Process for producing packing paper for heating non-combustion tobacco

A heating and non-combustion type, production process technology, applied in the direction of non-woody plant/crop pulp, paper, paper making, etc., can solve the problems of limited heat production, deviation from production requirements, and more smoke, to reduce heat loss, promote The effect of uniform heating and less fixed particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A kind of wrapping paper production process of heat-not-burn tobacco, including the preparation of the inner wrapping paper and the preparation of the outer wrapping paper,

[0029] The preparation of described inner wrapping paper comprises the steps:

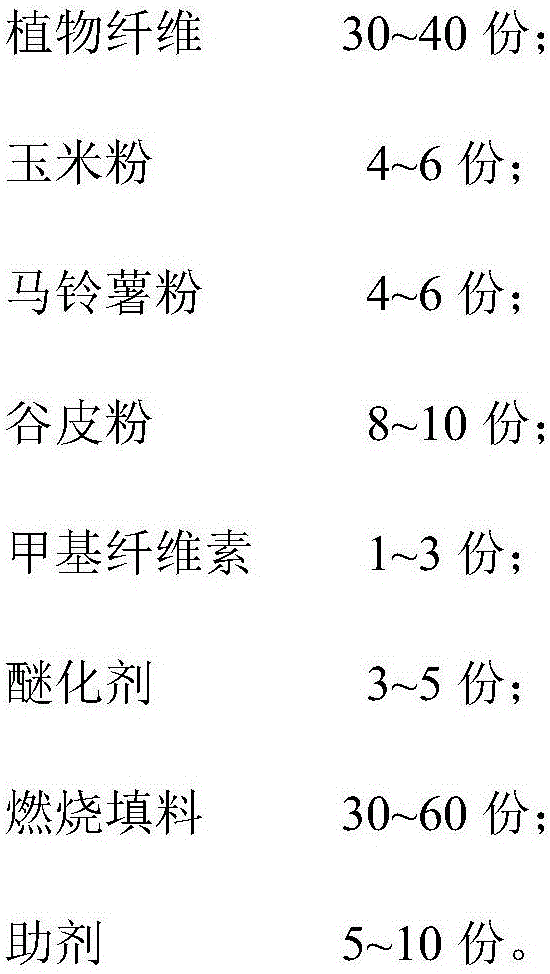

[0030] (1) Prepare combustion layer: mix plant fiber with water, add combustion filler, auxiliary agent, etherification agent, stir evenly, filter out slurry after stirring, slurry is mixed with corn flour, potato flour, grain husk powder and The methyl cellulose is mixed to complete the pulp preparation, the pulp is pressed and dehydrated, and then pressed on the paper press after drying;

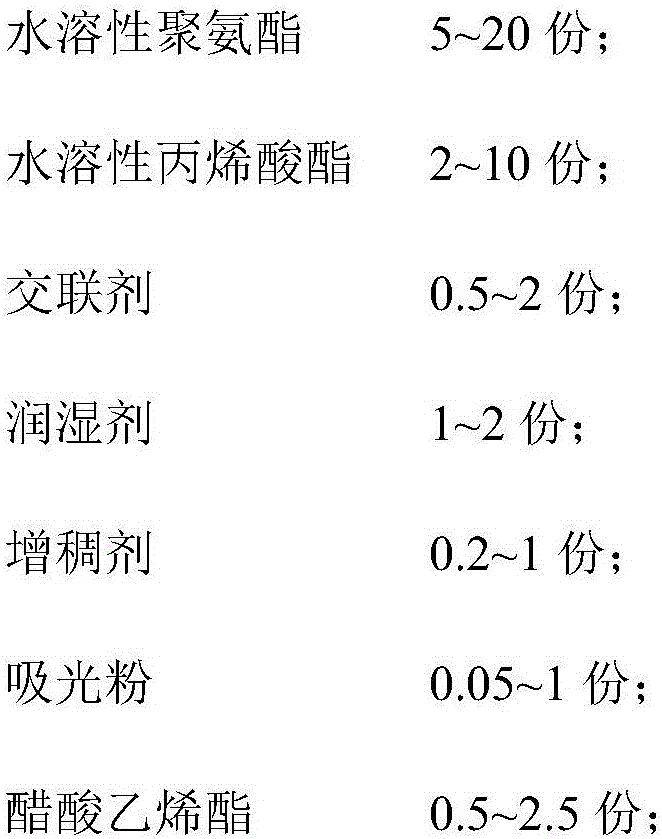

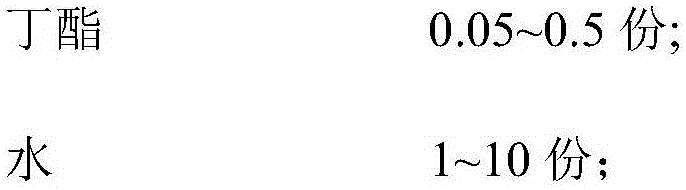

[0031] (2) Preparation of heat conduction layer: use the same preparation method as step (1) to prepare a base paper layer, coat the lower surface of the base paper layer with aluminum foil as a heating layer, and plate a grid-shaped aluminum foil on the upper surface of the base paper layer as a heat transfer layer, ...

Embodiment 2

[0047] Embodiment 2: A kind of packaging paper production process of heat-not-burn tobacco, including the preparation of the inner wrapping paper and the preparation of the outer wrapping paper,

[0048] The preparation of described inner wrapping paper comprises the steps:

[0049](1) Prepare combustion layer: mix plant fiber with water, add combustion filler, auxiliary agent, etherification agent, stir evenly, filter out slurry after stirring, slurry is mixed with corn flour, potato flour, grain husk powder and The methyl cellulose is mixed to complete the pulp preparation, the pulp is pressed and dehydrated, and then pressed on the paper press after drying;

[0050] (2) Preparation of heat conduction layer: use the same preparation method as step (1) to prepare a base paper layer, coat the lower surface of the base paper layer with aluminum foil as a heating layer, and plate a grid-shaped aluminum foil on the upper surface of the base paper layer as a heat transfer layer, ...

Embodiment 3

[0067] Embodiment 3: A kind of packaging paper production process of heat-not-burn tobacco, including the preparation of the inner wrapping paper and the preparation of the outer wrapping paper,

[0068] The preparation of described inner wrapping paper comprises the steps:

[0069] (1) Prepare combustion layer: mix plant fiber with water, add combustion filler, auxiliary agent, etherification agent, stir evenly, filter out slurry after stirring, slurry is mixed with corn flour, potato flour, grain husk powder and The methyl cellulose is mixed to complete the pulp preparation, the pulp is pressed and dehydrated, and then pressed on the paper press after drying;

[0070] (2) Preparation of heat conduction layer: use the same preparation method as step (1) to prepare a base paper layer, coat the lower surface of the base paper layer with aluminum foil as a heating layer, and plate a grid-shaped aluminum foil on the upper surface of the base paper layer as a heat transfer layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com