Cashmere separating device

A separation device, cashmere technology, applied in textiles and papermaking, fiber processing, fiber cleaning machines, etc., can solve problems such as difficult handling, inconvenient movement, and wear of motor shafts or cams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

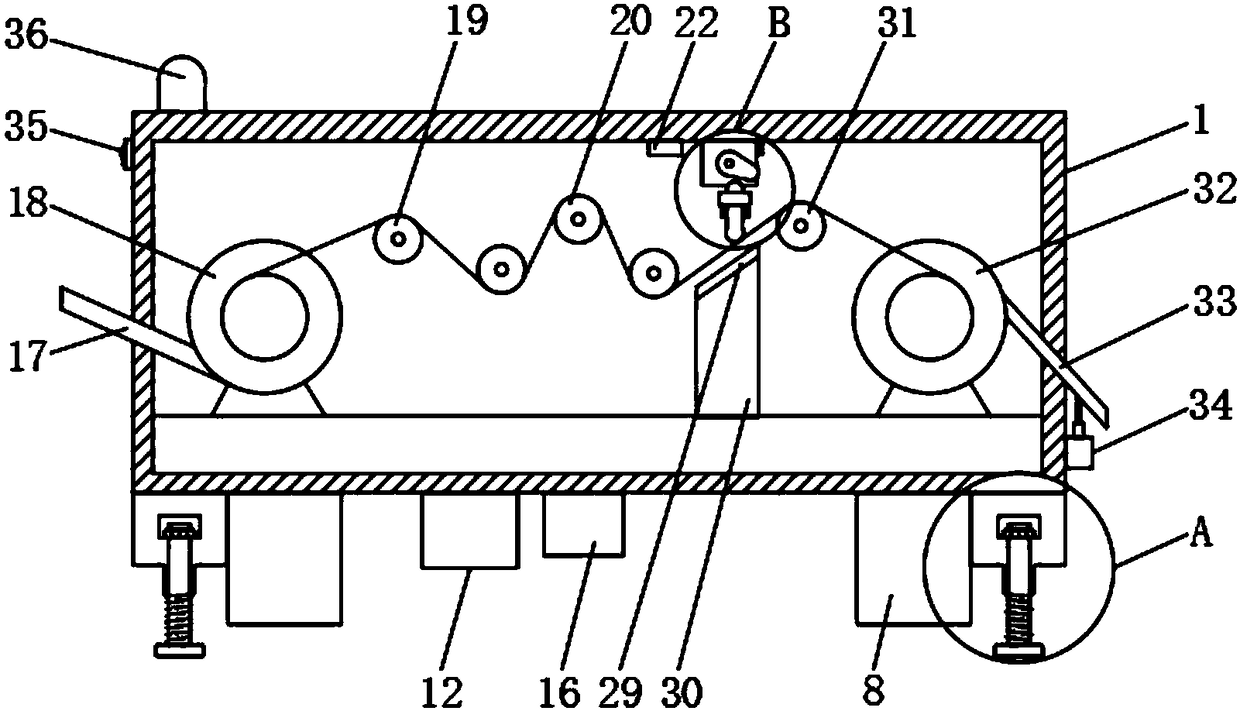

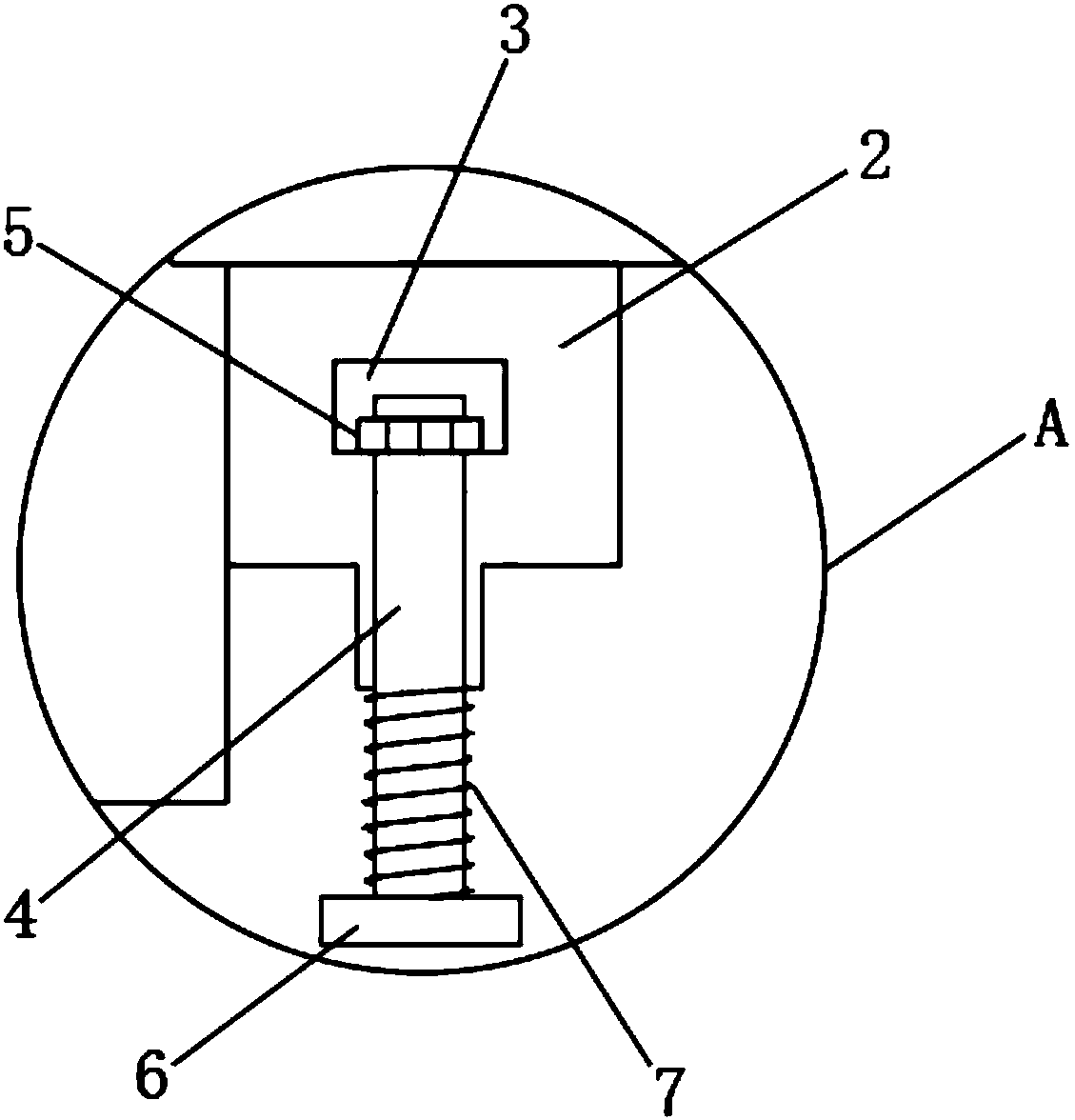

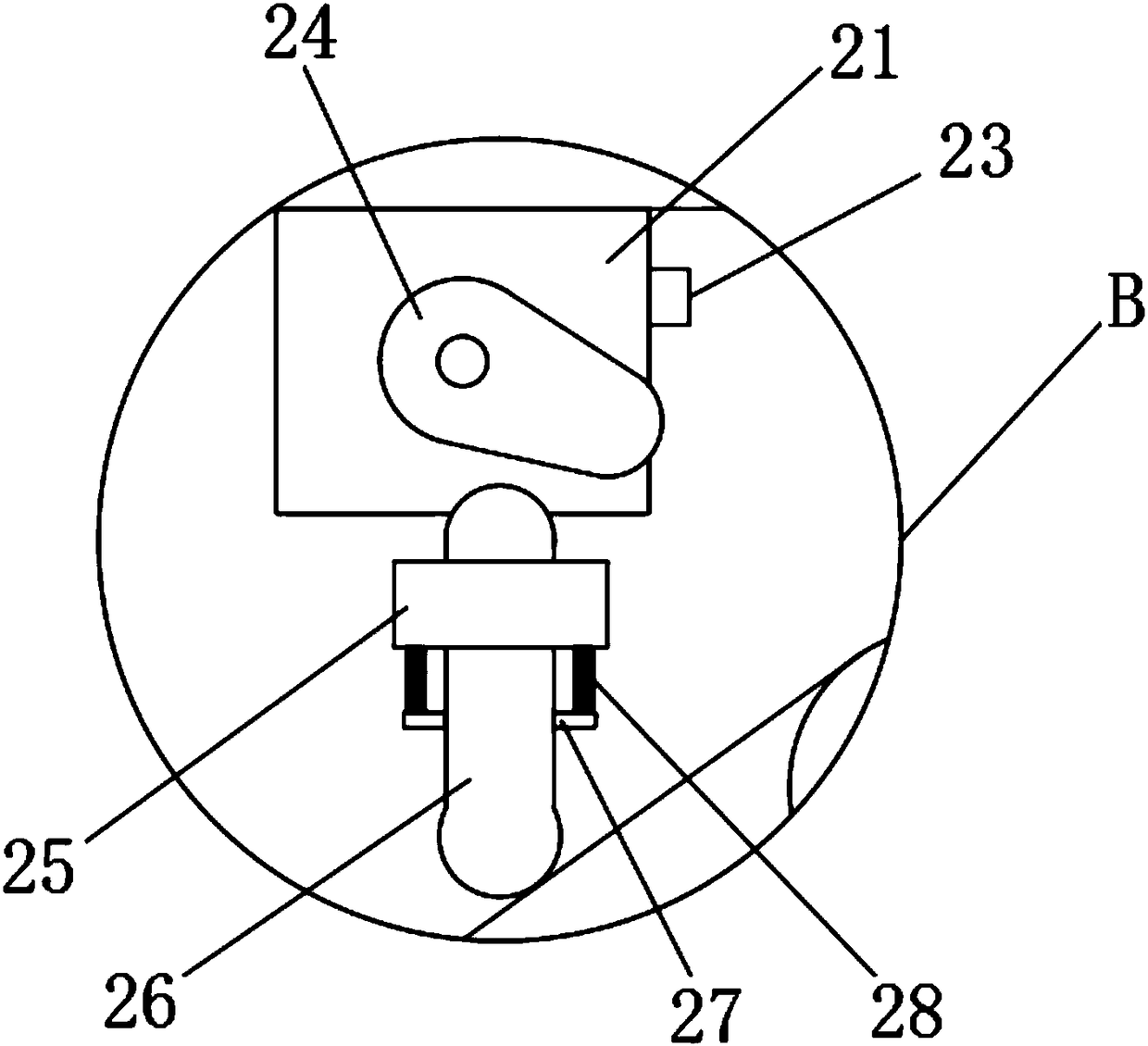

[0022] see Figure 1-5 , the present invention provides a technical solution: a cashmere separation device, including a device body 1, a connecting block 2, a groove 3, a support rod 4, a bolt cap 5, a support plate 6, a shock absorbing spring 7, a leg 8, an inner Groove 9, hydraulic cylinder 10, pulley 11, hydraulic station 12, servo motor 13, two-way gear pump 14, hydraulic oil tank 15, air compressor 16, feed port 17, cashmere fiber output part 18, output roller 19, cashmere fiber pull Extension 20, transmission motor 21, displacement sensor 22, PLC controller 23, cam 24, axle sleeve 25, screw mandrel 26, connecting erbium 27, return spring 28, electrostatic adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com