Patents

Literature

62results about How to "Improve output rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for preparing high-purity nano polyaluminium chloride with high efficiency, energy saving and environmental protection

InactiveCN101734703AEasy dischargeEfficient heat dissipationEnergy inputAluminium chloridesAluminium chlorohydrateProcess engineering

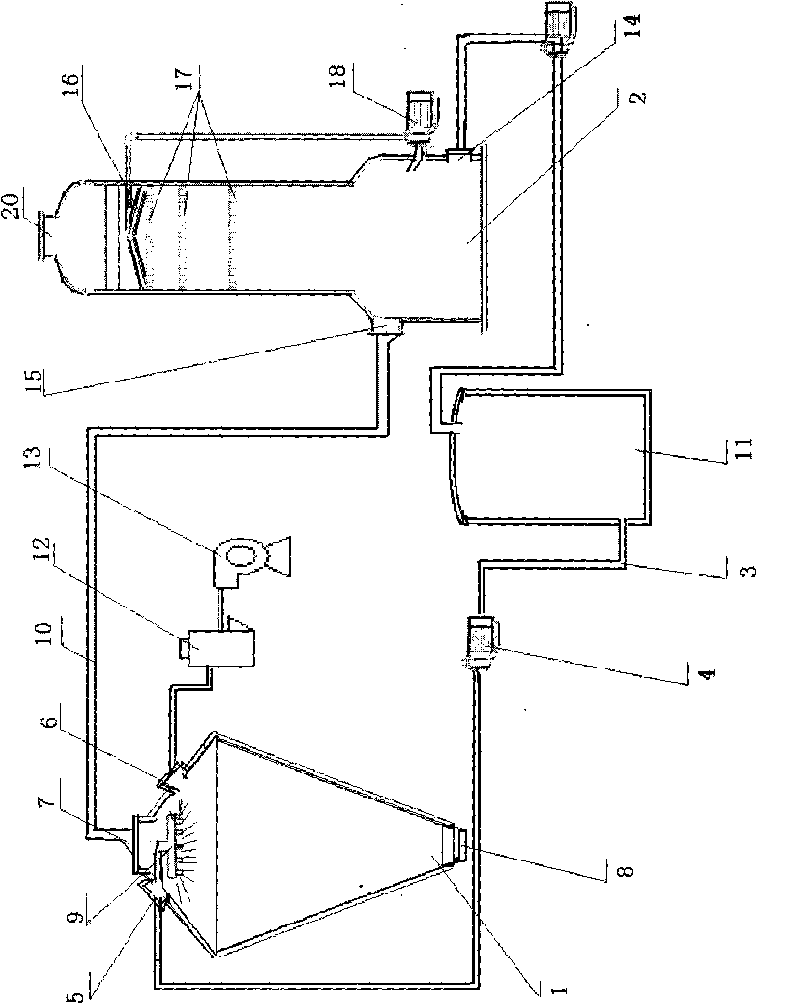

The invention relates to a device for utilizing the residual heat of tail gas in the production of polyaluminium chloride, which comprises a drying part of the liquid material of the polyaluminium chloride. The device is characterized in that the drying part of the liquid material of the polyaluminium chloride is provided with a drying tower 1 and a tail gas absorption tower 2, wherein a device for recovering the residual material of the tail gas and recycling the residual heat is arranged in the tail gas absorption tower 2; the utilization method of the device comprises a drying technology and a tail gas absorption technology. The method is characterized in that part of the liquid material is still in an atomization state after the liquid material is dried, and enters the tail gas absorption tower 2 along with the tail gas together, the circulation of the liquid material is carried out in the tail gas absorption tower 2 at any moment by a circulation pump 18, and the liquid material is heated and concentrated by the residual heat of the tail gas. The invention has the advantages that the liquid material is concentrated by utilizing the tail gas, the residual material and the residual heat of the tail gas are fully utilized, energy resources are saved, the mass output rate is enhanced, the discharge of the waste gas and the waste heat is reduced, the pollution is reduced, and the cost is lowered.

Owner:TIANJIN RUNWO WATER SUPPLY INSTALLATION ENG

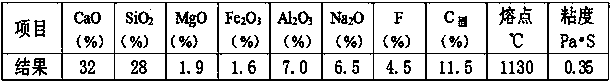

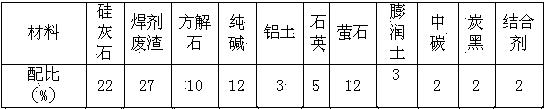

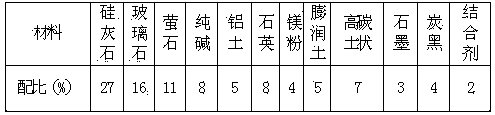

Square billet low-medium carbon steel continuous casting crystallizer mold powder and production method thereof

ActiveCN103785805AIncrease profitReduce bulk buildupMicroballoon preparationMicrocapsule preparationSpray GranulationSlag

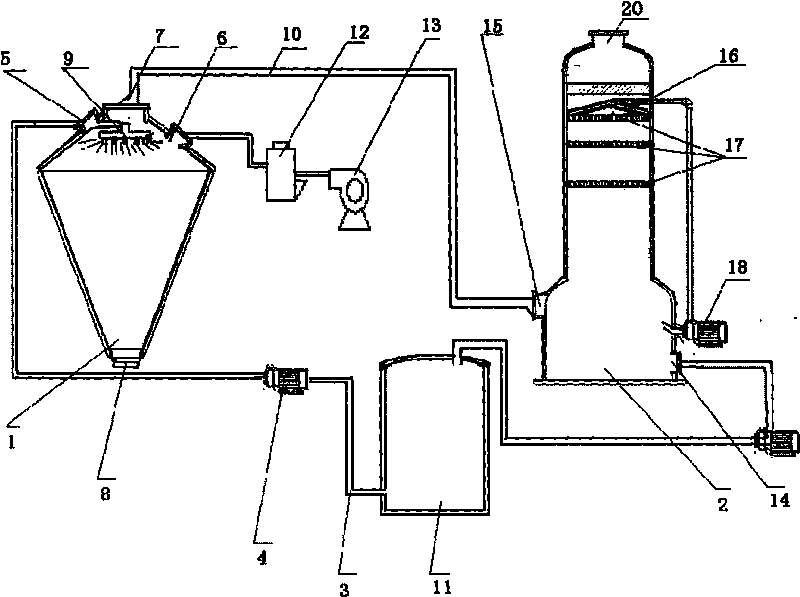

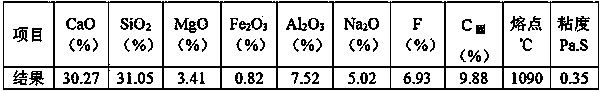

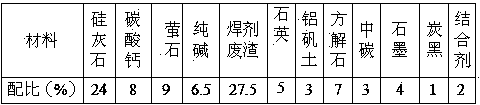

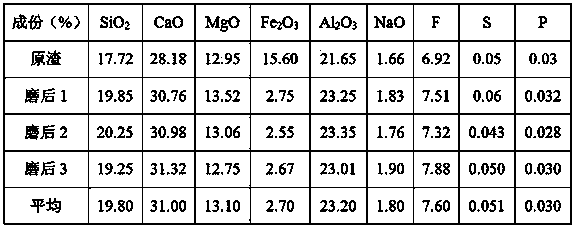

The invention discloses square billet low-medium carbon steel continuous casting crystallizer mold powder and a production method thereof. The mold powder is composed of 29-32Wt% of CaO, 28-31Wt% of SiO2, 1.6-2.2Wt% of MgO, 1.6-2.5Wt% of Fe2O3, 6.5-8.5Wt% of Al2O3, 4.5-6.5Wt% of Na2O, 4.5-6.5Wt% of F and 11.5-13.5Wt% of solid C. The production method includes raw material pretreatment and detection, mold powder formula designing, burdening and pulping, spray granulation, screening dedusting and product detection. The production method is low in production cost, quality of the mold powder and utilization efficiency of yellow phosphorus slag can be improved, and contribution to environment is great; tests show that compared with using of conventional raw materials, due to adopting the yellow phosphorus slag as a raw material, cost can be lowered by 256-309 RMB / ton, and primary qualified rate of casting blanks is increased by 2.4-2.9% after being used for production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

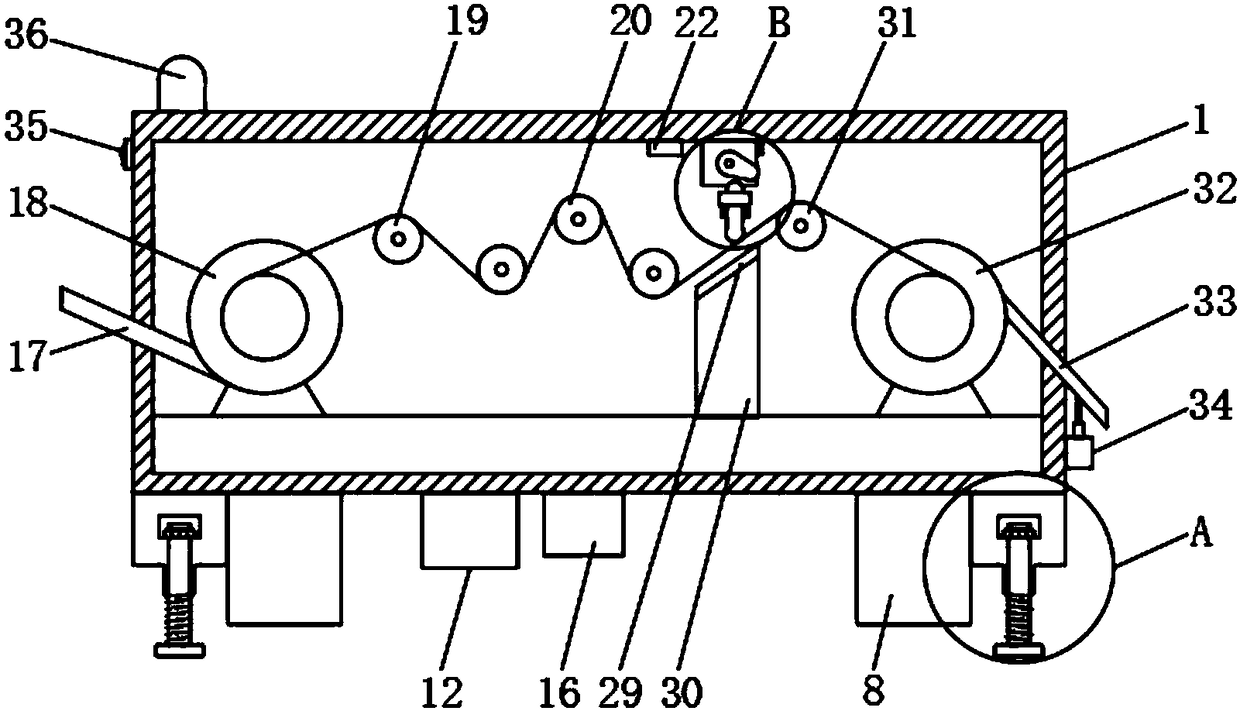

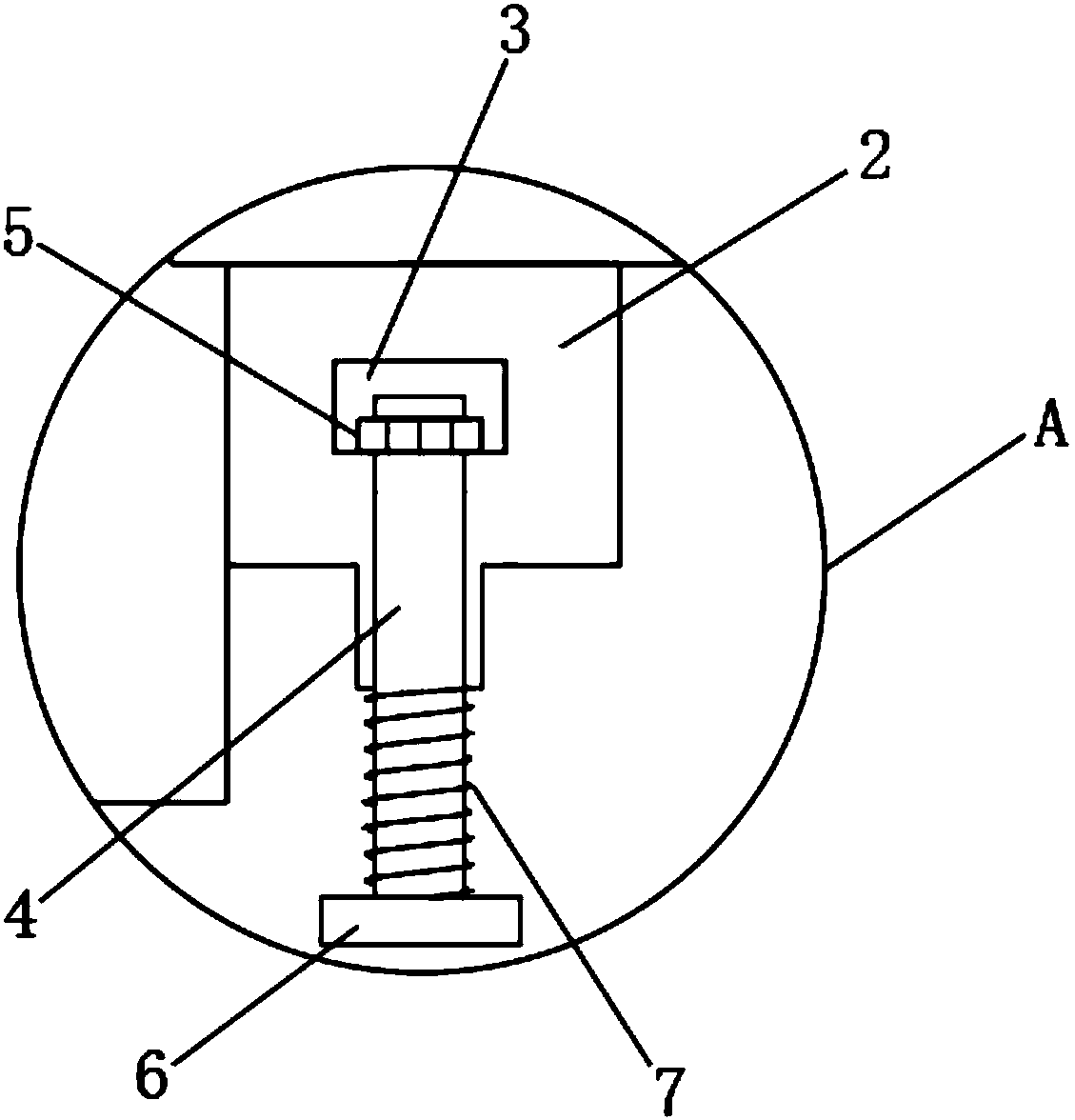

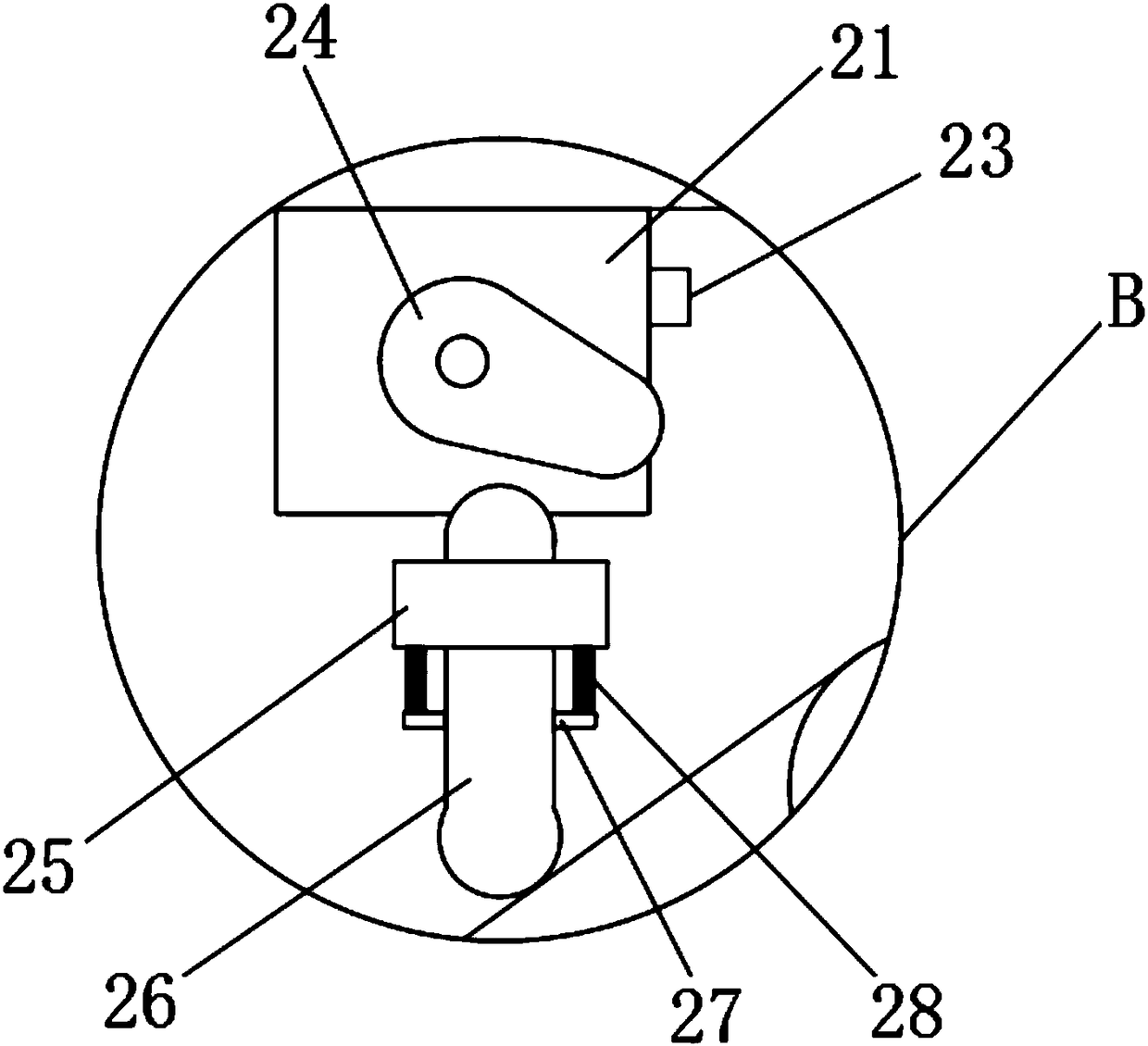

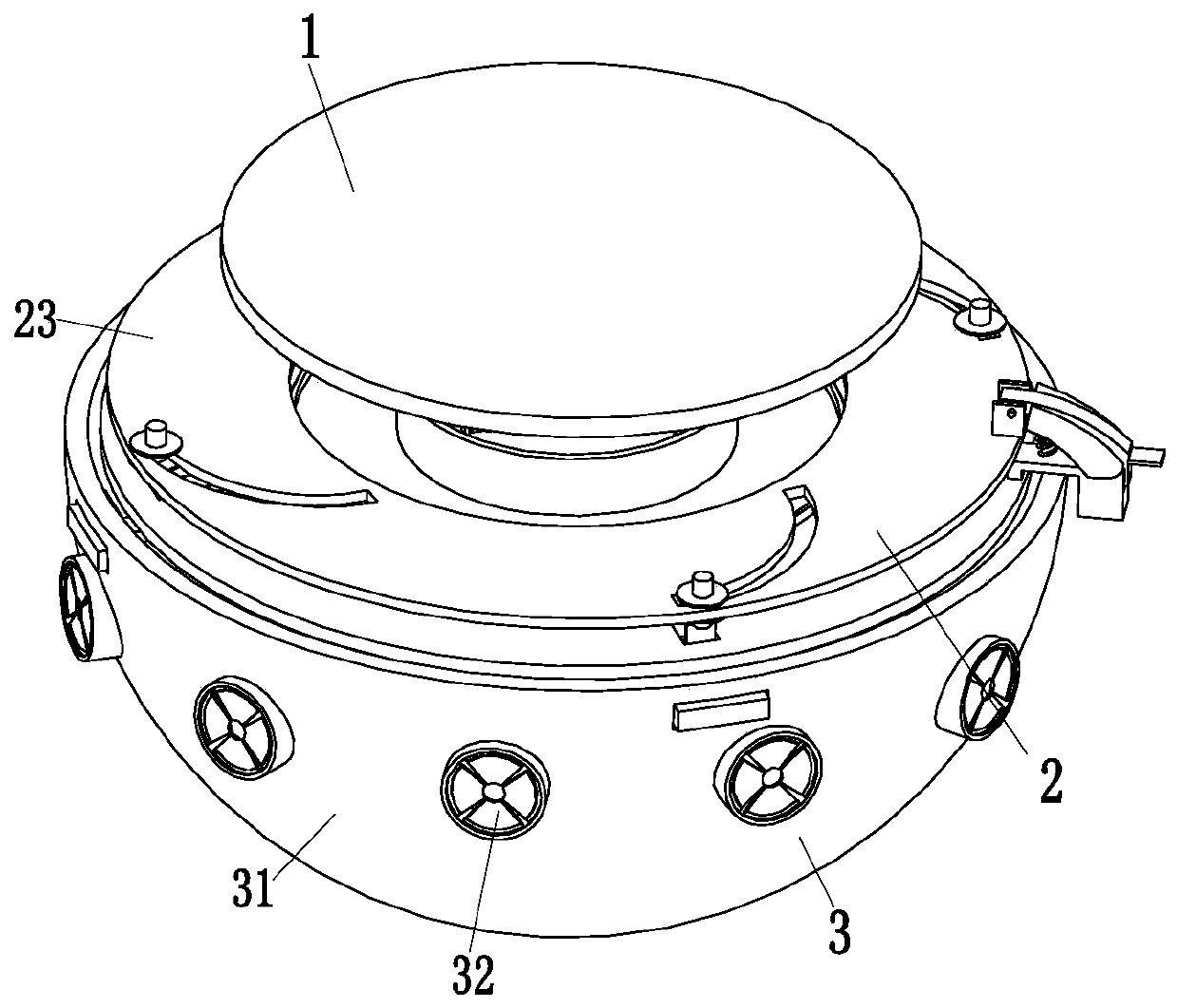

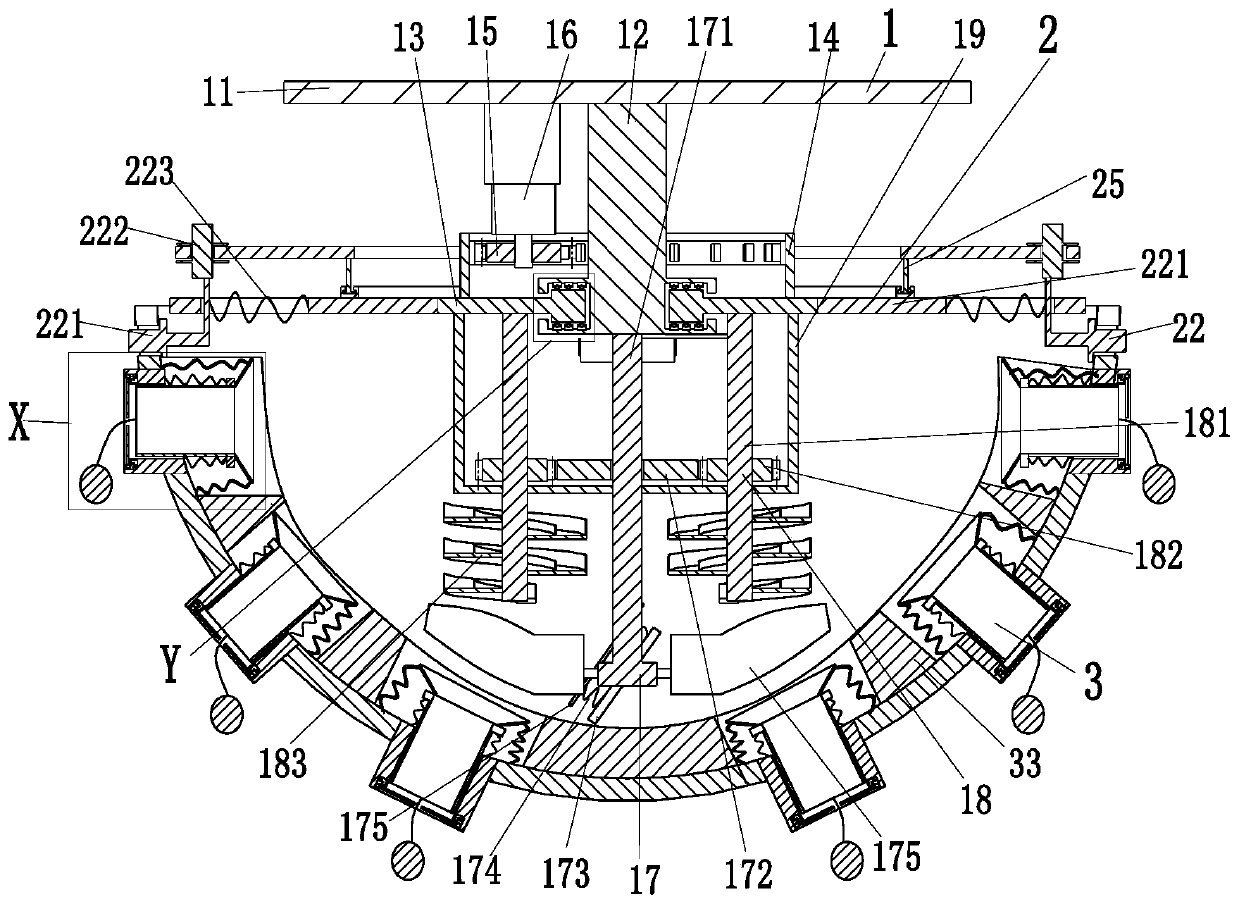

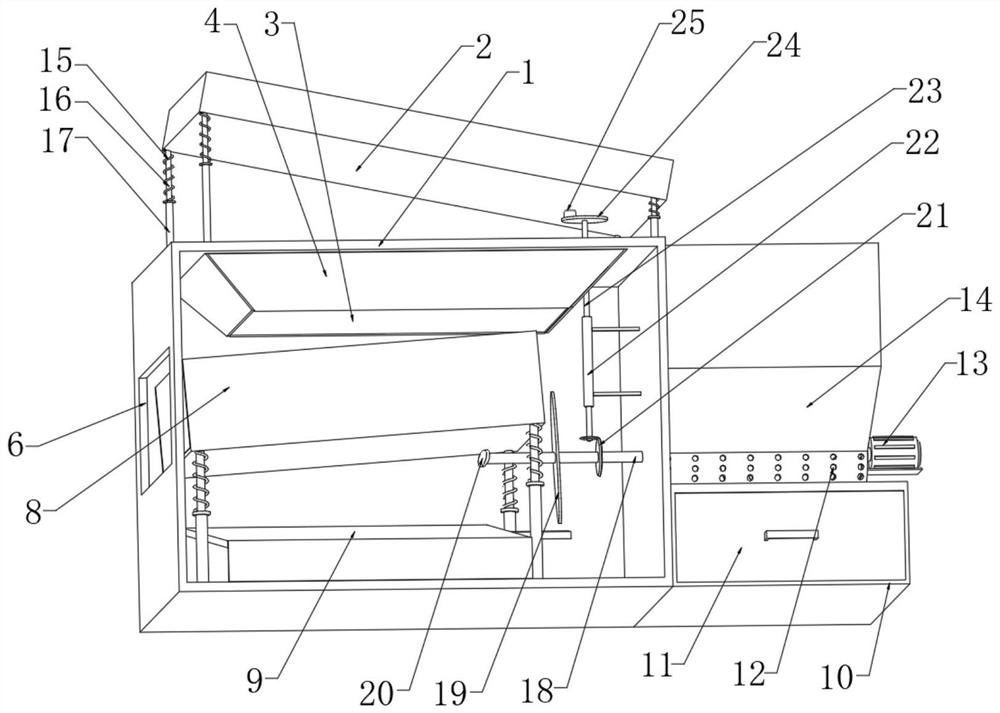

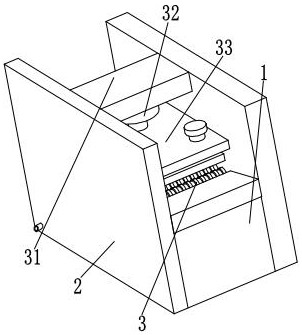

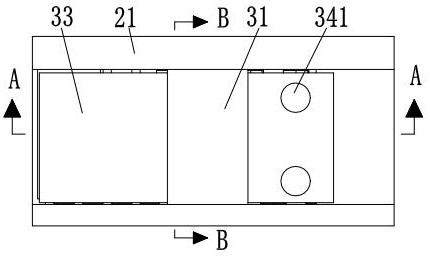

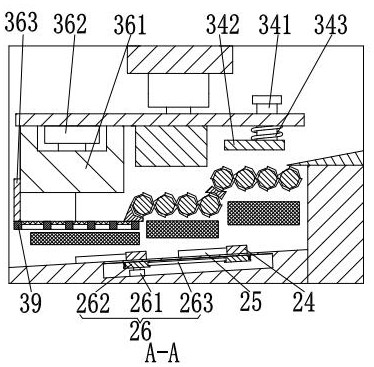

Cashmere separating device

InactiveCN108265349AReduce wearImprove stabilityFibre cleaning/opening machinesDrive motorProgrammable logic controller

The invention discloses a cashmere separating device. The device comprises a device body, wherein damping springs are nested in the positions, close to support disks, of the bottom ends of support rods, pulleys are mounted at one end of each hydraulic cylinder, hydraulic stations are mounted on the inner sides of support legs, a cashmere fiber output part is mounted at one end of a feeding port, an output roll is mounted on one side of the cashmere fiber output part, a cashmere fiber stretching part is mounted on one side of the output roll, a driving motor is mounted on the side wall of the top end of one side of the cashmere fiber stretching part, a displacement sensor is mounted on one side of the driving motor, a PLC (programmable logic controller) is mounted on the other side of the driving motor, a cam is mounted at one end of the driving motor, and a screw rod is inserted into a shaft sleeve. The cashmere separating device is simple in structure and can remove dust difficult toremove in cashmere fiber; besides, the device can monitor the driving motor in real time, is convenient to move and high in stability during work, can absorb shock and reduce noise and is high in discharging speed and convenient to use.

Owner:陕西通海绒业股份有限公司

Ginger sugar sheet production method

InactiveCN1843188AShorten the production cycleImprove output rateConfectioneryFood preservationSugarShelf life

Owner:WEIHAI JILI FOODS CORP

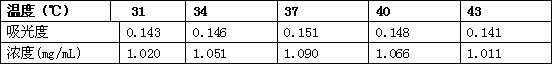

Compound enzyme protein peptide extraction method used for sesame

The invention discloses a compound enzyme protein peptide extraction method used for sesame, comprising the following steps: (1) adding equal mass of compound enzyme to sesame dregs, and performing enzymolysis in an environment with temperature of 37 DEG C and pH value of 8.3, and carrying out enzymolysis for 2h, to obtain an enzymatic hydrolysate; (2) centrifuging the enzymatic hydrolysate for 15min at 4000rpm to obtain a sesame polypeptide mixed solution, and concentrating, freezing and reserving for later use. By adopting the manner, according to the compound enzyme protein peptide extraction method used for sesame, by adopting trypsin and acid protease with composition proportion of 3:1 as the compound enzyme, and performing enzymolysis experiment on the sesame dregs at the optimal temperature, pH and time, sesame protein peptide is extracted maximally, the method is novel, materials are saved, output rate is inreased, efficiency is increased, and the compound enzyme protein peptide extraction method used for sesame has wide market prospect in popularization.

Owner:JIANGSU JIUSIXIANG FOOD TECH

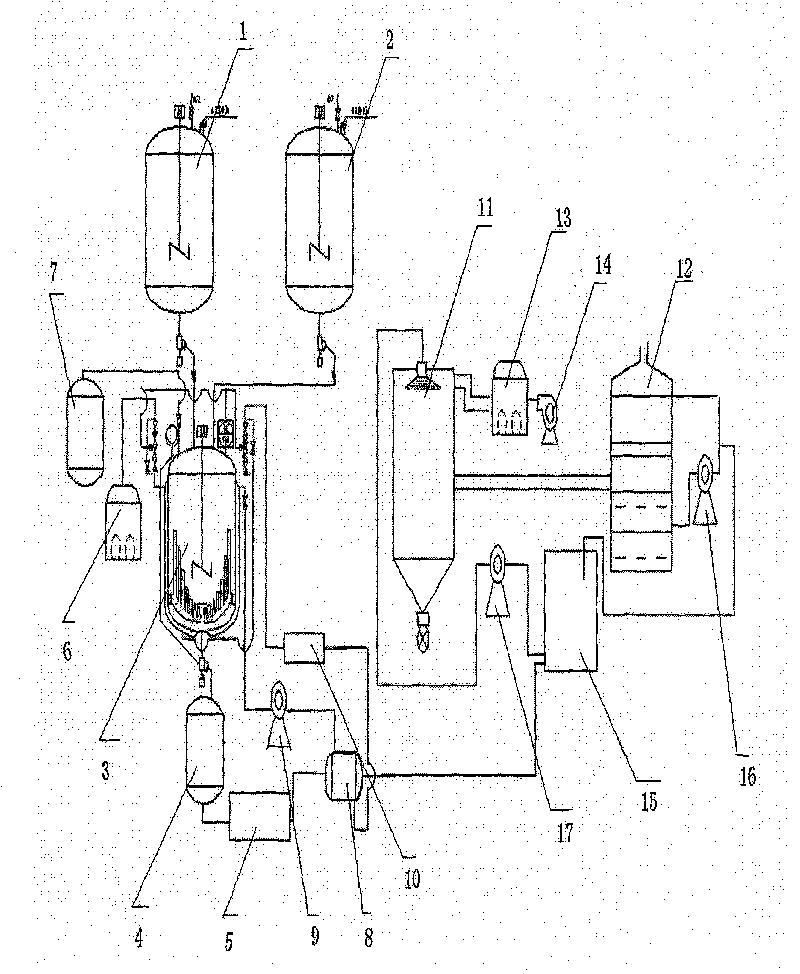

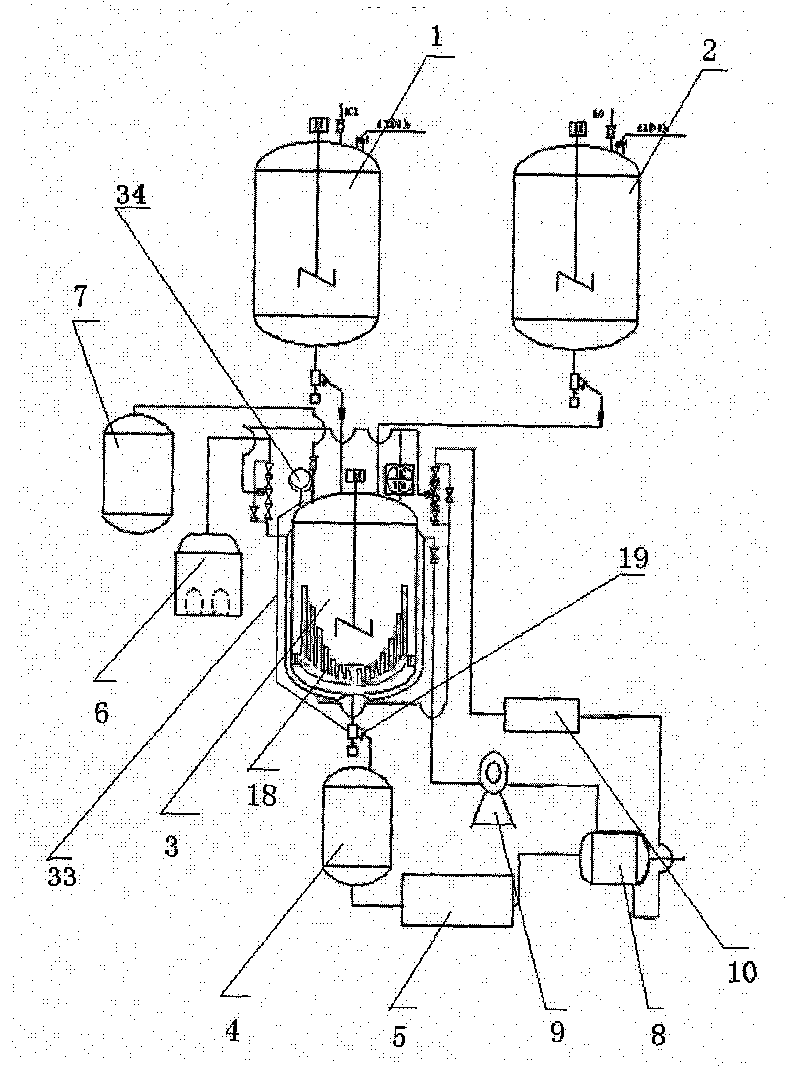

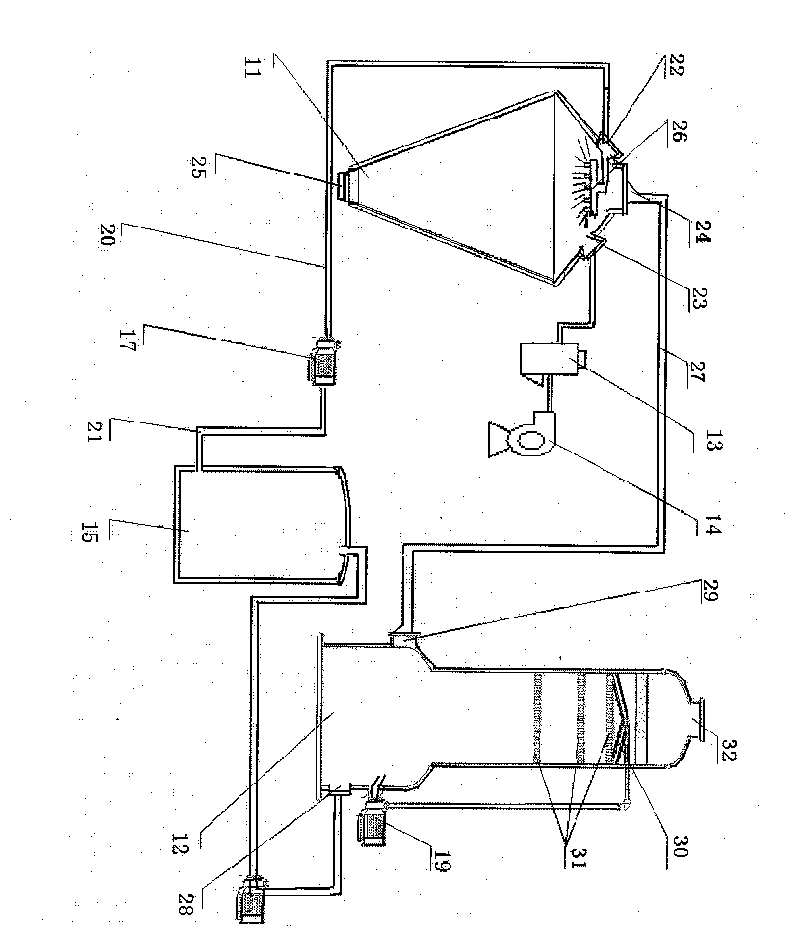

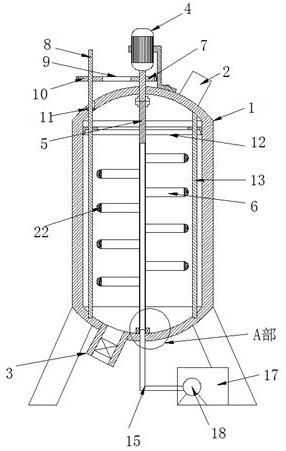

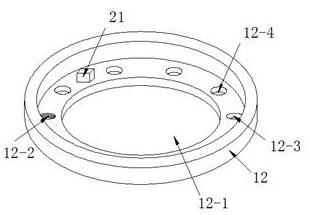

Tail gas waste heat utilization device in aluminium polychlorid production and method

InactiveCN101746801AEasy dischargeSave energyEnergy inputAluminium chloridesAluminium chlorideGeneration process

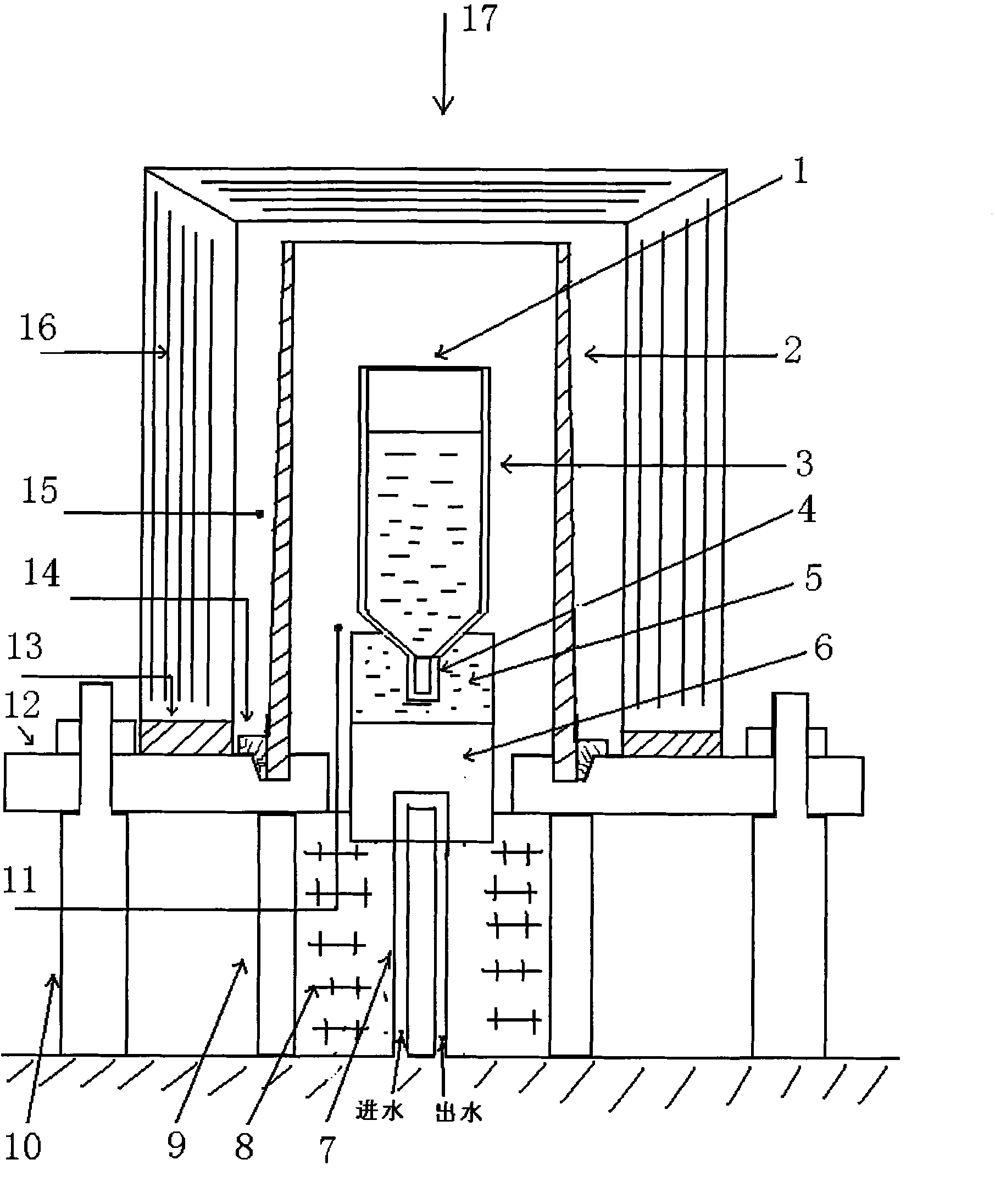

The invention relates to a high-efficiency energy-saving environment-protection preparation device of high-purity nanometer polymeric aluminium, which is composed of a liquid material generation part and a liquid material drying part; the preparation device is characterized in that: a liquid material generation agitated reactor is a high-efficiency agitated reactor 3, the heat of a membrane distillation device 8 for liquid material concentration is provided by waste heat of circulating water of a sleeve layer in the high-efficiency agitated reactor 3, and a tail gas absorption tower 12 is provided with a tail gas remainder recovery and waste heat re-utilization device; the high-efficiency energy-saving environment-protection preparation method comprises liquid material generation process and liquid material drying process; the method is characterized in that: the liquid material generation process comprises nitrogen adding technology and agitated reactor waste heat utilization technology; the liquid material drying process comprises the tail gas waste heat utilization technology; the invention has the advantages that the equipment structure is simplified to be convenient for control; the reaction efficiency of the nitrogen adding is improved, in the concentration process, the circulating water in the sleeve layer is utilized to provide heat, the tail gas remainder and waste heat are utilized, the energy source is saved, the discharging rate is improved, waste gas and waste heat discharge is reduced, the pollution is reduced and the cost is reduced.

Owner:TIANJIN RUNWO WATER SUPPLY INSTALLATION ENG

Continuous casting crystallizer casting powder of square billet casting powder low-carbon and medium-carbon steel and production method of continuous casting crystallizer casting powder

ActiveCN103624227AWide variety of sourcesLow priceGranulation by liquid drop formationSpray GranulationMetallurgy

The invention discloses continuous casting crystallizer casting powder of square billet casting powder low-carbon and medium-carbon steel and a production method of the continuous casting crystallizer casting powder. The continuous casting crystallizer casting powder comprises, by weight, 28-31% of CaO, 29-32% of SiO2, 2.4-3.6% of MgO, 0.8-1.4% of Fe2O3, 7.5-9% of Al2O3, 5-7 of Na2O5, 5.5-7.5% of F and 9.5-10.5 of solid C. The method comprises the steps of preprocessing and detection on raw materials, the design of the formula of the casting powder, dosing and pulping, spray granulation, screening for dust removal, and product detection. The method is simple in production process, little in dust and good in spreadability and contributes to environment largely. According to detection, compared with the mode adopting conventional raw materials, the mode of using soldering flux waste residues as raw materials has the advantages that the cost of the casting powder is lowered by 359-478 yuan / ton; after the continuous casting crystallizer casting powder is used in production, the class one qualified rate of casting blanks is improved by 2.7-3.3% year on year.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

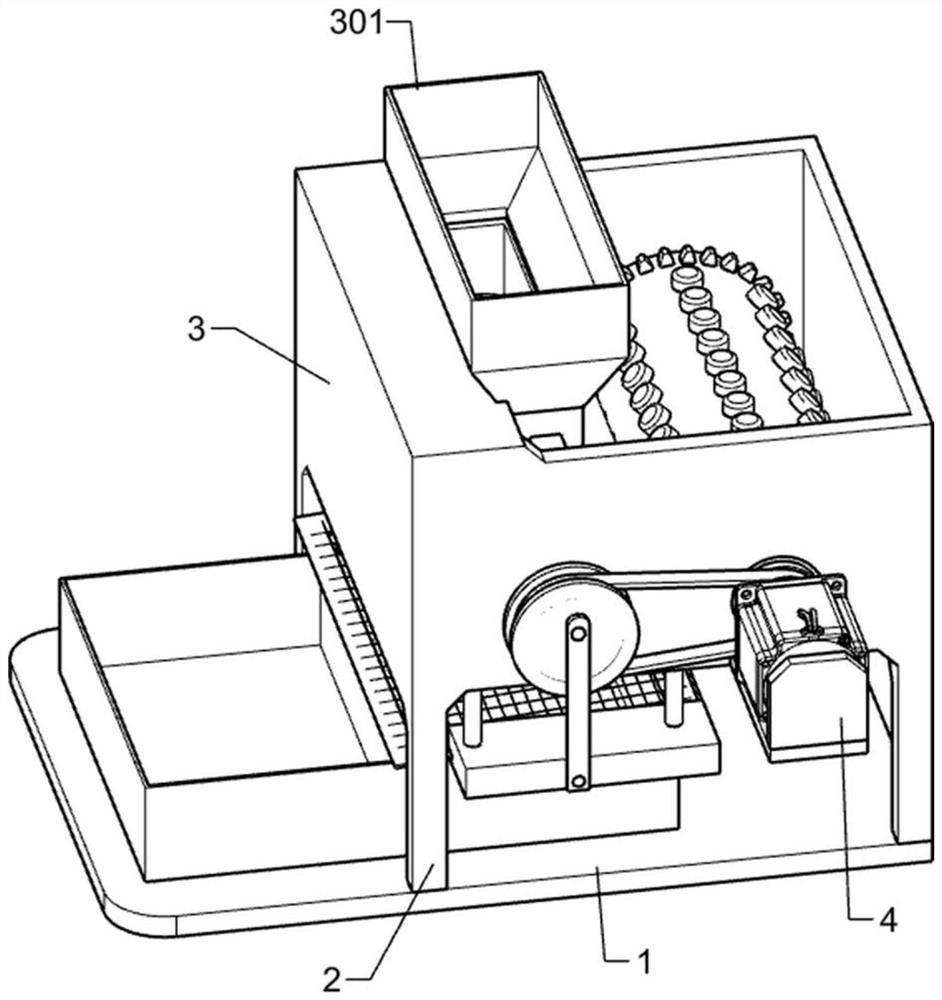

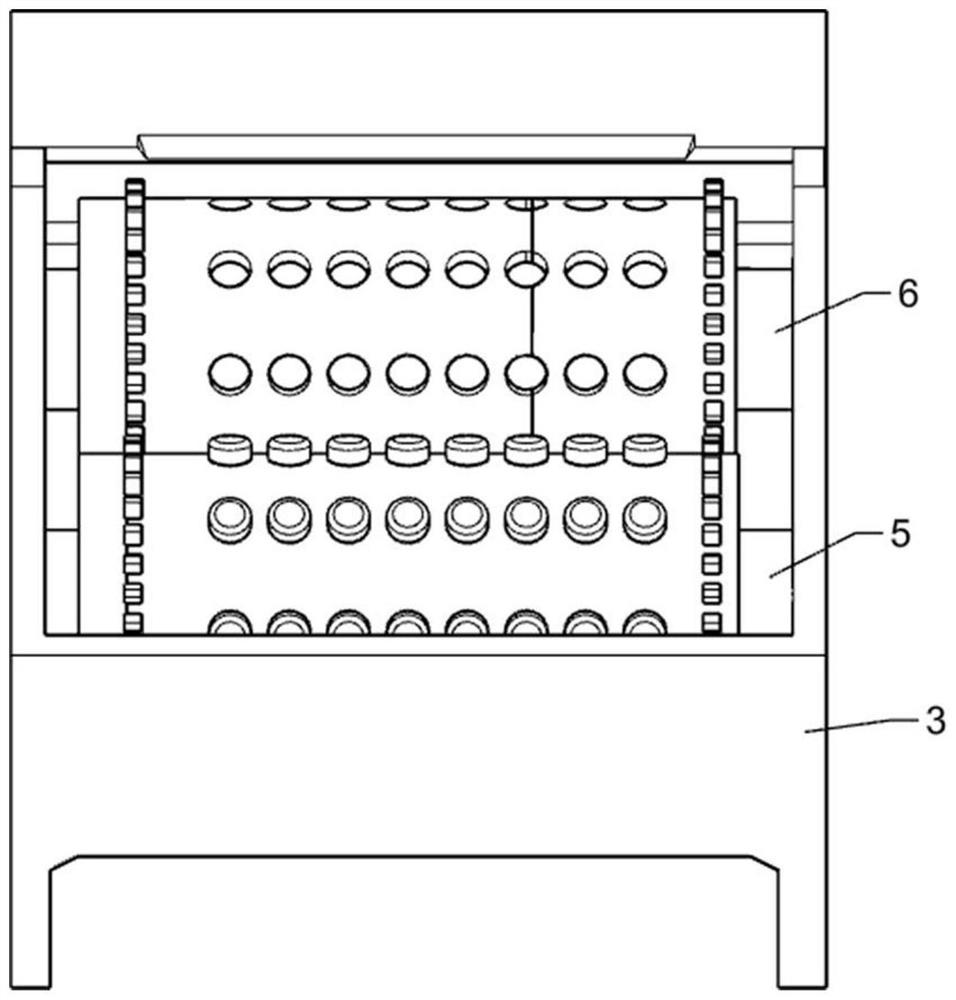

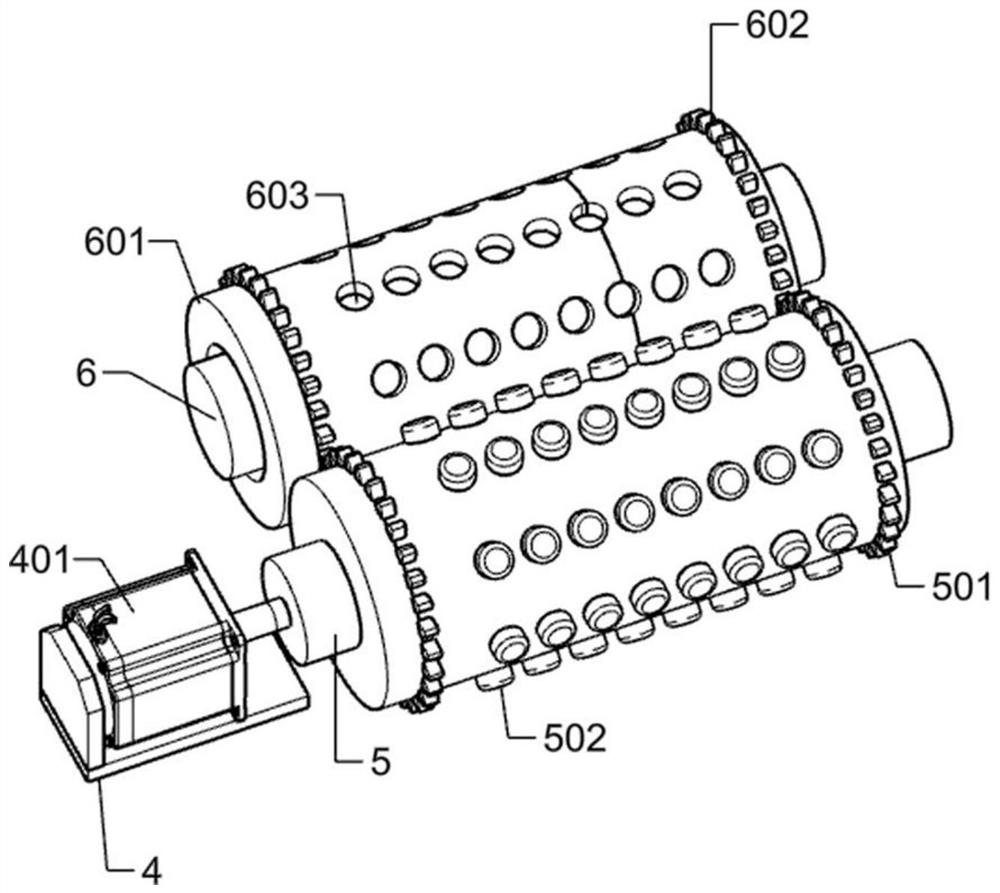

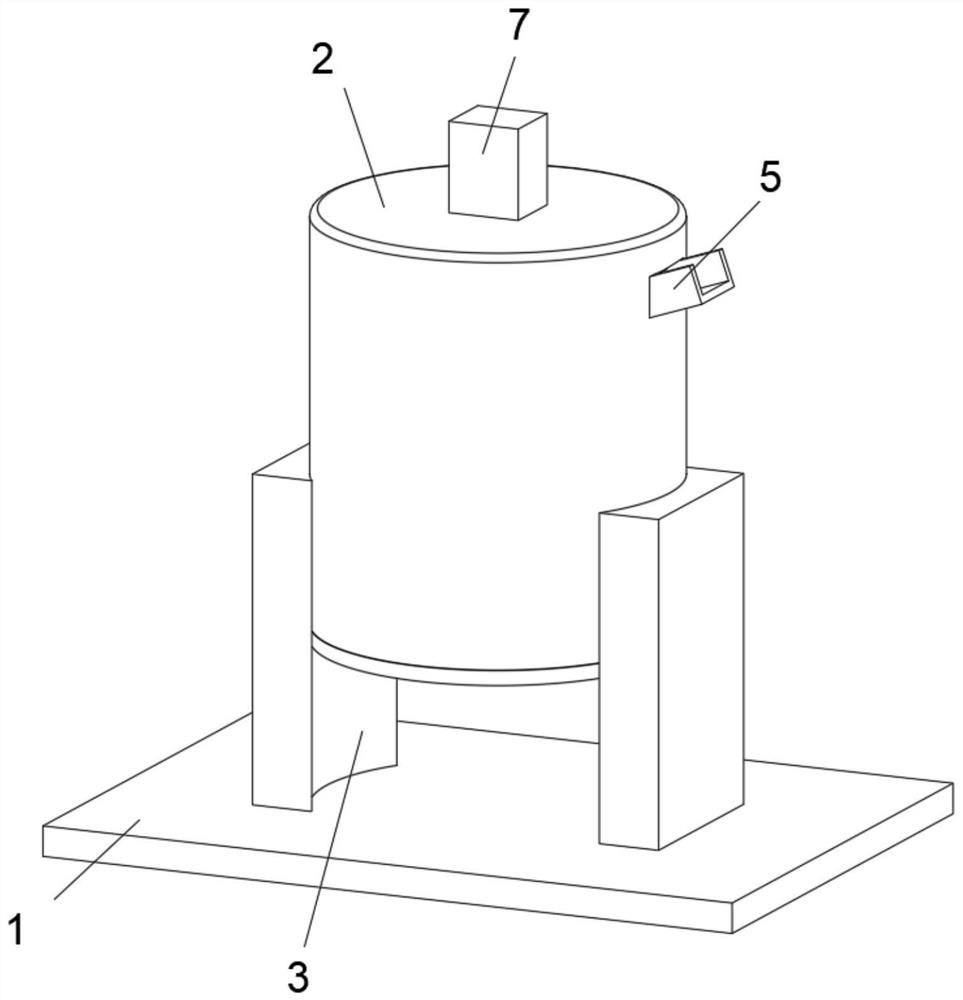

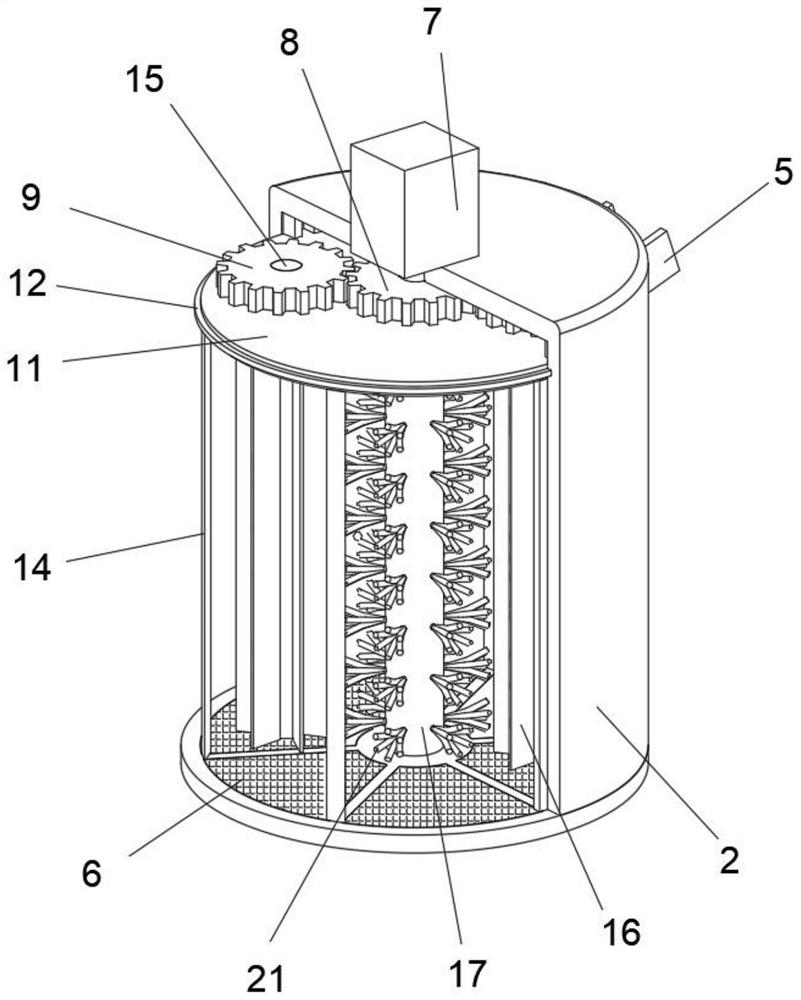

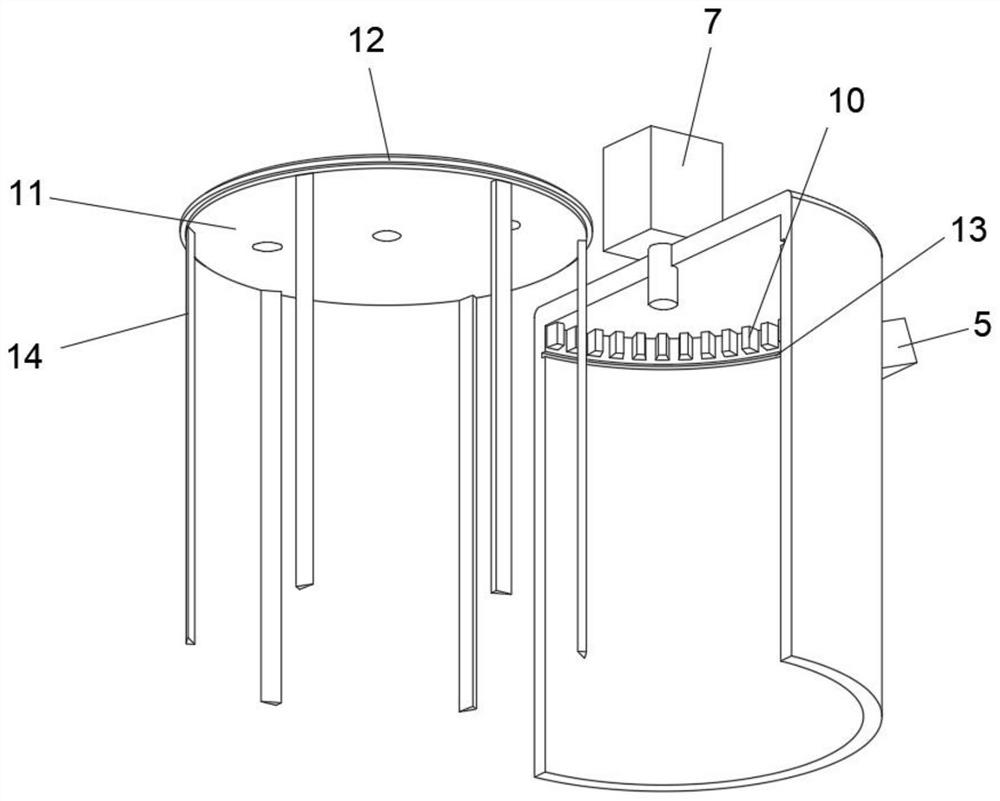

Granulation equipment for compound fertilizer production

InactiveCN112473558AImprove output rateImprove pass rateGranulation by pressingSolid/semi-solid fertilisersAgricultural scienceAgricultural engineering

The invention relates to a granulation device, in particular to granulation equipment for compound fertilizer production. The technical problem to be solved is to provide the granulation equipment forcompound fertilizer production, which can be used for preparing granules with uniform size and can replace a mold. According to the technical scheme, the granulation equipment for compound fertilizerproduction comprises a bottom plate, supporting legs, a case, a feeding bin, a rack, a motor, a granulation device and the like. Four supporting legs are fixedly connected to the bottom plate, the case is fixedly connected to one end of each of the supporting legs, the feeding bin is installed at the top of the case, the rack is fixedly connected to one side of the case, the motor is fixedly connected to the rack, the granulation device is rotatably connected to the case, and the granulation device is fixedly connected with the motor. The granulation device, the screen and the baffle are additionally arranged, the discharging rate of the granulation device is high, the screen and the baffle can improve the percent of pass of finished products, and therefore the sizes of processed fertilizer particles are uniform.

Owner:李丹丹

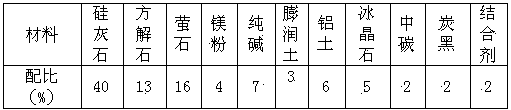

Continuous casting used crystallizer casting powder for plate blank and preparing method thereof

The invention discloses continuous casting used crystallizer casting powder for a plate blank and a preparing method thereof. The casting powder comprises, by weight, 28-30% of SiO2, 35-37% of CaO, 3.3-4.8% of MgO, 0.7-1.3% of Fe2O3, 5-7% of Al2O3, 9-11% of Na2O, 8-10% of F, 3-5% of solid carbon. The method comprises the steps of raw material preprocessing and detection, casting powder formula design, batching and slurrying, spray granulation, screen-dedusting and product detection. According to the method, the production technology is simple, the amount of dust is small, spreadability is good, slugging can be achieved evenly and stably, and contribution to the environment is big. Detection proves that compared with a method using conventional raw materials, the method has the advantages that due to the adoption of soldering flux waste residues which serve as the raw material, the cost of the casting powder is reduced by 255-308 yuan / ton, and after the casting powder is used for production, the primary qualified rate of casting blanks is increased by 3.0-3.8% on year-on-year basis.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

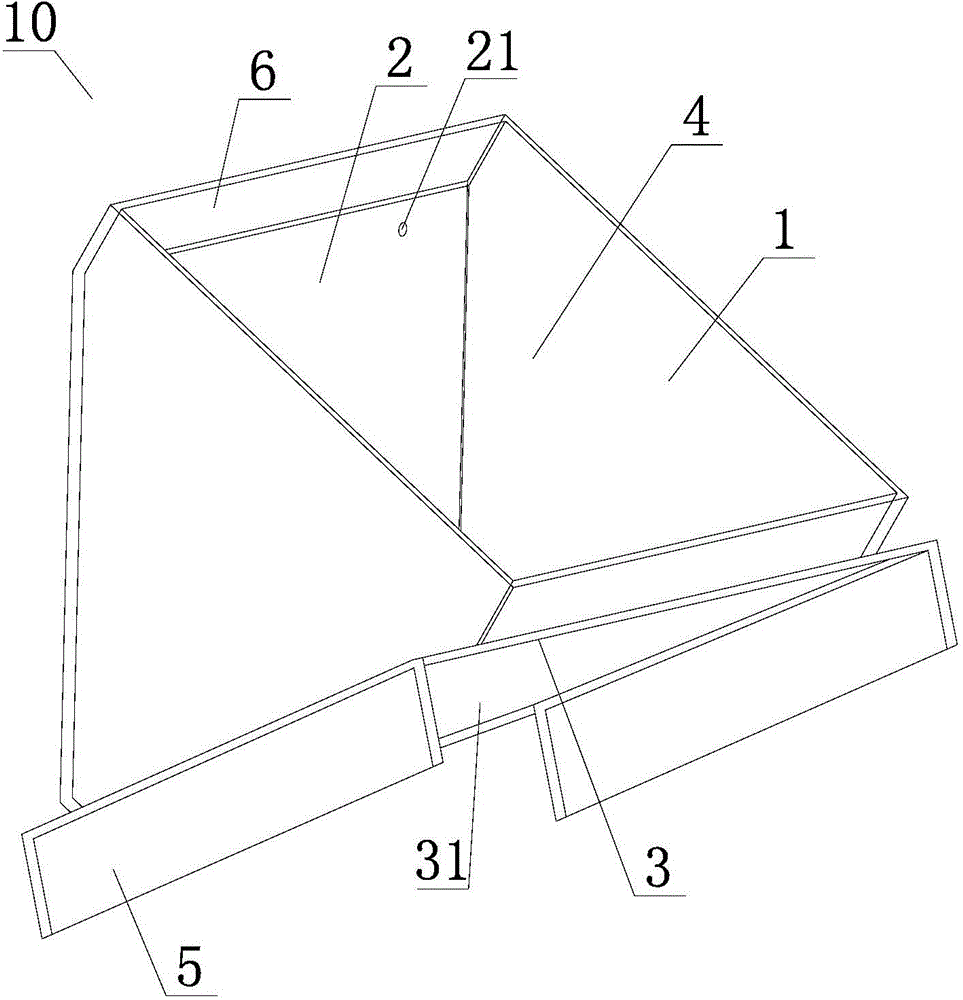

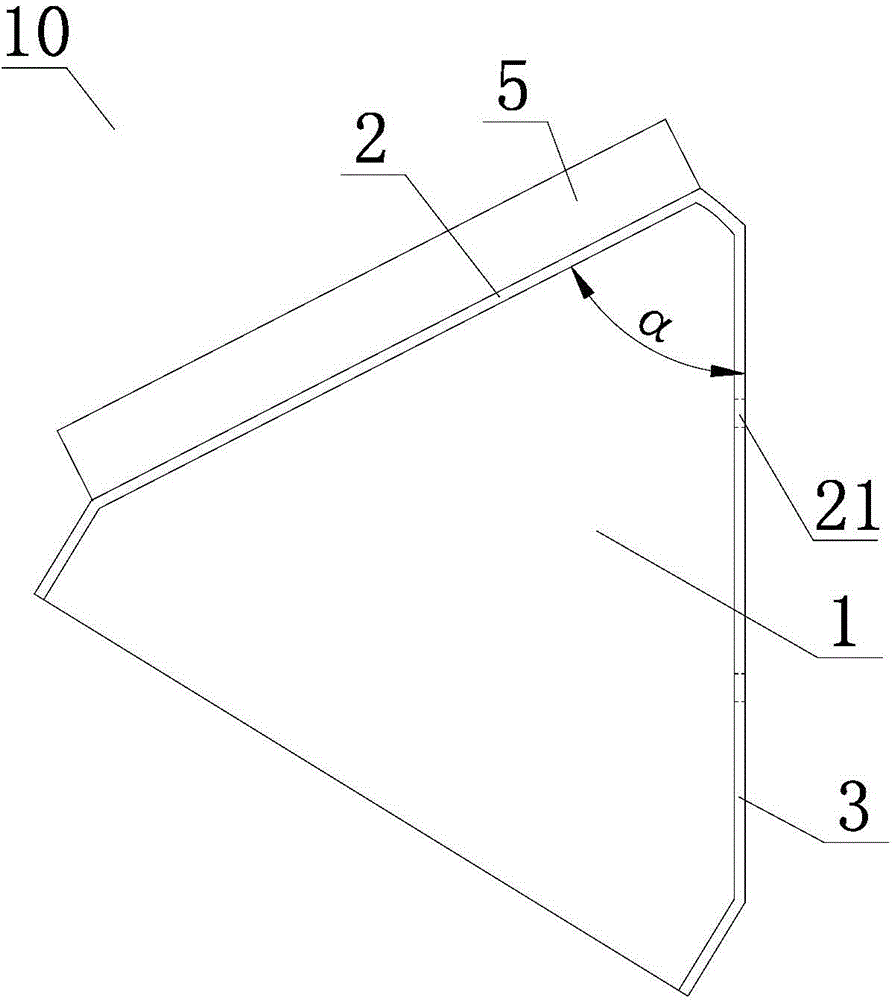

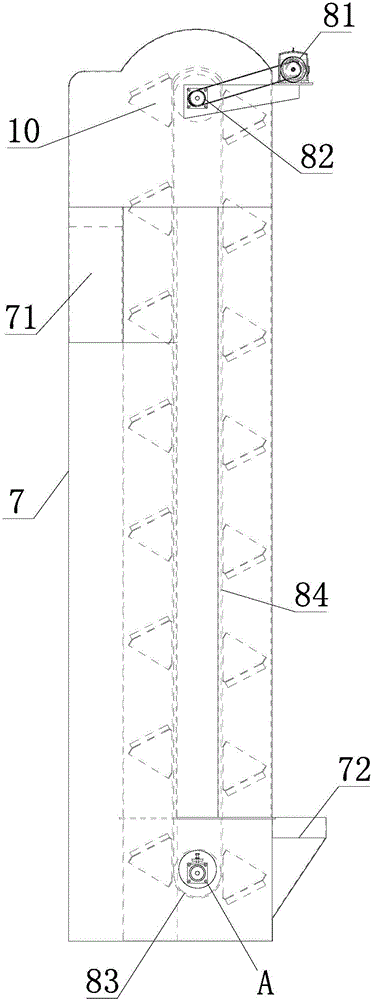

Bucket structure and bucket elevator

InactiveCN105083857AImprove output rateRealize secondary unloadingConveyorsAcute angleDischarge rate

The invention relates to a bucket structure and a bucket elevator and relates to the technical field of material elevating equipment. The bucket structure and the bucket elevator are mainly designed to solve the problem that in the prior art, the discharging rate of a bucket of an elevator is low when the bucket is turned over for discharging. According to the major technical scheme, the bucket structure is used for the bucket elevator and comprises a bucket; the bucket comprises a guide part and an installation part used for installing the bucket on the bucket elevator; the guide part is opposite to the installation part; the installation part comprises an installation plane, the guide part comprises a guide plane, and an acute angle is formed between the installation plane and the guide plane; the guide plane is provided with a guide structure used for guiding materials scattered to the guide structure to a designated area. The bucket structure is mainly used for the bucket elevator.

Owner:SHIHEZI DEV ZONE TIANZUO SEED MACHINERY

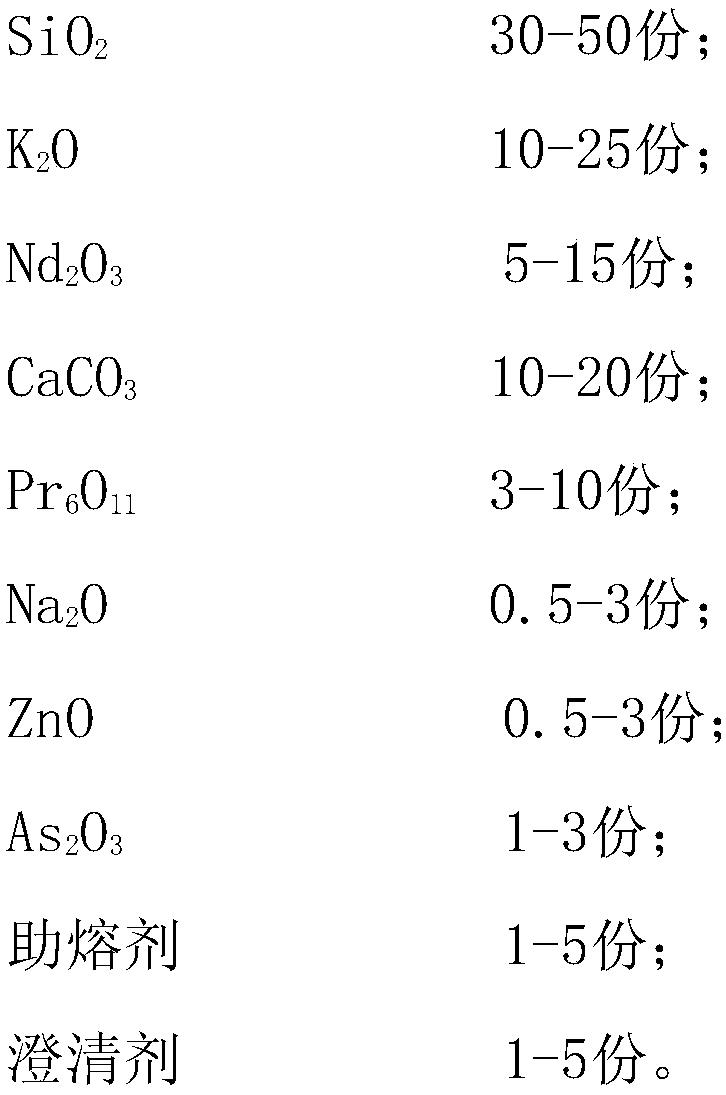

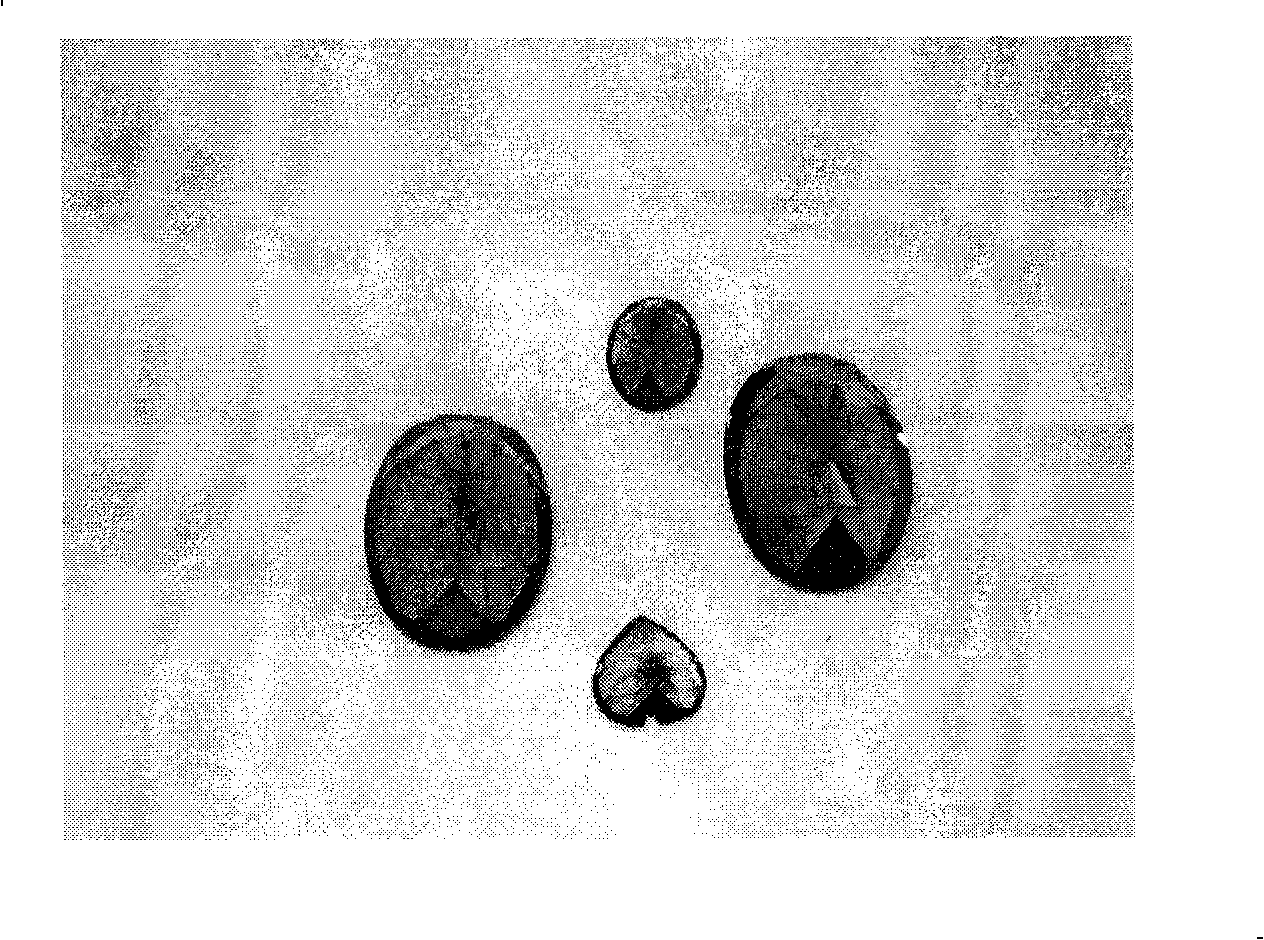

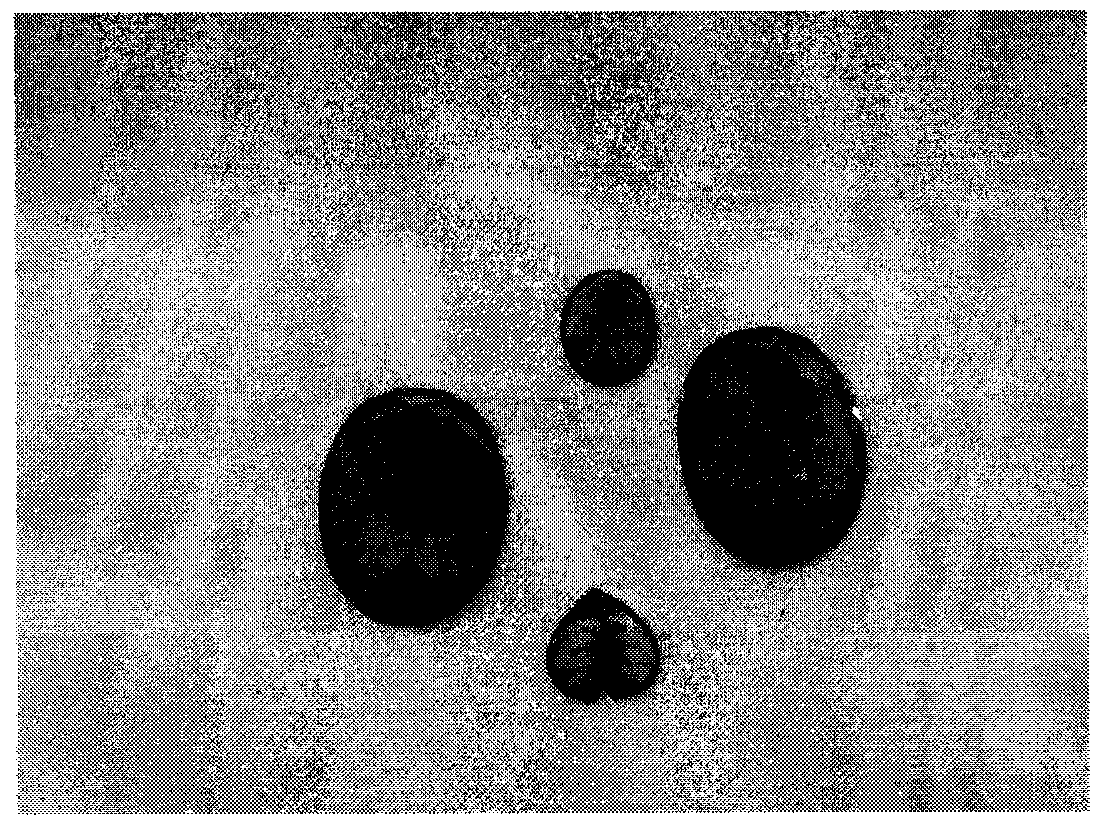

Artificial phenomenal gem and preparation method thereof

ActiveCN108373261AWide range of colors and tonesSimple structureGlass shaping apparatusHueMaterials science

The invention belongs to the technical field of artificial gems, and particularly relates to an artificial phenomenal gem and a preparation method thereof. The artificial phenomenal gem comprises SiO2, K2O, Nd2O3, CaCO3, Pr6O11, Na2O, ZnO, As2O3, a fluxing agent and a clarifying agent. The preparation method comprises the following steps: (1) mixing various raw materials proportionally, and stirring uniformly to obtain a mixture A; (2) heating the mixture A to the temperature of 1350-1500 DEG C, and maintaining for 20 hours till the mixture A is melted completely to obtain a melt B; (3) cooling the melt B to the temperature of 1200-1250 DEG C, maintaining for 4 hours and then pouring the melt B into a mold to obtain a formed gem C; and (4) annealing the formed gem C. The artificial phenomenal gem can produce broad color and hue, and has bright green purple color-changing effect under different light rays; by the preparation method, the discharge rate can be increased obviously; and thepreparation method is environmentally friendly.

Owner:东莞市屹泰水晶工艺有限公司

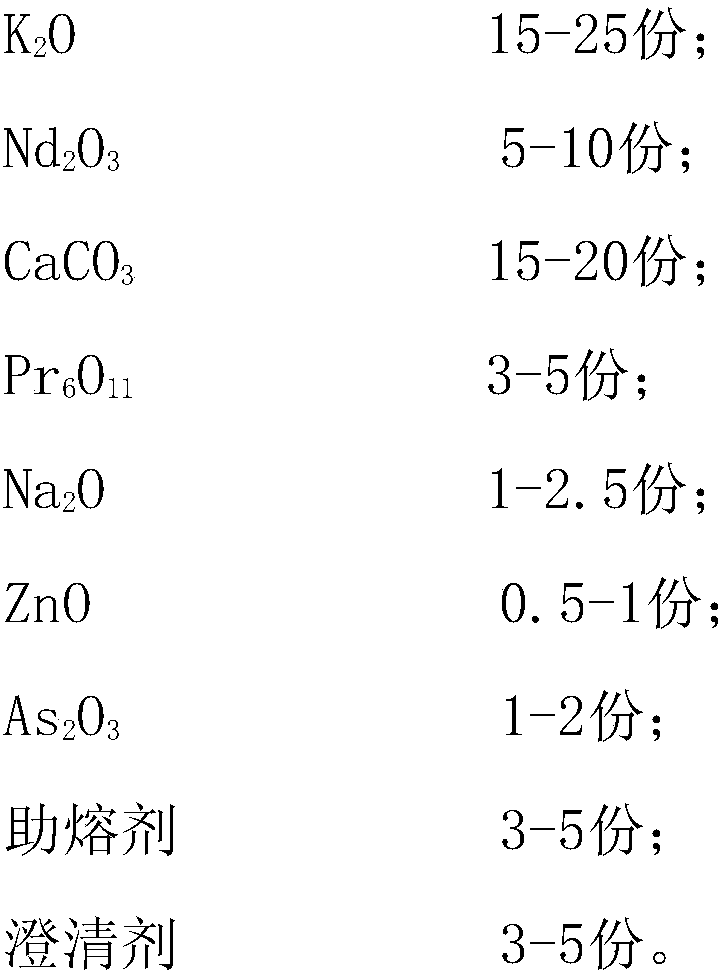

Plant protection unmanned aerial vehicle and plant protection operation method thereof

ActiveCN110001959APrevent leakageImprove output rateAircraft componentsLaunching weaponsDischarge rateEngineering

The invention relates to a plant protection unmanned aerial vehicle and a plant protection operation method thereof. The plant protection unmanned aerial vehicle comprises a driving device, a sealingcover, a charging cylinder and an unmanned aerial vehicle body, wherein the middle part of the driving device is connected with the sealing cover, the sealing cover is arranged at an upper end openingof the charging cylinder, and the upper end of the sealing cover is connected with the lower end of the unmanned aerial vehicle through screws. According to the plant protection unmanned aerial vehicle and the plant protection operation method thereof, the problems that when an existing unmanned aerial vehicle applies fertilizer, the number of discharging outlets is reduced during fertilizer applying due to the fact that the discharging outlets cannot be opened caused by influence of wind resistance and air turbulence, the fertilizer leakage condition is prone to appearing to existing discharging outlets when the fertilizer does not need to be supplied, and the discharging quantity of upper-end discharging outlets is less when fertilizer applying is carried out are solved; a motor drivesthe charging cylinder to rotate at a high speed, and a bottom stirring mechanism and two dispersing mechanisms stir, agitate and blow the fertilizer in the charging cylinder, so that the discharging rate of an upper-end conveying pipe of a charging frame is improved; and a gravity ball flies outwards through centrifugal force generated by high-speed rotation, thus the charging frame is driven to stretch out, and the fertilizer leakage when the fertilizer is not applied is avoided.

Owner:南通亿思特机器人科技有限公司

Mixed reaction kettle for processing pressure-sensitive collagen glue solution

InactiveCN111644137AStir wellImprove output rateChemical/physical/physico-chemical stationary reactorsAdhesiveDrive wheel

The invention relates to the technical field of pressure-sensitive adhesive production, in particular to a mixed reaction kettle for processing a pressure-sensitive collagen adhesive solution, a driving wheel is connected with a driven wheel through a chain, the driven wheel is fixed to the upper end of a lead screw, and the lower end of the lead screw penetrates through the top wall of a reactionkettle body through a first bearing and then is movably inserted into the inner bottom wall of the reaction kettle body. A scraping plate is vertically and movably arranged in the reaction kettle body and is of an annular structure with an inner annular hole formed in the center, a threaded hole in the horizontal plane of the annular structure is in threaded connection with the lead screw, a guide rod is movably inserted into a guide hole in the horizontal plane of the annular structure, and the upper end and the lower end of the guide rod are fixed to the upper inner wall and the lower innerwall of the reaction kettle body correspondingly; the width of the lower edge of the vertical surface of the annular structure is smaller than that of the upper edge, and the outer side wall of the vertical surface of the annular structure is propped against the inner wall of the reaction kettle body. Pressure-sensitive adhesives attached to the inner wall of a reaction kettle can be effectivelyscraped off in the later discharging period, and the finished product discharging rate is increased.

Owner:常州都铂高分子有限公司

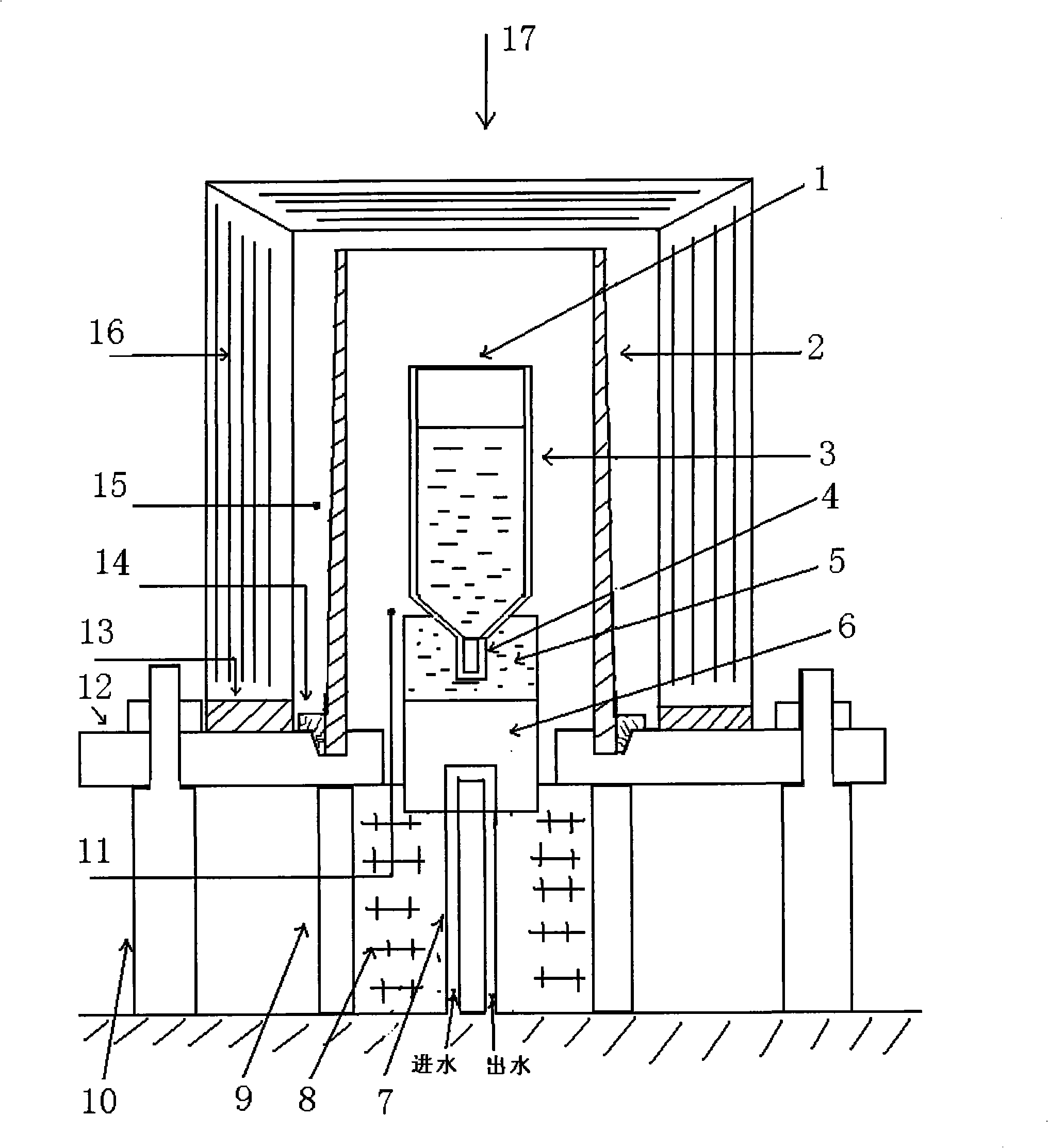

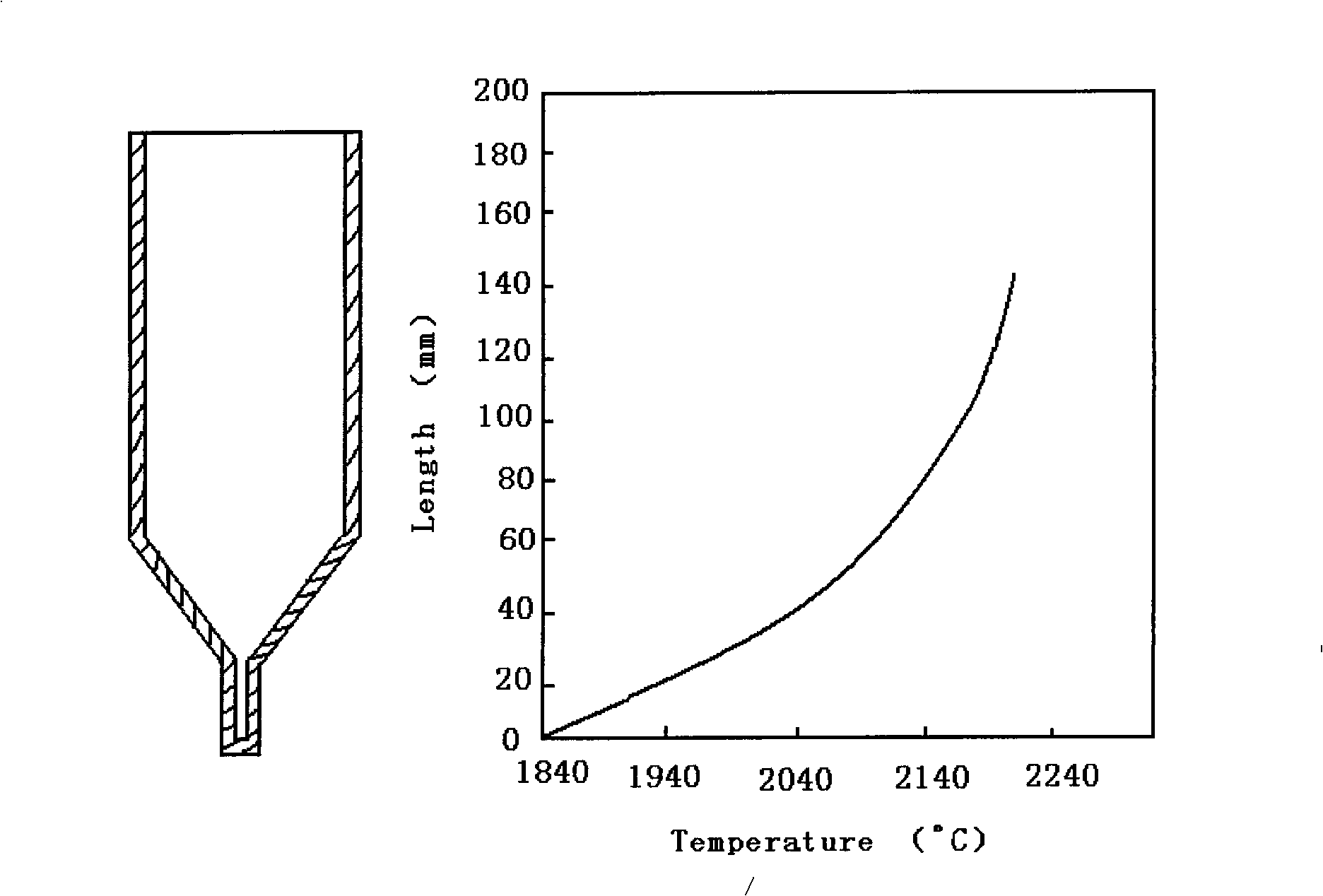

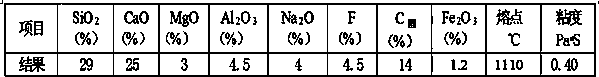

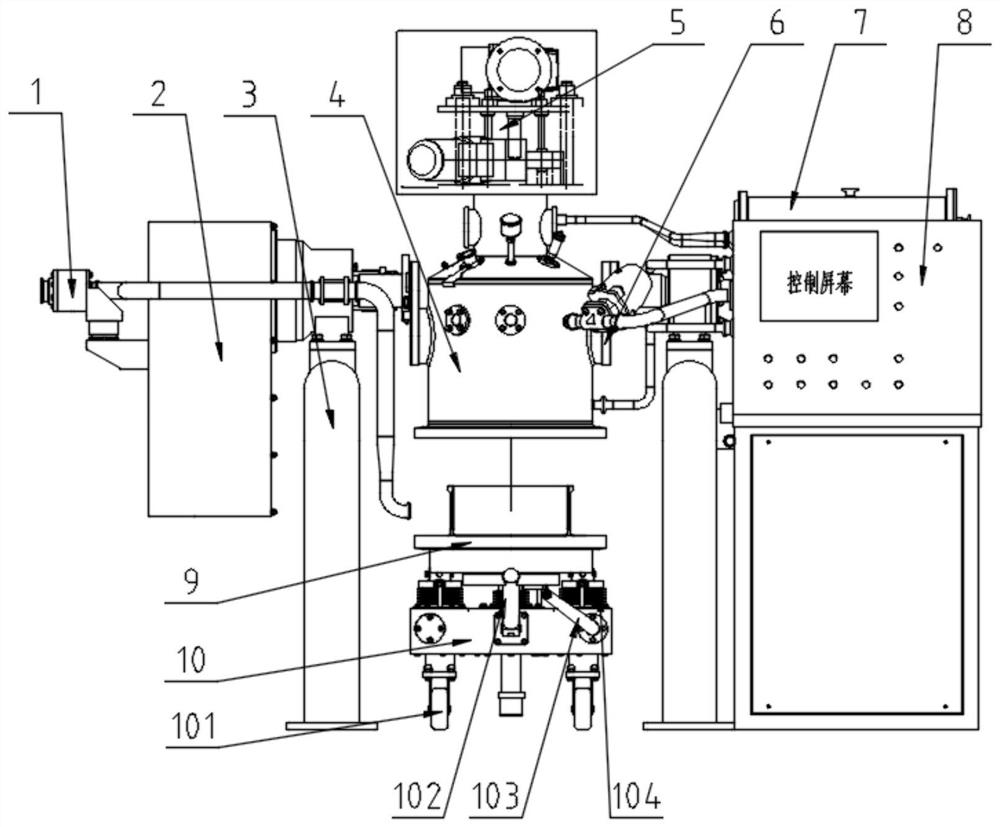

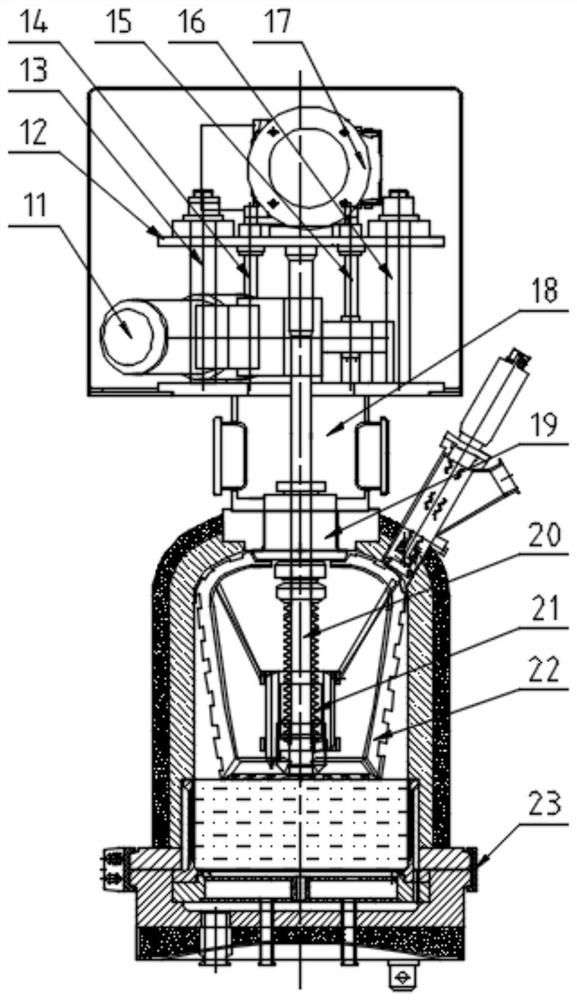

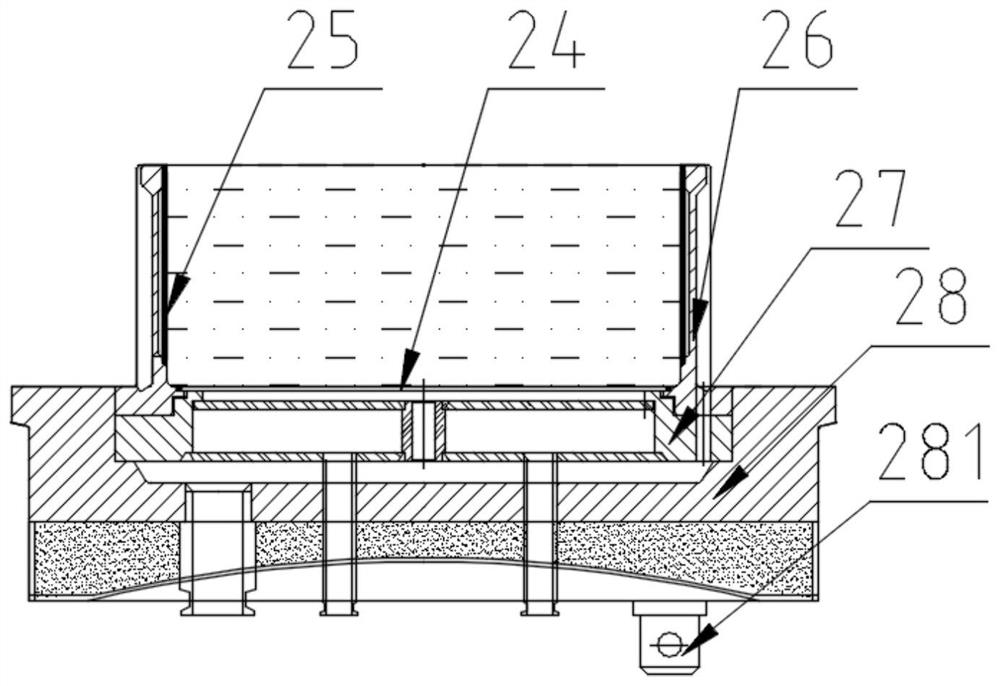

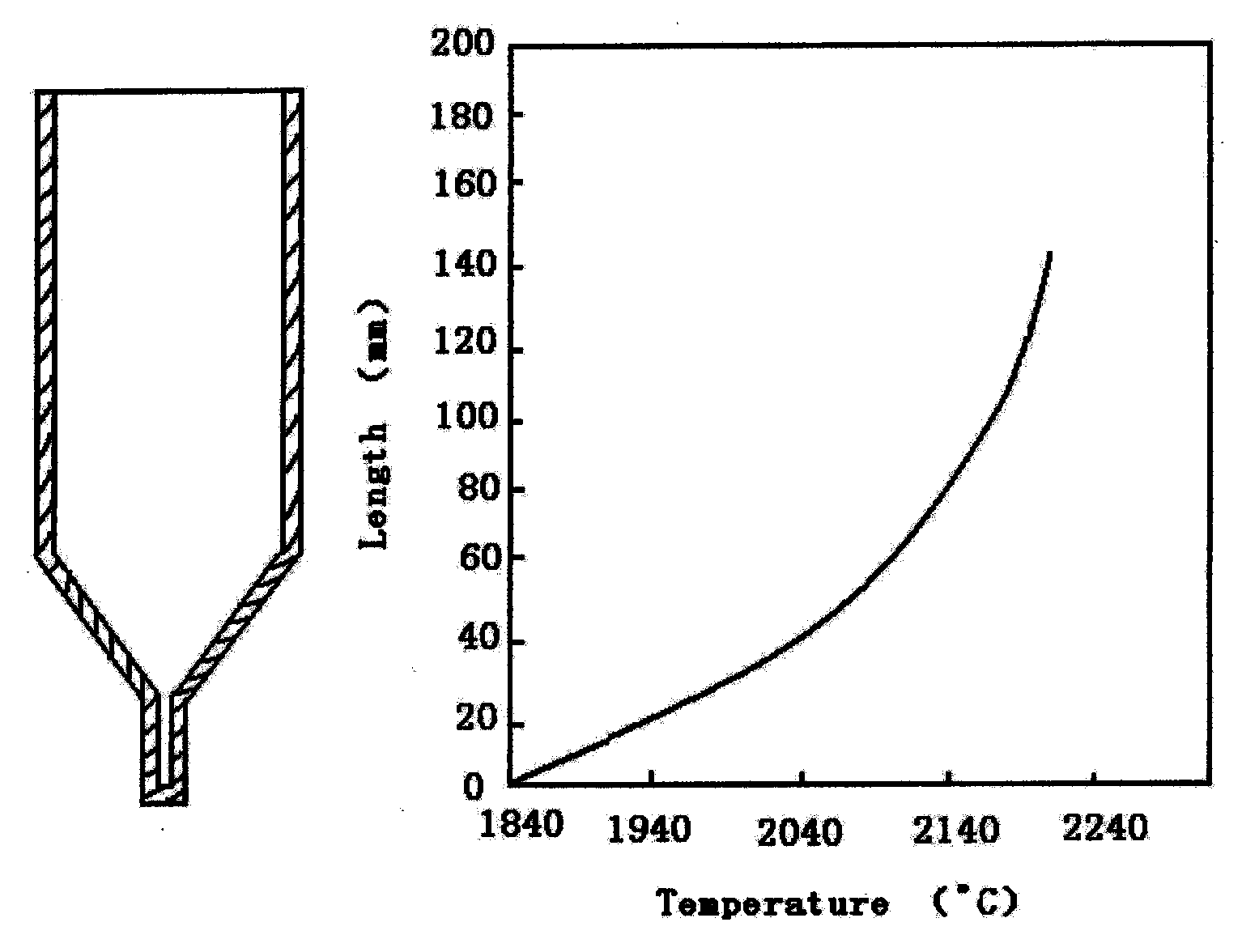

Beryllium aluminate crystal substrate color changing gem, and preparation and growth apparatus thereof

The invention discloses a beryllium aluminate crystal substrate phenomenal gem, a preparation method and a growth device thereof, which is characterized in that, in a special growth device, BeAl2O4 monocrystal substrate is proportionally blended with Cr<3+>, Fe<3+>, Ti<3+> or Ni<2+> three transition element ions, and a vertical static temperature gradient method is used for preparing the artificial phenomenal gem with strong color change effect. The invention aims at meeting the constant requirements of people on the color and hue of the gems of chrysopal group, wishing that more distinct variation can be obtained in the aspect of color change effect between red and green, and solving the civil batch production problem of the gem. The phenomenal gem which can generate broader color and hue has obvious color change effect between red and green. The preparation method has the advantages of obviously enhancing mass output rate, having relatively simple equipment, and overcoming the defective impact of mechanical drive and vibration on crystal growth, thus being beneficial to the scale production of high-quality gems.

Owner:NINGBO UNIV

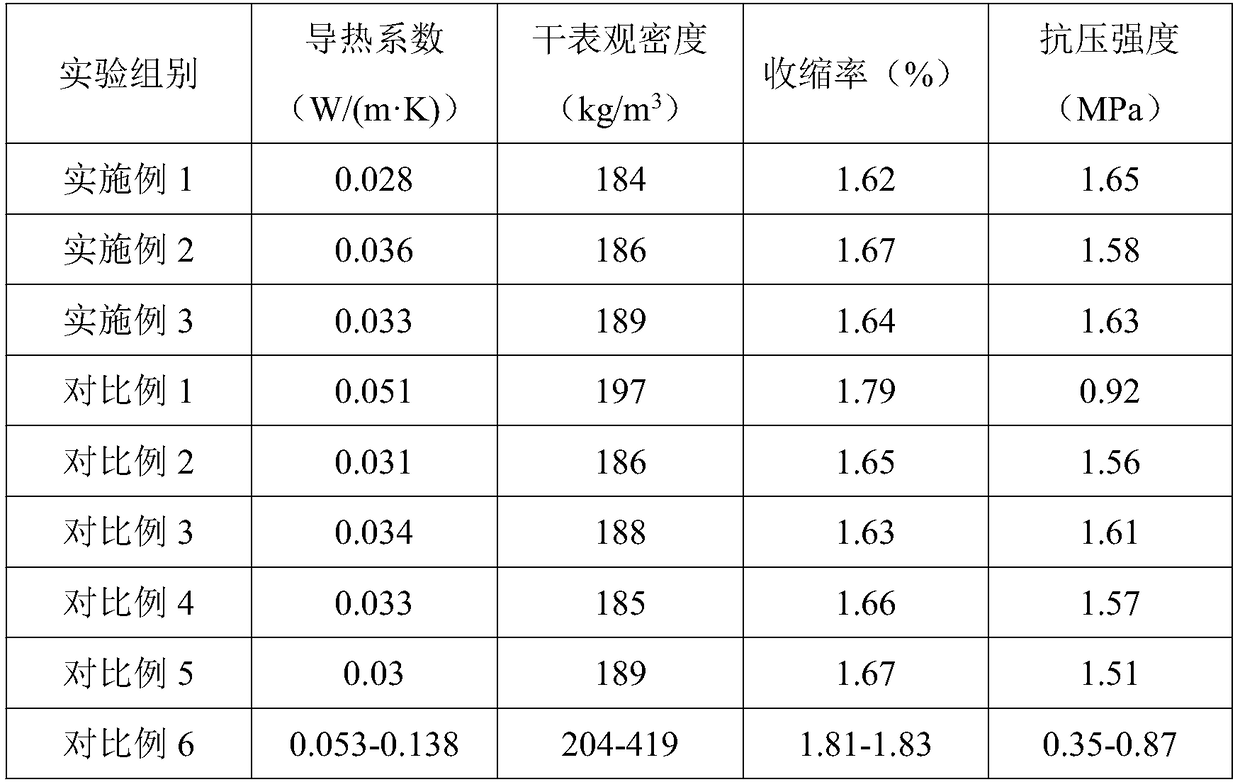

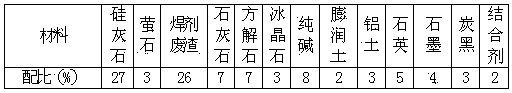

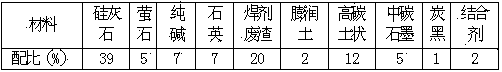

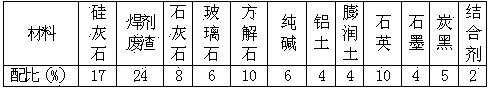

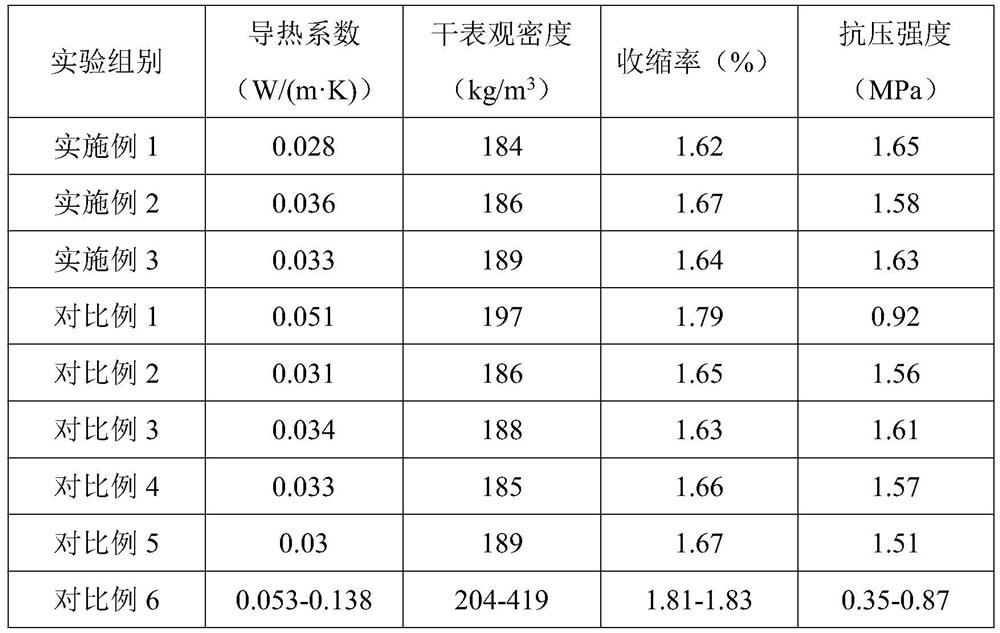

Thermal insulating mortar and preparation method thereof

ActiveCN108069660AImprove responseLow thermal conductivityCeramicwareSodium BentonitePolystyrene particle

The invention discloses a thermal insulating mortar and a preparation method thereof and belongs to the technical field of preparation of building materials. The thermal insulating mortar is preparedfrom the following raw materials including silicate cement, coal ash, limestone powder, polystyrene particles, bentonite, thickener, heavy calcium carbonate powder, tackifier, carboxyethyl methylcellulose, lauryl sodium sulfate, calcium fluoride, styrene maleic anhydride copolymer and organosilicon-polyurethane copolymer, sodium carbonate and hydrochloric acid through the steps of mixing, stirringand the like. The thermal insulating mortar can improve the compressive strength and reduce dry apparent density, heat conductivity coefficient and water absorption per volume.

Owner:东至安东祥源新型建材有限公司

Round billet continuous casting crystallizer casting powder and preparation method thereof

The invention discloses round billet continuous casting crystallizer casting powder and a preparation method of the round billet continuous casting crystallizer casting powder. The casting powder comprises, by weight, 30-33% of SiO2, 26-29% of CaO, 1-3% of MgO, 0.5-0.9% of Fe2O3, 6-8% of Al2O3, 5-7% of Na2O, 2.5-3.5% of F and 13-17% of solid C. The method includes the steps of raw material processing and detection, casting powder formula design, dosing, pulp making, spray granulation, screening dust extraction and product detection. The method is simple in production process, little in dust, good in spreadability and large in contribution to the environment, the detection shows that compared with conventional raw materials, the cost of each ton of the casting powder is reduced by RMB 245 yuan to RMB 298 yuan when soldering flux waste residues serve as the raw materials, and after the round billet continuous casting crystallizer casting powder is used for production, the class-one casting blank percentage of pass is improved by 2.1% to 2.5%.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Formula and production technology of environment-friendly foamed cotton

The invention relates to the technical field of production technologies of foamed cotton, and discloses a production technology of environment-friendly foamed cotton. The production technology of theenvironment-friendly foamed cotton comprises the steps of firstly, mixing and plastifying corresponding components of a material and reinforcing filler, and conducting primary banburying treatment; secondly, adding zinc oxide and stearic acid into a product obtained in the reaction for secondary banburying treatment; then adding a foaming agent, a foaming cross-linking agent, a PU colorant, an odor elimination agent and a stabilizer for tertiary banburying treatment; and finally, carrying out a milling-sheet extruding-cutting-foaming-cooling treatment technology process in sequence to obtain the polyurethane environment-friendly foamed cotton at last. According to the physical and chemical performance of the reactant components, reasonable sectional banburying treatment is conducted, thusthe output rate and quality of the foamed cotton are effectively improved, a mould-pressing physical gas foaming method is adopted, no chemical agents are used, thus chemical pollution is avoided, thetechnology is more environmentally friendly, and by controlling ageing and temperature of the reaction, foamed particles which are even in foam cell, controllable in size and controllable in foamingdensity can be obtained.

Owner:东莞方德泡绵制品厂有限公司

Round-billet continuous-casting crystallizer covering slag and production method thereof

The invention discloses round-billet continuous-casting crystallizer covering slag and a production method thereof. The covering slag comprises, by weight, 23-27% of CaO, 29-32% of SiO2, 1-3% of MgO, 4.5-6.5% of Al2O3, 4-6% of Na2O, 2.5-4.5% of F, 14-18% of Csolid and less than or equal to 2% of Fe2O. The production method includes raw material pretreatment and testing, covering slag formulation design, compounding and pulping, spray granulation, screening dedusting and product testing. The production method is low in cost, capable of improving quality of the covering slag and increasing utilization rate of yellow phosphorus waste slag and great in contribution to the environment; tests show that compared with a conventional raw material, the yellow phosphorus waste slag taken as a raw material has the advantages that cost of the covering slag is lowered by 223-276 RMB / ton, and first-class qualified rate of cast billets is increased by 2.3-3.1% on year-on-year basis.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

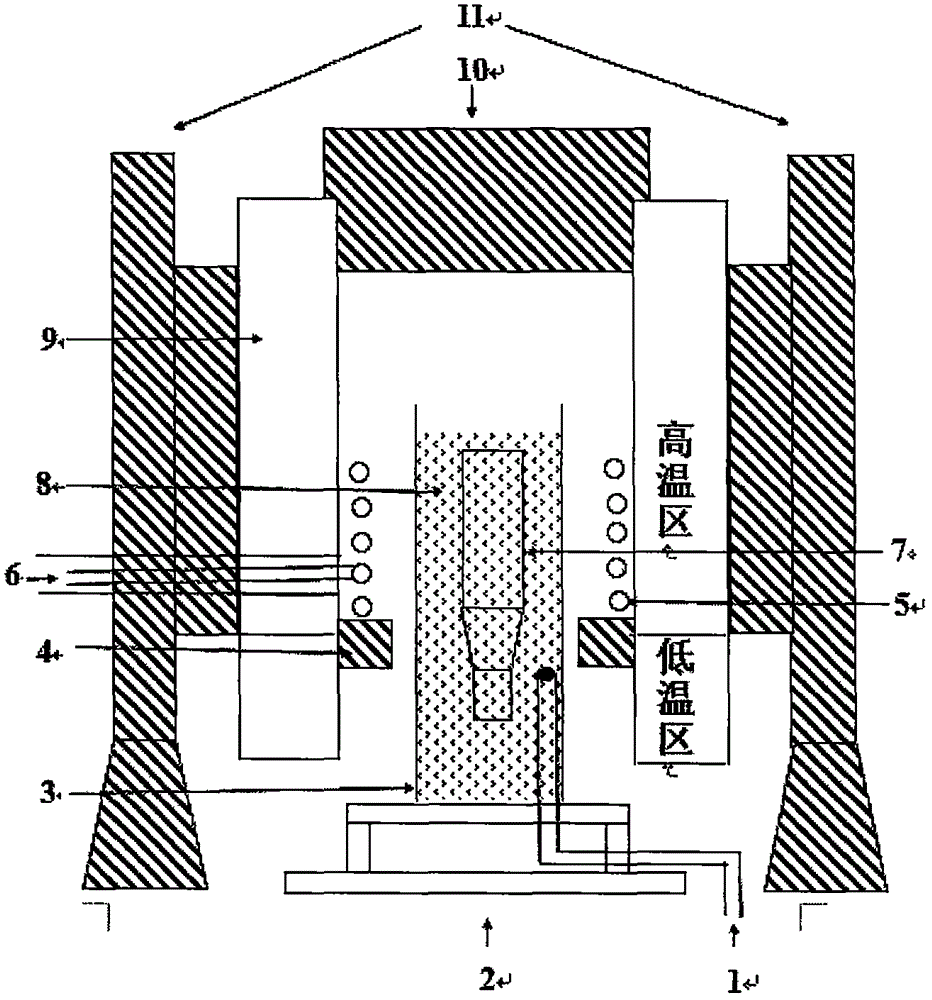

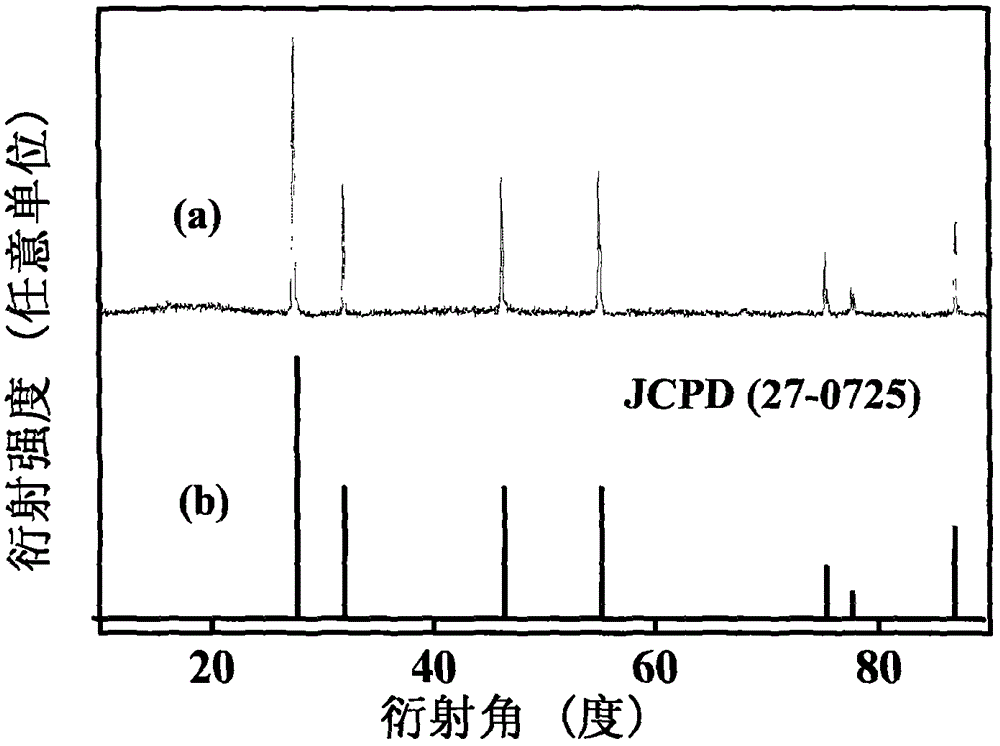

Er<3+>/Pr<3+> co-doped Na5Lu9F32 monocrystal and growth method thereof

InactiveCN105780117AImprove luminous efficiencyReduce particle countPolycrystalline material growthFrom frozen solutionsCrystal growthWave band

The invention discloses an Er<3+> / Pr<3+> co-doped Na5Lu9F32 monocrystal and a growth method thereof. Ions Er<3+> and Pr<3+> are doped in a Na5Lu9F32 monocrystal and Pr<3+> is used as a sensitizing ion. The content of OH- ions in the monocrystal is low, no absorption occurs at a wave band 2.7mu m, and the maximum phonon energy is low (440cm<-1>). Under the excitation of a 98nm laser diode, a greatly enhanced 2.7mu m luminous effect is obtained. By adopting a heating temperature field up-shifting method to perform crystal growth, the growth method has the characteristics of simple equipment, strong practicability and the like. The technique can overcome the defects of colored tapes, growth stripes and the like caused by mechanical transmission to the crystal, and facilitate obtaining a high-quality monocrystal.

Owner:NINGBO UNIV

Inclined filtering, washing and drying machine

PendingCN113599886ALarge filter areaImprove heating efficiencyStationary filtering element filtersProcess engineeringMother liquor

The invention discloses an inclined filtering, washing and drying machine which comprises a charging cylinder, the charging cylinder is connected with an inclined system, the inclined system is connected with a rotary rear cover plate on an auxiliary process cylinder, a front cover plate of the auxiliary process cylinder is provided with process pipeline connectors, and the rotary rear cover plate is provided with a process rotary connector. The process rotary connector is connected with each pipe orifice on the charging cylinder through a hard pipe, the bottom of the charging cylinder is communicated with a filtering assembly, and the bottom of the filtering assembly is connected with a mother liquor rotary connector through a hard pipe pipeline; the rotary center of a rotary rear cover plate, the rotary center of the mother liquor rotary connector and the rotary center of the charging cylinder are positioned on the same axis; a lifting trolley for lifting and transferring the filtering assembly is arranged under the charging cylinder; and a stirring shaft and a stirring paddle connected with the outer side of the stirring shaft are arranged at the center position in the charging cylinder, and a rotary lifting assembly is arranged at the top of the charging cylinder. The invention provides a more efficient dynamic filtering, washing and drying machine, and the efficiency and operability of the whole machine are comprehensively improved.

Owner:SHANGHAI RUIPAI MACHINERY

Preparation method of beryllium aluminate crystal substrate color changing gem

InactiveCN101407402BImprove output rateObvious red-green discoloration effectAluminateSingle crystal

The invention discloses a beryllium aluminate crystal substrate phenomenal gem, a preparation method and a growth device thereof, which is characterized in that, in a special growth device, BeAl2O4 monocrystal substrate is proportionally blended with Cr<3+>, Fe<3+>, Ti<3+> or Ni<2+> three transition element ions, and a vertical static temperature gradient method is used for preparing the artificial phenomenal gem with strong color change effect. The invention aims at meeting the constant requirements of people on the color and hue of the gems of chrysopal group, wishing that more distinct variation can be obtained in the aspect of color change effect between red and green, and solving the civil batch production problem of the gem. The phenomenal gem which can generate broader color and hue has obvious color change effect between red and green. The preparation method has the advantages of obviously enhancing mass output rate, having relatively simple equipment, and overcoming the defective impact of mechanical drive and vibration on crystal growth, thus being beneficial to the scale production of high-quality gems.

Owner:NINGBO UNIV

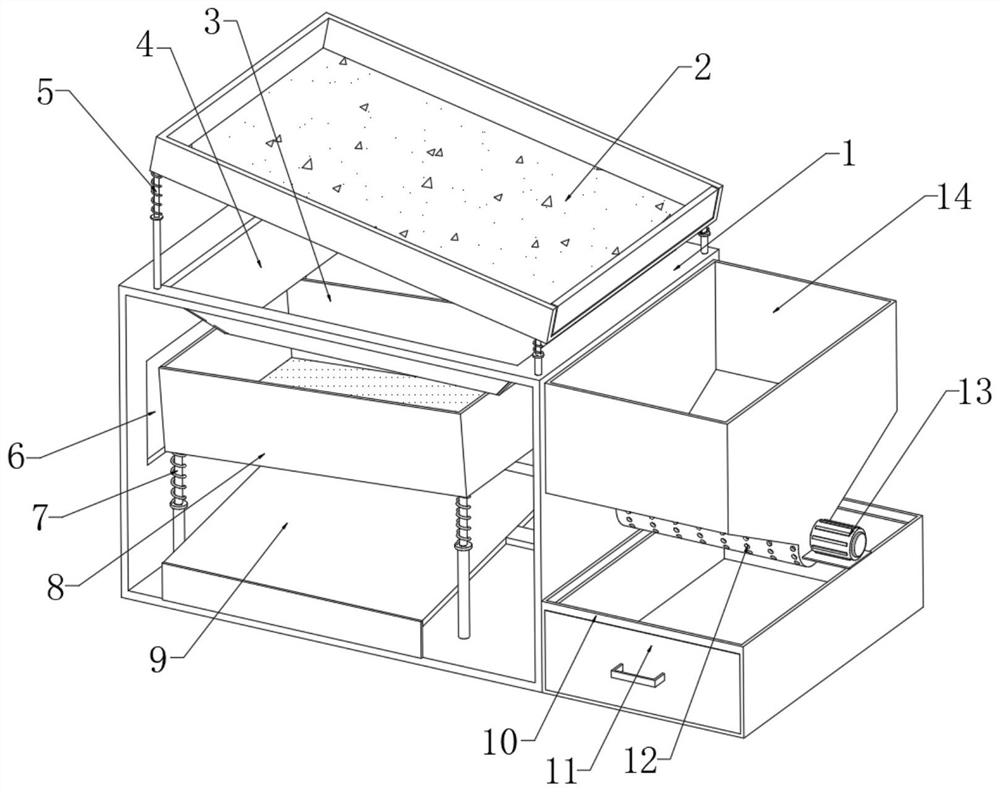

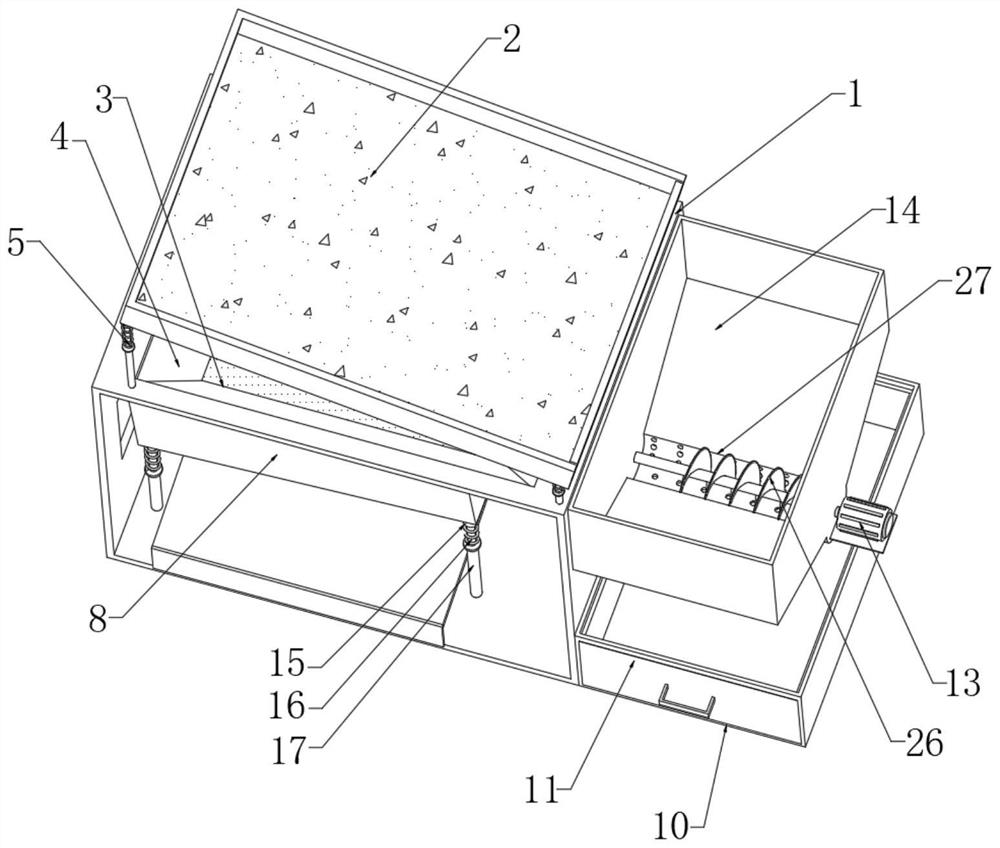

Impurity removing and screening device for clean coal processing

ActiveCN114210544AImprove output rateGuaranteed screening qualitySievingScreeningStructural engineeringBriquette

The invention relates to the technical field of clean coal processing, in particular to an impurity removing and screening device for clean coal processing, which comprises a main frame body, a primary screening mechanism and a secondary screening mechanism are sequentially arranged on the main frame body, and the primary screening mechanism comprises a filtering inclined net cage arranged at the top end of the main frame body; the secondary screening mechanism comprises a filtering inclined net cage, a first vibration guide assembly is arranged on the side, opposite to the main frame body, of the filtering inclined net cage, meshes of the filtering inclined net cage are matched with clean coal briquettes, the secondary screening mechanism comprises a screening net cage, and a second vibration guide assembly is arranged on the side, opposite to the main frame body, of the screening net cage. According to the screening device, the arranged second oval disc can rotate along with the shaft rod, so that the screening net cage is pressed at fixed frequency, and the purpose of improving the screening effect of the screening net cage is achieved; and the arranged first elliptic disc can abut against the arranged side block at a fixed frequency along with rotation of the shaft rod so as to be matched with the arranged connecting spring to drive the vibration discharging plate to vibrate, and therefore screened small impurities are shaken off.

Owner:唐山国华科技国际工程有限公司 +1

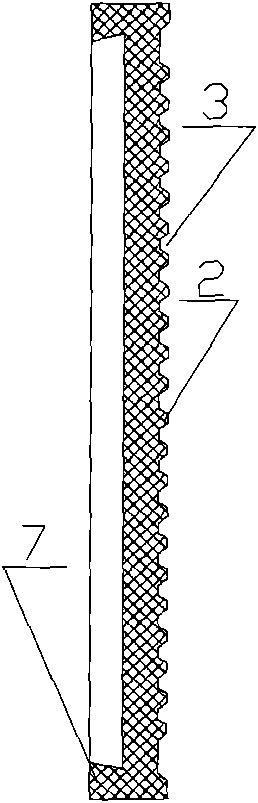

Large grid plate for air pressure filter

InactiveCN101601941ASolution to short lifeTaste effectAlcoholic beverage preparationFiltration separationFood safetyEngineering

The invention relates to a large grid plate for an air pressure filter, which can improve the safety class of food and rice wine taste fundamentally. The surface of a large silicone rubber grid plate forms a concavo-convex liquid-flow surface through multiple cycles of element rests; and the concavo-convex liquid-flow surface is provided with a deflector hole. The large silicone rubber grid plate has the advantages of innocuity, no odor, acid resistance, alkali resistance, high and low temperature resistance, insusceptibility to oxidation and photochemical action and long service life. In addition, the large silicone rubber grid plate not only does not exert any influence on the rice wine taste, but also really retains the original taste and flavor in a rice wine-making process and improves the safety class of the food. The large silicone rubber grid plate improves the squeezing efficiency of squeezed materials effectively to improve the discharging rate of the materials by more than 10 percent and reduces the discharging cost of the squeezed materials effectively. After being discarding as worthless material, the large silicone rubber grid plate can be recycled so as to protect environment.

Owner:杭州余杭新兴过滤机厂

High-efficiency automatic feeding equipment

InactiveCN110817477AImprove output rateAvoid Caton SituationsCleaning using toolsLoading/unloadingDrive shaftElectric machinery

The invention discloses high-efficiency automatic feeding equipment which comprises a charging barrel. The charging barrel is transversely installed. A feeding pipe is perpendicularly welded to the middle of the upper surface of the charging barrel. The two side walls of the charging barrel are each fixedly provided with a barrel cover. A discharging hopper and a fixing frame are welded to the outer walls of the sides, away from each other, of the two barrel covers respectively, the longitudinal section of the fixing frame is in a concave shape, and a motor is fixedly installed at the middle of the outer wall of the side, away from the charging barrel, of the fixing frame. A sealing sleeve is welded between the middles of the outer walls at the two sides of one barrel cover, and a rotatingshaft is perpendicularly and movably connected to the middle of one side wall of the motor through the fixing frame. A nut is arranged on the outer surface of the rotating shaft, and the outer surface of the nut is fixedly sleeved with an annular disc. According to the high-efficiency automatic feeding equipment, the feeding equipment can apply stirring force to materials so as to enhance the practical effect, the discharging rate is increased, and meanwhile materials on the surface of a driving shaft can be cleaned away so as to ensure the smooth effect of conveying.

Owner:苏州吉玛自动化科技有限公司

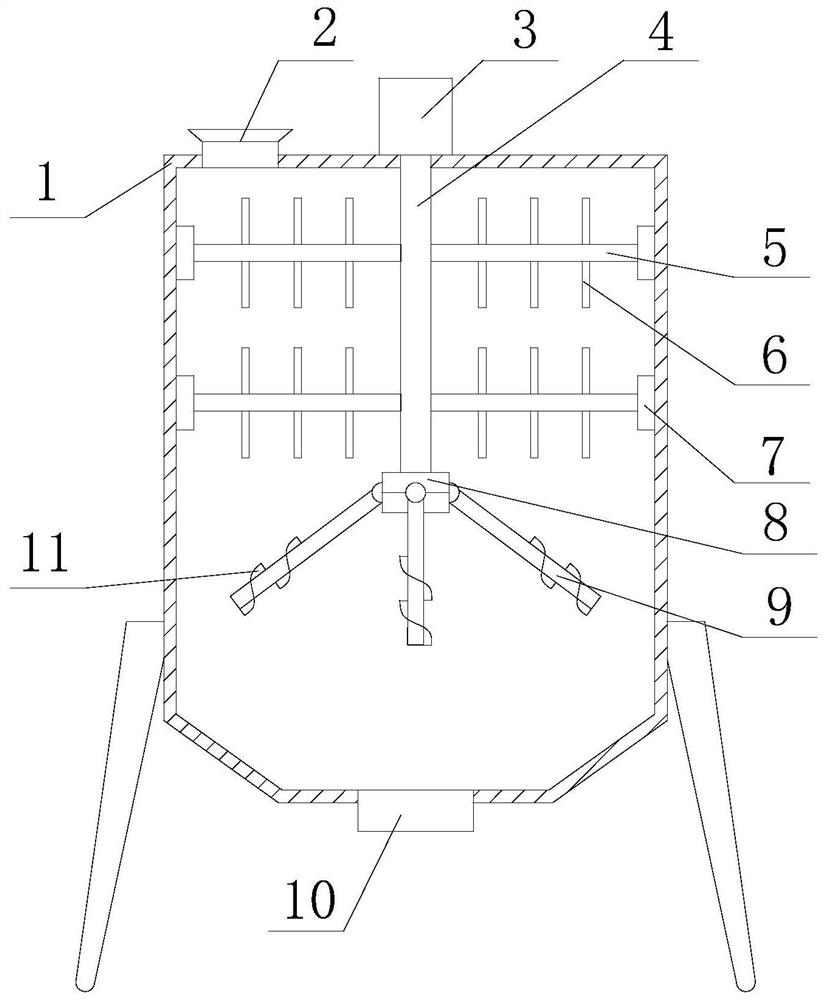

Breaking and refining device for environment-protecting remediation of soil

PendingCN113399052AImprove liquidityEnhance the fineness of crushingHollow article cleaningGrain treatmentsEdaphicAgricultural engineering

The invention discloses a breaking and refining device for environment-protecting remediation of soil, and belongs to the technical field of soil remediation. The breaking and refining device for environment-protecting remediation of the soil comprises a base, wherein the output end of a motor penetrates through the top face of a baffle, extends to the lower portion and is coaxially and fixedly connected with a middle shaft; a plurality of rotating rods are evenly arranged on the outer wall of the middle shaft in an inserted mode at equal intervals, limiting grooves are formed in the positions, corresponding to limiting rings, in an interlayer of the outer wall of the middle shaft, and a plurality of stirring rods are annularly and fixedly arranged at the outer side end of the rotating rods at equal intervals; and a fixing shaft is coaxially arranged in the middle portion of a shaft groove, a plurality of circular discs are linearly arranged outside the fixing shaft in a sleeving mode at equal intervals, a plurality of tooth grooves are annularly formed in the outer walls of the circumferences of the circular discs at equal intervals, and bevel gears are coaxially and fixedly connected to the positions, corresponding to the tooth grooves, of the inner side ends of the rotating rods. According to the breaking and refining device for environment-protecting remediation of the soil, the breaking fineness of the soil can be greatly enhanced, so that dead angles do not exist in the breaking and refining process of the soil inside a refining cylinder, soil refining and breaking work is faster, and more time and labor are saved.

Owner:刘志华

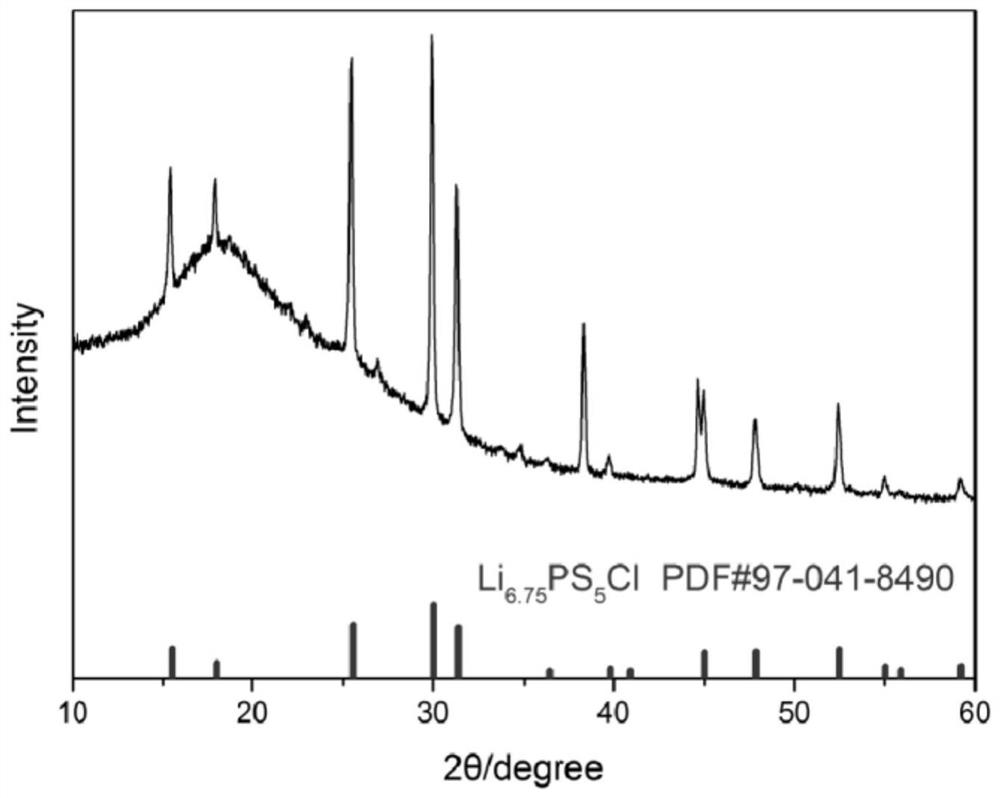

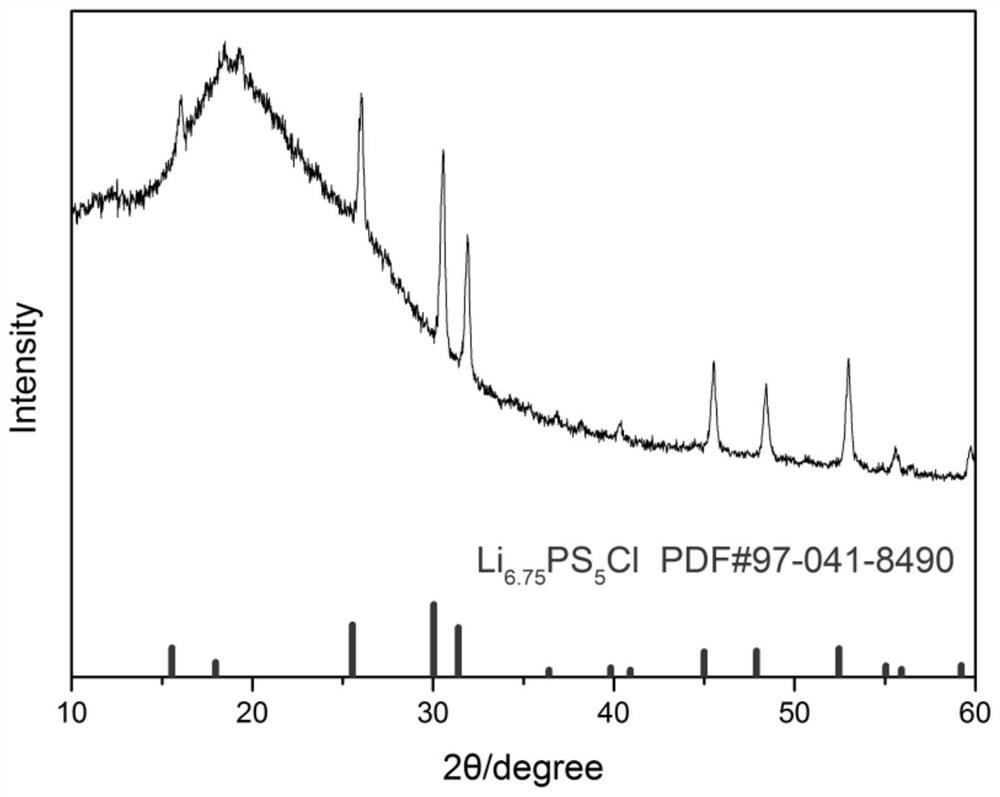

Efficient preparation method of sulfur halide compound solid electrolyte

ActiveCN114163240ASolve the problem that energy input is not as good as dry ball millingPrevent evaporationFinal product manufactureLi-accumulatorsSolid state electrolytePhysical chemistry

The invention discloses a preparation method of an efficient sulfur halide compound solid electrolyte. The preparation method comprises the following steps: weighing Li2S, P2S5 and X-containing lithium salt according to a required stoichiometric ratio; weighing a grinding medium; the preparation method comprises the following steps: adding raw materials into a vacuum ball milling tank, filling argon into the ball milling tank, and performing primary ball milling in a positive pressure state; vacuumizing and heating the ball milling tank, and carrying out secondary ball milling; cooling the ball-milling tank, filling argon, and carrying out third-time ball-milling to obtain uniformly mixed solid electrolyte precursor slurry; drying the solid electrolyte precursor slurry under the protection of an inert atmosphere; and sintering the dried solid electrolyte precursor at high temperature, cooling, grinding and screening to obtain the sulfur halide compound solid electrolyte with high ionic conductivity. The sulfur halide compound solid electrolyte prepared by the invention has relatively high ionic conductivity and a relatively wide electrochemical window. In addition, compared with a traditional preparation method, the method has the potential of large-scale production.

Owner:湖南恩捷前沿新材料科技有限公司

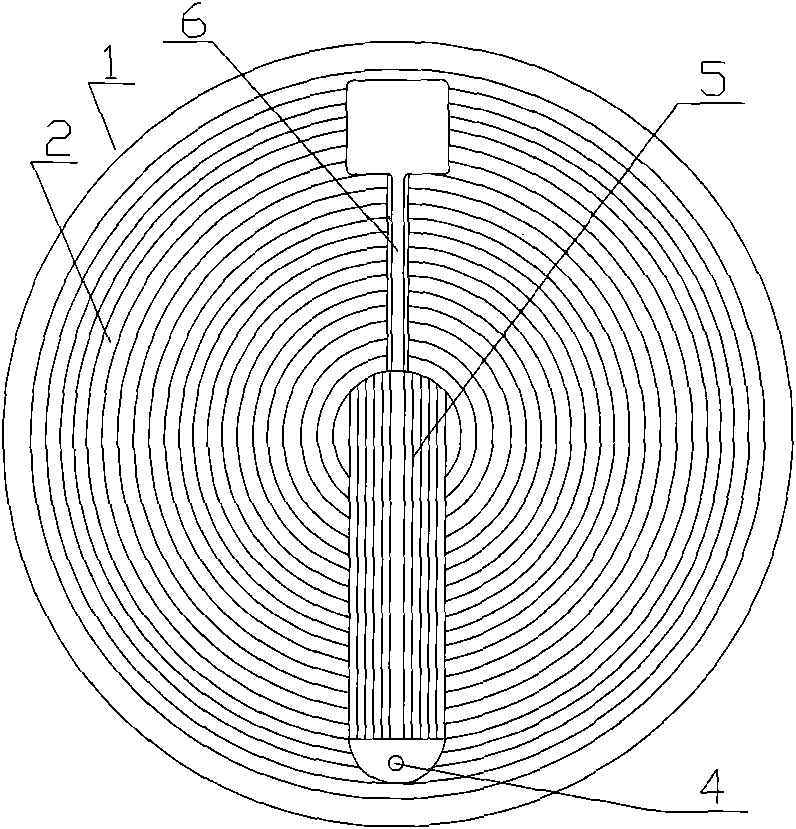

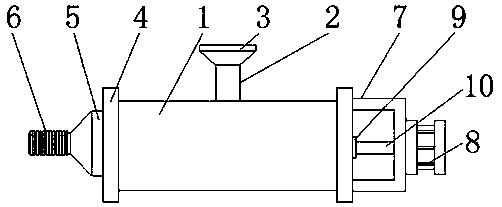

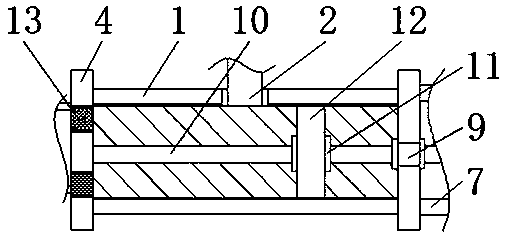

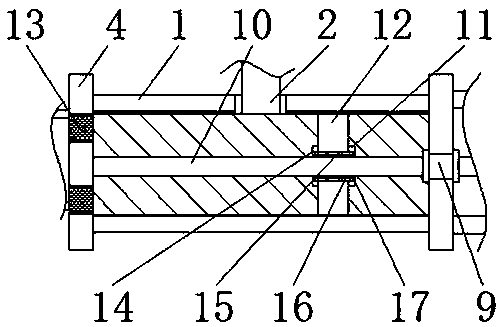

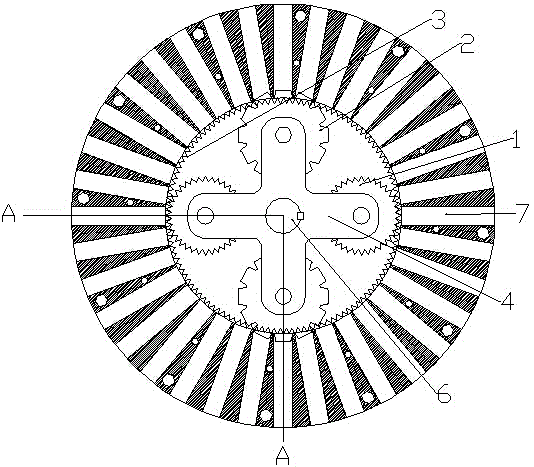

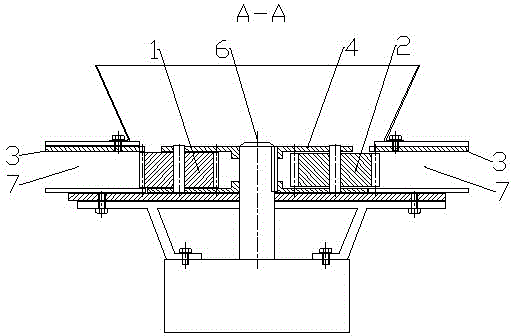

Composite straw forming machine

A composite straw forming machine comprises saw-toothed compression rollers (1), forming compression rollers (2), a saw-toothed compression plate (3), a crisscross connecting plate (4), a power shaft (6), and an extrusion die (7). The composite straw forming machine is characterized in that an extrusion forming component and a shearing pre-compression component are disposed at the same time, the power shaft (6) is vertically disposed at the center of the extrusion die, the crisscross connecting plate (4) is horizontally disposed on the power shaft (6), two forming compression rollers (2) are symmetrically disposed on the crisscross connecting plate (4), two saw-toothed compression rollers (1) are symmetrically disposed on the crisscross connecting plate (4), the saw-toothed compression plate (3) is horizontally disposed on the upper portion of the extrusion die (7), and the power shaft (6) drives the crisscross connecting plate (4), the forming compression rollers (2) and the saw-toothed compression rollers (1) to rotate. The composite straw forming machine has the advantages that raw materials are sheared and rolled by the saw-toothed compression rollers and the saw-toothed compression plate first, raw material adaptability is increased, reactive power loss is reduced, abrasion of forming parts is lowered, and forming effect is improved.

Owner:YANCHENG SILU INFORMATION TECH SERVICE CO LTD

Mixing and stirring device for concrete preparation

PendingCN114161578AStir wellReduce lossCement mixing apparatusElectric machineStructural engineering

The invention discloses a mixing and stirring device for concrete preparation, and belongs to the technical field of concrete preparation, the mixing and stirring device comprises a stirring tank, a driving motor is arranged on the stirring tank, a rotating rod connected with the driving motor is arranged in the stirring tank, and a first stirring rod is horizontally arranged on the rotating rod; a connecting block is arranged at the free end of the rotating rod, and a second stirring rod is hinged to the connecting block; a stirring insertion strip is arranged on the first stirring rod, and the stirring insertion strip is perpendicular to the first stirring rod; stirring blades are arranged on the second stirring rod. The multi-angle stirring device can realize multi-angle stirring, so that the stirring is more uniform, and the stirring efficiency is improved.

Owner:天津市统建混凝土有限公司

A kind of thermal insulation mortar and preparation method thereof

The invention discloses a preparation method of high-strength thermal insulation mortar, and belongs to the technical field of building material preparation. The preparation method comprises the following steps: S1, mixing Portland cement, fly ash, limestone powder, polystyrene particles, bentonite, a thickening agent, heavy calcium carbonate powder, a tackifier and carboxyethyl methyl cellulose in parts by weight, and uniformly stirring to obtain slurry; S2, adding lauryl sodium sulfate into the slurry while stirring, stirring for 10 to 15min, and standing for 30 to 60min; and S3, adding calcium fluoride, a styrene-maleic anhydride copolymer or an organic silicon-polyurethane copolymer, sodium carbonate and hydrochloric acid on the basis of the step S2, and performing uniform stirring with a stirrer so as to obtain the high-strength thermal insulation mortar. The high-strength thermal insulation mortar can improve the compressive strength and reduce the dry apparent density, the heatconductivity coefficient and the volume water absorption rate.

Owner:东至安东祥源新型建材有限公司

A construction concrete preparation sand and gravel screening machine

ActiveCN113634349BImprove output rateSolve the problem of low outputGrain treatmentsArchitectural engineeringMechanical engineering

The invention relates to the technical field of building concrete, in particular to a screening machine for preparing sand and gravel from building concrete, which includes a base, an auxiliary separation device and a crushing and filtering device. In the separation device; the present invention improves the discharge rate of fine sand and gravel by first crushing the cohesive group of sand and gravel and then grinding and pulverizing the oversized sand and gravel, thereby solving the problem that the direct screening method cannot completely remove the sand and gravel. The problem of separation and low output of high-performance concrete; the invention adopts the method of winnowing and discharging, so that the materials that do not meet the size of the screening particles will not be stuck by the mesh due to extrusion, and the materials will be screened again by raising dust again Separate the material, so as to solve the problem of low efficiency of winnowing and screening.

Owner:睢宁县泰宁建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com