Flow rate control device

A fluid control device and fluid technology, applied to valve devices, fuel injection devices, valve operation/release devices, etc., can solve problems such as the reduction of engine operating frequency, and achieve the effects of reducing piping, reducing costs, and suppressing pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

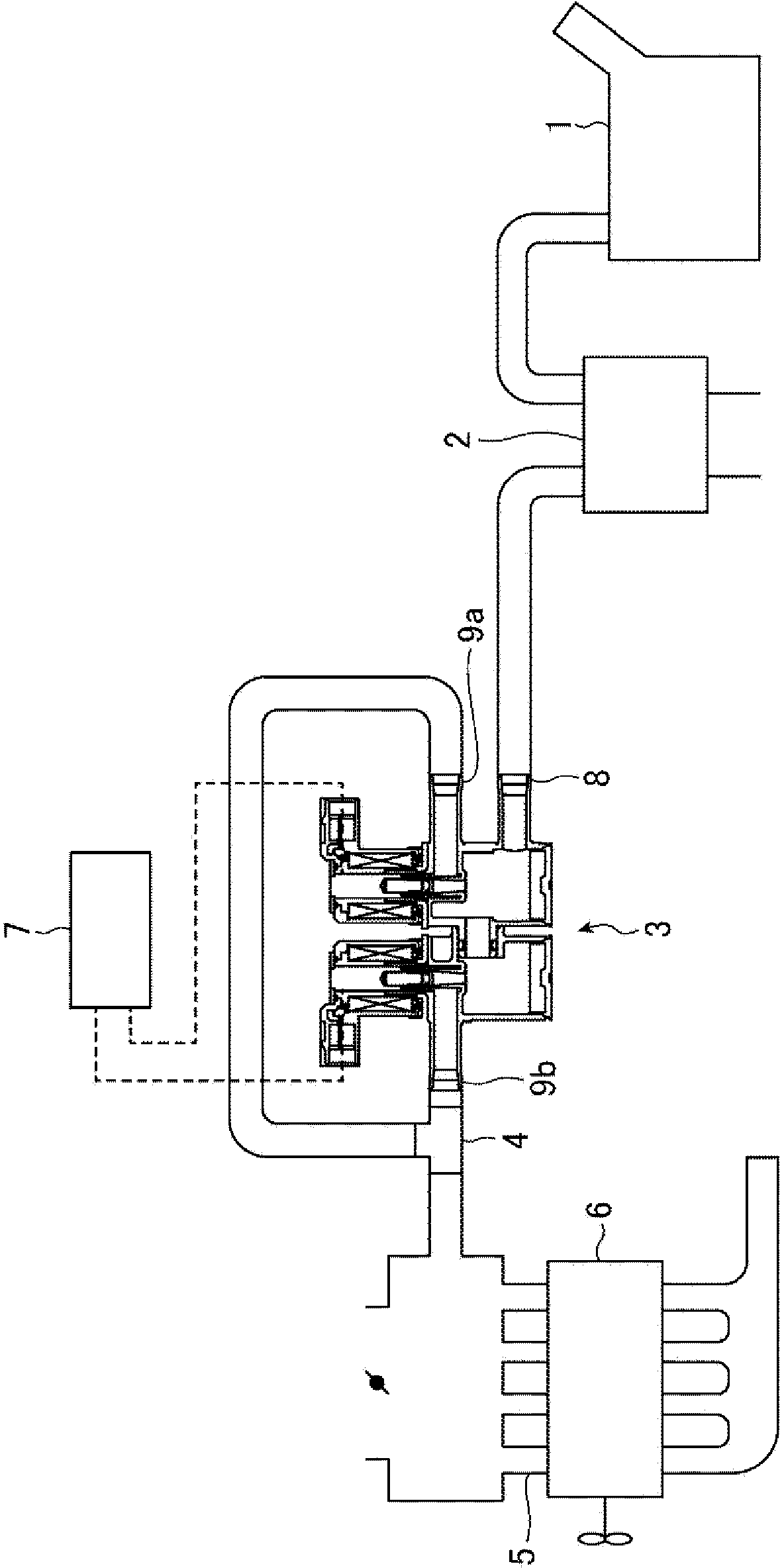

[0030] exist figure 1 In the shown boil-off gas treatment system, boil-off gas generated in a fuel tank 1 is temporarily adsorbed in a device called a carbon canister 2 using activated carbon. After the engine 6 is started, combustion occurs when the mixture of absorbed air and evaporated gasoline flows from the carbon canister 2 into the engine 6 due to the negative pressure of the intake manifold 5 . At this time, the flow control device 3 controls the flow rate of the air-fuel mixture introduced from the canister 2 to the engine 6 according to the driving signal of the control unit 7 .

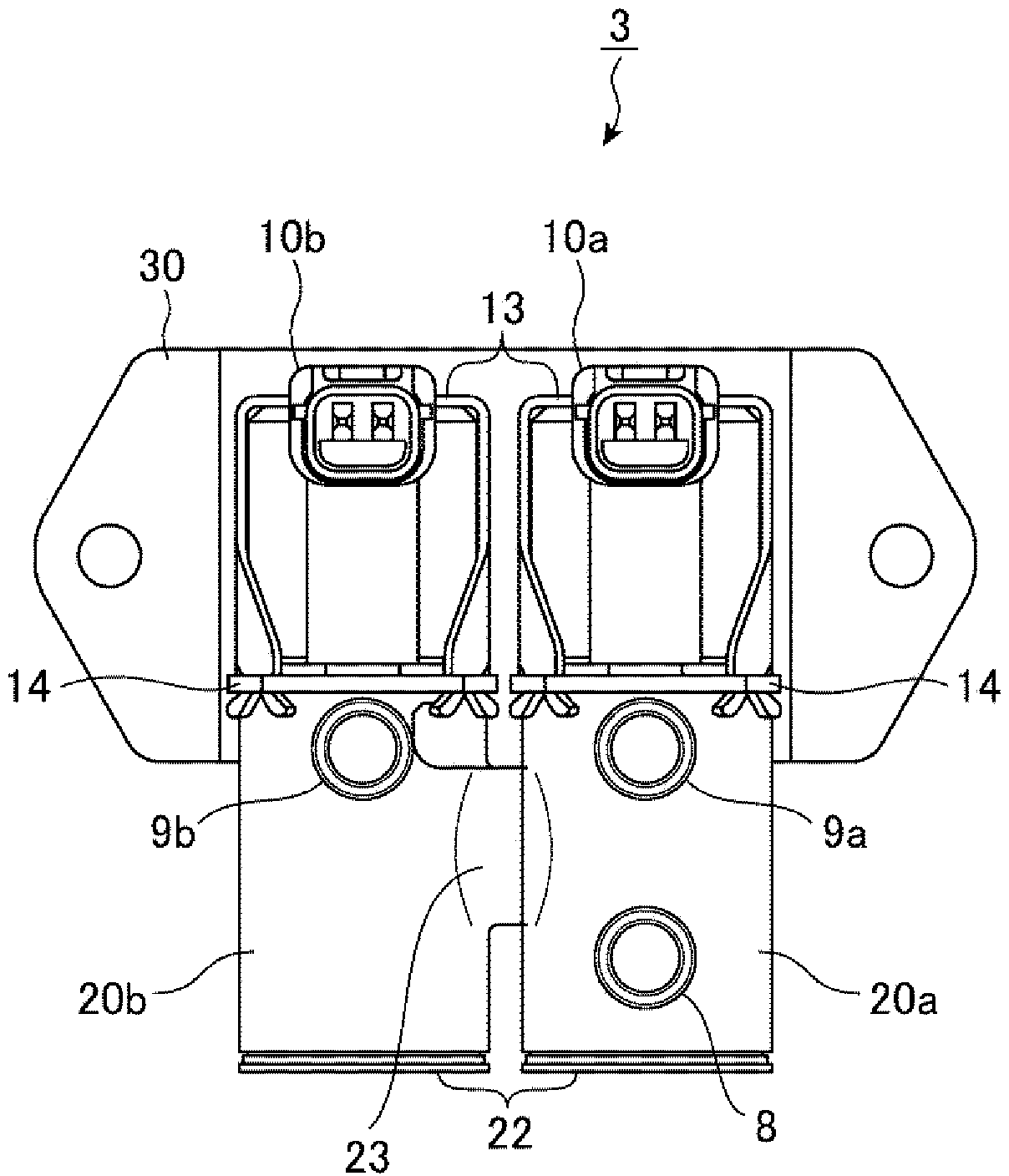

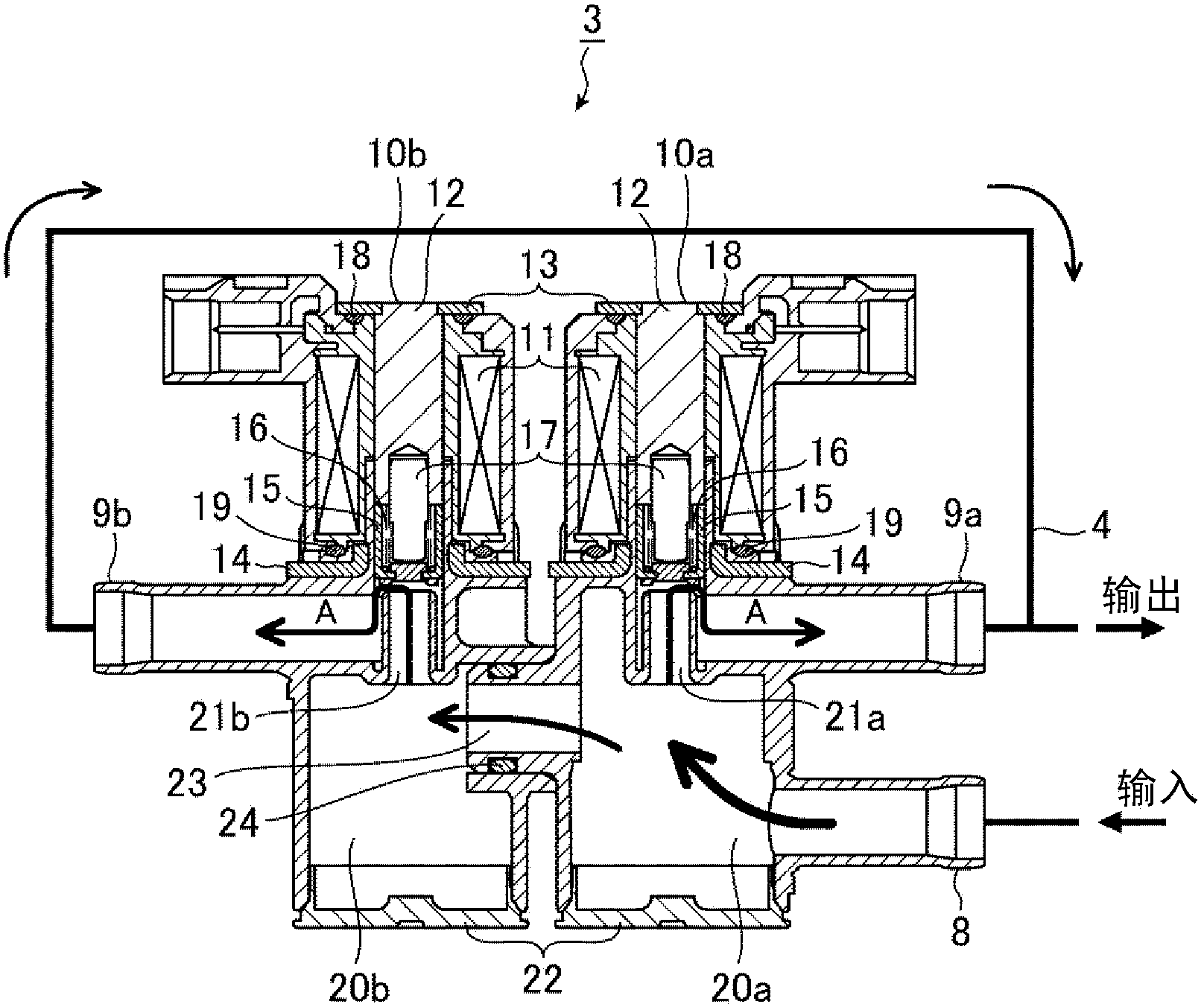

[0031] figure 2 is a front view showing the structure of the flow control device 3, image 3 is a sectional view. This flow control device 3 is a structural example in which two solenoid valves are combined, and one solenoid valve is constituted by the solenoid part 10a and the chamber 20a, and one solenoid valve is constituted by the solenoid part 10b and the chamber 20b. There is one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com