Device for preparing monotectic alloy through laser-strong magnetic field composite fusion casting

A monotectic alloy and strong magnetic field technology, which is applied in the field of laser-strong magnetic field composite melting and casting, can solve the problems of monotectic alloy macro-segregation, low production efficiency, and uneven structure, so as to reduce the movement speed, suppress convection, reduce The effect of tissue segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

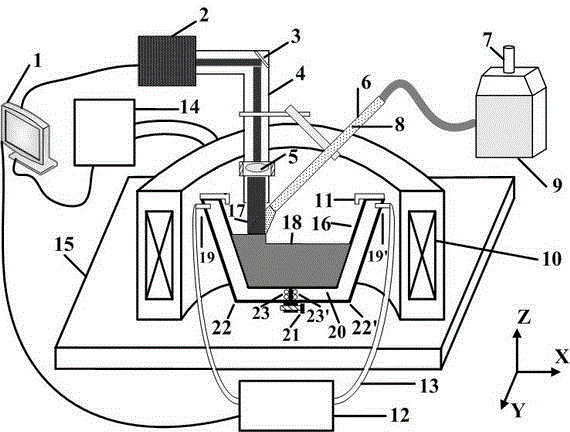

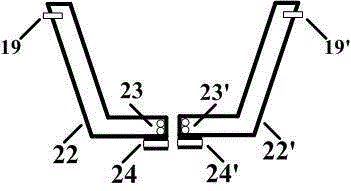

[0010] Such as figure 1 and figure 2 As shown, the present invention mainly includes CO 2 Laser, side-axis automatic powder feeder 9, strong magnetic field device 14, copper casting mold 16, processing machine tool 15, and numerical control system 1. Wherein, copper mold 16 is made of left half copper mold 22 and right half copper mold 22 '. When working, the specific implementation method and steps are as follows:

[0011] The first step: according to the chemical composition of the monotectic alloy, the metal powder of each component is mixed according to the mass percentage, and added to the film-forming material and mechanically stirred to prepare a slurry;

[0012] Step 2: After mixing the prepared slurry evenly with a planetary ball mill, place it in a drying box and dry it at a temperature of 120~250°C, and then mechanically grind it into a mono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com