Hydraulic loop for multifunctional tool of excavator

A hydraulic circuit and multi-functional technology, applied in the field of excavator hydraulics, can solve the problems of low utilization rate, unusable, labor-intensive and time-consuming problems of a single set of pipelines, and achieve the effect of improving maintainability, improving utilization rate and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

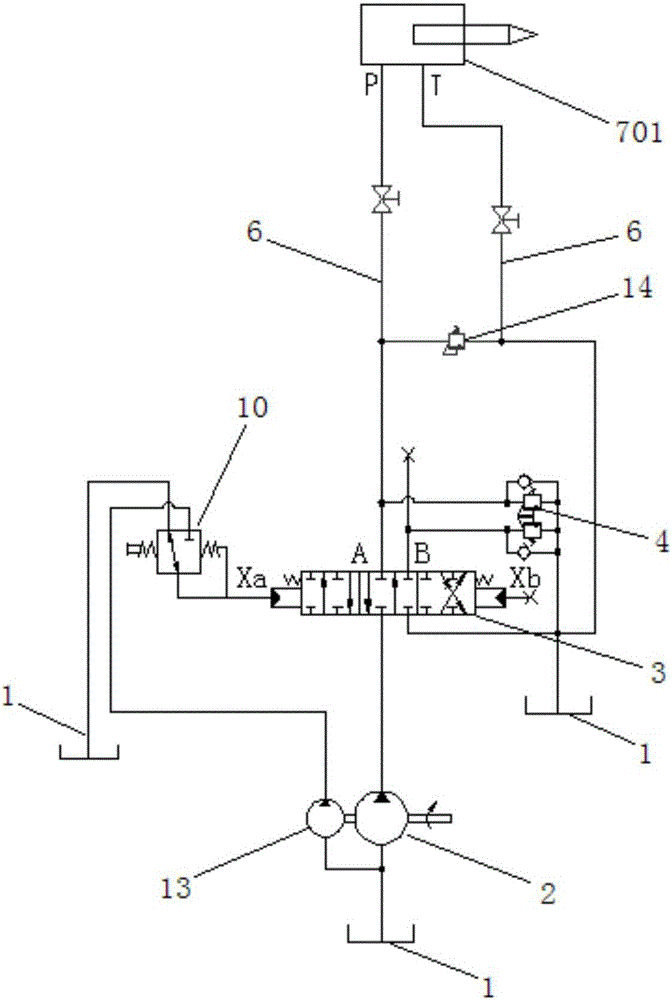

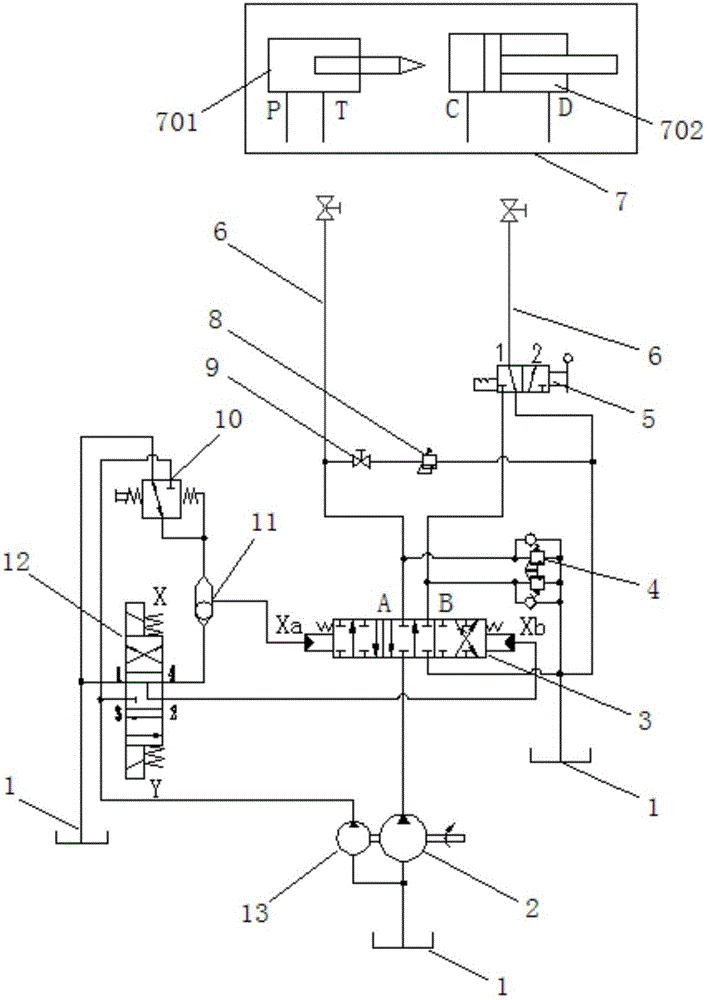

[0017] refer to figure 2 , the specific embodiment adopts the following technical solutions: a hydraulic circuit for excavator multi-functional tools, including a hydraulic oil tank 1, a main pump 2, a spare valve core 3, a port overflow valve 4, and a two-position three-way reversing valve 5. Working device pipeline 6, multi-function machine tool 7, crushing overflow valve 8, stop valve 9, crushing pilot control valve 10, shuttle valve 11, pilot solenoid valve 12 and pilot pump 13, Xa pilot side of spare spool 3 Connect with the shuttle valve 11, the two ends of the shuttle valve 11 are respectively connected with the crushing pilot control valve 10 and the pilot solenoid valve 12, when different pilot control units control the same valve core and the same position through the pressure signal, the pressure signal is selected through the shuttle valve 11 and transmission; the Xb pilot side of the spare spool 3 is connected to the pilot solenoid valve 12, and the X side and Y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com