Patents

Literature

32results about How to "Quick degassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for the production of a sandwich component having a honeycomb core and the sandwich component obtained in this way

InactiveUS20090252921A1Improve adhesionEnhance layeringLamination ancillary operationsSynthetic resin layered productsShell moldingAdhesive

The invention relates to a method for the production of a fiber reinforced sandwich component (10) having a honeycomb core (12), the honeycombs of which are closed on both sides. The honeycomb core is closed at least on one side by a cover layer (14) made of fiber material, which is embedded in matrix material. The method comprises the following steps: —Producing a fabric comprising the honeycomb core and at least on one side of the honeycomb core, disposed from the inside to the outside, a curable adhesive layer (20), a barrier layer (16) and a fiber layer (14); —Locking the fabric on a one-sided molding tool (30) in a gastight chamber, which is formed up by a vacuum foil (48) on the one-sided molding tool; —Creating a vacuum in this gastight chamber, —After creating the vacuum, hardening or partial hardening of the adhesive layer between the honeycomb core and barrier layer in this vacuum such that the honeycomb cells (18) are evacuated at least partially before they are closed off by the barrier layer; —After hardening or partially hardening of the adhesive layer, infusion of the fiber layer in a vacuum with a matrix material; and —Hardening of the matrix material in a vacuum.

Owner:EURO COMPOSITES

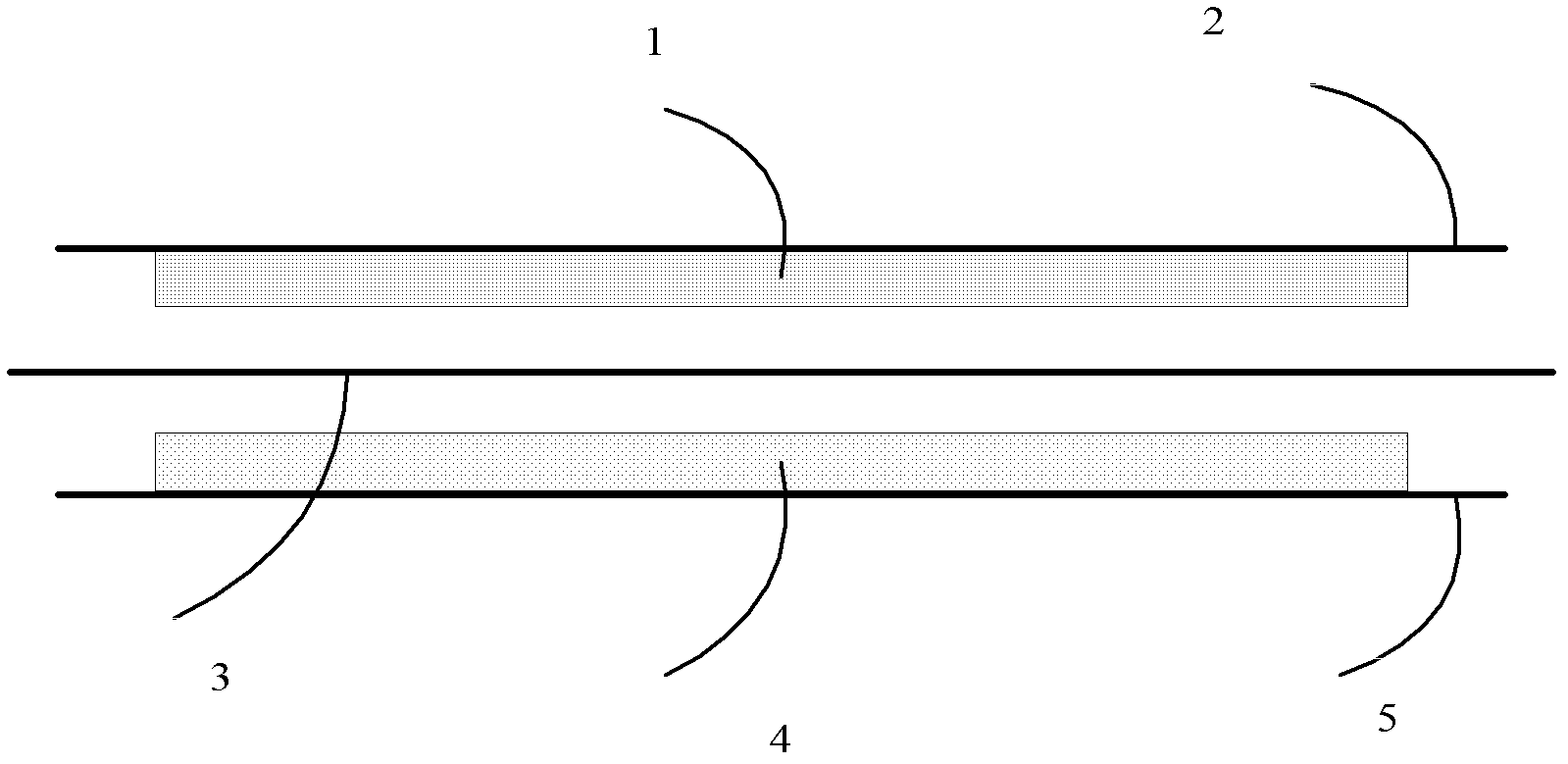

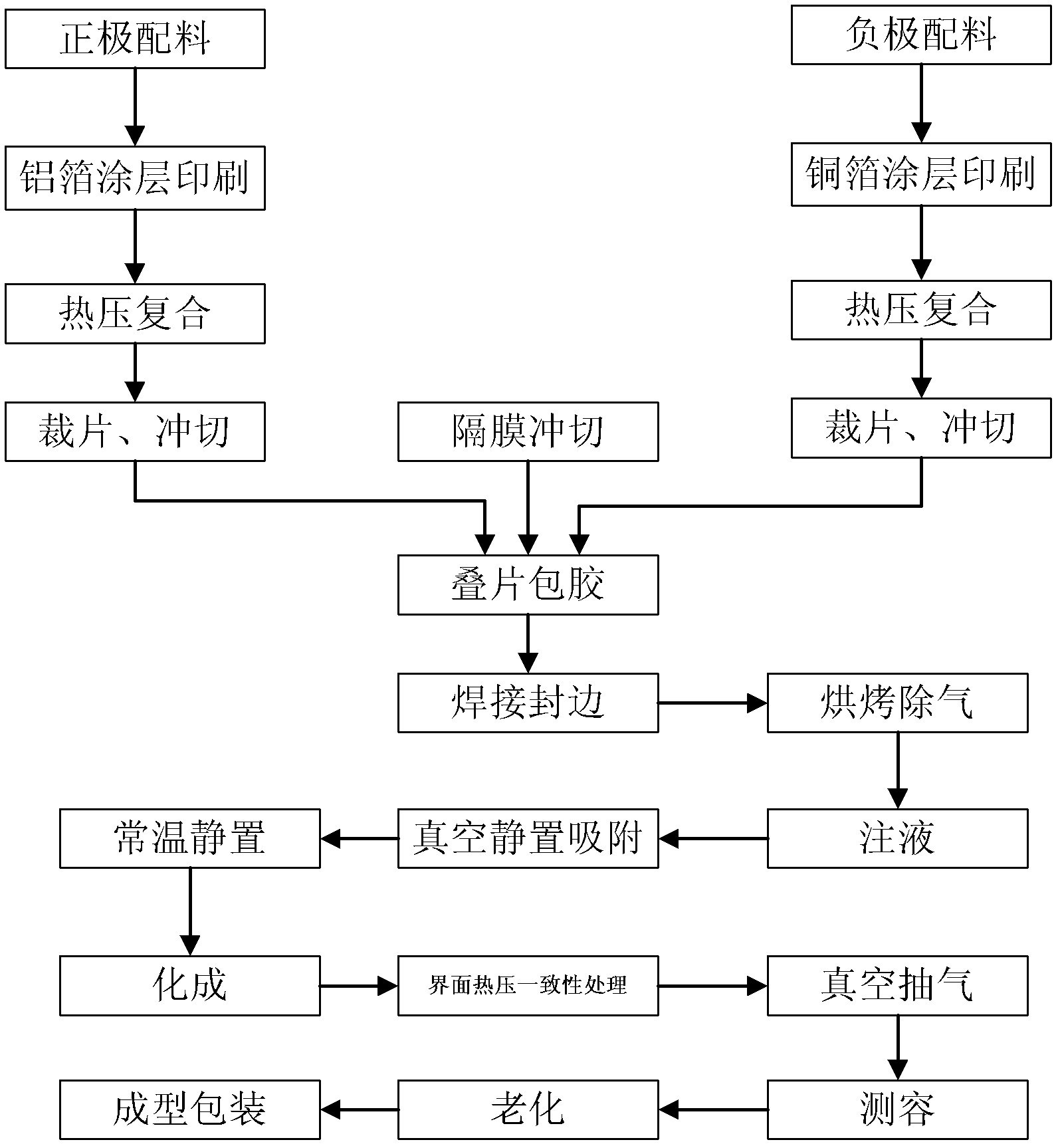

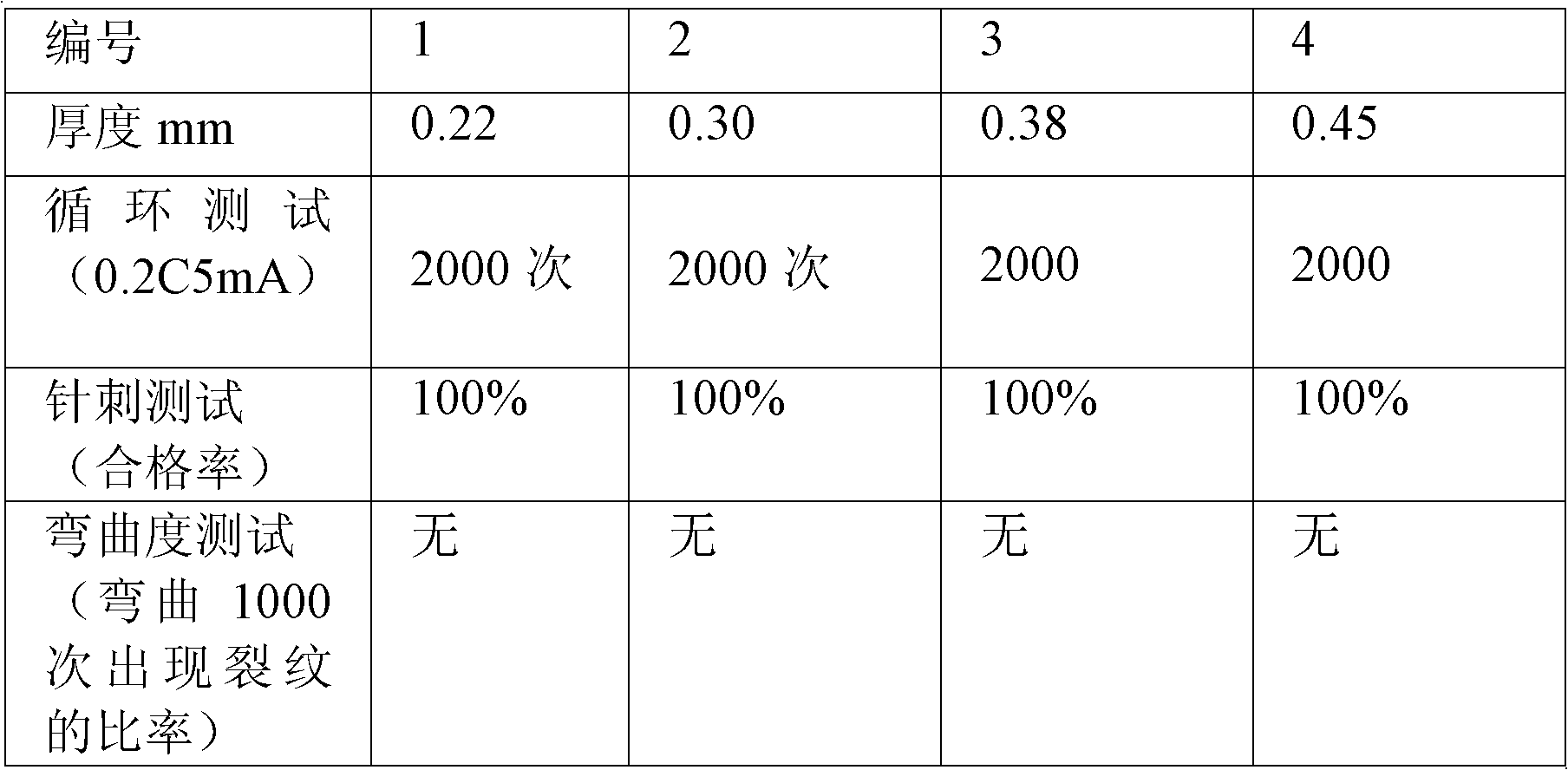

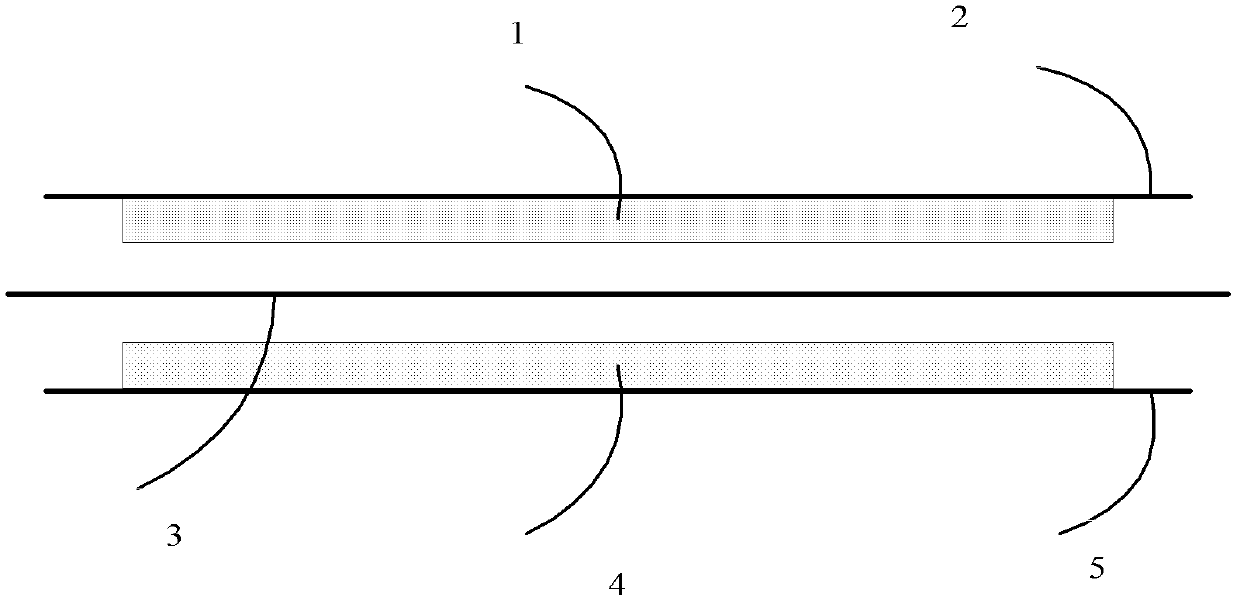

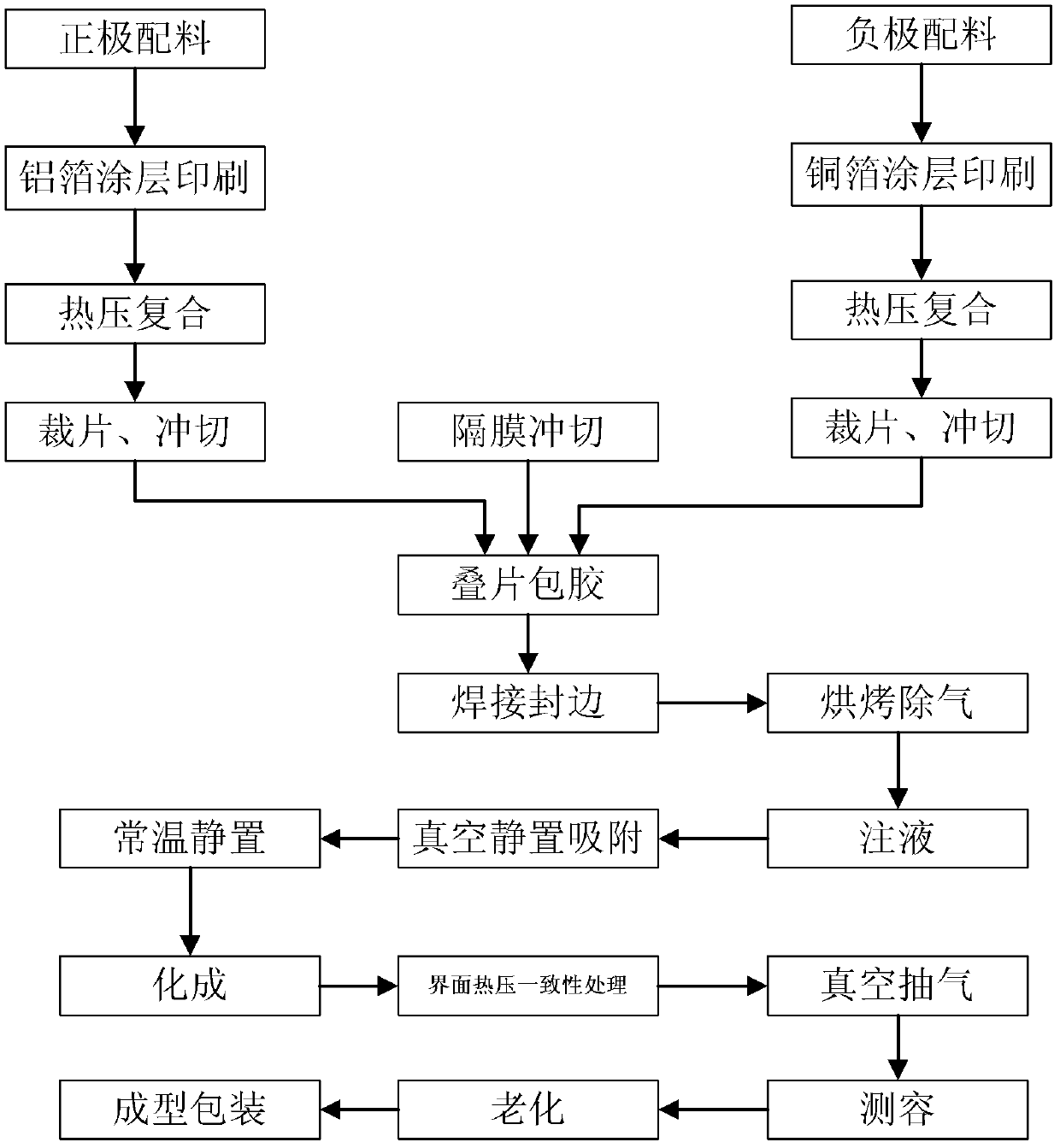

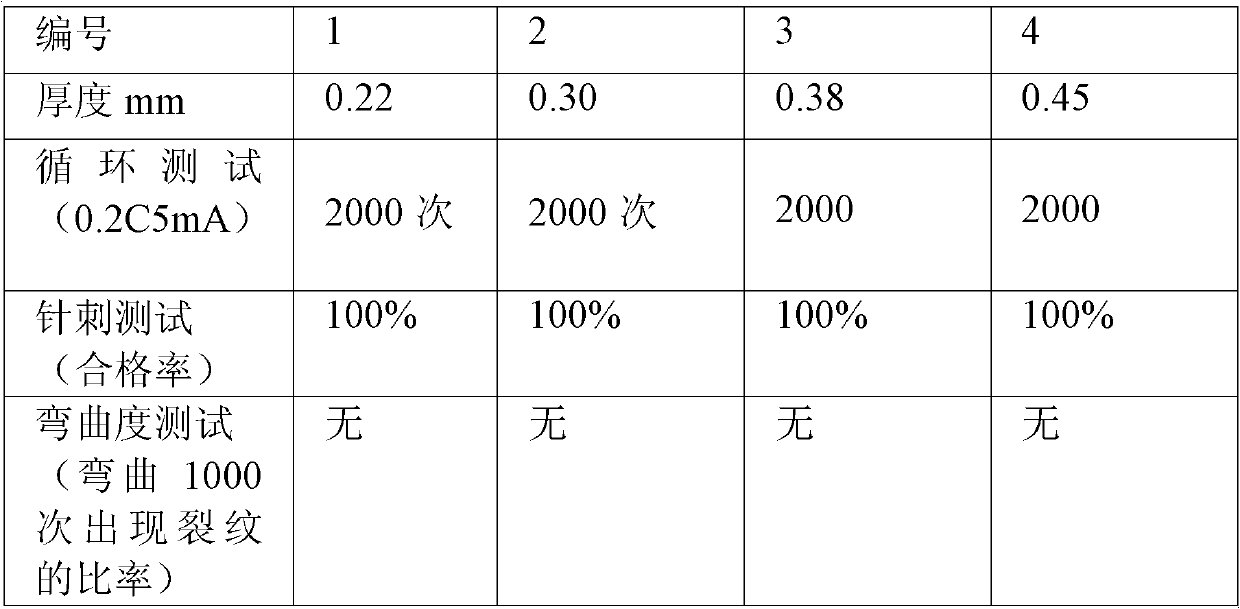

Flexible thin film lithium ion battery and manufacturing method thereof

ActiveCN102522595AImprove securityGood thickness consistencyCell electrodesFinal product manufactureFiberComposite film

The utility model discloses a flexible thin film lithium ion battery and a manufacturing method thereof. The flexible thin film lithium ion battery is composed of a positive layer, a diaphragm, a negative layer and an external packing layer; the positive layer is composed of aluminum foil with a thickness of 16-30 microns and a positive material printed on one surface of the aluminum foil by adopting intaglio printing technology; the negative layer is composed of copper foil with a thickness of 10-30 microns and a negative material printed on one surface of the copper foil by adopting the intaglio printing technology; the external packing layer is an aluminum plastic composite film; the positive material of the battery comprises dispersant Hypermer KD-1; and the negative material of the battery comprises conductive agent vapor-grown carbon fiber. The flexible thin film lithium ion battery provided by the invention has the benefits that the safety is high, the thickness consistency is good, and the thickness of the battery can be controlled and lowered to 0.25MM, besides, the flexibility is good, the performance and the shape of the battery can not be affected even though the flexible thin film lithium ion battery is bent for several times.

Owner:江苏百特福新能源科技有限责任公司

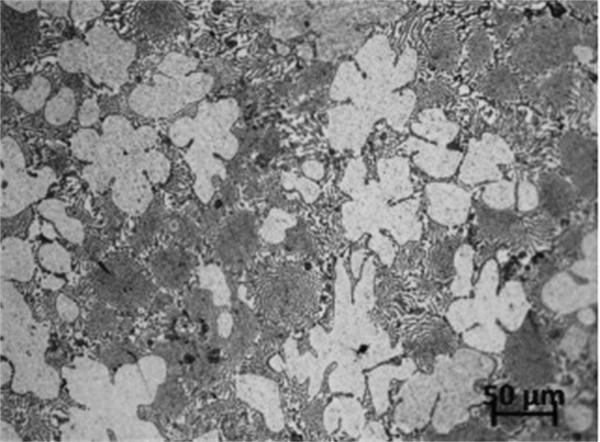

Semi-solid forming and casting technology of aluminum magnesium alloy pot

The invention discloses a semi-solid forming and casting technology of aluminum magnesium alloy pot. The semi-solid smelting of the casting technology adopts the rheological slurry temperature control smelting technology; metal tree crystal is broken up in rheological slurry temperature control smelting by electromagnetic mixing to form spherical crystal, the metal crystalline state as well as the metallic crystal nodularity of the aluminum magnesium alloy pot are improved, so that the aluminum magnesium alloy pot has high strength and high tenacity and is light in weight and firm compared with the traditional cast aluminum magnesium alloy pot; the smelting temperature of semi-solid slurry is low compared with the traditional casting, therefore, not only the energy consumption is greatly saved, but also the service life of casting dies is prolonged; and the aluminum magnesium alloy pot has no bubbles and needle holes on the surface, and the firm part has compact crystal and no casting defects. The technology realizes the semi-solid rheological extrusion forming of the aluminum magnesium alloy pot, and has high production efficiency, therefore, not only the quality of casts and the utilization ratio of materials are improved, but also the surface quality of the product is improved and the interior quality is equivalent to forging products; and the invention is suitable for scale production and has great popularization and application value.

Owner:李扬德

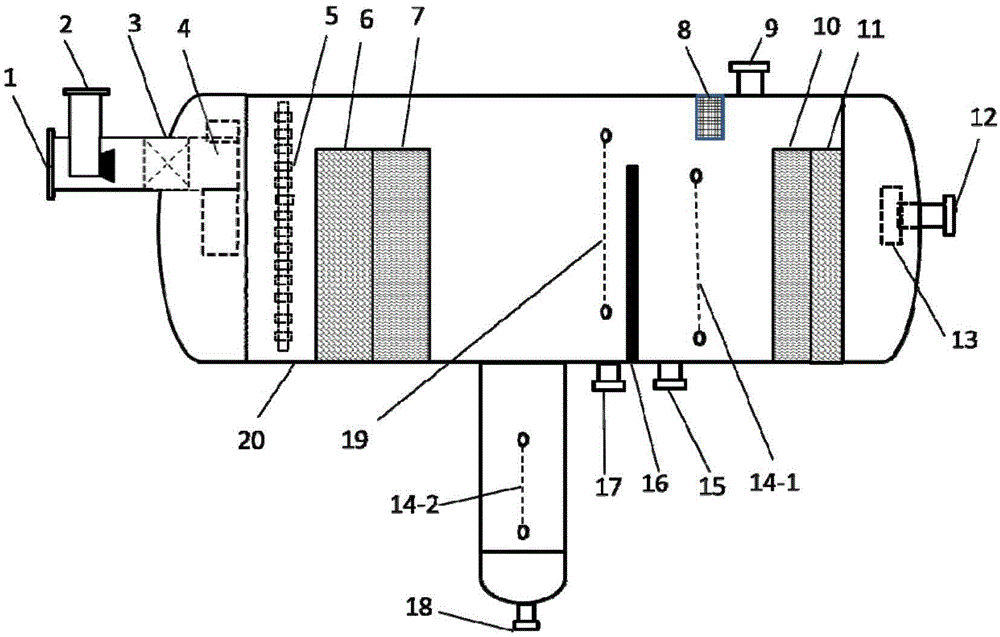

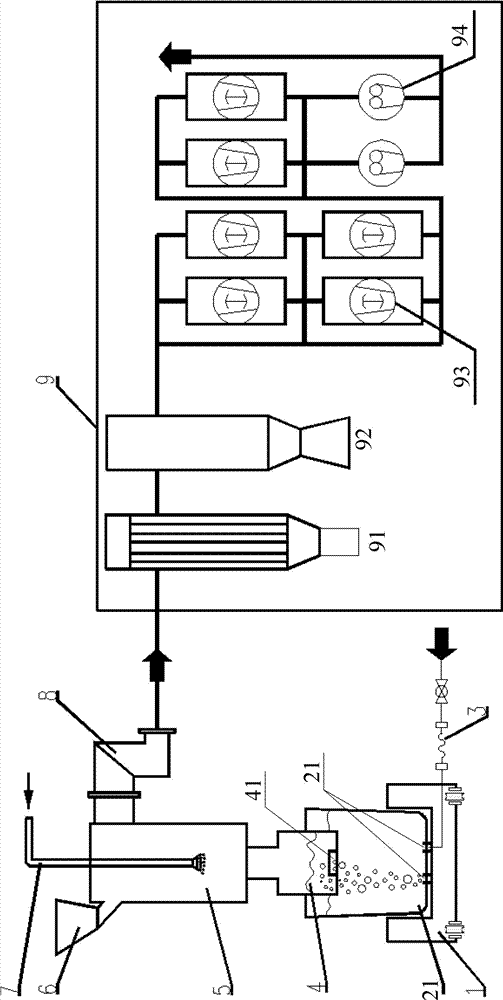

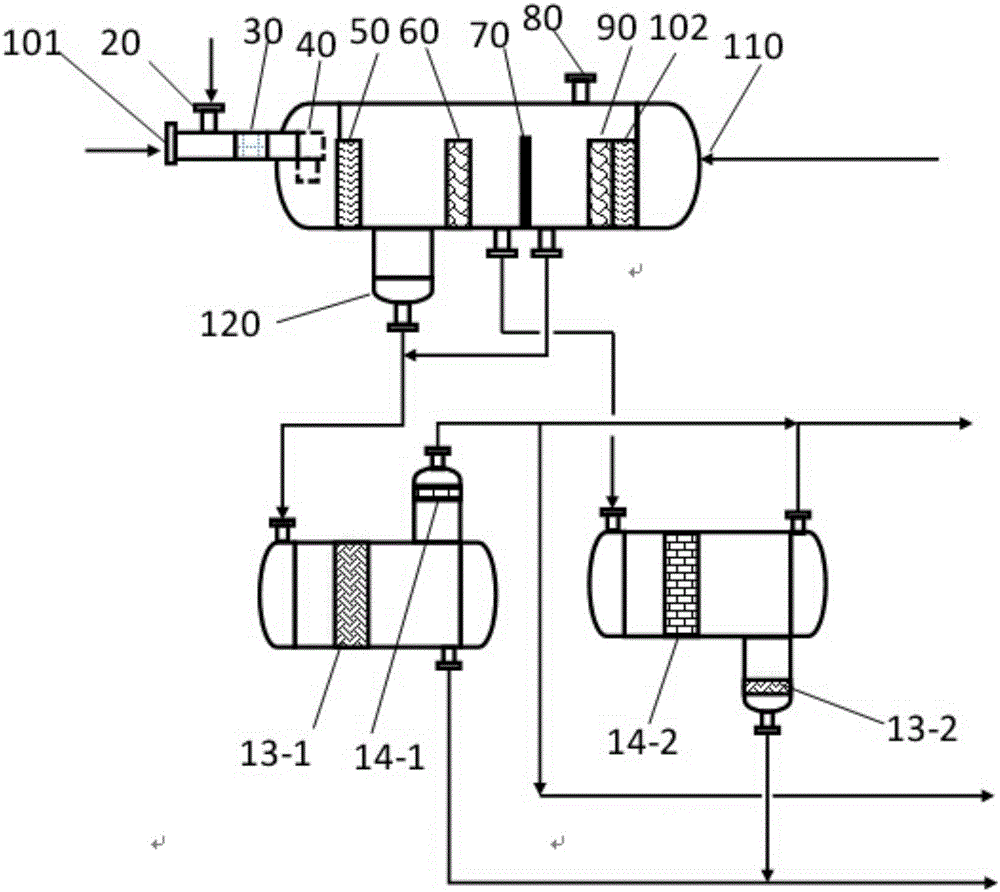

Method and device for strengthening oil-water separation and coupled desalting functions in cold low pressure separator

ActiveCN104667579AQuick degassingSimple structureLiquid separation auxillary apparatusTreatment with plural serial refining stagesFiberGas phase

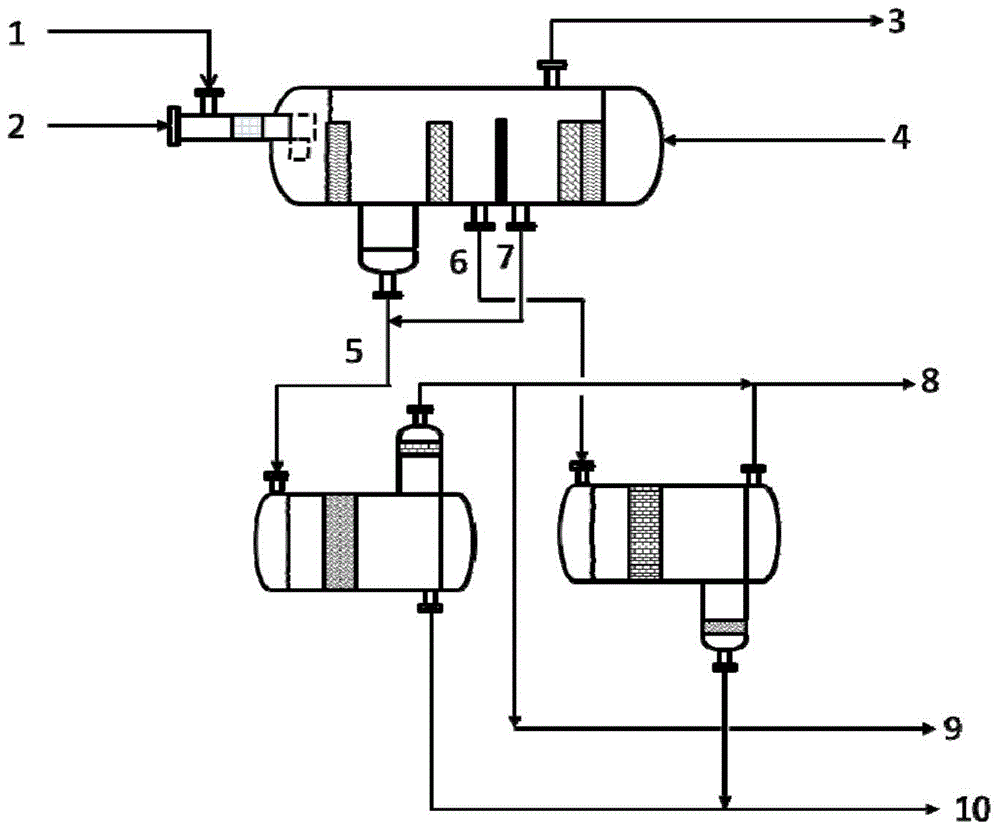

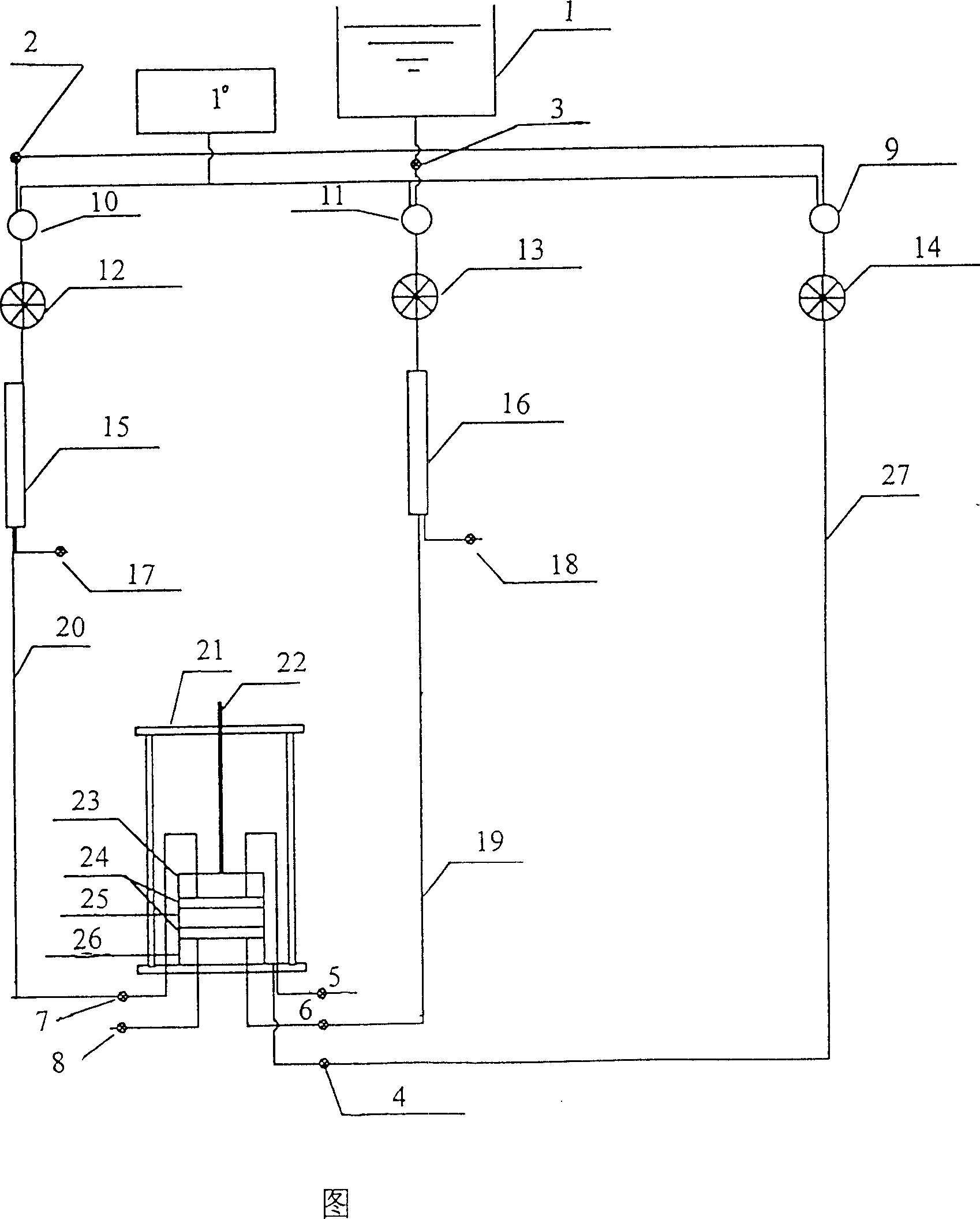

The invention relates to a method and a device for strengthening oil-water separation and coupled desalting functions in a cold low pressure separator. The method comprises the following steps: performing countercurrent mixing on water-containing low-content oil and desalted water with the volume ratio of 0-1 percent at the inlet section, allowing the mixture to enter a T-shaped liquid-gas separator for being subjected to degassing treatment, rapidly separating the gas phase subjected to step-down flash in the low-content oil, and allowing the oil-water mixture to flow to a rectification distributor on the lower part of the low-pressure separator from a left seal head to a right seal head so as to realize uniform distribution on the radial section; rapidly separating the oil water by virtue of a coarse graining module and a CPI module sequentially, discharging one part of water, allowing oil and trace water (0-0.01 percent) to enter a deep separation section by virtue of a separator, performing deep dehydration on the oil by virtue of a fiber combined module, discharging the oil, performing further deep deoiling on the intercepted water by virtue of the combined fiber module, and discharging the water. According to the method and the device disclosed by the invention, the oil-water separation performance of the cold low pressure separator can be strengthened, the desalting function in the oil can be realized, the occupied area of the low pressure separator is reduced, and the defects of the conventional low pressure separator are overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

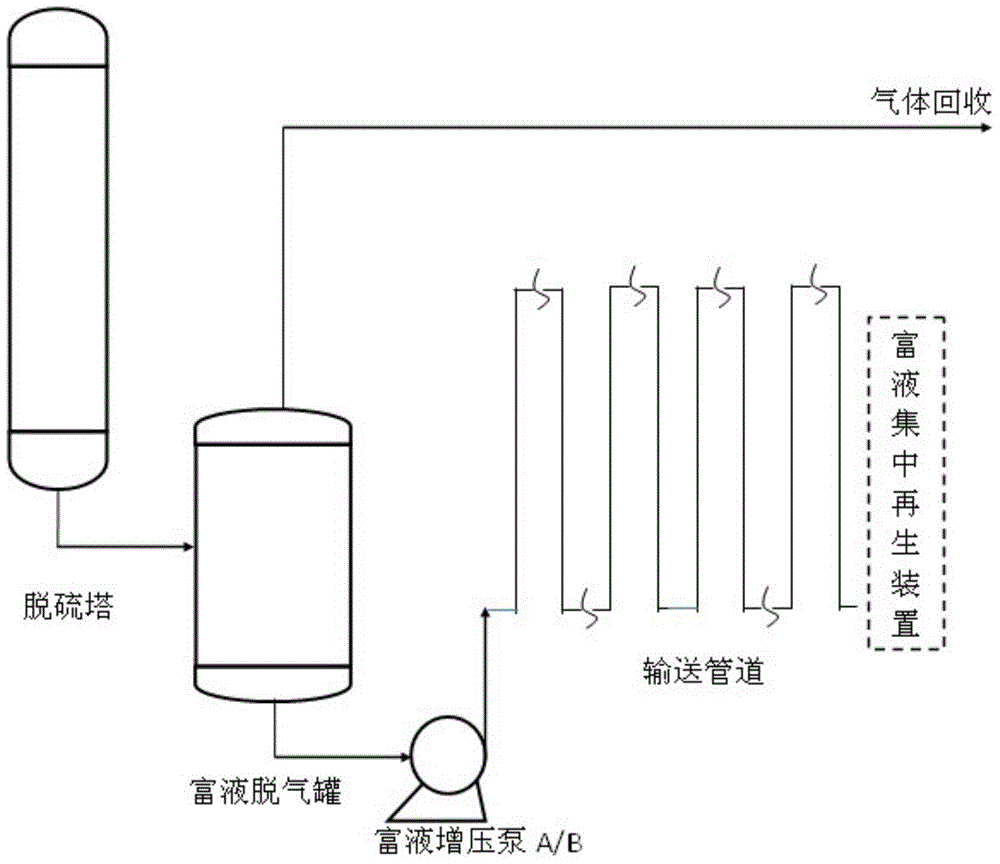

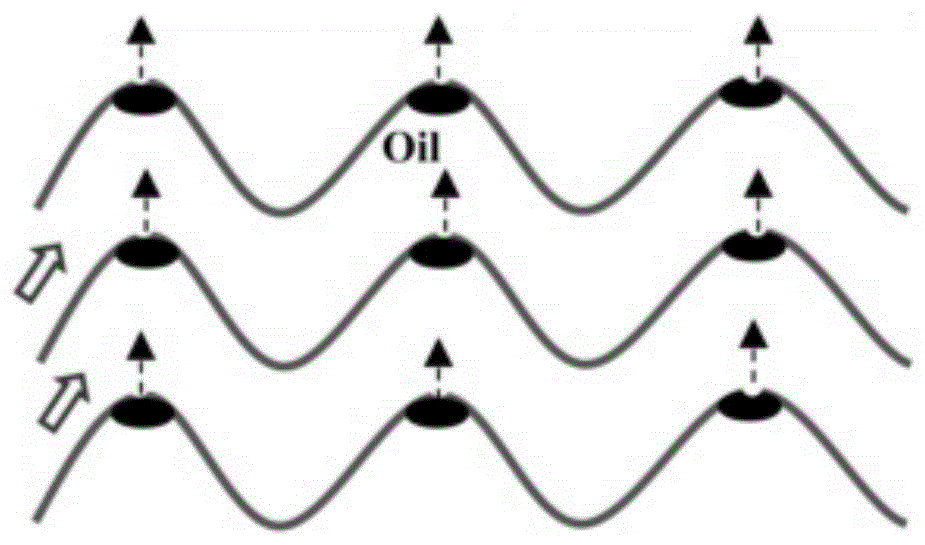

Step-by-step oil-water mixture separation method coupled with oil gas washing

ActiveCN104673367AProtection for long-term operationEfficient separationFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiberWastewater

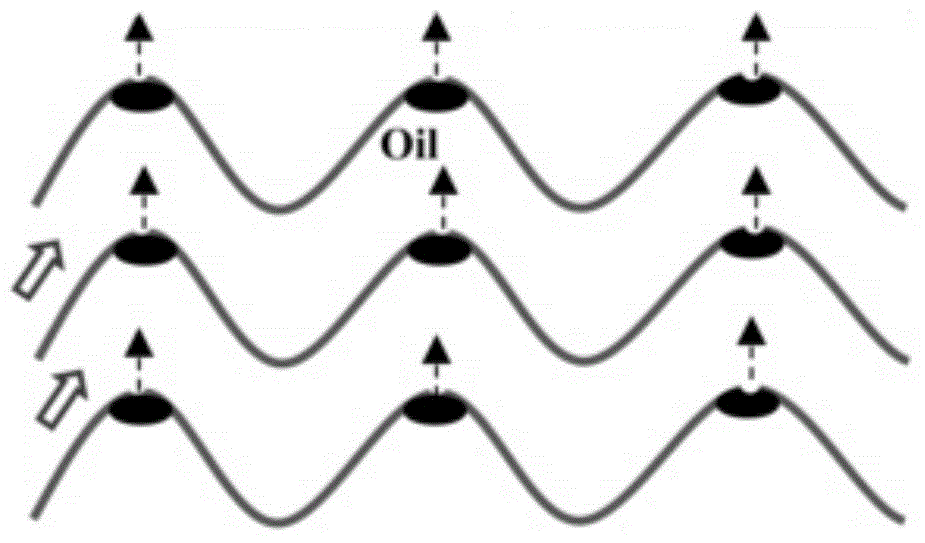

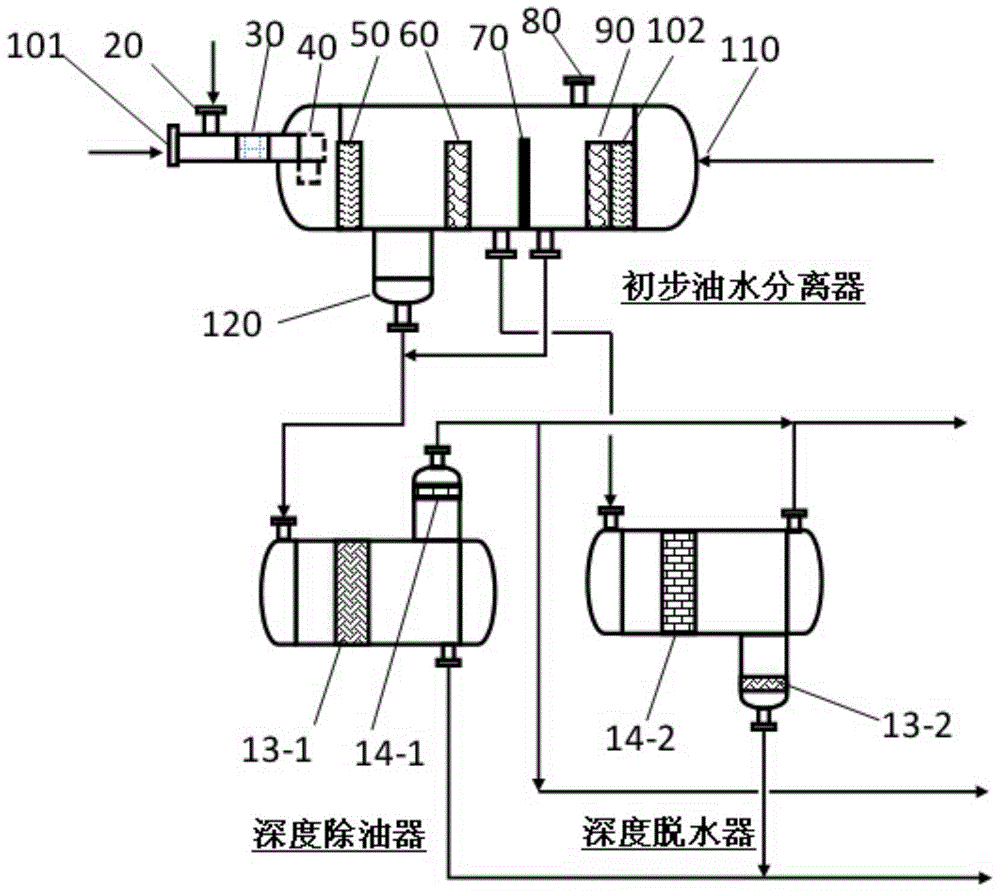

The invention relates to a step-by-step oil-water mixture separation method coupled with oil gas washing. The method comprises the following steps: first light oil containing 0.5-6 percent of synthetic water and low-pressure separator gas containing a trace amount of hydrocarbon are mixed and washed, then the light oil containing a trace amount of hydrocarbon flows into a primary oil-water separator from a left sealing head, and wastewater containing 0.05-0.5 percent of oil flows into the primary oil-water separator from a right sealing head; purified low-pressure separator gas is discharged from the top, mixed liquid is discharged into a deep dehydrater, and about 0.05-0.5 percent of water is removed from the light oil; wastewater on the left side flows into a water drum to be discharged, oil-removed wastewater on the right side is discharged nearby the right side of partition board into a deep oil remover, and about 0.03-0.6% of oil is removed from the water; by virtue of deep dehydration as well as oil removal and dehydration by a specially knitted conjugate fiber module in the oil remover, after the water content in the light oil is smaller than 0.02% and the oil content in the water is smaller than 0.01, the light oil and the water are transported outside. According to the method oil-water separation and step-by-step separation are combined, oil dehydration and wastewater oil removal can be realized rapidly and efficiently and oil is recycled to the maximum extent.

Owner:EAST CHINA UNIV OF SCI & TECH

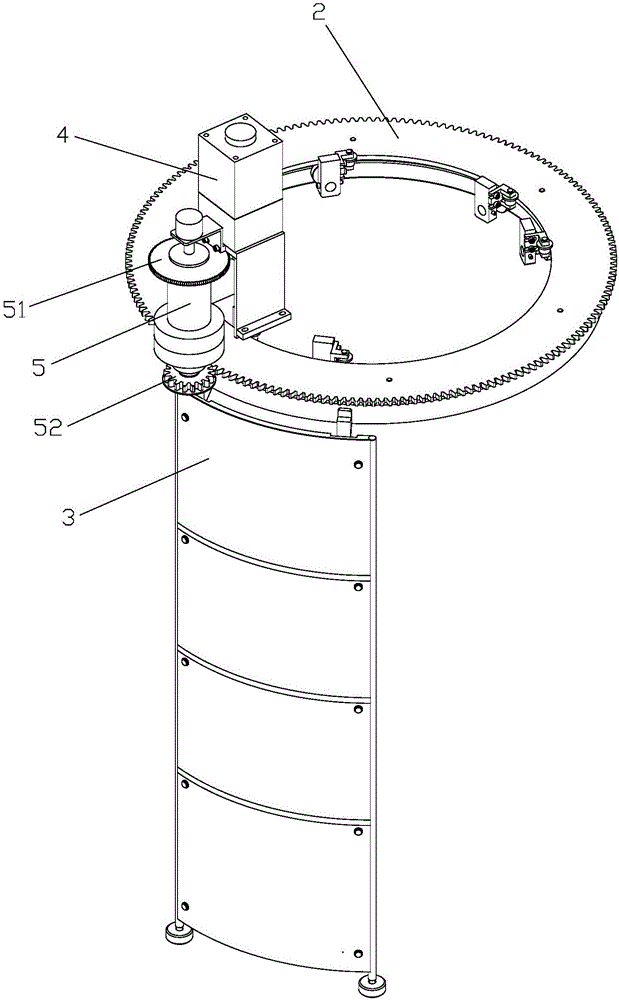

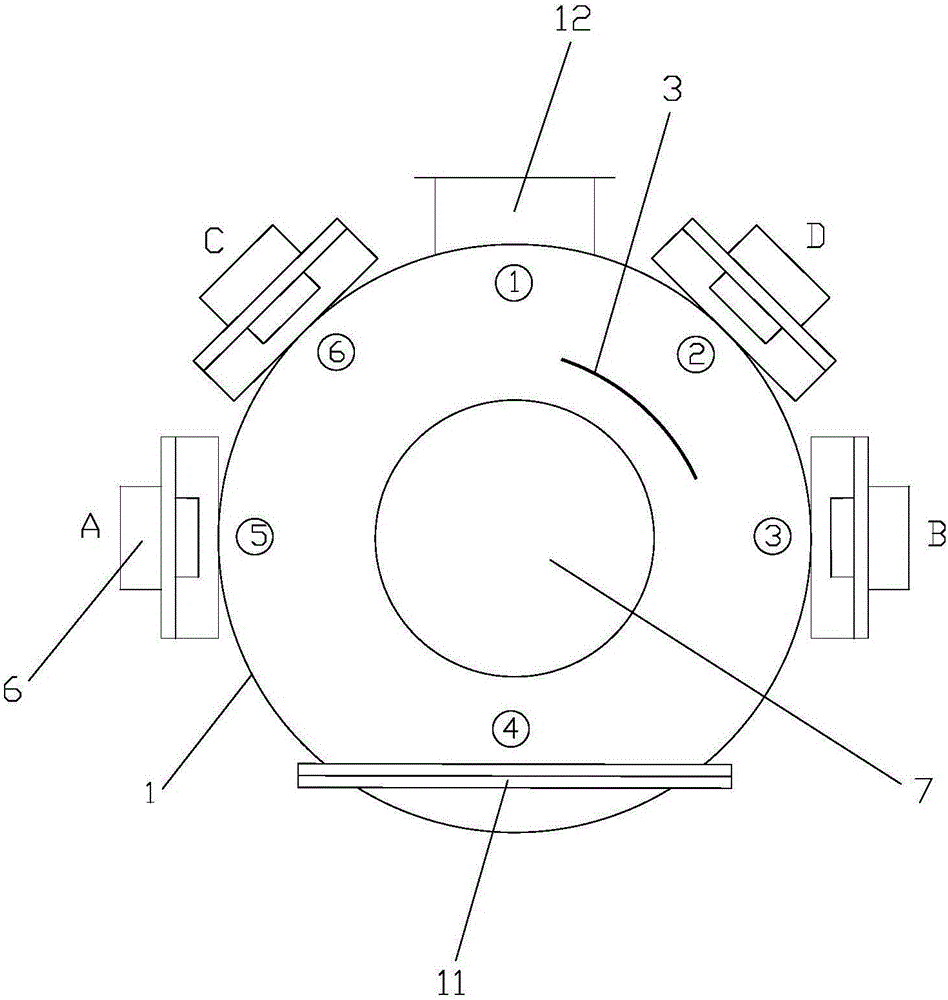

Intelligent source baffle plate system and method thereof for preparing hard coating

ActiveCN106148905ASimple structural designReasonable structural designVacuum evaporation coatingSputtering coatingEngineeringVacuum pump

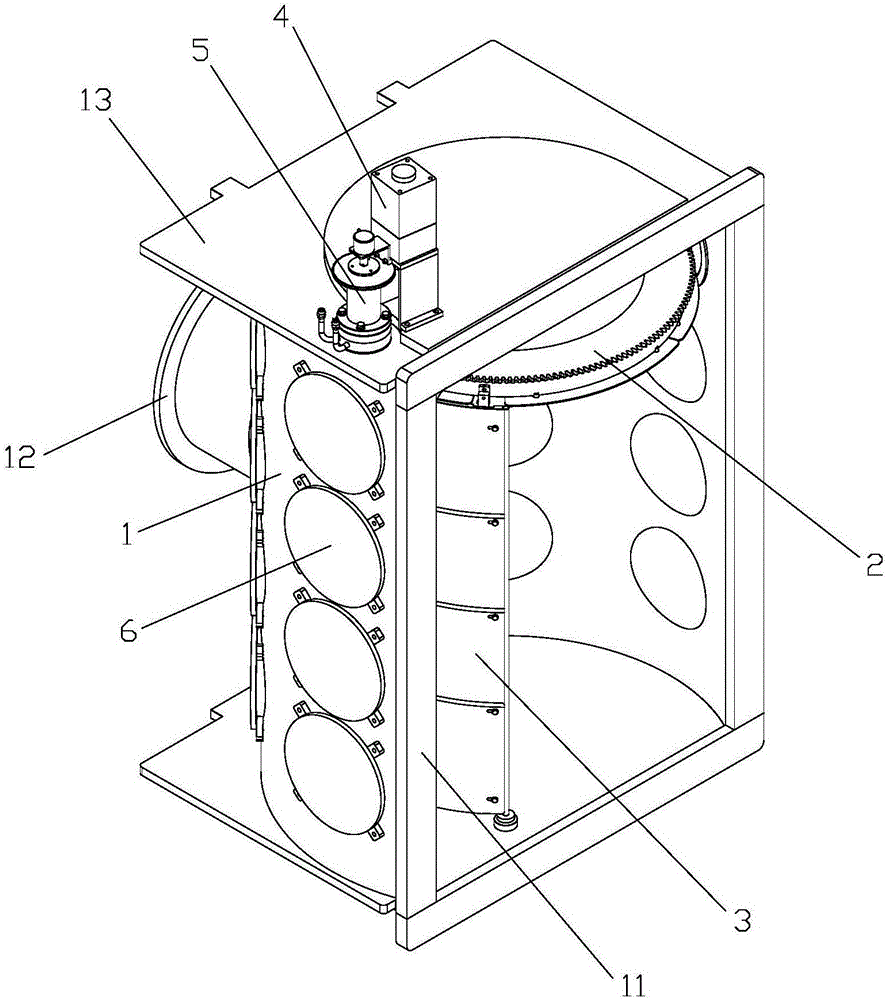

The invention relates to an intelligent source baffle plate system and a method thereof for preparing a hard coating. The system comprises a vacuum chamber, a circular gear ring, an intelligent source baffle plate, a gear reducer motor and a magnetofluid sealing transmission shaft. The method comprises the steps of (1) carrying out coating pretreatment; (2) carrying out vacuum pumping; (3) starting argon ion bombardment cleaning; (4) continuously carrying out high vacuum pumping to (4.0 to 9.0) * 10<-3> Pa, and carrying out target source predischarge cleaning; (5) continuously carrying out high vacuum pumping till the vacuum degree reaches 3.0 * 10<-3> Pa or above; (6) detecting the leakage rate of the vacuum chamber; (7) carrying out main arc metal ion bombardment and preparing a metal transition layer; (8) preparing a nitride coating through plating; and (9) after coating, inflating the vacuum chamber which is cooled to 150 to 250 DEG C, and after inflation, opening a door of the vacuum chamber to take out a workpiece. According to the system and the method, the content of residual gases in the vacuum chamber can be effectively decreased, the bonding strength of the hard coating and the surface of a base material and the performance of the hard coating are improved, mutual pollution between different cathode targets can be effectively prevented, and the quality and performance of a multi-layer or composite coating are improved.

Owner:北京丹普表面技术有限公司

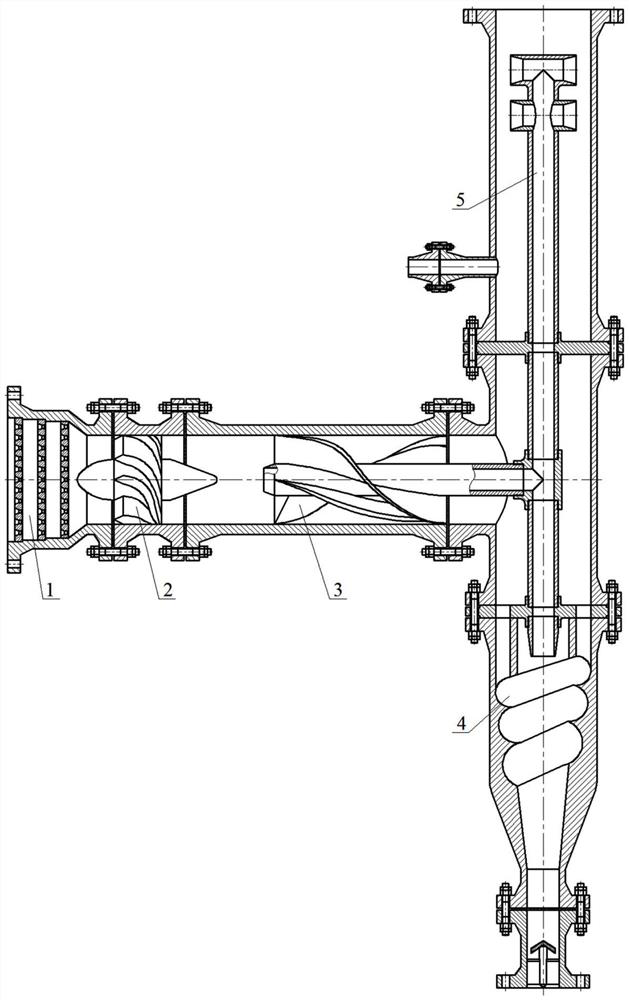

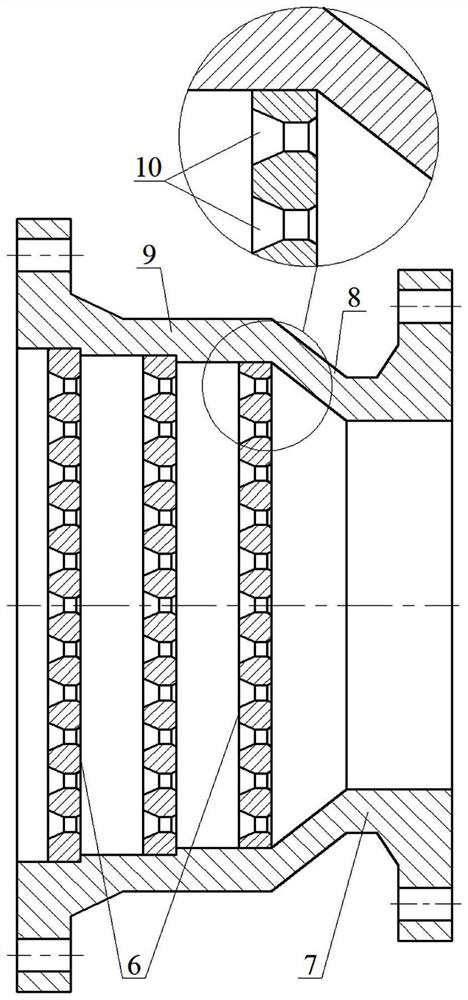

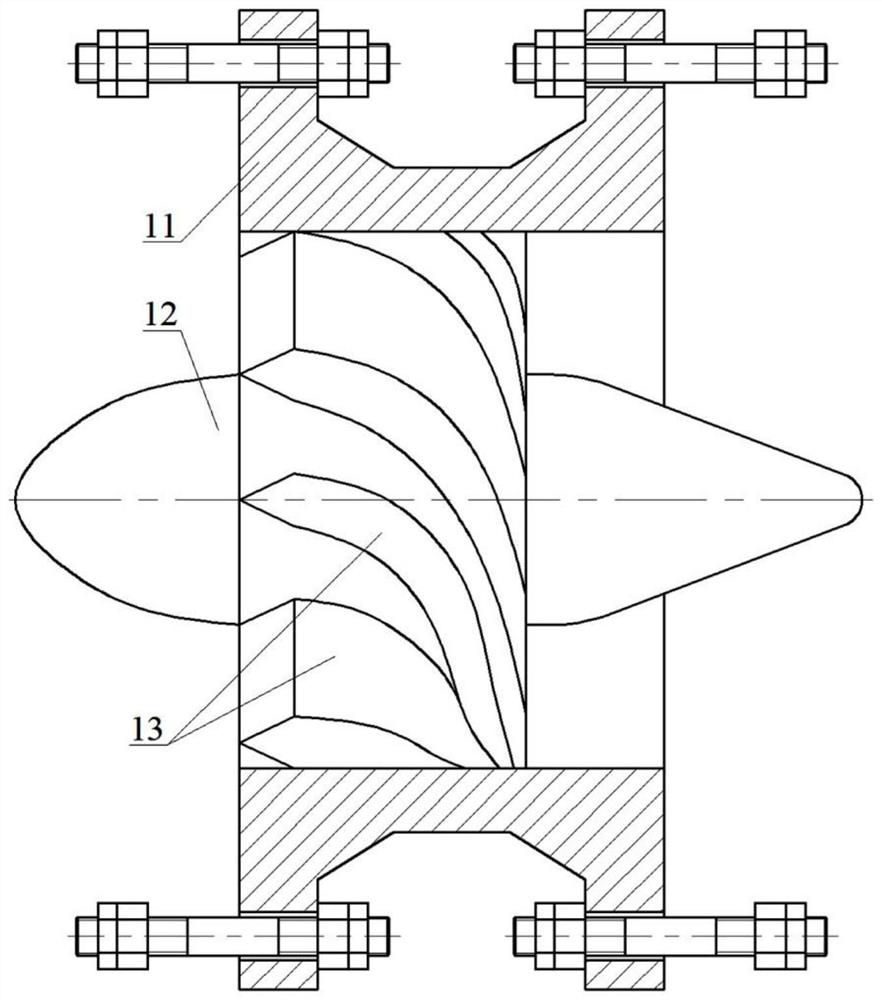

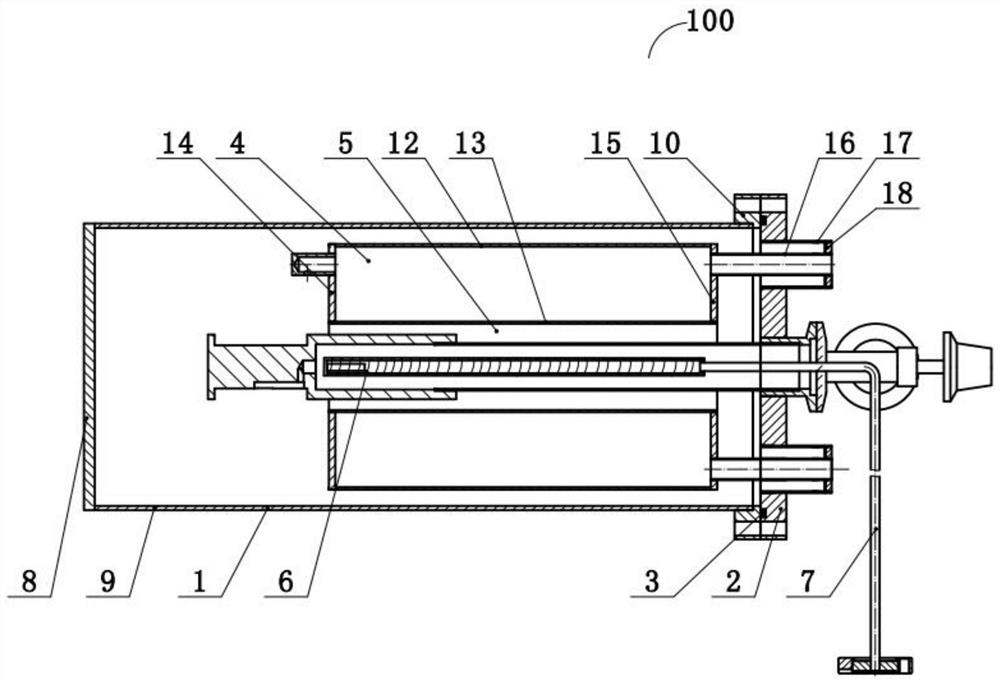

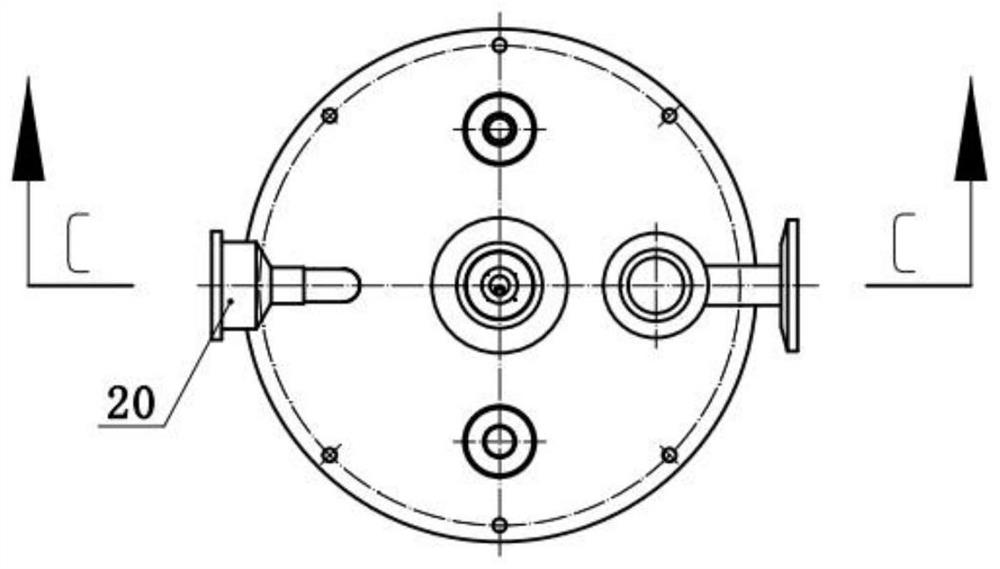

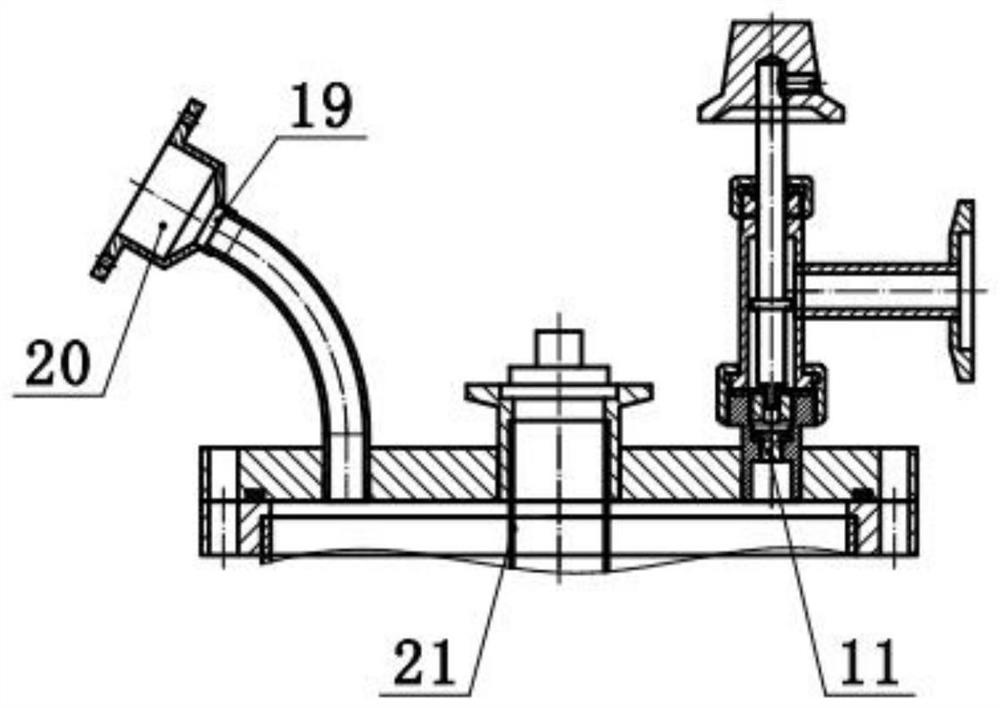

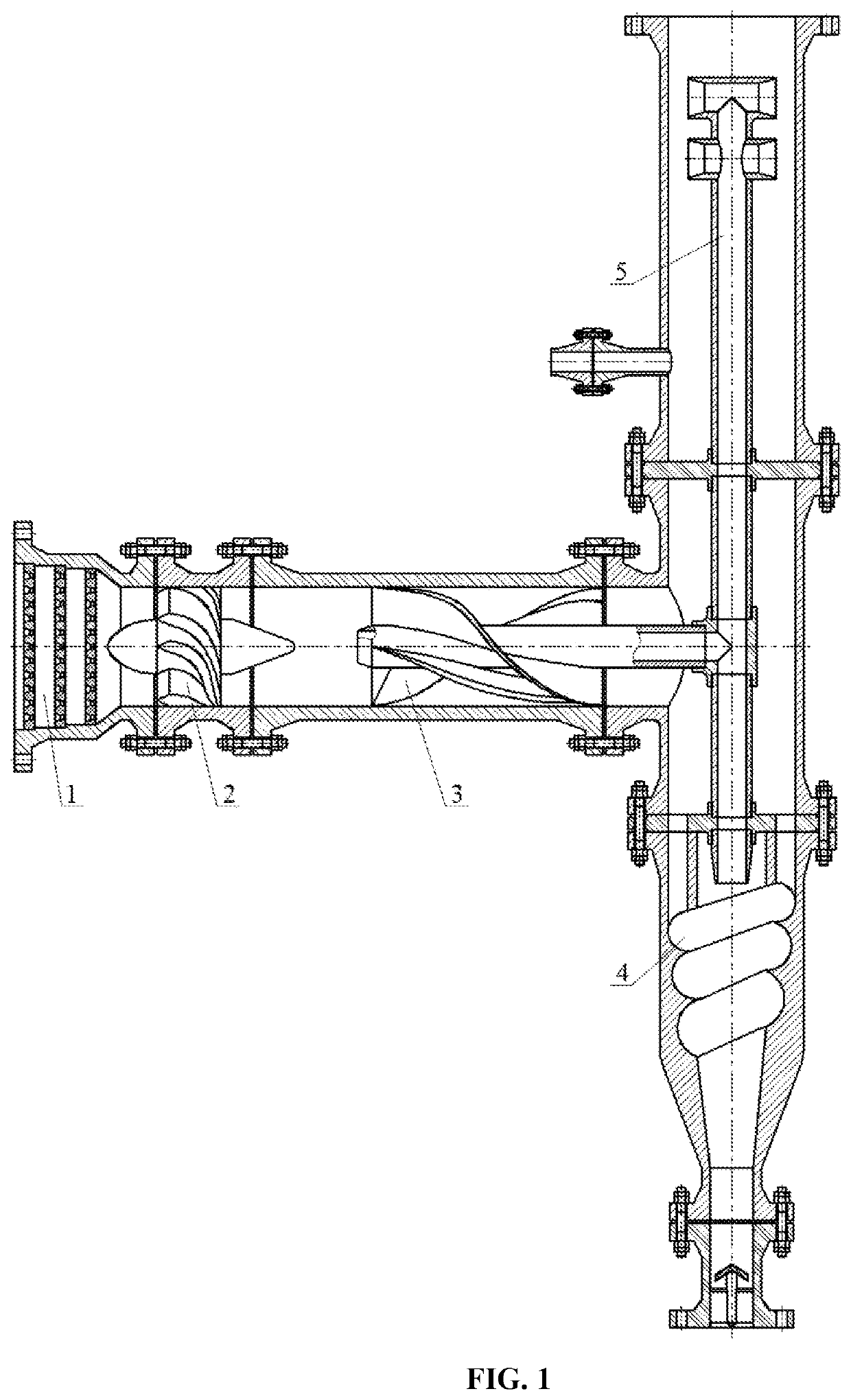

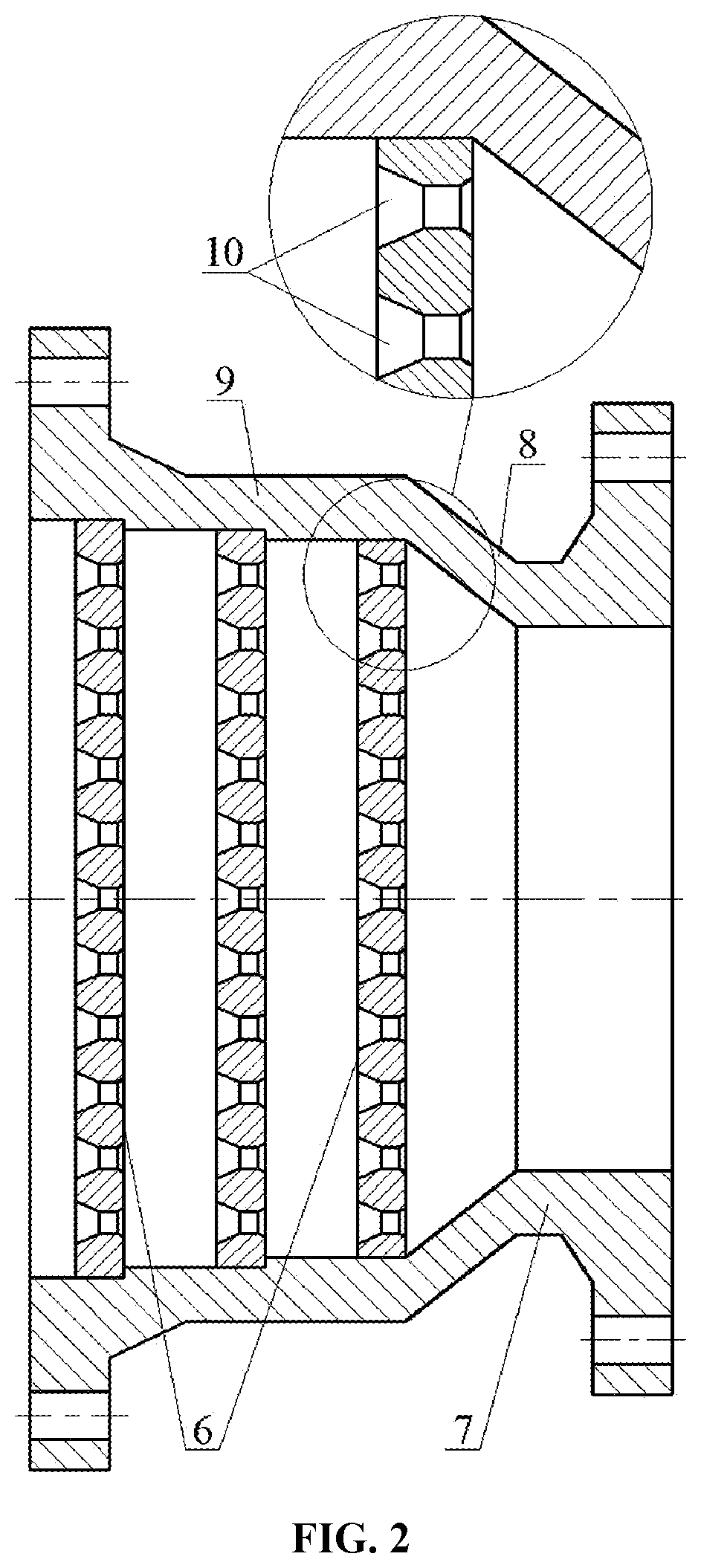

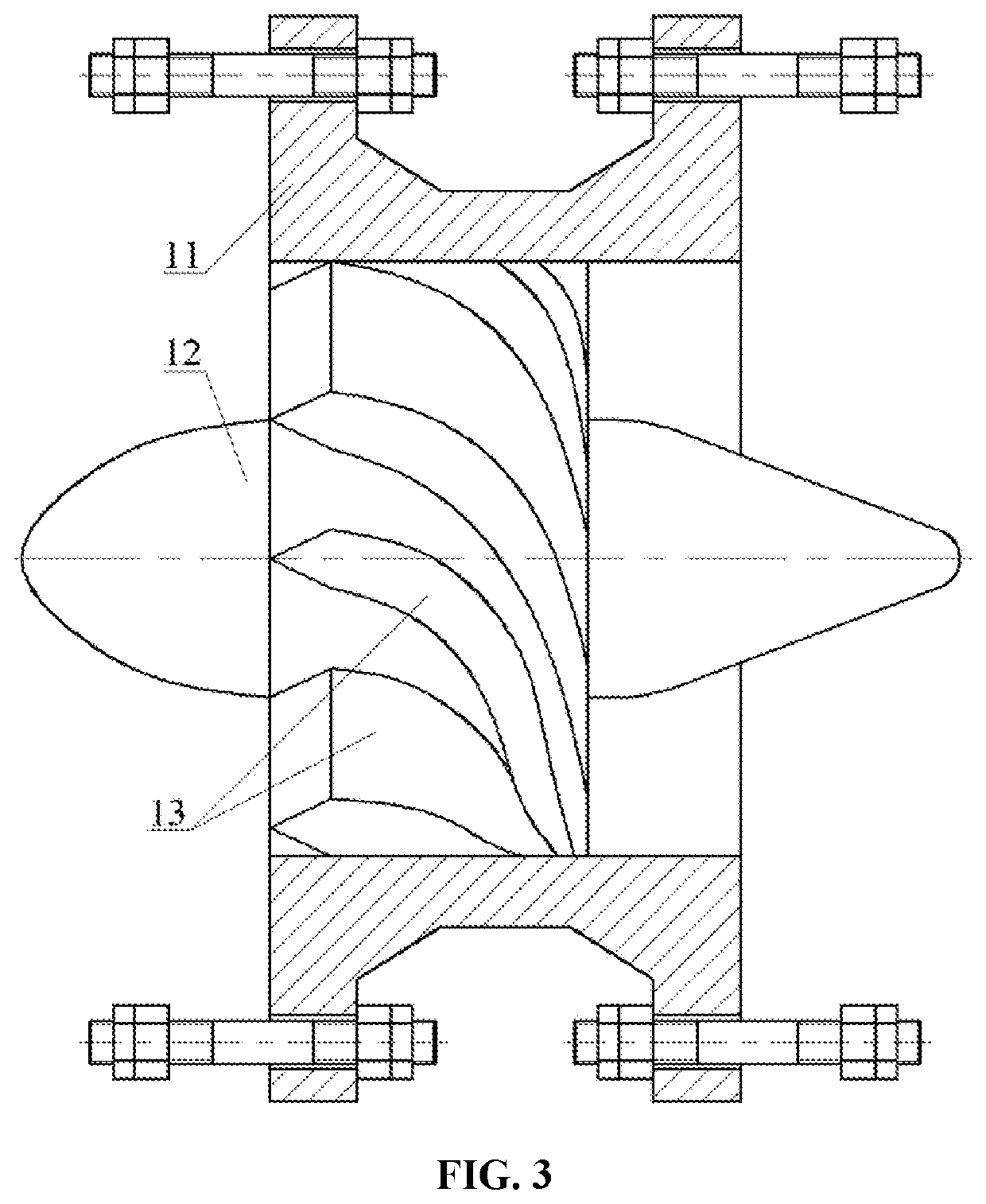

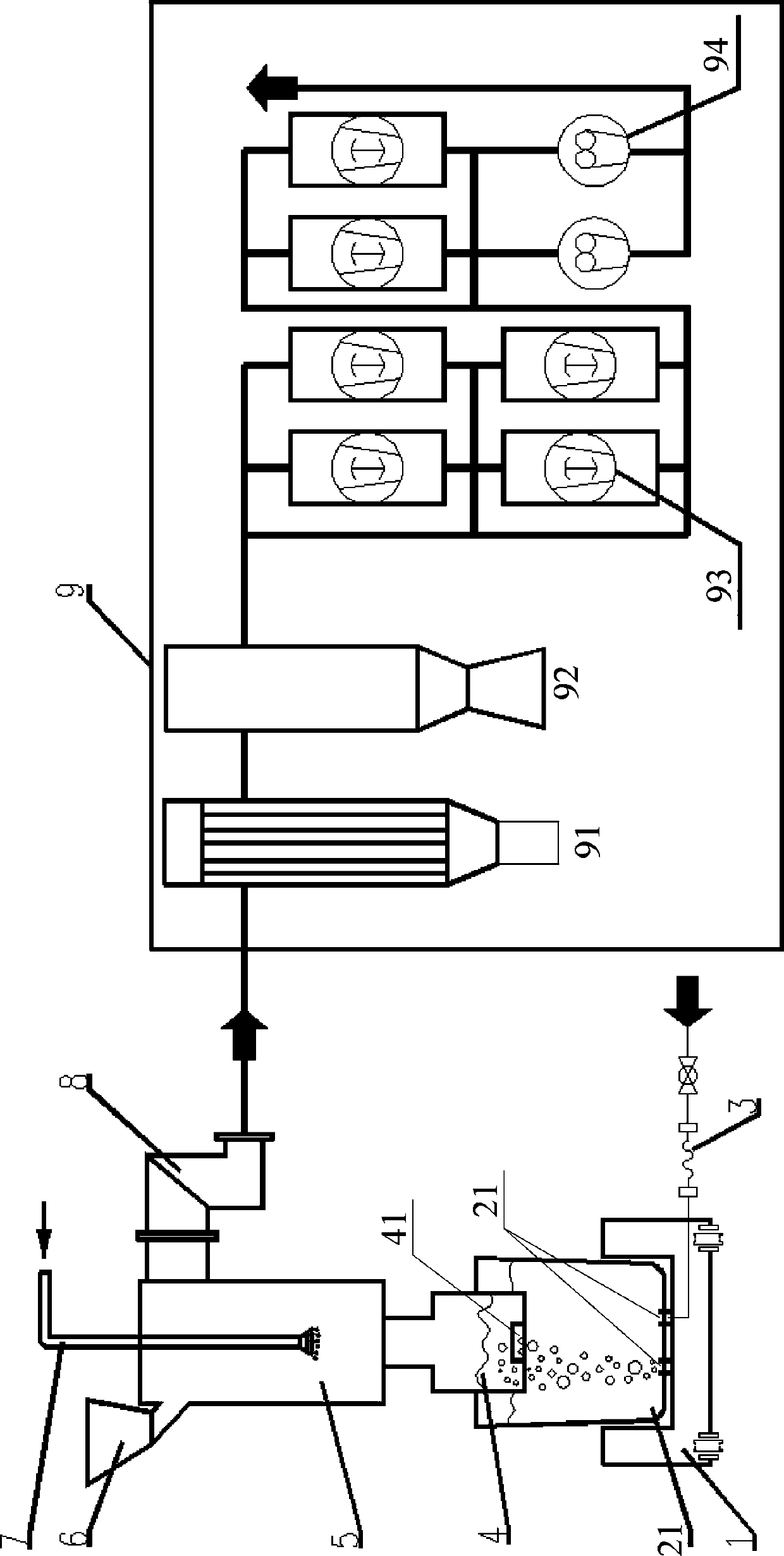

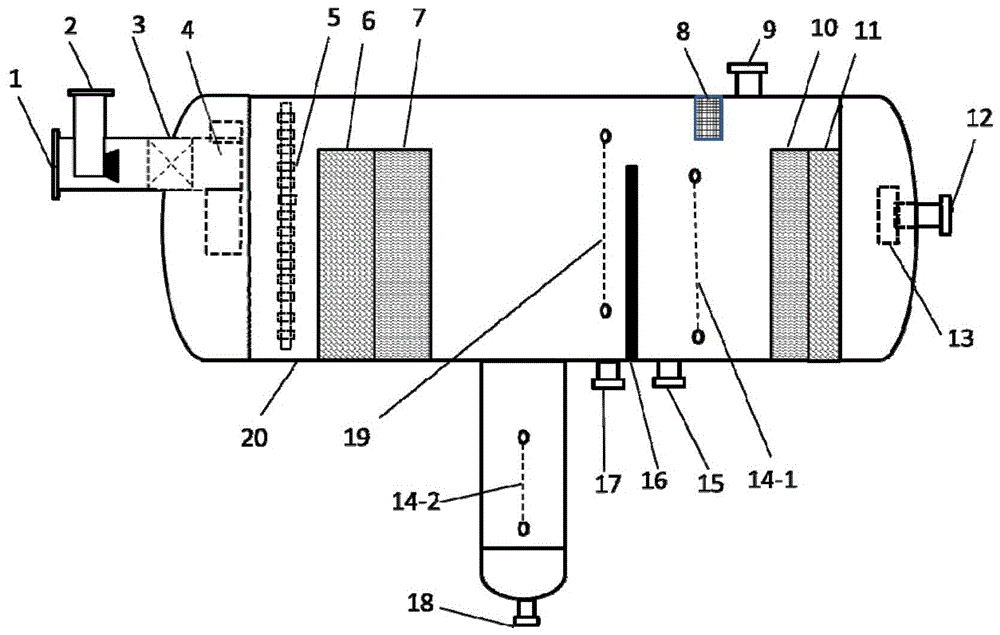

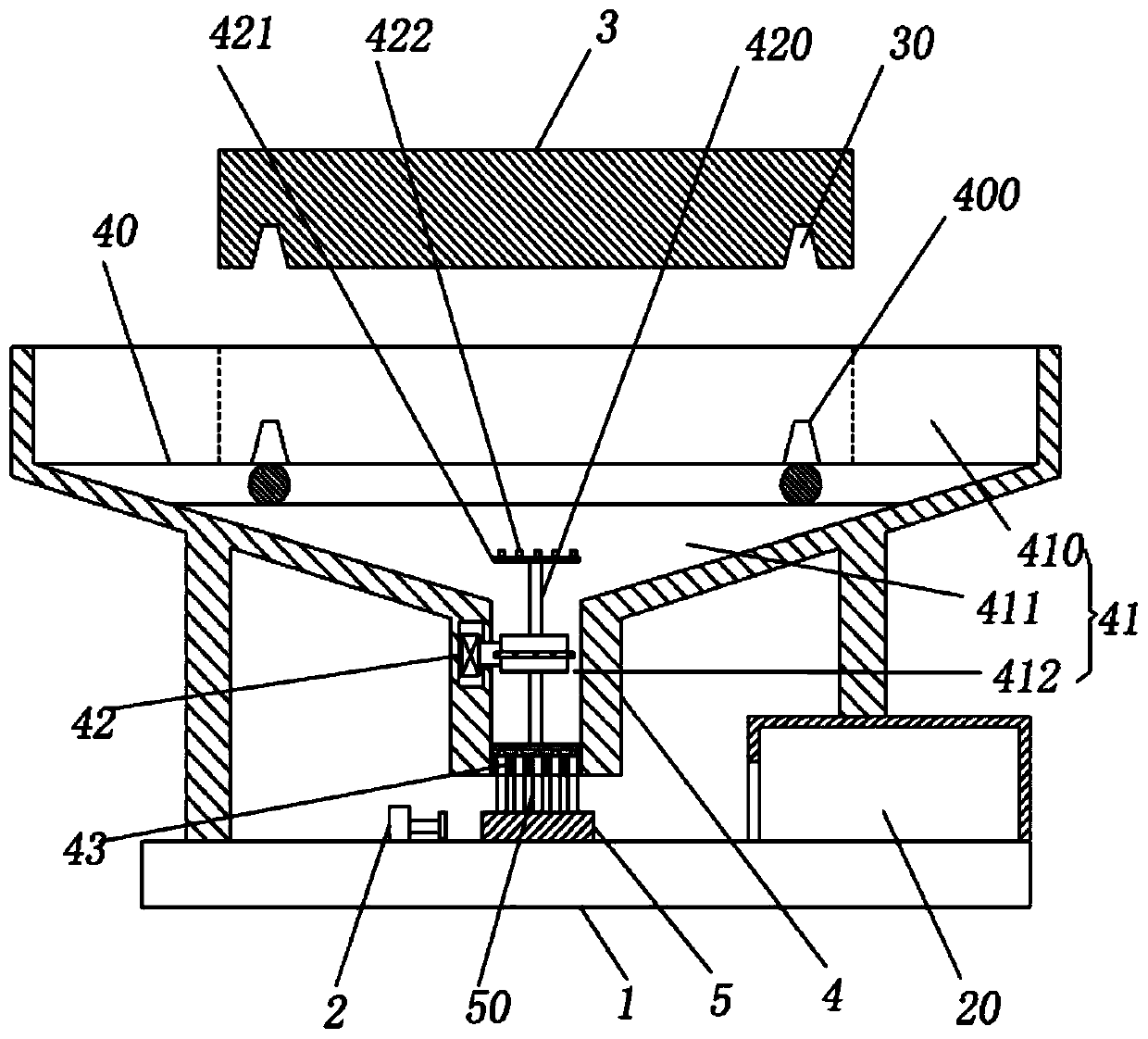

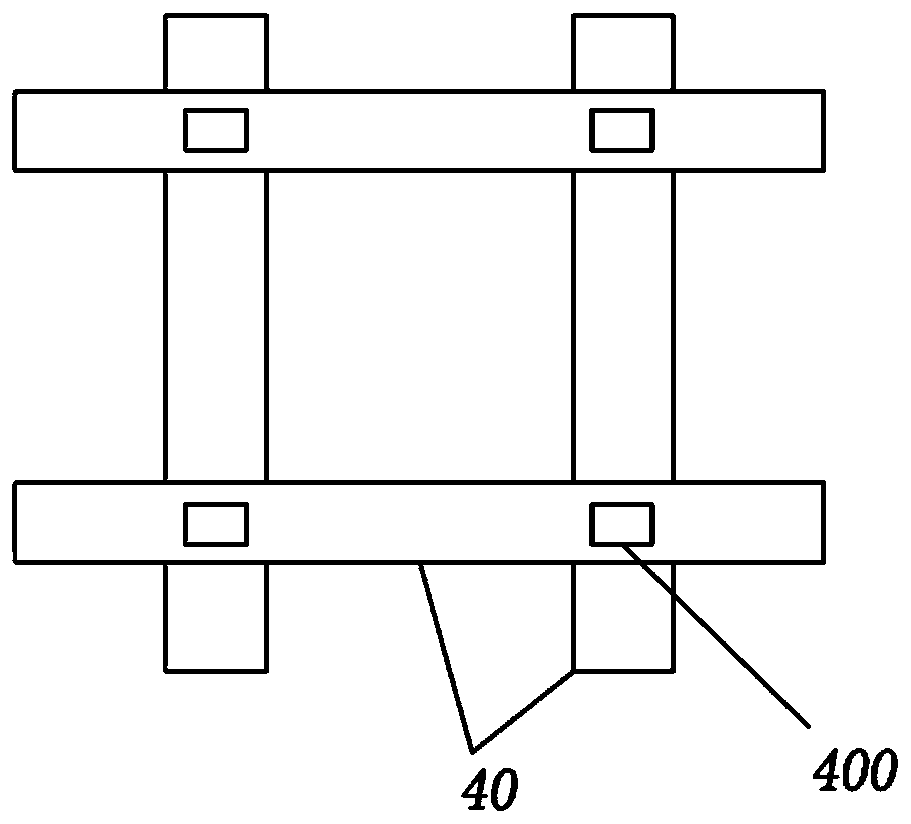

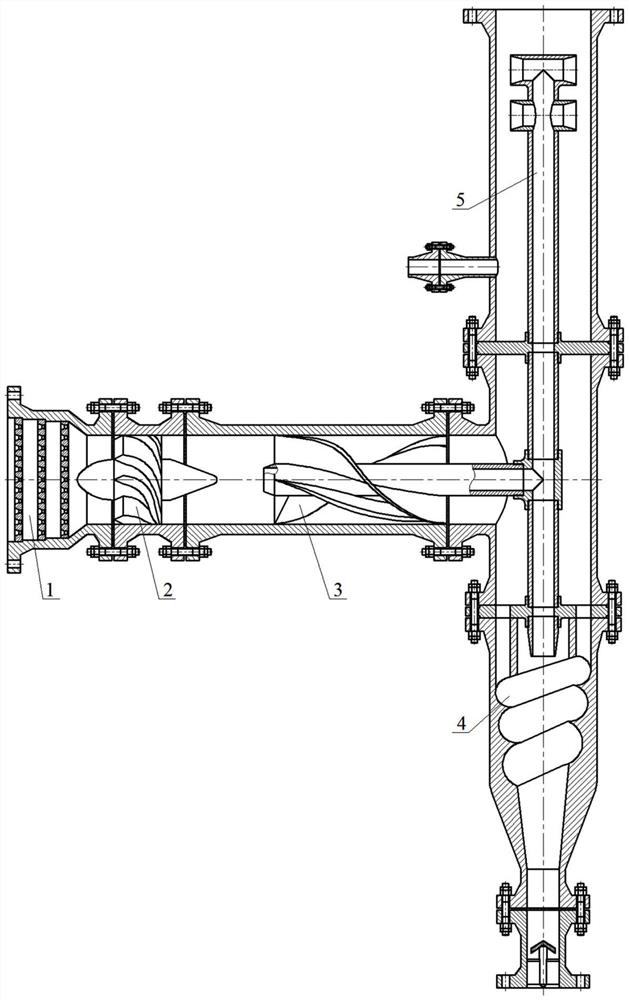

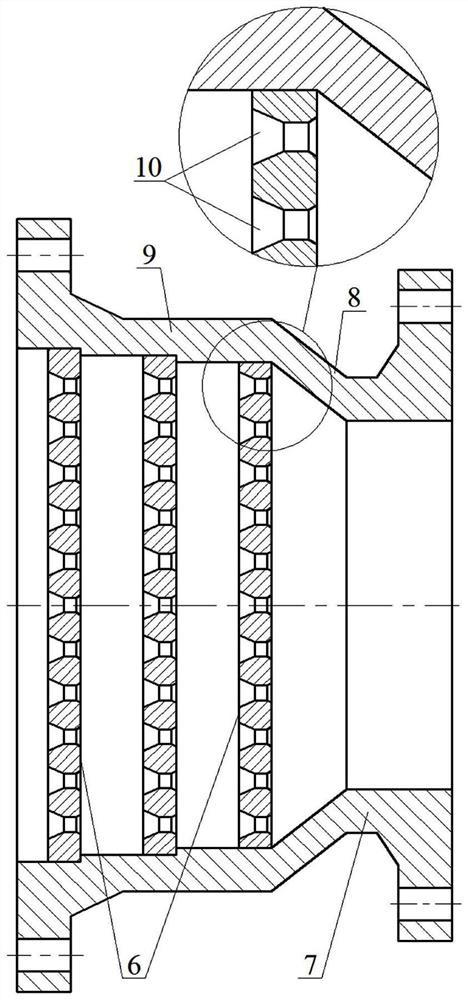

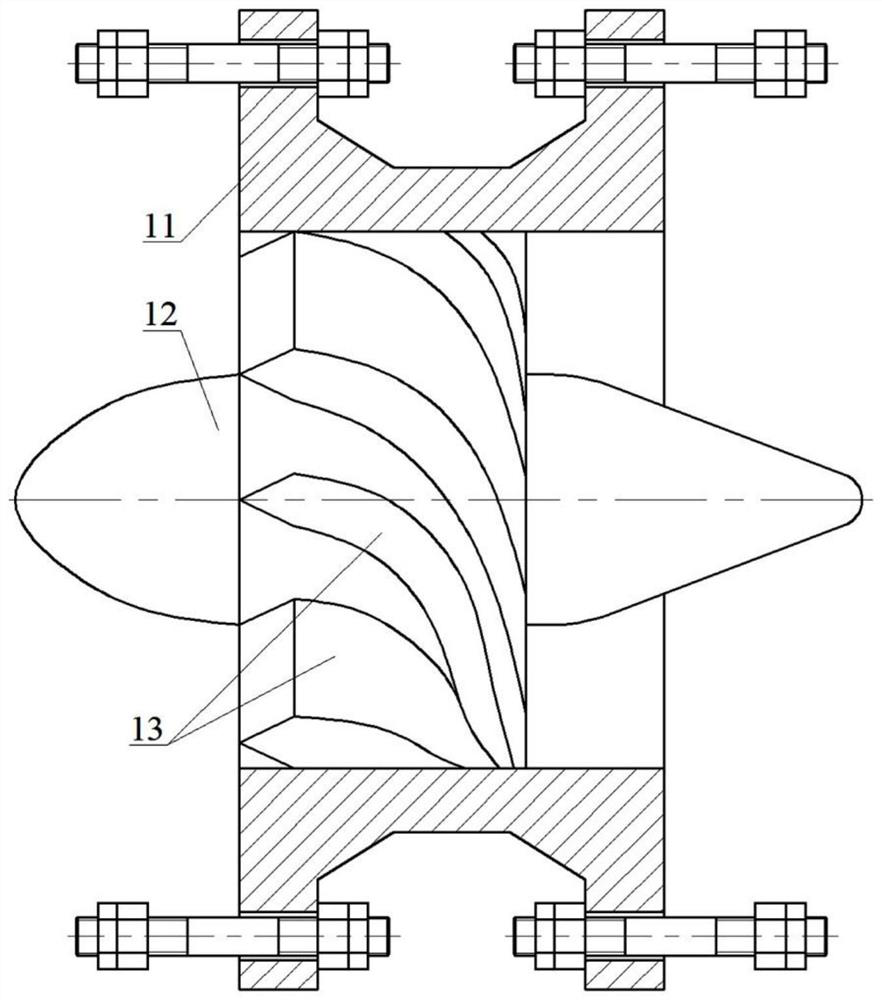

Micro-bubble axial flow and rotational flow double-field triode type T-shaped degassing device

ActiveCN112892001AQuick degassingLow liquid content in gasFluid removalLiquid degasification arrangementsLiquid jetMicrobubbles

The invention provides a micro-bubble axial flow and rotational flow double-field triode type T-shaped degassing device, which is applied to rapid degassing of gas-liquid two-phase flow. According to the triode type T-shaped degassing device, a rapid degassing technology combining a micro-bubble uniform mixing rotating shaft flow field, a spiral flow channel conical swirling flow field and layered jet flow collision reversing deep degassing is adopted, and a micro-bubble uniform mixing device adjusts gas-liquid two-phase flow containing large bubbles into micro-bubble uniform mixing axial flow; a micro-bubble spinning machine adjusts a micro-bubble uniform mixing axial flow into a split rotating-axis flow containing microbubbles, and a rotating-axis flow degasser implements horizontal microbubble uniformly-mixed split rotating-axis flow degassing operation to remove most of the microbubbles to form an axial flow gas and an axial flow liquid, a conical rotational flow degasser implements vertical spiral flow channel single-strand conical rotational flow degassing operation and removes a small amount of remaining micro-bubbles to form rotational flow gas and rotational flow liquid, and a jet flow reversing degasser implements vertical layered jet flow collision reversing degassing operation and removes small-particle-size liquid drops to form reversing gas and reversing liquid.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

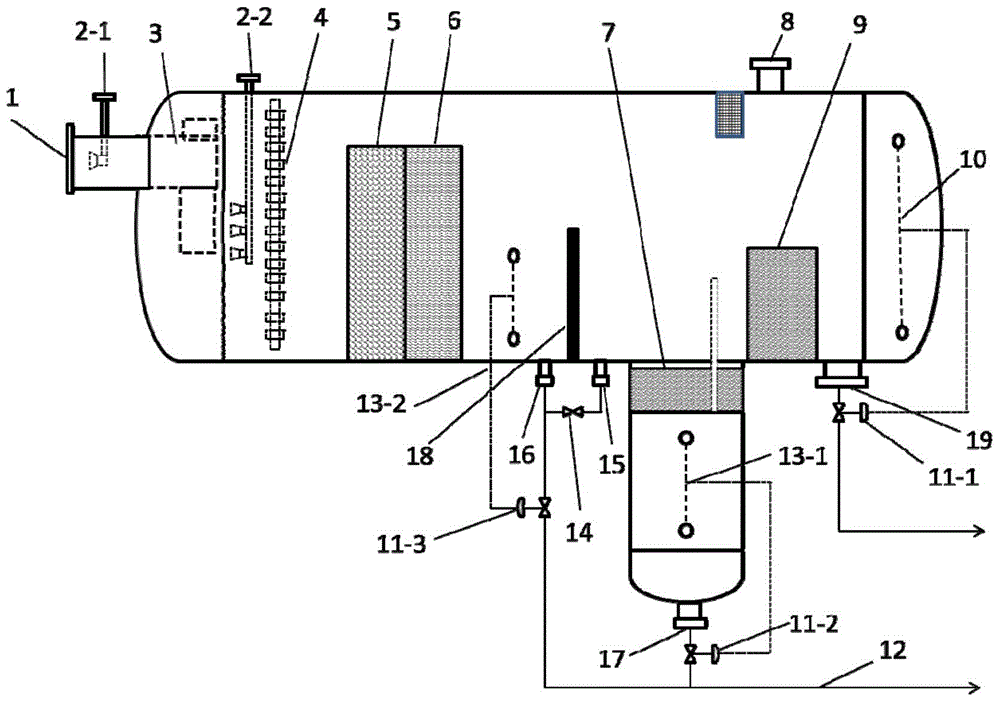

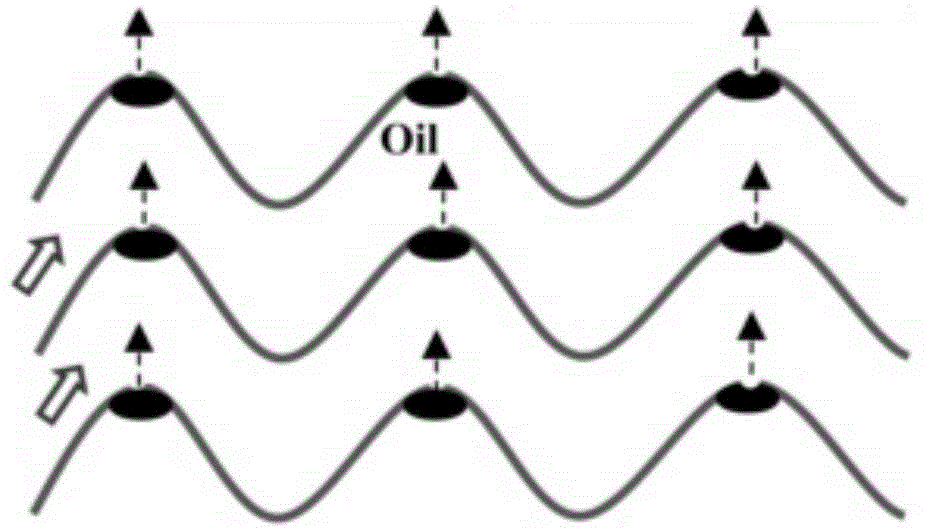

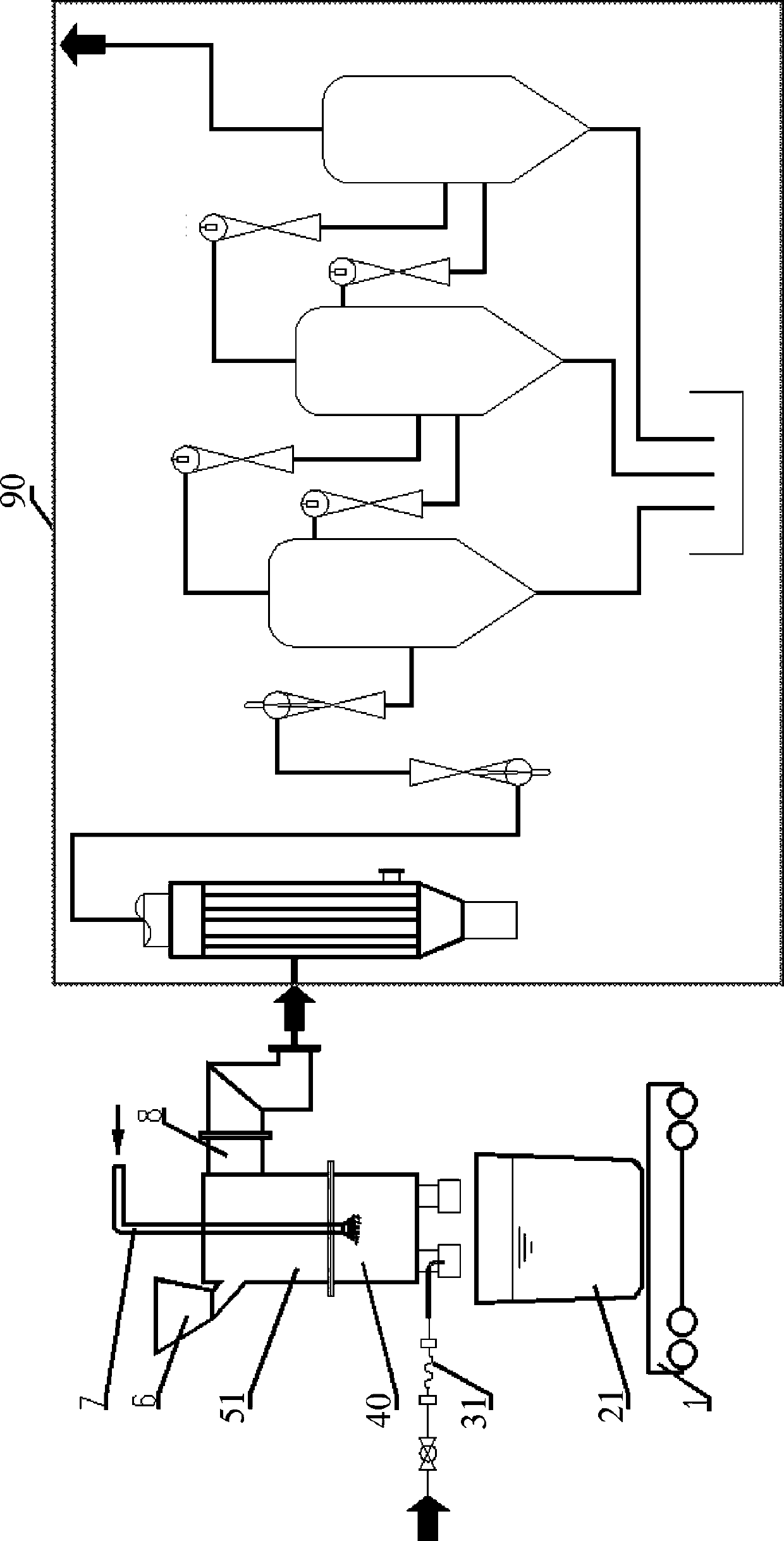

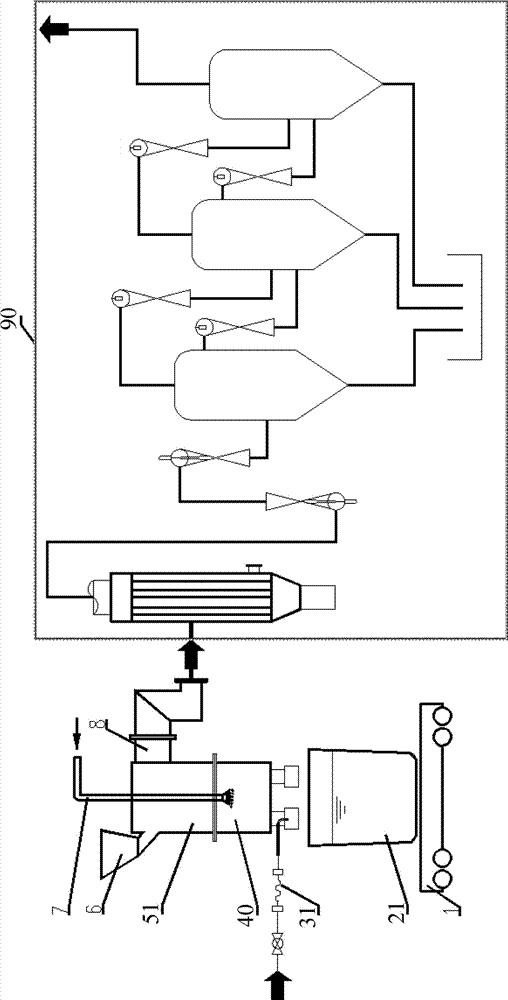

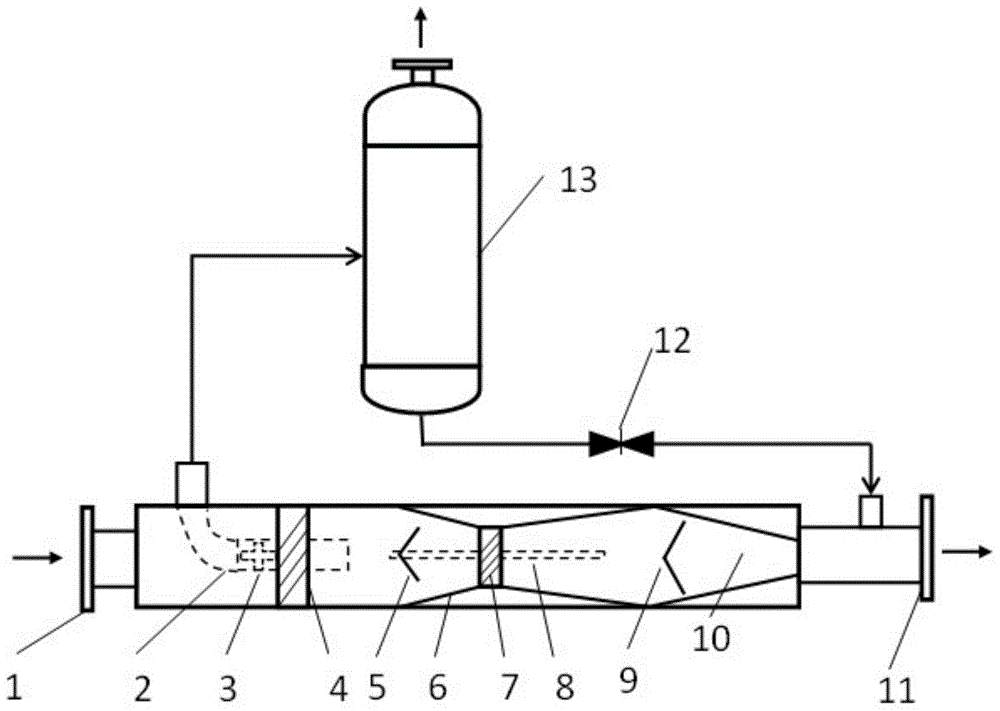

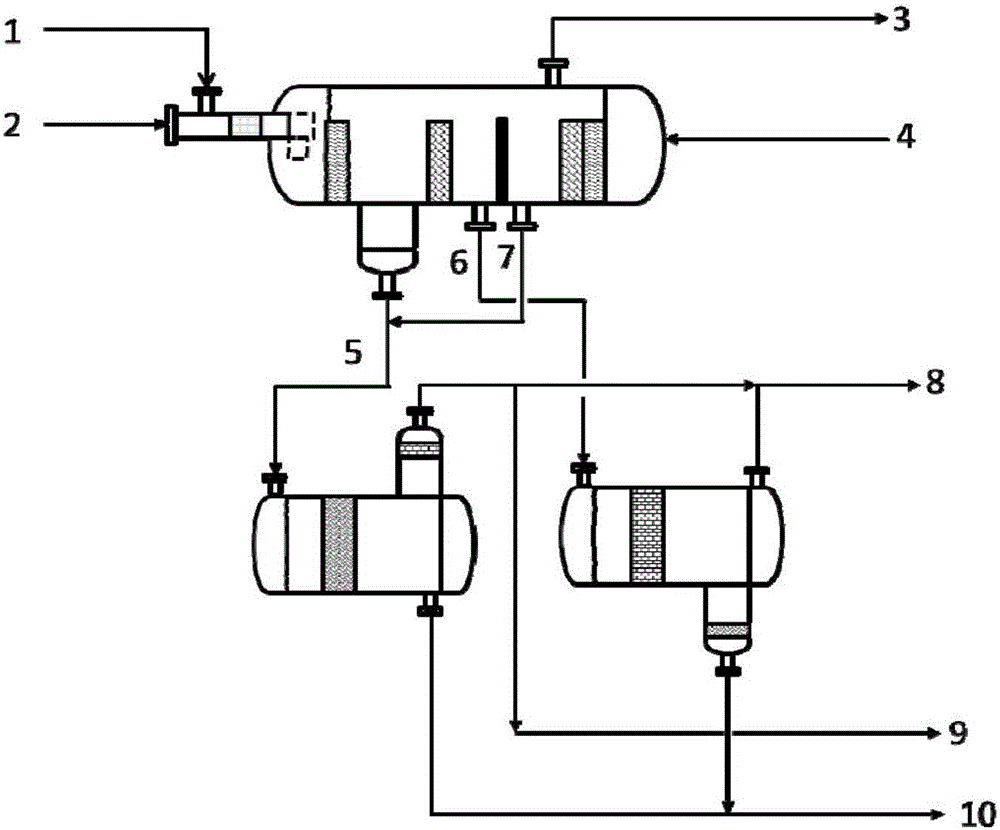

Oil-gas-washing-coupled oil-water initial separation method and device

ActiveCN104629794AQuick degassingSimple structureDewatering/demulsification with mechanical meansCombustible gas purificationThermodynamicsOil water

The invention relates to an oil-gas-washing-coupled oil-water initial separation method and device. The method comprises the following steps: light oil containing 0.5-6% of synthetic water and hydrocarbon-component-containing gas enters a tubular mixer at an inlet section to wash hydrocarbon components in the gas, and are subjected to liquid separation by a T-shaped liquid-gas separator; the water-containing oil sequentially passes through a rectifying distributor, a water drop coarse granulation module and a CPI quick dewatering module from left to right, and the water enters a water drum; sewage containing 0.05-0.5% of oil enters from a right end socket, and freely flows leftwards to sequentially pass through an oil drop coarse granulation module and an CPI quick oil removal module to perform oil removal; and finally, the water in the water drum and the water obtained by right partition oil removal are discharged by an oil-water interface controller; and the oil separated from the right side of the partition is communicated with the oil on the left side via the upper part of the partition, and is discharged under the action of a liquid level controller. The method couples the functions of oil dewatering, water oil-removal and oil-gas washing recycling, has the advantages of small occupied space and quick and efficient separation, and overcomes the defects in the prior art.

Owner:EAST CHINA UNIV OF SCI & TECH

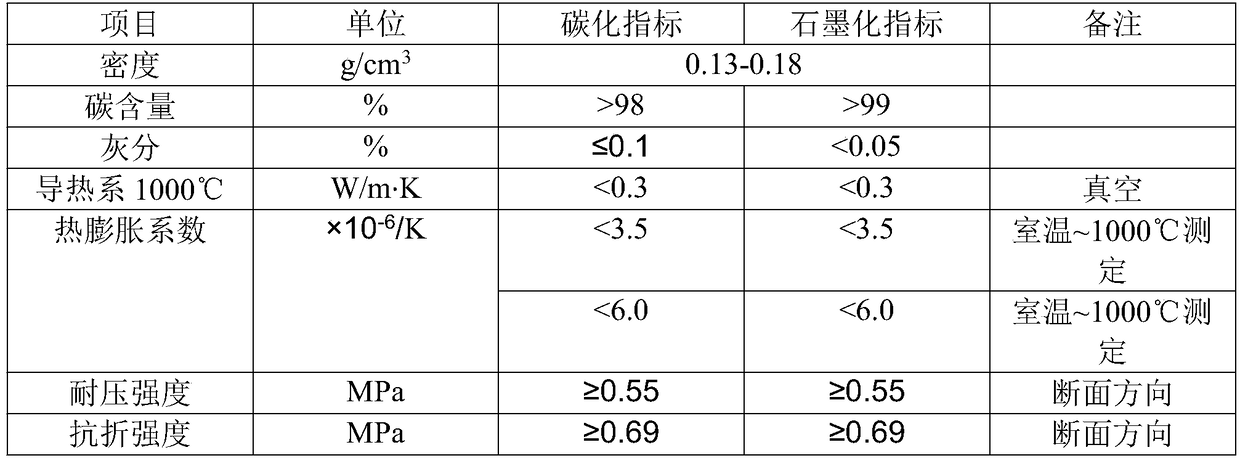

High-efficiency energy-saving cured carbon felt, and preparation method thereof

InactiveCN108625185ANo pollutionIncrease effective spaceNon-woven fabricsThermal insulationCarbon felt

The invention discloses a high-efficiency energy-saving cured carbon felt, and a preparation method thereof. The high-efficiency energy-saving cured carbon felt is prepared from, by weight, 650 to 720parts of soft felt, 30 to 40 parts of a dilluent, 50 to 100 parts of a curing agent, 200 to 300 parts of a resin, and 25 to 35 parts of an inorganic filing material. The preparation method comprisesfollowing steps: 1, felt cutting; 2, rubber preparation; 3, rubber coating; 4, manufacturing and moulding; 5, high temperature oven drying; 6, machining; 7, coating; 8 high temperature calcining; and9, detection. The high-efficiency energy-saving cured carbon felt is low in thermal conductivity, excellent in thermal insulation performance, uniform in density, low in heat storage capacity, quick in degassing, low in outgassing amount in vacuum, possesses heat impact resistance; product pollution or hearth pollution is not caused; furnace body effective space is enlarged; installation and maintenance are convenient; thermal insulation requirements of various monocrystalline growth furnaces and polysilicon ingot furnaces are satisfied. The preparation method is simple, is suitable for largescale industrialized production, and is promising in application prospect.

Owner:NINGJIN JINGXING ELECTRONICS MATERIAL

Device and method for separating krypton and xenon in rock sample

PendingCN113358452AQuick degassingDomestic cooling apparatusLighting and heating apparatusKryptonPhysical chemistry

A disclosed device for separating krypton and xenon in a rock sample comprises a cylinder and an upper cover, the cylinder internally comprises a liquid nitrogen layer and a heat conduction agent layer, the liquid nitrogen layer sleeves the heat conduction agent layer, a cavity between the outer wall of the liquid nitrogen layer and the cylinder can be vacuumized, and an inner cavity of the liquid nitrogen layer can accommodate liquid nitrogen; a cold finger is arranged in an inner cavity of the heat conduction agent layer, a heat conduction agent can be contained between the inner wall of the heat conduction agent layer and the cold finger, the cold finger is connected with a heating element, a temperature measuring element and an experiment cavity, an inner cavity of the cold finger is communicated with the experiment cavity, and the experiment cavity can be communicated with external mixed gas. The invention further provides a method for separating krypton and xenon in the rock sample, the method is used in the pretreatment process of mass spectrometry of inert gas samples, operation is easy and convenient, rare gas can be separated in a high-quality and high-efficiency mode, the experiment time is shortened, the background is reduced, and meanwhile the purity of the rare gas is improved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

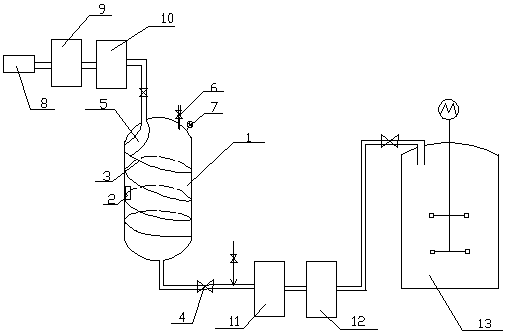

Liquid fermentation culture medium online degassing apparatus

The invention relates to a liquid fermentation culture medium online degassing apparatus, which comprises a tank body, wherein the tank body is provided with a material inlet and a material outlet, a liquid level sensor is arranged on the middle portion of the inner wall of the tank body, a spiral flow guiding plate is arranged along the inner wall of the tank body, the liquid level sensor is connected to an electromagnetic valve arranged on the material inlet, the upper liquid level line detecting position of the liquid level sensor is on the middle-upper portion of the flow guiding plate, the lower liquid level line detecting position is on the end of the flow guiding plate, the material inlet is connected to a variable diameter flow guiding pipe having a diameter of larger than a material liquid port, the material liquid flowing out of the variable diameter flow guiding pipe flows along the flow guiding plate, and the top portion of the tank body is provided with a gas discharge port for discharging the gas in the tank body, and a pressure gauge. According to the present invention, with the liquid fermentation culture medium online degassing apparatus, the liquid fermentation culture medium can be degassed before entering the liquid filter, such that the normal filtration of the material liquid filter filtering core is ensured so as to substantially improve the filtration efficiency and the filtration flux of the filtering core.

Owner:LUOYANG QIHONG BIOTECH

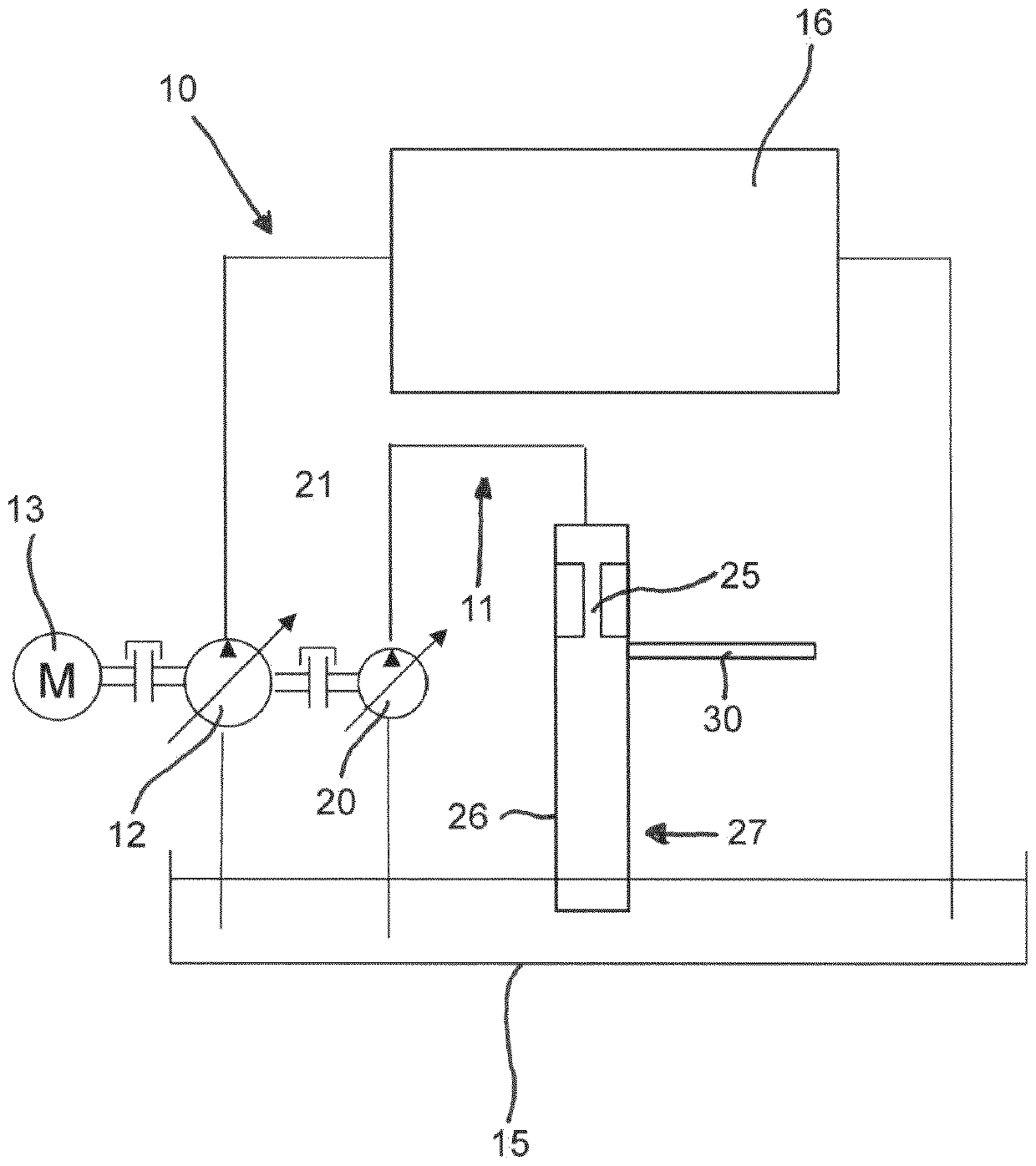

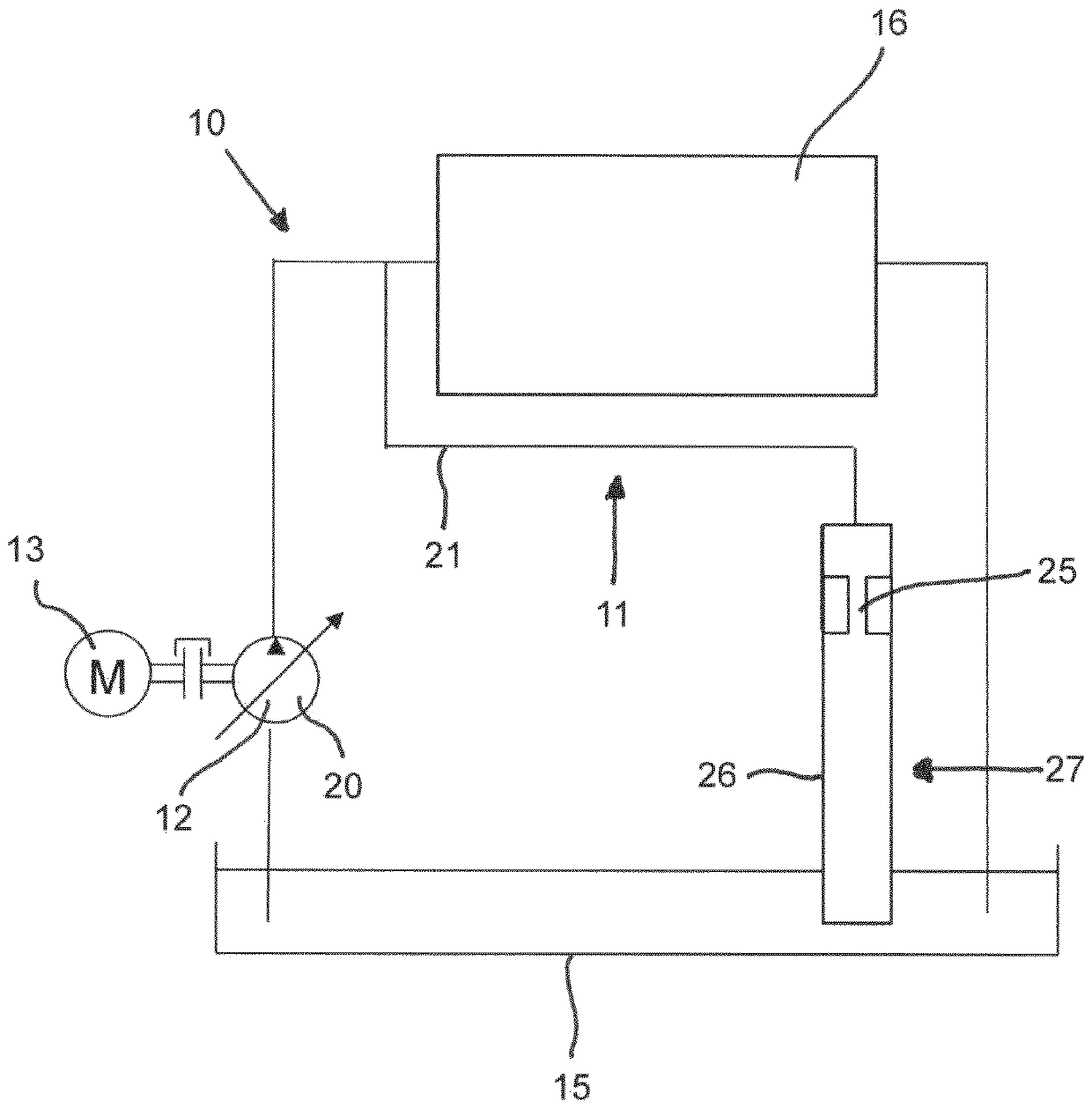

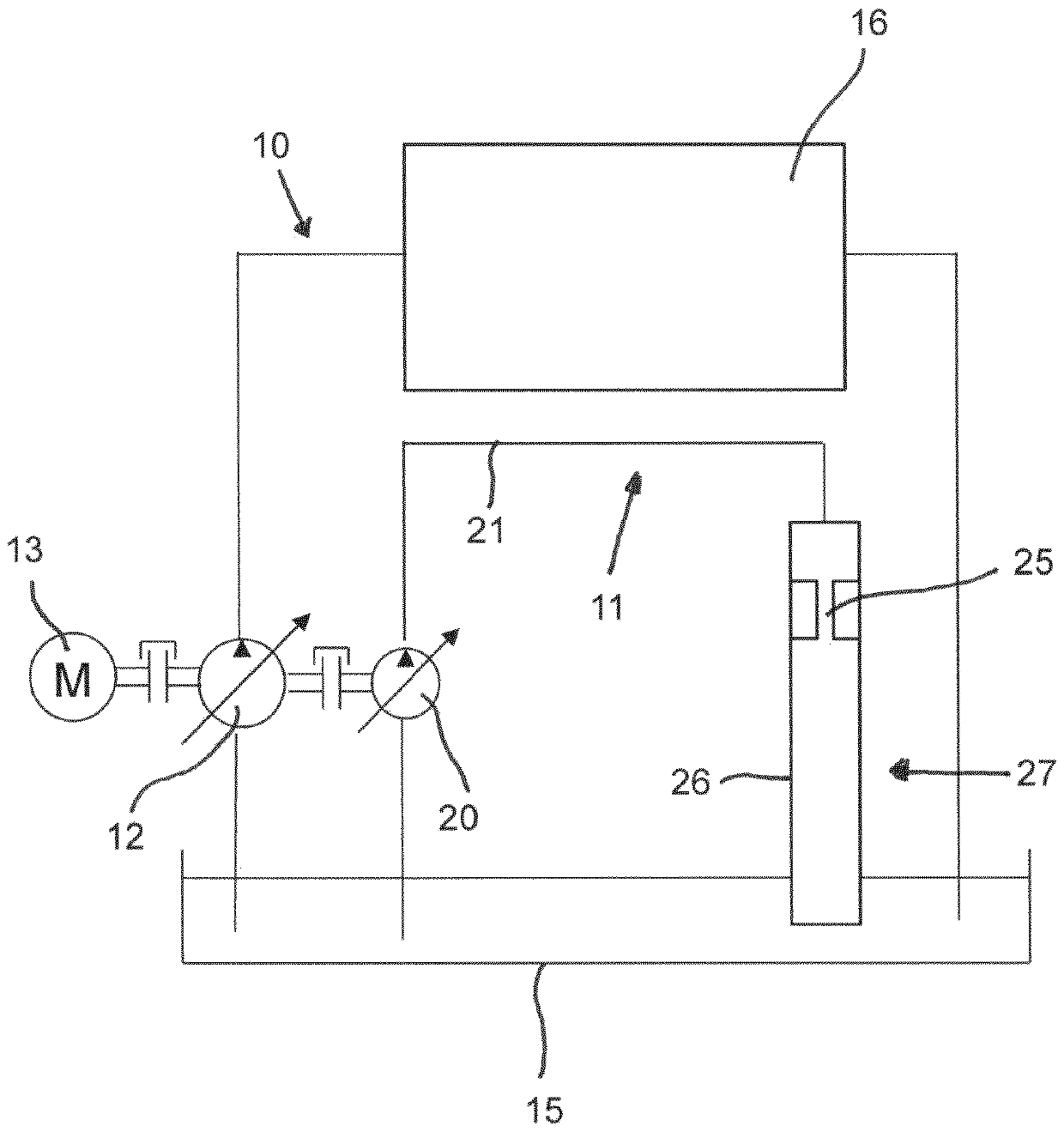

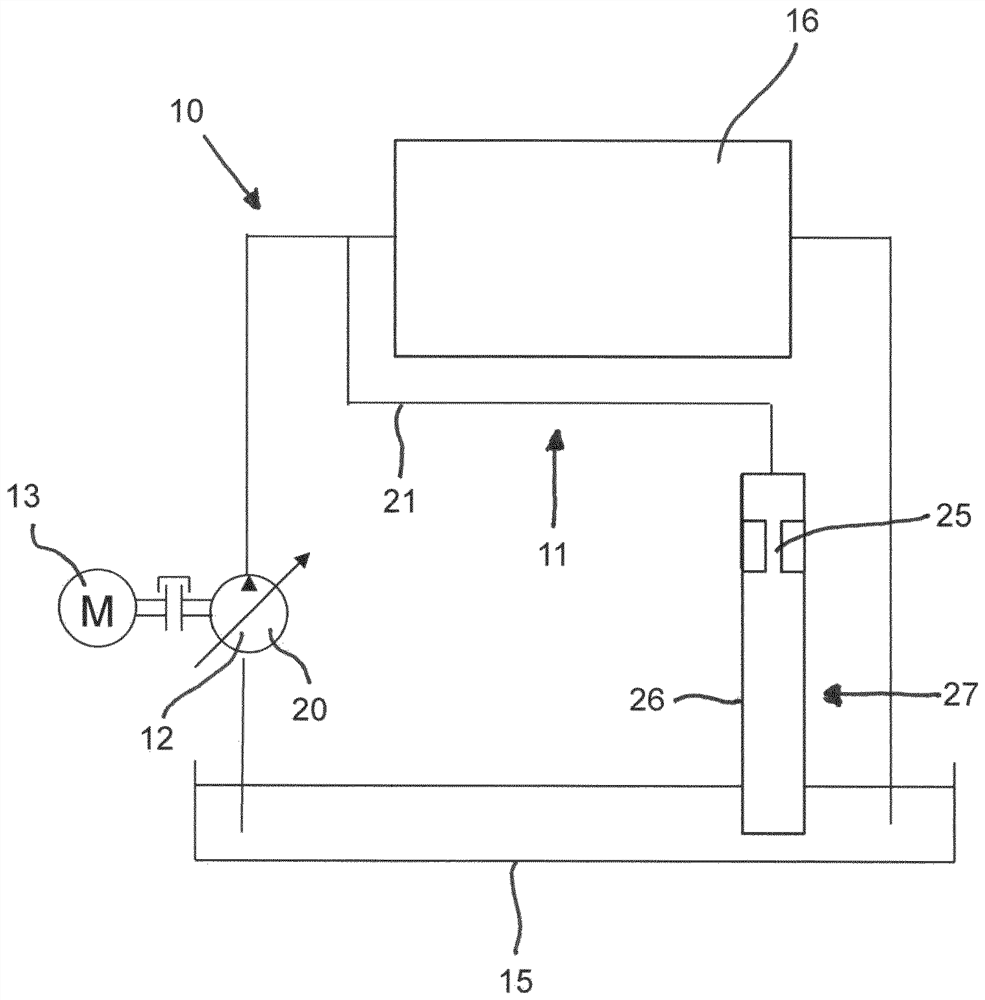

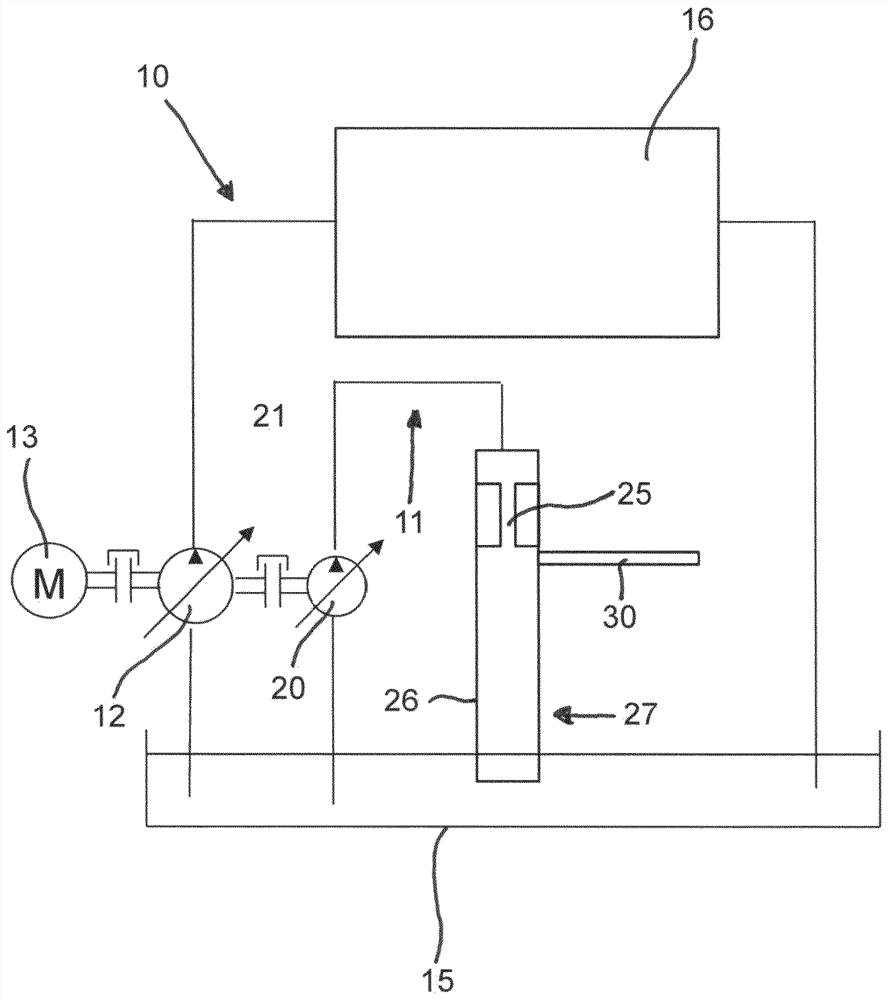

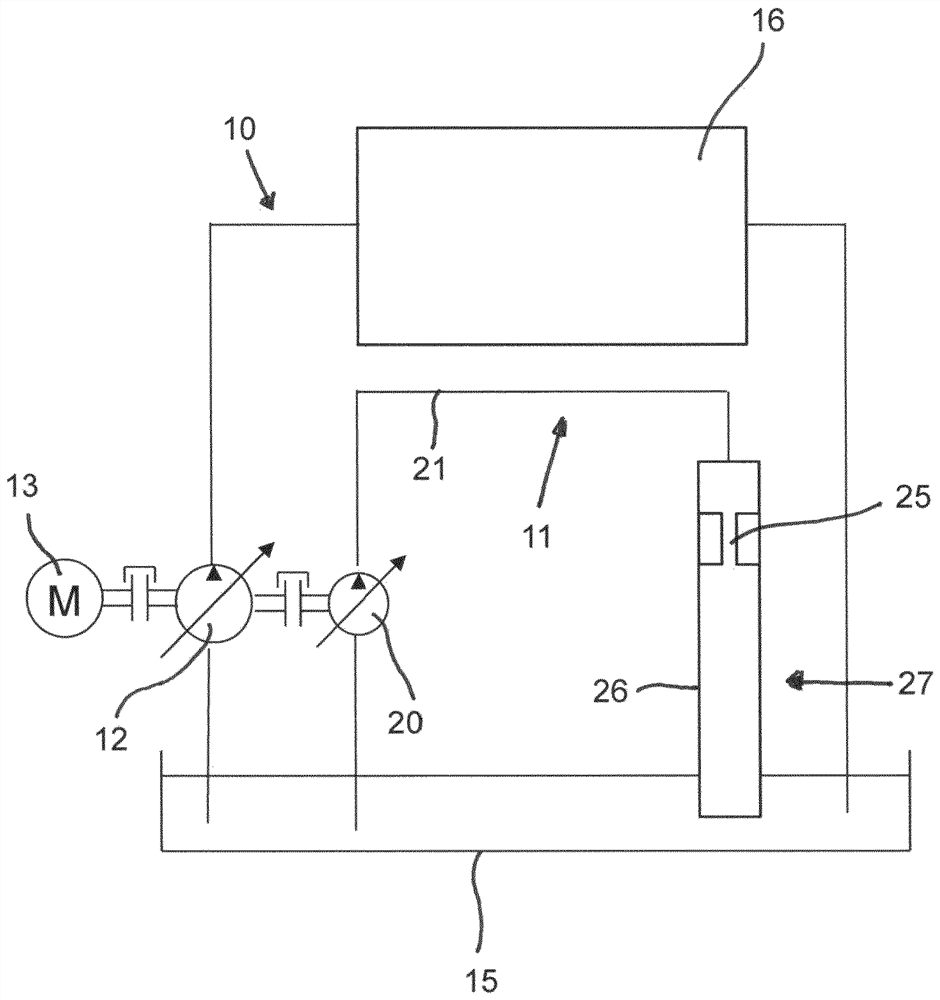

Hydraulic device for degassing and dewatering a hydraulic oil

ActiveCN109642597AEfficient degassing and dehydrationLow costPump assembliesLiquid degasification regulation/controlEnvironmental geologyThrottle

The invention relates to a hydraulic device for degassing and dewatering a hydraulic oil, comprising a pressure source from which a liquid to be degassed flows via a throttle point. The invention is characterized in that the quantity of liquid flowing via the throttle point and the flow cross-section of the throttle point are matched such that a cavitation or super cavitation zone is formed downstream of the throttle point, and a device is provided by means of which any kind of air can be introduced into the hydraulic oil from the outside.

Owner:ROBERT BOSCH GMBH

Three-stage tubular t-shaped degassing device with microbubble axial flow and spiral flow fields

PendingUS20220219100A1Low liquid contentEfficient solutionFluid removalLiquid degasification arrangementsDegasserMicrobubbles

A three-stage tubular T-shaped degassing device with microbubble axial flow and spiral flow fields is provided, which is applied to quick degassing of a gas-liquid two-phase flow. The three-stage tubular T-shaped degassing device adopts a quick degassing technology combining a microbubble uniform mixed rotational axial flow field and a spiral runner conical spiral flow field with layered jet collision reversing depth degassing. A microbubble uniform mixer is configured to adjust gas-liquid two-phase flow containing big bubbles into microbubble uniform mixed axial flow. A microbubble cyclone is configured to adjust the microbubble uniform mixed axial flow into multiple strands of rotational axial flows containing microbubbles. A rotational axial flow degasser implements the horizontal type microbubble uniform mixed multiple strands rotational axial flow degassing operation to remove most microbubbles to form axial flow gas and axial flow liquid.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Flexible wall permeameter for measuring coefficient of permeability

InactiveCN1312466CPrevent leakageAvoid precision requirementsSurface/boundary effectPermeability/surface area analysisC changeEngineering

This invention relates to a flexible wall penetration device to measure penetration parameters, which comprises the following structure: the confined pressure pipe, drainage pipe, water-in pipe are separately controlled to join the penetration pressure room; the confined pressure pipe and the drainage pipe and the water-in pipe are separately connected the pressure meter, air adjusting valve, pressure supply device and B-part changing pipe, pressure meter, air adjusting valve, supply device and C changing tube, pressure meter, air adjusting valve, supply device, air adjusting valve water box exit

Owner:HOHAI UNIV

An online transformer oil dielectric loss processing device

InactiveCN102592786BNo need to quit runningEasy to operateTransformers/inductances coolingWater dischargePositive pressure

An online transformer oil medium loss processing device, including a transformer, the oil inlet solenoid valve of transformer 1 sequentially passes through a primary filter, a heater, an atomizing device, an oil-water separator, a negative pressure adsorption tank, a two-way gear pump, and a positive pressure adsorption Tank, third-stage filter and oil return solenoid valve of the transformer are connected; there is a second manual valve between the oil inlet solenoid valve and the primary filter, a first manual valve between the third-stage filter and the transformer, and a second manual valve. The pipeline between the manual valve and the primary filter is connected through the pipeline between the neutral solenoid valve and the first manual valve and the third-stage filter. When the transformer oil dielectric loss treatment device is working, the pressure difference between the oil inside and outside Under the action of the inlet, it enters the primary filter for filtration. After the oil is heated, the oil and gas are separated, and the water is discharged. The oil enters the negative pressure adsorption tank for adsorption. The oil is heated in the pipeline and seeps into the positive pressure adsorption tank for adsorption. The oil is filtered by a three-stage filter and flows back to the transformer body, which has the advantages of online processing.

Owner:陕西恒成电力技术有限责任公司

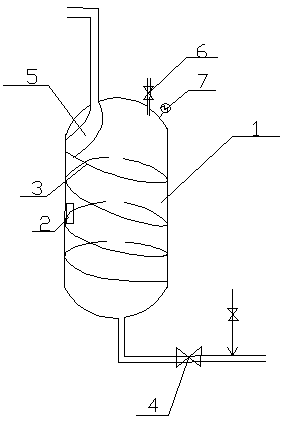

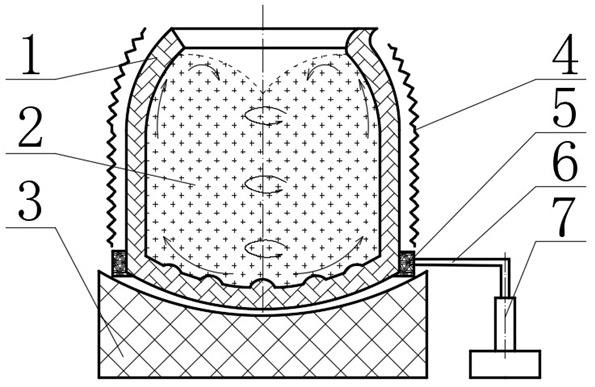

Hood-shaped circulation vacuum degassing device and method of use thereof

The invention relates to the field of vacuum treatment of molten iron alloys, in particular to a hood-shaped circulating flow vacuum degassing device. The hood-shaped circulating flow vacuum degassingdevice comprises a steel ladle trolley (1) and a steel ladle (2), and is characterized by further comprising a bottom blowing argon valve station (3), an insertion hood (4), a vacuum degassing tank (5), an alloy material charging device (6), a top blowing oxygen gun (7), a hot bending pipe (8) and a dry-type mechanical vacuum pump exhaust device (9); the vacuum degassing tank (5) is arranged overan opening of the steel ladle (2); the bottom of the vacuum degassing tank (5) is connected with the top of the insertion hood (4); the bottom of the insertion hood (4) is provided with a deslaggingtank (41). An application method of the hood-shaped circulating flow vacuum degassing device is characterized by comprising the following steps of a, deslagging and b, steel making. The hood-shaped circulating flow vacuum degassing device and the application method thereof have the advantages of rapid degassing, inclusion removal, high adaptability, high efficiency and low consumption.

Owner:CHINA METALLURGICAL EQUIP SHANGHAI ENG & TECH

Oil consuming system

PendingCN112204269AFully degassedQuick degassingFriction clutchesCouplingsThermodynamicsProcess engineering

The invention relates to an oil consuming system, and the system comprises at least one rotary component and at least one oil supply flow from an oil reservoir, the oil consuming system having an oilreturn flow to a first reservoir and an oil supply flow via at least one second reservoir.

Owner:MAGNA POWERTRAIN AG & CO KG

Hood-shaped circulating flow vacuum degassing device and application method thereof

The invention relates to the field of vacuum treatment of molten iron alloys, in particular to a hood-shaped circulating flow vacuum degassing device. The hood-shaped circulating flow vacuum degassingdevice comprises a steel ladle trolley (1) and a steel ladle (2), and is characterized by further comprising a bottom blowing argon valve station (3), an insertion hood (4), a vacuum degassing tank (5), an alloy material charging device (6), a top blowing oxygen gun (7), a hot bending pipe (8) and a dry-type mechanical vacuum pump exhaust device (9); the vacuum degassing tank (5) is arranged overan opening of the steel ladle (2); the bottom of the vacuum degassing tank (5) is connected with the top of the insertion hood (4); the bottom of the insertion hood (4) is provided with a deslaggingtank (41). An application method of the hood-shaped circulating flow vacuum degassing device is characterized by comprising the following steps of a, deslagging and b, steel making. The hood-shaped circulating flow vacuum degassing device and the application method thereof have the advantages of rapid degassing, inclusion removal, high adaptability, high efficiency and low consumption.

Owner:CHINA METALLURGICAL EQUIP SHANGHAI ENG & TECH

Hydraulic units for the degassing of hydraulic oils and for their dehydration

ActiveCN109642597BQuick degassingEasy to separateLiquid degasification regulation/controlPump assembliesDehydrationPetroleum engineering

According to the invention, a hydraulic unit for degassing and dehydrating hydraulic oil with a pressure source from which the liquid to be degassed flows through a throttling point, characterized in that the flow through said throttling point The amount of liquid is coordinated with the flow cross-section of the restriction, so that a cavitation or supercavitation is formed downstream of the restriction, and there is a device by which any Kind of air is introduced into the hydraulic oil.

Owner:ROBERT BOSCH GMBH

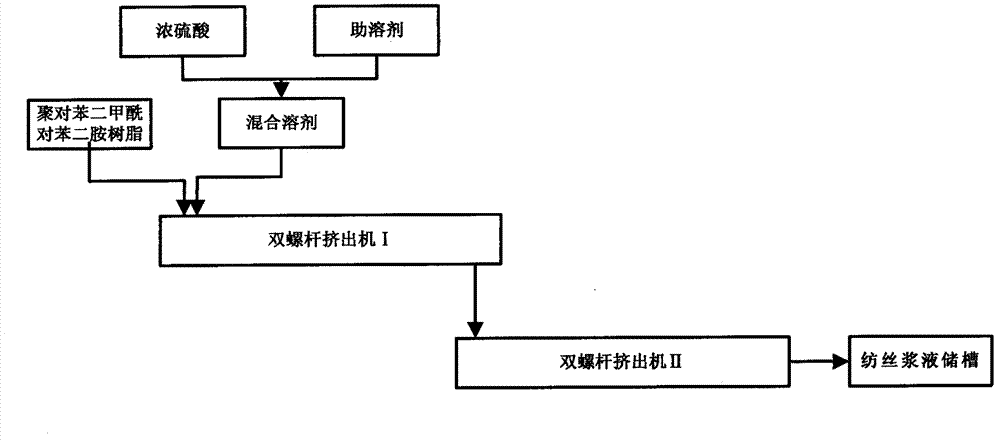

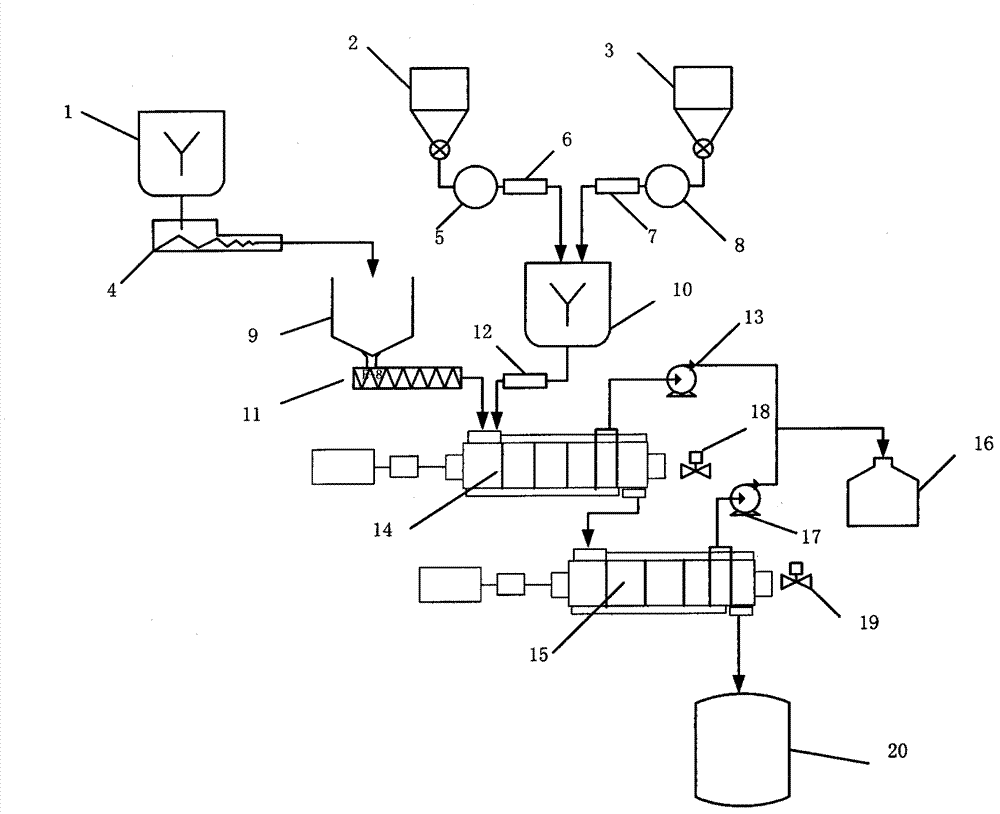

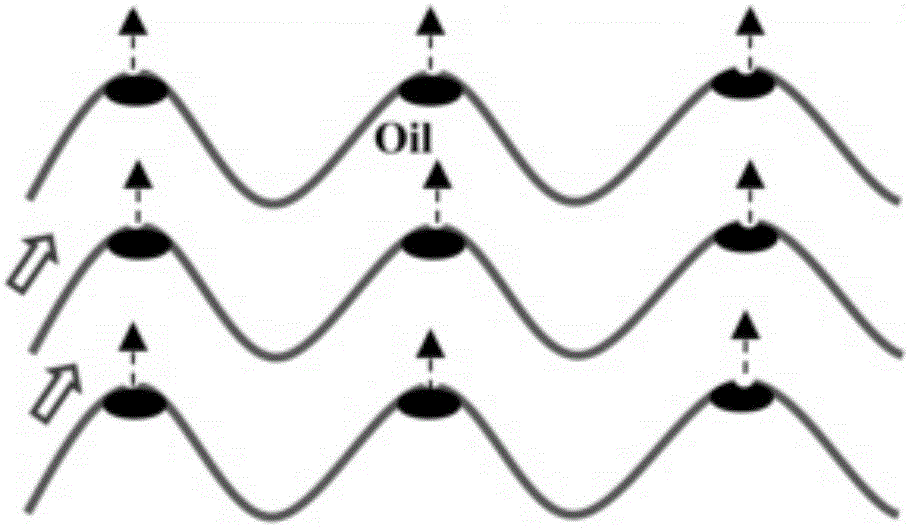

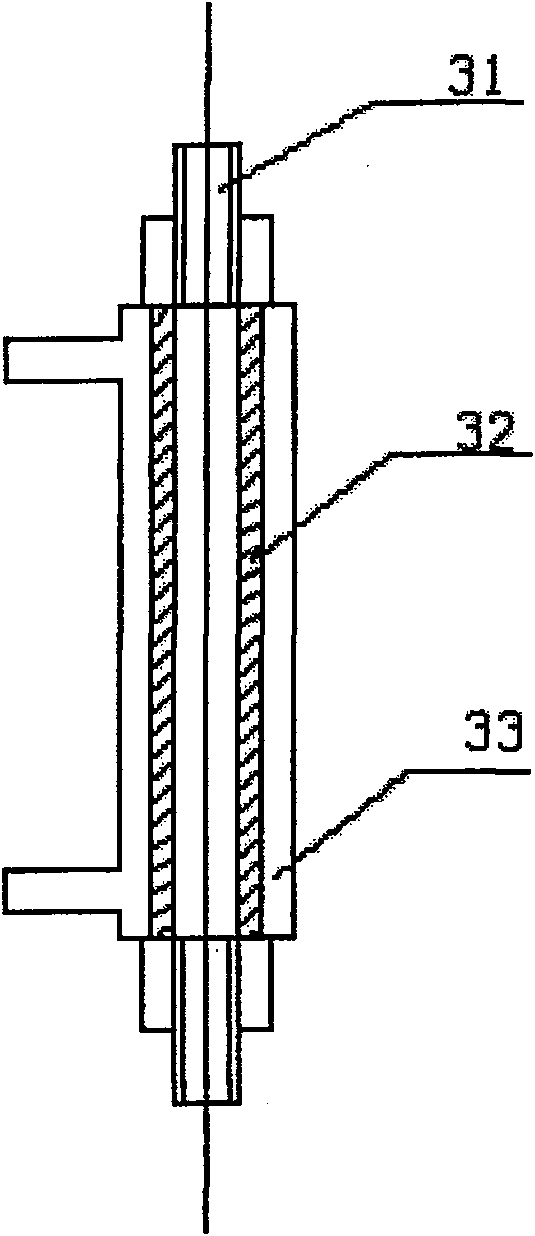

Device and method for efficiently dissolving poly(p-phenytene terephthalamide) resin

ActiveCN102268743BSolve product instabilityFast dissolutionSpinning solutions preparationFiberSlurry

The invention discloses a device and a method for efficiently dissolving poly(p-phenytene terephthalamide) resin, belongs to the field of polymer material manufacture, and relates to a high-polymer fiber material processing technology, in particular to a technology for preparing a poly(p-phenytene terephthalamide) spinning solution. The key points are that: a preparation device is used and the method comprises the following steps of: preparing a solvent for dissolving poly(p-phenytene terephthalamide); adding the solvent and dried poly(p-phenytene terephthalamide) resin with logarithmic specific concentration viscosity of 4.0-8.5dl / g into a first twin-screen extruder; and tightening a second twin-screw extruder to obtain high-efficiency uniformly dissolved slurry. The invention has the advantages that: defects in the prior art are overcome, and a process and a device suitable for industrial continuous high-efficiency and high-quality production are realized.

Owner:上海舟汉纤维材料科技股份有限公司

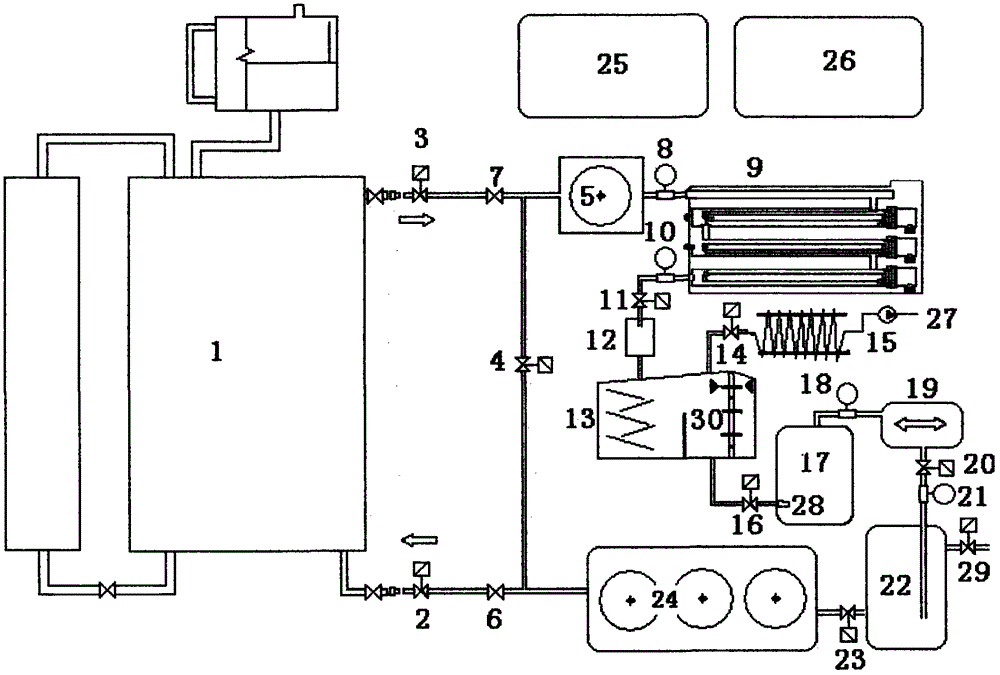

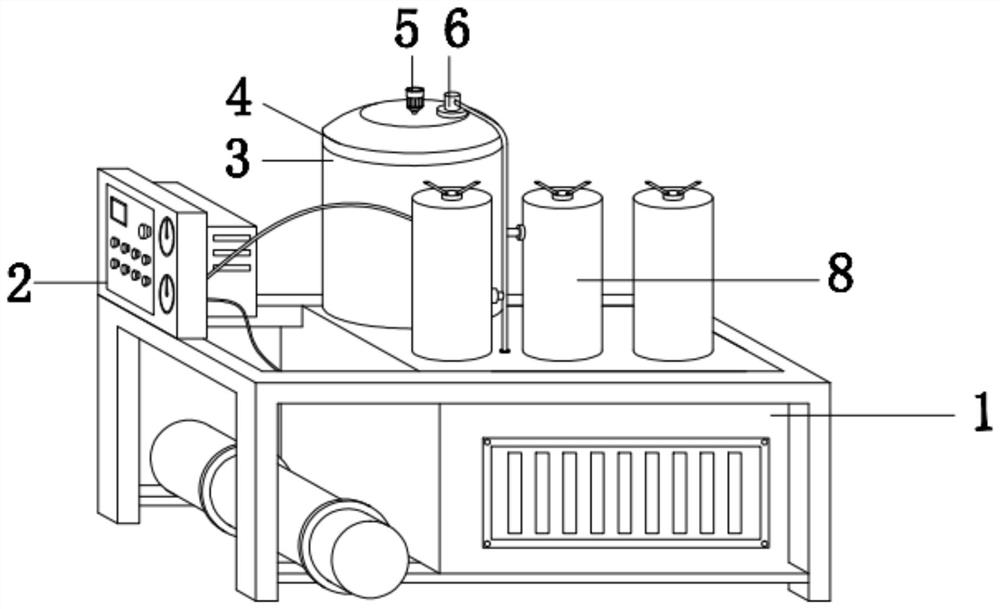

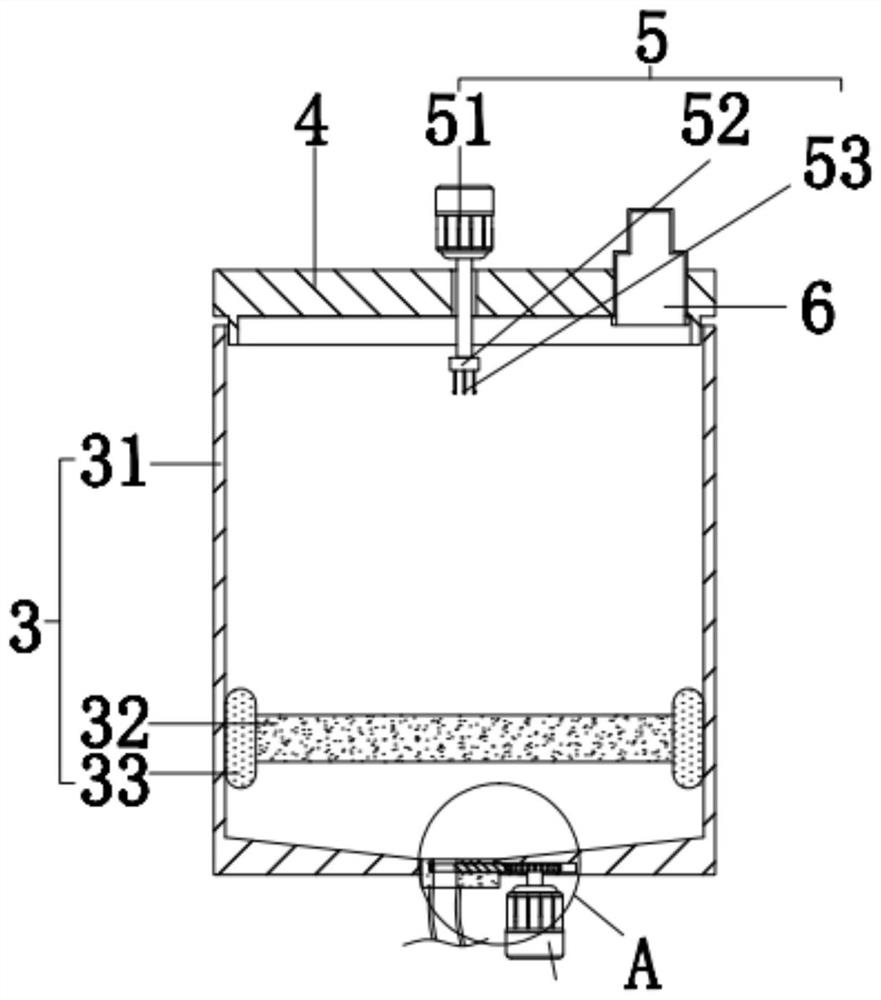

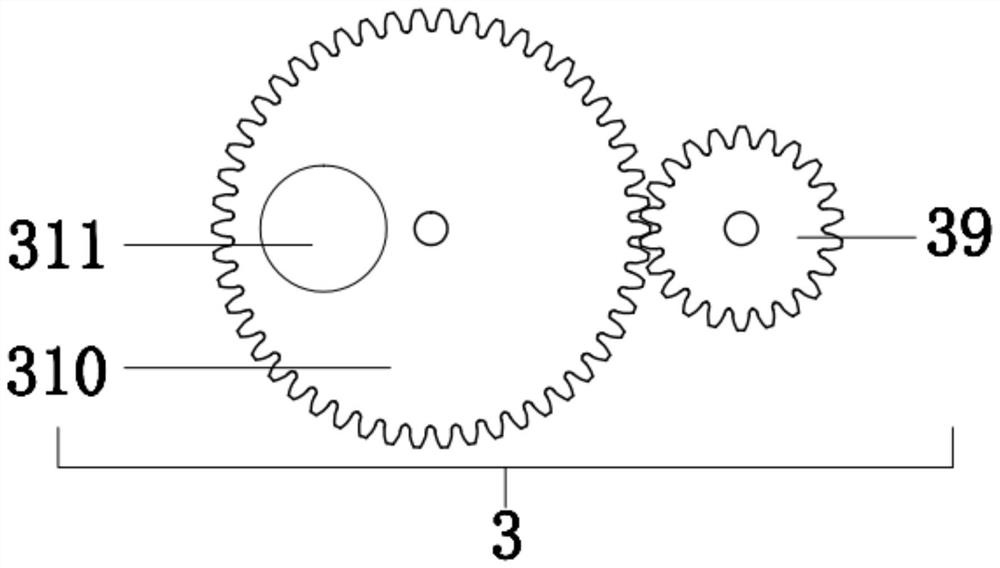

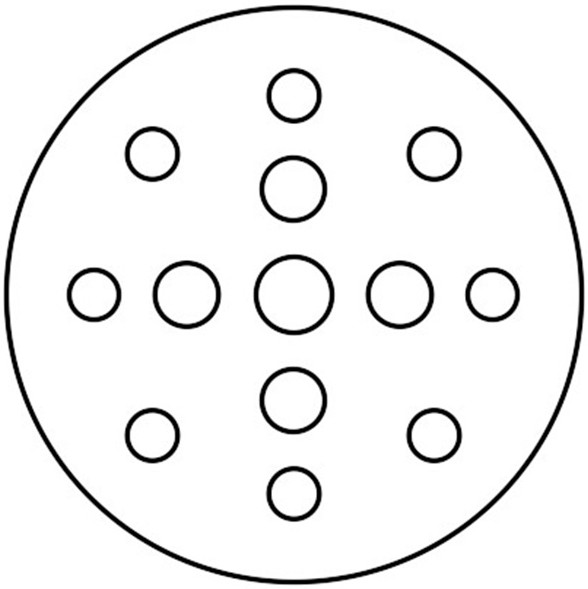

Modularized transformer oil chromatography degassing device

InactiveCN113289403AReduce pressureQuick degassingComponent separationHollow article cleaningThermodynamicsTransformer oil

The invention discloses a modularized transformer oil chromatography degassing device which comprises a base, a controller, a storage mechanism, a top cover and an oil filter, wherein the controller, the storage mechanism and the oil filter are all mounted at the top end of the base, and the top cover is placed at the top end of the storage mechanism; a clamping mechanism which can be assembled at the bottom end of the driving mechanism; the storage mechanism comprises an oil barrel which is installed at the top end of the base, and the top cover is placed at the top end of the oil barrel. According to the modularized transformer oil chromatography degassing device, in actual use, the occupied area can be saved while the degassing time is guaranteed to be saved, meanwhile, the first through hole can be closed or opened at any time, transformer oil sucked away by the oil filter is prevented from flowing back, or impurities such as cleaning fluid are prevented from flowing into the oil filter, and the inner wall of the oil drum can be easily and conveniently cleaned.

Owner:常州市佳华电子有限公司

A kind of zinc alloy smelting equipment and its production process

ActiveCN111536796BImprove purityImprove uniformityStirring devicesCharge treatment typeZinc alloysMaterials science

Owner:贵州森远增材制造科技有限公司

Online degassing method and device for pipeline fluid

The invention relates to an online degassing method and device of a pipeline fluid. The method comprises the following steps: changing the linear motion of the pipeline fluid to the rotary flow motion through a helical flow guider, and initially and quickly degassing liquid under the action of a rotary centrifugal force; then, separating out part of dissolved gas under micro negative pressure formed by a venturi ejector with the helical flow guider and quickly and deeply degassing liquid containing trace gas under the action of the centrifugal force; at last, discharging the gas to a gas liquid separation tank for separation through a flow guide pipe, discharging the separated gas, and returning the liquid in the liquid separation tank to a pipeline. The device realizing the method comprises an inlet outlet joint flange, the helical flow guider, an umbrella-shaped top cap, the venturi ejector, the gas flow guide pipe, the liquid separation tank and a liquid discharging valve. The device is ingenious in design and small in size, can be directly connected to the pipeline, has energy-saving and consumption-reducing effects on conveying of gas-containing fluid, and can be widely applied to various fluid conveying processes in petrochemical industry.

Owner:EAST CHINA UNIV OF SCI & TECH

Flexible thin film lithium ion battery and manufacturing method thereof

ActiveCN102522595BPrecise Package ThicknessReduce thicknessCell electrodesFinal product manufactureFiberComposite film

The invention discloses a flexible thin-film lithium-ion battery and a manufacturing method thereof. The flexible thin-film lithium-ion battery is composed of a positive electrode layer, a diaphragm, a negative electrode layer and an outer packaging layer. The positive electrode material is printed on one side of aluminum foil, and the negative electrode layer is composed of copper foil with a thickness of 10-30μM and the negative electrode material printed on one side of the copper foil by gravure printing technology. The outer packaging layer is aluminum-plastic composite film. The positive electrode material of the battery includes the dispersant Hypermer KD-1, and the negative electrode material of the battery includes the conductive agent vapor phase growth carbon fiber. The flexible thin-film lithium-ion battery of the present invention has the beneficial effects of high safety, good thickness consistency, thickness control reduced to 0.25MM, good flexibility, no deformation after repeated bending, and no influence on battery performance.

Owner:江苏百特福新能源科技有限责任公司

Ceramic slabs and a method for manufacturing thereof

InactiveCN101835725AEasy to degasQuick degassingPigmenting treatmentClaywaresDiiron TrioxideHematite

Owner:GRANITIFIANDRE

A step-by-step separation method of mixed oil and water coupled with oil and gas washing

ActiveCN104673367BProtection for long-term operationEfficient separationFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiberSewage

Owner:EAST CHINA UNIV OF SCI & TECH

A method and device for preliminary separation of oil and water coupled with oil and gas washing

ActiveCN104629794BQuick degassingSimple structureDewatering/demulsification with mechanical meansCombustible gas purificationThermodynamicsAqueous droplet

The invention relates to an oil-gas-washing-coupled oil-water initial separation method and device. The method comprises the following steps: light oil containing 0.5-6% of synthetic water and hydrocarbon-component-containing gas enters a tubular mixer at an inlet section to wash hydrocarbon components in the gas, and are subjected to liquid separation by a T-shaped liquid-gas separator; the water-containing oil sequentially passes through a rectifying distributor, a water drop coarse granulation module and a CPI quick dewatering module from left to right, and the water enters a water drum; sewage containing 0.05-0.5% of oil enters from a right end socket, and freely flows leftwards to sequentially pass through an oil drop coarse granulation module and an CPI quick oil removal module to perform oil removal; and finally, the water in the water drum and the water obtained by right partition oil removal are discharged by an oil-water interface controller; and the oil separated from the right side of the partition is communicated with the oil on the left side via the upper part of the partition, and is discharged under the action of a liquid level controller. The method couples the functions of oil dewatering, water oil-removal and oil-gas washing recycling, has the advantages of small occupied space and quick and efficient separation, and overcomes the defects in the prior art.

Owner:EAST CHINA UNIV OF SCI & TECH

Car shell model material recovery device

ActiveCN108326008BAvoid manual collectionEasy to operateSievingScreeningAutomobile designProcess engineering

The invention belongs to the technical field of automobile design, and in particular relates to a vehicle shell model material recovery device; it includes a frame, a workbench and an oven installed on the frame, and also includes a collection box and a recovery box both installed on the frame; The top opening of the box is designed, and the top of the collection box is provided with a support frame for supporting the workbench. A receiving chamber is formed between the workbench and the collection box. The bottom of the tank is provided with a blanking screen, and the blanking screen has a number of blanking holes; the recovery box includes a support shell and a number of collection pipes that are rotatably connected to the support shell. One alignment; the recovery box is also provided with a driving mechanism for driving some collecting tubes to rotate. The scheme can conveniently recycle the oil sludge, reduce the air bubbles in the oil sludge, and improve the uniform mixing effect of the oil sludge.

Owner:重庆迪科科技产业有限公司

Micro-bubble axial flow and swirl double-field three-stage tube type T-type degassing device

ActiveCN112892001BQuick degassingLow liquid content in gasFluid removalLiquid degasification arrangementsLiquid jetMicrobubbles

The invention provides a three-stage tube-type T-type degassing device with micro-bubble axial flow and swirl flow, which is applied to the rapid degassing of gas-liquid two-phase flow. The three-stage tubular T-type degassing device adopts the rapid degassing technology combining the micro-bubble homogeneous rotating axial flow field and the conical swirling field of the spiral channel with the stratified jet collision and reversing deep degassing. The gas-liquid two-phase flow containing large bubbles is adjusted to a microbubble homogeneous axial flow, and the microbubble swirler adjusts the microbubble homogeneous axial flow to a split rotating axial flow containing microbubbles, and the rotating axial flow degasser implements Horizontal micro-bubble homogeneous mixing split-share rotary axial flow degassing operation, remove most of the micro-bubbles to form axial flow gas and axial flow liquid, conical swirl degasser implements vertical spiral channel single-strand conical swirl Degassing operation, removing the remaining small amount of micro-bubbles to form swirling gas and swirling liquid, jet flow reversing degasser implements vertical layered jet collision reversing degassing operation, removing small-sized droplets to form reversing Gas and reversing liquid.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

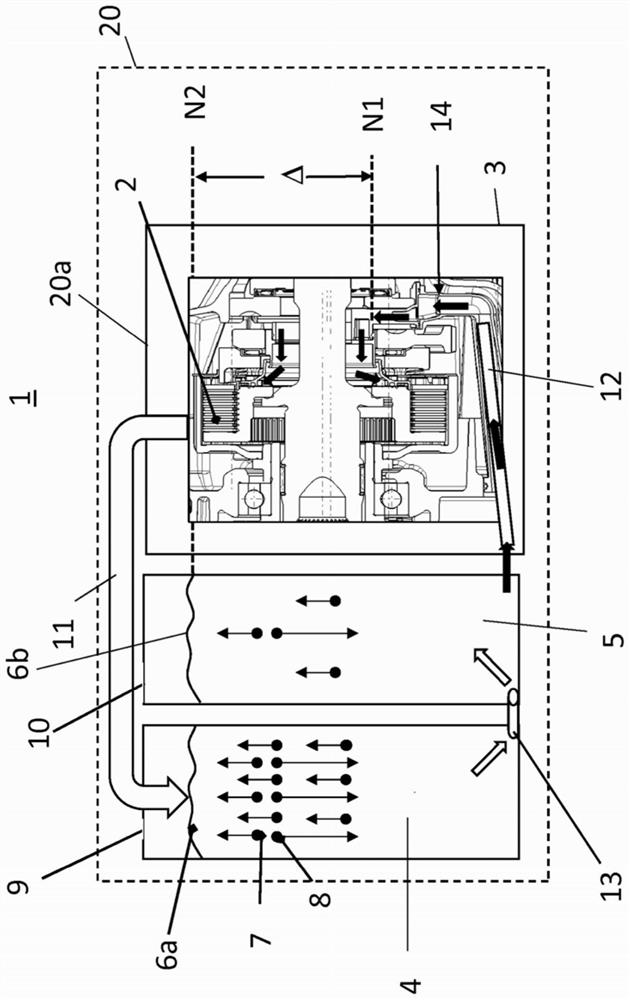

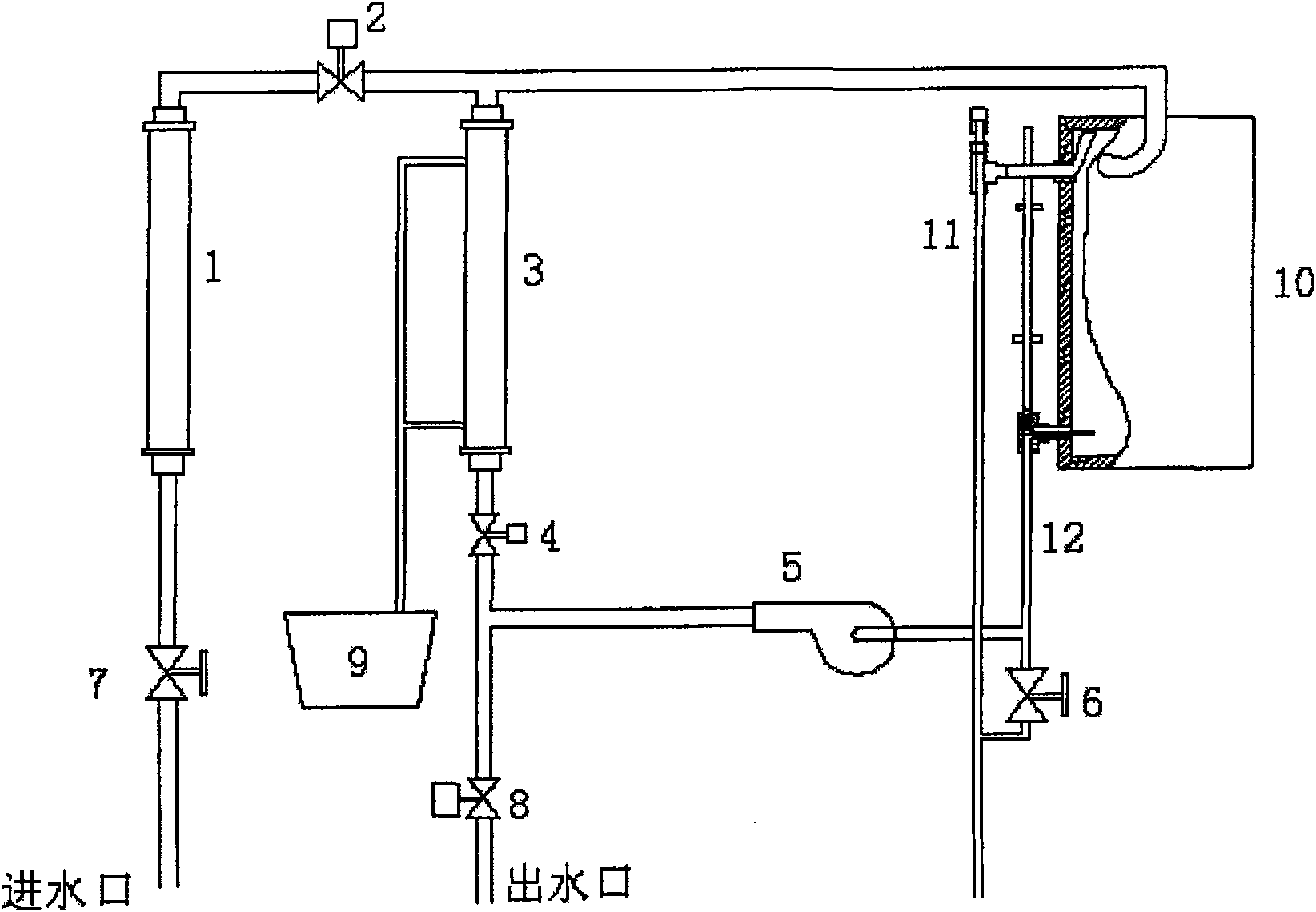

Ultrasound tumor treating system water treating device

InactiveCN100594957CReduced sealing requirementsQuick degassingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyTherapeutic DevicesTumor therapy

The invention discloses a water processing device of an ultrasonic tumor therapy system, including a degassing pipe, a water pump, a vacuum pump and a water tank; a water inlet of the water tank, a water outlet of the water tank and a water overflow port are arranged on the water tank, the water outlet of the water tank is connected with a water inlet end of the water pump by a pipeline, a water outlet end of the water pump is connected with the degassing pipe by the pipeline, the degassing pipe is connected with the water tank by the pipeline, an exhaust end of the vacuum pump is connected with the degassing pipe, a first valve is arranged on a connecting pipeline of the water pump and the degassing pipe, the connecting pipeline of the water pump and the degassing pipe is connected with awater outlet pipeline, and a second valve is arranged on the water outlet pipeline. The water processing device of the ultrasonic tumor therapy system carries out the degassing treatment of water bytaking the degassing pipe and the vacuum pump as the core; the invention can reduce the sealing requirements of the whole degassing device, have rapid degassing and improve degassing efficiency, so the invention is a great progress of ultrasonic tumor therapy equipments.

Owner:SHENZHEN LANDWIND IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com