Patents

Literature

61results about How to "Reduce piping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

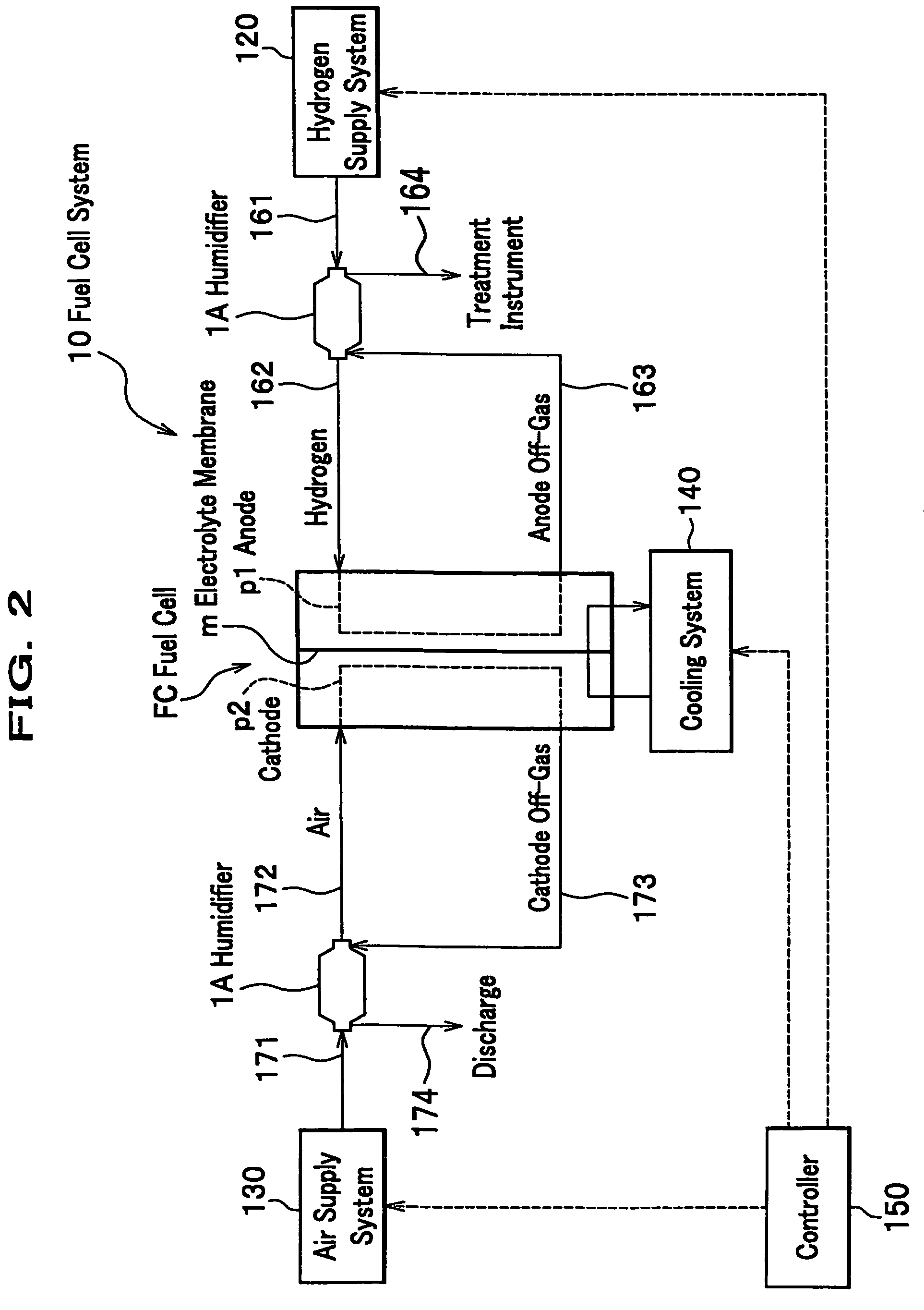

Humidifier for fuel cell system

InactiveUS20060147774A1Easy to dropEasily introducedFuel cell auxillariesIsotope separationProduct gasEngineering

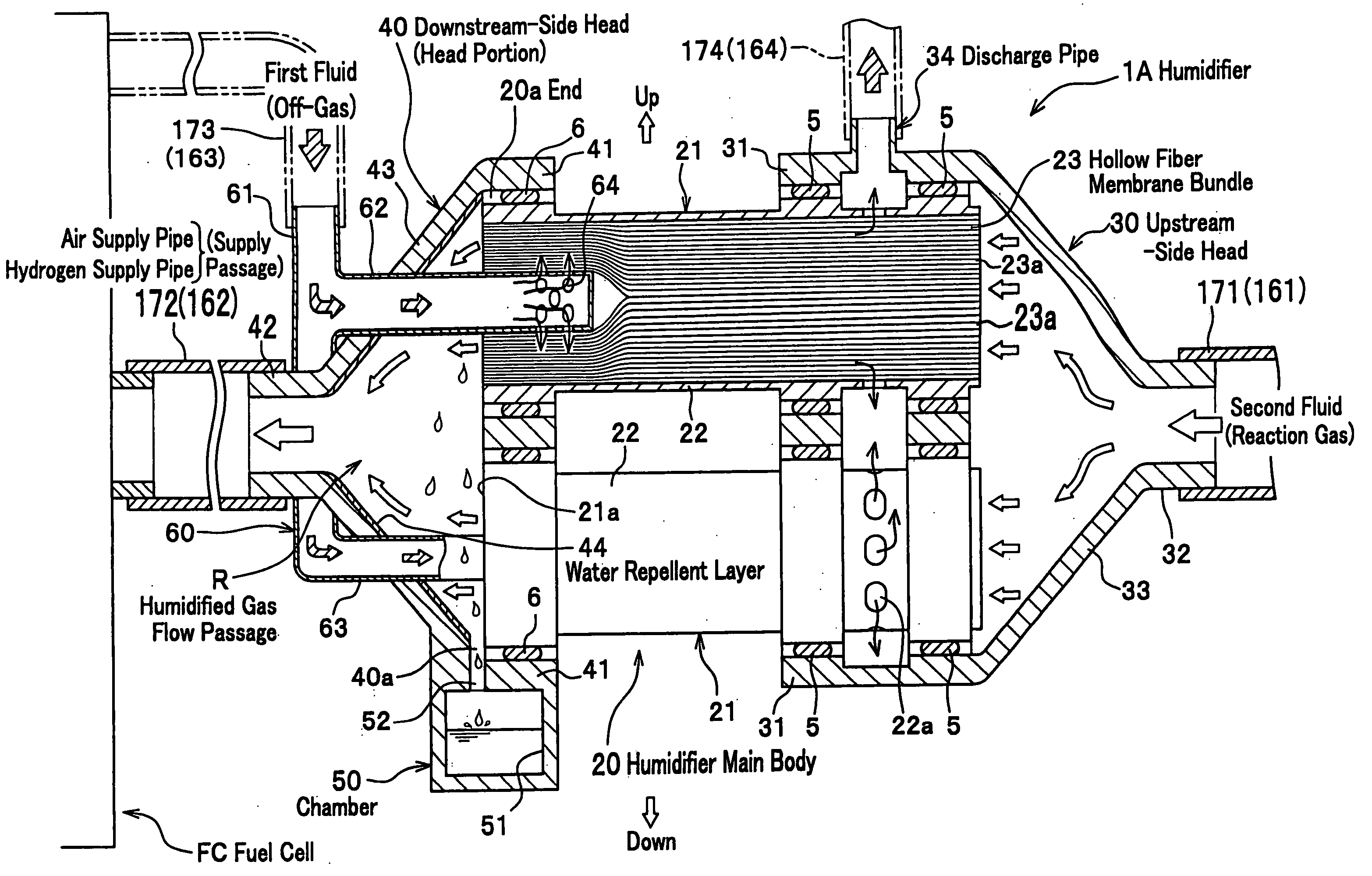

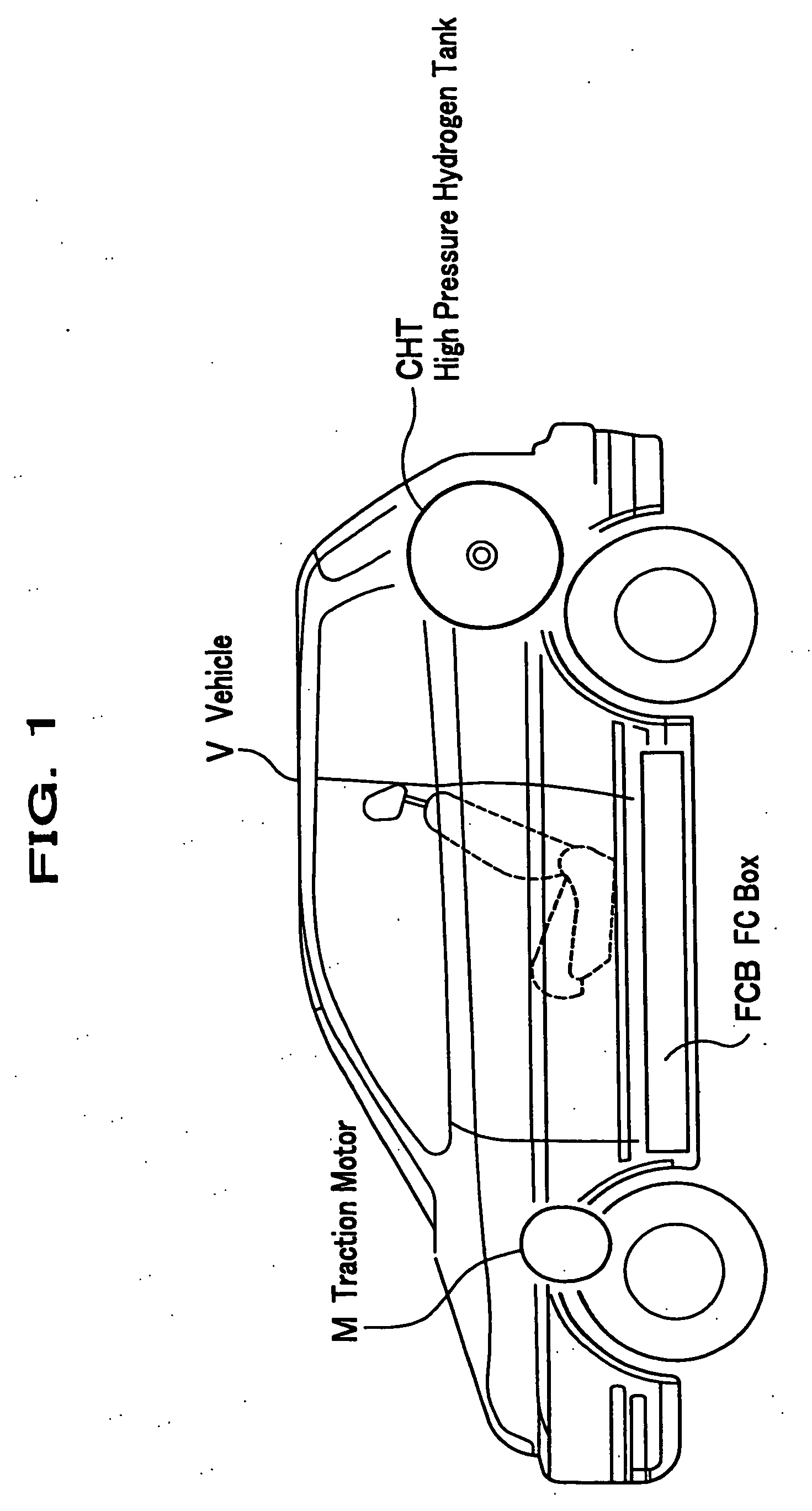

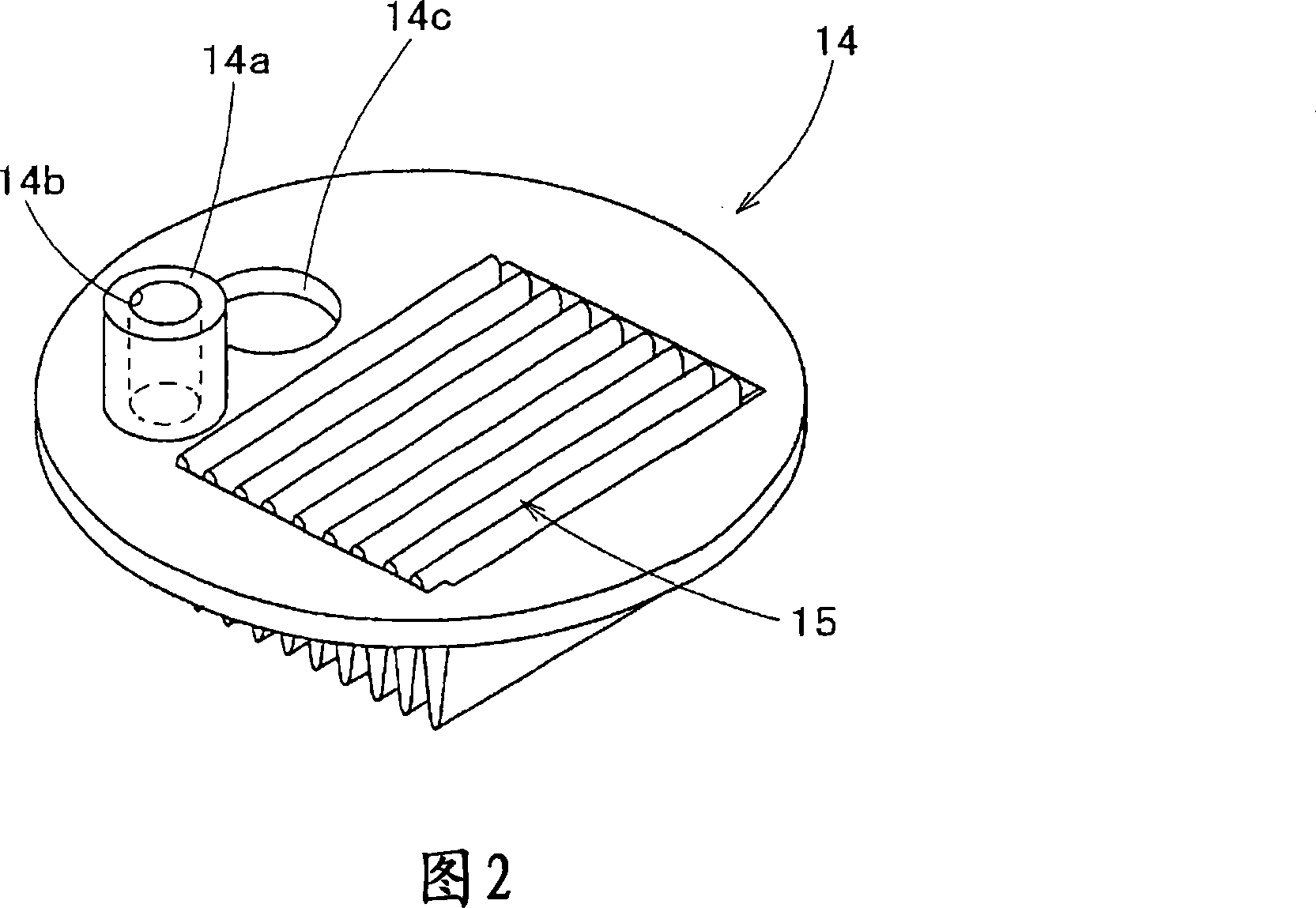

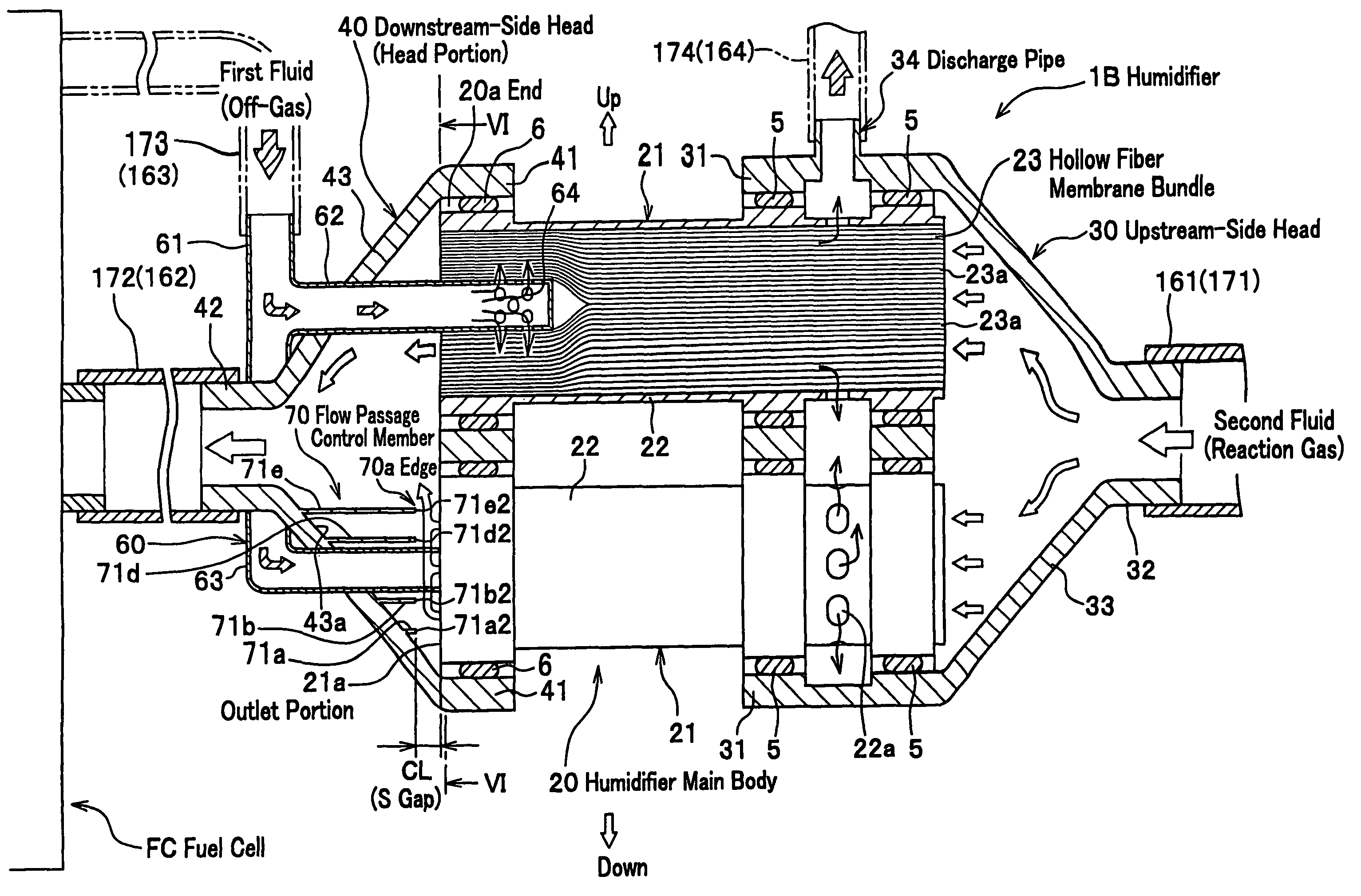

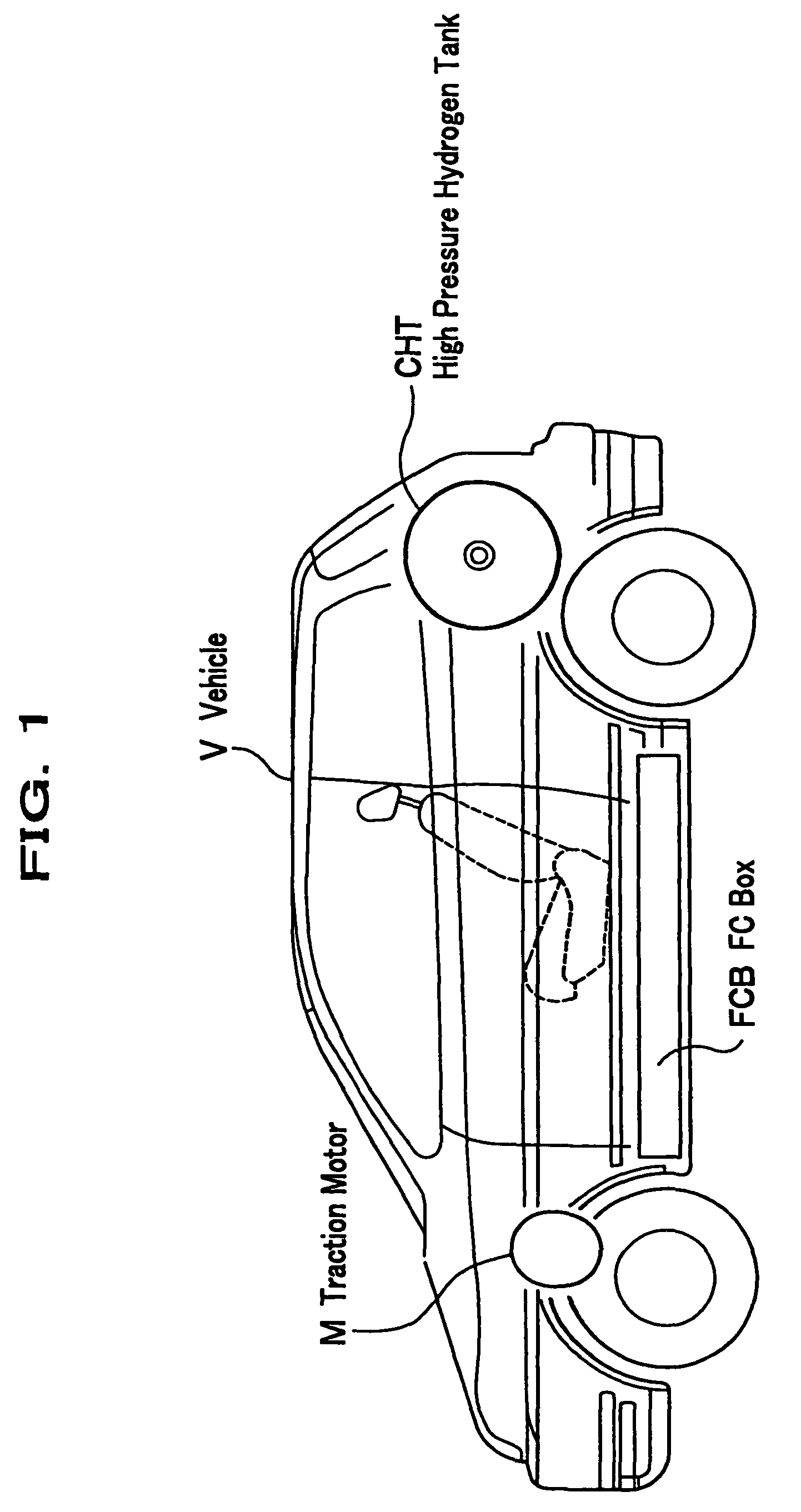

A humidifier of the present invention includes a humidifier main body for humidifying a second fluid, using a humidified first fluid discharged from a fuel cell; a head portion of which one end is connected to an end of the humidifier main body and the other end is connected to the fuel cell or a supply passage extending from the fuel cell, and which supplies the second fluid after humidification to the fuel cell; and a chamber for communicating a bottom portion of a humidified gas flow passage formed within the head portion.

Owner:HONDA MOTOR CO LTD

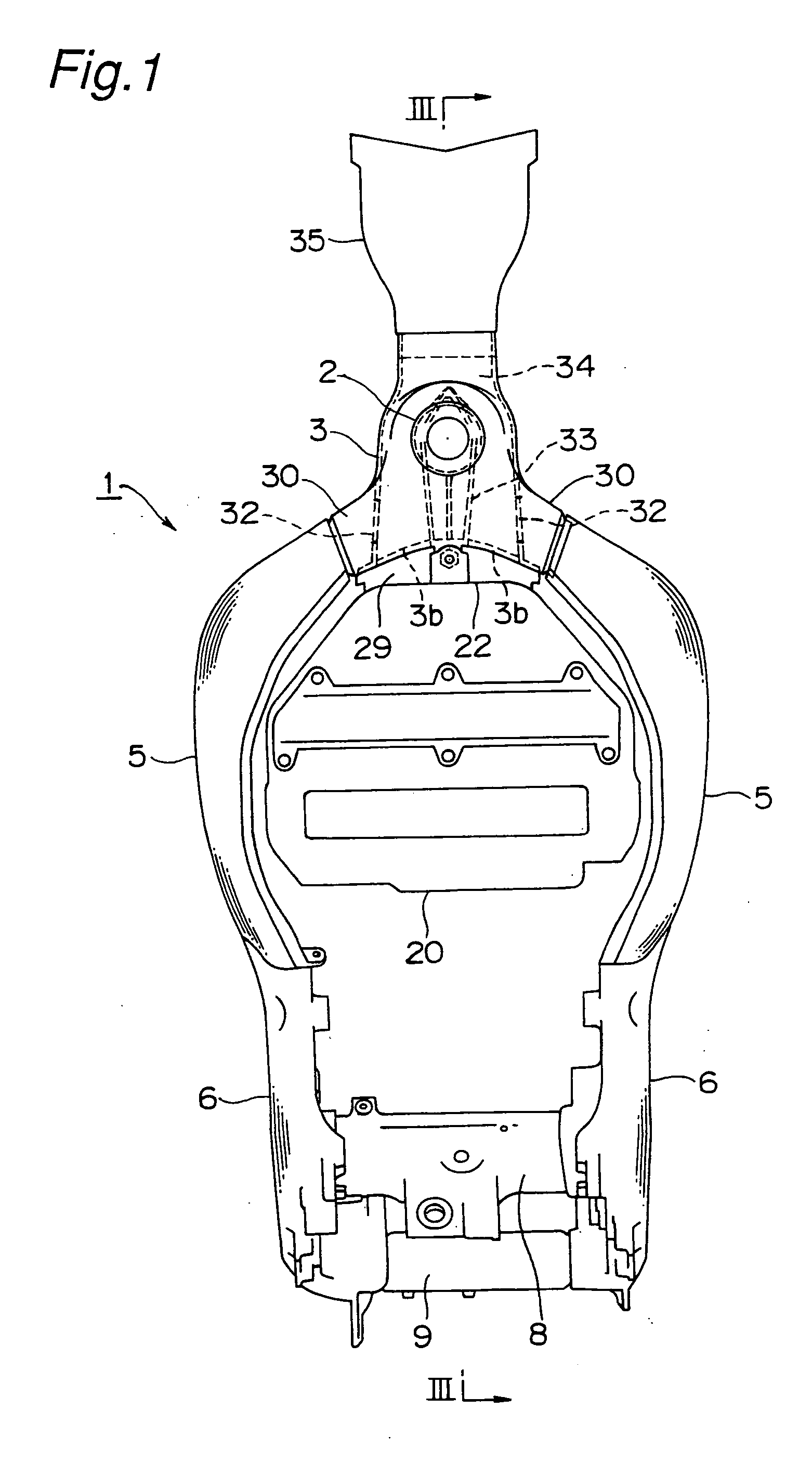

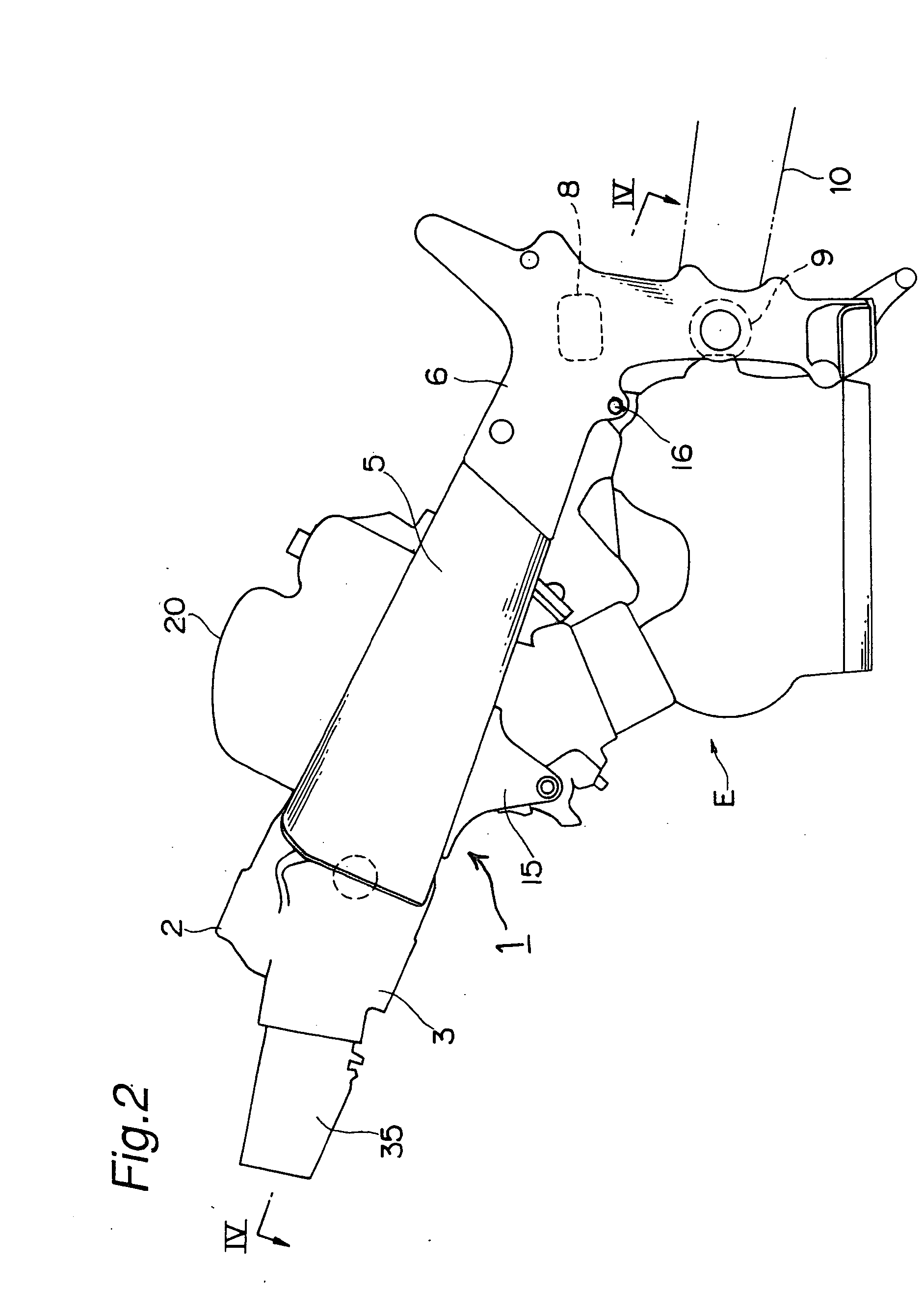

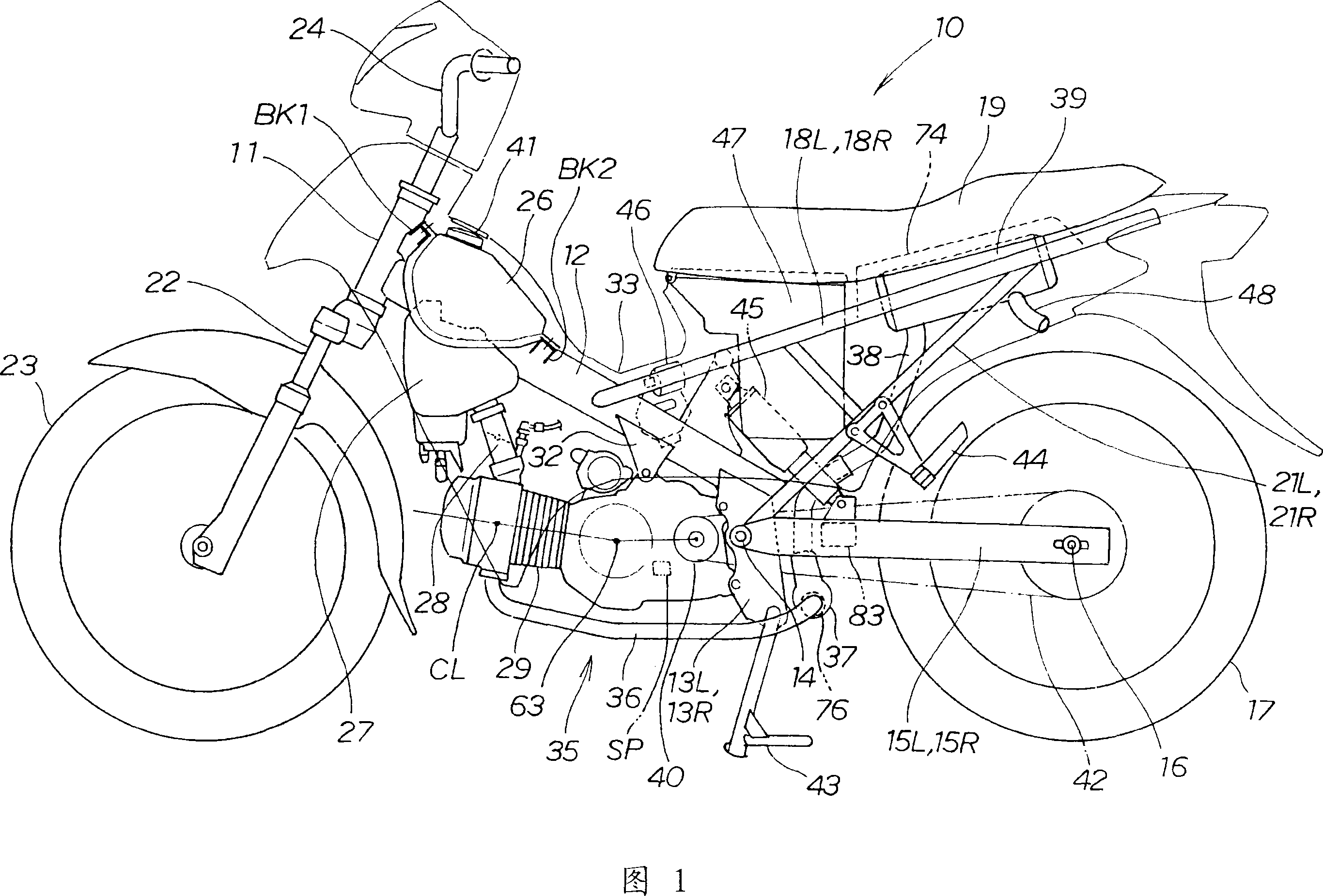

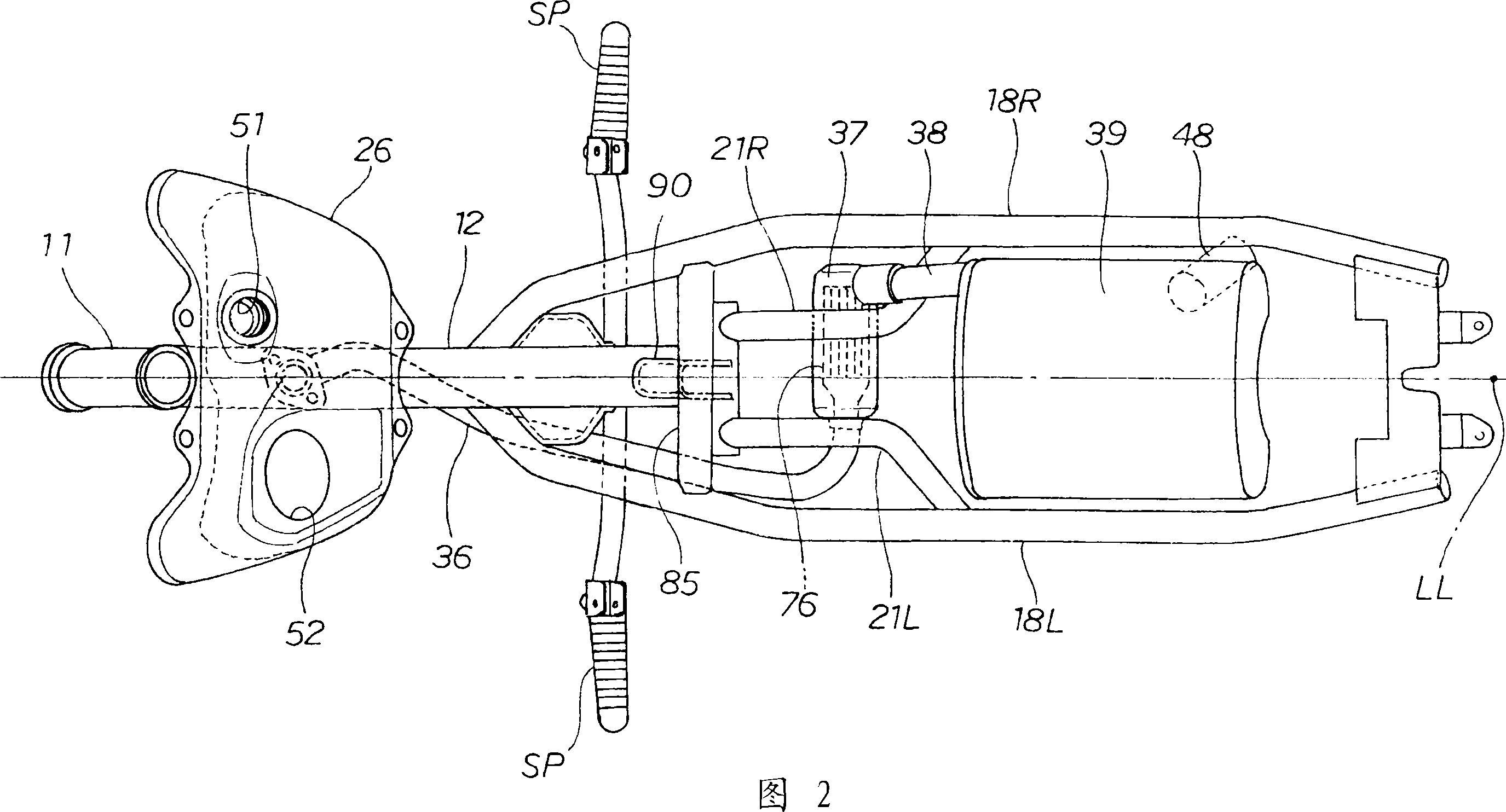

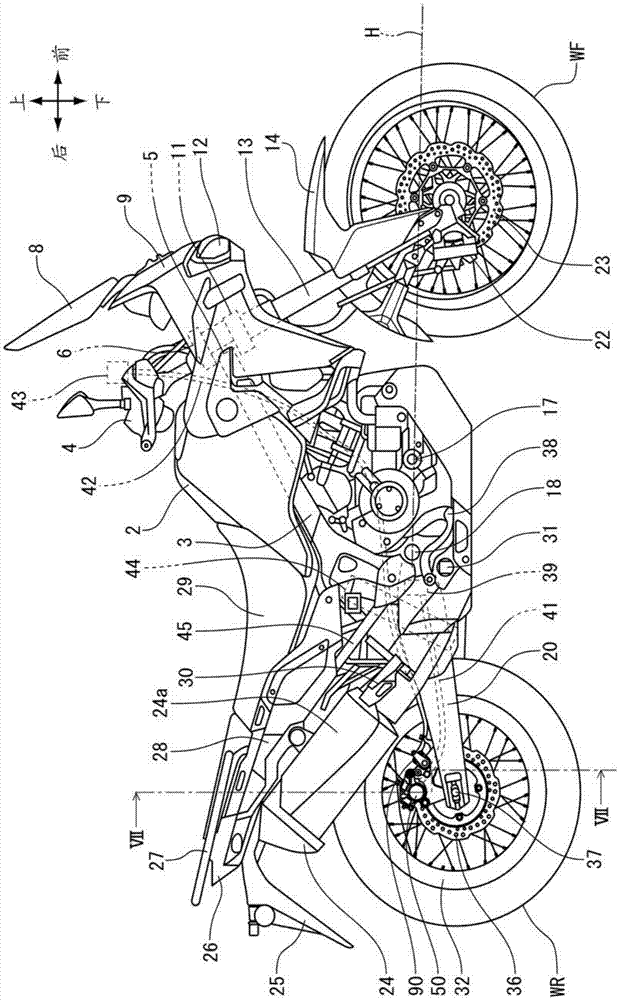

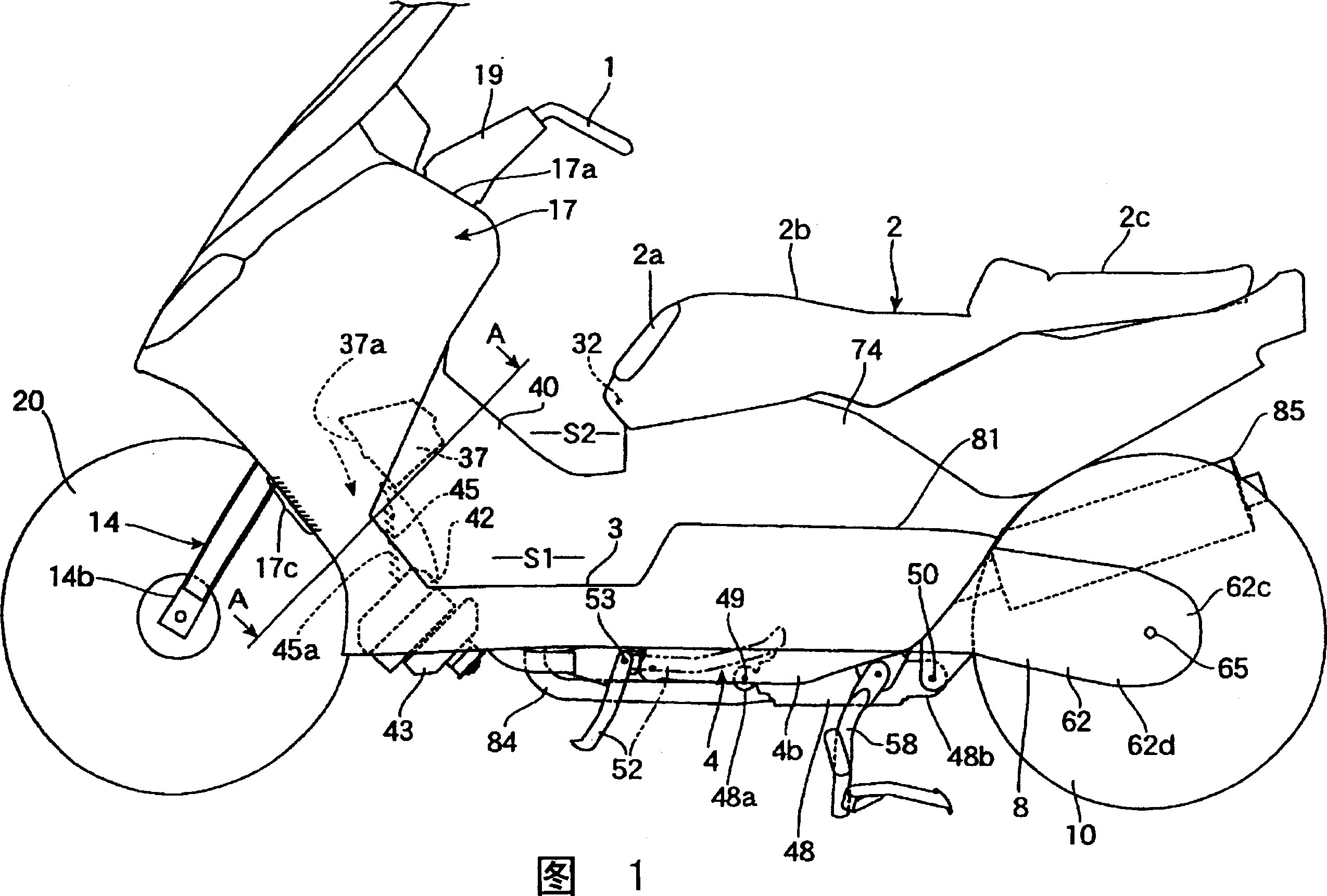

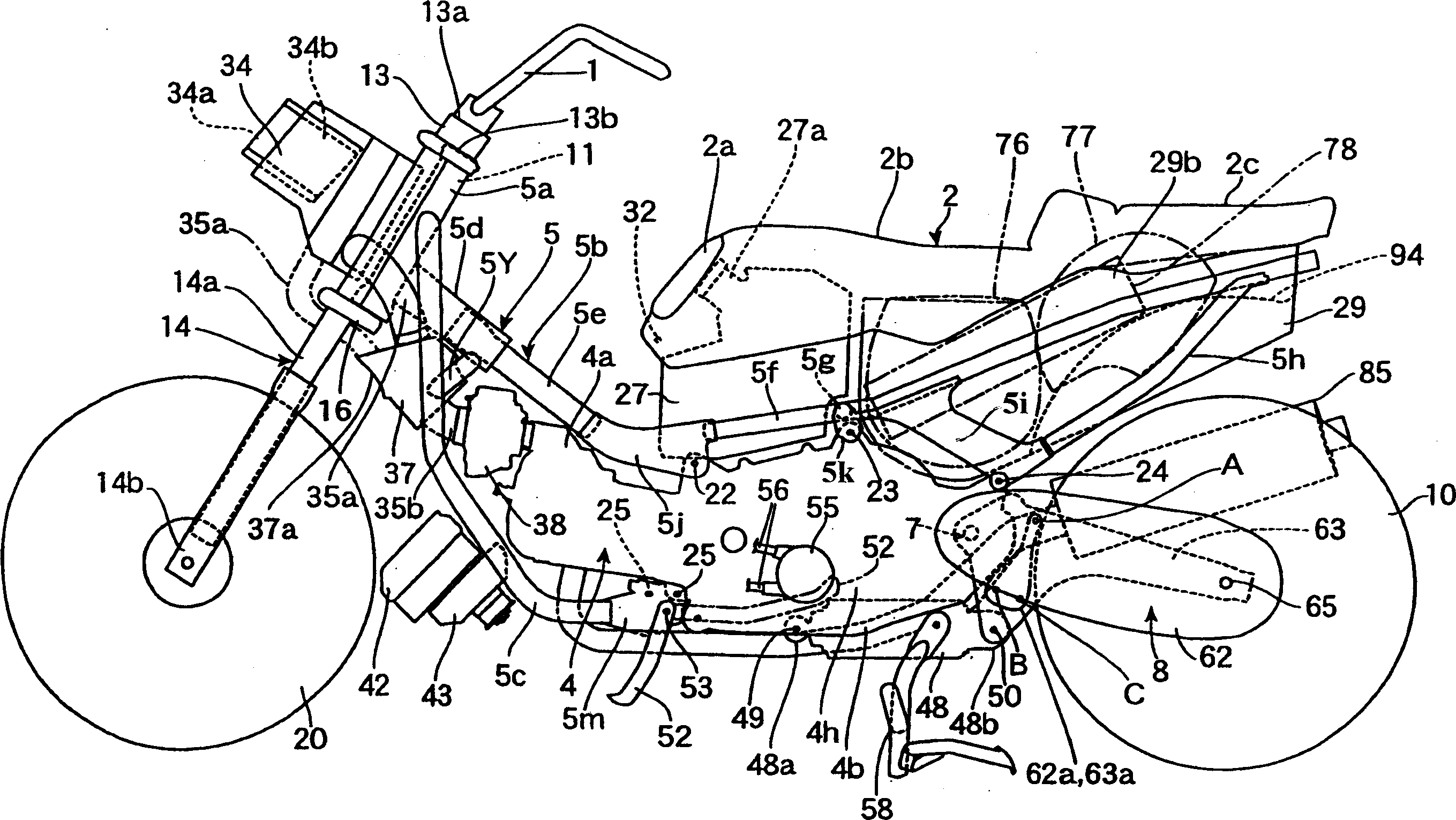

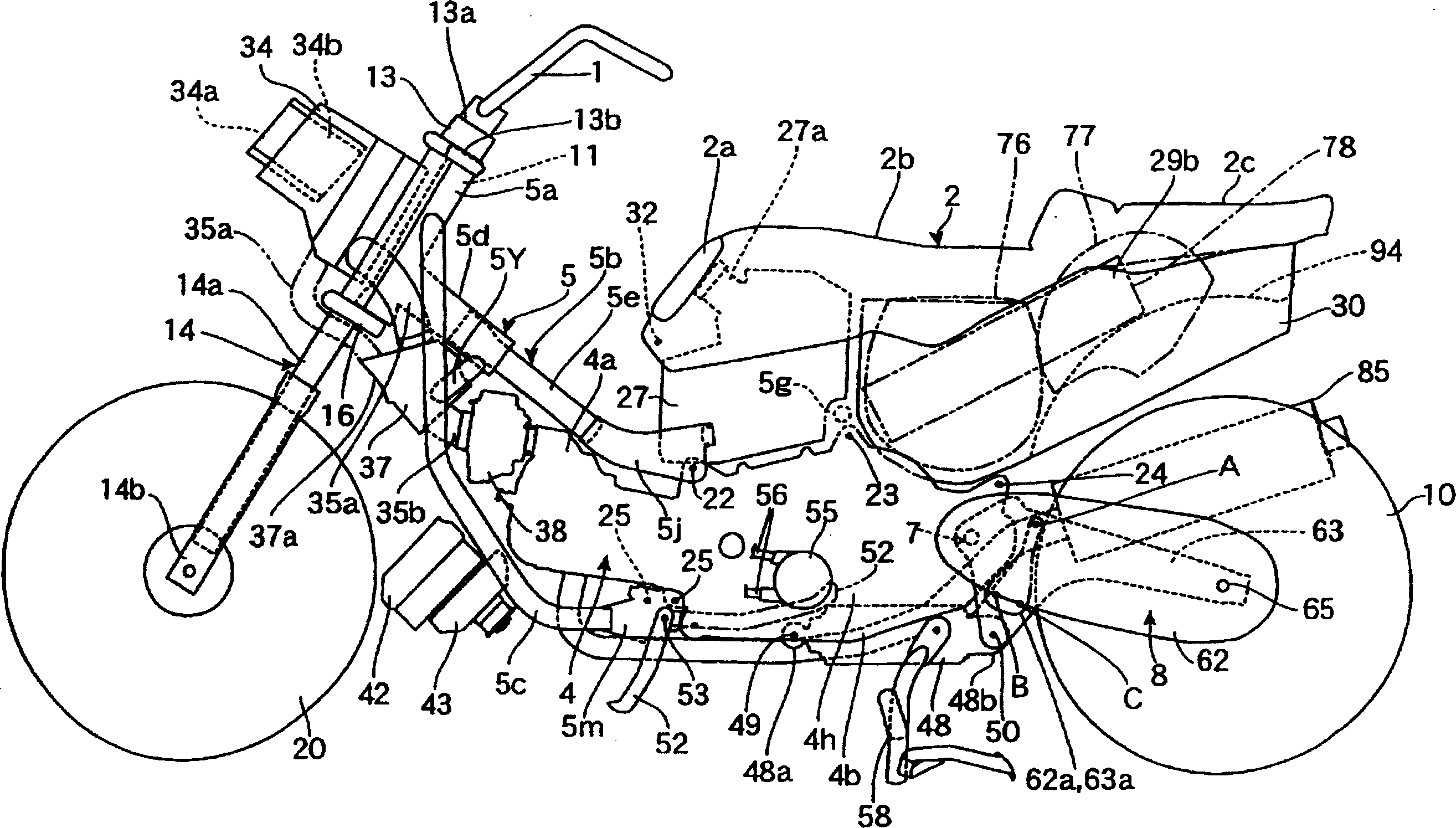

Air intake device for two-wheeled motor vehicle

ActiveUS20060027202A1Increase in sizeReduce pulsationNon-fuel substance addition to fuelCycle equipmentsMobile vehicleEngineering

An air intake apparatus for a two-wheeled motor vehicle. A body frame of the vehicle includes a hollow head box and a pair of right and left hollow main frames extending rearwards from the right and left sides of the head box. An air intake duct is positioned in front of the head box, a front inlet of an air cleaner positioning behind the head box is connected to a rear outlet of the head box, and an inside of the head box is connected to insides of the main frames. Preferably, insides of rear edges of the main frames communicate with each other through a hollow cross pipe.

Owner:KAWASAKI MOTORS LTD

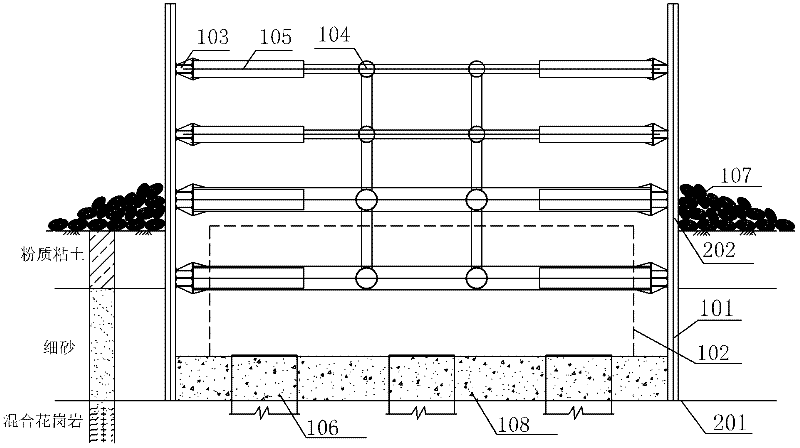

Deepwater single-wall steel plate pile cofferdam structure with low buried depth and construction method thereof

The invention discloses a deepwater single-wall steel plate pile cofferdam structure with low buried depth. The structure comprises a plurality of bored piles, a steel plate pile cofferdam around the bored piles, bagged sand positioned outside the cofferdam and arranged on the surface of a river bed, and high-pressure rotary jet piles constructed in the cofferdam and outside the bored piles, wherein the plane size of the cofferdam is greater than that of a bearing platform to be constructed so as to reserve a construction space. By using the steel plate pile cofferdam, the deepwater low pile bearing platform and the underwater part of a pier of a bridge can be constructed with relatively low cost and minimum construction risk, and a double-wall steel cofferdam scheme with relatively high cost does not need to be adopted for construction, so that the turnover steel consumption of the cofferdam serving as a temporary project is saved, and the application range of the deepwater steel plate pile cofferdam construction technology is enlarged.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG +1

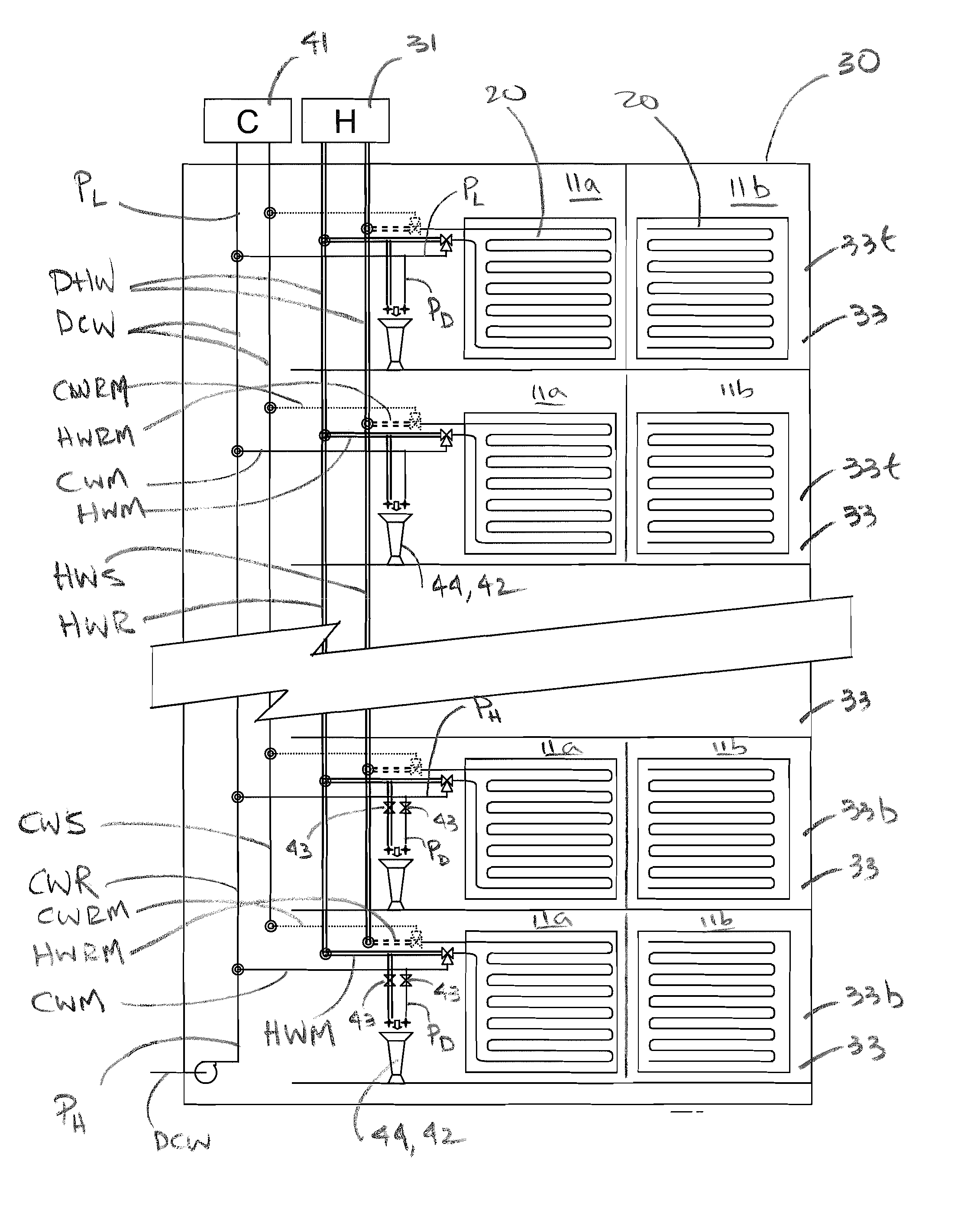

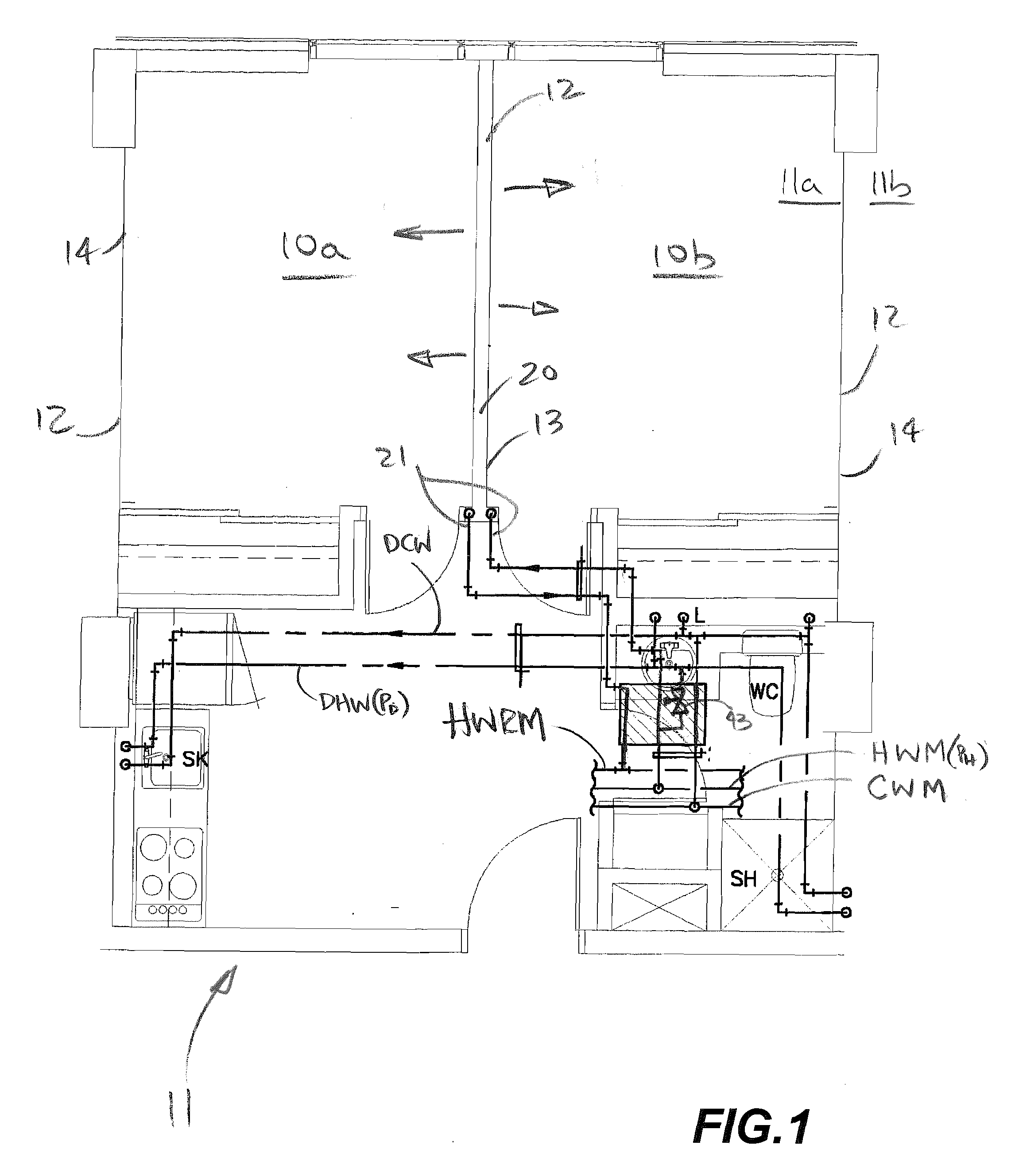

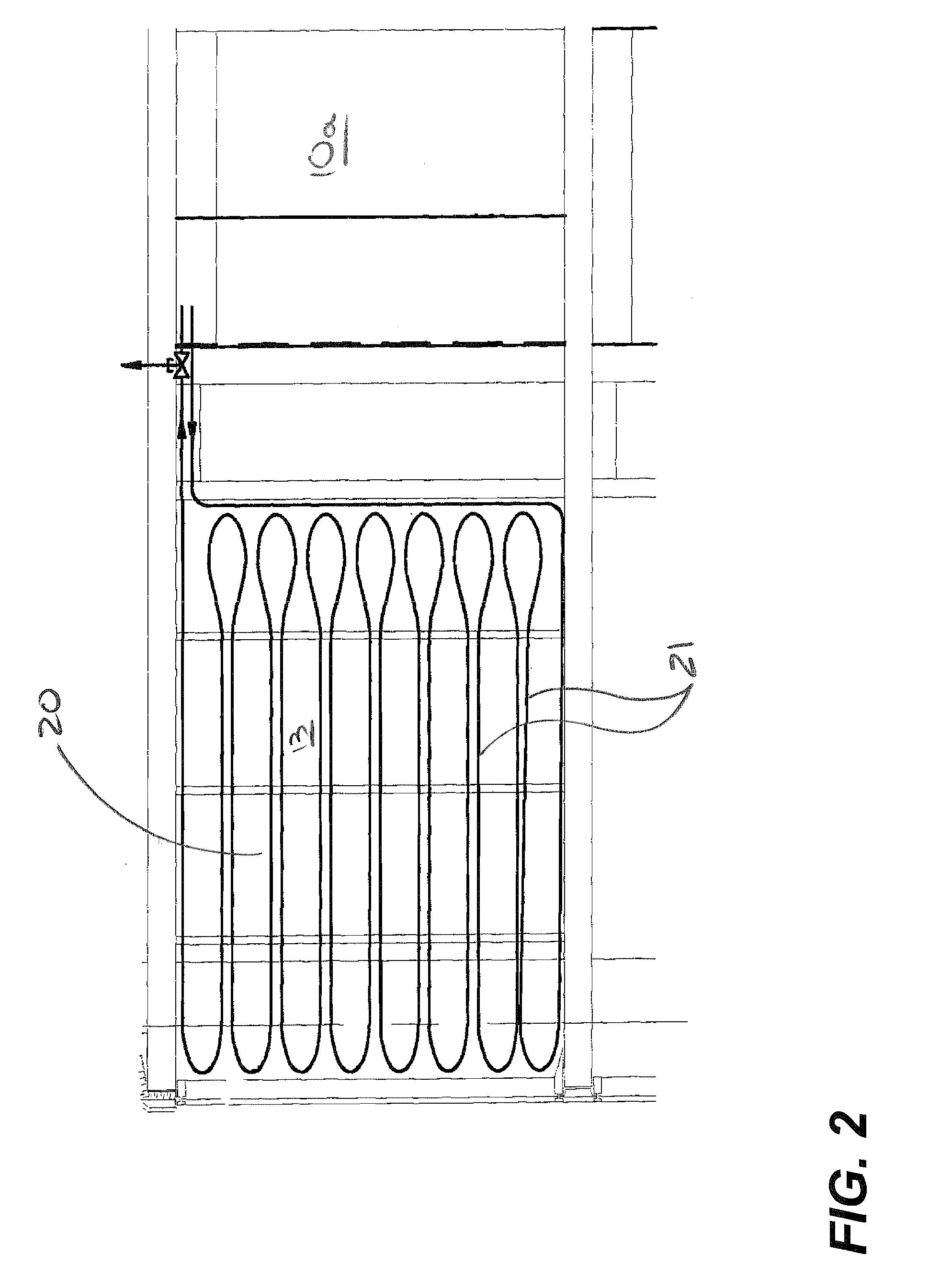

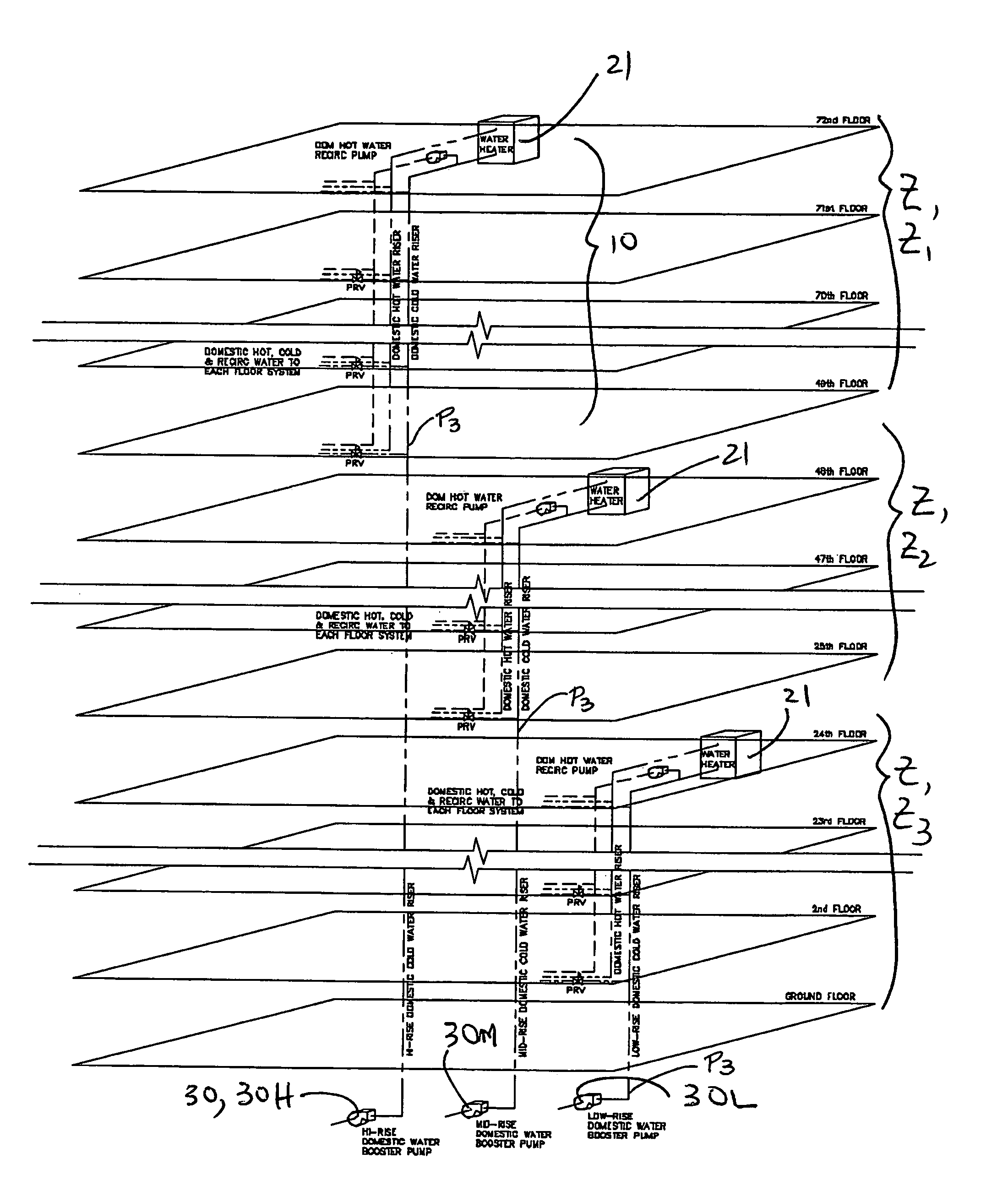

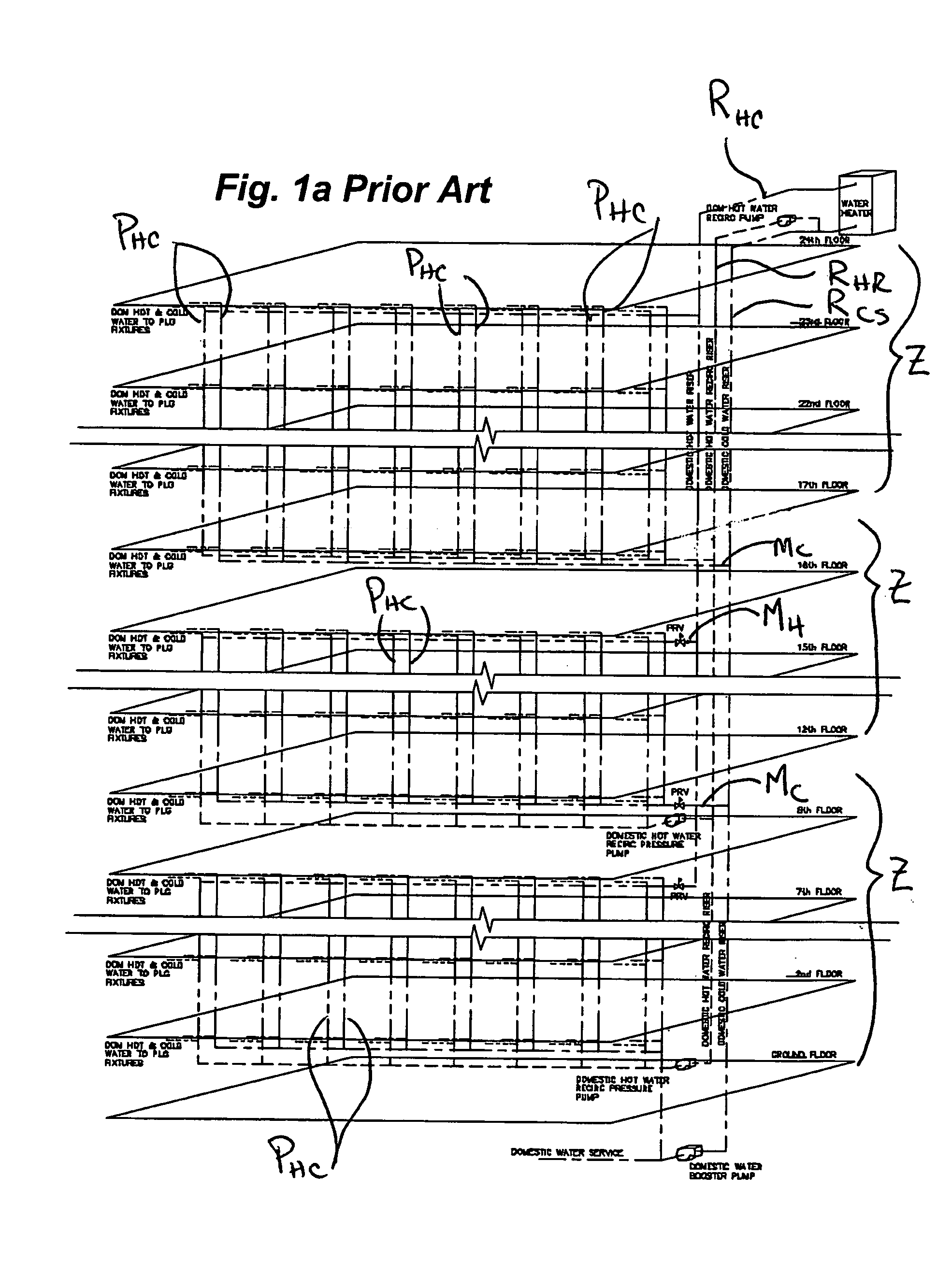

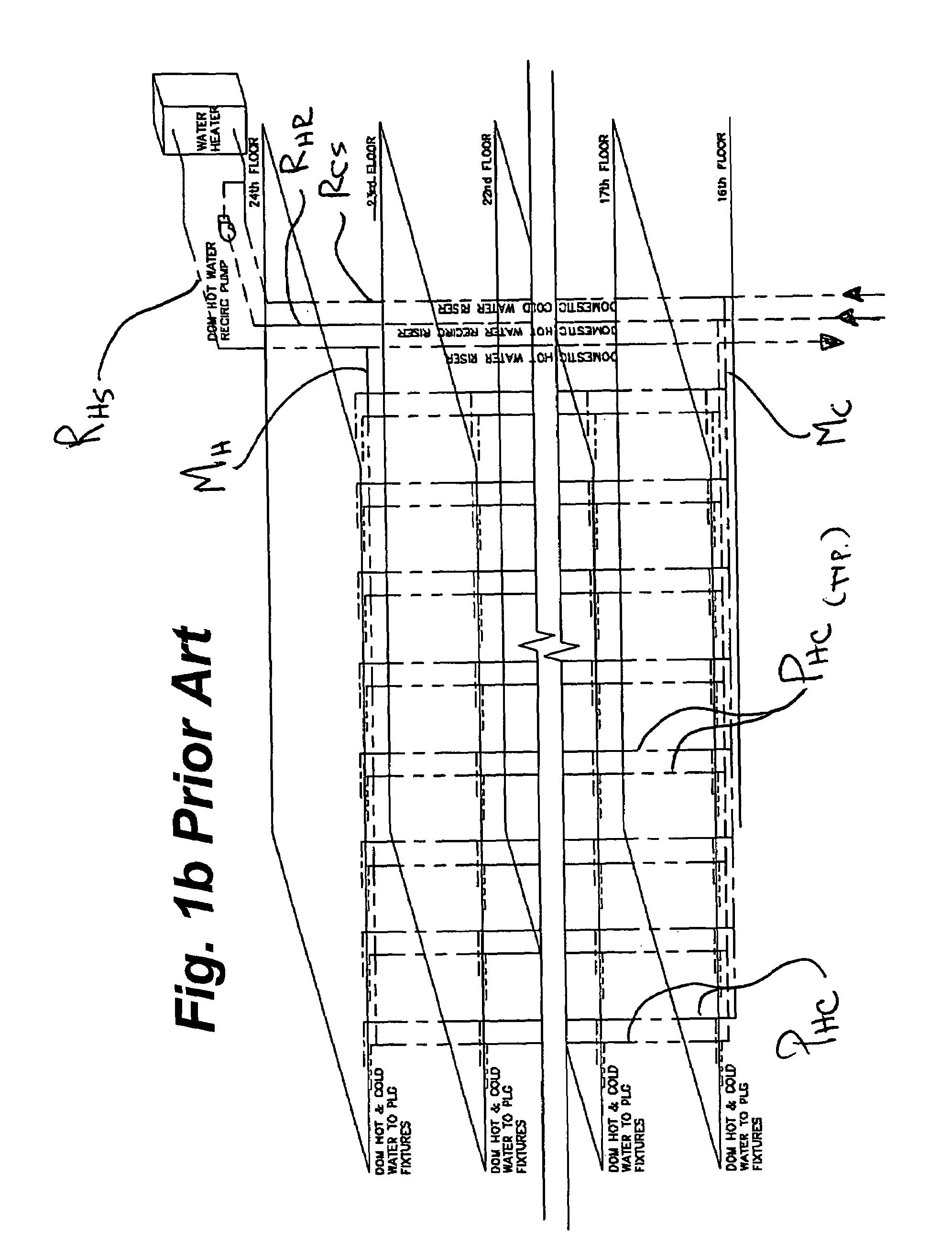

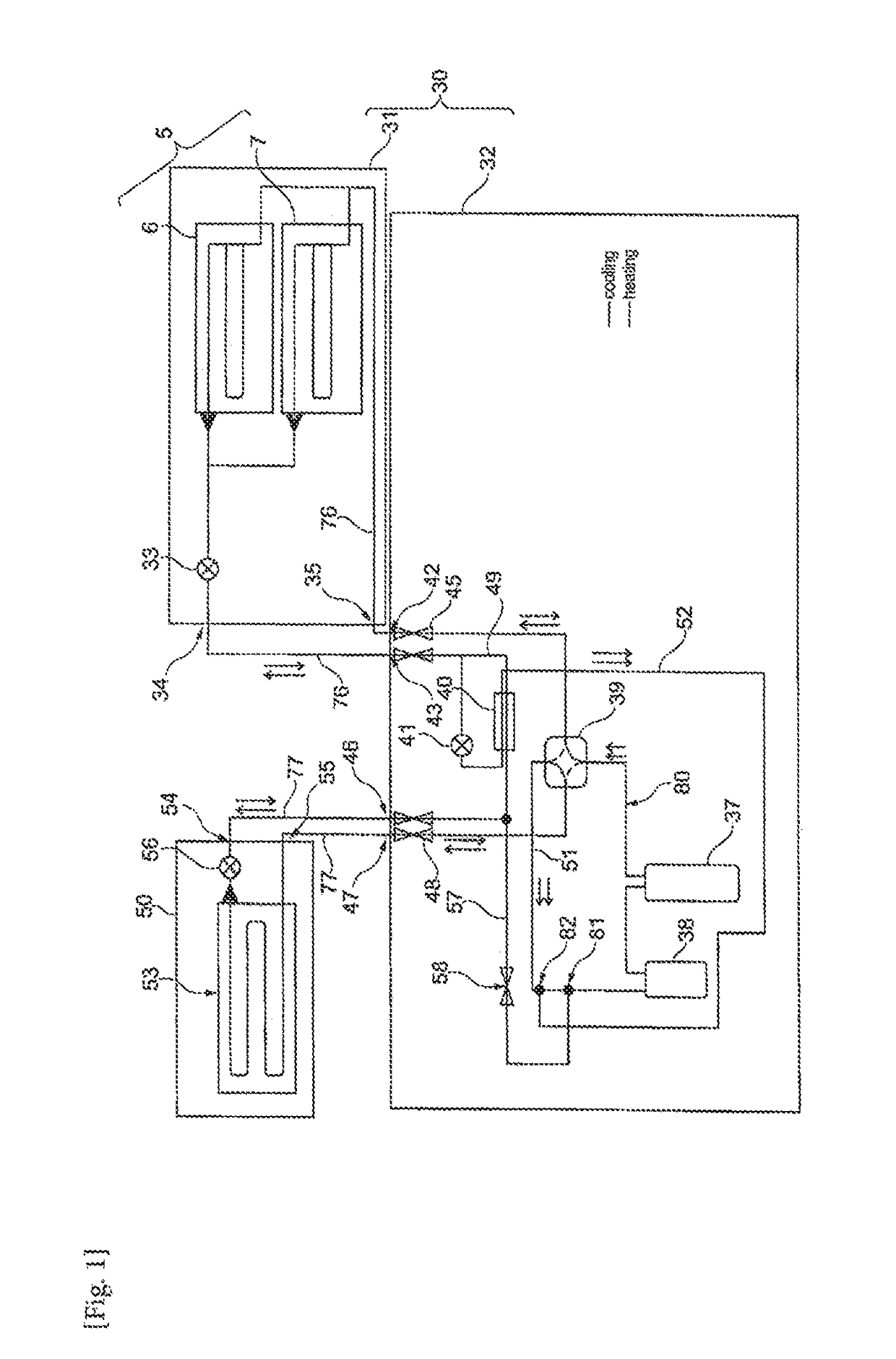

Multi-story water distribution system

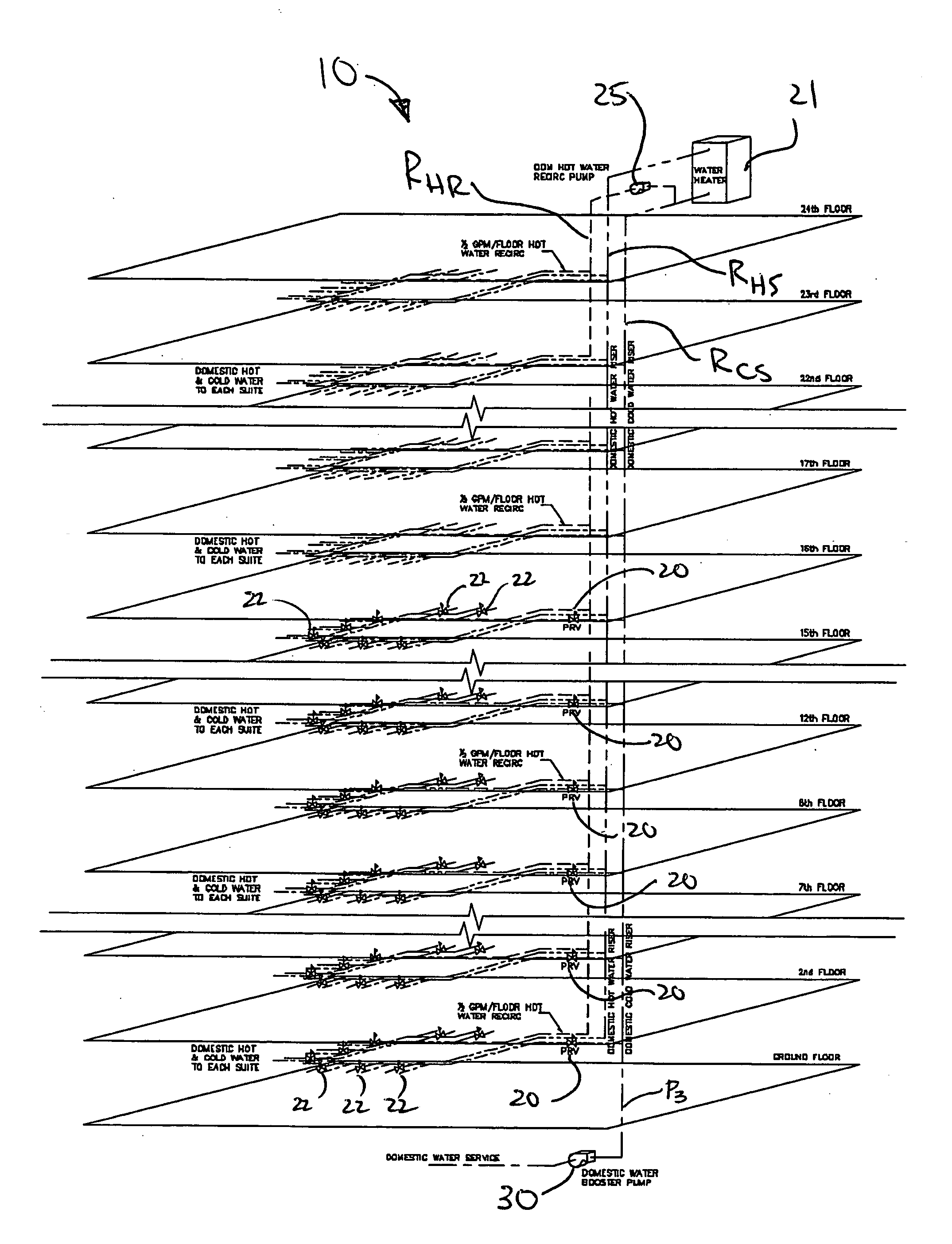

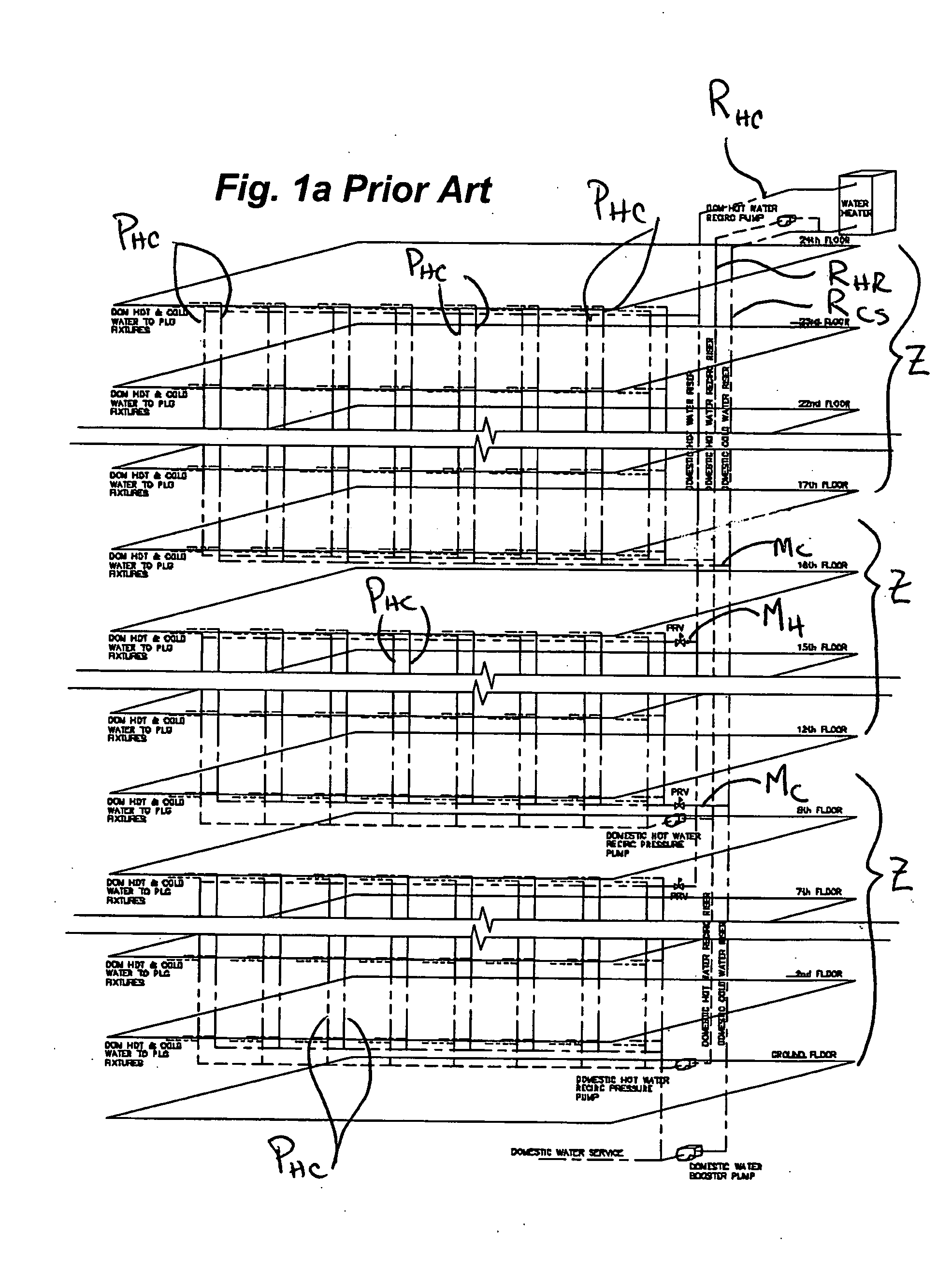

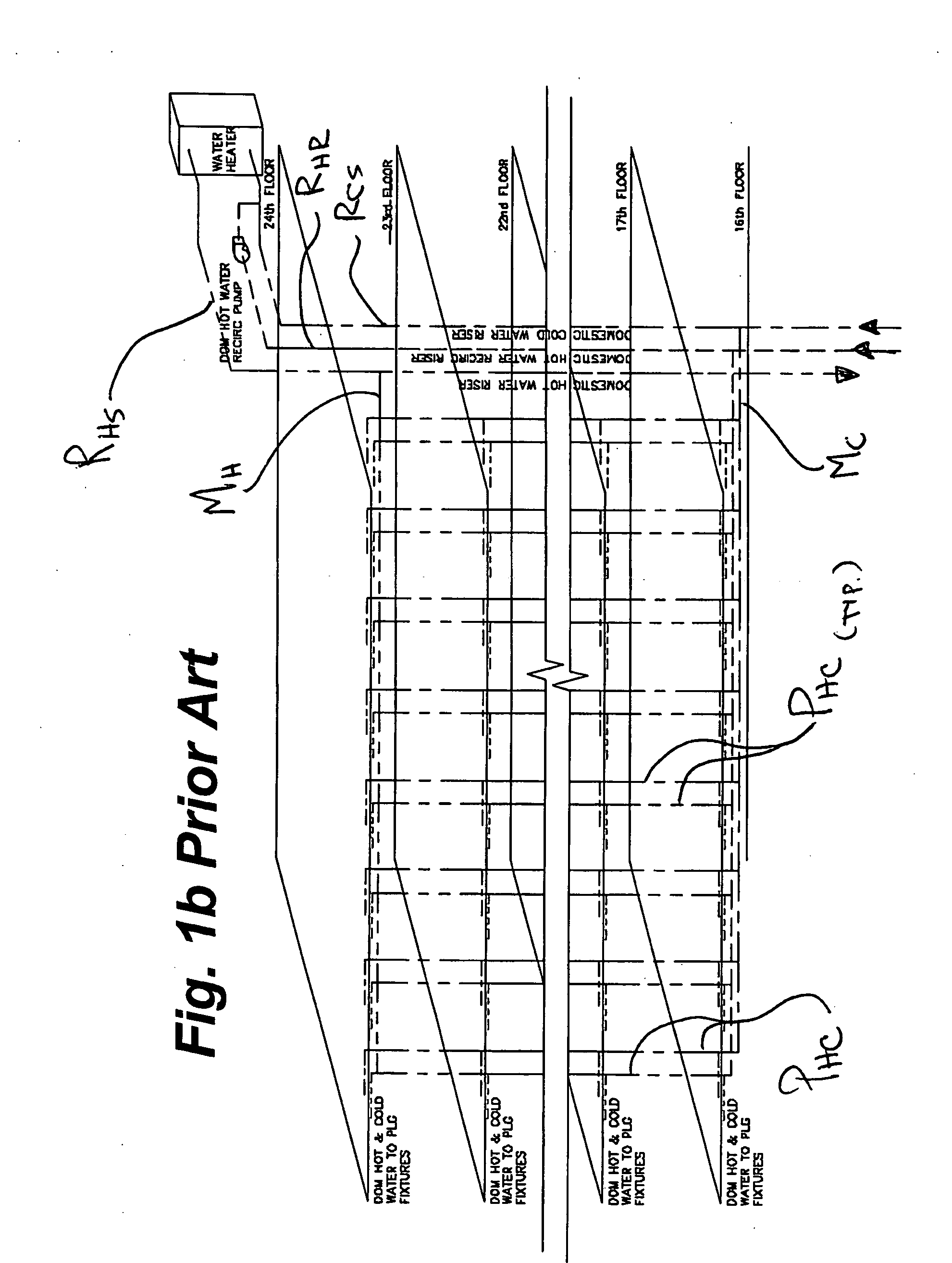

InactiveUS20050183773A1Reduce pipingReduce numberLighting and heating apparatusPipesFloor levelPiping

A method and system for the distribution of water in a high rise building is provided using a minimum number of piping risers. The system has a domestic cold water riser, and a domestic hot water supply riser and a return riser. At each serviced floor, a cold water supply main extends from the domestic cold water riser and a hot water supply main extends from the domestic hot water supply riser. On each floor at which riser pressure is higher than domestic use pressures, a valve reduces the pressure of the entire cold water supply main to domestic use pressures. One or more valves at each of one or more suites on the floor reduce the pressure of the hot water to each suite, leaving the hot water supply main for the floor at full riser pressure. Coupling fan-coils with chilled water supply and the full pressure domestic hot water provides an efficient piping system for both environmental controls and domestic hot water use. Regular and periodic circulation through fan-coils avoid stagnation of the domestic hot water supply.

Owner:SINCLAIRE ROSS

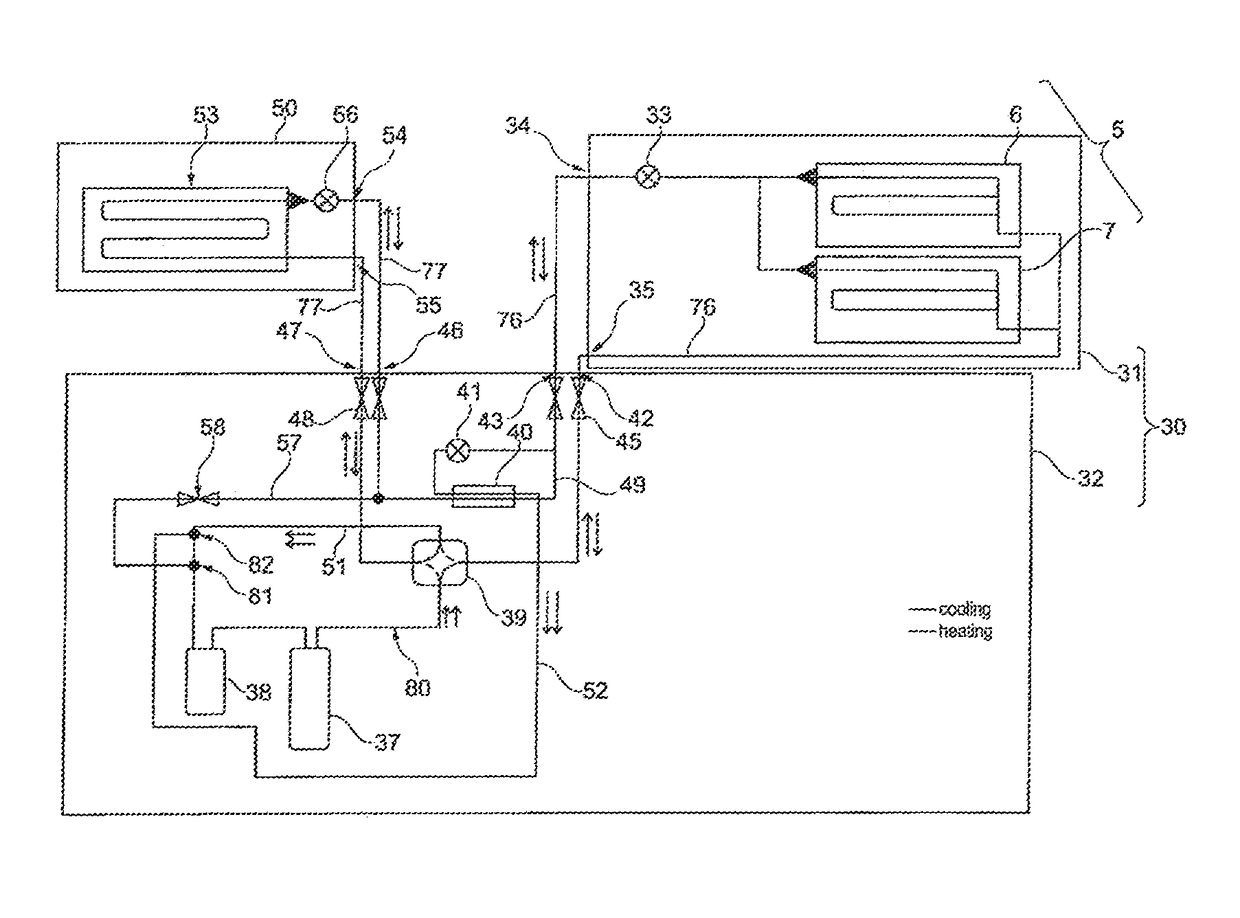

Temperature conditioning radiant wall system for buildings

InactiveUS20070108307A1Reduce pipingReduce in quantityFluid heatersHot-air central heatingTemperature conditioningEngineering

Owner:CREATIVE ENERGY SOLUTIONS

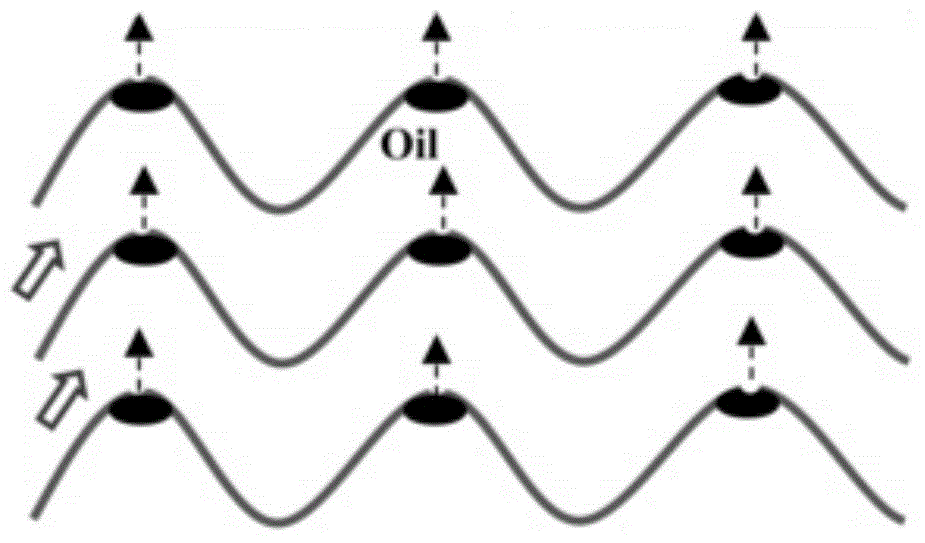

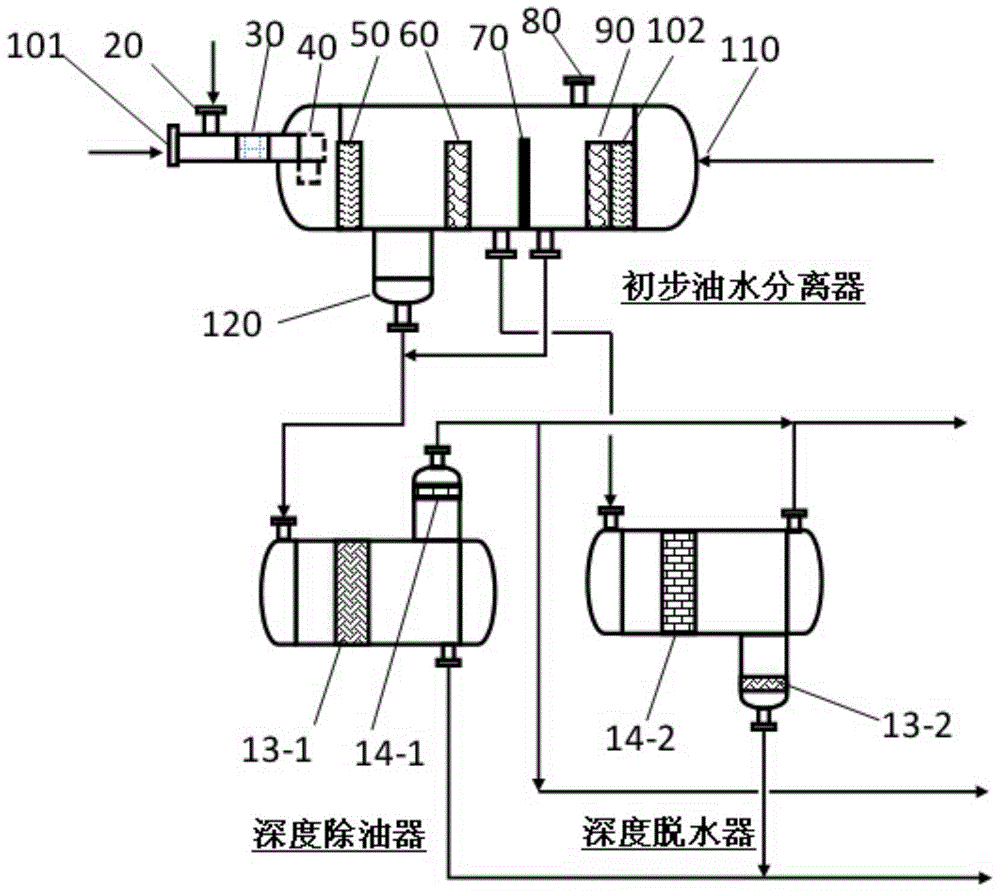

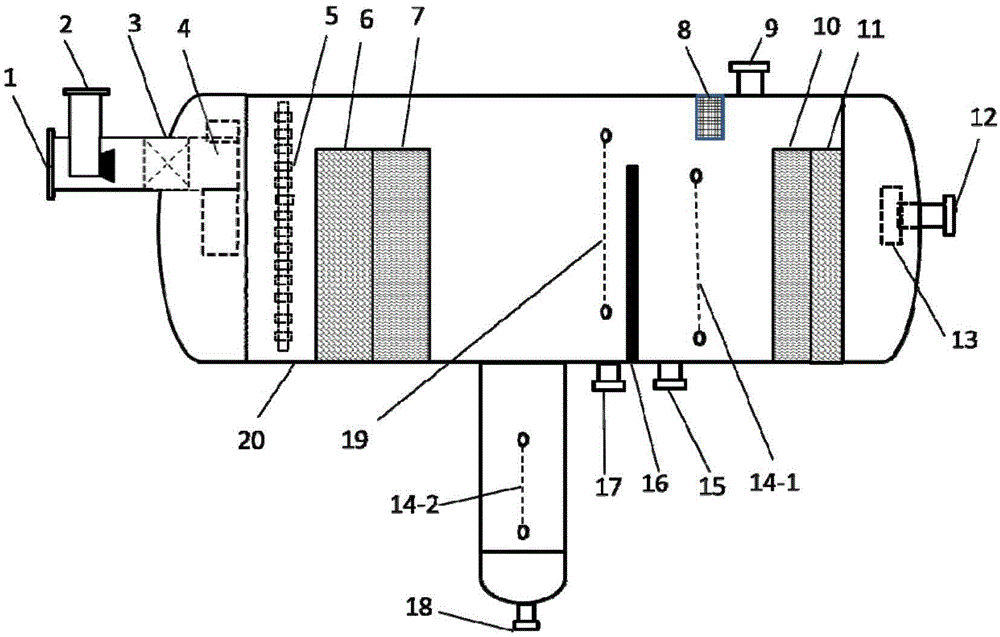

Step-by-step oil-water mixture separation method coupled with oil gas washing

ActiveCN104673367AProtection for long-term operationEfficient separationFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiberWastewater

The invention relates to a step-by-step oil-water mixture separation method coupled with oil gas washing. The method comprises the following steps: first light oil containing 0.5-6 percent of synthetic water and low-pressure separator gas containing a trace amount of hydrocarbon are mixed and washed, then the light oil containing a trace amount of hydrocarbon flows into a primary oil-water separator from a left sealing head, and wastewater containing 0.05-0.5 percent of oil flows into the primary oil-water separator from a right sealing head; purified low-pressure separator gas is discharged from the top, mixed liquid is discharged into a deep dehydrater, and about 0.05-0.5 percent of water is removed from the light oil; wastewater on the left side flows into a water drum to be discharged, oil-removed wastewater on the right side is discharged nearby the right side of partition board into a deep oil remover, and about 0.03-0.6% of oil is removed from the water; by virtue of deep dehydration as well as oil removal and dehydration by a specially knitted conjugate fiber module in the oil remover, after the water content in the light oil is smaller than 0.02% and the oil content in the water is smaller than 0.01, the light oil and the water are transported outside. According to the method oil-water separation and step-by-step separation are combined, oil dehydration and wastewater oil removal can be realized rapidly and efficiently and oil is recycled to the maximum extent.

Owner:EAST CHINA UNIV OF SCI & TECH

Multi-story water distribution system

InactiveUS7308906B2Reduce pipingReduce in quantityLighting and heating apparatusPipesWater useDecreased pressure

A method and system for the distribution of water in a high rise building is provided using a minimum number of piping risers. The system has a domestic cold water riser, and a domestic hot water supply riser and a return riser. At each serviced floor, a cold water supply main extends from the domestic cold water riser and a hot water supply main extends from the domestic hot water supply riser. On each floor at which riser pressure is higher than domestic use pressures, a valve reduces the pressure of the entire cold water supply main to domestic use pressures. One or more valves at each of one or more suites on the floor reduce the pressure of the hot water to each suite, leaving the hot water supply main for the floor at full riser pressure. Coupling fan-coils with chilled water supply and the full pressure domestic hot water provides an efficient piping system for both environmental controls and domestic hot water use. Regular and periodic circulation through fan-coils avoid stagnation of the domestic hot water supply.

Owner:SINCLAIRE ROSS

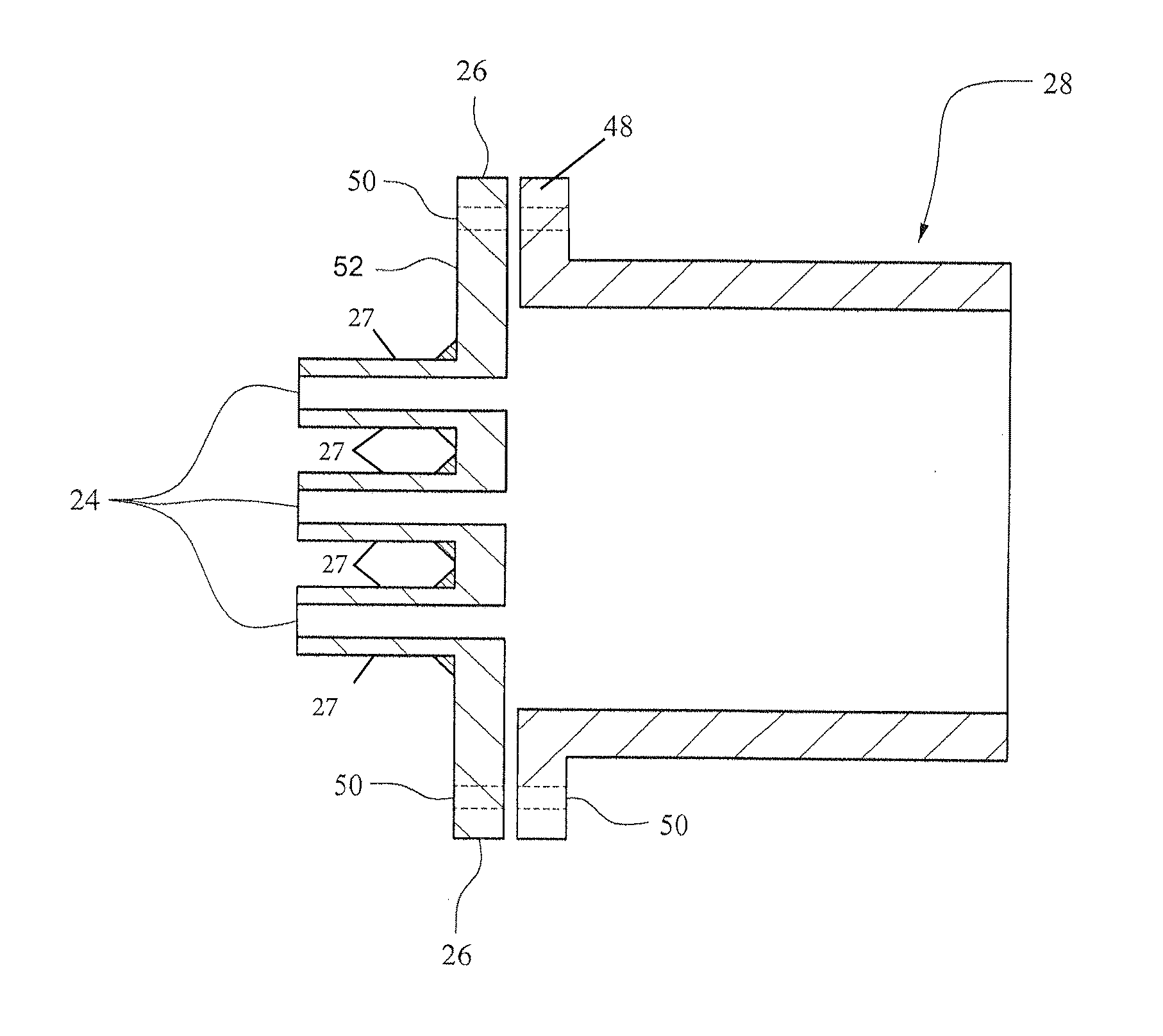

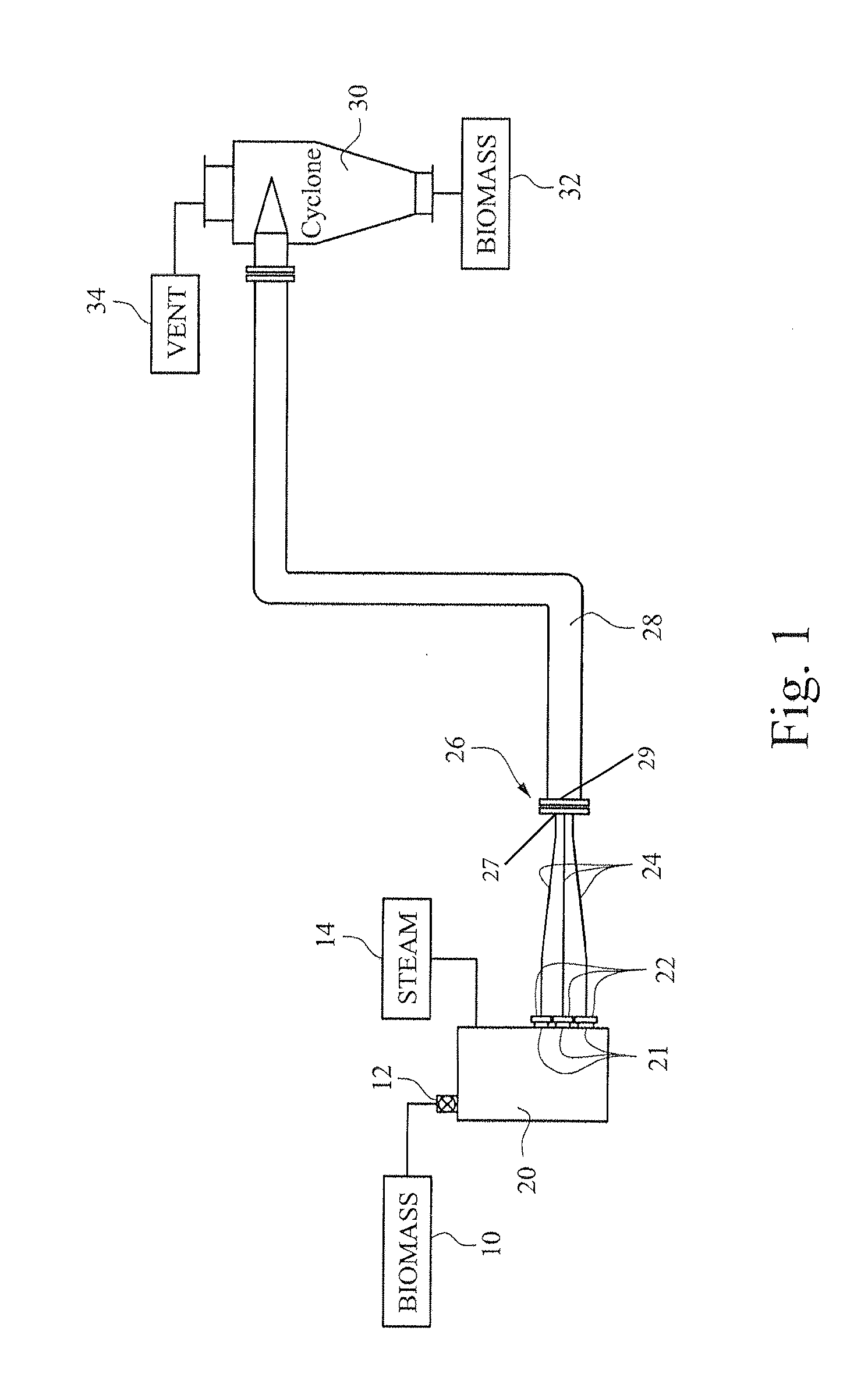

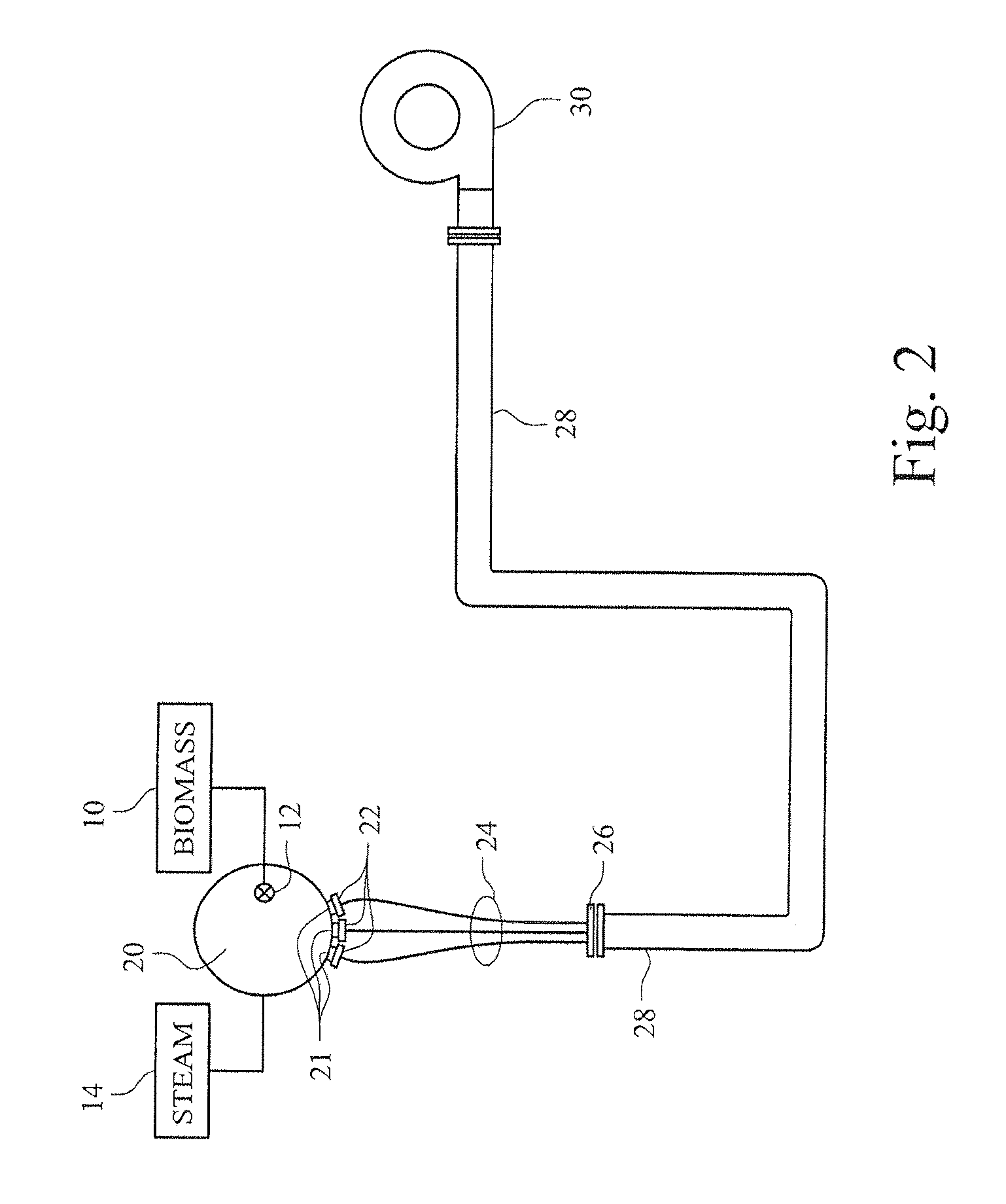

Piping system from reactor to separator and method to control process flow

InactiveUS20140110069A1Reduce amountShorten length of pipingPretreatment with water/steamDigestersPipingBiomass

An apparatus, for the steam explosion treatment of biomass, having a pressurized reactor vessel to receive a biomass material and steam, discharge lines connecting the pressurized reactor vessel to the separation device, the lines sized and positioned to allow for the steam explosion of biomass material. At the outlet end of the discharge lines is a collection-expansion manifold to connect the outlet end of each of the discharge lines to a collection line, wherein the collection line provides a passage for biomass material and steam flowing from the discharge lines. The collection line passage has a substantially larger cross-sectional area than the cross-sectional area of a single discharge line. The collection line is coupled to a separation device such that the separation device receives the biomass material and steam from the collection line.

Owner:ANDRITZ INC

Automotive tumbrel

InactiveCN101172503ALower supply costsReduce installation costsFuel tanksMotorcyclesAir filterFuel tank

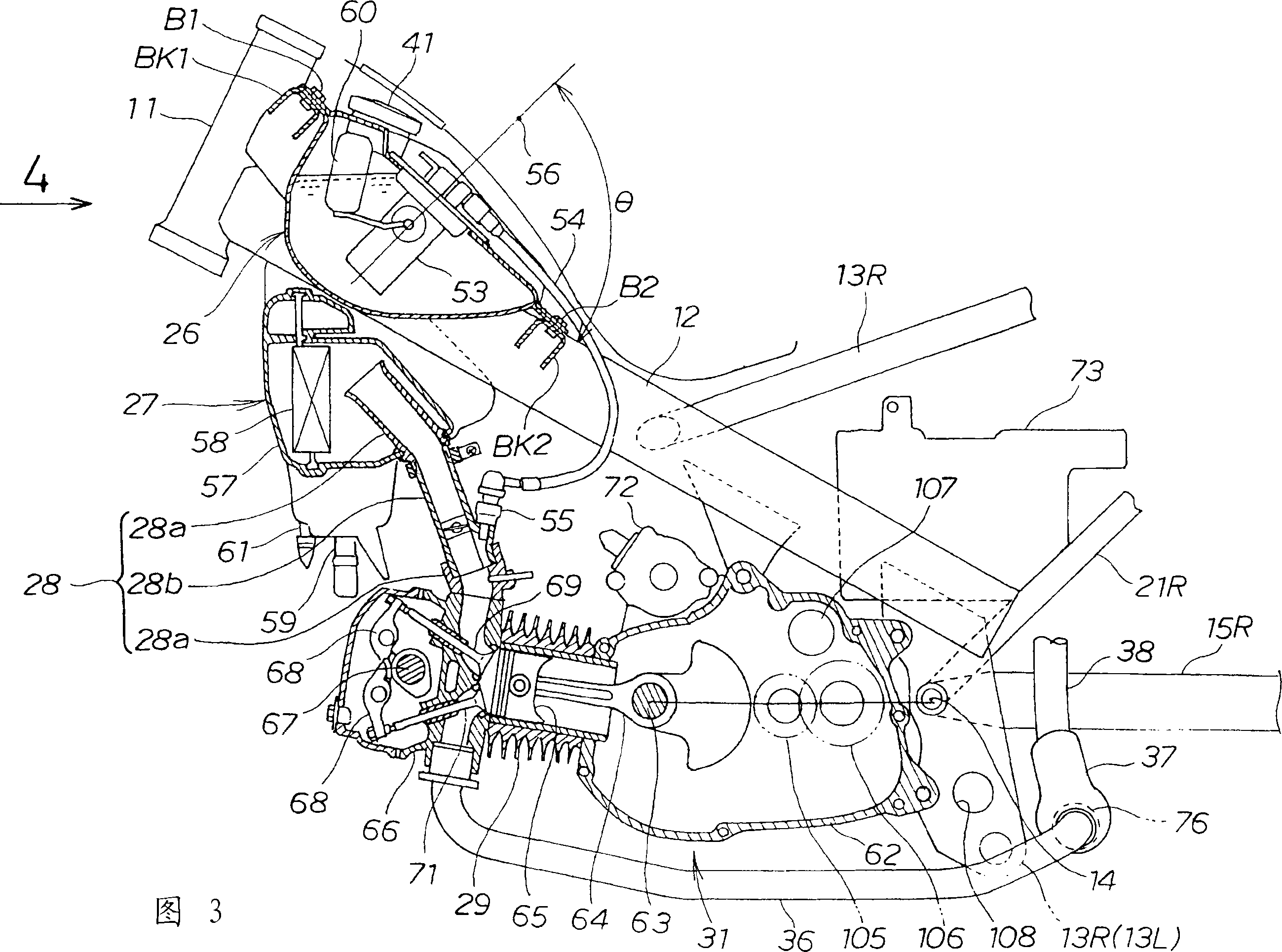

The invention aims at providing a configuration of a flexible tumbrel which can shorten a fuel tubing as well as ensure the convenience for passengers to across get on or get off. A fuel tank (26) is arranged at the front part of a single beam type frame (12) adjacent to a jointing pipe (11). An air filter (27) is arranged at the bottom of the fuel tank (26) and the front top of an engine. An inspiration system (28) (in the figure 3 consisting of a connecting pipe (28a), an air damper body (28b) and an intake manifold (28c) is extended to the back bottom of the air filter (27). The bottom of the single beam type frame (12) hangs a cylinder (29) and an engine extended to the forward horizontally. The inspiration system (28) is connected with the cylinder (29). The fuel tank is arranged at the single beam type frame near the horizontal cylinder. Namely, the fuel tank is arranged at the top of the cylinder, thereby shortening the fuel tubing.

Owner:HONDA MOTOR CO LTD

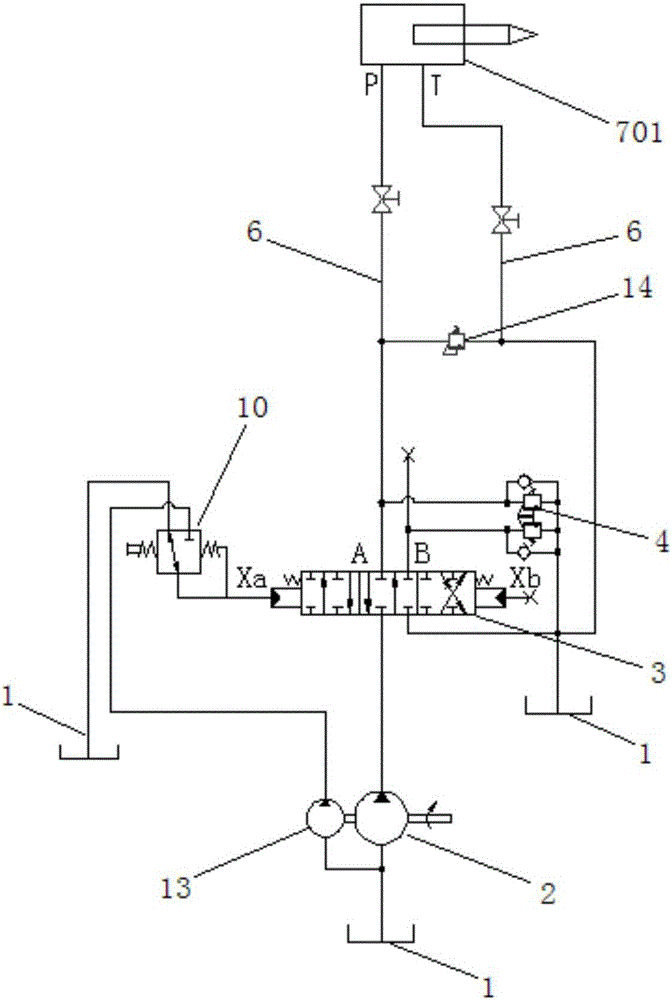

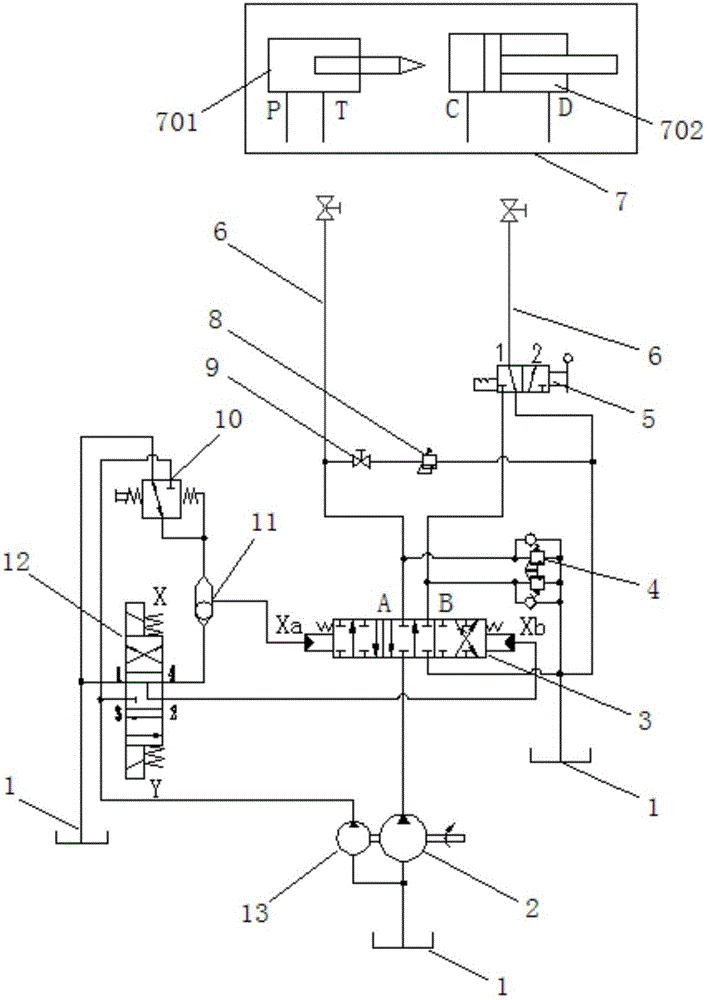

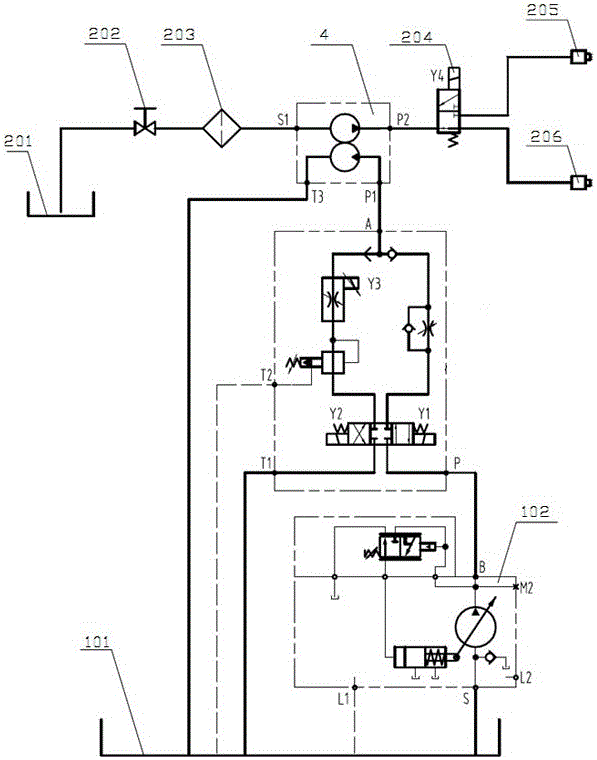

Hydraulic loop for multifunctional tool of excavator

ActiveCN106050771AImprove performanceRealize one machine with multiple functionsServomotor componentsServomotorsMaintainabilitySolenoid valve

The invention discloses a hydraulic loop for a multifunctional tool of an excavator, and relates to the technical field of excavator hydraulic pressure. The pilot side Xa of a spare valve element is connected with a shuttle valve. The two ends of the shuttle valve are connected with a breaking pilot control valve and a pilot solenoid valve correspondingly. The pilot side Xb of the spare valve element is connected with the pilot solenoid valve. A main pump is connected with the spare valve element. End port overflow valves are arranged on oil ways of the spare valve element and connected to a hydraulic oil tank. The oil ways of the spare valve element are connected with work device pipelines without control valve blocks to the multifunctional tool. A two-position three-way reversing valve is mounted on the work device pipeline connected with one oil way. The other oil way of the spare valve element is further connected to the hydraulic oil tank through a stop valve and a breaking overflow valve. According to the hydraulic loop, the pipelines are optimized; maintainability is high; the utilization rate of a single pipeline is effectively increased; the function of being provided with multiple auxiliary tools is achieved; and cost is low.

Owner:XCMG EXCAVATOR MACHINERY

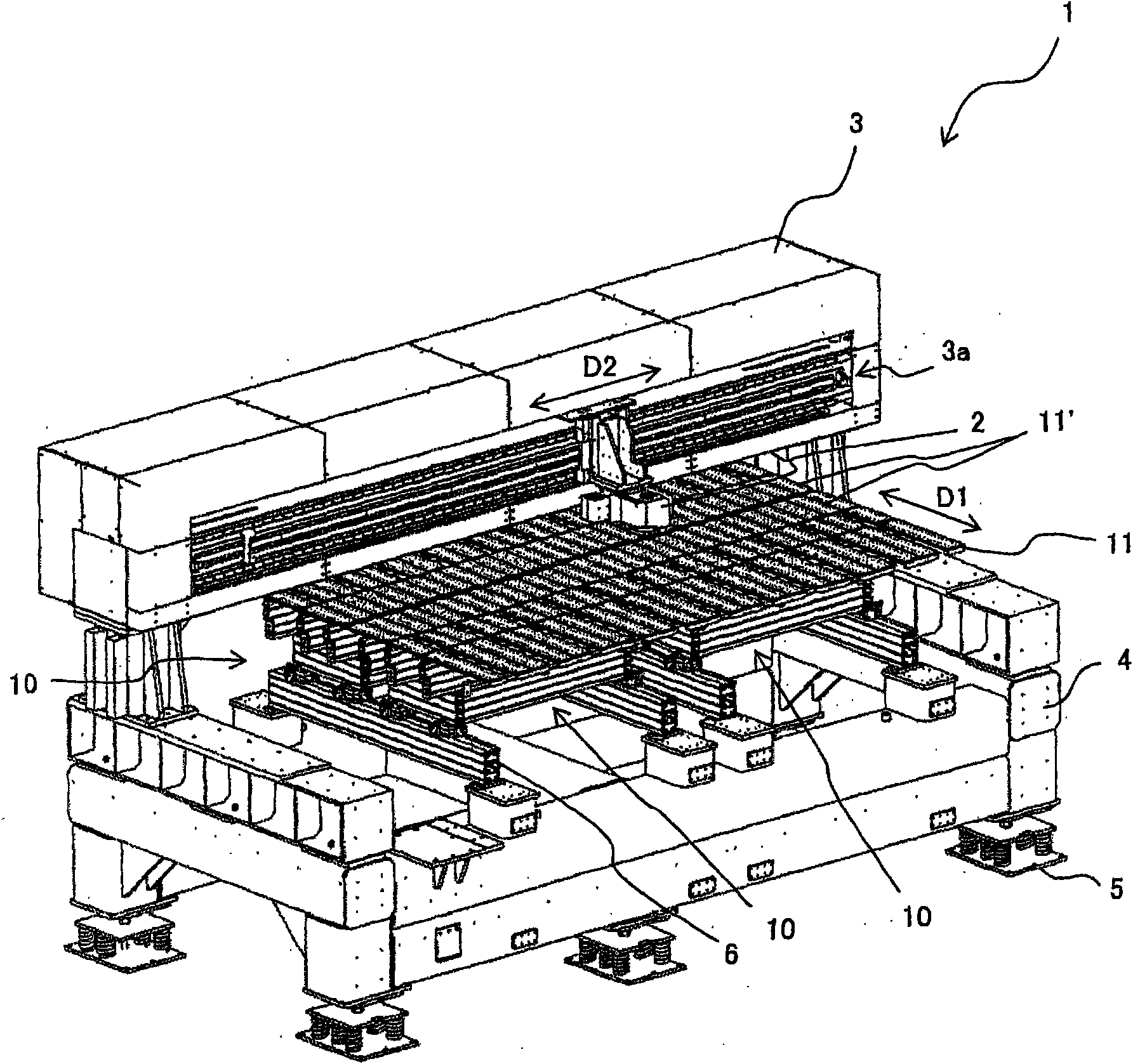

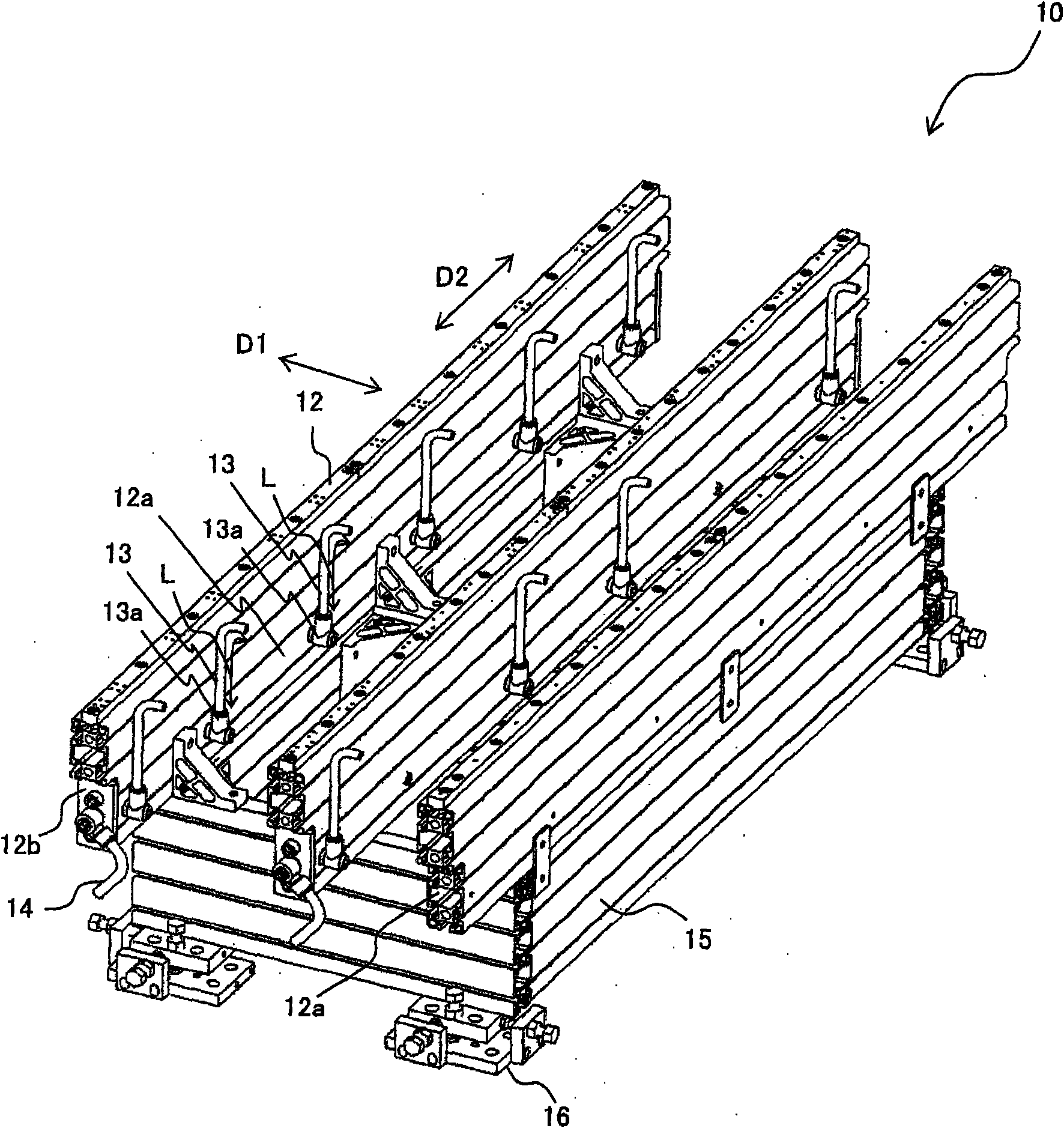

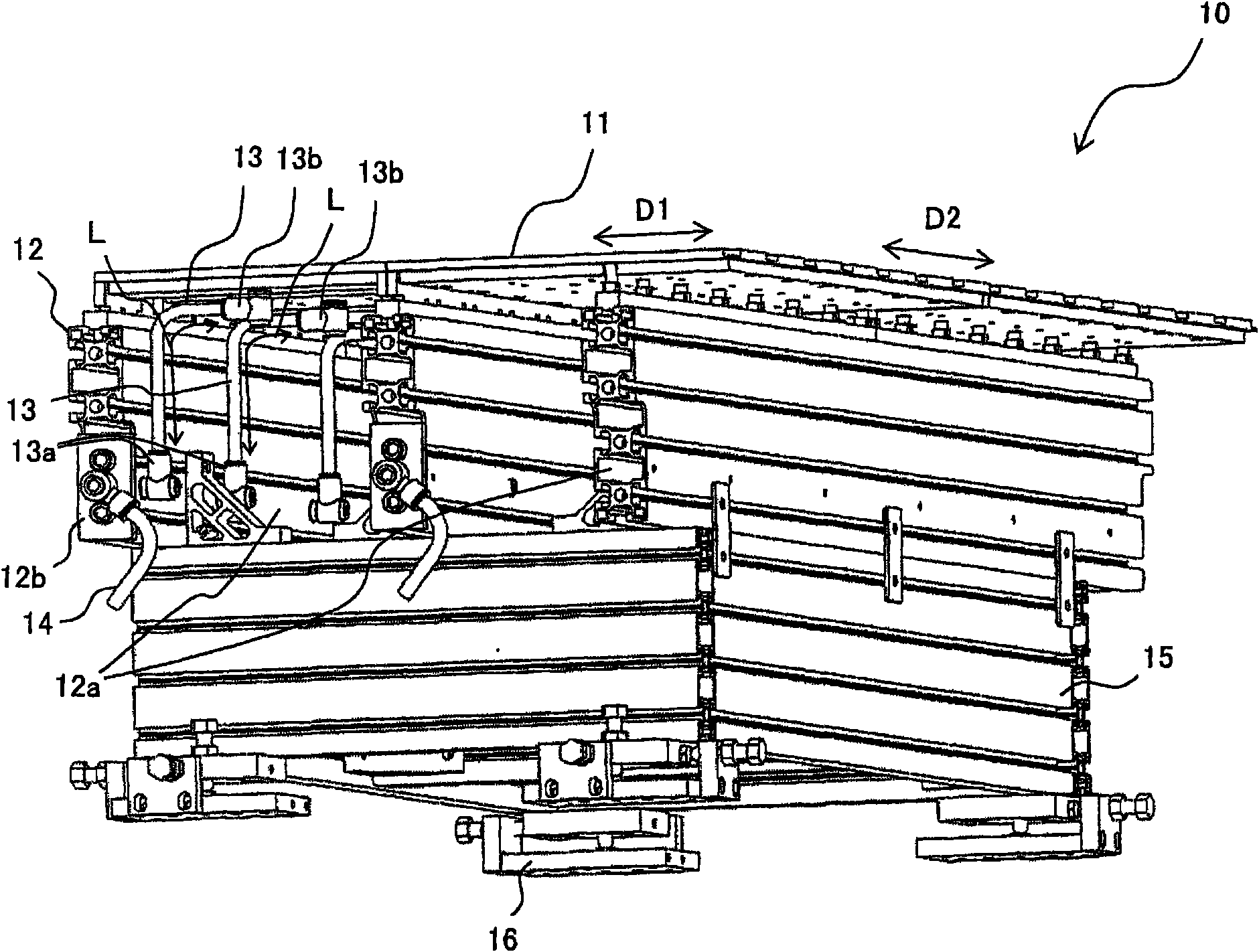

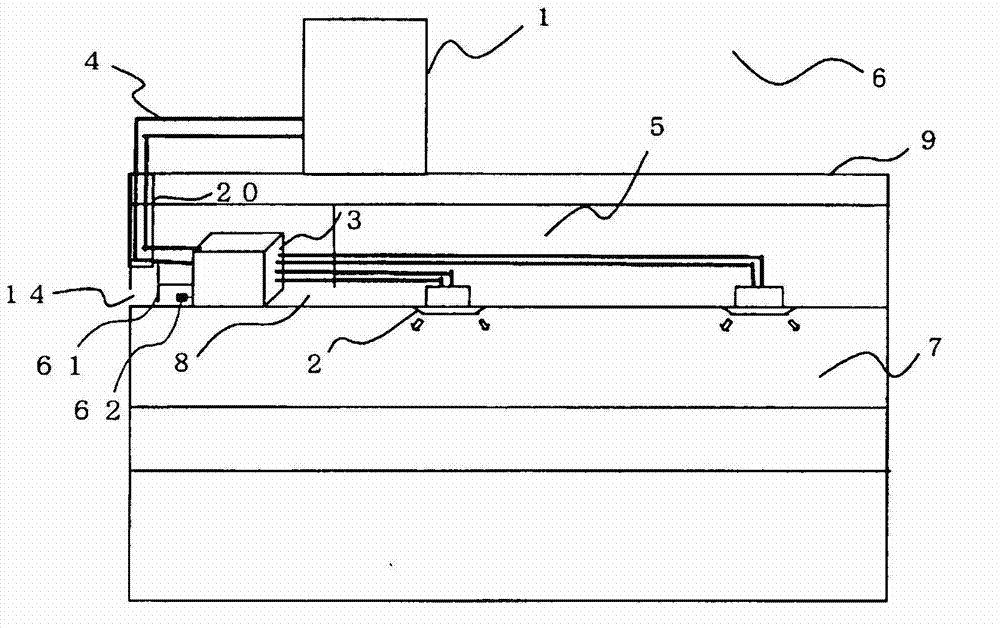

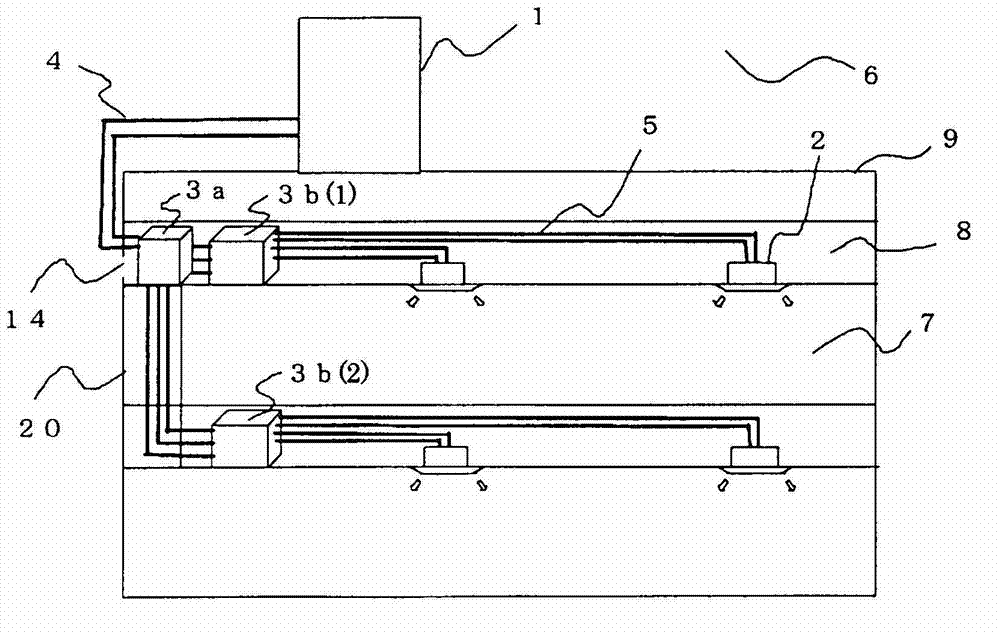

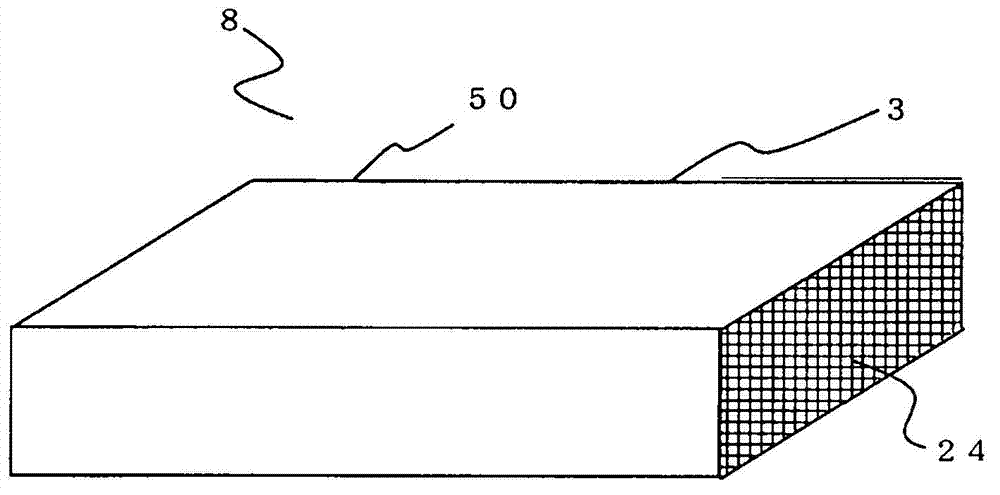

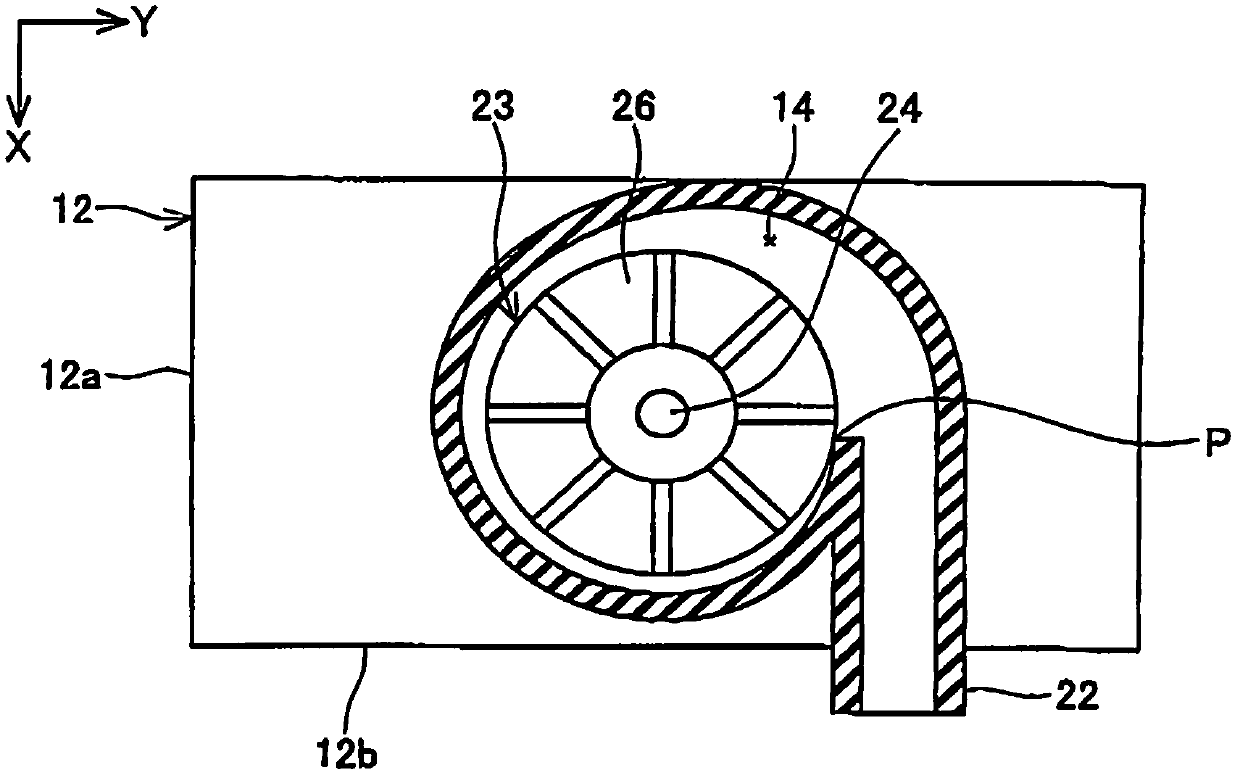

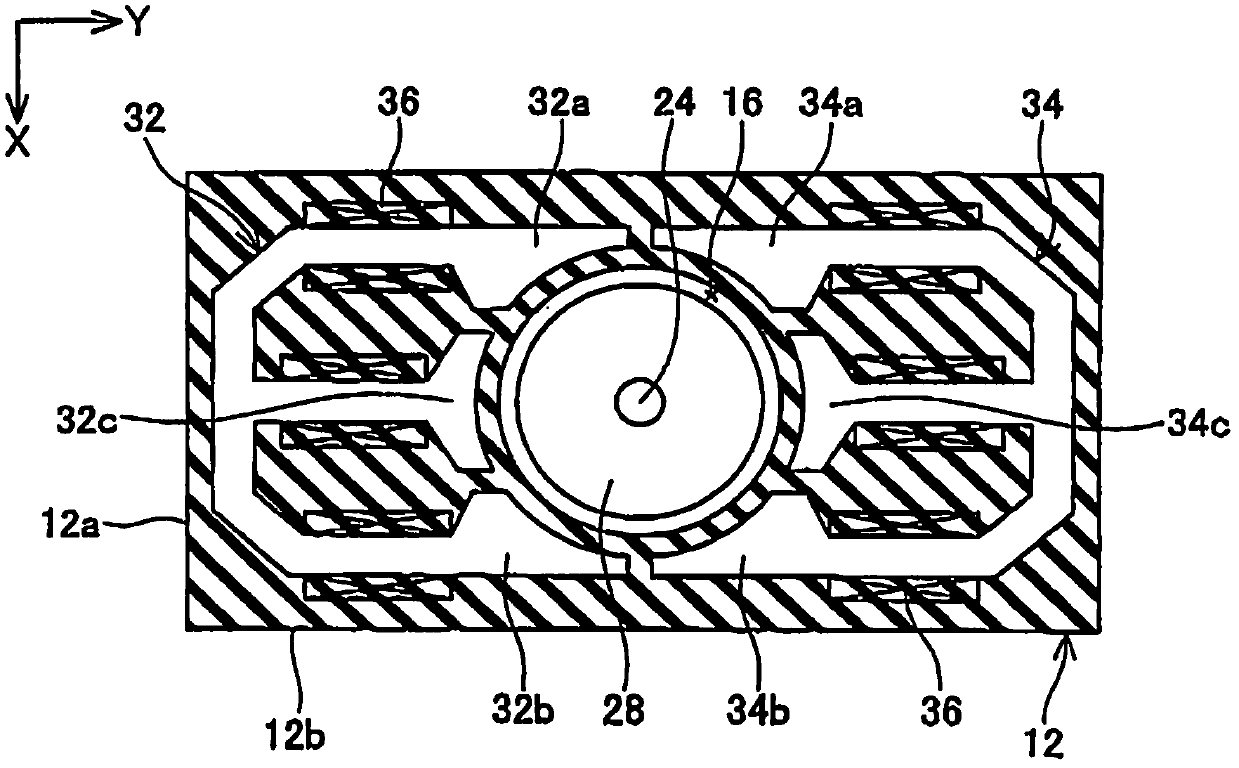

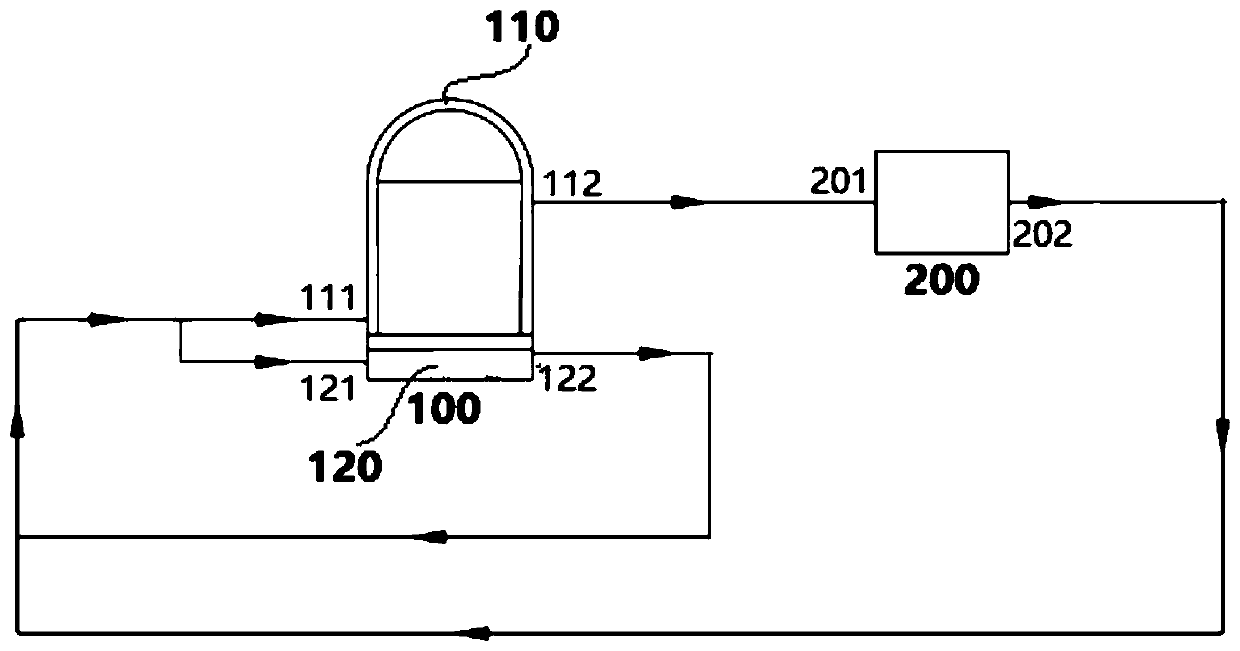

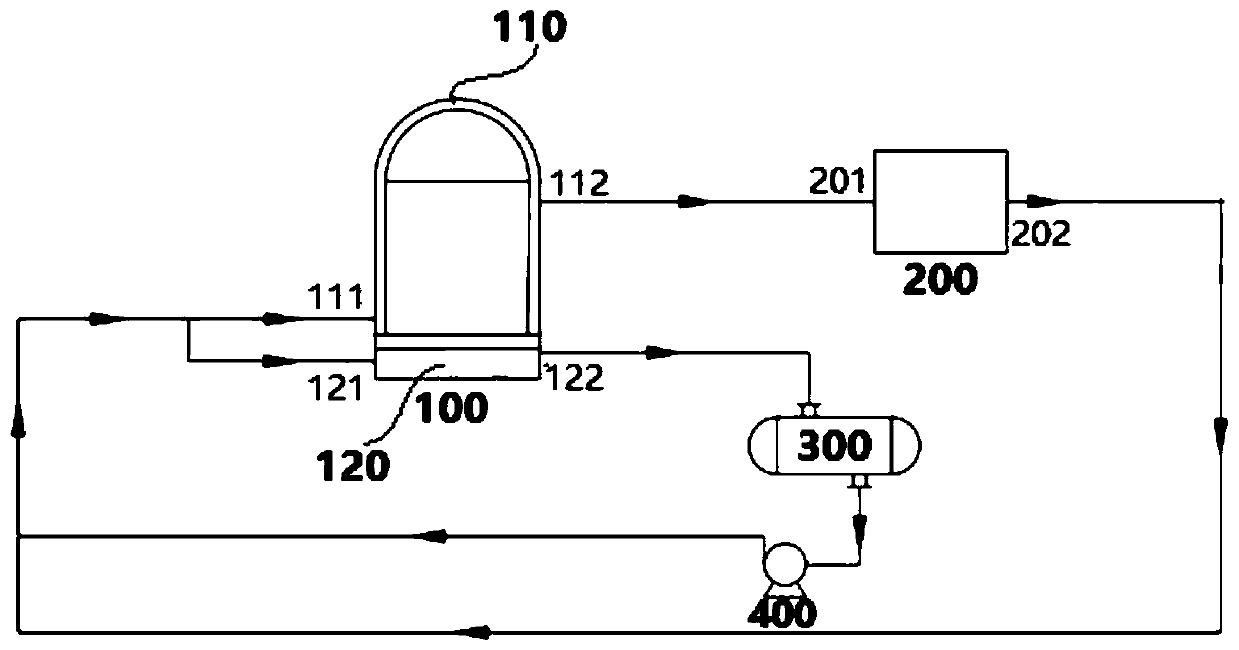

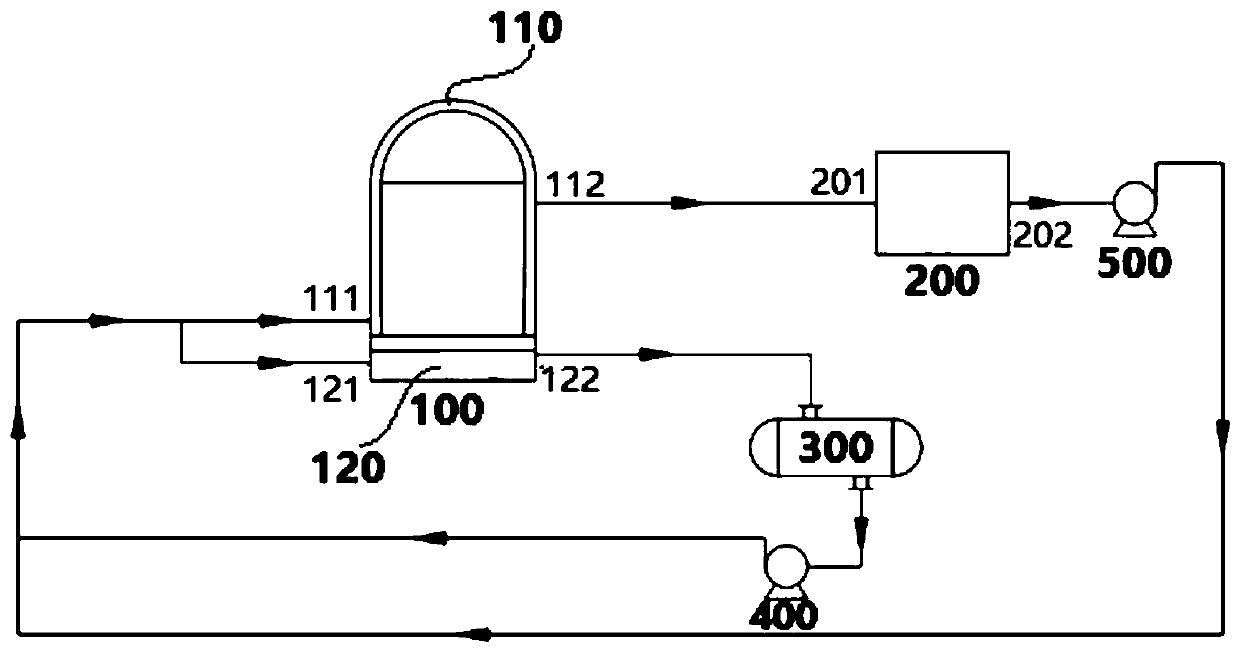

Substrate floating device

InactiveCN101643150AReduce pipingPrevents poor pressure lossMeasurement devicesSemiconductor/solid-state device manufacturingBuffer tankEngineering

The present invention provides a substrate floating device. In the substrate floating device, the air with constant pressure is supplied to a floating plate with a simple structure. The substrate floating device (10) comprises the following components: a plurality of floating plates (11) which discharge the air used for floating the substrate; a buffer tank (12a) which temporarily stores the air supplied by the plurality of floating plates (11); and a plurality of air tubes (13) which respectively supply air for the plurality of floating plates (11) from the buffer tank (12a), wherein, the floating plates (11) are of rectangular tile shaped and are arranged with a matrix shape. The buffer tank (12a) is configured below the area used for configuring the plurality of floating plates (11), and extends along one direction in the arrangement directions (arrows D1 and D2) of the floating plates (11). The plurality of air tubes (13) connect the buffer tank (12a) with the plurality of floating plates (11) with a substantially same length.

Owner:OLYMPUS CORP

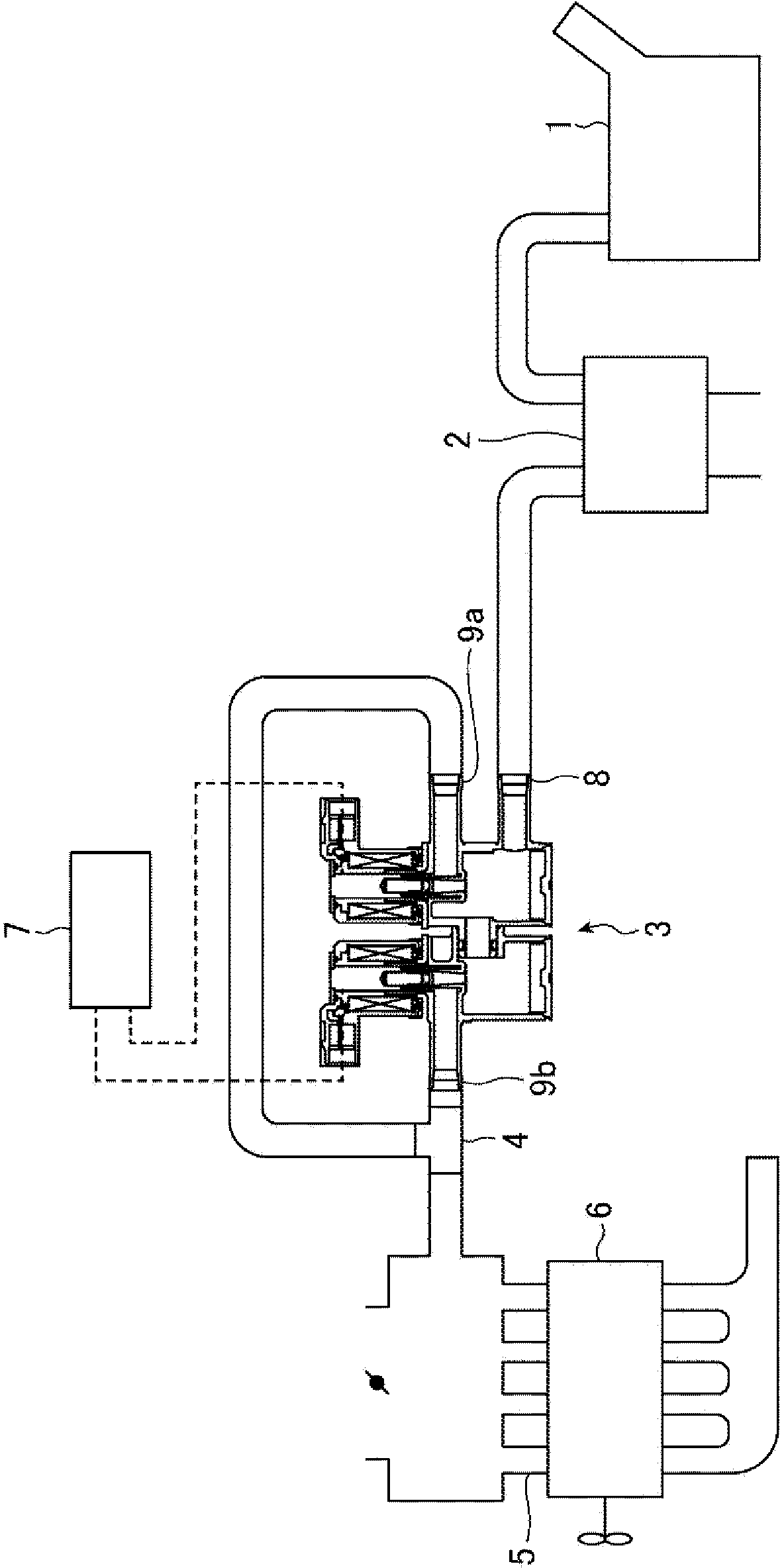

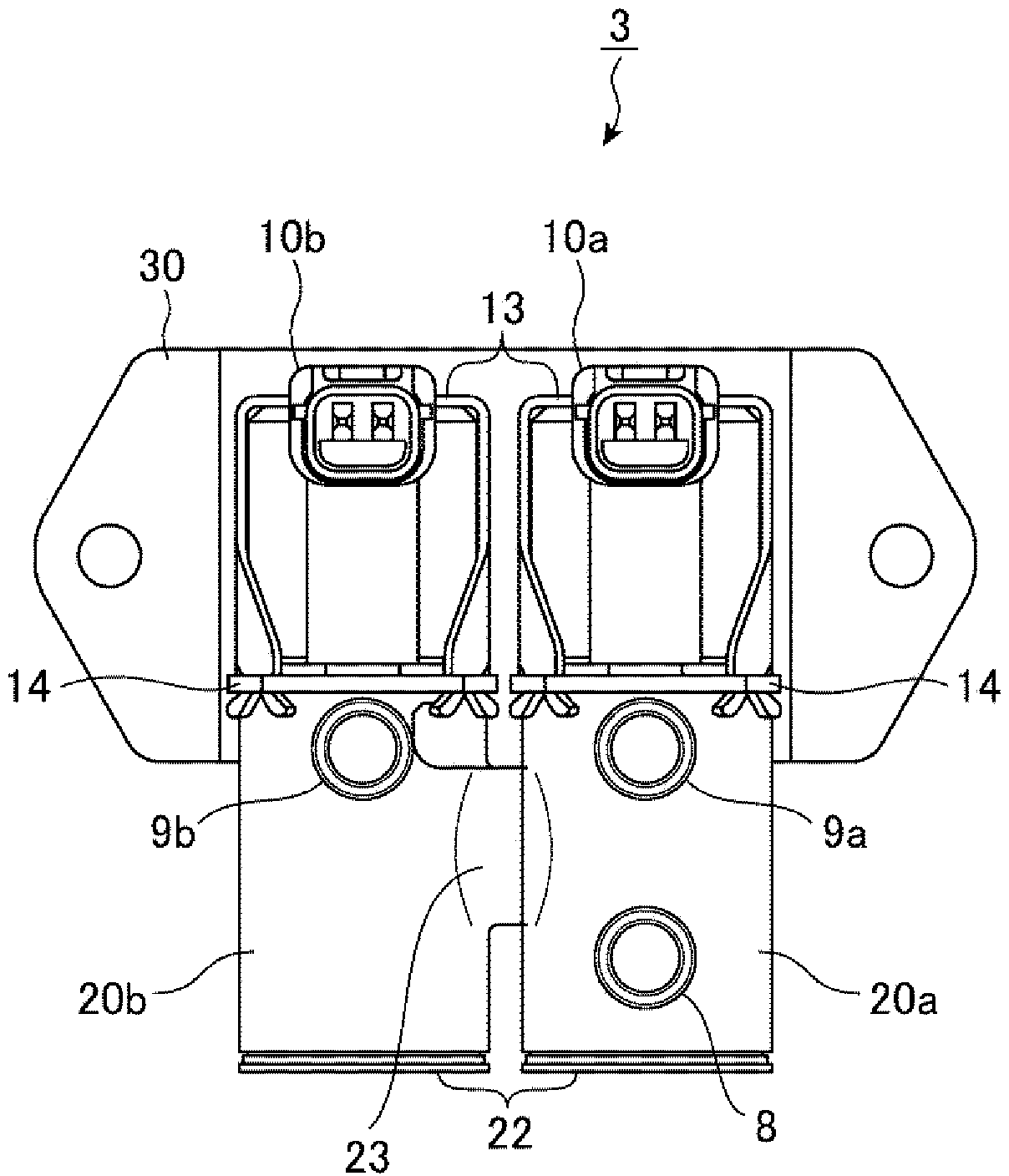

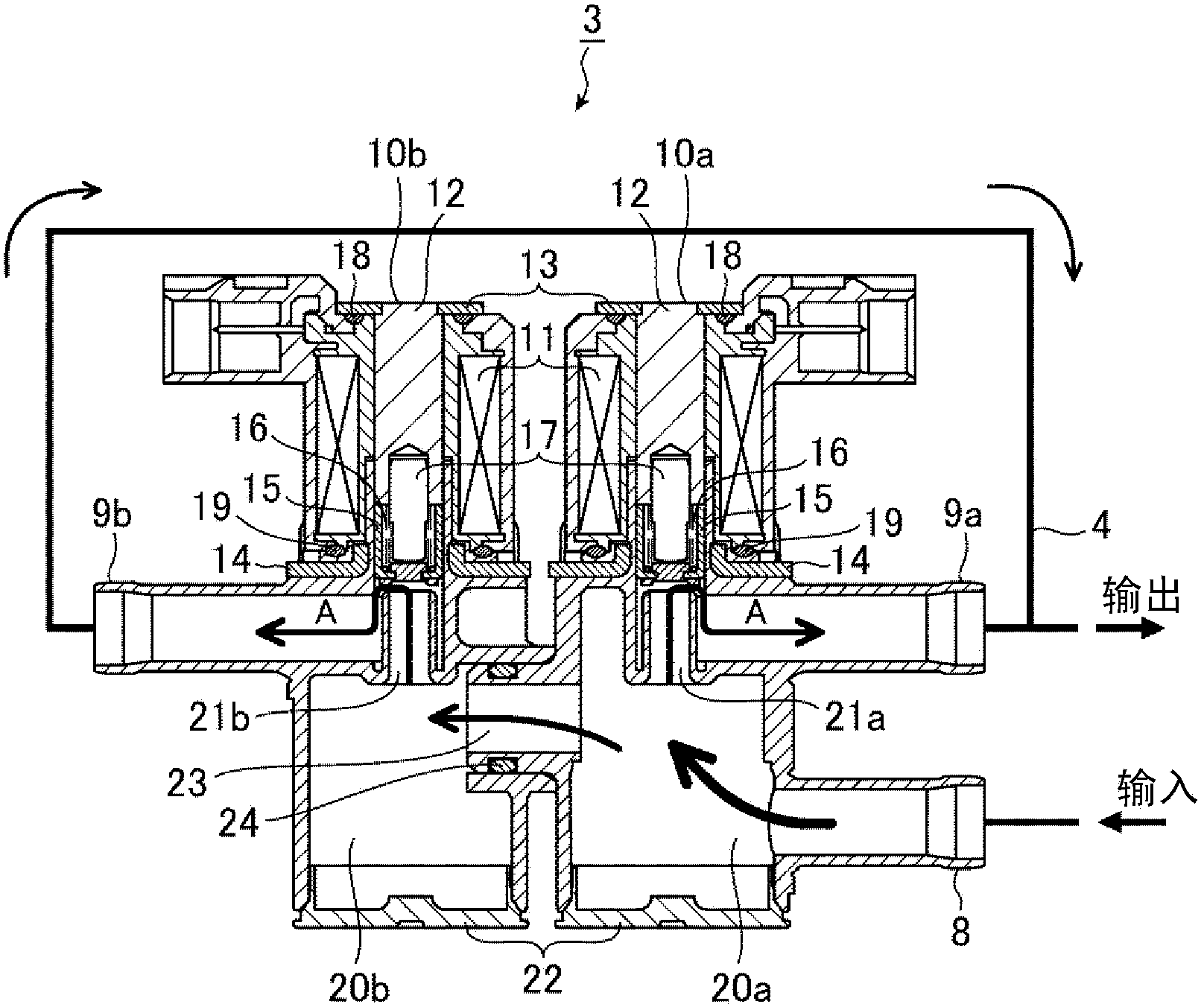

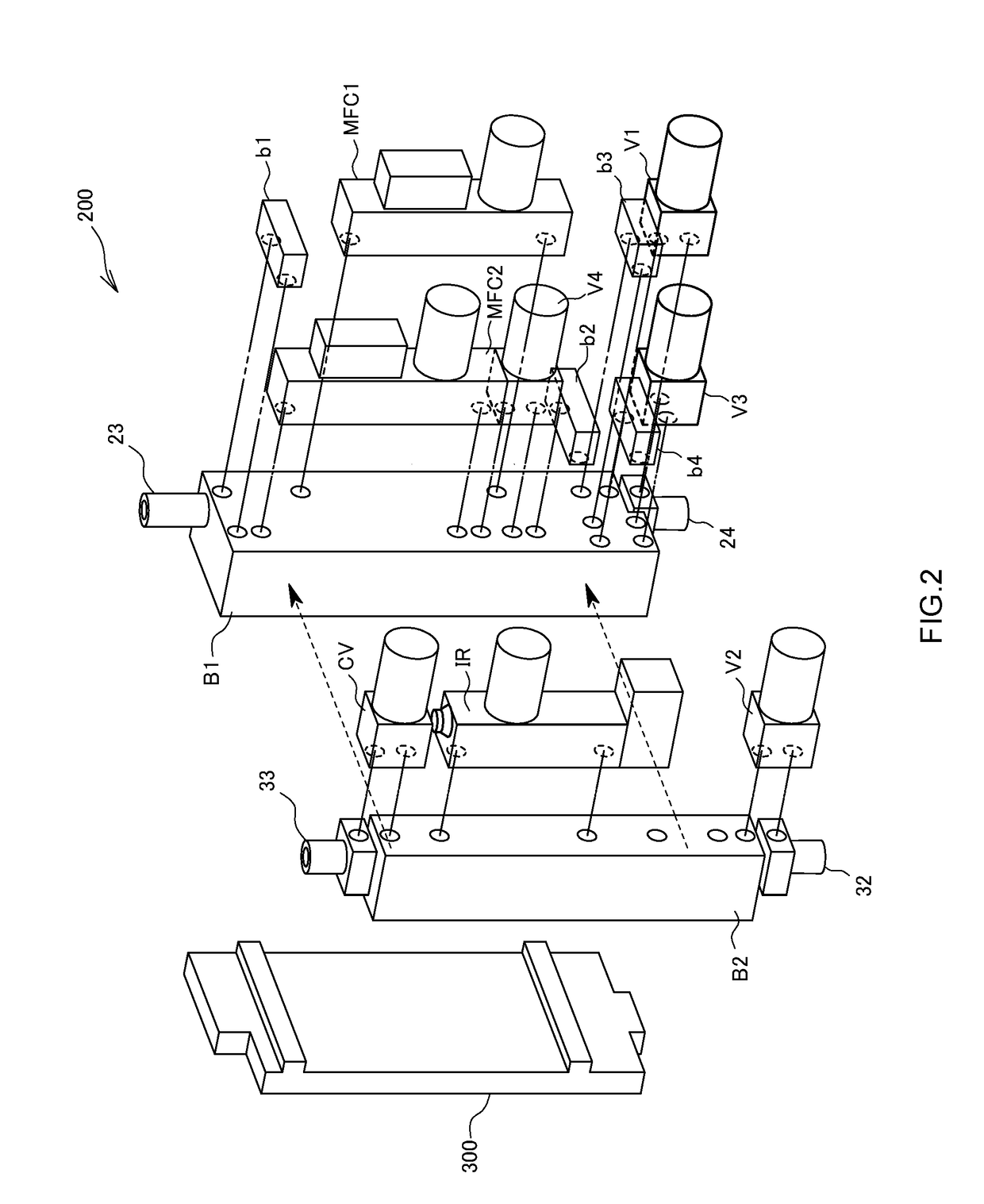

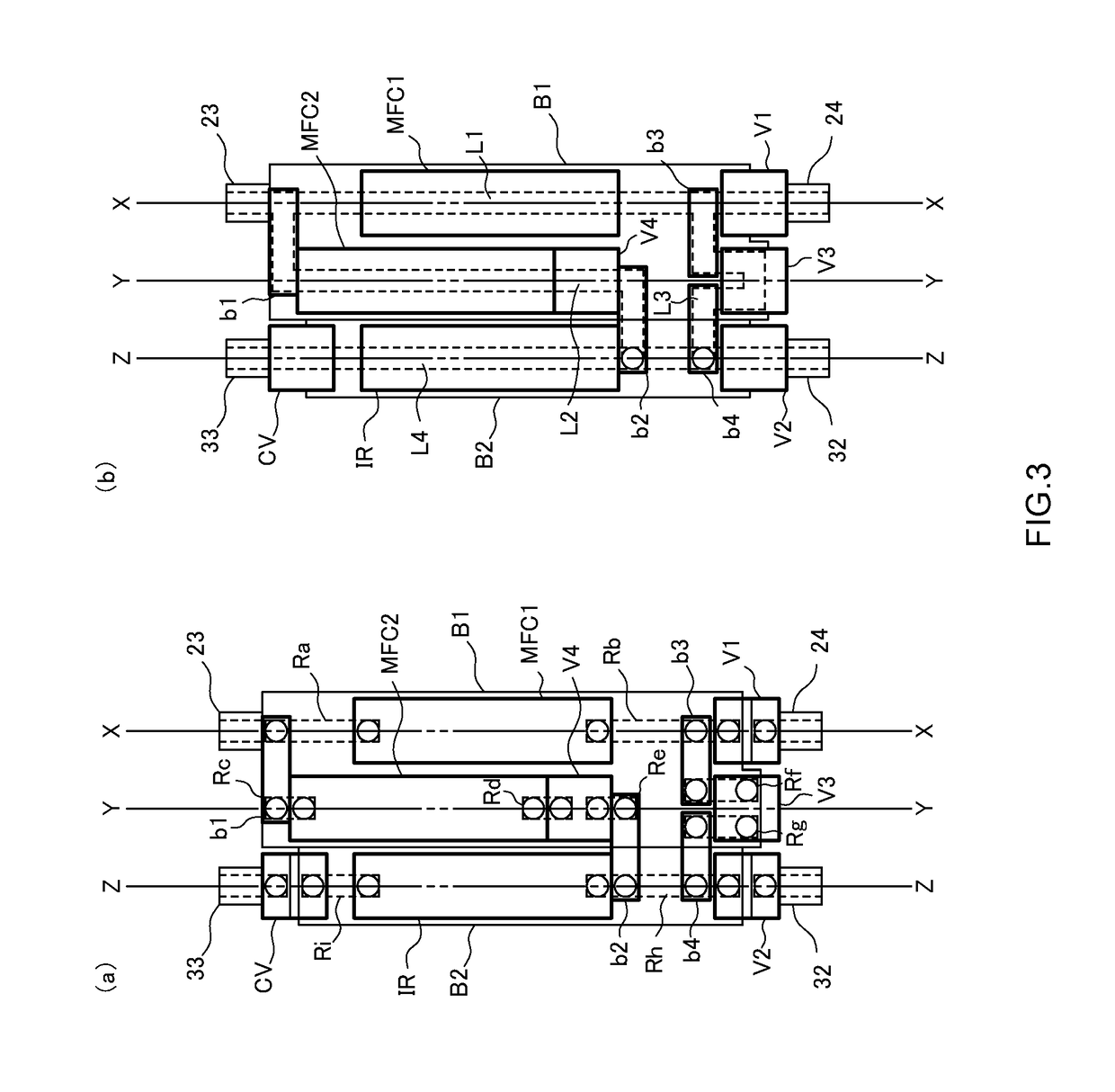

Flow rate control device

ActiveCN103814247ALow costImprove flowOperating means/releasing devices for valvesNon-fuel substance addition to fuelSolenoid valveEngineering

A flow rate control device is provided with an input port (8) connecting to the chamber (20a) of one of the two solenoid valves. Output ports (9a, 9b) are connected to the respective opening-closing passages (21a, 21b) of the two solenoid valves. The flow rate control device is also provided with a connection port (23) for connecting the chambers (20a, 20b), and this also allows fluid to flow to the chamber (20b), the fluid having been introduced into the chamber (20a) from the input port (8).

Owner:MITSUBISHI ELECTRIC CORP

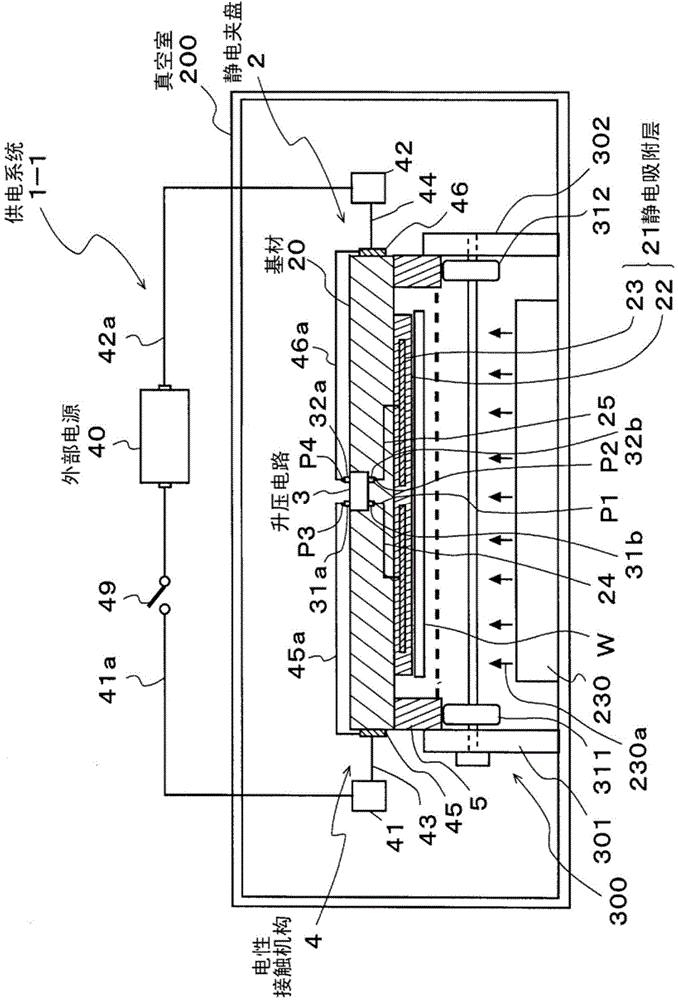

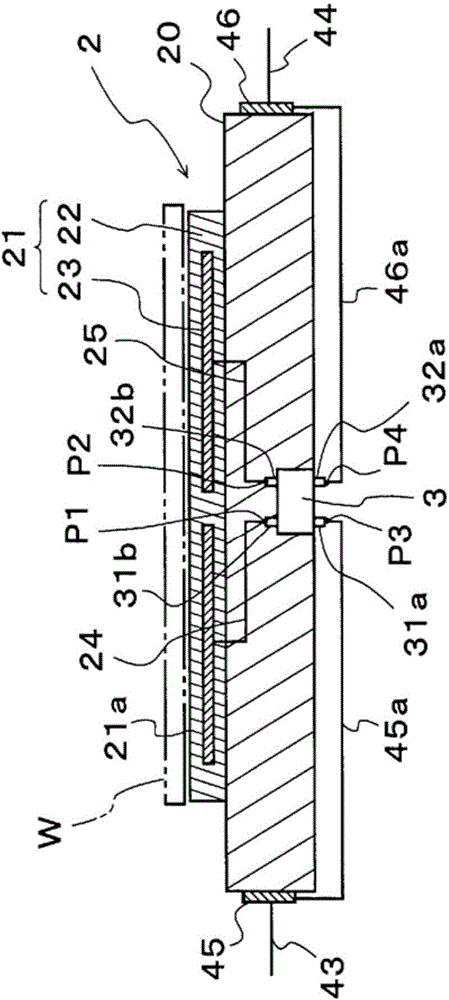

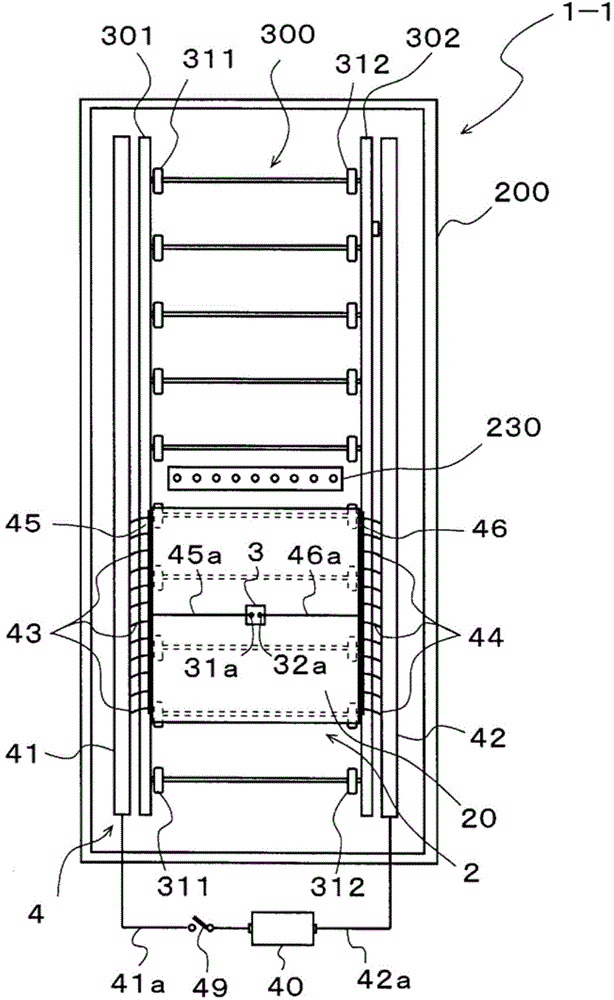

Electrostatic chuck and power supply system

ActiveCN104838484AAvoid damageSuppresses electrical damage modesSemiconductor/solid-state device manufacturingPositioning apparatusEngineeringHigh voltage

[Problem] To provide an electrostatic chuck and a power supply system, wherein high-voltage drive is performed without generating electrical discharge even in a vacuum atmosphere, and a structure of the power supply system for the electrostatic chuck is simplified. [Solution] This power supply system is provided with: an electrostatic chuck (2) having a booster circuit (3); and an electric contact mechanism (4). Merely terminals (31a, 32a) of the booster circuit (3) are exposed to the outside. The terminals (31b, 32b) are connected to an attraction electrode (23). The electric contact mechanism (4) is configured from rails (41, 42), and flexible contacts (43, 44) in contact with the rails. The rails (41, 42) are connected to an external power supply (40), and the flexible contacts (43, 44) are provided on conductive plates (45, 46) of the electrostatic chuck (2). The conductive plates (45, 46) are connected to the terminals (31a, 32a) of the booster circuit (3).

Owner:CREATIVE TECH CORP

Air conditioner

ActiveCN102770715AAchieve protectionInhibition of Intrusion SituationsMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

Provided is an air conditioner wherein it is possible to conserve energy and to ensure safety with regard to the refrigerant. Disclosed is an air conditioner equipped with: a heat medium exchanger (3) disposed within a space (8) in a building (9), which is different from the space in which the air is conditioned, and provided with inter-heat medium heat exchangers (15a, 15b) which exchange the heat between a flammable refrigerant and a heat medium that is different from the refrigerant, and a housing (50) which houses the inter-heat medium heat exchangers (15a, 15b), and has an air vent (24) that allows air to flow through the housing space and the outside of the housing space; one or more outdoor units (1) which circulate the refrigerant by being connected to the heat medium exchanger (3) via a pipe, and which are disposed on the outside of the building (9) or an outdoor space (6) within the building (9), which leads to the outside of the building (9); and one or more indoor units (2) which are connected to the heat medium exchanger (3) via a pipe by means of a different system from the outdoor units (1), and which are provided with a use-side heat exchanger (26) which exchanges the heat between the heat medium and the air in the indoor space (6) by circulating the heat medium.

Owner:MITSUBISHI ELECTRIC CORP

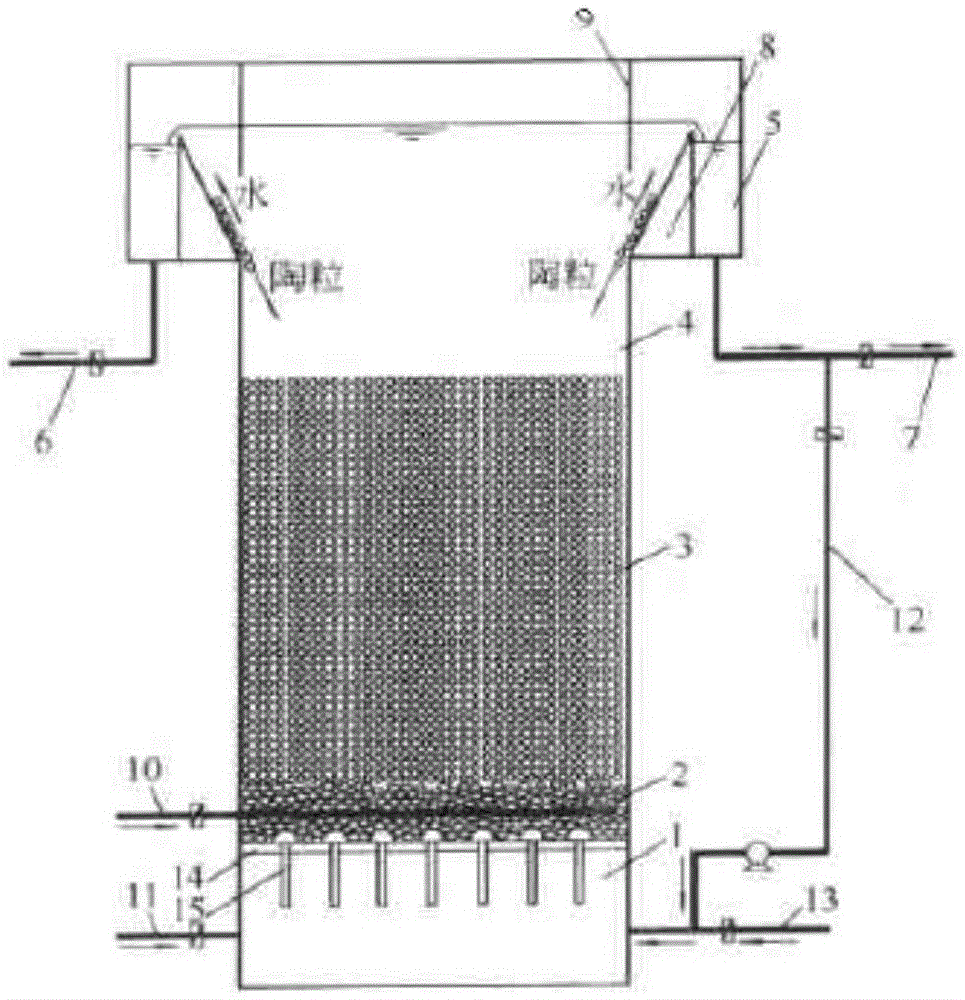

High-efficiency biological aerated filter (BAF) device used for explosive wastewater treatment

InactiveCN105621612ARealize fully automated unmanned operationEmbodies the processing functionWater treatment parameter controlSpecific water treatment objectivesWater dischargeTherapeutic effect

The invention relates to a high-efficiency biological aerated filter (BAF) device used for explosive wastewater treatment, belongs to the field of wastewater treatment, and aims to effectively overcome the defects during the explosive wastewater reuse of complex treatment process, high treatment cost and the like of ammonia nitrogen and organic matter degradation; the device comprises a water intake system, a water discharge system, an aerating system, a backwash water intake system, a backwash water discharge system, a supporting layer and a filler layer. According to the high-efficiency biological aerated filter (BAF) device used for explosive wastewater treatment, the physicochemical process and the biochemical process are combined, fine suspended matters are intercepted under the adsorptive filtration action of the filler, and most of ammonia nitrogen and organic pollutants are removed under the internal and external biochemical treatment action of the filler, and the condition that effluent can reach the standard and be reused is ensured; besides, the device is low in cost and good in treatment effect, ammonia nitrogen after wastewater treatment is reduced to be 5 mg / L or below, and COD is smaller than 50 mg / L.

Owner:CHINA NORTH ENERGY CONSERVATION & ENVIRONMENT PROTECTION

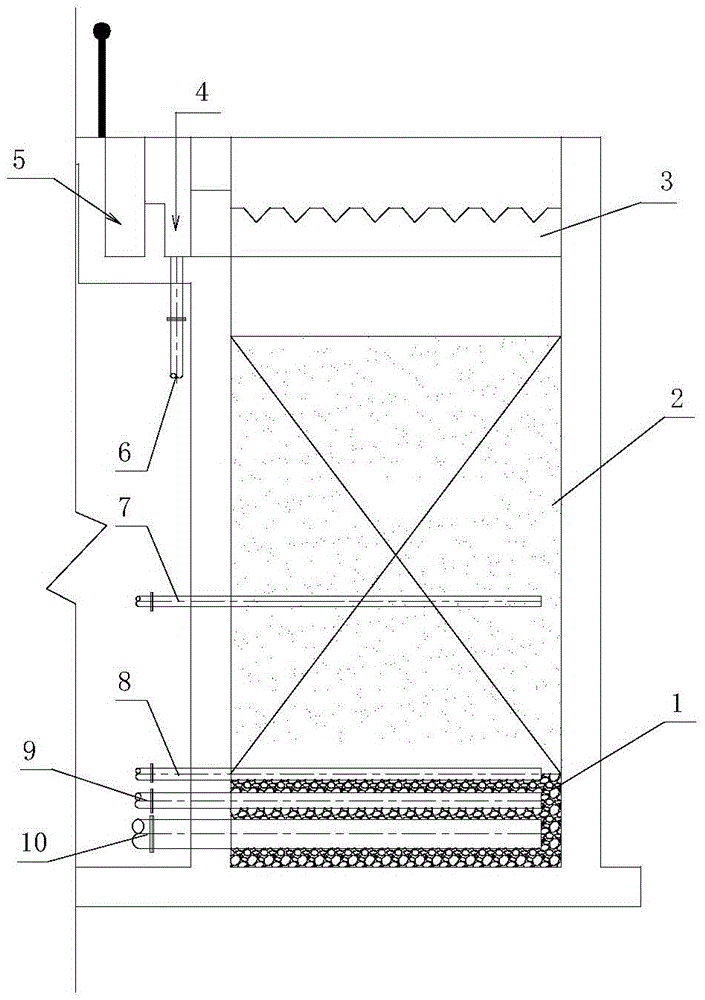

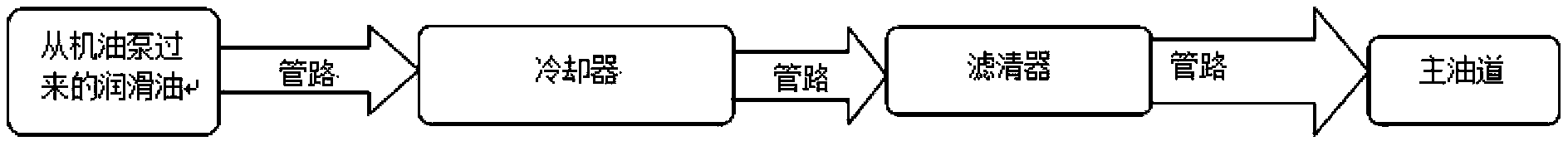

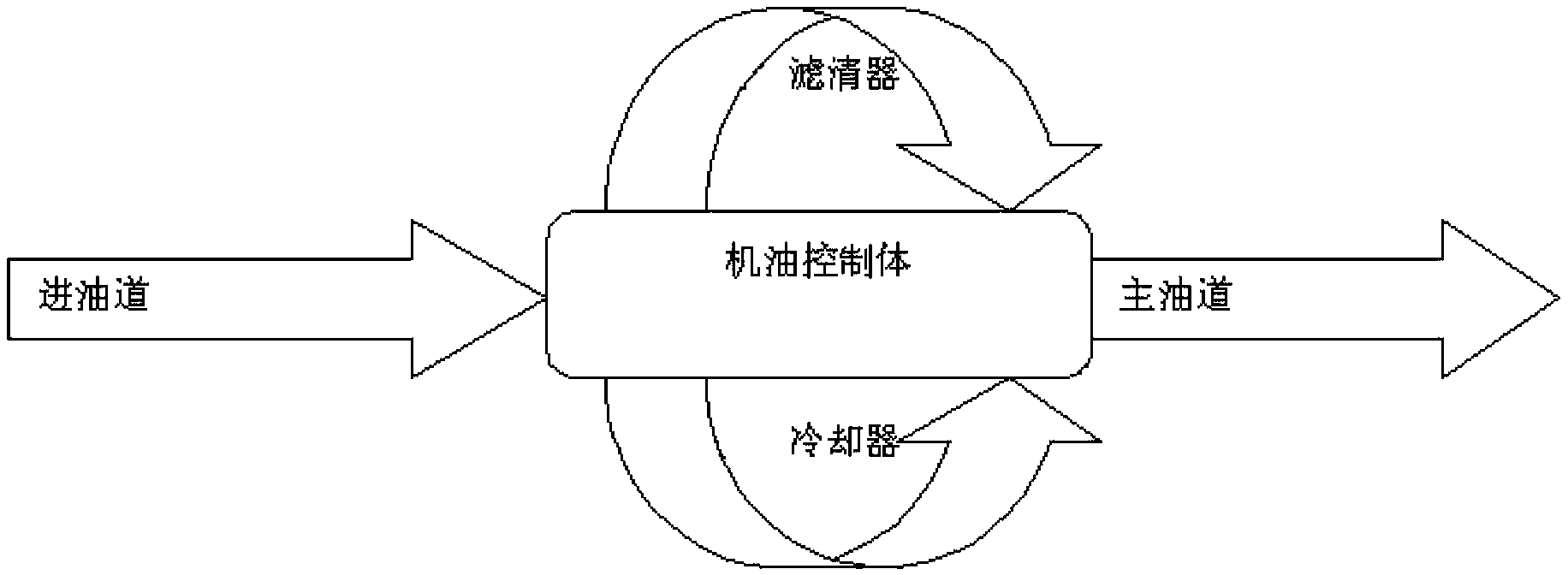

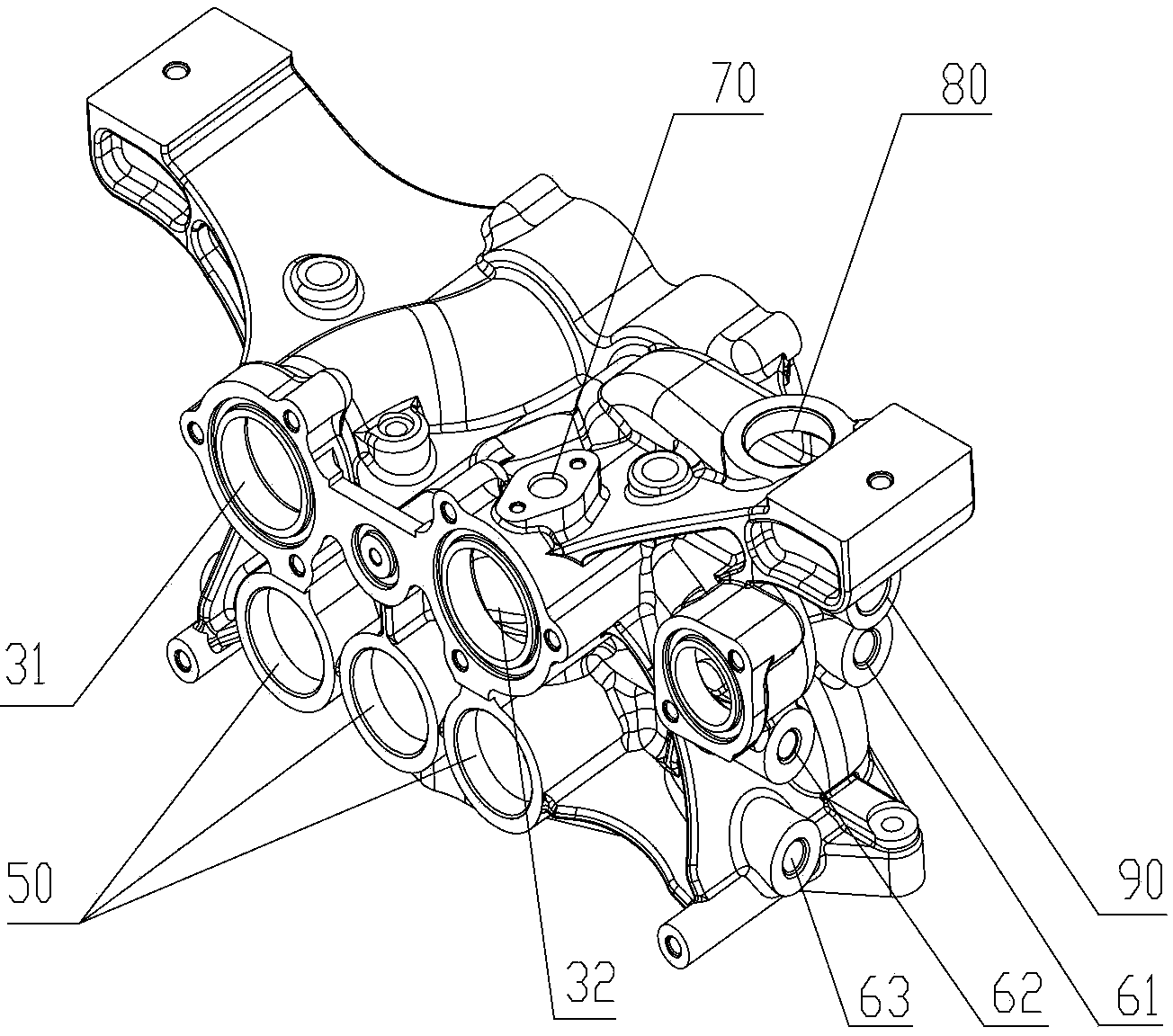

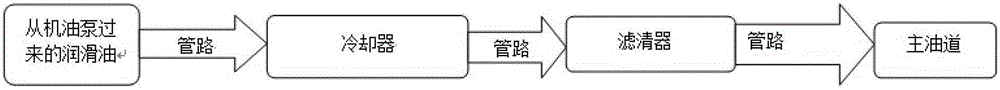

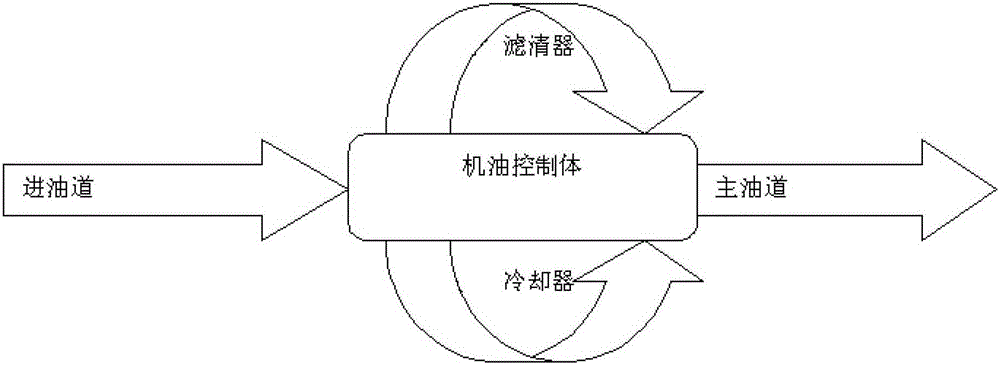

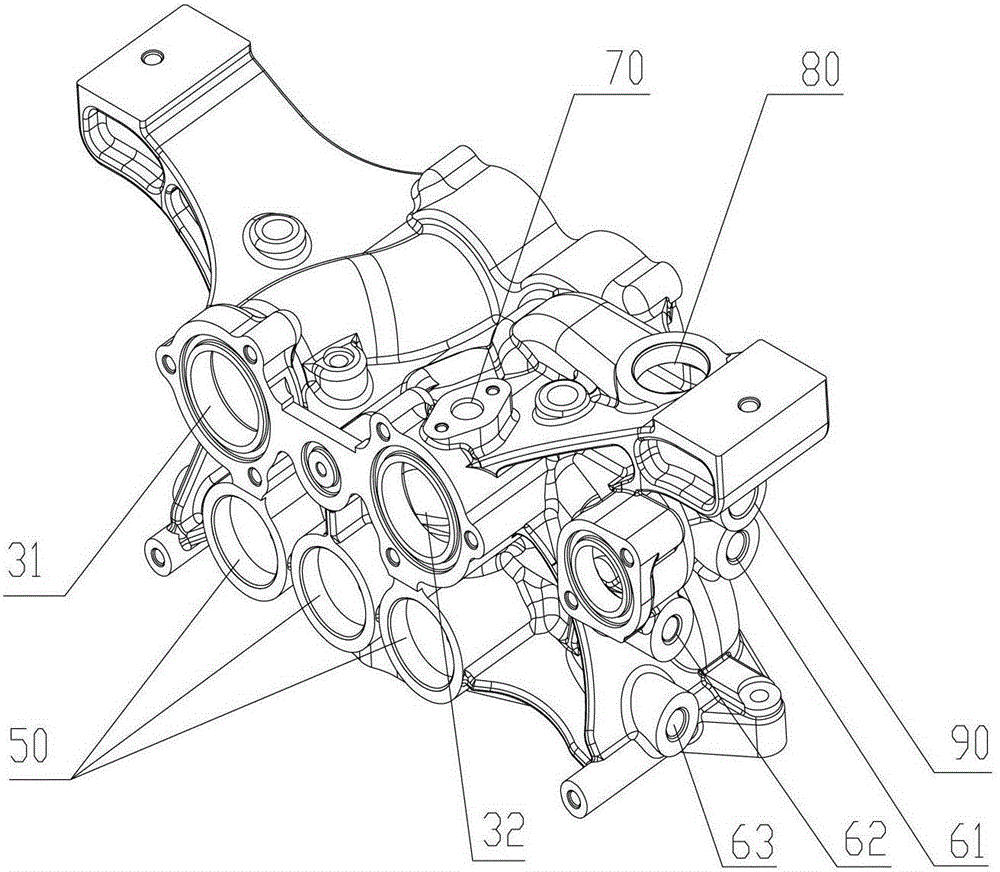

Engine oil control body

ActiveCN103397924ASimple structureBeautify the appearanceMachines/enginesPressure lubricationButt jointPetroleum engineering

The invention discloses an engine oil control body. The engine oil control body comprises a filter oil inlet connector, a filter oil outlet connector, a cooler oil inlet connector, a cooler oil outlet connector, a main oil channel oil inlet connector, an engine oil pump oil outlet connector, a first lubricating oil channel, a second lubricating oil channel and a third lubricating oil channel, wherein the first lubricating oil channel, the second lubricating oil channel and the third lubricating oil channel are arranged inside the engine oil control body, the first lubricating oil channel is communicated with the engine oil pump oil outlet connector and the cooler oil inlet connector, the second lubricating oil channel is communicated with the cooler oil outlet connector and the filter oil inlet connector, and the third lubricating oil channel is communicated with the filter oil outlet connector and the main oil channel oil inlet connector. An engine oil pump, a filter, a cooler and an engine main oil channel can be directly installed to the engine oil control body in a butt joint mode, a pipeline does not need to be arranged, the structure of a whole lubricating system is simplified, and appearance is beautified. The lubricating oil channels are arranged inside the engine oil control body to form an integral module and are not mutually interfered, and the state is stable. In addition, the engine oil control body serves as a supporting mechanism of the cooler and the filter, and the structure for supporting the cooler and the filter does not need to be specially arranged.

Owner:WEICHAI POWER CO LTD

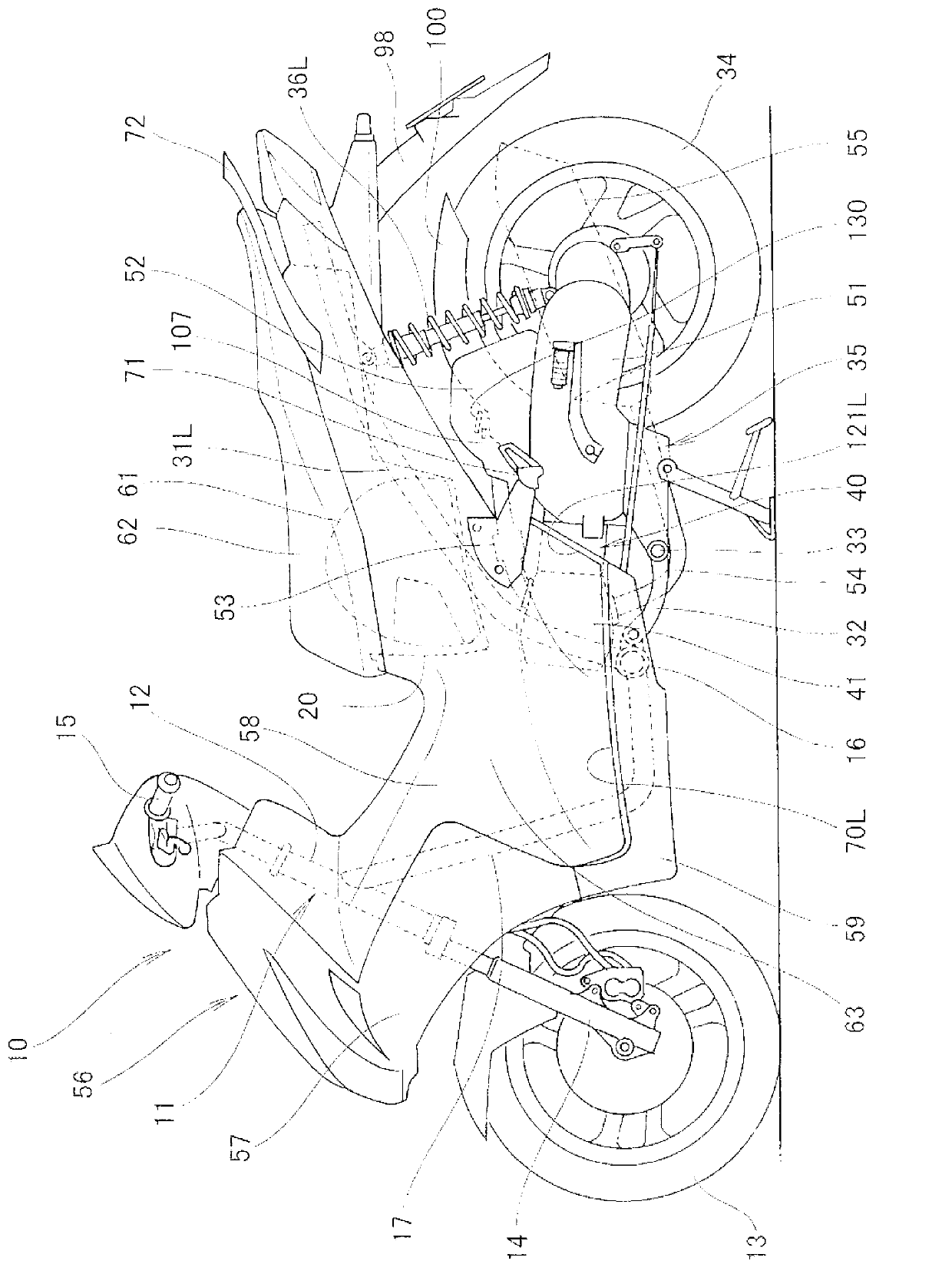

Miniature motorcycle type vehicle

ActiveCN103101595AReduce pipingImprove work efficiencyMotorcyclesCycle containersEngineeringWater cooling

The invention provides a miniature motorcycle type vehicle, a configuration structure of a storage box in the miniature motorcycle type vehicle carrying a water cooling type engine is provided, the size and shape of an accommodating box and a pedal can be freely decided. As is shown in (b), the storage box (130) is disposed in a back splash guard (100). Since the storage box (130) is disposed in the back splash guard (100), the size and the shape of a receiving box (20) can be decided without influence of the storage box (130). The pedal (70R) is also the same, and the size and the shape can be decided without influence of the storage box (130).

Owner:HONDA MOTOR CO LTD

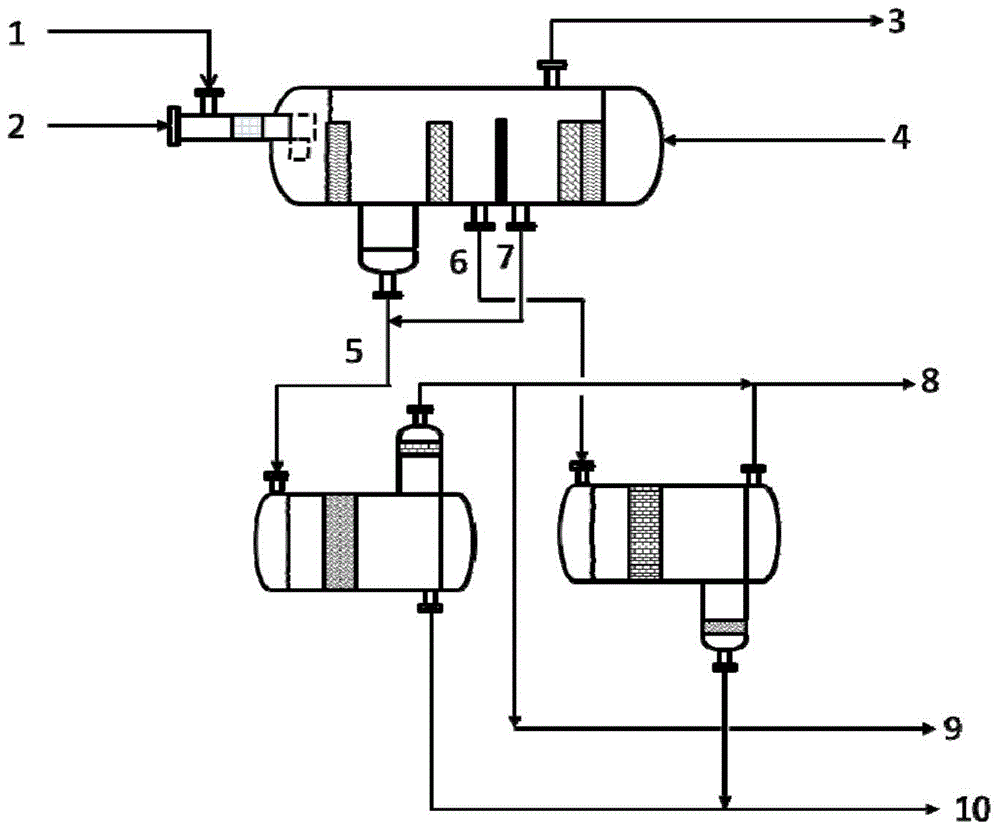

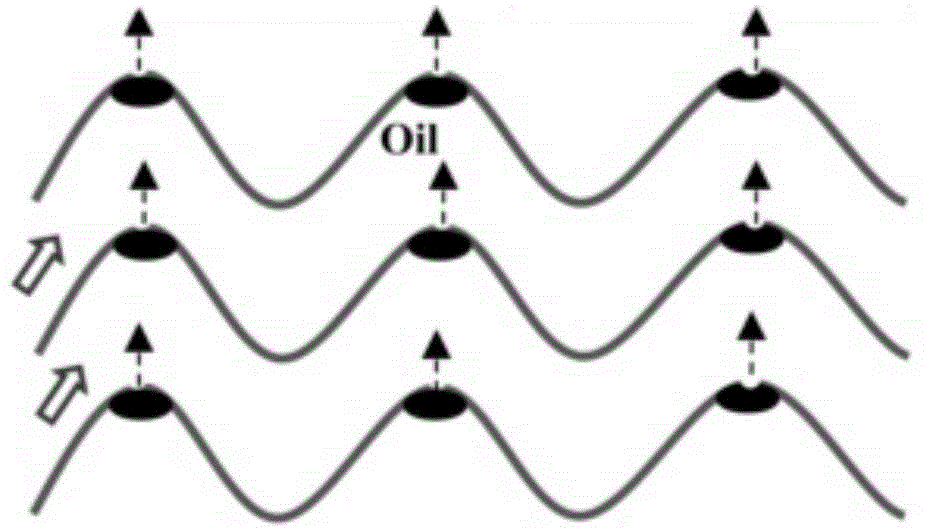

Oil-gas-washing-coupled oil-water initial separation method and device

ActiveCN104629794AQuick degassingSimple structureDewatering/demulsification with mechanical meansCombustible gas purificationThermodynamicsOil water

The invention relates to an oil-gas-washing-coupled oil-water initial separation method and device. The method comprises the following steps: light oil containing 0.5-6% of synthetic water and hydrocarbon-component-containing gas enters a tubular mixer at an inlet section to wash hydrocarbon components in the gas, and are subjected to liquid separation by a T-shaped liquid-gas separator; the water-containing oil sequentially passes through a rectifying distributor, a water drop coarse granulation module and a CPI quick dewatering module from left to right, and the water enters a water drum; sewage containing 0.05-0.5% of oil enters from a right end socket, and freely flows leftwards to sequentially pass through an oil drop coarse granulation module and an CPI quick oil removal module to perform oil removal; and finally, the water in the water drum and the water obtained by right partition oil removal are discharged by an oil-water interface controller; and the oil separated from the right side of the partition is communicated with the oil on the left side via the upper part of the partition, and is discharged under the action of a liquid level controller. The method couples the functions of oil dewatering, water oil-removal and oil-gas washing recycling, has the advantages of small occupied space and quick and efficient separation, and overcomes the defects in the prior art.

Owner:EAST CHINA UNIV OF SCI & TECH

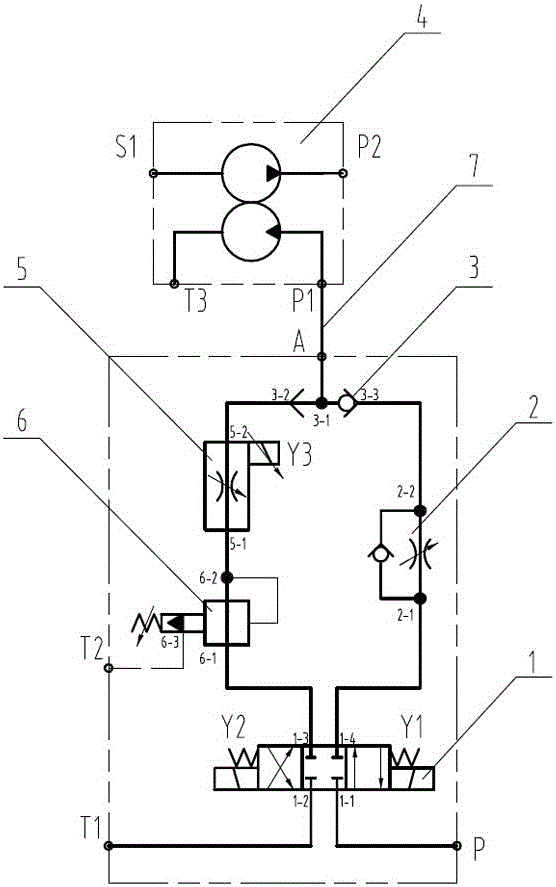

High-low hydraulic switching mechanism as well as water spraying system and method for pavement milling machine

ActiveCN106762898AImprove maintenance convenienceReduce the number of shutdowns to add waterServomotor componentsServometer circuitsElectricityEngineering

The invention provides a high-low hydraulic switching mechanism as well as water spraying system and method for a pavement milling machine. The high-low hydraulic switching mechanism comprises an electromagnetic reversing valve (1), wherein a three-position four-way electromagnetic reversing valve serves as the electromagnetic reversing valve (1); an oil port I (1-1) of the electromagnetic reversing valve (1) is connected to an oil inlet (P); an oil port II (1-2) of the electromagnetic reversing valve (1) is connected to an oil return port (T1); an oil port III (1-3) of the electromagnetic reversing valve (1) is connected to a second oil port (3-2) of a shuttle valve (3) through a pressure reducing valve (6) and an electric proportional speed regulating valve (5); an oil port IV (1-4) of the electromagnetic reversing valve (1) is connected to a third oil port (3-3) of the shuttle valve (3) through a one-way throttling valve (2); and a first oil port (3-1) of the shuttle valve (3) is connected to an oil outlet (A). By adoption of the high-low hydraulic switching mechanism as well as water spraying system and method provided by the invention, switching between the high pressure and the low pressure can be achieved.

Owner:柳工无锡路面机械有限公司

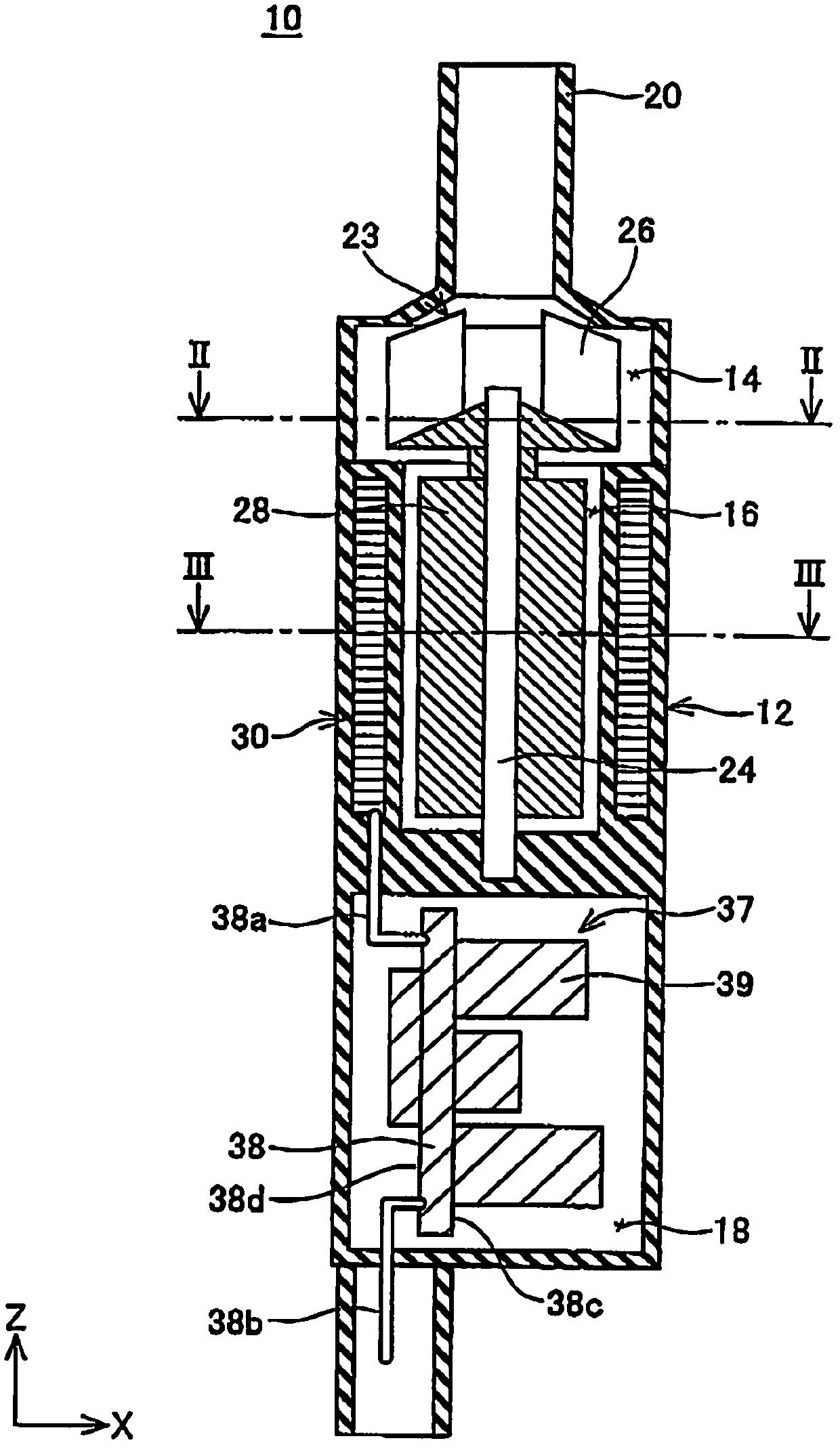

Electric pum

The invention provides an electric pump improving the installation efficiency of the electric pump. The electric pump is provided with motor parts (28, 32, 34, 36), an impeller driven by the motor parts for rotating, a pump chamber used for receiving the impeller. The rotary shafts of the motor parts and the pump chamber are arranged along a rotary shaft of the impeller. The electric pump is also provided with a suction inlet used for suctioning liquid into the pump chamber and a discharge port used for discharging liquid in the pump chamber. The suction inlet and the rotary shaft extend in parallel. On the other hand, the discharge port (22) extends along a direction perpendicular to the rotary shaft. The shape of a cross section of the motor parts (28, 32, 34, 36) which are perpendicular to the rotary shaft is in a flat shape.

Owner:AISAN IND CO LTD

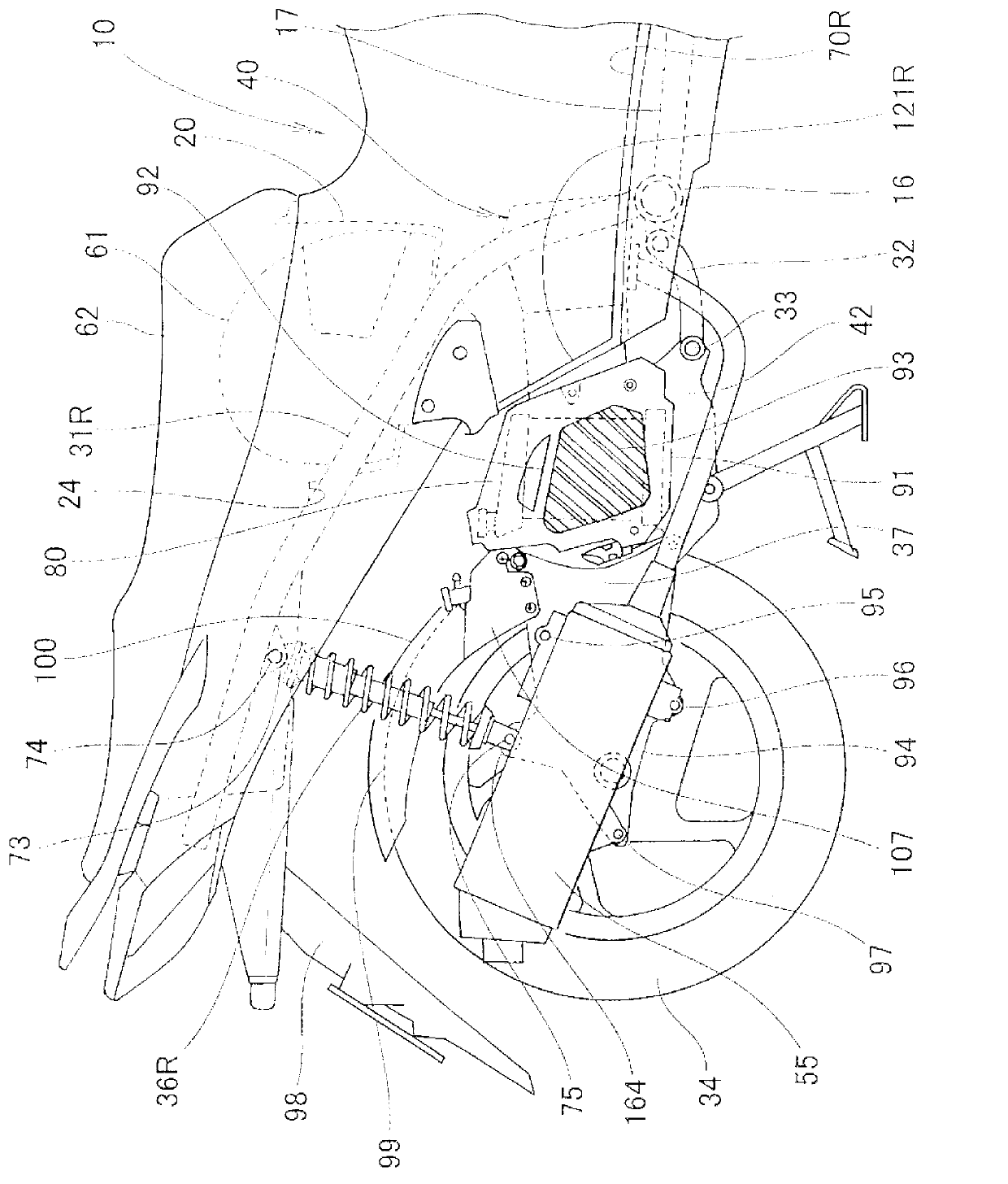

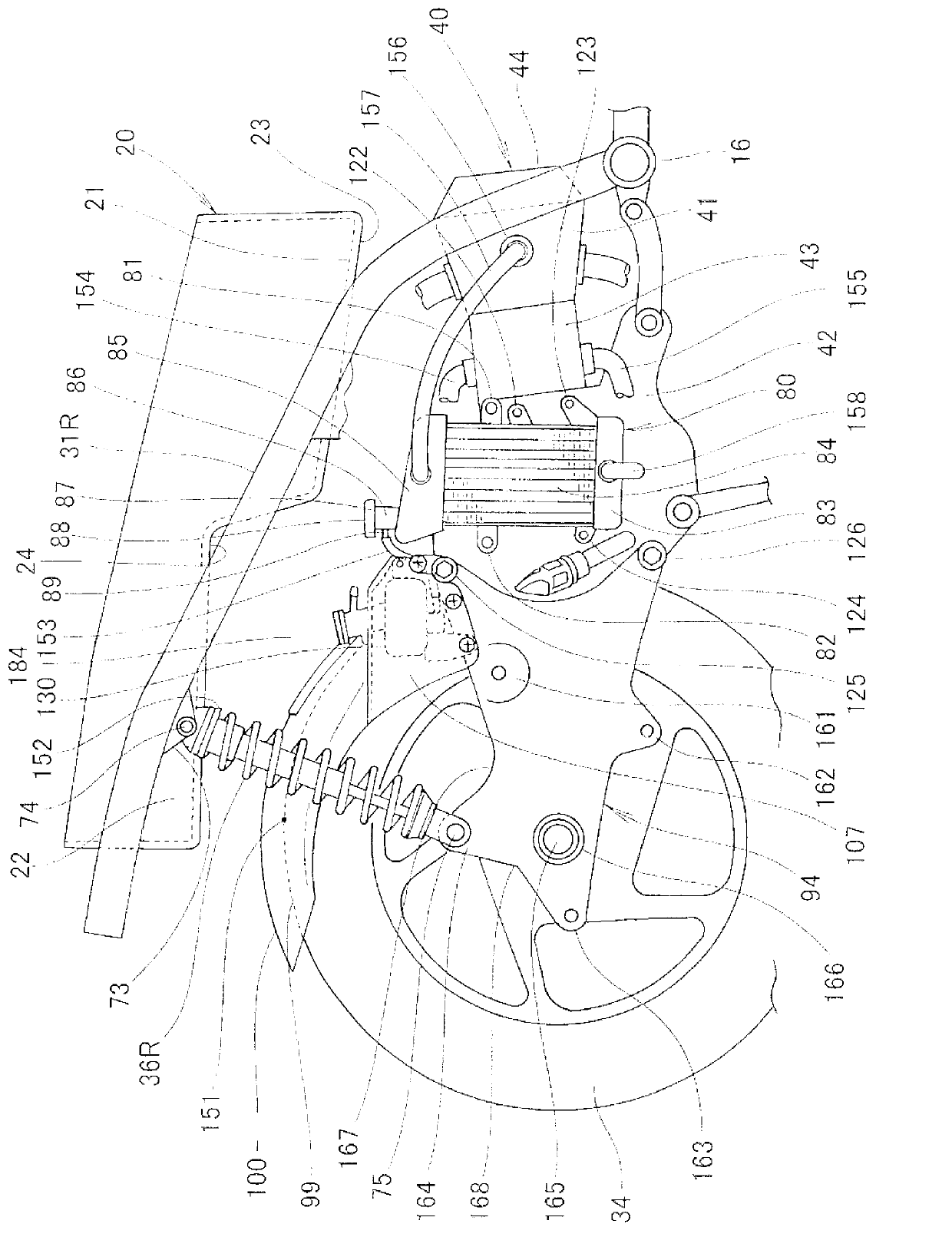

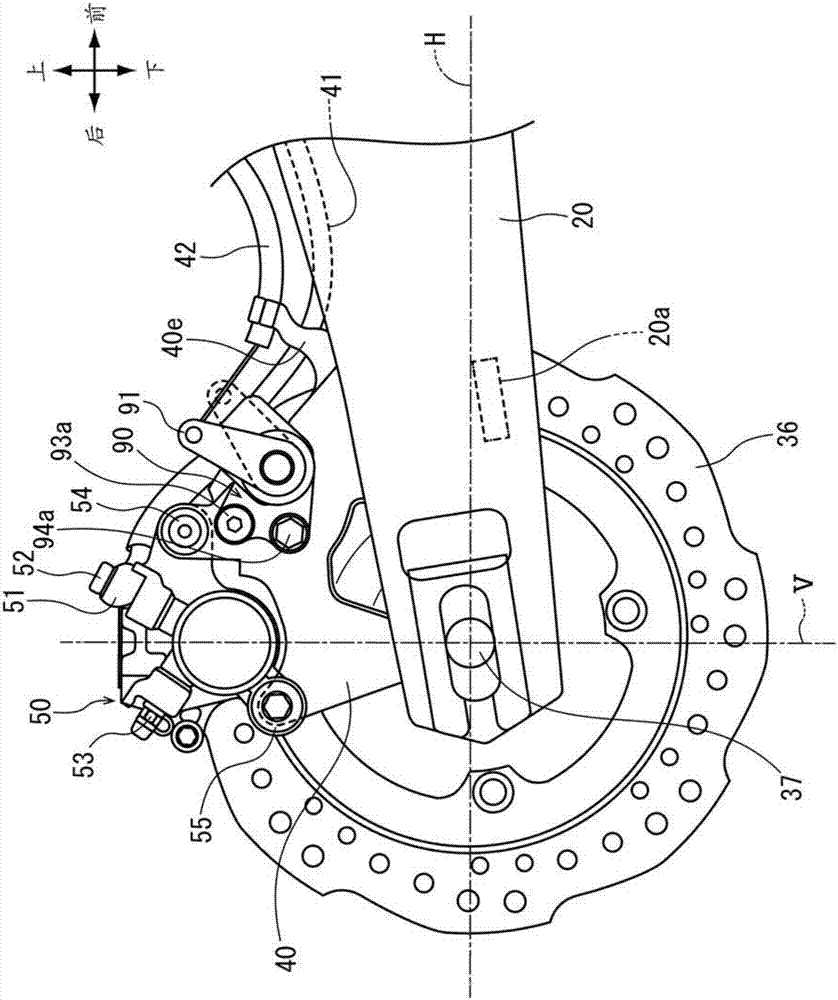

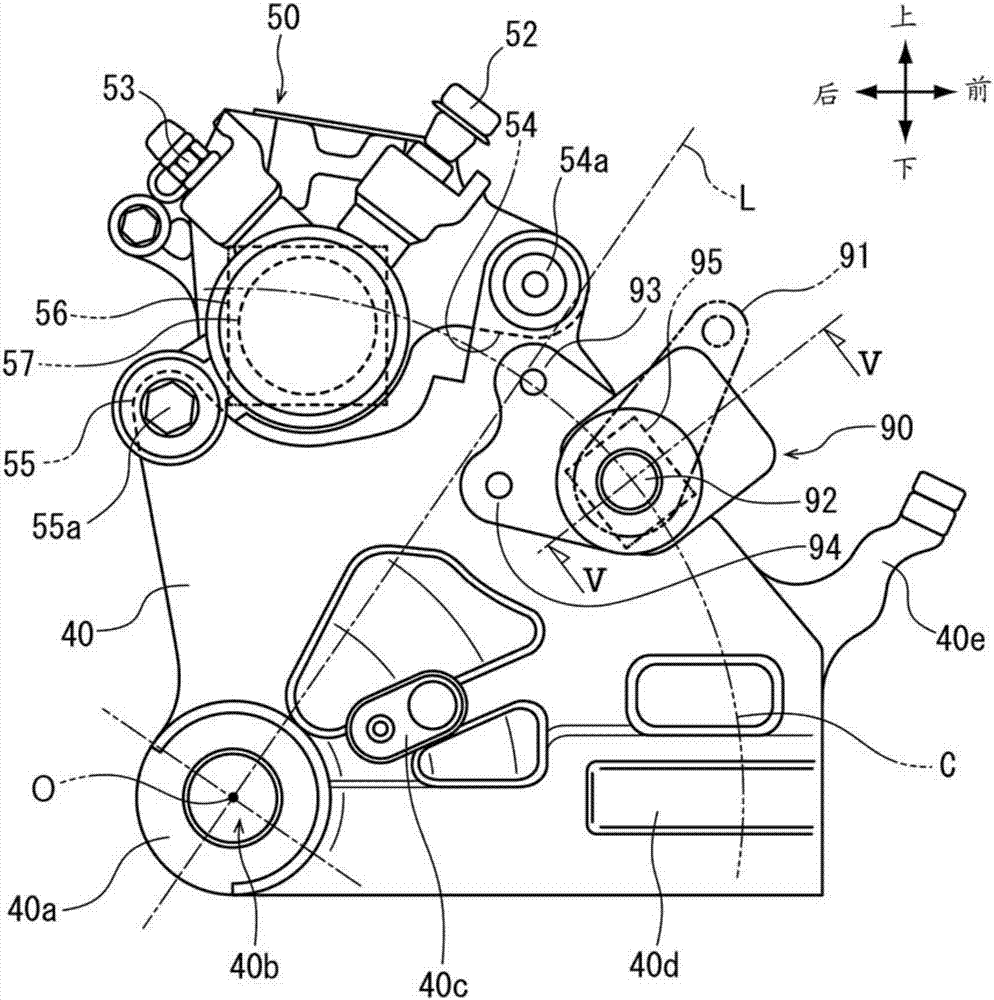

Rear brake device of vehicle

InactiveCN107878658ARealization of small size and light weightReduce pipingAxially engaging brakesMotorised scootersCalipersParking brake

A rear brake device of a vehicle is provided. A service brake caliper (50) and the parking brake caliper (hereinafter called P caliper) (90) are supported by a swing arm (20) rotatably supporting therear wheel (WR). The service brake caliper (50) and the P caliper (90) are configured to brake the brake disc (36). In the rear brake device of the vehicle, the service brake caliper (50) and the P caliper (90) are fixed to a stay member (40), the stay member (40) being supported by the swing arm (20). At least some of the service brake caliper (50) and the P caliper (90) are arranged in positionsforward of a vehicle body and upward of the vehicle body from an axle (37) of the rear wheel (WR). A first boss (54) and a third boss (93) are arranged on a straight line (L) passing through a centerpoint (O) of the axle (37).

Owner:HONDA MOTOR CO LTD

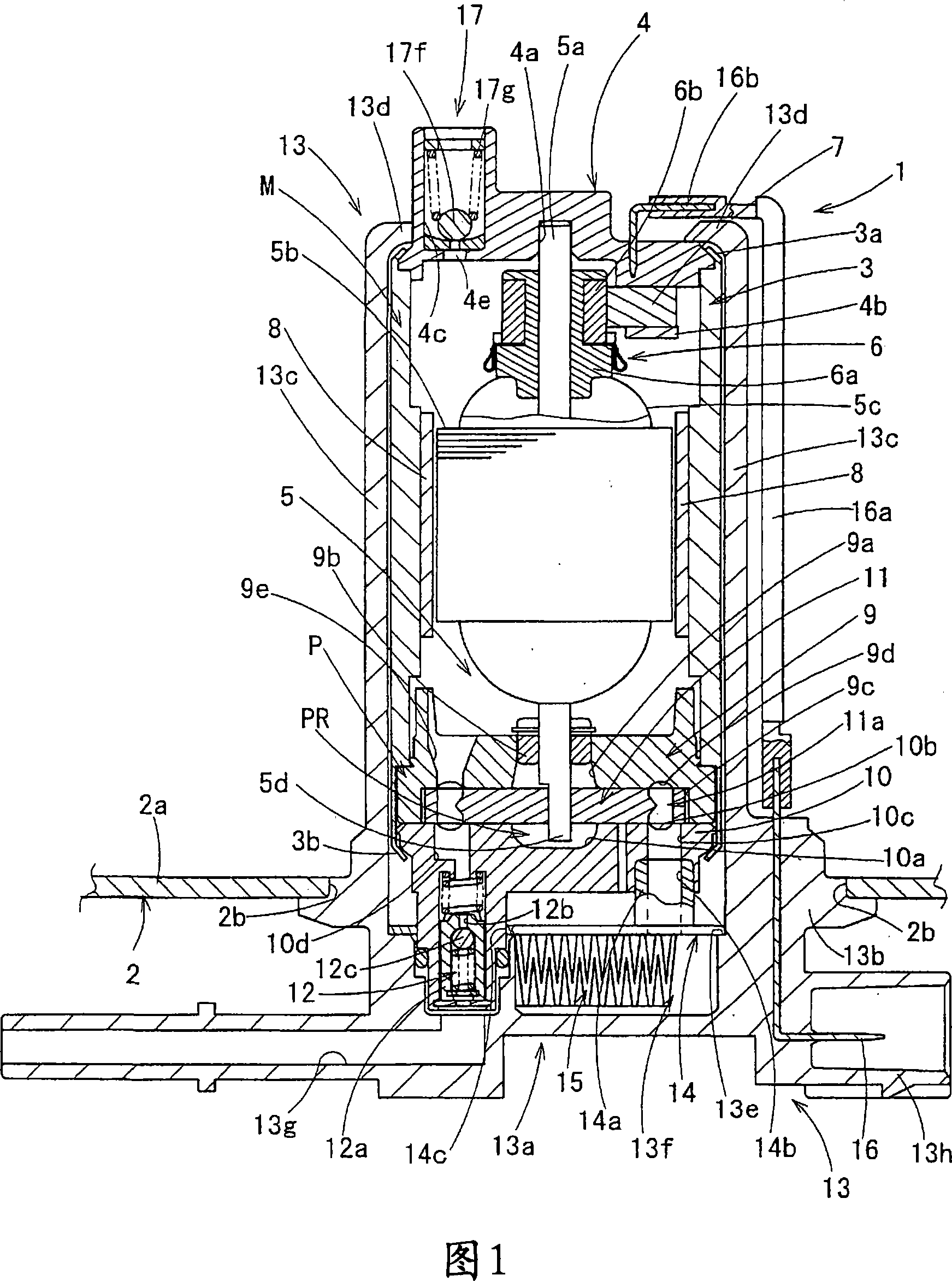

Fuel pump

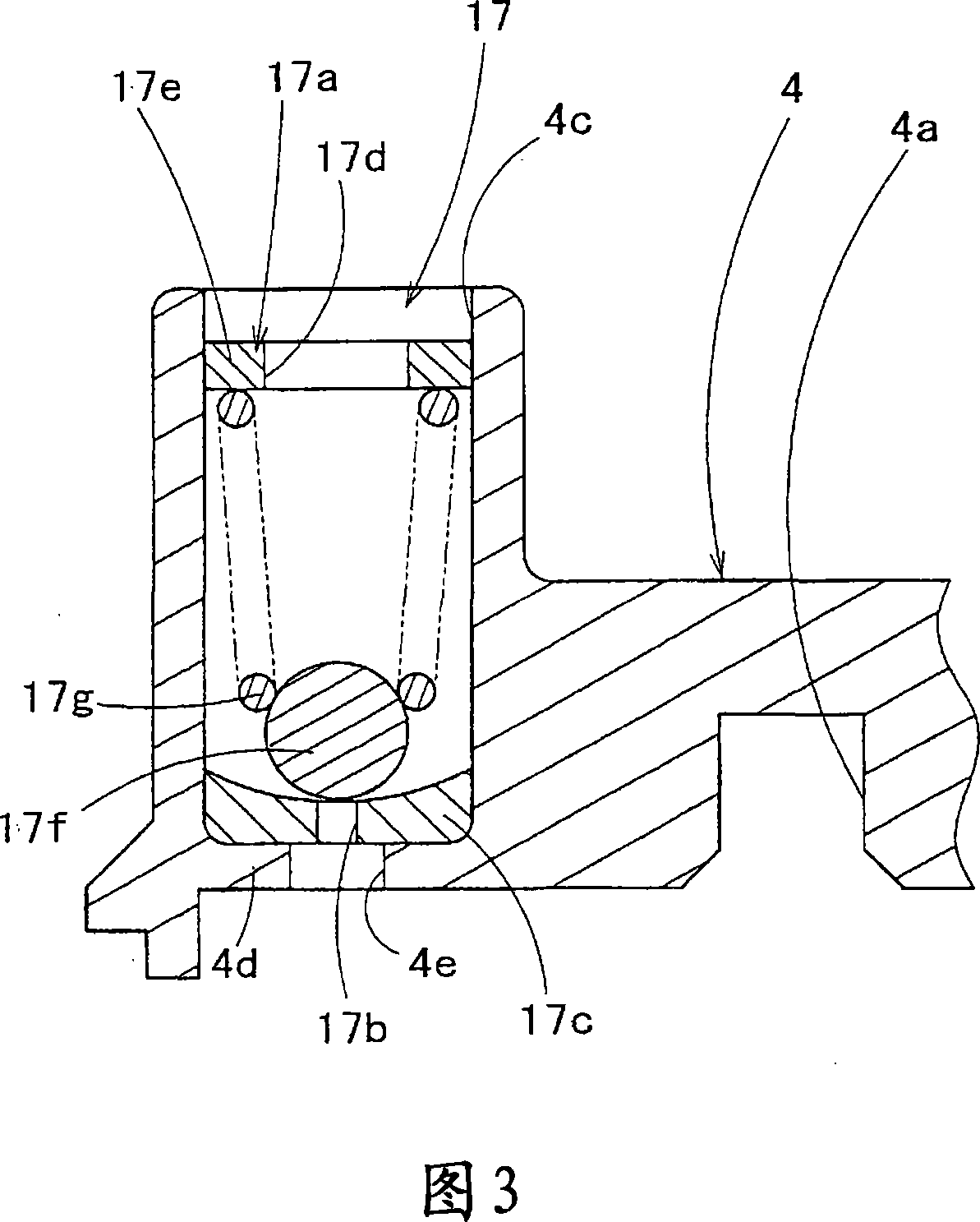

InactiveCN101213362AIncreased durabilityReduce pipingCircumferential flow pumpsTransverse flow pumpsEngineeringFuel supply

A fuel pump enabling a reduction in the size of a fuel feeder and an increase in the durability thereof. The fuel pump (1) comprises a pump part (P) disposed on the lower part of a cylindrical yoke (3) and a brush type motor part (M) disposed on the upper part of the yoke (3) and driving the pump part (P). A pump bracket (10) covering the pump part (P) side end part of the yoke (3) comprises a fuel suction part (10c) sucking a fuel into the pump part (P) and a fuel discharge part (10d) discharging the fuel to the outside of the pump part (P). An upper side bracket (4) forming the motor part (M) comprises a pressure regulating device (17).

Owner:MITSUBA CORP +1

Humidifier for fuel cell system

InactiveUS7838160B2Quick thawReduce pipingFuel cell auxillariesIsotope separationFuel cellsProduct gas

A humidifier of the present invention includes a humidifier main body for humidifying a second fluid, using a humidified first fluid discharged from a fuel cell; a head portion of which one end is connected to an end of the humidifier main body and the other end is connected to the fuel cell or a supply passage extending from the fuel cell, and which supplies the second fluid after humidification to the fuel cell; and a chamber for communicating a bottom portion of a humidified gas flow passage formed within the head portion.

Owner:HONDA MOTOR CO LTD

Cooling system and method for polycrystalline silicon reduction furnace

The invention discloses a cooling system and method for a polycrystalline silicon reduction furnace. The system comprises a reduction furnace body and a heat exchanging device, wherein the reduction furnace body comprises a bell jar and a chassis; the bell jar is provided with a first inlet for cooling water and an outlet for bell jar high-temperature water; the chassis is provided with a second inlet for the cooling water and an outlet for chassis high-temperature water; the outlet for the chassis high-temperature water is connected with the first inlet for the cooling water and / or the second inlet for the cooling water; the heat exchanging device is provided with an inlet for the bell jar high-temperature water and an outlet for cooling water after heat exchange; the inlet for the bell jar high-temperature water and the outlet for the bell jar high-temperature water are connected; the outlet for the cooling water after heat exchange is connected with the first inlet for the cooling water and / or the second inlet for the cooling water. Through adopting the system, not only is the pipeline of an existing cooling system for the polycrystalline silicon reduction furnace is remarkably simplified, butthe efficient and graded recycling of the energy of the bell jar high-temperature water and the chassis high-temperature water is also realized; meanwhile, the remote recycling amount of the polycrystalline silicon reduction furnace cooling water is remarkably reduced, and the safe and stable operation of the polycrystalline silicon reduction furnace is realized.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

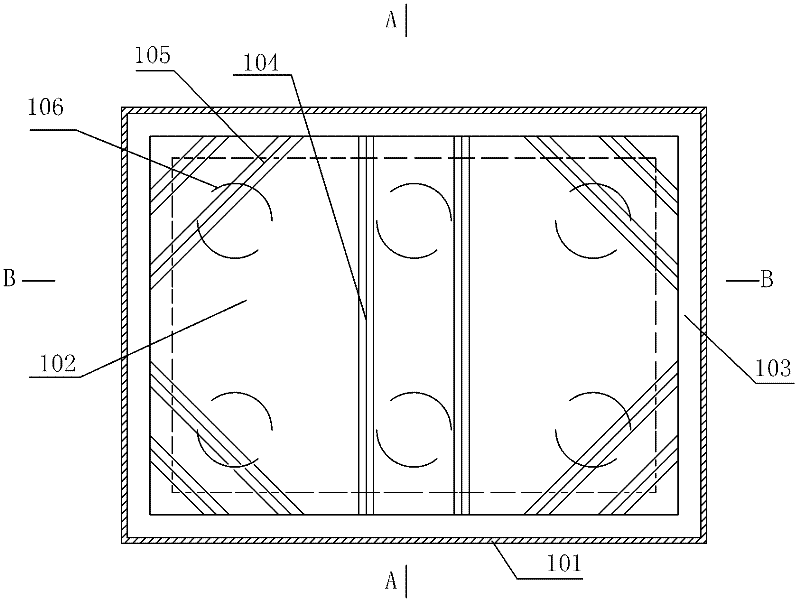

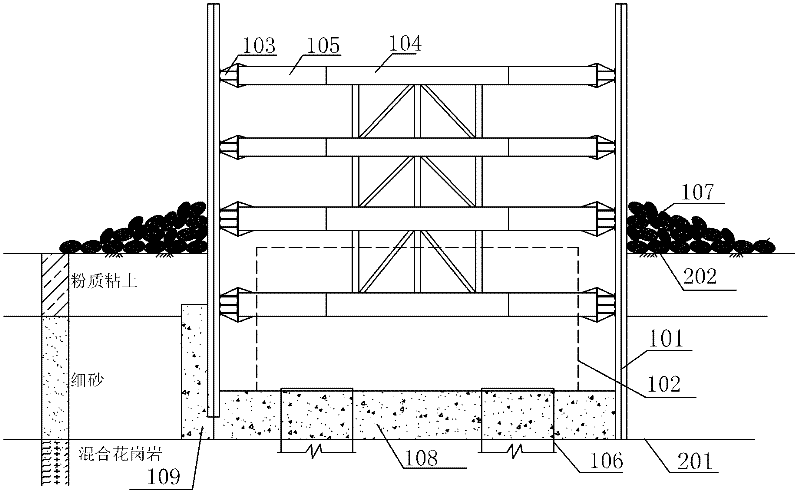

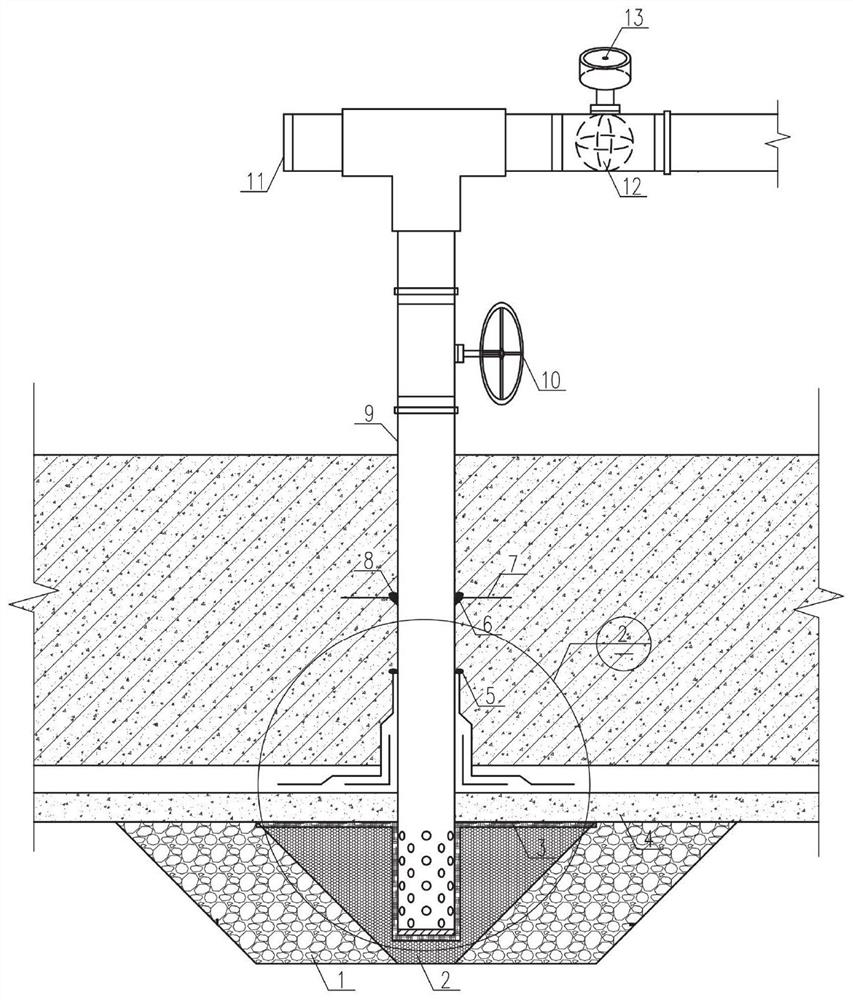

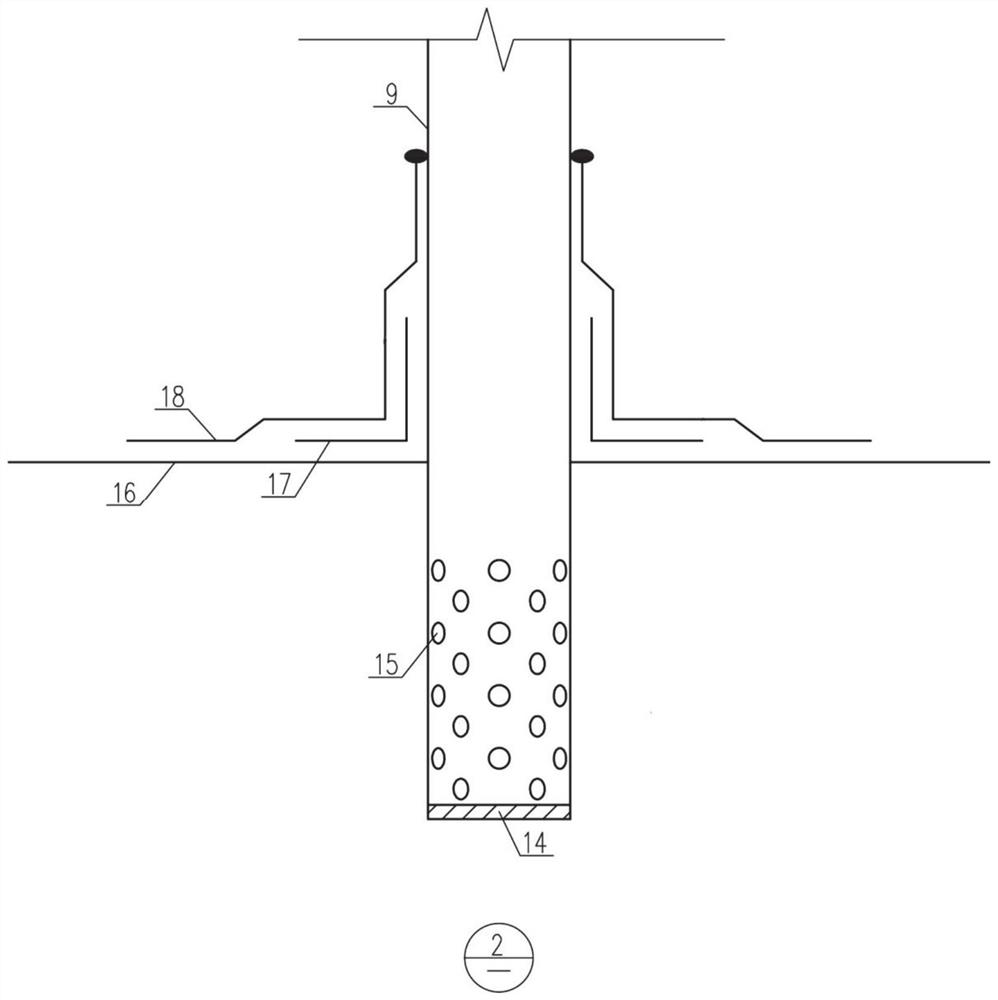

Automatic underground water pressure control device suitable for underground structure and construction mode

PendingCN113202121AGuaranteed to oozeForce is not affectedFoundation engineeringFiltration circuitsArchitectural engineeringPipe

The invention discloses an automatic underground water pressure control device suitable for a underground structure and a construction mode. The automatic underground water pressure control device comprises a steel pipe, wherein a bottom sealing steel plate is arranged at the bottom of the steel pipe, a plurality of screen holes are evenly formed in the bottom of the side wall of the steel pipe, a reinforced waterproof layer is arranged on the lower middle portion of the outer side wall of the steel pipe, the flexible waterproof layer and the flexible waterproof reinforcing layer are fixedly bonded through a double-faced self-adhesive adhesive tape, a water stop flange is arranged in the middle of the steel pipe, a filter screen cleaning plug is installed at the output end of one side of the T-shaped flow dividing pipe, and an automatic pressure relief and drainage ball valve is installed on a pipeline connected with the output end of the other side of the T-shaped flow dividing pipe. According to the automatic underground water pressure control device, a user can reduce anti-floating facilities in the underground structure design stage, and the manufacturing cost is saved; on-demand precipitation is realized in the use stage and the unloading and redevelopment stage, so that the use safety of the underground structure is effectively ensured; and in the construction stage, compensation precipitation can be effectively carried out, and the problems of local precipitation well damage and poor precipitation well effect in the construction stage are solved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

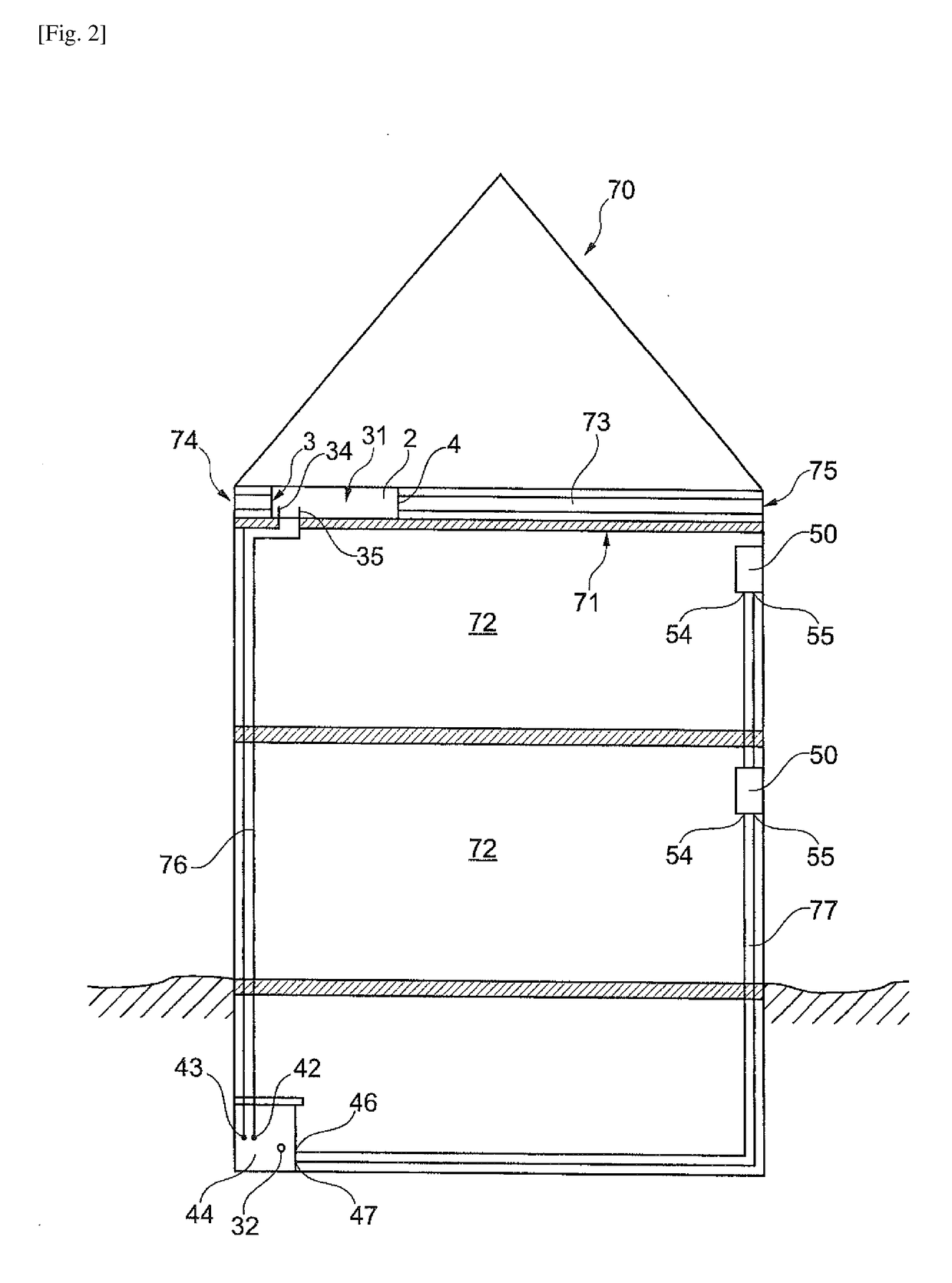

Arrangement of radiator of small size motorcycle

InactiveCN1152795CReduce pipingIncrease the areaPassenger cyclesMachines/enginesHeat spreaderAutomotive engineering

This invention provides a radiator disposing structure of motor scooter type vehicle located in a place such that it can catch a wind easily and occupy a large area, and further, capable of shortening the length of the piping between the engine and the radiator. A scooter type vehicle comprises low deck type footrests 3 between a handle 1 and a seat 2, and a water-cooled engine 4 at the bottom of a body. An engine-cooling radiator 42 with large lateral width is located downwardly of the footrest surface of said footrest.

Owner:YAMAHA MOTOR CO LTD

Compressor unit, heat source unit, and air conditioner

InactiveUS20180128505A1Improve efficiencyIncrease installation costHeat pumpsCompression machines with reversible cycleEngineeringRefrigerant

A compressor unit for an air conditioner includes a compressor disposed in a first casing, and first and second heat source heat exchanger unit ports configured to connect the compressor unit to a heat source heat exchanger of a heat source heat exchanger unit of the air conditioner, the heat source heat exchanger being disposed in a second casing separate from the first casing and being configured to exchange heat with a heat source, first and second indoor unit ports configured to connect the compressor unit to an indoor heat exchanger of at least one indoor unit of the air conditioner, a first refrigerant piping fluidly connecting the first heat source heat exchanger unit port and the first indoor unit port, and a sub-cooling heat exchanger disposed inside the first casing and fluidly connected to the first refrigerant piping for heat transfer with the refrigerant to be flown through the first refrigerant piping.

Owner:DAIKIN IND LTD +1

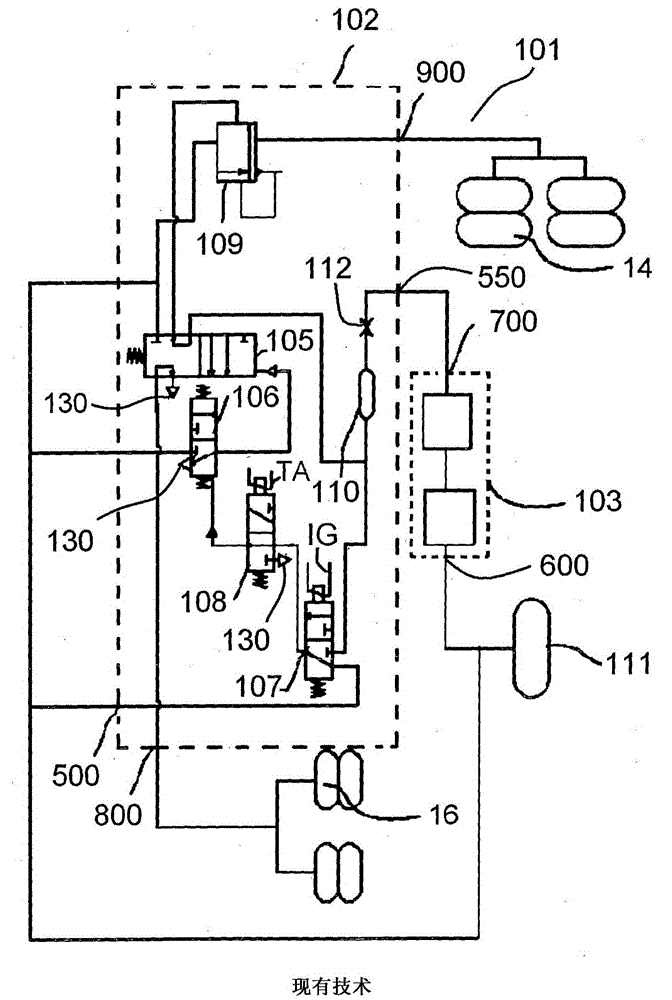

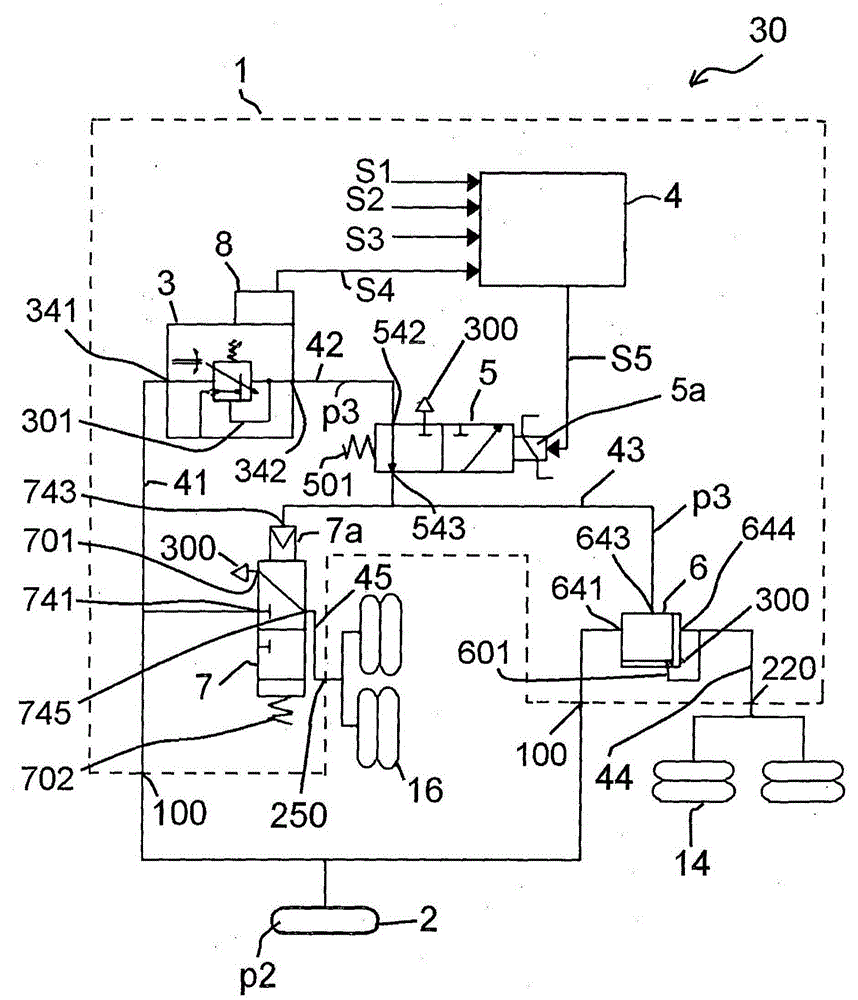

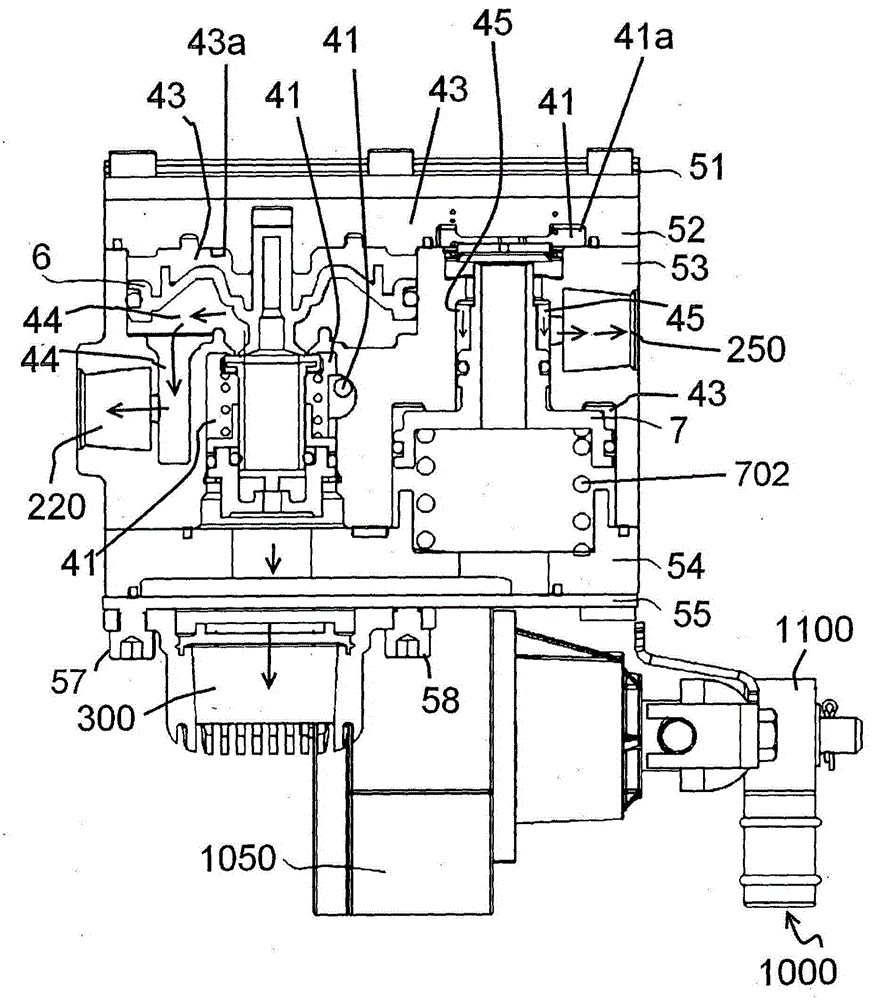

Lift axle control unit for a motor vehicle

ActiveCN105392646AReduce hardware costsReduce pipingResilient suspensionsTrucksMotor vehicle partElectronic control unit

The invention refers to a lift axle control unit (1) for a lift axle suspension system (30) of a vehicle (1000), said lift axle control unit (1) comprising at least: an electronic control unit (4) receiving at least a first electric input signal (S1) and a position indicating signal (S4), at least one supply input port (100) to be connected to a pressure reservoir (2), a first delivery port (220) to be connected to at least one suspension bellow (14) and a second delivery port (250) to be connected to at least one lift bellow (16), a load detection valve (3) being connectable to load variable parts (1010) of said vehicle (1000) and delivering an pressure output signal (p3) in dependence of an axle load of the vehicle (1000), a first relay valve (6) connected to said first delivery port (220) for feeding said suspension bellow (14), a second relay valve (7) connected to said second delivery port (250) for feeding at least one lift bellow (16), a solenoid valve (5) for receiving an electric control signal (S5) from said electronic control unit (4) and for connecting said load detection valve (3) to said first and second relay valve (6, 7) or separating it from said first and second relay valve (6, 7) in dependence of said electric control signal (S5).

Owner:WABCO TVS (INDIA) LIMITED

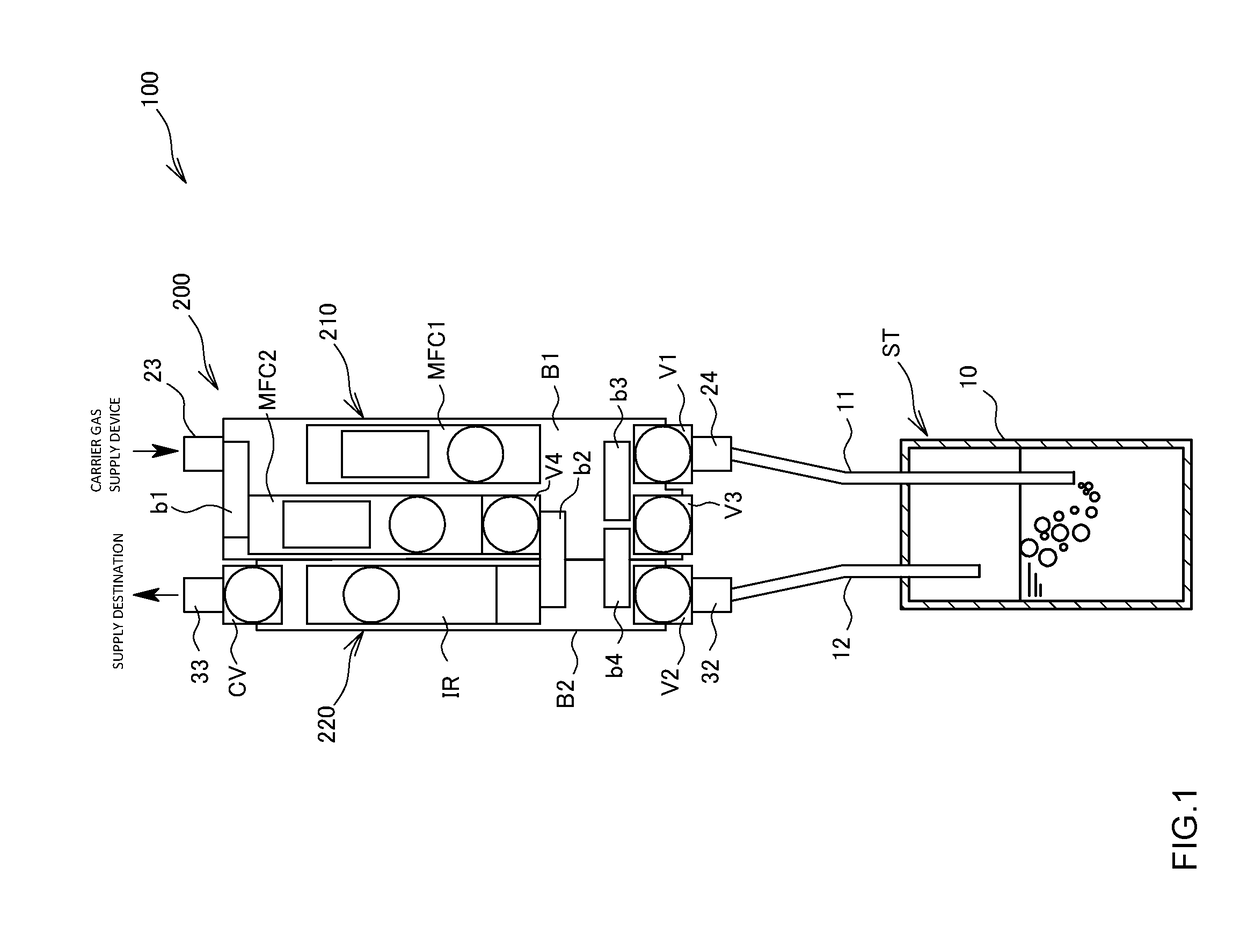

Concentration control apparatus and material gas supply system

ActiveUS20190085444A1Reduce pipingImprove responsivenessVacuum evaporation coatingSputtering coatingVaporizationEngineering

Provided is a concentration control apparatus that, without reducing maintainability, can shorten piping to improve responsiveness. The concentration control apparatus is one adapted to introduce carrier gas into a storage tank storing a material, and control the concentration of material gas that is led out of the storage tank as mixed gas with the carrier gas and results from vaporization of the material. Also, the concentration control apparatus includes: a first unit that controls the flow rate of the carrier gas to be introduced into the storage tank; and a second unit that detects the concentration of the material gas led out of the storage tank.

Owner:HORIBA STEC CO LTD

an oil control body

ActiveCN103397924BReduce pipingSimple structureMachines/enginesPressure lubricationButt jointPetroleum engineering

The invention discloses an engine oil control body. The engine oil control body comprises a filter oil inlet connector, a filter oil outlet connector, a cooler oil inlet connector, a cooler oil outlet connector, a main oil channel oil inlet connector, an engine oil pump oil outlet connector, a first lubricating oil channel, a second lubricating oil channel and a third lubricating oil channel, wherein the first lubricating oil channel, the second lubricating oil channel and the third lubricating oil channel are arranged inside the engine oil control body, the first lubricating oil channel is communicated with the engine oil pump oil outlet connector and the cooler oil inlet connector, the second lubricating oil channel is communicated with the cooler oil outlet connector and the filter oil inlet connector, and the third lubricating oil channel is communicated with the filter oil outlet connector and the main oil channel oil inlet connector. An engine oil pump, a filter, a cooler and an engine main oil channel can be directly installed to the engine oil control body in a butt joint mode, a pipeline does not need to be arranged, the structure of a whole lubricating system is simplified, and appearance is beautified. The lubricating oil channels are arranged inside the engine oil control body to form an integral module and are not mutually interfered, and the state is stable. In addition, the engine oil control body serves as a supporting mechanism of the cooler and the filter, and the structure for supporting the cooler and the filter does not need to be specially arranged.

Owner:WEICHAI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com