Welding method for annular header

A welding method and ring header technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems that the welding deformation cannot be effectively controlled, the assembly accuracy cannot meet the requirements, and the stress concentration of the ring header can be solved. , to meet the accuracy requirements and effectively control the welding deformation, reduce the welding workload and reduce the welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

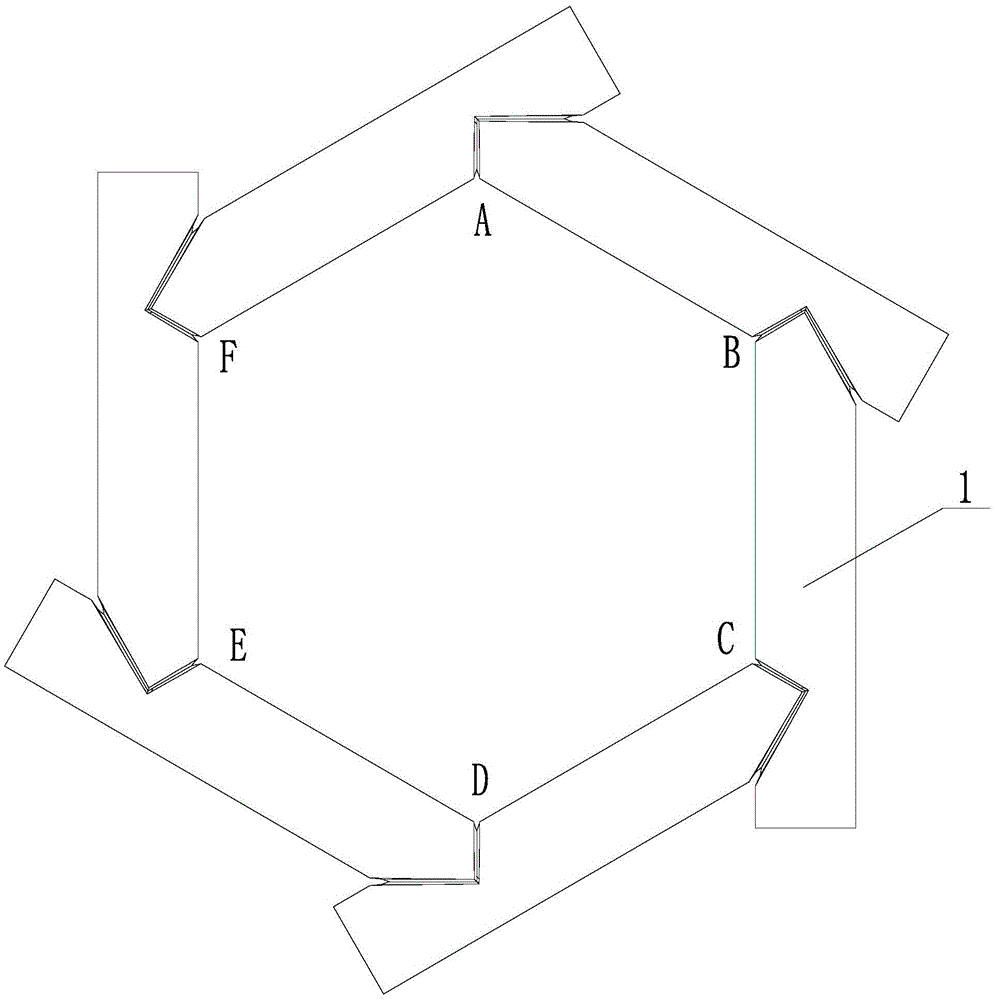

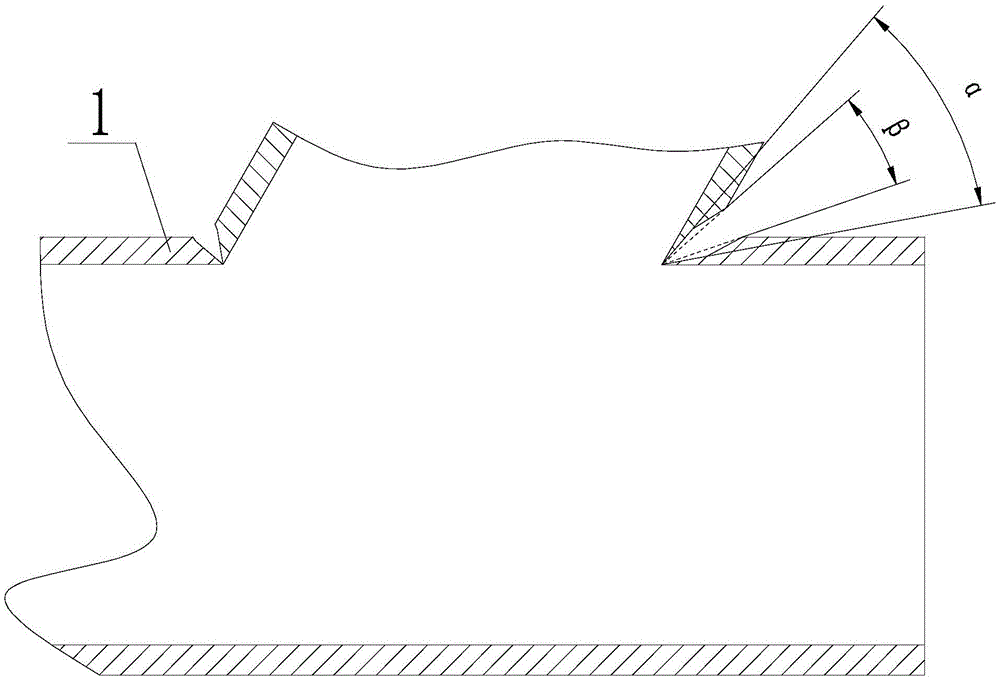

[0019] Such as figure 1 and figure 2 Shown, the welding method of annular header of the present invention,

[0020] Arrange and fix all the mitered pipes first, and then start welding. Welding is divided into three steps:

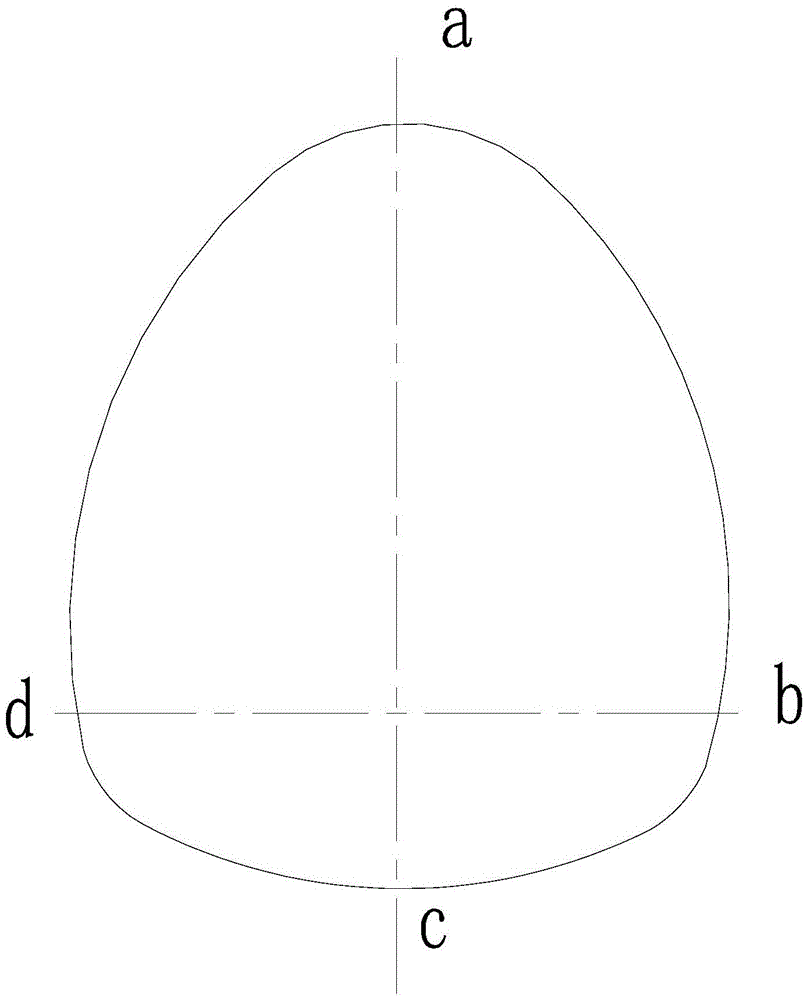

[0021] 1. Positioning welding, positioning welding adopts tungsten inert gas shielded welding, there are two arc-shaped welding areas connected at the butt joint of adjacent mitered pipes, and the arc lengths of the two arc-shaped welding areas are different, and the relatively long arc-shaped welding area It is the first arc-shaped welding area, and the relatively short arc-shaped welding area is the second arc-shaped welding area. The first arc-shaped welding area and the second arc-shaped welding area are connected to form a complete welding area. The welding area contains 4 Welding points—a, b, c, d, the four points...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com