Method for machining hot-mounted dam roller

A processing method and hot-loading technology, which are applied in the processing field of hot-loading dam rolls, can solve the problems of long product process, product quality defects, long process flow, etc. The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

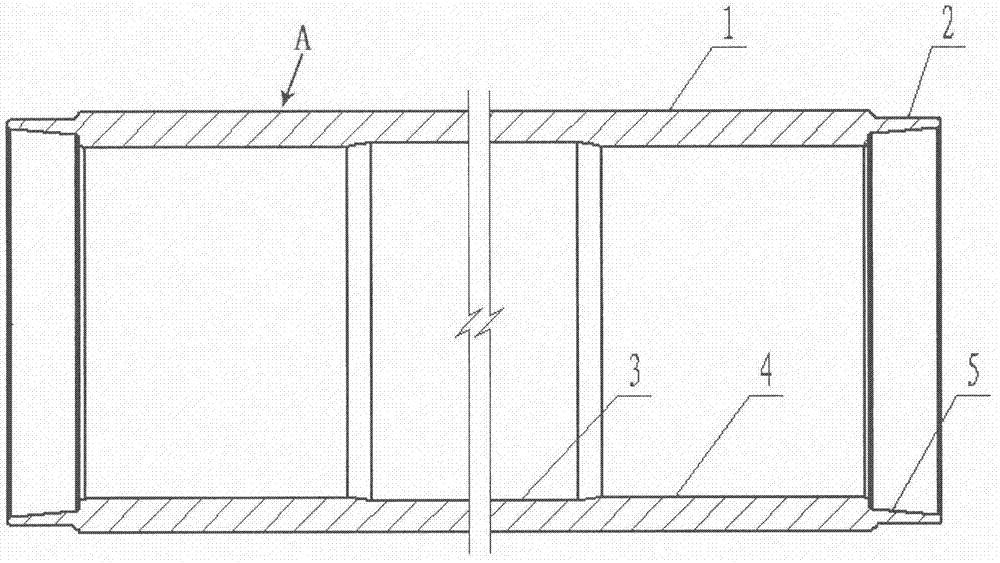

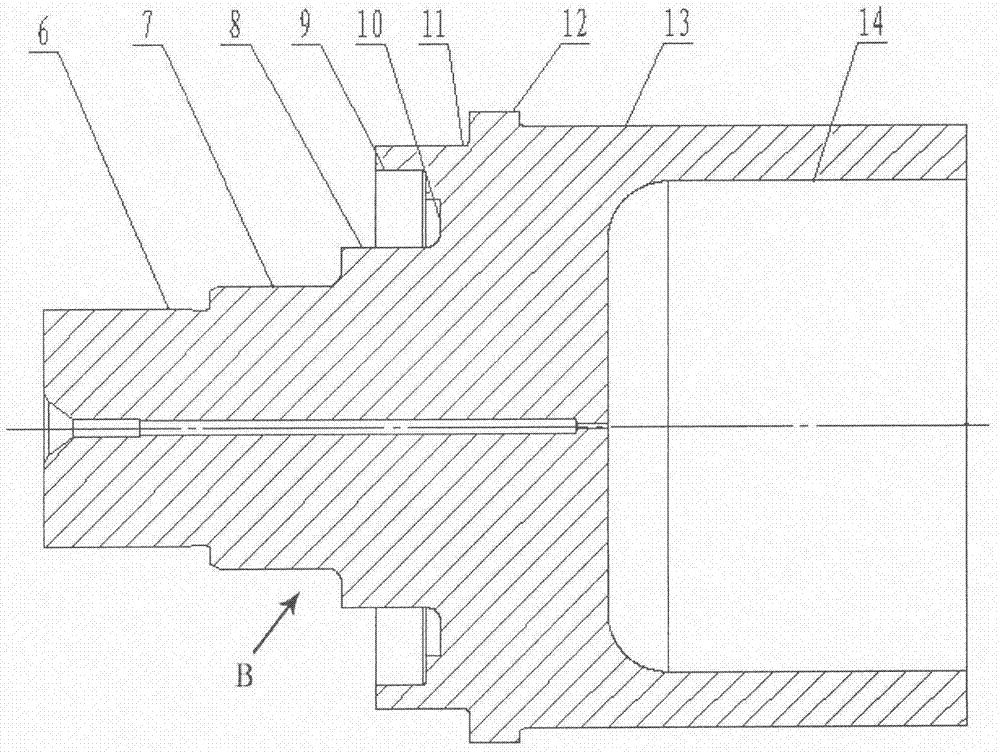

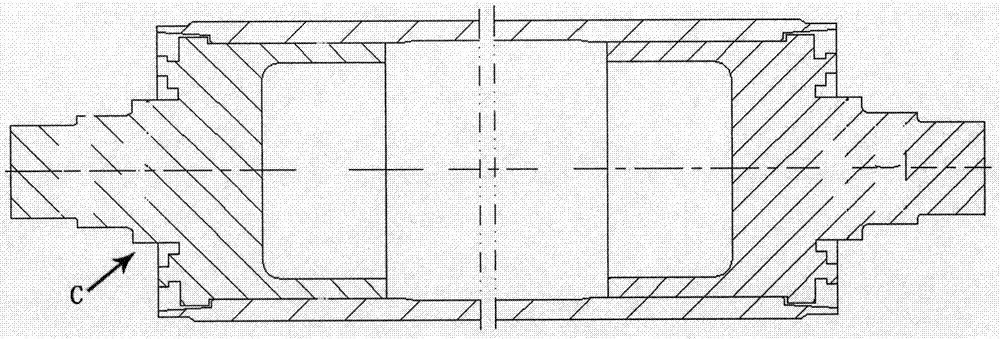

[0057] Such as Figure 1 to Figure 3 As shown, the processing method of the heat-loading type dam roller of the present invention includes the processing of the roller A, the processing of the spindle head B and the assembly of the roller and the spindle head, as follows:

[0058] Described roller A processing comprises the following steps:

[0059] 1. Forging billet, normalizing treatment:

[0060] Carry out normalizing treatment to the forged roll A, so that the hardness of the roll A is controlled at ≤228HB.

[0061] 2. Rough car:

[0062] Carry out rough turning on the first outer circle 1 of the roller A by using a common lathe, and control the roundness, roughness and margin of the first outer circle 1; the rough turning is to use a common lathe to turn the first outer circle 1 , the margin is 5.5-6.5mm, the roundness of the first outer circle 1 is within 0.2, and the roughness is Ra6.3um. The first inner hole 4 is processed to within φ150, the purpose is to reduce the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com