Impurity removing and screening device for clean coal processing

A screening device and coal processing technology, applied in the fields of screening, solid separation, chemical instruments and methods, etc., to achieve the effect of improving the screening effect, increasing the discharge rate, and ensuring the screening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

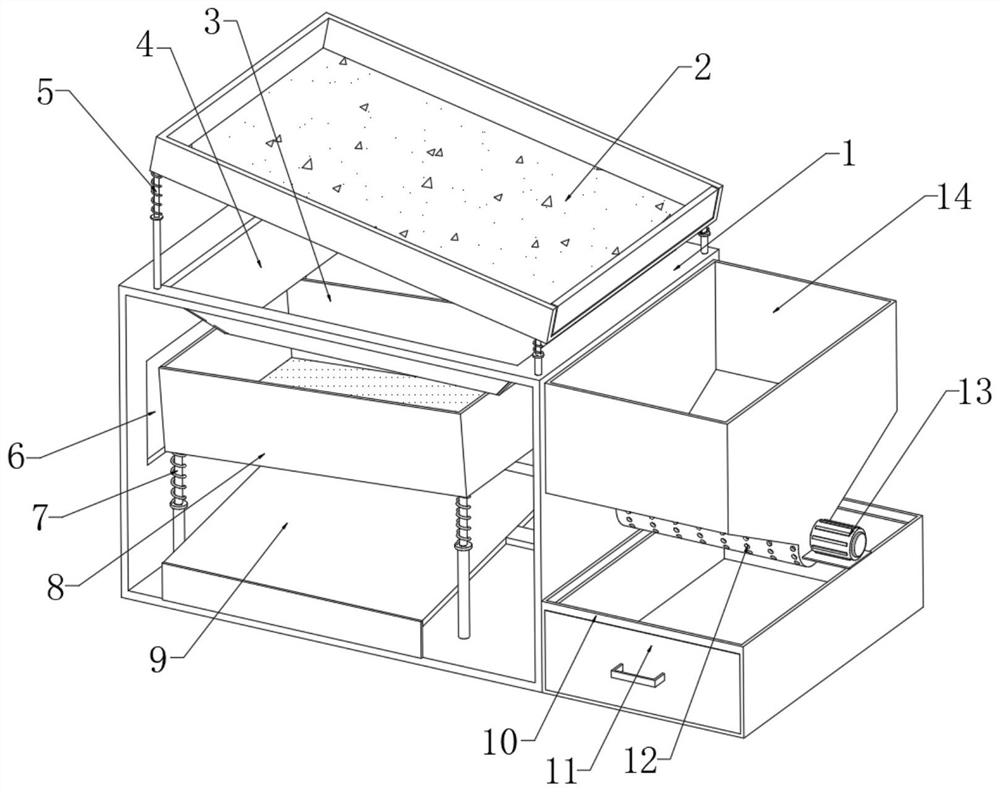

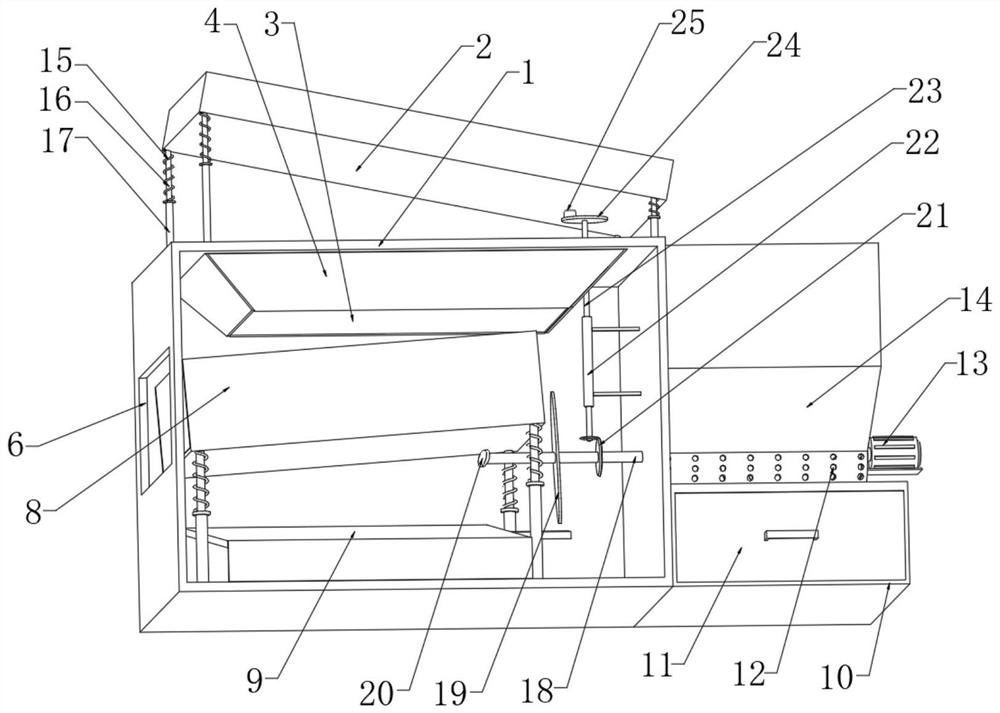

[0038] Such as Figure 1-Figure 6 As shown, an impurity removal and screening device for clean coal processing includes a main frame body 1, on which a primary screening mechanism and a secondary screening mechanism are sequentially arranged, and the primary screening mechanism includes a main frame body 1, the filter inclined net box 2 at the top, and the opposite side of the filter inclined net box 2 and the main frame body 1 is provided with a vibration guide assembly-5, the mesh of the filtered inclined net box 2 is compatible with the clean coal block, and the secondary The screening mechanism includes a screening net box 8, and the opposite side of the screening net box 8 and the main frame body 1 is provided with a vibration guide assembly 2 7, the sieve hole of the screening net box 8 is smaller than the clean coal block, and the main frame body 1 One side is provided with a lump coal processing mechanism, and the opposite side of the lump coal processing mechanism and...

Embodiment 2

[0048] Based on the impurity removal and screening device for clean coal processing provided in the first embodiment of the application, the second embodiment of the application proposes another impurity removal and screening device for clean coal processing. The second embodiment is only a preferred manner of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0049] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

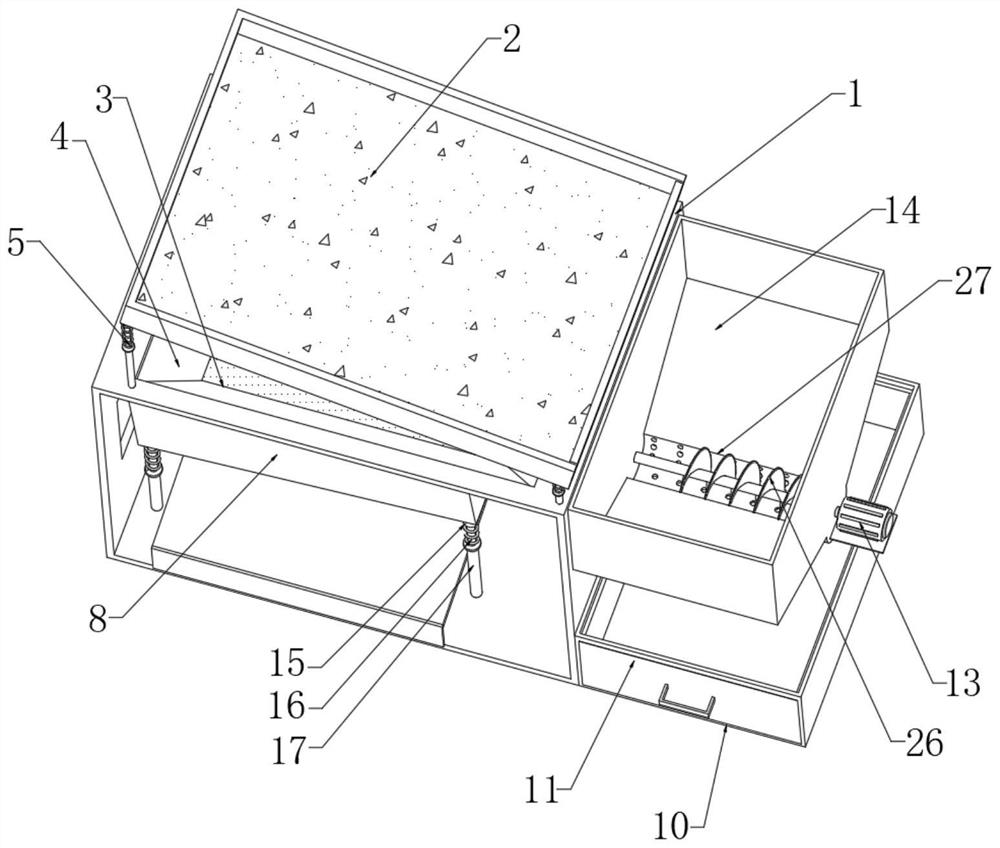

[0050] Such as Figure 7-Figure 9 As shown, in the second embodiment, the top outer wall of the vibrating blanking plate 9 is fixedly connected with a plurality of material guide plates 901, and both ends of the first elliptical plate 19 and the second elliptical plate 20 are provided with installation cavities. Both are rotatably connected with a pulley 32; by means of the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com