Composite straw forming machine

A molding machine and composite technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of high failure rate, high energy consumption, low production capacity of molding machines, etc., to reduce wear and improve molding rate. and discharge rate, the effect that is conducive to feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

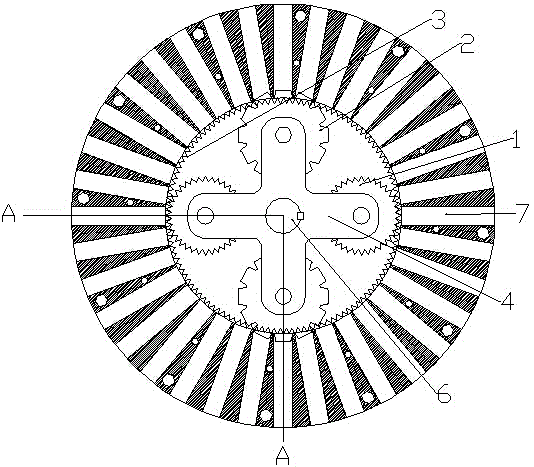

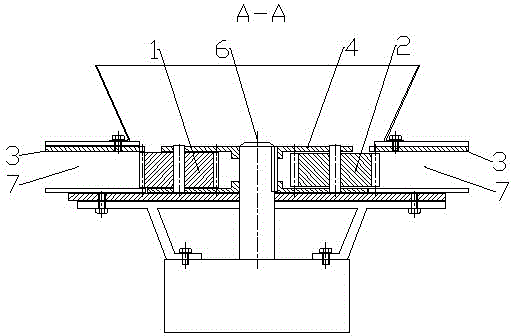

[0009] exist figure 1 , figure 2 In the process, the extrusion molding component and the shearing preloading component are set at the same time: the power shaft 6 is vertically set in the center of the extrusion die 7, the cross-shaped connecting plate 4 is horizontally set on the power shaft 6, and the cross-shaped connecting plate 4 is symmetrically set Two forming pressure rollers 2 and two sawtooth pressure rollers 1; a sawtooth pressure plate 3 is arranged horizontally on the upper part of the extrusion die 7, and the power shaft 6 drives the cross-shaped connecting plate 4, the forming pressure roller 2, and the sawtooth pressure roller 1 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com