Patents

Literature

176results about How to "Taste effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot pot bottom material and its preparation method and use method

The invention belongs to the field of food, and particularly relates to a hotpot seasoning as well as a preparation method and using method thereof. The invention provides a hotpot seasoning which can ensure the seasoning mouthfeel and avoid inflammation symptom after being eaten. The peppery hotpot seasoning provided by the invention contains major ingredient, seasoning accessories, spice accessories and oil, wherein the major ingredient is black bean sauce; the seasoning accessories comprise ginger, green onion, garlic, hot pepper, pepper, fermented blank bean and crystal sugar; and oil is any one of colza oil and blend oil or a mixture of colza oil and blend oil. The seasoning provided by the invention is characterized in that the seasoning accessories consist of Chinese traditional medicine bulk pharmaceutical chemicals with heat clearing and detoxicating function and common spice, wherein the key Chinese traditional medicine bulk pharmaceutical chemicals consists of the following components in parts by weight: 4-6 parts of isatis root, 2-5 parts of chrysanthemum, 0.5-1.5 parts of rhubarb, 8-12 parts of mint, 6-10 parts of dried tangerine peel, 3-5 parts of semen cassiae and 5-6 parts of houttuynia cordata. The hotpot seasoning provided by the invention not only has spicy and fresh mouthfeel, but also can avoid the inflammation symptom after being eaten; and the food material has fresh taste and long-lasting hot, sweet and peppery flavor.

Owner:龚国华

Application of L-arabinopyranose as dealcoholic agent

Owner:SHENGQUAN HEALTANG

Lactose-free milk preparation method based on separation membrane technologies

The invention discloses a lactose-free milk preparation method based on separation membrane technologies, in which the four membrane technologies of microfiltration, ultrafiltration, electrodialysis and nanofiltration are coupled. The method includes the steps that firstly, most components in milk are intercepted through microfiltration and ultrafiltration, a penetrating solution is an aqueous solution containing lactose and inorganic salt, and after the inorganic salt is recovered by electrodialysis, desalinated liquid containing lactose and a small amount of inorganic salt is obtained; then,the desalinated liquid is subjected to nanofiltration separation to intercept lactose, and thus lactose removal is completed; components except lactose are recombined to obtain lactose-free milk powder through spray drying. By means of the method, the lactose interception rate reaches up to 95.85%; the production of the lactose-free milk powder is realized; meanwhile, water added in the production process can be effectively recovered and reused, lactose is also recovered by nanofiltration, and thus the method can guarantee that the whole process is environmentally friendly and free of by-product generation and raw material waste; besides, no chemical substance is added in the process, and thus the taste of milk will not be affected.

Owner:ZHEJIANG UNIV OF TECH

Production method of green tea

InactiveCN105341200AInhibits enzymatic oxidationPromote formationPre-extraction tea treatmentGreen teasEngineering

The invention discloses a production method of a green tea. The production method comprises the following specific steps of withering with hot blast: uniformly spreading a thin layer of picked fresh leaves on a withering trough, wherein the leaf spreading thickness is 5cm, and the withering temperature is 60-70 DEG C, so that the fresh leaves are uniformly and consistently withered, and compared with the fresh leaves which are picked a moment ago, the mass loss of the tea leaves is 20-25% in percentage by mass; fixation with hot blast: placing the withered fresh leaves with hot blast in a roller fixation machine, wherein the roller temperature is 350-380 DEG C, the fixation time is 3-5s, 500-600kg of the leaves are put, and compared with the tea leaves which are picked a moment ago, the water loss of the tea leaves is 65-70% in percentage by mass; then, sequentially performing the following operation steps of spreading the fresh leaves after fixation for the first time so that the fresh leaves after the fixation are cooled, performing resurgence on the cooled fresh leaves, tidying tea strips, performing depilation, spreading the fresh leaves after the depilation for the second time so that the fresh leaves after the depilation are cooled, performing resurgence on the fresh leaves, shaping the tea leaves, baking the shaped tea leaves, sorting the baked tea leaves, flavor distilling and the like; and limiting the corresponding technological parameters, and improving the fragrance and the taste of the green tea. The operation step sequence is reasonably designed, and the activity of oxidase in fresh tea leaves is destroyed at high temperature and inactivated, so that the tea leaves are soft, and give out delicate fragrance, which is favorable for the formation of the fragrance of the tea leaves.

Owner:泸州市天绿茶厂

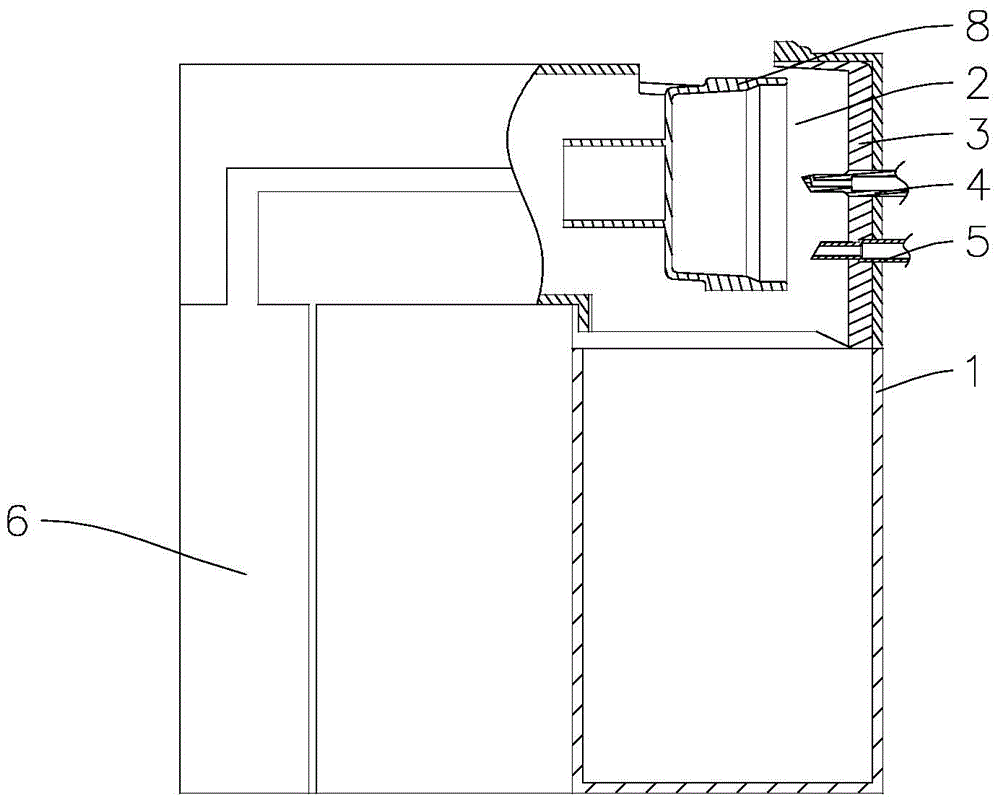

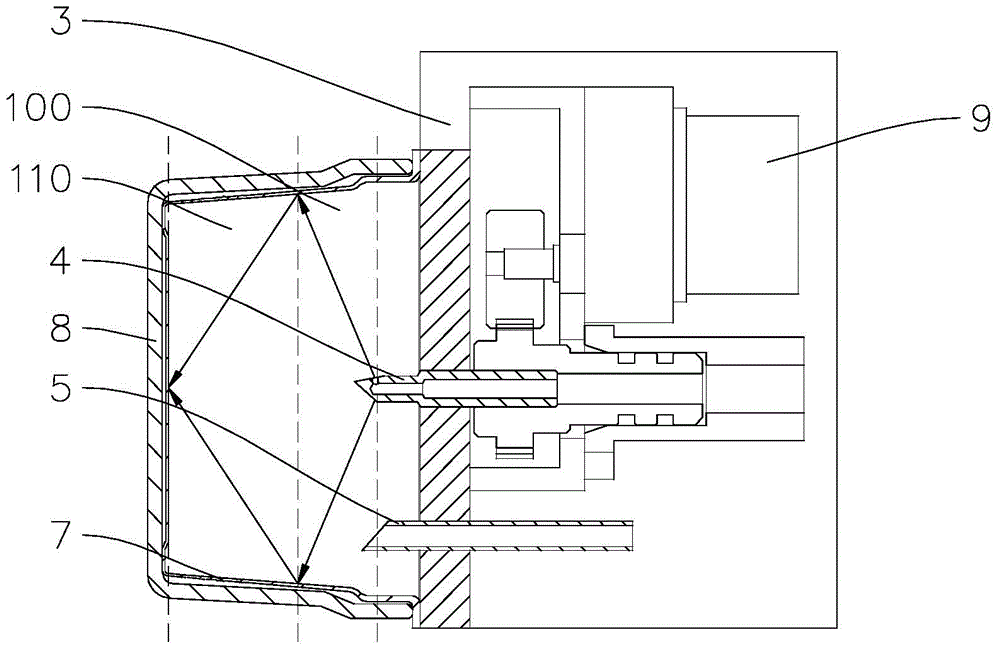

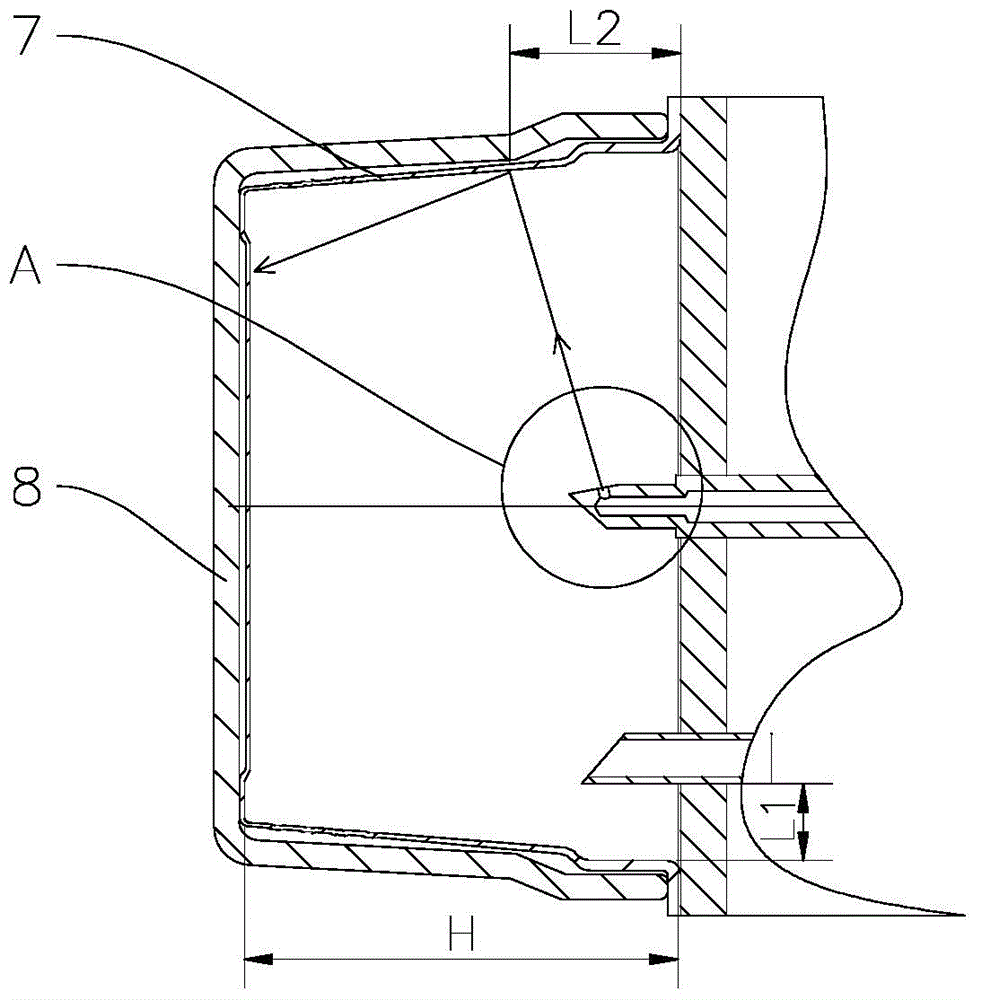

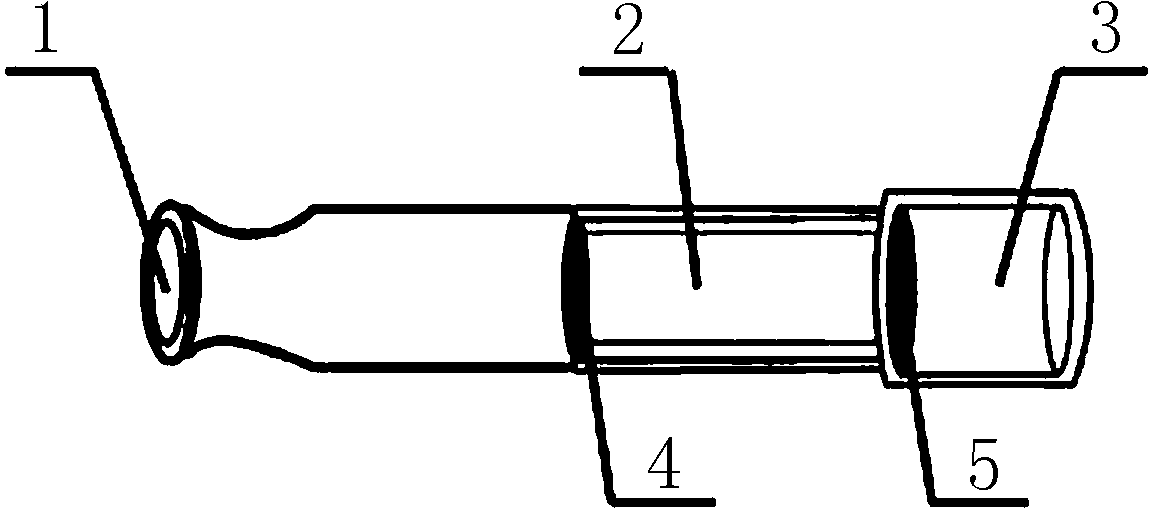

Beverage making method of horizontal type rotation beverage making machine

The invention discloses a beverage making method of a horizontal type rotation beverage making machine. The beverage making machine comprises a machine base with a brewing cavity, a brewing head, a water inlet pricking needle arranged at the brewing head, a leading-out pricking needle arranged at the brewing head, a liquid supply mechanism for supplying liquid to the brewing head and a brewing cup for containing a material bag; and one end of the brewing head is connected with the liquid supply mechanism, and the other end of the brewing head supplies the liquid to the interior of the material bag. The beverage making method includes the water inlet step, the making step and the beverage discharging step; a driving device is additionally used in the making step to drive the water inlet pricking needle to rotate, so that a jet flow area is formed by the water inlet pricking needle, beverage powder is flushed by liquid flow in the jet flow area so as to be mixed and dissolved, and therefore mixing dissolution of the liquid and the beverage powder is quickened; in addition, the beverage powder is sufficiently dissolved, residues are avoided, and the taste and the nutritive value of a beverage are improved; meanwhile, the rotation jet flow motion is formed by the water inlet pricking needle in the rotation process, dissolution of the beverage powder is better promoted, and the making efficiency and the taste of the beverage are improved.

Owner:JOYOUNG CO LTD

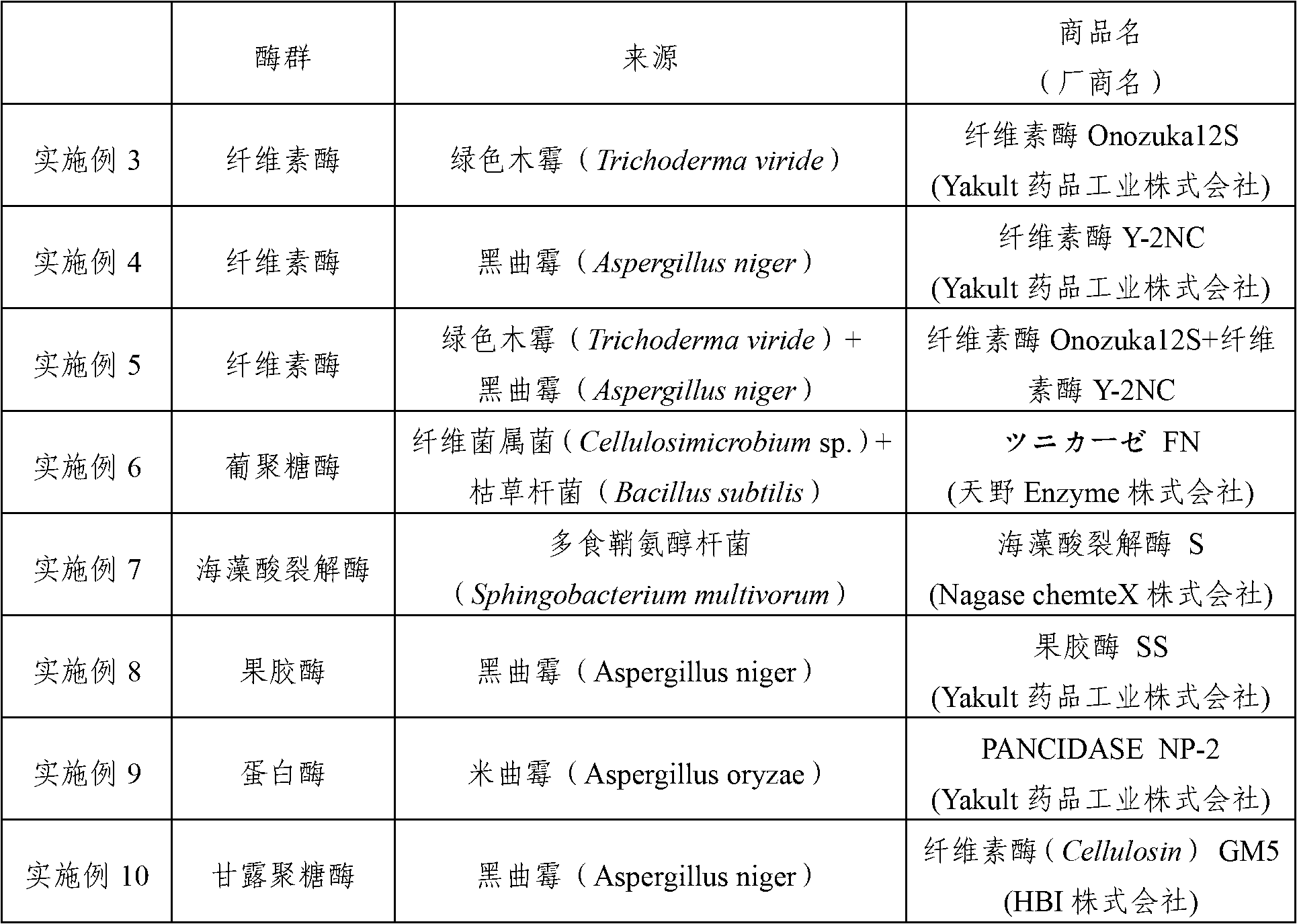

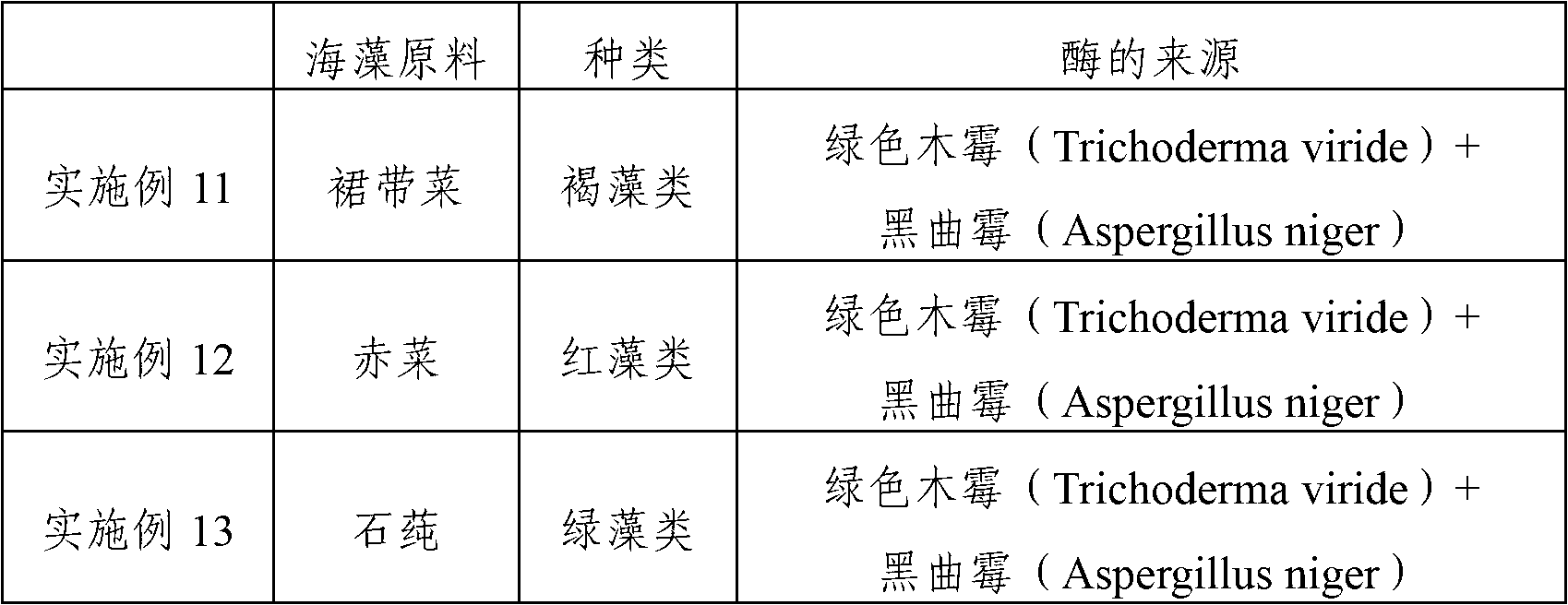

Taste-improving agent for potassium-chloride-containing foods and beverages and process for producing potassium-chloride-containing foods and beverages

Provided is a taste-improving agent for potassium-chloride-containing foods and beverages that is capable of effectively improving the unfavorable taste typical of potassium chloride, such as bitterness and acridity, without negatively affecting the taste of such foods and beverages. Also provided is a process for producing highly-palatable potassium-chloride-containing foods and beverages having reduced bitterness and acridity of potassium chloride. The process involves the use of enzyme-decomposed seaweed, which is obtained by decomposing seaweed with an enzyme, in order to improve the taste of potassium-chloride-containing foods and beverages. The enzyme-decomposed seaweed is preferably a product obtained by decomposing seaweed with at least one type of enzyme selected from the group consisting of cellulase, glucanase, pectinase, alginate lyase, mannanase, and protease.

Owner:YAIZU SUISAN KAGAKU KOGYO CO LTD

Production method of maofeng

InactiveCN105285186AAvoid Thermal Inertia ProblemsQuality improvementPre-extraction tea treatmentBiotechnologyPhenolic content in tea

The invention discloses a production method of maofeng. A specific method of operation comprises the steps of hot air withering: picked fresh leaves are uniformly and thinly spread in a withering trough, wherein the thickness of the spread leaves is not less than 10cm, the withering temperature is 60 to 70 DEG C, the withering of the fresh leaves is enabled to be uniform, compared with the picked fresh leaves, the water loss of tea is 20 to 25 percent in percentage by weight; hot air deactivating: fresh leaves treated by hot air withering are put into a cylinder deactivatingmachine, wherein the temperature of a cylinder is 350 to 380 DEG C, the deactivatingtime is 3 to 5s; then sorting, rolling, deblocking, tea strip tidying for the first time, tea strip tidying for the second time, drying for the first time, spreading and airing and drying for the second time are performed in sequence, technological parameters of production process steps are reasonably designed, and the influence on aroma and quality of taste of the maofeng is effectively avoided; the sequence of operation steps of the maofeng is reasonably designed, a hot air deactivatingstep is performed after hot air withering is treated, enzymatic oxidation of TP (tea polyphenol) and the like in the fresh leaves is inhibited, and the effect of improving maofeng tea quality is achieved.

Owner:泸州市天绿茶厂

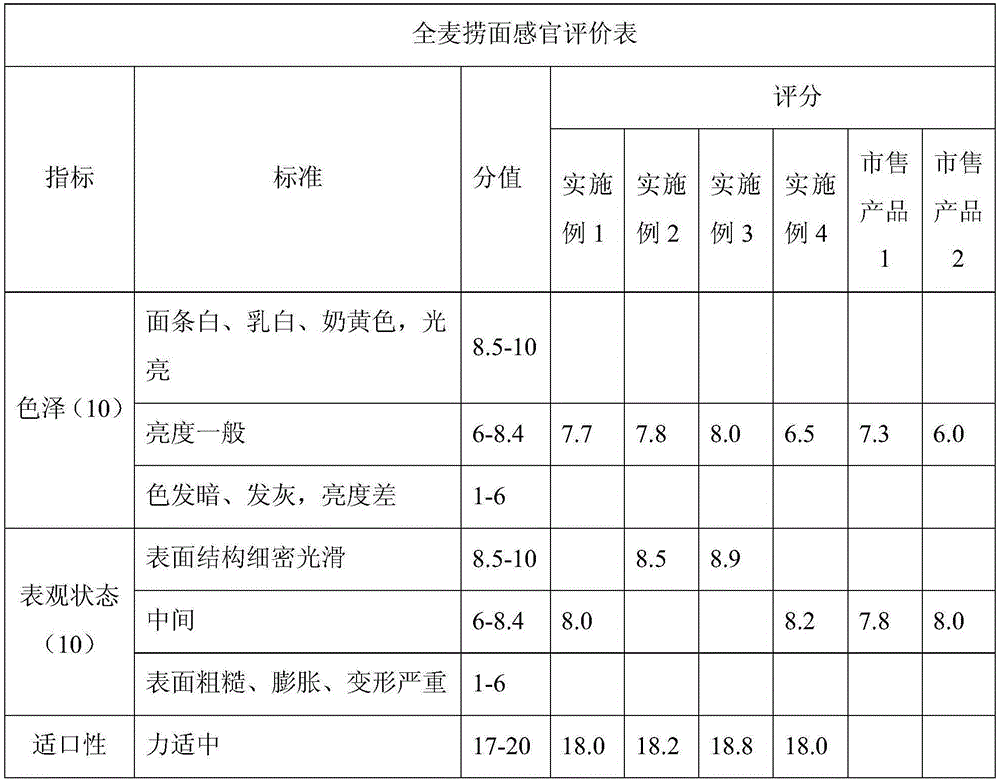

Poison-reducing body-building cigarette filter

ActiveCN103892464AEasy to prepareWide range of medicinesTobacco pipesActivated carbonCigarette filter

The invention relates to a cigarette filter which comprises a cigarette holder tail end and a cigarette inserting end. A composite filter element is arranged between the cigarette holder tail end and the cigarette inserting end. The composite filter element is fixed by two grids and internally provided with a filtering agent which is formed by mixing traditional Chinese medicine effective components and activated carbon, wherein the weight ratio of the traditional Chinese medicine effective components to the activated carbon is 0.3 to 1:2. According to the cigarette filter, the effective components of traditional Chinese medicine are effectively extracted with multiple manners, the activated carbon is combined and used for cigarette holder filtering, hazardous substances in cigarette main stream smoke can be reduced, hazards of smoking is relieved, and particularly substances such as phenol and ammonia in the cigarette main stream smoke are obviously reduced, the taste of cigarettes is not affected obviously, and the application range is wide.

Owner:山东恒昌聚材化工科技股份有限公司

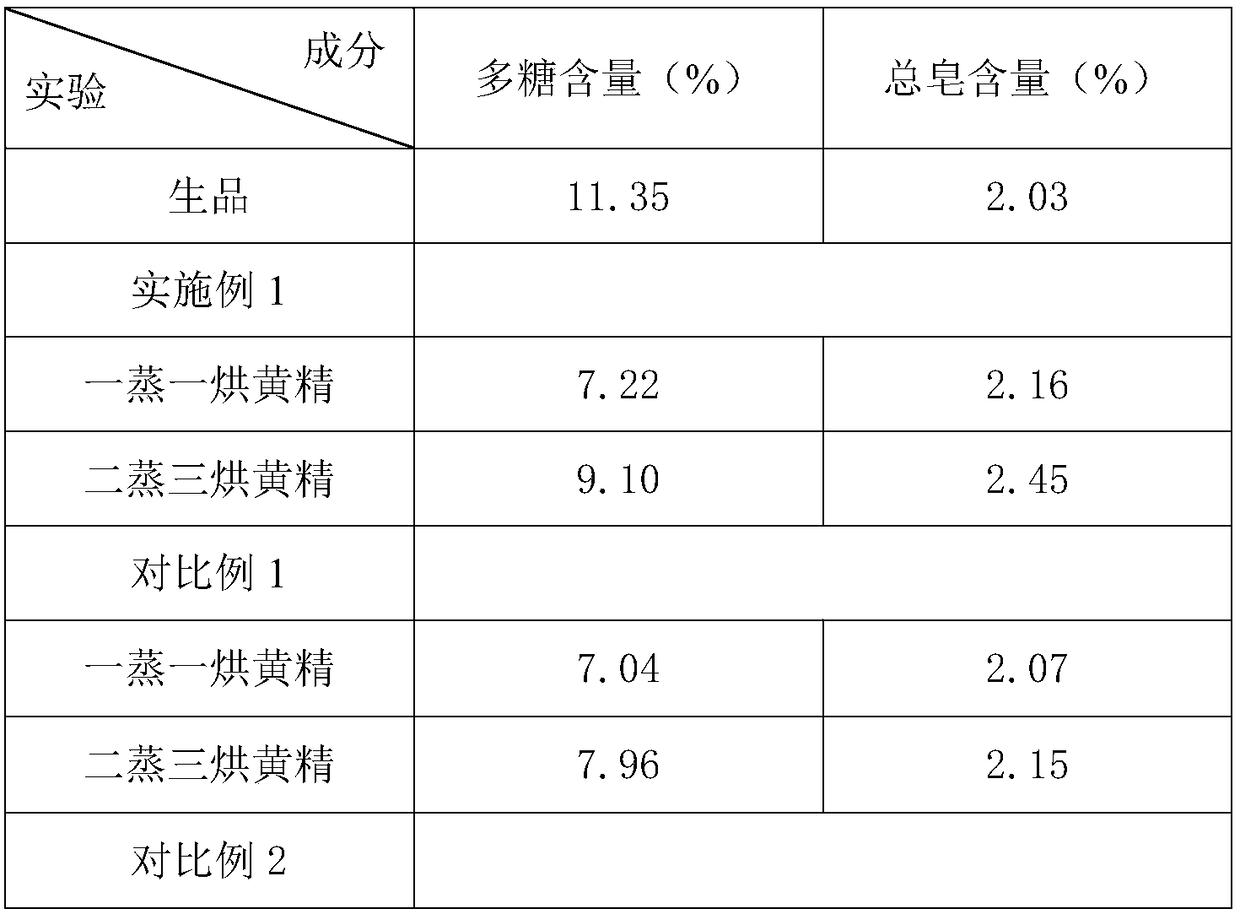

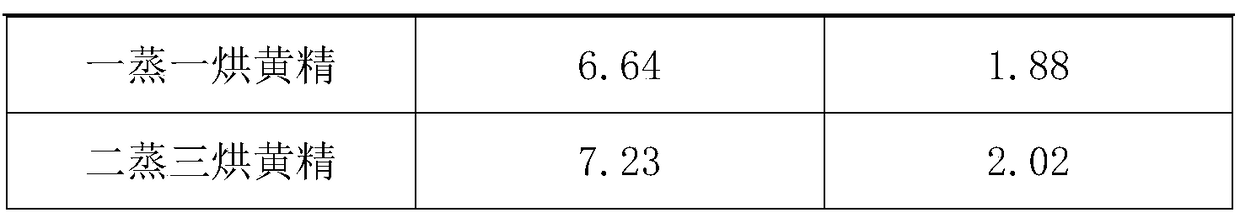

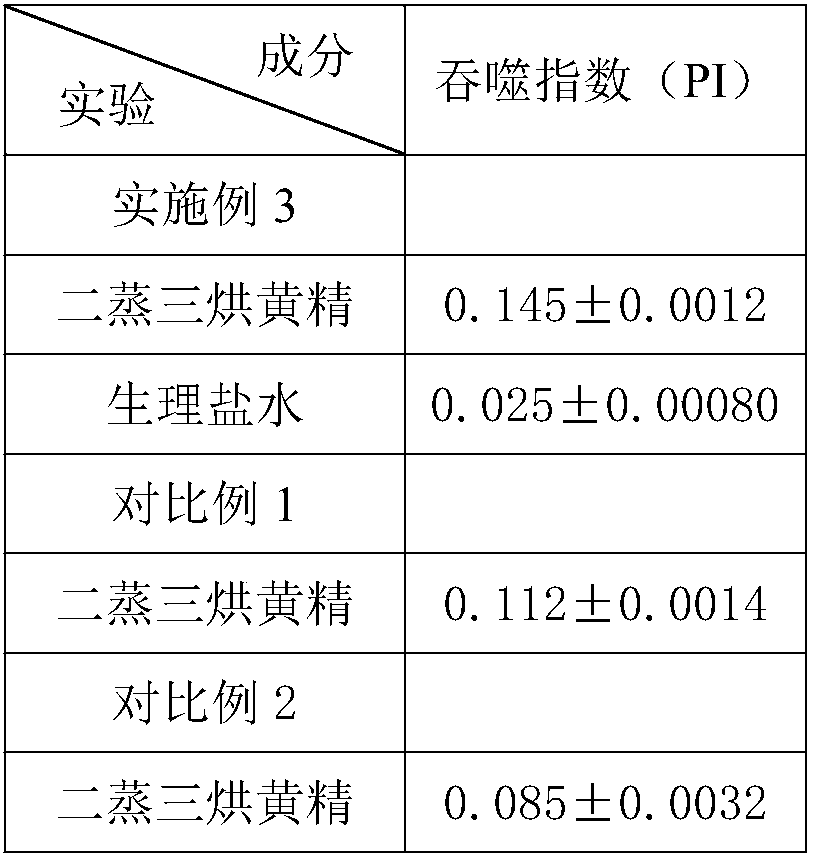

Processing method for Rhizoma Polygonati steamed in clear soup

The invention discloses a processing method for Rhizoma Polygonati steamed in clear soup. The processing method comprises the following steps: (1) cleaning Rhizoma Polygonati, then putting the cleanedRhizoma Polygonati into a container, adding clear water accounting for 1 / 5-1 / 2 the weight of the Rhizoma Polygonati, carrying out soaking for 1-2 hours, adding tea accounting for 1 / 20-1 / 5 the weightof the Rhizoma Polygonati, and putting the container in a cooking pot for steaming at a pressure of 0.10-0.20 MPa for 6-8 hours so as to obtain primarily-steamed Rhizoma Polygonati and primarily-steamed Rhizoma Polygonati juice after steaming; (2) taking out the primarily-steamed Rhizoma Polygonati, carrying out slicing, and then carrying out drying for 4-6 hours so as to obtain primarily-steamedprimarily-dried Rhizoma Polygonati; (3) putting the primarily-steamed primarily-dried Rhizoma Polygonati into the container again, moistening the primarily-steamed primarily-dried Rhizoma Polygonati with the primarily-steamed Rhizoma Polygonati juice for 1-2 hours, and carrying out steaming at a pressure of 0.10-0.20 MPa for 4-6 hours so as to obtain secondarily-steamed Rhizoma Polygonati and secondarily-steamed Rhizoma Polygonati juice; and (4) taking the secondarily-steamed Rhizoma Polygonati out for drying for 4-6 hours, carrying out sieving to remove tea leaves, moistening the secondarily-steamed Rhizoma Polygonati with the secondarily-steamed Rhizoma Polygonati juice for 2-4 hours, and carrying out drying for 8 to 12 hours so as to obtain secondarily-steamed tertiarily-dried Rhizoma Polygonati. The method of the invention is simple in process, reduces the loss of the polysaccharides and total saponins of Rhizoma Polygonati, and enhances the efficacy of the steamed Rhizoma Polygonati.

Owner:HUNAN XINHUI PHARMA

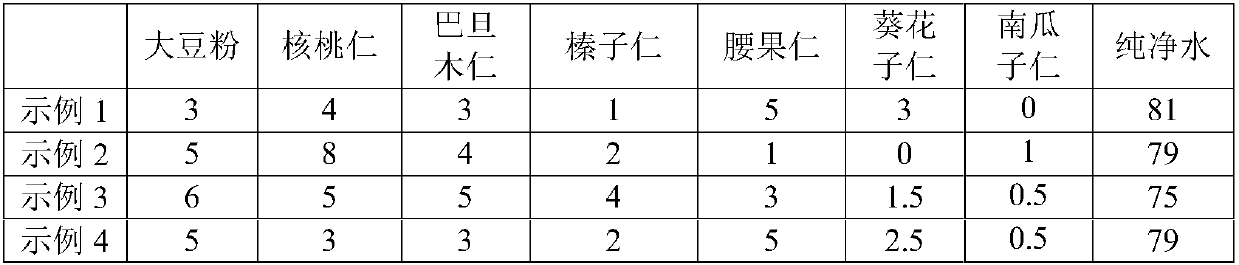

Nut beverage and preparation technology thereof

The invention discloses a nut beverage and a preparation technology thereof, and belongs to the field of food processing. The nut beverage comprises the following components in parts by weight of 3-10parts of soybean flour, 3-8 parts of walnut kernels, 3-8 parts of almond kernels, 1-5 parts of hazelnut kernels, 1-5 parts of cashew kernels and 1-3 parts of melon seed kernels. The preparation technology of the nut beverage comprises the following steps of performing peeling, performing selecting, performing baking, performing premixing, performing refining, performing blending, performing homogenizing and performing sterilization. The nut beverage disclosed by the invention solves the problem that a conventional nut beverage is high in production cost, single in nutrients and poor in mouthfeel and flavor. The soybean flour, the walnut kernels, the almond kernels, the hazelnut kernels, the cashew kernels and the melon seed kernels are matched and mixed in proportion, so that the nut beverage is prepared, the nut beverage is guaranteed to have rich nutrient substances. Besides, the cost is reduced, and the mouth feel and the flavor of the prepared nut beverage are good.

Owner:CHACHA FOOD CO LTD

A kind of production technology of purple sweet potato rice cake

The invention discloses a production process of a purple sweet potato rice cake. The process flow is as follows: processing the purple sweet potato, preparing rice flour, firstly fermenting, secondarily fermenting, cooking, packing and storing. Compared with the primary process, two-time fermentation is adopted in the production process disclosed by the invention and emulsification is carried outon the purple sweet potato, so that the emulsified purple sweet potato is added when secondary fermentation is carried out. By using the production process in the invention, the bad influence of souring caused by the first fermentation is overcome, and the influence of addition of purple sweet potato on foamability and taste of rice cake is also eliminated; therefore, the produced purple sweet potato rice cake is not only rich in nutrient component and effect component, but also has exquisite taste, good foamability and special purple sweet potato smell.

Owner:犍为县迪梓园食品有限责任公司

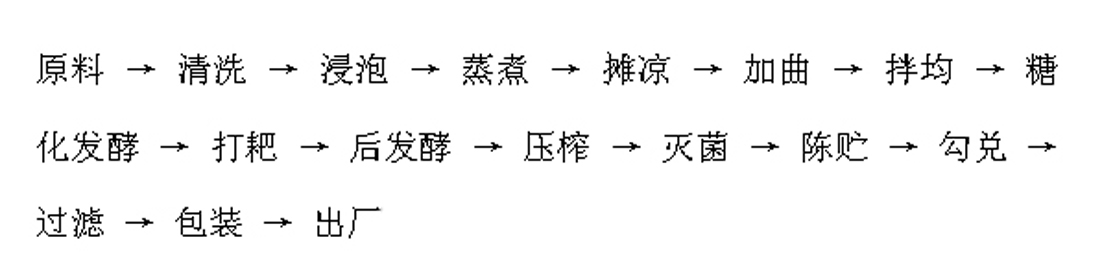

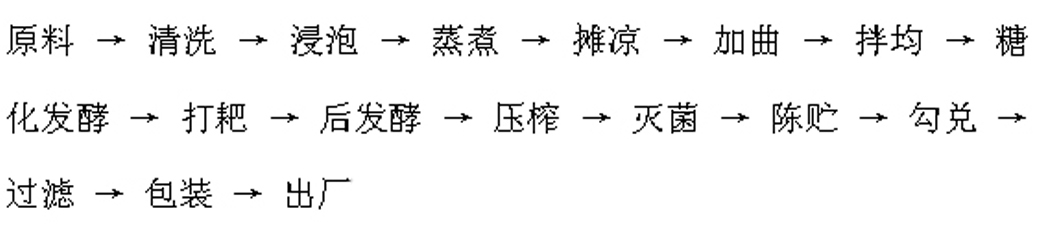

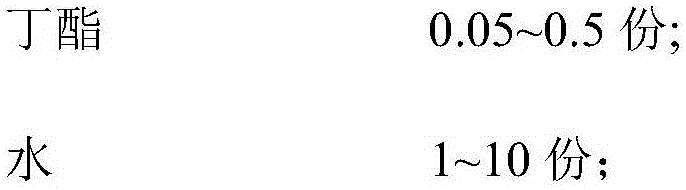

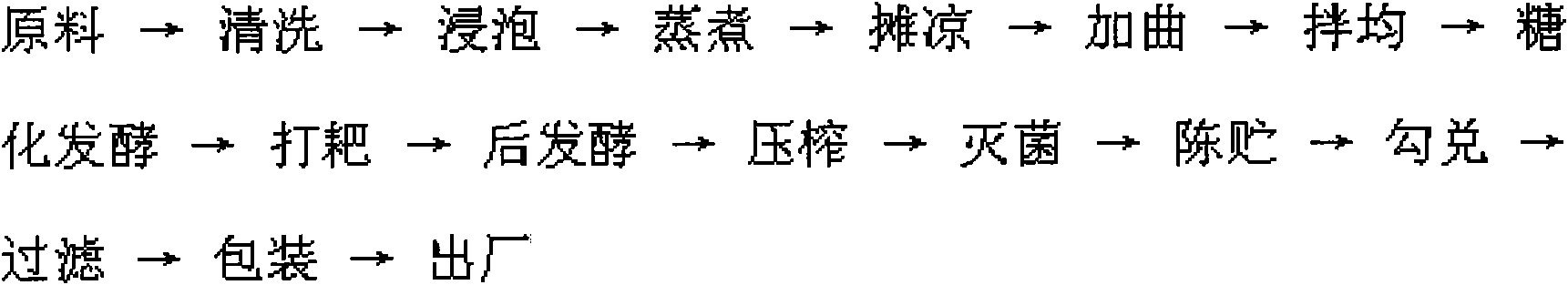

Improved process for producing yellow wine

InactiveCN101906372AHigh yieldHigh nutritional valueAlcoholic beverage preparationMicroorganism based processesYeastFlavor

The invention relates to an improved process for producing yellow wine and aims to solve the problem of mash rancidity and increase yellow wine yield. The production process comprises the following steps of: cleaning raw materials; dipping the cleaned materials; cooking the dipped materials; spreading the cooked materials for cooling; performing inoculation on the cooled materials; uniformly stirring the materials; performing diastatic fermentation on the mixture; raking the mixture; performing after-fermentation on the mixture; pressing the fermented mixture; sterilizing the pressed mixture; storing the sterilized mixture; blending the stored mixture; filtering the blended mixture; and packaging the filtered mixture, wherein the weight ratio of glutinous millet to mung bean to red jujube to fenugreek serving as raw materials is 100:3:3:0.5; 0.15 percent of active dried yeast based on the weight of the glutinous millet and 5 percent of wheat koji special for spirit distilled in Fenyang based on the mass of the glutinous millet are added during the inoculation; 0.1 percent of sweet osmanthus flower spice based on the weight of the glutinous millet is added at an after-fermentation stage; and white spirit or Dachu white spirit is added at the after-fermentation stage. The process has the advantages of increasing the yellow wine yield, solving the problem of the mash rancidity and enhancing the nutritional value and bouquet of the yellow wine.

Owner:山西四达酒类饮料有限责任公司

Making method of brown rice and potato whole wheat flour mixed nutritional porridge

The invention provides a making method of brown rice and potato whole wheat flour mixed nutritional porridge. The making method has the advantages that by using brown rice, the nutritional ingredients of cereals are improved; the brown rice is pretreated, wherein the brown rice is frozen at minus 5 DEG C firstly to enable rice grain tissue to be destroyed a little to generate bee-ball-shaped small holes, then the brown rice is treated in a treating solution prepared in advance to enable effective ingredients in the treating solution to permeate into the brown rice, and therefore the nutritional value of the brown rice is increased; the treating solution is mainly prepared from radix saposhnikoviae, mulberry leaves, common lophatherum herb and fructus broussonetiae, and therefore a very good treatment effect on eye diseases of adolescents is achieved; meanwhile, added mulberry leaves and common lophatherum herb have the faint scent of plants, fructus broussonetiae has sweet taste, mulberry leaves, common lophatherum herb and fructus broussonetiae are added into the nutritional porridge together, and then the nutritional porridge achieves the very good aroma and mouthfeel.

Owner:李志军

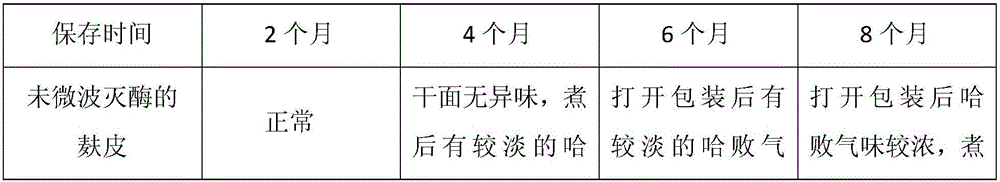

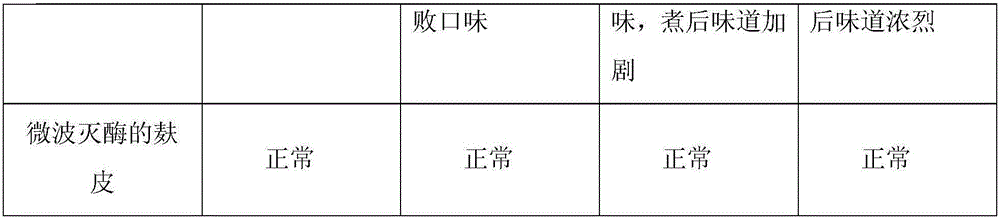

Whole wheat boiled noodle

InactiveCN105831588AHigh strengthLow water absorptionFood dryingFood ingredient functionsMaillard reactionAntioxidant

The invention provides whole wheat boiled noodle, which is prepared from the following raw materials (by weight): 60-70 parts of flour, 5-10 parts of wheat bran, 5-10 parts of corn flour, 0.02-0.04 part of a compound enzyme preparation, 2-3 part of vital gluten, 0.06-0.1 part of sodium stearoyl lactylate, 20-35 parts of water and 2-5 parts of edible salt. Lipase activity of maize meal and wheat bran is eliminated by microwave treatment. Due to the Maillard reaction happed during the enzyme deactivation process, unique flavor is generated, and taste of the boiled noodle is enhanced. Shelf life of the whole wheat boiled noodle is prolonged because of an antioxidant generated during the Maillard reaction process. Thus, the problem that most whole wheat boiled noodles in the market have short shelf life and are not easy to store is solved. In comparison with a traditional backing technology, the microwave enzyme deactivation technology has the following advantages: reaction time is saved, factory energy resources are saved, and the smell of burnt food that is generated by wheat bran after excessive baking is prevented such that taste of the noodle is not influenced.

Owner:宜垦(天津)农业制品有限公司

Granular medicine for cigarette tip filtration and preparation method thereof

ActiveCN103932396AEasy to prepareWide range of medicinesTobacco smoke filtersFiltrationHazardous substance

The invention belongs to the technical field of cigarettes and discloses granular medicine for cigarette tip filtration and a preparation method thereof. The granular medicine is formed by mixing of traditional Chinese medicine effective components and activated carbon according to a weight ratio of 0.2-1:1, wherein the traditional Chinese medicine effective components include dandelion, Parthenocissus himalayana (Royle) Planch, pawpaw, Radix Sophorae Tonkinensis, Lobed Kudzuvine roots and the like. According to the granular medicine for cigarette tip filtration and the preparation method thereof, the traditional Chinese medicine effective components are effectively extracted with multiple methods and used for cigarette tip filtration together with activated carbon, harmful substances in main stream smoke of cigarettes can be reduced, smoking harmfulness can be reduced, phenol and ammonia matter in the main stream smoke of cigarettes can be reduced remarkably, the taste of the cigarettes is not affected obviously, and application prospects are good.

Owner:山东恒昌聚材化工科技股份有限公司

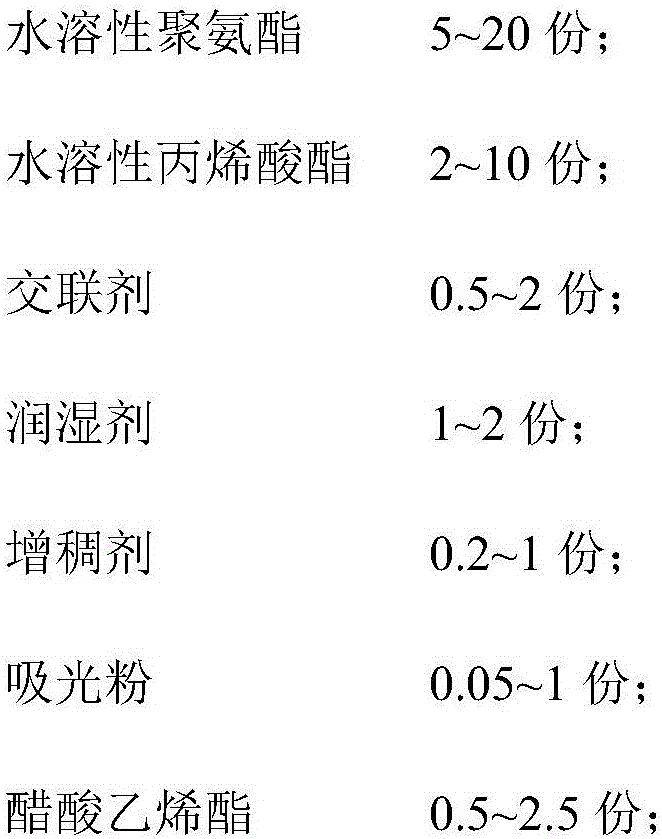

Process for producing packing paper for heating non-combustion tobacco

ActiveCN105780581ATaste effectReduce lossesLaminationLamination apparatusCombustionPolyethylene terephthalate

The invention discloses a process for producing packing paper for heating non-combustion tobacco, comprising preparation of inner packing paper and preparation of outer packing paper. The preparation of the inner packing paper includes the following steps: (1), preparing a combustion layer, (2), preparing a heat conducting layer, and (3), applying glue for compositing; the preparation of the outer packing paper includes the following steps: (4), preparing an outer packing layer, coating the back of the outer packing paper with an aluminum foil as a heat-insulating layer; (5), applying waterborne matte laser transfer coating to a PET (polyethylene terephthalate) film; (6), mold pressing with a mold press to obtain a matte laser film; (7), attaching the matte laser film to a glue layer of the outer packing layer to obtain the outer packing paper; (8), attaching the heat-insulating layer of the outer packing paper to a combustion layer of the inner packing paper, and integrating the inner and outer packing paper by mechanical extrusion. Tobacco package of the invention comprises the inner packing paper and the outer packing paper, little smoke is generated during combustion, and tobacco shreds can be fully heated.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

Instant corn noodle

InactiveCN104824556ADelicate tasteTaste effectFood freezingMulti-step food processesPowder mixtureCold store

The invention discloses an instant corn noodle. The instant corn noodle is prepared from corn keratin endosperm powder and corn farinaceous endosperm powder, and is prepared through the following steps: uniformly mixing the corn keratin endosperm powder with the corn farinaceous endosperm powder according to a ratio of 1:1, adding salt accounting for 0.6% of the weight of the above obtained powder mixture and normal temperature drinking water accounting for 30-35% of the weight of the powder mixture, fully stirring to obtain a wet powder mixture, putting the wet powder mixture in a spiral puffing machine, carrying out puffing extrusion to form cooked noodles, sending the cooked noodles to a regulating chamber, regulating, packaging the regulated noodles by a food stage plastic bag, rapidly sending the bag to a quick freeze chamber, quickly freezing, and moving to a cold store for storage in order to obtain the finished instant corn noodle. The instant corn noodle can be directly eaten after direct boiling without immersion, and has the advantages of good boiling fastness, no soup turbidity after long time boiling, good elasticity, no fracture, smoothness in mouth, and fine mouthfeel.

Owner:辽宁曙光食品有限公司

Production process of yellow rice wine

InactiveCN101942372AHigh yieldHigh nutritional valueAlcoholic beverage preparationMicroorganism based processesFlavorYeast

The invention relates to an improved production process of yellow rice wine in order to solve the problem of mash rancidity and increase the yield of the yellow rice wine. The production process comprises the following steps in sequence: raw material washing, soaking, cooking, spreading for cooling, qu adding, stirring uniformly, saccharifying and fermenting, raking, after-fermenting, squeezing, sterilizing, storing, blending, filtering and packaging, wherein the used raw materials are millet, mung bean, red dates and sophora alopecuroides with weight part ratio of 100:4.6-5.0:4.6-5.0:0.3-0.5. Active dry yeast with weight being 0.15% of that of the millet is added during adding qu. Wheat qu or Daqu with mass being 5% of that of the millet is added during adding qu. Sweet osmanthus spices with weight being 0.1% of that of the millet and white wine or Daqu white wine with weight being 50-80% of that of the millet are added at the stage of after-fermentation. The production process increases the yield of the yellow rice wine, solves the problem of mash rancidity and simultaneously improves the nutritional value and aroma of the yellow rice wine.

Owner:山西四达酒类饮料有限责任公司

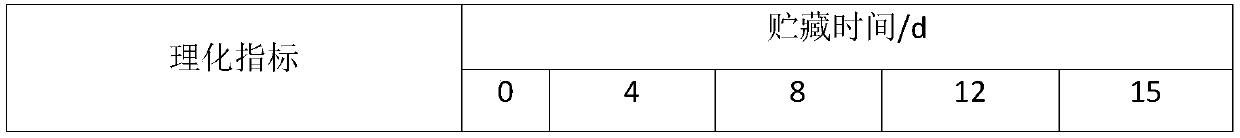

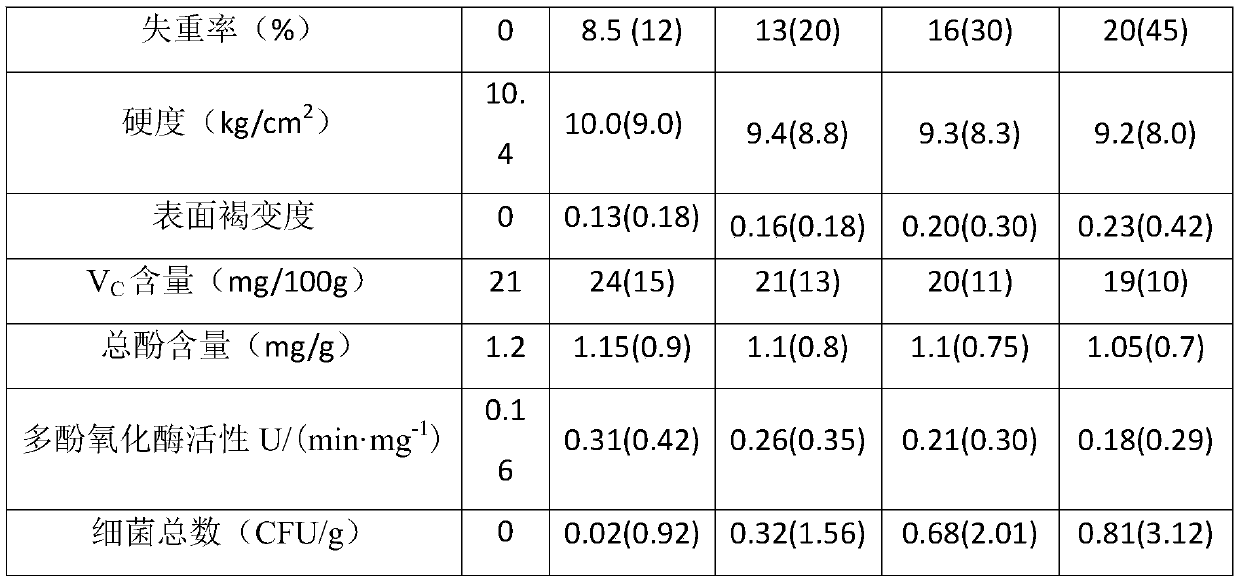

Fresh-keeping liquid for fresh cut fruits and vegetables

InactiveCN110269093AGrowth inhibitionLow toxicityFood ingredient as antioxidantFruit and vegetables preservationSolubilitySpoilage bacteria

The invention discloses a fresh-keeping liquid for fresh cut fruits and vegetables. The fresh-keeping liquid is prepared by compounding lactobacillus plantarum, carbon dots, ascorbic acid, citric acid, disodium ethylene diamine tetraacetate, glycerol and calcium propionate. According to the fresh-keeping liquid, the lactobacillus plantarum and the carbon dots are combined for fresh keeping of the fresh cut fruits and vegetables for the first time, the capability of lactic acid bacteria to inhibit the growth of spoilage bacteria and pathogenic bacteria is fully exerted, abundant radicals on the surfaces of the carbon dots are utilized, the water solubility, the reducibility and the antibacterial activity are good, the permeation effect on plant cells is enhanced, and the technical effects of synergistic bacteriostasis, sterilization and enzyme activity inhibition are achieved. All raw materials involved in a formula of the fresh-keeping liquid are of the food grade, the fresh cut fruits and vegetables can be directly eaten after being soaked in the fresh-keeping liquid, and the taste of the fresh cut fruits and vegetables cannot be adversely influenced. A preparation process is simple, the fresh-keeping effect is excellent, and the shelf life of the fresh cut fruits and vegetables can be prolonged to 12-15 days after the fruits and the vegetables are soaked in the fresh-keeping liquid and stored at the low temperature.

Owner:AGRO PROD PROCESSING RES INST YAAS

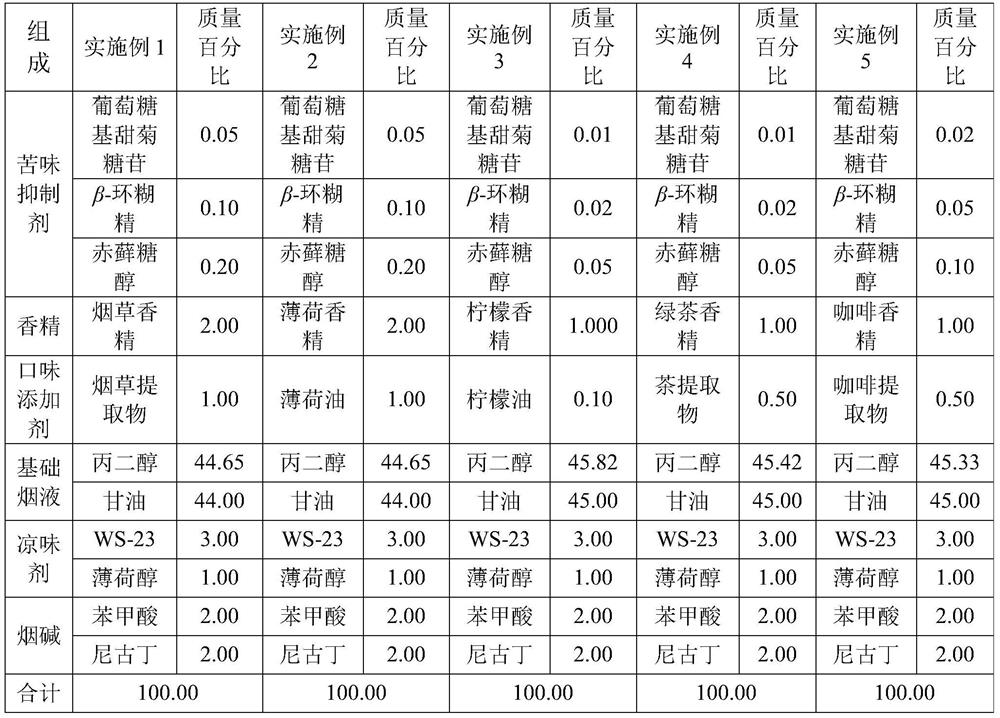

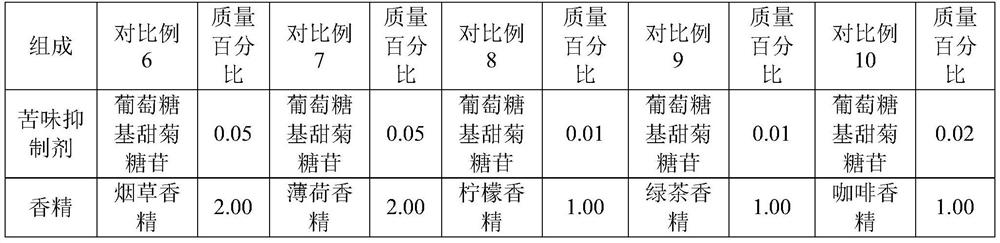

Bitterness inhibitor, application, electronic atomized liquid and preparation method thereof

The invention relates to a bitterness inhibitor, application, electronic atomized liquid and a preparation method thereof. The bitterness inhibitor comprises glucosyl stevioside, beta cyclodextrin anderythritol, and the mass ratio of the glucosyl stevioside to the beta cyclodextrin to the erythritol is (1-10): (2-20): (5-100). Glucosyl stevioside in the bitterness inhibitor is obtained in a way that the stevioside is glycosylated by through an enzymolysis method, and then beta-glucosyl conformation is converted into alpha-glucosyl through hydrolysis, transfer, cyclization and disproportionation effects, the number of glucosyl groups is increased, and the overall steviol is subjected to conformation change. The produced micro-cavity capsule structure can play a role in embedding and shielding bad fragrant substances, the embedding effect of beta-cyclodextrin and the sweet taste of erythritol are combined, the unpleasant feeling brought by bitter substances in the atomized liquid can beeffectively shielded, and the irritating feeling and the offensive odor feeling are reduced.

Owner:SHENZHEN XUEWU TECH CO LTD

Compound sweetening agent

The invention discloses a composite sweetener. The compositions by weight percentage of the composite sweetener comprise 2 to 5 percent of aspartame and 95 to 98 percent of fillers. A plurality of fillers such as fructose, lactose, glucose, maltodextrin and so on can be selected in order to obtain different flavors, and a small amount of anticaking agents can be added to prevent the product from being caked so as to be convenient for storage. Because the effective compositions comprise the aspartame, the amount of the sweetener is reduced, the calorie intake index, the blood sugar index and the decayed tooth index are effectively reduced. The sweetener adopts a special formula and quickly tastes sweet after eaten; the mouth is filled with a soft and smooth feel; when the sweetener is added into drink for drinking, people can not feel poor after-taste and the time of the sweet taste staying in the mouth is long; and the sweetener has better mouthfeel compared with similar products.

Owner:江苏维多股份有限公司

Processing method of euphausia superba low in fluorine

InactiveCN105029515AReduce fluorine contentReduce loss rateFood preparationMagnesium saltMicrowave power

The invention relates to a processing method of euphausia superba low in fluorine, which comprises the following steps: (1) pretreating; (2) steam heating: steam heating euphausia superba flesh to 60 to 70 DEG C, carrying out heat preservation for 20 to 30 minutes, collecting water soluble extractum of the euphausia superba flesh; (3) processing the water soluble extractum: adding pure water in the water soluble extractum according to the mass ratio of the water extractum to the pure water, wherein the mass ratio is 1 to (8 to 10), adjusting the pH value to 7.0 to 7.5, adding in magnesium salt and enabling the concentration of the magnesium salt to be 0.04 to 0.85 percent, carrying out heat preservation for 1 to 2 hours under the temperature of 40 to 50 DEG C, filtering and taking supermatant to obtain a finished solution product of the water soluble extractum; (4) microwave heating: immersing the euphausia superba flesh subjected to the steam heating in a water-retaining agent, and the mass ratio of the euphausia superba flesh to the water-retaining agent is 1 to (3 to 5), heating for 5 to 10 minutes under the microwave power of 500 to 800W; (5) back boiling: immersing the euphausia superba flesh subjected to the microwave heating in the finished solution product of the water soluble extractum according to the mass ratio of 1 to (2 to 4), poaching for 10 to 15 minutes under the temperature of 50 to 60 DEG C; (6) packaging. The processing method is easy in operation; a finished product is low in fluorine content; the dissolution rate of the fluorine can reach more than 95 percent during processing; the lost nutrient substances are less; the loss ratio of protein is lower than 10 percent; the euphausia superba flesh of the product is good in taste.

Owner:ZHEJIANG OCEAN UNIV

Application of L-arabinose to coloring agent of fried minced fillet product

ActiveCN103948016AGood colorUniform colorFood ingredient functionsFood preparationBiotechnologyGolden syrup

The invention relates to the technical field of a food coloring agent, and in particular relates to an application of L-arabinose to a coloring agent of a fried minced fillet product. The application comprises the following steps: feeding the coloring agent containing the L-arabinose into oil with the weight being equal to that of the coloring agent; preheating the mixture and frying into the caramel color; feeding 5-10 times of water to prepare golden syrup; and putting the minced fillet product into the syrup to enable the surface of the product is evenly stained with the syrup, and frying. A caramelization reaction is carried out, and the colored syrup exists on the coating of the surface of the minced fillet product, so that the minced fillet product has attractive golden yellow color after being fried; the coloring agent not only is good in coloring effect and even in coloring, but also has small possibility of generating carcinogenic substances such as acrylamide due to low temperature, short time and rapid coloring in the frying process.

Owner:SHENGQUAN HEALTANG CO LTD

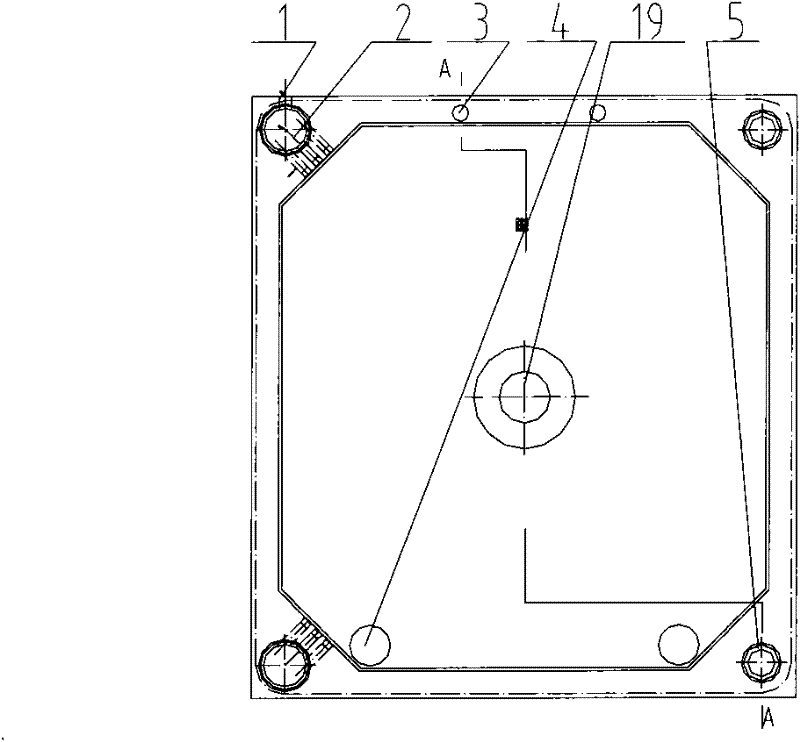

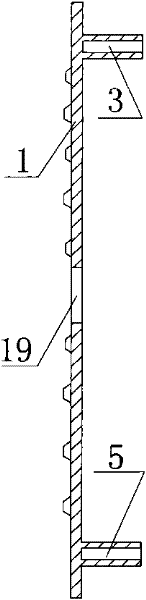

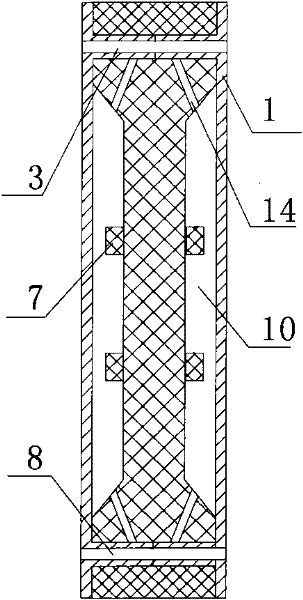

Air chamber-type press filter-used diaphragm plate

The invention relates to an air chamber-type press filter-used diaphragm plate, which comprises a diaphragm plate, wherein the diaphragm in the diaphragm plate is of the flaky silicon gel diaphragm; the back surfaces of the four corners of the flaky silicon gel diaphragm are provided with a boss-type liquid out passage and a boss-type liquid washing passage; a boss-type air passage is arranged between the boss-type liquid out passage and the boss-type liquid washing passage; a sealing surface of a plate core of the diaphragm plate is provided with an air hole that is communicated with a core cavity of the plate core; the plate core is provided with a boss-type liquid washing passage and a boss-type liquid out passage; the core surface of the plate core is provided with three or more than three bosses that are distributed around a liquid inlet of the plate core; and the boss-type liquid out passage, the boss-type liquid washing passage and the boss-type air passage are respectively spliced and matched with a liquid outlet, a liquid washing hole and the air hole that are arranged on the surface of the plate core. The air chamber-type press filter-used diaphragm plate has the advantages that: 1, the adverse effect to the mouthfeel of wine can not be caused; 2, the sealing is reliable, and the corrosion resistance is good; 3, the extrusion deformation between a filter plate and the diaphragm can be avoided, and the diaphragm can be prevented from being broken due to the extrusion; 4, the hidden air passage can not consume material and does not have trouble.

Owner:杭州余杭新兴过滤机厂

Special coloring agent of deep-fried minced fillet type products

ActiveCN103960650AAttractive golden colorPlay a synergistic roleSugar food ingredientsFood ingredient functionsBiotechnologyArabinose

The invention relates to the technical field of food coloring agents, and in particular relates to a special coloring agent of deep-fried minced fillet type products. The coloring agent is prepared from the following components in parts by weight: 0.5-99.5 parts of L-arabinose, 0.5-99.5 parts of D-xylose and 0-60 parts of glucose. A preparation method of the coloring agent comprises the following steps: the L-arabinose, the D-xylose and the glucose are uniformly mixed, then are added into oil with weight equal to that of the mixture and are preheated for hot frying to obtain caramel; 5-10 times of water is added to prepare gold-yellow syrup; minced fillet type products are put into the syrup to uniformly cover the surfaces of the products with the syrup and then are fried. Therefore, the gold-yellow color of the deep-fried minced fillet type products is attractive, and the taste of the deep-fried minced fillet type products cannot be affected; in a deep-frying process, the temperature is low, the time is short, and the coloring speed is high, so that cancerogenic substances such as acrylamide are almost not generated.

Owner:SHENGQUAN HEALTANG

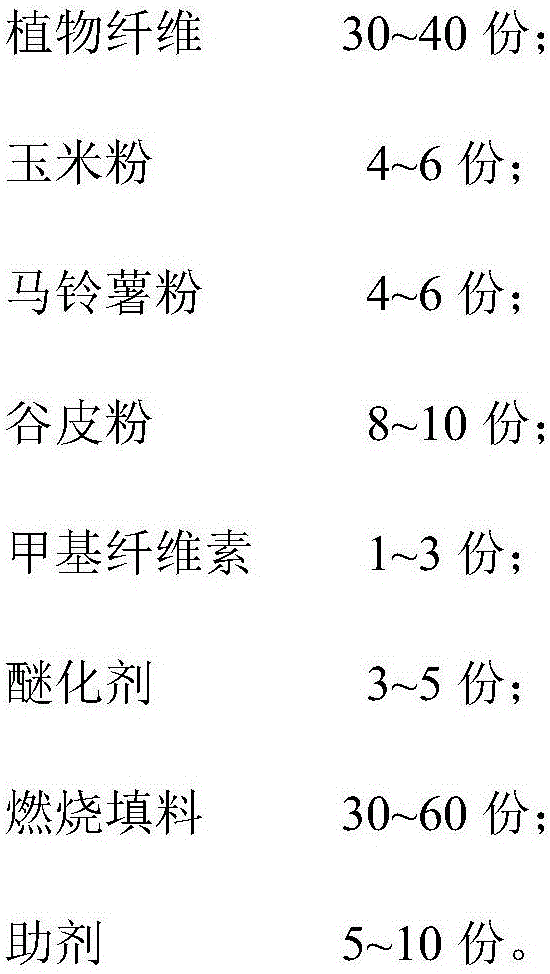

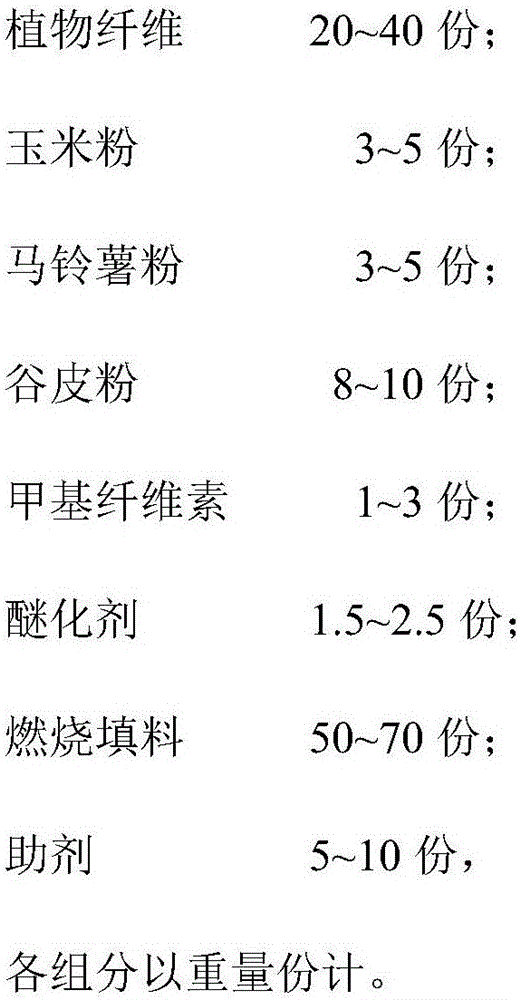

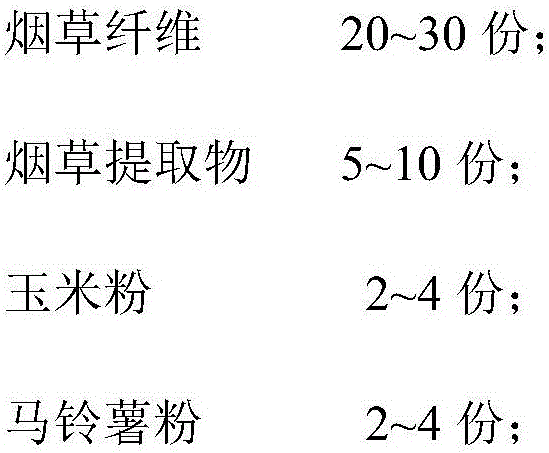

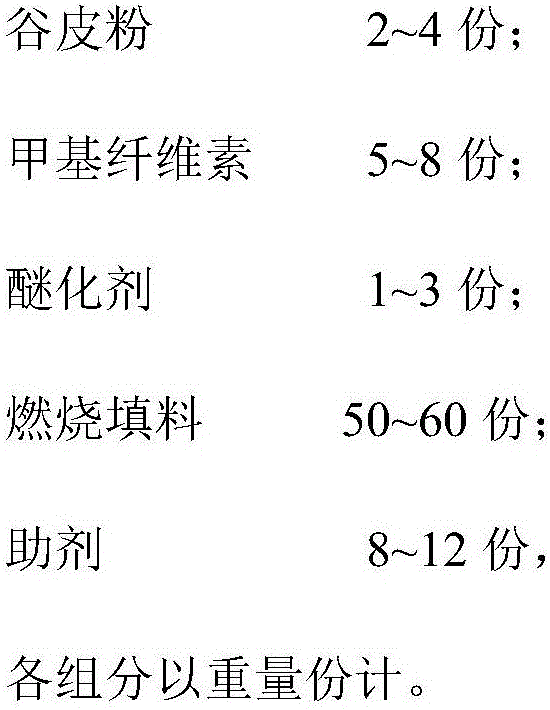

Heat-not-burn tobacco packing paper

ActiveCN105768208APromotes even heatingReduce solid particlesCigar manufactureInorganic compound additionPaper sheetMethyl cellulose

The invention discloses heat-not-burn tobacco packing paper. The packing paper comprises a burning layer and a heat conducting layer which are bond together through a composite adhesive, wherein the heat conducting layer consists of a body paper layer, a grid-like aluminum foil layer and a sheet-like aluminum foil layer, the grid-like aluminum foil layer and the sheet-like aluminum foil layer are composited on upper and lower sides of the body paper layer respectively, the grid-like aluminum foil layer is contacted with the burning layer, and the sheet-like aluminum foil layer covers cut tobacco. The burning layer and the heat conducting layer of the packing paper both contain burning materials such as corn flour, potato powder, grain husk powder, methyl cellulose and the like which can prolong the burning time, meanwhile, the materials can burn sufficiently, few solid particles are produced, and the taste of tobacco cannot be affected; besides, the burning layer and the heat conducting layer produce more heat, and the defect of insufficient heating of traditional heat-not-burn tobacco is overcome.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

Production method of vegetable leaf fermented bean curd

InactiveCN103155995AGuaranteed aestheticsGuaranteed tasteCheese manufactureFood scienceBiotechnologyMoisture

The invention relates to a production method of a vegetable leaf fermented bean curd, and belongs to the technical field of bean product processing. Moisture content, color degree and softness of the vegetable leaves are keys for production. For moisture content, the vegetable leaves are cleaned and naturally air-dried at constant temperature of 5-10 DEG C and humidity of 60%-70%; and moisture content is controlled at 10%-20% through a weighing method. For color degree, the vegetable leaves can not be exposed to sunlight during the air drying process, and suspended vegetable leaves keep a distance of 2-3 cm with each other. For softness, the vegetable leaves are placed in a special basket, and a towel with water removed is covered on the surface. Control of moisture content of the vegetable leaves is a guarantee for later fermentation with fermented bean curd, product quality and shelf life; color degree affects appearance of the vegetable leaf fermented bean curd, and if exposed to the sunlight, the leaves will appear yellow spots at local positions; and the best condition of softness is that when packaged, surfaces of the vegetable leaves and the fermented bean curd are connected seamlessly, and the vegetable leaves and fermented bean curd will not separate or produce small bubbles at local positions in a later fermentation process, so as to realize sufficient later fermentation and pure taste.

Owner:BIJIE CITY SHIYIMA FOOD

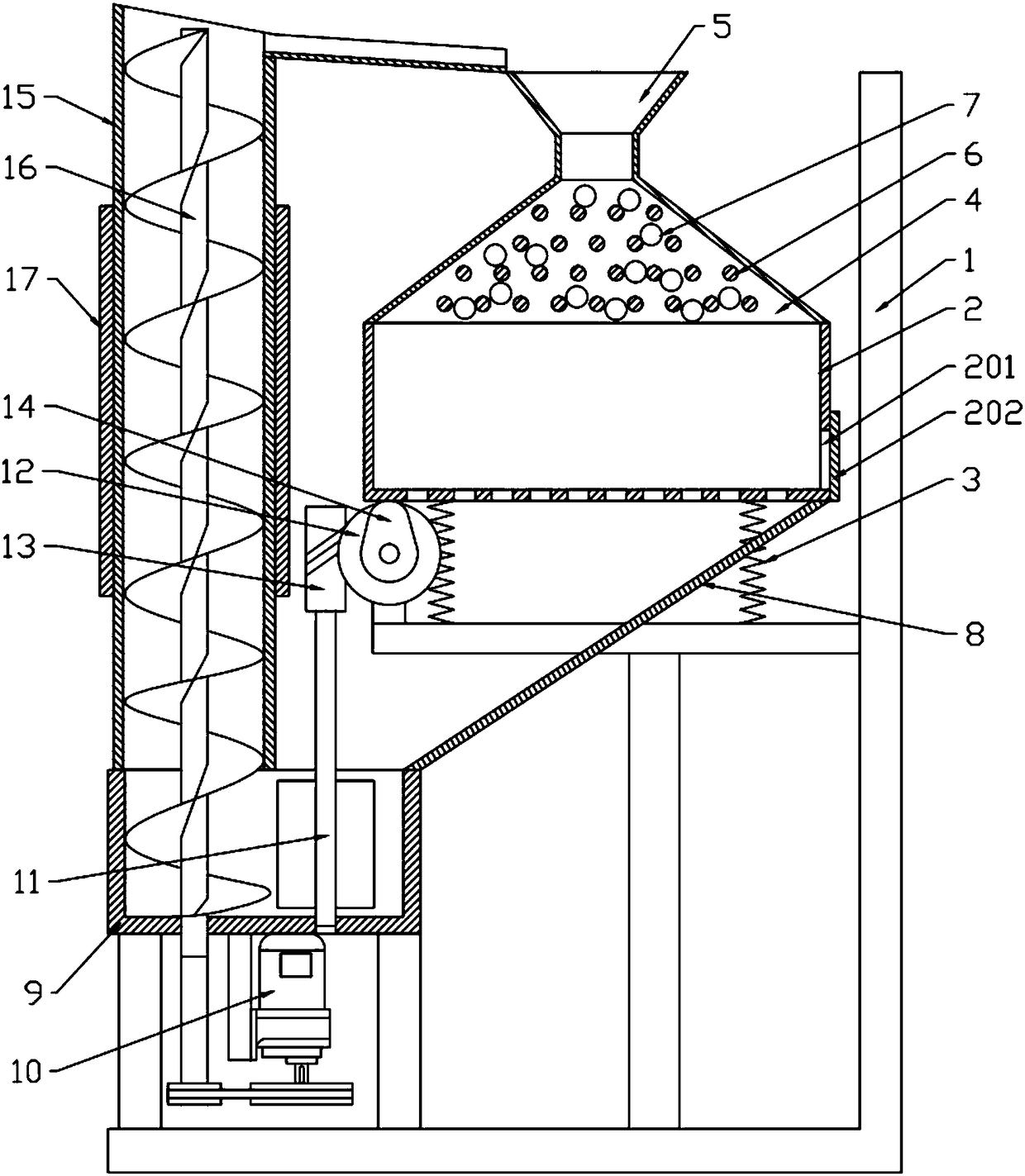

Tea leaf flattening and uniform drying device

InactiveCN111772000AImprove drying effectAvoid accumulationPre-extraction tea treatmentEngineeringMechanical engineering

The invention discloses a tea leaf flattening and uniform drying device which comprises a mounting box, a mounting cavity is formed in the mounting box, a placement mechanism is arranged in the mounting cavity, and the placement mechanism comprises a placement pipe which is fixedly mounted on the upper end wall of the mounting cavity and connected to the outside of the mounting box; a second connecting U-shape baffle is slidably mounted in the left end face of the containing pipe, a driving spring is fixedly connected between the left end face of the second baffle and the left end wall of themounting cavity, and a track groove is formed in the rear end wall of the mounting cavity. According to the tea leaf drying device, the tea leaves are evenly laid on the containing plate with the small holes, the tea leaves are dried, the tea leaves can be shaken in the drying process, the tea leaf drying effect is better, the tea leaves are stirred, tea leaf accumulation is prevented, disintegrating slag can be discharged, and the influence on the taste of the tea leaves is avoided.

Owner:瑞安影宽电子科技有限公司

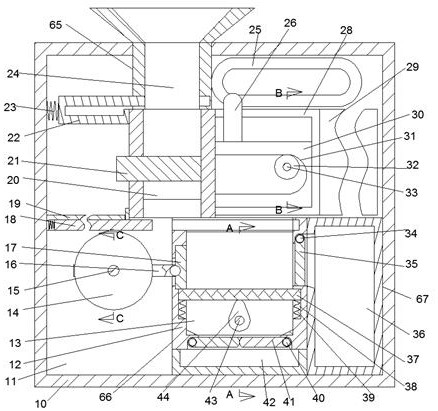

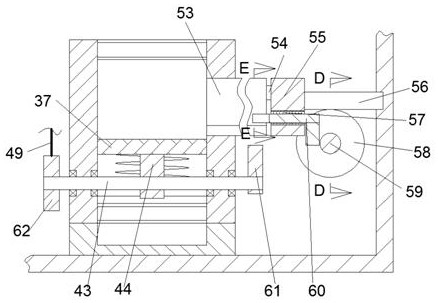

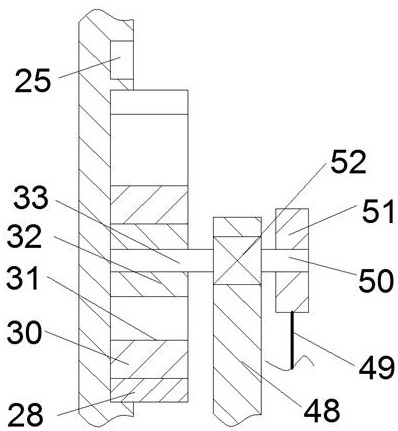

Quick thawing machine

InactiveCN108157485AQuick thawAvoid damageMeat/fish preservation by freezing/coolingEngineeringMechanical engineering

The invention relates to the field of thawing after freezing, and discloses a quick thawing machine. The quick thawing machine comprises a machine frame, a thawing tank, an ice melting device and a vibrating mechanism, wherein edges of the bottom of the thawing tank are mounted on the machine frame through pressure springs; the vibrating mechanism is mounted on the bottom surface of the thawing tank; the ice melting device comprises a ball dispersing mechanism, a ball receiving plate, a transporting mechanism, a heating device and a plurality of metal balls; the ball dispersing mechanism comprises a fixing plate; the fixing plate is vertically fixed to a tank opening of the thawing tank; a ball inlet is formed in the upper part of the fixing plate; a plurality of ball separating columns which are distributed in a crisscross manner are fixed to the fixing plate under the ball inlet; a plurality of through holes are formed in the bottom surface of the thawing tank; the ball receiving plate is obliquely arranged under the thawing tank; a ball receiving tank is arranged at the bottommost end of the ball receiving plate; one end of the transporting mechanism is connected to the ball receiving tank, and the other end of the transporting mechanism is connected to the ball inlet of the ball dispersing mechanism; and the heating device is arranged on the transporting mechanism. The invention aims to provide a thawing device which is used for quickly thawing raw materials of which the surfaces are coated by coagulated ice housings.

Owner:重庆好弟兄食品有限公司

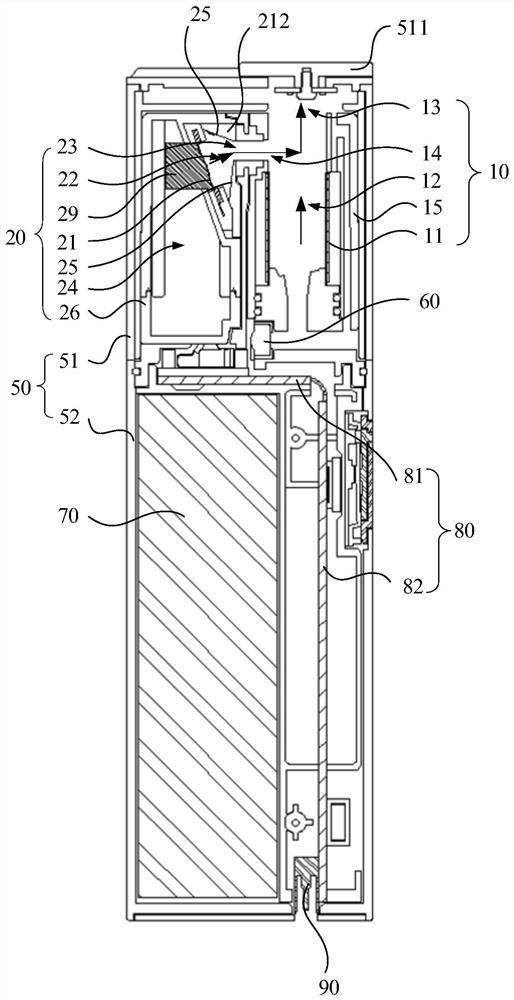

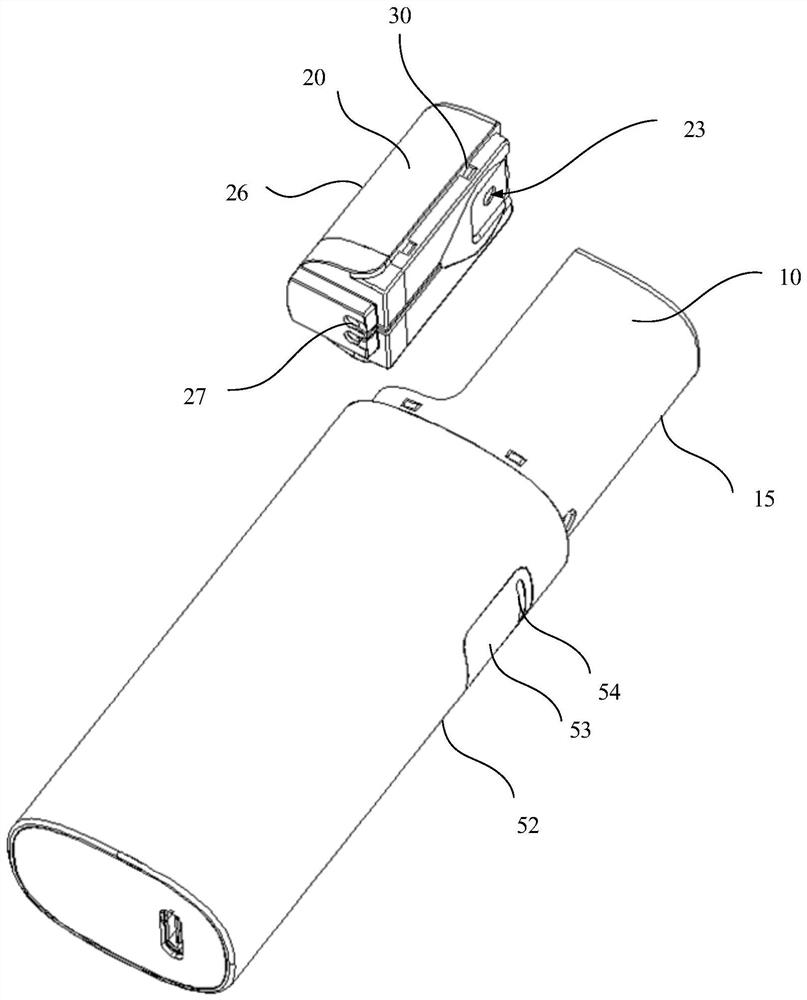

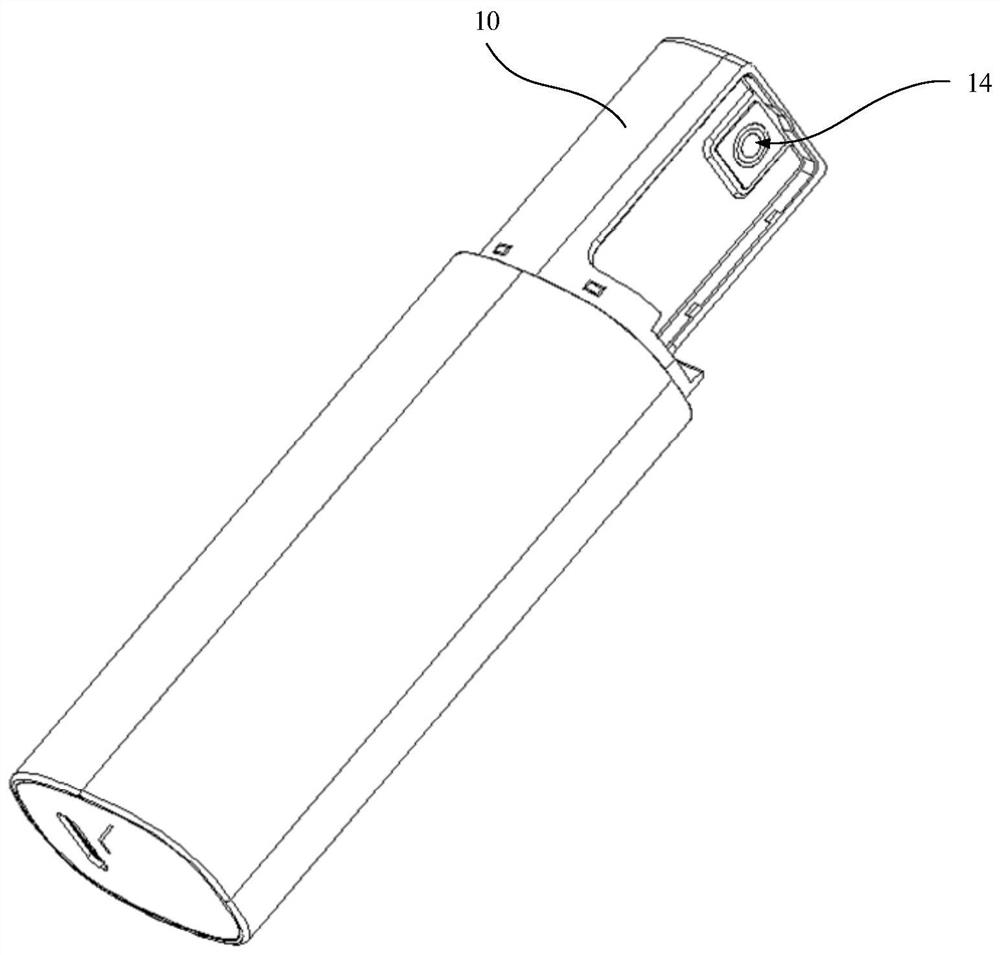

Aerosol generating device

The invention discloses an aerosol generating device. The aerosol generating device comprises a heating assembly and an atomizing assembly, the heating assembly comprises a heater, a first storage cavity is formed in the heating assembly, the heater is contained in the first storage cavity, the heating assembly is further provided with an opening and a second aerosol inlet, the second aerosol inlet is communicated with the opening, the opening is communicated with the first storage cavity, and the opening is used for discharging first aerosol; the second aerosol inlet is arranged above the heater; the atomization assembly comprises an atomizer, an atomization cavity communicated with the atomizer is formed in the atomization assembly, a second aerosol outlet is formed in the atomization cavity, and second aerosol is stored in the atomization cavity and then discharged out of the atomization assembly from the second aerosol outlet; the atomizer is close to the second aerosol outlet, the second aerosol outlet is close to the second aerosol inlet, the second aerosol outlet is communicated with the second aerosol inlet, the second aerosol sequentially passes through the second aerosol outlet and the second aerosol inlet and is discharged from the opening, and aerosol with better taste can be obtained.

Owner:SHENZHEN JIYOU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com