Patents

Literature

32results about How to "Guaranteed broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forging method for improving microstructure uniformity of TC18 titanium alloy bars

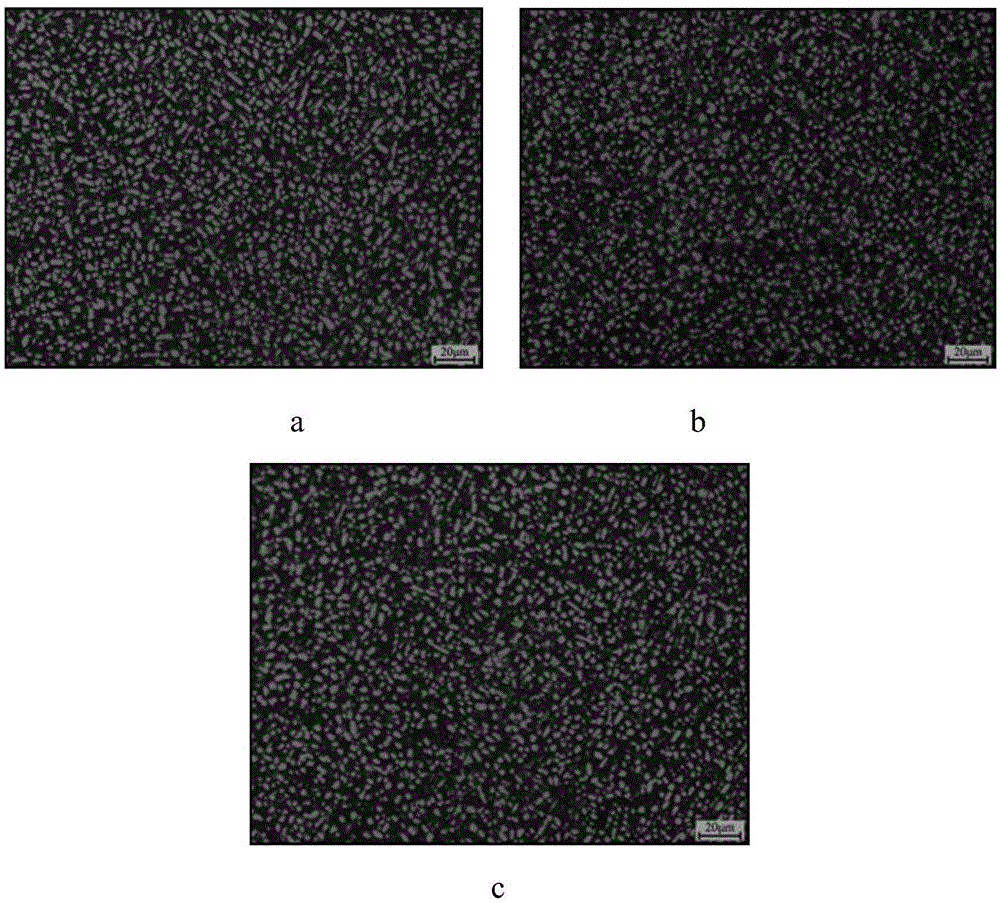

The invention discloses a forging method for improving the microstructure uniformity of TC18 titanium alloy bars. The method comprises the following steps: heating TC18 titanium alloy ingots, carrying out upsetting and rolling forging once, and pressing down the forged ingots in a downward pressing process to crush an original cast microstructure; and carrying out upsetting and rolling forging on the obtained forging stock at a temperature being greater than a beta phase transition point 2-3 times, carrying out upsetting and rolling forging on the obtained forging stock at a temperature being smaller than the beta phase transition point 2-4 times to prepare a 16-surface object, and carrying out precise forging on the 16-surface object at a temperature of Tbeta-50DEG C once to finally produce TC18 titanium alloy bars with the diameter of 160-260mm. The method improves the microstructure uniformity of the TC18 titanium alloy bars and effectively reduces the deformation microstructure risk through adopting a less upsetting and rolling + high control precision precise forging technology on the premise of guaranteeing the refinement and fragmentation of the microstructure; and the method reduces the production cost and the quality risk and shortens the production period of the bars through reducing the forging frequency and adopting continuous melting, and is suitable for large-scale batch production of the TC18 titanium alloy bars.

Owner:西部超导材料科技股份有限公司

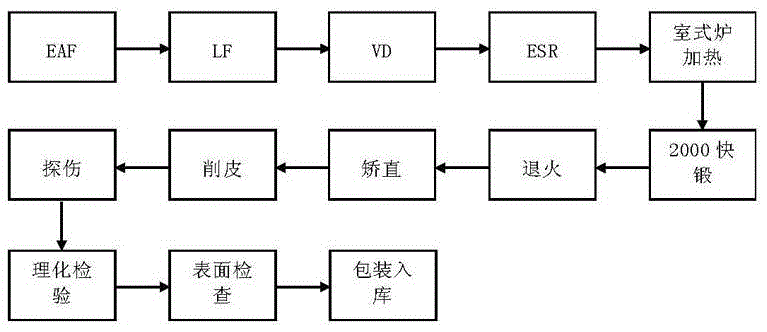

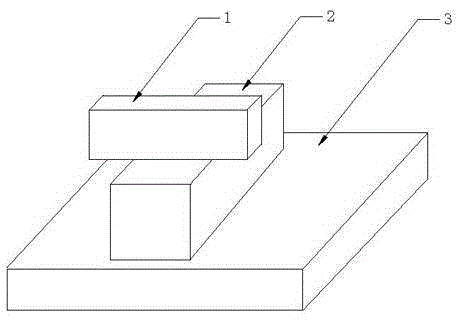

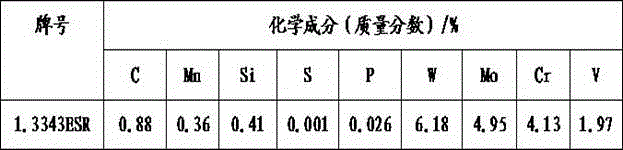

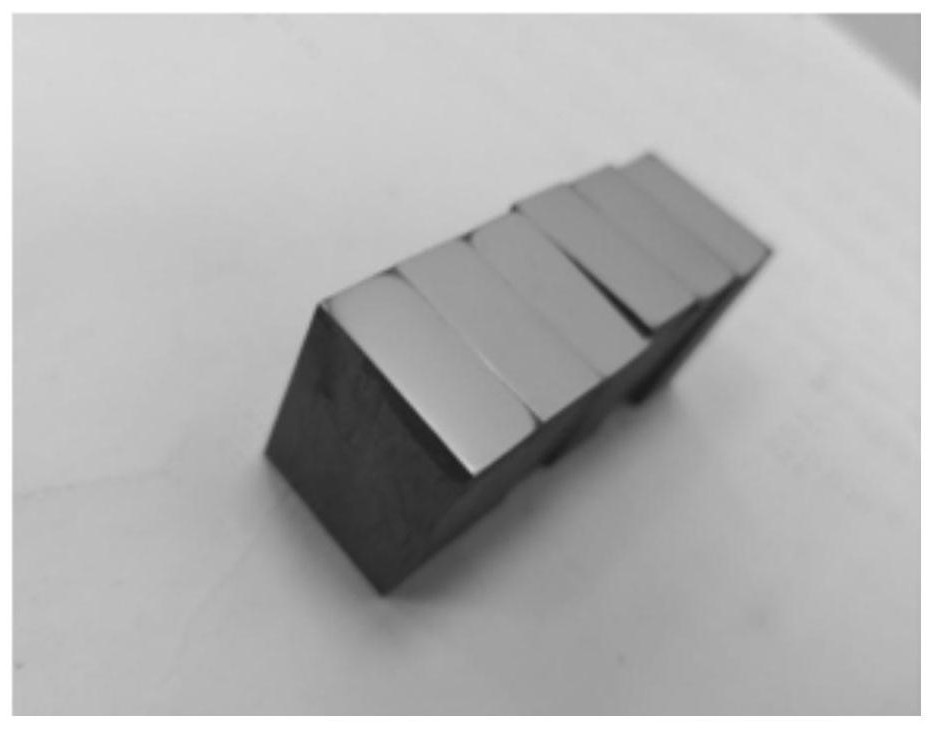

Manufacturing method for large section forgings of high-speed tool steel

InactiveCN105522085AReduce tissue segregationExcellent ingredient controlMetal-working apparatusProcess efficiency improvementTool steelForging

The invention discloses a manufacturing method for large section forgings of high-speed tool steel, and aims to solve the problem that internal cracks and surface cracks in the forgings are increased. According to the technical scheme adopted by the invention, the cleanliness of the molten steel is improved by steel-making processes such as LF refining, VD degassing, aluminum wire feeding and the like, and eutectic carbide segregation and steel hot-working plasticity are improved by controlling electroslag remelting output power and carrying out homogenization treatment before forging; large-particle carbides are crushed and unevenness of the eutectic carbides is improved by controlling forging times and different deformation amount of steel ingots of large high-speed tool steel; according to ASTMA388 standards, the ultrasonic flaw detection does not reach the level of a flat-bottom hole not greater than phi 3. The manufacturing method has the following advantages: carbon saturation is reasonably controlled, cleanliness of molten steel is controlled, segregation of components and carbides is reduced, the inner part of steel is sufficiently deformed, and the carbides of the steel internal structure are guaranteed to be crushed.

Owner:FUSHUN SPECIAL STEEL SHARES

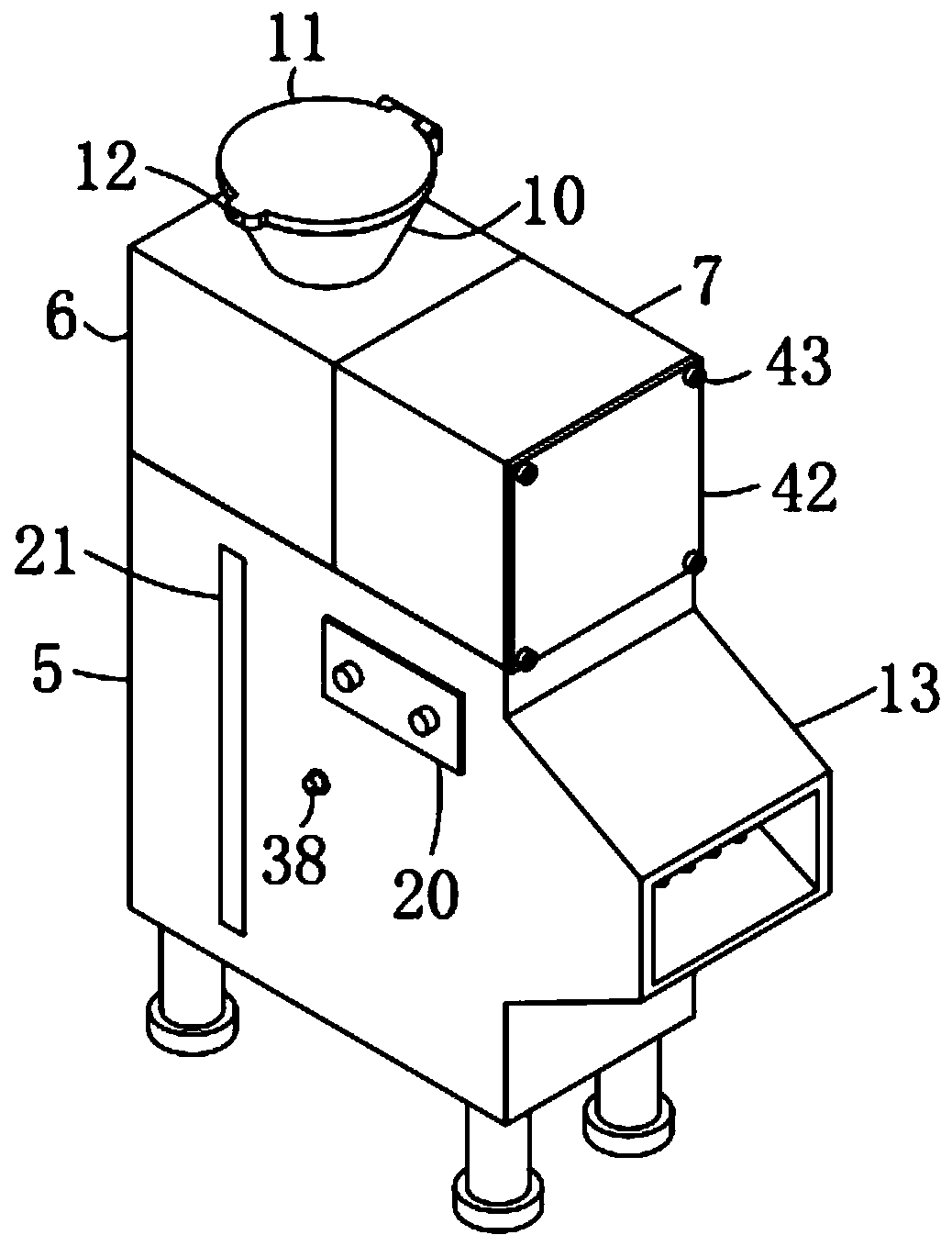

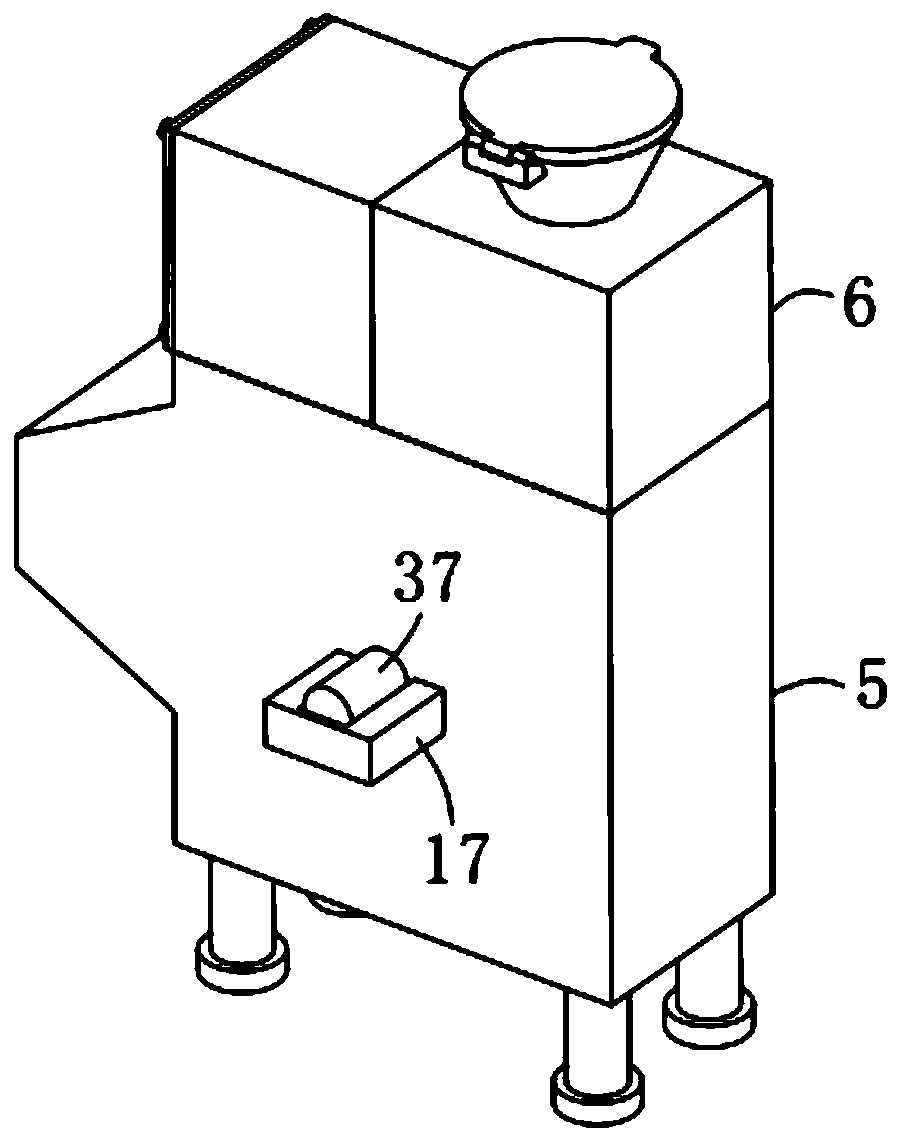

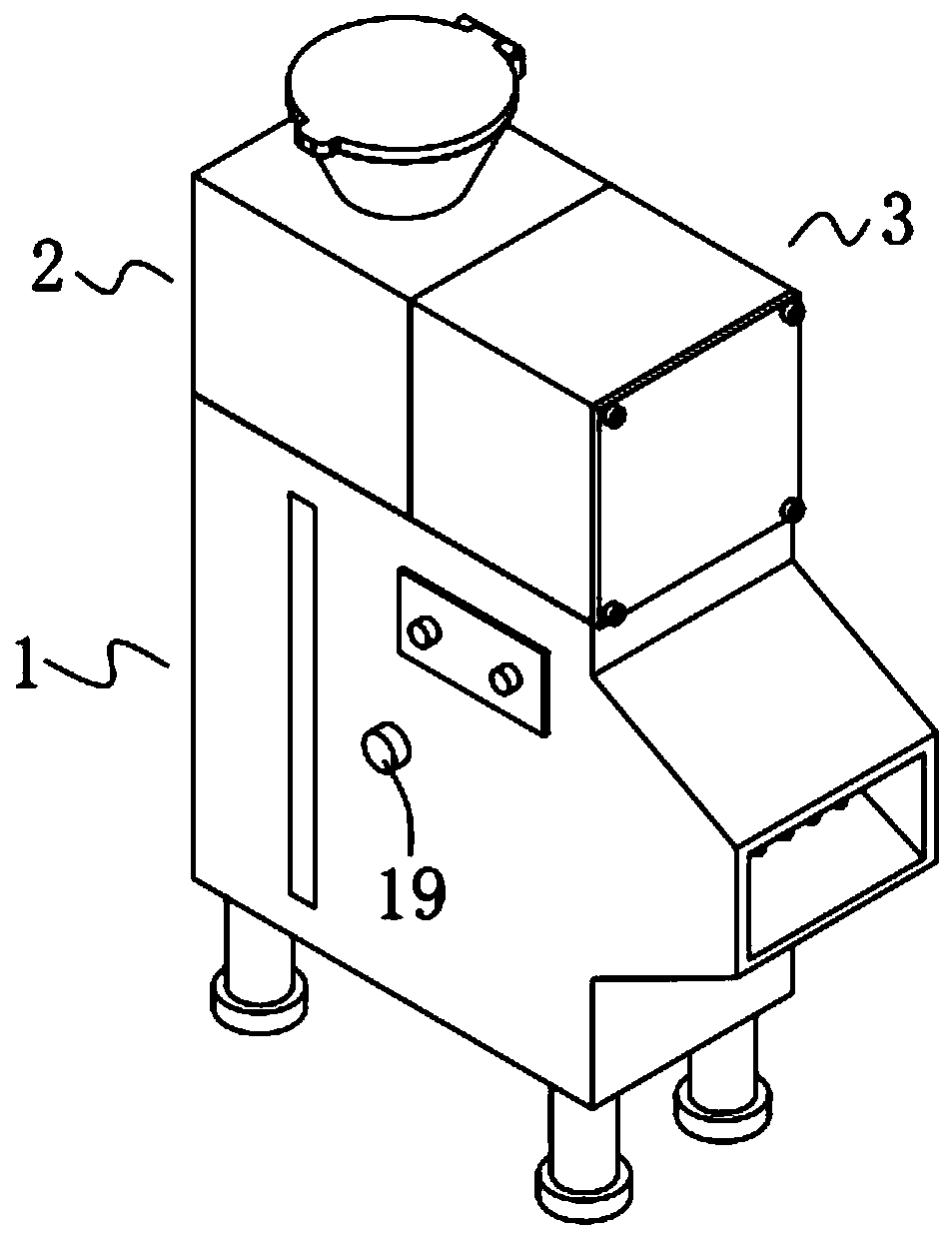

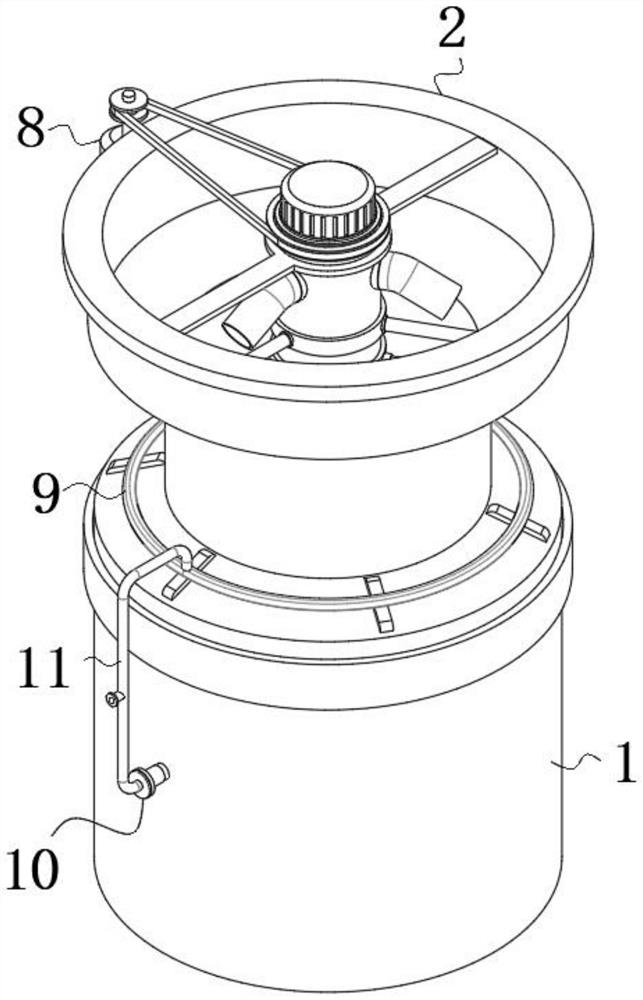

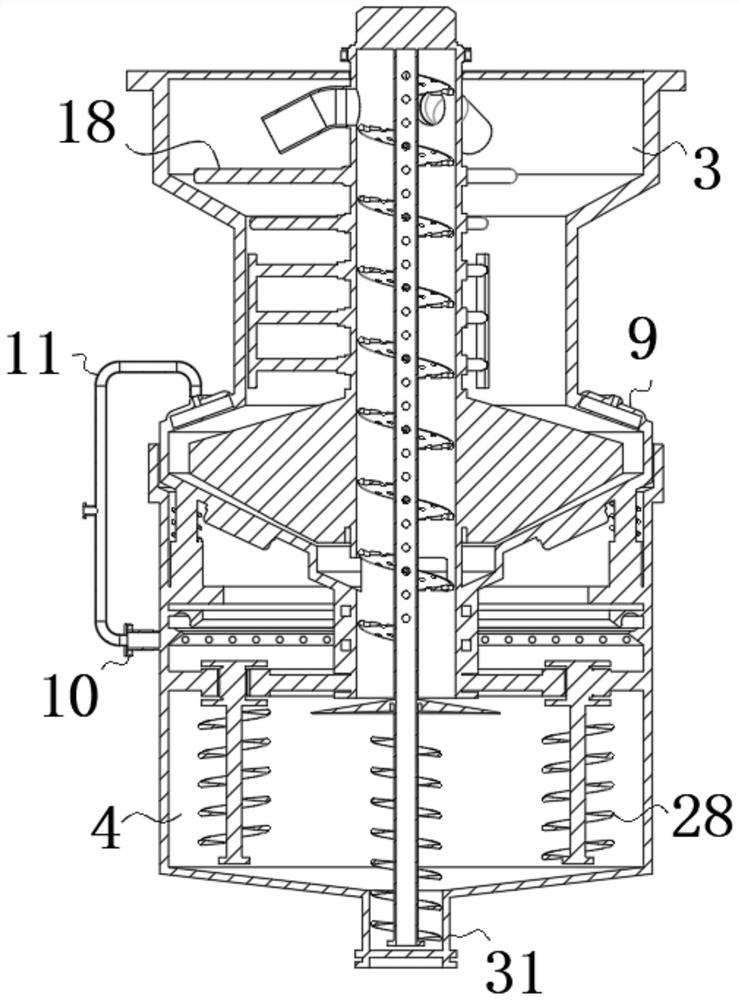

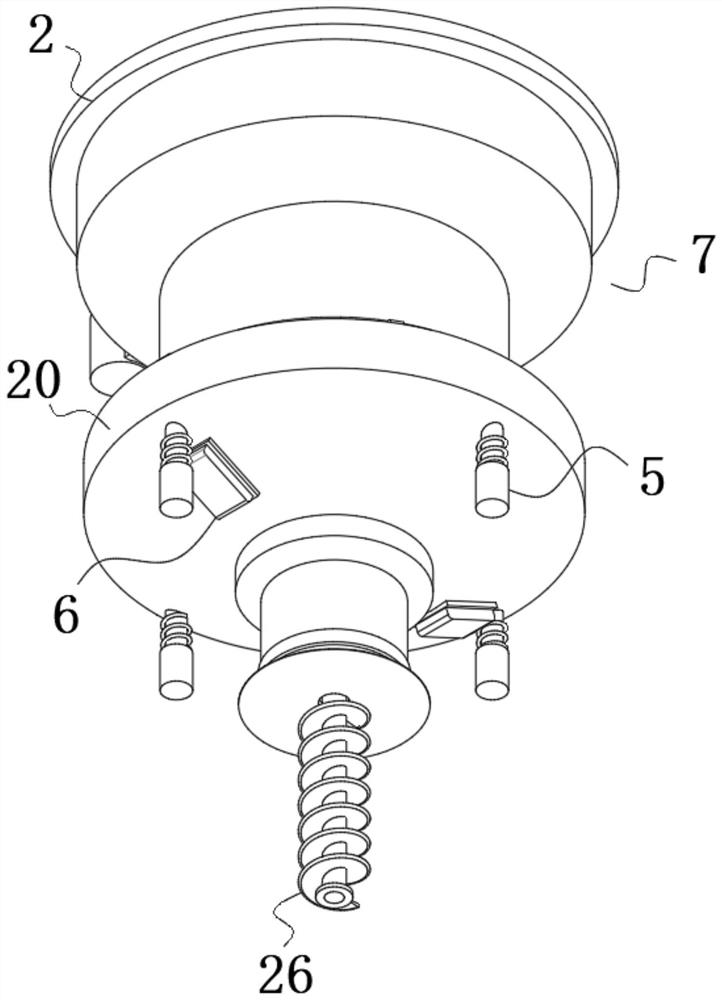

Gynecological garbage treatment device and protective layer thereof

ActiveCN111558602AGood workmanshipPrevent fallingAntifouling/underwater paintsSolid waste disposalDisinfectantMedical waste

The invention discloses a gynecological garbage treatment device and a protective layer thereof. The gynecological garbage treatment device comprises a disinfection treatment part, a feeding part, a crushing part and a discharging part, wherein the disinfection treatment part is arranged at the bottommost part, and the feeding part is arranged at the upper part of the disinfection treatment part.According to the device, the medical waste disposal process for gynecology is simple and convenient, the device is particularly suitable for temporarily carrying out disinfection treatment on medicalwaste generated by gynecology in hospitals, it is ensured that all the input medical waste can be crushed, the crushed medical waste can conveniently make full contact with a disinfectant, the disinfection of the medical waste generated in the gynecology department is sufficient and thorough, the disinfection treatment quality is good, discharging is convenient, and the trouble that the treated medical waste needs to be taken out from the interior of the device can be avoided; and the prepared protective layer has good corrosion resistance, abrasion resistance, bacteria resistance and aging resistance, the service life of the device can be effectively prolonged, and more importantly, large-area granular dirt can be prevented from being adhered to the device in the using process.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

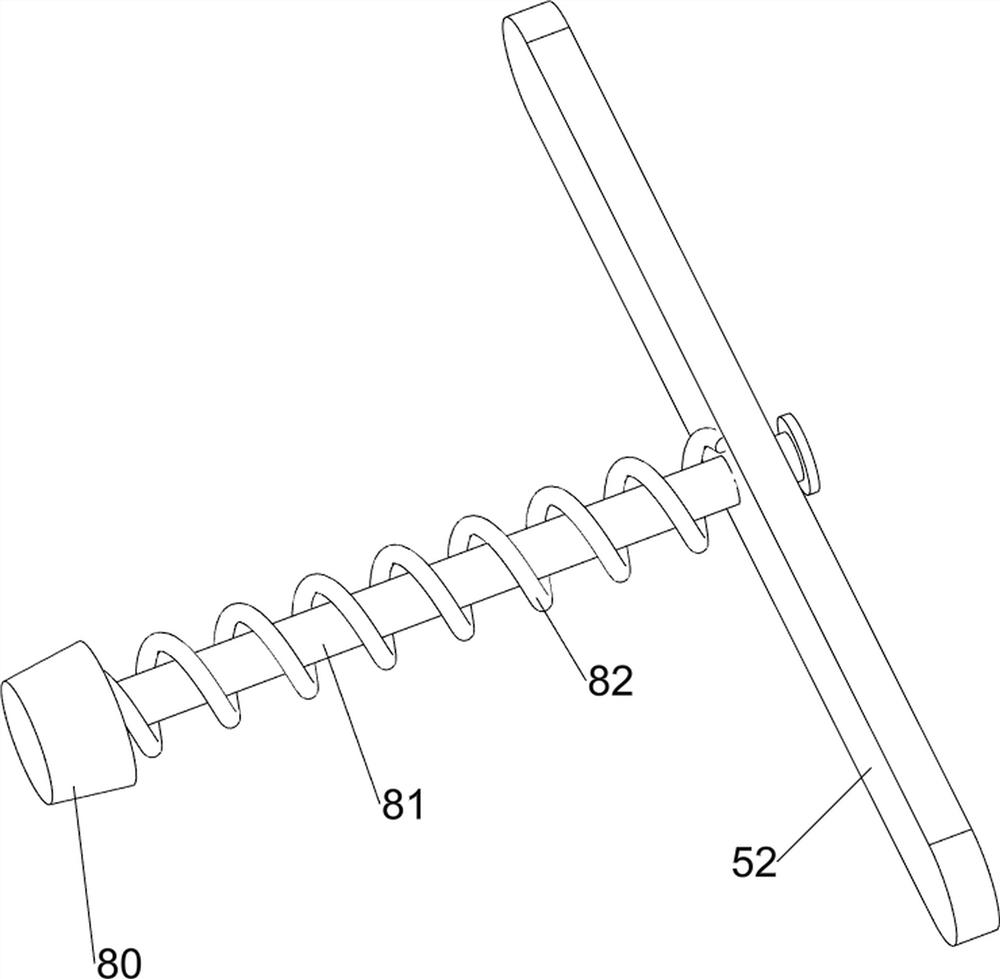

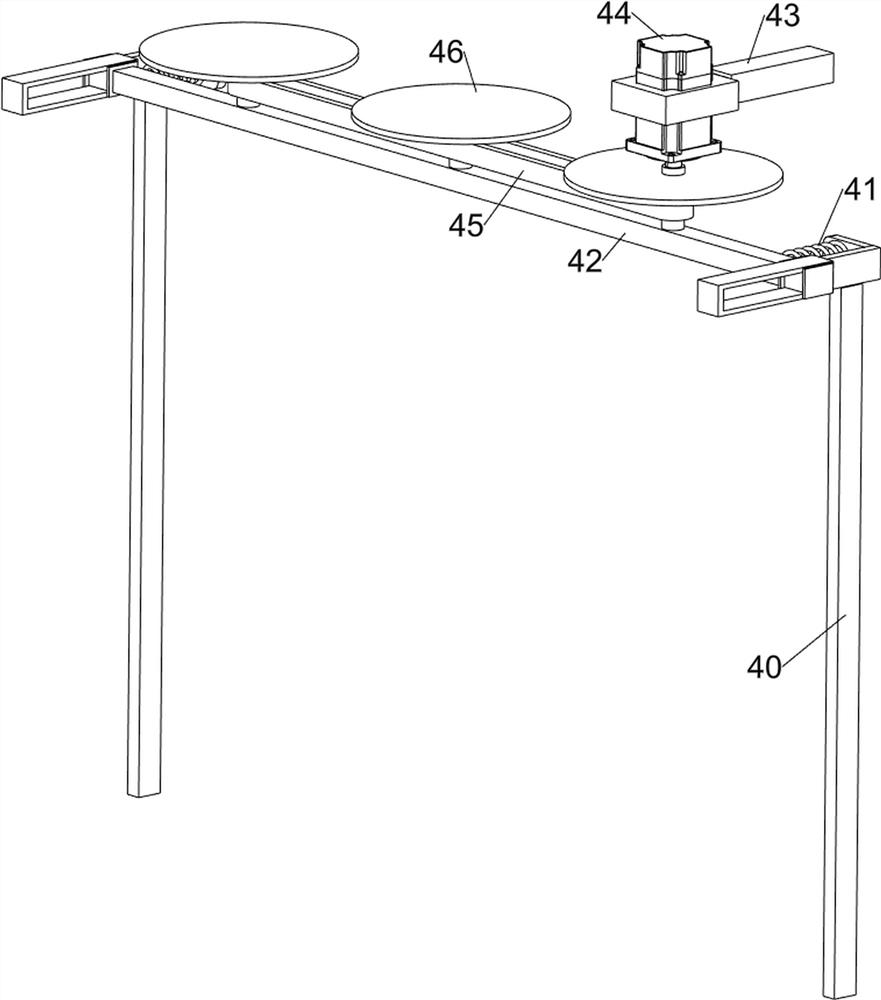

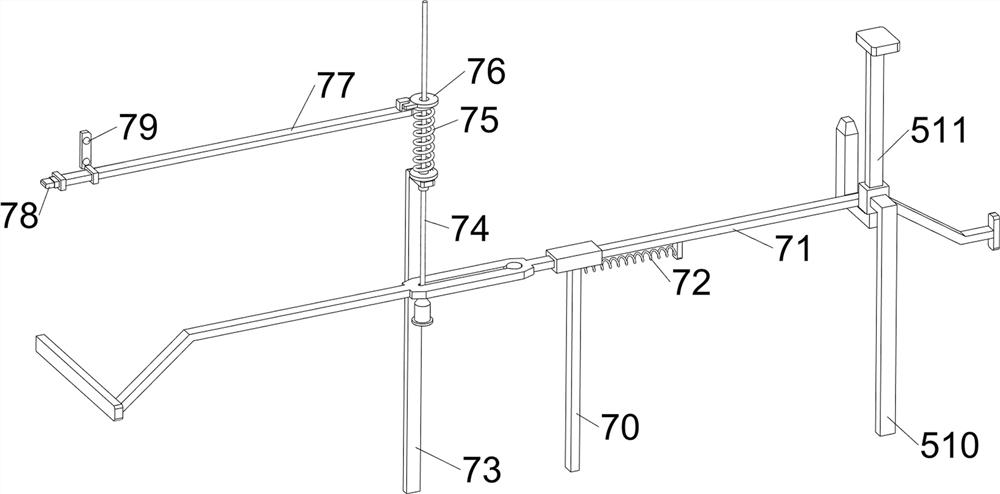

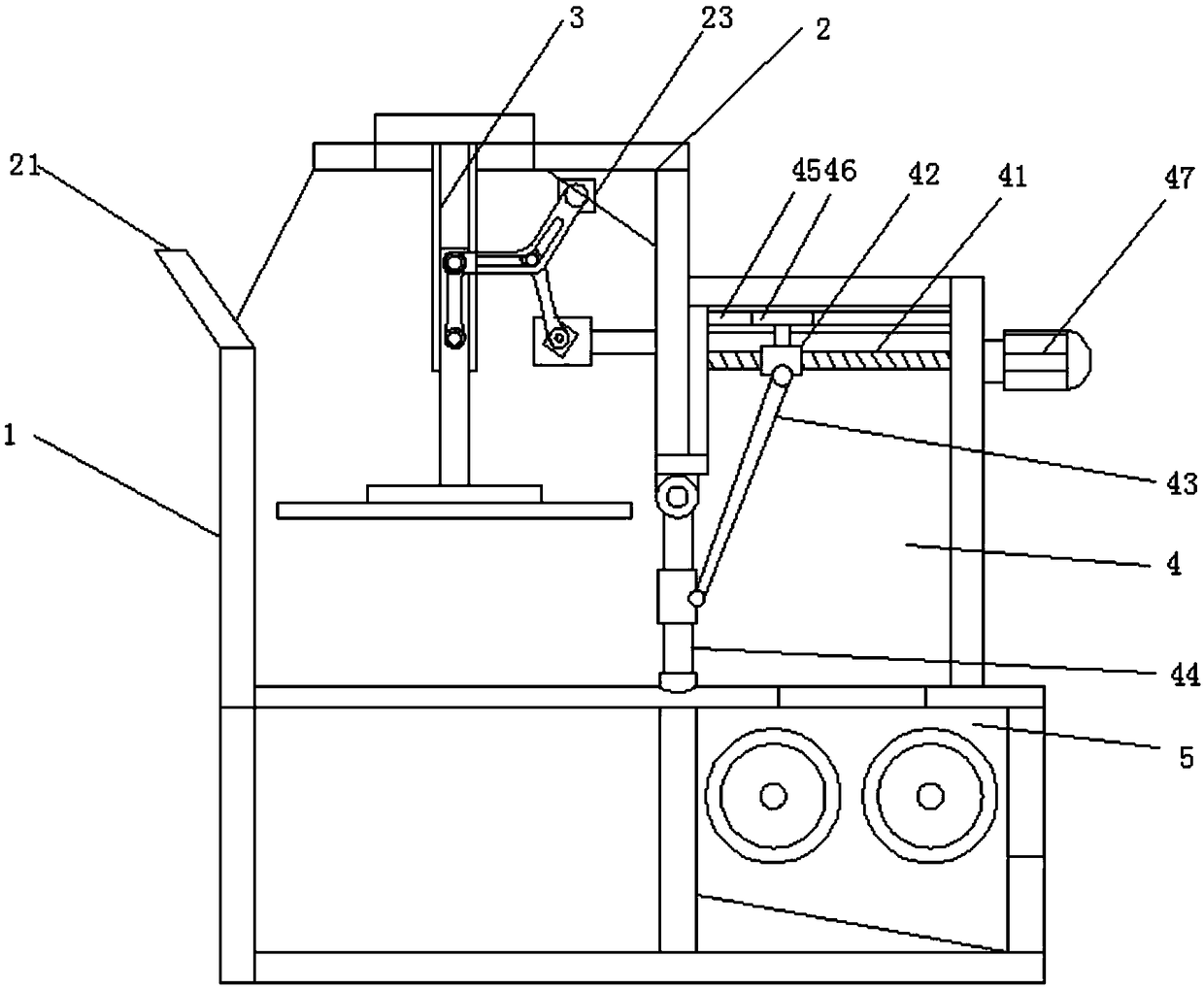

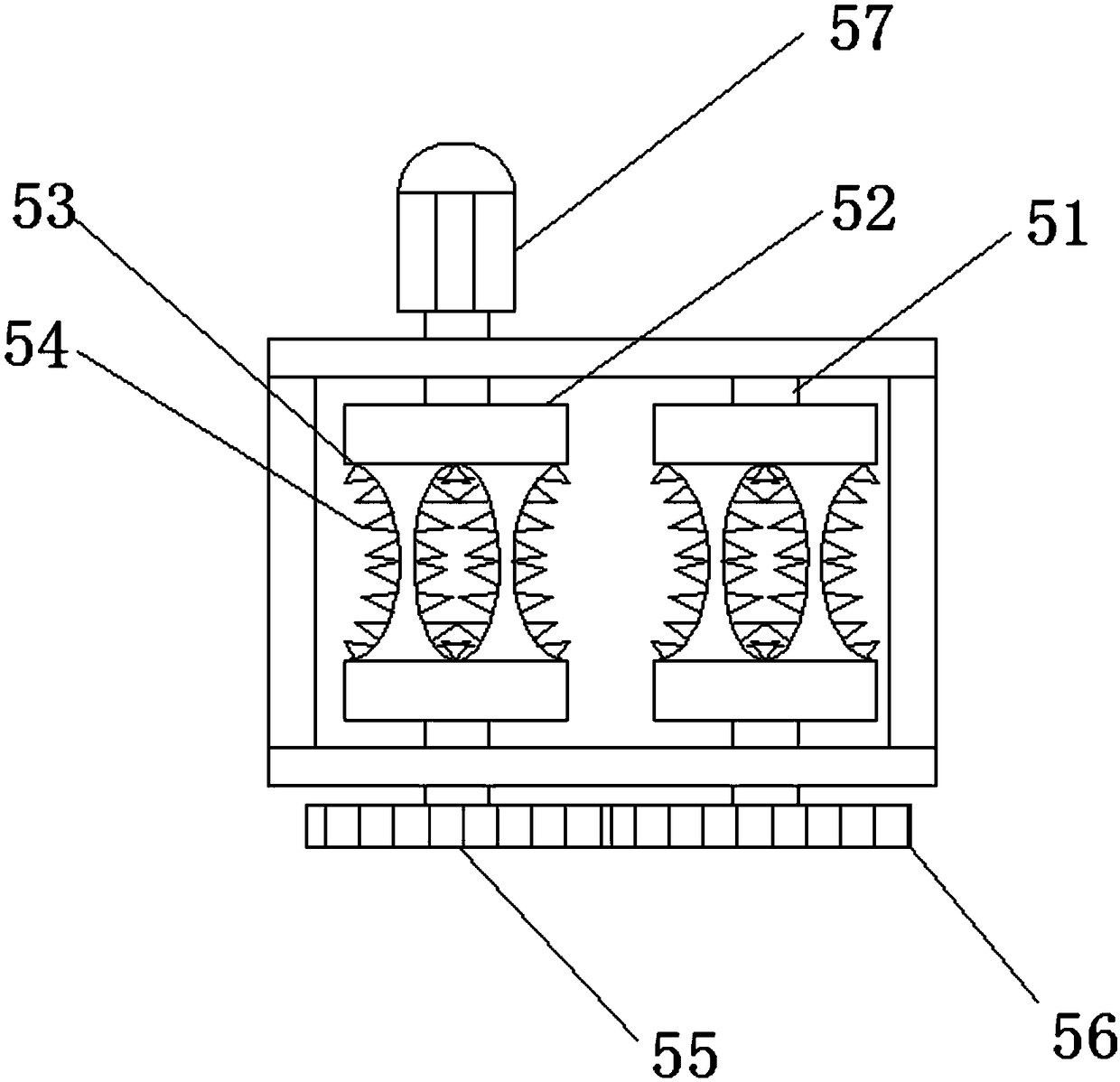

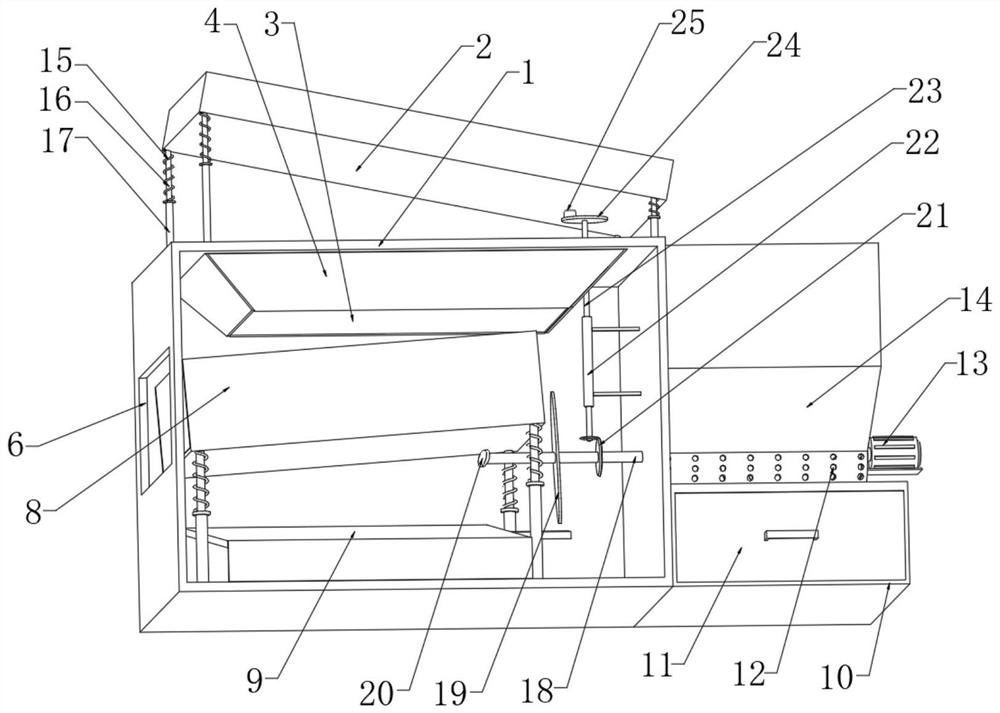

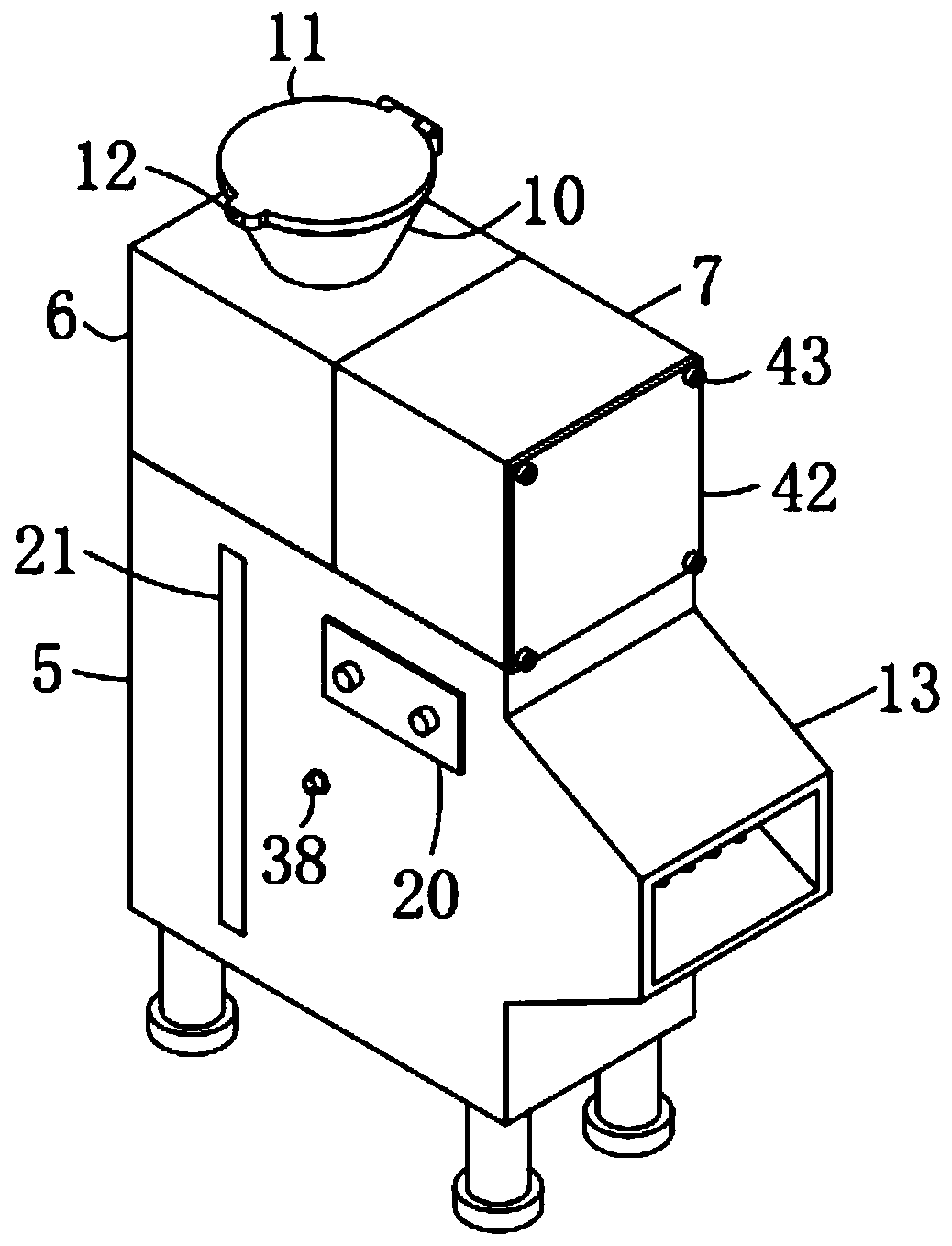

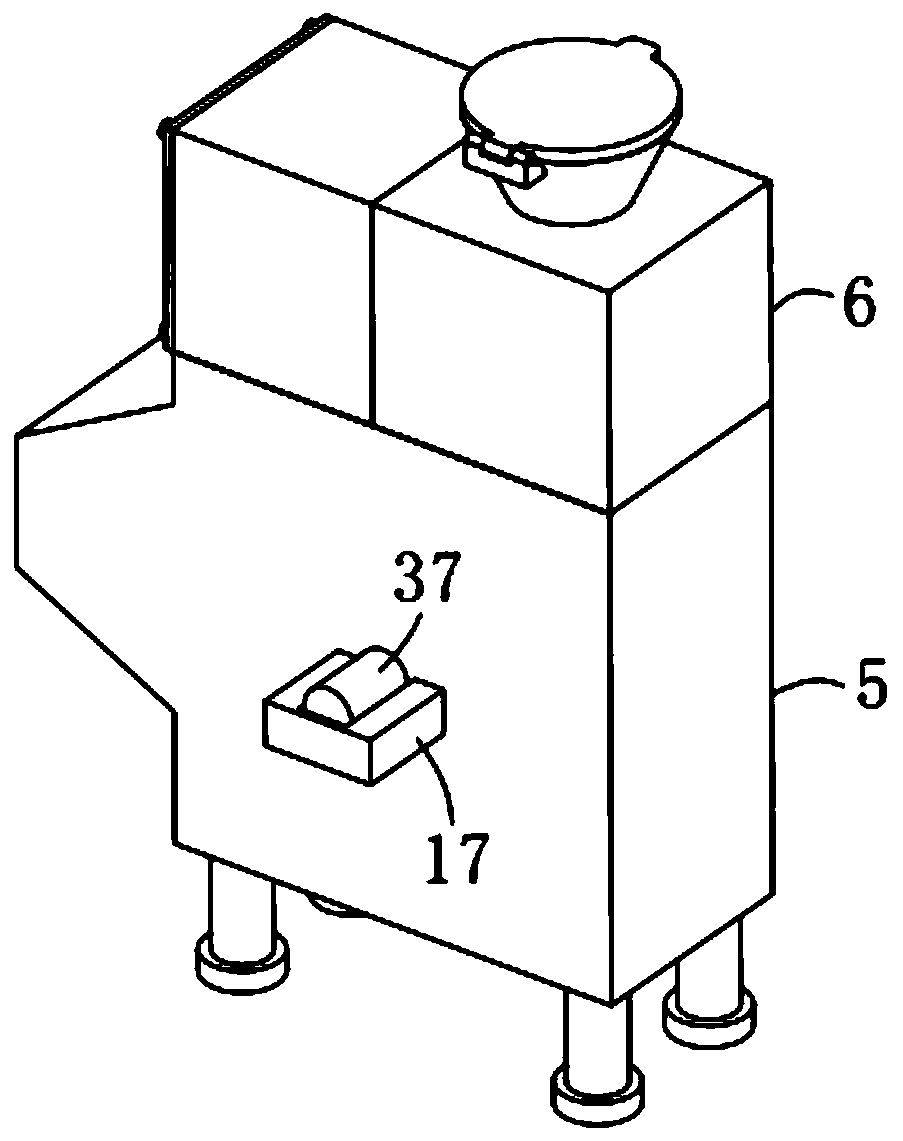

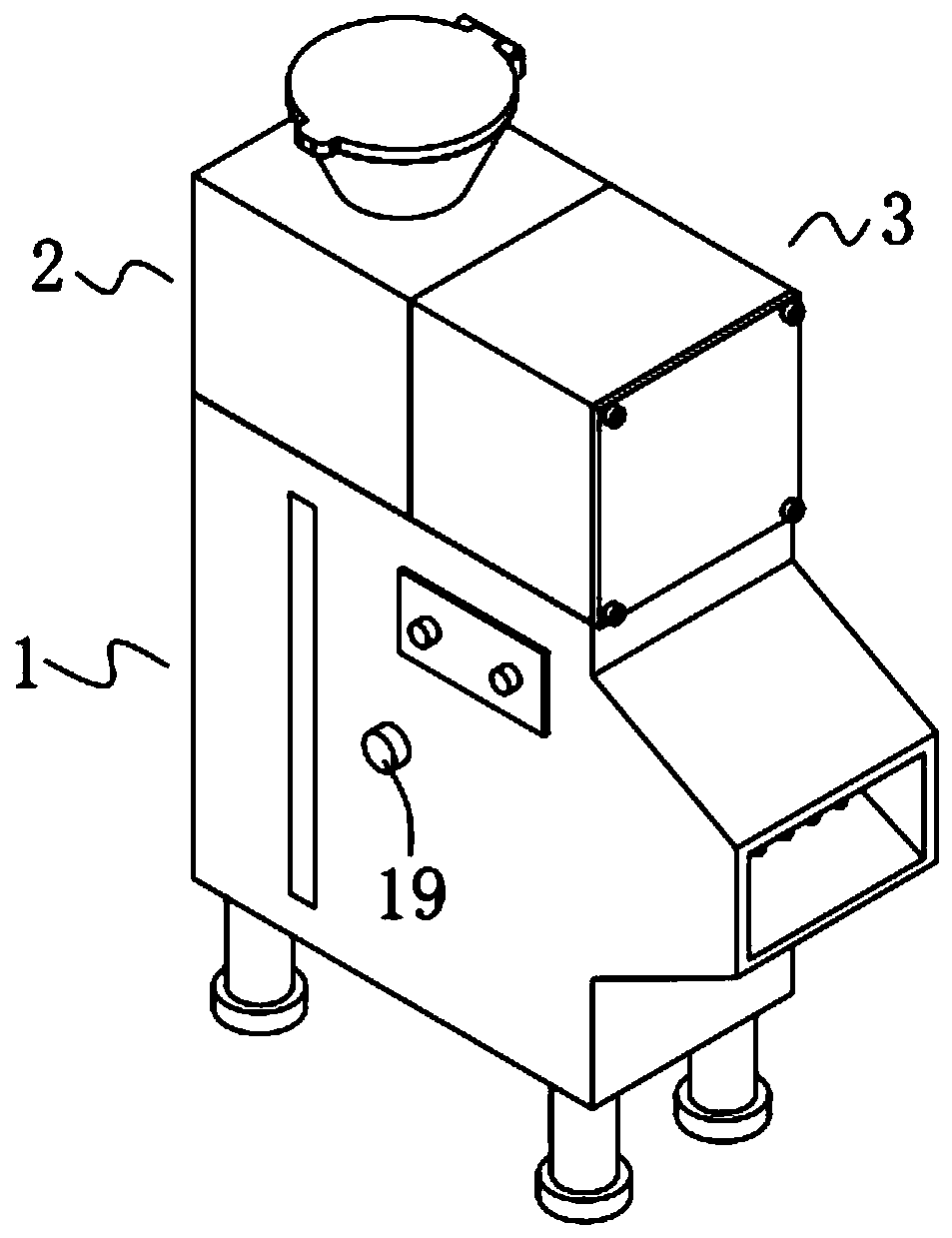

Casting processing sand mixer with self-cleaning function and application method

InactiveCN111774524AReduce residual ratePlay a cleaning roleMould handling/dressing devicesThermodynamicsElectric machinery

The invention discloses a casting processing sand mixer with a self-cleaning function and an application method and relates to the technical field of sand mixers. The casting processing sand mixer comprises a fine mixing tank and a coarse mixing tank. The fine mixing tank is internally provided with a coarse mixing cavity. The coarse mixing tank is internally provided with a fine mixing cavity. The bottom end of the coarse mixing cavity fixedly communicates with the fine mixing cavity. The top surface of the fine mixing cavity is fixedly connected with a set of damping and buffering parts distributed in a circular array mode. The top surface of the fine mixing tank is fixedly connected with the coarse mixing tank through connection of the damping and buffering parts. The bottom surface ofthe coarse mixing tank is fixedly connected with two vibration motors arranged symmetrically. Through the design of a turnover mechanism, the coarse mixing cavity and the fine mixing cavity, traditional single-stage crushing and mixing of sand is changed to double-stage crushing and mixing. During material processing, the casting processing sand mixer can conduct coarse mixing and fine mixing andcan effectively enhance the crushing and mixing effects through grade-by-grade crushing and mixing. Through the design of the turnover mechanism, traditional static single-time crushing is changed tocyclic multiple-time crushing.

Owner:马鞍山金瓦格机械科技有限公司

Mixing and stirring device

ActiveCN106492672AEnsure consistencyQuality assuranceLiquid degasificationTransportation and packagingPulp and paper industryCoating

The invention relates to the field of coating production equipment, in particular to a mixing and stirring device. The mixing and stirring device comprises a casing, a stirring shaft and an arc-shaped stirring blade, wherein the stirring shaft is rotationally lifted; the arc-shaped stirring blade is warped upwards; the casing is connected with an upper cover; the lower end of the stirring shaft penetrates through the upper cover and is positioned in the casing; the arc-shaped stirring blade is fixedly connected with the lower end of the stirring shaft; the stirring shaft is connected with a support plate, and a connecting column is arranged on the support plate; a hollow material inlet plate is arranged on the support plate; both ends of the material inlet plate are material outlet ends, each material outlet end is provided with a material outlet, the interior of the upper end of the stirring shaft is provided with a material inlet cavity, and the material inlet cavity is communicated with a cavity of the material inlet plate; air outlet holes are formed in the side walls of the casing, and are connected with air conveying pipes; the bottom surface of the casing is connected with two round columns. The mixing and stirring device aims at solving the problem of low quality of a finished coating in the prior art because the materials are directly added into the stirrer and the stirring is not uniform.

Owner:CHONGQING ALL COLOR WORLD COATING CO LTD

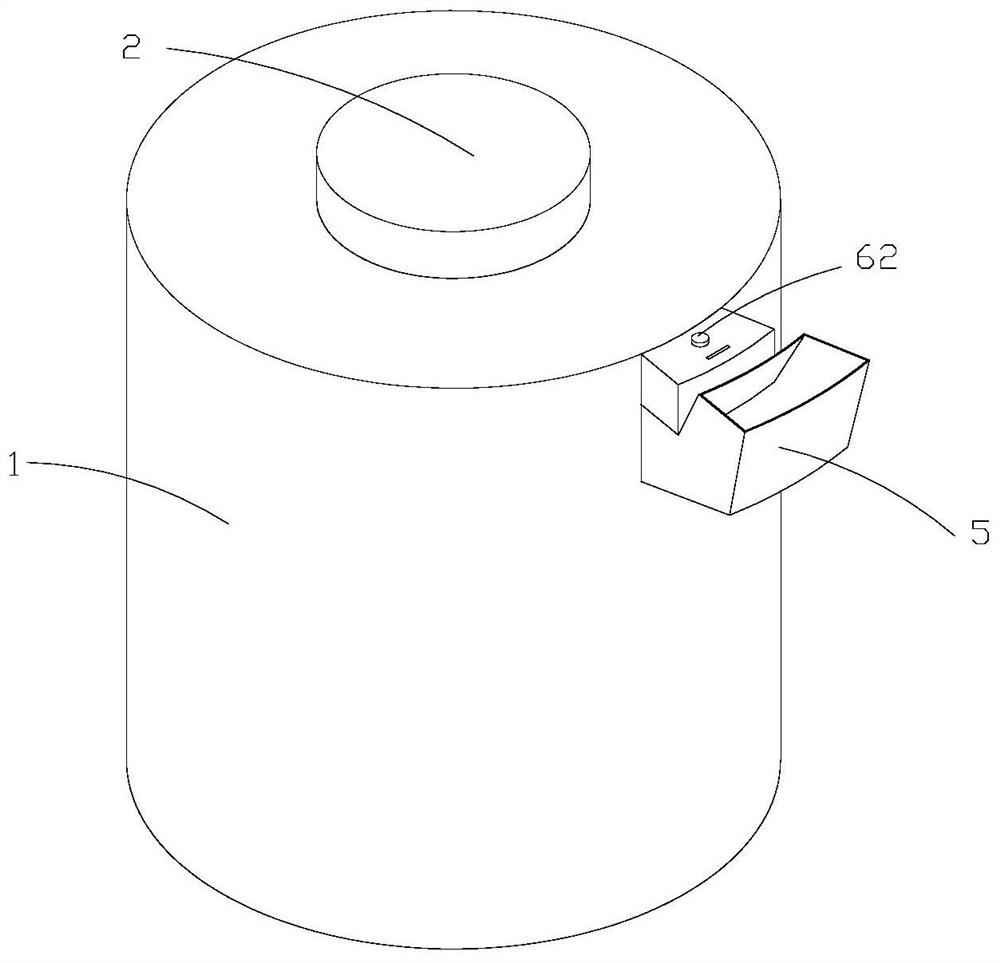

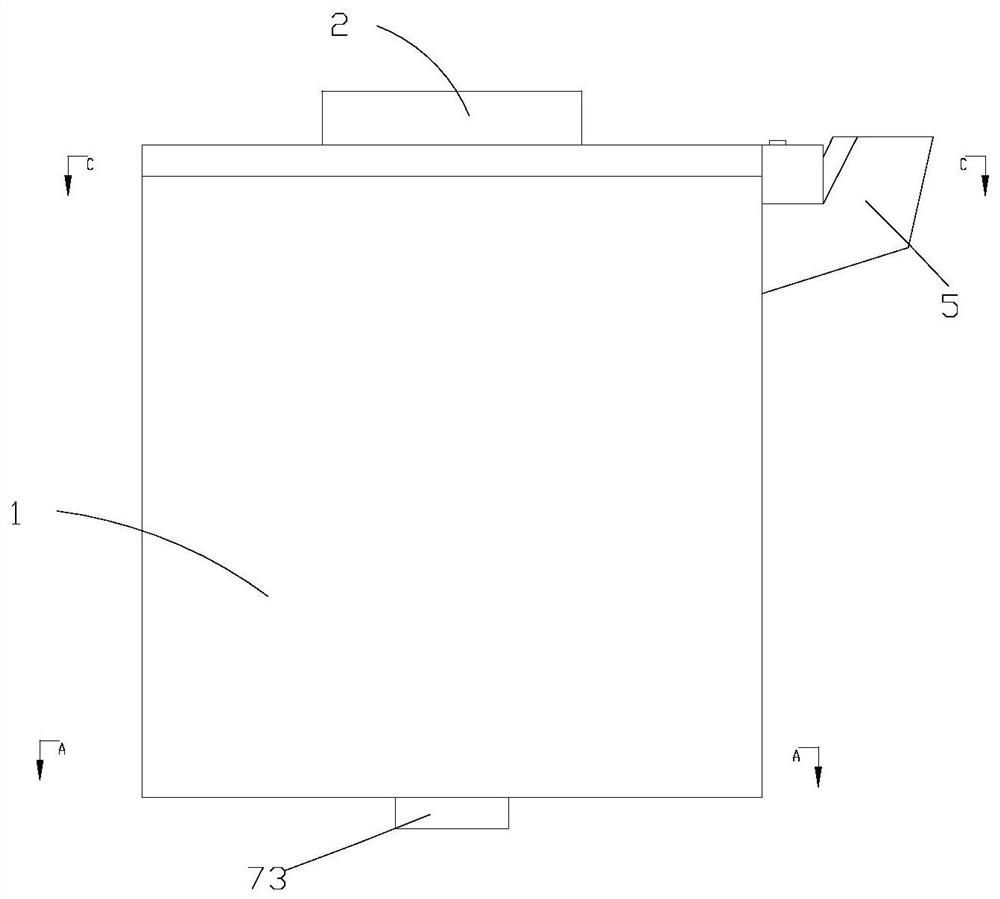

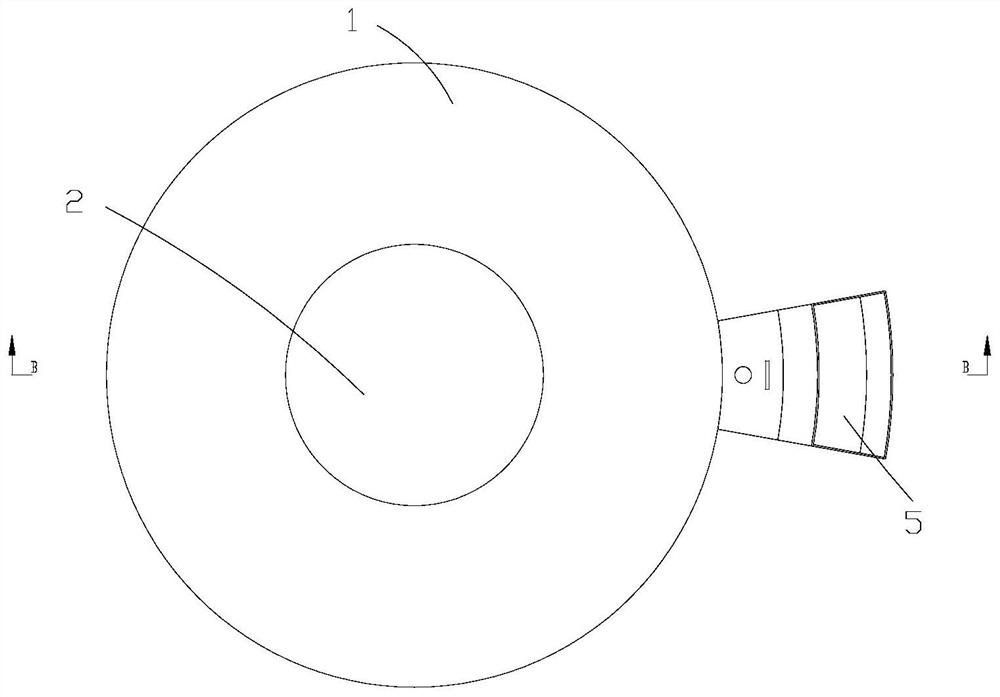

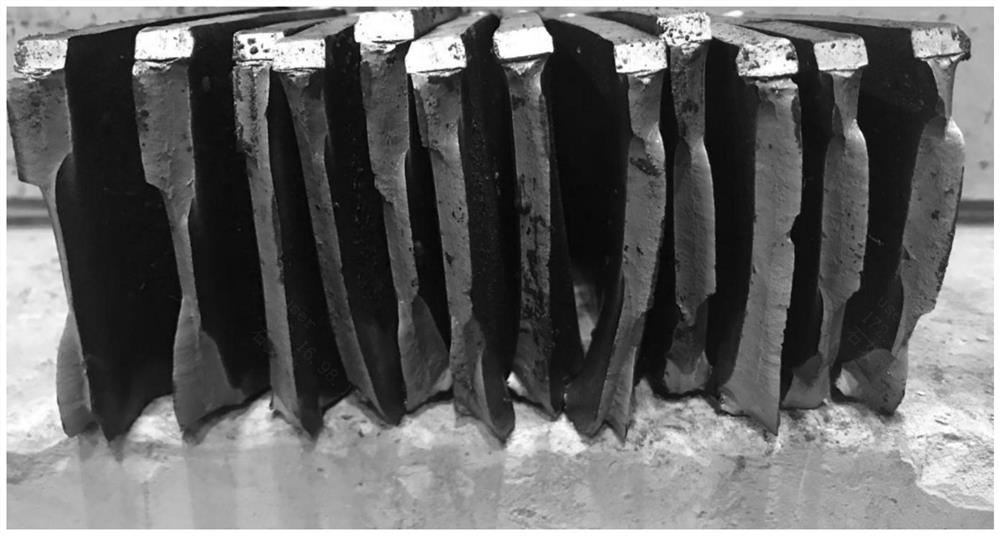

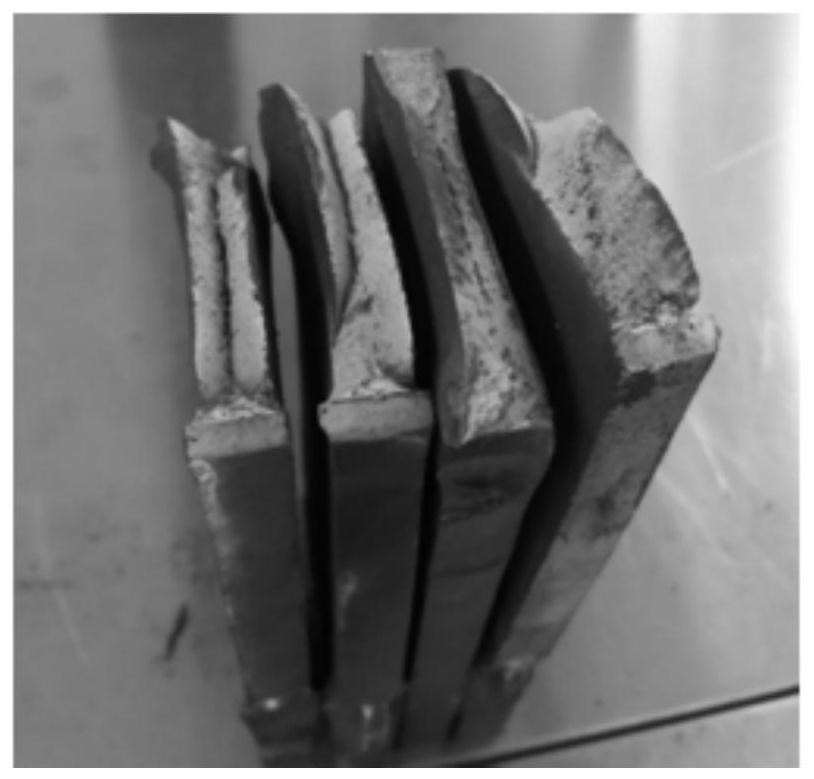

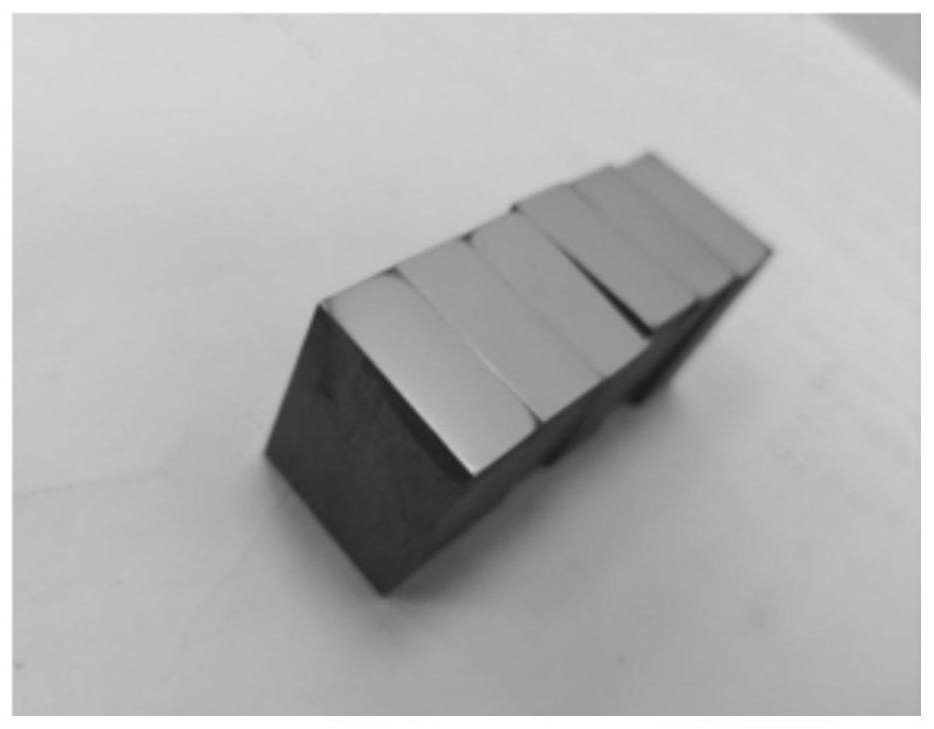

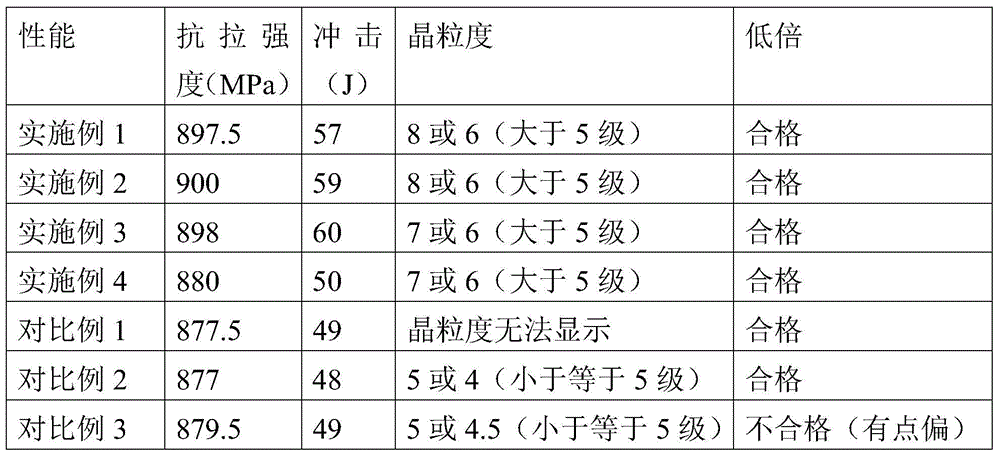

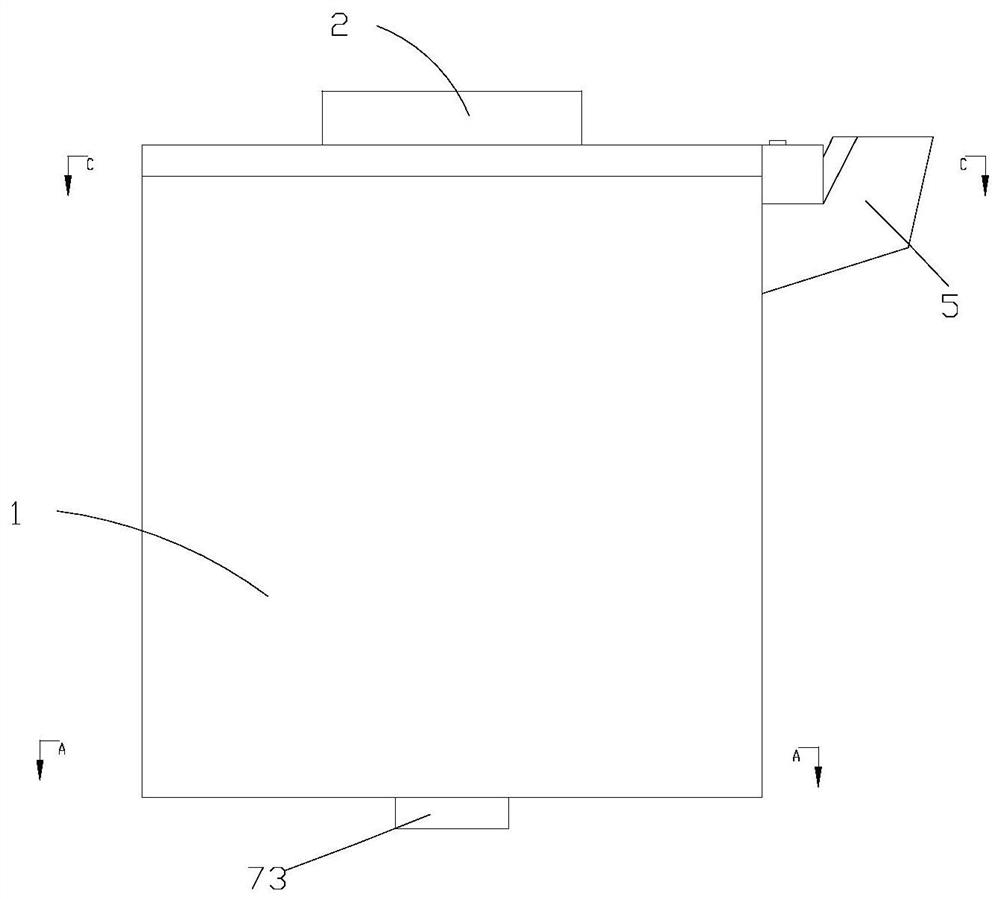

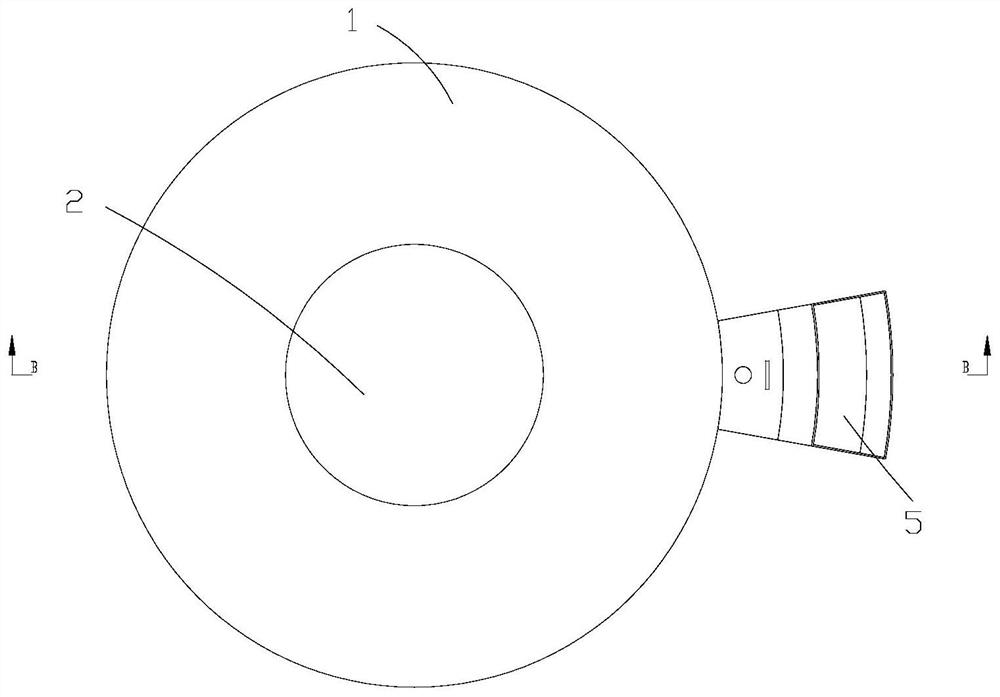

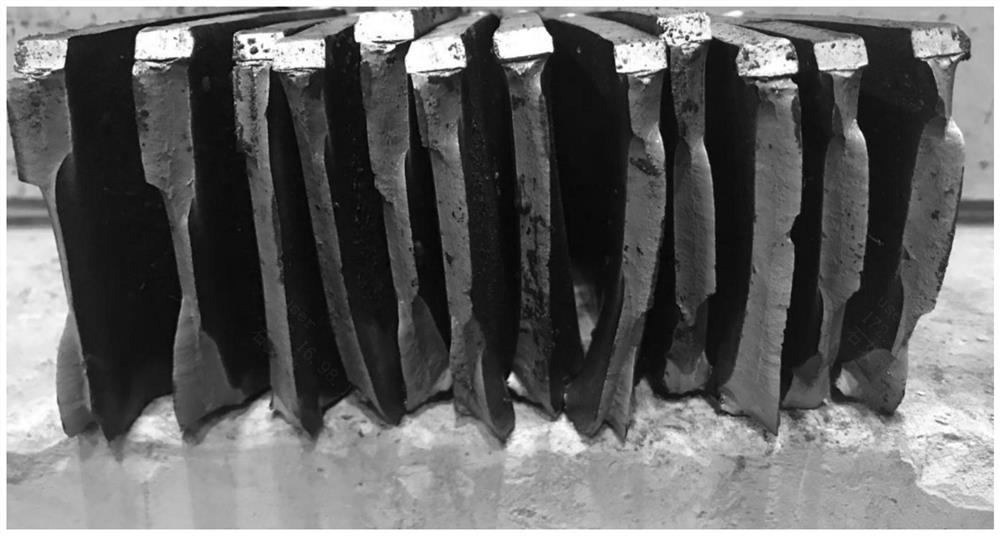

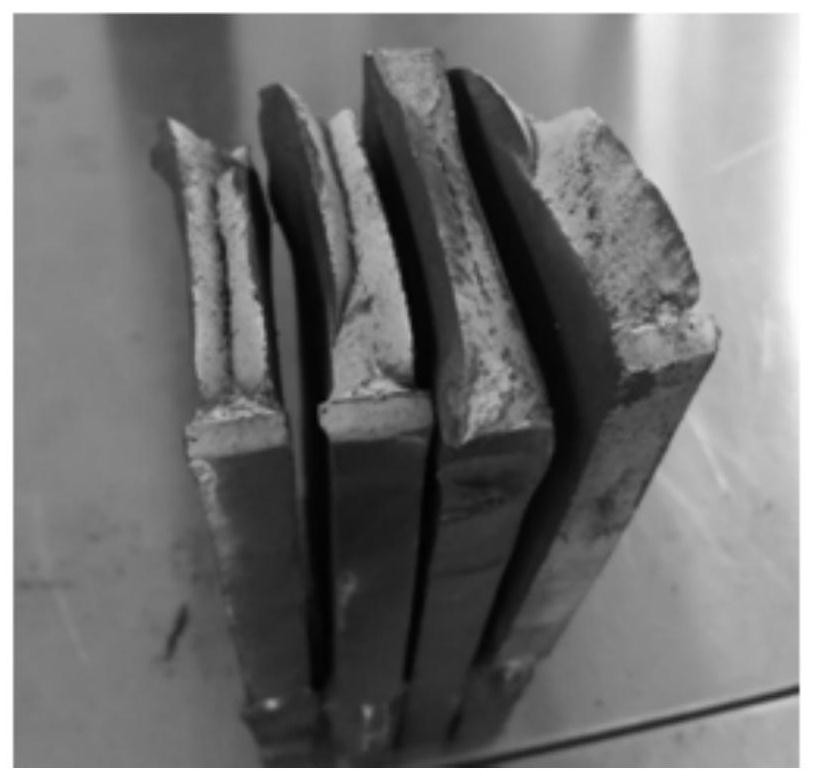

E2 vertical roller forging forming technology

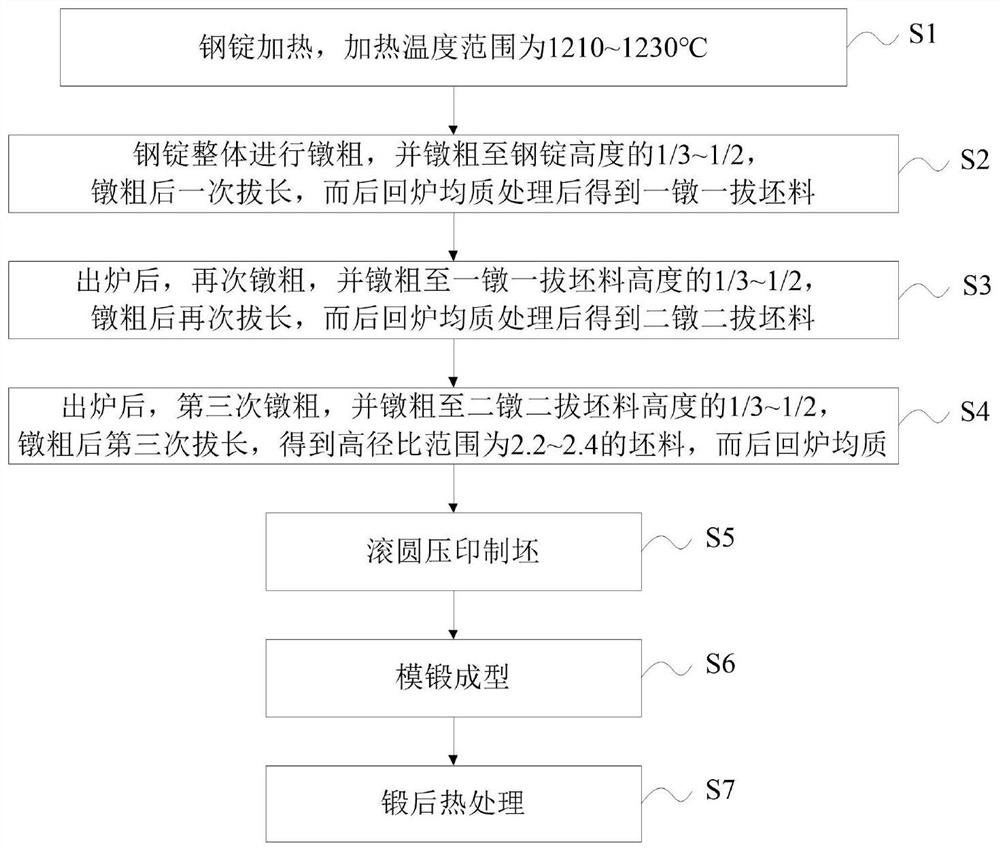

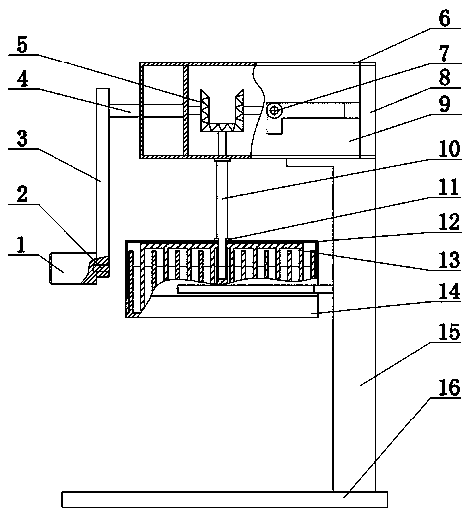

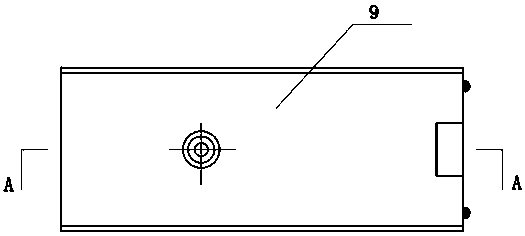

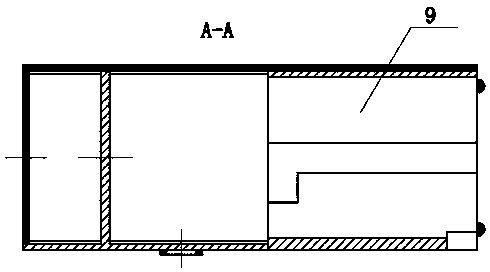

ActiveCN111496153AQuality improvementGuaranteed brokenMetal-working apparatusEngine componentsIngotHeat treating

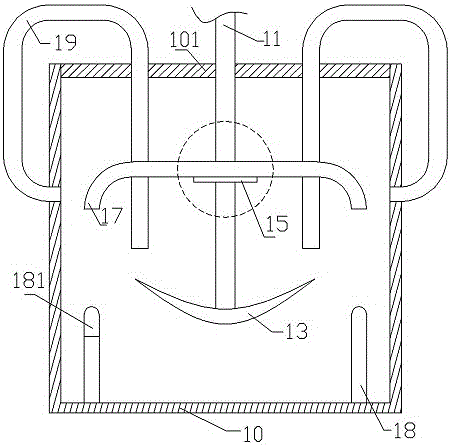

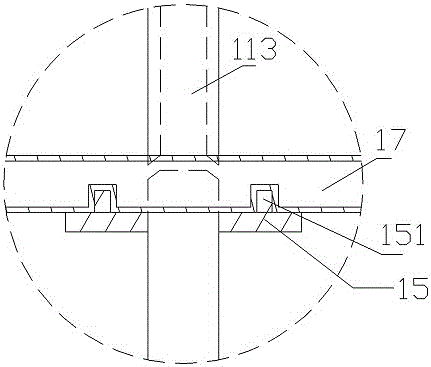

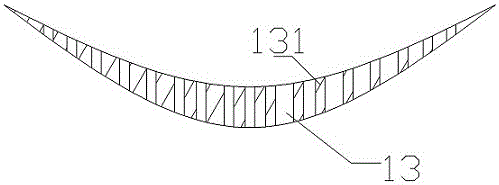

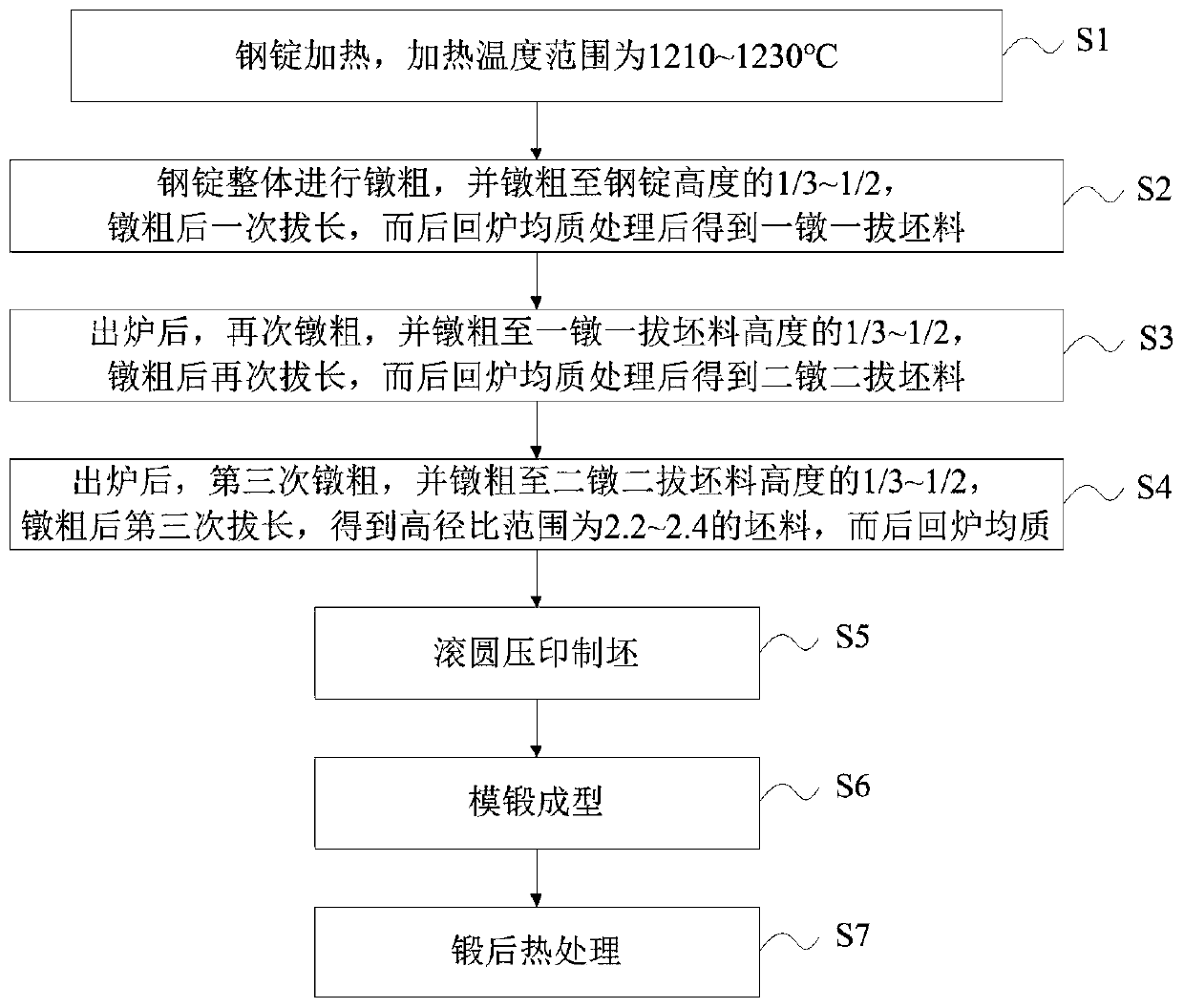

The invention discloses an E2 vertical roller forging forming technology. The E2 vertical roller forging forming technology comprises the steps that steel ingot heating is conducted, and the heating temperature range is 1,210 DEG C-1,230 DEG C; integral steel ingot upsetting is conducted, a steel ingot is subjected to upsetting to 1 / 3-1 / 2 of the height of the steel ingot, and after upsetting, first-time drawing is conducted, and then, the steel ingot returns to a furnace for homogenizing; after furnace discharging, upsetting is conducted again, upsetting is conducted to 1 / 3-1 / 2 of the heightof a first-upsetting and first-drawing blank, and after upsetting, drawing is conducted again, and then, the steel ingot returns to the furnace for homogenizing; after furnace discharging, third-timeupsetting is conducted, upsetting is conducted to 1 / 3-1 / 2 of the height of a second-upsetting and second-drawing blank, and after upsetting, third-time drawing is conducted, a blank with the height-diameter ratio being 2.2-2.4 is obtained, and then the blank returns to the furnace for homogenizing; rounding embossing blank manufacturing is conducted; die forging forming is conducted; and heat treatment after forging is conducted. By adoption of the forging forming technology, the three-upsetting and three-drawing production manner is adopted, crushing of a steel ingot cast-state structure canbe sufficiently guaranteed, and in combination with deformation and reversion and recrystallization effects, grains are sufficiently refined; and through forging production, the quality of a preparedE2 vertical roller is good, and volume production and quality requirements can be met.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Medical anesthetic liquid medicine bottle crushing device

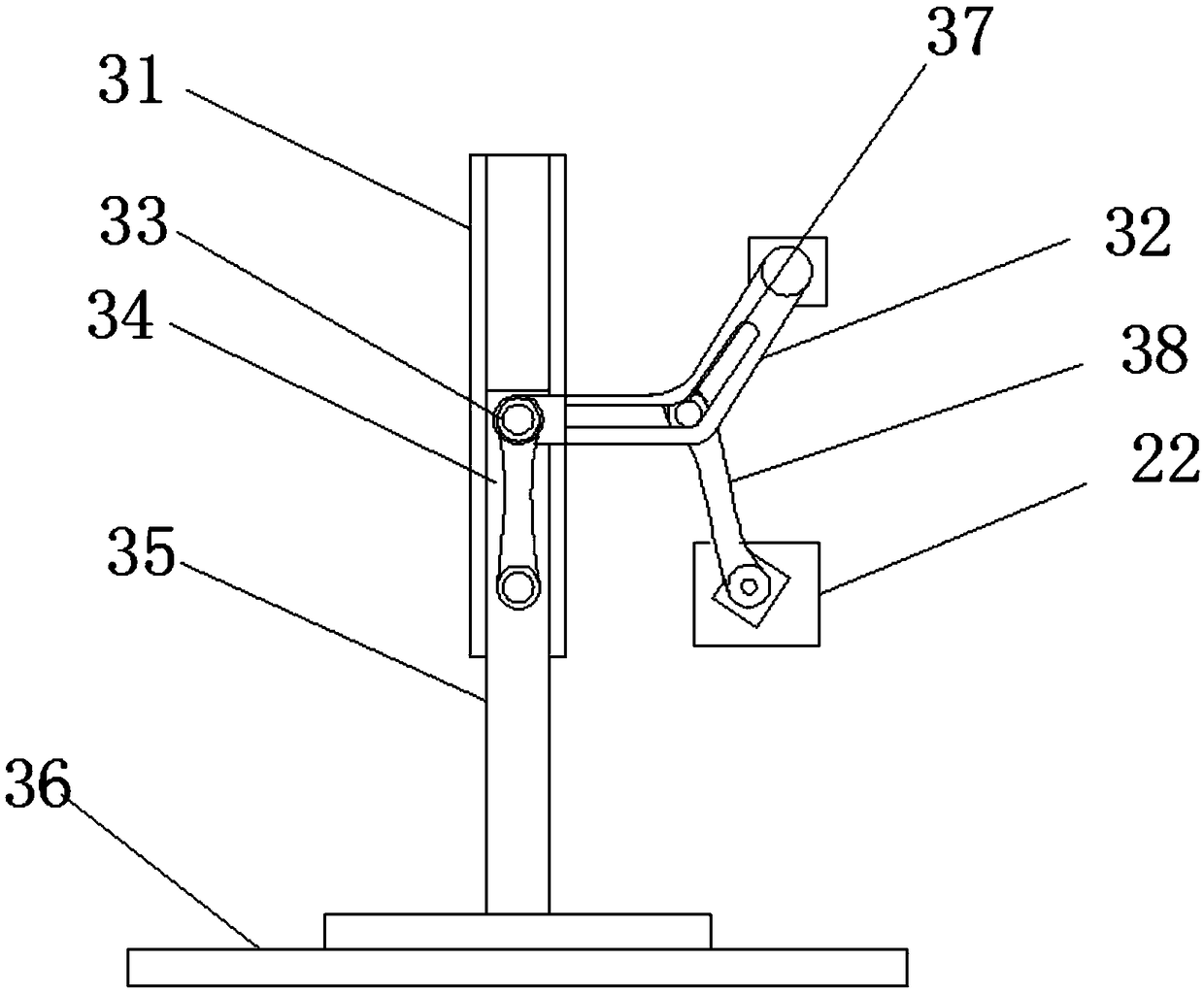

PendingCN112850612AGuaranteed brokenBottle/container closurePower operated devicesWaste materialMedicine bottles

The invention relates to a crushing device, in particular to a medical anesthetic liquid medicine bottle crushing device. The technical problem to be solved by the invention is to provide the medical anesthetic liquid medicine bottle crushing device which can automatically crush medicine bottles and can collect waste parts of medicine bottles. The medical anesthetic liquid medicine bottle crushing device comprises a bottom plate, a supporting mechanism and a downward pressing mechanism, wherein the bottom plate is used for supporting the whole device; the supporting mechanism is arranged at the upper part of the bottom plate; and the downward pressing mechanism is arranged between the bottom plate and the supporting mechanism. The medical anesthetic liquid medicine bottle crushing device provided by the invention achieves the effects that the medicine bottles can be automatically crushed, and the waste parts of the medicine bottles can be collected; and a triangular block moves downwards to drive a sliding rod and a saw blade to move forwards, so that the saw blade can cut the medicine bottles, and cut parts of the medicine bottles can be pushed out under the action of a push plate.

Owner:胡志颖

Building material recycling and smashing device

InactiveCN109126945AIncrease heightGuaranteed crushing efficiencyGrain treatmentsOblique angleMechanical engineering

The invention discloses a building material recycling and smashing device. The building material recycling and smashing device comprises a machine frame; the machine frame is provided with an extruding cavity, a transporting cavity and a smashing cavity; a transmission machine frame is mounted in the extruding cavity and comprises a limiting guide rail and a transmission guide rail; the limiting guide rail is mounted on a top plate of the extruding cavity; a fixed plate is mounted at the position of an oblique angle of the extruding cavity; the transmission guide rail is mounted on an erectionplate through a movable shaft; a transmission block is mounted in the limiting guide rail; a straight rod is mounted at the bottom end of the transmission block; an extruding plate is mounted at thebottom end of the straight rod; a transmission plate is mounted on a side wall of the extruding cavity; a first transmission rod is mounted on the transmission plate; and a clamping bolt is mounted atthe top end of the first transmission rod and in the transmission guide rail. According to the invention, the extruding plate is transmitted by a multi-stage connecting rod to extrude and smash material, and the effect of impacting the material powerfully can be achieved, so that the smashing efficiency of material can be ensured, and the situation of material jamming can be prevented.

Owner:HENAN HUANQIU AVIATION EQUIP TECH CO LTD

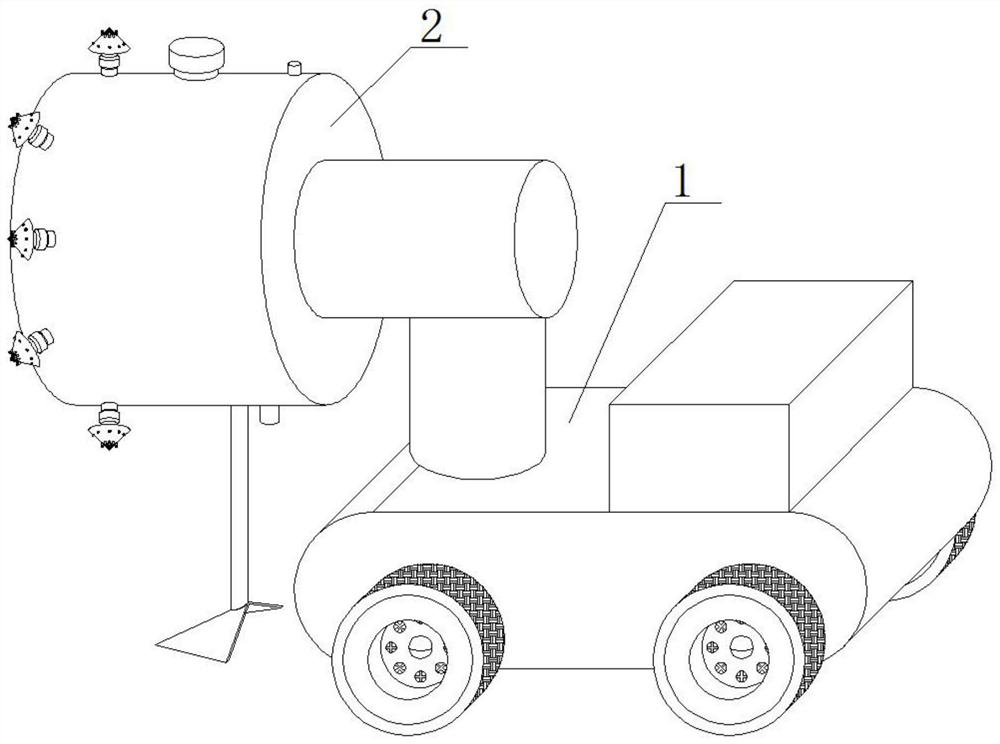

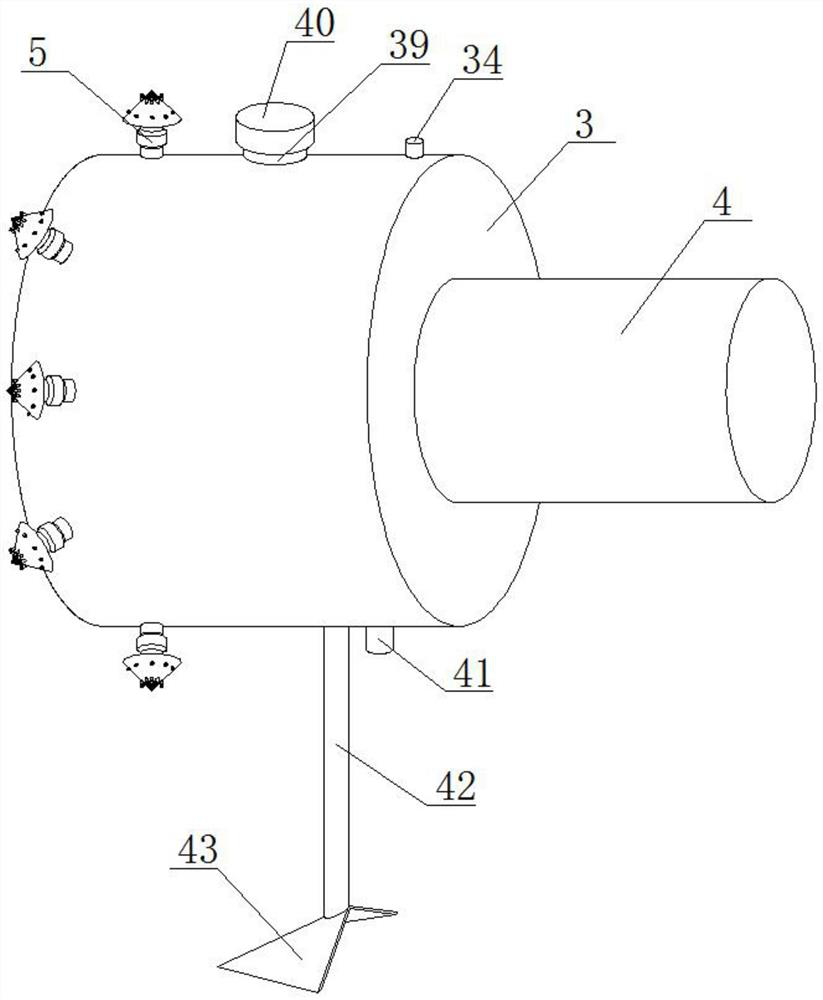

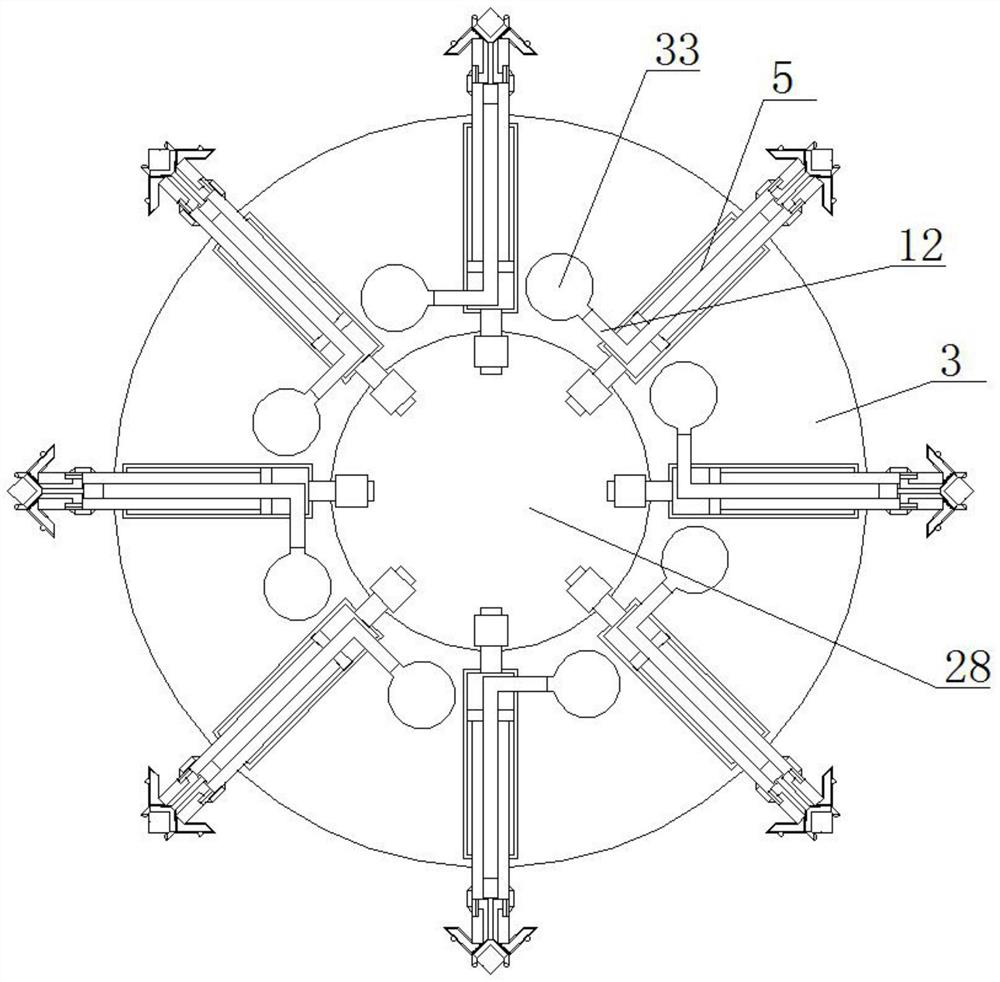

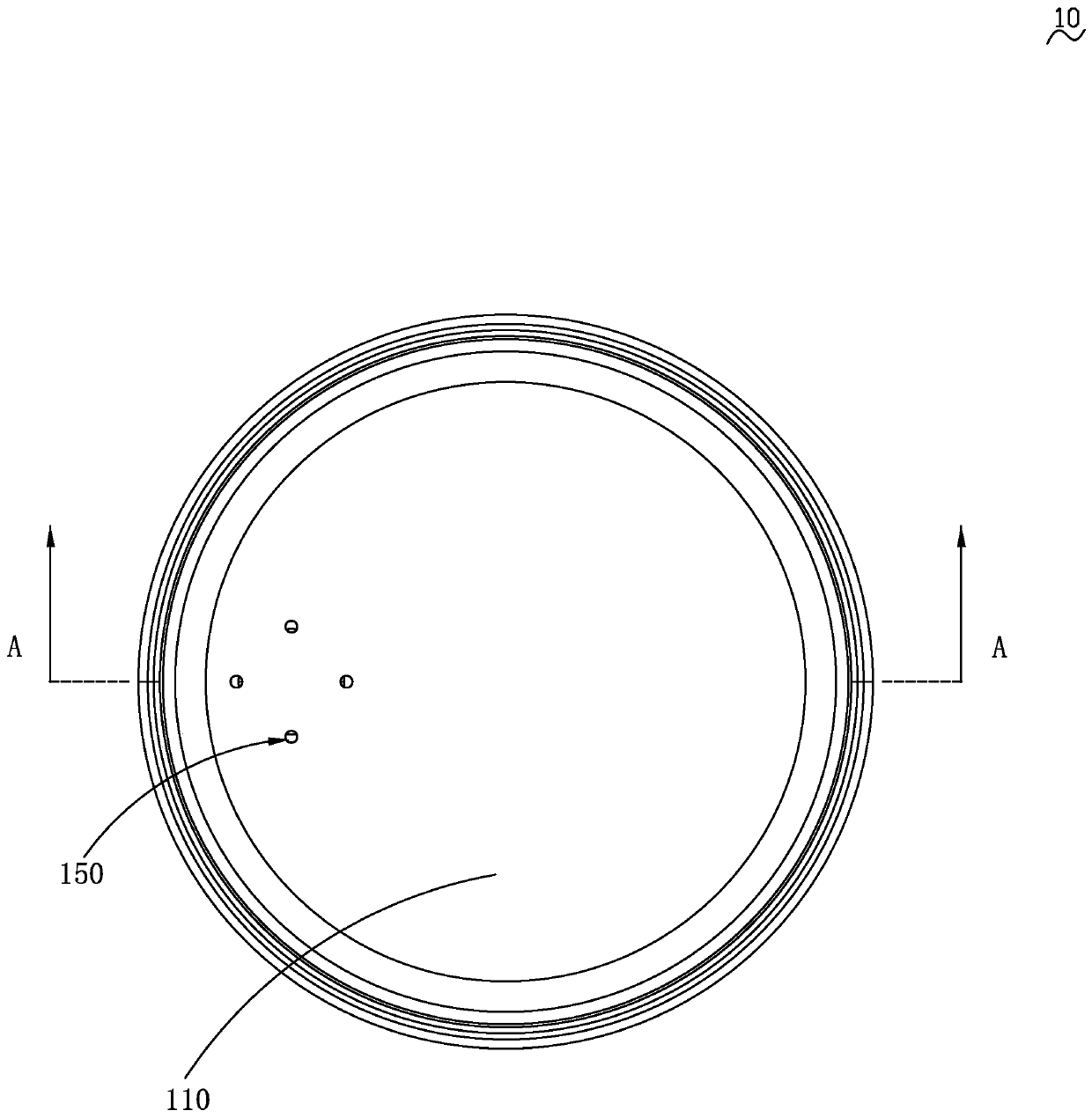

Pipeline cleaning and impurity removing device suitable for various pipeline diameters

ActiveCN112893345AImprove adaptabilityImprove crushing efficiencyHollow article cleaningFiltration separationSelf adaptiveEngineering

The invention provides a pipeline cleaning and impurity removing device suitable for various pipeline diameters. The pipeline cleaning and impurity removing device suitable for the various pipeline diameters comprises a remote control car and a pipe scale cleaning device, wherein the pipe scale cleaning device comprises a self-adaptive cleaning head, a mounting seat and a plurality of pipe scale crushing mechanisms, wherein each pipe scale crushing mechanism comprises a fixed column, a rotating head and a telescopic rod; convex telescopic grooves are formed in one ends of the fixed columns; and moving seats are movably mounted in the convex telescopic grooves. The pipeline cleaning and impurity removing device suitable for the various pipeline diameters is reasonable in design; the plurality of pipe scale crushing mechanisms on the self-adaptive cleaning head can stretch out and be attached to the surfaces of pipe scales on the inner wall of a pipeline, so that the pipe scales can be crushed and cleaned; and when the pipe scale crushing mechanisms make contact with the pipe scales on the inner wall of the pipeline, the pipe scale crushing mechanisms stop stretching due to resistance, and hydraulic oil continues to push the pipe scale crushing mechanisms which do not make contact with the pipe scales to stretch, so that the adaptability to the environment in the pipeline can be effectively improved.

Owner:SHANDONG HUABAOLONG LIGHT IND MACHINERY

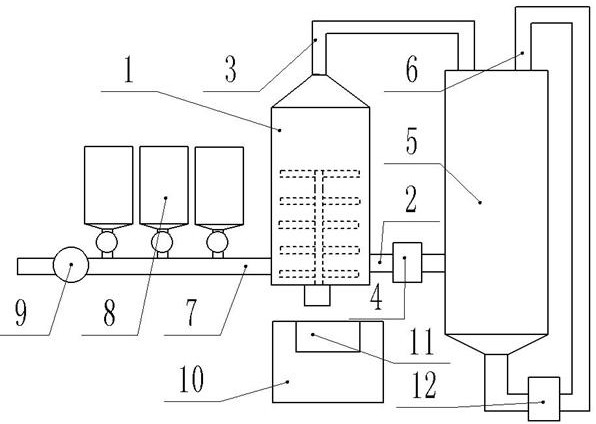

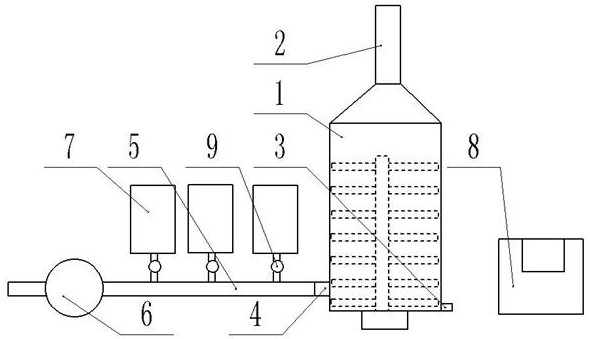

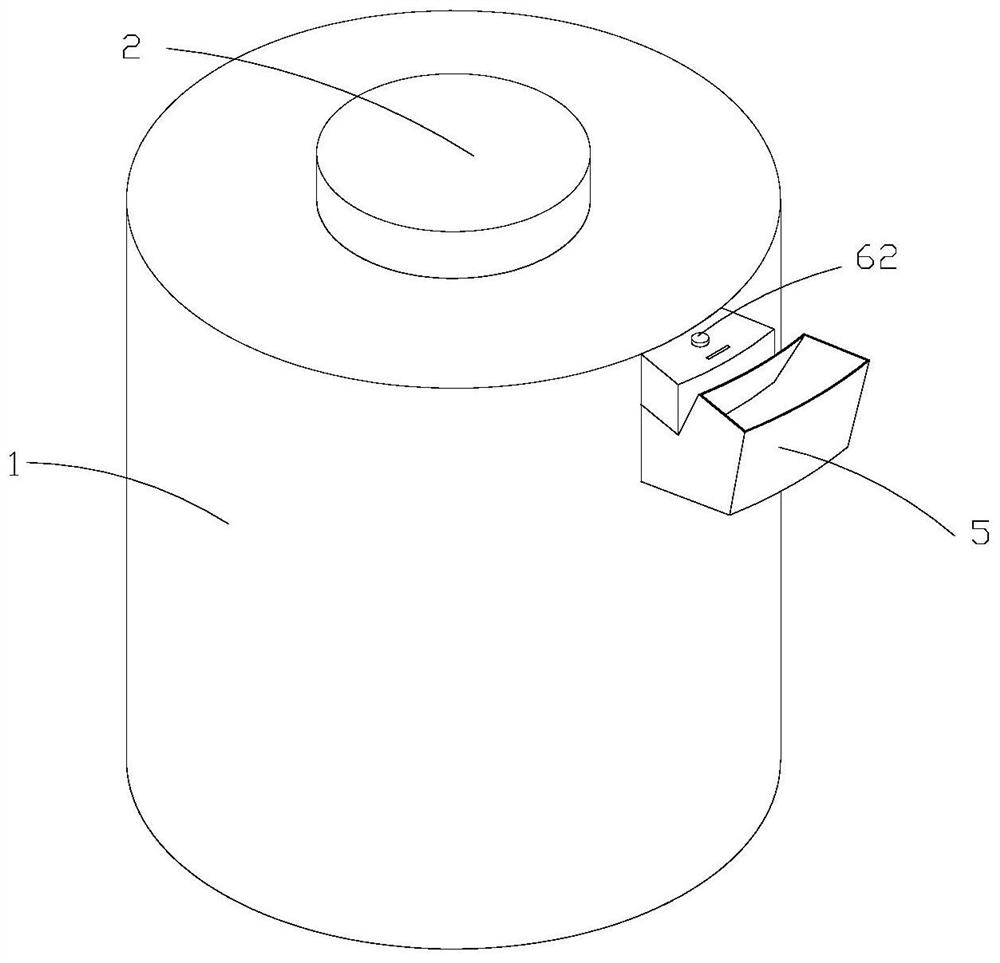

Silicon carbide micro-powder grinding system and using method thereof

The invention discloses a silicon carbide micro-powder grinding system and a using method thereof, and belongs to the technical field of smashing machinery. The silicon carbide micro-powder grinding system comprises a storage box, a feeding pipe is arranged on the side wall of the lower end of the storage box, and a first feeding pump is installed on the feeding pipe; the feeding pipe is connected with a grinding mechanism, and a discharging pipe is arranged between the upper end of the grinding mechanism and the upper end of the storage box for connection; the lower end of the grinding mechanism is connected with an air inlet pipe, a fan is installed on the air inlet pipe, a plurality of medium storage tanks are installed on the air inlet pipe between the fan and the grinding mechanism in parallel, and the different medium storage tanks are used for storing silicon carbide media with different particle sizes; and a control box is arranged on one side of the grinding mechanism, the control box is connected with a control panel, and the control box is electrically connected with the first feeding pump, the grinding mechanism and the fan.

Owner:潍坊凯华碳化硅微粉有限公司

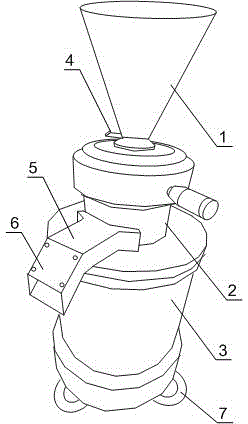

Shockproof colloid mill

The invention discloses a shockproof colloid mill which comprises a grinding head, a feeding hole, a discharging hole and a drive mechanism, wherein the feeding hole is formed in the grinding head, the drive mechanism is connected with the grinding head, the discharging hole is formed in the bottom of the grinding head, an insertion sheet is arranged at the bottom of the feeding hole, and movably arranged at the bottom of the feeding hole; a plurality of shockproof food pads are arranged at the bottom of the drive mechanism. During machining, a material enters in the grinding head through the feeding hole, a series of dispersing, crushing, emulsifying, homogenizing and uniform-mixing operations are started to be performed under the drive of the drive mechanism; because a device in the grinding head runs at a high speed, small shocking of the mill is caused. The plurality of shockproof food pads at the bottom of a supporting frame can be used for relieving the shocking generated by the mill per se, so that displacement or swinging is prevented from occurring in a machining process of the mill, and procedures such as dispersing, crushing, emulsifying, homogenizing and uniform-mixing are enabled to be stably performed.

Owner:张丹

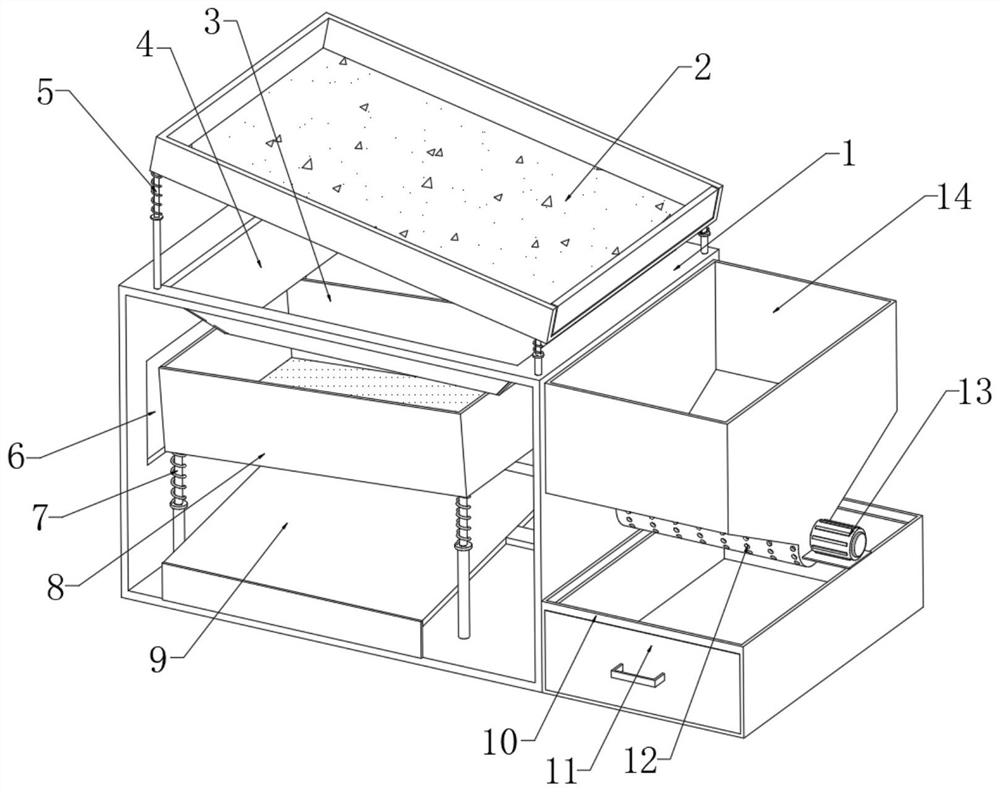

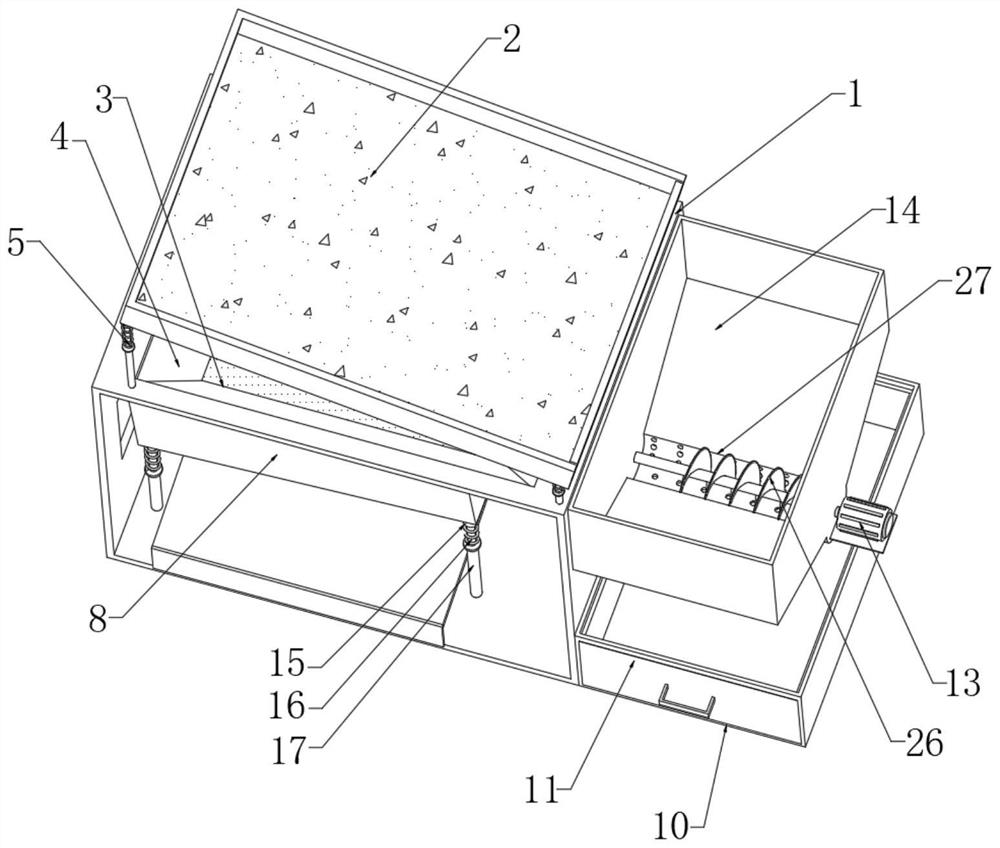

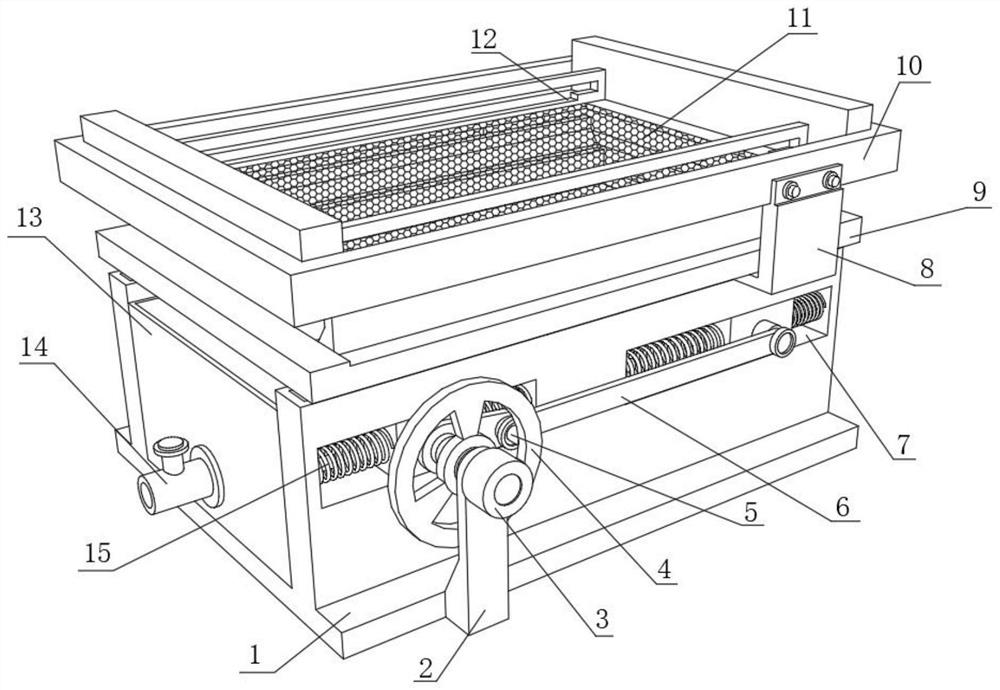

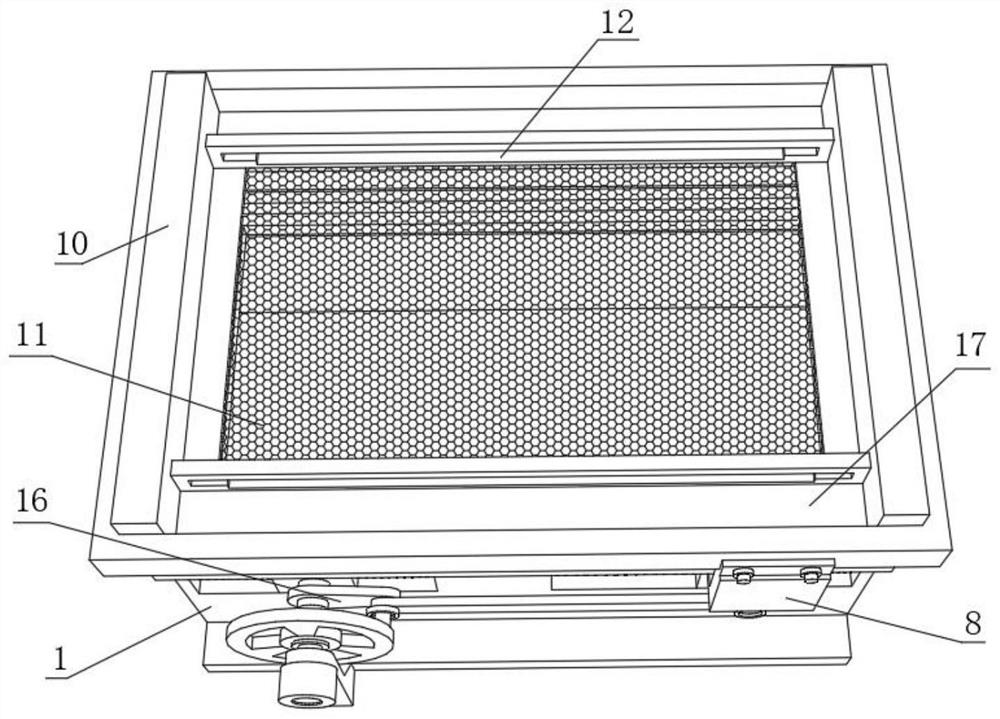

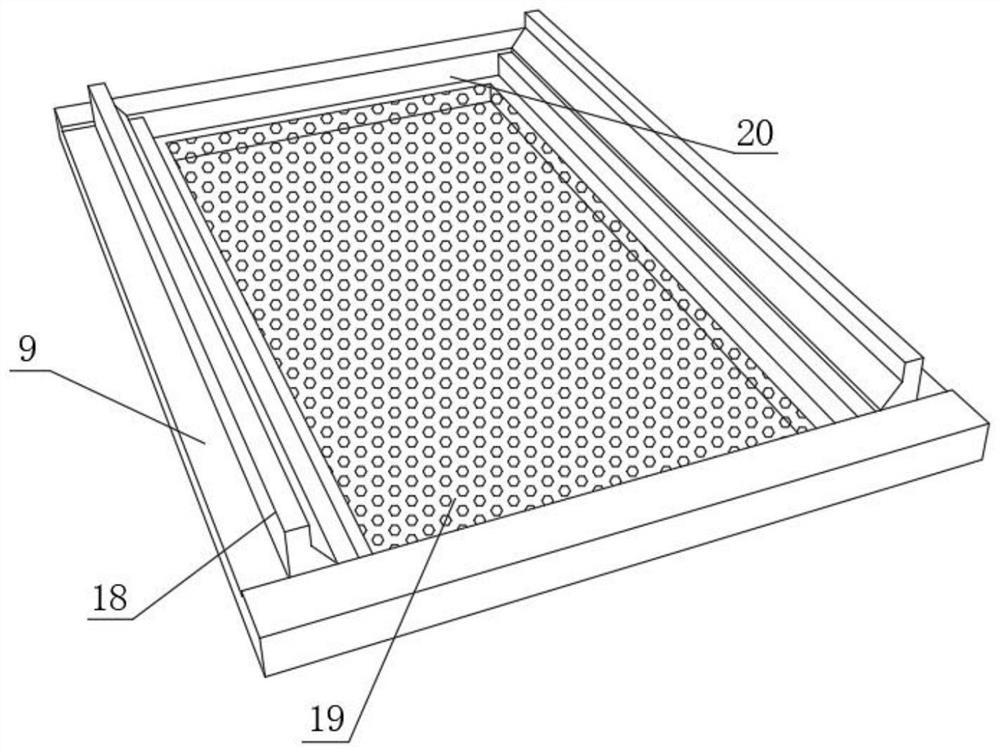

Impurity removing and screening device for clean coal processing

ActiveCN114210544AImprove output rateGuaranteed screening qualitySievingScreeningStructural engineeringBriquette

The invention relates to the technical field of clean coal processing, in particular to an impurity removing and screening device for clean coal processing, which comprises a main frame body, a primary screening mechanism and a secondary screening mechanism are sequentially arranged on the main frame body, and the primary screening mechanism comprises a filtering inclined net cage arranged at the top end of the main frame body; the secondary screening mechanism comprises a filtering inclined net cage, a first vibration guide assembly is arranged on the side, opposite to the main frame body, of the filtering inclined net cage, meshes of the filtering inclined net cage are matched with clean coal briquettes, the secondary screening mechanism comprises a screening net cage, and a second vibration guide assembly is arranged on the side, opposite to the main frame body, of the screening net cage. According to the screening device, the arranged second oval disc can rotate along with the shaft rod, so that the screening net cage is pressed at fixed frequency, and the purpose of improving the screening effect of the screening net cage is achieved; and the arranged first elliptic disc can abut against the arranged side block at a fixed frequency along with rotation of the shaft rod so as to be matched with the arranged connecting spring to drive the vibration discharging plate to vibrate, and therefore screened small impurities are shaken off.

Owner:唐山国华科技国际工程有限公司 +1

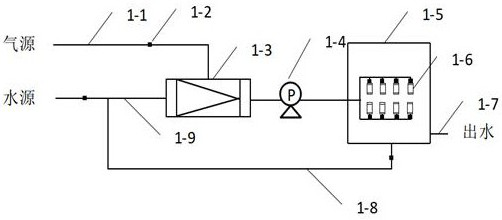

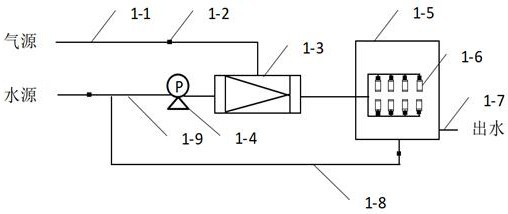

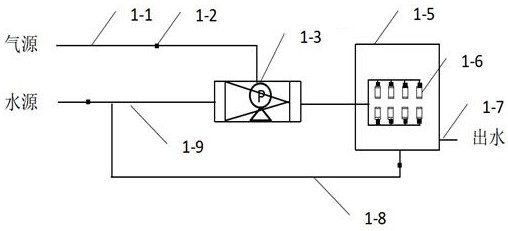

Micro-nano bubble generator with adjustable bubble particle size and adjusting method

PendingCN112661278AGuaranteed brokenIncrease concentrationWater aerationSustainable biological treatmentMicro nanoStream flow

The invention discloses a micro-nano bubble generator with an adjustable bubble particle size and an adjusting method. The micro-nano bubble generator comprises a water supply pipeline, a gas supply pipeline, a mixer, a booster pump, a gas-liquid mixed pipeline, a buffer tank, a spray head, a circulating pipeline and a water outlet pipeline, wherein the water supply pipeline, the mixer, the booster pump, the gas-water mixed liquid pipeline, the buffer tank, the spray head and the circulating pipeline are sequentially connected; and the gas supply pipeline, the mixer, the booster pump, the gas-water mixed liquid pipeline, the buffer tank, the spray head and the circulating pipeline are sequentially connected. By controlling the flow of a water supply pipeline, a gas supply pipeline, a spray head and a circulating pipeline, the pressure rise of a booster pump is controlled, the inclination angle of the spray head, the axial interval of the spray head and the like are swung, gas-water mixed liquid is in continuous contact, collides and effectively shears, and then micron bubbles or micro-nano bubbles or nano bubbles are generated and adjusted. The method disclosed by the invention has important theoretical value and practical significance for quickly improving water environments such as rivers, lakes and reservoirs and eliminating all black and odorous water.

Owner:JIANGSU UNIV

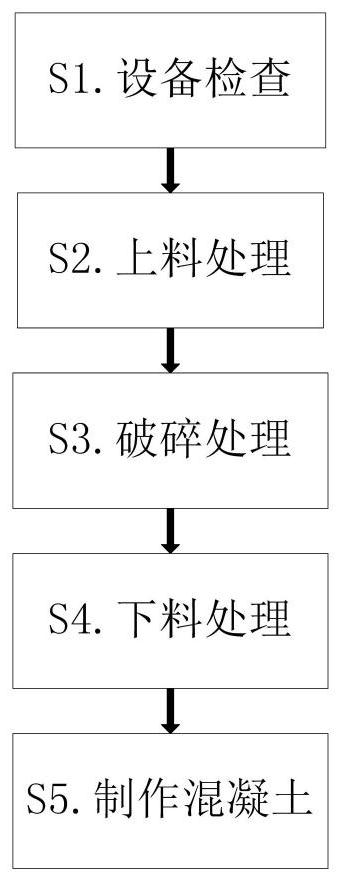

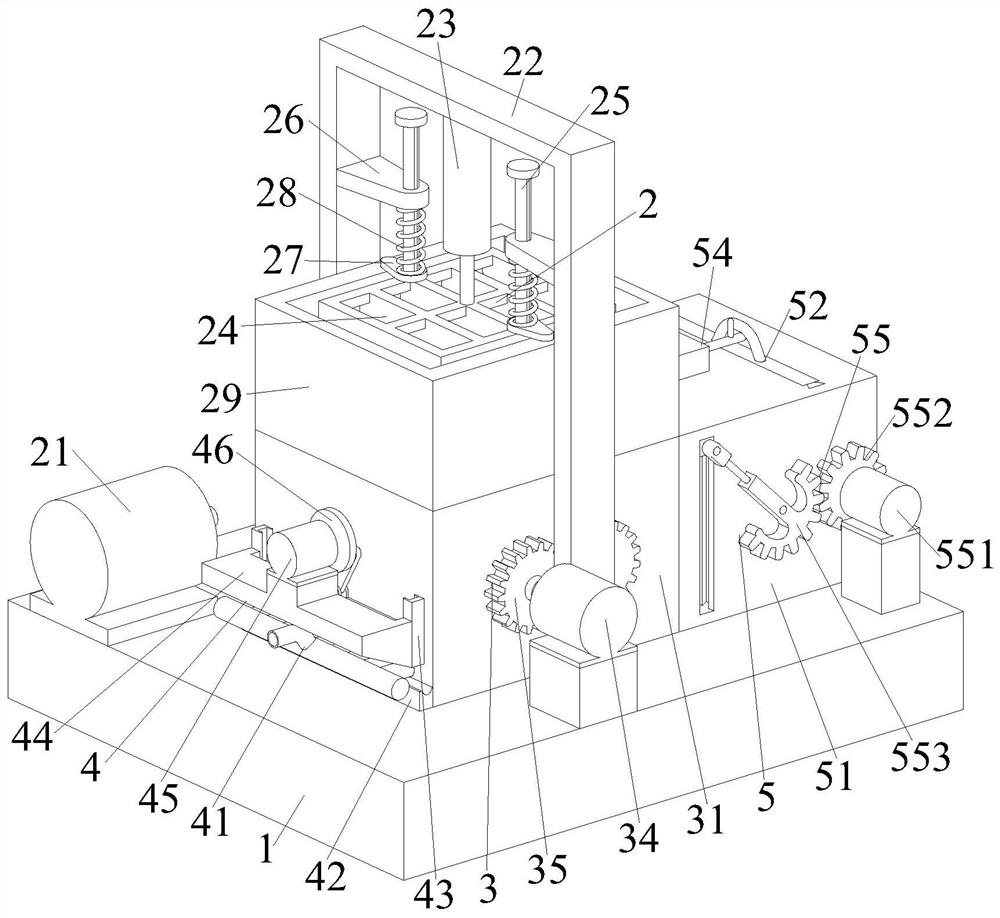

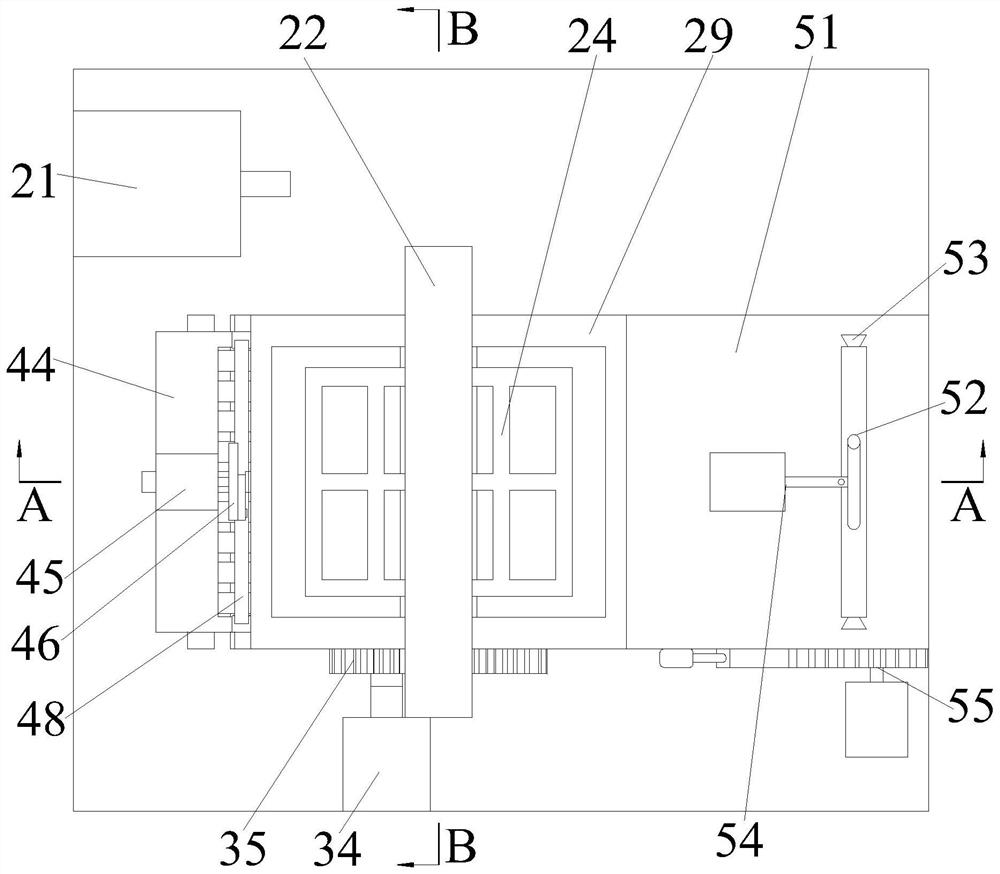

Method for improving compressive strength of aerated recycled concrete

InactiveCN112808415AHigh compressive strengthGuaranteed brokenDispersed particle filtrationTransportation and packagingGlass fiberCompressive strength

The invention relates to a method for improving the compressive strength of aerated recycled concrete. The aerated concrete with the compressive strength improved is completed through cooperation of a bottom plate, a feeding device, a crushing device, an air blowing device and a discharging device. According to the method for improving the compressive strength of the aerated recycled concrete, the problems that the crushing speed of waste glass fibers is low, after the waste glass fibers are crushed, the waste glass fibers are not screened, the waste glass fibers are unqualified after being crushed, existing recycled concrete manufacturing equipment does not adjust the waste glass fibers during blanking after crushing, the proportion of the waste glass fibers added into the concrete is difficult to control, and the compressive strength of the aerated concrete is difficult to improve due to the fact that when the existing recycled concrete manufacturing equipment is used for manufacturing and existing waste glass fiber crushing equipment is used for crushing the waste glass fibers, pressing feeding is not carried out on the waste glass fibers can be solved.

Owner:张雨婷

Lithium battery recovery process

ActiveCN112828006AAvoid mixingImprove recycling effectSolid waste disposalTransportation and packagingThermodynamicsProcess engineering

The invention discloses a lithium battery recycling process. The lithium battery recycling process comprises the following steps that a, firstly, a lithium battery is discharged; b, the lithium battery subjected to discharging treatment in the step a is disassembled; c, electrolyte in the disassembled lithium battery in the step b is discharged; and d, the lithium battery in the step c is fed into a sorting and recycling device for crushing and recycling. The recycling device comprises a body, a first motor, a rotating plate, a crushing device, a feeding hole, a sealing device, a sorting device, a U-shaped groove, a rack, a moving block, a gear, a rotating roller, a filtering plate, a crushing cutter and a driving mechanism. According to the lithium battery recycling process, the waste lithium battery cannot explode when being crushed through discharge treatment, so that the safety of lithium battery recovery is improved; the crushing device can realize screening when the battery crushed, so that metal powder adhered to metal is separated, and the battery recovery efficiency is improved; the sealing device can enable the battery to be in a vacuum state during crushing, so that the crushing safety is improved; and the battery recycling effect is further improved.

Owner:广东威玛新材料股份有限公司

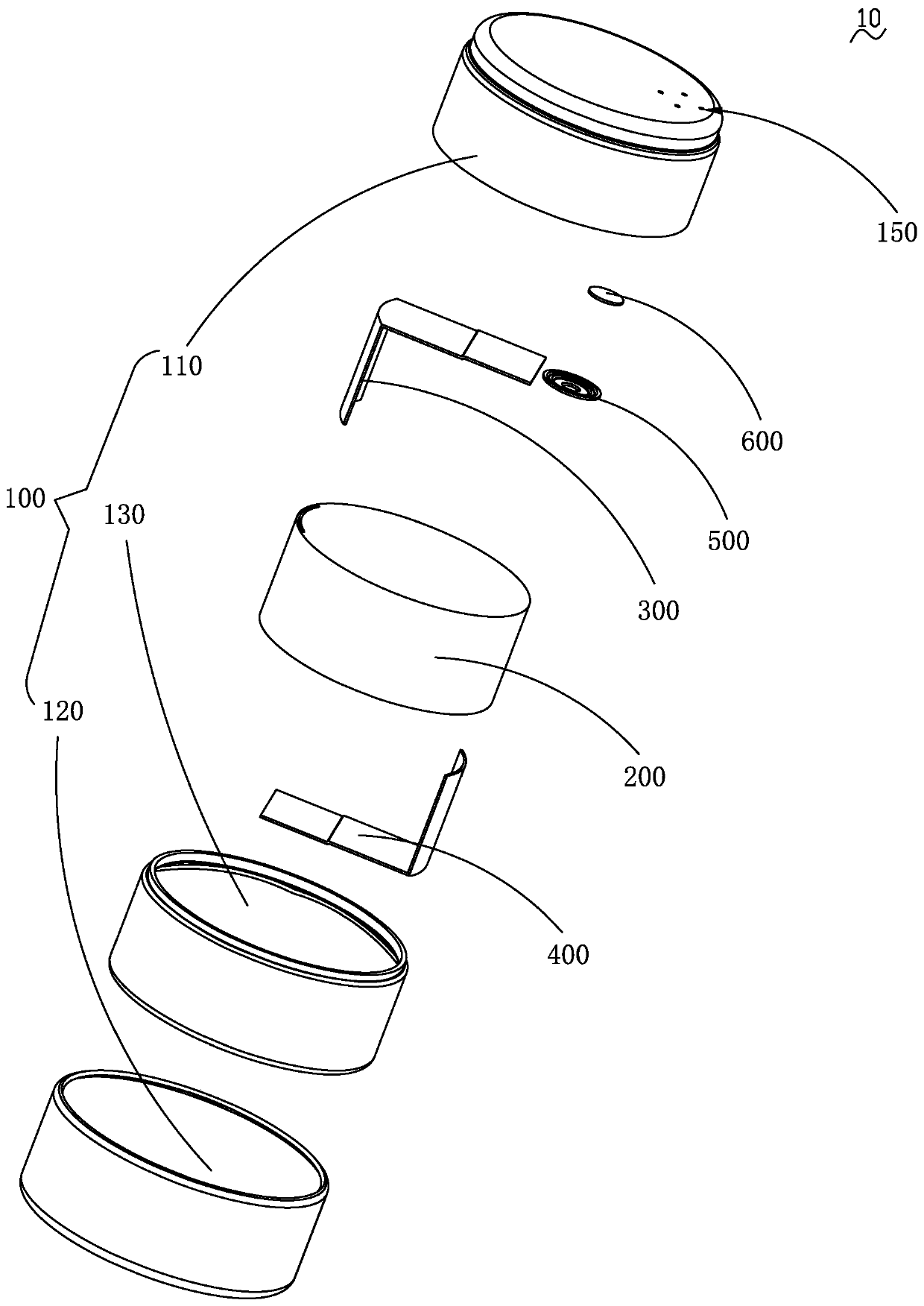

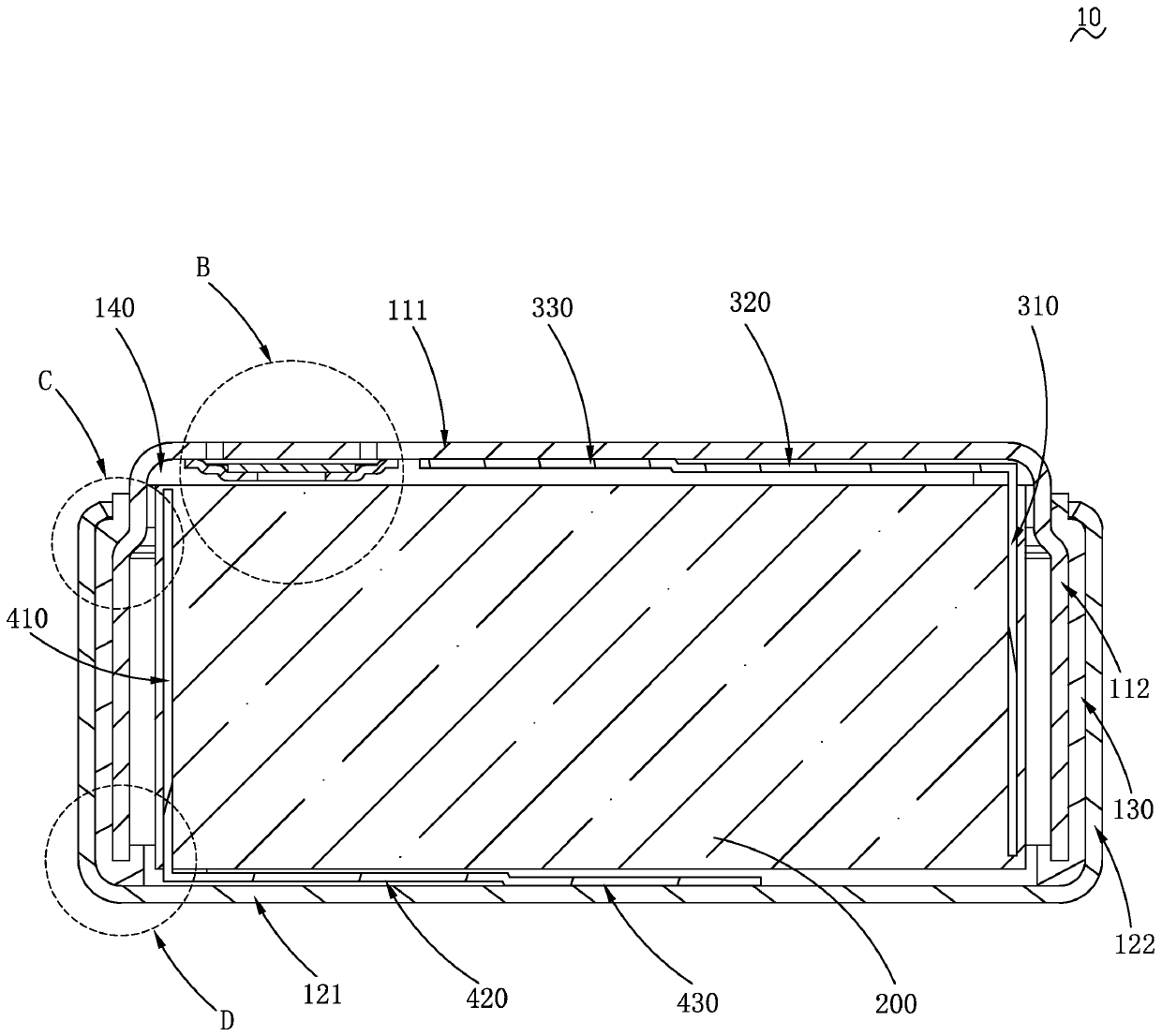

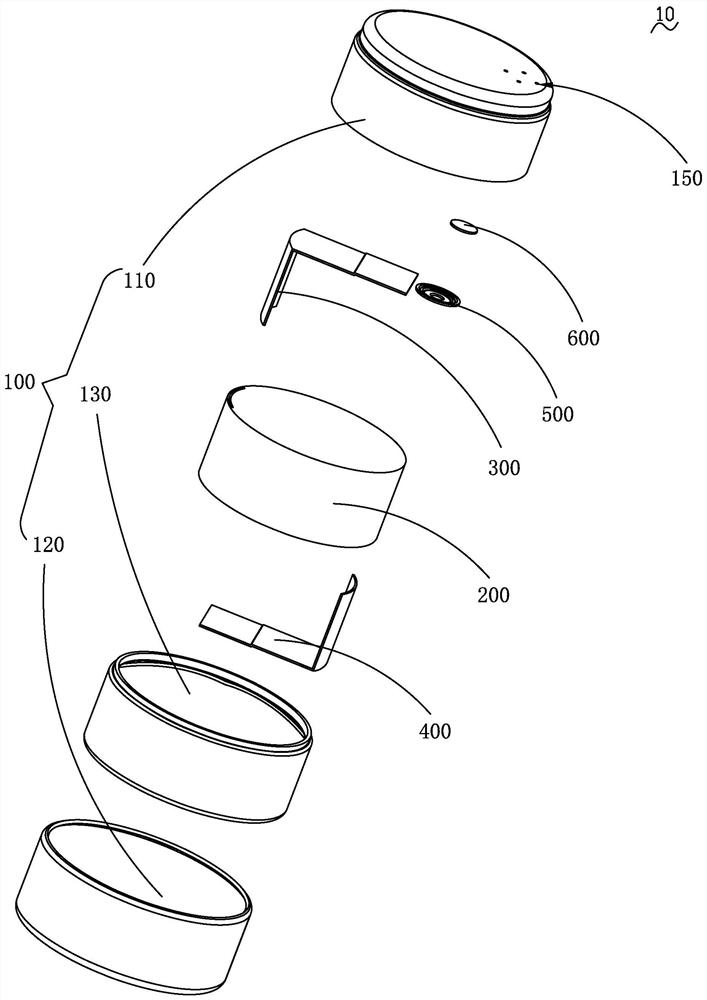

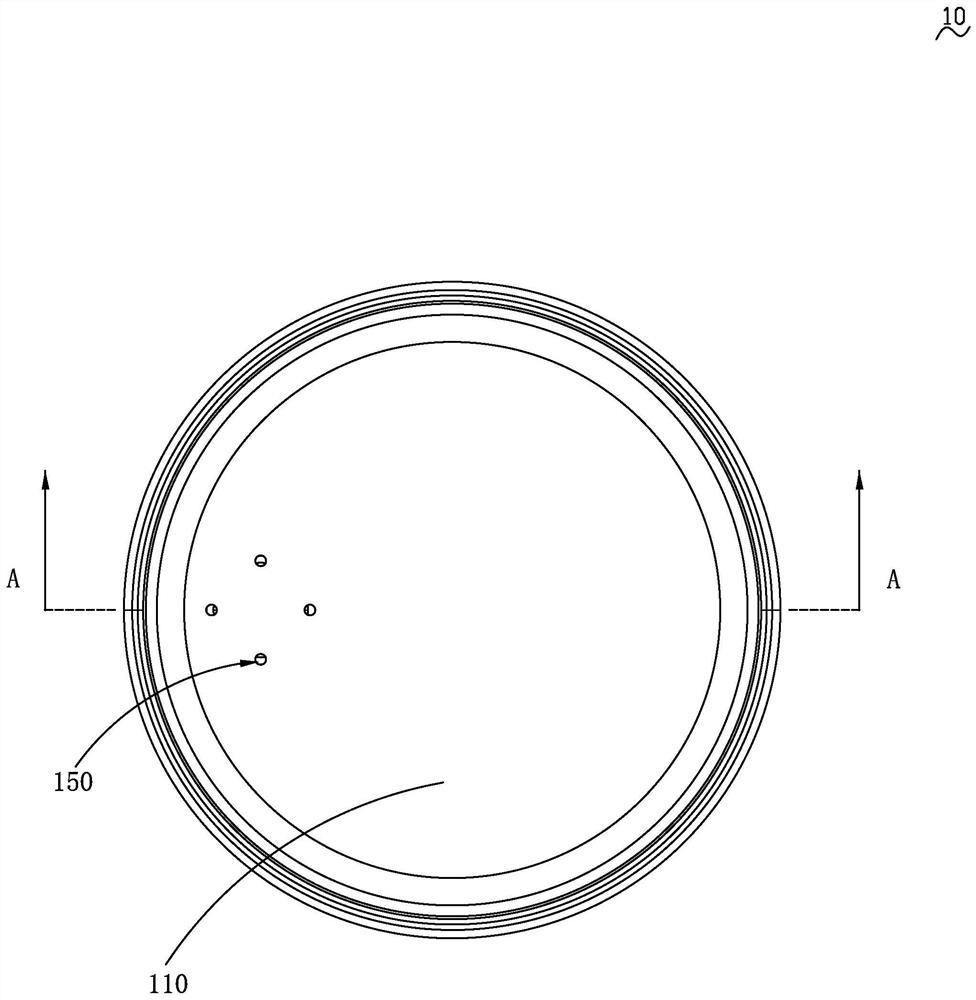

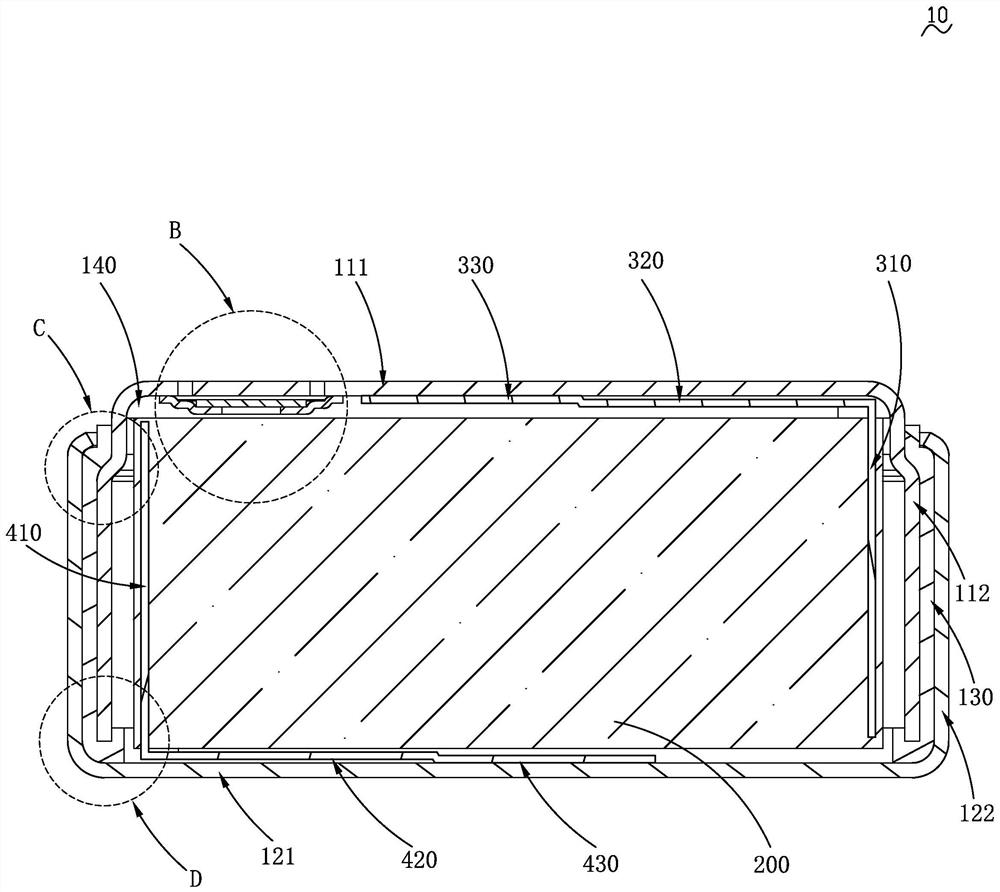

Button cell and electronic equipment

ActiveCN111525071AGuaranteed sealing performanceGuaranteed brokenCell sealing materialsBatteriesButton batteryElectrical battery

The invention provides a button cell and electronic equipment. The button cell comprises: a shell provided with a first accommodating cavity; and a battery body accommodated in the first accommodatingcavity, wherein a first through hole communicated with the first accommodating cavity is formed in the shell, a cover body is arranged in the first accommodating cavity, is used for sealing the firstthrough hole, and is provided with a second through hole, the second through hole is sealed through an explosion-proof membrane, the explosion-proof membrane can be melted at a preset temperature orbroken at a preset pressure so as to communicate the first accommodating cavity with the first through hole through the second through hole, and the projection of the first through hole on the cover body in the axis direction of the first through hole does not coincide with the explosion-proof membrane. According to the invention, the explosion-proof membrane can be melted at a preset temperatureor broken at a preset pressure so as to ensure that the explosion-proof membrane is melted or broken when the button cell is charged and discharged abnormally or the positive electrode and the negative electrode are short-circuited, and gas in the first accommodating cavity can pass through the second through hole and be exhausted from the first through hole.

Owner:AAC TECH NANJING

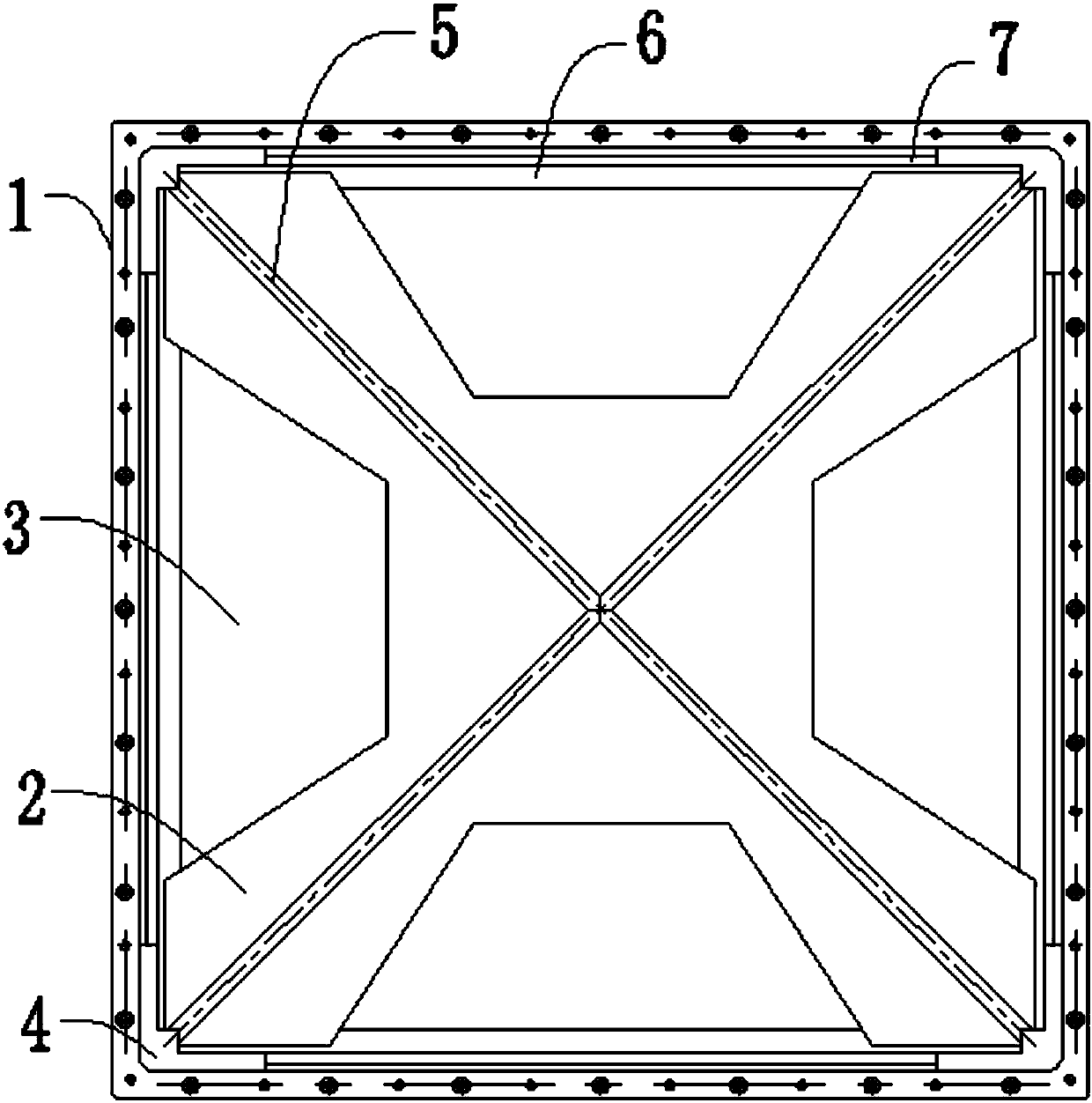

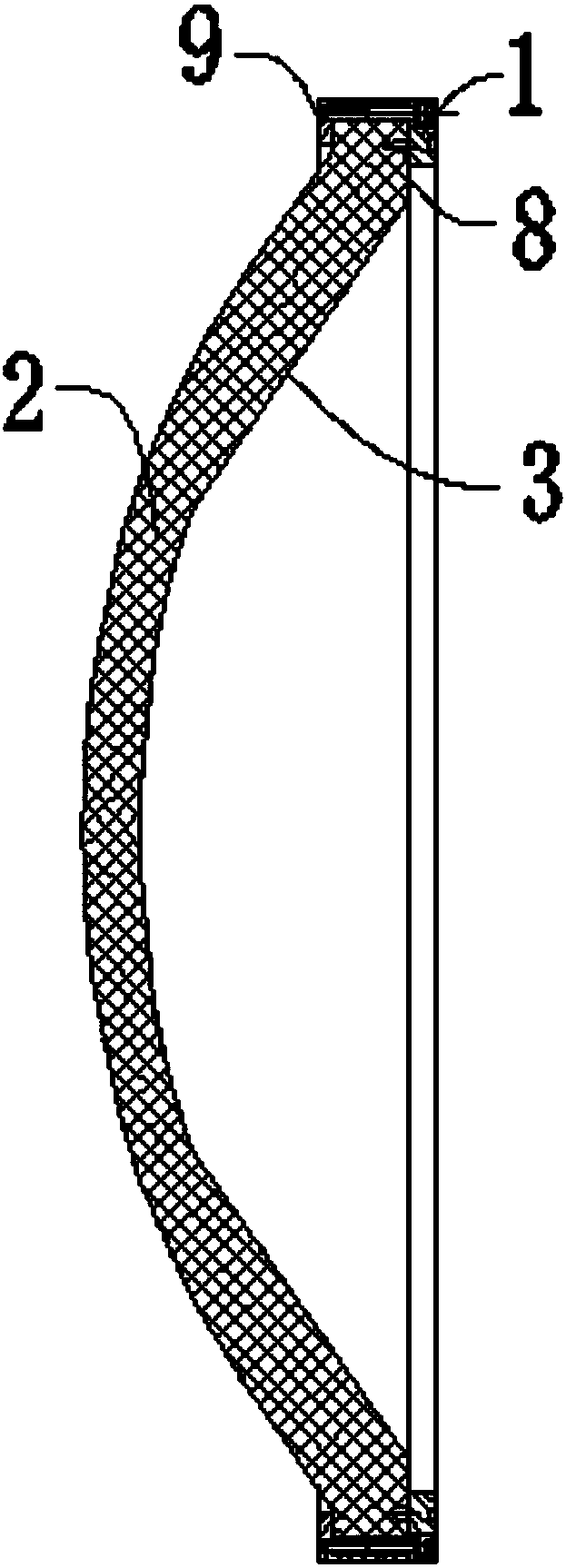

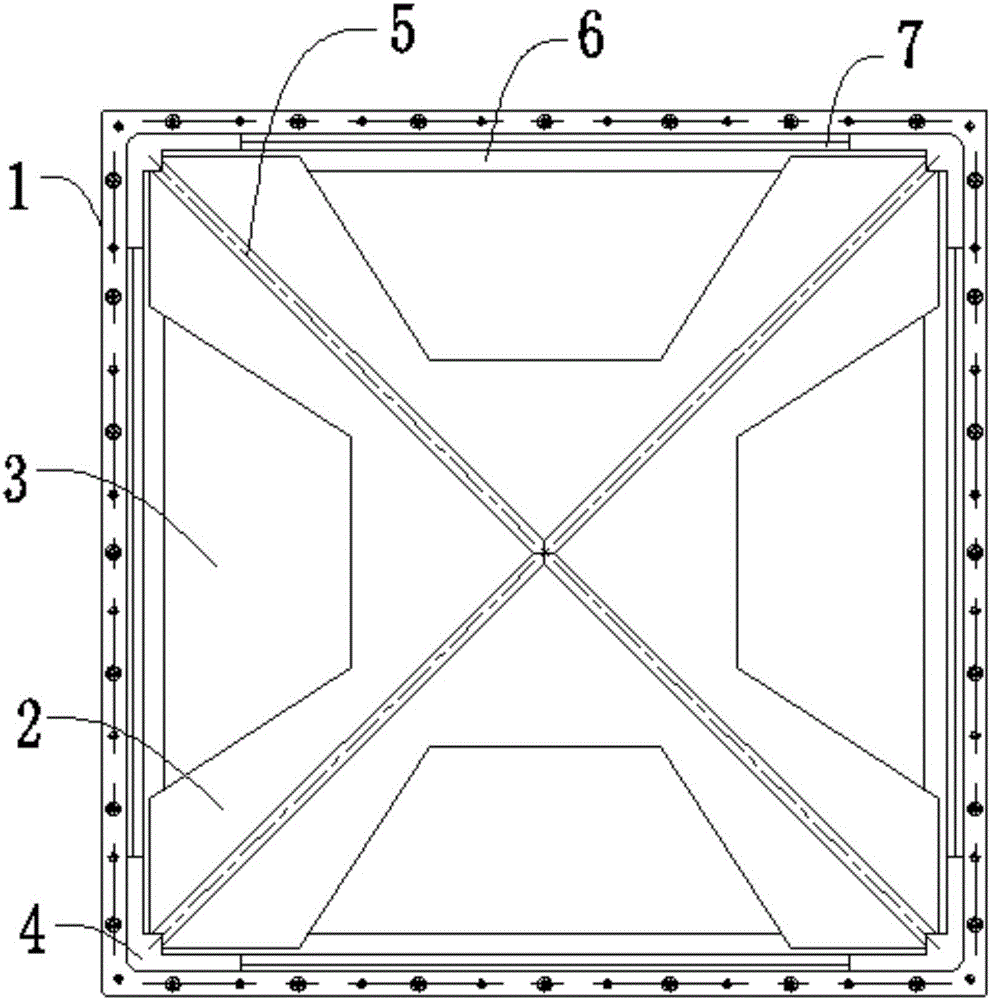

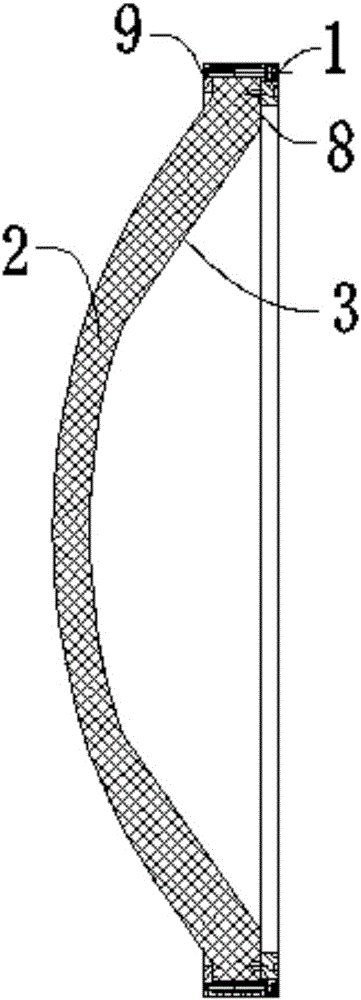

A square frame type fragile protection cover structure with large positive and negative pressure difference

The invention discloses a box-type fragile protective cover structure with a large positive-negative pressure difference. The box-type fragile protective cover structure with the large positive-negative pressure difference comprises an end frame; a cover body is arranged on one side of the end frame and is an elliptical face protruding outwards; a convex face and a concave face of the elliptical face are used for bearing positive pressure and negative pressure correspondingly; and the positive pressure is larger than three times the negative pressure. A plurality of reinforcement layers thickening gradually are symmetrically arranged between the center of the concave face of the cover body and the bottom side close to the end frame. First weakening grooves, second weakening grooves and third weakening grooves are formed in the diagonals of the internal concave face of the cover body, the four lateral sides of the end frame and the peripheral corners of the end frame correspondingly, and are different in depth. The box-type fragile protective cover structure with the large positive-negative pressure difference solves the design problem of a fragile protective cover structure with the positive pressure being larger than three times the negative pressure.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

Silicon carbide micro-powder grinding device and using method thereof

The invention discloses a silicon carbide micro-powder grinding device and a using method thereof, and belongs to the technical field of silicon carbide micro-powder production. The silicon carbide micro-powder grinding device comprises a grinding tank, a stirring shaft is installed in the grinding tank, a plurality of evenly-distributed stirring blades are installed on the stirring shaft, one end of the stirring shaft penetrates through the grinding tank to be connected with a driving motor, and a material port for feeding and discharging materials is formed in the upper portion of the grinding tank; a discharging port is formed in the bottom of the grinding tank, a feeding port is formed in the position, close to the discharging port, of the side wall of the grinding tank, the feeding port is connected with a material channel pipe, and a fan used for screening silicon carbide micro-powder is installed on the material channel pipe; a plurality of medium storage tanks are connected to the portion, between the fan and the grinding tank, of the material channel pipe in parallel, and silicon carbide media with different particle sizes are stored in the different medium storage tanks; and a control box is installed on one side of the grinding tank, and a control panel is installed on the control box.

Owner:潍坊凯华碳化硅微粉有限公司

Button batteries and electronic equipment

ActiveCN111525071BGuaranteed sealing performanceGuaranteed brokenCell sealing materialsBatteriesButton batteryMechanical engineering

The invention provides a button battery and electronic equipment. A button battery includes a casing, the casing has a first accommodating cavity; and a battery body, the battery body is accommodated in the first accommodating cavity. The shell is provided with a first through hole communicating with the first accommodating cavity, and a cover is provided in the first accommodating cavity, the cover is used to seal the first through hole, the cover is provided with a second through hole, and the second through hole is arranged on the cover. The two through holes are sealed by an explosion-proof membrane, which can be melted at a preset temperature or broken at a preset pressure, so that the first accommodating cavity is connected to the first through hole through the second through hole, and the first through hole is along its axis The projection of the direction on the cover does not coincide with the explosion-proof membrane. The explosion-proof membrane can be melted at a preset temperature or broken at a preset pressure to ensure that the explosion-proof membrane is melted or broken when the button battery is abnormally charged and discharged or the positive and negative electrodes are short-circuited, and the gas in the first accommodating cavity can pass through the second through hole And discharged by the first through hole.

Owner:AAC TECH NANJING

Device and method for preparing molten iron heat preservation slag melting agent for ironmaking

The invention provides a device and a method for preparing a molten iron heat preservation slag melting agent for ironmaking. The device comprises a material mixing device, a tubular granulation device and a composite separation device, the composite separation device comprises a screening bin body; a spiral screening mechanism is axially and rotationally arranged in the screening bin body, the spiral screening mechanism comprises a supporting barrel and screening spiral pieces arranged in the circumferential direction of the supporting barrel, and a material blocking mechanism is arranged between the lower edges of the screening spiral pieces and the supporting barrel; the outer diameter of the screening spiral piece is matched with the inner diameter of the screening bin body, and the screening spiral piece is a mesh plate. A plurality of wave guiding openings are formed in the circumferential direction of the bin wall of the screening bin body and correspond to the spiral screening mechanism, and ultrasonic generators are correspondingly connected with the wave guiding openings. The preparation device is compact in structure, efficient separation of granules and powder in the heat preservation slag melting agent can be achieved, roasting and curing of the granules of the heat preservation slag melting agent are achieved, floor occupation of a plant is reduced, and the production efficiency of the granules of the heat preservation slag melting agent is improved.

Owner:西峡县创新炉料有限公司

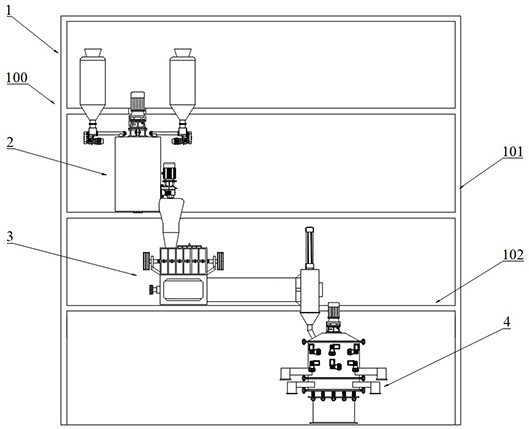

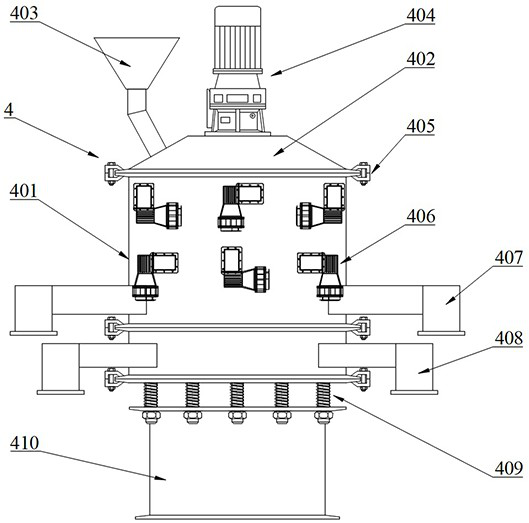

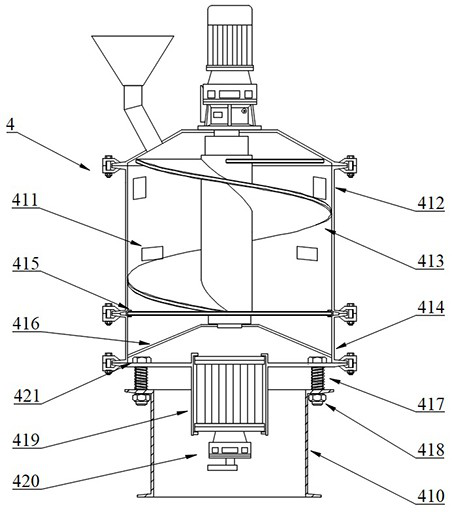

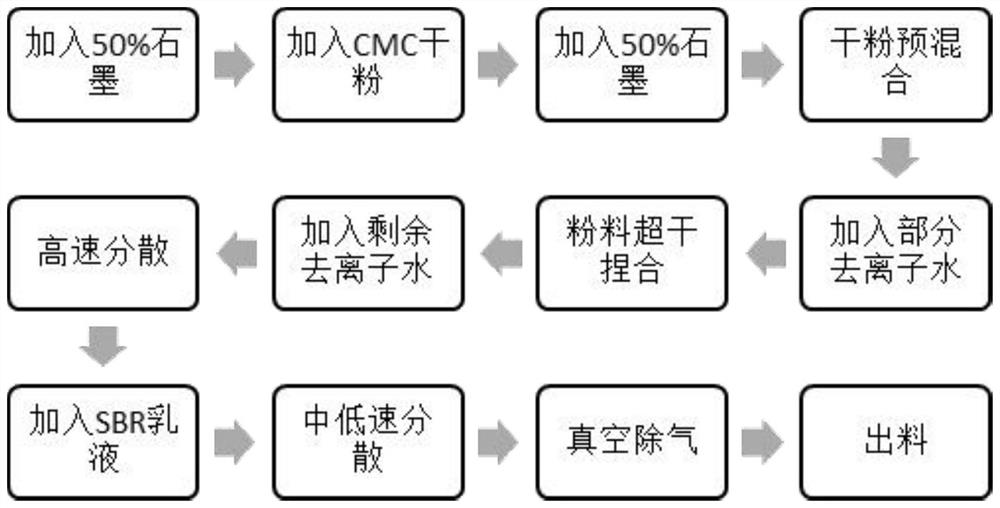

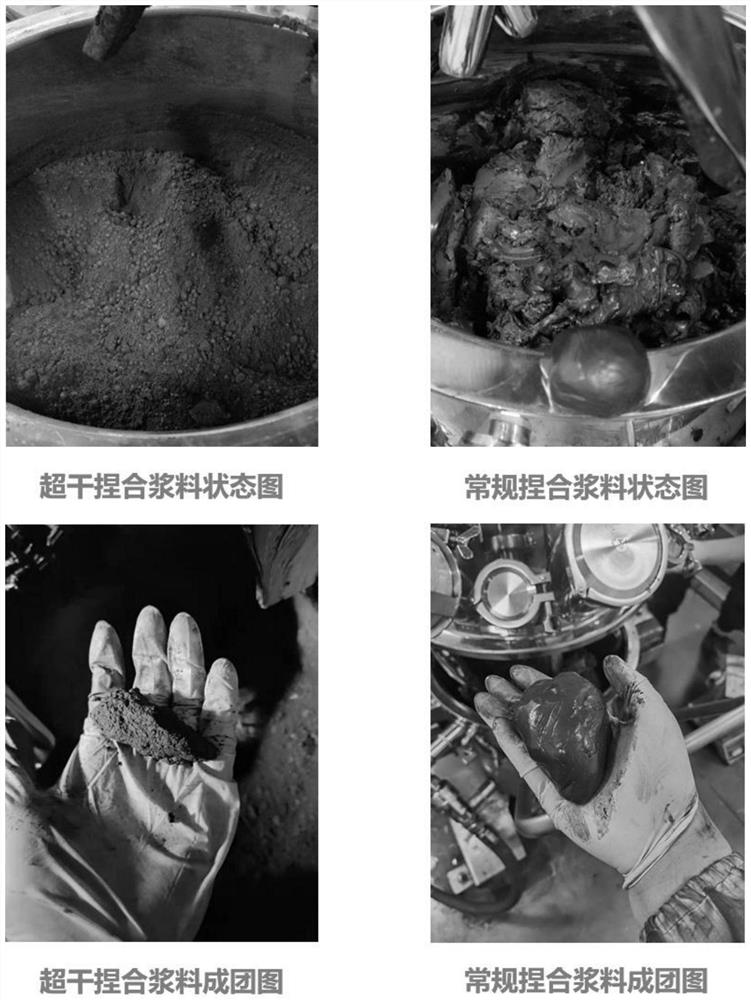

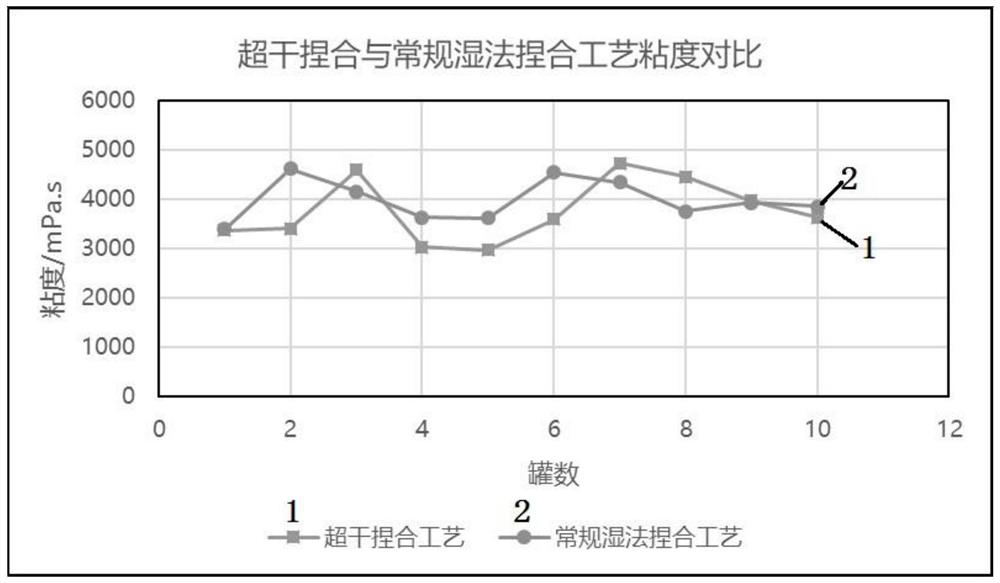

Negative electrode slurry dry-type preparation method

PendingCN113991106ASmall finenessFully coveredCell electrodesSecondary cellsElectrical batterySlurry

The invention belongs to the technical field of battery slurry preparation, and particularly relates to a negative electrode slurry dry-type preparation method which comprises the following steps: S1, mixing and stirring a negative electrode active material and a thickening agent to obtain a first premix; s2, adding part of the solvent into the first premix, stirring, and performing dry kneading to obtain a second premix; s3, adding the residual solvent into the second premix, and stirring and dispersing to obtain a third premix; and S4, adding a binder into the third premix, and stirring and dispersing to obtain the negative electrode slurry. According to the dry-type preparation method of the negative electrode slurry, a conduction agent is not used, the step of preparing a glue solution is omitted, the dry mixing time is shortened, meanwhile, dry-type kneading can crush large-particle negative electrode active substances, the fineness of the slurry is reduced, and the stability and uniformity of the negative electrode slurry are guaranteed.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

A gynecological waste disposal device

ActiveCN110681672BGood workmanshipPrevent fallingSolid waste disposalPaints with biocidesMedicineMedical waste

The invention discloses a gynecological garbage treatment device, which comprises a disinfection treatment part, a feeding part, a crushing part and a feeding part. The disinfection treatment part is arranged at the bottom, and the feeding part is arranged at the upper part of the disinfection treatment part. The present invention has a relatively simple and convenient treatment process for the medical waste generated by the gynecology department, and is especially suitable for hospitals to temporarily sterilize the medical waste generated by the gynecology department. Liquid contact, the disinfection of medical waste generated in gynecology is more complete and thorough, the quality of disinfection treatment is better, and the cutting is more convenient, which can avoid the trouble of pulling out the treated medical waste from the inside, and the prepared protective layer has better The anti-corrosion, wear-resistant, anti-bacterial and anti-aging properties can effectively prolong its service life, and it is especially important to prevent it from adhering to a large area of granular dirt during use.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

A method for producing x65 acid-resistant pipeline steel plates used under low-cost and ultra-low temperature conditions by a coiling furnace

ActiveCN112410647BGuaranteed heating effectGuaranteed brokenGas emission reductionLine tubingPhysical chemistry

The invention relates to a method for producing low-cost X65 acid-resistant pipeline steel plates used under ultra-low temperature conditions by a coiling furnace. The process is: KR molten iron pretreatment (desulfurization in advance)—BOF smelting—RH vacuum degassing—LF refining—RH vacuum degassing Gas—Continuous casting into 150mm thick continuous casting slab—Continuous casting slab with cover and slow cooling—Continuous casting slab inspection and cleaning—Casting slab reheating—High pressure water descaling—Rolling-Flying shear segmentation—ACC cooling—Straightening— Steel plate shearing—inspection and storage. The yield strength of the steel plate is 460-600MPa, the tensile strength is 550-700MPa, the elongation is ≥30%, and the yield ratio Rt 0.5 / Rm≤0.90, the product can meet the requirements of ultra-low temperature and acid service conditions with Charpy impact energy ≥ 100J at ‑60°C and drop weight shear area ≥85% at ‑50°C.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A Forging Process of E2 Vertical Roller

ActiveCN111496153BQuality improvementGuaranteed brokenMetal-working apparatusEngine componentsIngotForming processes

The invention discloses an E2 vertical roll forging process, which comprises the steps of: heating a steel ingot with a heating temperature range of 1210-1230° C.; upsetting the steel ingot as a whole, and upsetting to 1 / 3-1 / 2 of the height of the steel ingot, After upsetting, it is drawn for one time, and then returned to the furnace for homogenization; after being released from the furnace, it is upset again, and upsetting to 1 / 3 to 1 / 2 of the height of the billet for one upsetting and one drawing. After coming out of the furnace, upsetting for the third time, and upsetting to 1 / 3~1 / 2 of the height of the two upsetting and two drawing billets, and the third drawing after upsetting to obtain a billet with a height-diameter ratio ranging from 2.2 to 2.4, and then Homogenized by returning to furnace; spheronizing and stamping billet; die forging; post-forging heat treatment. Using this forging forming process, through the production method of three upsetting and three pulling, the breaking of the as-cast structure of the steel ingot can be fully guaranteed. Combined with the deformation amount and the effect of recovery and recrystallization, the grains can be fully refined, and then forged to produce, The prepared E2 vertical roll is of good quality and can meet the requirements of high-volume production and quality.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Garlic crusher

The invention relates to food processing appliances, in particular a garlic crusher. The garlic crusher is characterized in that a shell is fixed on a support; a driven shaft is fixed with the shell and a top cover through a bearing; a rotary knife is fixed on the driven shaft in a threaded connection mode; a handle or a motor drives the rotary knife to rotate through the driven shaft; the spacingbetween the rotary knife and a reamer on a bottom cover can satisfy the particle sensing requirement on garlic; and meanwhile, the loss of the garlic juice is reduced, and the qualified garlic clovesare discharged from through holes in the bottom cover, so that the garlic processing is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Box-type fragile protective cover structure with large positive-negative pressure difference

The invention discloses a box-type fragile protective cover structure with a large positive-negative pressure difference. The box-type fragile protective cover structure with the large positive-negative pressure difference comprises an end frame; a cover body is arranged on one side of the end frame and is an elliptical face protruding outwards; a convex face and a concave face of the elliptical face are used for bearing positive pressure and negative pressure correspondingly; and the positive pressure is larger than three times the negative pressure. A plurality of reinforcement layers thickening gradually are symmetrically arranged between the center of the concave face of the cover body and the bottom side close to the end frame. First weakening grooves, second weakening grooves and third weakening grooves are formed in the diagonals of the internal concave face of the cover body, the four lateral sides of the end frame and the peripheral corners of the end frame correspondingly, and are different in depth. The box-type fragile protective cover structure with the large positive-negative pressure difference solves the design problem of a fragile protective cover structure with the positive pressure being larger than three times the negative pressure.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

Manufacturing method of marine crankshaft material and marine crankshaft manufactured by the method

The invention discloses a method for manufacturing a crankshaft material for a ship and a crankshaft for a ship manufactured by the method. The method comprises the following steps: (1) casting the smelted molten steel into steel ingots; (2) forging the steel ingots by adopting a two-upsetting and two-drawing mode; and (3) performing after-treatment on the forged steel in the step (2) by adopting a heat treatment mode of sequentially cooling and performing isothermal annealing. According to the method disclosed by the invention, the crankshaft manufactured by adopting the method meets the requirement of the forged steel 42CrMoA (+Ni+V), and the method can be applied to a crankshaft of an internal combustion engine for the ship.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

A lithium battery recycling process

ActiveCN112828006BImprove securityImprove recycling effectTransportation and packagingSolid waste disposalProcess engineeringMetal powder

Owner:广东威玛新材料股份有限公司

Method for producing X65 acid-resistant pipeline steel plate used under low-cost and ultralow-temperature conditions through curling furnace

ActiveCN112410647AAvoid temperature differenceGuaranteed finishing temperatureGas emission reductionLine tubingSlow cooling

The invention relates to a method for producing an X65 acid-resistant pipeline steel plate used under the low-cost and ultralow-temperature conditions through a curling furnace. According to the method, the process comprises the steps of KR molten iron pretreatment (advanced desulfurization), BOF smelting, RH vacuum degassing, LF refining, RH vacuum degassing, continuous casting to form a continuous casting billet with the thickness of 150 mm, continuous casting billet covering slow cooling, continuous casting billet checking and cleaning, casting billet reheating, high-pressure water descaling, rolling, flying shear segmentation, ACC cooling, straightening, steel plate shearing and inspection and warehousing. The method has the advantages that the yield strength of the steel plate is 460-600 MPa, the tensile strength is 550-700 MPa, the elongation rate is greater than or equal to 30%, the yield strength ratio Rt0.5 / Rm is less than or equal to 0.90, and the product can meet the use requirements under the ultralow-temperature and acid service conditions that the Charpy impact energy at -60 DEG C is greater than or equal to 100J and the drop hammer shear area at -50 DEG C is greaterthan or equal to 85%.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Marinating material recycling device used for producing and processing dried bean curd and using method

PendingCN112221943AImprove sieving and filteringGuaranteed brokenSievingSolid waste disposalElectric machineStructural engineering

The invention discloses a marinating material recycling device used for producing and processing dried bean curd and a using method. The marinating material recycling device comprises a base, a containing groove is formed in the outer wall of the top of the base, a material storage box is placed on the inner wall of the containing groove, a liquid outlet pipe is connected to the outer wall of oneside of the material storage box through threads, and a fixed base is fixed to the outer wall of one side of the base through bolts. A motor is connected to the outer wall of one side of the top of the fixed base through a supporting plate, a vibration screening mechanism is arranged at the output end of the motor, a first filter plate and a second filter plate are connected to the outer walls ofthe two sides of the top of the base in a sliding mode correspondingly, a first guide hole is formed in the inner wall of the top of the second filter plate, and a filter screen is fixed to the innerwalls around the guide hole through bolts. Partition plates are welded to the portions, close to bottoms of the two sides of the guide hole, of the second filter plate. By means of the marinating material recycling device and the using method, marinating materials are effectively guided into a sieve on the first filter plate from the filter screen and are then filtered by the sieve, and thereforethe solid-liquid separation efficiency of the marinating materials is effectively improved, and the recycling quality of the marinating materials is improved.

Owner:JINCAIDI FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com