Manufacturing method for large section forgings of high-speed tool steel

A high-speed tool steel and a manufacturing method technology, applied in the field of steel forging, can solve the problems of deterioration of carbide segregation, serious inhomogeneity of eutectic carbides in large-section forging materials, increase of internal cracks and surface cracking defects, etc., so as to reduce the structure The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Production of M2 round steel with a size of Φ179mm;

[0058] 1. The smelting branch produces M 2 Steel type, finished product specification Φ179mm (dimension tolerance -0mm, +2mm), chemical composition of electroslag ingot is shown in Table 1;

[0059] Table 1 Chemical composition of electroslag ingot

[0060]

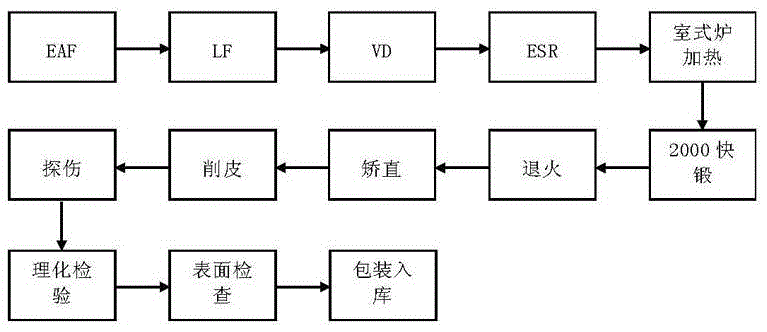

[0061] 2. EAF+LF+VD+ESR method is used for smelting, VD tapping temperature is 1510℃, pouring Φ250mm

[0062] Electrode, casting electrode carbon saturation Ac=0.79, electroslag remelting casting Φ480mm electroslag ingot;

[0063] 3. Heat the steel ingot to 800°C for 3 hours, then raise the temperature to 1180°C for 5 hours, and then take it out of the furnace for forging;

[0064] 4. The 1st and 2nd fires of forging adopt symmetrical forging, the reduction amount of each pass is not more than 20mm, the deformation amount of this process is 4%, and the final forging temperature is 960°C; the 3rd to 8th fires adopt asymmetric forging, and the forging Flip 18...

Embodiment 2

[0066] Production of 1.3343 round steel with a size of Φ202mm;

[0067] 1. The smelting branch produces 1.3343 steel grades, the finished product specification is Φ202mm (dimensional tolerance -0mm, +3mm), and the chemical composition of the electroslag ingot is shown in Table 2;

[0068] Table 2 Chemical composition of electroslag ingot

[0069]

[0070] 2. EAF+LF+VD+ESR method is used for smelting, VD tapping temperature is 1515℃, pouring Φ250mm

[0071] Electrode, casting electrode carbon saturation Ac=0.78, electroslag remelting casting Φ480mm electroslag ingot;

[0072] 3. Heat the steel ingot to 800°C for 3 hours, then raise the temperature to 1180°C for 5 hours, and then take it out of the furnace for forging;

[0073] 4. The 1st and 2nd fires of forging adopt symmetrical forging, the reduction amount of each pass is not more than 20mm, the deformation amount of this process is 3%, and the final forging temperature is 990°C; the 3rd to 8th fires adopt asymmetric fo...

Embodiment 3

[0075] Production of 1.3343ESR round steel with a size of Φ303mm;

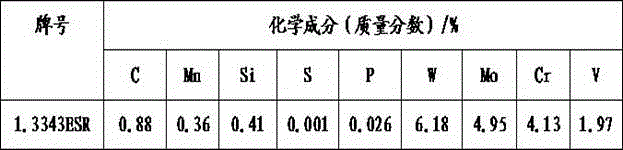

[0076] 1. The smelting branch produces 1.3343ESR steel grade, the finished product specification is Φ303mm (dimensional tolerance -0mm, +3mm), and the chemical composition of the electroslag ingot is shown in Table 3;

[0077] Table 3 Chemical composition of electroslag ingot

[0078]

[0079] 2. EAF+LF+VD+ESR method is used for smelting, VD tapping temperature is 1510℃, pouring Φ250mm

[0080] Electrode, casting electrode carbon saturation Ac=0.76, electroslag remelting casting Φ610mm electroslag ingot;

[0081] 3. Heat the steel ingot to 800°C for 3 hours, then raise the temperature to 1180°C for 6 hours, and then take it out of the furnace for forging;

[0082] 4. The 1st and 2nd fires of forging adopt symmetrical forging, the reduction amount of each pass does not exceed 20mm, the deformation amount of this process is 5%, and the final forging temperature is 970°C; the 3rd to 8th fires adopt asymmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com