nb based on layer-by-layer stacking 3 Al superconducting precursor wire preparation method

A precursor and wire technology, which is applied in the field of preparation of multi-core Nb3Al superconducting precursor wires, can solve the problems of uneven deformation, difficult adjustment, and low tube filling rate, and achieve uniform tightness and convenient displacement and deformation. , avoid the effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

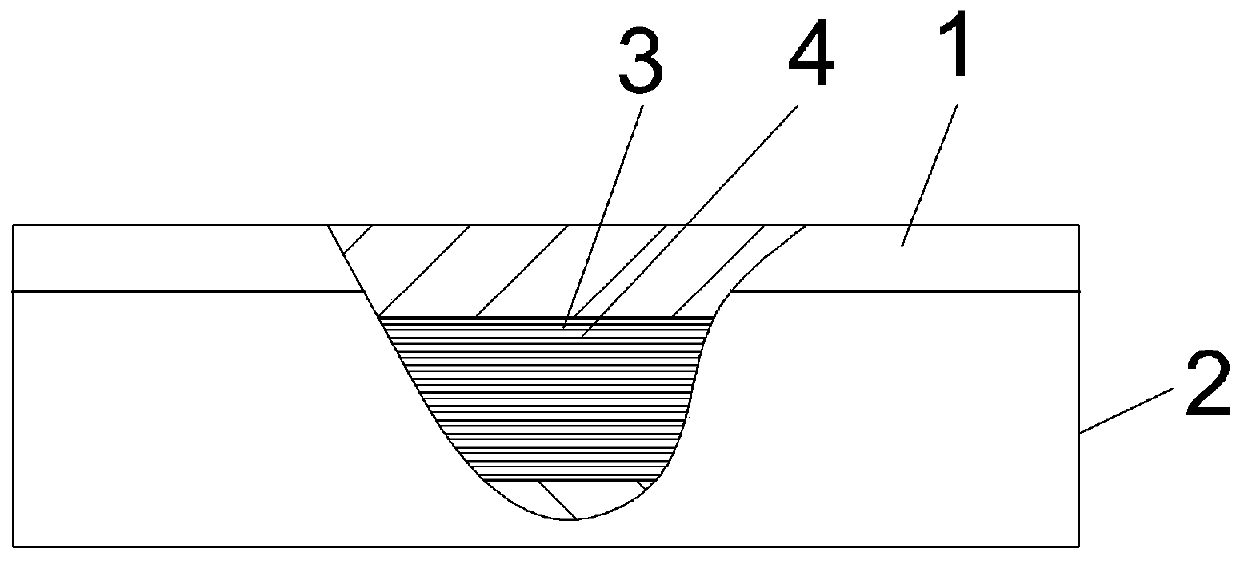

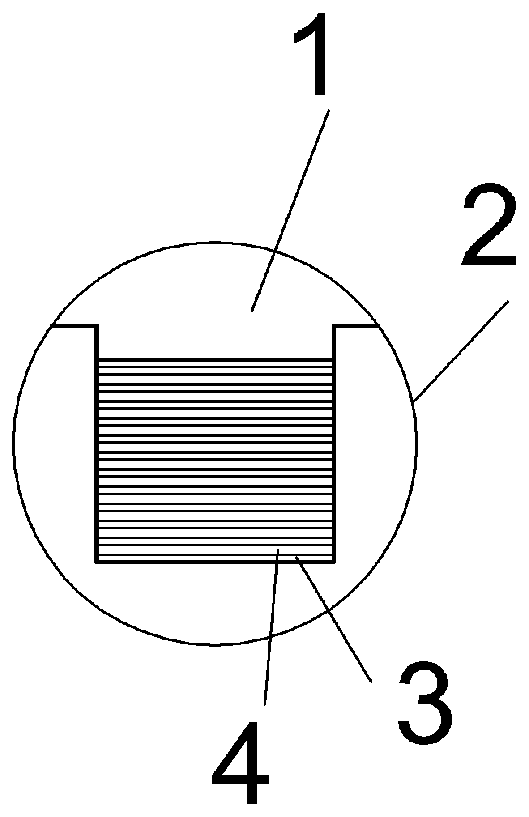

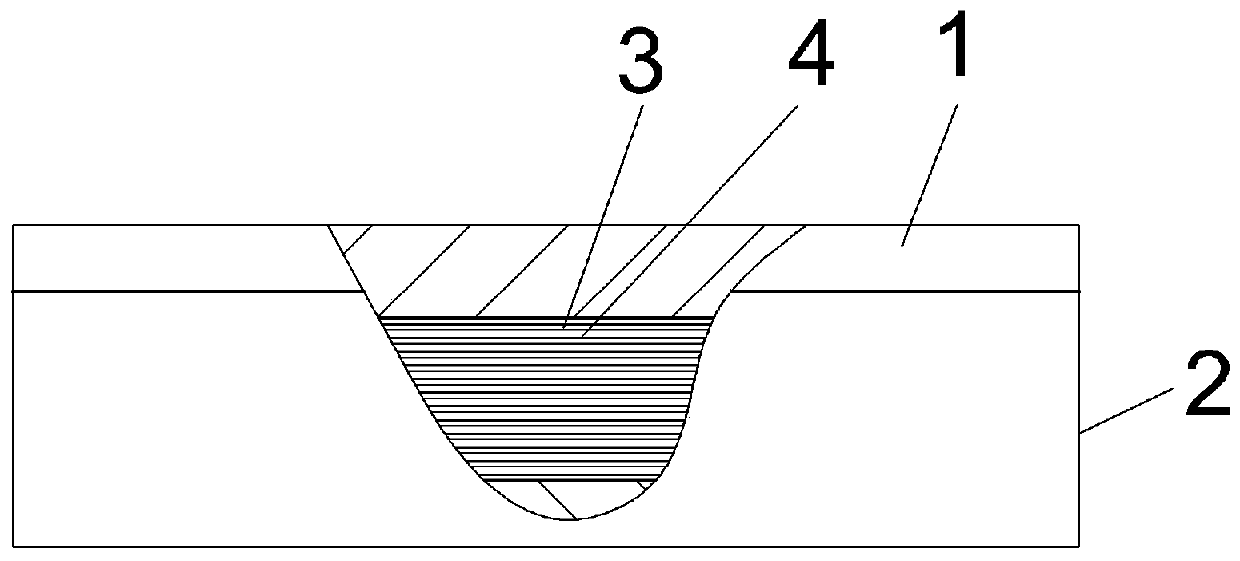

[0030] figure 1 , figure 2 It shows that a specific embodiment of the present invention is a layer-by-layer stacked Nb 3 A method for preparing an Al superconducting precursor wire, the steps of which are:

[0031] A. Preparation of Nb-Al composite sheath

[0032] Remove the upper cover 1 of the tubular Nb box 2, stack Nb foils 3 and Al foils 4 alternately in the rectangular groove of the tubular Nb box 2 from bottom to top, then cover the upper cover 1 of the tubular Nb box 2; finally put the tubular The Nb box 2 is set in the Cu tube, and the two ends of the Cu tube are welded and sealed by vacuum electron beams to obtain the Nb-Al composite sheath;

[0033] The thickness of the Nb foil 3 is 0.03mm, the thickness of the Al foil 4 is 0.01mm, and the purity of the Nb foil 3 and the Al foil 4 are both better than 99.9%.

[0034] The number of layers of the Nb foil 3 or Al foil 4 is 100, and the wall thickness of the Nb box 2 is 1mm.

[0035] The ratio of the volume of the...

Embodiment 2

[0042] A layer-by-layer stacking of Nb 3 The preparation method of Al superconducting precursor wire rod, its steps are:

[0043] A. Preparation of Nb-Al composite sheath

[0044] Remove the upper cover 1 of the tubular Nb box 2, stack Nb foils 3 and Al foils 4 alternately in the rectangular groove of the tubular Nb box 2 from bottom to top, then cover the upper cover 1 of the tubular Nb box 2; finally put the tubular The Nb box 2 is set in the Cu tube, and the two ends of the Cu tube are welded and sealed by vacuum electron beams to obtain the Nb-Al composite sheath;

[0045] The thickness of the Nb foil 3 is 0.13mm, the thickness of the Al foil 4 is 0.05mm, and the purity of the Nb foil 3 and the Al foil 4 are both better than 99.9%.

[0046] The number of layers of the Nb foil 3 or Al foil 4 is 125, and the wall thickness of the Nb box 2 is 5 mm.

[0047] The ratio of the volume of the rectangular slot of the Nb box 2 to the volume of the whole Nb box 2 is 2.5:4.

[004...

Embodiment 3

[0054] A layer-by-layer stacking of Nb 3 The preparation method of Al superconducting precursor wire rod, its steps are:

[0055] A. Preparation of Nb-Al composite sheath

[0056] Remove the upper cover 1 of the tubular Nb box 2, stack Nb foils 3 and Al foils 4 alternately in the rectangular groove of the tubular Nb box 2 from bottom to top, then cover the upper cover 1 of the tubular Nb box 2; finally put the tubular The Nb box 2 is set in the Cu tube, and the two ends of the Cu tube are welded and sealed by vacuum electron beams to obtain the Nb-Al composite sheath;

[0057] The thickness of the Nb foil 3 is 0.3mm, the thickness of the Al foil 4 is 0.1mm, and the purity of the Nb foil 3 and the Al foil 4 are both higher than 99.9%.

[0058] The number of layers of the Nb foil 3 or Al foil 4 is 150, and the wall thickness of the Nb box 2 is 10 mm.

[0059] The ratio of the volume of the rectangular slot of the Nb box 2 to the volume of the whole Nb box 2 is 3:4.

[0060] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com