Quick thawing machine

A fast, rack-mounted technology, applied in the direction of preservation of meat/fish by freezing/cooling, etc., can solve problems such as damage to raw materials, reducing the efficiency of food production and processing, and affecting the taste of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

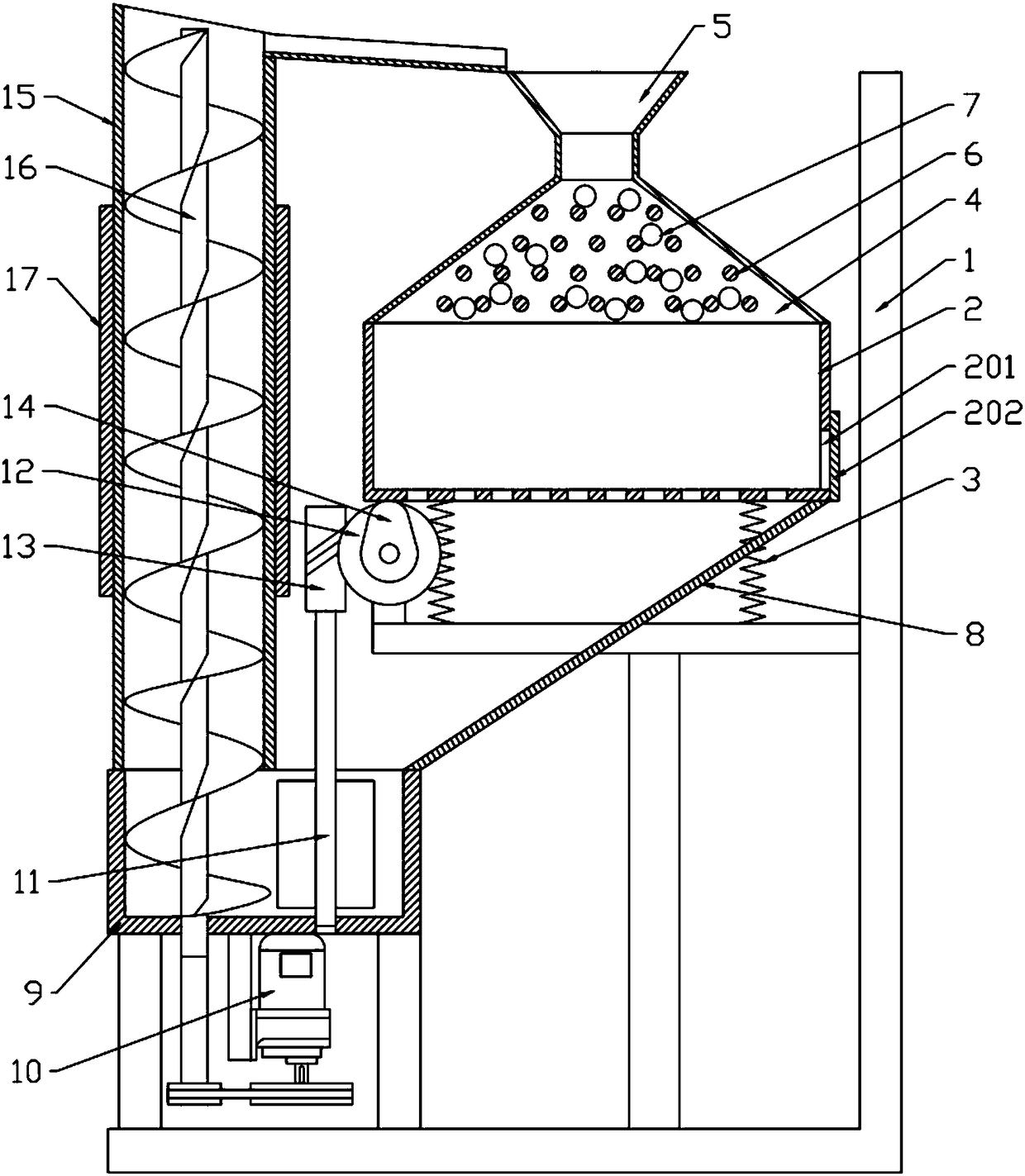

[0016] The reference signs in the accompanying drawings of the description include: frame 1, thawing tank 2, discharge port 201, baffle plate 202, compression spring 3, fixed plate 4, goal opening 5, ball distribution column 6, metal ball 7, connection Ball plate 8, ball receiving groove 9, motor 10, power transmission shaft 11, worm wheel 12, worm screw 13, cam 14, delivery tube 15, screw propulsion rod 16, heating plate 17.

[0017] The embodiment of fast thawing machine is basically as attached figure 1 Shown: including frame 1, thawing tank 2, deicing device and vibration mechanism driving thawing tank 2 to vibrate, there is a discharge port 201 on the side of the thawing tank 2, and the discharge port 201 is provided with a cover discharge The baffle plate 202 of the port 201, the edge of the bottom of the thawing tank 2 is installed on the frame 1 through the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com