A liquid plastic thin-walled sleeve clamp with a return mechanism

A technology of material return mechanism and plastic thin-wall, which is applied in the field of mechanical processing, can solve the problems of limited expansion range of thin-wall sleeves that cannot meet the accuracy requirements of workpiece positioning holes, complicated clamping process, fast clamping speed, etc., and achieves easy disassembly, Fast clamping speed and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

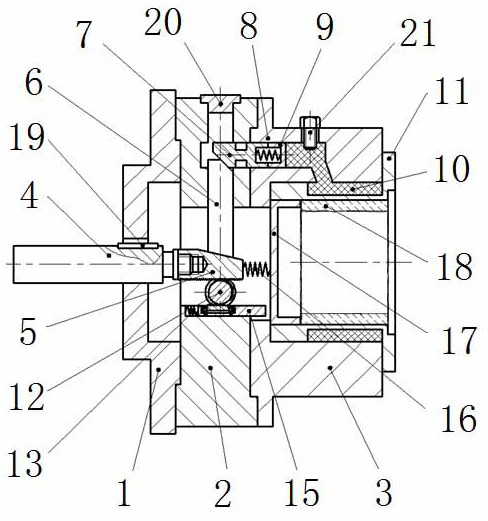

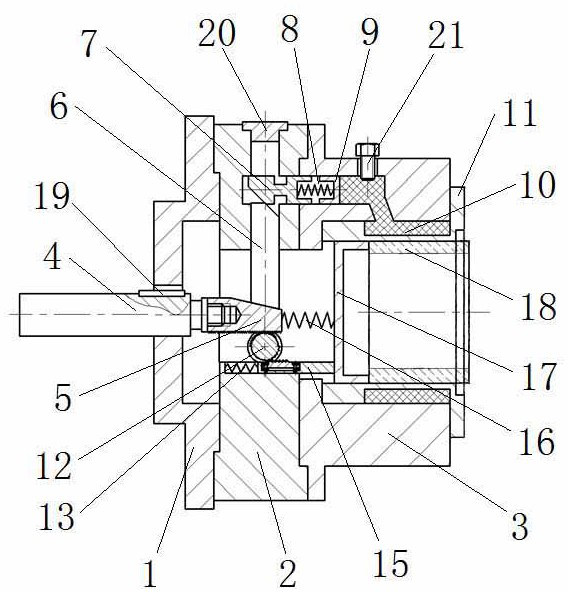

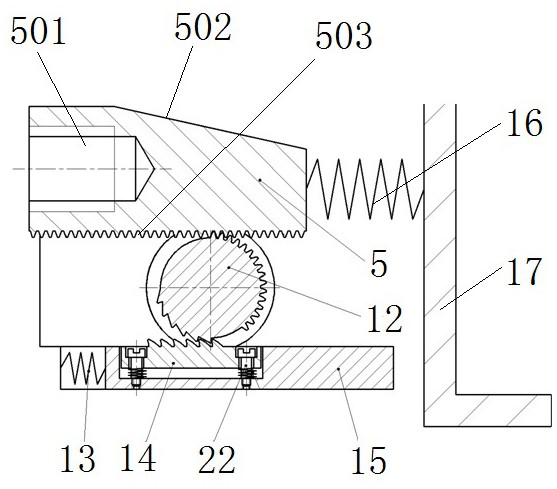

[0028] Such as Figure 1-6 As shown, a liquid plastic thin-walled sleeve fixture with a material ejection mechanism according to the present invention includes a fixing device and a pushing mechanism connected in the fixing device, a linkage clamping mechanism and a linkage ejection mechanism, and the fixing device consists of The fixed guide frame 2 is composed of the transition plate 1 and the clamp body 3 fixedly connected by bolts; the pushing mechanism is composed of a pull rod 4 connected to an inclined block 5, the inclined block 5 is located inside the fixed guide frame 2, the front end of the pull rod 4 is connected with the inclined block 5, and the middle part Connected through the transition plate 1, the upper end of the inclined block 5 is slidingly connected with the linkage clamping mechanism, and the lower end is rollingly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com