Tail gas waste heat utilization device in aluminium polychlorid production and method

A technology of polyaluminum chloride and exhaust gas, which is applied in the direction of aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of reducing cost, reducing waste gas, and improving output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

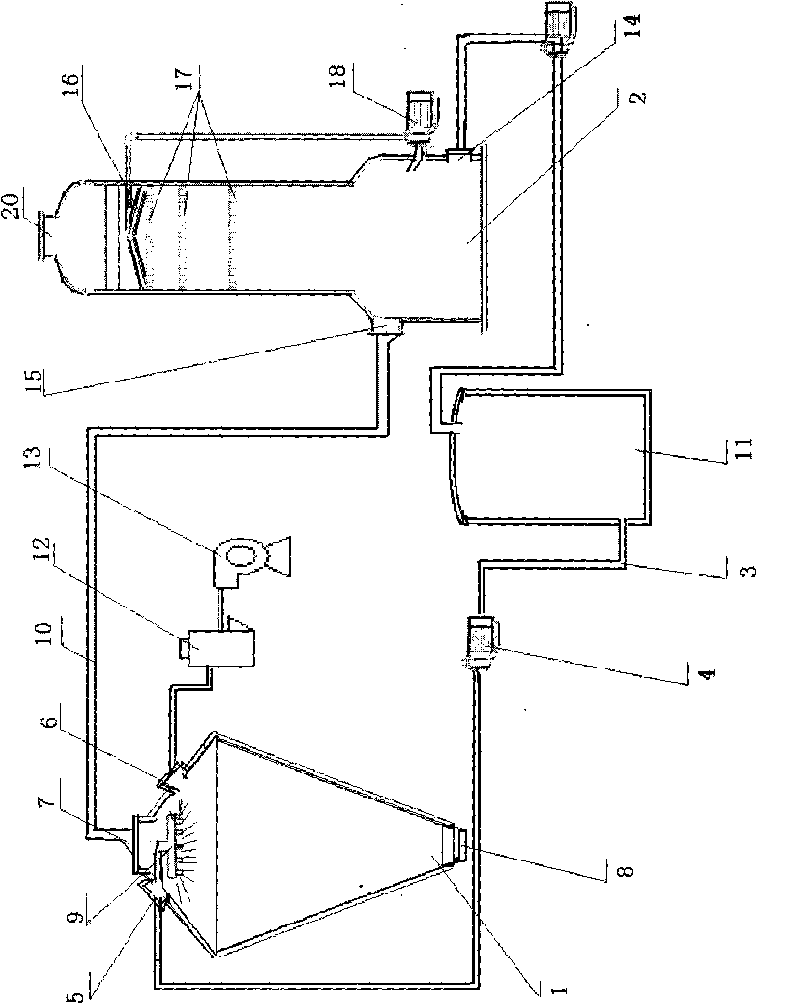

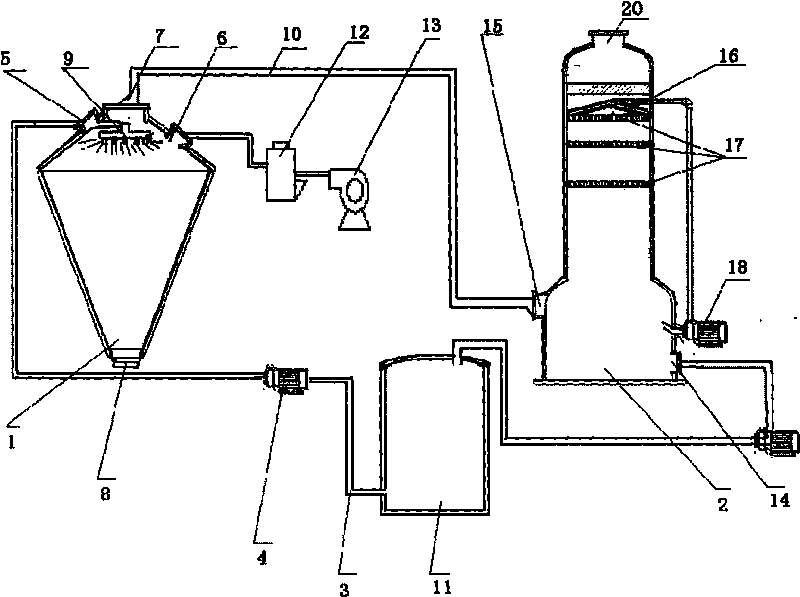

[0012] As shown in the accompanying drawings: a utilization device for the waste heat of tail gas in the production of polyaluminum chloride, which is composed of the drying part of the liquid material of polyaluminum chloride, and is characterized in that; the drying part of the liquid material is provided with a drying tower (1) and a tail gas. The absorption tower (2) and the tail gas absorption tower (2) are provided with a tail gas residual material recovery and waste heat reuse device.

[0013] The above-mentioned drying tower (1) is provided with a liquid material inlet (5), a hot air outlet (6), a tail gas outlet (7) and a solid material outlet (8); an atomizer is provided in the drying tower (1) (9), which is connected with the liquid material inlet (5), and the liquid material inlet (5) is connected with the liquid material storage tank (11); the hot air port (6) is supplied with hot air by the combustion furnace (12) and the blower (13).

[0014] The tail gas absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com