Die steel with high performance and preparation method of die steel

A die steel and high-performance technology, which is applied in the field of high-performance die steel and its preparation, can solve problems such as insufficient die steel performance, and achieve the effects of improving performance indicators, improving work efficiency, and improving tissue segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A tool steel with high performance, comprising the following components by weight percentage:

[0030] 0.8%C, 1.0%Si, 5%Cr, 1.0%Mn, 0.4%Mo, 0.08%Al, 0.02%MgO, 0.5%V, 0.03%CaF 2 , 0.02% CaC 2 , the balance being Fe.

[0031] The above-mentioned preparation method of high-performance die steel comprises the following steps:

[0032] (1) Mix C, Si, Cr, Mn, Al, V and Mo according to the formula, heat and melt at 1500-2000°C under an argon atmosphere, and then spray into CaF 2 , MgO and CaC 2 , continue to melt for 3 hours, remove impurities, and collect molten steel;

[0033] (2) Under the condition of 10MPa, pour molten steel into a piece, then heat it at 900°C for 3h, then raise the temperature to 1300°C at a rate of 140°C / h, and keep it warm for 1h;

[0034] (3) The product obtained in step (2) is forged at 1000°C for 1 hour, then quenched at 860°C, and tempered at 160°C.

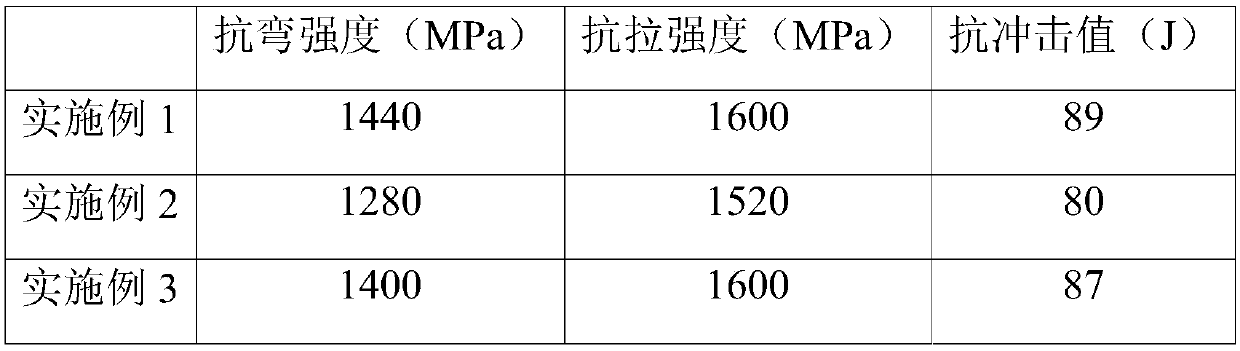

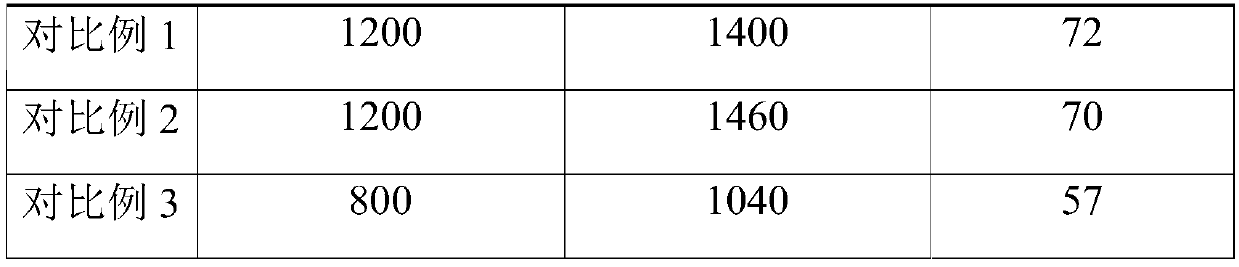

[0035] According to GB / T10561-2005 A-method inspection and rating, the prepared mold steel i...

Embodiment 2

[0037] A tool steel with high performance, comprising the following components by weight percentage:

[0038] 0.8%C, 1.0%Si, 4.5%Cr, 0.5%Mn, 0.2%Mo, 0.02%Al, 0.01%CaF 2 , 0.02% CaC 2 , the balance being Fe.

[0039] The above-mentioned preparation method of high-performance die steel comprises the following steps:

[0040] (1) Mix C, Si, Cr, Mn, Al and Mo according to the formula, heat and melt under argon at 1500°C, and then spray into CaF 2 , CaC 2 , continue to melt for 5 hours, remove impurities, and collect molten steel;

[0041] (2) Under the condition of 15MPa, pour molten steel into a piece, then heat it at 800°C for 1h, then raise the temperature to 1500°C at a rate of 100°C / h, and keep it warm for 2h;

[0042] (3) The product obtained in step (2) is forged at 1200°C for 2 hours, then quenched at 900°C, and tempered at 300°C.

[0043] According to the A method inspection and rating of GB / T10561-2005, the prepared mold steel inclusions are inspected. Among them, ...

Embodiment 3

[0045] A tool steel with high performance, comprising the following components by weight percentage:

[0046] 1.5%C, 1.0%Si, 5%Cr, 1.0%Mn, 0.4%Mo, 0.1%Al, 0.05%MgO, 0.05%CaF 2 , 0.08% CaC 2 , the balance being Fe.

[0047] The above-mentioned preparation method of high-performance die steel comprises the following steps:

[0048] (1) Mix C, Si, Cr, Mn, Al and Mo according to the formula, heat and melt at 2000°C under an inert gas atmosphere, and then spray into CaF 2 , MgO and CaC 2 , continue to melt for 3 hours, remove impurities, and collect molten steel;

[0049](2) Under the condition of 12MPa, pour molten steel into a piece, then heat it at 900°C for 1~3h, then raise the temperature to 1500°C at a rate of 200°C / h, and keep it warm for 2h;

[0050] (3) The product obtained in step (2) is forged at 1200°C for 2 hours, then quenched at 900°C, and tempered at 300°C.

[0051] According to GB / T10561-2005 A-method inspection and rating, the prepared mold steel inclusions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com