Production process of yellow rice wine

A production process and rice wine technology, applied in the field of winemaking technology, can solve problems such as mash rancidity, and achieve the effects of long aftertaste, prominent sweet-scented osmanthus fragrance, and solving mash rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

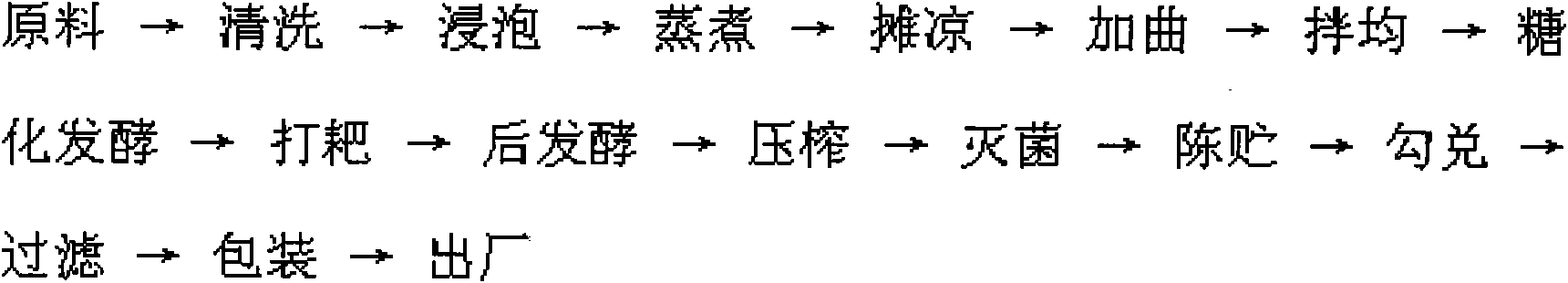

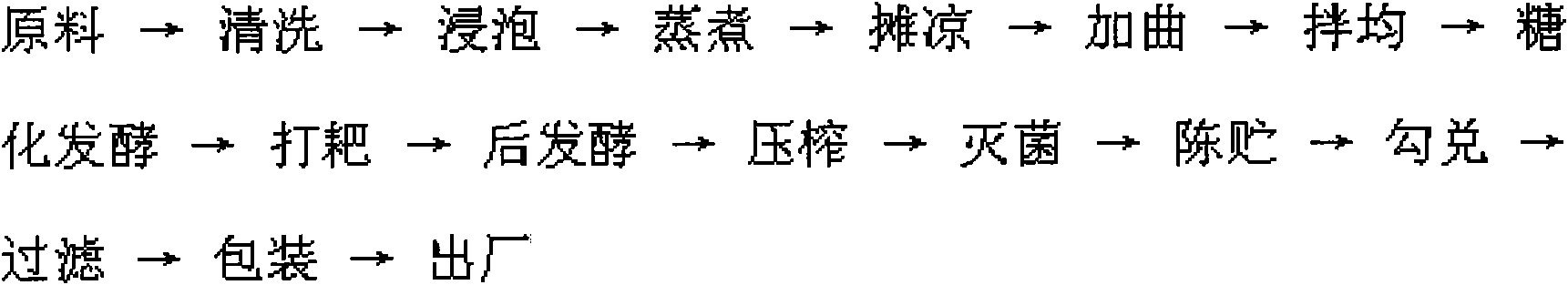

Image

Examples

Embodiment 1

[0021] (1) Ingredients:

[0022] Yellow rice: feed 100kg; mung beans: 4.6kg; red dates: 4.6kg; bitter beans: from Shanxi Province

[0023] High-quality bitter beans produced in Dai County, 0.3kg; wheat koji: 5kg; active dry yeast: 0.15kg.

[0024] (2) Process flow:

[0025] 1) Soak yellow rice for more than 12 hours.

[0026] 2) Steaming: It must be steamed well, without filling. It is required to steam for 1 hour and then stew the rice. Stew the rice for 1 hour, and stir twice in the middle.

[0027] 3) Spreading to air: the temperature is controlled below 35°C.

[0028] 4) Add koji, saccharification and fermentation: add koji into the tank, add active dry yeast and common wheat koji or Daqu, the specific operation of adding active dry yeast is to first weigh 6 kg of warm water at about 35°C, and then accurately weigh the amount of dry yeast , Pour into the prepared warm water, mix well, and set aside after 2 hours. When adding koji, sprinkle the active dry yeast on the ...

Embodiment 2

[0037] (1) Ingredients:

[0038] According to the batching method of embodiment 1, just the feeding ratio of yellow rice, mung beans, red dates and bitter beans is replaced by 100kg: 4.9kg: 4.9kg: 0.4kg.

[0039] (2) Process flow:

[0040] According to the step operation of embodiment 1, just in the 6th) step, after transferring to post-fermentation, immediately add 61% vol white wine 50kg, stir 1 time every day, seal after the surface is clear, post-fermentation period is more than 85 days.

Embodiment 3

[0042] (1) Ingredients:

[0043] According to the method batching of embodiment 2, just the feeding ratio of yellow rice, mung beans, red dates and bitter beans is replaced by 100kg: 5.0kg: 5.0kg: 0.4kg.

[0044] (2) Process flow:

[0045] Operate according to the steps of Example 2, but in step 6), after transferring to post-fermentation, immediately add 61% vol white wine 50 kg and sweet-scented osmanthus fragrance 0.1 kg, stir once a day, seal until the surface is clear, post-fermentation period 85 more than days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com