High-efficiency automatic feeding equipment

A feeding equipment and high-efficiency technology, applied in the field of high-efficiency automatic feeding equipment, can solve the problems of low discharge rate, surface material cleaning that cannot drive the shaft, stuck, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

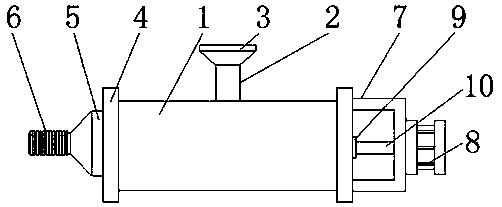

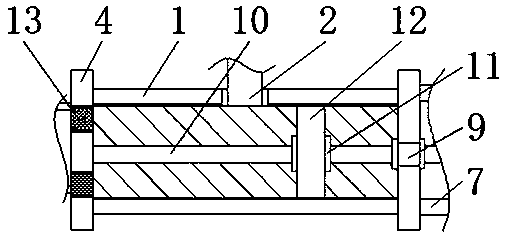

[0023] refer to Figure 1-2 , a high-efficiency automatic feeding equipment, including a barrel 1, the barrel 1 is installed horizontally, and the middle position of the upper surface of the barrel 1 is vertically welded with a feed pipe 2, and the two side walls of the barrel 1 are fixedly installed with a barrel Cover 4, the two groups of cylinder covers 4 are welded with a hopper 5 and a fixing frame 7 on the side of the outer wall that is far away from each other. A motor 8 is installed in a fixed position, and a sealing sleeve 9 is welded between the middle positions of the outer walls on both sides of a group of cylinder covers 4, and the middle position of the side wall of the motor 8 is vertically movably connected with a rotating shaft 10 through a fixed frame 7, and the outer parts of the rotating shaft 10 A screw sleeve 11 is arranged on the surface, and an annular disc 12 is fixedly sleeved on the outer surface of the screw sleeve 11 .

[0024] Wherein, the lower ...

Embodiment 2

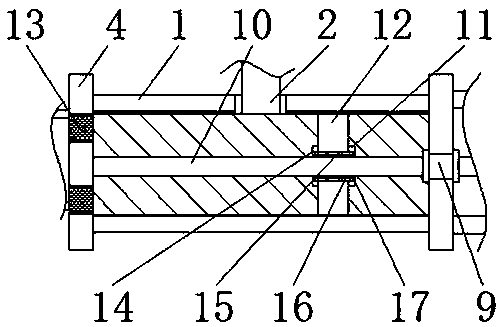

[0031] refer to figure 1 image 3 , a high-efficiency automatic feeding equipment, including a barrel 1, the barrel 1 is installed horizontally, and the middle position of the upper surface of the barrel 1 is vertically welded with a feed pipe 2, and the two side walls of the barrel 1 are fixedly installed with a barrel Cover 4, the two groups of cylinder covers 4 are welded with a hopper 5 and a fixing frame 7 on the side of the outer wall that is far away from each other. A motor 8 is installed in a fixed position, and a sealing sleeve 9 is welded between the middle positions of the outer walls on both sides of a group of cylinder covers 4, and the middle position of the side wall of the motor 8 is vertically movably connected with a rotating shaft 10 through a fixed frame 7, and the outer parts of the rotating shaft 10 A screw sleeve 11 is arranged on the surface, and an annular disc 12 is fixedly sleeved on the outer surface of the screw sleeve 11 .

[0032] Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com