Direct-current large-current fused salt defreezing and preheating device of groove type vacuum heat collecting pipe

A technology of vacuum heat collecting tube and preheating device, which is applied to a preheating device, in the field of melting salt thawing in the vacuum heat collecting tube, to achieve the effects of small heat transfer resistance, short preheating time and saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

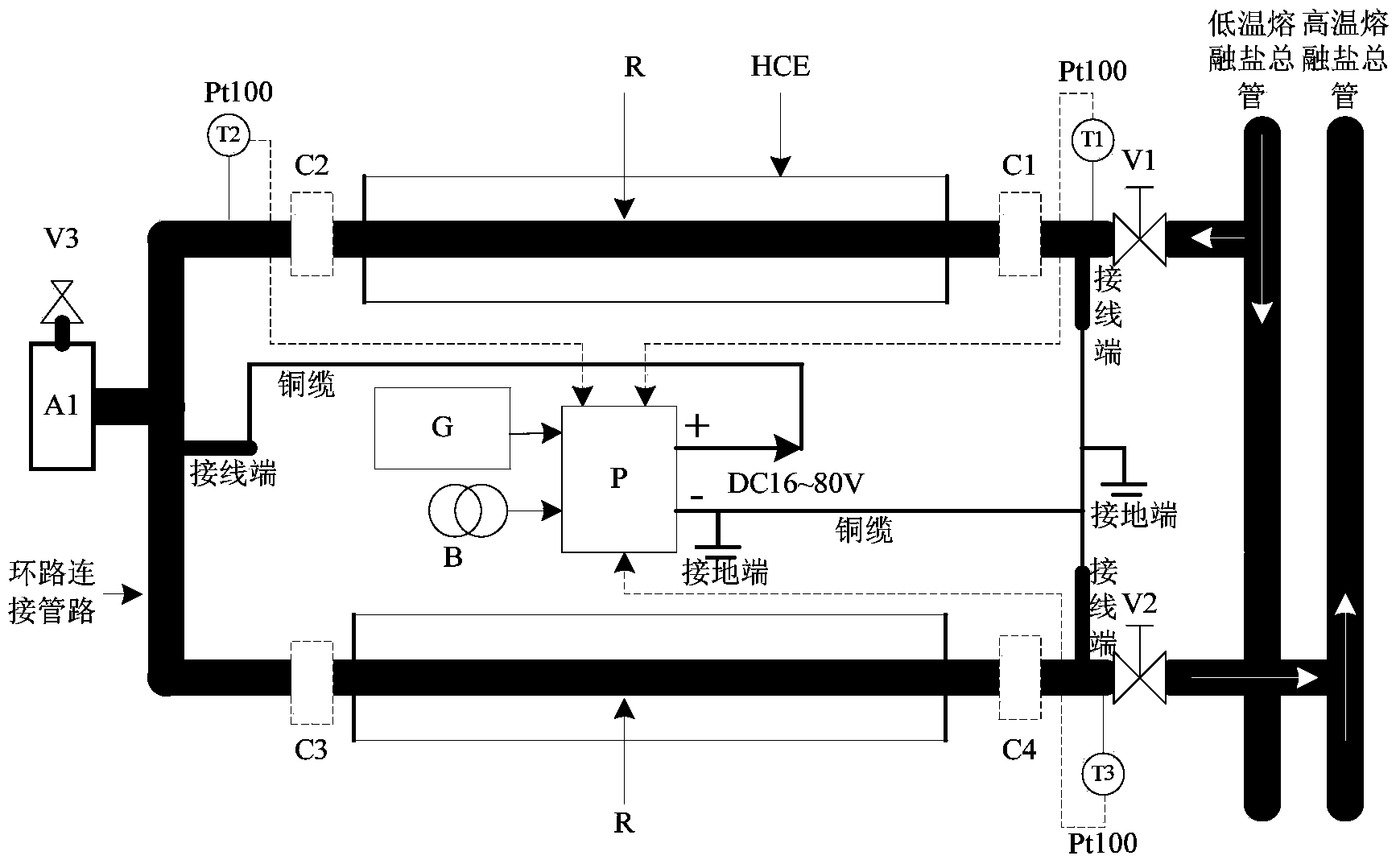

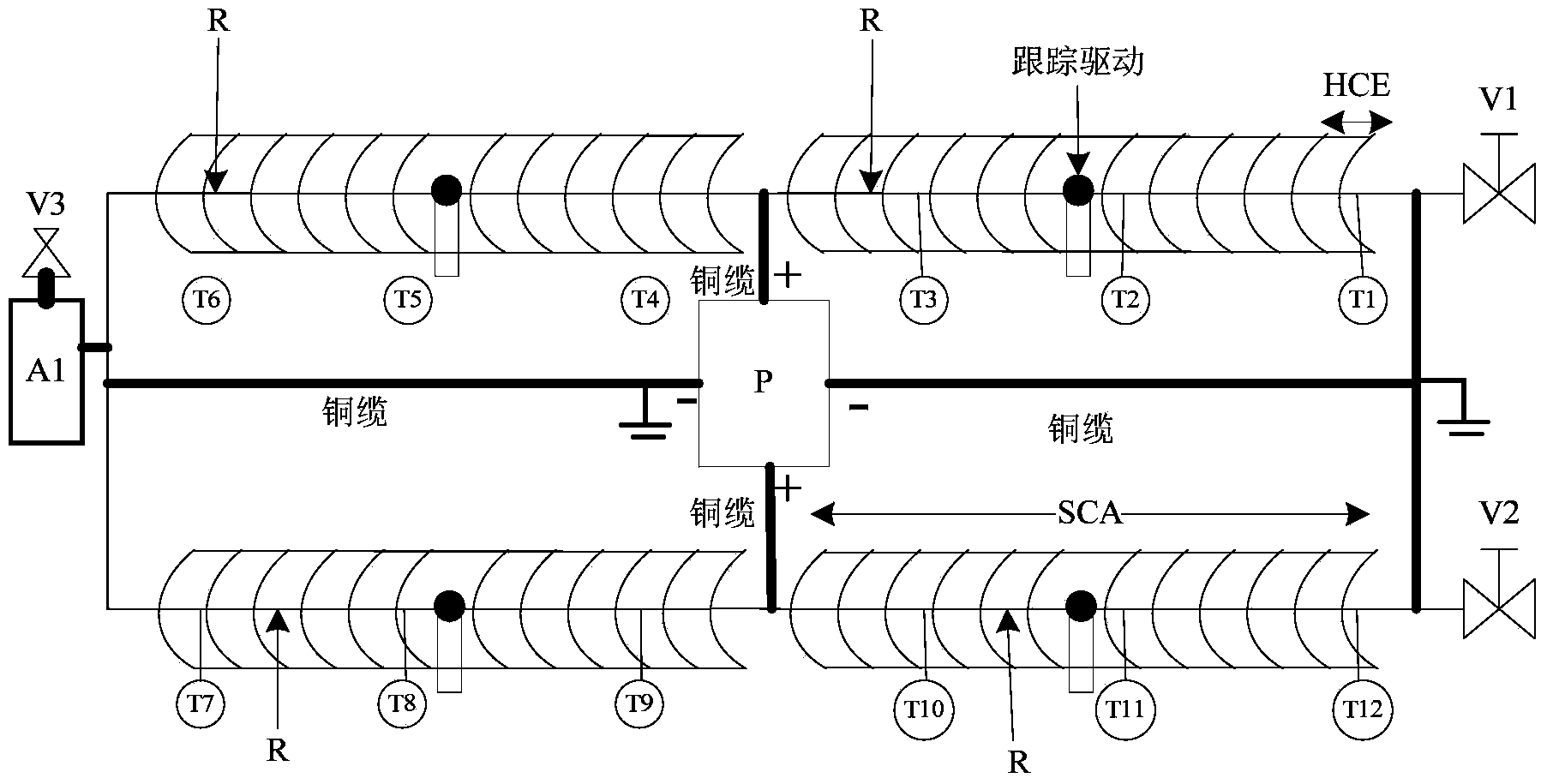

[0024] combine figure 1 , further explain the specific implementation of this patent:

[0025] The on-site transformer B provides the power required for thawing and preheating the collectors of the entire power plant, and the backup generator G only provides the power required for thawing and preheating the collectors of a single circuit when the system is powered off or requires special treatment.

[0026] The AC / DC conversion module and control system P are responsible for providing low-voltage and high-current DC power and can adjust the output voltage value for different SCA lengths to provide corresponding electric power. The maximum DC output voltage is 80V.

[0027] According to the output current capability of the AC / DC conversion module, the number of loops it can handle is determined, and each AC / DC conversion module can handle 1 to 2 loops.

[0028] T1, T2, and T3 are used as temperature sensors at the head, tail and middle of the circuit for system thawing and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com