Rotation apparatus, rotor type compressor applying rotation apparatus, and fluid motor applying rotation apparatus

一种转动装置、缸体的技术,应用在旋转活塞式机械、旋转活塞式发动机、发动机的密封装置等方向,能够解决增加摆动挡块磨损、不能保证气缸密封、不可能实现滚动等问题,达到减轻动量不平衡、提高工作可靠性、避免精度要求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

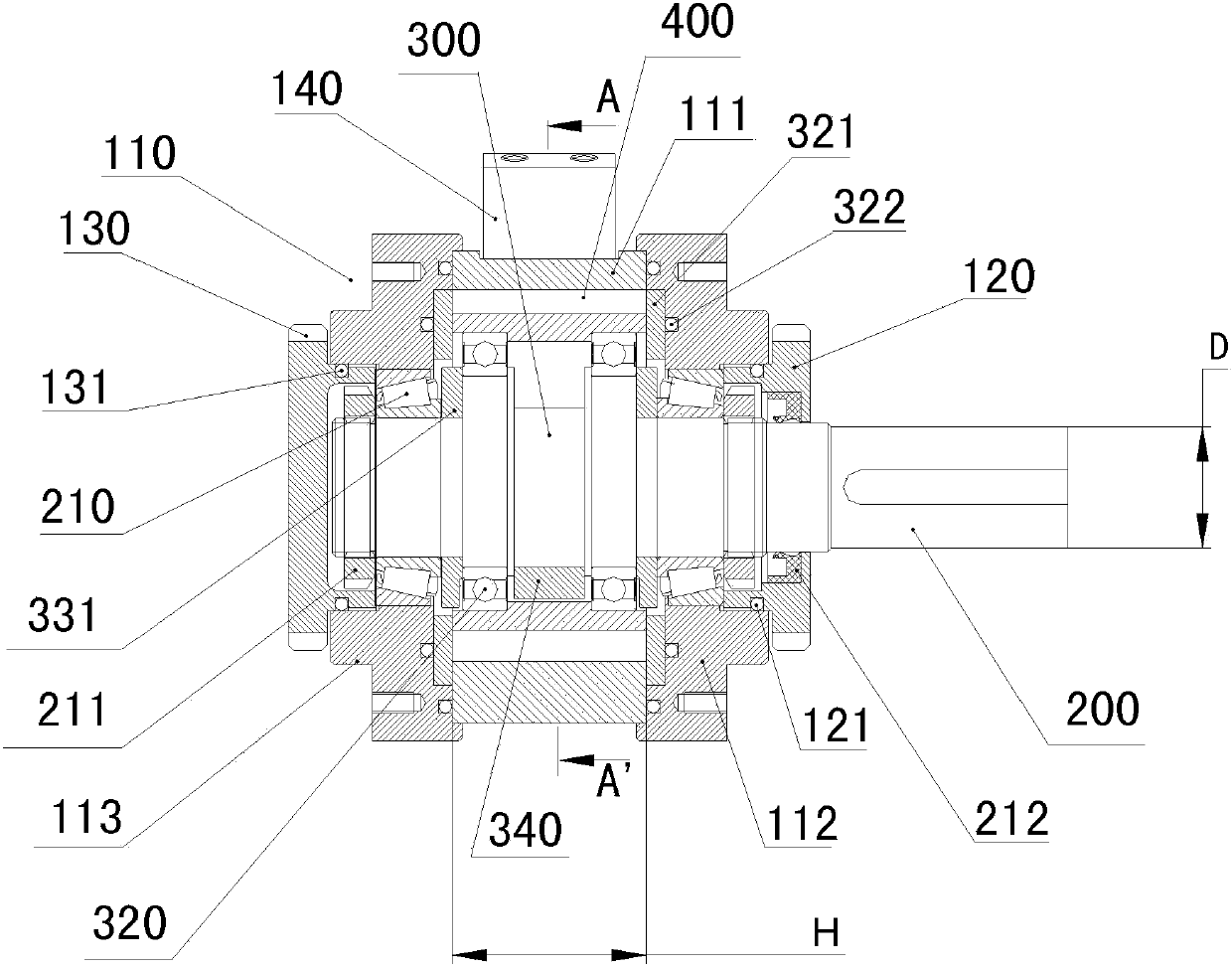

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. It should be noted that, in the drawings or descriptions of the specification, similar or identical parts all use the same figure numbers. Implementations not shown or described in the accompanying drawings are forms known to those of ordinary skill in the art. For the convenience of understanding, firstly, the main components involved in the present invention are numbered and described, as follows:

[0043] [Description of the main component symbols of the present invention]

[0044]

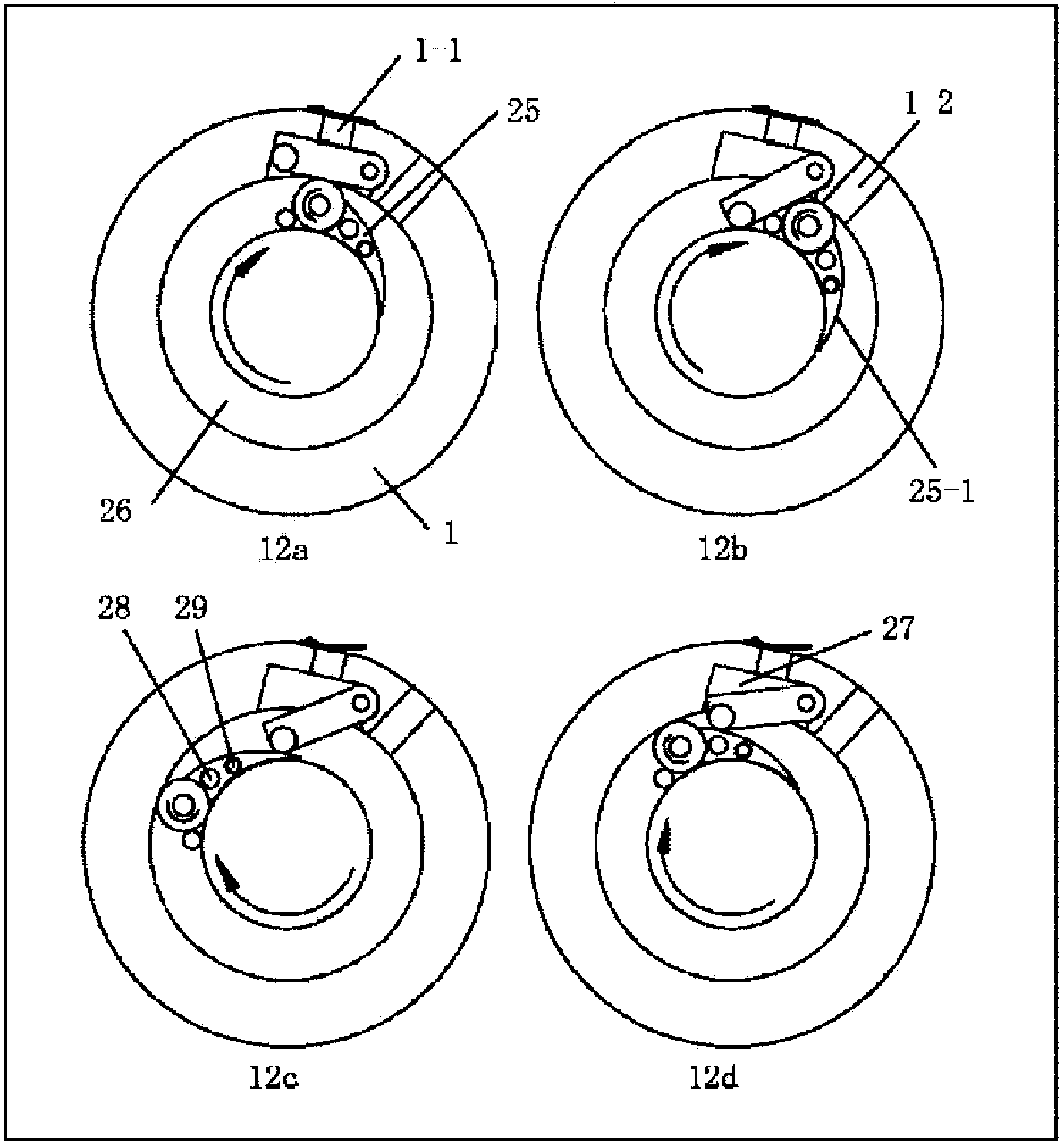

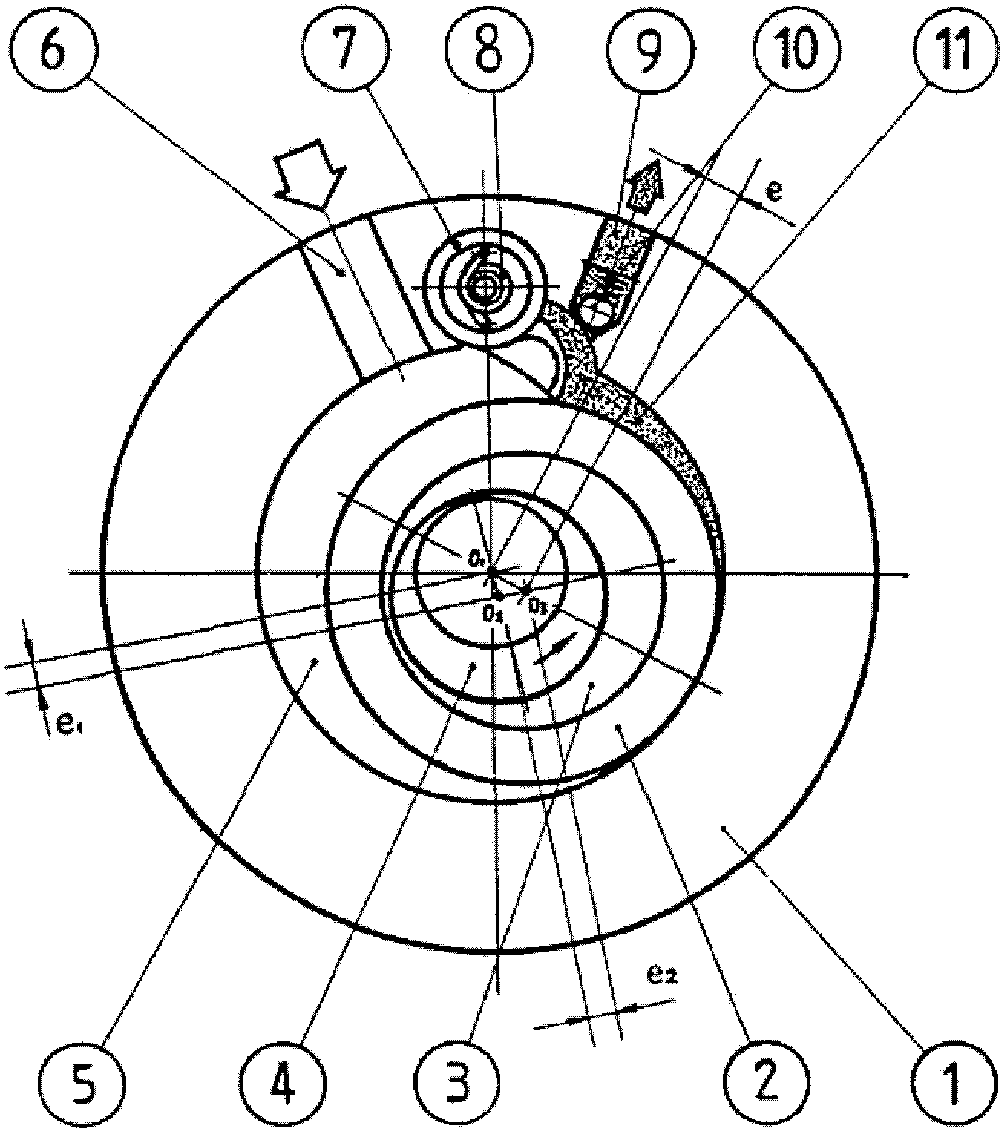

[0045] The invention provides a rotating device and a rotary compressor and a fluid motor using the same. In this rotating device, a rolling bearing is used between the eccentric shaft and the rolling piston wheel, and the reliable seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com