Winter garbage unfreezing system and method in household garbage incineration power plant

A technology for domestic waste incineration and power plants, which is applied in combustion methods, incinerators, combustion types, etc., can solve the problems of waste not easily fermented and dehydrated, and achieve the effects of promoting waste fermentation and dehydration, low operating costs, and high thawing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

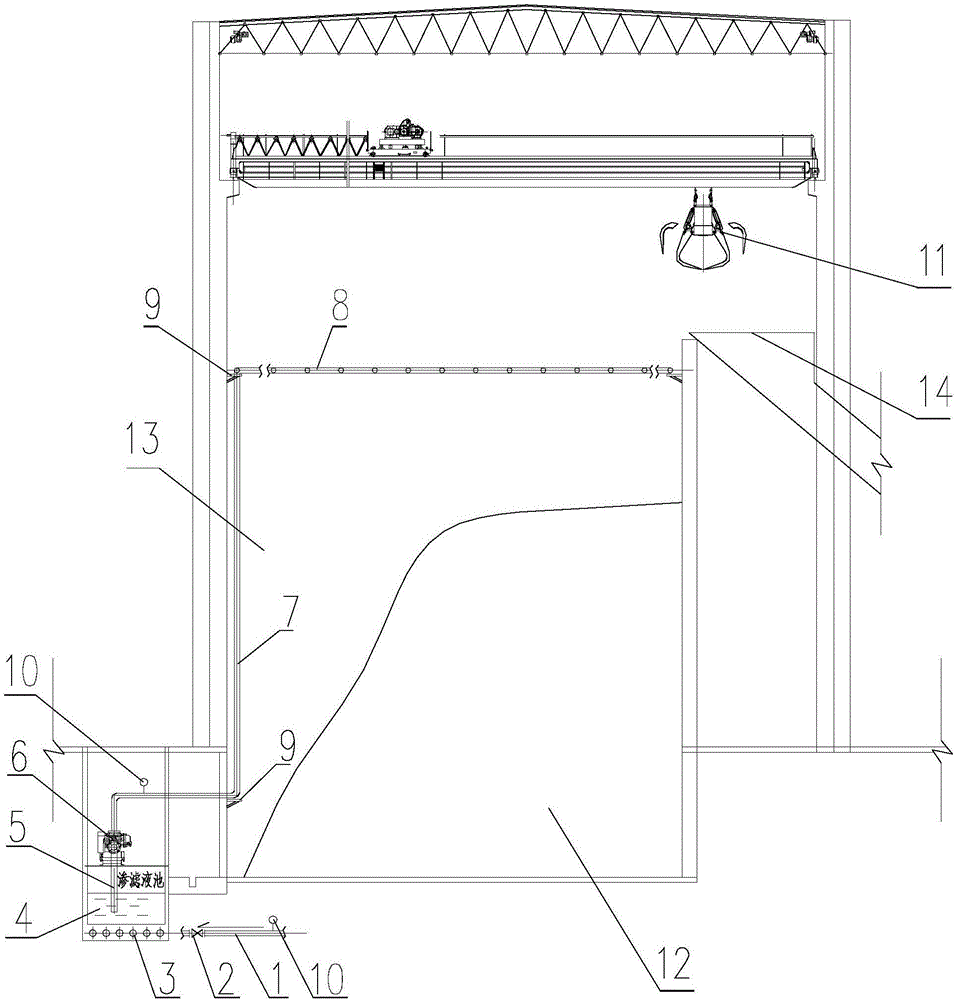

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] Such as figure 1 As shown, a winter garbage thawing system of a domestic waste incineration power plant includes a garbage storage pit 13, a garbage crane 11, a garbage receiving hopper 14, and a leachate pool 4; a leachate pump 6 and a leachate pump are installed in the leachate pool 4 6 Connect the leachate spray pipe 8 arranged above the garbage storage pit 13 through the liquid outlet pipe; a plurality of hot water coils 3 are arranged at the bottom of the leachate pool 4, and the hot water coils 3 are externally connected to hot water The inlet pipe 1 and the water outlet pipe are equipped with a temperature detection instrument 10 and a valve 2 on the hot water inlet pipe 1; a temperature detection instrument is also installed on the liquid outlet pipe connected between the leachate pump 6 and the leachate spray pipe 8 10.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com