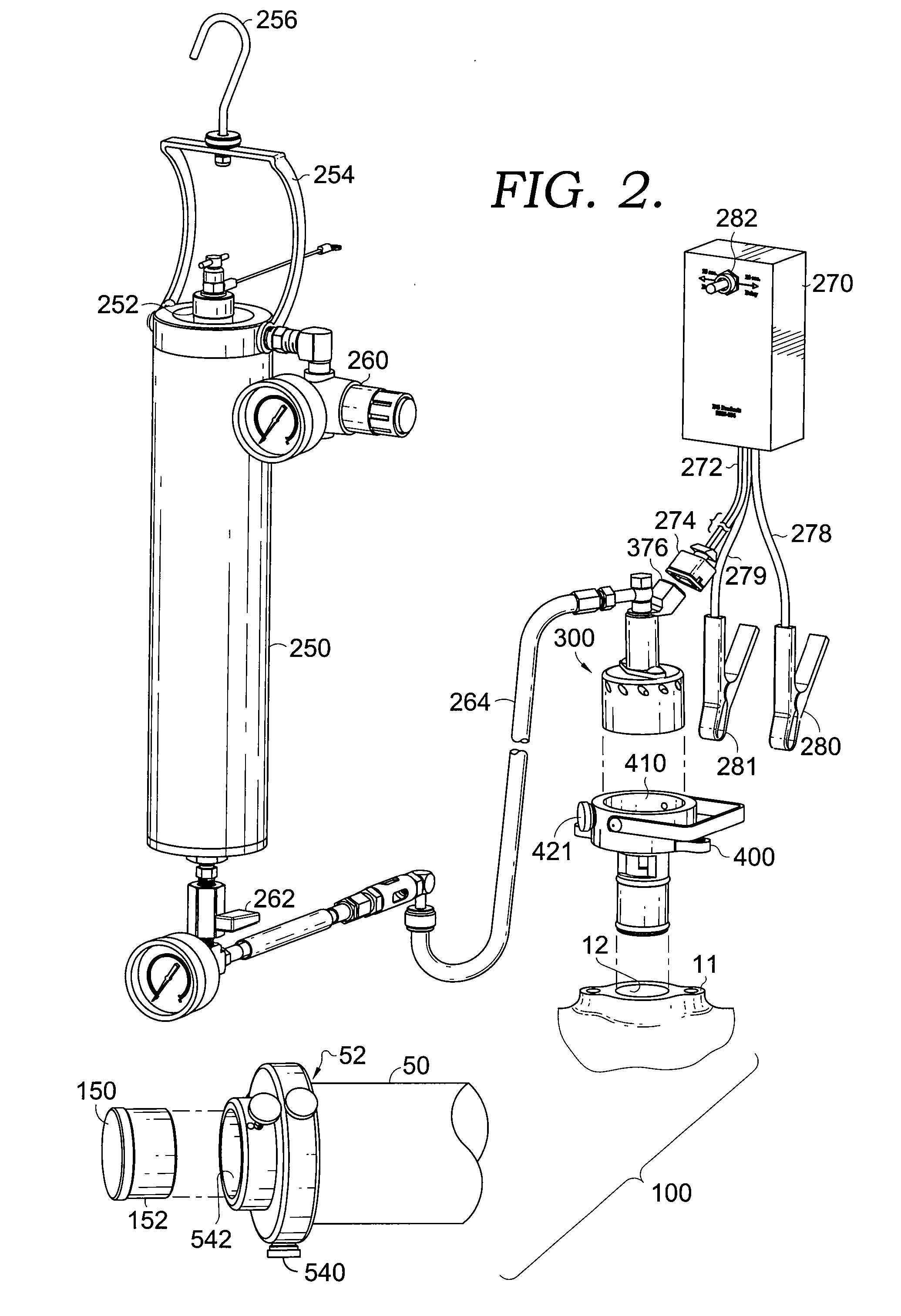

Method and device for cleaning the air intake system of a diesel vehicle

InactiveUS20080010774A1Increase air flow velocityIncrease vacuumSuction cleanersHollow article cleaningDiesel engineDiesel fuel

A device and method for cleaning the air-intake system of an EGR-valve-equipped diesel engine includes a dispersion component which mixes air and a liquid cleaning solution before delivering them to the air intake system of a running diesel engine. A main air intake is blocked and the EGR valve is removed and replaced with a coupler that receives the dispersion component, whereby a pressure drop is created. The pressure drop creates sufficient vacuum so that cleaner may be administered into the air-intake duct of the running engine. The cleaning solution is provided to the dispersion component under pressure supplied by a pressurized air source.

Owner:BG PRODS

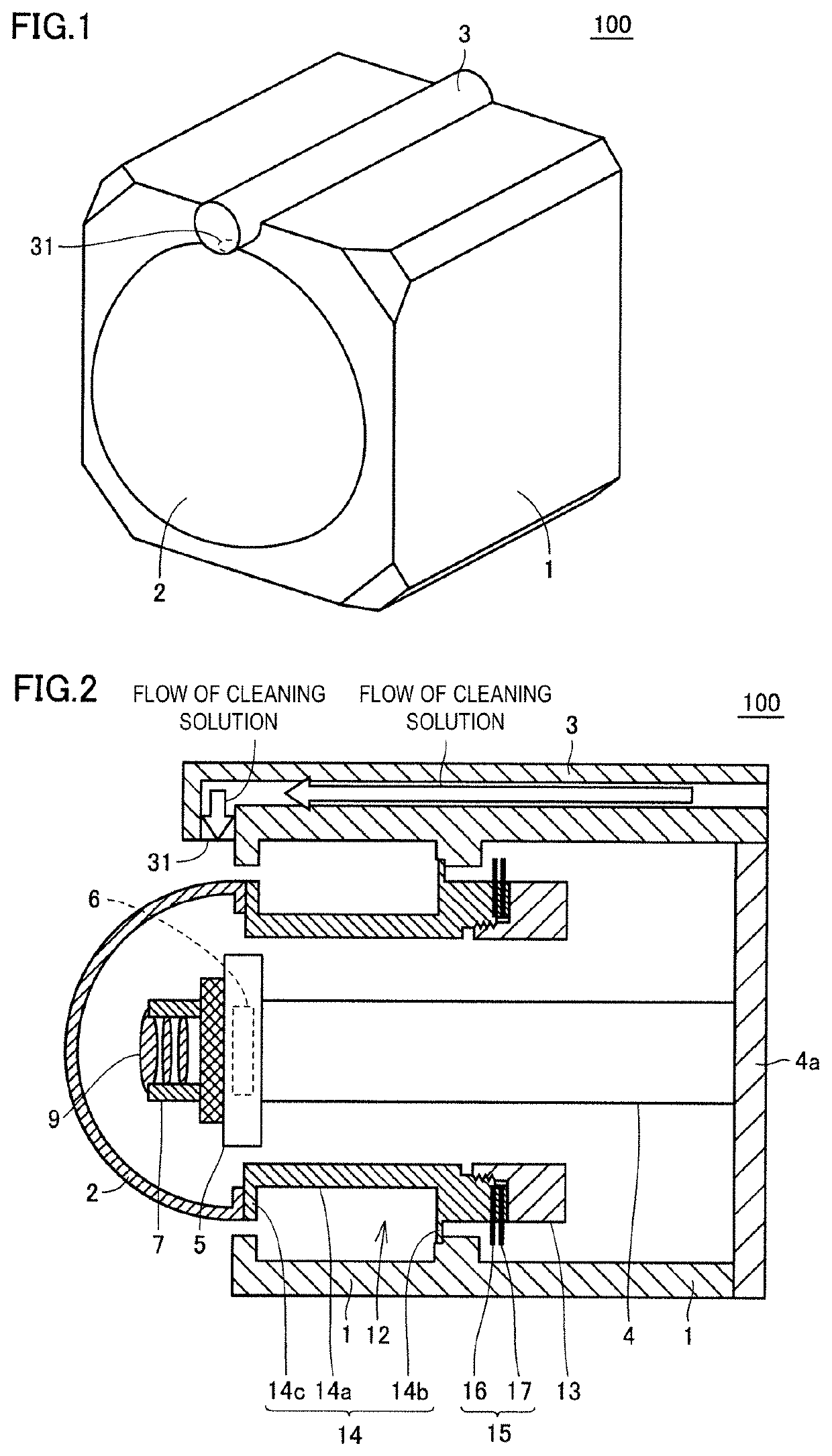

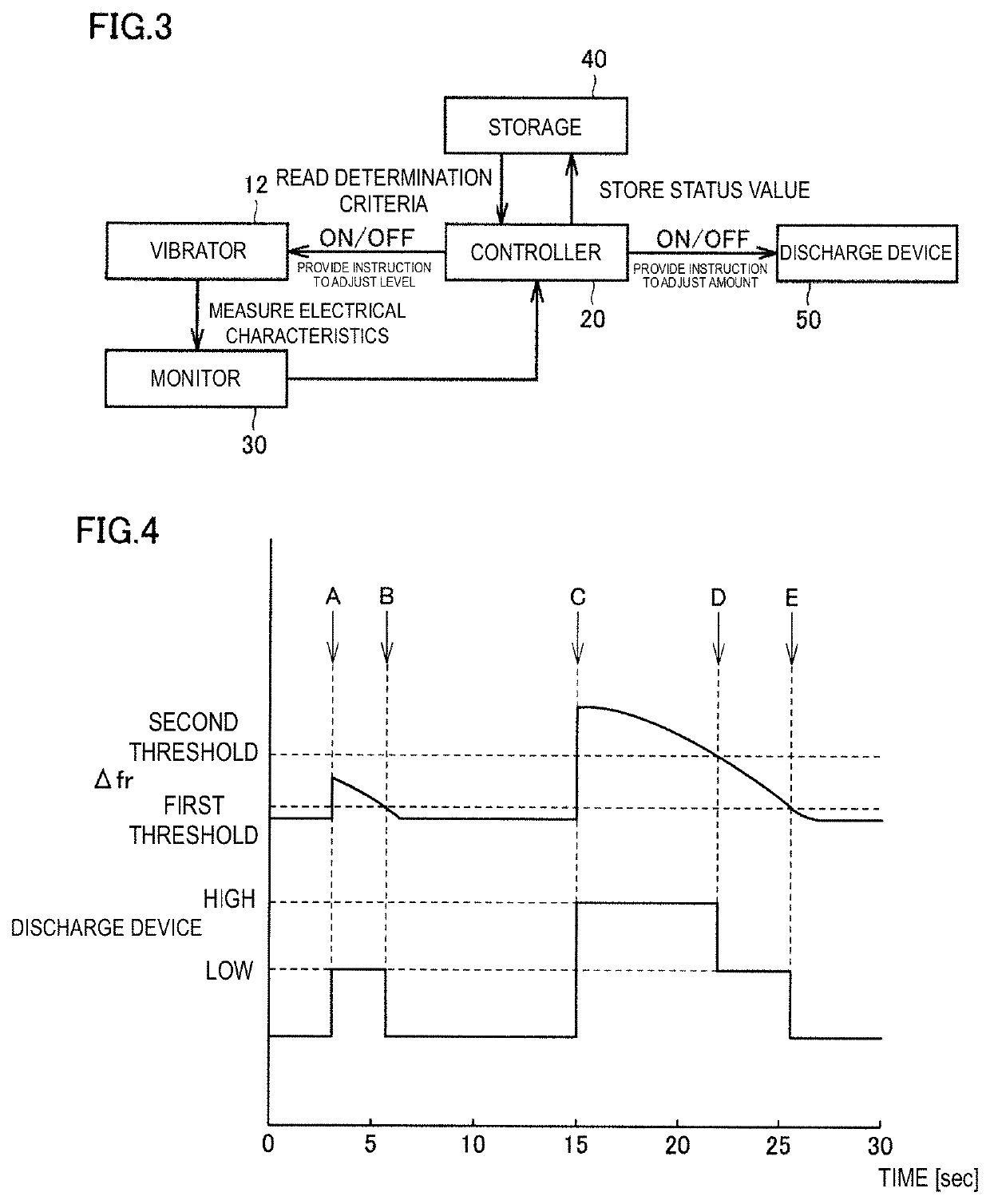

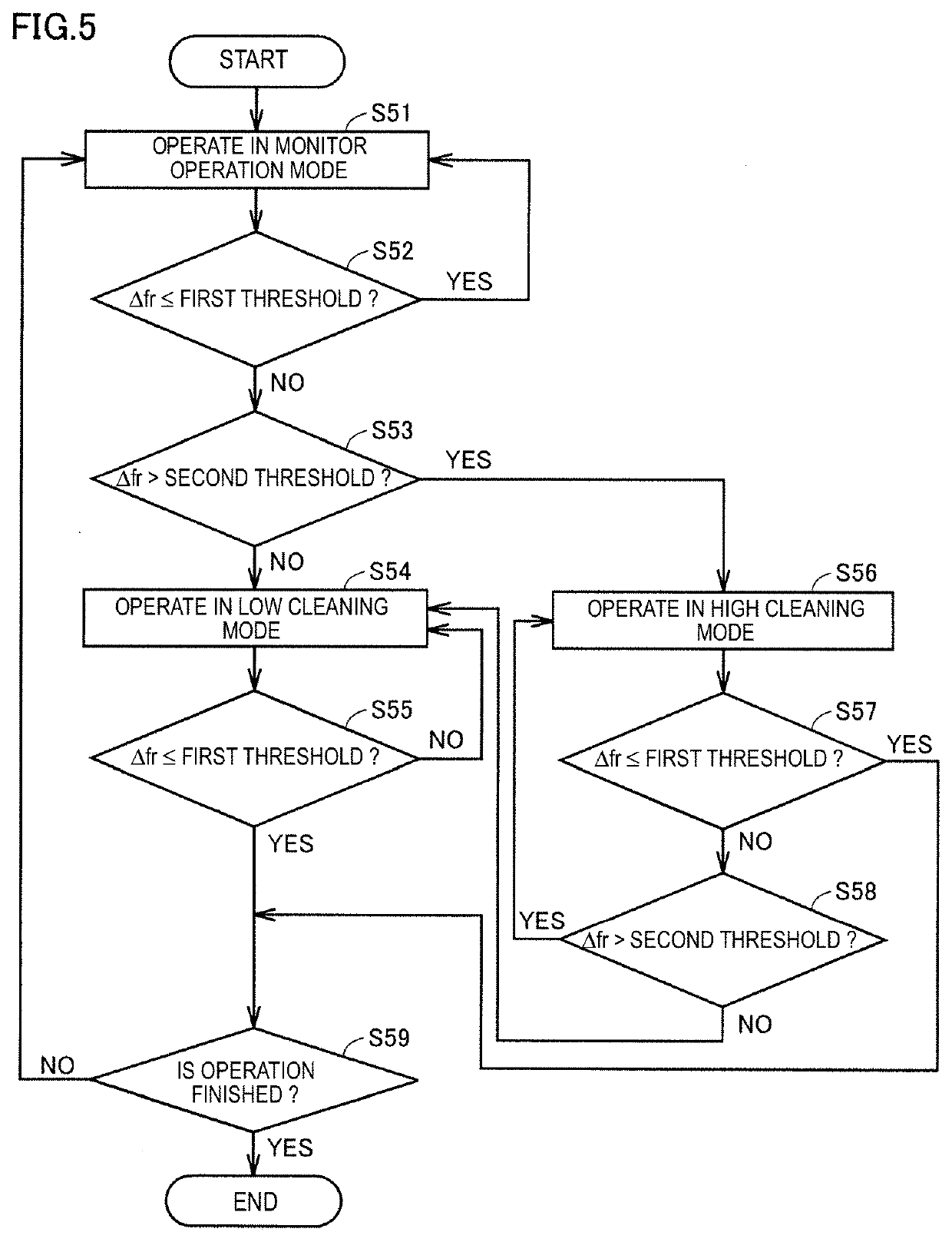

Cleaning device, and image capturing apparatus including cleaning device

ActiveUS20200057301A1Control cleanlinessExcessive cleaning or insufficient cleaning is reduced or preventedVehicle componentsVehicle cleaningControl engineeringMechanical engineering

Owner:MURATA MFG CO LTD

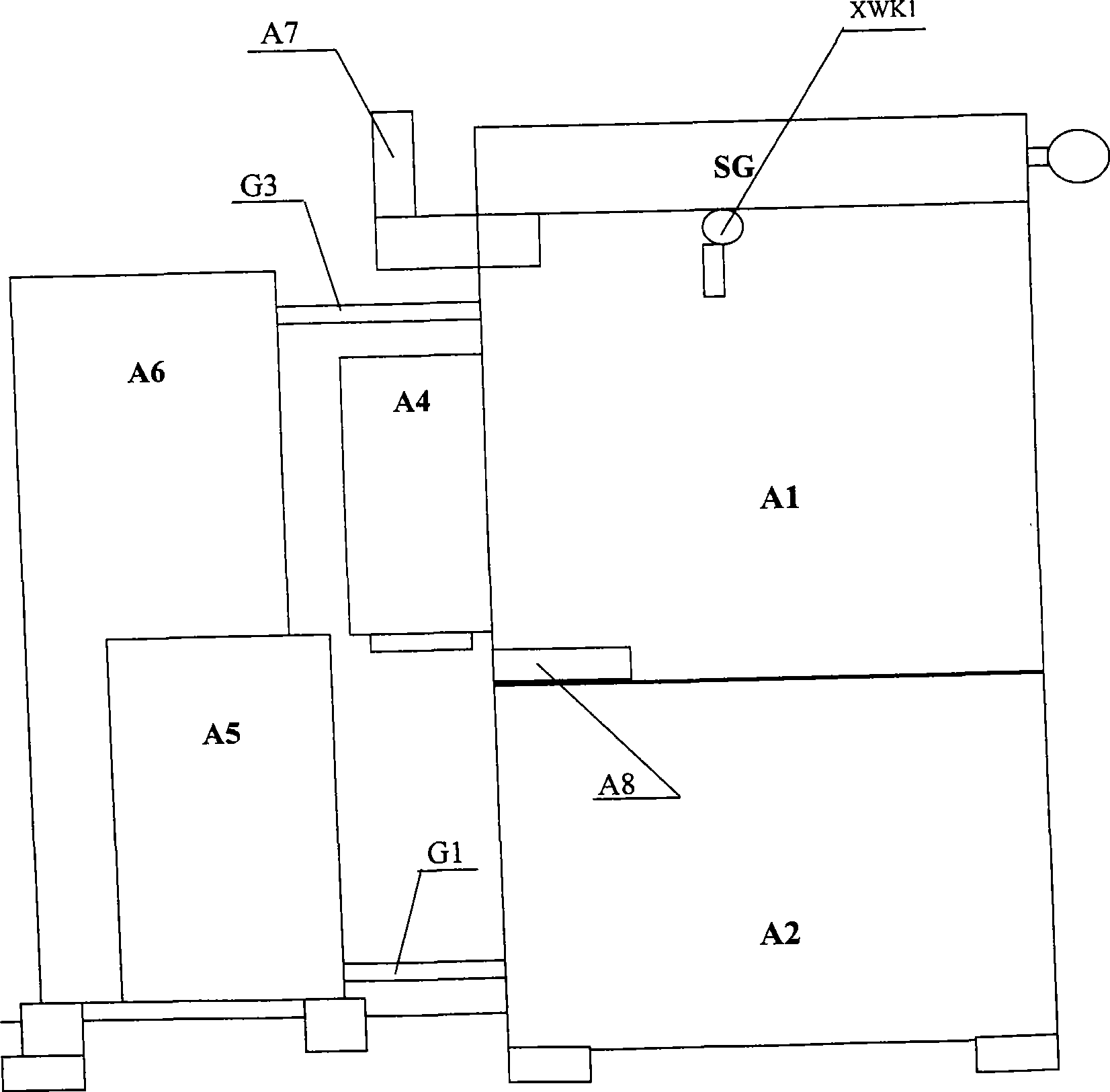

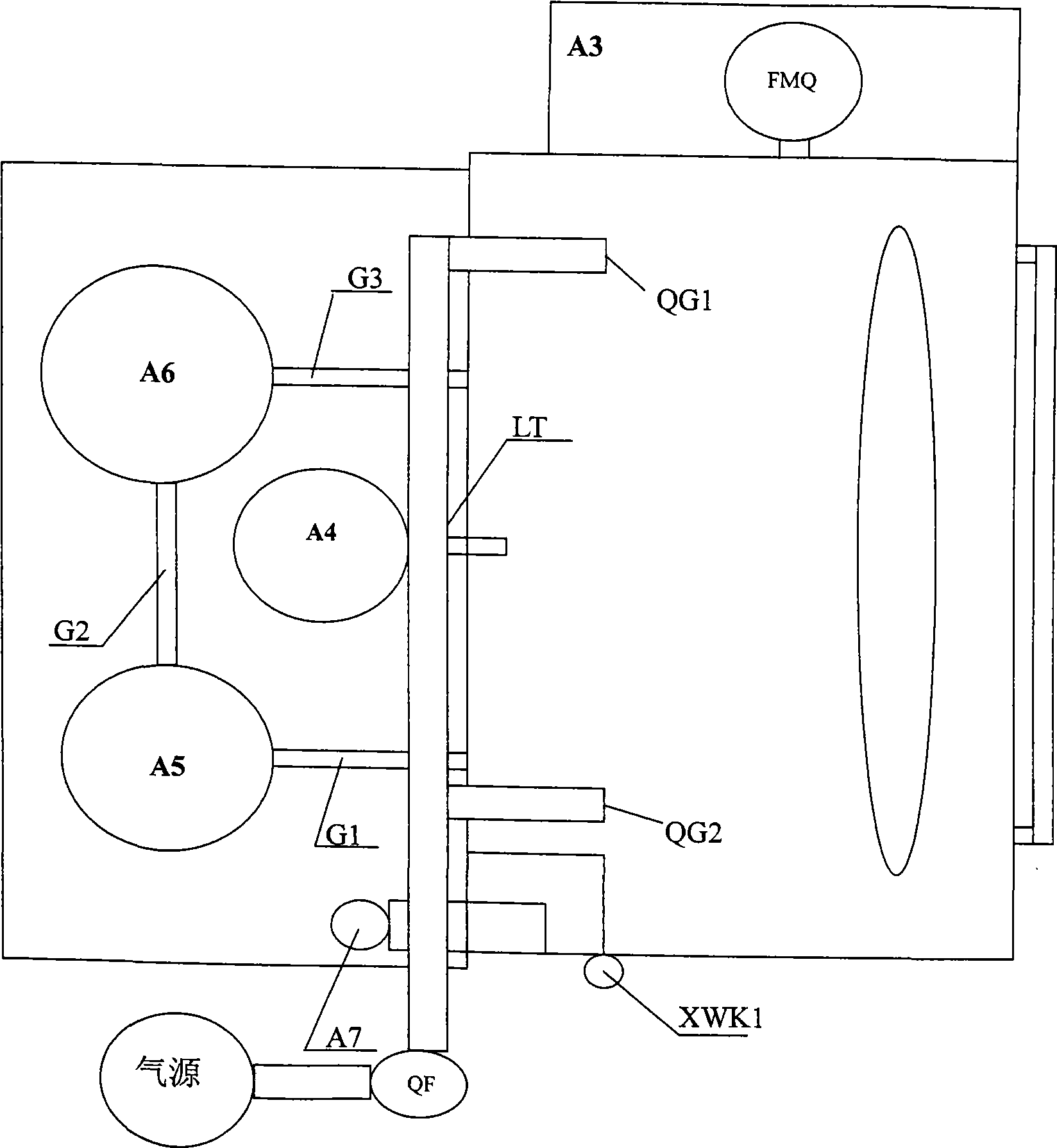

Device and method for cleaning middle shell cavity of automotive turbine supercharger

The invention provides a device and a method for cleaning a middle shell cavity of an automotive turbine supercharger. The invention adopts the technical proposal that the device comprises a cleaning room and is characterized in that a netlike turntable is arranged in the cleaning room, the periphery of the netlike turntable is provided with at least one seat, a first branch pipe on a first pipeline is extended into the cleaning room and connected with a high-pressure oil distributing valve, at least one second branch pipe on the first pipeline is extended into the cleaning room, an electric control air valve is connected with an air pipe, and the end parts of the air pipe are extended into the cleaning room and arranged on the upper part and the lower part of the netlike turntable respectively. The method comprises: putting a middle shell of the automotive turbine supercharger into the cleaning room, then cleaning a cavity of the middle shell by using the high-pressure oil distributing valve, and cleaning the outer surface of the middle shell by using the second branch pipe and the air pipe. The device and the method for cleaning the middle shell cavity of the automotive turbine supercharger have the advantage that the device and the method can achieve full-automatic cleaning.

Owner:SHANGHAI XIECHANG HUONING MACHINERY MFG

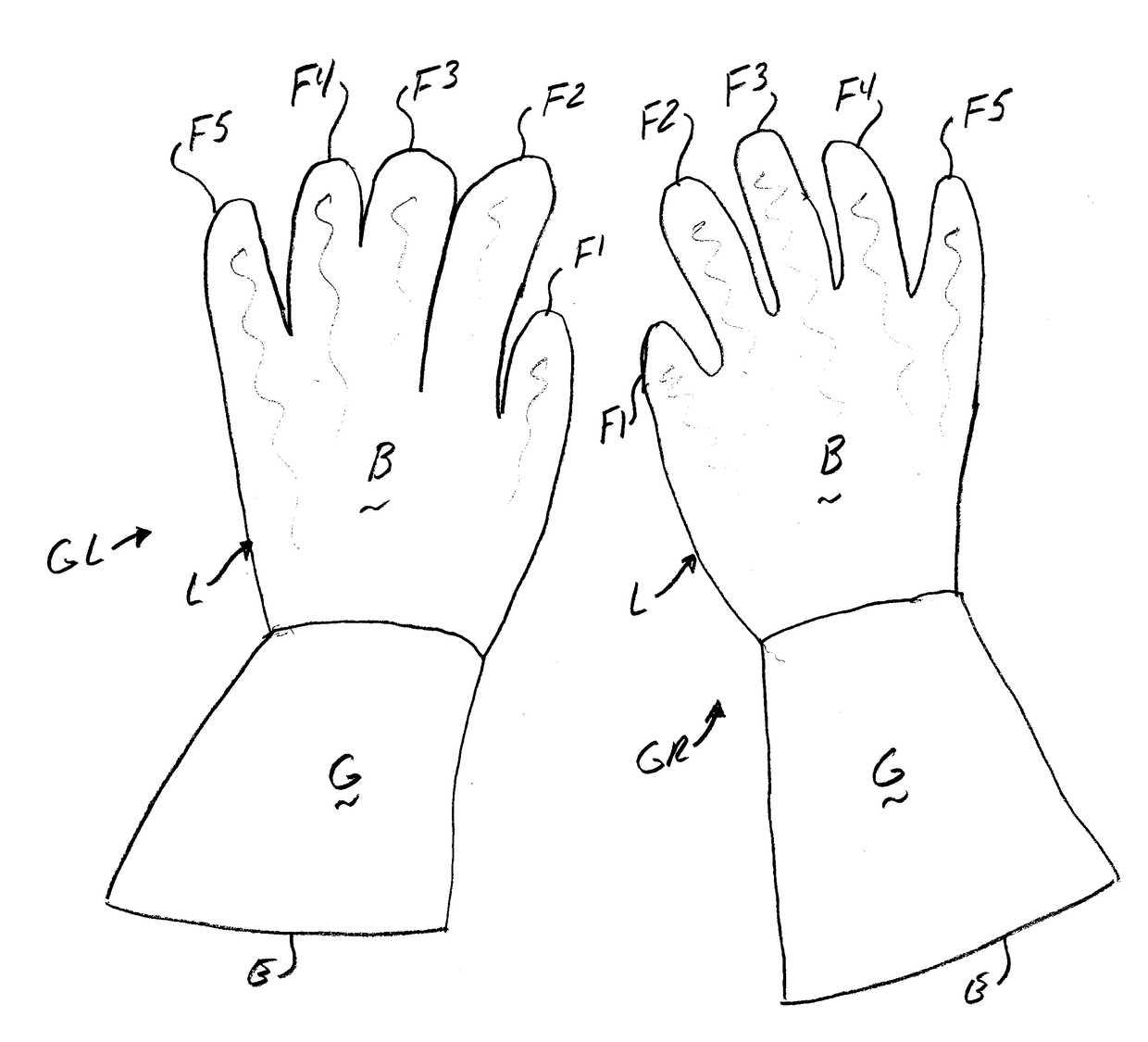

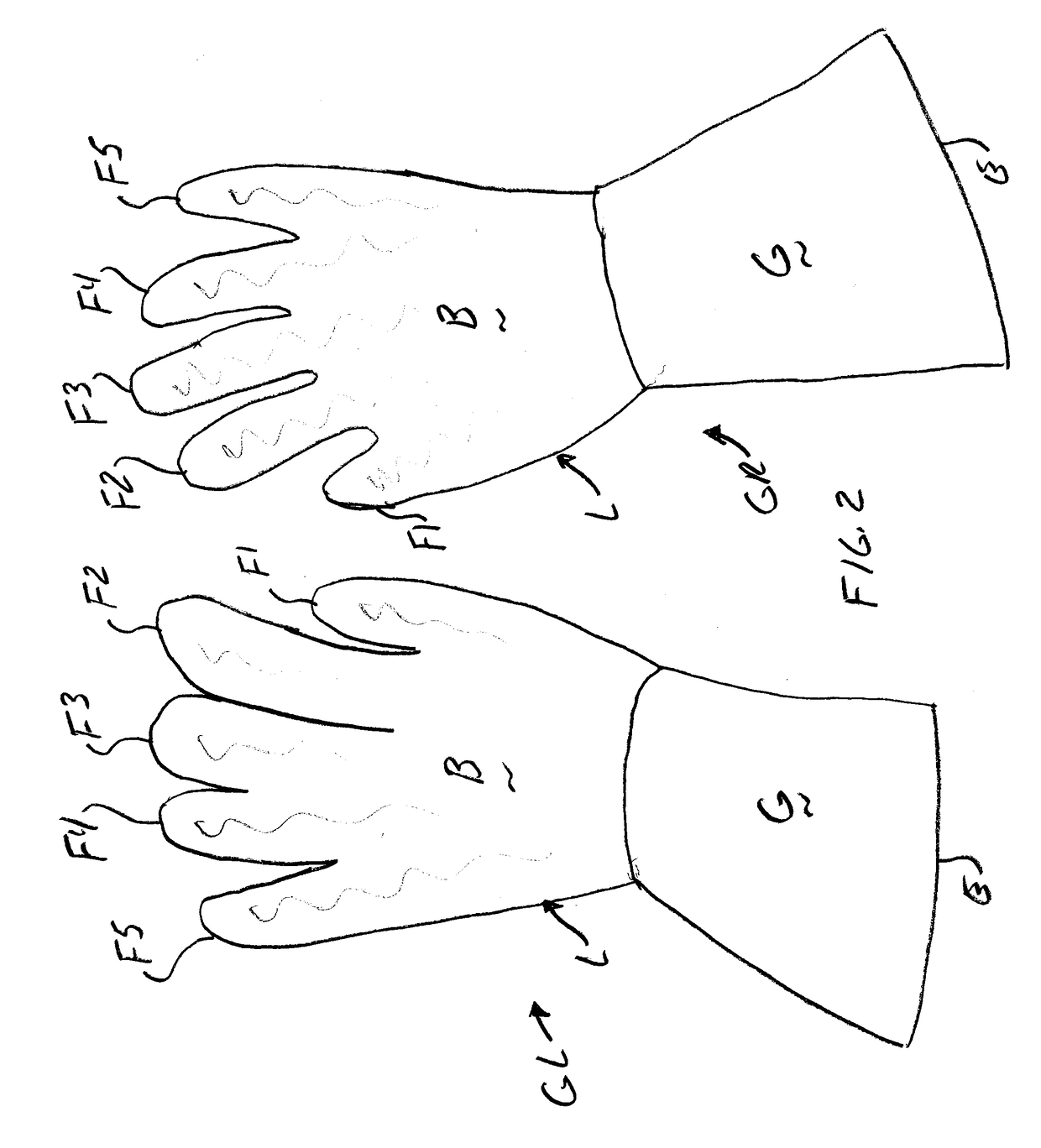

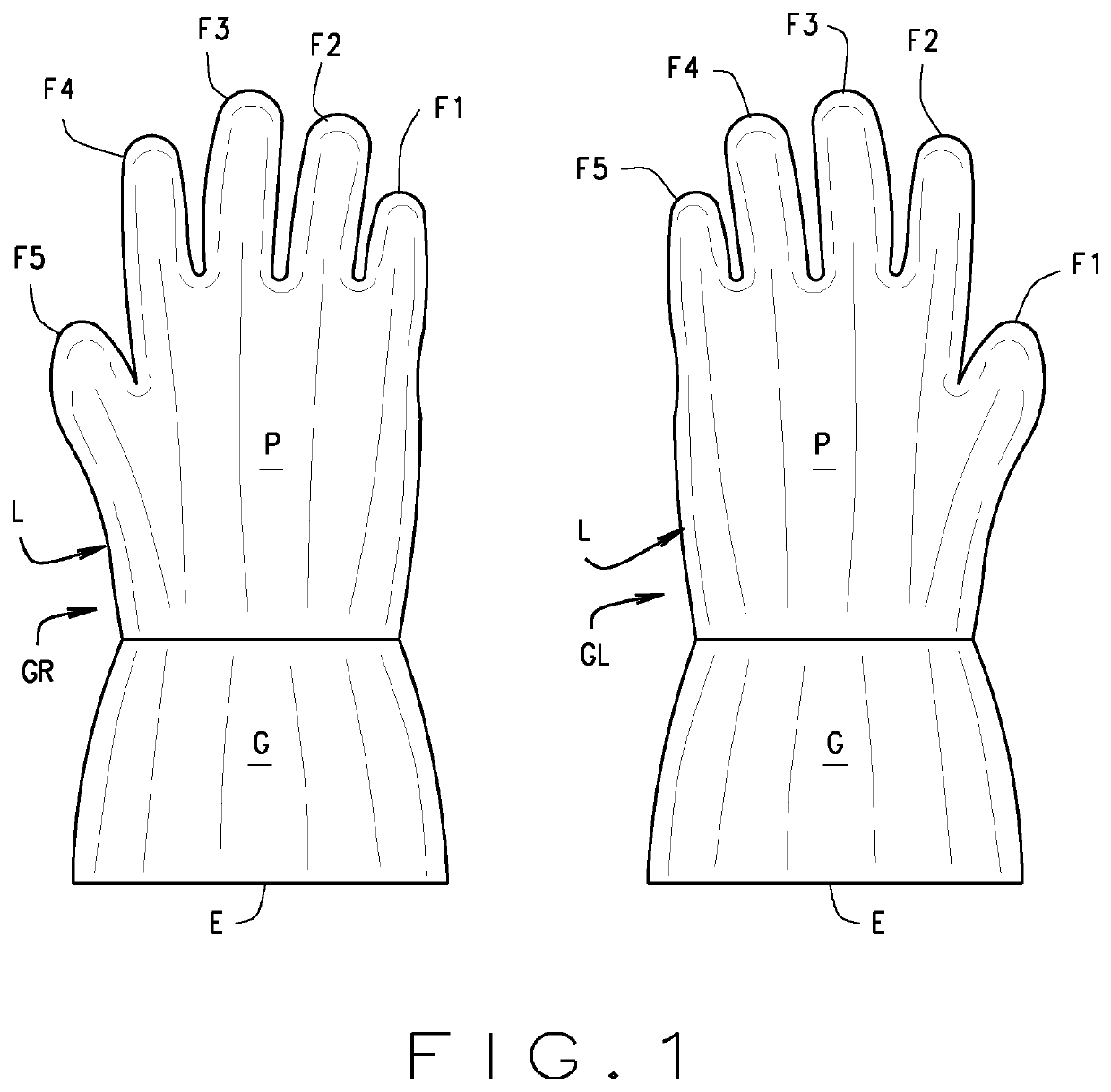

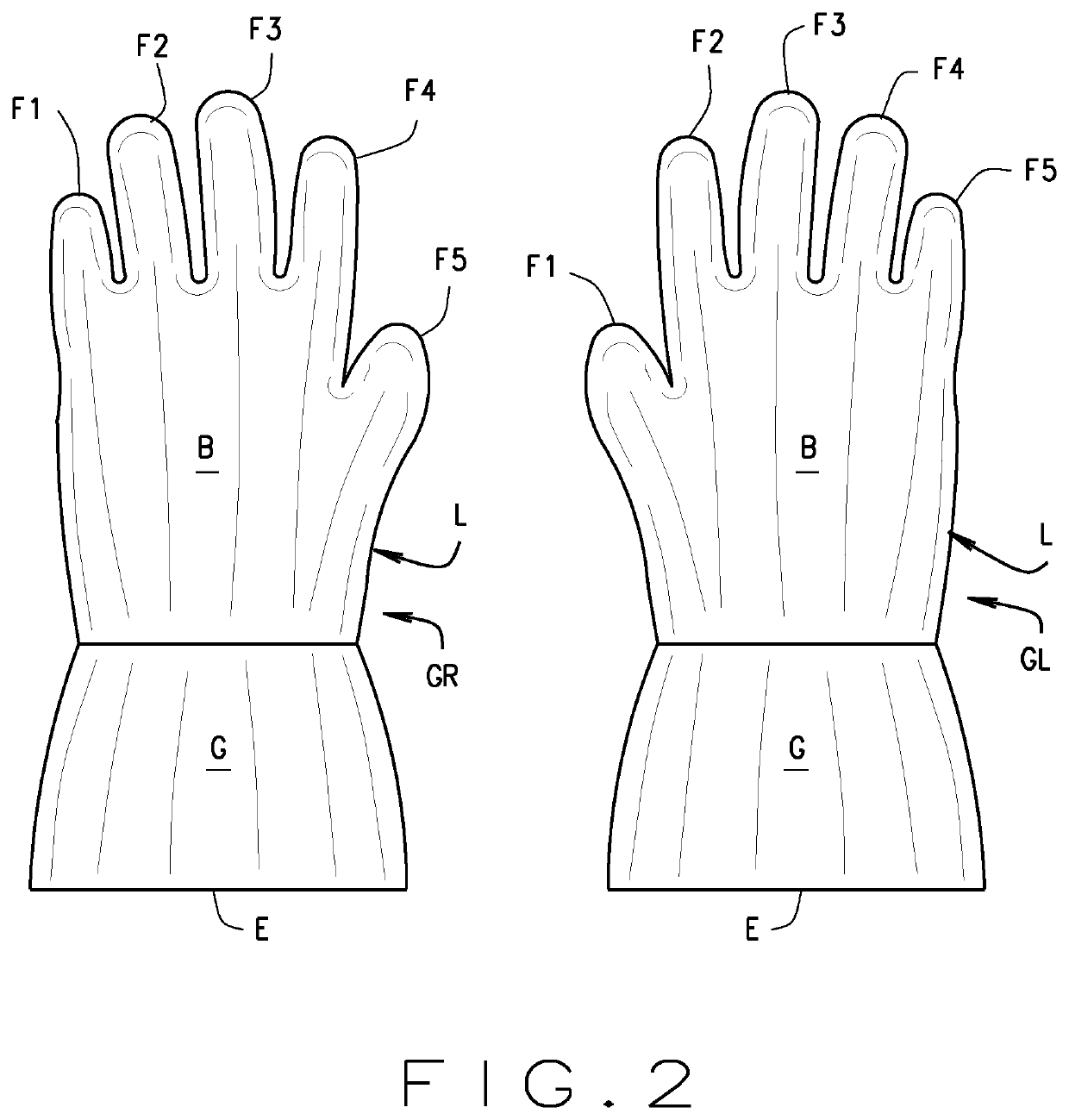

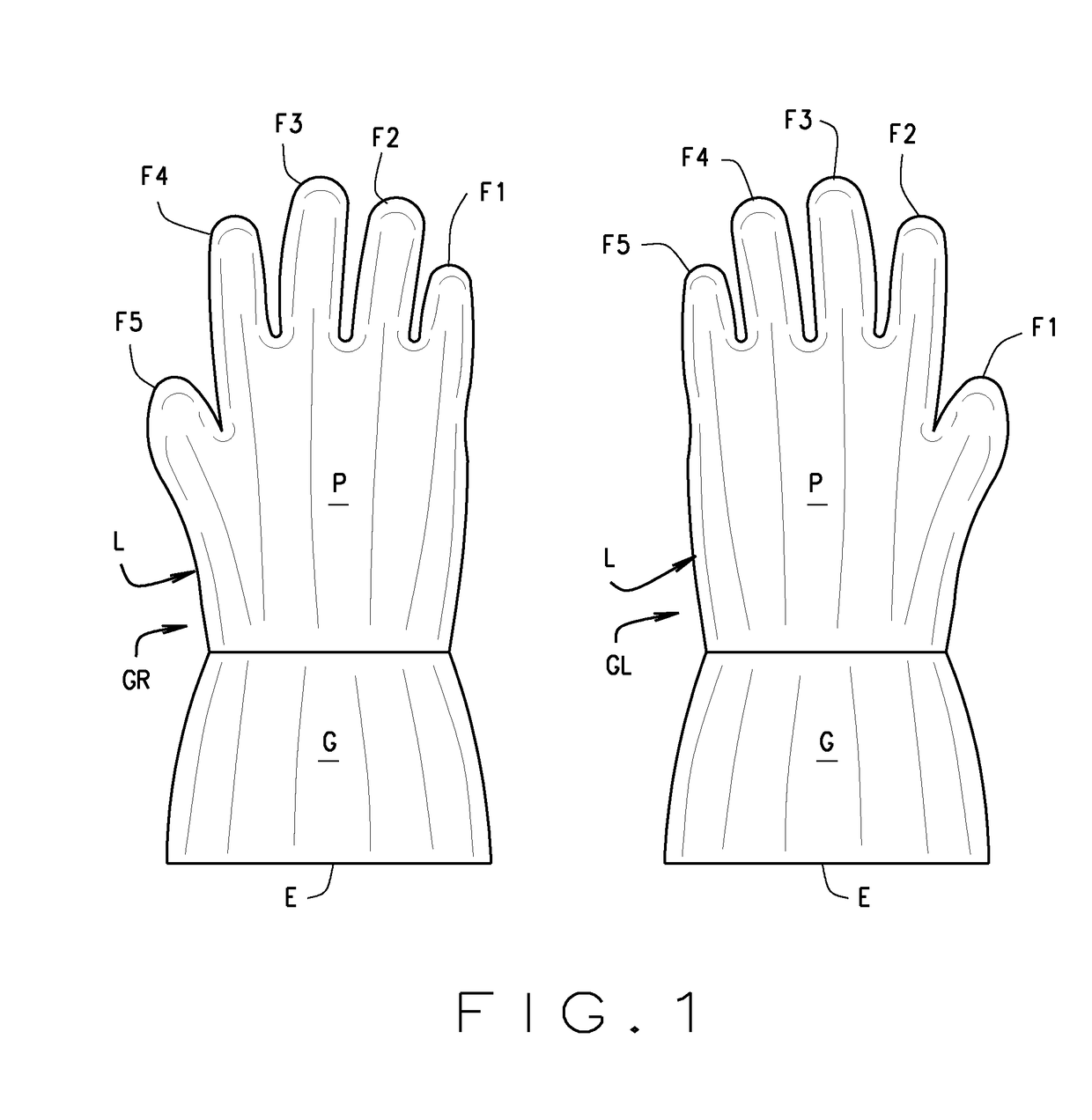

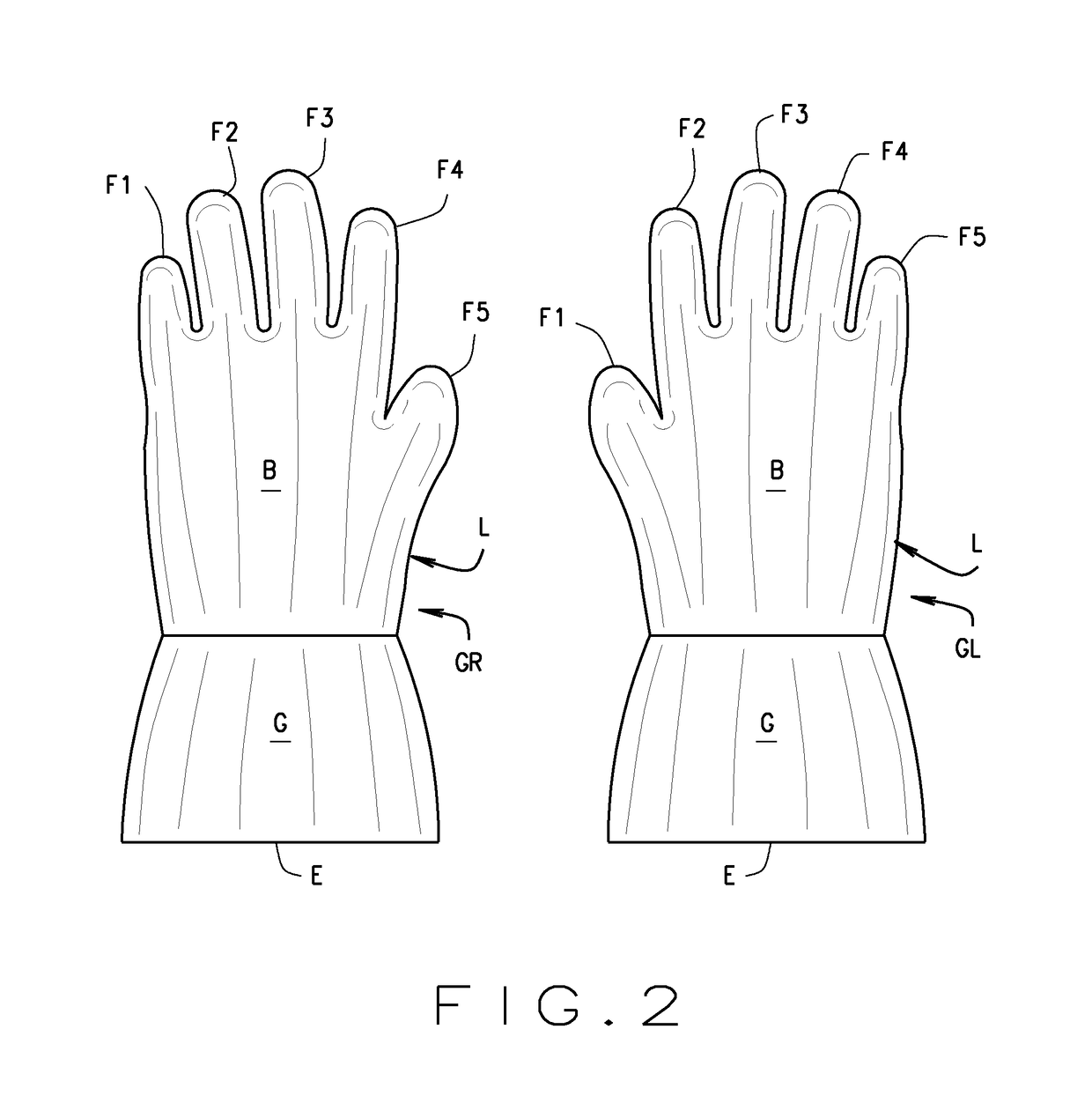

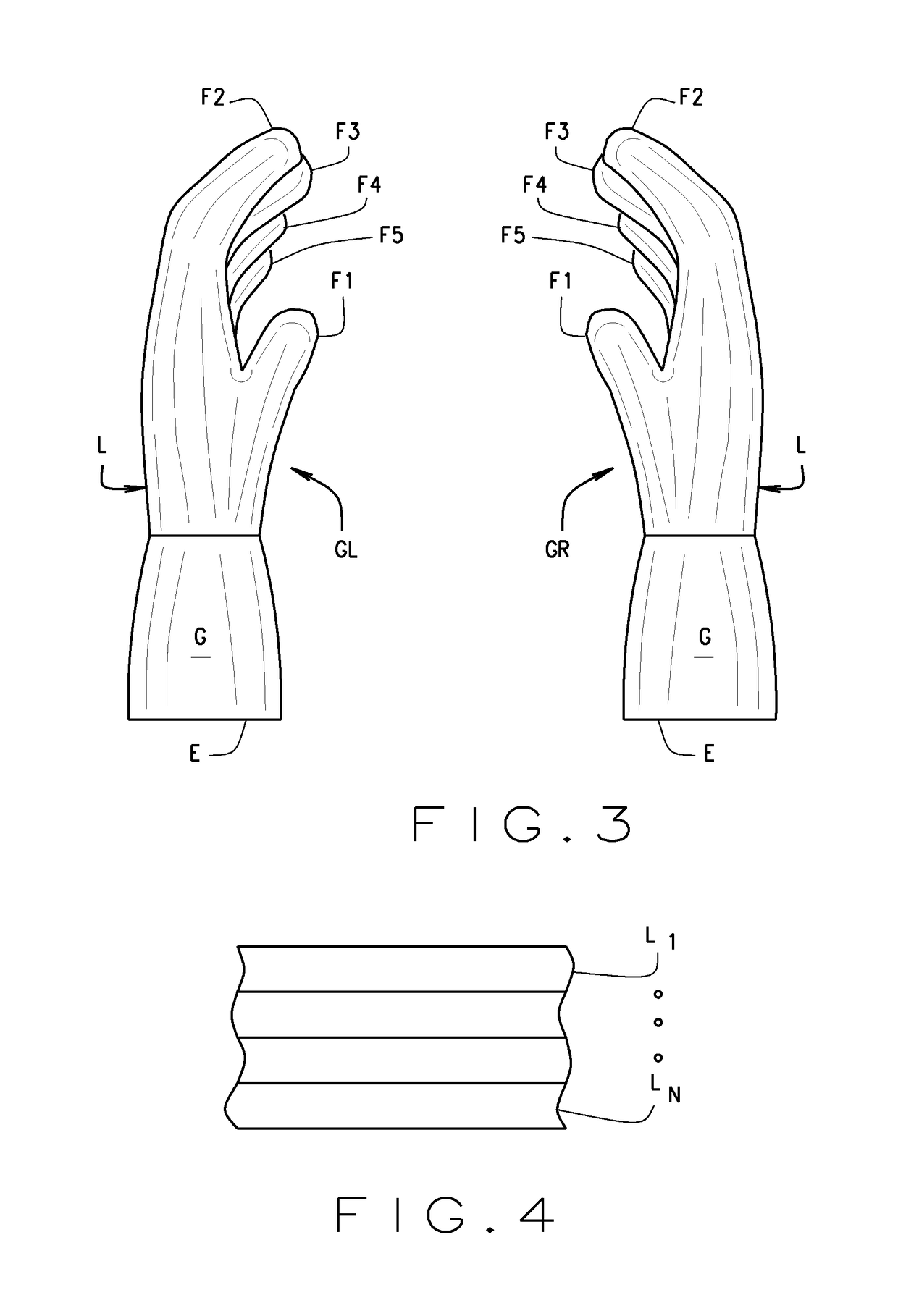

Scrub glove for cleaning various articles

InactiveUS20170143178A1Low costReduce cleaningCarpet cleanersBrush bodiesBiomedical engineeringAbrasive

A cleaning utensil for expeditiously and thoroughly cleaning dirty surfaces includes an ergonomic scrub glove (10) worn by a person doing the cleaning. The scrub glove has a base portion made of a material impervious to liquids and which covers the person's hand and wrist and at least a portion of their forearm when worn. An outer layer (L) of the scrub glove comprises an abrasive woven mesh material which encases the portion of the scrub glove covering the person's hand. A cleaning solution is poured onto this outer layer for the wearer to apply the solution to a surface being cleaned by the wearer by moving their hand over and about a surface to be cleaned. The base portion of the scrub glove prevents the person's hand, wrist and forearm from coming in contact with the cleaning solution.

Owner:MESITI NATHAN

Semiconductor silicon wafer corrosive liquid and corrosion method thereof

InactiveCN106024675AReduce damageEasy to controlSemiconductor/solid-state device manufacturingMicroelectronicsCorrosion

The invention relates to the technical field of microelectronic processing and especially to a semiconductor silicon wafer corrosive liquid. The semiconductor silicon wafer corrosive liquid is formed by mixing nitric acid, hydrofluoric acid, and glacial acetic acid according to a volume ratio of 4-14: 4-14: 6-18. A semiconductor silicon wafer is placed in a closed container containing the semiconductor silicon wafer corrosive liquid in order to be corroded on a low-temperature condition. Different corrosion demands are satisfied by regulating the ratio of the nitric acid to the hydrofluoric acid. The corrosion rate and the corrosion depth of the semiconductor silicon wafer, and the surface cleanliness of the corroded semiconductor silicon wafer can be controlled on the low-temperature condition. The corrosion rate at a low-temperature environment is less than that at a normal-temperature environment, so the corrosive uniformity of the semiconductor silicon wafer is easier to control. The semiconductor silicon wafer corrosive liquid is easy to form, attainable in raw material, low in cost, and very suitable for industrial production of semiconductor microelectronics.

Owner:江苏佑风微电子有限公司

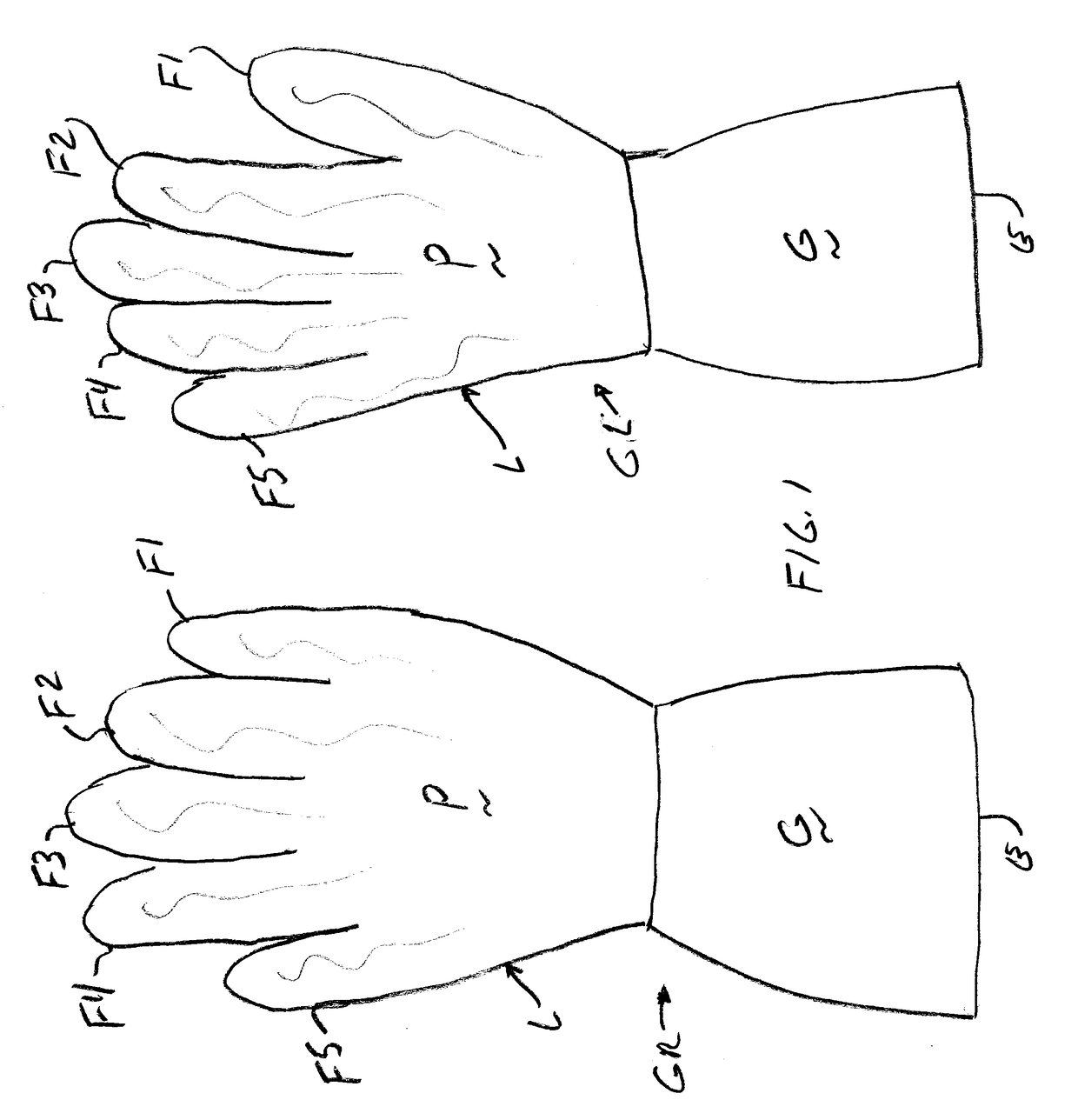

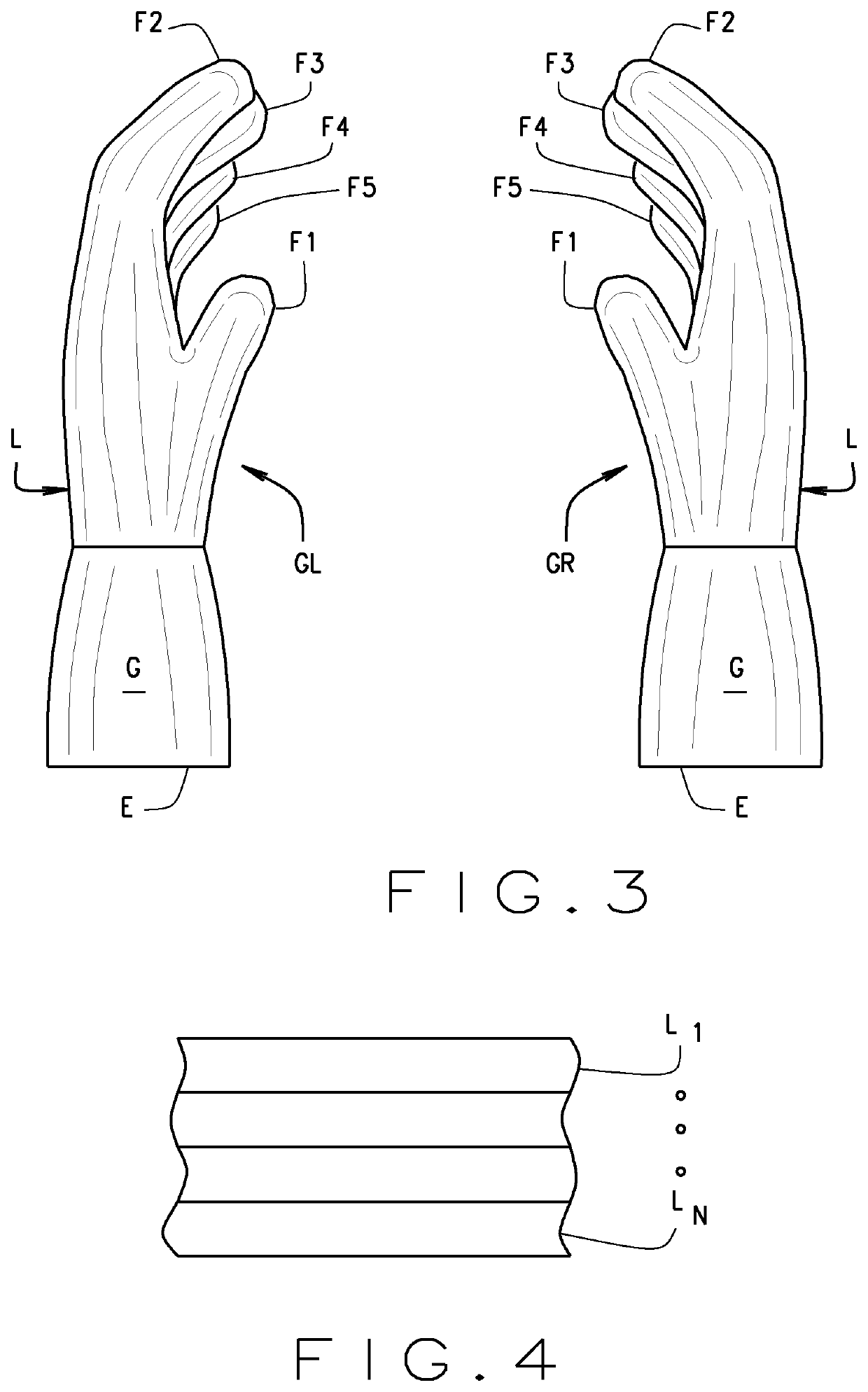

Scrub glove for cleaning various articles

ActiveUS11129513B2Low costReduce the amount requiredCarpet cleanersBrush bodiesPhysical medicine and rehabilitationPhysical therapy

A scrub glove (G′) has an inner layer (IL) fitting over a wearer' thumb, fingers, palm, and back of their hand, the wearer's wrist and a portion of their forearm. The glove further has an outer layer (OL) of an abrasive, woven mesh material formed to fit over the inner layer and enclosing the wearer's thumb, fingers, palm, the back of their hand, and their wrist. A band (D) fits over an open end of the outer layer where it fits over the open end and a cuff portion of the inner layer and is permanently secured to both the inner and outer layers. While the outer layer fits over the inner layer, it does not adhere to the inner layer whereby when the glove is used fin cleaning, the outer layer is free to move separately from the inner layer.

Owner:MESITI NATHAN

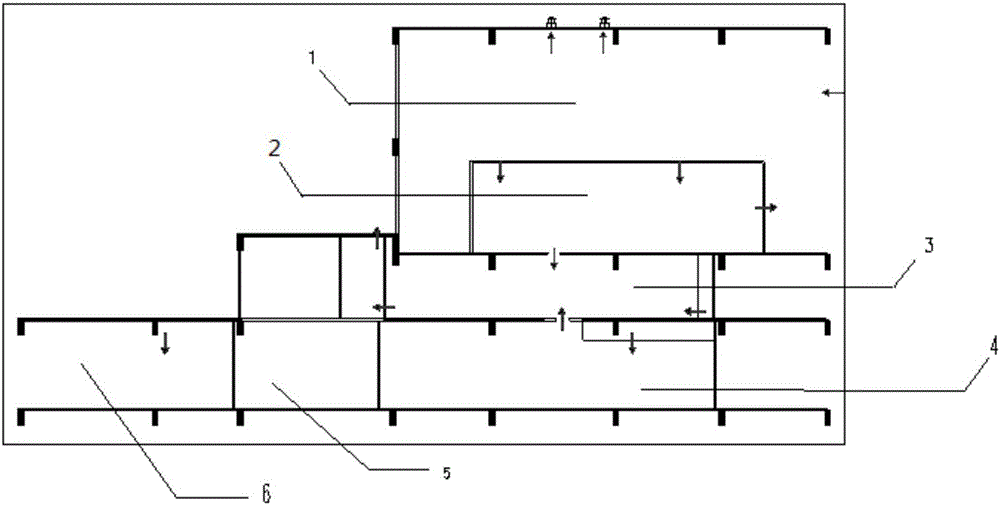

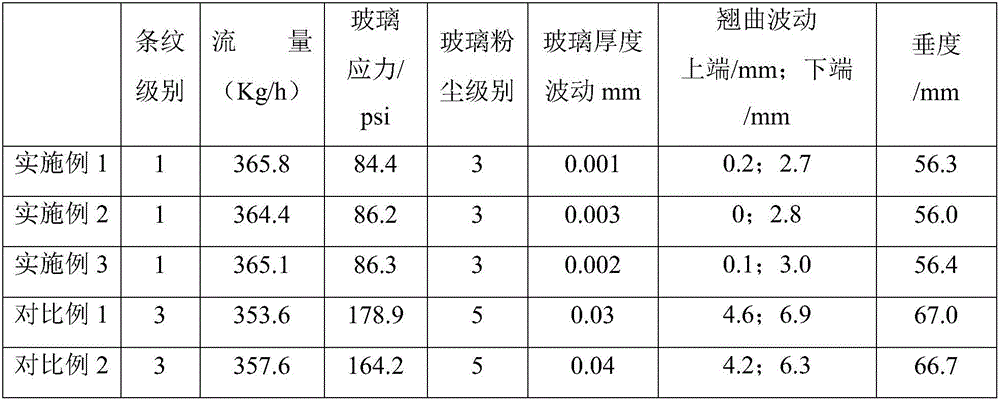

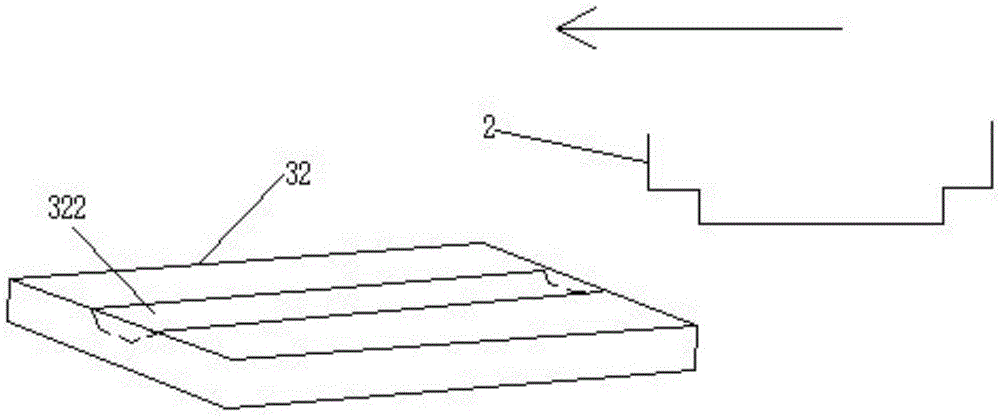

Production method of liquid crystal glass substrate

ActiveCN105948460AImprove yieldImprove qualityGlass furnace apparatusGlass severing apparatusWork in processAtmospheric pressure

The invention discloses a production method of a liquid crystal glass substrate. The method includes the steps that 1, raw materials are sent to a pool furnace area for melting; 2, molten glass liquid is sent to a platinum area for purification; 3, the purified glass liquid is sent to a forming area for curing; 4, a glass plate is sent to a hot-cutting area for cutting and then transported by a hot-cutting peripheral area into a half-packaging area, packaging of the liquid crystal glass substrate is completed after check is conducted, and a semi-finished product of the liquid crystal glass substrate is obtained; the environmental pressure of the pool furnace area is controlled to be 4-6 Pa higher than the atmospheric pressure, the environmental pressure of the platinum area is controlled to be14-16 Pa higher than the atmospheric pressure, the environmental pressure of the forming area is controlled to be 10.5-12.5 Pa higher than the atmospheric pressure, the environmental pressure of the hot-cutting area is controlled to be 14-16 Pa higher than the atmospheric pressure, the environmental pressure of the hot-cutting peripheral area is controlled to be 11-13 Pa higher than the atmospheric pressure, and the environmental pressure of the half-packaging area is controlled to be 6-8 Pa higher than the atmospheric pressure. By means of the production method of the liquid crystal glass substrate, quality of the liquid crystal glass substrate can be remarkably improved.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

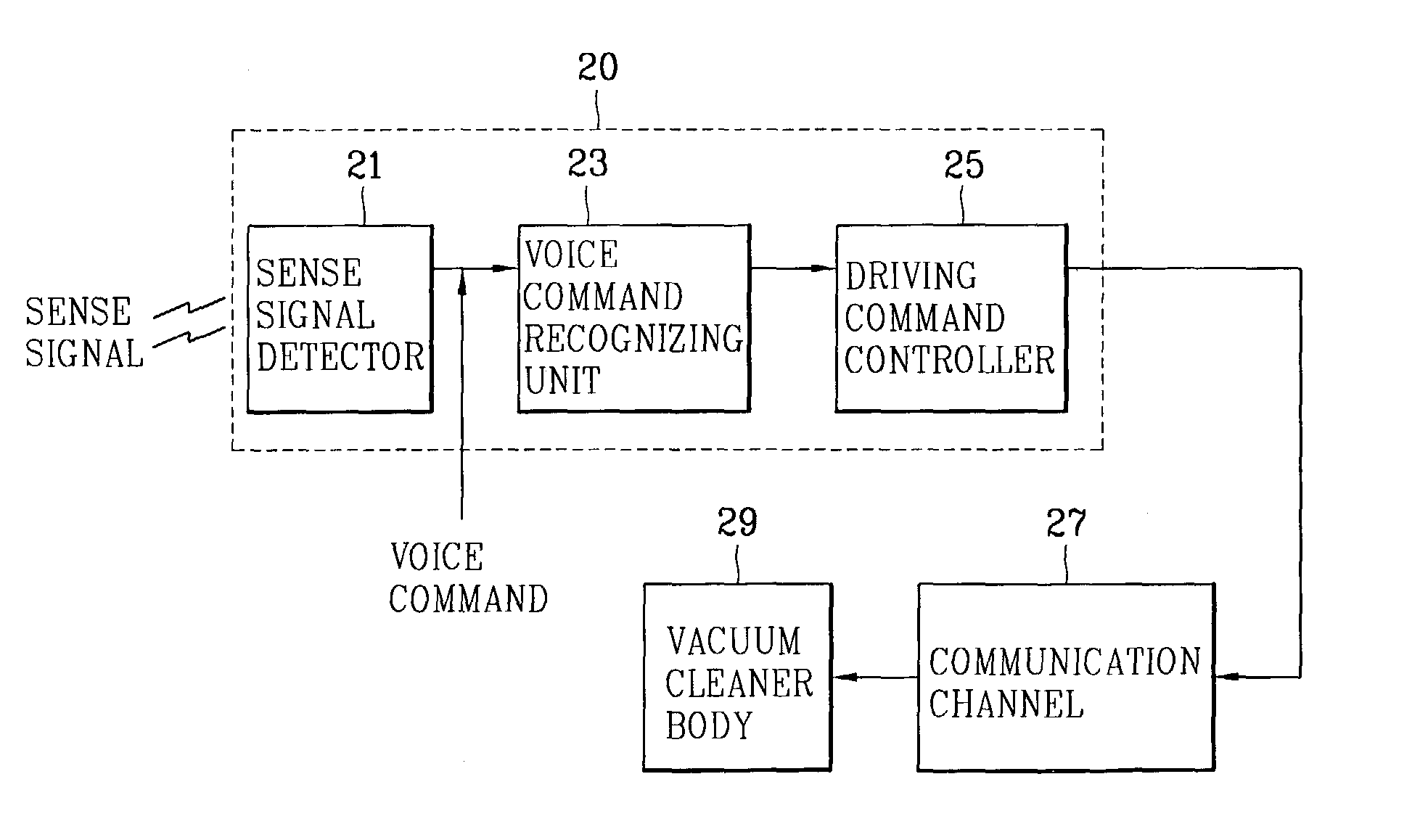

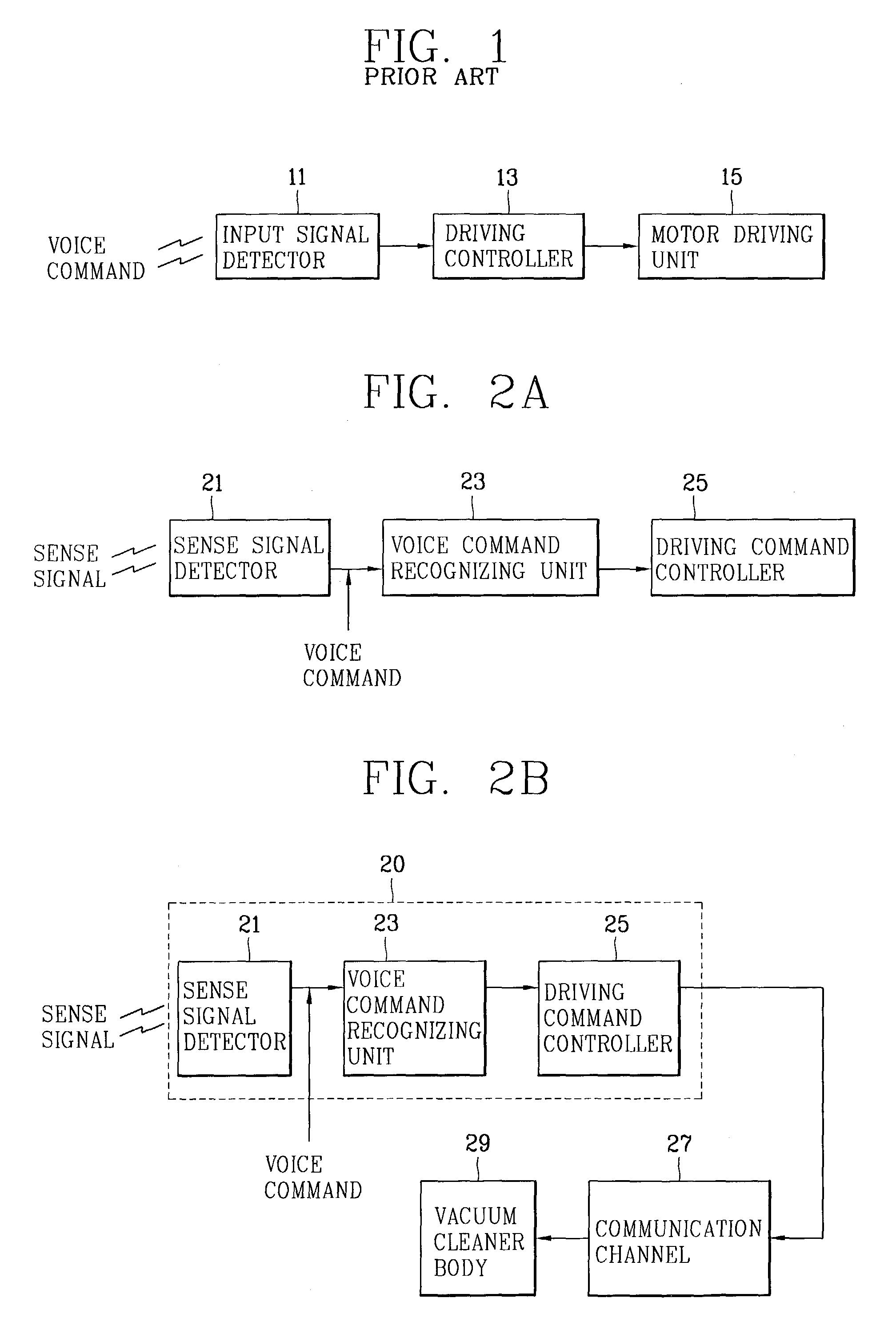

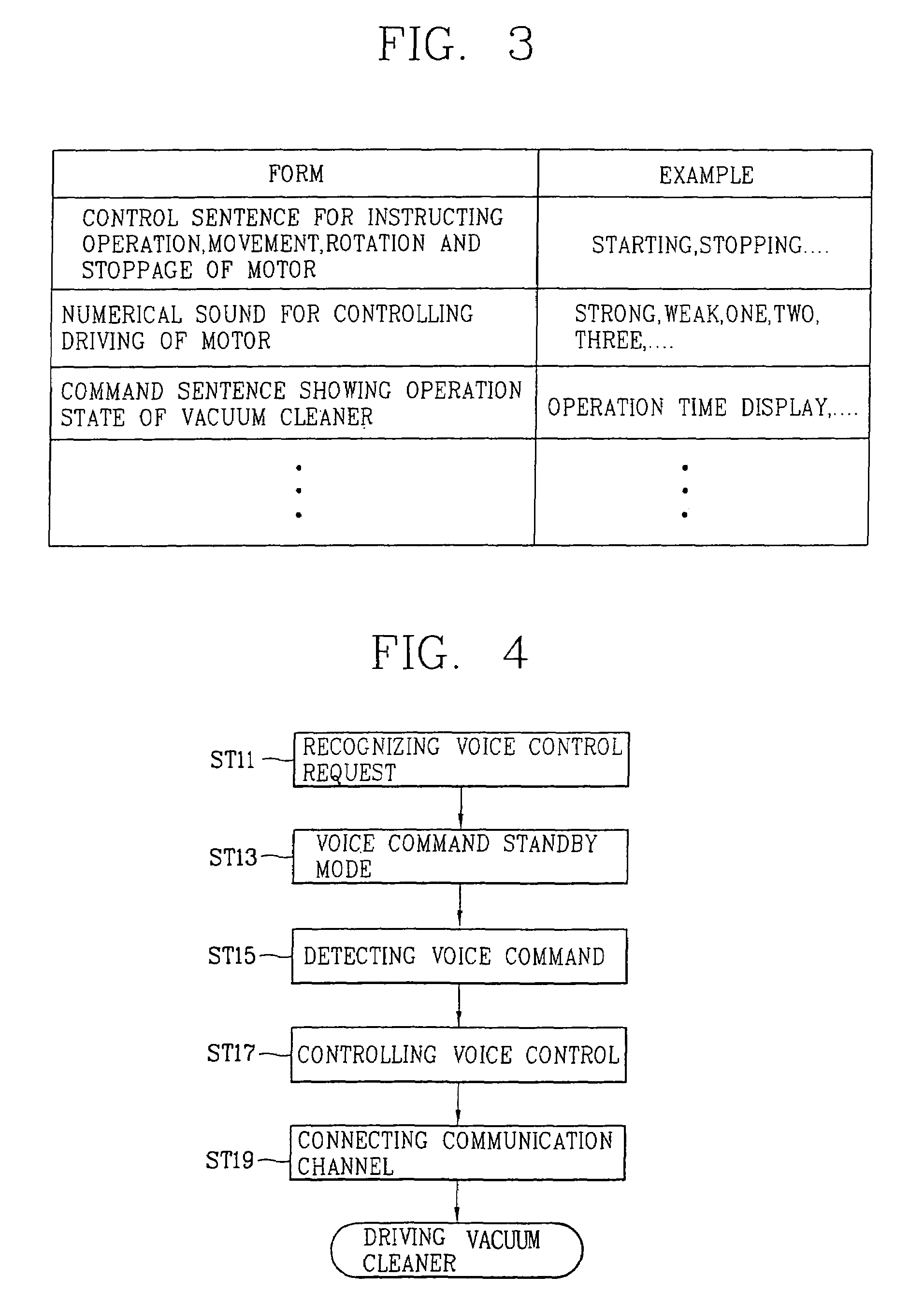

Voice control apparatus of vacuum cleaner and method thereof

ActiveUS7310603B2Effective controlEfficient executionMechanical cleaningPressure cleaningControl signalSignal detector

A voice control apparatus of a vacuum cleaner includes: a sense signal detector for detecting a sense signal provided from a user to provide a voice recognizable environment in an ambience; a voice command recognizing unit for temporarily stopping a driving of a motor upon receiving the detected sense signal and, at the same time, outputting a voice command control signal previously set in a voice command set corresponding to a voice command instructed by the user; and a driving command controller for controlling a function and a mode of a vacuum cleaner upon receiving the voice command control signal. By providing a voice recognizable environment, the vacuum cleaner can be effectively controlled through a user's voice command even in an environment with a strong noise.

Owner:LG ELECTRONICS INC

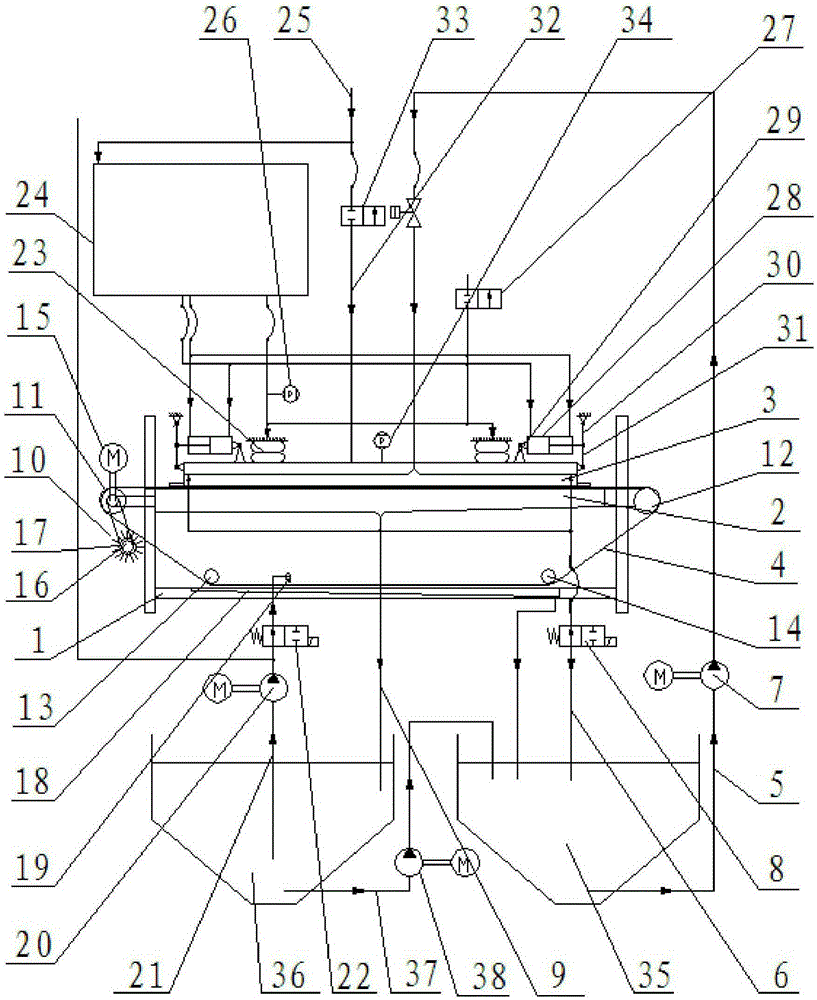

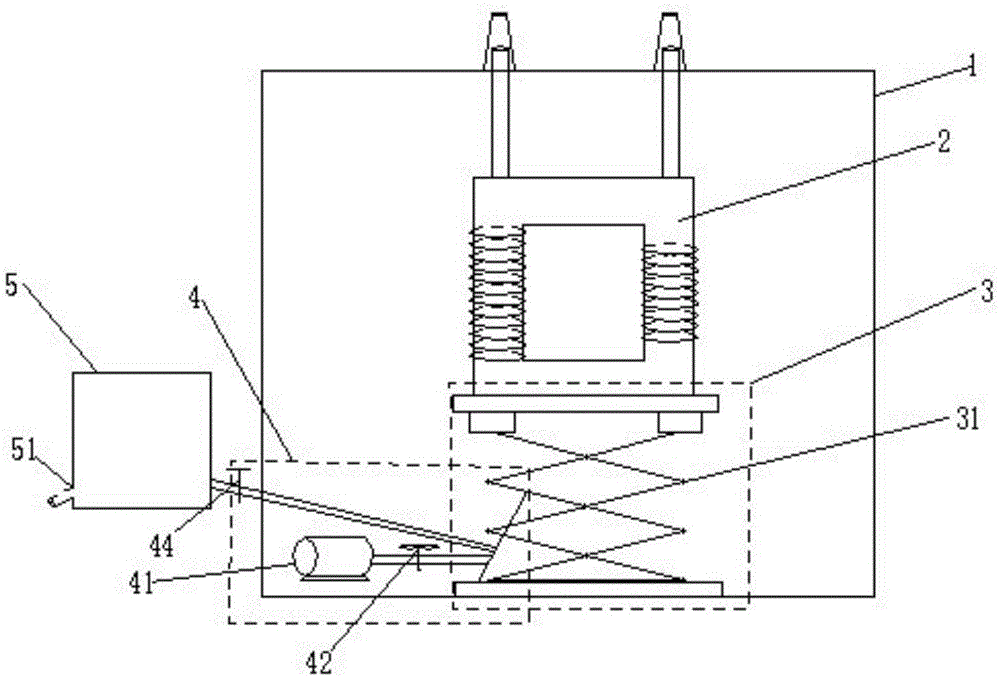

Positive pressure filter

ActiveCN105396356AAchieve recyclingControl cleanlinessMembrane filtersStationary filtering element filtersPositive pressureLiquid tank

The invention relates to a positive pressure filter including a filter pressing frame; the filter pressing frame is fixedly provided with a clear liquid collecting cavity, a waste liquid filtering cavity and a circulating filter belt; the waste liquid filtering cavity is arranged at the vertical upper side of the clear liquid collecting cavity; the top of the clear liquid collecting cavity sealedly communicates with the bottom of the waste liquid filtering cavity; the circulating filter belt is arranged between the clear liquid collecting cavity and the waste liquid filtering cavity; the top of the waste liquid filtering cavity is provided with a pressing lifting device used for pressing downwards and lifting upwards the waste liquid filtering cavity; the waste liquid filtering cavity communicates with a waste liquid tank through a first pipeline and a second pipeline, the first pipeline is provided with a waste liquid lifting pump, and the second pipeline is provided with a waste liquid discharge electromagnetic valve; the clear liquid collecting cavity communicates with a clear liquid tank through a third pipeline; a hairbrush assembly for cleaning and brushing the circulating filter belt is arranged outside the clear liquid collecting cavity and on the filter pressing frame. Circulating use of the filter belt is realized, the cleanliness of a cooling liquid is effectively controlled, the filtering efficiency is improved and the production operation cost is reduced.

Owner:烟台开发区博森科技发展有限公司

High-cleaning/moderate abrasive silica materials and dentifrice containing such materials

InactiveUS20060110337A1Desirable abrasiveGood thickening effectCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

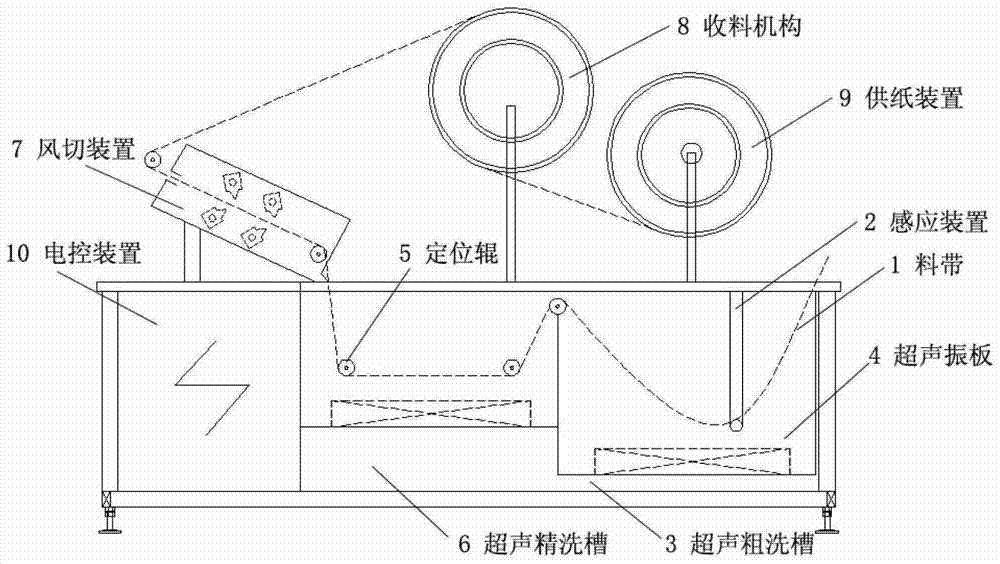

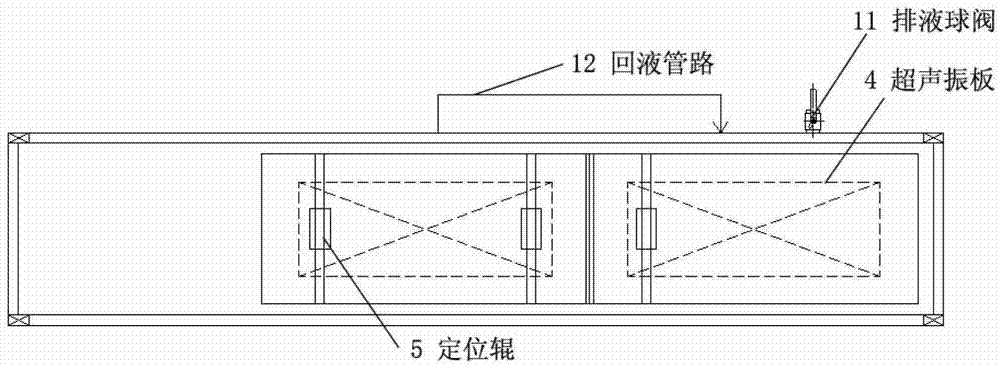

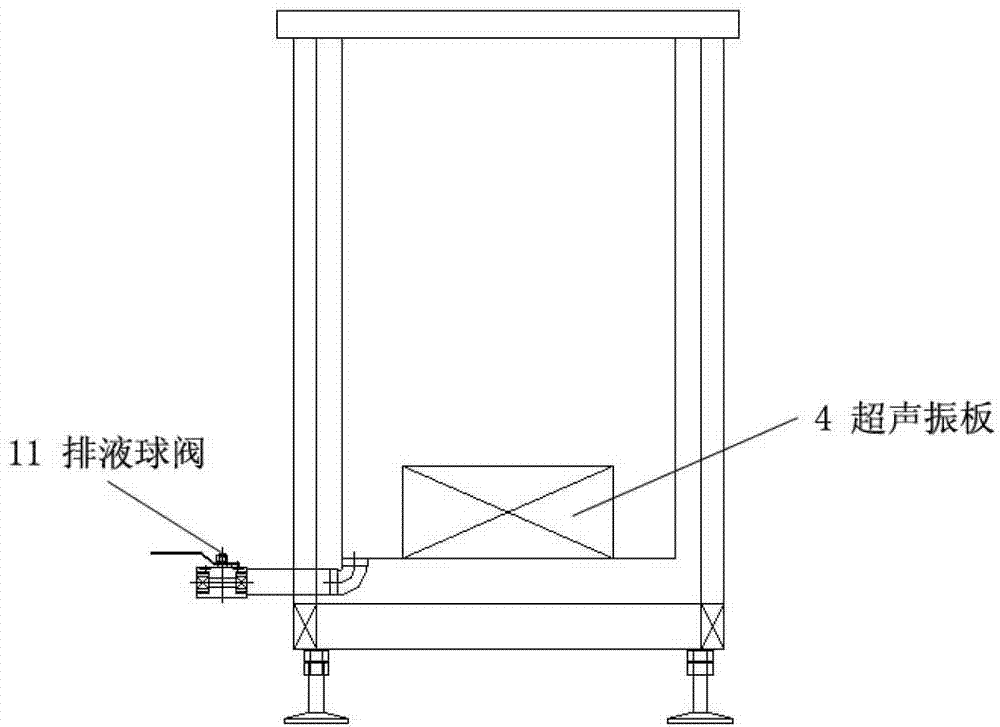

Cleaning device and cleaning method for high-cleanliness ultrasonic material belt

InactiveCN103084357ASolve the problem of mutual frictionNo damageCleaning using liquidsEngineeringCleansing Agents

The invention relates to a cleaning device for a high-cleanliness ultrasonic material belt. The cleaning device for the high-cleanliness ultrasonic material belt comprises a tank body, and an electric control device is hermetically arranged inside the tank body. The cleaning device for the high-cleanliness ultrasonic material belt is characterized in that an ultrasonic rough washing tank and an ultrasonic fine washing tank are arranged inside the tank body in a separated mode, ultrasonic vibrating plates are respectively arranged on the bottoms of the ultrasonic rough washing tank and the ultrasonic fine washing tank, a wind cutting device used for drying the material belt is arranged above the tank body, a positioning roller is arranged on the wind-cutting device in a connected mode, and a material collecting mechanism and a paper made paper supply device used for separating the material belt are arranged above the tank body. With the technical scheme of the cleaning device for the high-cleanliness ultrasonic material belt, the problem of mutual friction of the material belt in material collecting process is effectively solved, and no harm is done to the material belt. More importantly, the cleanliness of cleaning agents can be effectively controlled, and the cleaning effect of the material belt is improved.

Owner:ZHANGJIAGANG ULTRASONIC & ELECTRIC

Single-phase oil-immersed transformer

ActiveCN105513755ASimple operating principleImprove maintenance efficiencyTransformers/reacts mounting/support/suspensionTransformers/inductances coolingSingle phaseEngineering

The invention provides a single-phase oil-immersed transformer which comprises a box body with a box cover, an iron core, coils, radiating tubes and an oil conservator. The iron core is a single-frame double-core column and is arranged at the center of the box body and immersed in oil, the single-frame double-core column is wounded with the coils respectively, the coils are led out of the box cover, leads are respectively sleeved with a high-pressure insulation sleeve and a low-pressure insulation sleeve, the radiating tubes are arranged on the side wall of the box body, and the oil conservator is arranged at the upper end of one side of the box body. The single-phase oil-immersed transformer further comprises a lifting mechanism, a power mechanism and an oil tank, wherein the oil tank is connected with the power mechanism and is arranged outside the box body. The single-phase oil-immersed transformer uses the oil in the box body as a power source through the power mechanism, drives the lifting mechanism to take out the iron core, stores the oil in the box body to the oil tank, facilitates iron core maintenance and oil change operation, saves the cost and also improves the overhaul efficiency.

Owner:JIANGSU MINGAN ELECTRIC

Scrub glove for cleaning various articles

A scrub glove (G′) has an inner layer (IL) fitting over a wearer' thumb, fingers, palm, and back of their hand, the wearer's wrist and a portion of their forearm. The glove further has an outer layer (OL) of an abrasive, woven mesh material formed to fit over the inner layer and enclosing the wearer's thumb, fingers, palm, the back of their hand, and their wrist. A band (D) fits over an open end of the outer layer where it fits over the open end and a cuff portion of the inner layer and is permanently secured to both the inner and outer layers. While the outer layer fits over the inner layer, it does not adhere to the inner layer whereby when the glove is used fin cleaning, the outer layer is free to move separately from the inner layer.

Owner:MESITI NATHAN

Single-phase oil-immersed transformer and special iron core therefor

ActiveCN105469945ASolve the gap problemGuaranteed uptimeTransformers/inductances coolingTransformers/inductances magnetic coresTransformerLow voltage

The invention provides a single-phase oil-immersed transformer and a special iron core therefor. The single-phase oil-immersed transformer comprises a box body with a box cover, an iron core, a radiating pipe, an oil conservator, a lifting mechanism, a power mechanism and an oil tank, wherein the iron core is a single-frame dual-core column with a groove, is arranged at the center of the box body and is immersed by an oil body; a coil is led out of the box cover; a high-voltage insulating sleeve and a low-voltage insulating sleeve respectively sleeve a lead; the radiating pipe is arranged on the side wall of the box body; the oil conservator is arranged at the upper end of one side of the box body; the lifting mechanism is arranged below the iron core; the bottom end of the lifting mechanism is fixedly connected with the box body; the power mechanism is connected with the lifting mechanism; the oil tank is connected with the power mechanism; and the oil tank is arranged outside the box body. The single-phase oil-immersed transformer can drive the lifting mechanism to take out the iron core by taking the oil in the box body as a power source through the power mechanism and stores the oil in the box body into the oil tank, so that maintenance of the iron core and oil-change operation are facilitated; the cost is saved; and the maintenance efficiency is also improved.

Owner:JIANGSU MINGAN ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com