Patents

Literature

180results about How to "Quick thaw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibrin-containing composition

InactiveUS20060128016A1Improve performanceRapidly and simply producingSenses disorderFibrinogenFiberPurification methods

It is intended to provide a scaffold material having favorable properties and being appropriate for cell proliferation and differentiation in regeneration therapy. Namely, a fibrin-containing biological scaffold material to be used in the case of employing a fibrin composition for the regeneration of a human tissue and cell proliferation, characterized by containing a mixture of a fibrinogen concentrate, which is obtained from human plasma by a quick and rough purification method, with a fibrinogen activator.

Owner:ASAHI KASEI MEDICAL CO LTD

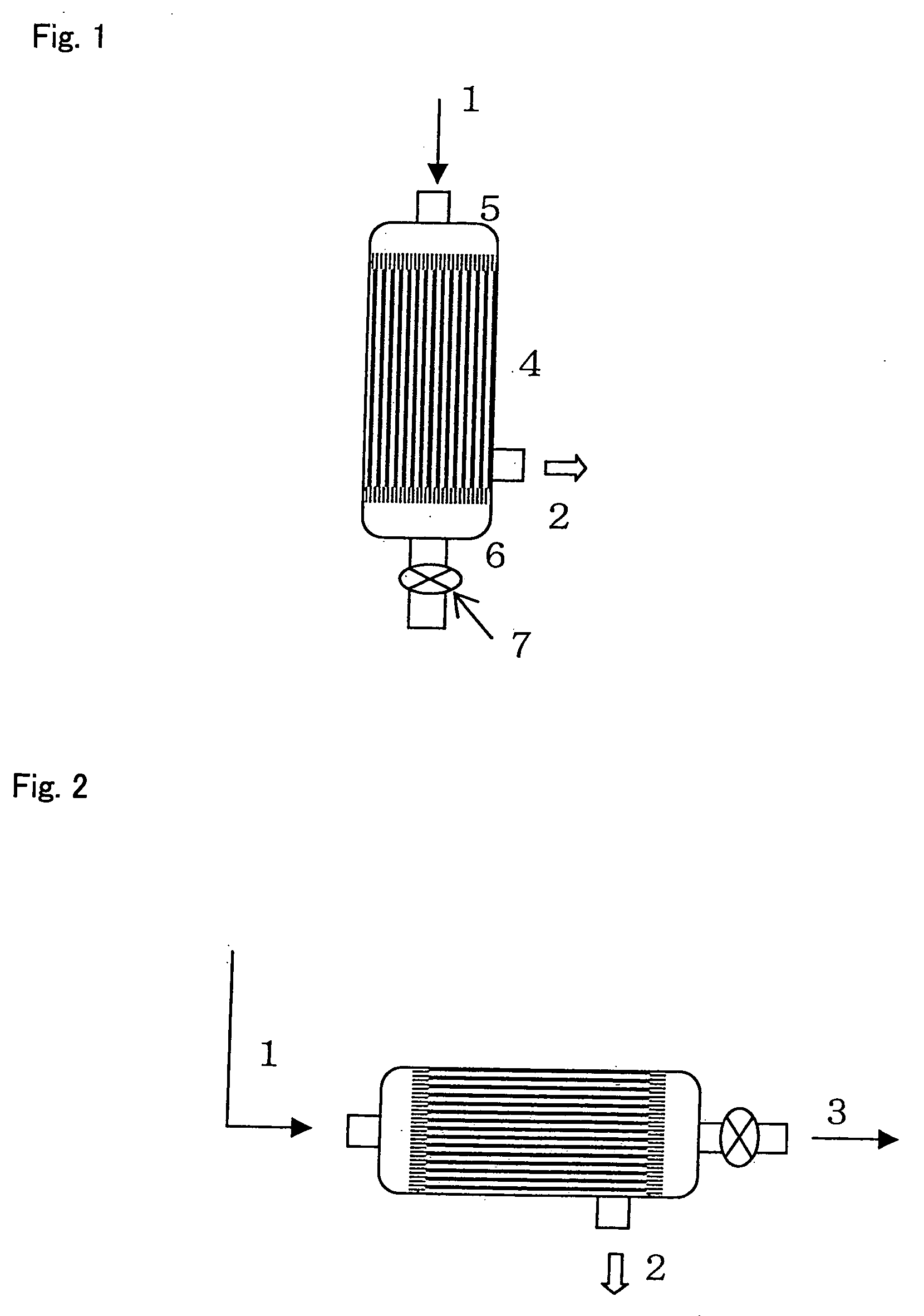

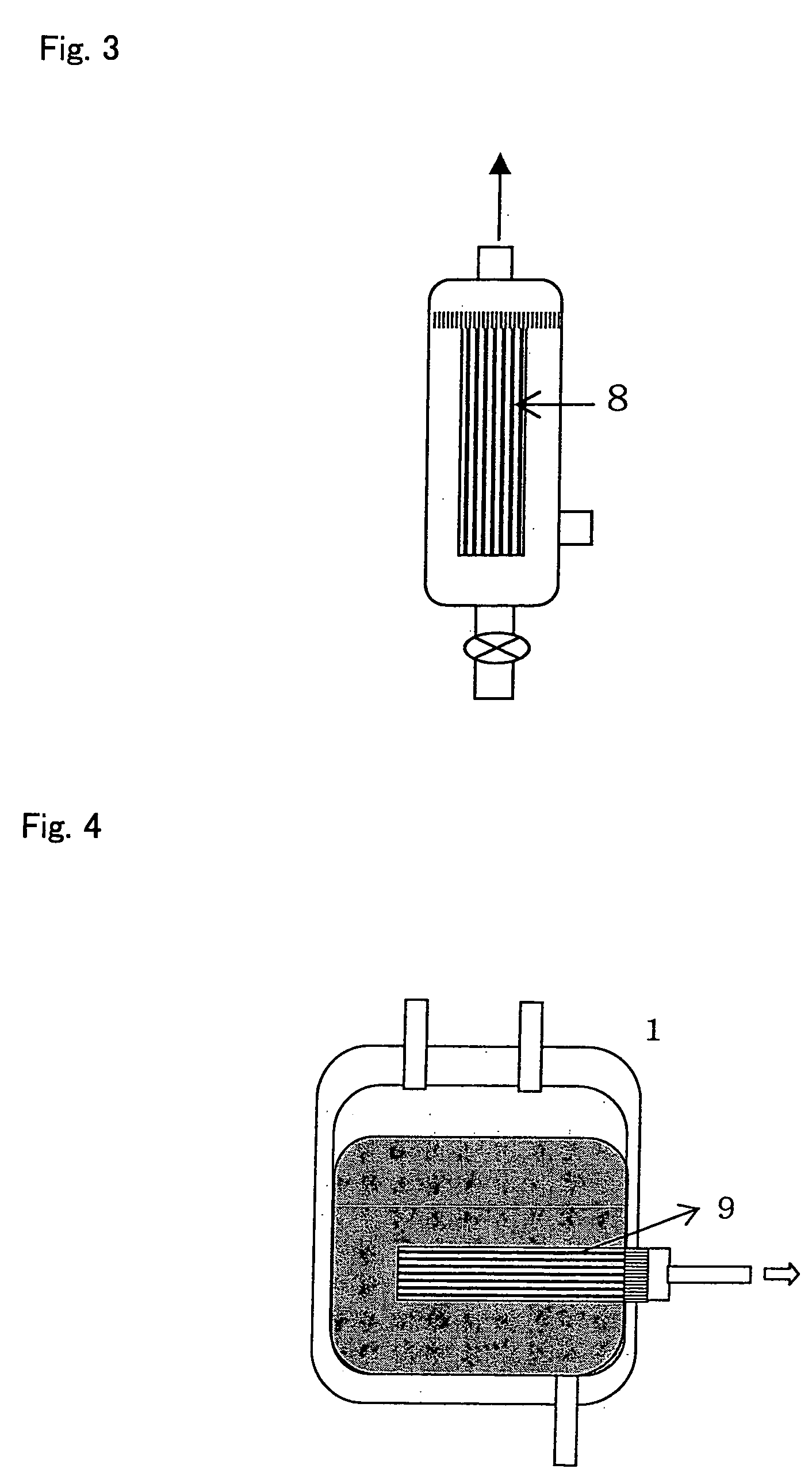

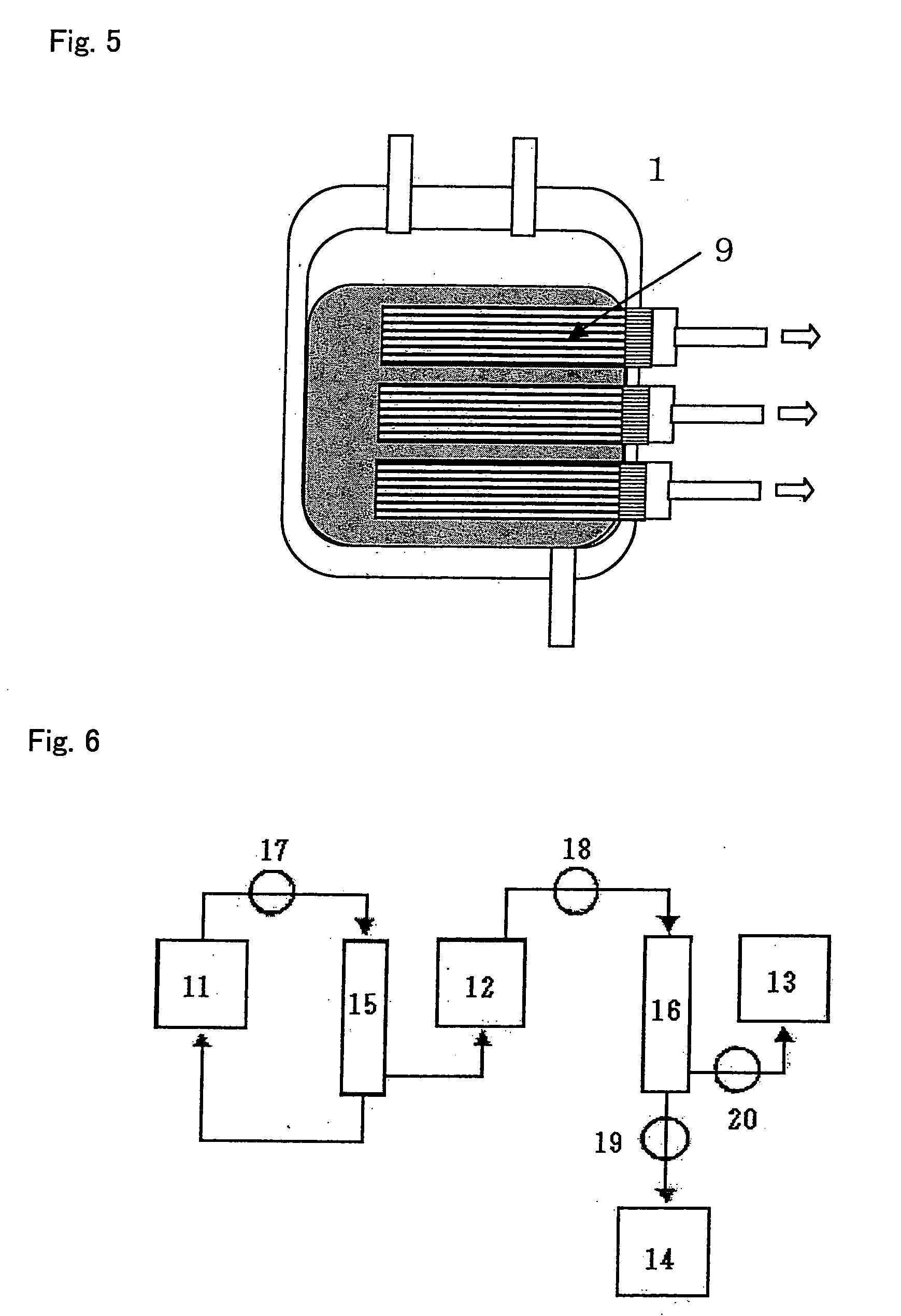

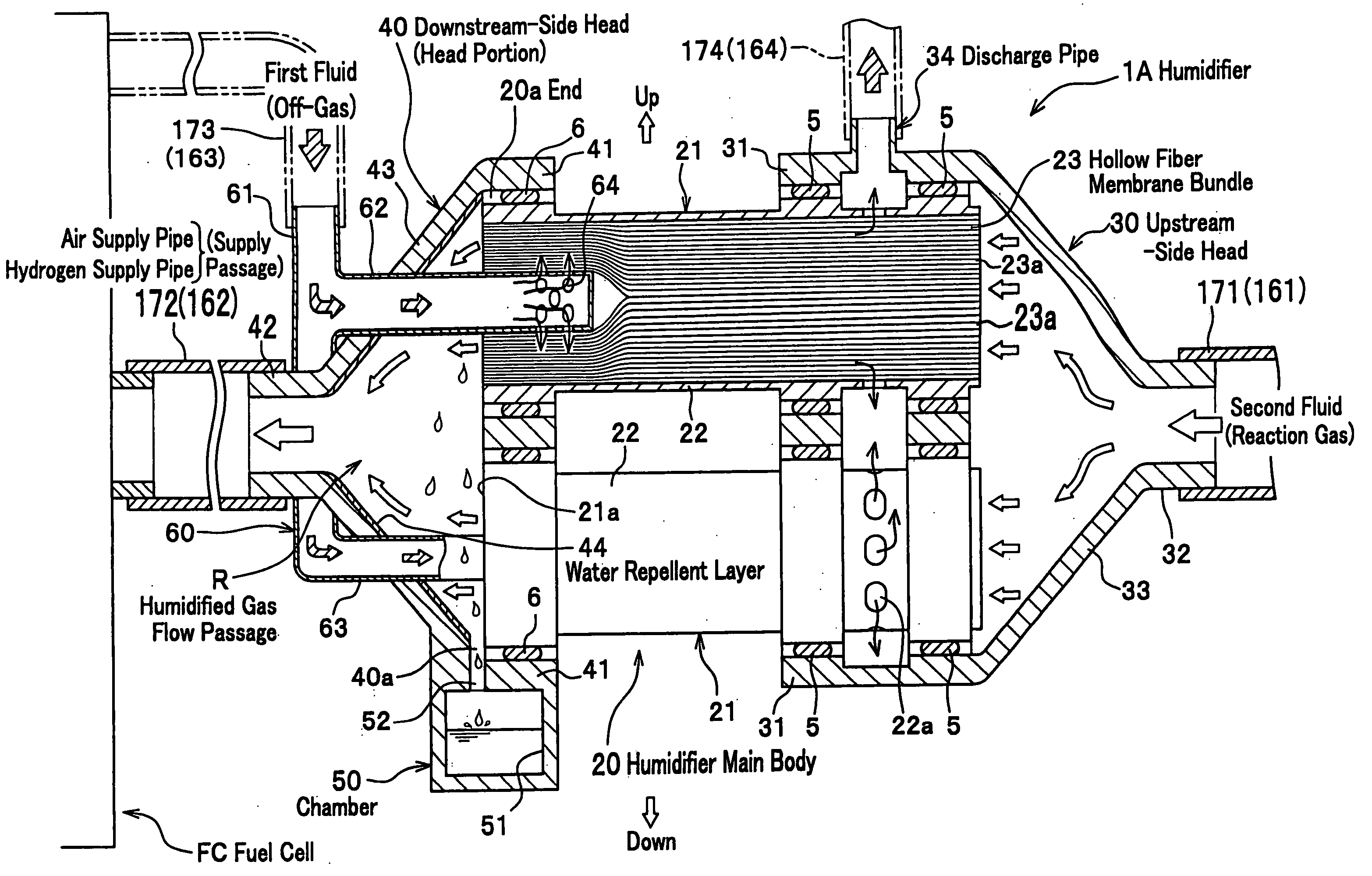

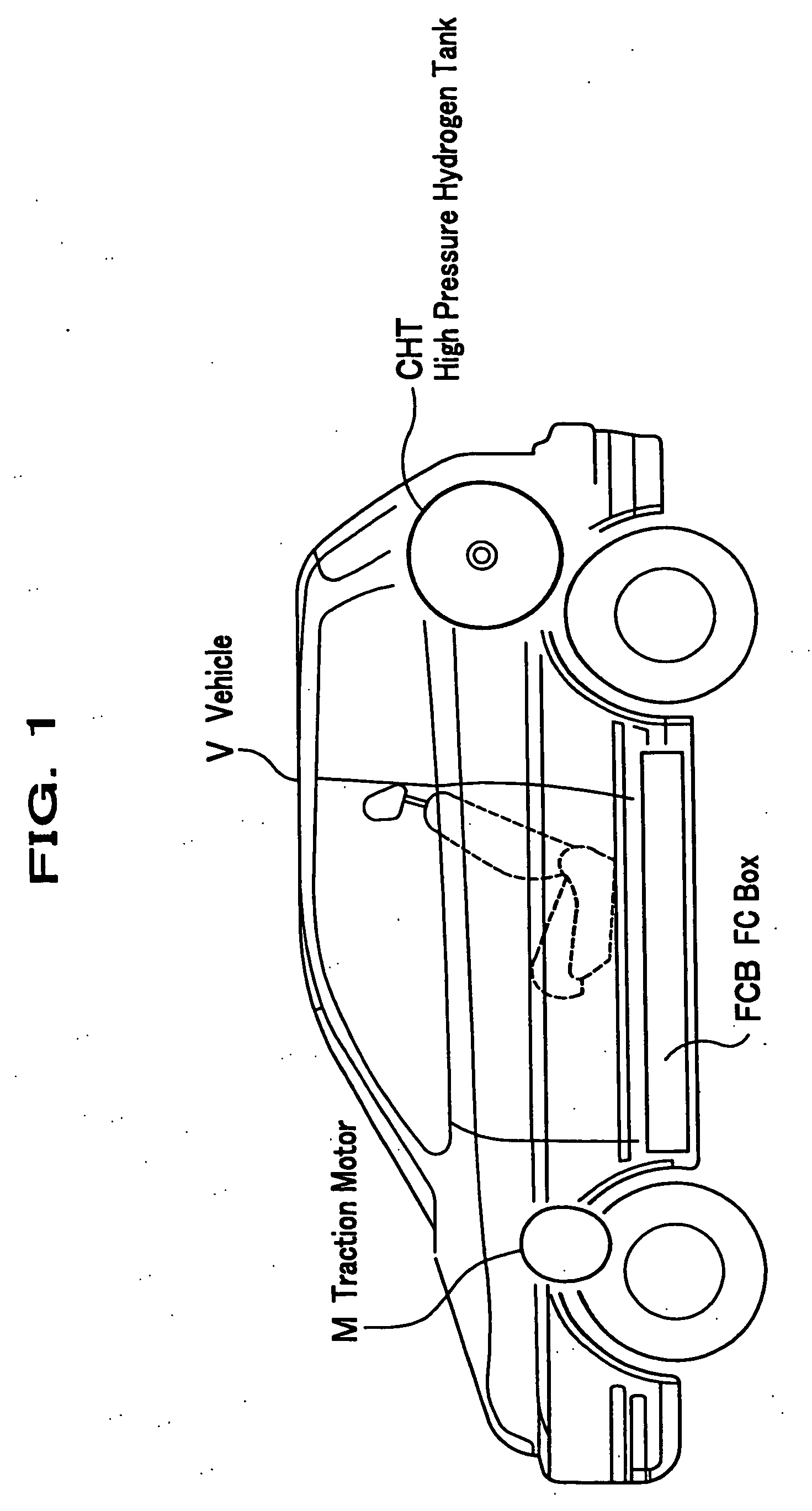

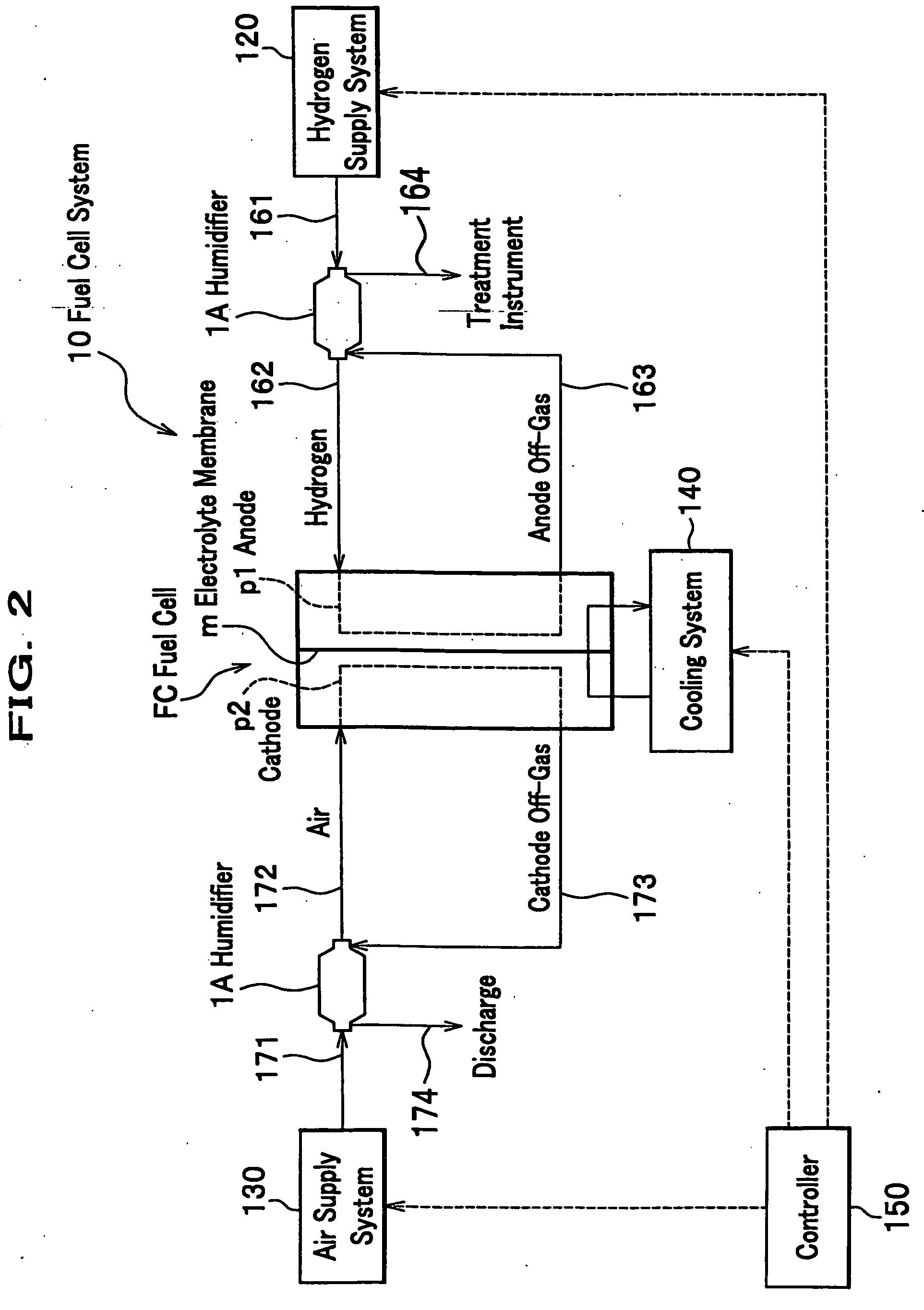

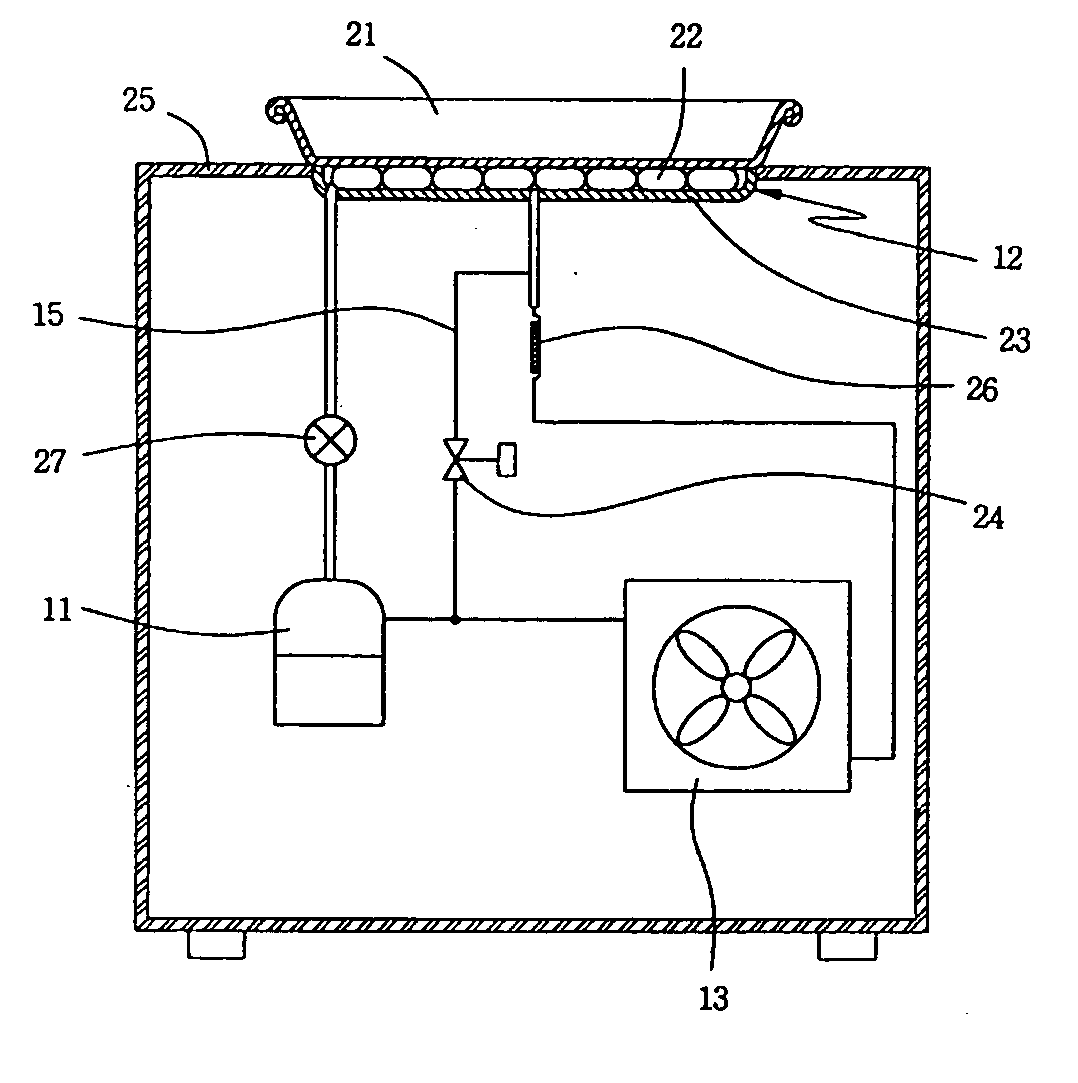

Humidifier for fuel cell system

InactiveUS20060147774A1Easy to dropEasily introducedFuel cell auxillariesIsotope separationProduct gasEngineering

A humidifier of the present invention includes a humidifier main body for humidifying a second fluid, using a humidified first fluid discharged from a fuel cell; a head portion of which one end is connected to an end of the humidifier main body and the other end is connected to the fuel cell or a supply passage extending from the fuel cell, and which supplies the second fluid after humidification to the fuel cell; and a chamber for communicating a bottom portion of a humidified gas flow passage formed within the head portion.

Owner:HONDA MOTOR CO LTD

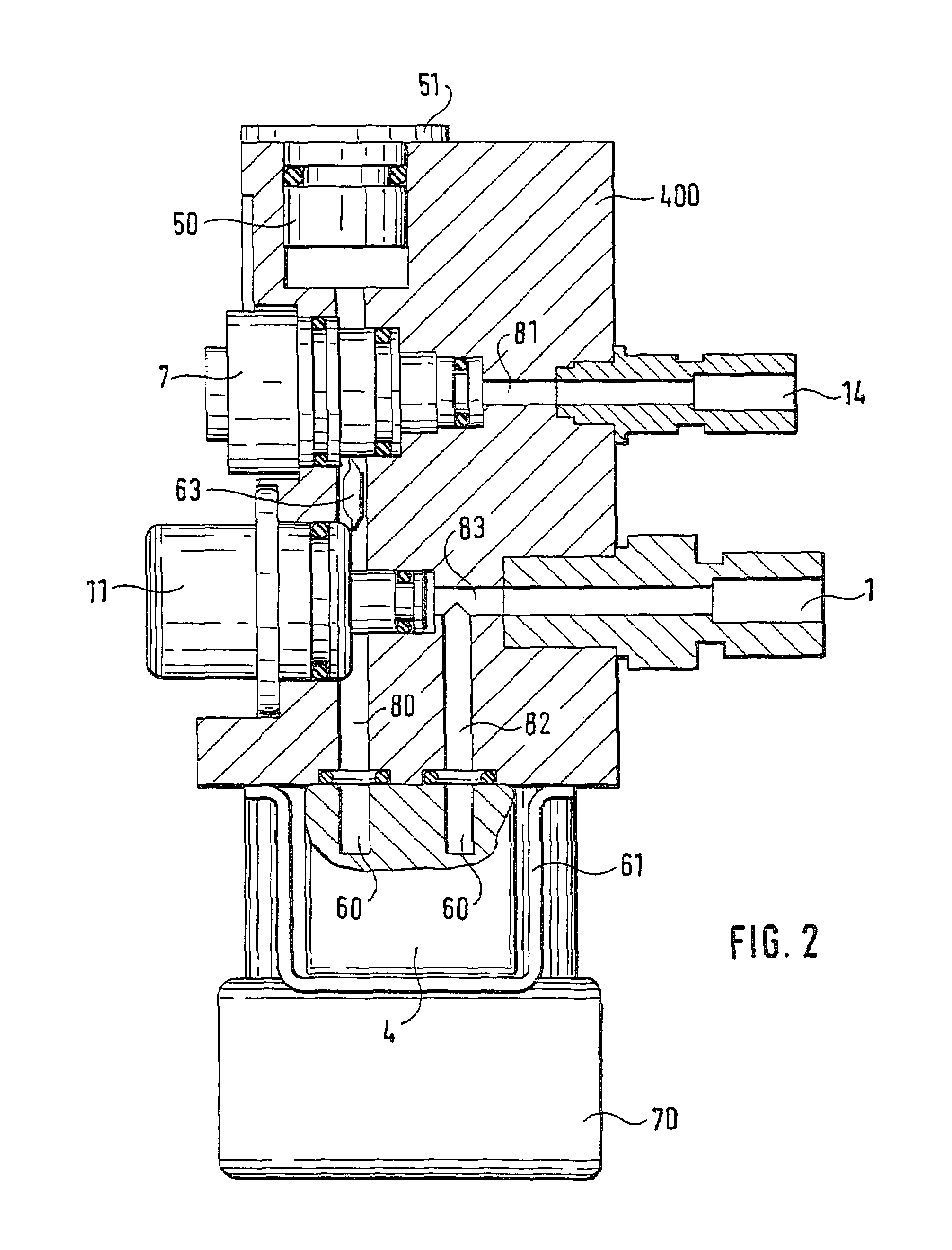

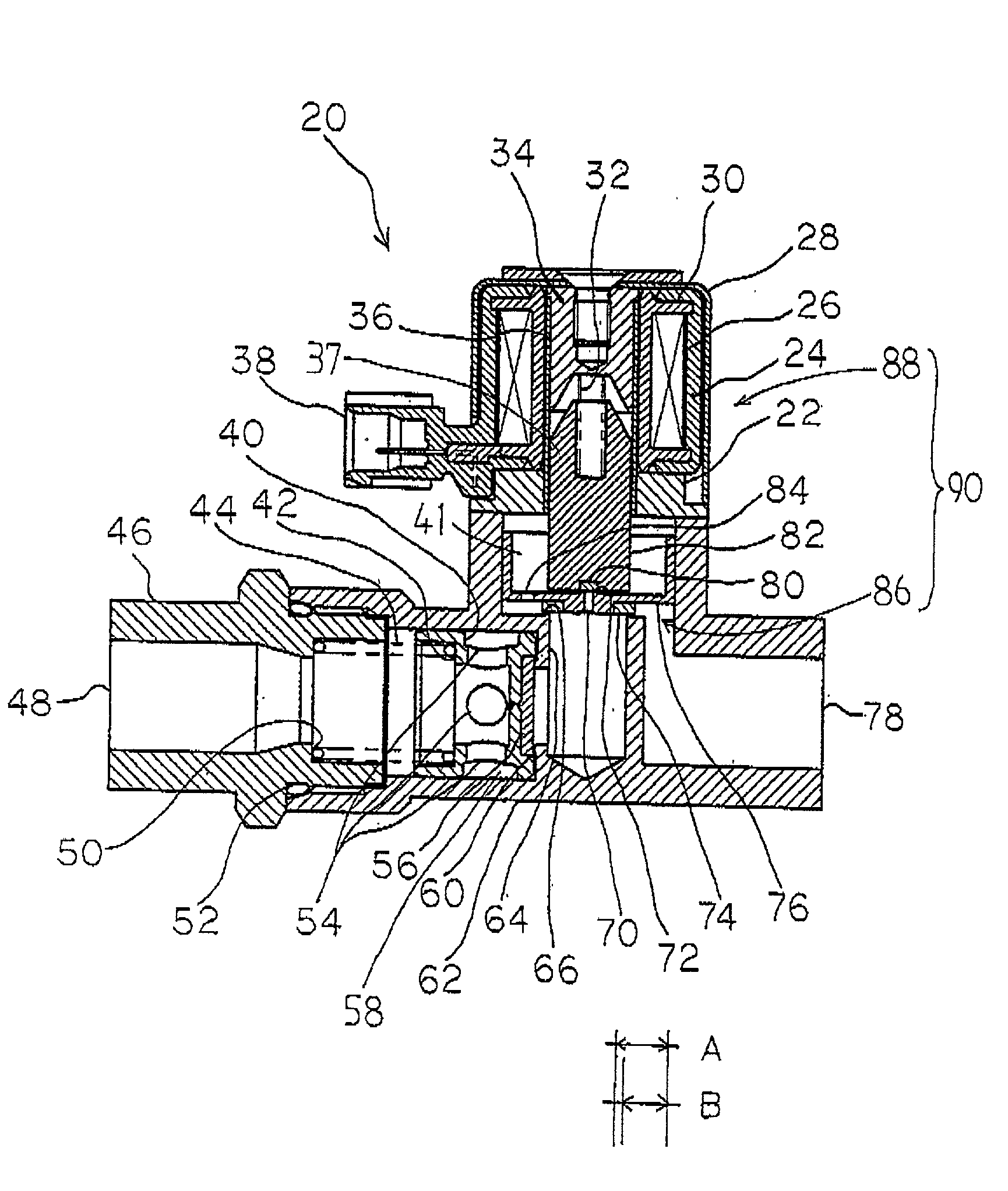

Device for the dosing of a reducing agent

InactiveUS7481049B2Produced economicallyRich basic functionsLiquid surface applicatorsInternal combustion piston enginesNitrogen oxidesEngineering

An apparatus for metering a urea or a urea-water solution for delivery to a catalytic converter assembly for removing nitrogen oxides from the exhaust gases of a Diesel engine, includes a housing block supporting function components communicating via a line, formed by recesses in the housing block, for transporting the reducing agent, and the walls of the line are formed by the housing block. This apparatus assures a simple line layout for reducing agent with a minimum number of sealing points that is accordingly appropriate for large-scale mass production.

Owner:ROBERT BOSCH GMBH

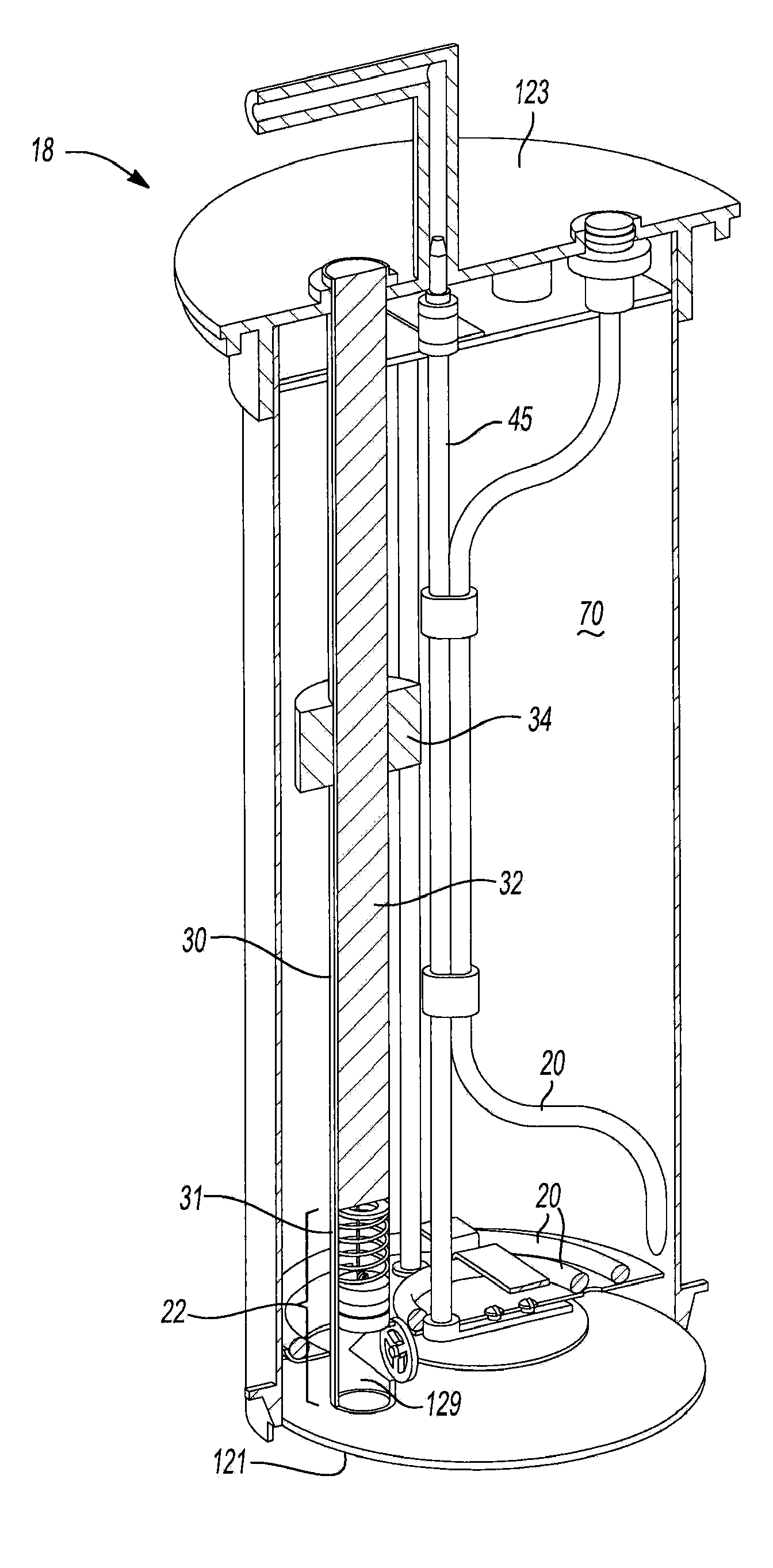

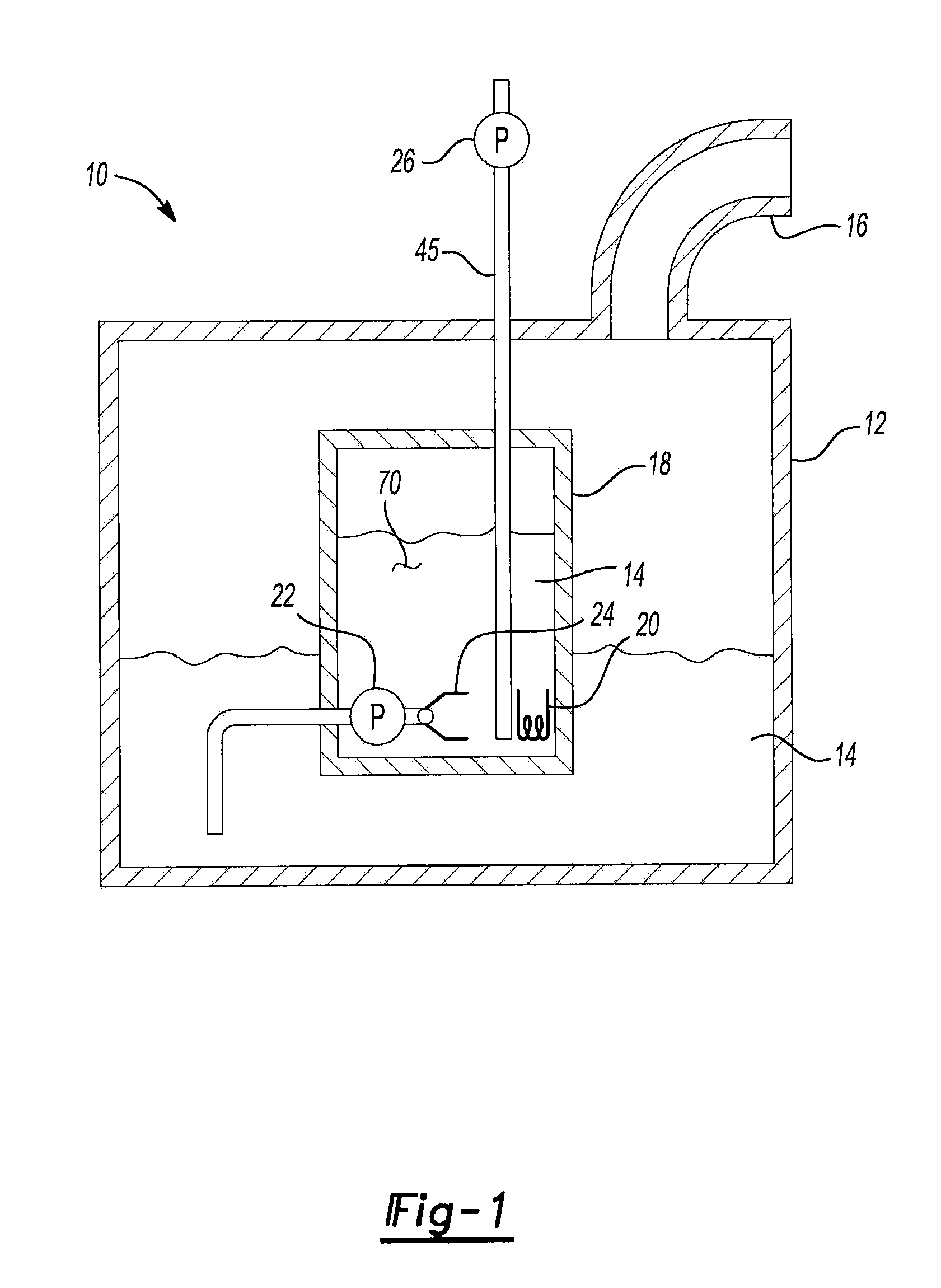

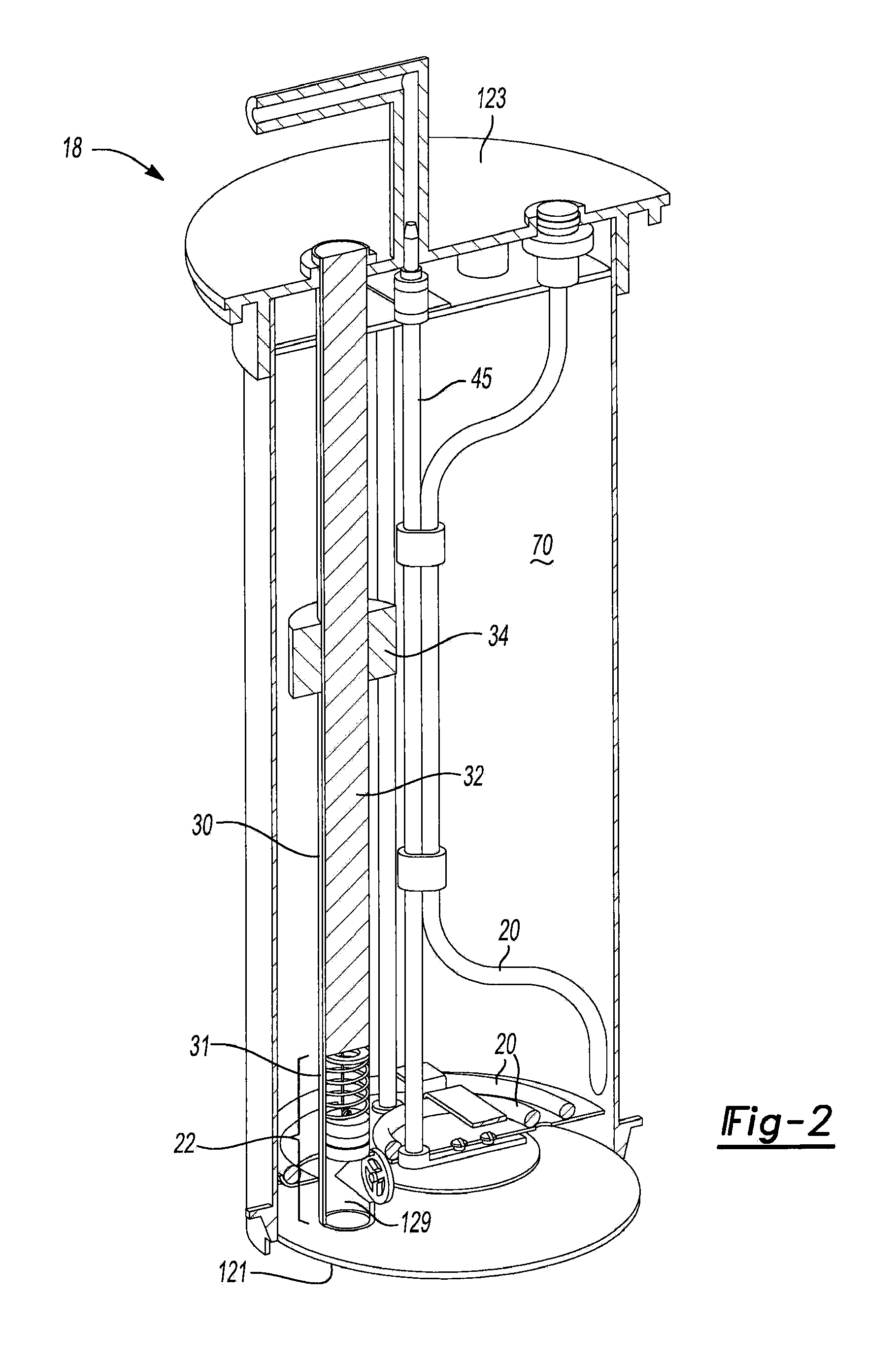

Urea storage system

InactiveUS20100154907A1Quick thawOptimization mechanismInternal combustion piston enginesExhaust apparatusEngineeringActuator

A urea storage system comprising a storage tank for a urea solution is provided. The system comprises a heated reservoir, a channel connecting the storage tank to the heated reservoir and a pump for drawing urea from the heated reservoir. A second pump including an actuator comprising a memory shape metal for drawing urea from the storage tank to the heated reservoir is also provided.

Owner:DELPHI TECH INC

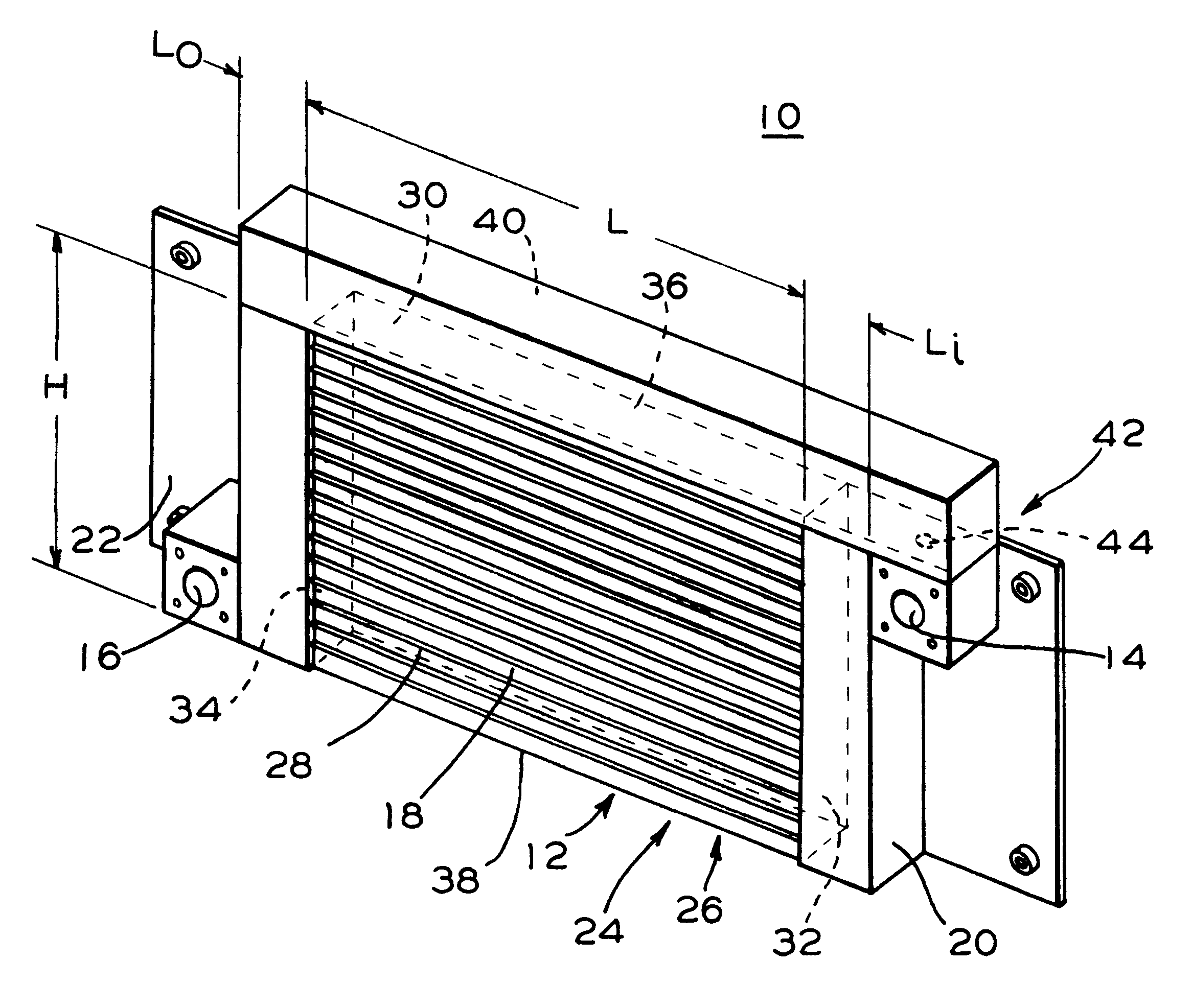

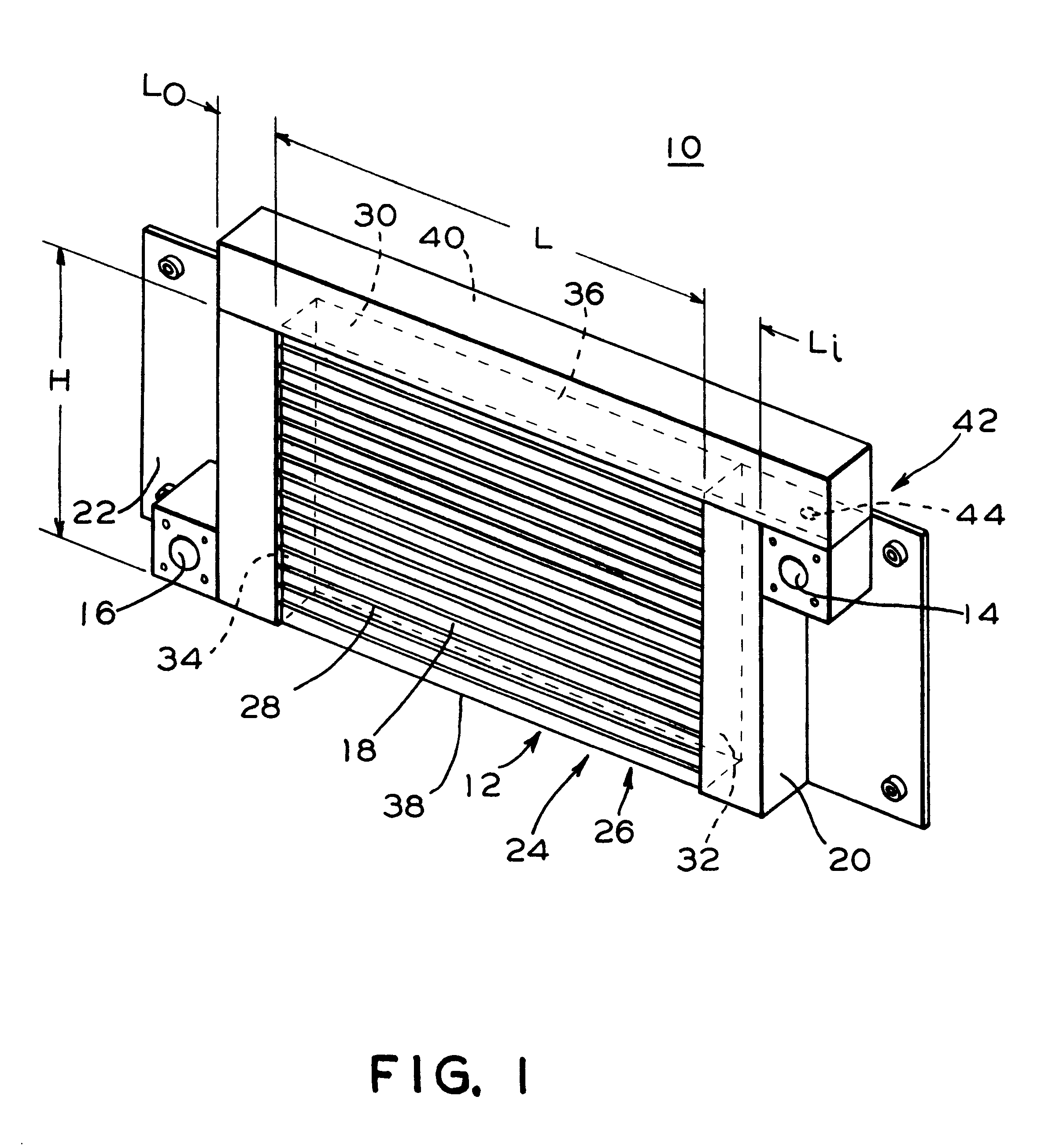

Aftercooler having bypass passage integrally formed therewith

InactiveUS6167956B1Quick thawEasy constructionPositive displacement pump componentsTemperatue controlDifferential pressureCompressed fluid

An aftercooler for cooling a compressed fluid exiting from a compressor, the aftercooler including a radiator unit for receiving the compressed fluid exiting from the compressor and for cooling the compressed fluid, the radiator unit having an inlet for receiving the compressed fluid, an outlet for discharging the compressed fluid and a plurality of heat exchange passageways connecting the inlet and the outlet for transferring heat from the compressed fluid. The aftercooler also includes a bypass channel for bypassing the plurality of heat exchange passageways which extends from a first point substantially adjacent the inlet of the radiator unit to a second point substantially adjacent the outlet of the radiator unit. The aftercooler also includes a bypass flow proportioning mechanism that is effective to proportion the flow of the compressed fluid exiting from the compressor and flowing through the aftercooler between the radiator unit and the bypass channel dependent upon a pressure differential across the radiator unit. Preferably, the bypass flow proportioning mechanism is a substantial restriction disposed along the bypass channel which operates to continuously proportion flow between the radiator unit and the bypass channel. The bypass channel is formed substantially integrally with the radiator unit. Preferably, the plurality of heat exchange passageways are arranged to form an array and at least a portion of a length of the bypass channel extends contiguous with a portion of a periphery of the array of the heat exchange passageways.

Owner:WESTINGHOUSE AIR BRAKE CO

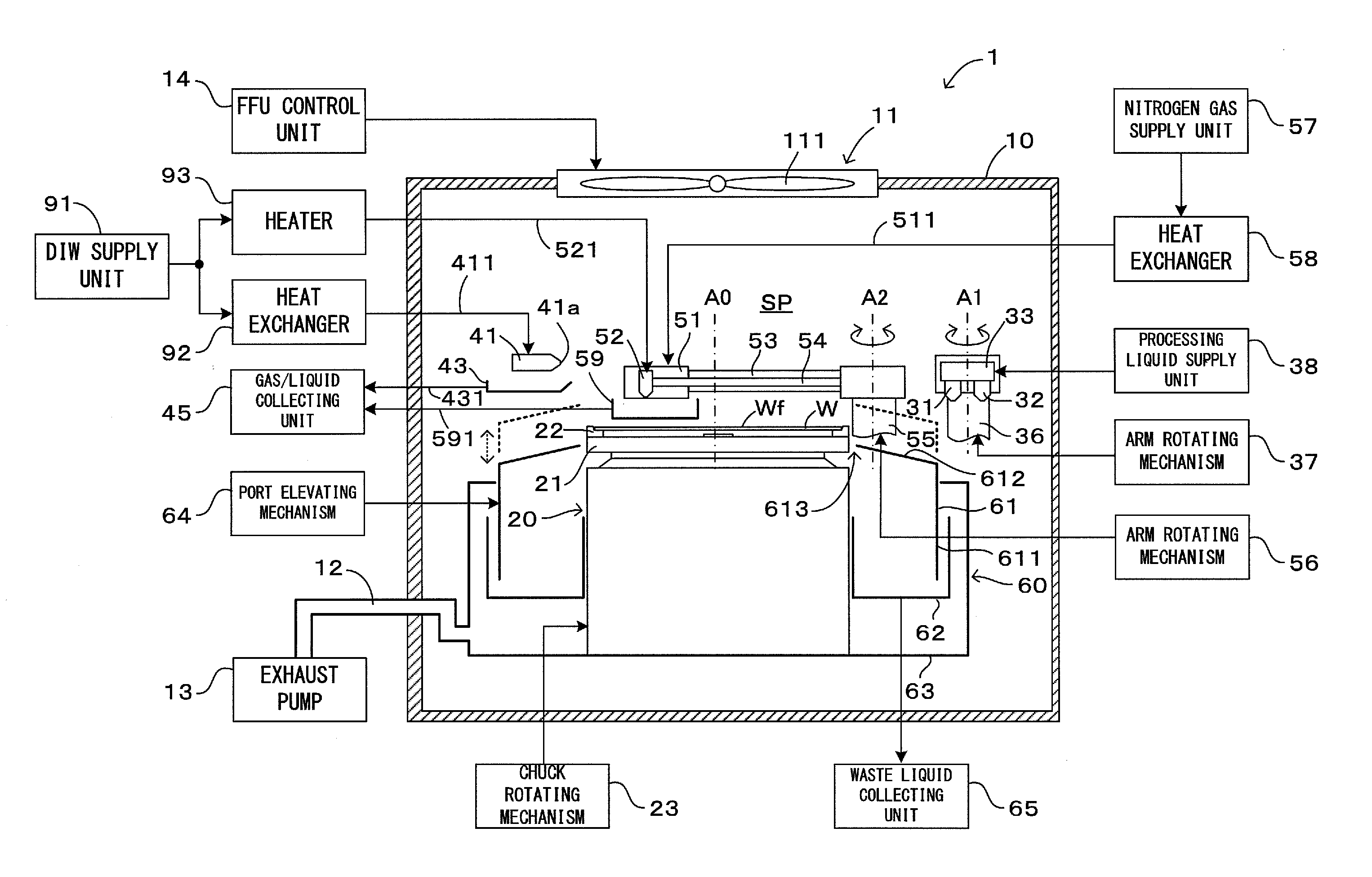

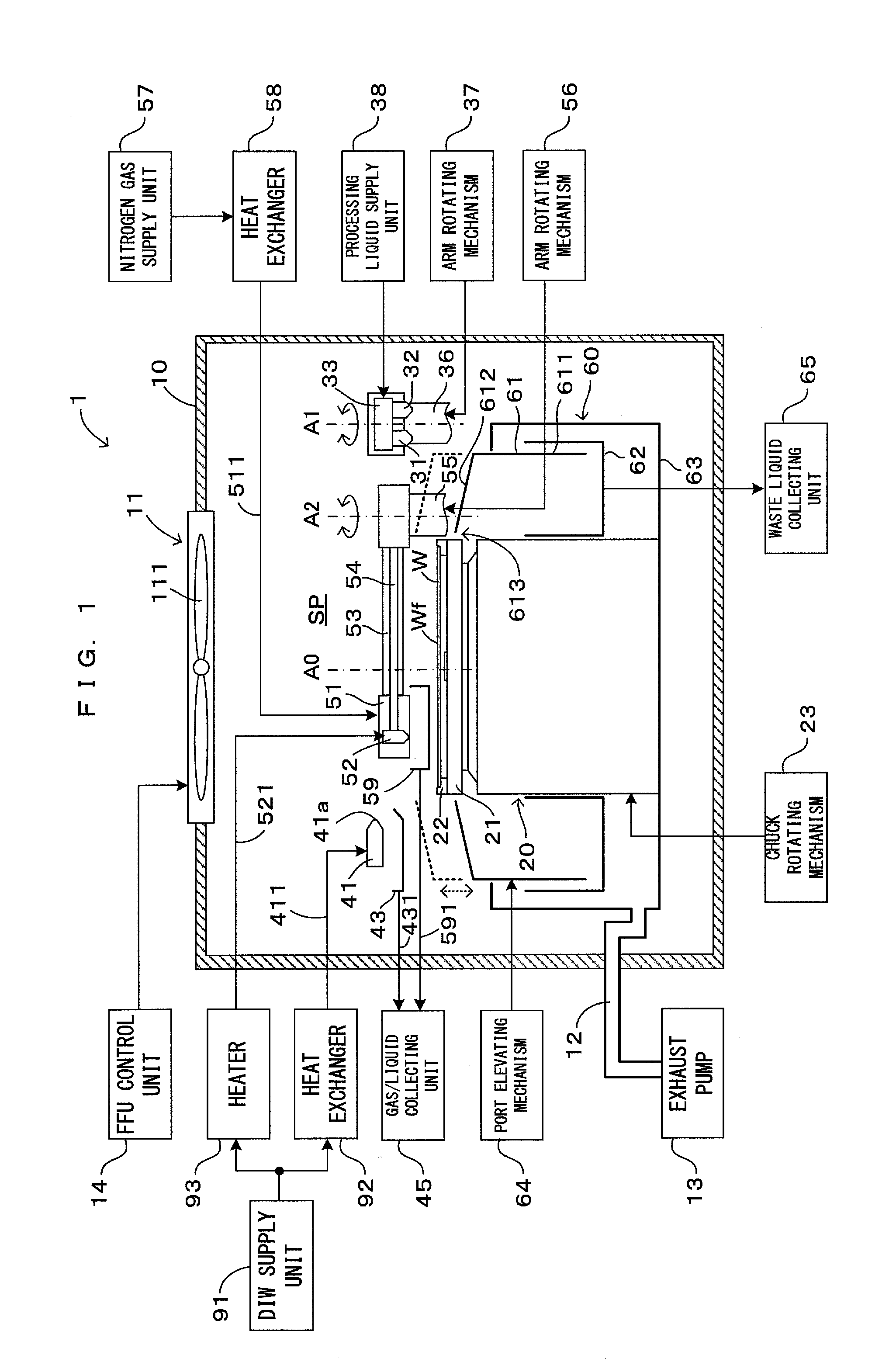

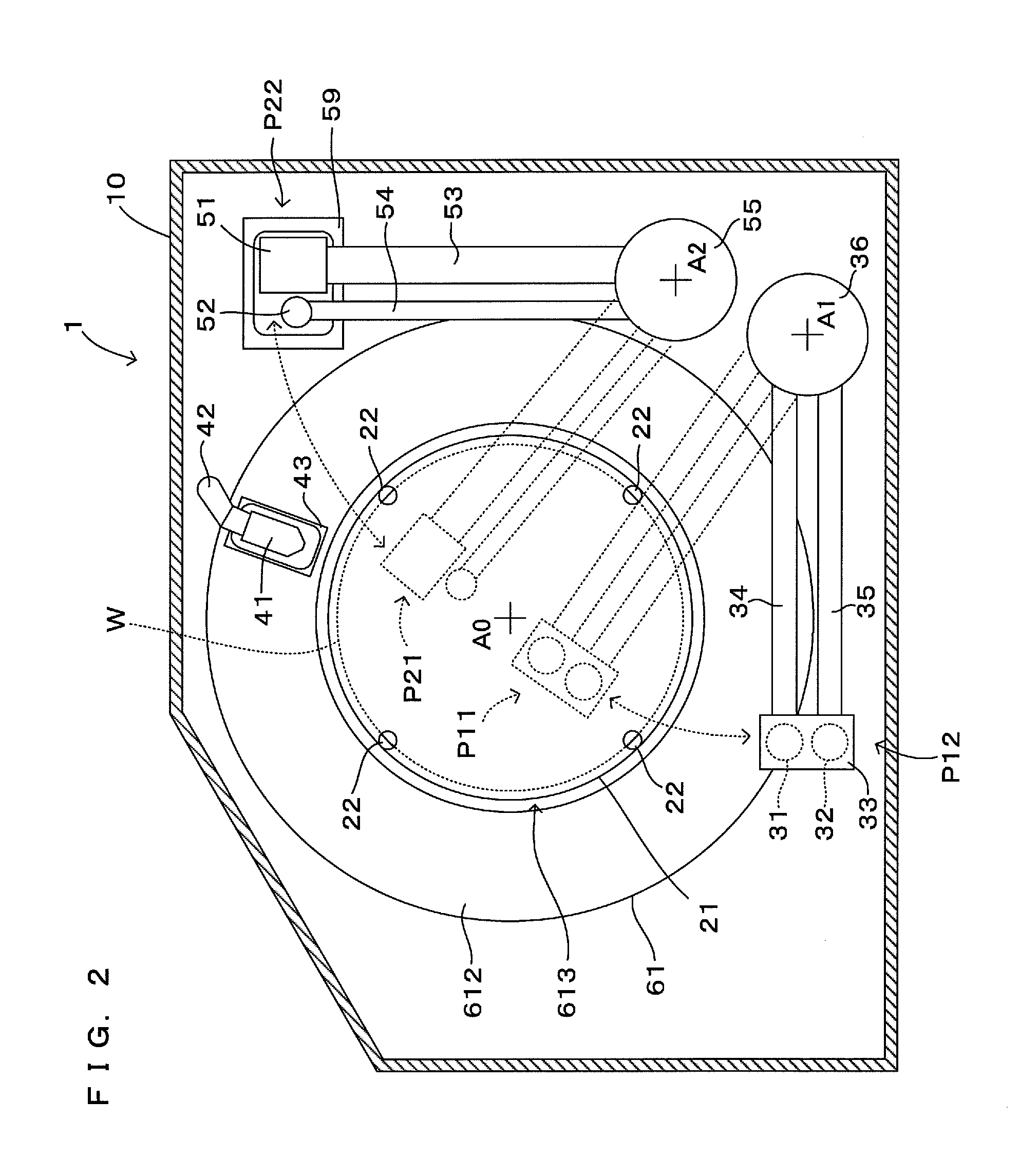

Substrate processing apparatus and substrate processing method

InactiveUS20150020850A1Obstructing flow passageImprove throughputSemiconductor/solid-state device manufacturingCleaning using liquidsThin membraneEngineering

A substrate processing apparatus comprises: a liquid film former which forms a liquid film by supplying a liquid on an upper surface of the substrate W held horizontally; a cooling gas discharge nozzle which discharges cooling gas of a temperature lower than a freezing point of the liquid forming the liquid film to the liquid film; a thawing liquid discharge nozzle which discharges a thawing liquid to a frozen film formed by freezing the liquid film; a thawing liquid supplier which supplies the heated thawing liquid to the thawing liquid discharge nozzle via a pipe; and a receiver which receives the cooling gas and the thawing liquid respectively discharged from the cooling gas discharge nozzle and the thawing liquid discharge nozzle at the respective retracted position and guides the cooling gas and the thawing liquid to a common flow passage.

Owner:DAINIPPON SCREEN MTG CO LTD

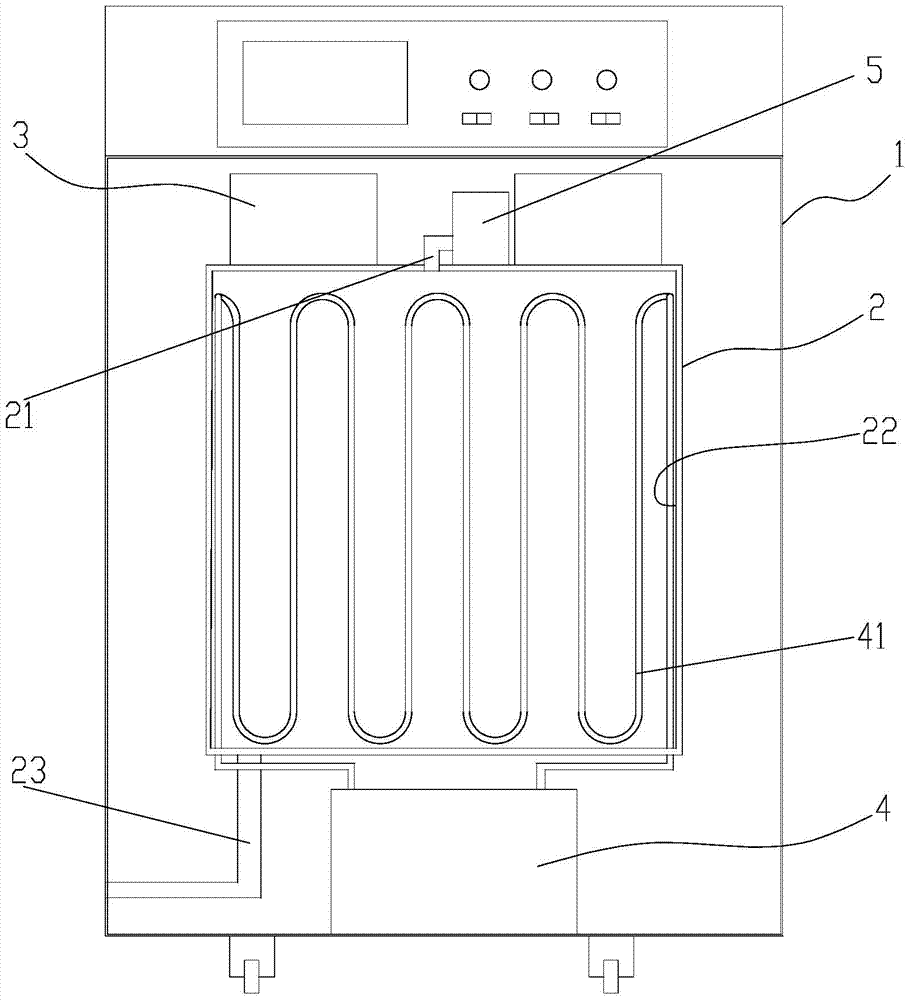

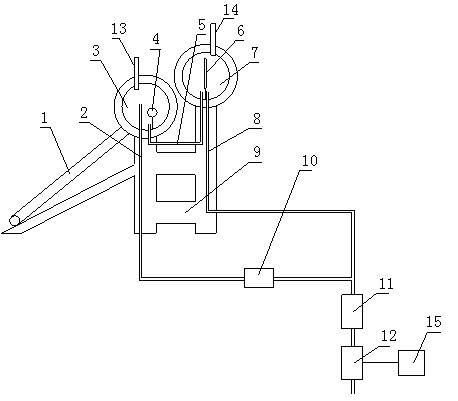

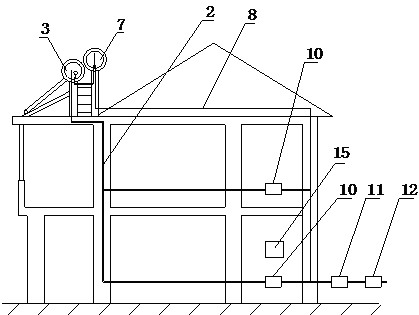

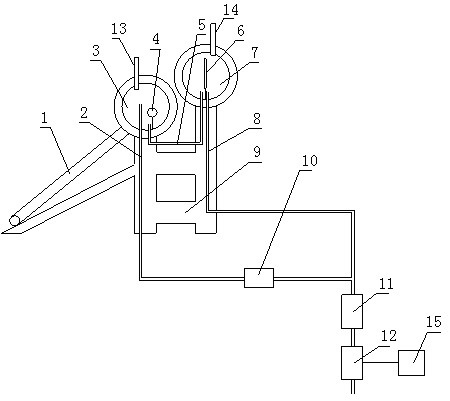

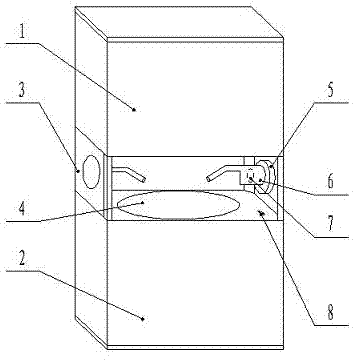

Ultrasonic thawing device and method and application in ice breaking and defrosting

PendingCN106721903AKeep it authenticEasy to break awayOverhead installationFood freezingProcess engineeringFreezing environment

The invention relates to a thawing technology, in particular to an ultrasonic thawing device and method and application in ice breaking and defrosting. The ultrasonic thawing device comprises a machine body and a freezing area arranged on the machine body, wherein the freezing area comprises a thawing cabinet and a cold storage cabinet capable of freezing food, the thawing cabinet is provided with an ultrasonic thawing apparatus, the ultrasonic thawing apparatus breaks ice on the frozen food in the thawing cabinet under the freezing environment, so that nutritional substances of the food can be prevented from being lost along with the water, the original taste of the food is ensured, the taste is good, and the thawing efficiency is improved. The ultrasonic thawing method can be used for ice breaking of ocean, rivers, roads, railways, bridges, electric power and telecommunication circuits, can also be used for defrosting of fast-freezing tunnels, subzero storages, refrigerators, and air conditioner condensers, is not only short in ice breaking time and high in efficiency, but also low in energy consumption and convenient in operation.

Owner:HUNAN JIASHENG FRESH PRESERVATION TECH

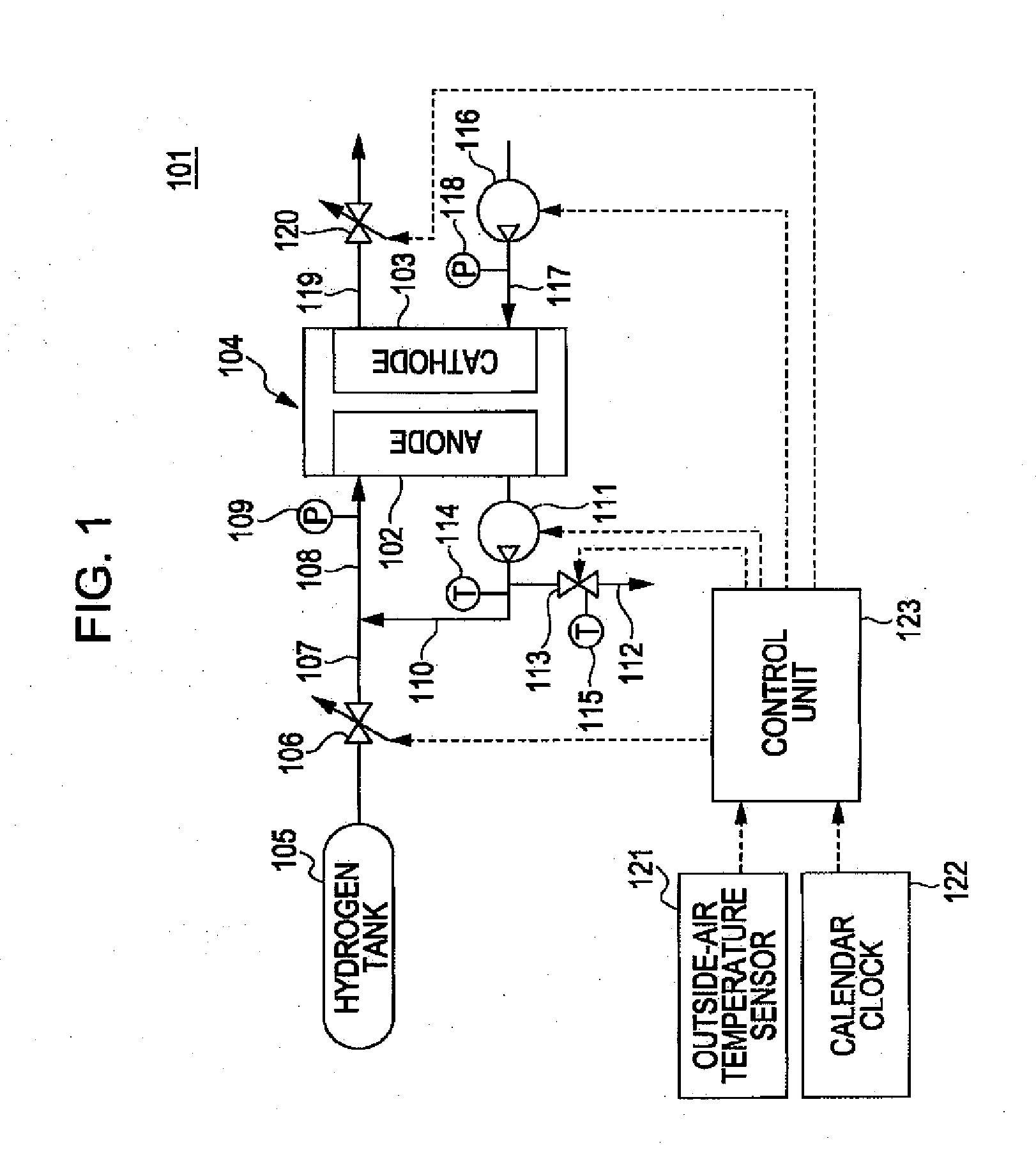

Fuel cell valve and fuel cell system using the valve

ActiveUS20100071781A1Quick thawConcentrated heatingOperating means/releasing devices for valvesValve members for heating/coolingFuel cellsEngineering

A valve for a fluid passage in a vehicle fuel cell system. A housing includes an inflow passage connected to an upstream side of the fluid passage and an outflow passage connected to a downstream side of the fluid passage. A valve body is disposed in the housing and includes an intermediate fluid passage configured to provide fluid communication between the inflow passage and the outflow passage. A heating element is configured to apply heat directly to the valve body.

Owner:NISSAN MOTOR CO LTD

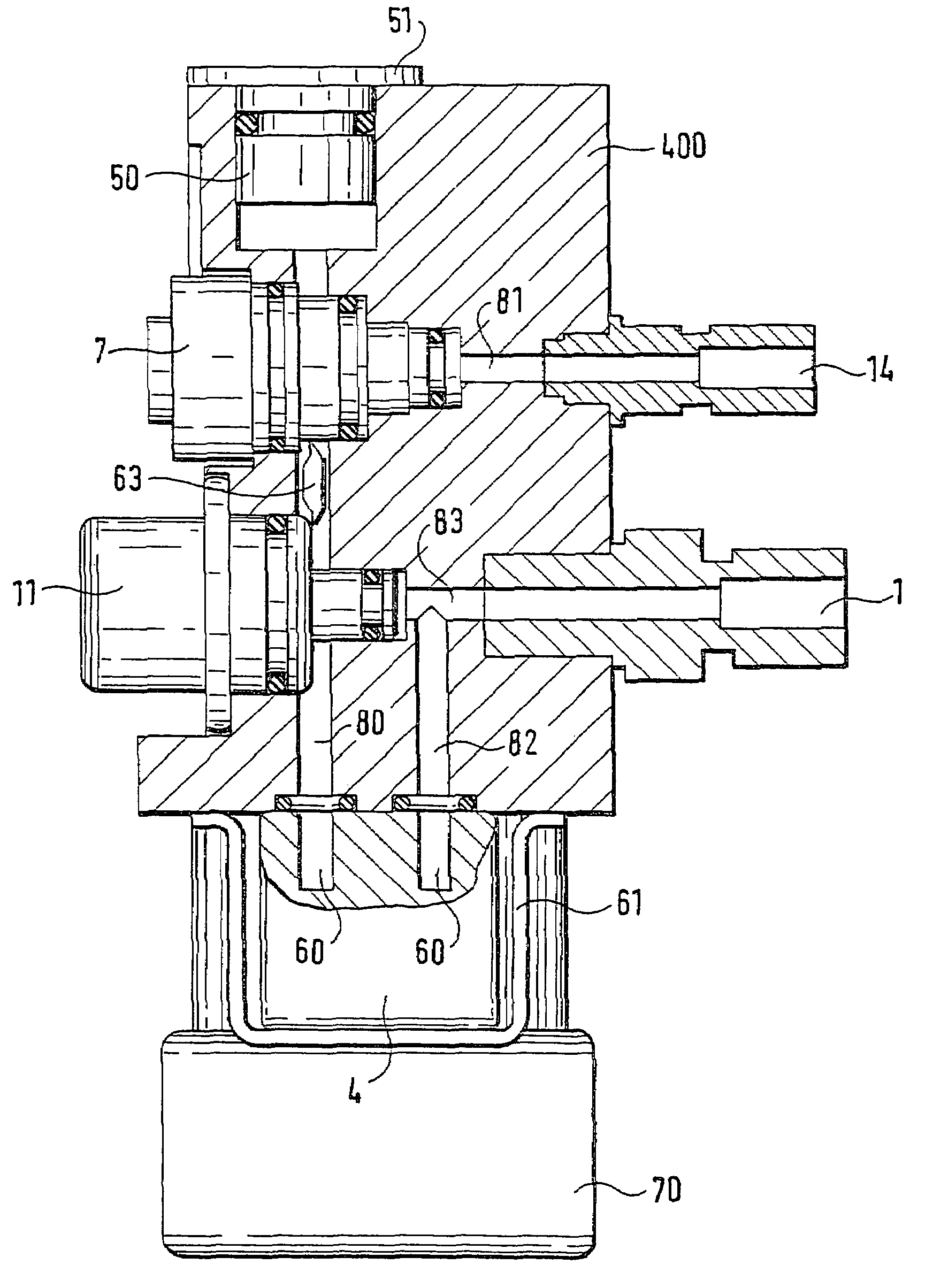

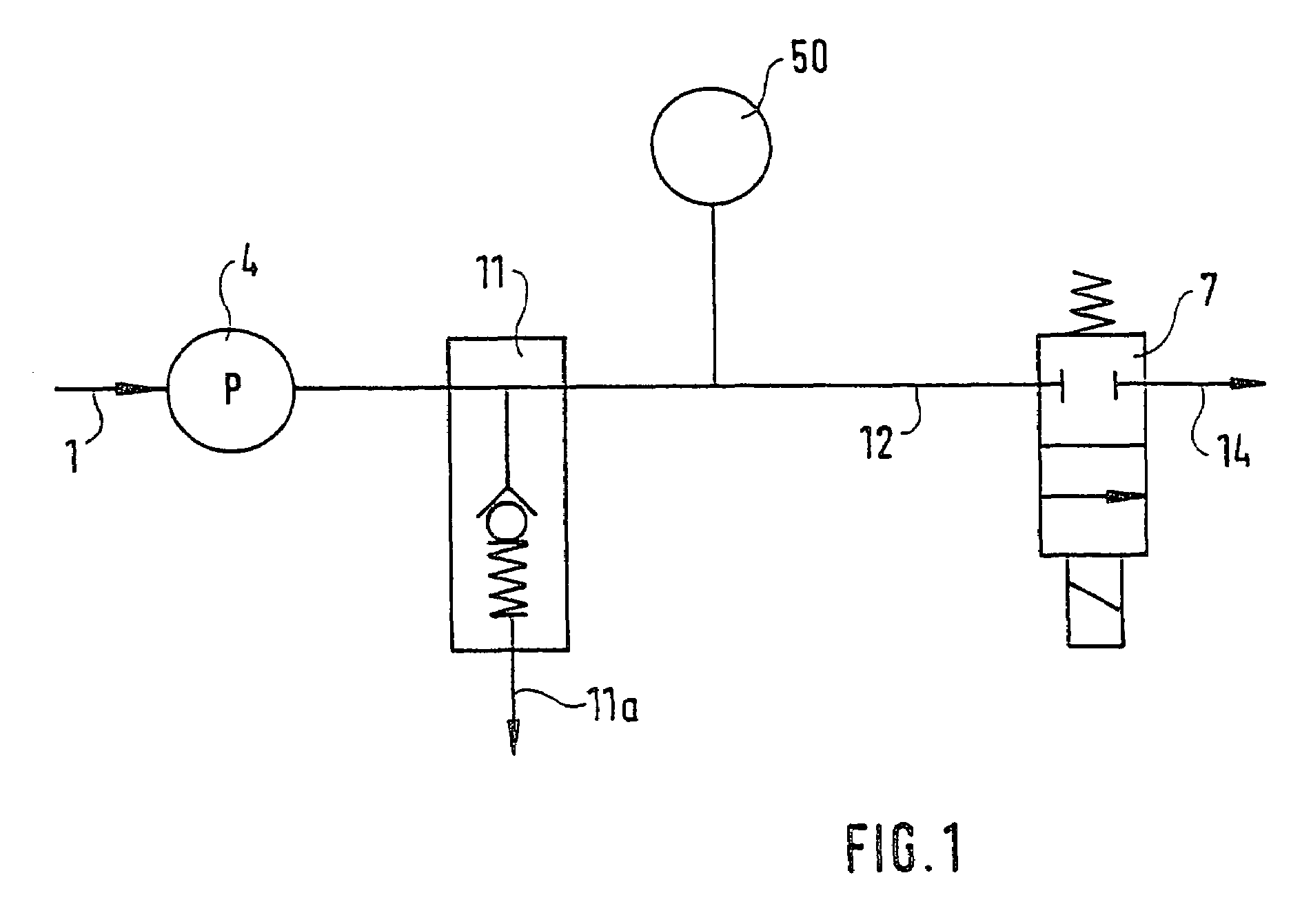

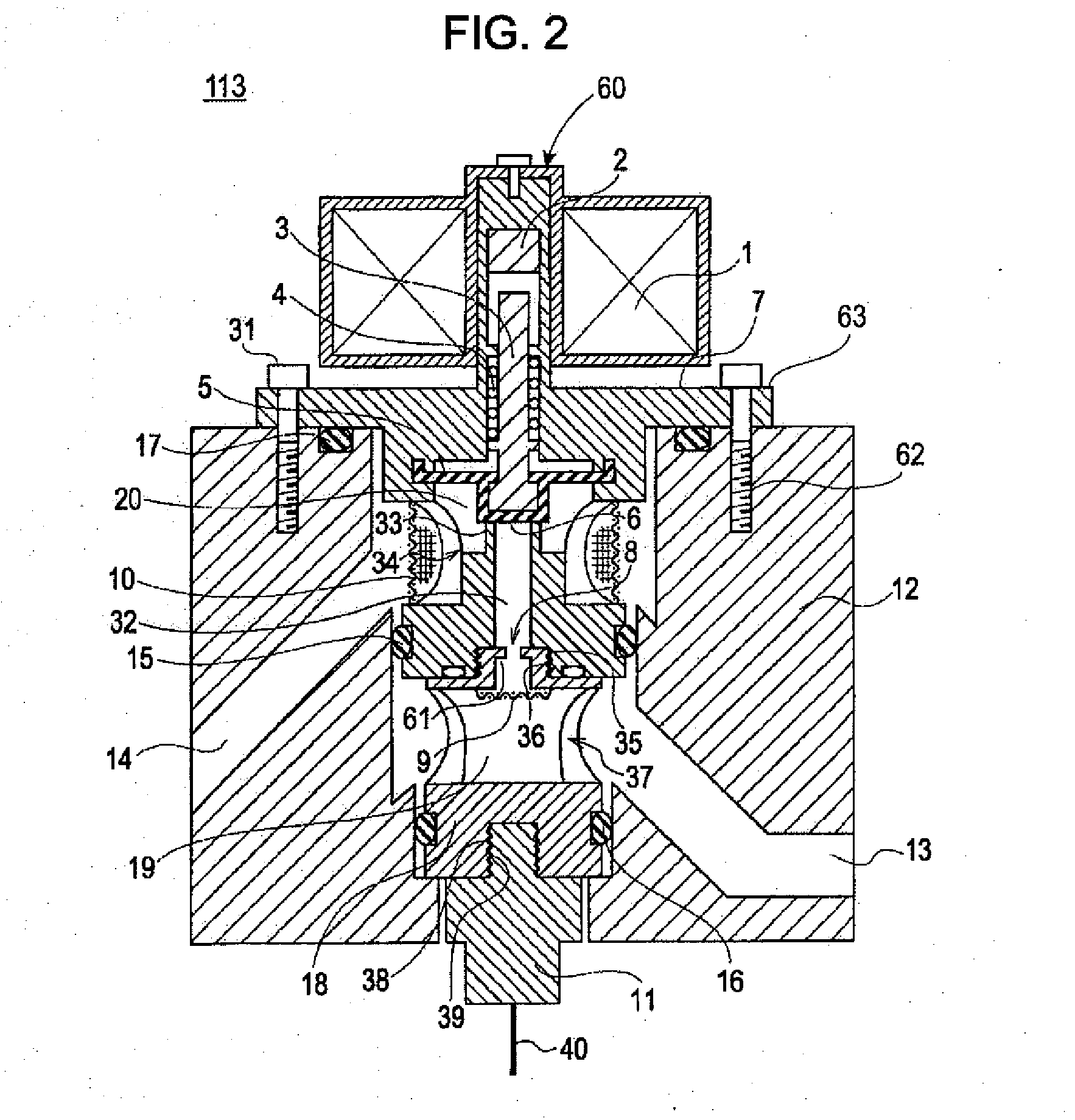

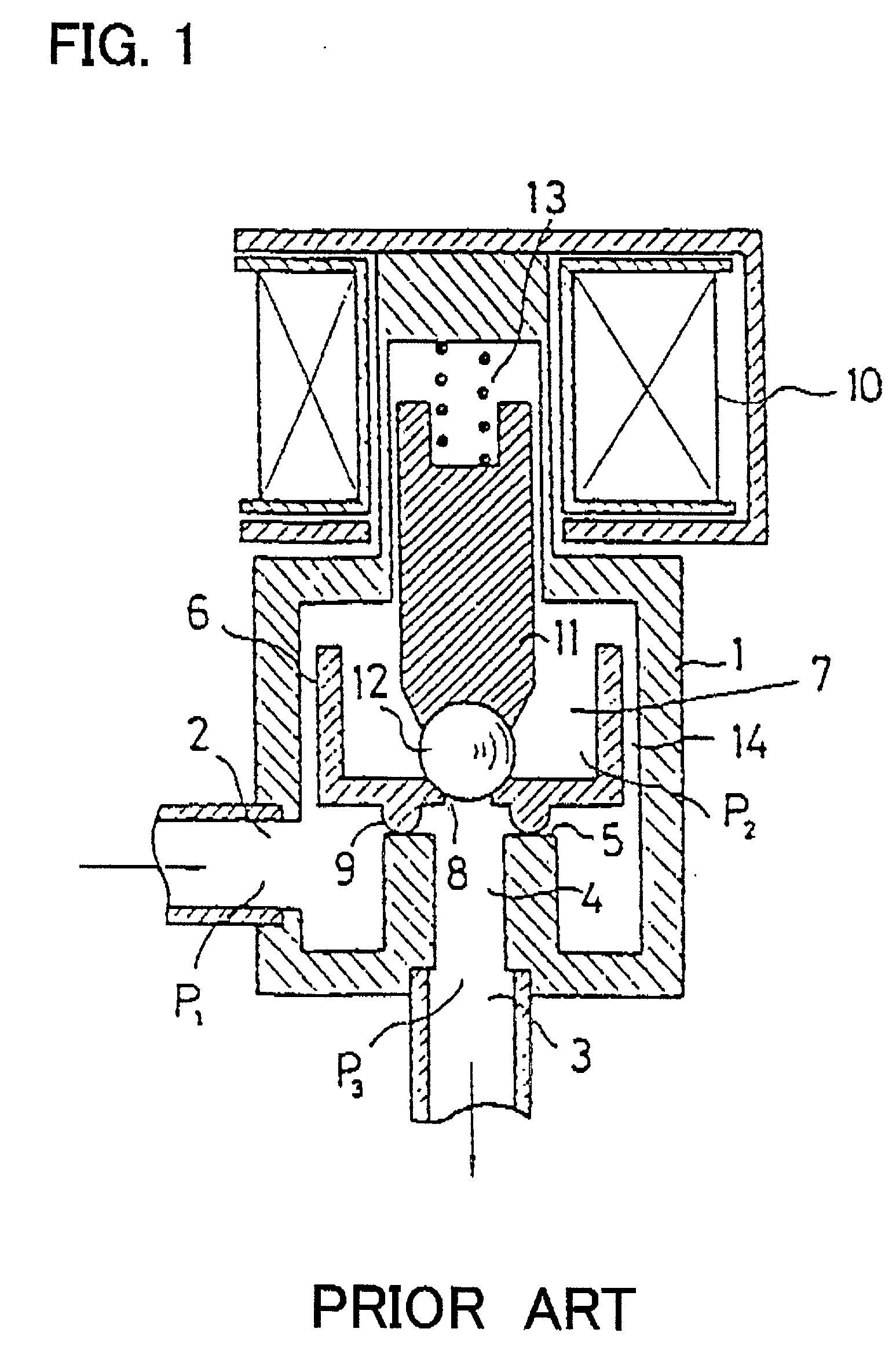

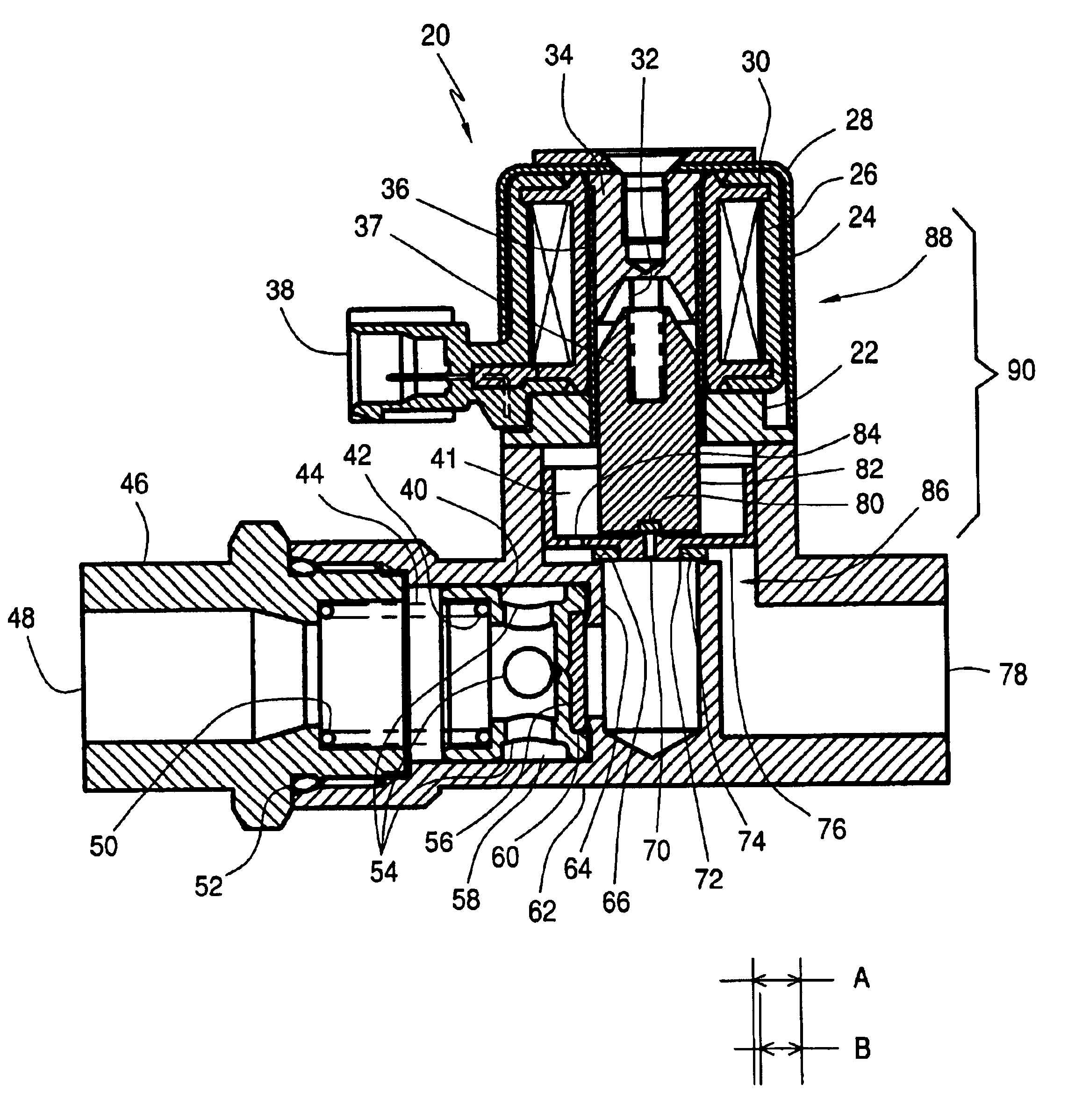

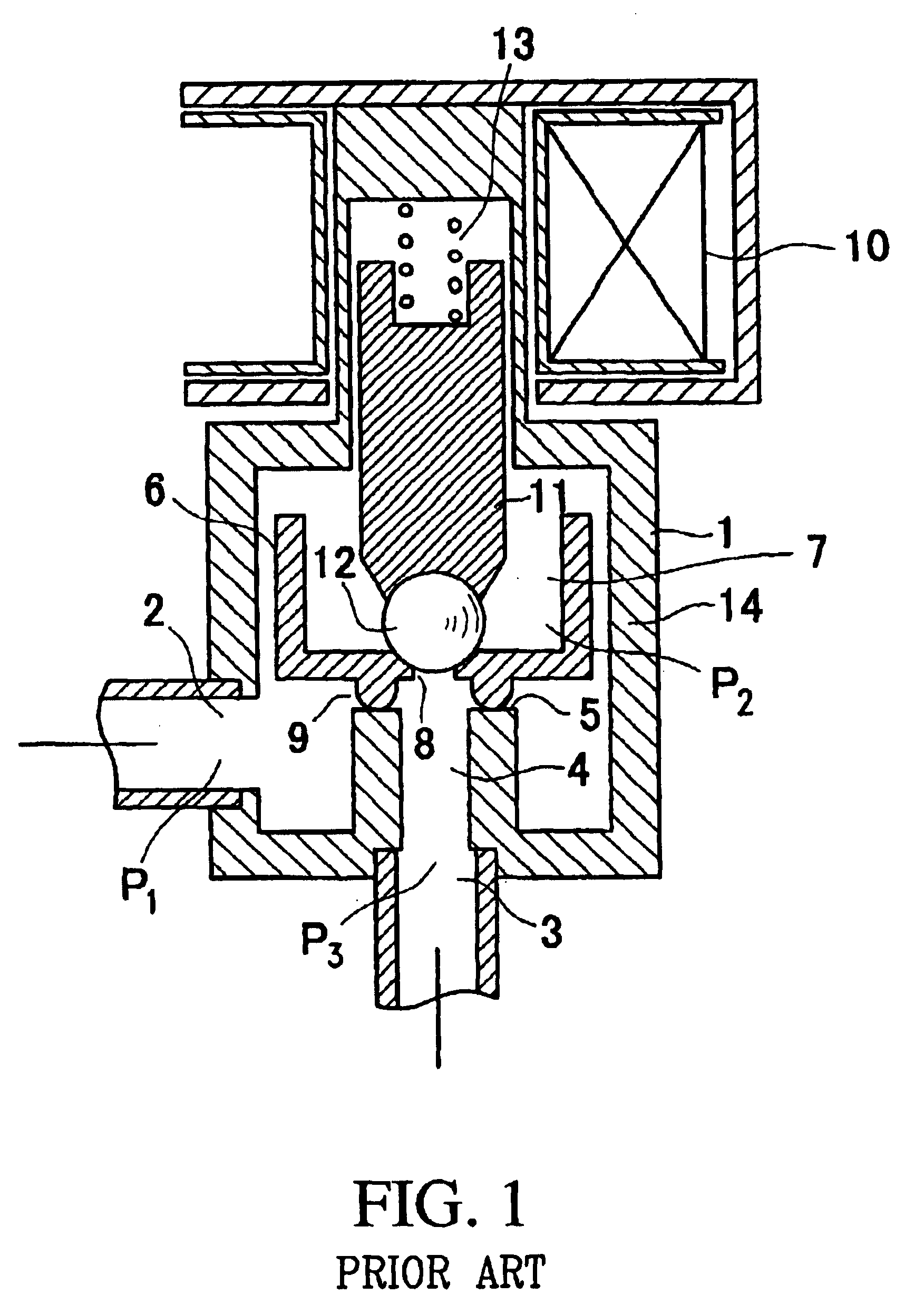

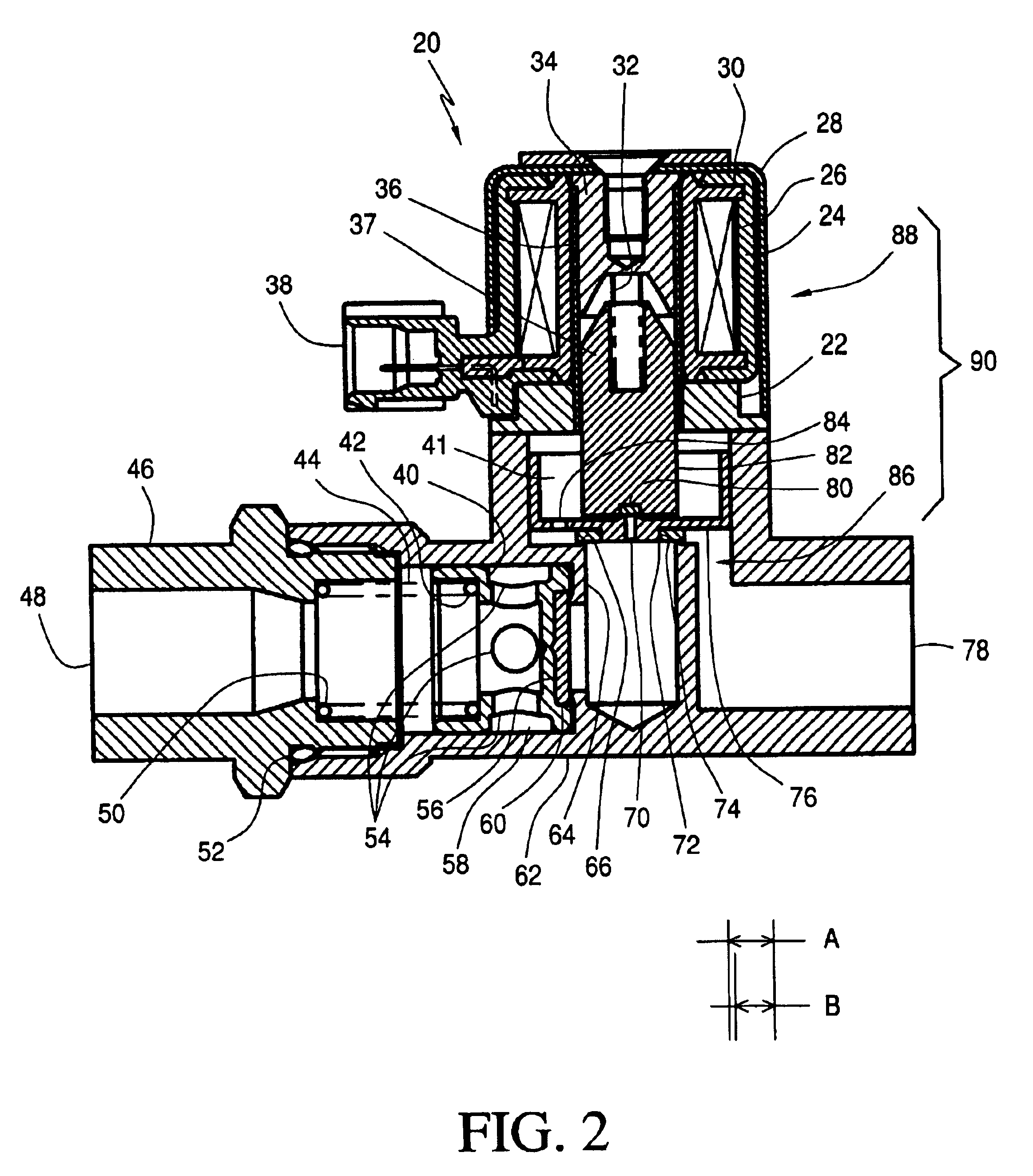

Pilot-type channel valves providing counter-flow prevention

InactiveUS20020088955A1Efficient transferQuick thawOperating means/releasing devices for valvesValve members for heating/coolingCounter flowWater vapor

A counter-flow prevention valve is disposed within a body of a pilot-type channel valve. While electrical power is applied to a solenoid coil and the pilot-type channel valve is opened, i.e., while a gas is flowing through the counter-flow prevention valve and the gas is expanding, heat generated by the application of electrical power to the solenoid coil is conducted via the body and is effectively transferred to the counter-flow prevention valve. Therefore, even if the gas contains water vapor and even if this gas is cooled due to significant expansion, the water vapor can be prevented from freezing within the counter-flow prevention valve. Moreover, the volume of the pipe between the pilot-type channel valve and the counter-flow prevention valve is small, thereby resulting in a fast rise in pressure within the pipe and a quick opening of the counter-flow prevention valve, which provides an excellent valve-opening response.

Owner:AISAN IND CO LTD

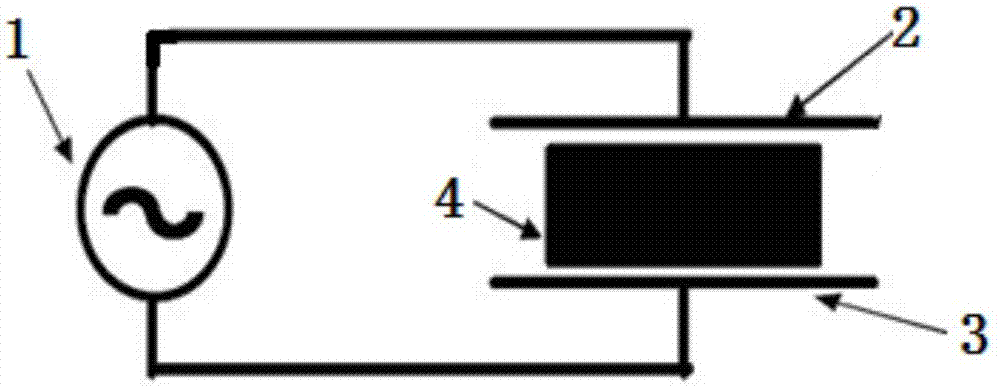

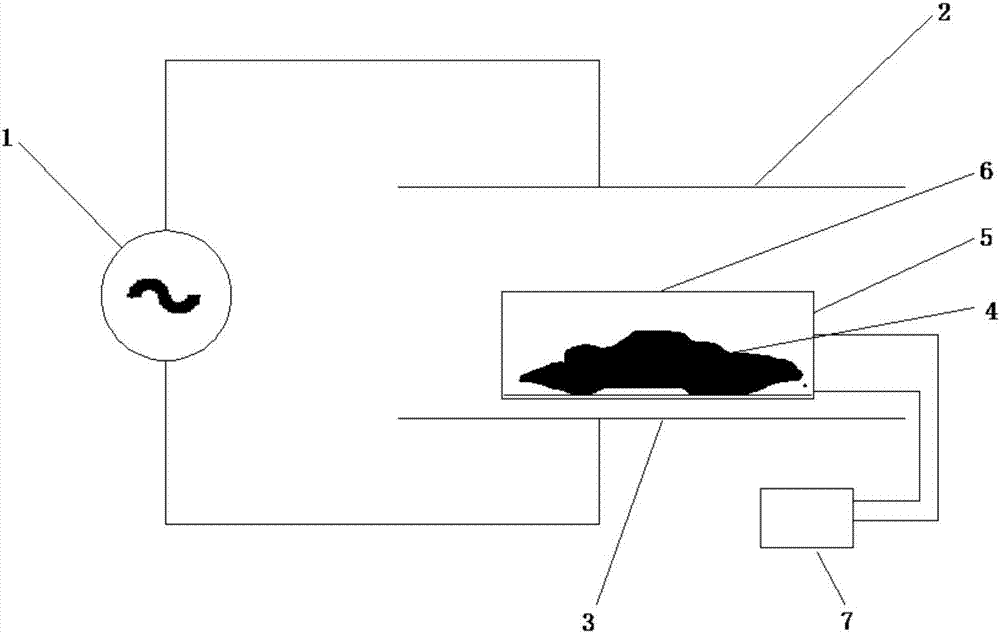

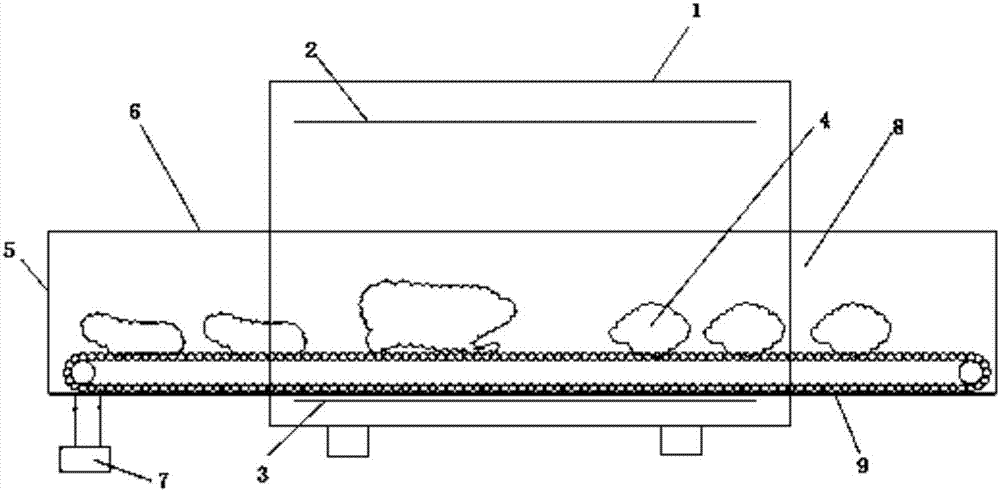

Uniform-unfreezing type radio frequency heating device

InactiveCN107373296AWide applicabilityImprove the quality of thawed foodDielectric heatingFood preservationRadio frequencyMedium vessel

Owner:SHANGHAI OCEAN UNIV

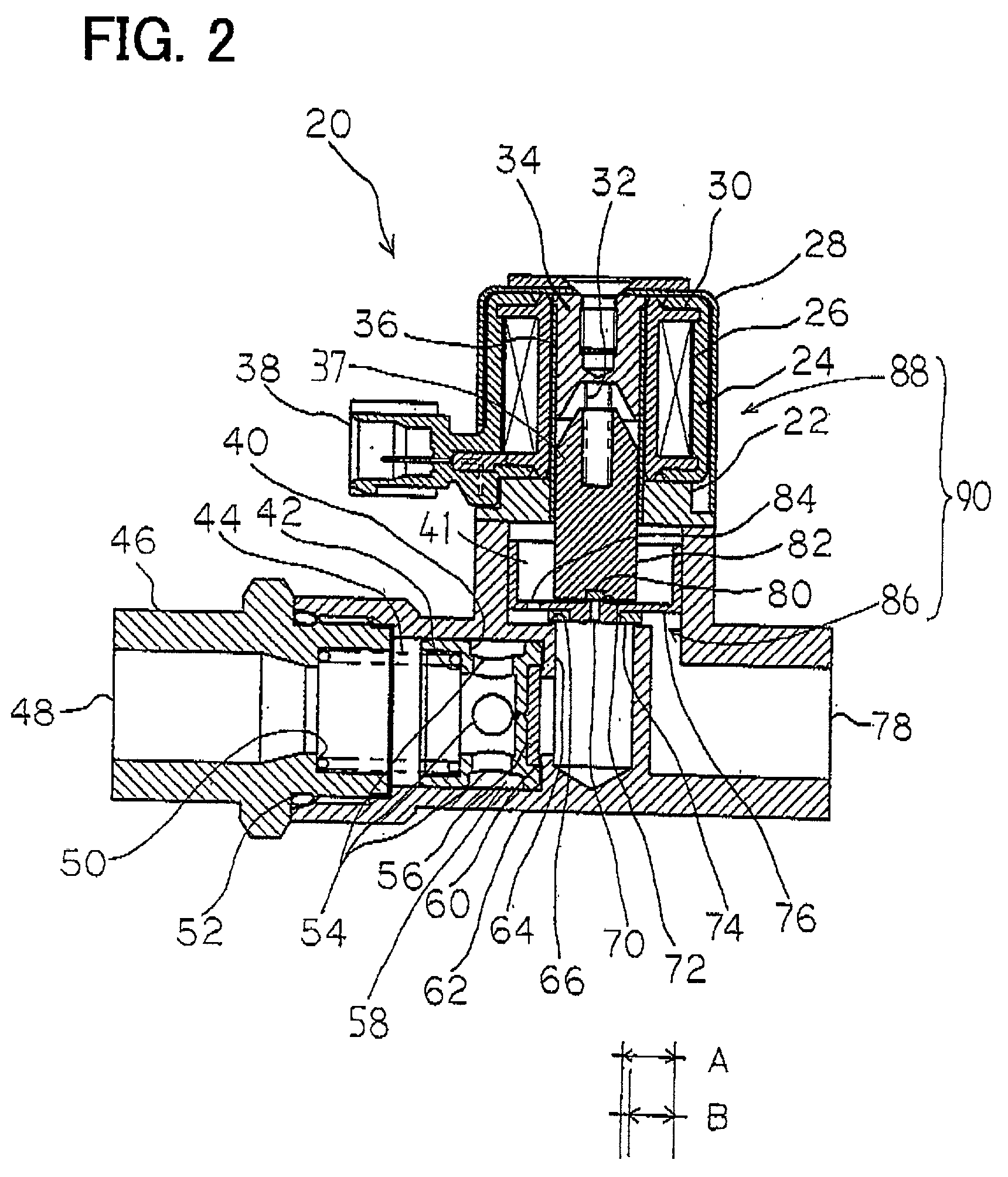

Pilot-type channel valves providing counter-flow prevention

InactiveUS6712088B2Efficient transferQuick thawOperating means/releasing devices for valvesValve members for heating/coolingCounter flowWater vapor

A counter-flow prevention valve is disposed within a body of a pilot-type channel valve. While electrical power is applied to a solenoid coil and the pilot-type channel valve is opened, i.e., while a gas is flowing through the counter-flow prevention valve and the gas is expanding, heat generated by the application of electrical power to the solenoid coil is conducted via the body and is effectively transferred to the counter-flow prevention valve. Therefore, even if the gas contains water vapor and even if this gas is cooled due to significant expansion, the water vapor can be prevented from freezing within the counter-flow prevention valve. Moreover, the volume of the pipe between the pilot-type channel valve and the counter-flow prevention valve is small, thereby resulting in a fast rise in pressure within the pipe and a quick opening of the counter-flow prevention valve, which provides an excellent valve-opening response.

Owner:AISAN IND CO LTD

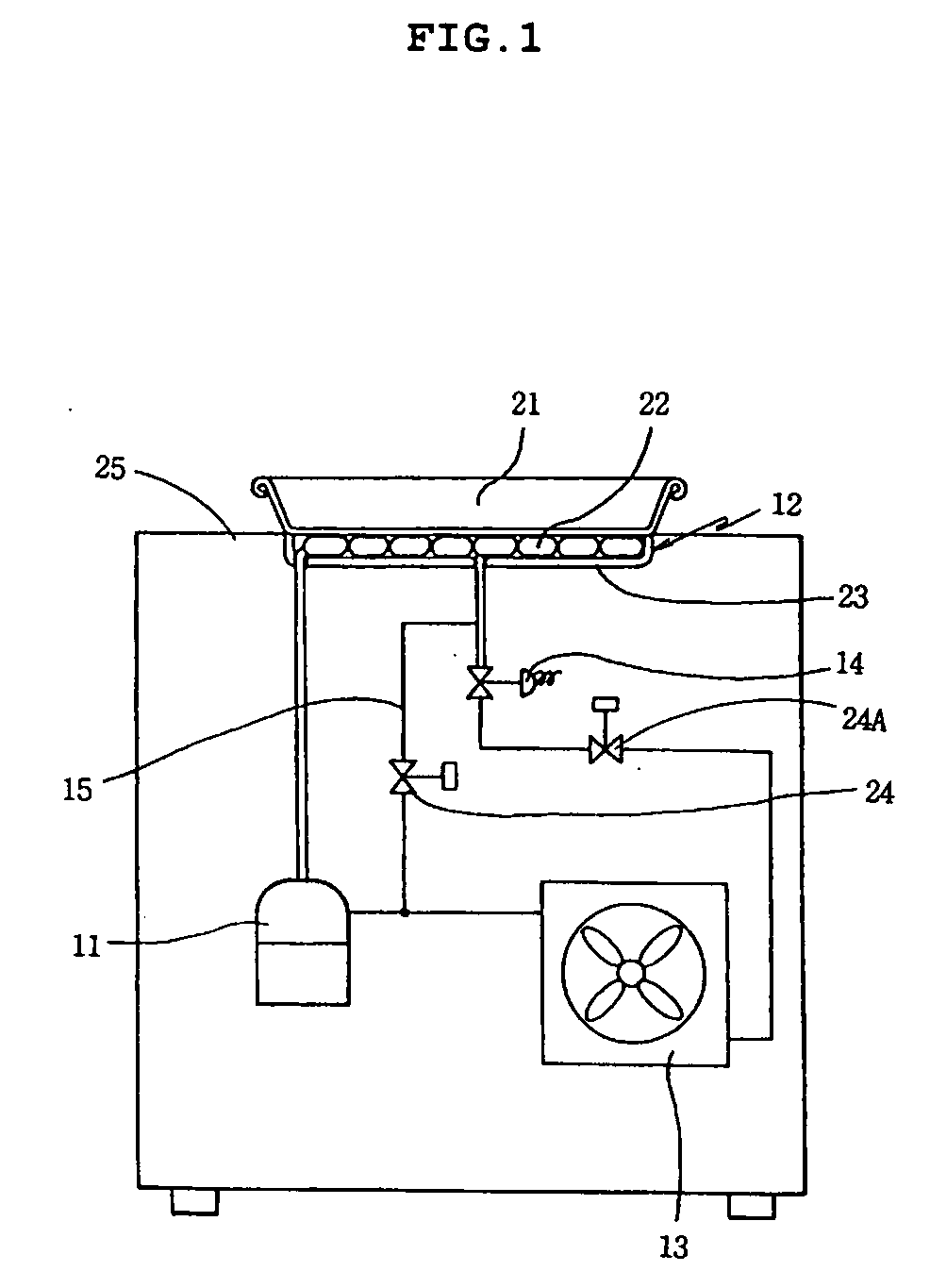

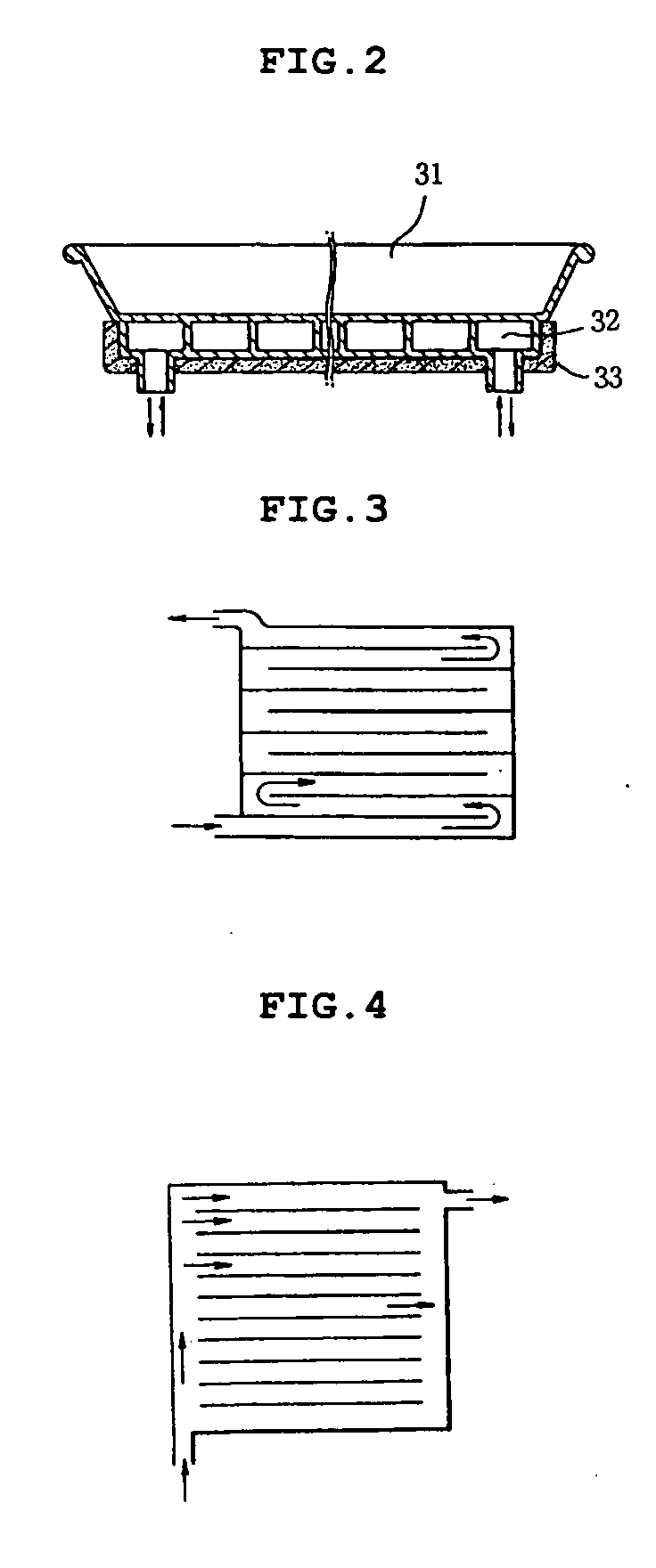

Apparatus for manufacturing ices

InactiveUS20060213214A1Easy to disassembleSimple structureIce productionEvaporators/condensersVALVE PORTCoolant

An apparatus for manufacturing ices via rapid ice facture and rapid ice thaw is provided. A switching operation between ice making and ice thawing is easily performed by only a single valve, to thereby simplify the structure of the apparatus and save the manufacturing cost therefor as well as make users conveniently manipulate the apparatus. Liquid particles are effectively separated from coolant gas re-circulated to a compressor after performing an ice thawing operation, to thereby prevent the compressor from being in trouble. A capillary tube is integrally installed along the coolant tube connecting a condenser and an evaporator, at a position before a connection portion connecting a bypass tube and a coolant tube.

Owner:CORN USA KOREA

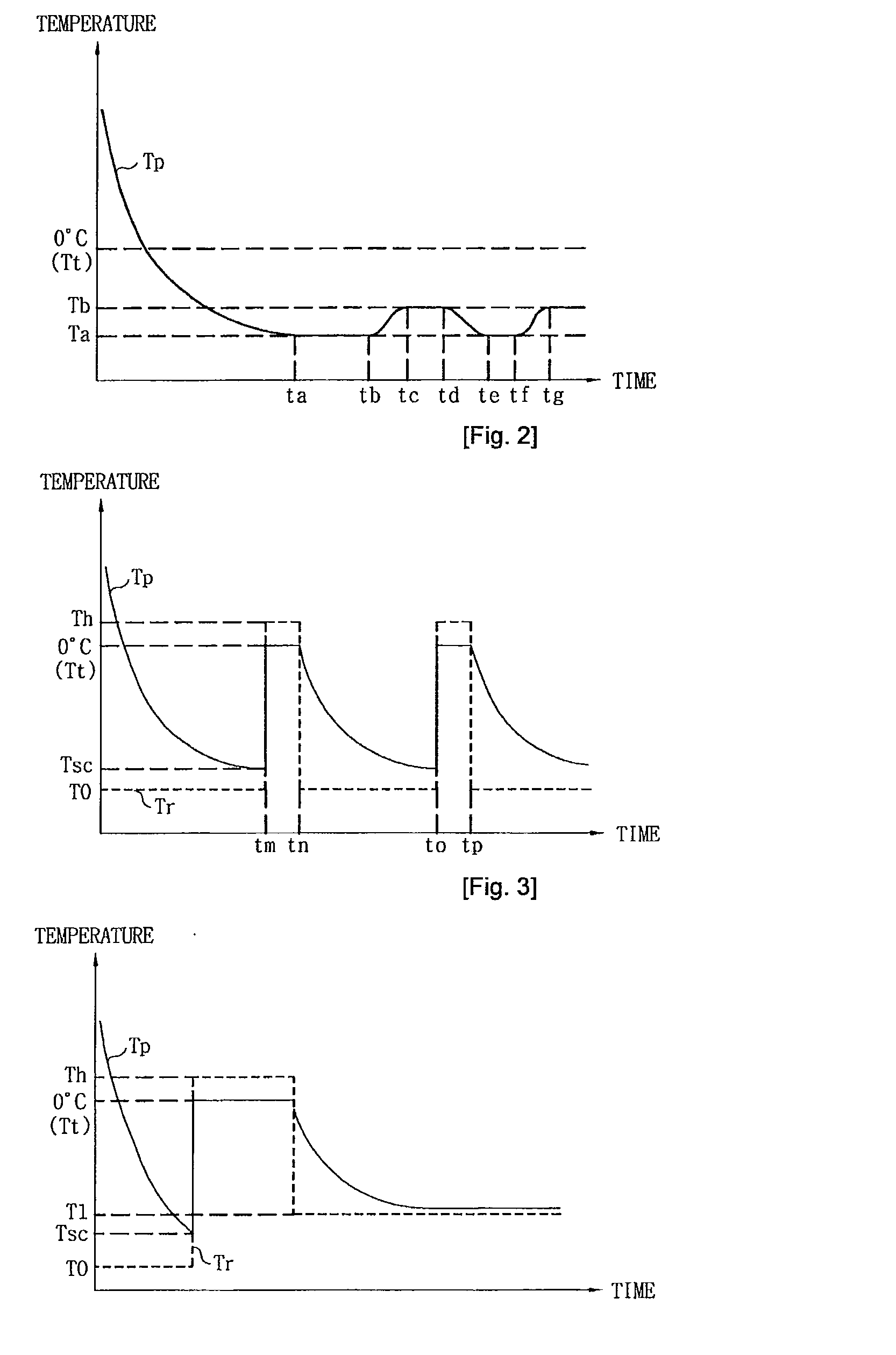

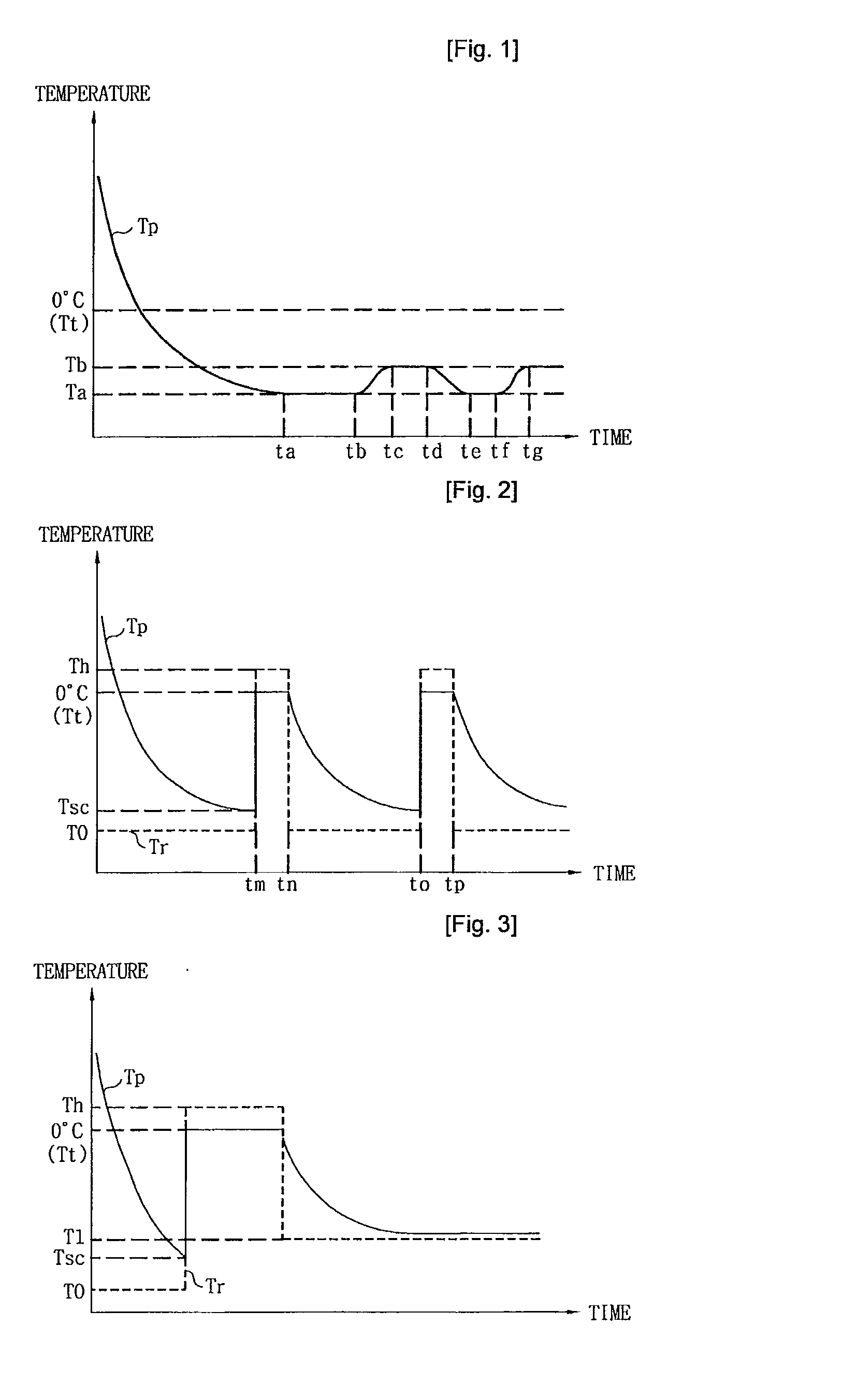

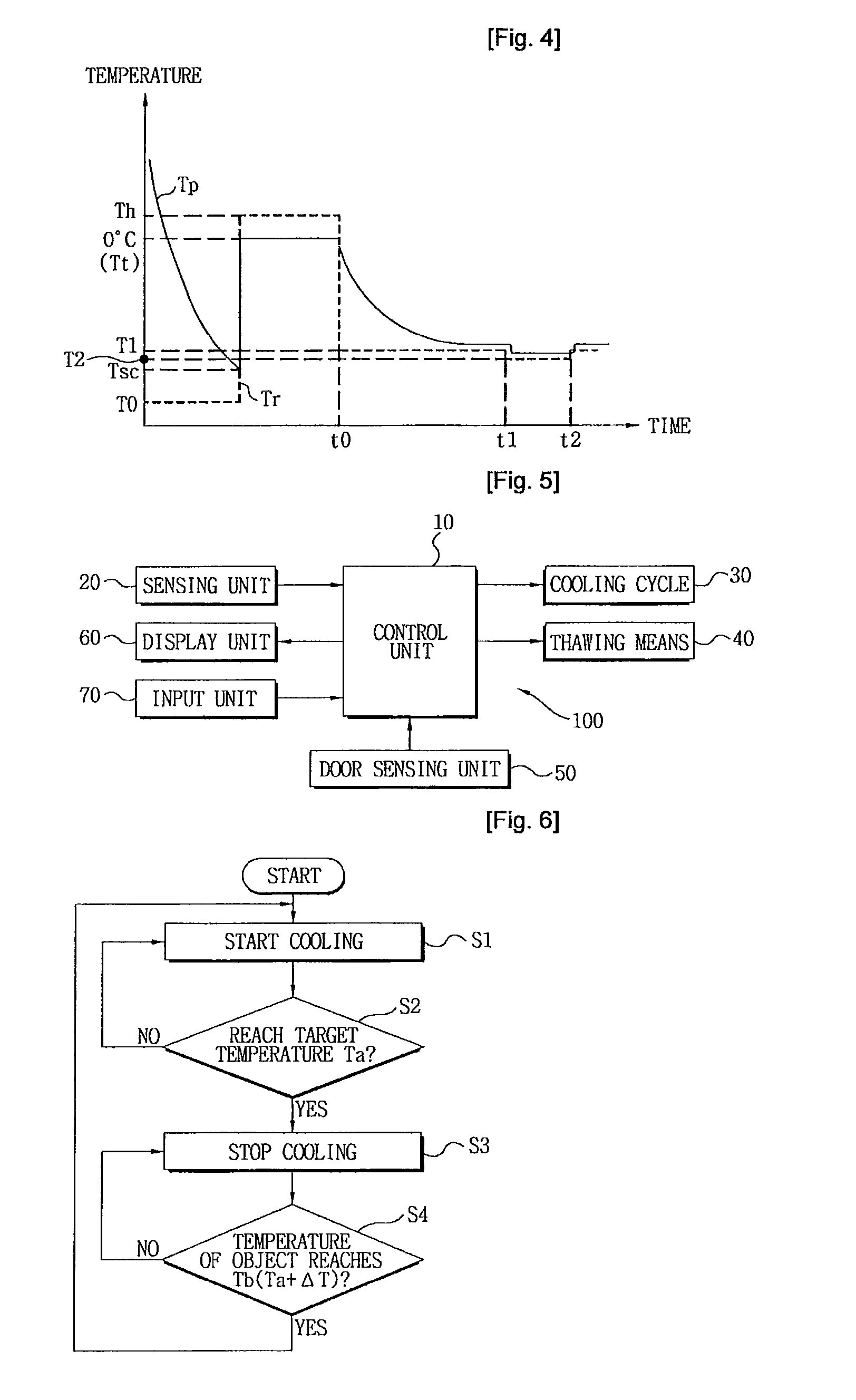

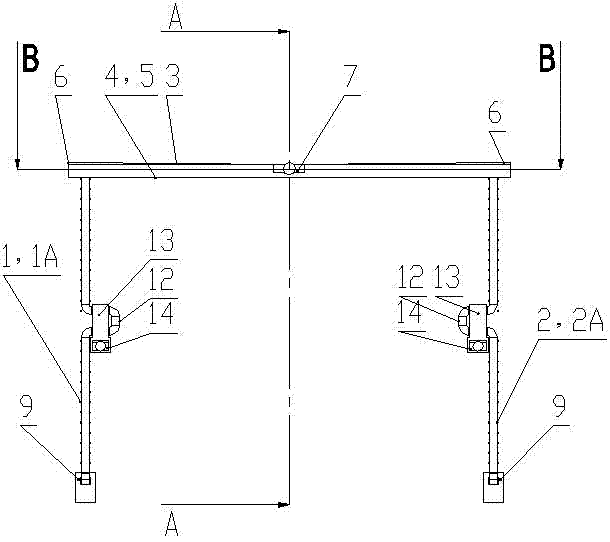

Supercooling method and supercooling apparatus

ActiveUS20100199692A1Optimal temperatureRapid detectionLighting and heating apparatusIce productionCooling temperatureEngineering

The present invention relates to a supercooling method and a supercooling apparatus which can maintain an object in a supercooled state. According to the present invention, a supercooling method includes a first cooling step of cooling a stored object toward a cooling temperature below a phase transition temperature thereof, a step of judging whether the stored object is released from a supercooled state in the first cooling step, a step of thawing the stored object when the stored object is released from the supercooled state, and a second cooling step of cooling the stored object toward a cooling temperature below zero that is higher than the lowest temperature of the stored object before the release of the supercooled state, wherein the first cooling step is continuously performed when the object is maintained in the supercooled state.

Owner:LG ELECTRONICS INC

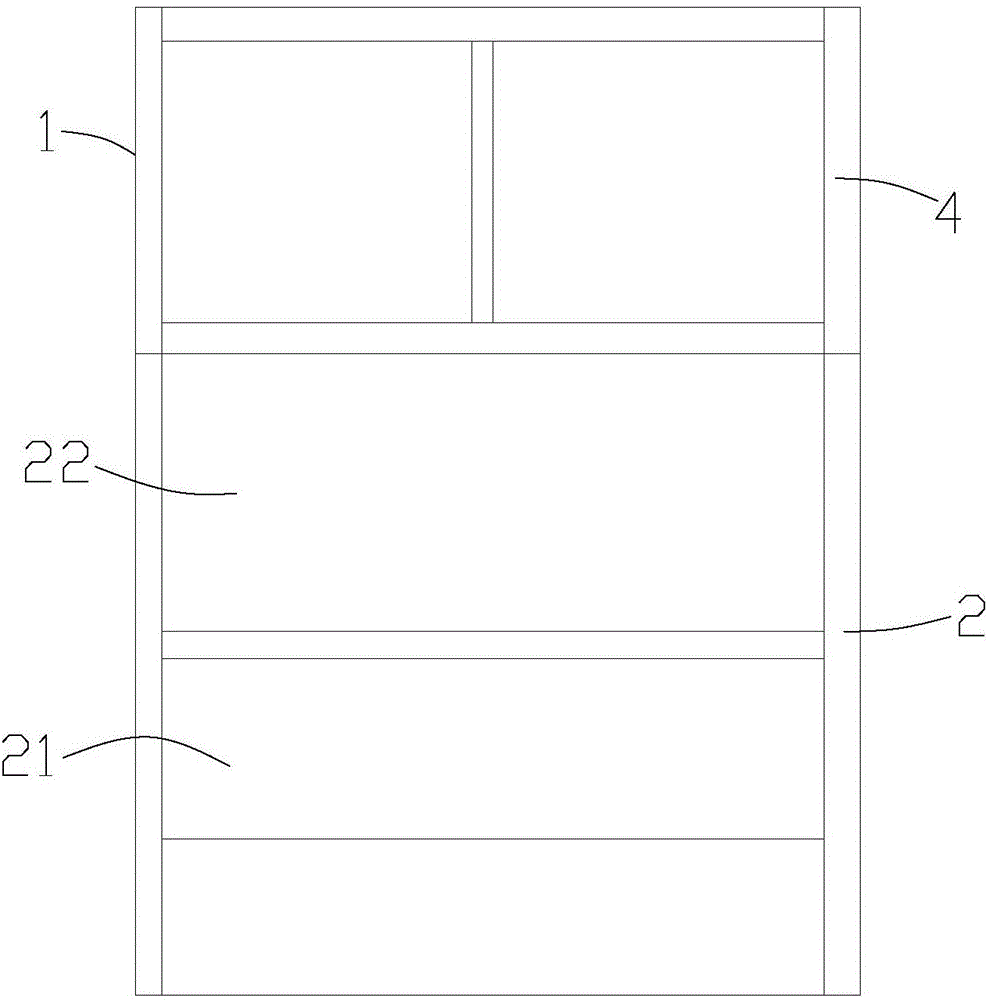

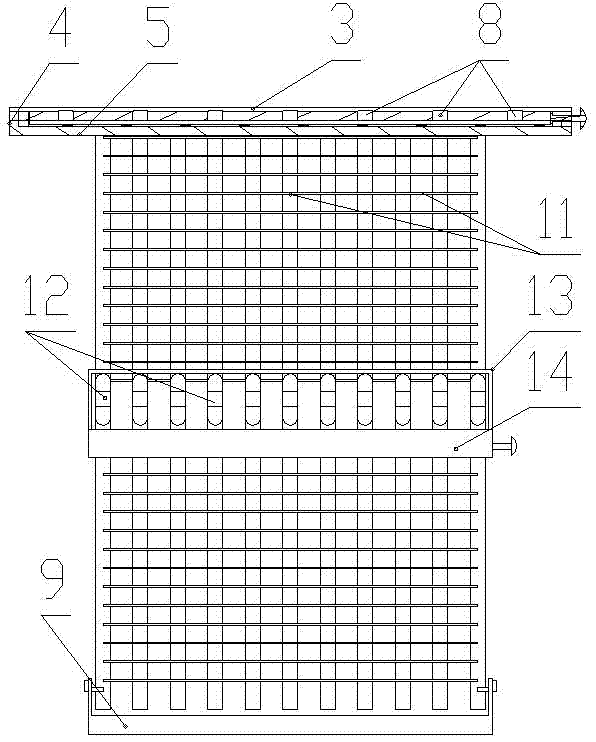

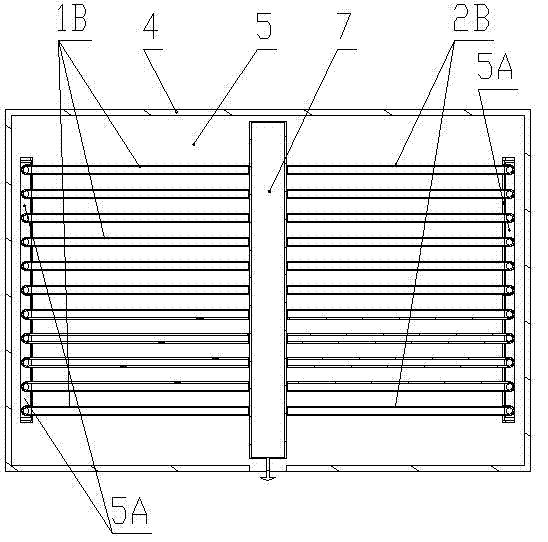

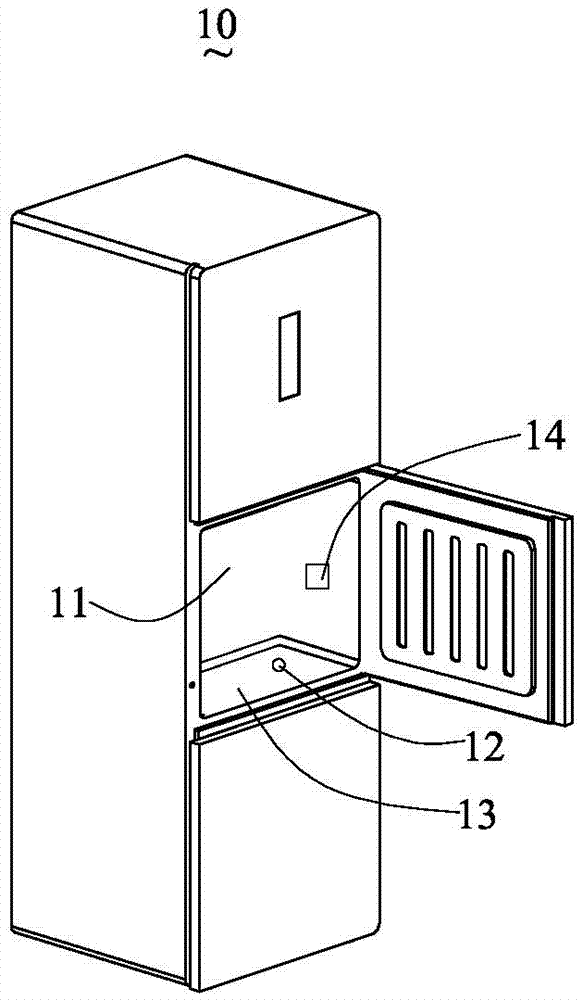

Thawing device and refrigerator with thawing device

ActiveCN102878756AIncrease flexibilityAchieve reuseLighting and heating apparatusDomestic refrigeratorsThermodynamicsIcebox

The invention discloses a thawing device, which comprises a first heat pipe group and a second heat pipe group, wherein the first heat pipe group and the second heat pipe group comprise vertical parts; the tops of the vertical parts are provided with transverse parts in a bending mode; the transverse parts of the first heat pipe group and the second heat pipe group are fixed by a fixing device, and free ends of the transverse parts of the two heat pipe groups are opposite to each other; the fixing device comprises a fixing frame; the top and bottom of the fixing frame are respectively and fixedly provided with an upper heat transfer storage rack plate and a lower heat transfer storage rack plate; the transverse parts of the first and second heat pipe groups are positioned between the upper and lower heat transfer storage rack plates; and protruding parts, which are matched with a liner slideway of a refrigerator freezer, are extended out of the left and right parts of the fixing frame. The invention also discloses a refrigerator with the thawing device. The refrigerator and the thawing device have the advantages that the refrigerator is convenient to use, the energy is saved, independent thawing space is not required, an electric heater is not required, the condensate water produced during thawing can be automatically collected, when the refrigerator with the thawing device is used, the temperature inside the freezer is uniform and the like.

Owner:HENAN XINFEI ELECTRICAL EQUIP

Rapid low-temperature microwave thawing method and thawing equipment

Owner:东莞市华青微波设备制造有限公司

Double-water-tank solar water heating system

InactiveCN101936604AEnsure water qualitySimple structureSolar heat devicesSolar thermal energy generationWater qualitySolar water heating system

The invention provides a double-water-tank solar water heating system which comprises a heat collector, a hot water tank and a bracket, wherein the upper end of the heat collector is communicated with the hot water tank; the heat collector and the hot water tank are erected on the bracket; one side of the hot water tank is provided with a cold water tank; the bottom of the cold water tank is communicated with the bottom of the hot water tank through a flow guide pipe; a water supply pipe is communicated with the bottom of the cold water tank; a water pump is arranged on the pipeline of the water supply pipe; a water level probe is arranged in the cold water tank; and the water level probe is connected with a controller used for controlling the on-off of the water pump. The invention has the advantages that the system has simple structure, convenient mounting and long service life; both the hot water tank and the cold water tank are arranged on the same bracket and have the functions of heat insulation and freeze proofing so as to effectively guarantee the quality of water in the water tanks; and during a freezing period, because the distance between the two water tanks is short, a water guide pipe is not easy to freeze, thus hot water in the hot water tank can be used for quickly thawing under the condition of freezing.

Owner:浙江宝阳新能源科技有限公司

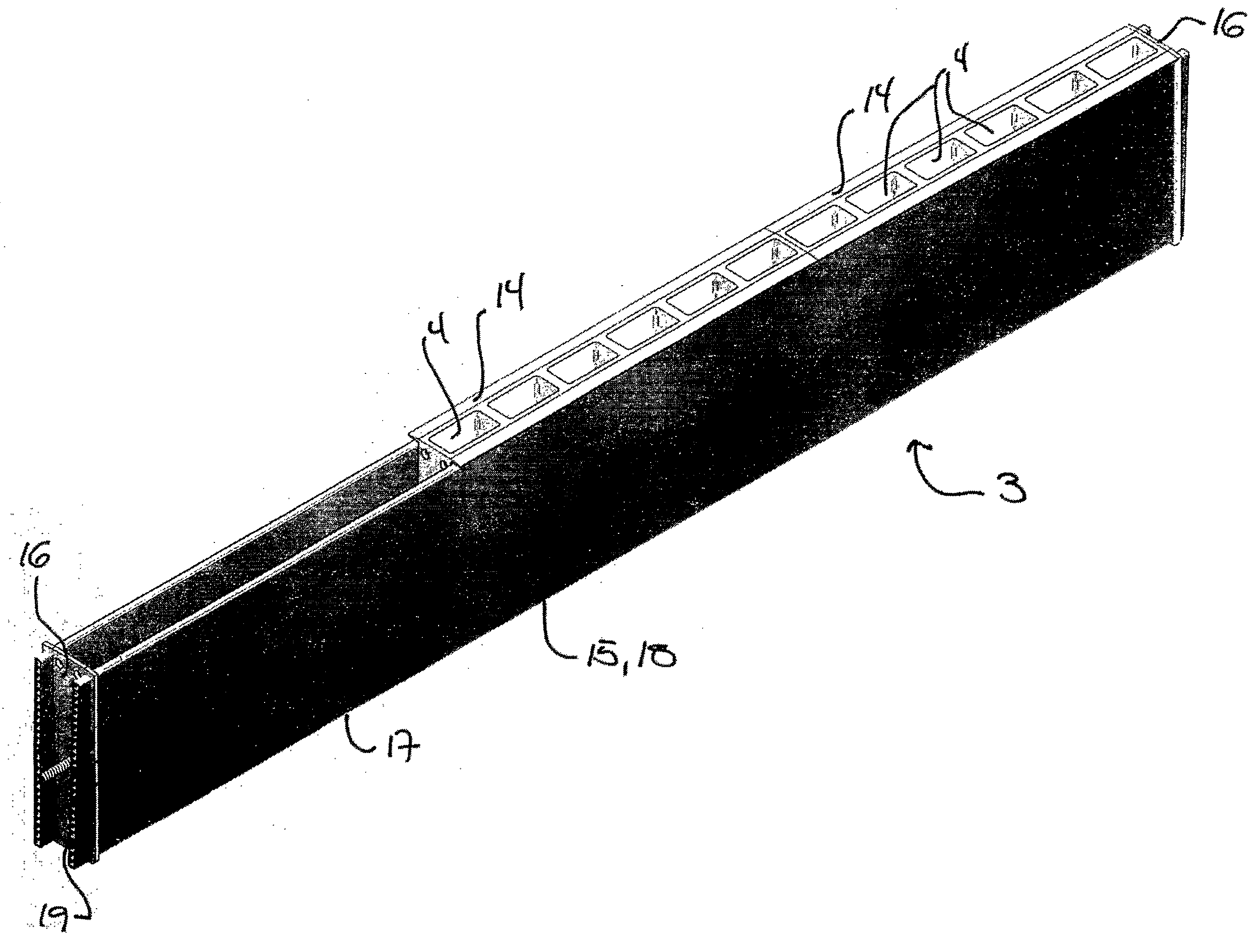

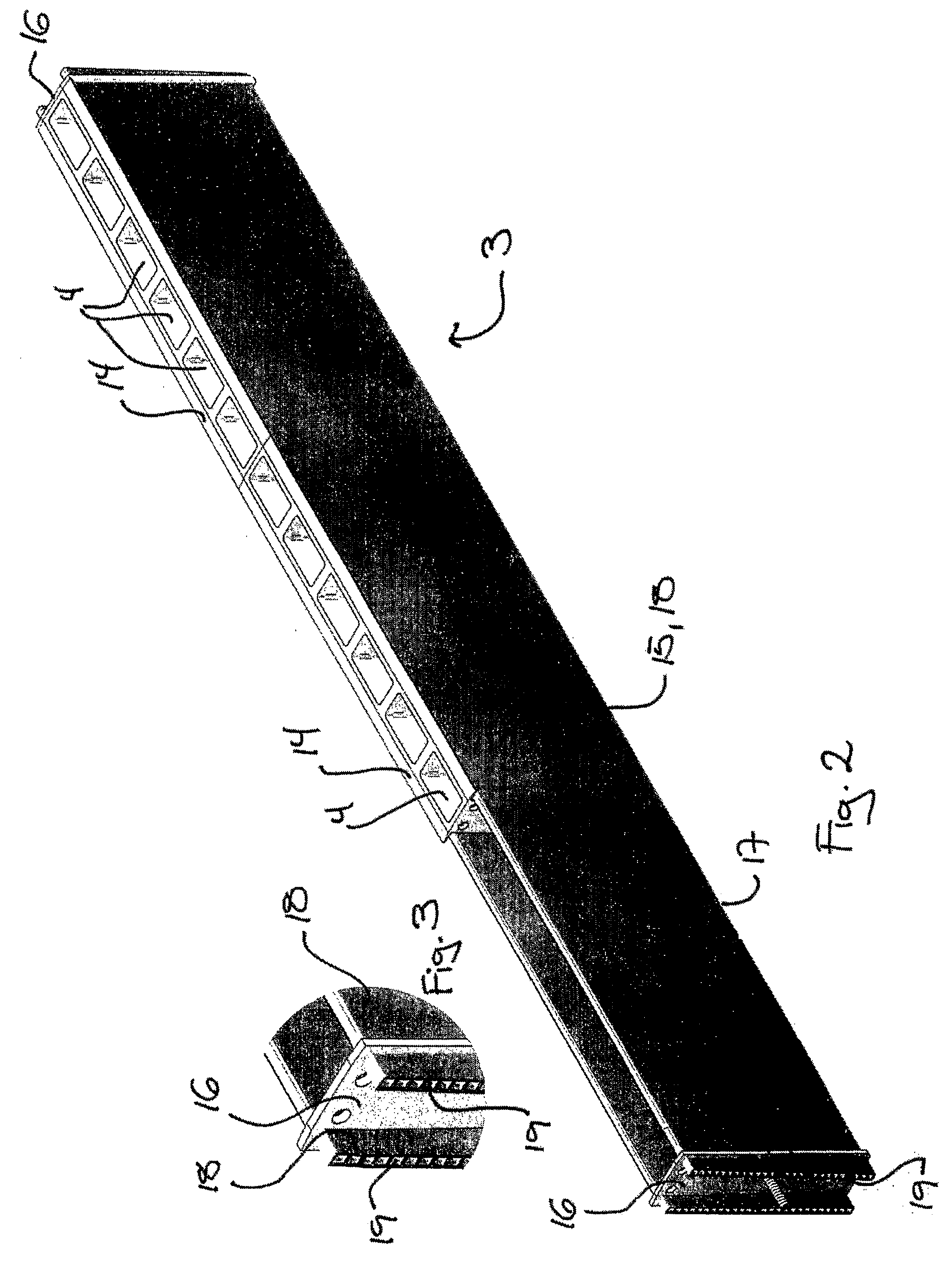

Freezer segment for a freezer for confectionary with segments including channels for direct evaporation of CO.sub.2

ActiveUS8763420B2Increase capacityCross sectional areaDomestic cooling apparatusLighting and heating apparatusSaline waterEvaporation

The present invention concerns a freezer segment for a freezer of the type used for casting confectionery in molds which are cooled for freezing and subsequently supplied with heat for a short period, whereafter stripping occurs. Cooling of the molds is effected by using direct evaporation of CO2. The advantage of such a freezer segment is that there is no use for both a primary and a secondary cooling circuit. Another advantage in using a system according to the invention is that working with temperatures down to about minus 50° C. is enabled, compared to about minus 40° C. with brine systems. The low freezing temperature entails that the capacity of a given system is increased by about 40%.

Owner:GRAM EQUIP

Method for manufacturing quick-freezing glutinous corn fragment and porridge made from the same and method for making porridge

ActiveCN101147542ARich in nutrientsGood health effectSeed preservation by freezing/coolingFood preparationBiotechnologyPreservative free

The present invention relates to a kind of quickly-frozen glutinous corn grits and its preparation method, and gruel made up by using said quickly-frozen glutinous corn grits and its gruel-making method. The quickly-frozen glutinous corn grits are made up by adopting the following steps: selecting material, steaming, threshing and quickly-freezing. The described gruel made up by using the invented quickly-frozen glutinous corn grits is made up by using quickly-frozen glutinous corn grits, water, white sugar and VC through the process of boiling and sterilization.

Owner:王超

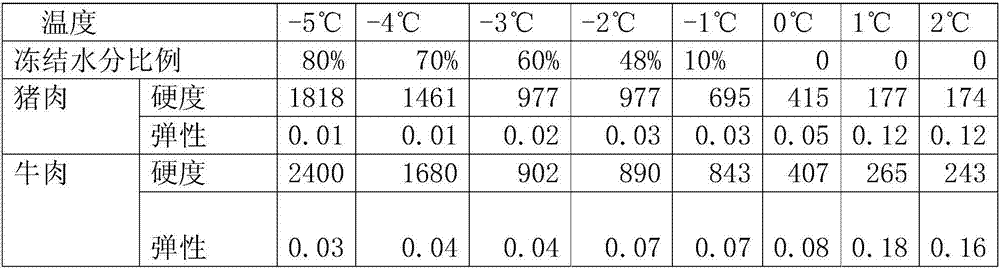

Rapid nutrient thawing method for frozen meat and refrigerator

InactiveCN107883641AAvoid quality lossReduce reproductionLighting and heating apparatusDomestic refrigeratorsMicrowaveEngineering

The invention relates to a rapid nutrient thawing method for frozen meat, and provides a refrigerator. The refrigerator comprises a control device and a thawing chamber, and is characterized in that the thawing chamber is a minus temperature thawing chamber of which the temperature is not higher than 0 DEG C and not lower than minus 3 DEG C; the minus temperature thawing chamber is further internally provided with a microwave generating device, and the microwave generating device is electrically connected with the control device; and the rapid nutrient thawing method for frozen meat comprisesthe step of microwave thawing of the frozen meat to the temperature of -3 DEG C to 0 DEG C in the minus temperature thawing chamber. Compared with the prior art, in the microwave thawing process, frozen food is evenly heated up in a frozen state, the thawing ambient temperature is controlled at 0 DEG C to -3 DEG C, so that the surface being thawed quickly by the action of microwaves and heat conduction can be prevented, uniform thawing for the inside and outside can be ensured, and the quality damage caused by the rapid increase of the surface temperature can be avoided.

Owner:JOYOUNG CO LTD

Cutting Apparatus for Bioprocessing Bone

InactiveUS20190343112A1Easy to follow upQuick thawCell dissociation methodsSurgeryBiomedical engineeringMechanical advantage

A bone cutting assembly includes a manually actuated upper cutting element that carries a plurality of cutting blades configured to cut through frozen bone segments. A lower cutting element supports a bone segment to be cut and can include cutting blades aligned with the cutting blades of the upper cutting assembly. A pivoting linkage or a rack and pinion arrangement can be provided between the upper cutting element and a manually operated handle to provide sufficient mechanical advantage or leverage to allow an operator to manually cut through the bone.

Owner:OSSIUM HEALTH INC

Refrigerator with vacuum unfreezing device

InactiveCN104729211AQuick thawDomestic cooling apparatusLighting and heating apparatusFreezing chamberRefrigerated temperature

The invention particularly relates to a refrigerator with a vacuum unfreezing device. The refrigerator with the vacuum unfreezing device comprises a refrigerating chamber, a freezing chamber and an unfreezing chamber, an unfreezing chamber door is arranged outside the unfreezing chamber, a control panel is arranged on the unfreezing chamber door, a partition plate is arranged in the unfreezing chamber, at least one vacuum pump is arranged on the left side of the partition plate, a water tank is arranged on the right side of the partition plate, and a holding tray is arranged in the water tank. The refrigerator has the advantages that an unfreezing device is provided, food frozen by the refrigerator can be unfrozen quickly by a vacuum unfreezing principle, and the problem that edible time of the frozen food is wasted since an existing refrigerator is incapable of unfreezing the frozen food quickly is solved.

Owner:XIAN YUHUA IND DEV

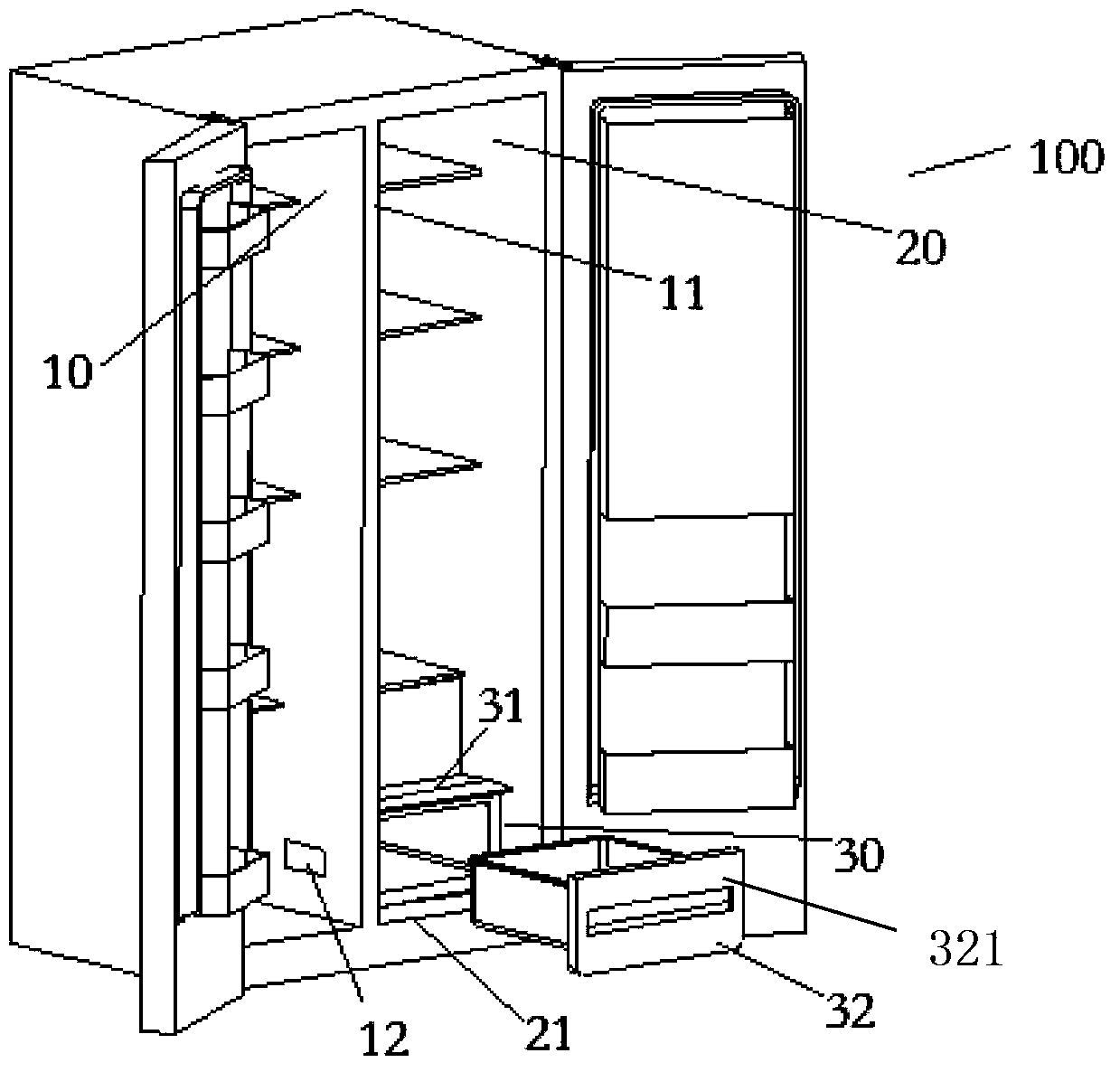

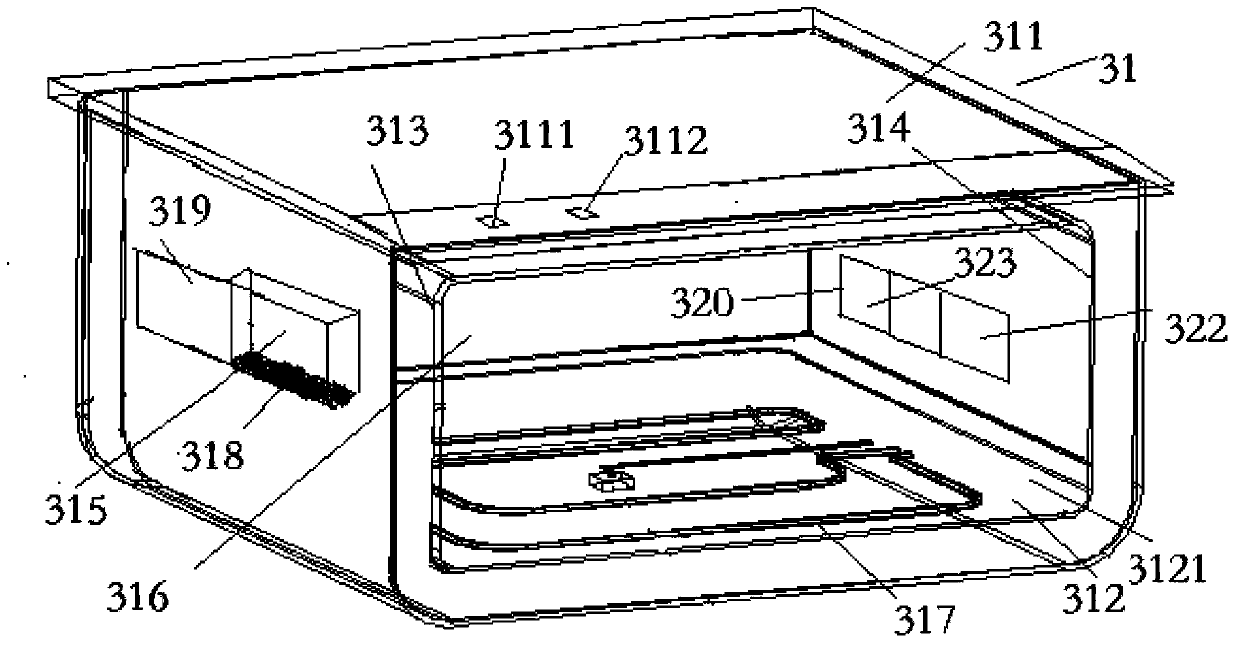

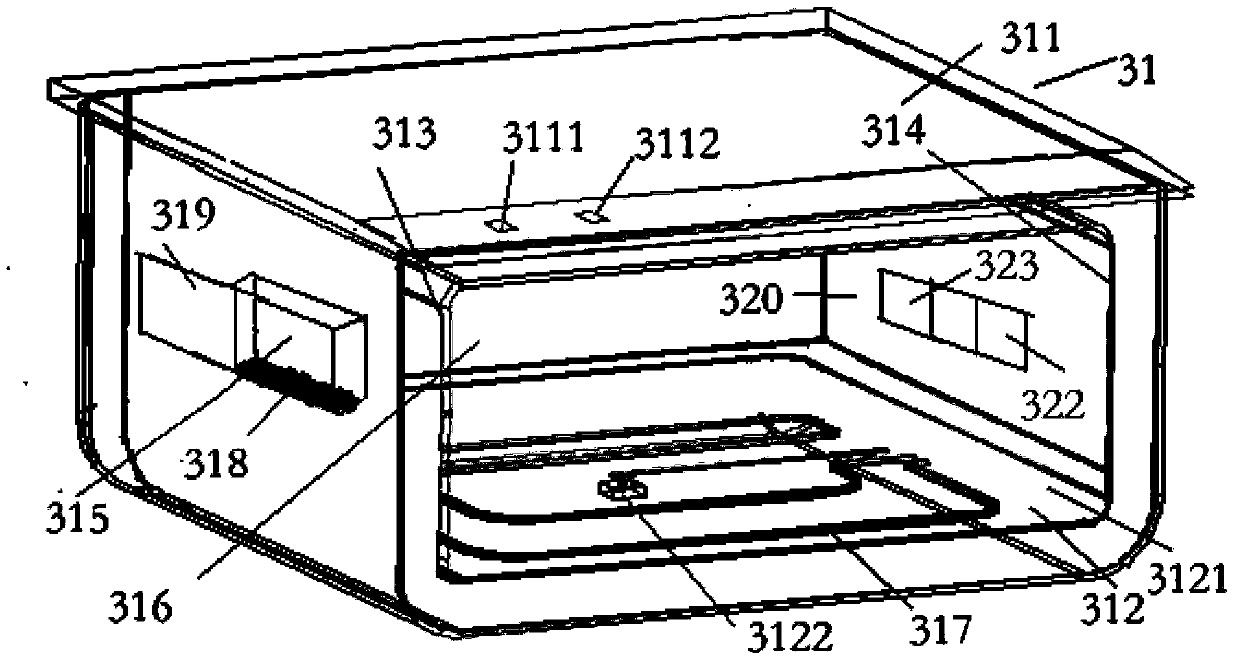

Unfreezing chamber in refrigerator and refrigerator with same

ActiveCN103629879ARapid coolingEfficient removalLighting and heating apparatusDomestic refrigeratorsControl switchRefrigerated temperature

The invention relates to an unfreezing chamber in a refrigerator and the refrigerator with the unfreezing chamber. The unfreezing chamber is arranged in a first storage chamber of the refrigerator, comprises an outer barrel and a storage box in the outer barrel and is provided with an electric heater and a control switch. In this way, objects stored at other positions of the refrigerator will not be affected in the unfreezing process.

Owner:HAIER GRP CORP +1

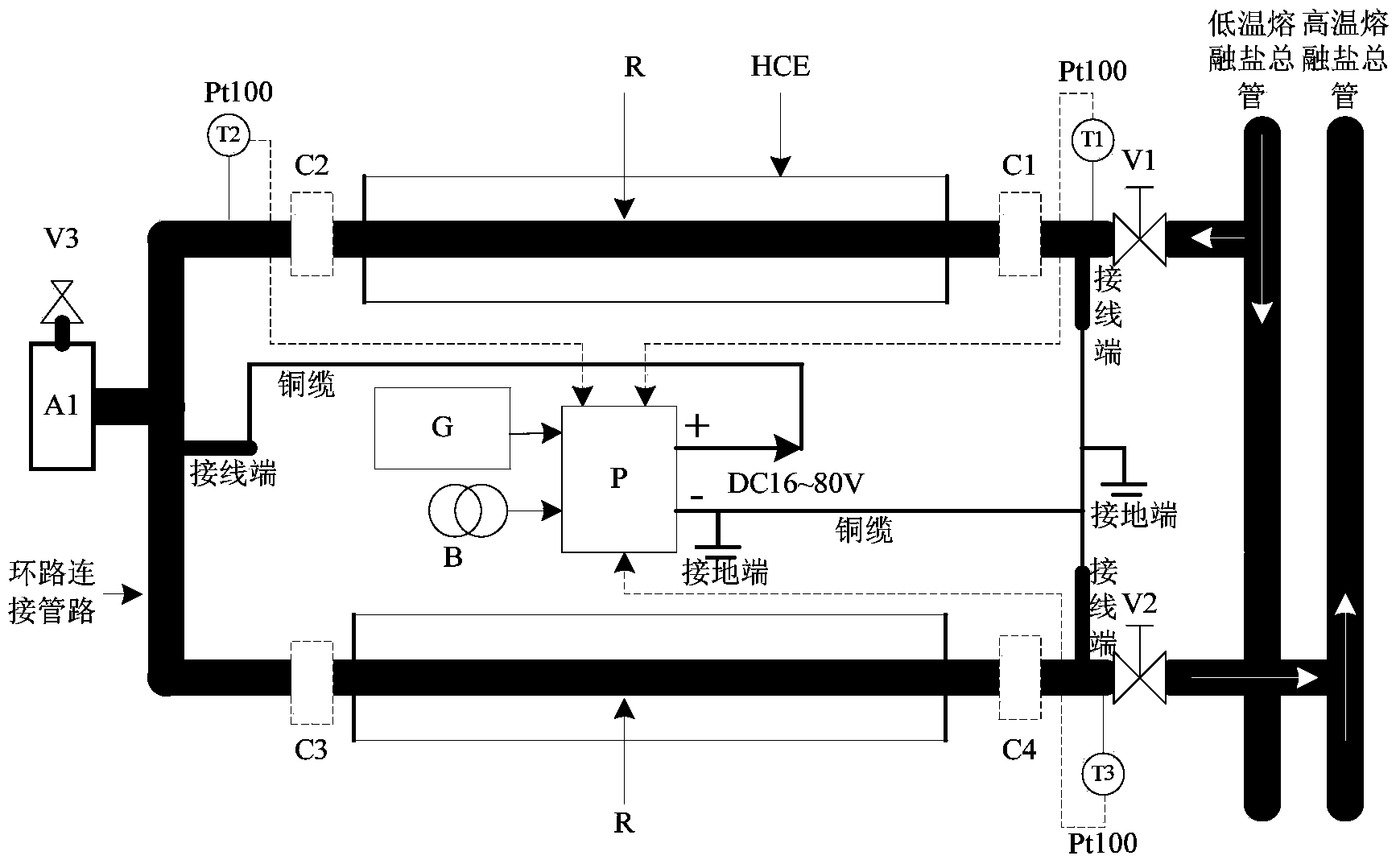

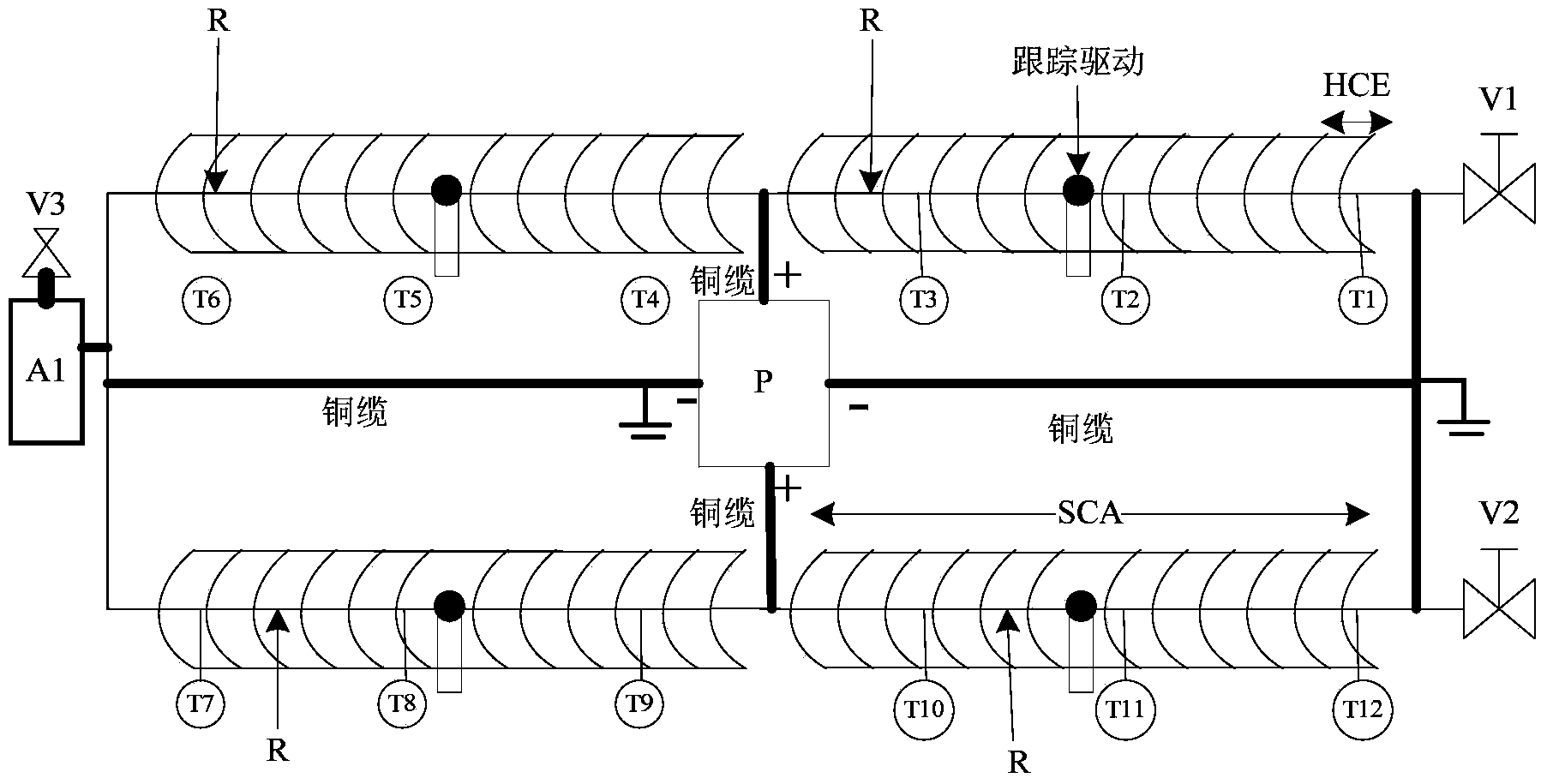

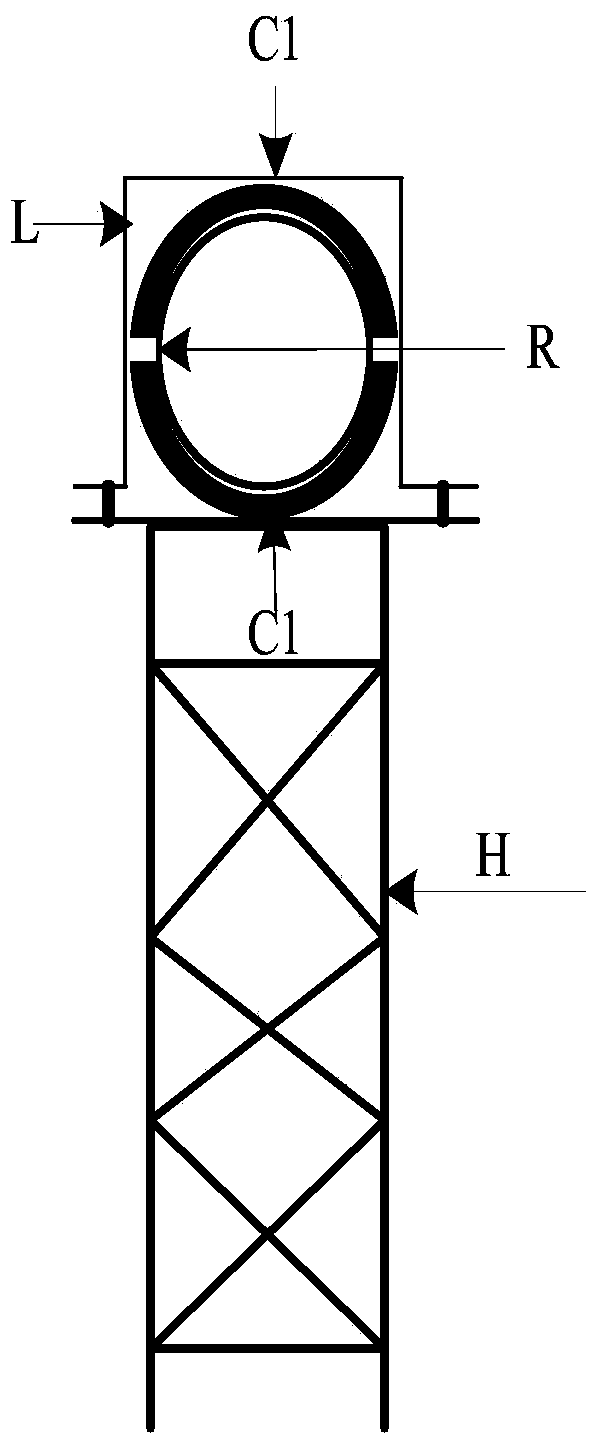

Direct-current large-current fused salt defreezing and preheating device of groove type vacuum heat collecting pipe

ActiveCN103712358ASave spaceEasy to implementSolar heat devicesPipe heating/coolingExpansion tankTransformer

The invention discloses a direct-current large-current fused salt defreezing and preheating device of a groove type vacuum heat collecting pipe and belongs to the technical field of thermal equipment. The direct-current large-current fused salt defreezing and preheating device is composed of a pipeline system and a direct electric heating system. The pipeline system comprises a voltage limiting valve V1, a voltage limiting valve V2, a ceramic electric insulating structure used for being connected with a heat absorber supporting mechanism, an expansion tank and a voltage limiting valve V3. The direct electric heating system comprises a field transformer, a standby alternator, an AC / DC module used for AC-DC conversion, a connection copper cable, a terminal block, a Pt100 temperature sensor T1, a Pt100 temperature sensor T2 and a Pt100 temperature sensor T3, wherein the Pt100 temperature sensor T1, the Pt100 temperature sensor T2 and the Pt100 temperature sensor T3 are used for controlling. According to the direct-current large-current fused salt defrosting and preheating device of the groove type vacuum heat collecting pipe, a body resistor in a stainless steel inner pipe of the vacuum heat collecting pipe is used as an electric-heating heating element, the problems of freezing and blocking of fused salt and preheating starting in the groove type system vacuum heat collecting pipe are solved, and the direct-current large-current fused salt defrosting and preheating device has the advantages of being convenient to carry out, capable of saving space in the vacuum heat collecting pipe, even in peripheral heating, little in heat transfer resistance and short in defreezing and preheating time.

Owner:河北井矿新能源科技有限公司

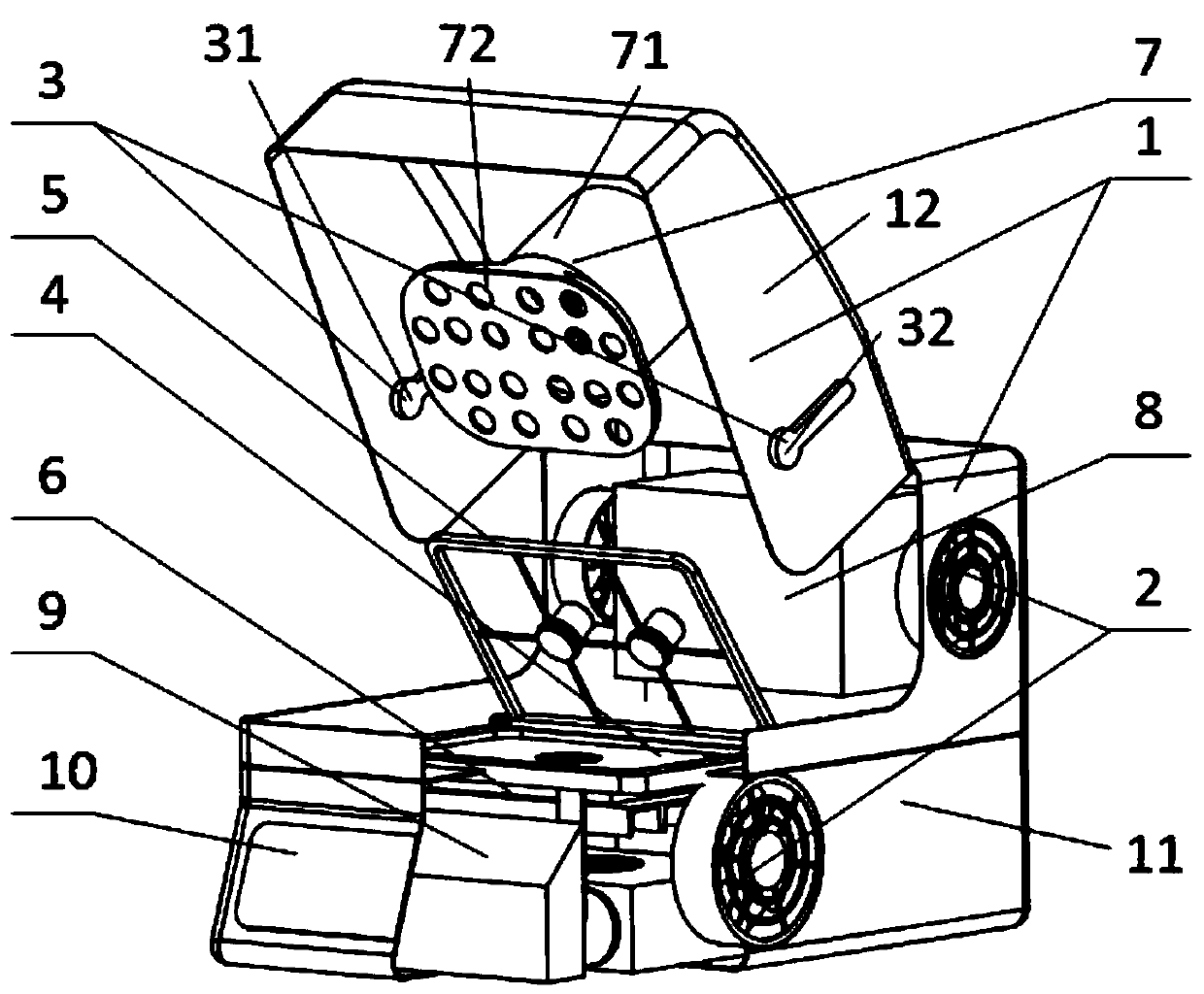

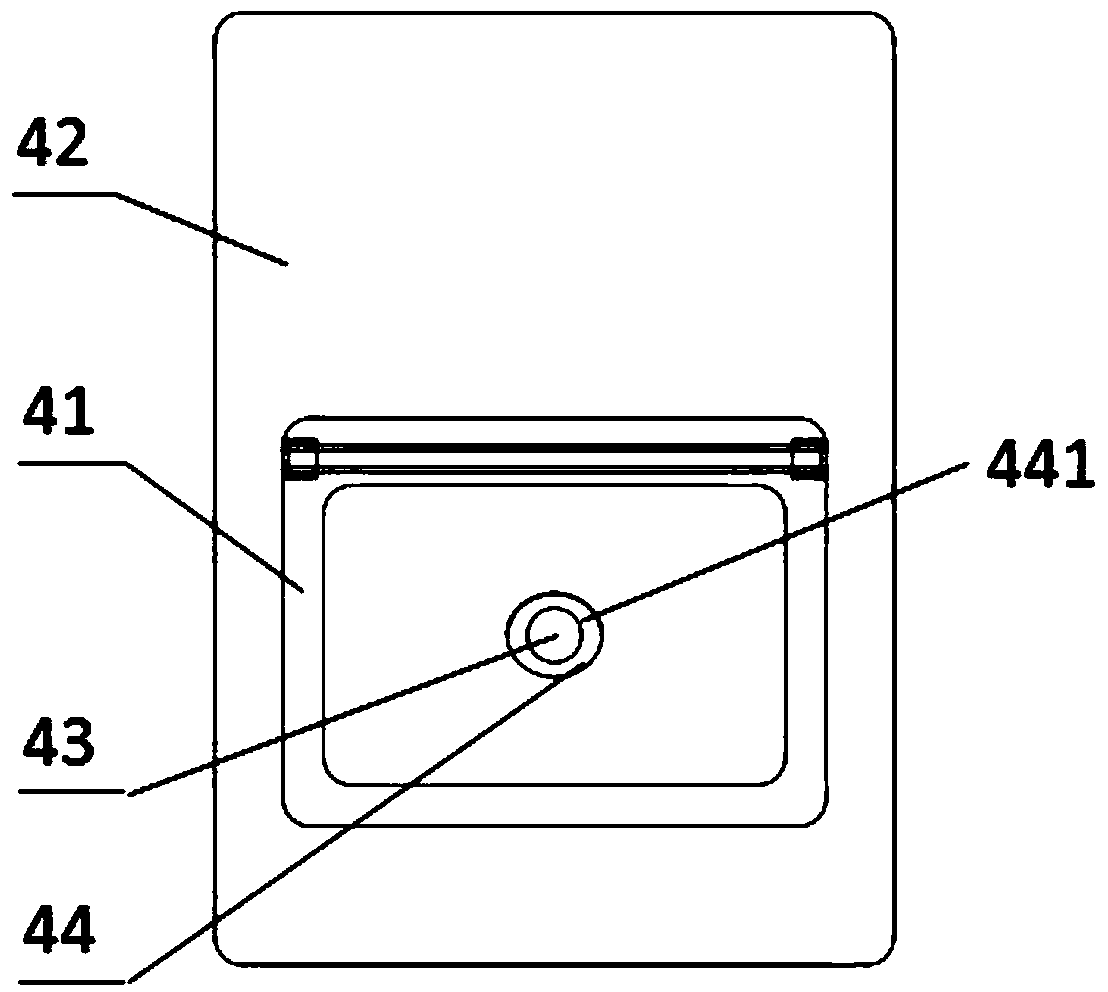

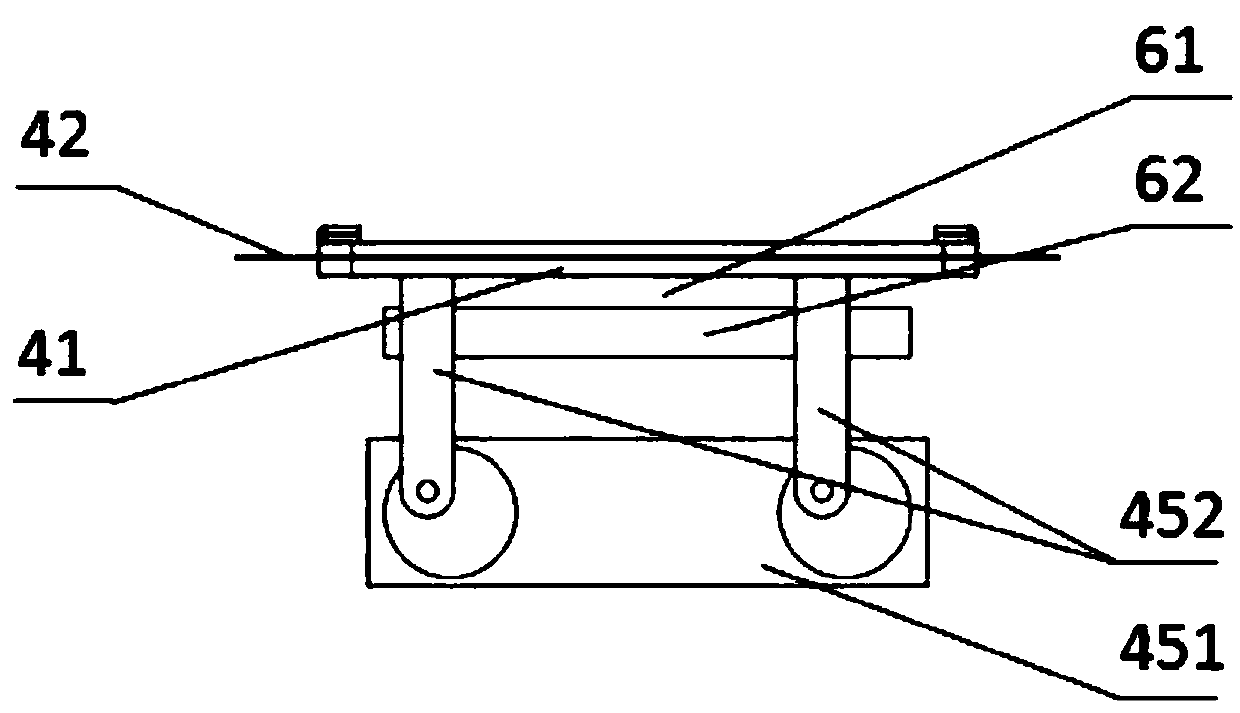

Dry recovery device of cell cryopreservation bags and working method

PendingCN109609347AHigh recovery rateReduce the risk of contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsNumerical controlTemperature control

The invention discloses a dry recovery device of cell cryopreservation bags, comprising a working cabin body, an air exhaust device, temperature measuring devices, a built-in rocker shaker, an elasticcover net, a temperature control device, a hot air flow generating device, ozone generating devices, a numerical control device and an operation interface; the working cabin body comprises a workingcabin main body and a cabin cover movably connected to the working bin main body; the air exhaust device is fixedly mounted on the lateral side of the working cabin body, the temperature measuring devices are arranged inside and outside the working cabin body, and the built-in rocker shaker is installed inside the working cabin body; the built-in rocker shaker is flexibly connected to the elasticcover net, and the temperature control device is installed in the built-in rocker shaker; the upper part of the built-in rocker shaker is equipped with the hot air flow generating device, and the hotair flow generating device is disposed in the cabin cover; and the ozone generating devices are disposed in the working cabin main body and the cabin cover, the numerical control device is installed below the built-in rocker shaker, and the operation interface is arranged outside the working cabin body.

Owner:赛慕特生物工程(上海)有限公司

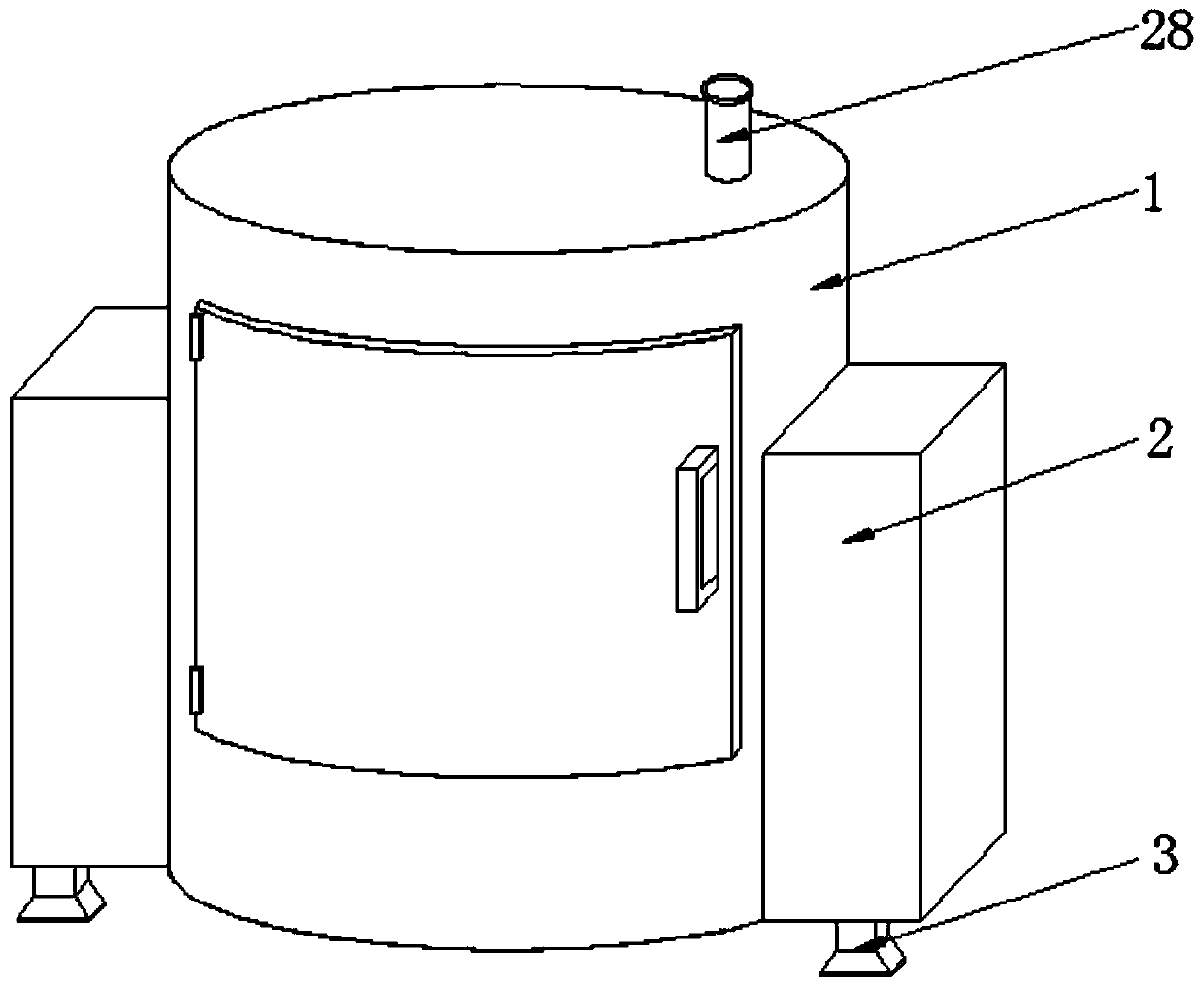

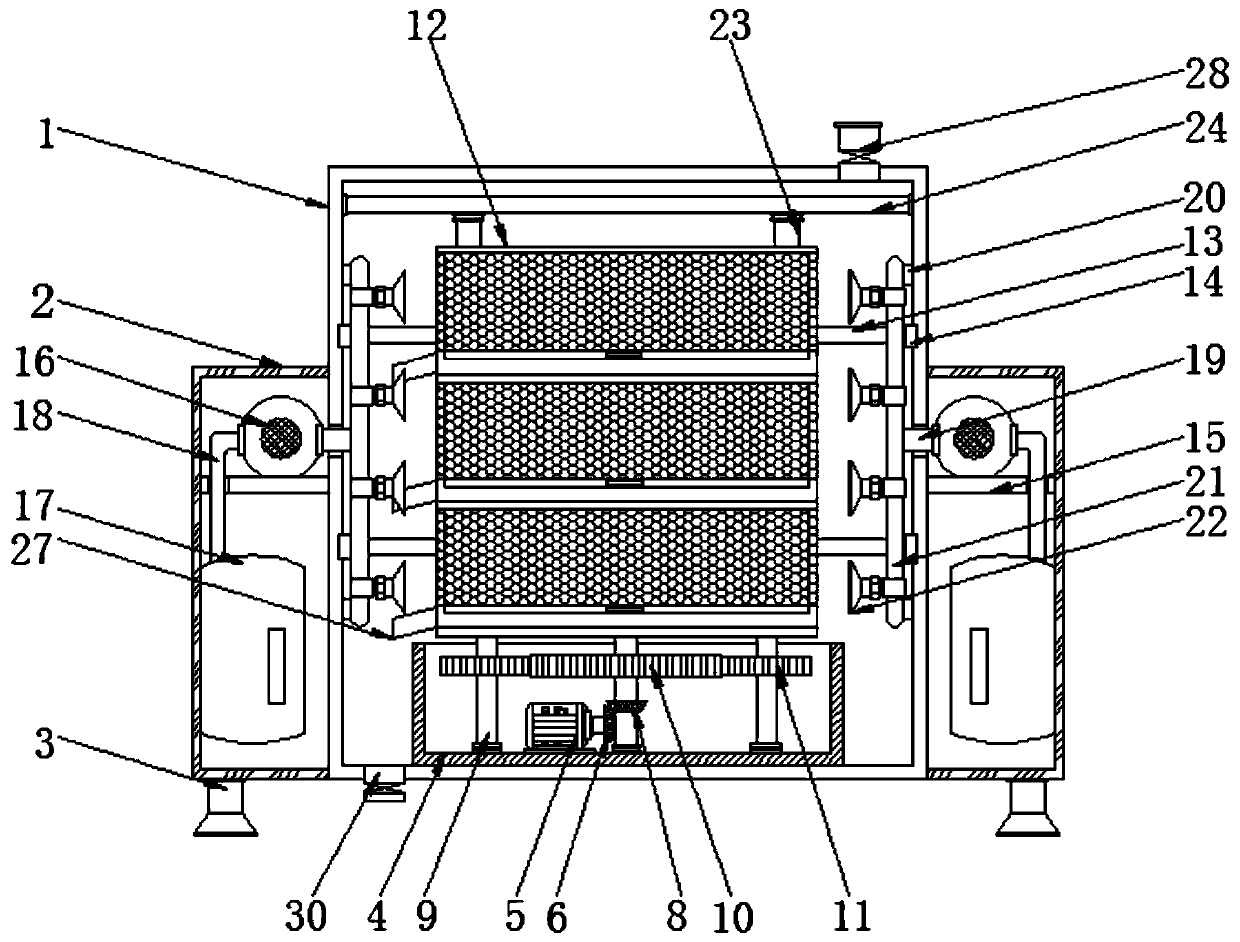

Rapid unfreezing equipment based on food processing

The invention discloses rapid unfreezing equipment based on food processing, and relates to the technical field of food processing equipment. The equipment comprises a cylinder body, shells and supporting legs, the shells are fixedly connected to two sides of the cylinder body, and the supporting legs are fixedly connected to the bottoms of the two shells; and a frame body is fixedly connected tothe bottom of the inner wall of the cylinder body, a motor is fixedly connected to the bottom of the inner wall of the frame body, and a first bevel gear is fixedly connected to one end of the outputshaft of the motor through a coupler. According to the rapid unfreezing equipment based on food processing, the frame body is fixedly connected to the bottom of the inner wall of the cylinder body, the bottom of the inner wall of the frame body is fixedly connected with the motor, when frozen products are unfrozen, the frozen products are heated more evenly, time is saved, the unfreezing effect isbetter, the unfreezing efficiency is improved, and through the fact that the top of a supporting plate is fixedly connected with an air pump, the frozen products are heated more evenly, the heating effect is better, the unfreezing is faster, and the use is convenient.

Owner:灵璧县童师傅食品有限公司

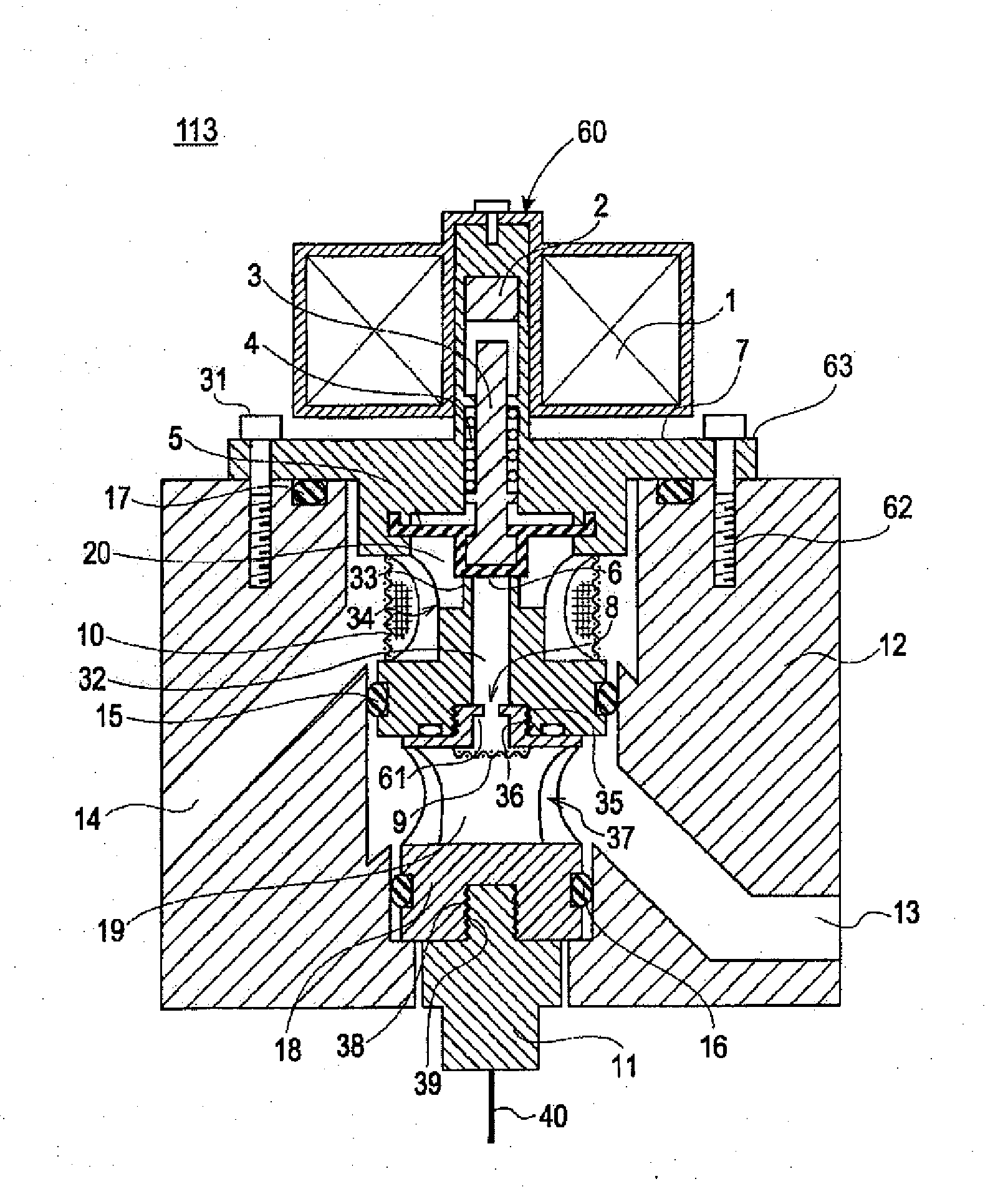

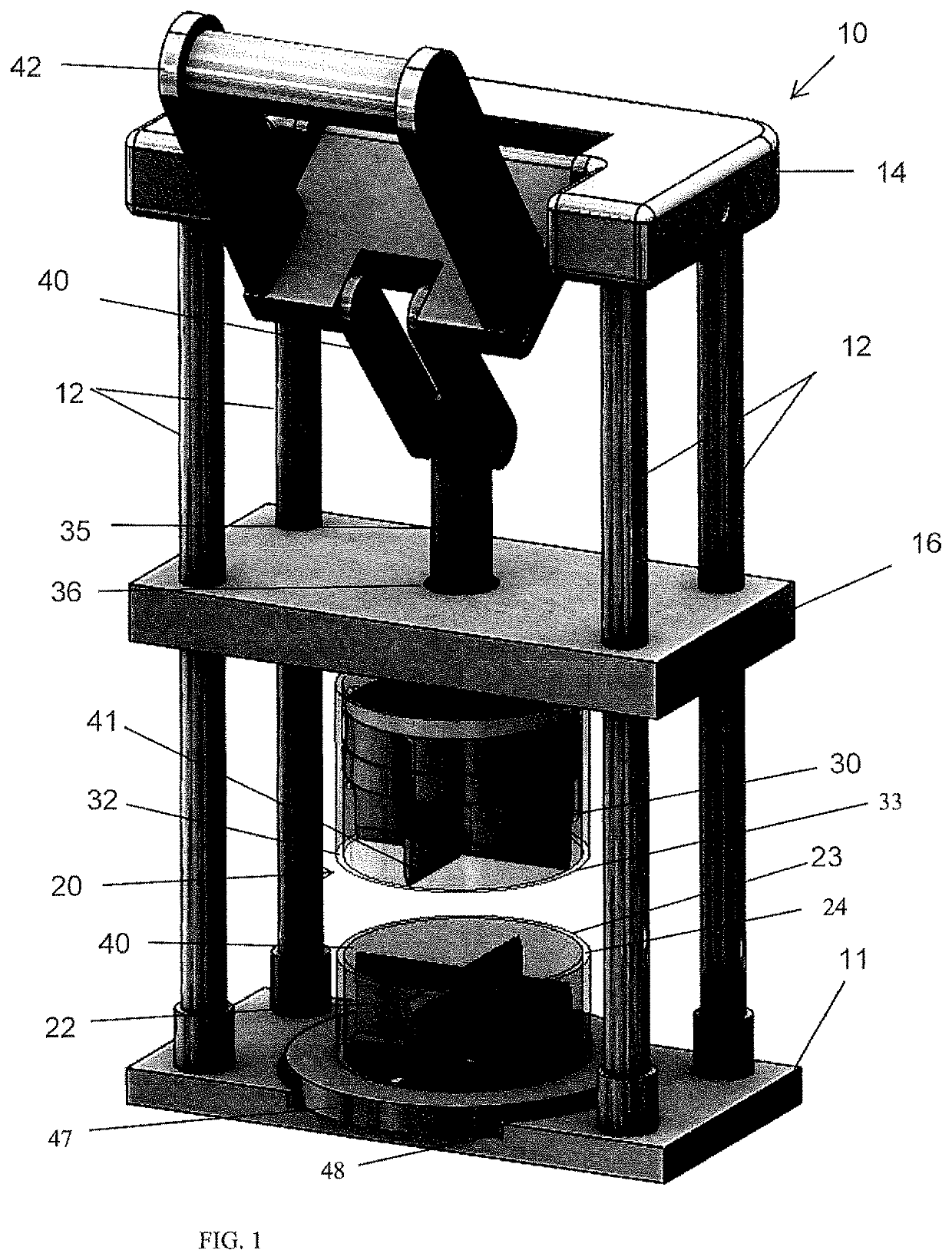

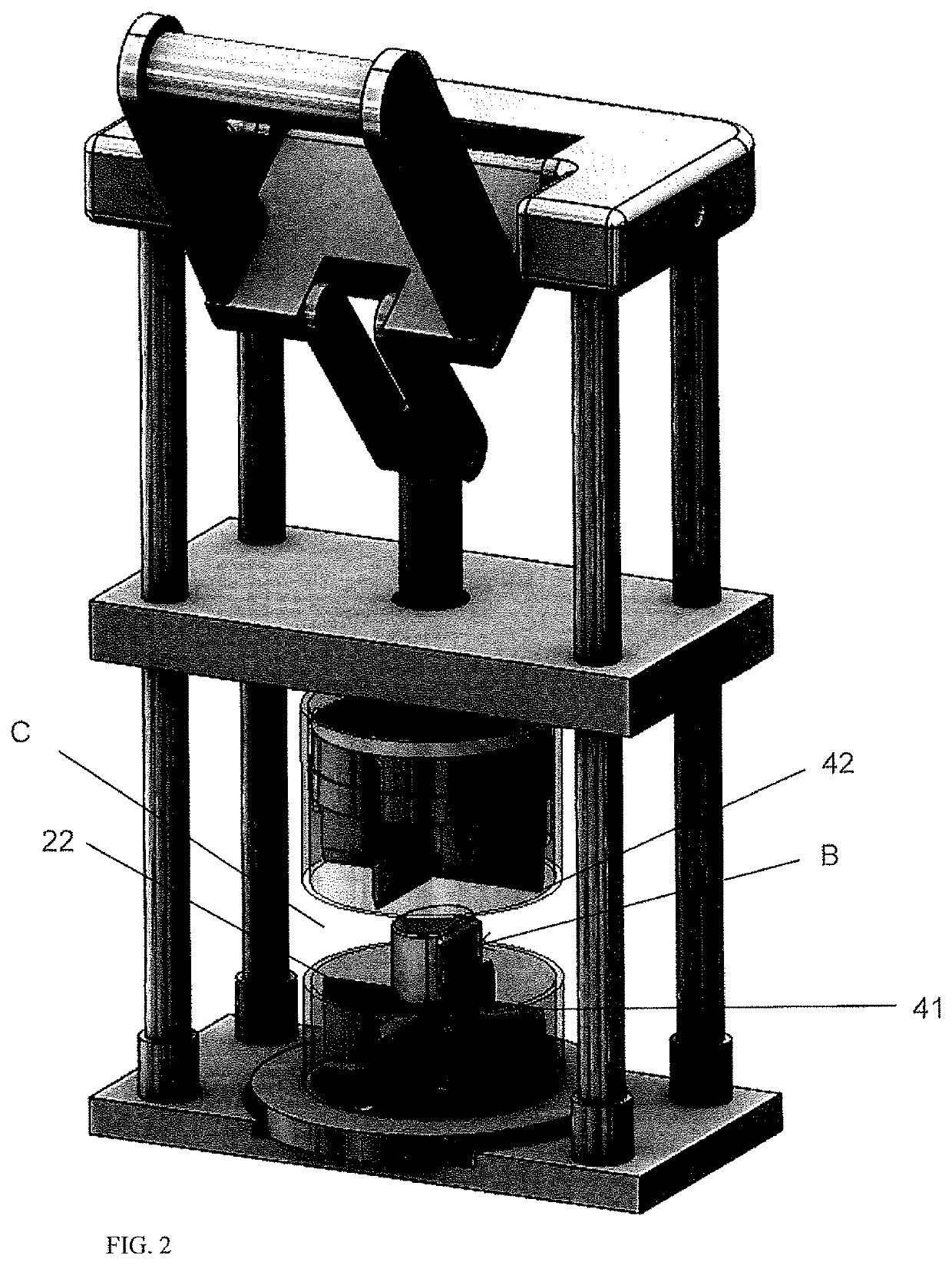

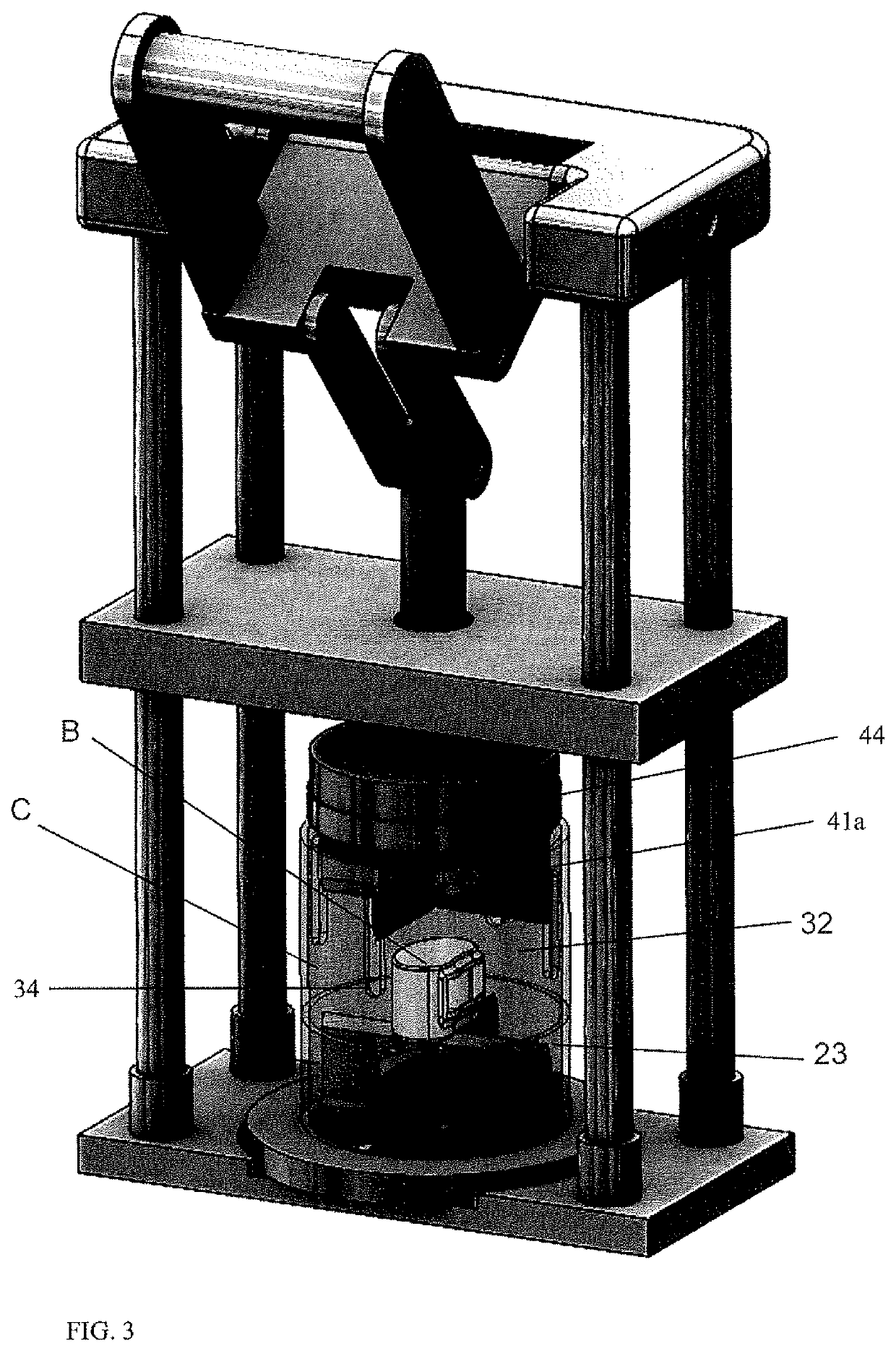

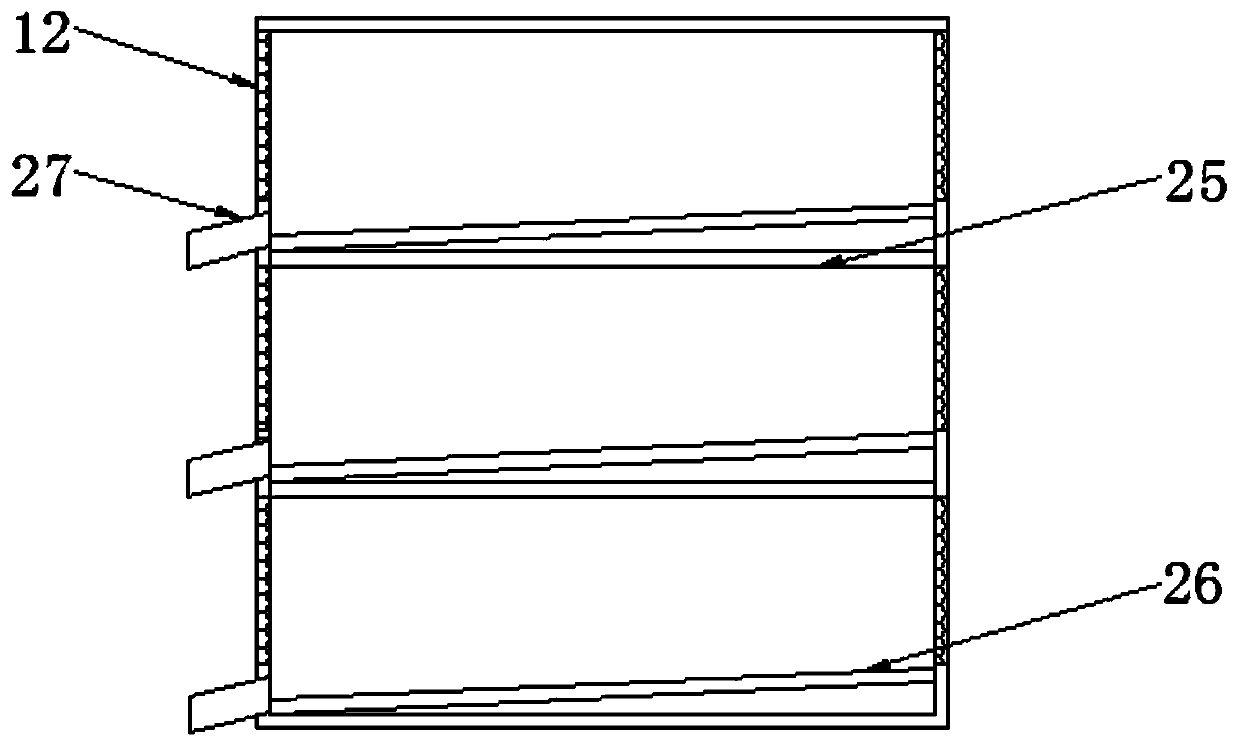

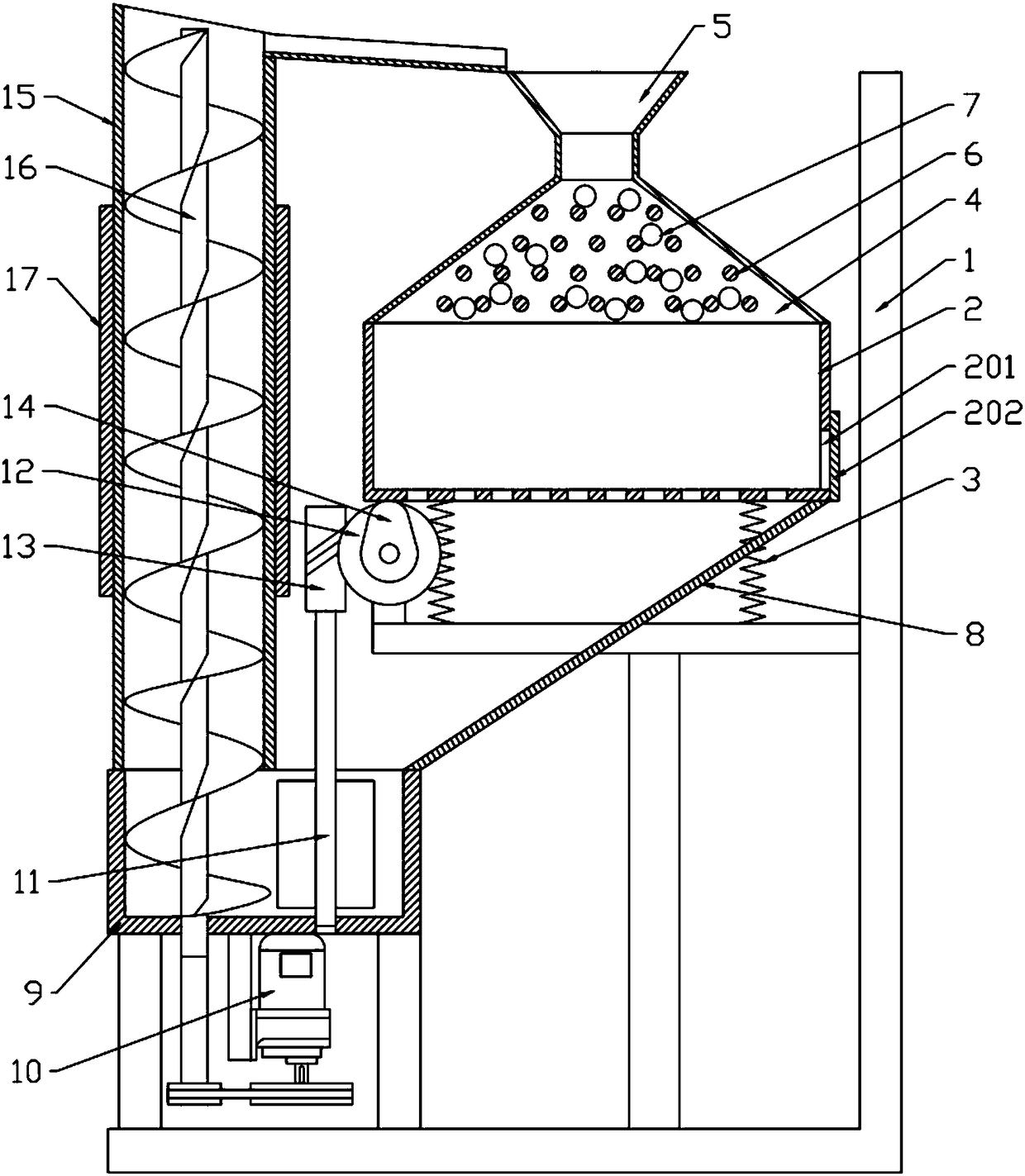

Quick thawing machine

InactiveCN108157485AQuick thawAvoid damageMeat/fish preservation by freezing/coolingEngineeringMechanical engineering

The invention relates to the field of thawing after freezing, and discloses a quick thawing machine. The quick thawing machine comprises a machine frame, a thawing tank, an ice melting device and a vibrating mechanism, wherein edges of the bottom of the thawing tank are mounted on the machine frame through pressure springs; the vibrating mechanism is mounted on the bottom surface of the thawing tank; the ice melting device comprises a ball dispersing mechanism, a ball receiving plate, a transporting mechanism, a heating device and a plurality of metal balls; the ball dispersing mechanism comprises a fixing plate; the fixing plate is vertically fixed to a tank opening of the thawing tank; a ball inlet is formed in the upper part of the fixing plate; a plurality of ball separating columns which are distributed in a crisscross manner are fixed to the fixing plate under the ball inlet; a plurality of through holes are formed in the bottom surface of the thawing tank; the ball receiving plate is obliquely arranged under the thawing tank; a ball receiving tank is arranged at the bottommost end of the ball receiving plate; one end of the transporting mechanism is connected to the ball receiving tank, and the other end of the transporting mechanism is connected to the ball inlet of the ball dispersing mechanism; and the heating device is arranged on the transporting mechanism. The invention aims to provide a thawing device which is used for quickly thawing raw materials of which the surfaces are coated by coagulated ice housings.

Owner:重庆好弟兄食品有限公司

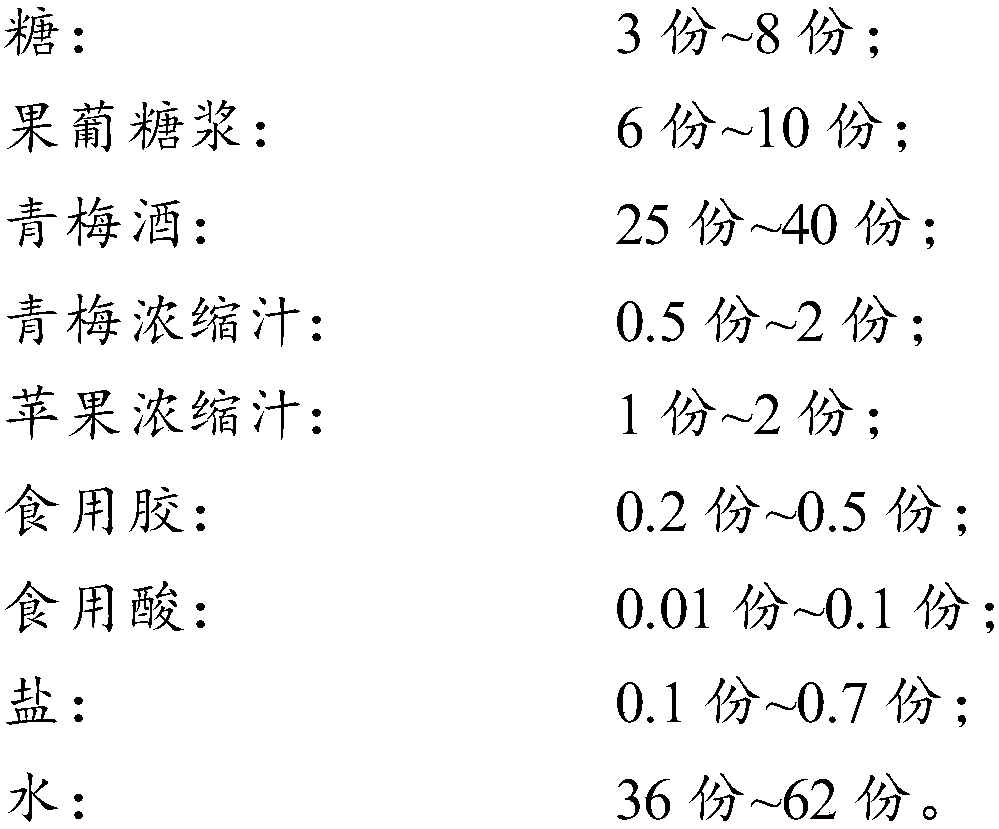

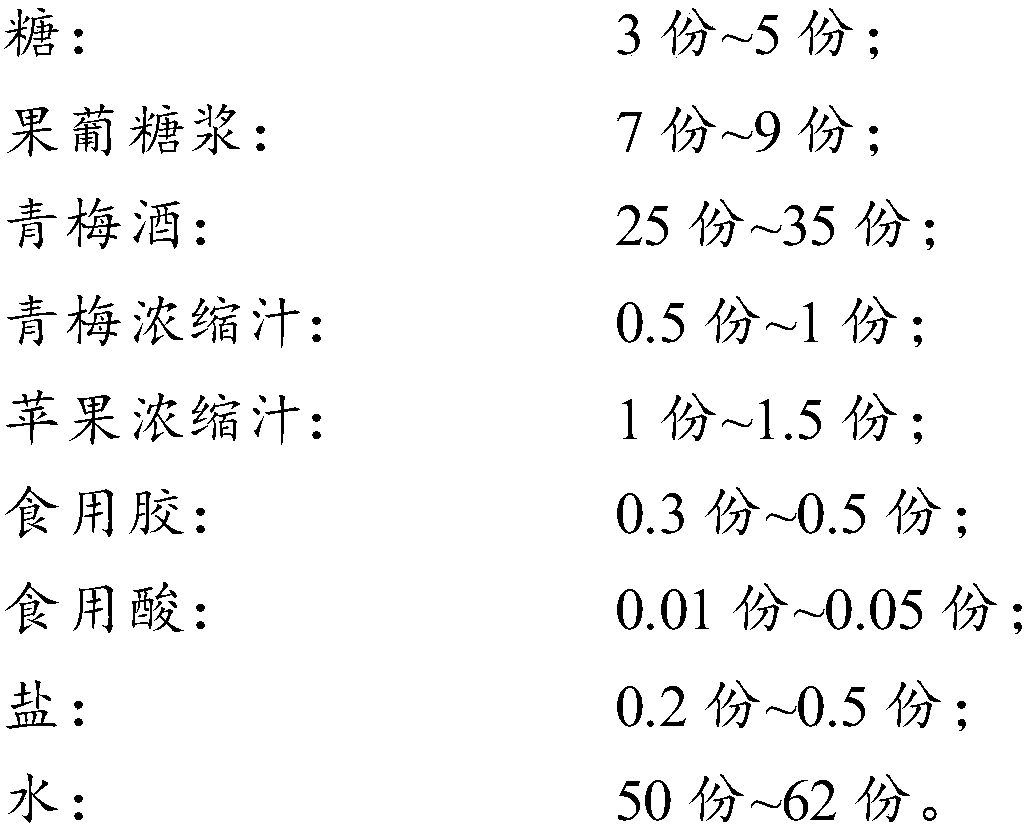

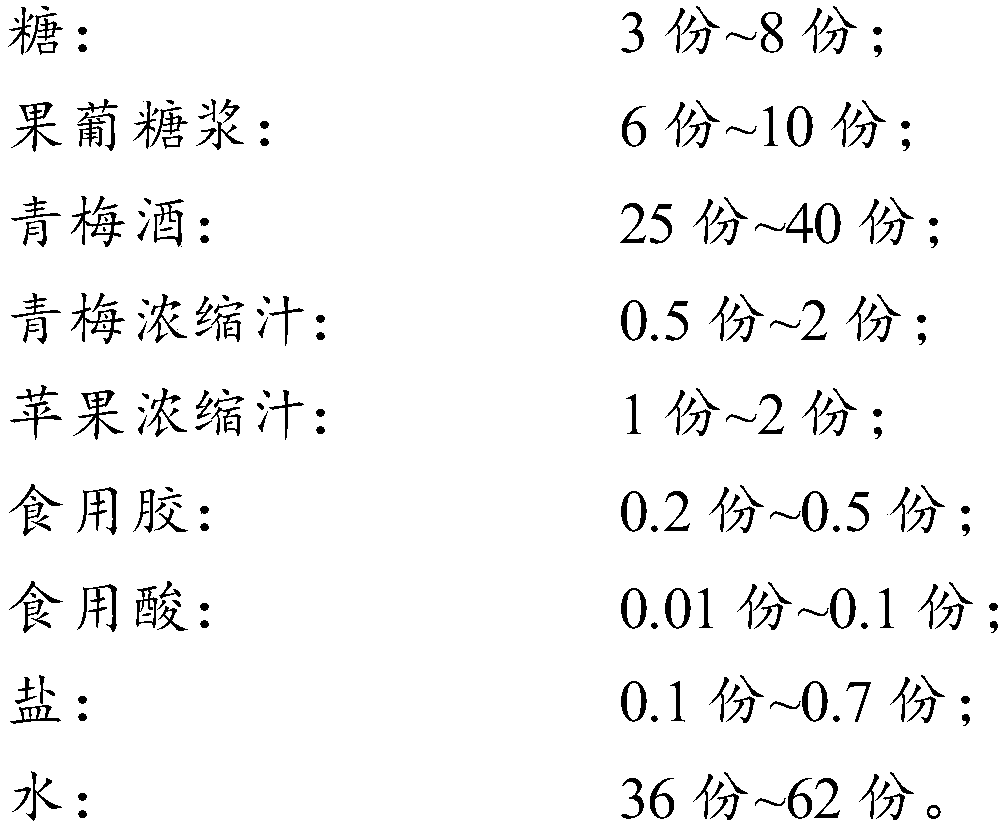

Plum wine jelly and preparation method thereof

PendingCN107772368AWith pure bloodWith sterilizationFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFlavorHigh-fructose corn syrup

The invention relates to the technical field of food and particularly relates to a plum wine jelly and a preparation method thereof. The plum wine jelly is prepared from the following raw materials inparts by weight: 3-8 parts of sugar, 6-10 parts of high fructose corn syrup, 25-40 parts of plum wine, 0.5-2 parts of plum concentrated liquor, 1-2 part of apple concentrated liquor, 0.2-0.5 part ofedible gum, 0.01-0.1 part of edible acid, 0.1-0.7 part of salt and 36-63 parts of water. By adding the plum wine and the plum juice into the jelly, the jelly has the functions of plums which purify blood, remove toxin and sterilize, so that the jelly has a unique function. The plum wine jelly prepared by the method provided by the invention is obvious in flavor, strong in wine flavor, smooth in taste, moderately sour and sweet and better in taste if being frozen.

Owner:I LAN FOODS IND +1

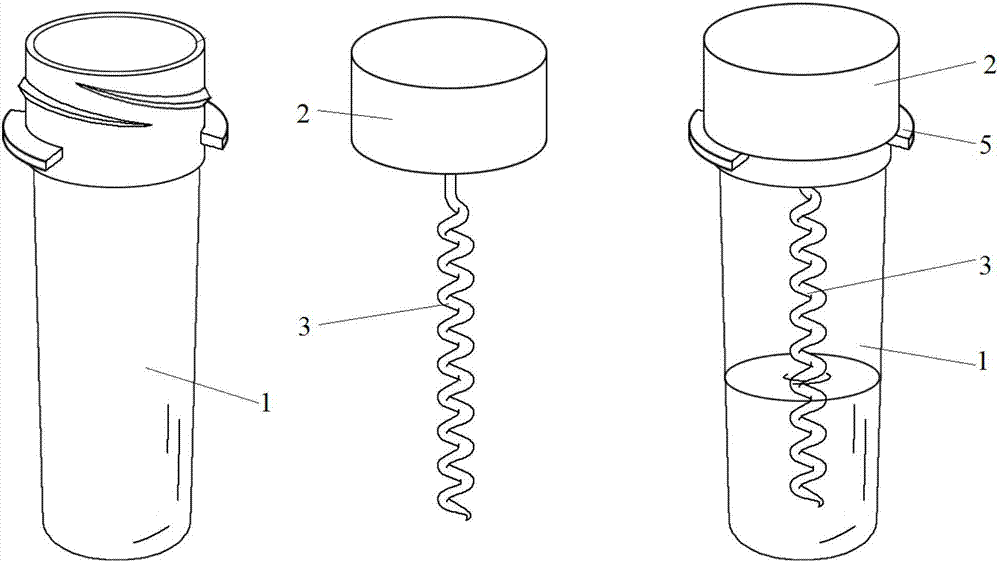

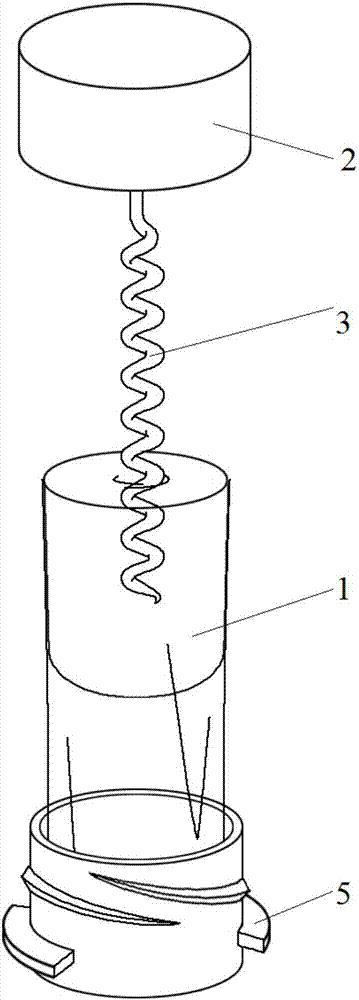

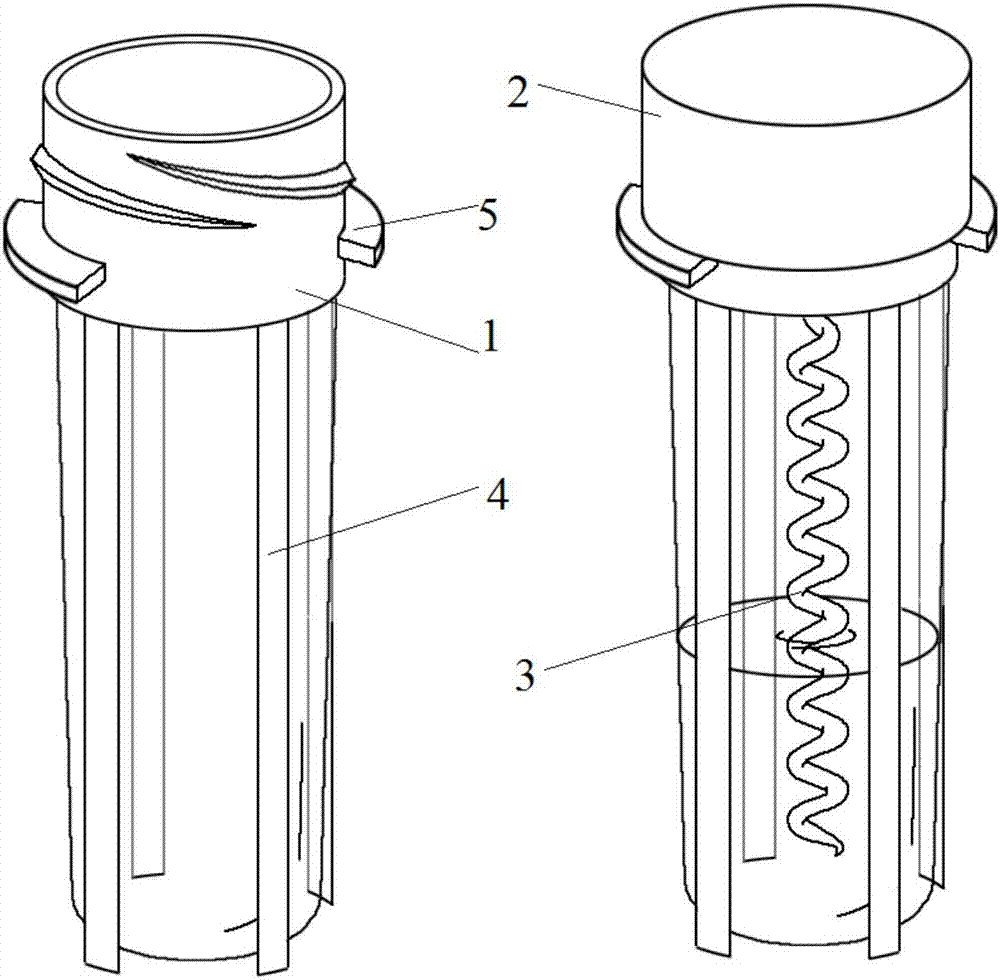

Cryogenic vial capable of being reversely rotated for rapid sampling and cryogenic box

InactiveCN107467012AQuick thawAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringVial

The invention provides a cryogenic vial capable of being reversely rotated for rapid sampling and a cryogenic box. The cryogenic vial comprises a tube body, a sealing cap, and a drawing rod, one end of the drawing rod is connected to the sealing cap, the other end of the drawing rod extends into the tube body, the drawing rod is helical, and the other end of the tube body is a flexible film tube. The cryogenic box comprises a box body, the box body is closed, one end surface of the box body is provided with a plurality of through holes, and the circumference of each through hole is provided with limit notches. As cells are thawed, frozen cell mixture is drawn out of the flexible film tube of the cryogenic vial by means of the drawing body, and the drawing body is cut off to directly put the frozen cell mixture into the cryogenic box; the box body of the cryogenic box is provided with the limit notches, ribs are correspondingly arranged on the cryogenic vial, the shape of the limit notch matches the shape of the rib on the cryogenic vial, consequently, the cryogenic vial can be stably placed in the cryogenic box, and the shaking of the cryogenic vial is prevented.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

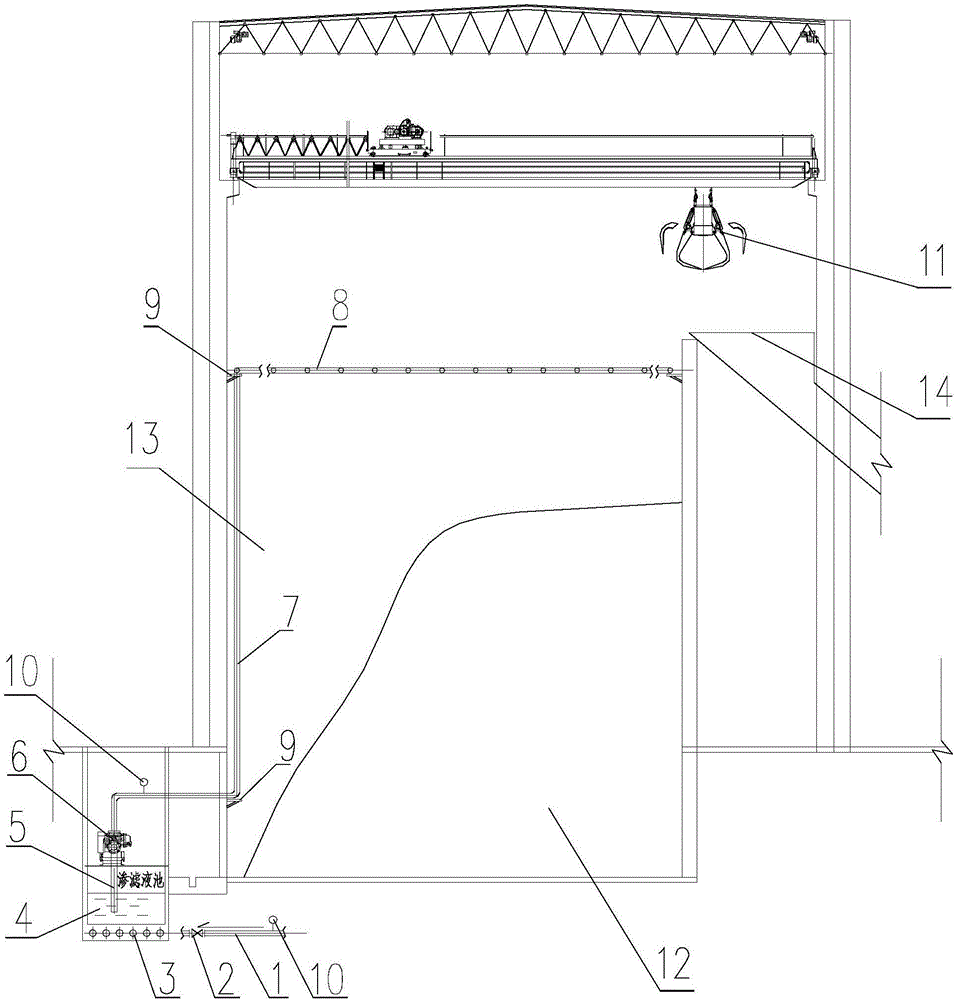

Winter garbage unfreezing system and method in household garbage incineration power plant

The invention discloses a winter garbage unfreezing system and method in a household garbage incineration power plant. The system comprises a garbage storage pit, a garbage crane, a garbage receiving hopper and a percolate pond. A percolate pump is installed in the percolate pond. The percolate pump is connected to a percolate spraying pipeline arranged above the garbage storage pit through a liquid outlet pipeline. A plurality of hot water coiled pipes are arranged at the bottom of the percolate pond. The hot water coiled pipes are externally connected with a hot water inlet pipe and a water outlet pipe. A temperature detection instrument and a valve are installed on the water inlet pipe. A temperature detection instrument is installed on the liquid outlet pipeline connected with the percolate and the percolate spraying pipeline. Due to the fact that the hot water pipeline additionally arranged at the bottom of the percolate pond is used for heating the percolate, the percolate heated inside the pond is conveyed to the spraying pipeline at the upper portion of the garbage storage pit through the percolate pump, the large amount of heated percolate is sprayed to garbage inside the garbage storage pit to be unfrozen and heated, and garbage fermentation and dehydration are promoted.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

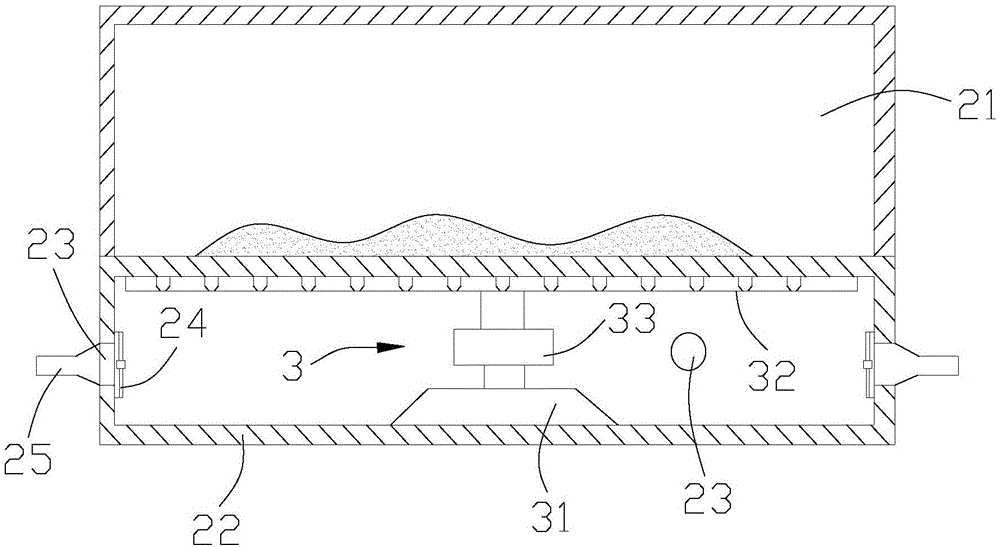

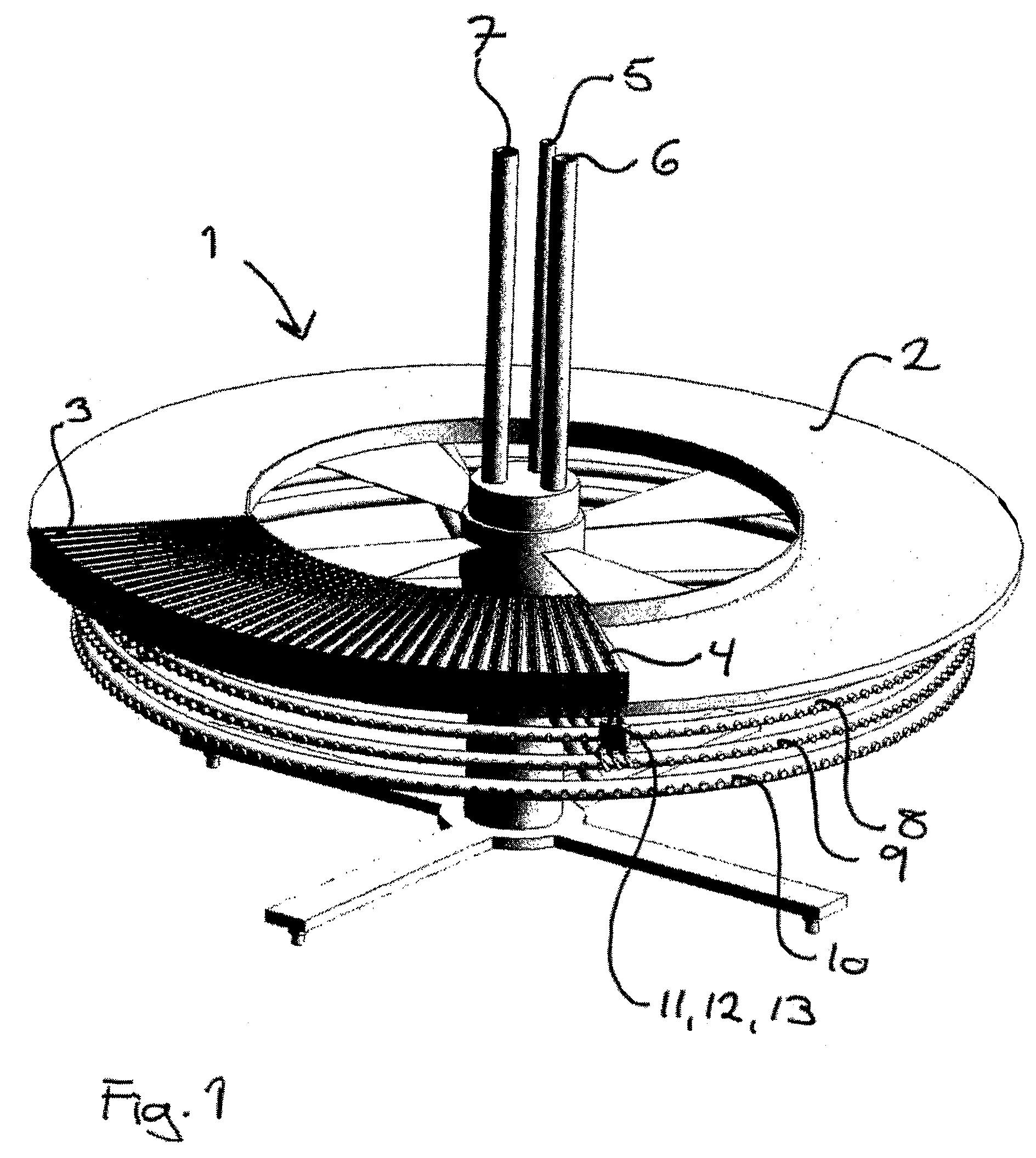

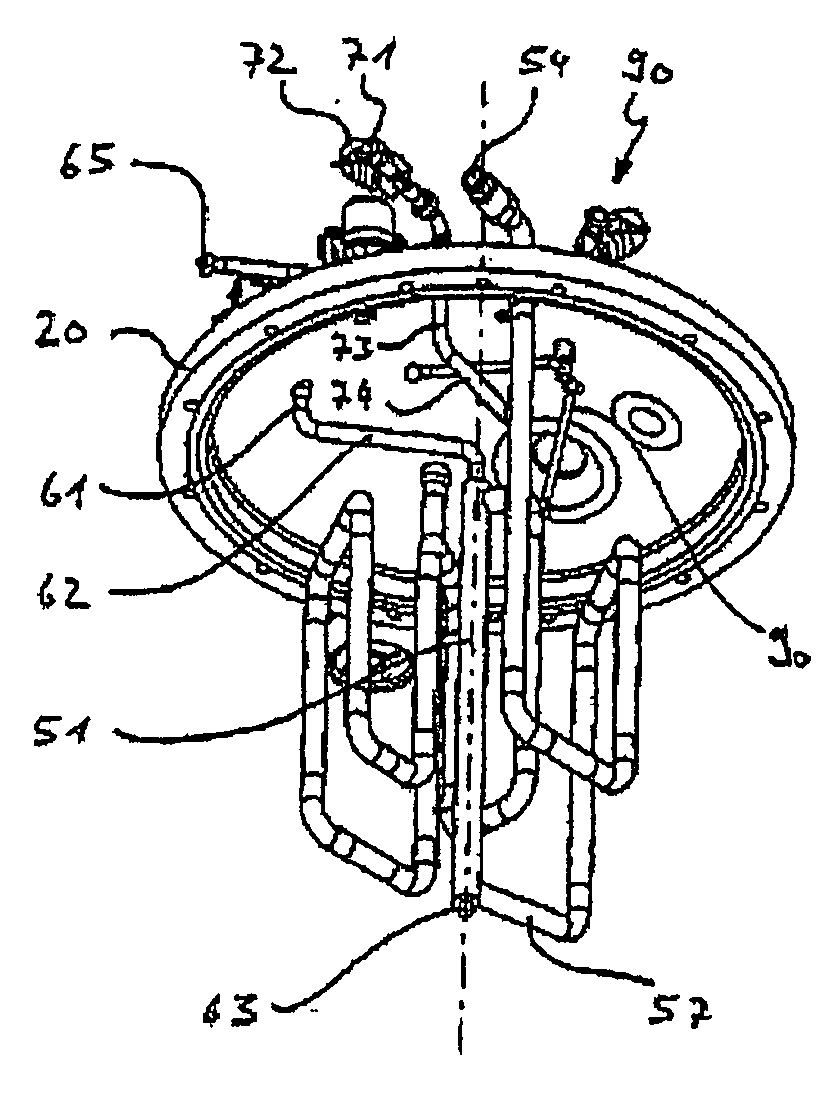

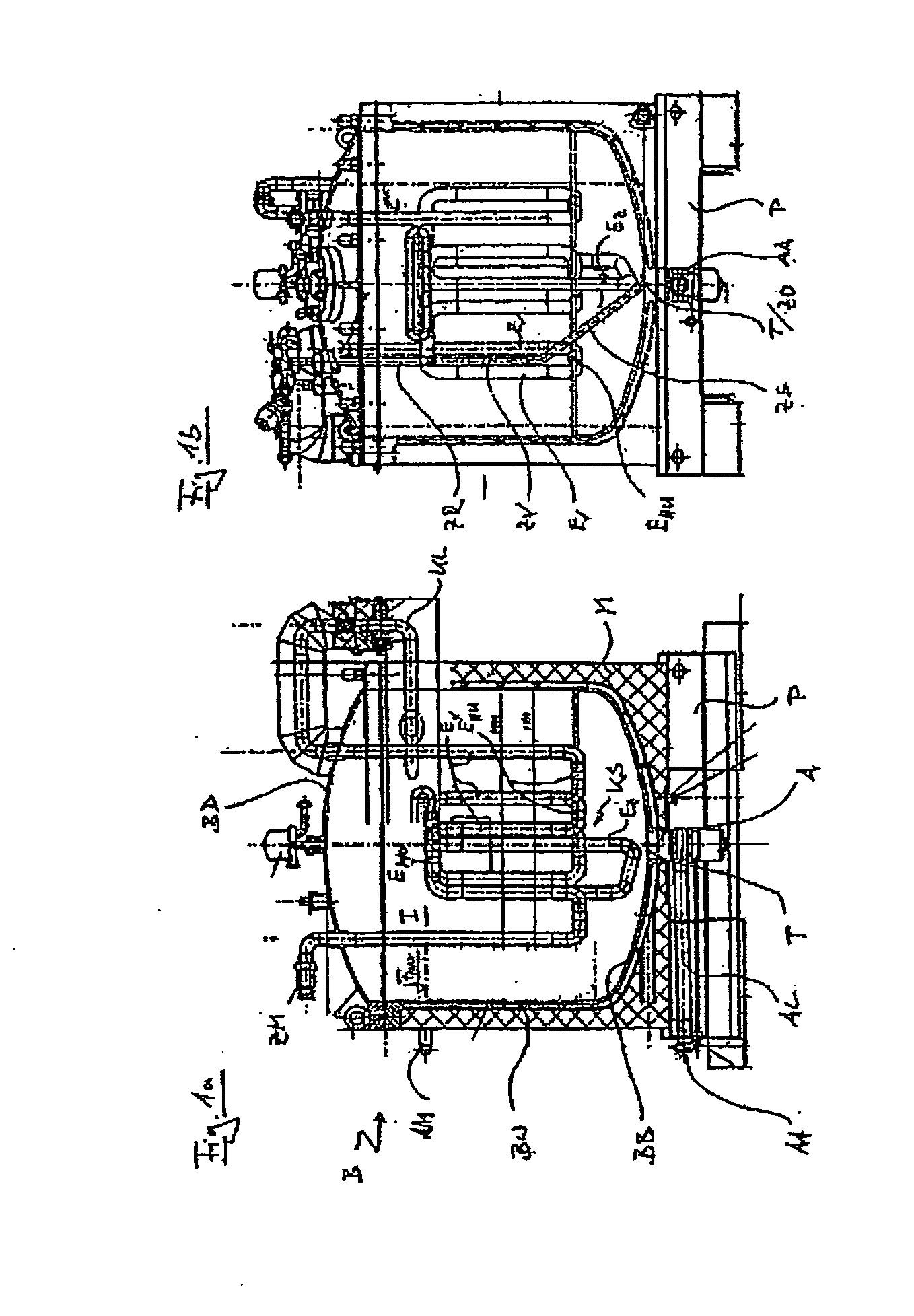

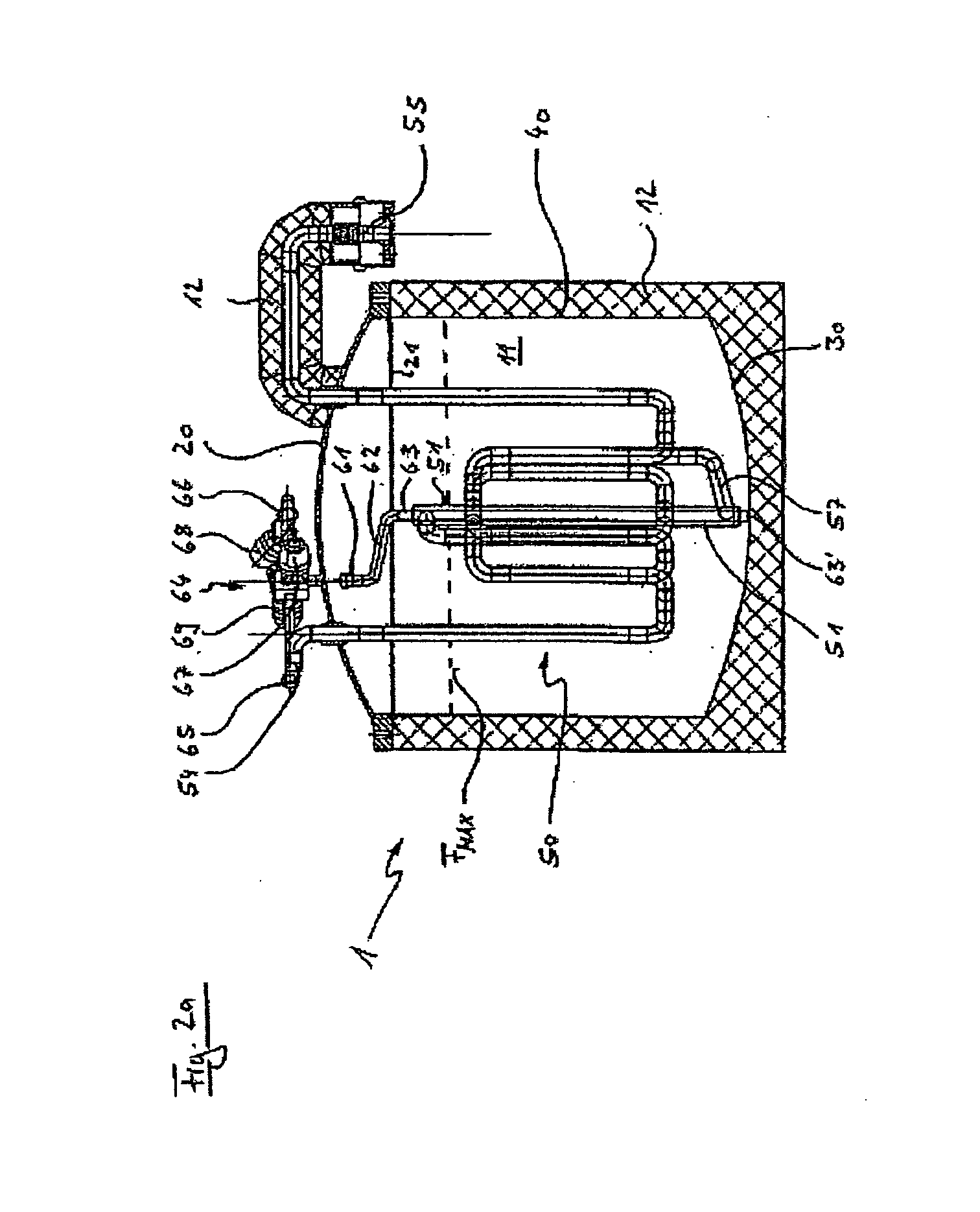

Device for Freezing,Transporting and Thawing Fluids

InactiveUS20090308567A1Maximum amount of operating optionWell mixedAir heatersStationary conduit assembliesFood industryLiquid product

The invention relates to a device (1) for freezing, transporting and thawing fluids, in particular sterile liquids, solutions and suspensions for the chemical, biotechnology, pharmaceutical and food industries. Said device comprises a container (10) with a lid (20), a wall (40) and a base (30) and at least one heat exchanger element (50) that is operatively connected to the fluids held in the container, such that said fluids can be cooled or heated. An immersion pipe (60) is operatively connected to at least one heat exchanger element (50) via at least one sub-region of its longitudinal extension, said region preferably extending approximately from a lowest point in the container to a maximum fill level. Preferably, the immersion pipe is in direct contact with at least one heat exchanger element and can be passively heated. During the thawing process, the thus liquefied product is withdrawn via the heatable immersion pipe(s), which preferably penetrate(s) the interior of the container from top to bottom and open(s) over the lowest point in the container. In comparison to known devices, in which the feed pipe is freely located in the container interior and thus freely located in the frozen product, the advantage of the heatable immersion pipe is that the frozen product thaws extremely quickly inside the immersion pipe and the withdrawal of the thawed liquid product is only blocked in the initial phase of the thawing process. During withdrawal, the thawed product is, in addition, gently heated during its passage through the heated immersion pipe, such that it can be fed, preferably from above, onto portions of the product that are still frozen at a temperature that is significantly higher than the freezing point, thus accelerating the thawing process.

Owner:ZETA BIOPHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com