Patents

Literature

48results about How to "Avoid precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

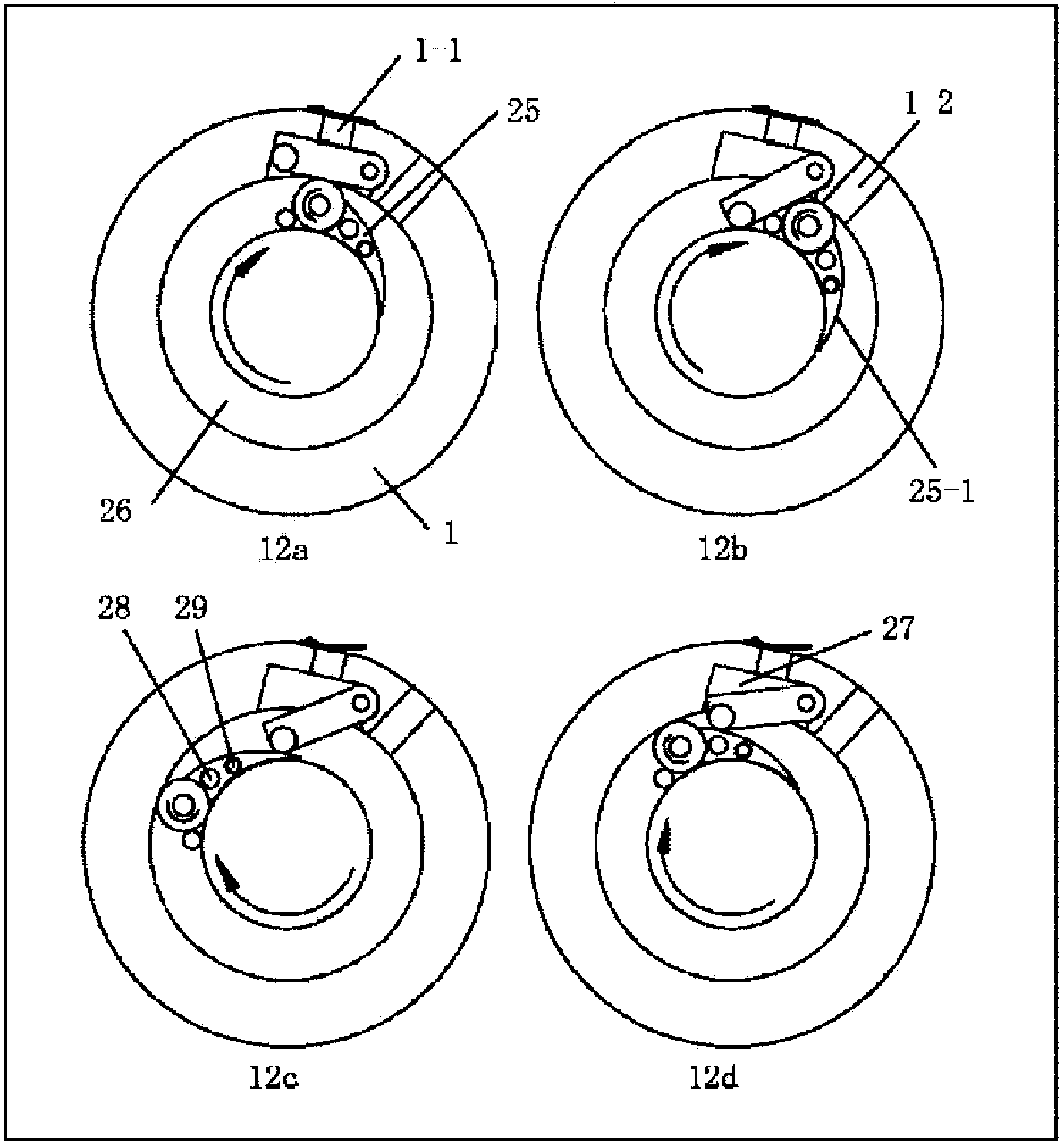

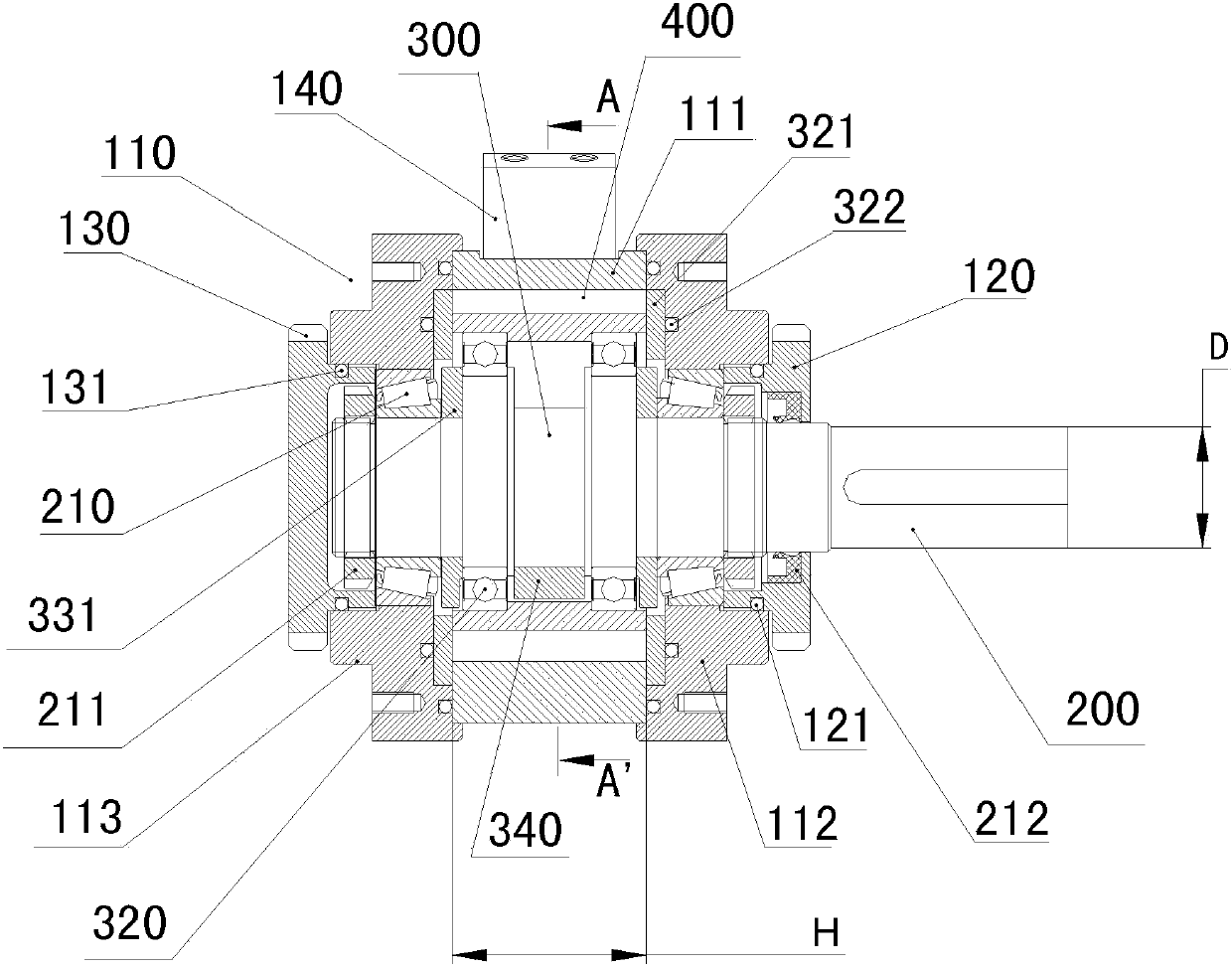

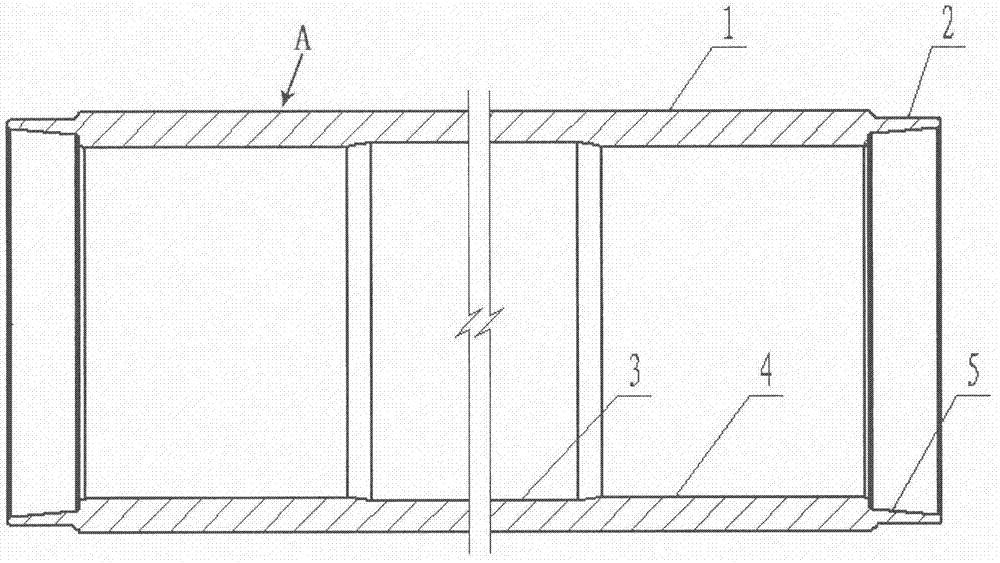

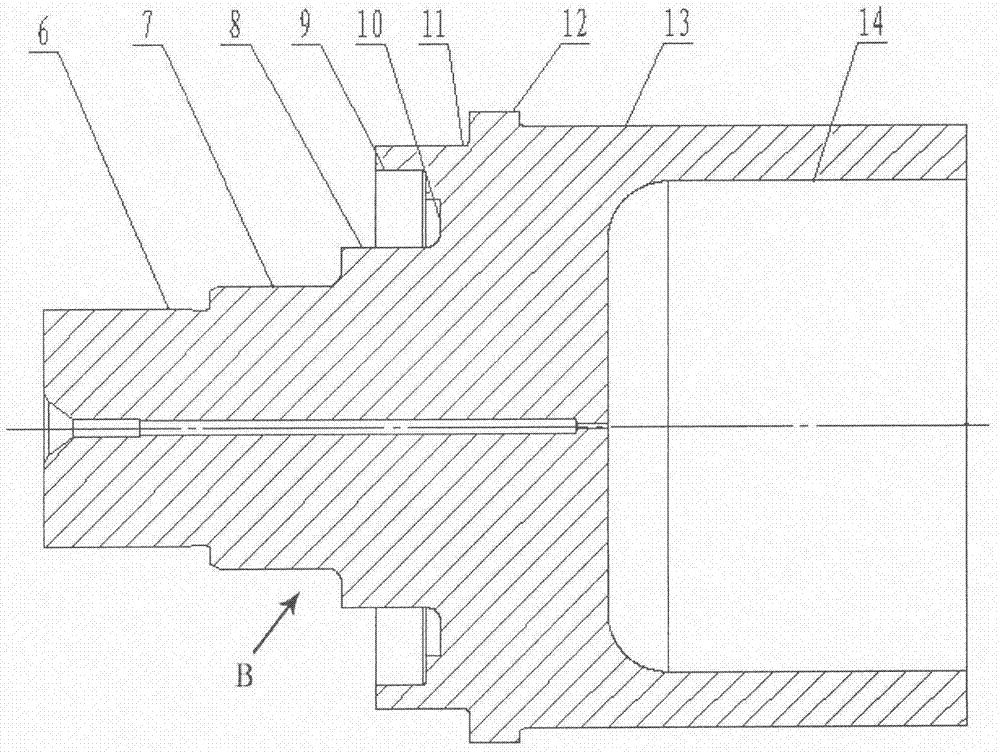

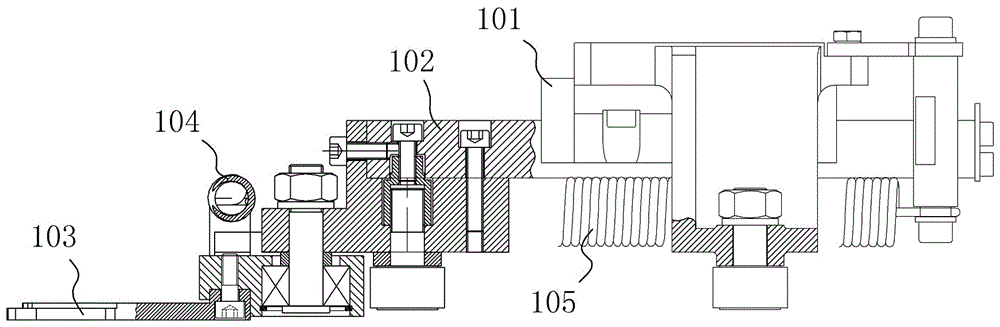

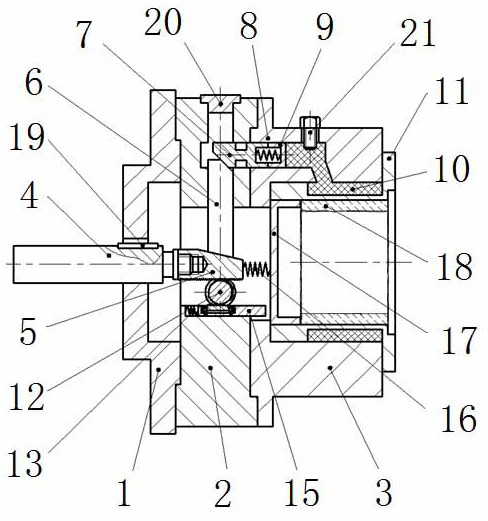

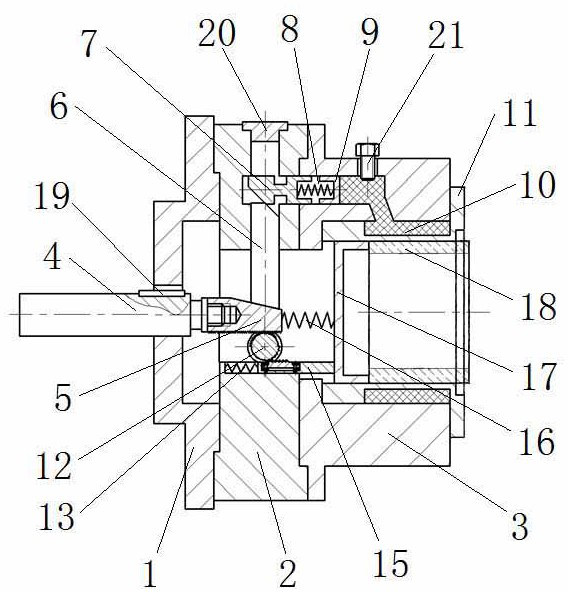

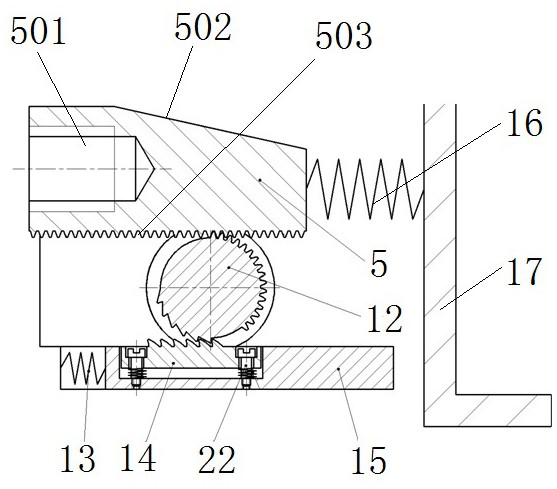

Rotation apparatus, rotor type compressor applying rotation apparatus, and fluid motor applying rotation apparatus

ActiveCN103967787AAvoid precision requirementsLow costRotary/oscillating piston combinations for elastic fluidsRolling contact bearingsEngineeringMechanical engineering

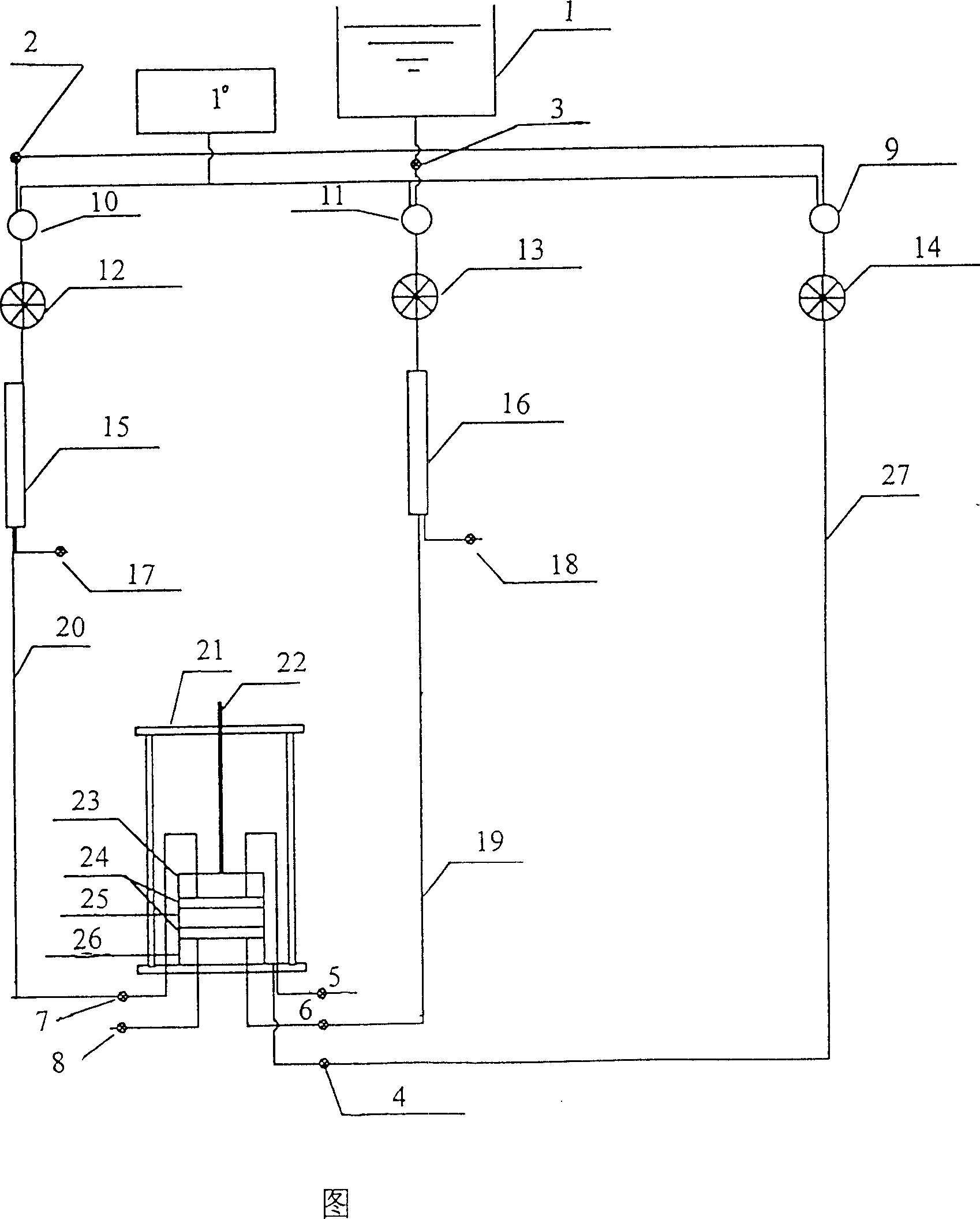

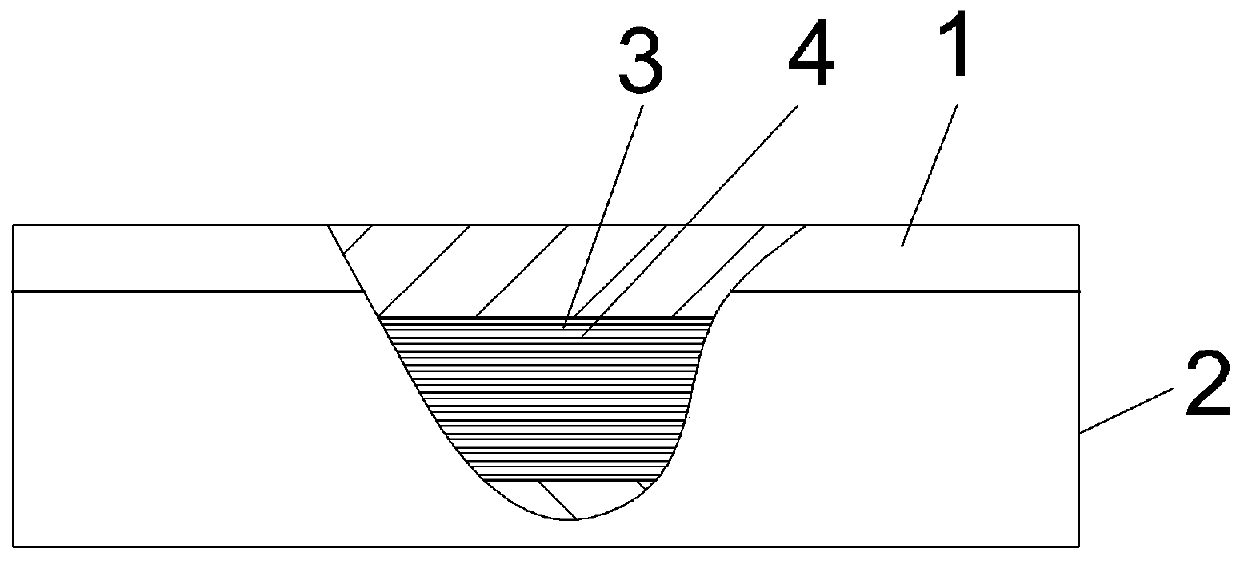

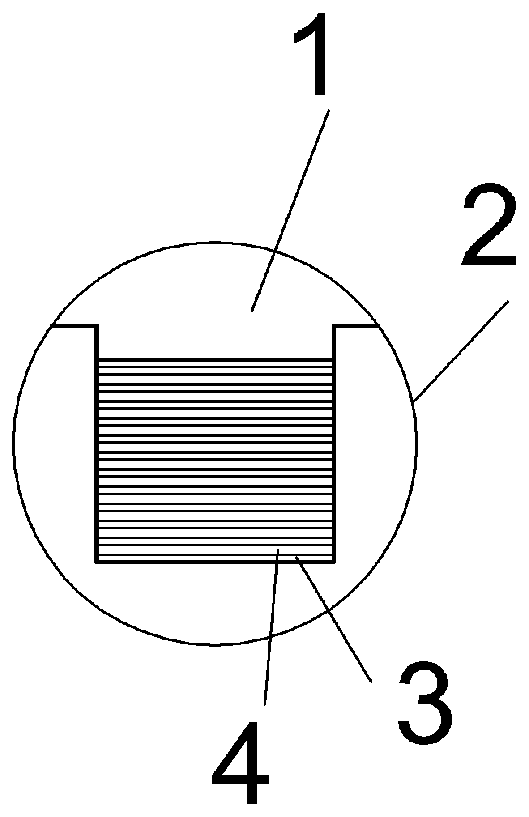

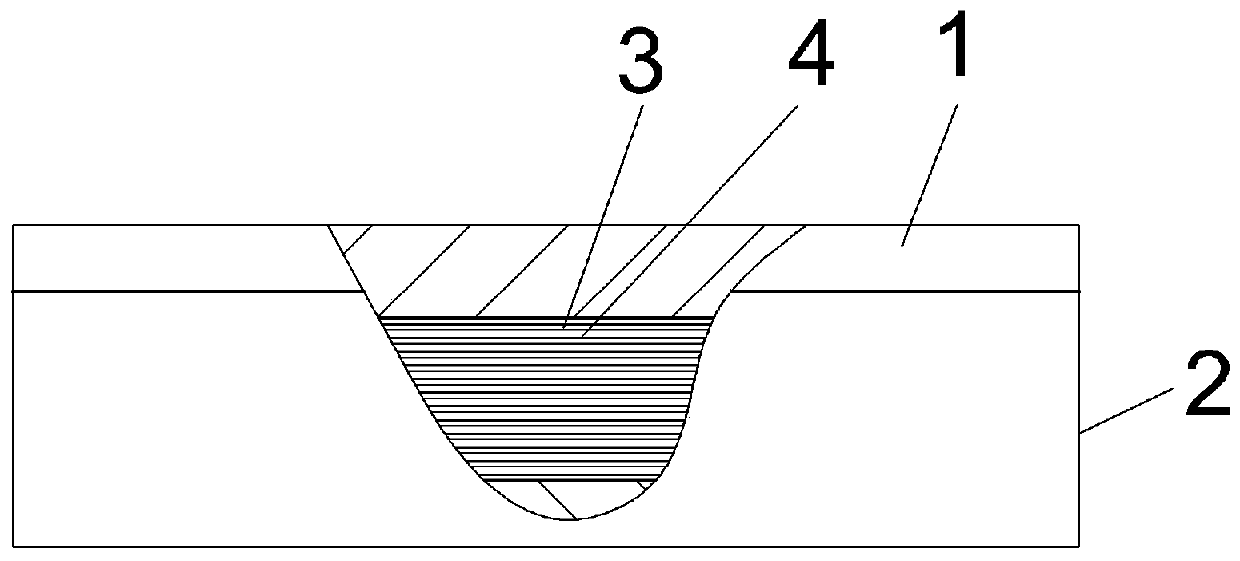

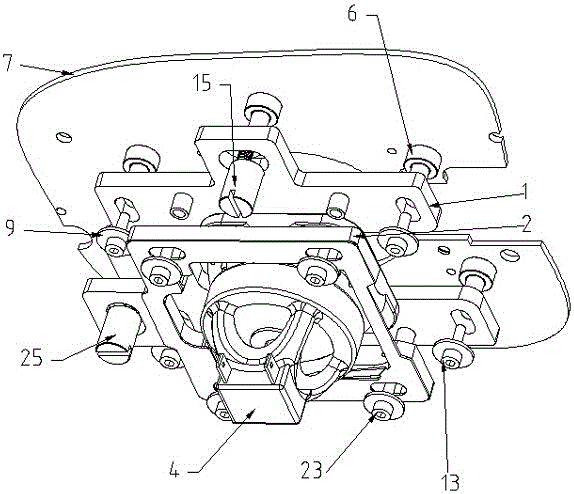

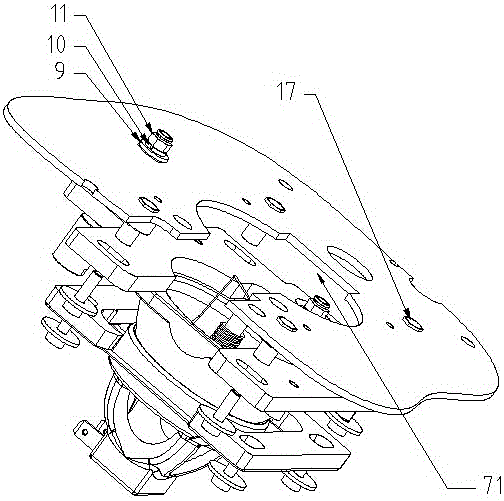

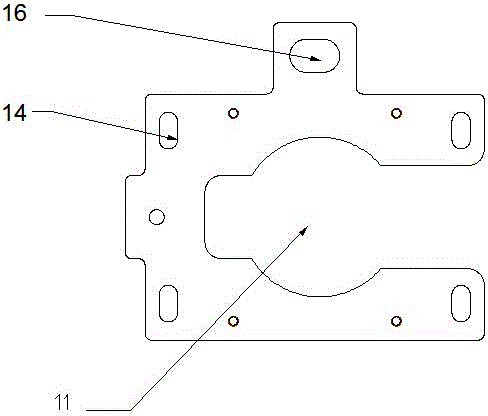

The present invention provides a rotation apparatus, a rotor type compressor applying the rotation apparatus, and a fluid motor applying the rotation apparatus. In the rotation apparatus, a rolling bearing manner is adopted between an eccentric shaft and a rolling piston wheel, reliable sealing of a cylinder is achieved through elastic pre-tightening force, and improvement is performed on a valve rotating body and a valve rotating body reset mechanism.

Owner:BEIJING ROSTAR TECH

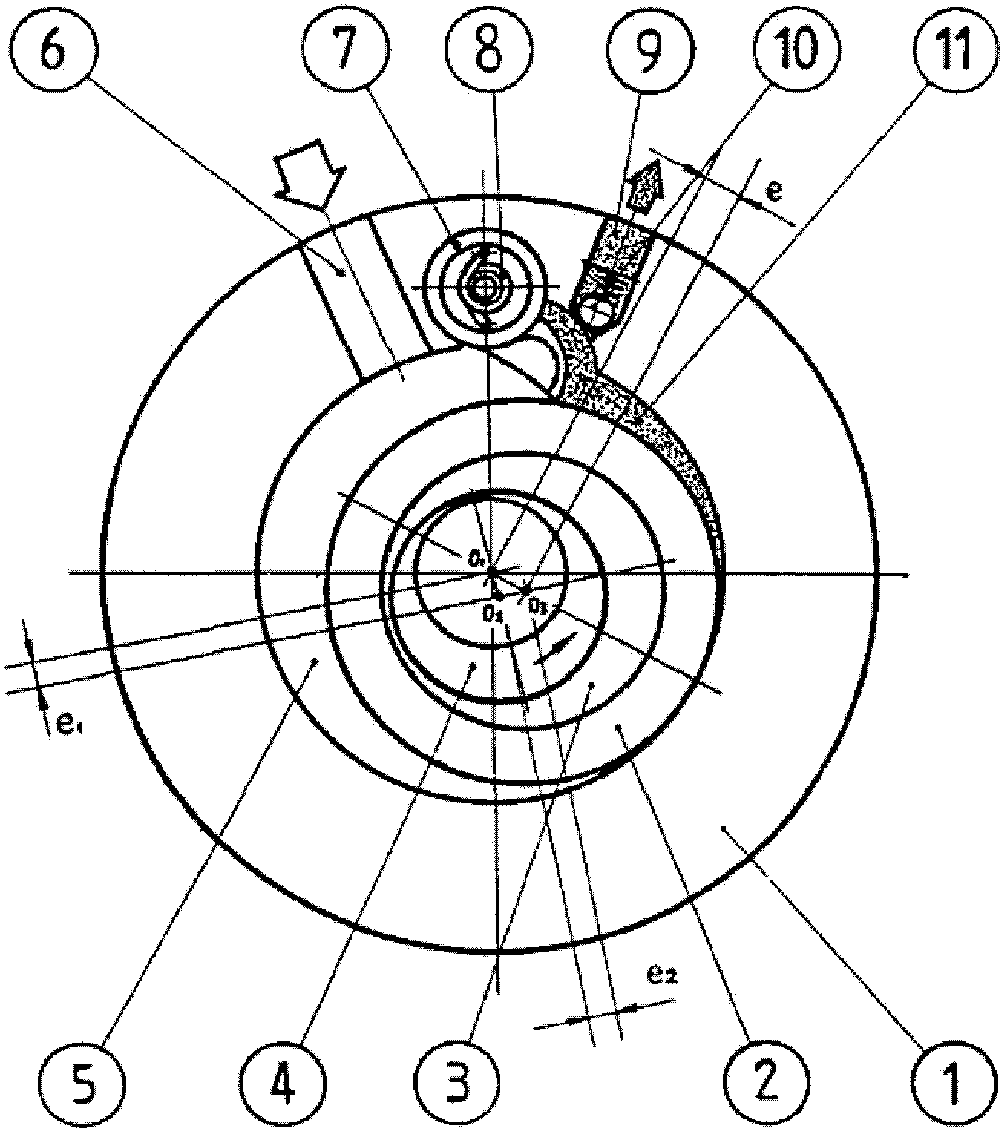

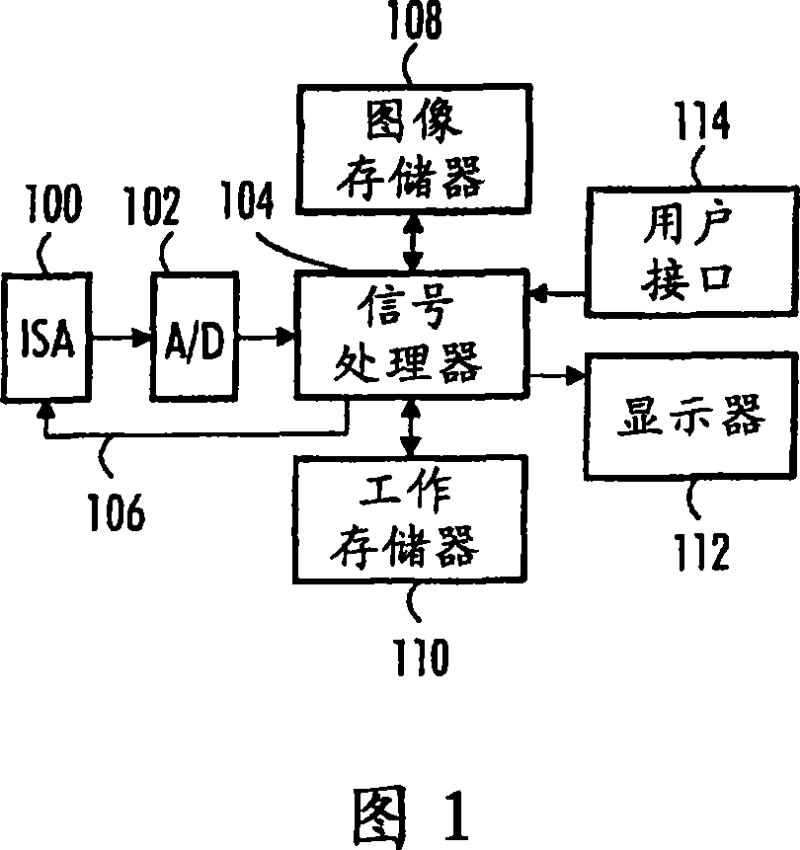

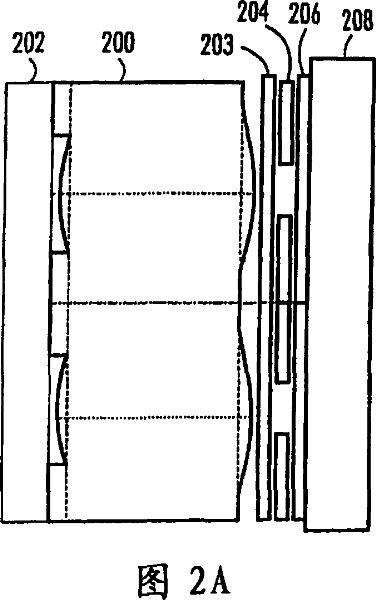

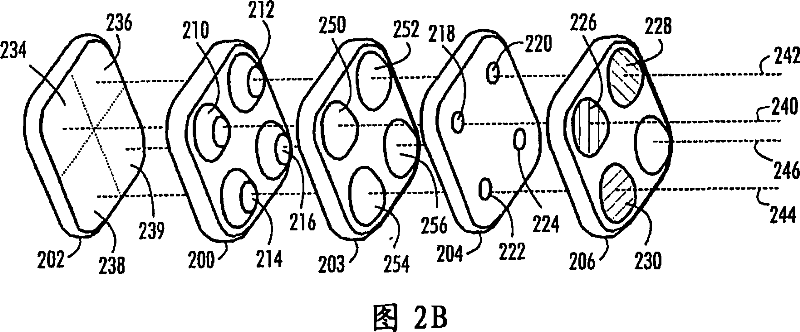

Method of creating color image, imaging device and imaging module

InactiveCN101036380AAvoid precision requirementsSolve the problem of irregular sparse samplingTelevision system detailsTelevision system scanning detailsCamera lensColor image

An imaging device comprising at least three image capturing apparatuses is provided. Each apparatus includes a lens system and a sensor and is configured to produce an image. The device further comprises a processor configured to combine at least a portion of the images with each other to produce a colour image. Each lens system comprises a phase mask which modifies the phase of incoming rays of light such that distribution of rays after the lens system is insensitive to the location of the sensor.

Owner:NOKIA CORP

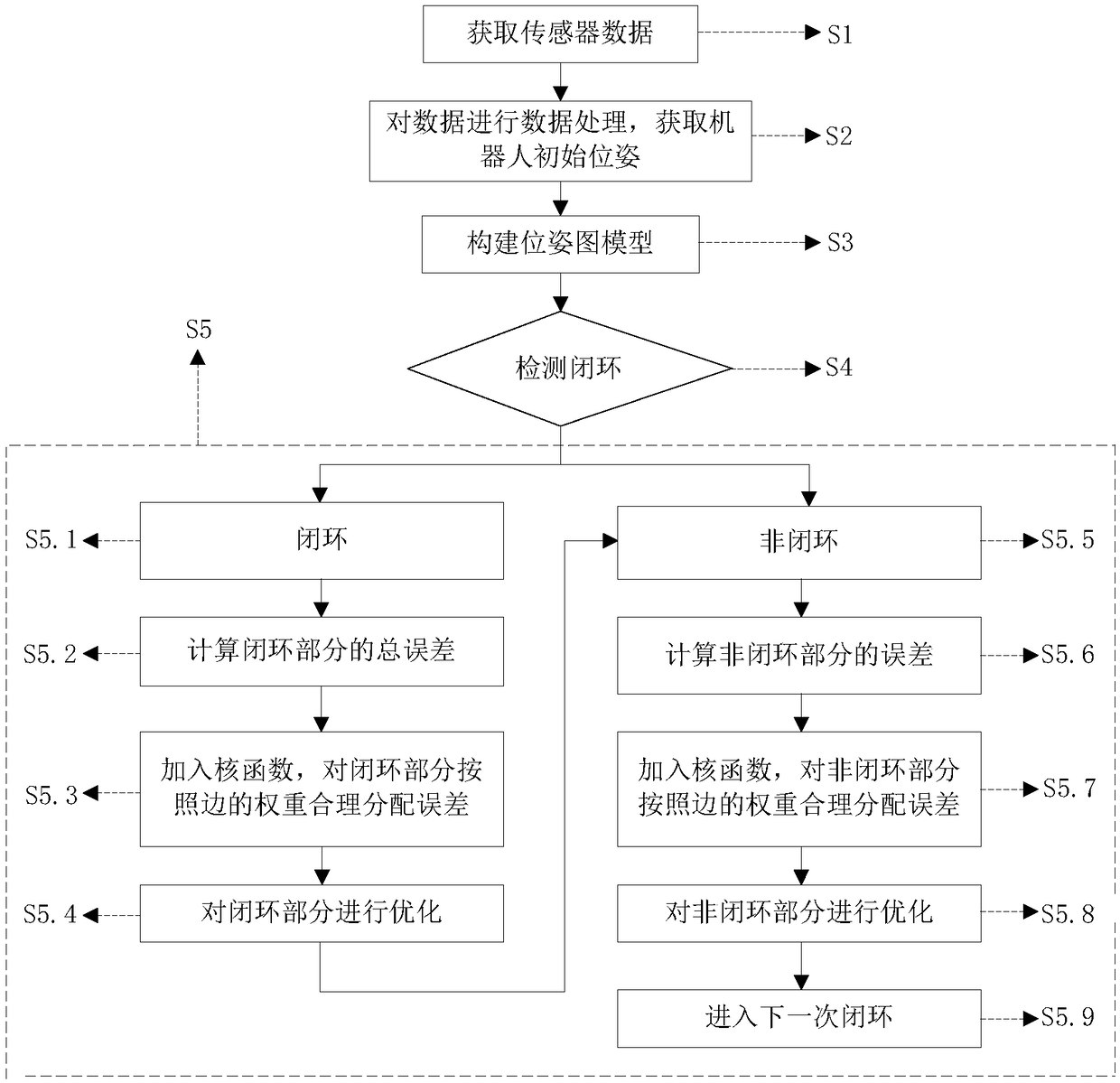

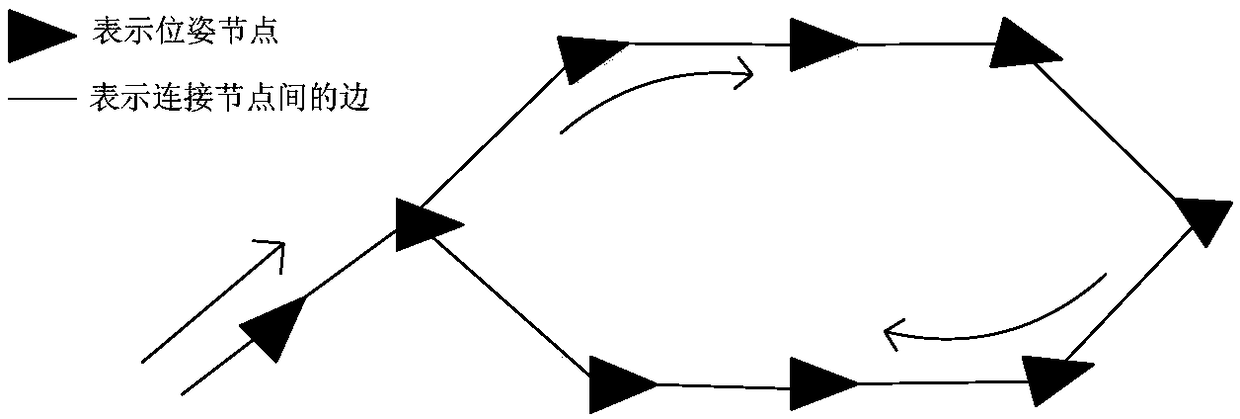

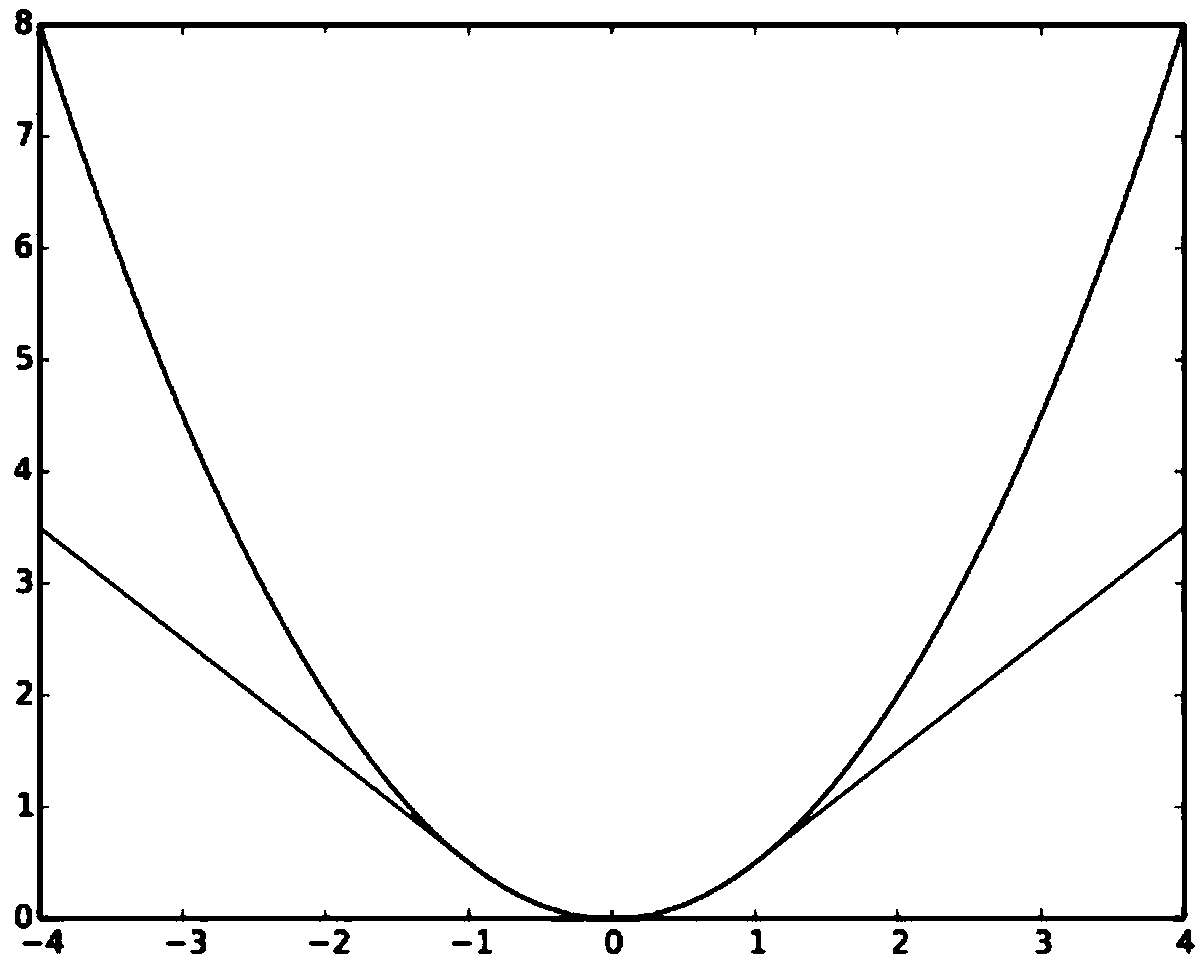

SLAM back-end trajectory optimization method based on loop detection

InactiveCN109343540AOptimization is fast and efficientSolve the problem of poor online real-time performancePosition/course control in two dimensionsVehiclesAlgorithmClosed loop

An SLAM back-end trajectory optimization method based on loop detection includes the following steps: S1, acquiring sensor data; S2, processing the data acquired in S1 to obtain the initial pose of arobot; S3, constructing a pose map model through the initial pose acquired in S2; S4, carrying out closed-loop detection on the pose map model constructed in S3, and separating the closed-loop part and the non-closed-loop part of the pose map model; and S5, optimizing the different parts after detection separately. Each time a closed loop is detected, optimization is carried out. Each time a closed loop appears, the total error of the closed-loop part is calculated, and then, the total error of the non-closed-loop part is calculated. The weight information of edges in the data provided by thefront end is utilized reasonably, and a kernel function (Huber kernel) is added. The pose error can be allocated quickly and effectively, the calculation efficiency can be improved, and the online real-time performance of the back-end optimization process of the robot can be enhanced. Moreover, the accuracy can be ensured.

Owner:GUANGDONG UNIV OF TECH

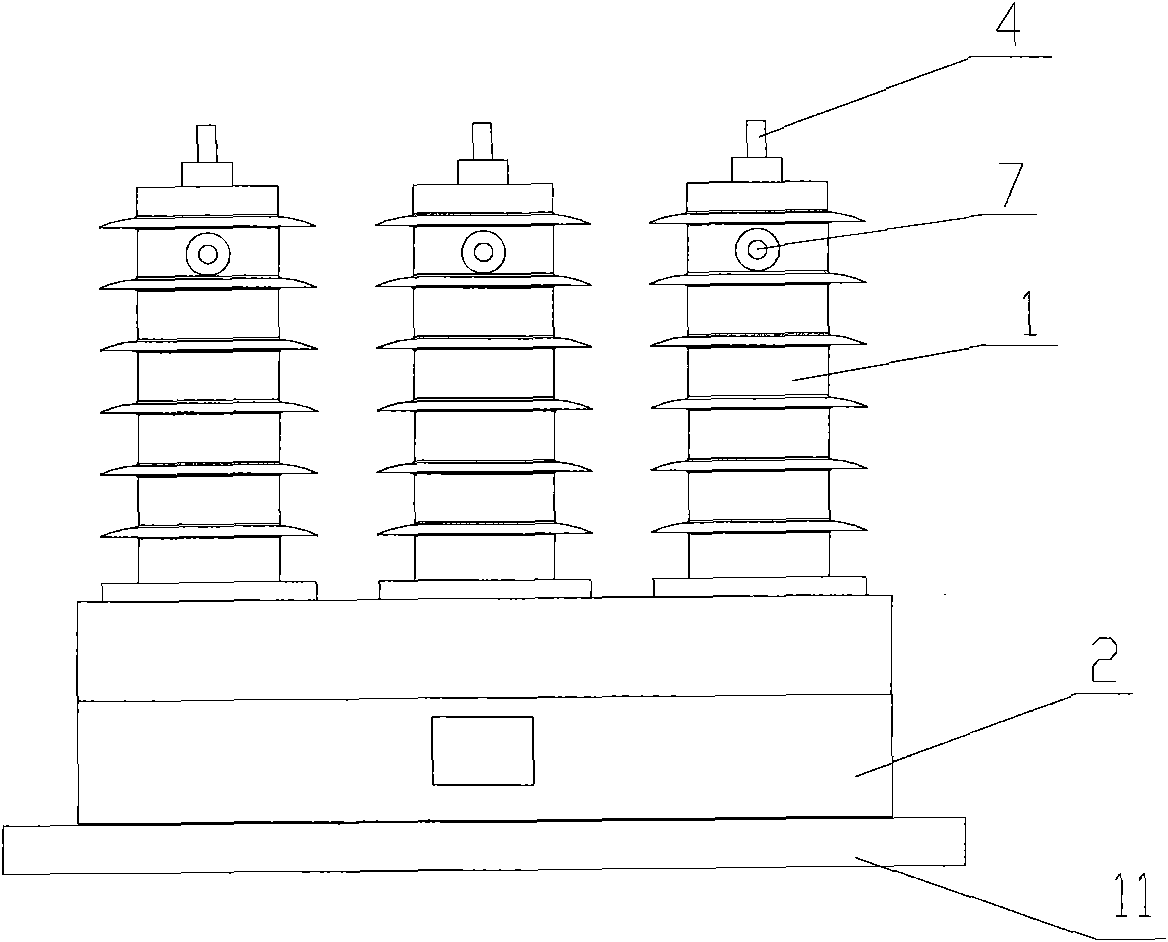

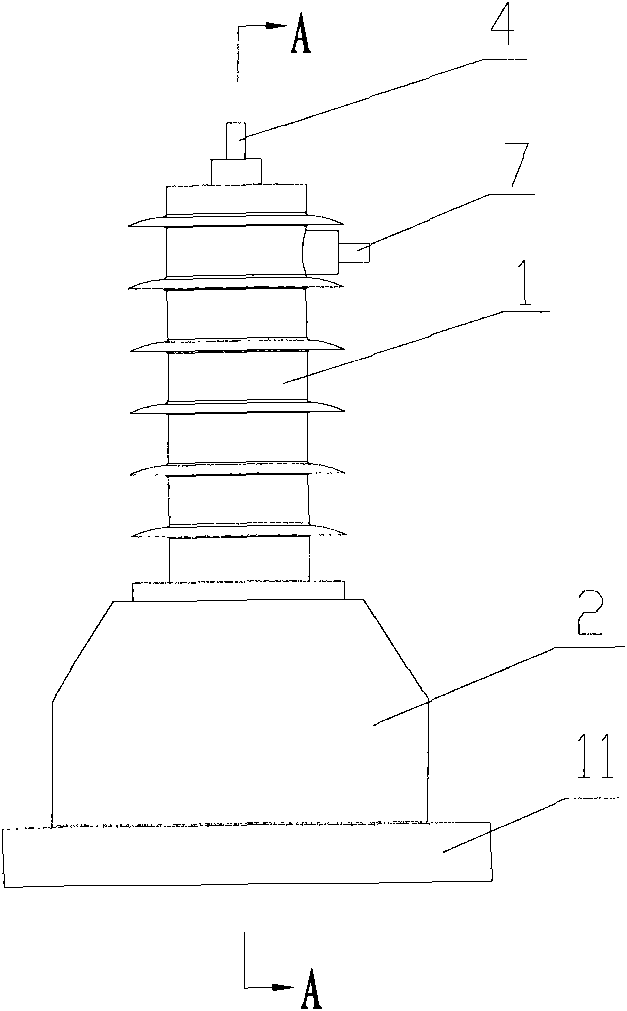

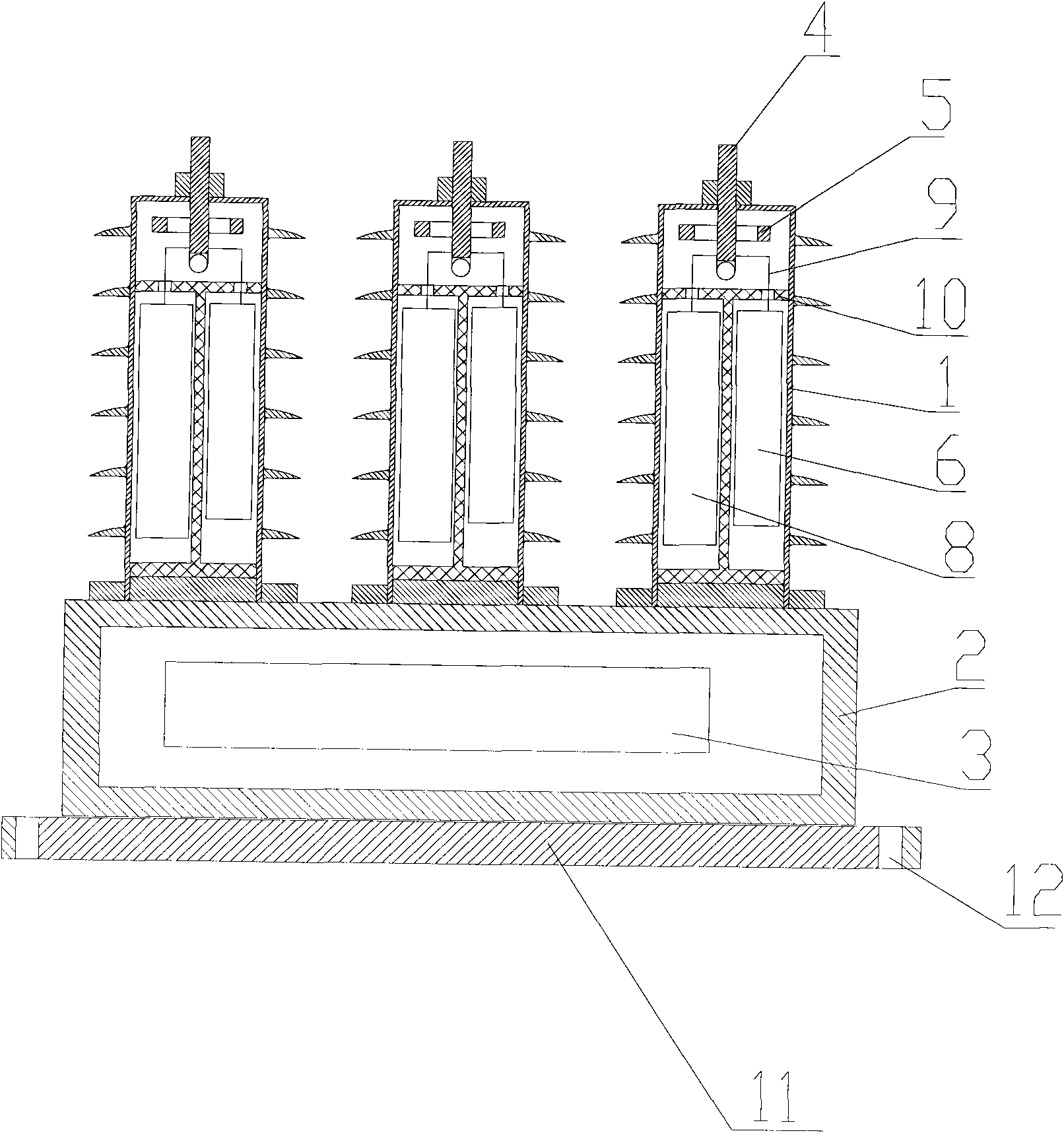

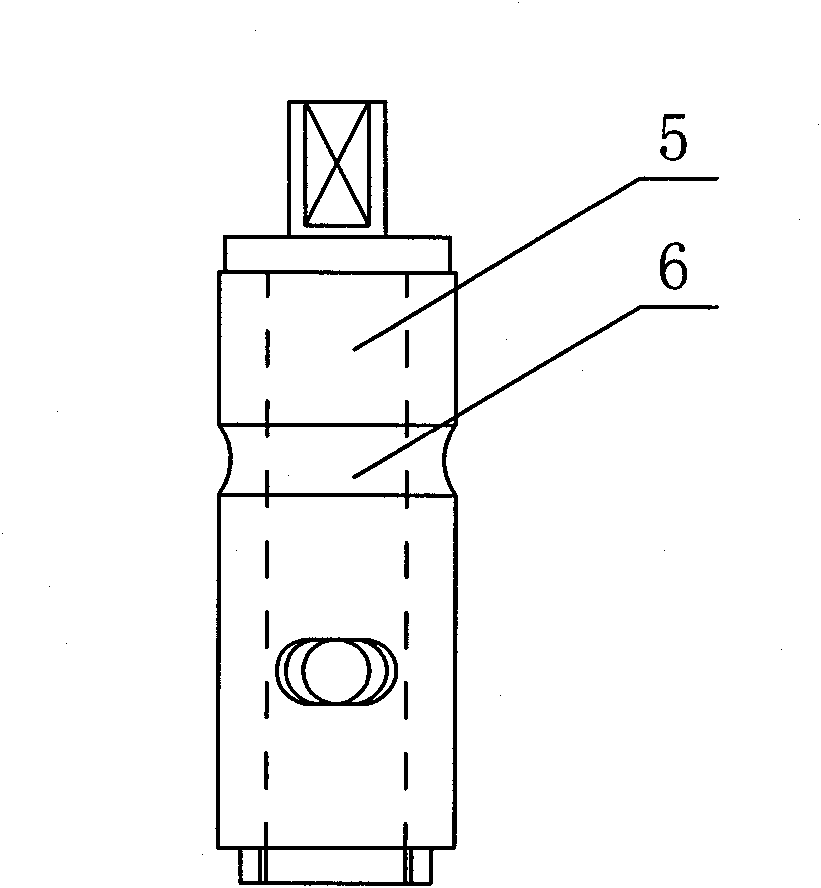

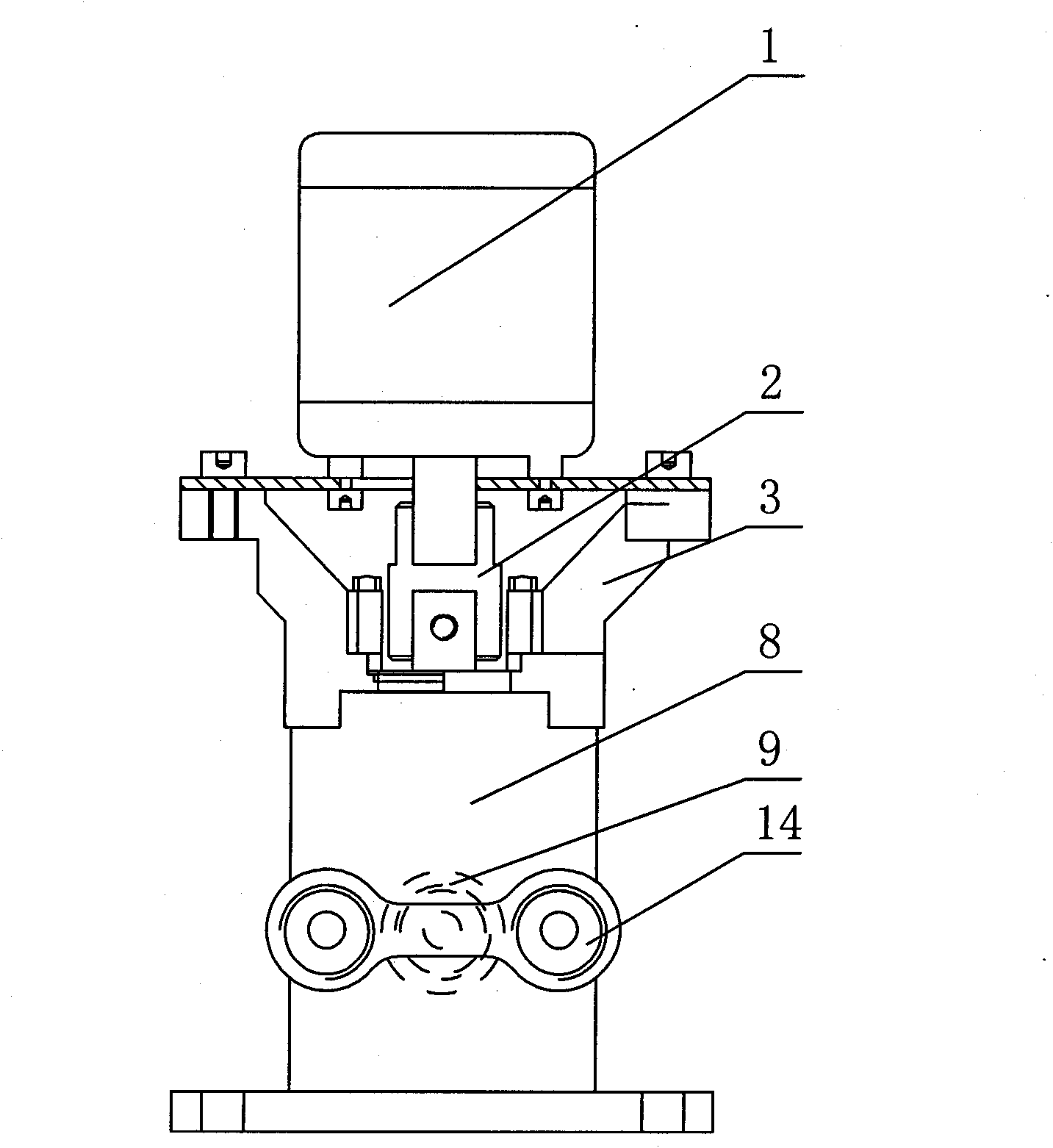

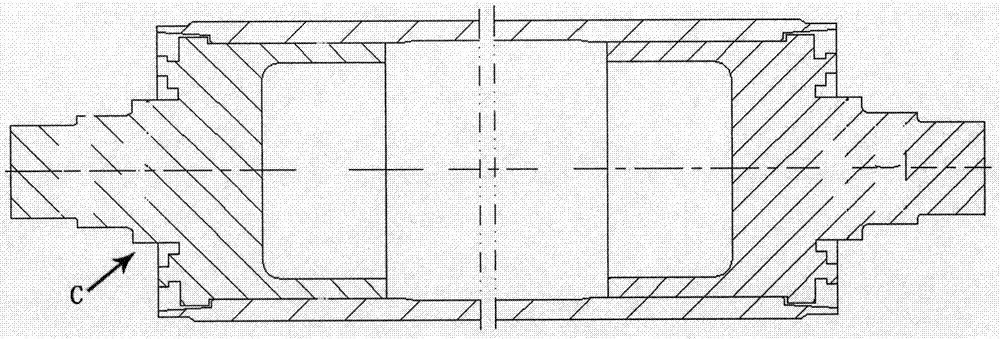

Minitype high-voltage electric energy meter directly arranged in 10KV power supply circuit

InactiveCN101571553AImprove efficiencyReduce volumeTime integral measurementElectricityCapacitor voltage

The invention discloses a minitype high-voltage electric energy meter directly arranged in a 10KV power supply circuit. The electric energy meter comprises a silicon rubber dry-type composite bushing (1), a box body (2), an electric energy metering unit (3), a high-voltage post head (4), an amorphous material current mutual inductor (5) and an isolation transformation circuit board (6), and is characterized in that the high-voltage post head (4) is inserted into the inside of the top end of the silicon rubber dry-type composite bushing (1); the amorphous material current mutual inductor (5) is arranged on the inner top of a cavity of the silicon rubber dry-type composite bushing (1), while the isolation transformation circuit board (6) and a capacitor voltage-reduction power supply circuit board (8) are arranged from the middle part to the lower part inside the cavity of the composite bushing (1); and the isolation transformation circuit board (6) and the capacitor voltage-reduction power supply circuit board (8) are respectively connected with the inner end of the high-voltage post head (4) through corresponding conducting wires (9). The high-voltage electric energy meter has simple and compact structure, convenient installation and high efficiency, and can improve metering precision.

Owner:力创科技股份有限公司

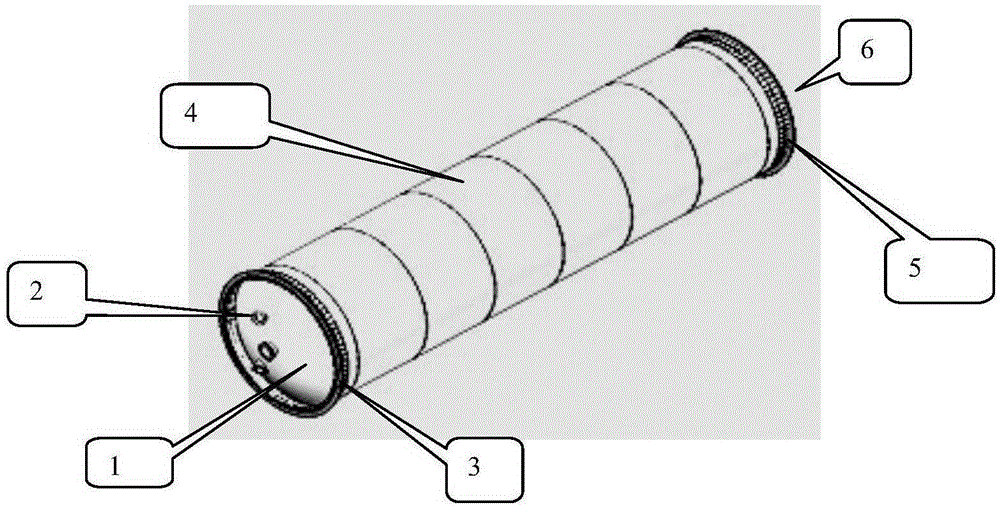

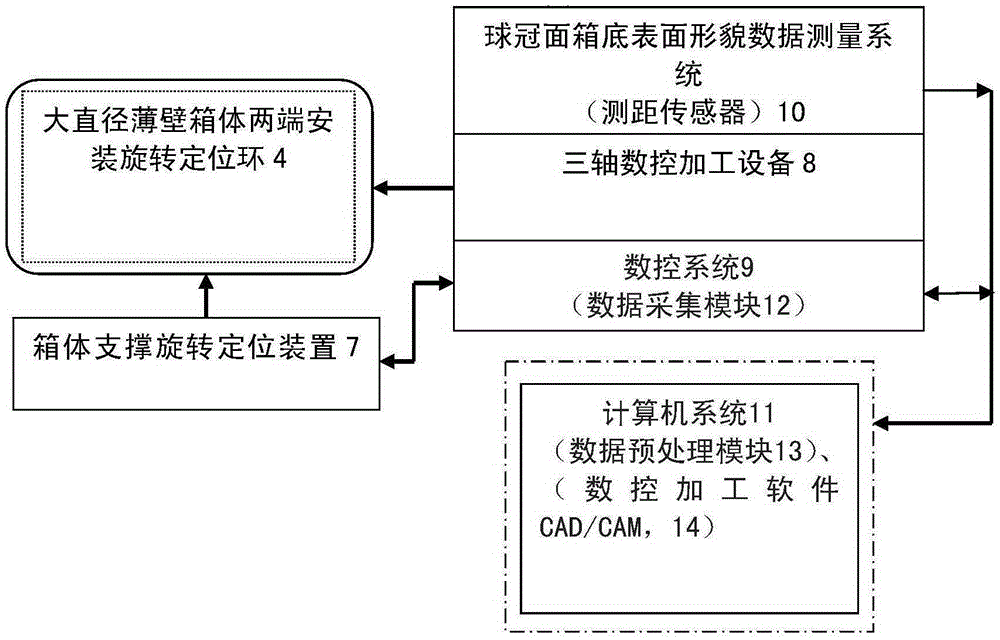

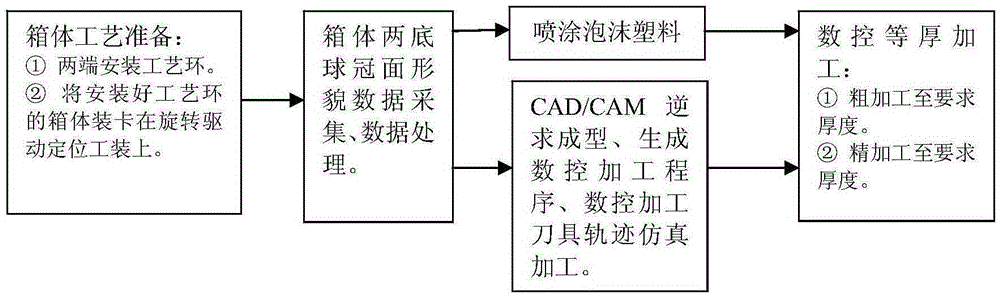

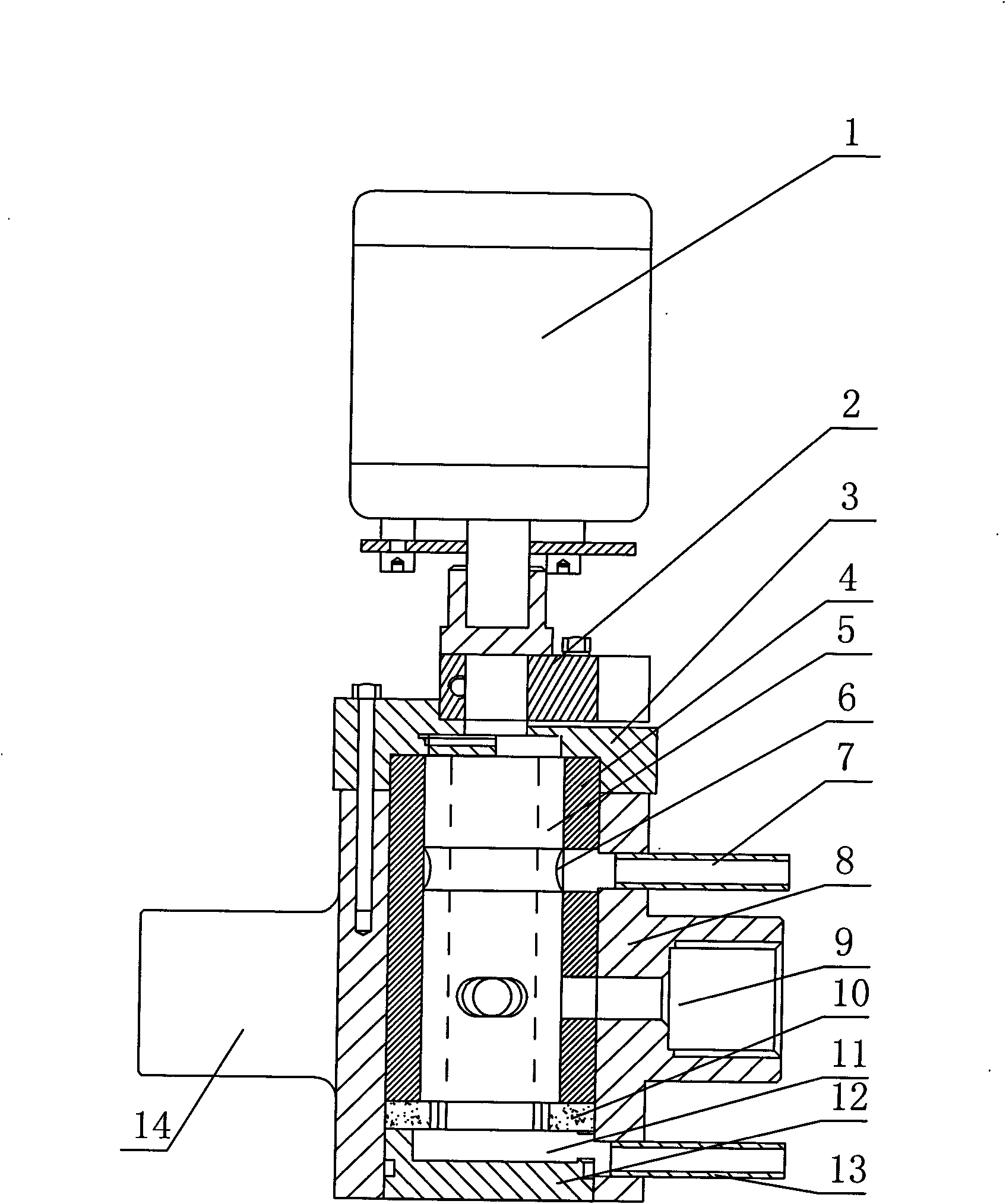

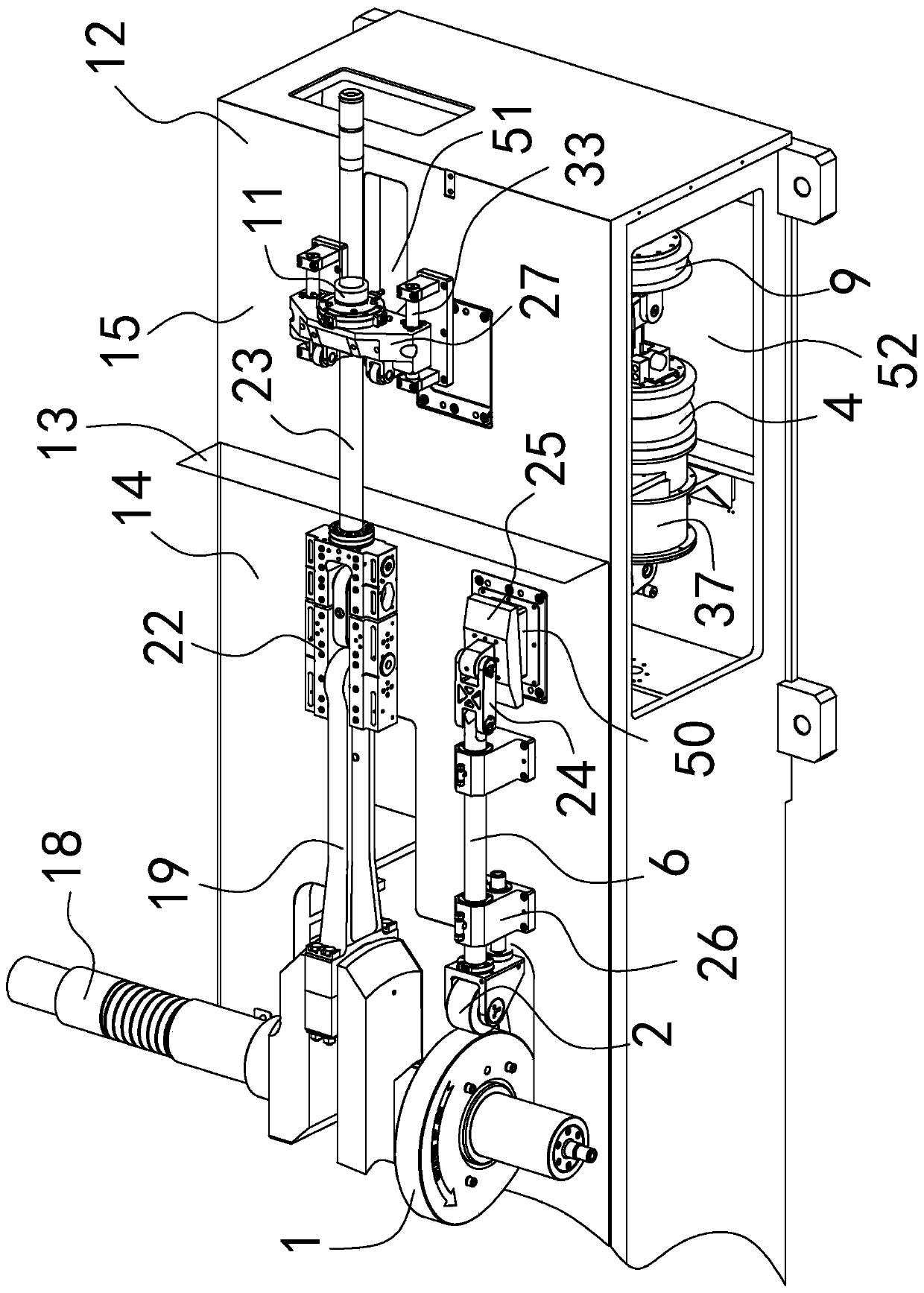

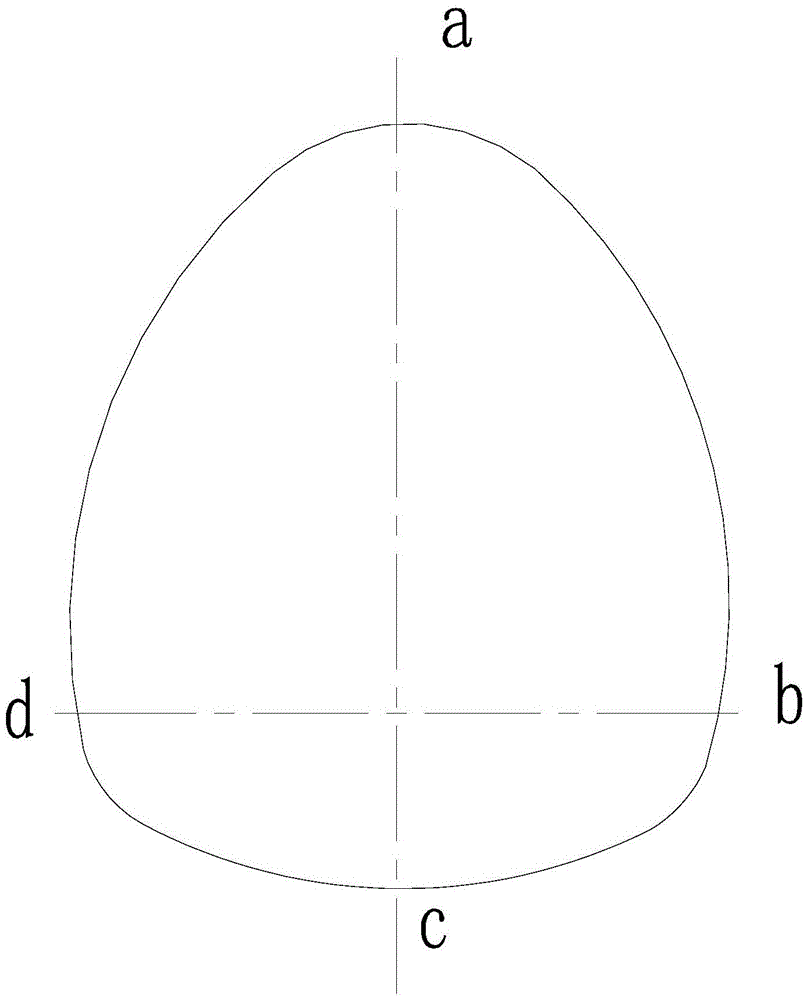

Uniform-thickness machining device and method for spherical crown face box bottom foam plastics of large-diameter thin-wall box

ActiveCN105270702AGood value for moneySatisfy surface finish and equal thicknessMilling equipment detailsRigid containersThin walledPre treatment

The invention relates to a uniform-thickness machining device and method for spherical crown face box bottom foam plastics of a large-diameter thin-wall box. The device comprises a rotating and positioning ring, a box supporting, rotating and positioning device, a three-axis numerical control machining device, a numerical control system, a spherical crown face box bottom metal surface morphology data measuring system, a computer system, a data acquisition module, a data pre-processing module and a numerical control machining software CAD / CAM module; the data acquisition module is embedded in the numerical control system; and the data pre-processing module and the numerical control machining software CAD / CAM module are embedded in the computer system. The device and method solve the uniform-thickness machining problem of foam plastics sprayed on the box spherical crown face, and it is verified and indicated through practical application that the requirements for surface smoothness and uniform thickness are met when the method is used for performing numerical control form copying on foam plastics sprayed at the spherical crown face box bottom.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

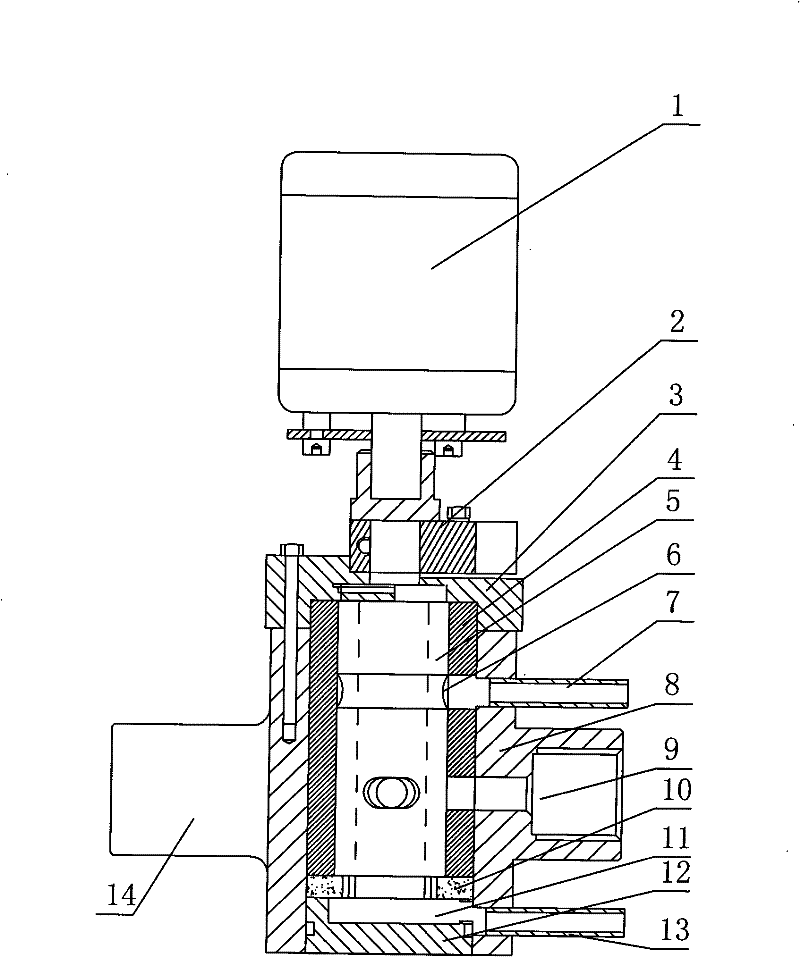

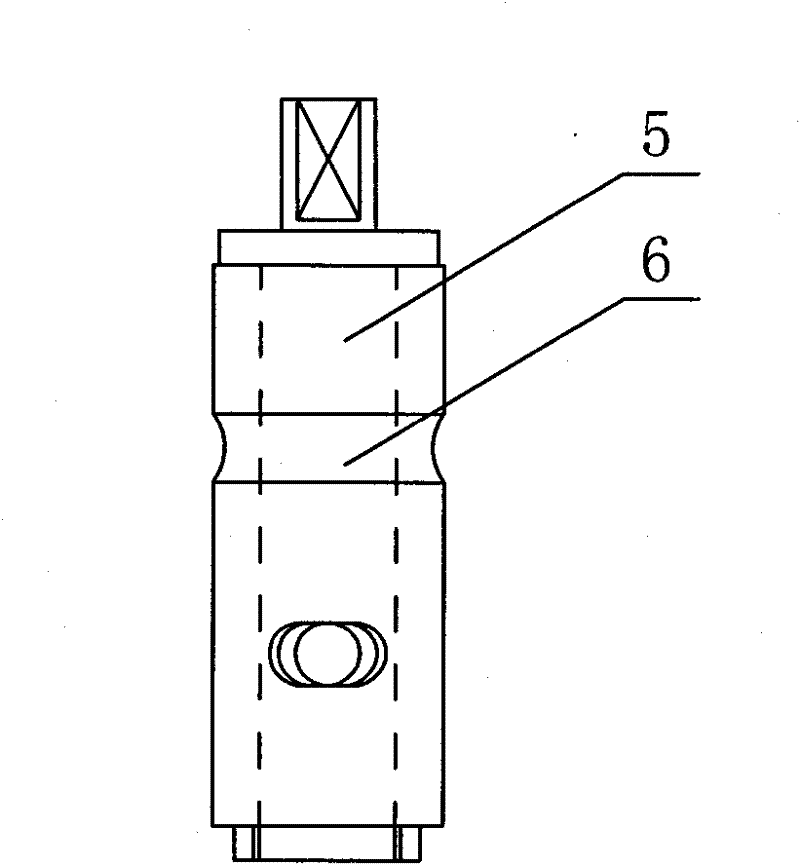

Conversion valve

ActiveCN101839357APrevent leakageImprove installation efficiencyOperating means/releasing devices for valvesMultiple way valvesEngineeringInterference fit

The invention relates to a conversion valve. A hollow inner wall of a valve body is in interference fit with a ceramic valve sleeve; a ceramic valve core is driven by a top motor; a shifting block is used for limiting; the middle part of the valve body is provided with a water inlet, a water outlet, an upper drain pipe and a lower drain pipe; the periphery of the valve core is provided with a ring-shaped concave water collecting tank; the valve core is in integrated clearance fit with the valve sleeve; the position of the upper drain pipe corresponds to the water collecting tank; and the position of the lower drain pipe corresponds to a lower water collecting cavity. The integrated ceramic valve core of the invention has the advantages of reasonable structure, convenient assembly, high installing efficiency and low manufacturing cost, and capability of greatly improving the reliability of the conversion valve and prolonging the service life of the conversion valve.

Owner:无锡书谱尔精密机械科技有限公司

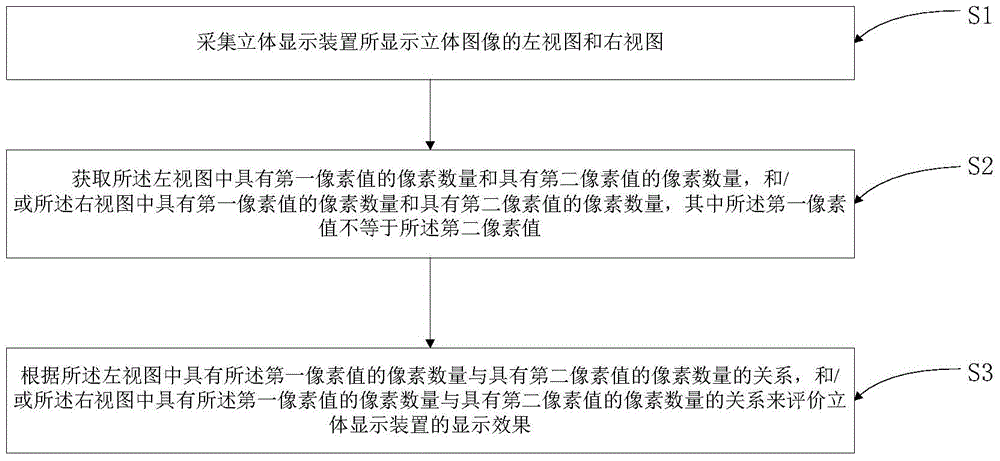

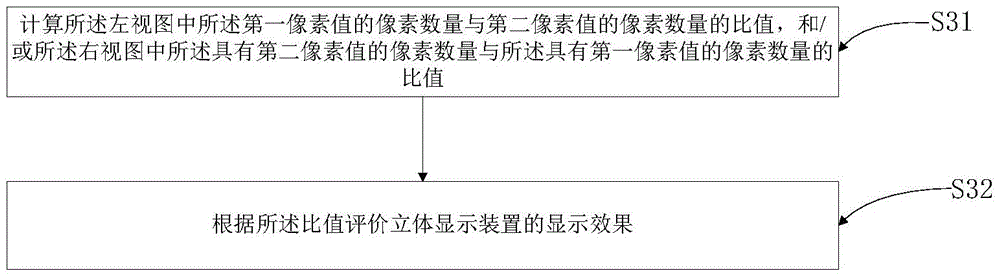

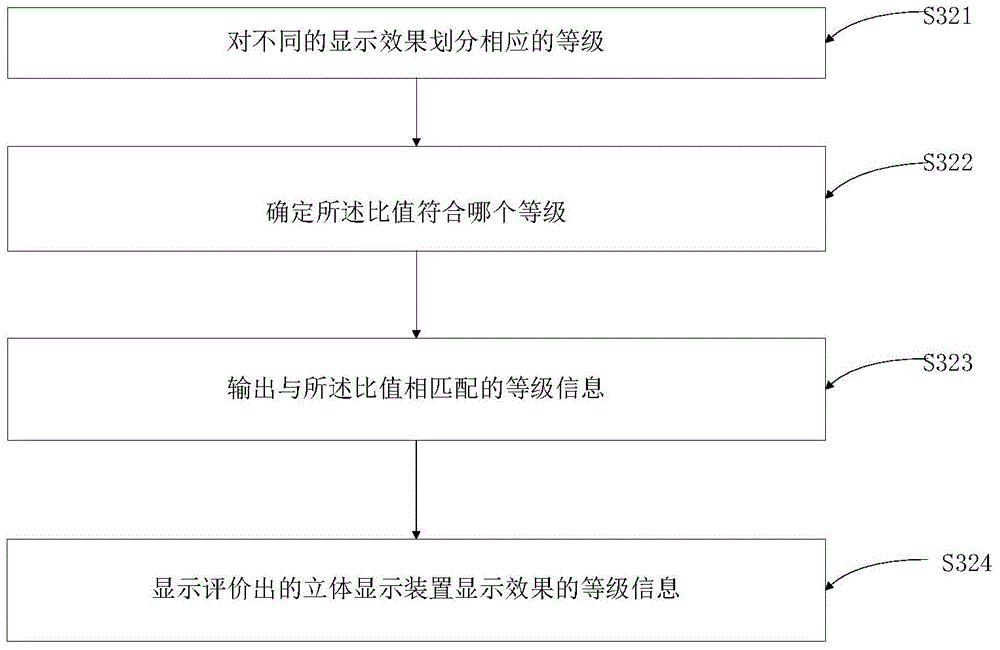

Method, equipment and system for evaluating display effect of stereo display device

ActiveCN105721858AImprove accuracyAvoid levelTelevision systemsSteroscopic systemsDisplay deviceComputer vision

The invention belongs to the technical field of stereo display, and provides a method for evaluating the display effect of a stereo display device. The method comprises: S1, acquiring a left view and a right view displayed by the stereo display device; S2, acquiring the quantity of pixels with a first pixel value and a second pixel value in the left view and / or the quantity of pixels with the first pixel value and the second pixel value in the right view, wherein the first pixel value is not equal to the second pixel value; and S3, evaluating the display effect of the stereo display device according to the relation between the quantity of the pixels with the first pixel value and the quantity of the pixels with the second pixel value in the left view and / or the relation between the quantity of the pixels with the first pixel value and the quantity of the pixels with the second pixel value in the right view. The invention further provides equipment and a system for evaluating the display effect of a stereo display device. The evaluating method, equipment and system simplify fussy operation of evaluating the display effect in the prior art, and improve the objectiveness and the accuracy of display effect evaluation.

Owner:SUPERD CO LTD

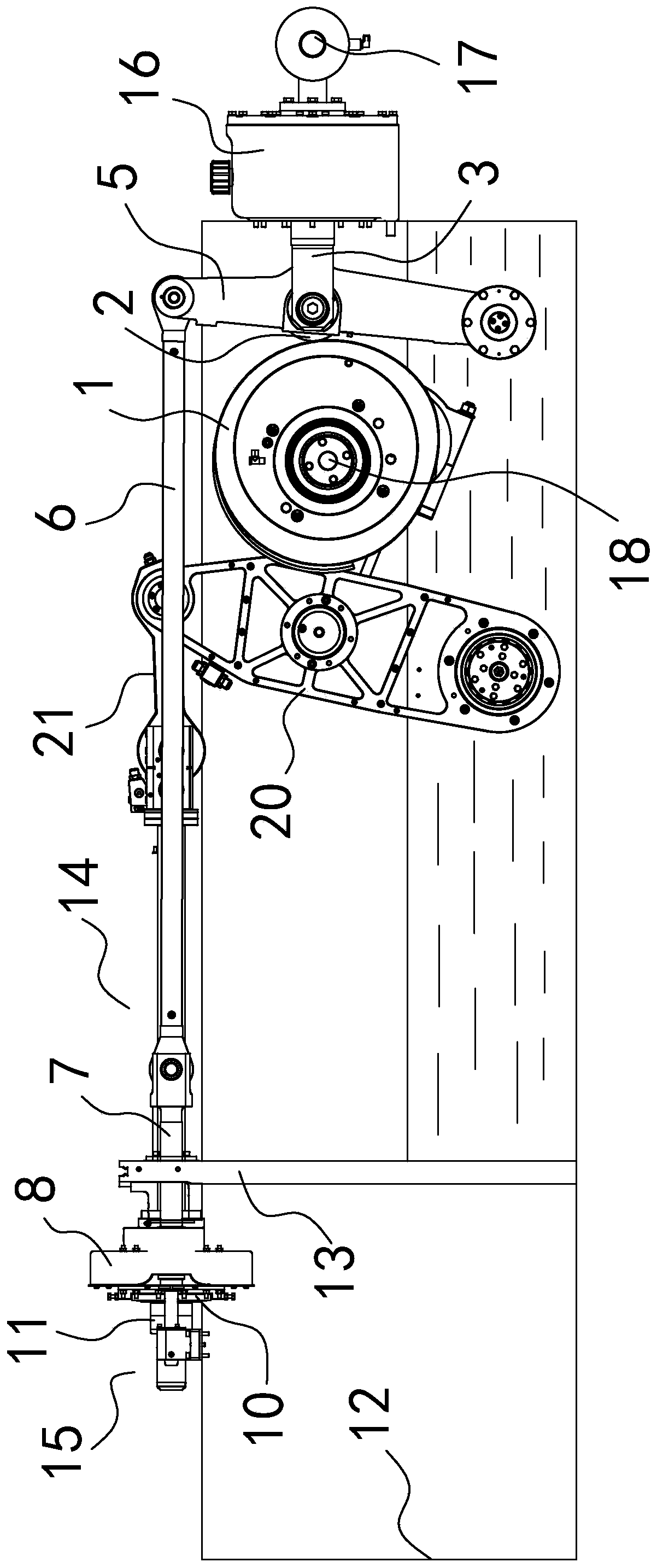

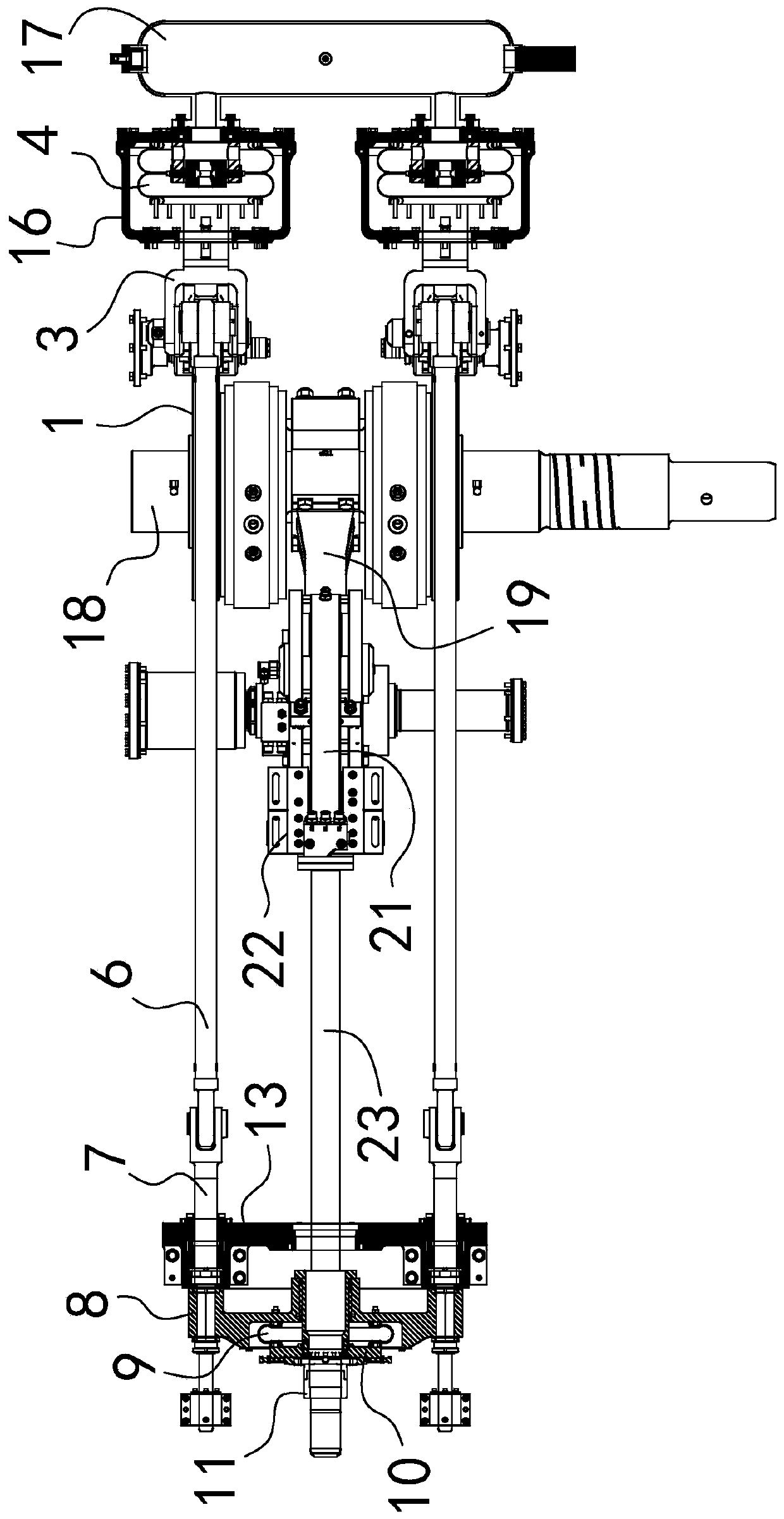

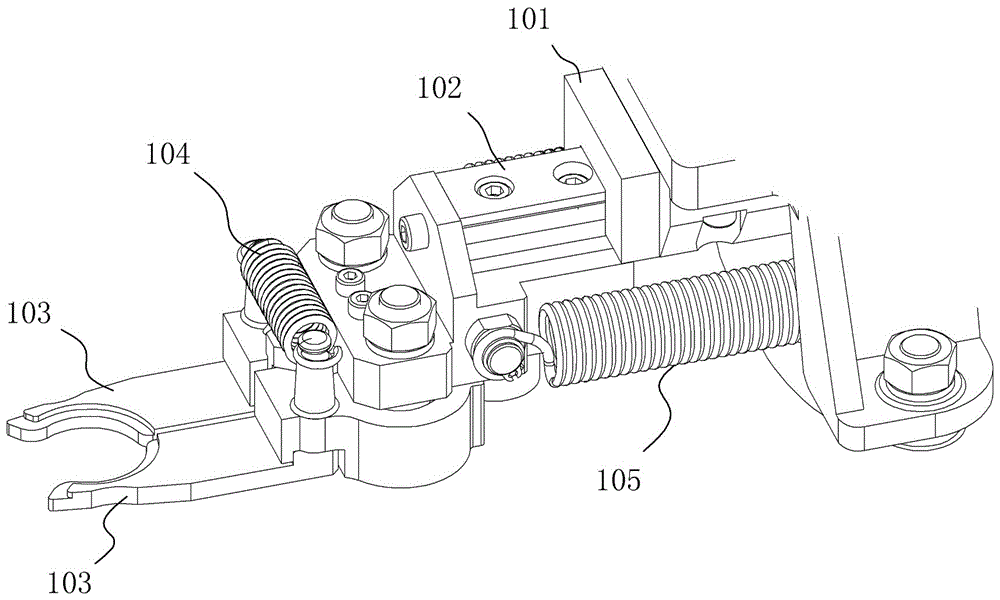

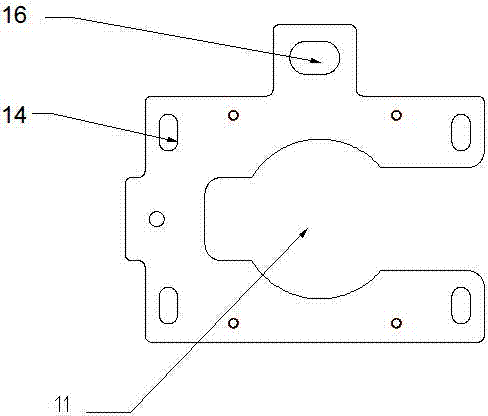

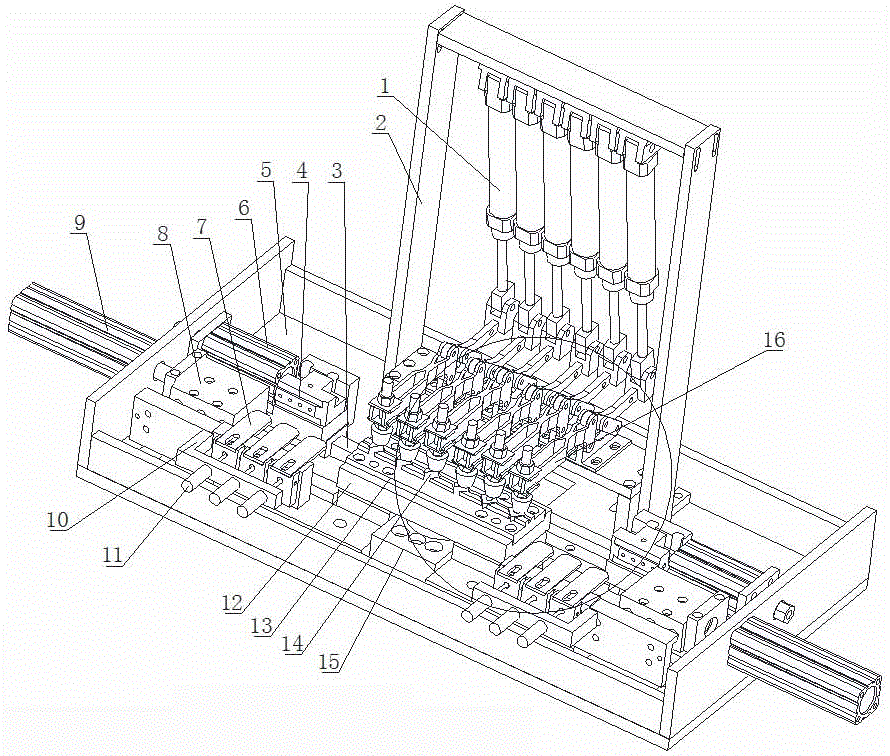

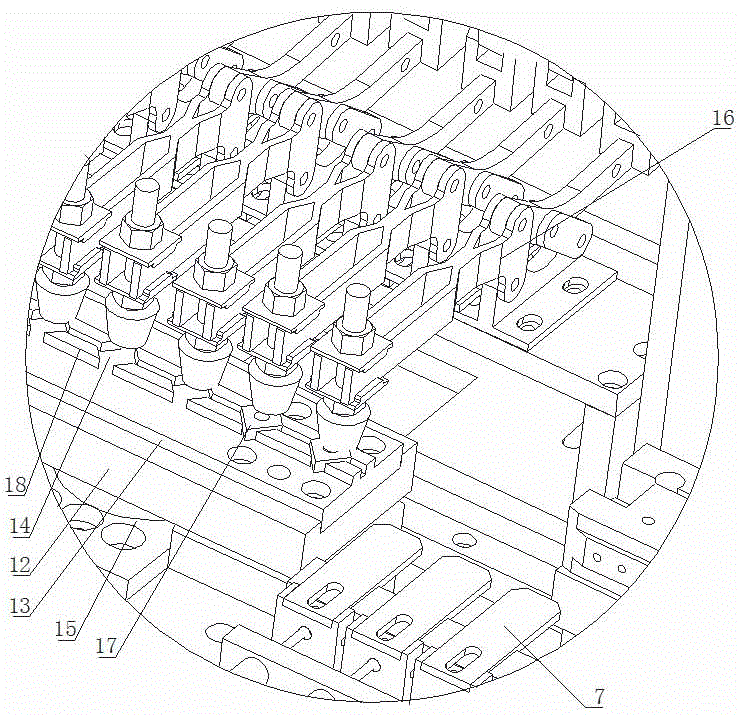

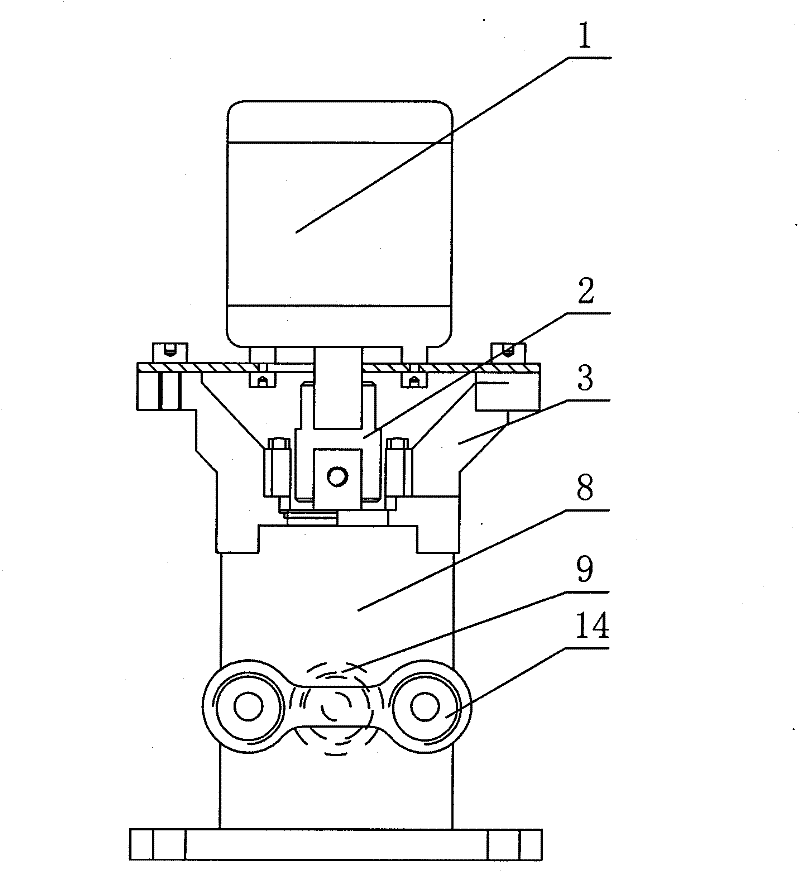

Edge pressing mechanism of high-speed can body stretcher

PendingCN111185513AOvercoming the problem of poor drive synchronizationSimple structureMetal-working feeding devicesPositioning devicesStructural engineeringCam

The invention discloses an edge pressing mechanism of a high-speed can body stretcher. The edge pressing mechanism of the high-speed can body stretcher is characterized in that a cam follower, an edgepressing push rod, a thrust arm, a follower lever, an edge pressing force arm, an edge pressing slider and an edge pressing sleeve are successively arranged from an edge pressing cam according to a driving chain; a torque shaft is arranged at a turning point for the edge pressing force arm or / and the thrust arm; a first elastic element is arranged for the cam follower to force the cam follower topress tightly the edge pressing cam; and a second elastic element is arranged for the edge pressing sleeve to force the edge pressing sleeve to move in the pressing direction; directions of the forcetransmitted to the follower lever by the first elastic element and the second elastic element are opposite, and a sliding pin at a joint between the follower lever and the edge pressing force arm ismade to be located at the position of one end of an oblong hole. According to the edge pressing mechanism, first, the structure of an original edge pressing mechanism is greatly simplified, and the problem of poor synchronicity of driving of double edge pressing mechanism cams is overcome at the same time; second, maintenance is provided with convenience; and third, the sealing difficulty caused by a previous edge pressing push rod penetrating through an oil separator plate and the problem of serious mutual pollution between oil and emulsion are avoided.

Owner:SUZHOU SLAC PRECISION EQUIP CO LTD

Method for machining hot-mounted dam roller

ActiveCN107470854ASolve the problem that the balance accuracy is not highAvoid product quality defectsInterference fitNumerical control

The invention relates to a method for machining a hot-mounted dam roller. The method for machining the hot-mounted dam roller comprises the steps of machining of a roller cylinder, machining of spindle heads and assembling of the roller cylinder and the spindle heads; assembling of the roller cylinder and the spindle heads comprises the following steps that the spindle heads and the roller cylinder are in interference fit to obtain the dam roller; unbalance amount of the dam roller is detected, center offset amount and the offset direction of the dam roller are calculated, when the unbalance amount is larger than 10 g based on a balance amount, a double-four-jaw chunk clamping device on a lathe is adopted to conduct eccentric borrowing on the dam roller, outer circle turning is conducted to remove the unbalance amount; and finish turning is conducted on a second outer circle of the roller cylinder and eighth outer circles, ninth outer circles and tenth outer circles of the spindle heads by adopting a numerical control lathe turning. The method for machining the hot-mounted dam roller has the advantage of high balance precision.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

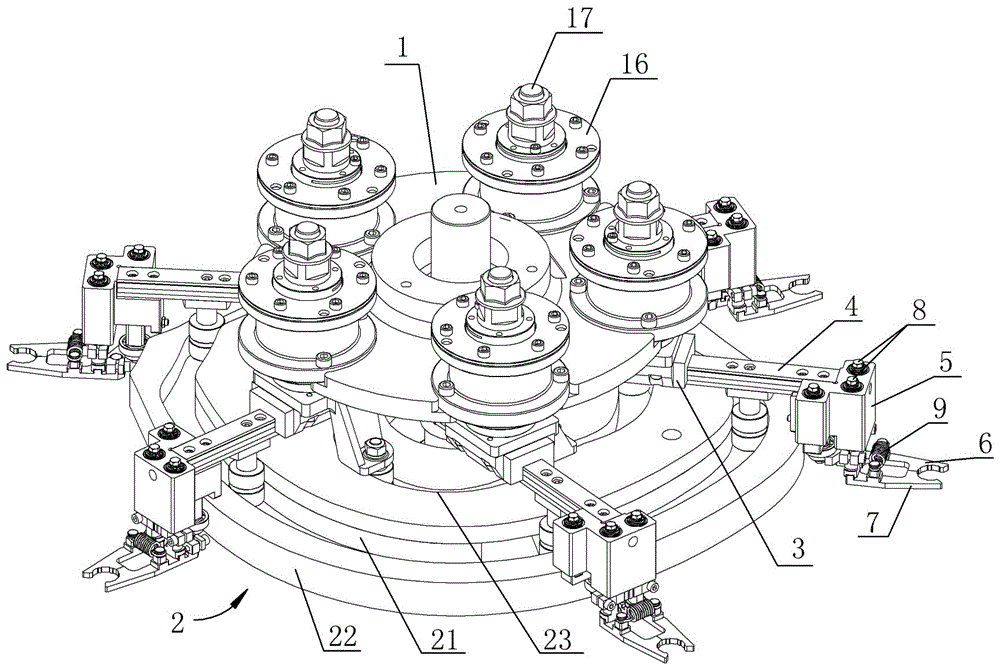

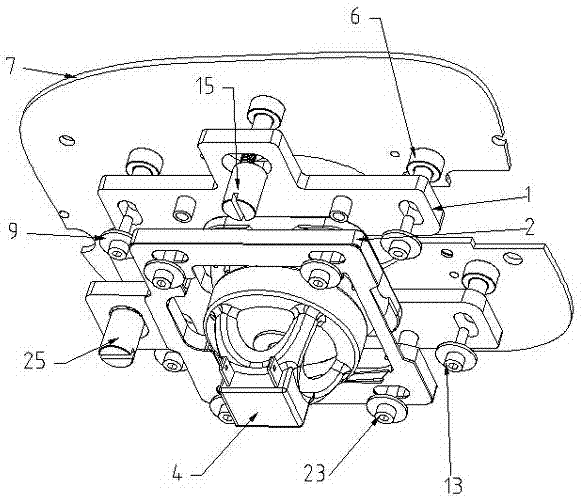

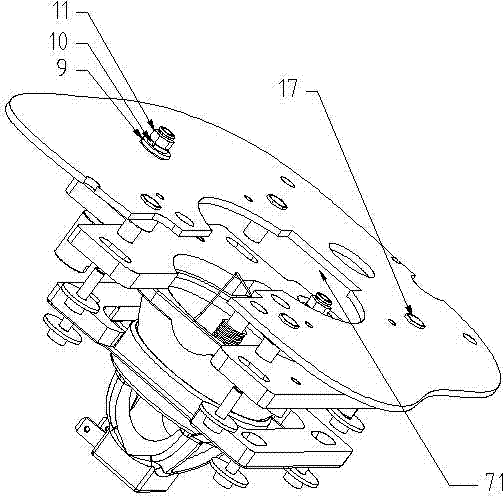

Opening and closing manipulator for bottle blowing machine

An opening and closing manipulator for a bottle blowing machine comprises a supporting plate and a cam plate which are rotated around corresponding axes, wherein a telescoping cam and an opening-closing cam are arranged on the cam plate; a slide block which is provided with a movable slide rail is mounted on the supporting plate; the slide rail extends to a bottle preform under the effects of a telescoping guide wheel and the telescoping cam; an opening-closing arm on a connecting plate at the tail end of the slide rail is used for driving a first clamping claw to open under the effects of an opening-closing guide rail and the opening-closing cam; the first clamping claw and a second clamping claw are mutually driven to synchronously open through a gear plate. According to the opening and closing manipulator for the bottle blowing machine, the clamping claws can be actively opened, so that the damage of the clamping claws to the bottle preform in a traditional driven opening manner and the requirement on the accuracy of the clamping claws can be avoided, and as a result, the bottle preform can be effectively protected, the product quality and the qualification rate can be improved, and meanwhile, the processing requirement of the clamping claws can be reduced.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Stage lamp

ActiveCN104501037AGood spot and beam output effectMeet the use requirementsLighting applicationsMechanical apparatusPhysicsEngineering

The invention discloses a stage lamp. The stage lamp comprises a lamp bulb assembly for emitting light, and further comprises a fixing plate and regulating devices, wherein the regulating devices comprise a first regulating device and a second regulating device; the lamp bulb assembly is mounted on the second regulating device; the first regulating device can move in parallel relative to the fixing plate in a first direction and is connected with the fixing plate; the second regulating device can move in parallel relative to the first regulating device in a second direction and is connected with the first regulating device; the first direction is perpendicular to the second direction. Through arrangement of the two regulating mechanisms, the positions of the lamp bulb assembly in two different directions on the same horizontal plane can be regulated, so that errors caused in the mounting and machining processes are overcome.

Owner:GUANGZHOU FINEART LIGHTING

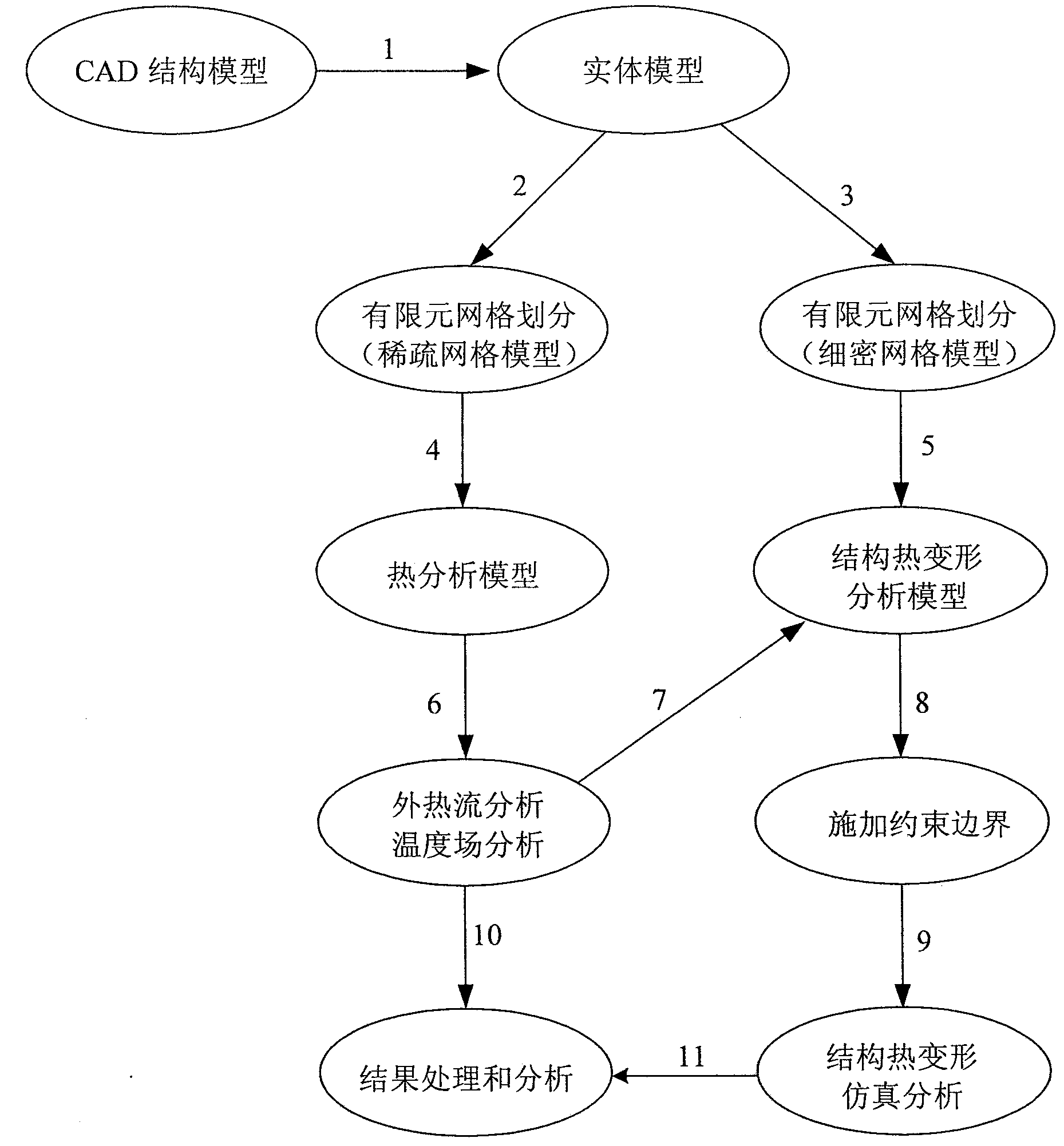

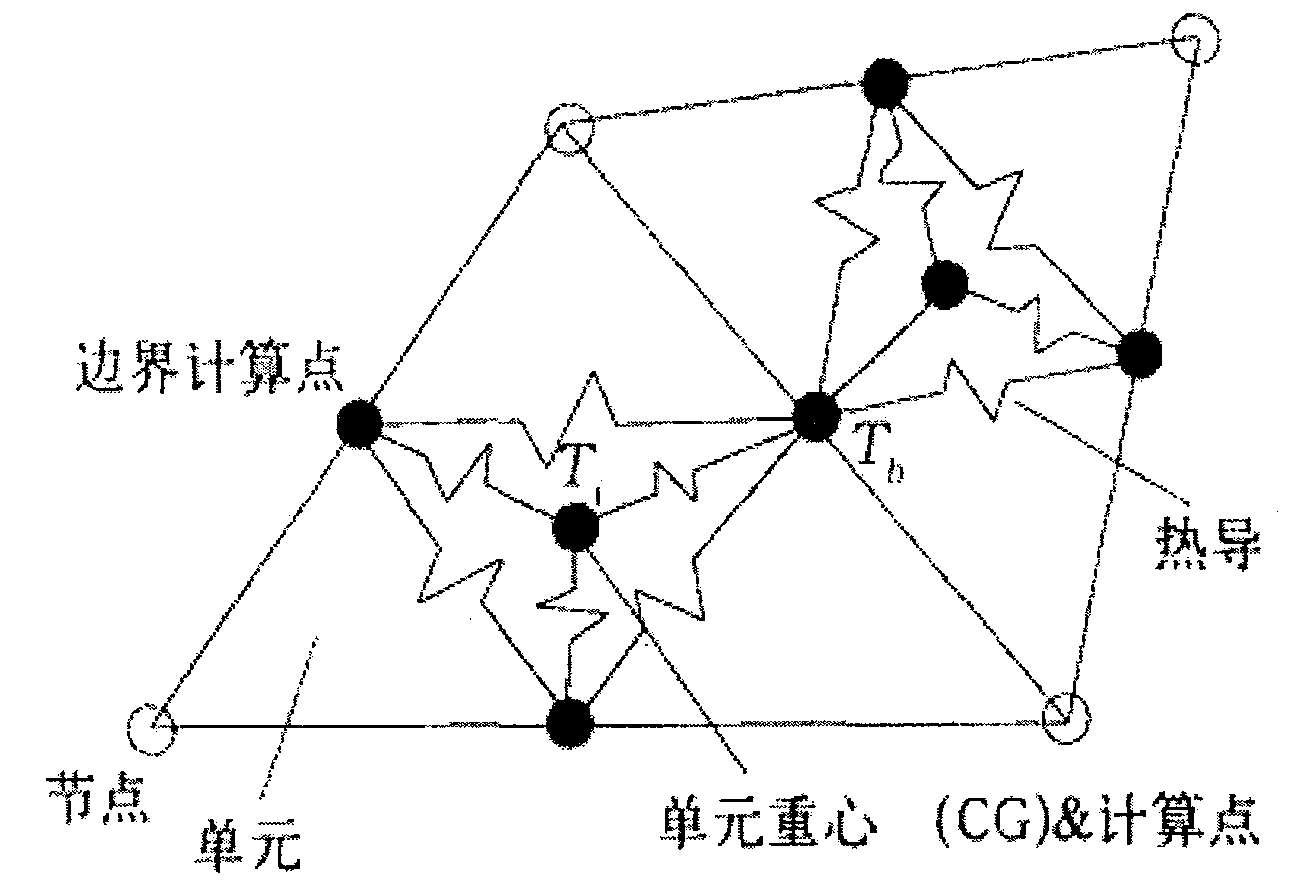

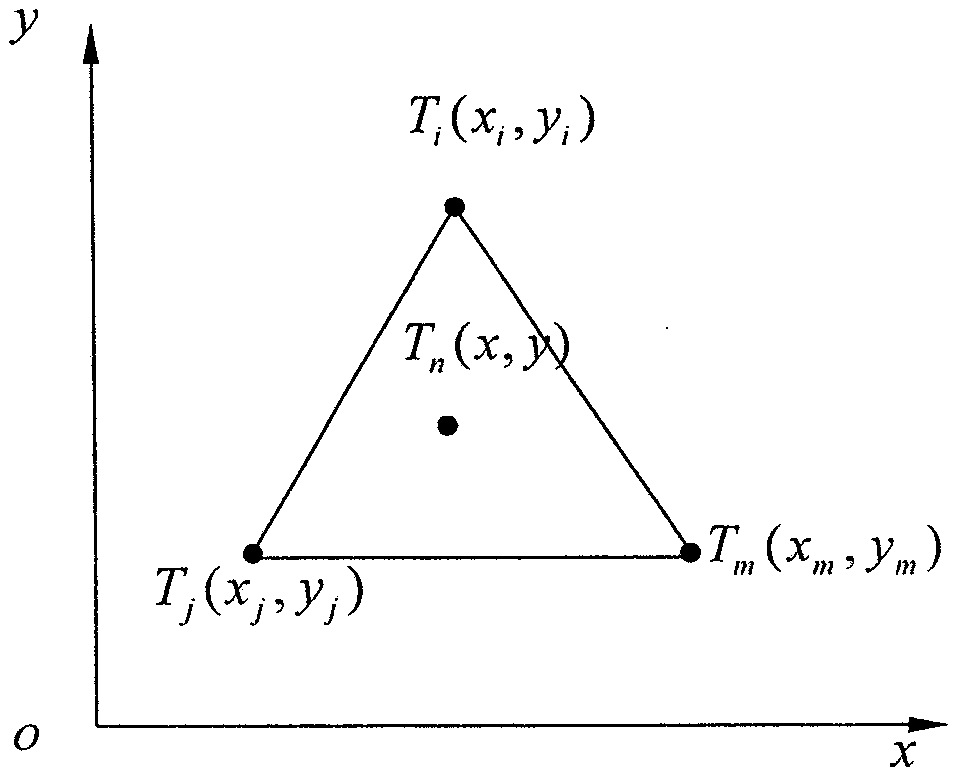

Coupling and integrated simulation analysis method for thermal structure of solar battery wings

ActiveCN105474799BResolve mismatchImprove efficiency of coupled simulation analysisSoftware simulation/interpretation/emulationUnit sizeMechanical models

The solar battery wing thermal structure coupling integrated simulation analysis method of the present invention is based on finite element grid division, and adopts the finite control volume method and the finite element method to respectively establish a solar battery wing on-orbit thermal analysis model and a mechanical model for structural thermal deformation analysis. The mesh division of the thermal analysis model is relatively sparse, and the scale of the model unit is controlled to realize the thermal analysis calculation. The mesh division of the mechanical model is relatively fine to meet the calculation accuracy of the thermal deformation analysis. Based on the uniform finite element mesh division method, the temperature result obtained from the thermal analysis model is smoothly mapped to the structural model as a load input by using the linear interpolation method, so that the analysis model and the structural analysis model can be organically combined.

Owner:SHANGHAI AEROSPACE SYST ENG INST

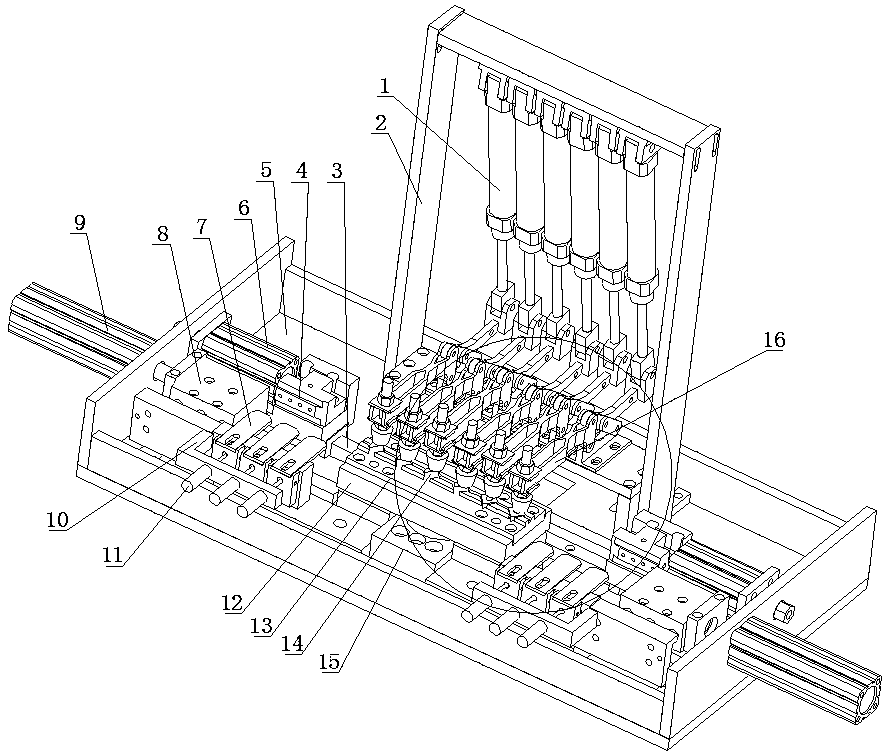

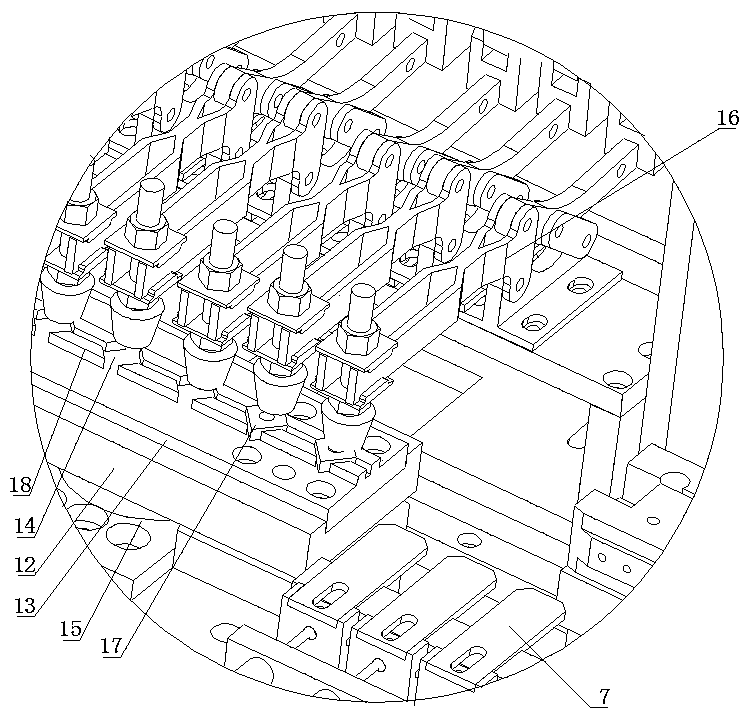

Automatic grinding fixture for numerical-control machine tool

ActiveCN106737181AAvoid elastic deformationImprove detection accuracyGrinding work supportsEngineeringMachine tool

The invention discloses an automatic grinding fixture for a numerical-control machine tool, and relates to the technical field of auxiliary accessories for numerical-control machining. The automatic grinding fixture is provided with a mounting plate. A rotary cylinder is arranged on the mounting plate, a die clamping seat is arranged on the rotary cylinder, positioning dies are arranged on the die clamping seat, and workpiece embedding grooves are formed in the positioning dies; a reference positioning slide rail is arranged on the mounting plate, positioning sliders are arranged on the reference positioning slide rail, reference positioning blocks are arranged on the positioning sliders, reference positioning cylinders are arranged on the mounting plate, piston rods of the reference positioning cylinders are connected with the positioning sliders, detection yielding cylinders are arranged on the mounting plate, detection positioning cylinders are arranged on the detection yielding cylinders, displacement detection frames are arranged on piston rods of the detection positioning cylinders, and displacement detection devices are arranged on the displacement detection frames; pliers are arranged on the mounting plate and are positioned at the rear side of the die clamping seat, jaws of the pliers are positioned above the workpiece embedding grooves, a support frame is arranged on the mounting plate, pliers driving cylinders are arranged on the support frame, and piston rods of the pliers driving cylinders are hinged to handles of the pliers. The automatic grinding fixture has the advantages that the automatic grinding fixture is simple in structure, convenient to use and high in production efficiency, and the labor intensity can be relieved.

Owner:威海威硬工具股份有限公司

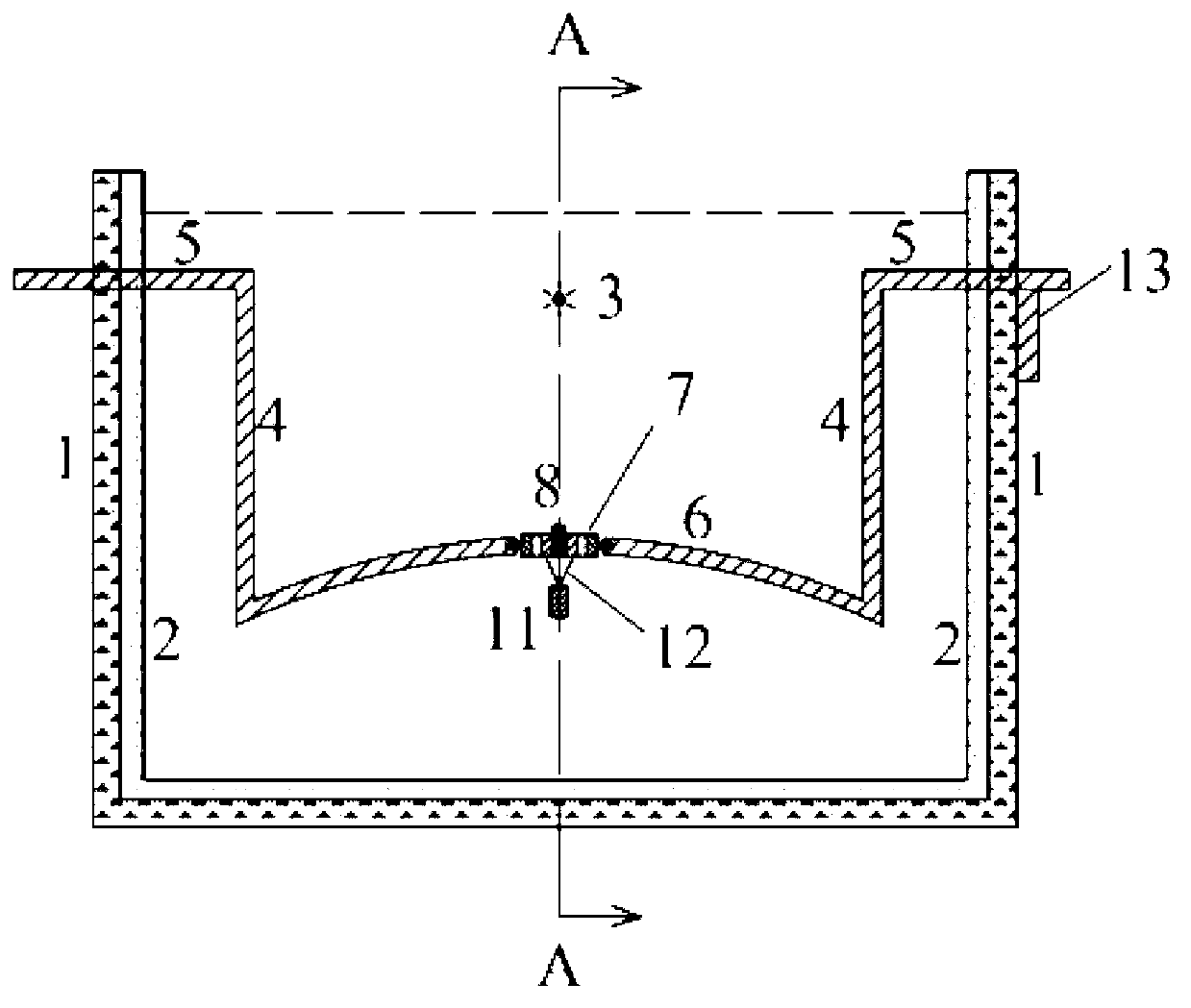

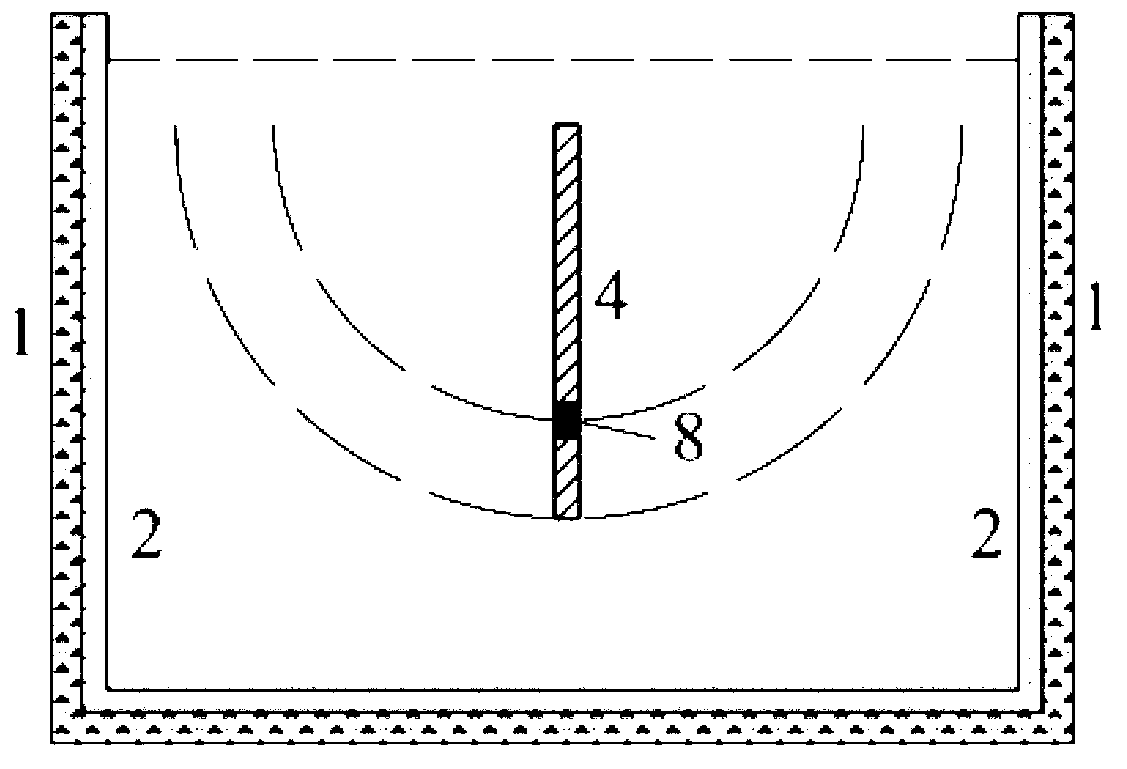

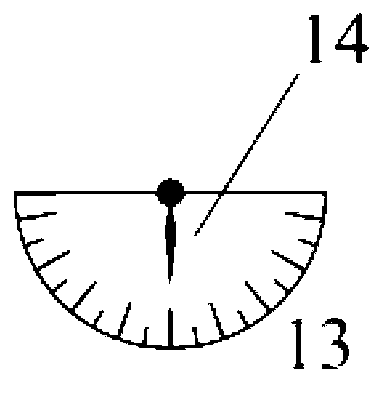

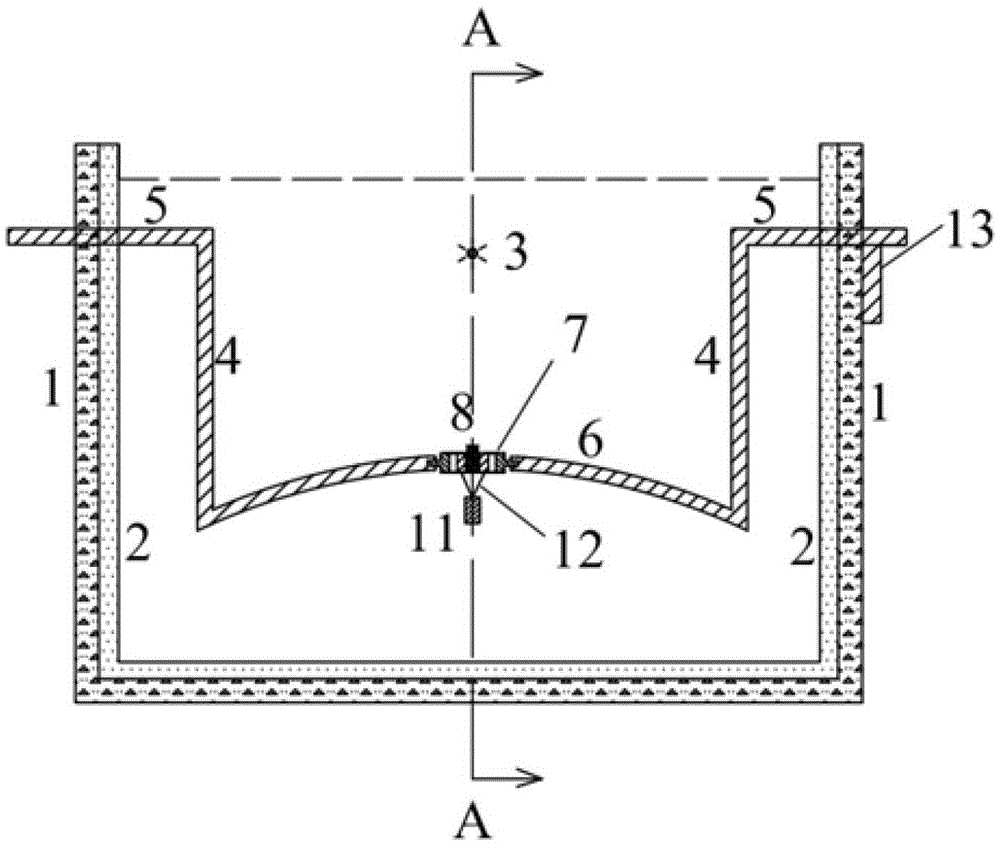

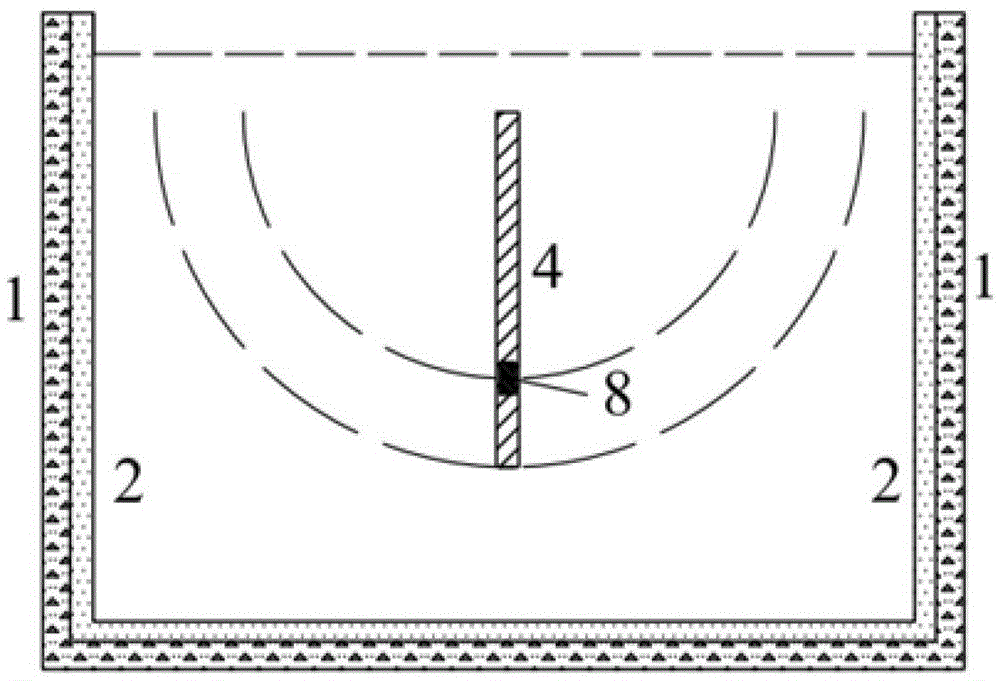

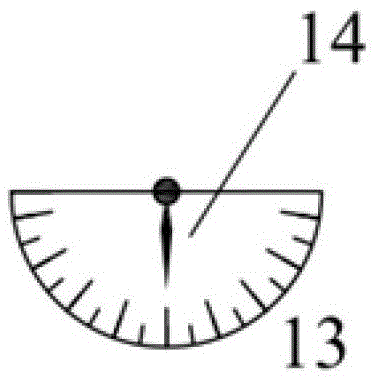

Device for measuring sensitivity of wave detector in reception direction of elastic waves

InactiveCN102914805AAvoid disadvantagesOvercoming Errors in Measuring AmplitudeGeological measurementsPhase detectorUniversal joint

The invention discloses a device for measuring sensitivity of a wave detector in a reception direction of elastic waves. The device comprises a water tank filled with water, wherein a shock absorption material is stuck at the inner side of the wall of the water tank; a support device is arranged on the water tank; rotating shafts at two ends of the support device are respectively connected with corresponding walls of the water tank; a universal joint is arranged at the middle position of the support device; a wave detector is arranged in the universal joint; the universal joint is connected with a counter weight through a connecting rod I; an electric spark emission probe is arranged at the position of the central line of the support device which is located at the upper side of the support device and below a water body; and a dial is arranged at the outside of the wall of the water tank. Due to the universal joint and the counter weight in the invention, a receiving surface of the wave detector is guaranteed to always keep horizontal when the rotating shafts are rotated for different angles; as the water tank and the support device are coated by rubber, the problem of reflected waves is solved; a lower cross rod is protruded out towards the electric spark emission probe to reduce interference from the reflected waves of the rod to the wave detector. The device for measuring sensitivity of the wave detector in the reception direction of elastic waves, disclosed by the invention, has an advantage of measuring sensitivity of the wave detector in the reception direction of elastic waves.

Owner:SHANDONG UNIV

Conversion valve

ActiveCN101839357BPrevent leakageNo need to useOperating means/releasing devices for valvesMultiple way valvesInterference fit

The invention relates to a conversion valve. A hollow inner wall of a valve body is in interference fit with a ceramic valve sleeve; a ceramic valve core is driven by a top motor; a shifting block is used for limiting; the middle part of the valve body is provided with a water inlet, a water outlet, an upper drain pipe and a lower drain pipe; the periphery of the valve core is provided with a ring-shaped concave water collecting tank; the valve core is in integrated clearance fit with the valve sleeve; the position of the upper drain pipe corresponds to the water collecting tank; and the position of the lower drain pipe corresponds to a lower water collecting cavity. The integrated ceramic valve core of the invention has the advantages of reasonable structure, convenient assembly, high installing efficiency and low manufacturing cost, and capability of greatly improving the reliability of the conversion valve and prolonging the service life of the conversion valve.

Owner:WUXI SHUPUER PRECISION MASCH TECH CO LTD

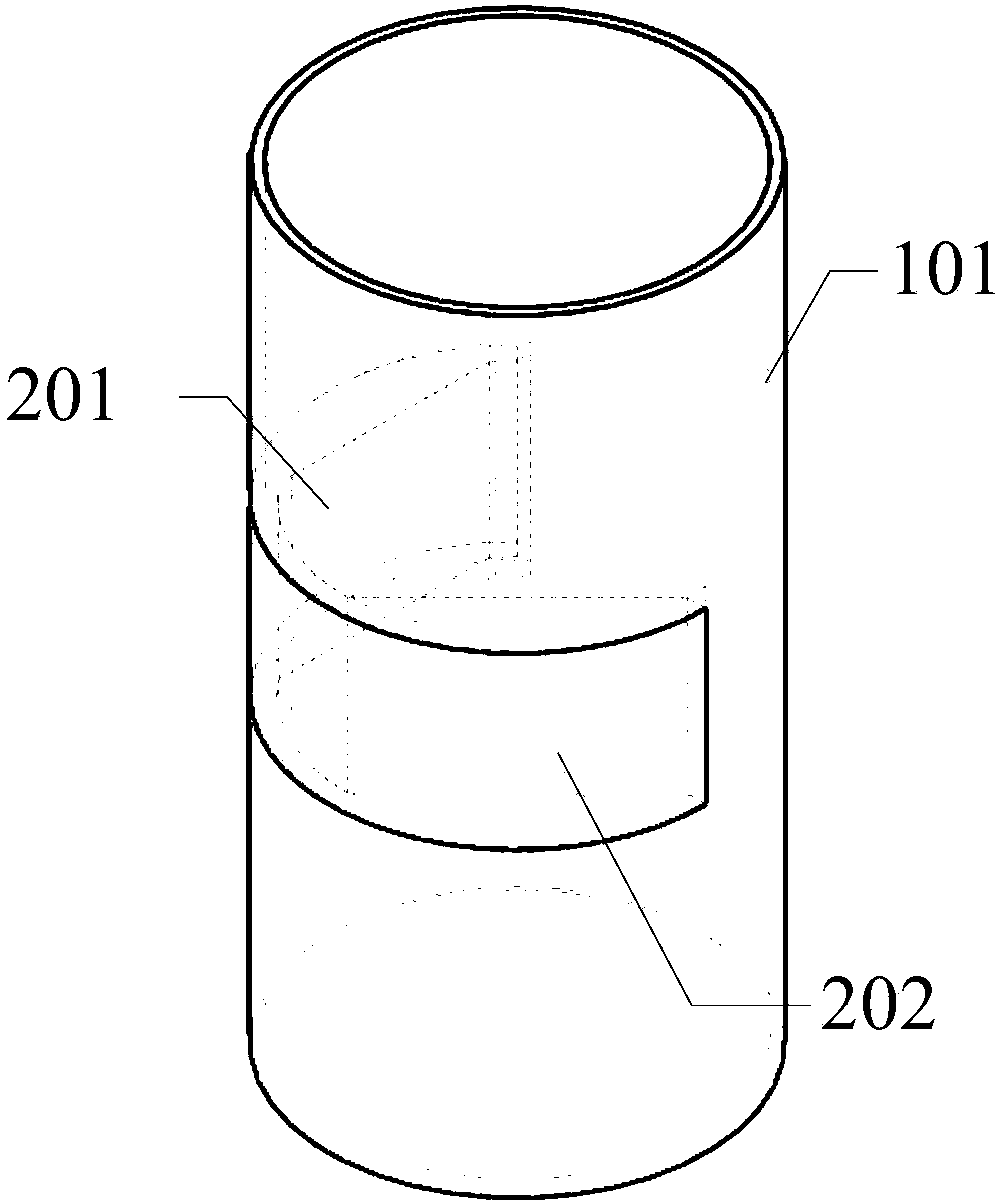

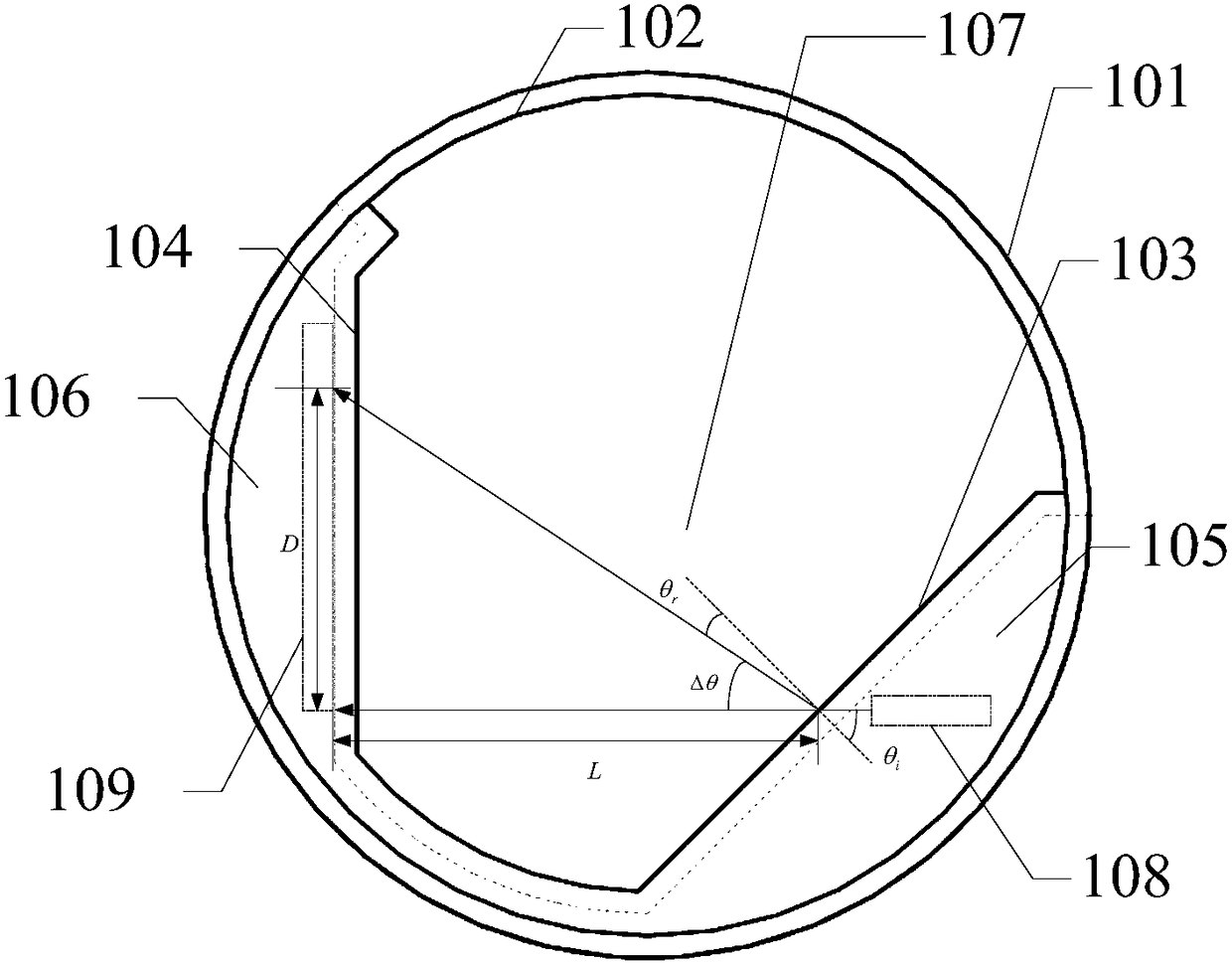

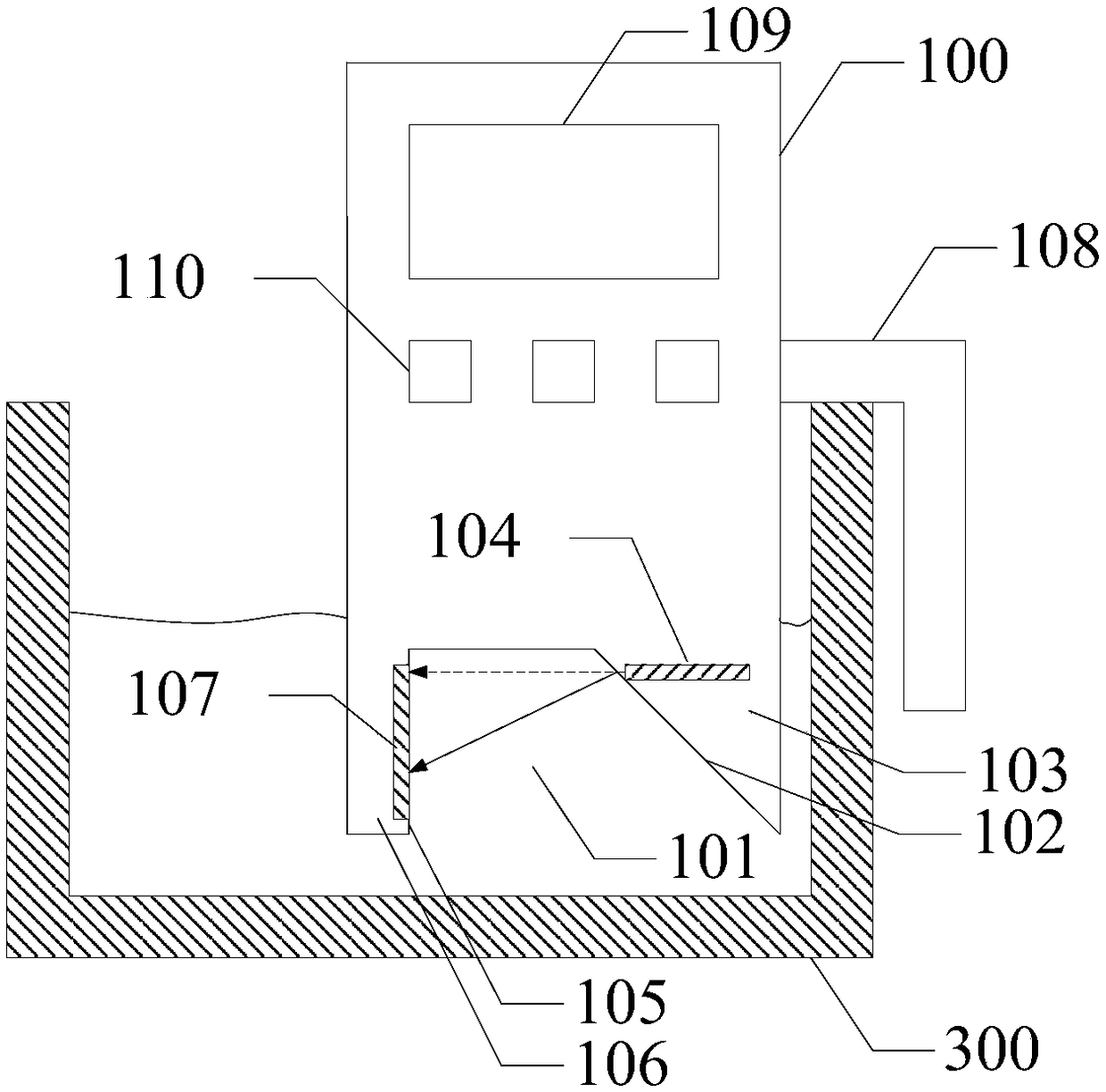

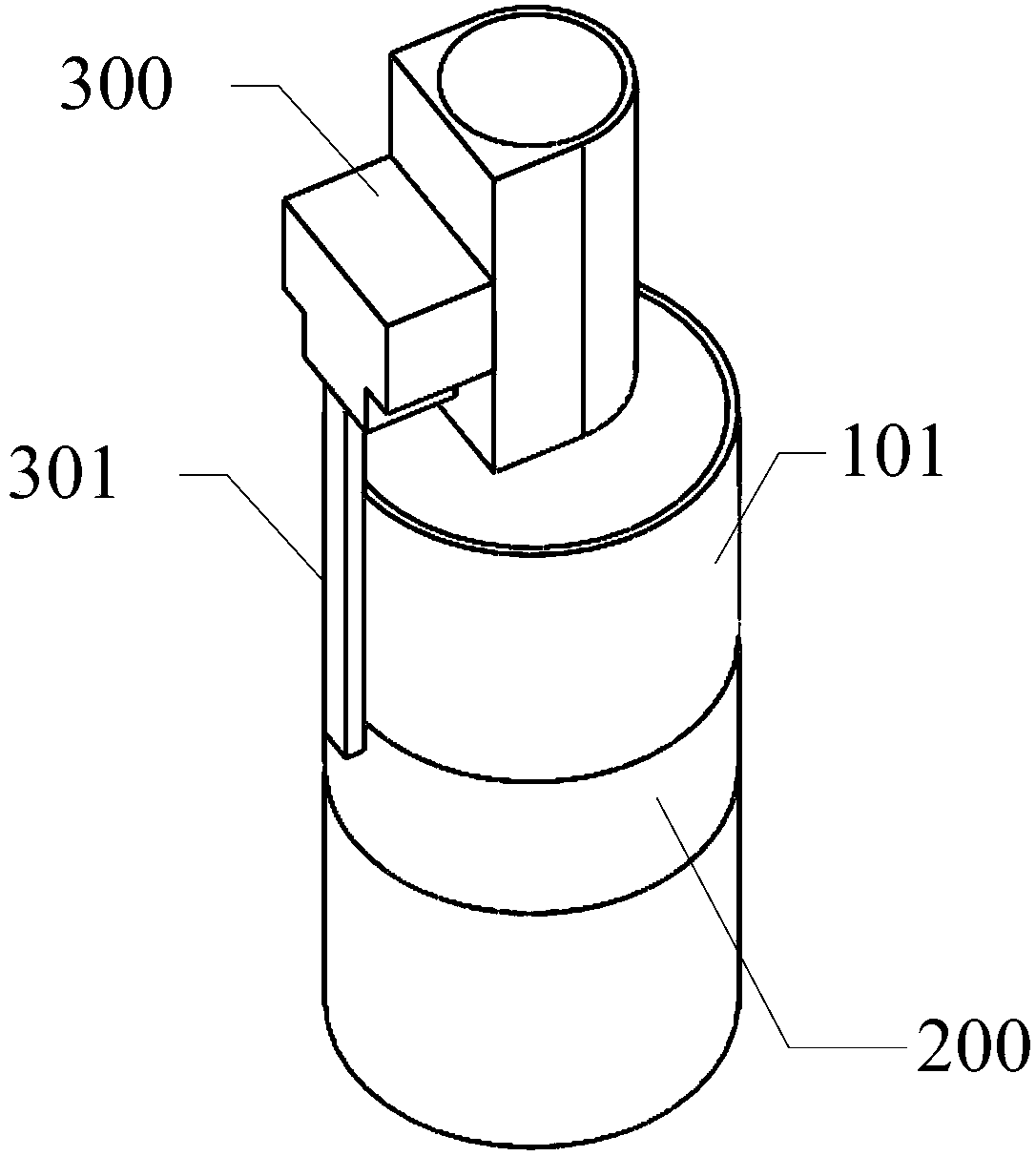

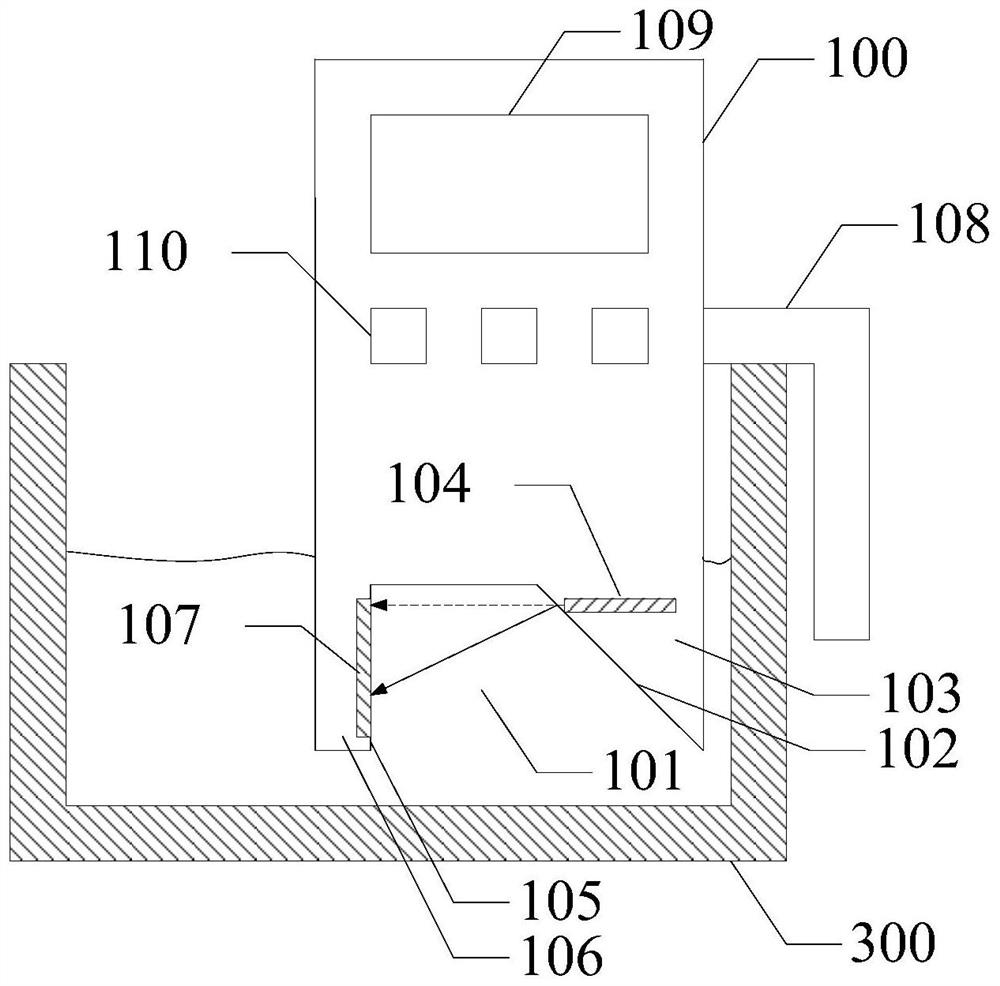

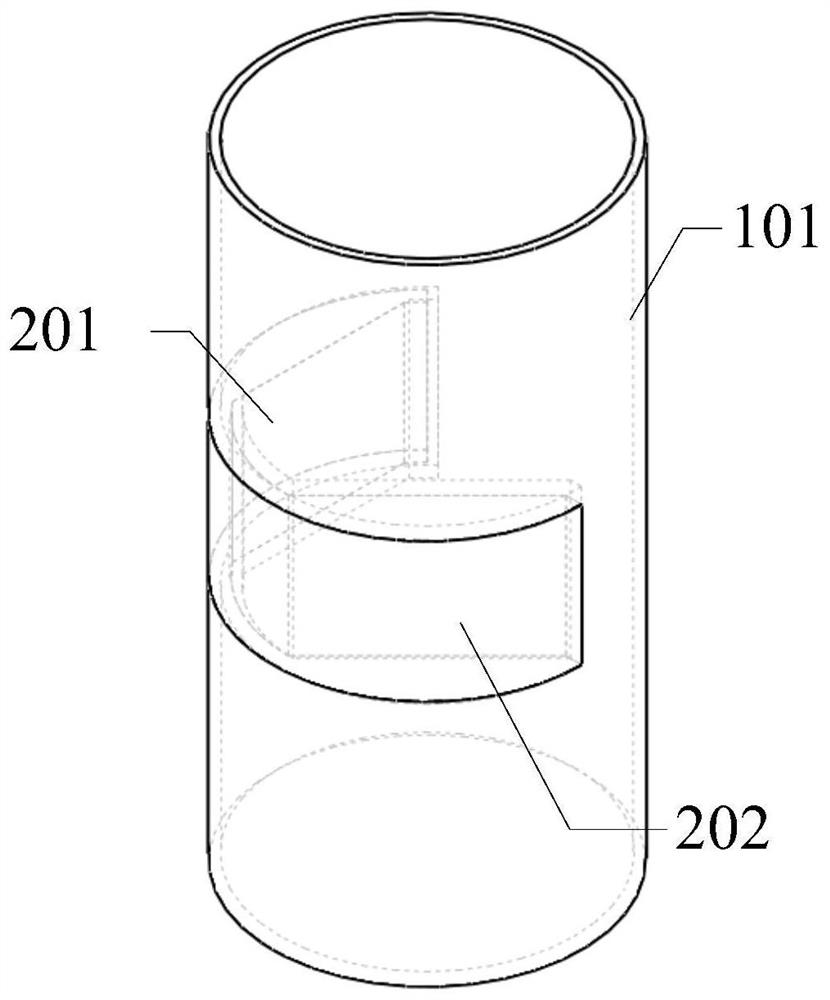

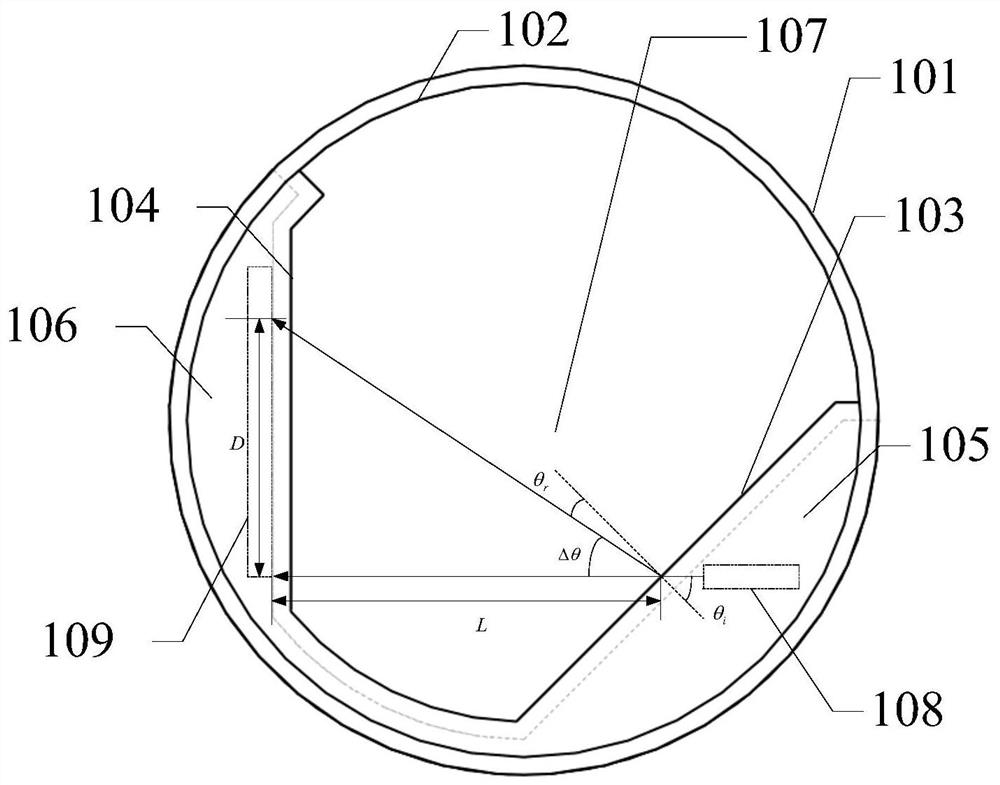

Intelligent water cup for measuring concentration of saline water and sweet water for kitchen

ActiveCN108593599AAccurate concentrationHigh precisionPhase-affecting property measurementsSaline waterRefractive index

The invention discloses an intelligent water cup for measuring the concentration of saline water and sweet water for a kitchen, and relates to a kitchen tool. The intelligent water cup comprises a cupbody, a first light emitting module, a second light receiving module and a main controller. The cup body comprises a first containing cavity for containing a solution. The first light emitting moduleand the second light receiving module are arranged on the first end face and the second end face outside a first light channel in the first containing cavity respectively. The first output end of themain controller is connected with the first light emitting module. The second light receiving module is connected with the second input end of the main controller. The main controller comprises a first light emitting control module, a refracted light receiving module, a refractivity solving module and a solution concentration solving module. The requirement for the precision of the solution proportioning of a weighing method is avoided, and the precision of the concentration of the prepared solution is improved; meanwhile, unlike the weighing method where the concentration needs to be obtained through artificial conversion, the concentration of the solution can be obtained again after the evaporation effect or the non-quantitative feeding effect.

Owner:浙江兰思教育科技有限公司

Flexible wall permeameter for measuring coefficient of permeability

InactiveCN1312466CPrevent leakageAvoid precision requirementsSurface/boundary effectPermeability/surface area analysisC changeEngineering

This invention relates to a flexible wall penetration device to measure penetration parameters, which comprises the following structure: the confined pressure pipe, drainage pipe, water-in pipe are separately controlled to join the penetration pressure room; the confined pressure pipe and the drainage pipe and the water-in pipe are separately connected the pressure meter, air adjusting valve, pressure supply device and B-part changing pipe, pressure meter, air adjusting valve, supply device and C changing tube, pressure meter, air adjusting valve, supply device, air adjusting valve water box exit

Owner:HOHAI UNIV

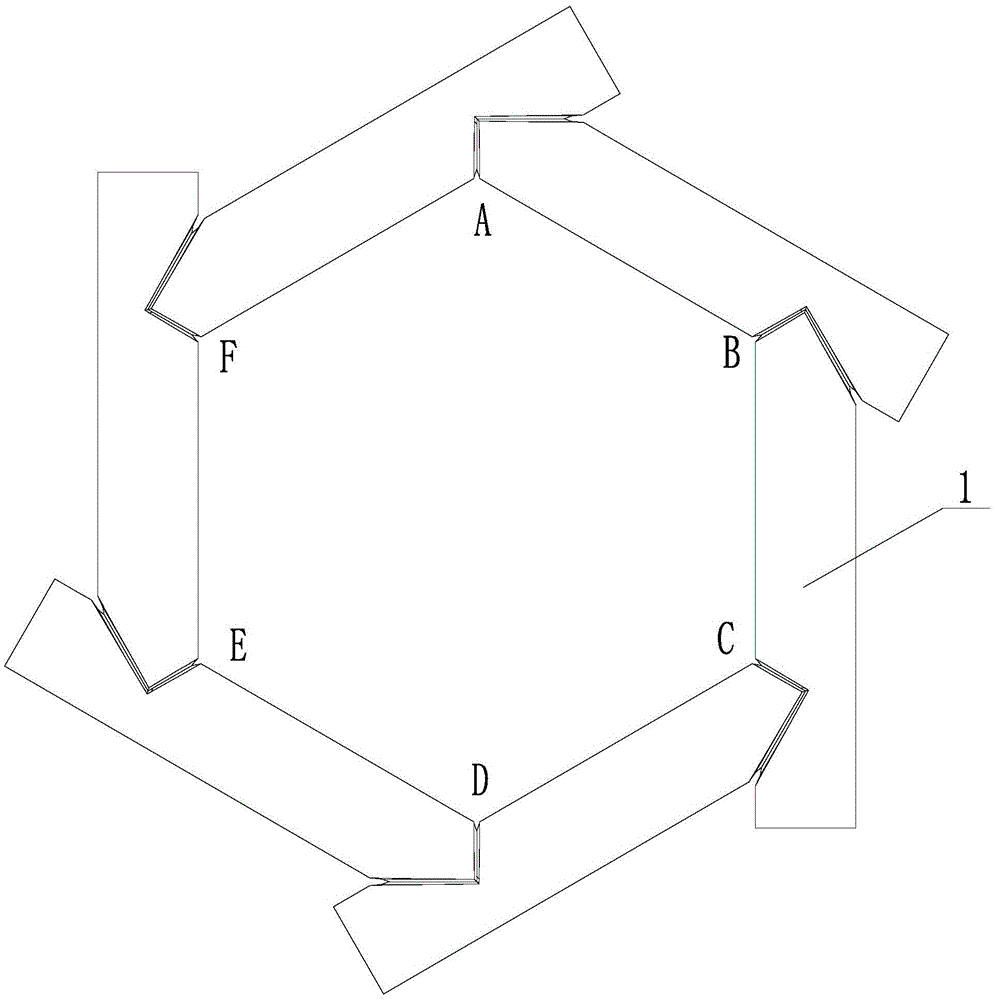

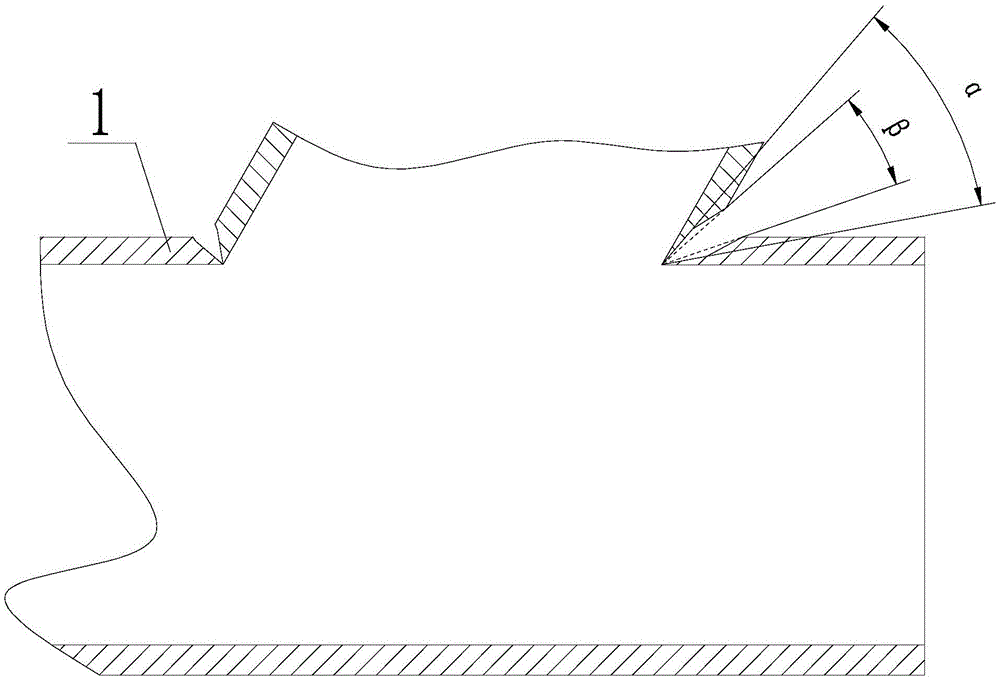

Welding method for annular header

ActiveCN105618903AAvoid precision requirementsAvoid stress concentrationArc welding apparatusStress concentrationShielded metal arc welding

The invention discloses a welding method for an annular header, which is capable of greatly reducing stress concentration. According to the welding method, all oblique nozzles are arranged and fixed at first, and then welding is started; and welding is divided into three steps: 1, fixed-position welding, wherein tungsten inert gas welding is adopted in the fixed-position welding, two sections of connected arc welding areas are arranged at the butt-joint part of each adjacent oblique nozzles and have different arc lengths, the relatively long arc welding area is a first arc welding area, and the relatively short arc welding area is a second arc welding area; 2, backing welding, wherein tungsten inert gas welding is adopted in the backing welding, the annular header is provided with six welding areas in total, which are a welding area A, a welding area B, a welding area C, a welding area D, a welding area E and a welding area F, and the six welding areas are clockwise arranged; and 3, welding seam-filling welding, wherein welding is carried out by virtue of a manual electric arc welding method in the welding seam-filling welding, odd layers and even layers are reversely welded, and so on, until the filling welding is completed. The welding method disclosed by the invention has the advantage of basically no stress concentration.

Owner:SUZHOU HAILU HEAVY IND

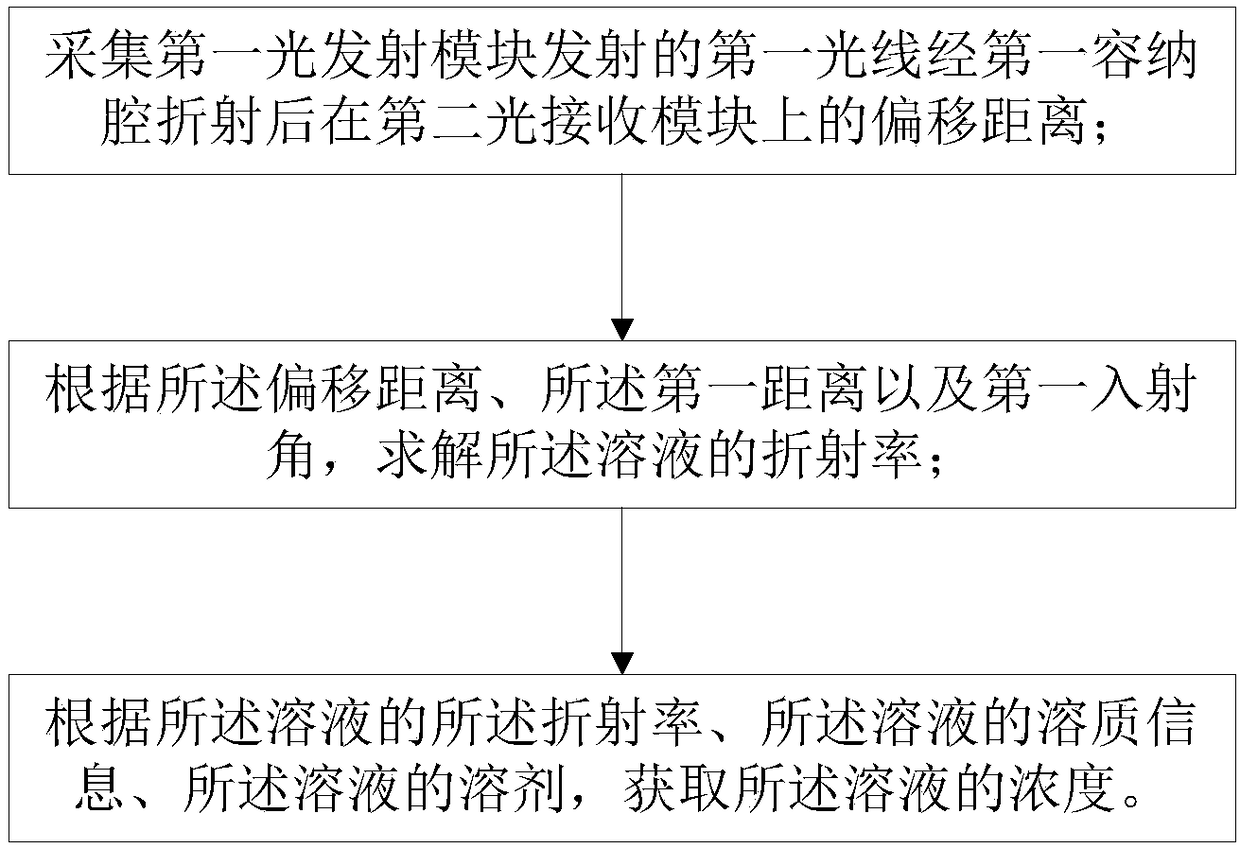

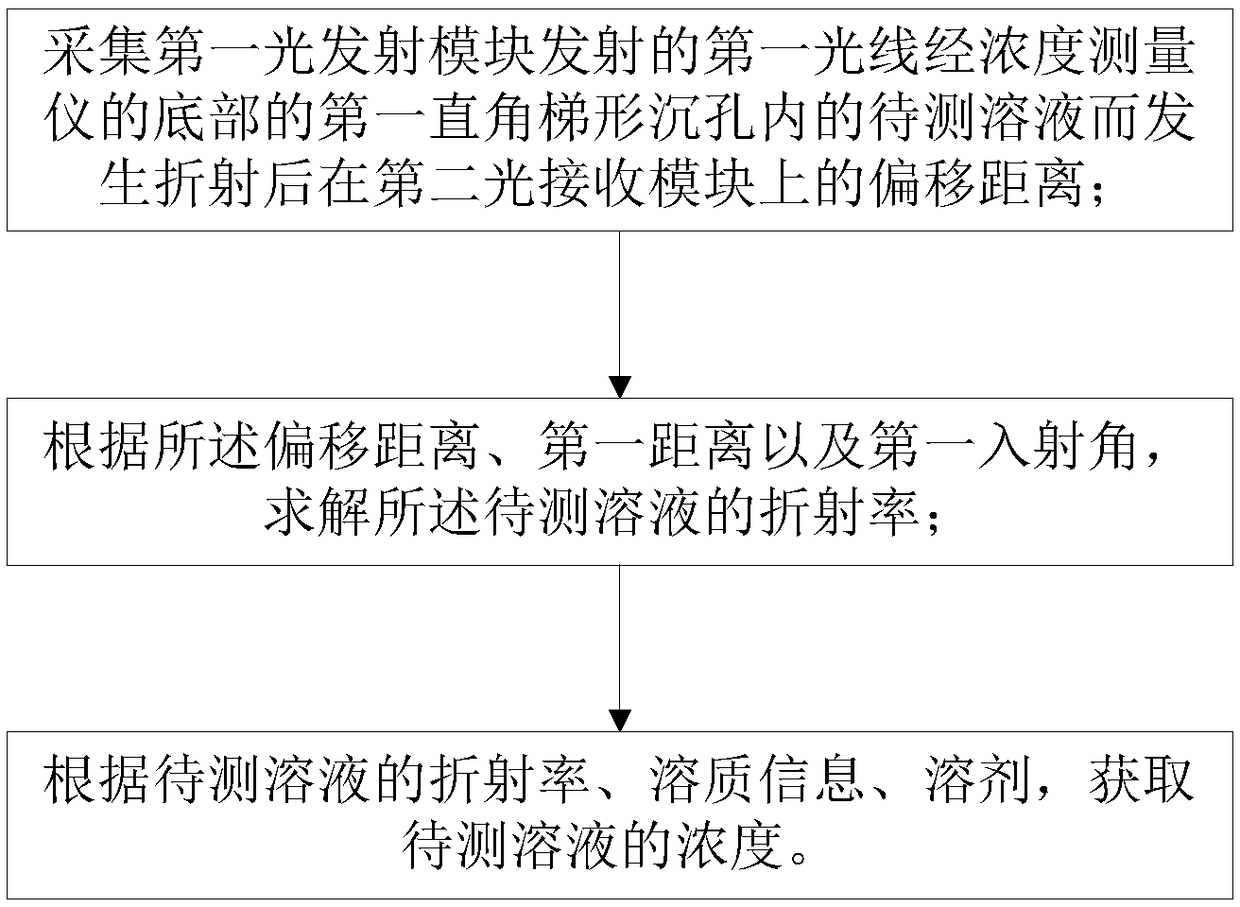

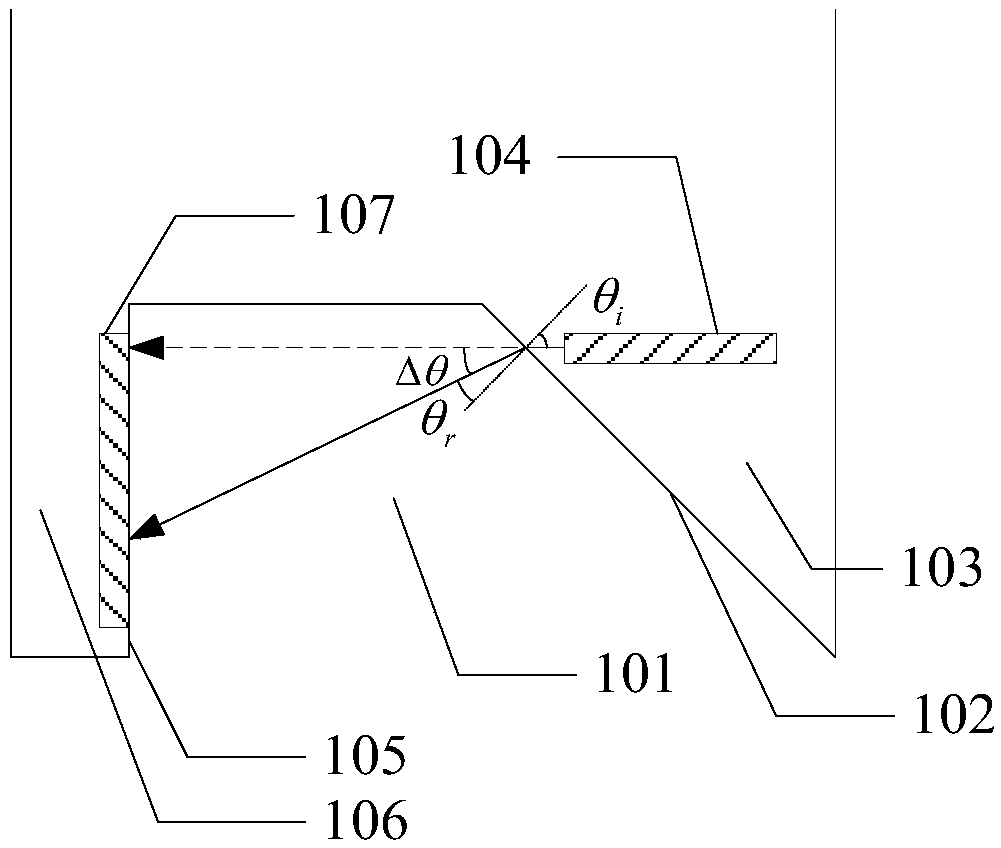

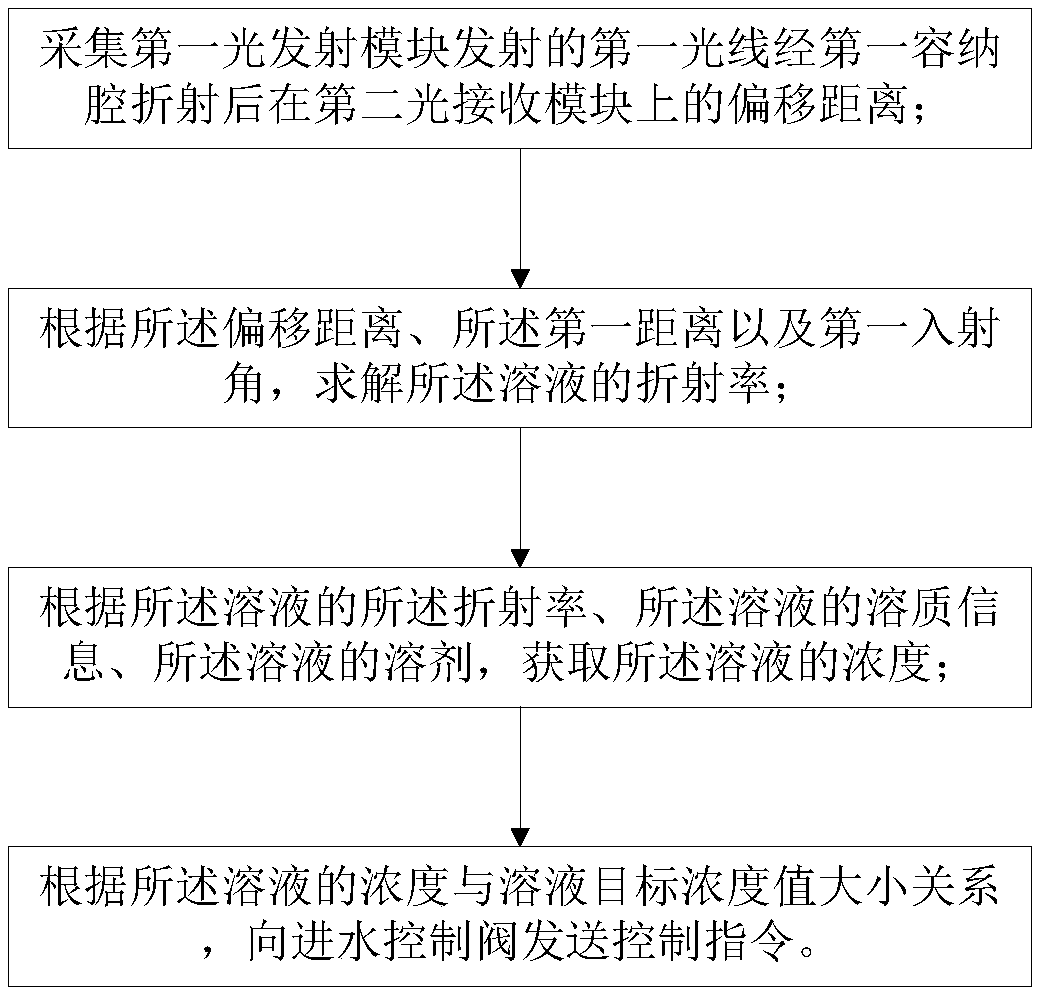

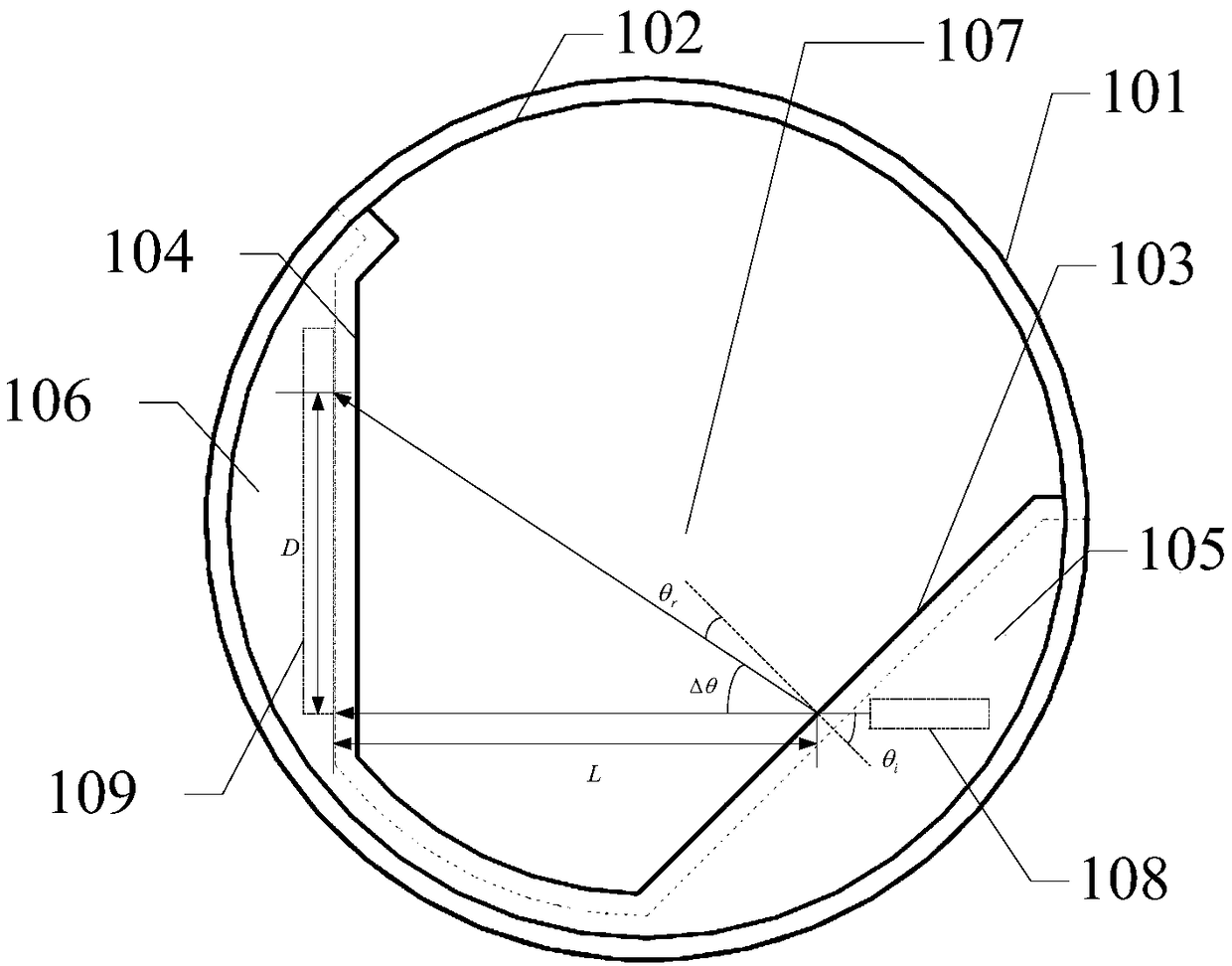

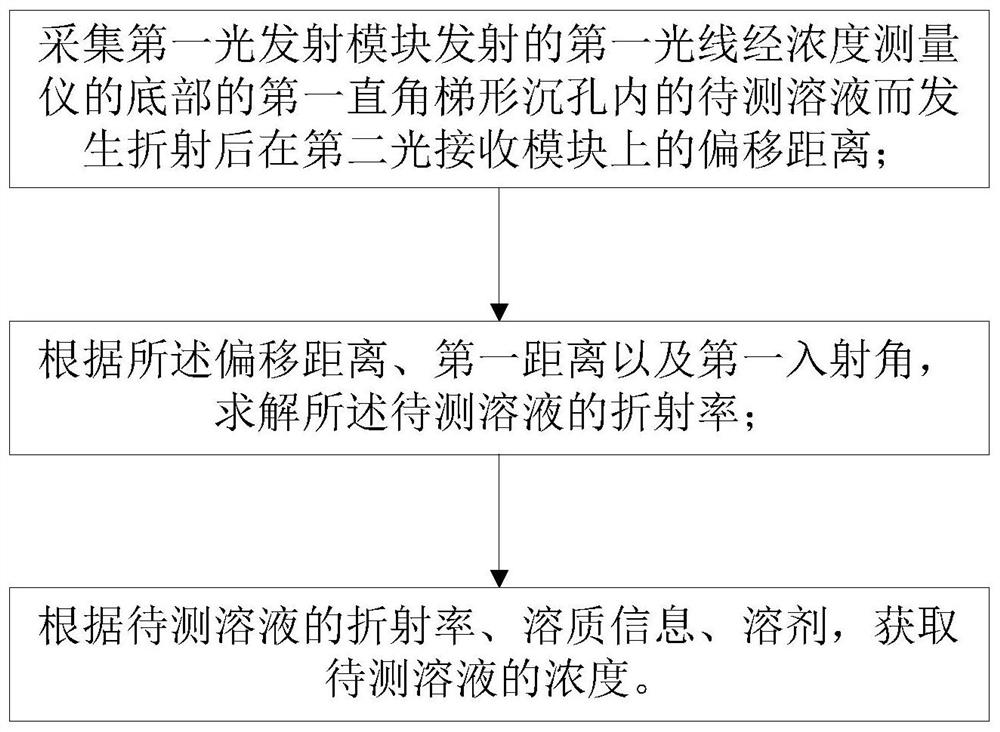

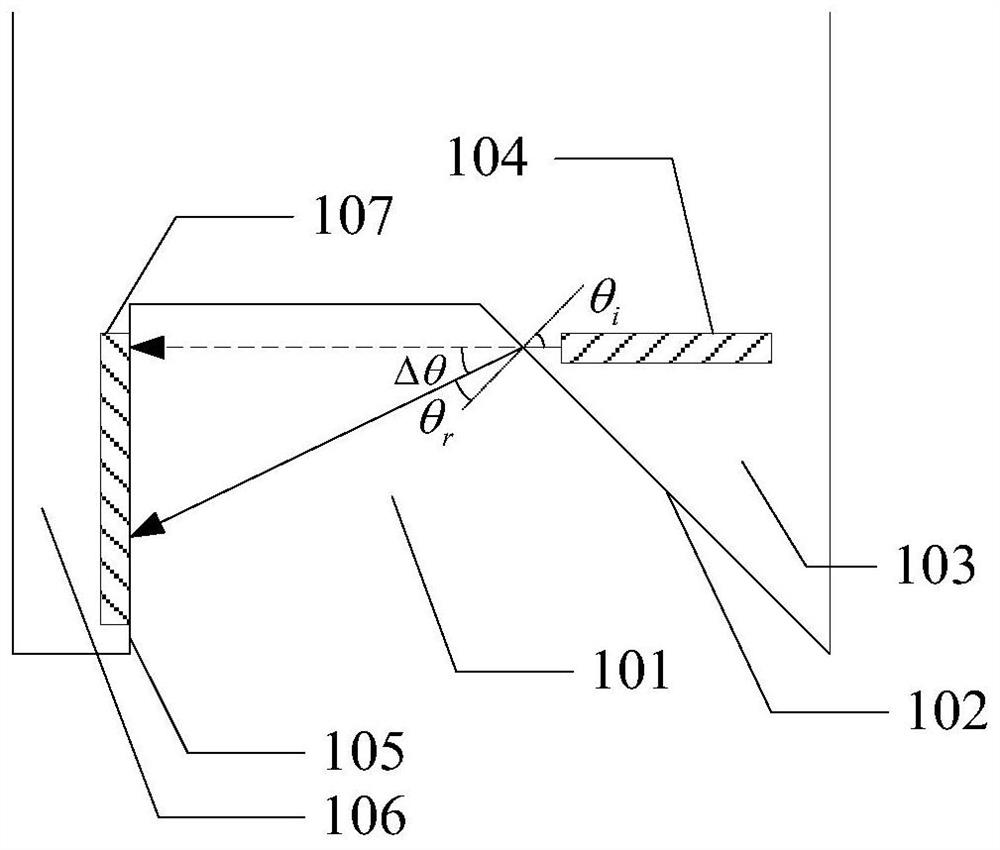

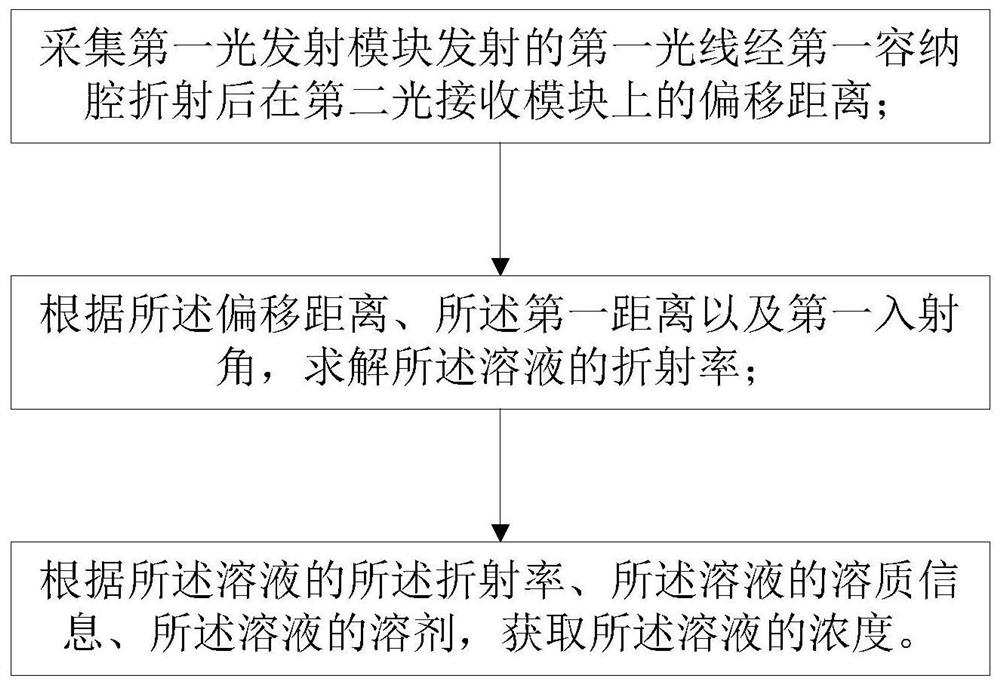

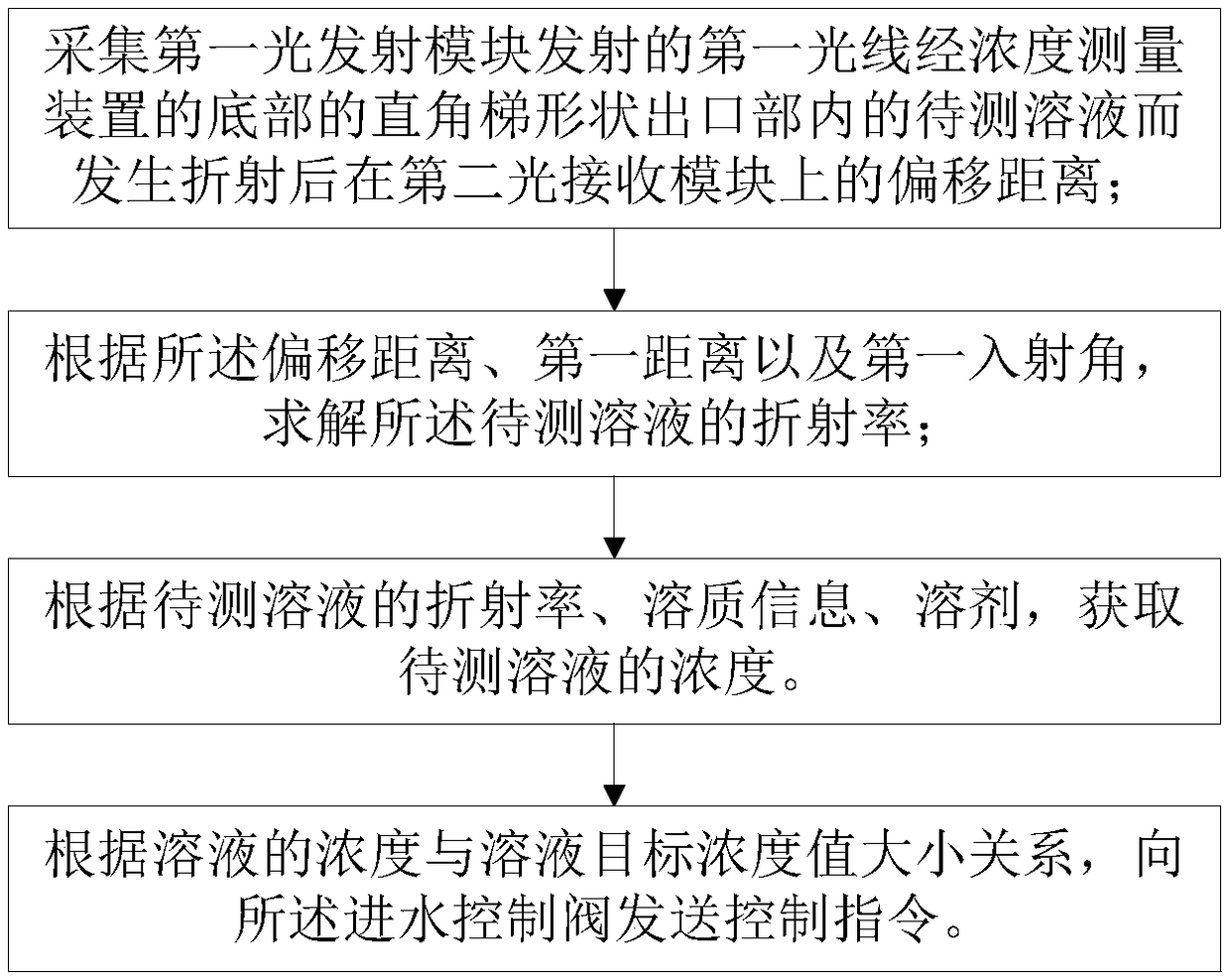

Home-use self-made beverage concentration measuring method

ActiveCN108732131AAccurate concentrationHigh precisionPhase-affecting property measurementsRefractive indexEvaporation

The invention discloses a home-use self-made beverage concentration measuring method, and relates to the field of a kitchen tool. The method comprises the following steps of firstly collecting the deviation distance of first light rays emitted from a first light emission module on a second light receiving module after the refraction generation through passing through a solution to be tested in a first right-angle trapezoidal sink hole formed in the bottom of a concentration measurement instrument; then, solving the refractive index of the solution to be tested according to the deviation distance, the first distance and the incidence angle; then, obtaining the concentration of the solution to be tested according to the refractive index of the solution to be tested, the solute information ofthe solution to be tested, and the solvent of the solution to be tested. The precision requirement of the solution proportioning ratio of the weighing method is avoided; the precision of the concentration of the prepared solution is improved; meanwhile, the requirement of manual conversion for concentration solving by a weighing method is not needed; for evaporation effects or non-quantitative feeding effects, the solution concentration can be obtained again.

Owner:绍兴东雀纺织品有限公司

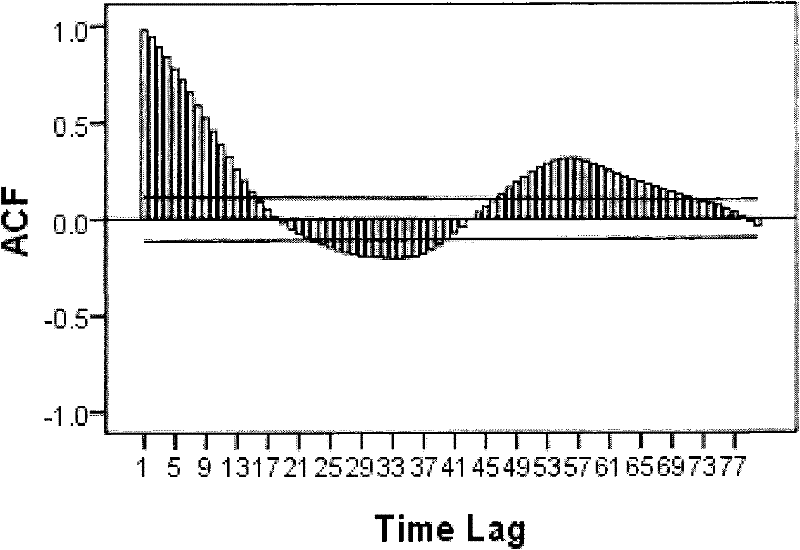

Sewage pump station water level prediction method base on neural network

InactiveCN101819407BImprove forecast accuracyAvoid precision requirementsAdaptive controlLifting capacityEngineering

The invention discloses a sewage pump station water level prediction method base on neural network. The method comprises the steps of: firstly selecting prediction model variables including input variables and output variables, wherein input variables include an upstream pump station lifting capacity, forebay liquid level variable quantity, pump station discharge rate and switch pump liquid levelcontrol setting quantity and the output variables include a pump station forebay water level; secondly normalizing the data; then setting up a BP neural network framework and training the BP neural network; and finally carrying out denormalization on the data of the neural network. The method has higher prediction accuracy compared with the traditional steady flow computing method.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

nb based on layer-by-layer stacking 3 Al superconducting precursor wire preparation method

ActiveCN108878054BSmall size deviationUniform tightnessSuperconductors/hyperconductorsReduction of cables/conductors sizeWire rodAlloy

A Nb based on layer-by-layer stacking 3 The preparation method of Al superconducting precursor wire mainly includes: A. Preparation of Nb-Al composite sheath: Nb foil and Al foil are alternately stacked in the rectangular groove of the tubular Nb box from bottom to top, and the upper cover is covered , in the Cu tube, welded and sealed; B. Preparation of Nb-Al single mandrel: the Nb-Al composite sheath is hydrostatically extruded, repeatedly drawn, and then corroded to remove the copper to obtain the Nb-Al single mandrel. Mandrel; C, Nb 3 Preparation of Al superconducting precursor wires: multiple Nb‑Al single mandrels are packed closely into Cu or Cu alloy sheaths, and multi-cores are obtained by electron beam sealing welding, hydrostatic extrusion, and repeated drawing. Wire rod; then corrode to remove copper. The method is simple to operate, the assembly filling rate of the foil material is high, and the compactness of each layer of foil material is uniform. The final superconducting wire prepared by it has good performance, strong consistency and high qualified rate. It is especially suitable for the preparation of long superconducting wires.

Owner:SOUTHWEST JIAOTONG UNIV

a stage lamp

ActiveCN104501037BAvoid precision requirementsMeet the use requirementsLighting applicationsMechanical apparatusStage lightingEngineering

The invention discloses a stage lamp. The stage lamp comprises a lamp bulb assembly for emitting light, and further comprises a fixing plate and regulating devices, wherein the regulating devices comprise a first regulating device and a second regulating device; the lamp bulb assembly is mounted on the second regulating device; the first regulating device can move in parallel relative to the fixing plate in a first direction and is connected with the fixing plate; the second regulating device can move in parallel relative to the first regulating device in a second direction and is connected with the first regulating device; the first direction is perpendicular to the second direction. Through arrangement of the two regulating mechanisms, the positions of the lamp bulb assembly in two different directions on the same horizontal plane can be regulated, so that errors caused in the mounting and machining processes are overcome.

Owner:GUANGZHOU FINEART LIGHTING

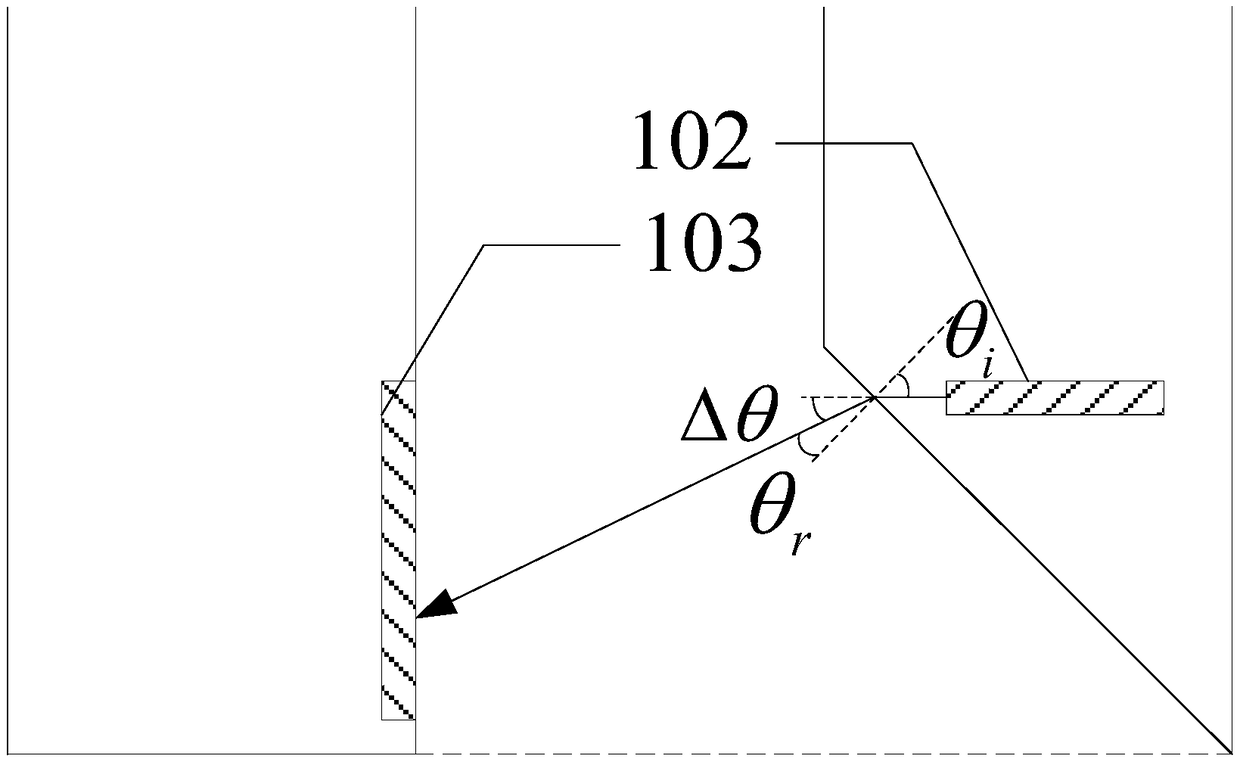

Saline-sugar solution concentration regulating method based on intelligent cup used for kitchen

ActiveCN108918464AAccurate concentrationSimple equipmentControlling ratio of multiple fluid flowsPhase-affecting property measurementsSaline waterAngle of incidence

The invention discloses a saline-sugar solution concentration regulating method based on an intelligent cup used for a kitchen, relating to the field of kitchenware. The method includes firstly collecting an offset distance D, on a second light receiving module, of first light emitted by a first light emission module after the first light is reflected by a first accommodating chamber of the intelligent cup; solving the refractive index n of a solution according to the offset distance D, a first distance L and a first angle of incidence [theta]i; acquiring the concentration c of the solution according to the refractive index n of the solution, solute information of the solution, and a solvent of the solution; and finally sending a control instruction to a water feeding control valve according to a relationship between the solution concentration c and a solution target concentration value c<goal>. The method avoids precision requirements on solution ratios in weighing methods, improves the accuracy of the concentration of a prepared solution, and does not need manual conversion to solve the concentration like weighing methods. The concentration of the solution can be acquired again after evaporation or addition of an indefinite quantity of a material.

Owner:绍兴蚕香纺织有限公司

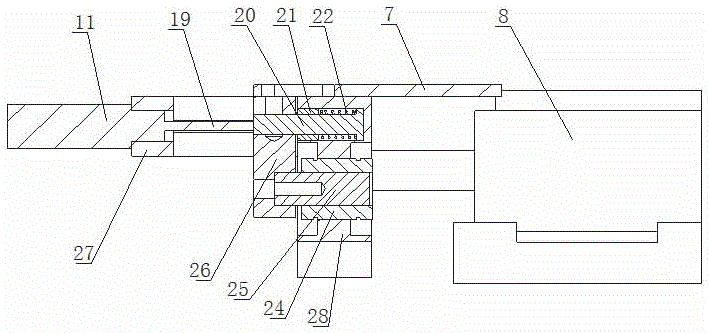

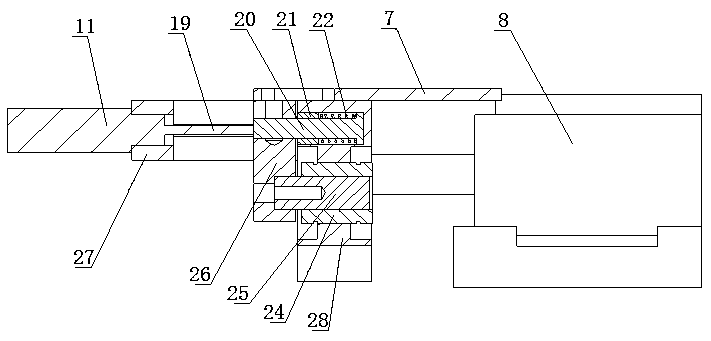

A liquid plastic thin-walled sleeve clamp with a return mechanism

ActiveCN112719330BMeet the requirements of positioning and clampingHigh precisionChucksControl theoryMechanical engineering

The invention discloses a liquid plastic thin-walled sleeve fixture with a material return mechanism, which includes a fixing device, a pushing mechanism connected in the fixing device, a linkage clamping mechanism and a linkage ejection mechanism, and the fixing device consists of The fixed guide frame is composed of a transition plate and a clamp body fixedly connected by bolts; the pushing mechanism is composed of a pull rod connected to a slanting block, the slanting block is located inside the fixed guide frame, and the front end of the pull rod is connected to the slanting block, The middle part is connected through the transition plate, the upper end of the inclined block is slidingly connected with the linkage clamping mechanism, and the lower end is rollingly connected with the linkage ejection mechanism; the linkage clamping mechanism and the linkage ejection mechanism are connected to the workpiece. The present invention adopts the structural form in which the push mechanism, the linkage clamping mechanism and the linkage ejection mechanism work together, and combines the flexible clamping function of the liquid plastic to improve the centering accuracy of the workpiece, reduce the workload of workers and machines, and improve the work efficiency.

Owner:ZHENGZHOU UNIV

A device for measuring the direction sensitivity of a geophone to receive elastic waves

InactiveCN102914805BAvoid disadvantagesOvercoming Errors in Measuring AmplitudeGeological measurementsGeophoneUniversal joint

The invention discloses a device for measuring sensitivity of a wave detector in a reception direction of elastic waves. The device comprises a water tank filled with water, wherein a shock absorption material is stuck at the inner side of the wall of the water tank; a support device is arranged on the water tank; rotating shafts at two ends of the support device are respectively connected with corresponding walls of the water tank; a universal joint is arranged at the middle position of the support device; a wave detector is arranged in the universal joint; the universal joint is connected with a counter weight through a connecting rod I; an electric spark emission probe is arranged at the position of the central line of the support device which is located at the upper side of the support device and below a water body; and a dial is arranged at the outside of the wall of the water tank. Due to the universal joint and the counter weight in the invention, a receiving surface of the wave detector is guaranteed to always keep horizontal when the rotating shafts are rotated for different angles; as the water tank and the support device are coated by rubber, the problem of reflected waves is solved; a lower cross rod is protruded out towards the electric spark emission probe to reduce interference from the reflected waves of the rod to the wave detector. The device for measuring sensitivity of the wave detector in the reception direction of elastic waves, disclosed by the invention, has an advantage of measuring sensitivity of the wave detector in the reception direction of elastic waves.

Owner:SHANDONG UNIV

A method for measuring the concentration of home-made drinking products

ActiveCN108732131BAccurate concentrationHigh precisionPhase-affecting property measurementsHome useAngle of incidence

The invention discloses a home-use self-made beverage concentration measuring method, and relates to the field of a kitchen tool. The method comprises the following steps of firstly collecting the deviation distance of first light rays emitted from a first light emission module on a second light receiving module after the refraction generation through passing through a solution to be tested in a first right-angle trapezoidal sink hole formed in the bottom of a concentration measurement instrument; then, solving the refractive index of the solution to be tested according to the deviation distance, the first distance and the incidence angle; then, obtaining the concentration of the solution to be tested according to the refractive index of the solution to be tested, the solute information ofthe solution to be tested, and the solvent of the solution to be tested. The precision requirement of the solution proportioning ratio of the weighing method is avoided; the precision of the concentration of the prepared solution is improved; meanwhile, the requirement of manual conversion for concentration solving by a weighing method is not needed; for evaporation effects or non-quantitative feeding effects, the solution concentration can be obtained again.

Owner:绍兴东雀纺织品有限公司

A smart water cup for measuring the concentration of salt water and sugar water in the kitchen

ActiveCN108593599BAccurate concentrationHigh precisionPhase-affecting property measurementsSaline waterSalt water

The invention discloses an intelligent water cup for measuring the concentration of saline water and sweet water for a kitchen, and relates to a kitchen tool. The intelligent water cup comprises a cupbody, a first light emitting module, a second light receiving module and a main controller. The cup body comprises a first containing cavity for containing a solution. The first light emitting moduleand the second light receiving module are arranged on the first end face and the second end face outside a first light channel in the first containing cavity respectively. The first output end of themain controller is connected with the first light emitting module. The second light receiving module is connected with the second input end of the main controller. The main controller comprises a first light emitting control module, a refracted light receiving module, a refractivity solving module and a solution concentration solving module. The requirement for the precision of the solution proportioning of a weighing method is avoided, and the precision of the concentration of the prepared solution is improved; meanwhile, unlike the weighing method where the concentration needs to be obtained through artificial conversion, the concentration of the solution can be obtained again after the evaporation effect or the non-quantitative feeding effect.

Owner:浙江兰思教育科技有限公司

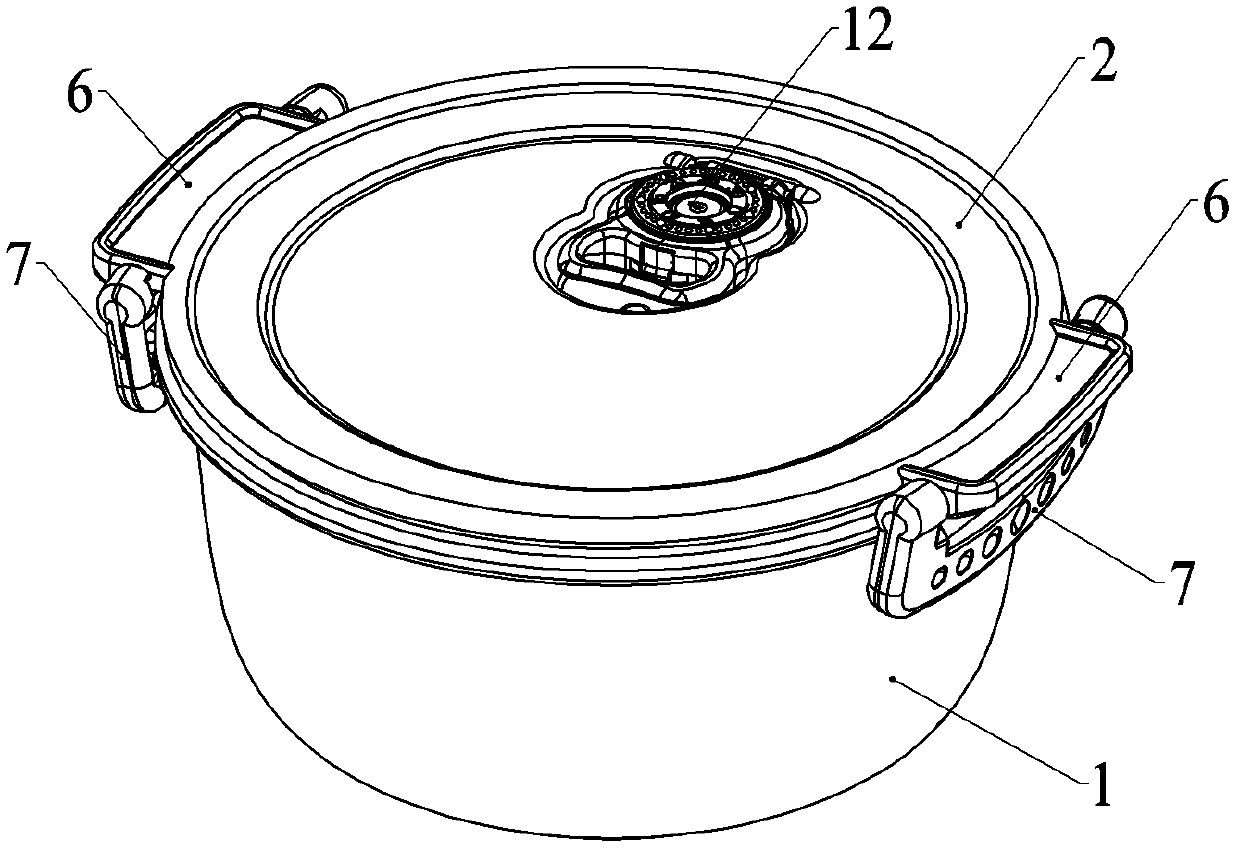

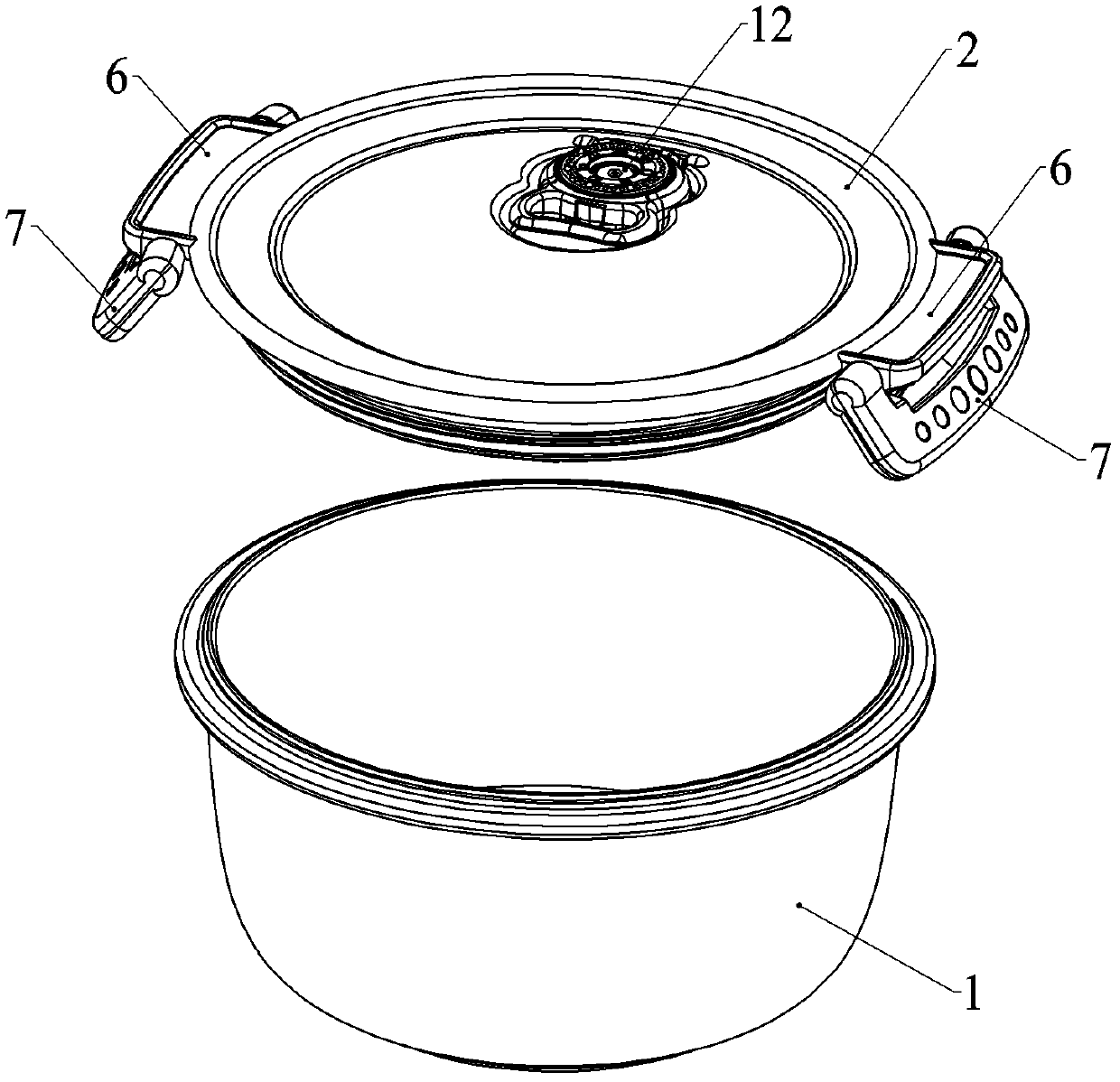

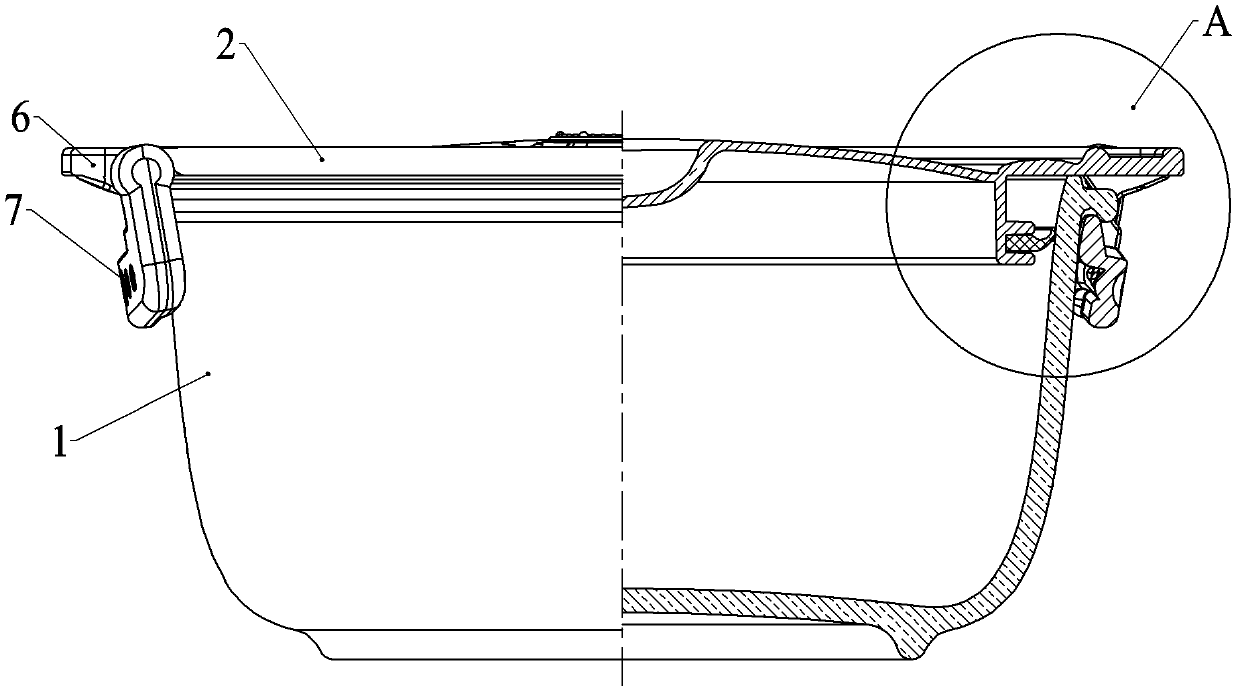

Sealing anti-scalding type microwave fresh-keeping ceramic container

ActiveCN102490977BEasy to produceAvoid precision requirementsClosure with auxillary devicesRemovable lids/coversMicrowaveMaterials science

The invention relates to a sealing anti-scalding type microwave fresh-keeping ceramic container, which comprises a ceramic container body and a container cover, wherein the container cover is provided with an inward-extension protruding ring which faces and extends into the ceramic container body. The inward-extension protruding ring is provided with a flexible annular leather cup, and the flexible annular leather cup forms a structure of expanding and sealing an inner wall of the ceramic container body by overturning an upwarp edge of the flexible annular leather cup when the container coveris covered into the ceramic container body. The container cover is further provided with a cover-connecting anti-scalding handle which is directly formed from the container cover and extends outwards, the anti-scalding handle is provided with an overturning type buckling handle, an angular buckling shoulder is arranged on the lower side of the anti-scalding handle, the overturning type buckling handle is provided with an angular sliding buckle capable of being connected and locked corresponding to the angular buckling shoulder, an annular buckling shoulder is formed on the outer side of an upper end wall of the ceramic container body, and the overturning type buckling handle is provided with a clamping-connection portion which is in supporting connection with a random annular position of the annular buckling shoulder arranged on the ceramic container body. The sealing anti-scalding type microwave fresh-keeping ceramic container has the advantages of being capable of effectively keep sealing, anti-scalding, easy to implement and convenient to use.

Owner:PANJIN HAIXING FINE CHEM TECH

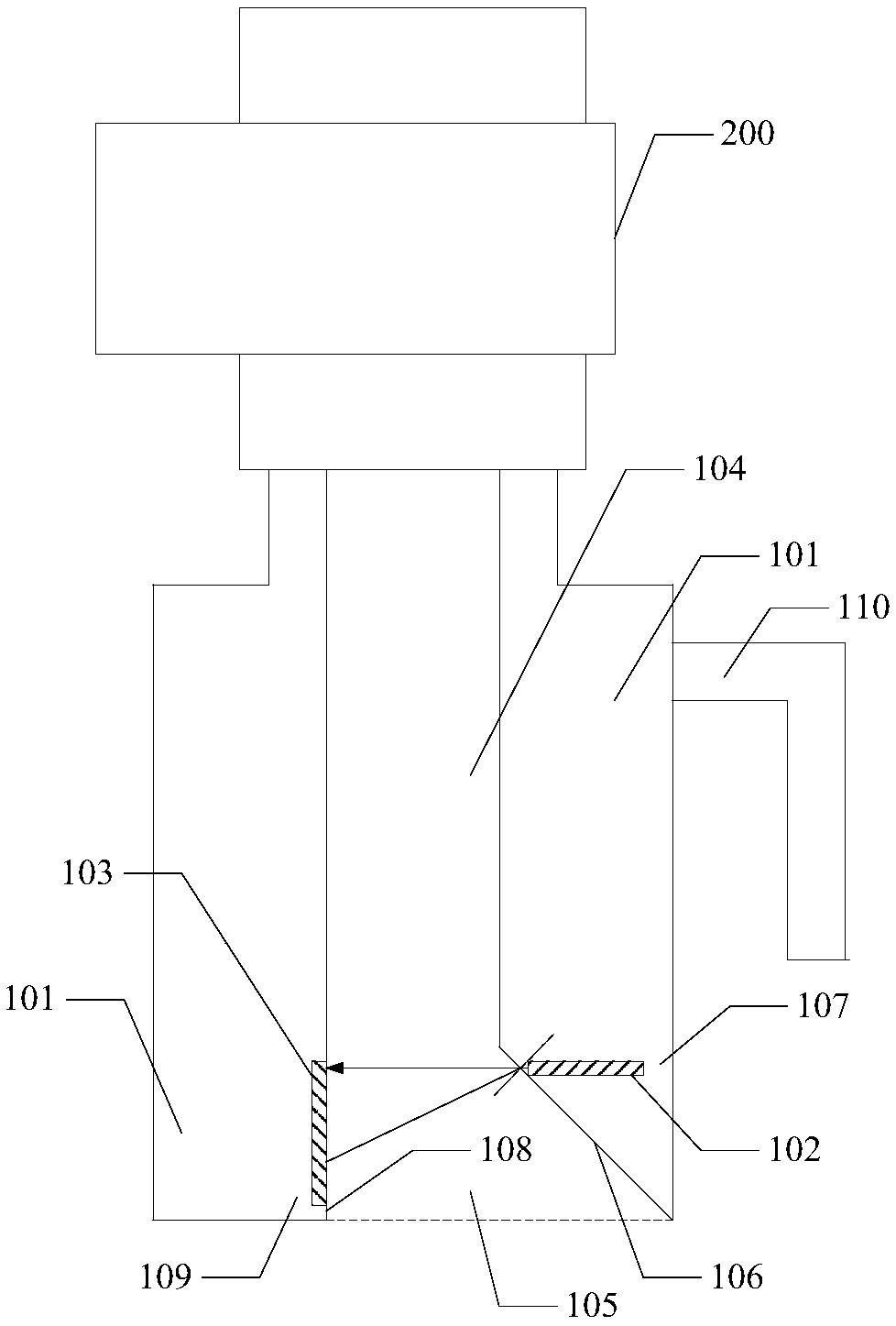

Household home-made drink concentration control device

ActiveCN108762322AImprove compatibilityAccurate concentrationControlling ratio of multiple fluid flowsPhase-affecting property measurementsComputer moduleEvaporation

The invention, which relates to the field of kitchen appliances, discloses a household home-made drink concentration control device comprising an annular case, a main controller, a first light emitting module, a second light receiving module and an inflow control valve. A first inflow channel is formed in the middle of the annular case in a radial direction; a first inlet of the first inflow channel is connected with an inflow control valve; and a second outlet of the first inflow channel includes a right-angle ladder type outlet portion. A first output terminal of the main controller is connected with the first light emitting module; the second light receiving module is connected to a second input terminal of the main controller; and a fifth output terminal of the main controller is connected with a control terminal of the inflow control valve. According to the invention, the accuracy requirement of the solution proportioning of the weighing method is avoided; and the accuracy of theconfigured solution concentration is improved. Meanwhile, the manual concentration calculation based on the existing weighing method is not needed; and the solution concentration can be obtained againafter the effect of evaporation or non-quantitative charging.

Owner:嘉兴市顺凯鹿科技有限公司

Automatic Grinding Fixtures for CNC Machine Tools

ActiveCN106737181BRealize double-sided processingAchieve positioningGrinding work supportsNumerical controlEngineering

The invention discloses an automatic grinding fixture for a numerical-control machine tool, and relates to the technical field of auxiliary accessories for numerical-control machining. The automatic grinding fixture is provided with a mounting plate. A rotary cylinder is arranged on the mounting plate, a die clamping seat is arranged on the rotary cylinder, positioning dies are arranged on the die clamping seat, and workpiece embedding grooves are formed in the positioning dies; a reference positioning slide rail is arranged on the mounting plate, positioning sliders are arranged on the reference positioning slide rail, reference positioning blocks are arranged on the positioning sliders, reference positioning cylinders are arranged on the mounting plate, piston rods of the reference positioning cylinders are connected with the positioning sliders, detection yielding cylinders are arranged on the mounting plate, detection positioning cylinders are arranged on the detection yielding cylinders, displacement detection frames are arranged on piston rods of the detection positioning cylinders, and displacement detection devices are arranged on the displacement detection frames; pliers are arranged on the mounting plate and are positioned at the rear side of the die clamping seat, jaws of the pliers are positioned above the workpiece embedding grooves, a support frame is arranged on the mounting plate, pliers driving cylinders are arranged on the support frame, and piston rods of the pliers driving cylinders are hinged to handles of the pliers. The automatic grinding fixture has the advantages that the automatic grinding fixture is simple in structure, convenient to use and high in production efficiency, and the labor intensity can be relieved.

Owner:威海威硬工具股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com