Patents

Literature

60results about How to "Uniform tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

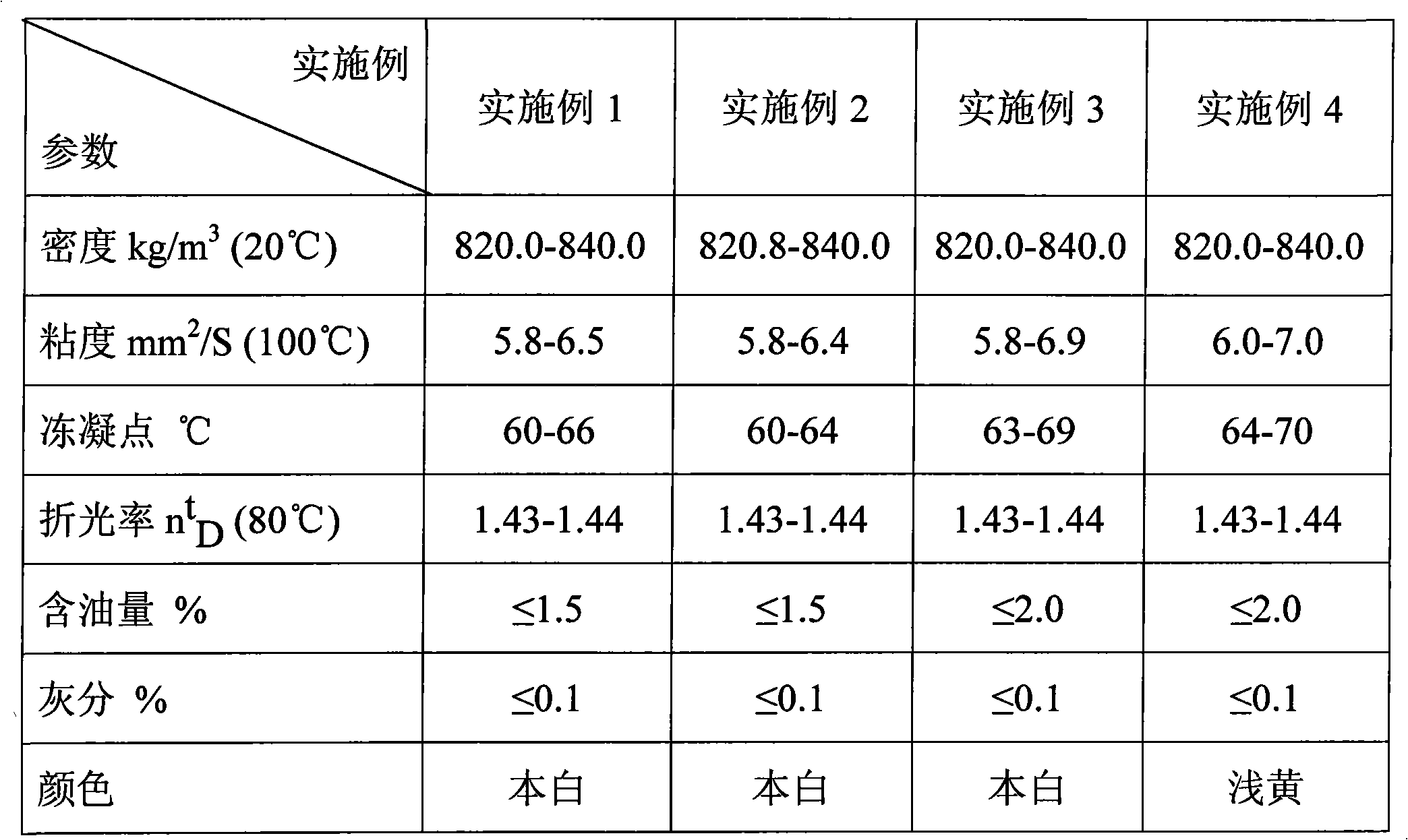

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

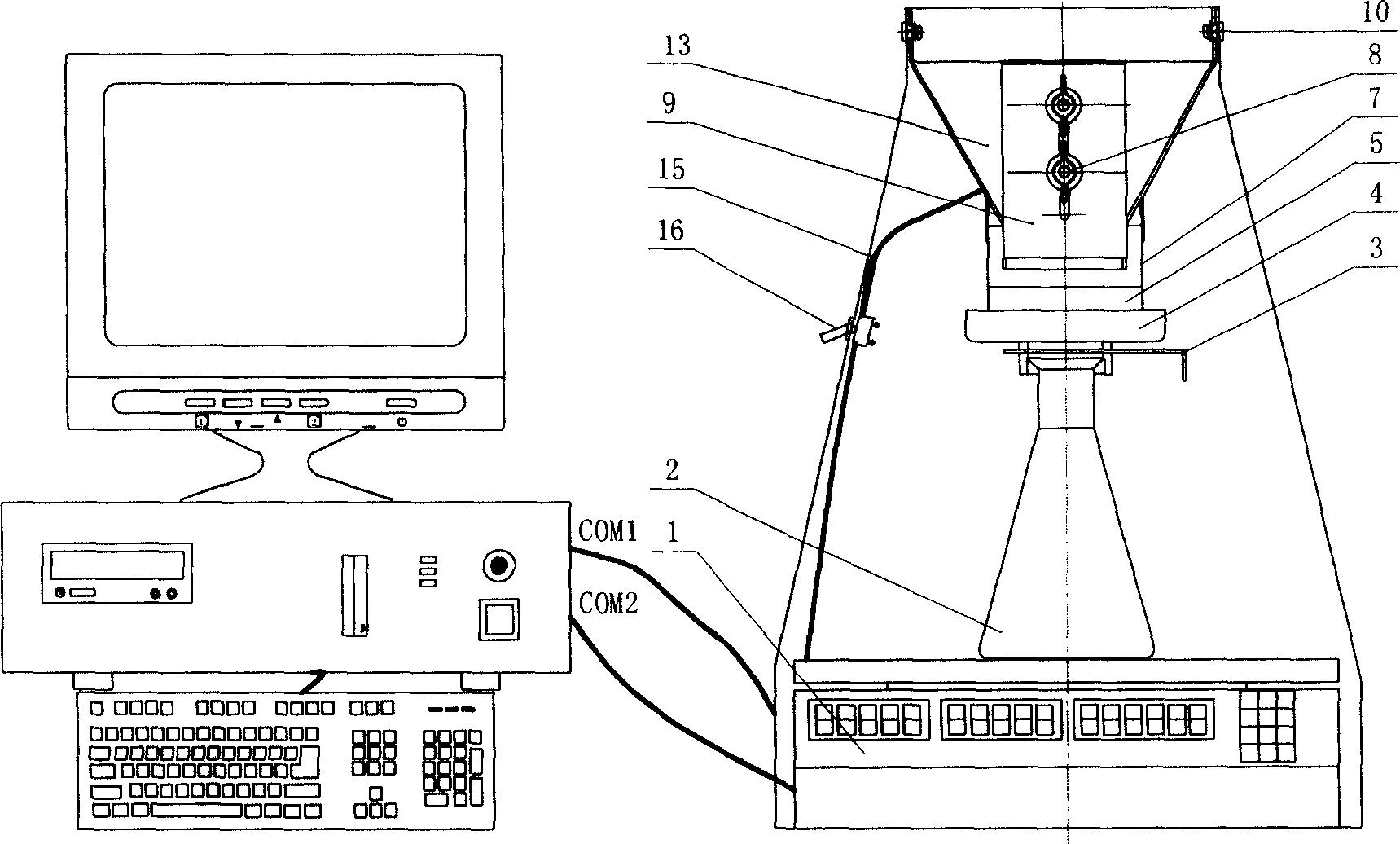

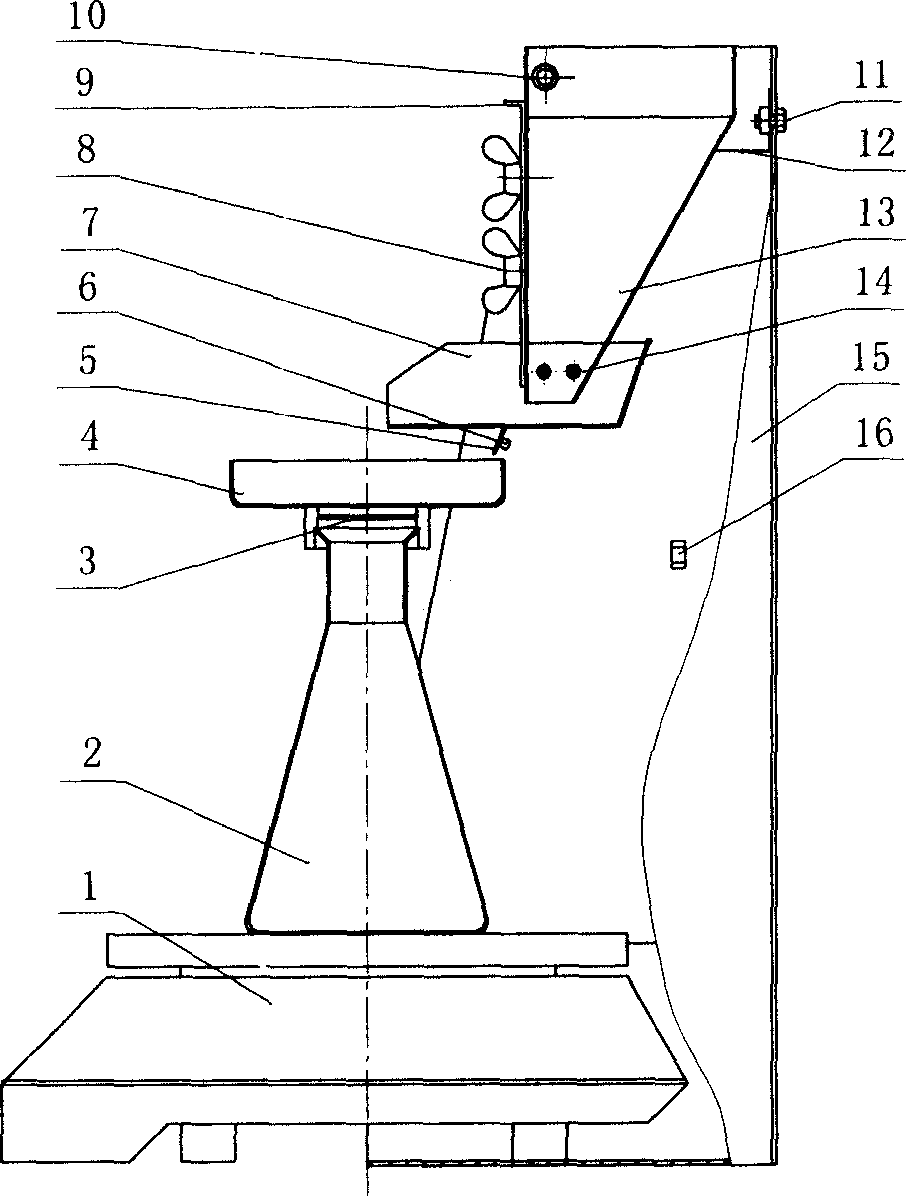

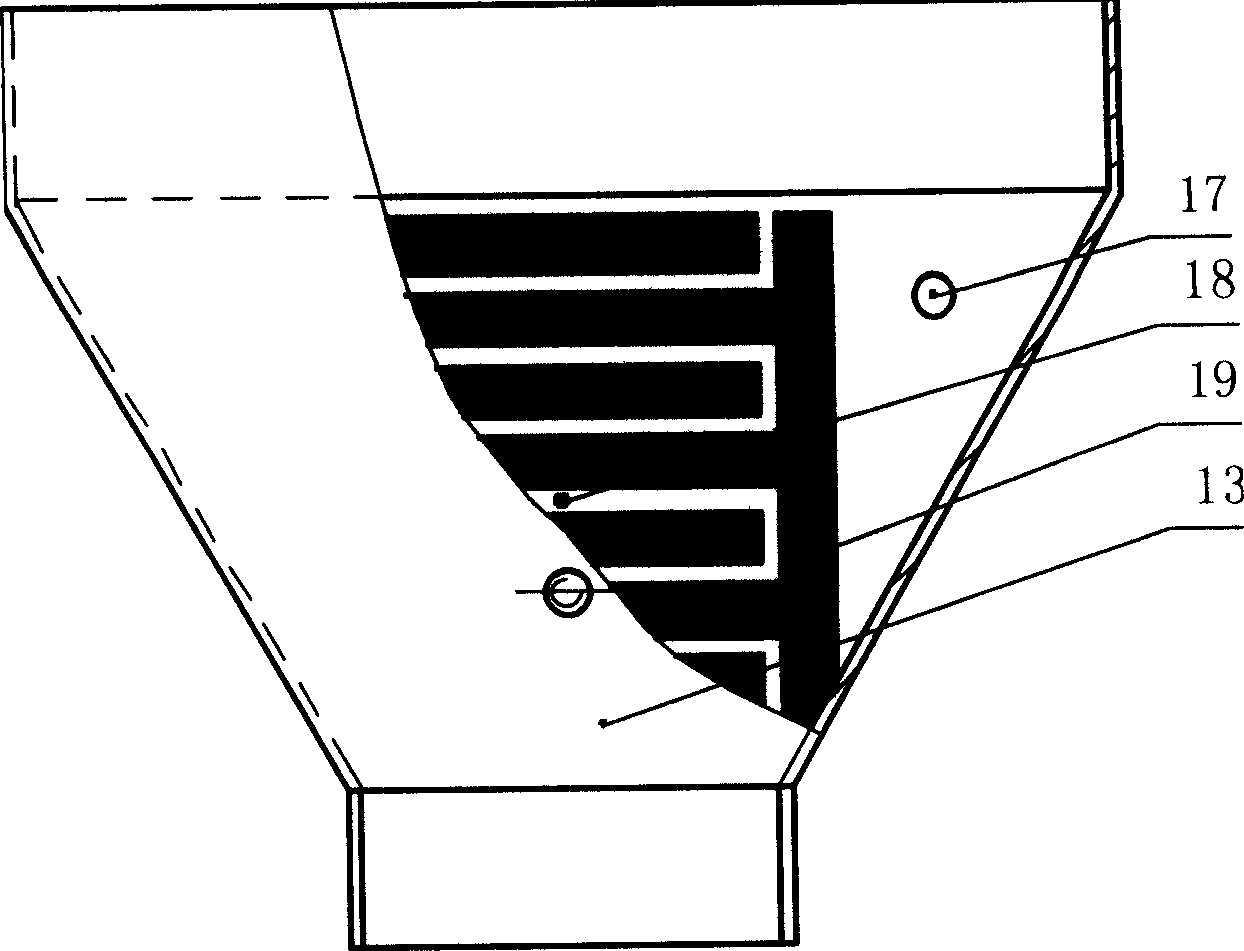

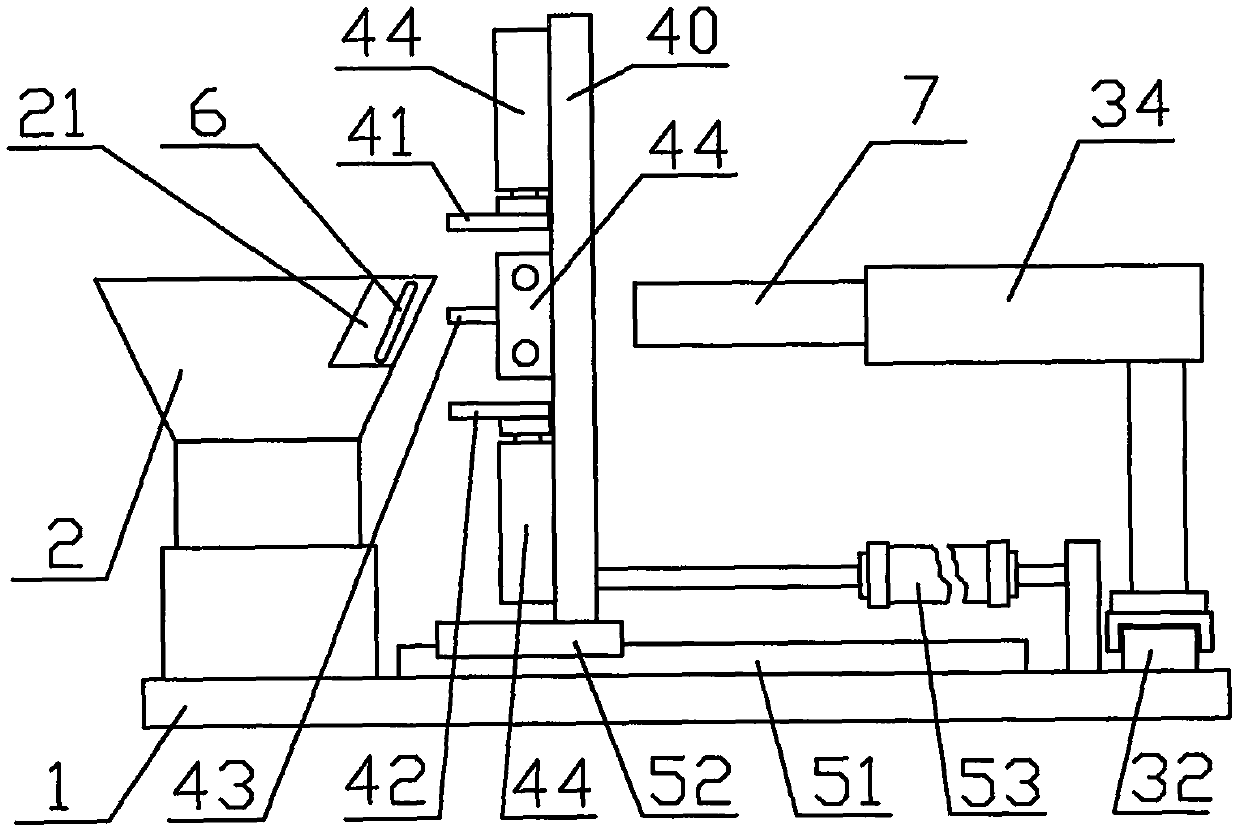

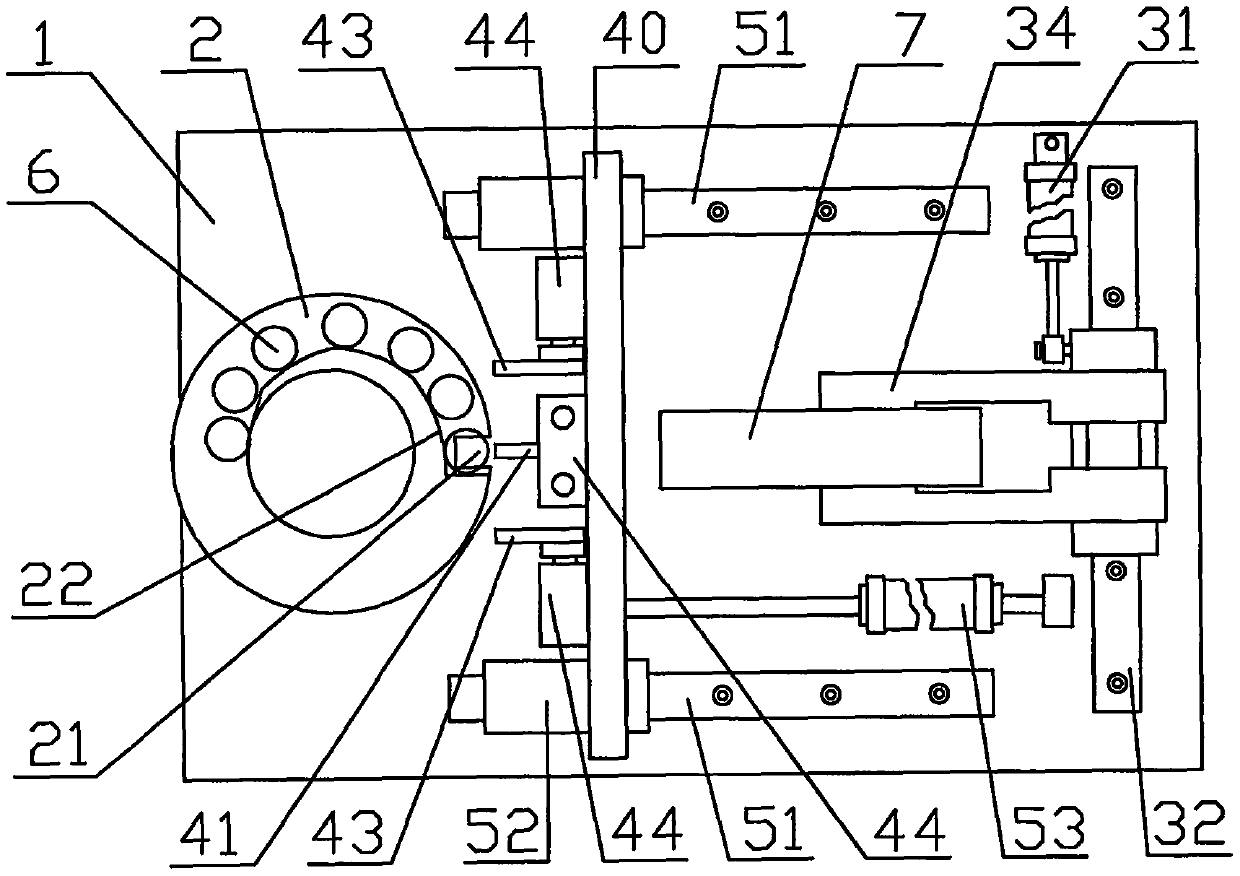

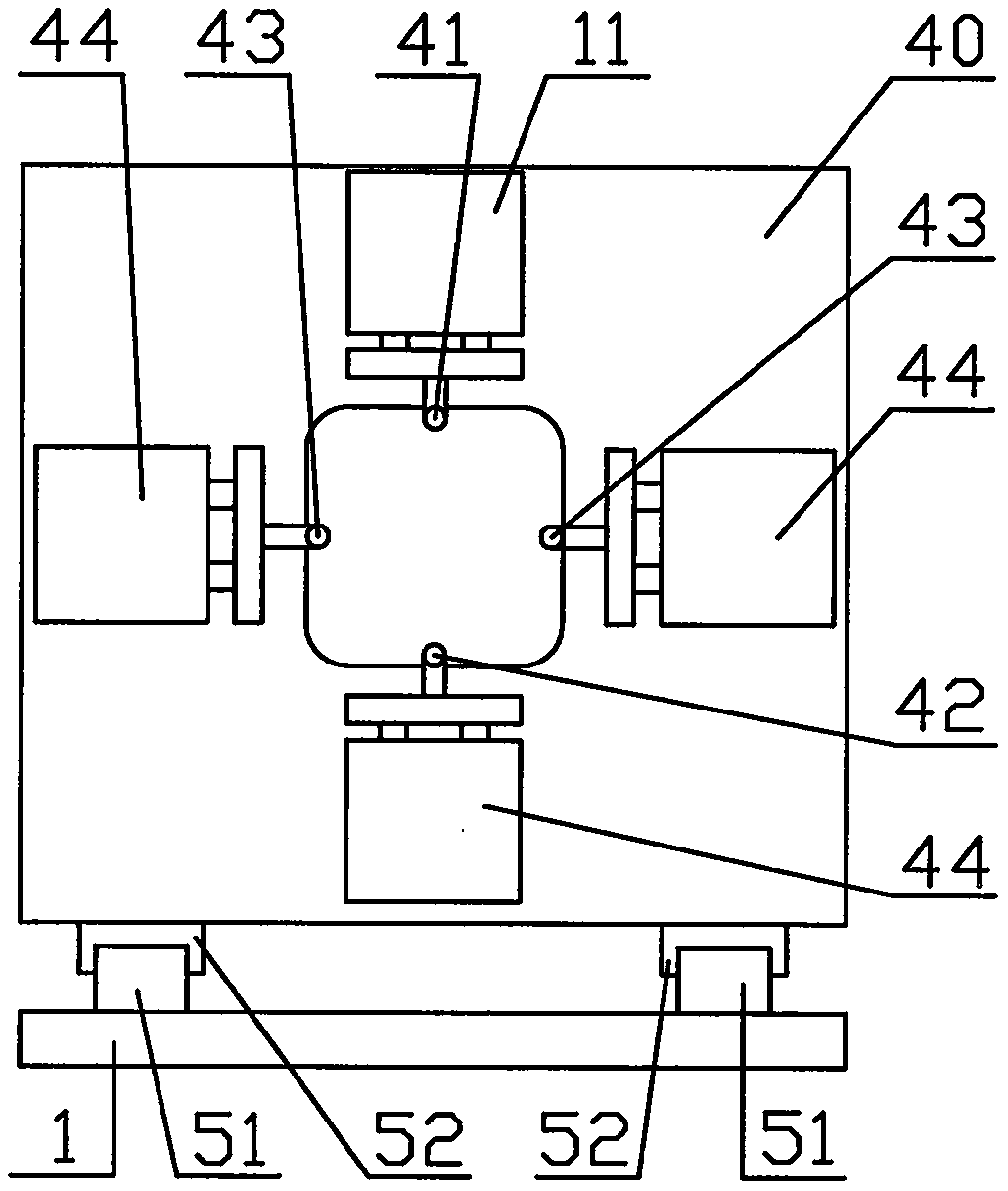

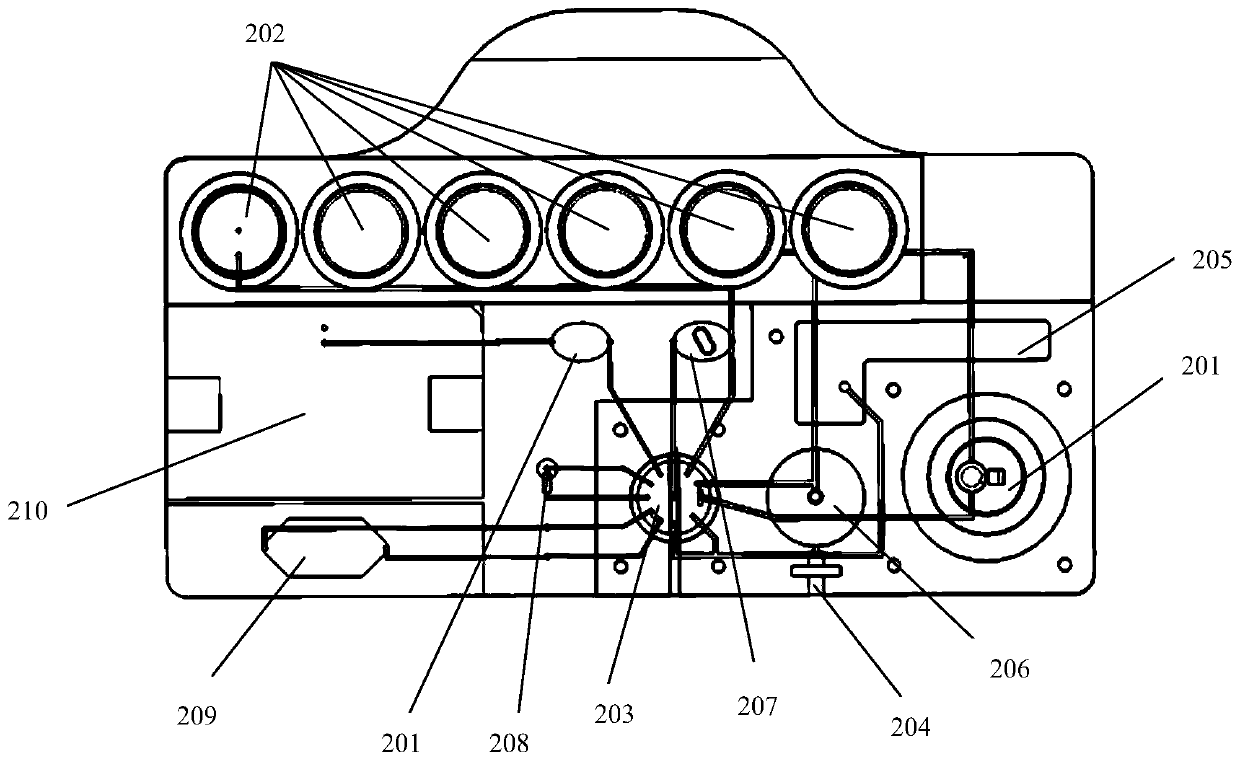

Cereal grade analyzer

InactiveCN1896736AStructure sheetEasy to operateMaterial capacitanceTesting foodCapacitanceDisplay device

A device applied to the corn quality grade detecting, especially applied to imports and exports , the department of store and transportation , purchase, detect and production ,to detect the moisture content etc., bulk density and quality grade of corn such as maize and wheat, including moisture detect element, weighing element, volume measure element , vibration transport element, charging hopper , outer covering , computer data handling element etc. Its characteristic is that transporting the material waiting for detecting to volume measure element by using mini-type vibration transport device equably, ascertain the quality grade of the corn according to the real bulk density and moisture content of the corn entering volume measure element. Putting the material waiting for measuring into a charging hopper first, transducing the moisture content and temperature of the material by interdigited capacitor counter electrode in the inner side of charging hopper's back, the measure result is transmitted to the computer data handle element by the highway; The tiny vibrator works to make the silo resonating under the shaking excitation , the material in charging hopper drop into capacity cups equably from the silo and the take-up pan, close the mains switch after the capacity cups is full of material, inserting the flashboard into the slot under the take-up pan, taking away the unnecessary material lightly from the take-up pan, the slot and the pan; After the electronic scale is stable, reading the quality and the bulk density of the material waiting for measuring from the electron digital display, transmitting the result of the quality and the bulk density to the computer data handling element by the highway at same time; Finally, the computer data handling element decides the grade of the corn according to national standard GB1353 , GB1351, and the information such as moisture content , the temperature , the bulk density.

Owner:CHANGCHUN JIDA SCI INSTR EQUIP

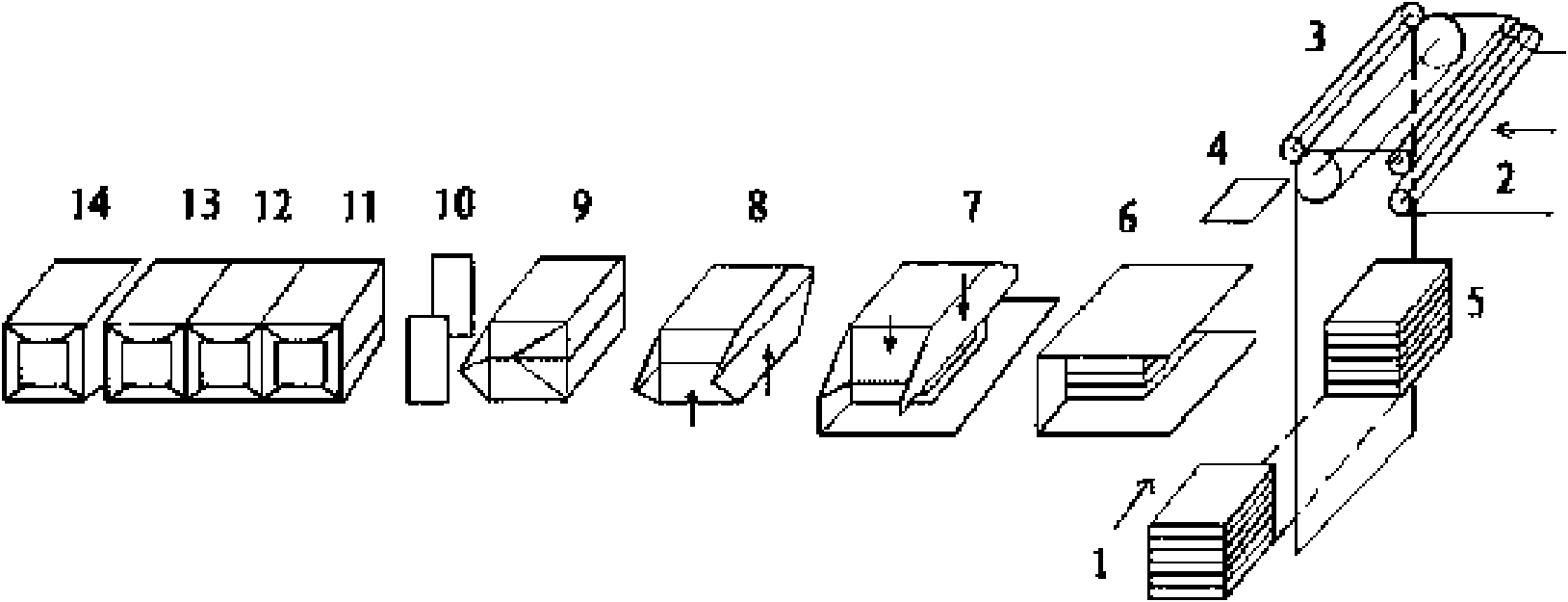

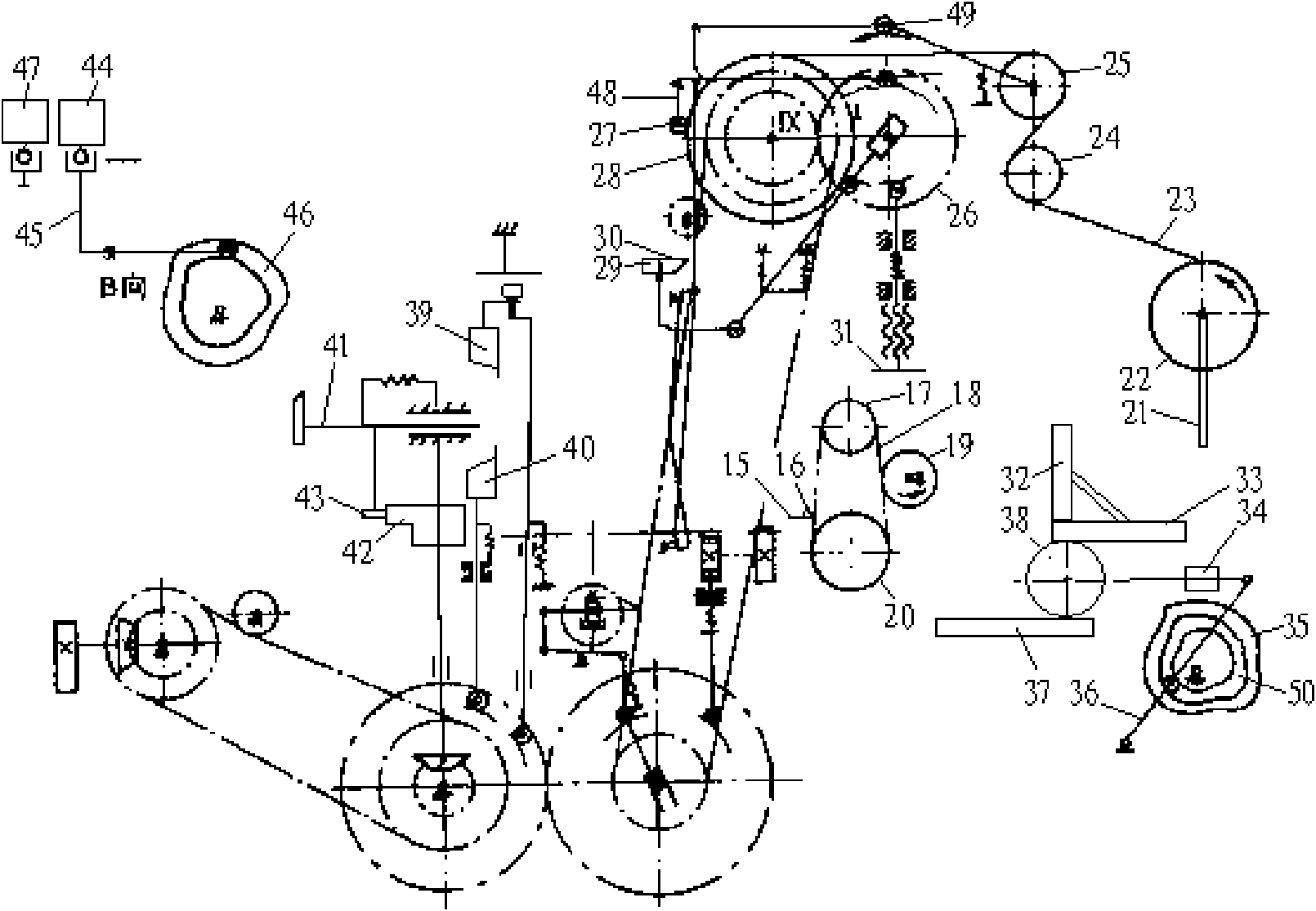

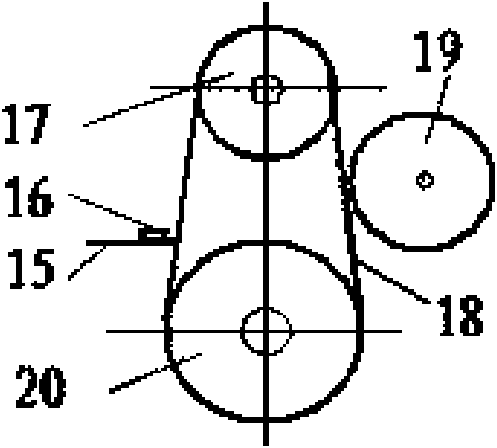

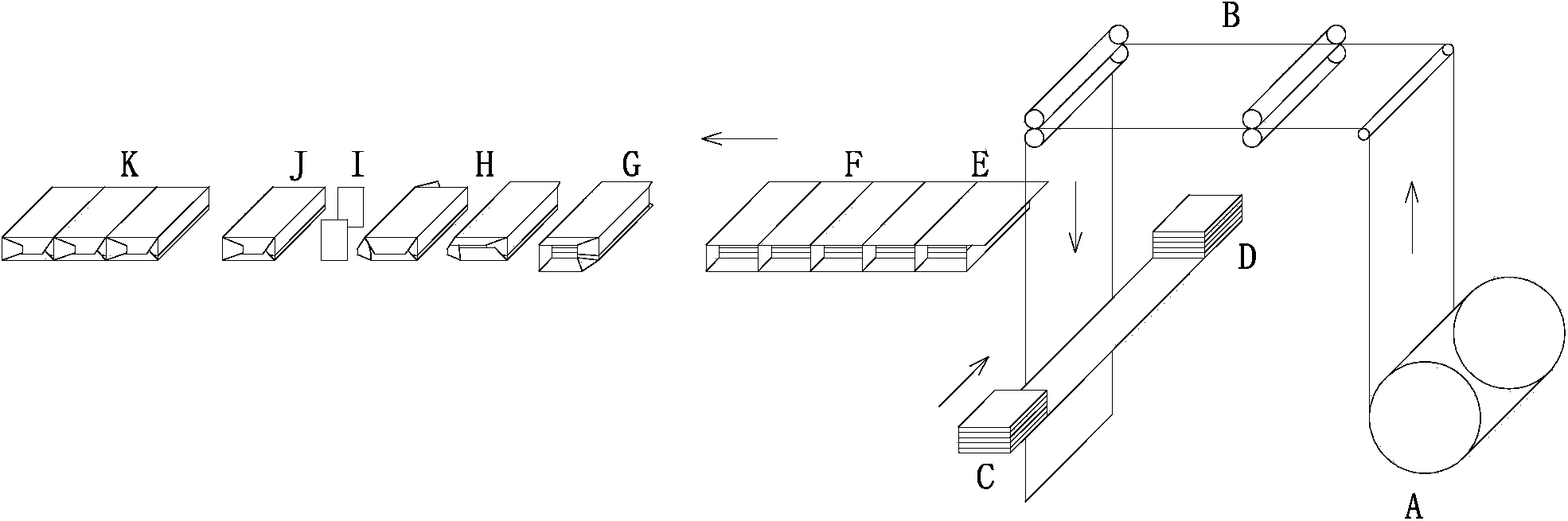

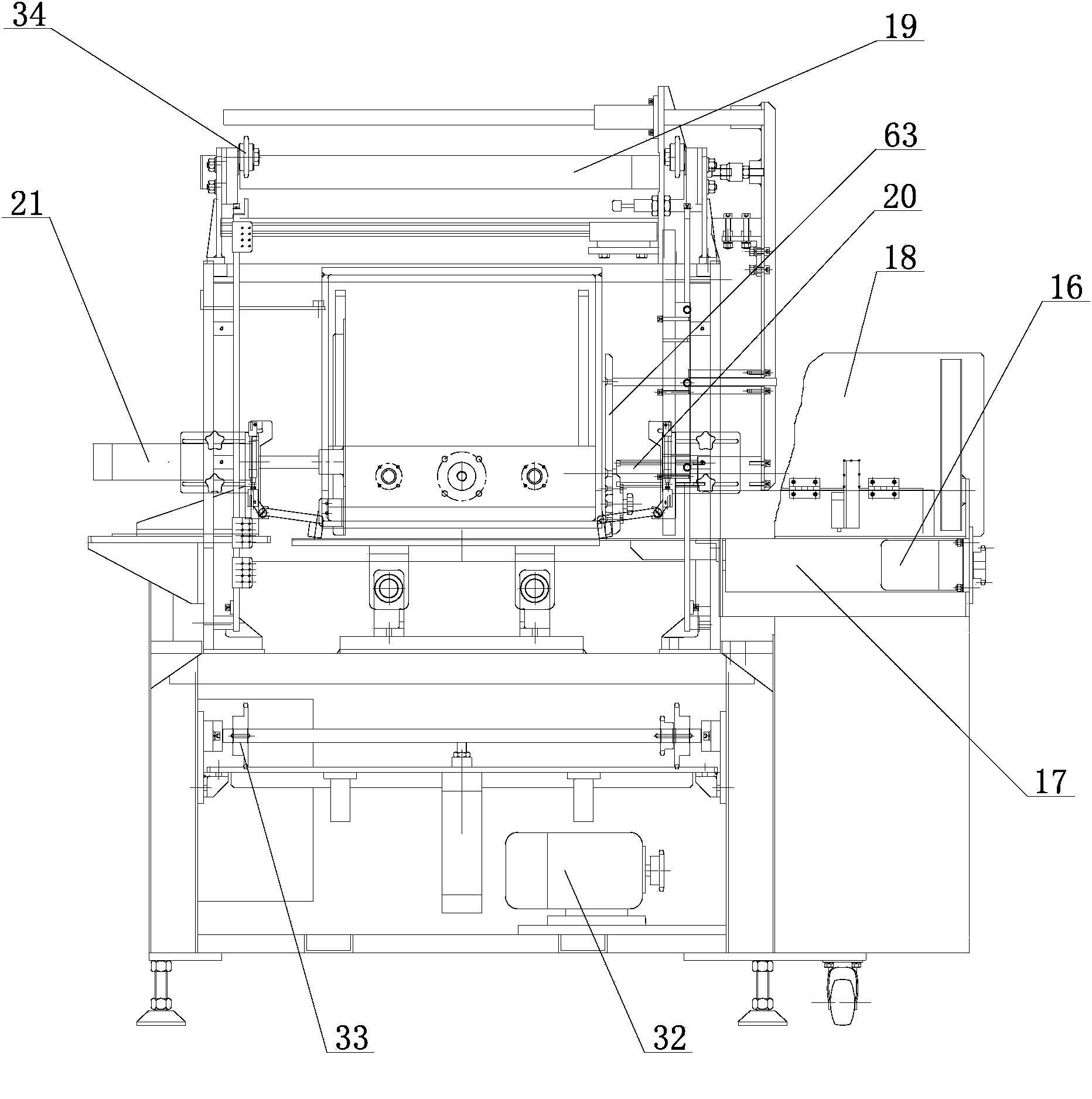

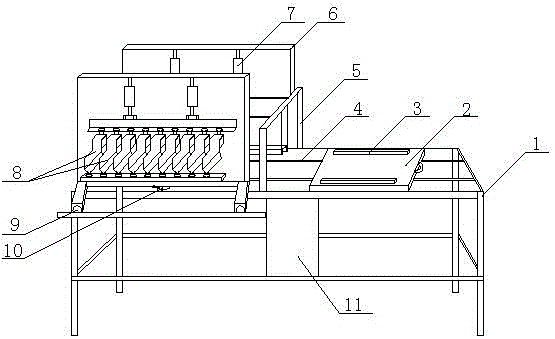

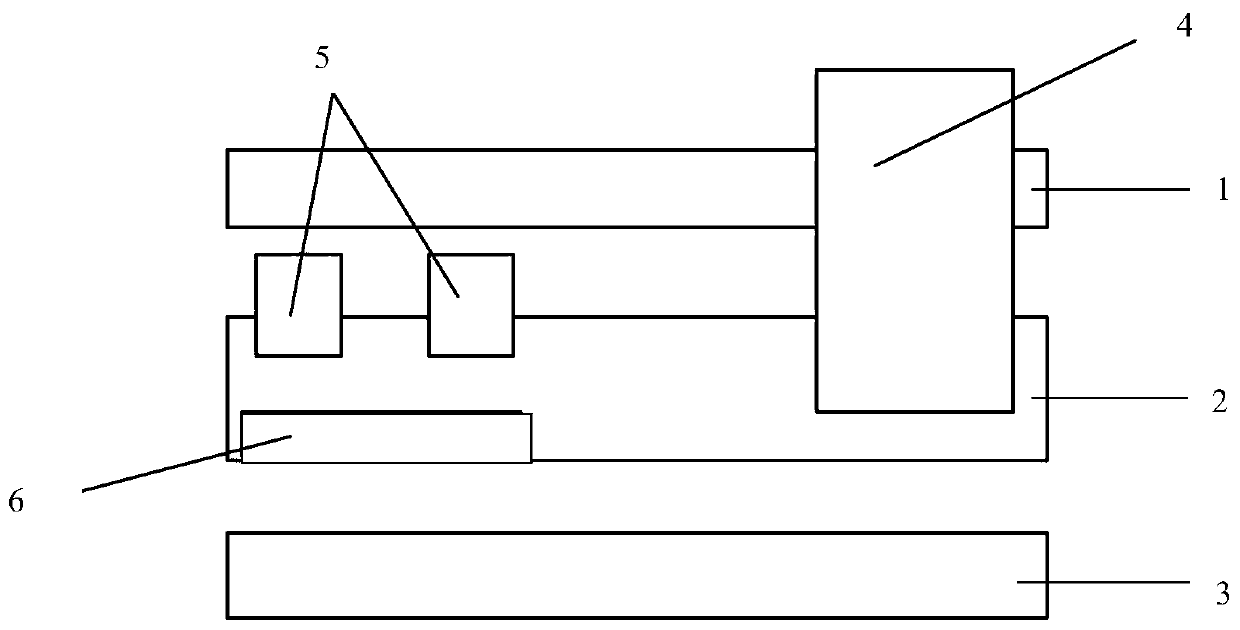

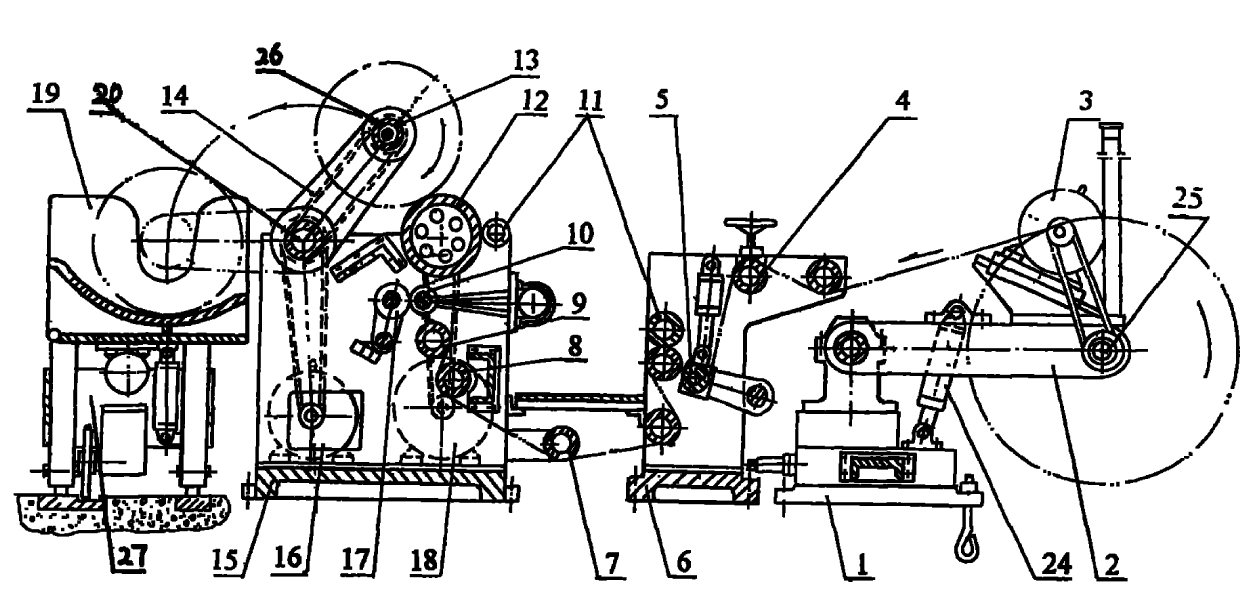

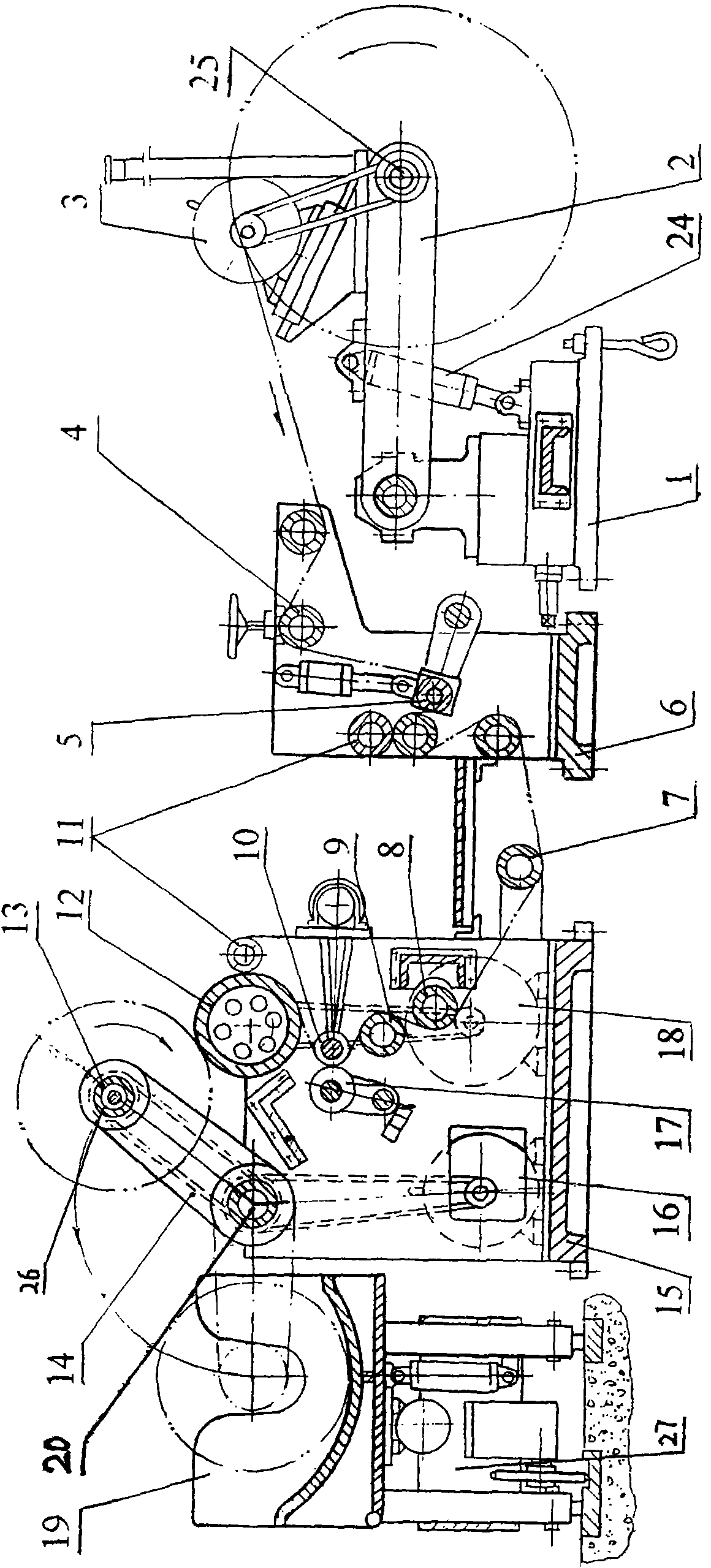

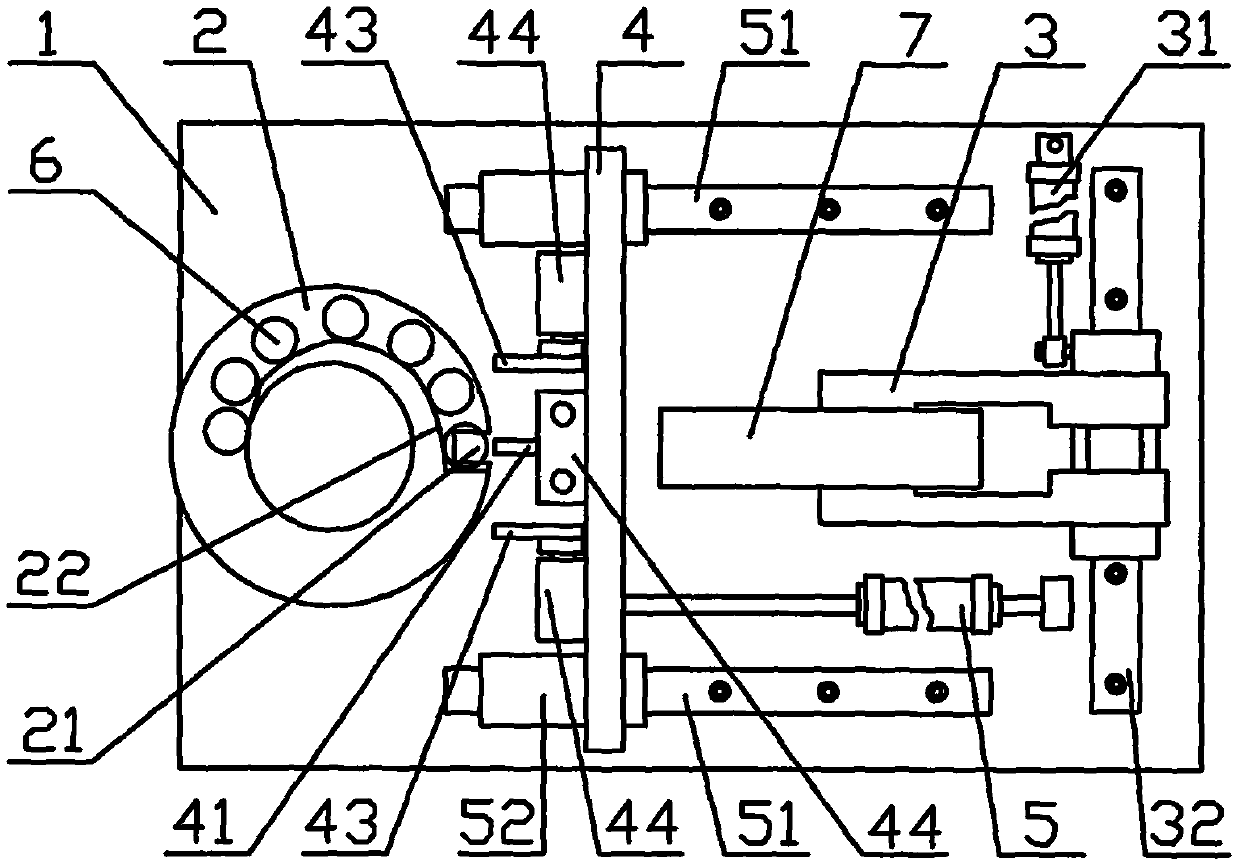

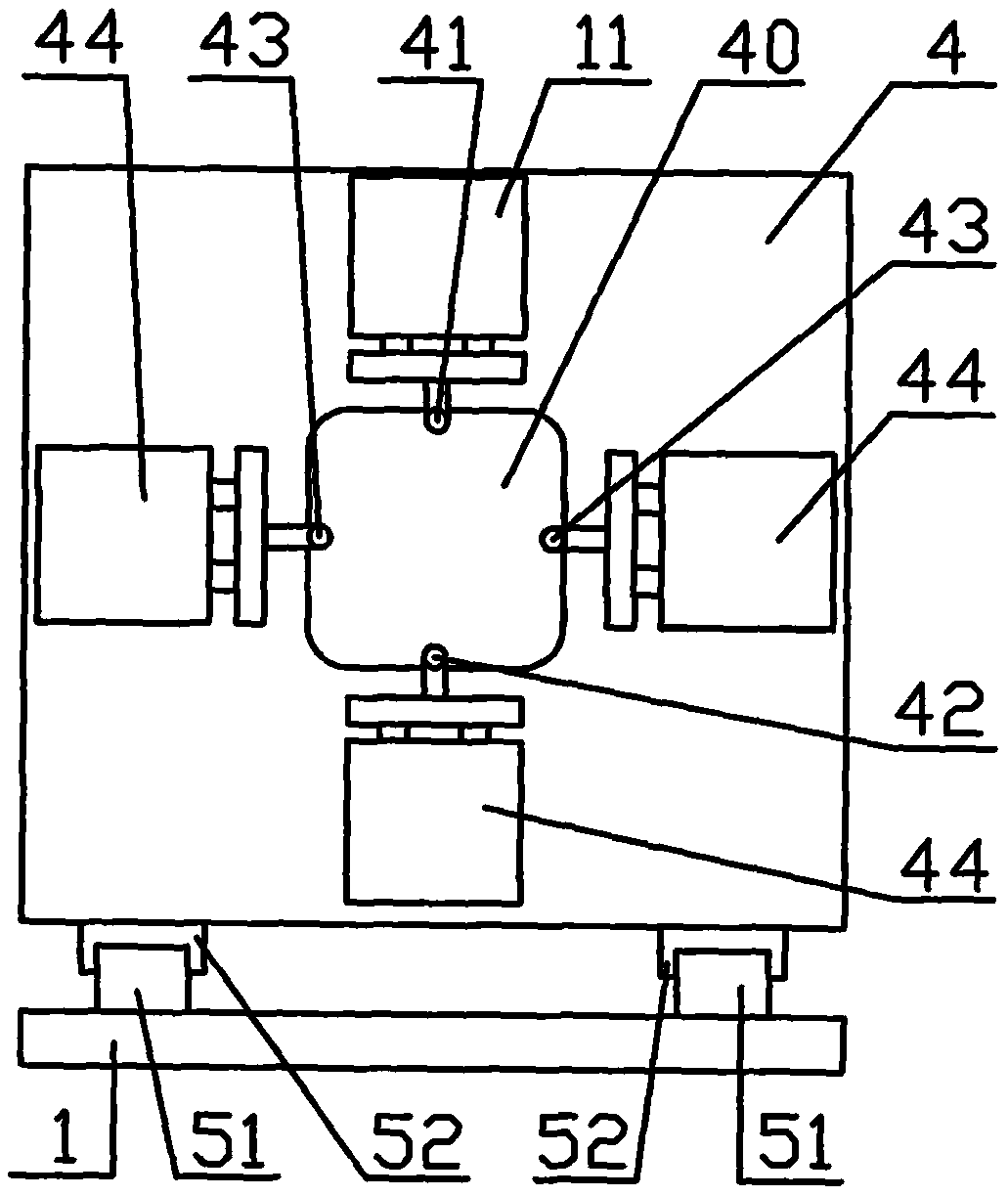

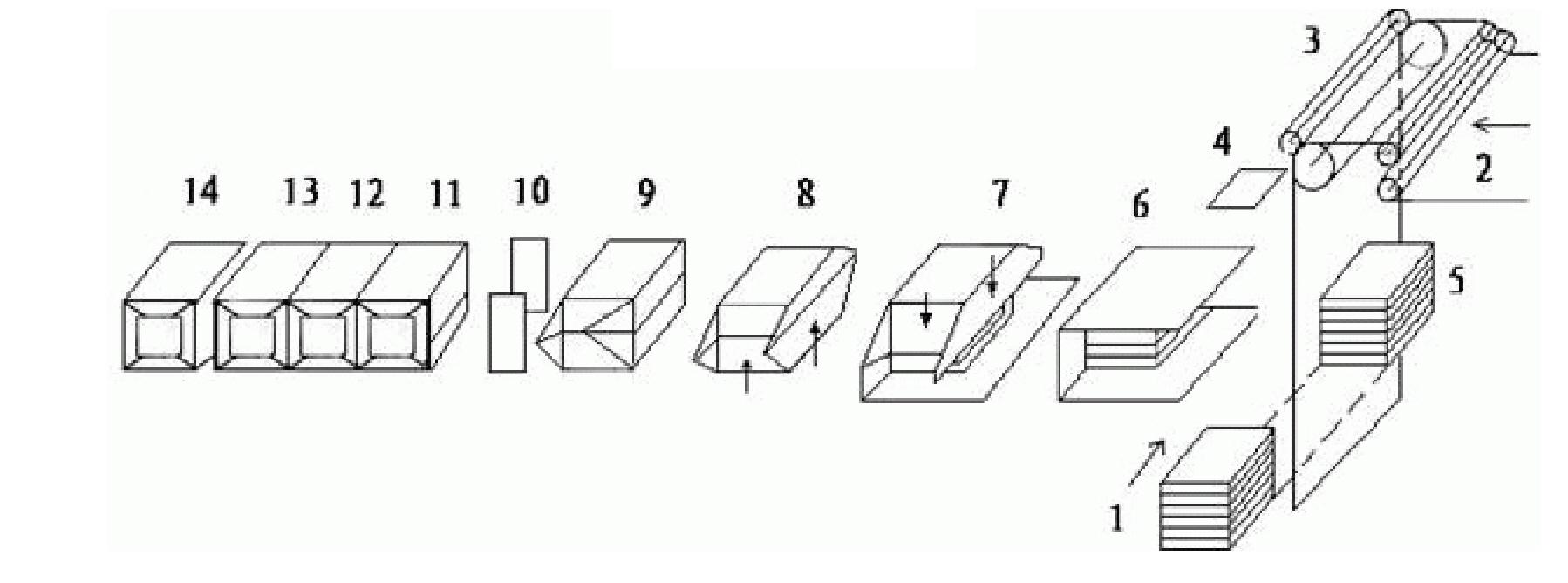

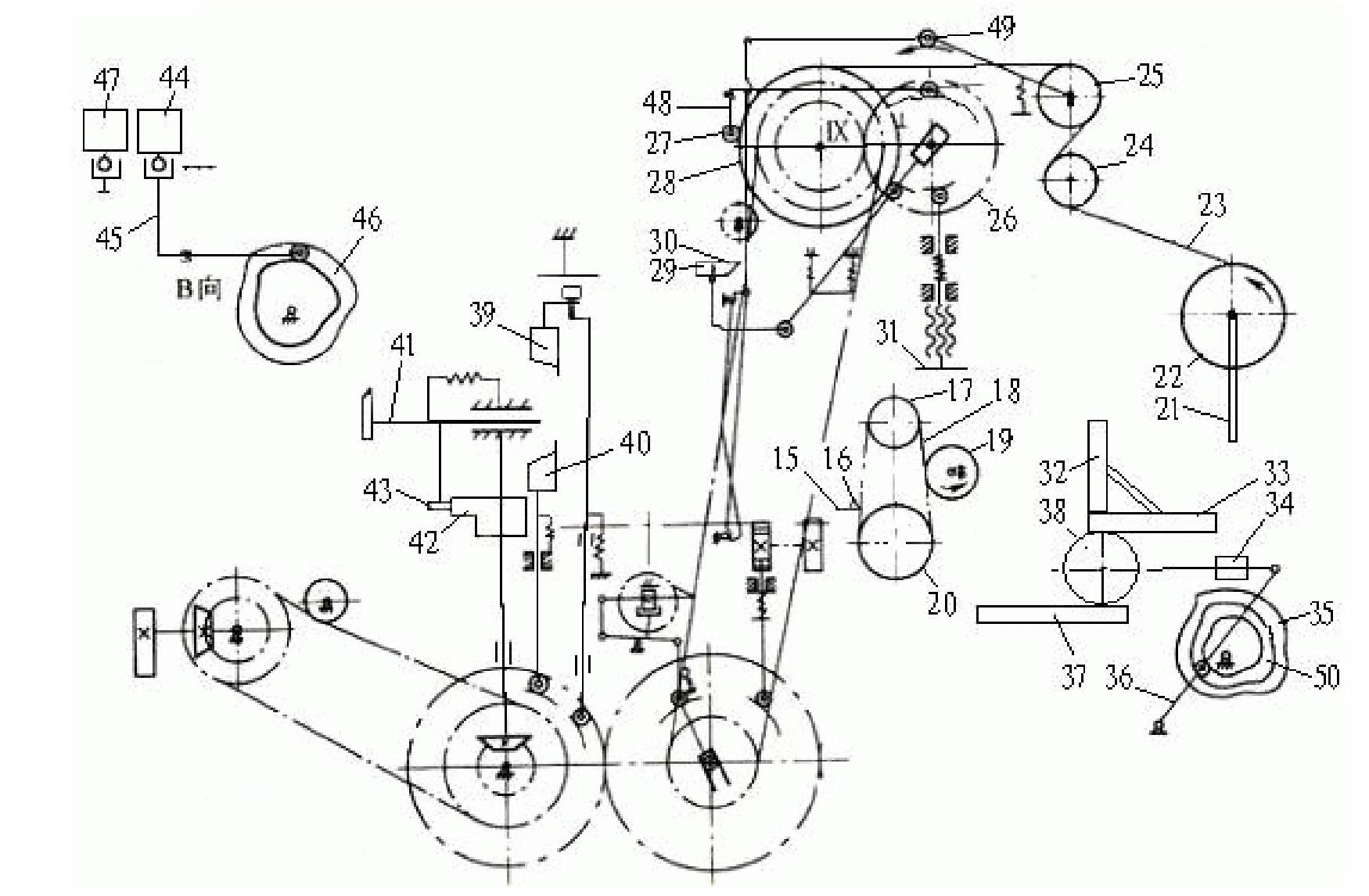

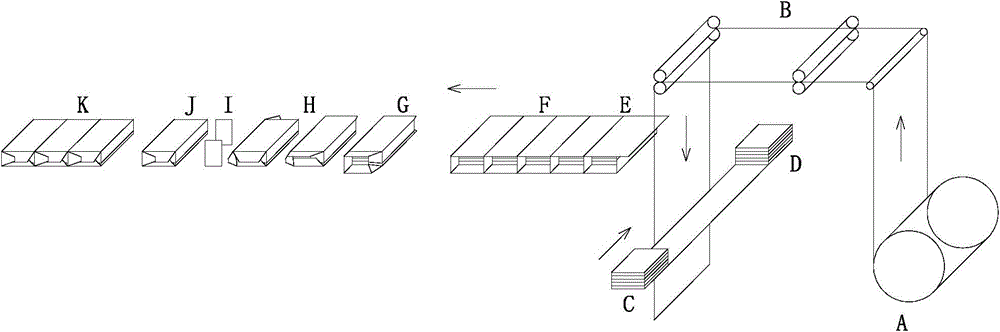

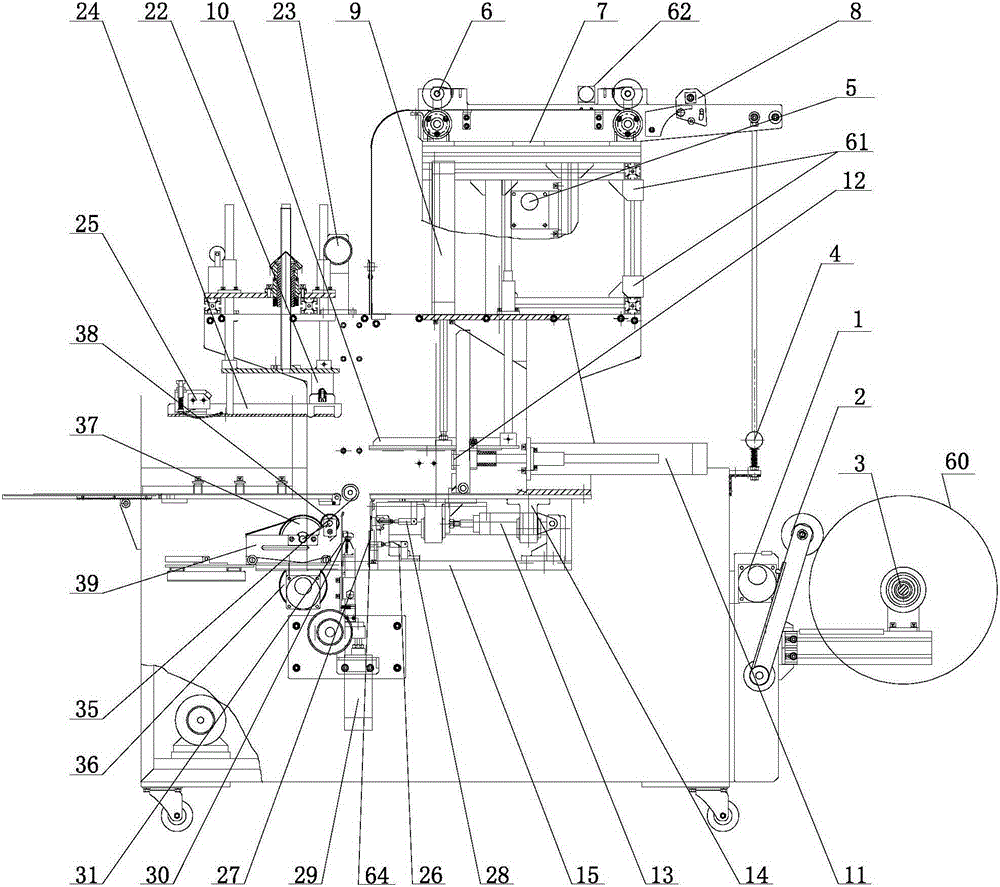

Full-automatic mechanical-type book bagging machine and bagging method thereof

InactiveCN101575015AReduce working noiseImprove working environmentWrapping material feeding apparatusWrapper folding/bending apparatusChain typeEngineering

The invention discloses a method for full-automatically mechanically bagging books, the method comprises, according to operating station sequence in process flow, the following steps: lateral feeding of books; paper guide; paper delivery; adhesive-injecting and cutting paper; positively pushing books; cylinder-forming; wrapping front opening and cornering up and down; scanning front side corner; bag-forming; lateral adhesive-injecting; sealing; bake-drying; and getting out of the bag; in the entire technological process, on the one hand, operating devices on operating stations are all connected with a main control device and all has a gear-type or chain-type transmission structure, thus fundamentally eliminating working noise and realizing coordinative and consistent transmission, on the other hand, transmission power of paper bags is originated from a positive book delivery device without a specific transmission device; in the process of getting out of the bag, the back bag of books always pushes the front bag of books, and shaping and drying of the paper bag are completed in a book outlet, thus fundamentally eliminating working noise and realizing coordinative and consistent transmission. The method of the invention has prominently reduced working noise, convenient operation and regulation, high quality of book bagging and high production efficiency as well as can effectively save the use amount of packing paper.

Owner:XIAN UNIV OF TECH

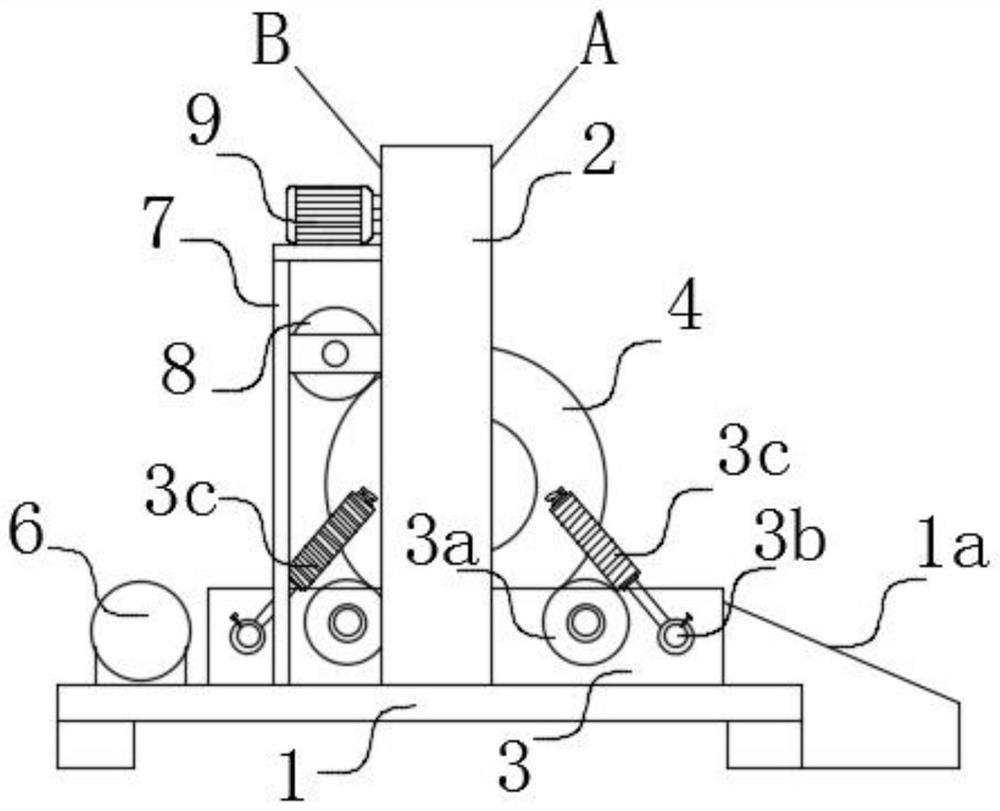

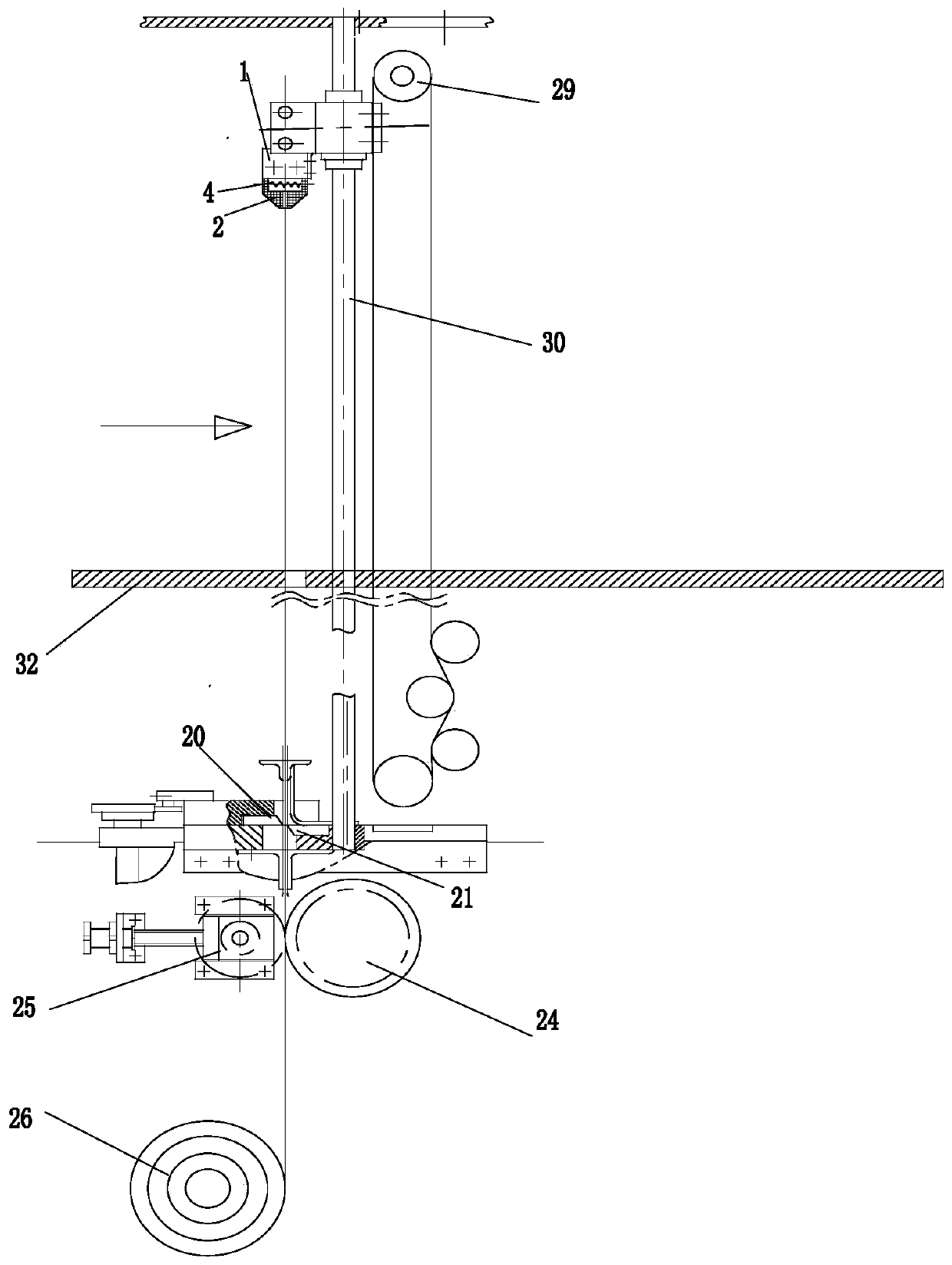

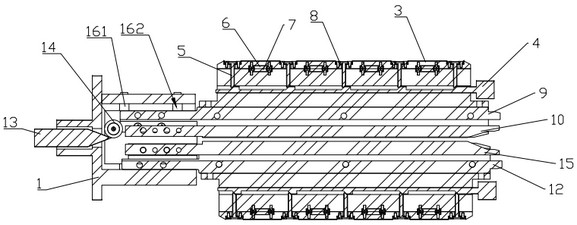

Winding device and winding method

ActiveCN101719561AStable winding tensionAvoid deformationFinal product manufactureFilament handlingEngineeringConductor Coil

Owner:GEESUN AUTOMATION TECH

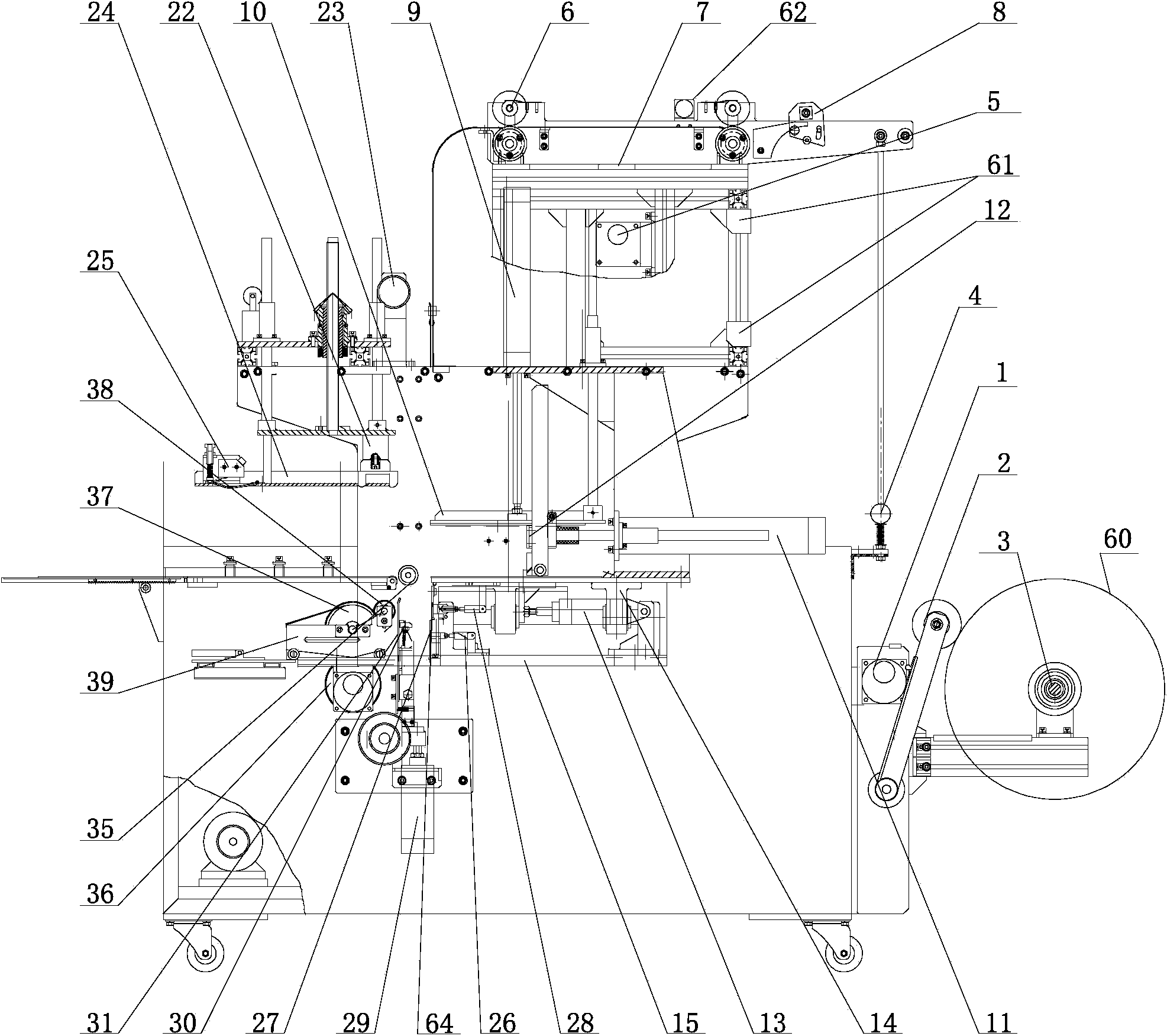

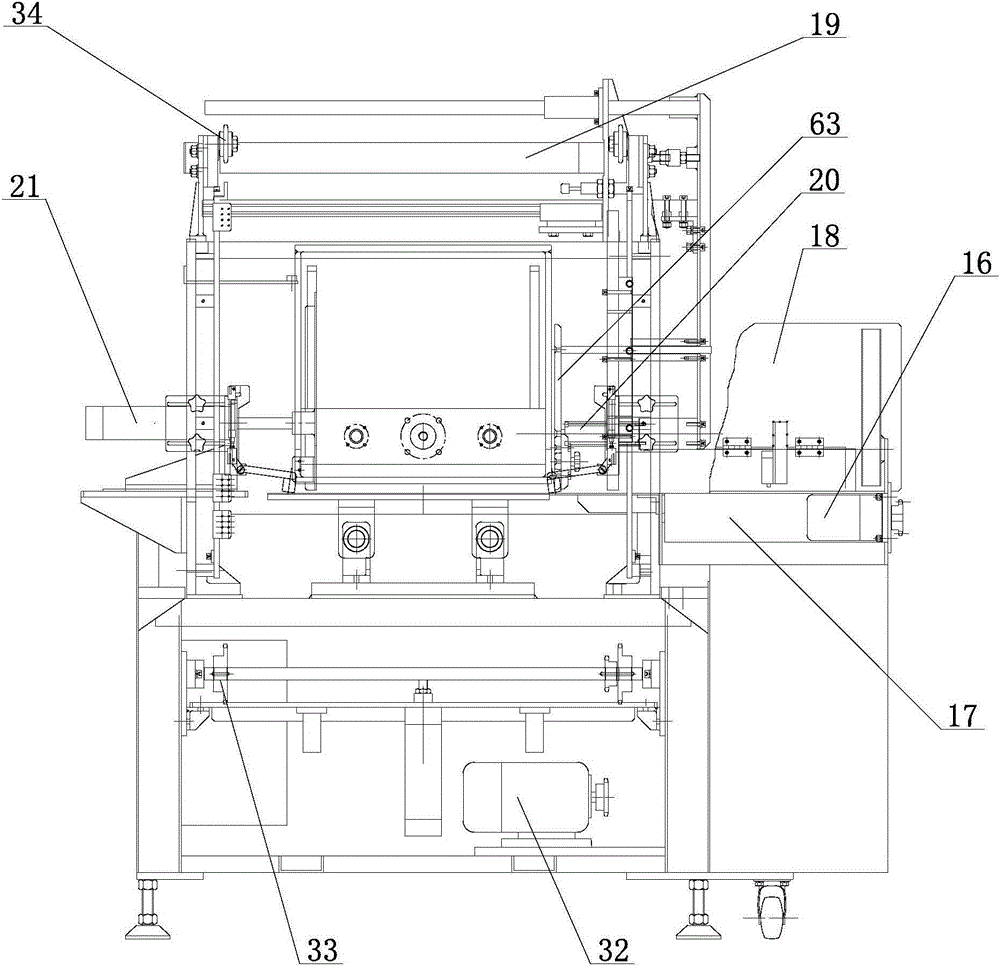

Full-automatic pneumatic type book and periodical packing machine

ActiveCN103662177ASave energyImprove efficiencyWrapping material feeding apparatusWrapper folding/bending apparatusControl systemConveyor belt

The invention provides a full-automatic pneumatic type book and periodical packing machine which comprises a main machine and an auxiliary machine which are split. A cylinder forming technology and an adhesion technology are completed by the main machine. An upper corner, lower corner, front side corner and rear side corner packing technology and an adhesive tape adhesion technology are completed by the auxiliary machine. According to the sequence of the technological process, the main machine comprises a paper feeding device, a paper delivery device, a front conveyor belt device, a transverse book pushing device, a first book pressing device, a longitudinal book pushing device, a paper clamping device, a gluing device, a second book pressing device, a paper cutting device, a paper guiding device, a glue supply device and the like. According to the sequence of the technological process, the auxiliary machine comprises a rear conveyor belt device, a rear folding device, an upper folding device, a lower folding device, a forward package pushing and folding device, an adhesive tape sealing device, a package outlet station and a control system. The cylinder forming process and the processes before that are completed by the main machine. The rear side corner packaging process and the processes after that are completed by the auxiliary machine. If the two sides of a book do not need to be packed, the cylinder forming process is conducted by the main machine working independently, so that energy is saved, and efficiency is improved.

Owner:BEIJING RUNDA MACHINERY MFG

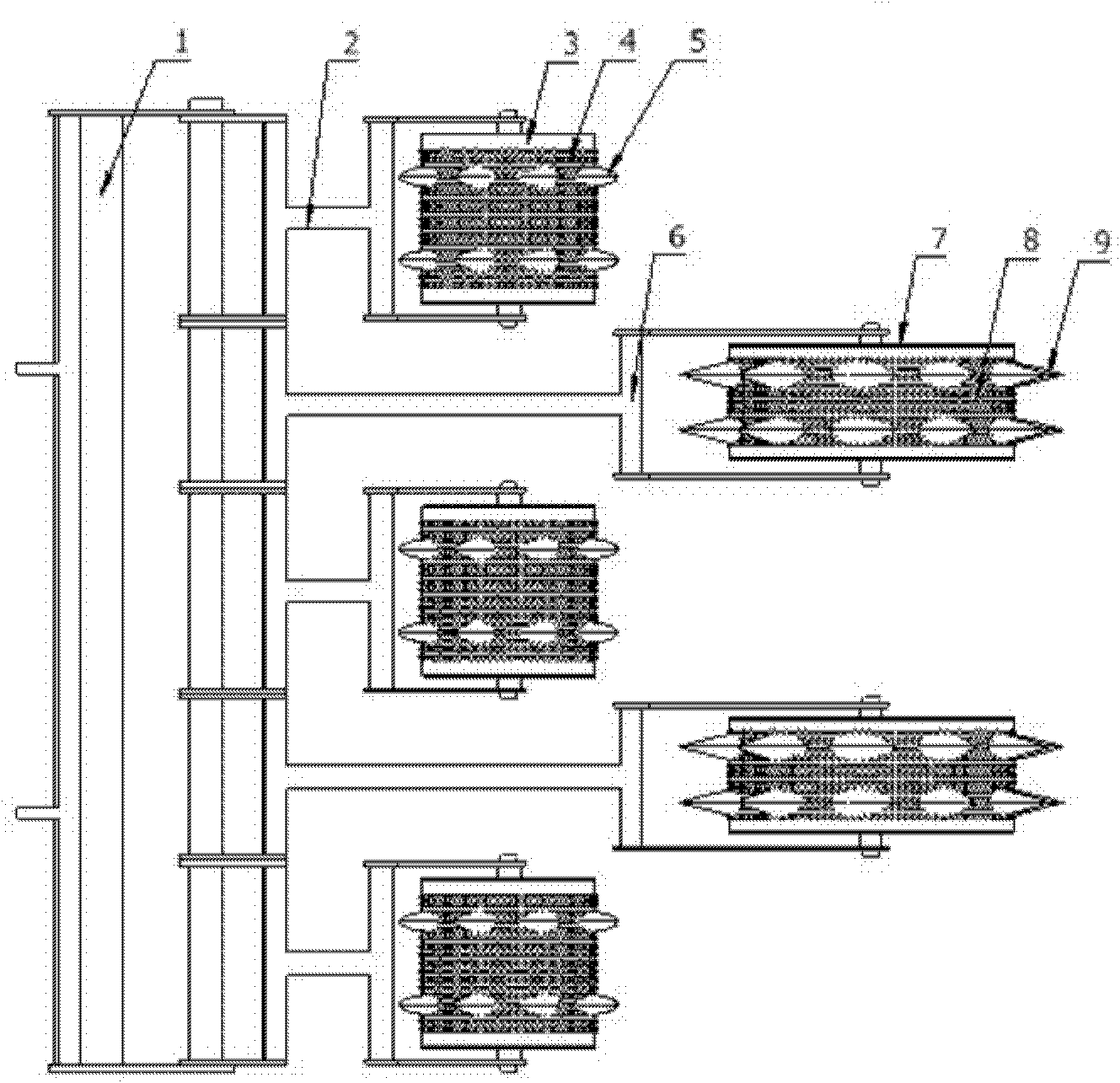

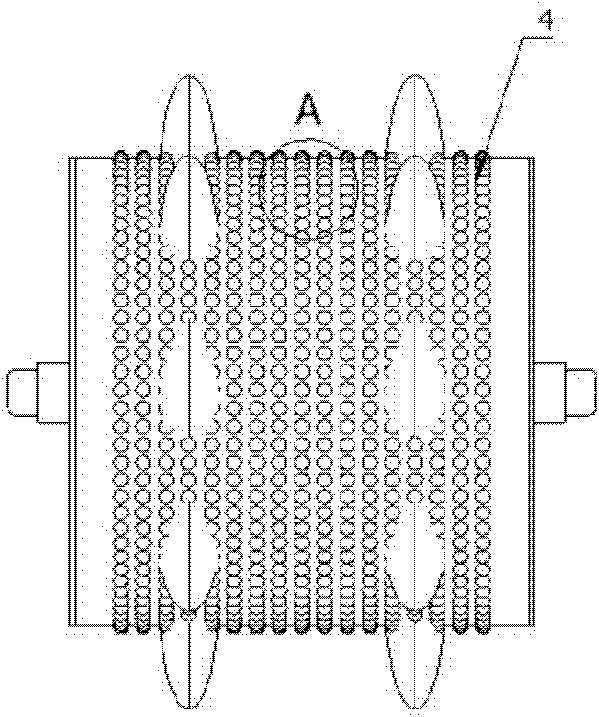

Process for preparing electrolytic capacitor paper

InactiveCN1793508AEvenly arrangedHigh purityFlexible coversNatural cellulose pulp/paperFiberElectrolysis

The invention relates to a paper technology, especially for electrolytic capacitor paper manufacturing method. The method includes the following steps: absorbing layer pulping; using paper pulp to manufacture paper; pressure layer pulping; using paper pulp to manufacture paper; compositing absorbing and pressure layers; the pulping degree of the absorbing layer is 12degreeSR-50degreeSR. And it adopts side wave fourdrinier paper machine to copy paper. But the pressure layer respectively is 30degreeSR-98degreeSR and cylinder paper machine. Thus the invention resolves the problem that cross direction water uptake of electrolytic capacitor paper is not very good. And the invention has the advantages of high purity, uniform paper quality, thickness, tightness, and fiber array.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL

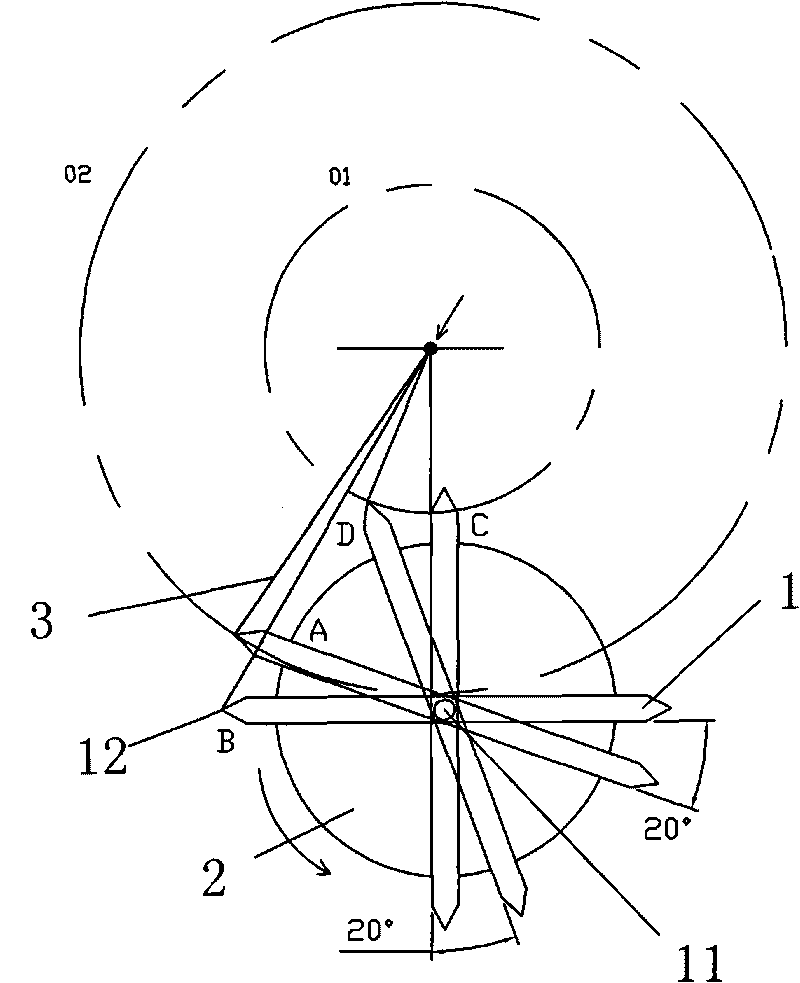

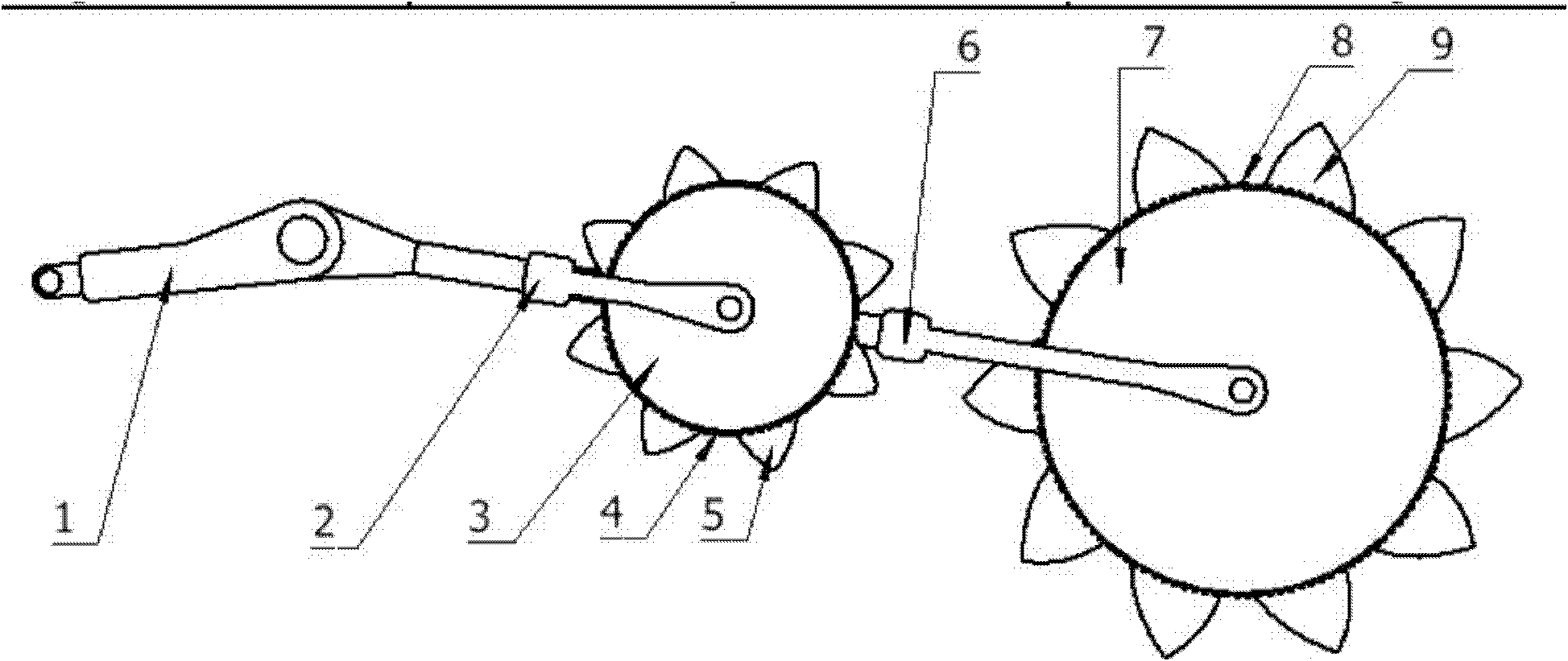

Ridge culture field soil surface microtopography processing bionic structure rolling soil-engaging part

The invention belongs to agricultural machinery, in particular relates to a rolling soil-engaging part for compacting soil and changing soil surface microtopography after seeding in a ridge culture mode, and in particular relates to a ridge culture field soil surface microtopography processing bionic structure rolling soil-engaging part. The part mainly comprises ridge table rollers, ridge trenchrollers and a total frame, wherein a plurality of ridge table rollers and ridge trench rollers are arranged, are connected in series on the total frame through a ridge table roller frame and a ridge trench roller frame respectively and can rotate around the total frame; a ridge table roller bushing and a ridge trench roller bushing are arranged on the surfaces of the ridge table roller frame and the ridge trench roller frame; and ridge table roller teeth and ridge trench roller teeth having geometric structures are uniformly distributed on the circumferences of the surfaces of the ridge tablerollers and the ridge trench rollers. On the premise of guaranteeing a soil compaction function, the rolling resistance is reduced, the adhesion between the part and soil is reduced, soil microtopography is changed, and soil water storage and soil moisture conservation capacity and agro-ecology are improved; therefore, farmland resists severe weather conditions, and sustainable production increase capacity is improved.

Owner:JILIN UNIV

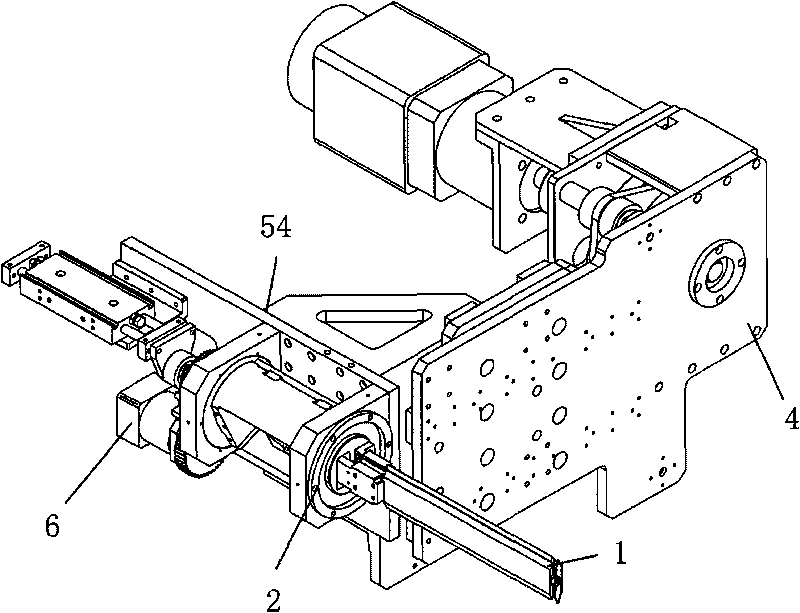

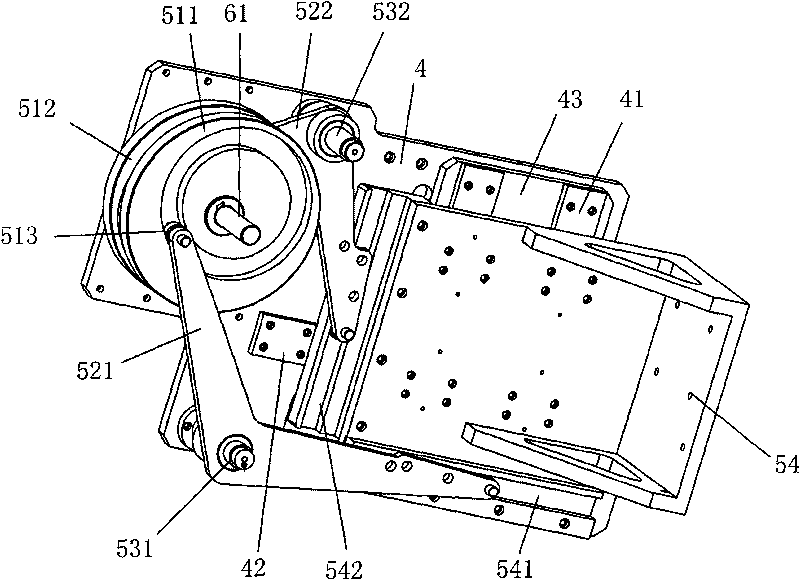

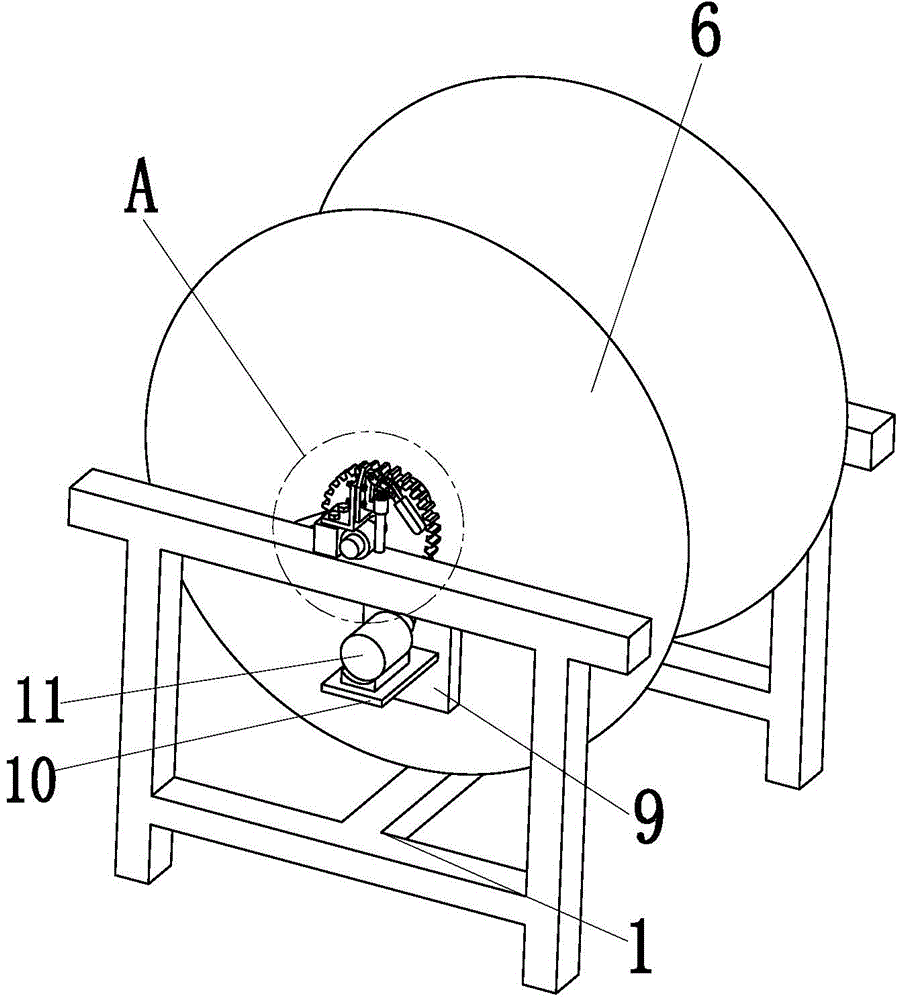

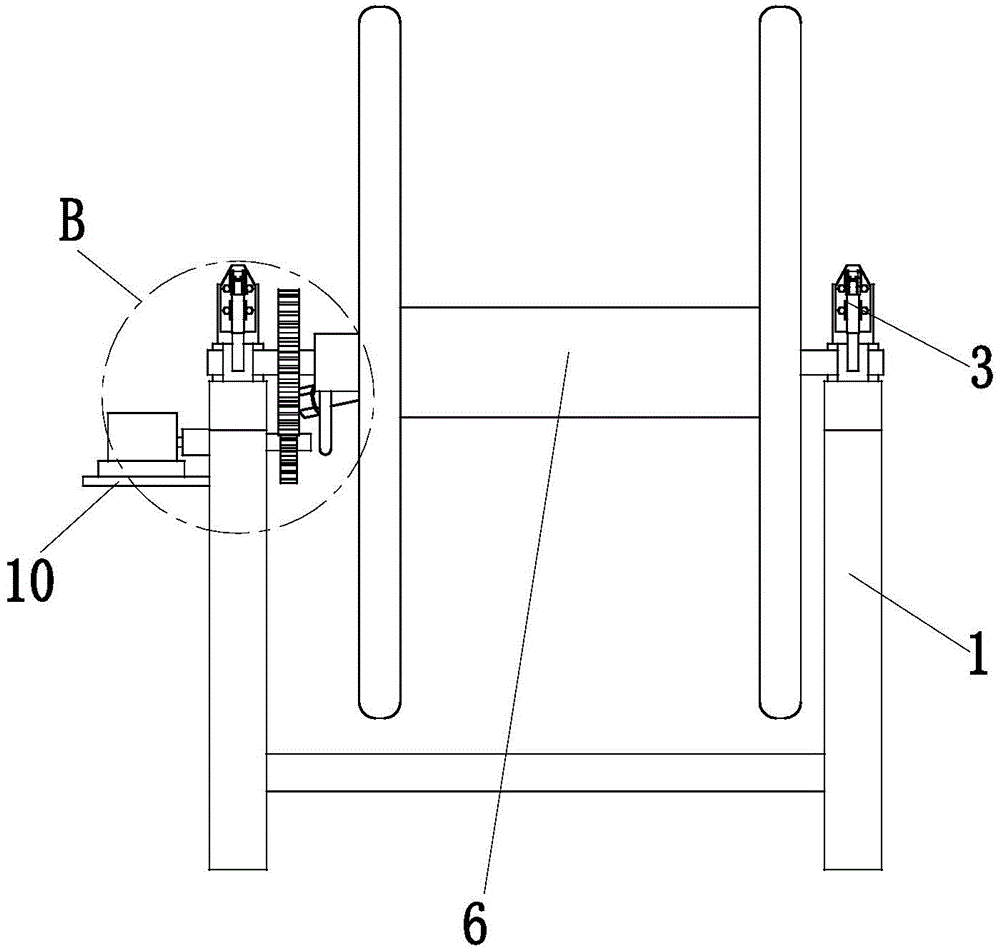

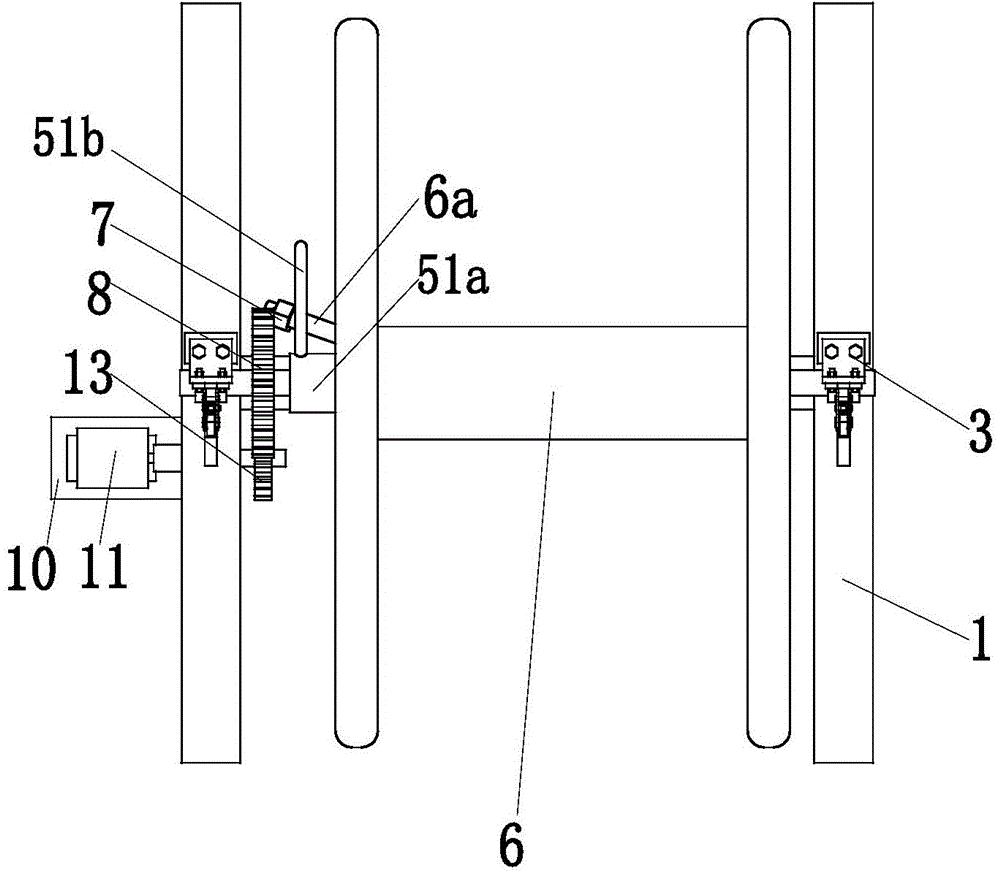

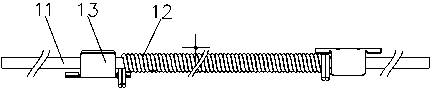

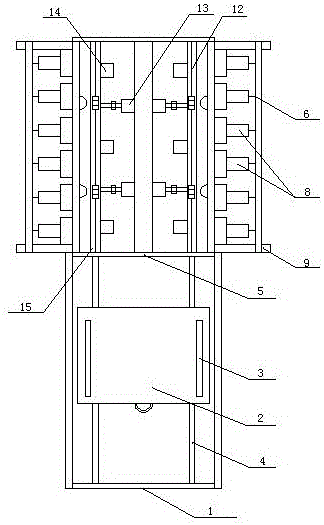

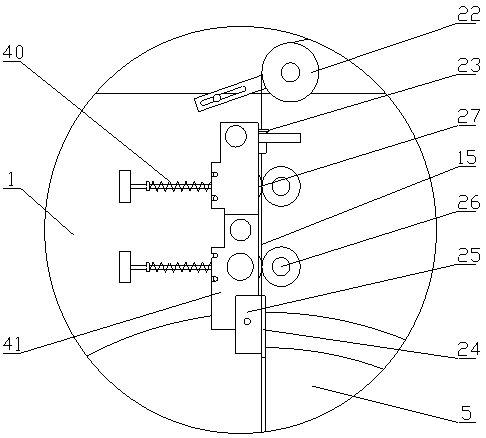

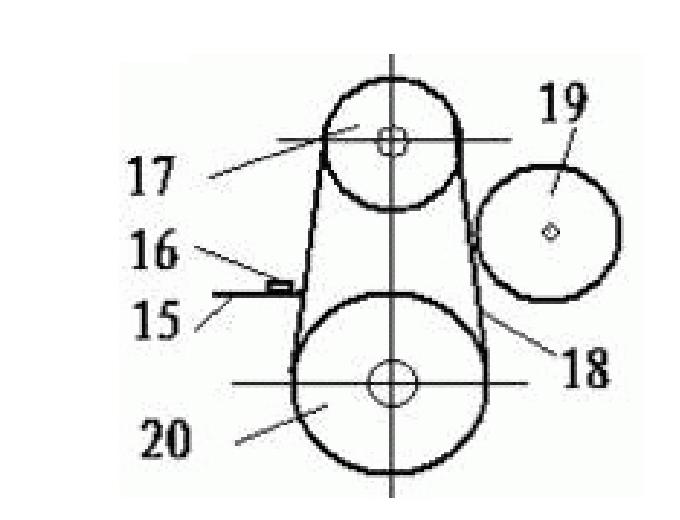

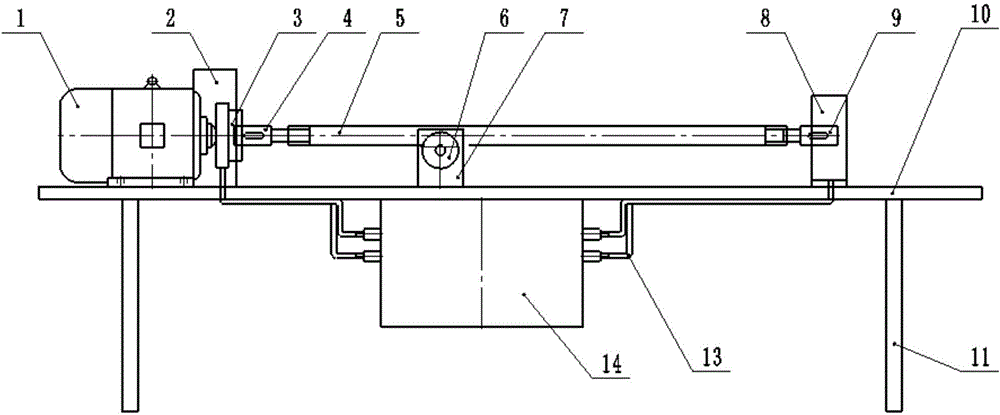

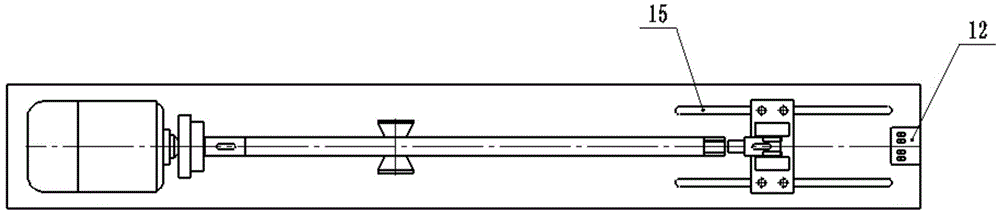

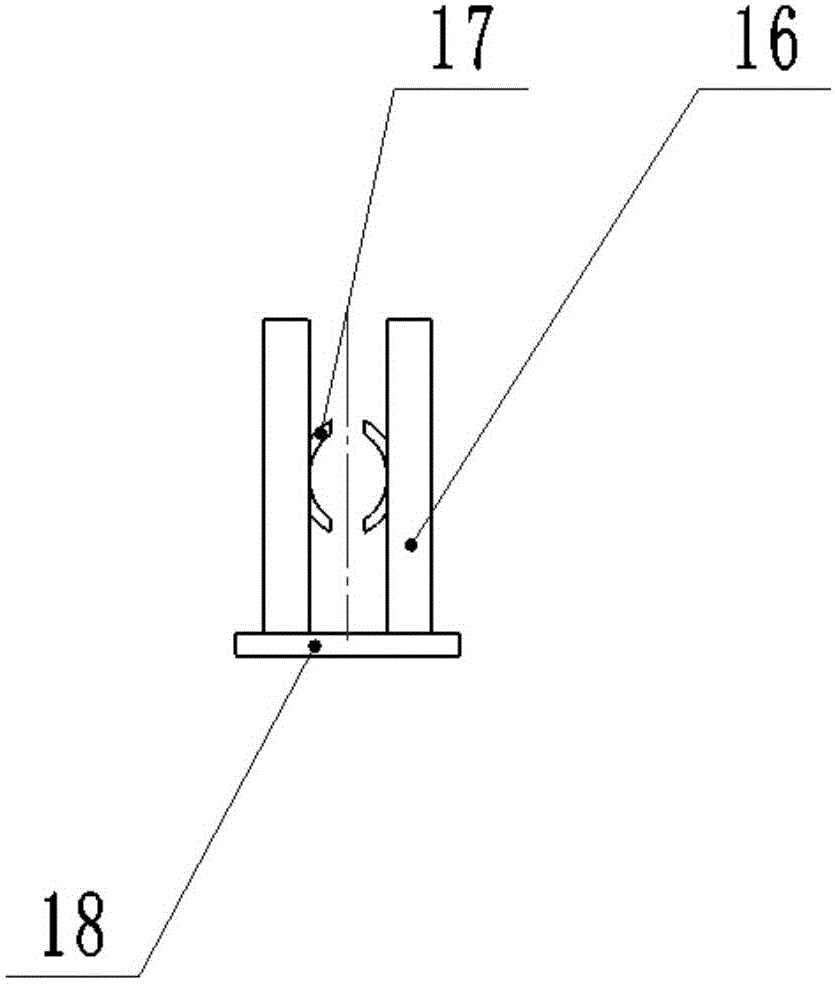

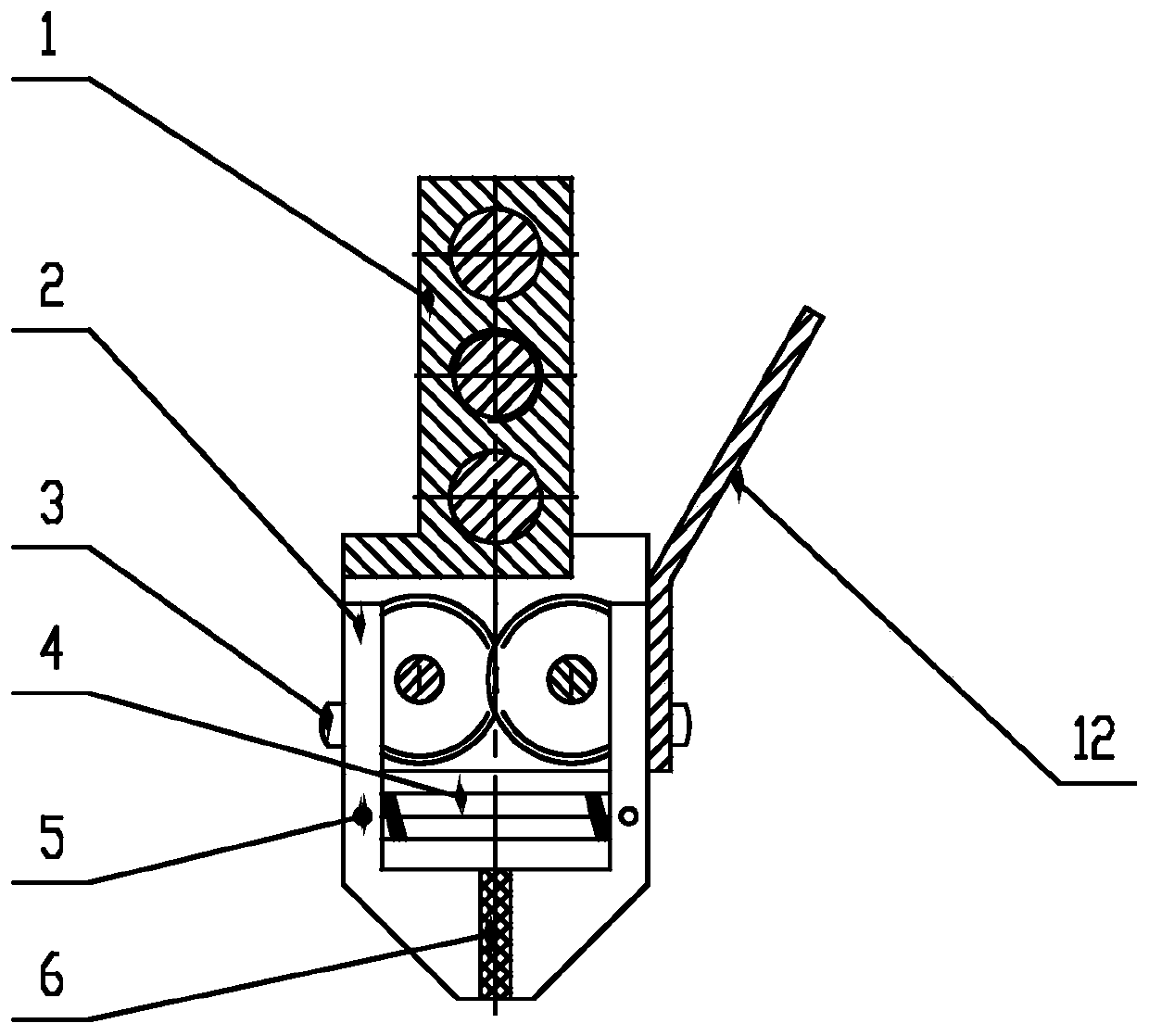

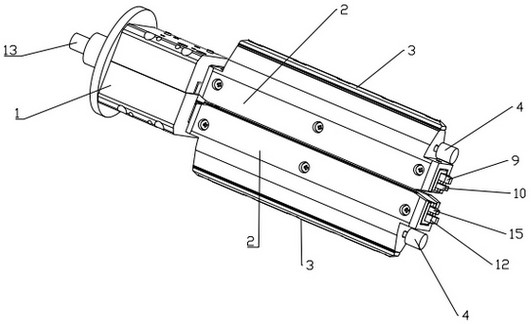

Cable winding device

ActiveCN104986614AReduce rotation speedUniform tightnessFilament handlingEngineeringMechanical engineering

Owner:岳阳新一步科技有限公司

Winding machine

The invention discloses a winding machine. The winding machine comprises a wire spool mechanism which drives a wire winding rod to rotate, a rod feeding mechanism which is used for positioning the wire winding rod, a wire feeding mechanism which moves in the axial direction of the wire winding rod and is used for conveying wires to the wire winding rod, a clamping mechanism which is used for obtaining wire clamps and clamping the wires on the wire winding rod, a cutting-off mechanism which is used for cutting off the wires, a rod discharging mechanism which is used for discharging a finished spring wire rod, and a control system. The winding machine has the advantages that spring wires can be wound automatically, needed auxiliary materials are the same as those of a manual winding method, cost of the auxiliary materials is not increased, parameters, such as pitch, number of circles, and winding speed, of the winding machine can be set, automatic winding is achieved, the degree of tightness is even, the wire winding speed is increased to 1.5 seconds per strand from 5 seconds per strand, the reject ratio is reduced to 0.5% from 5%, four workers can be emancipated by each winding machine, labor intensity is relieved, and safety performance is improved.

Owner:昆山奥泰克自动化科技有限公司

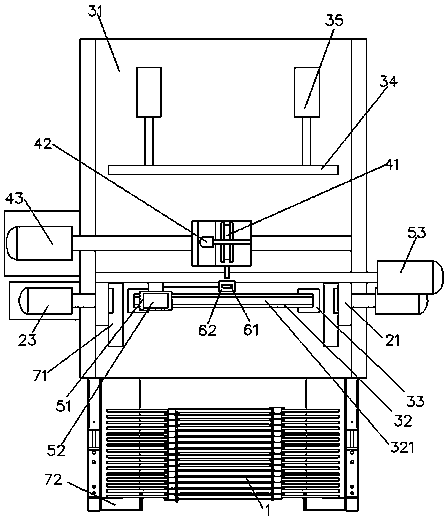

Automatic packaging device for pipe coils

PendingCN112046830AAutorotation speed stabilization controlUniform tightnessWrapping material feeding apparatusWrapping with article rotationStructural engineeringMechanical engineering

The invention discloses an automatic packaging device for pipe coils. The automatic packaging device comprises a base bottom plate, two parallel rotary fixing bases, two containing rotary rollers, coiling door frame, an annular fixing base and a winding sliding ring, wherein the two parallel rotary fixing bases are fixed to the base bottom plate, the two placement rotary rollers arranged on the rotary fixing bases and used for placing the pipe coils, the coiling door frame is arranged on the base bottom plate and stretching across the two rotary fixing bases, the annular fixing base is arranged on the coiling door frame and used for coiling and packaging the pipe coils, and the winding sliding ring is installed on the annular fixing base in a limited mode. According to the automatic packaging device for the pipe coils, the placement rotating rollers used for driving the pipe coils to rotate in a limited mode are installed on the base bottom plate, in addition, the pipe coils are coiledand packaged through the annular fixing base and the winding sliding ring which stretch across the coiling door frame of the pipe coils and a coiling belt installation shaft and a coiling guide rod which are arranged on the winding sliding ring, therefore, the coiling efficiency is improved, manpower is saved, the rotating speed of the coiling belt installation shaft and the autorotation speed ofthe pipe coils can be stably controlled, so that the tightness of the pipe coils is more balanced, and the product quality is guaranteed.

Owner:TIANJIN ZHONGCAI PROFILES

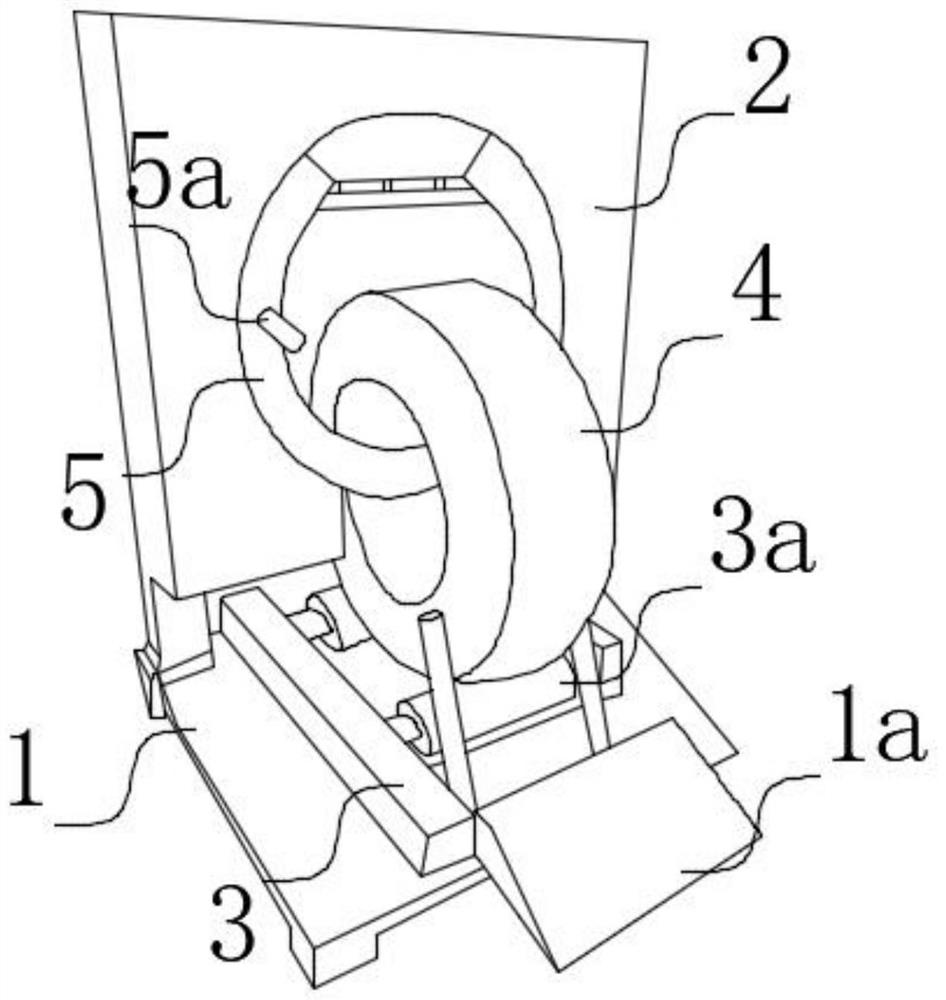

Binding machine by means of annular rubber band

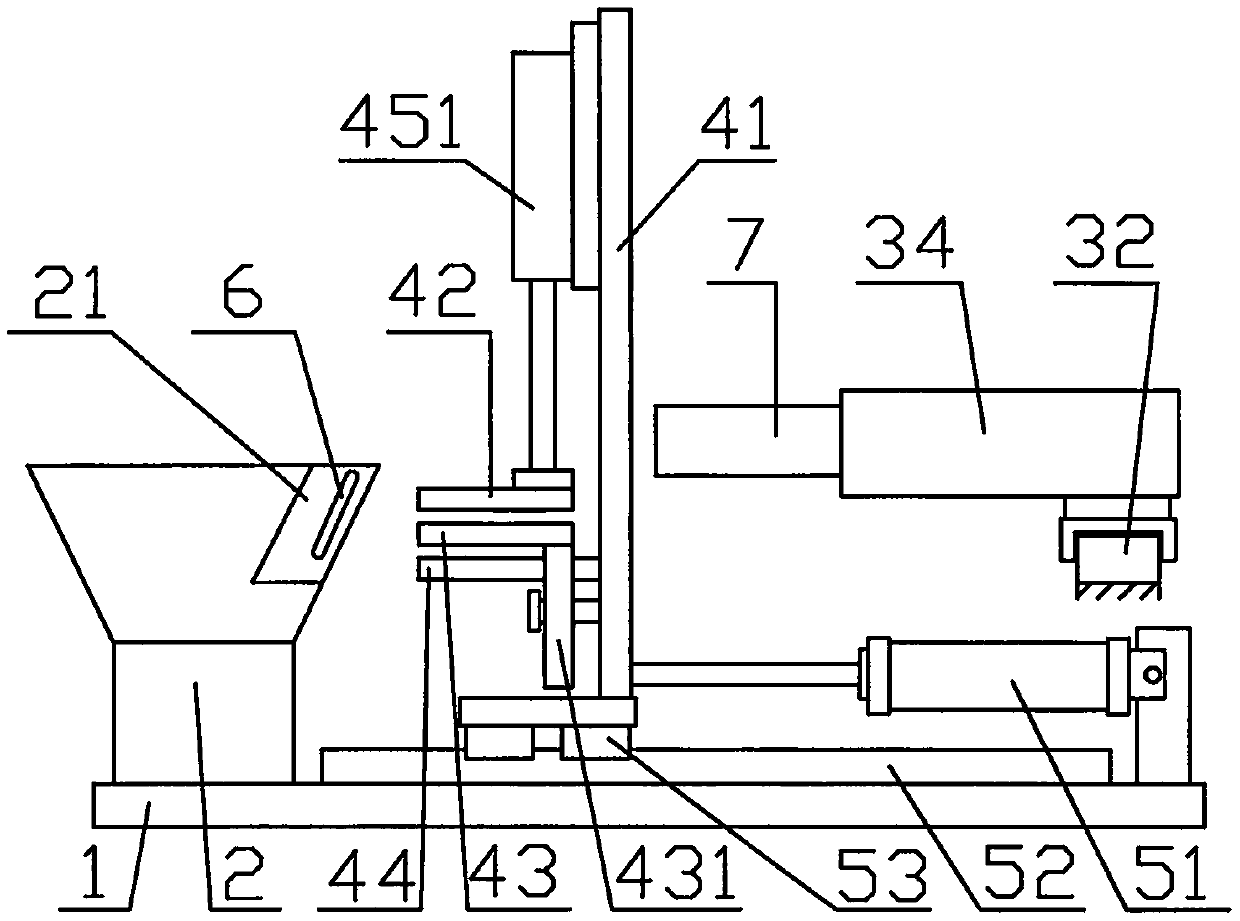

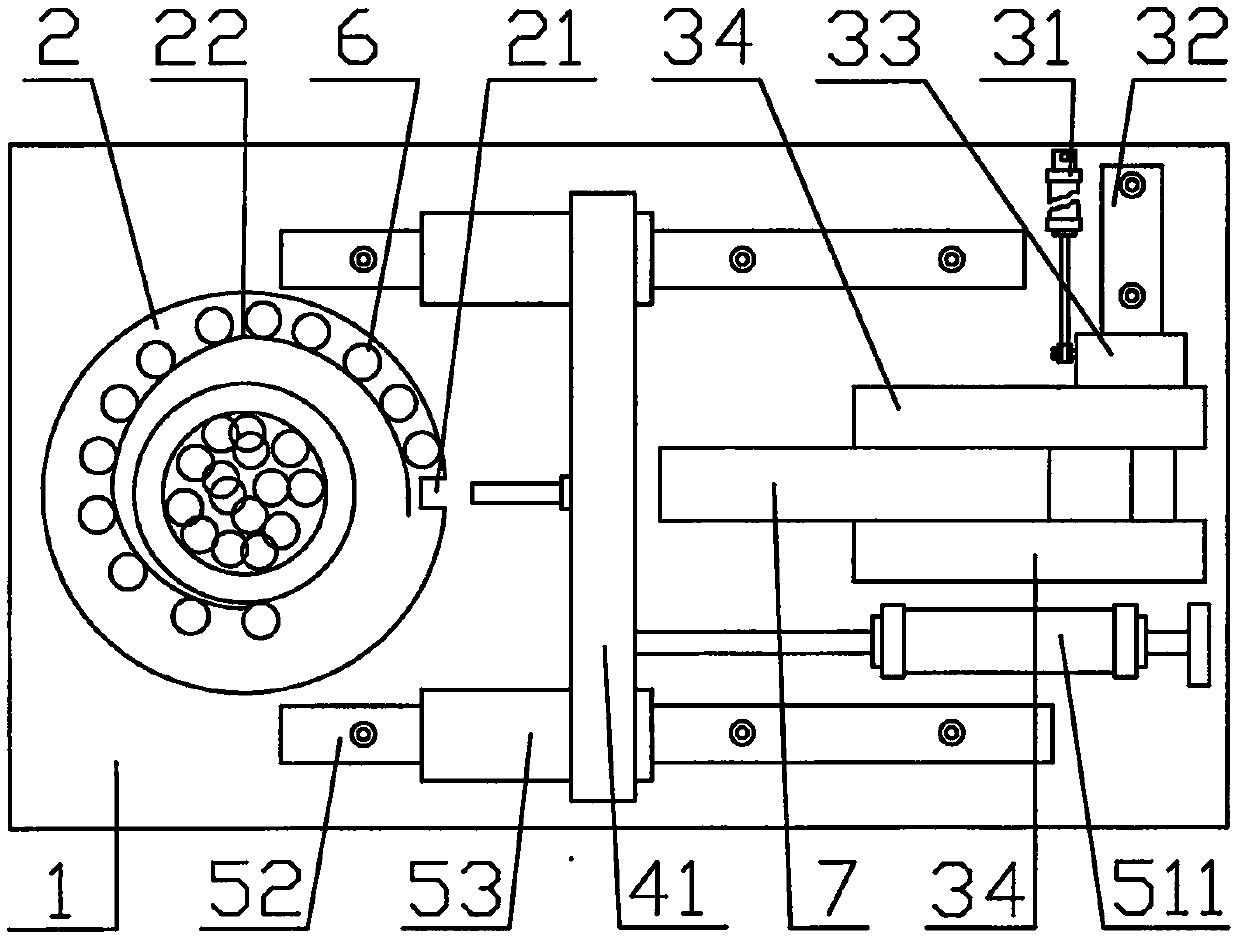

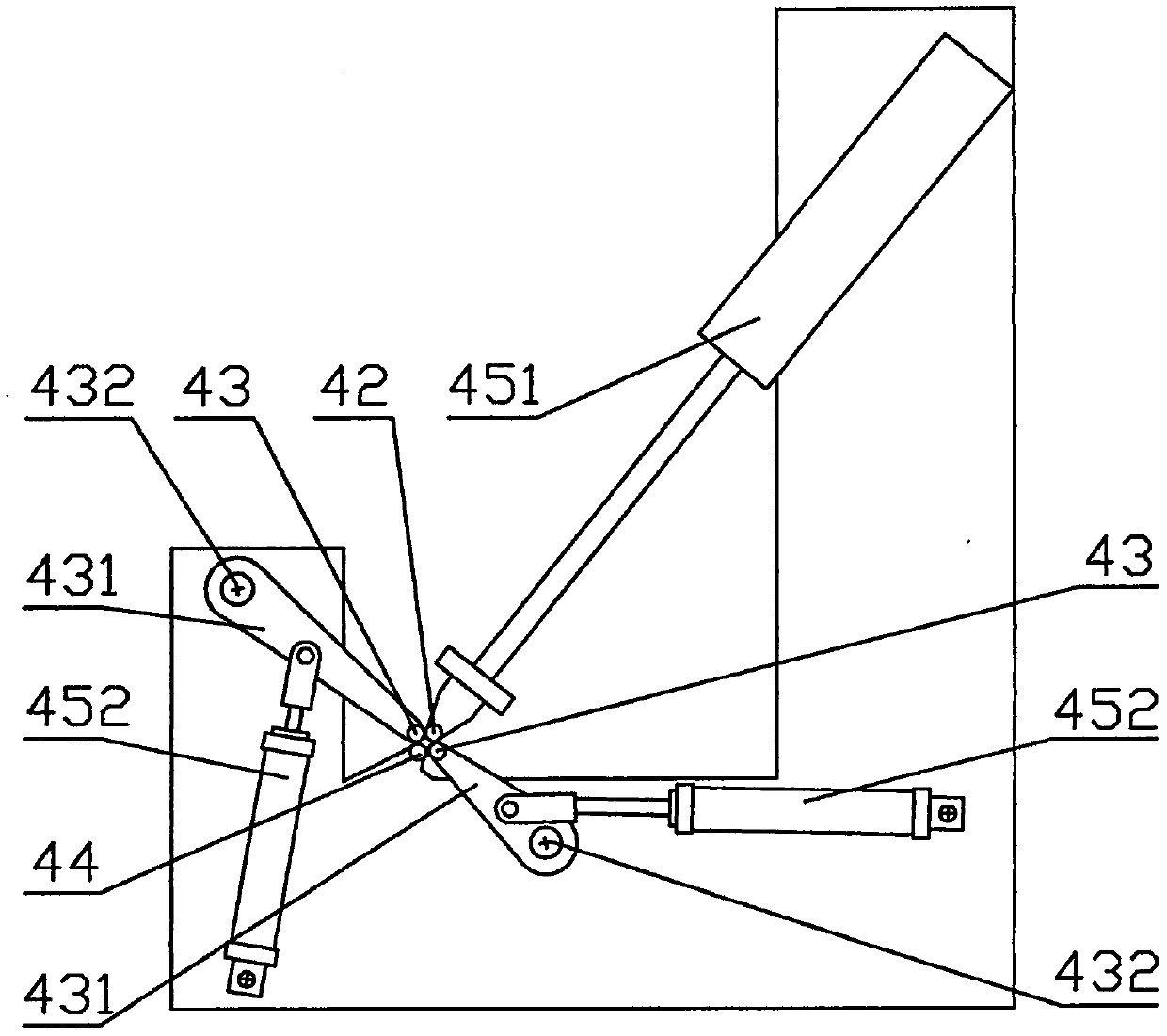

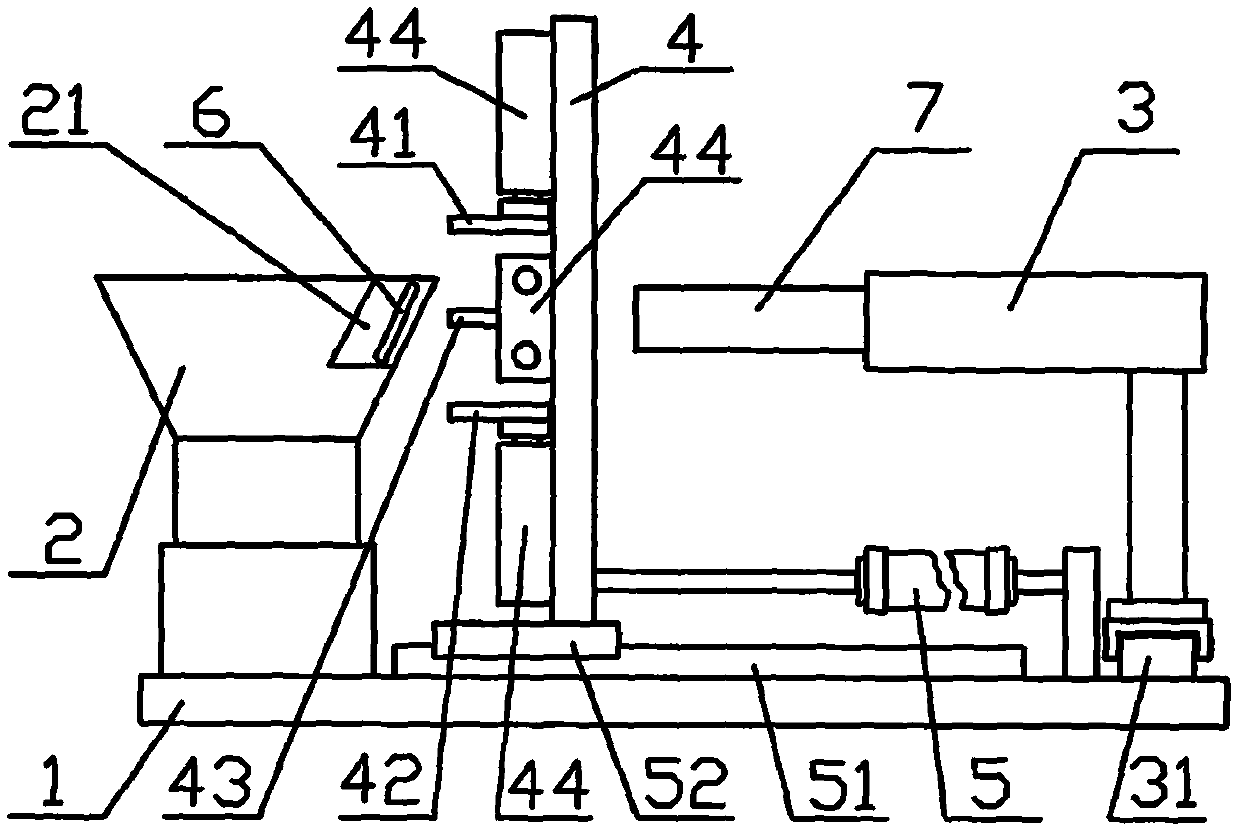

InactiveCN109552687AReduce the chance of work errorsCompact structureBinding material applicationEngineeringManipulator

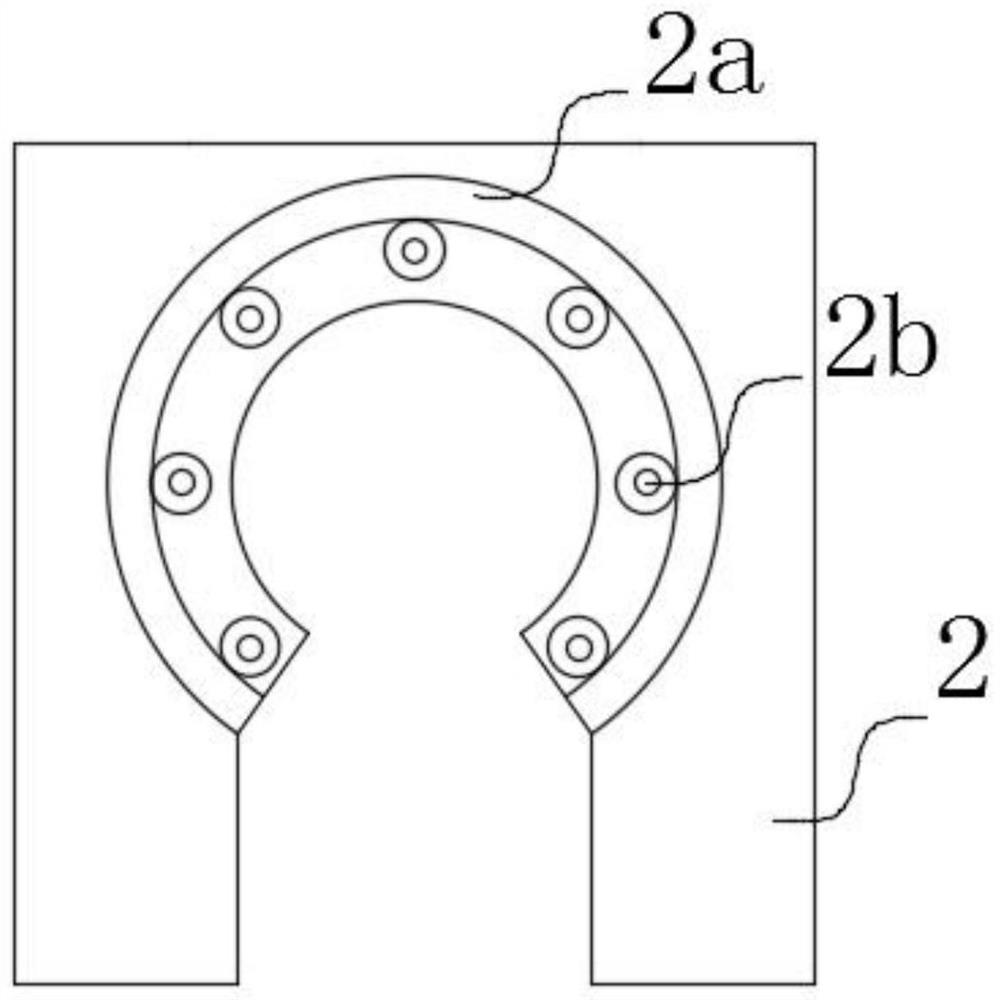

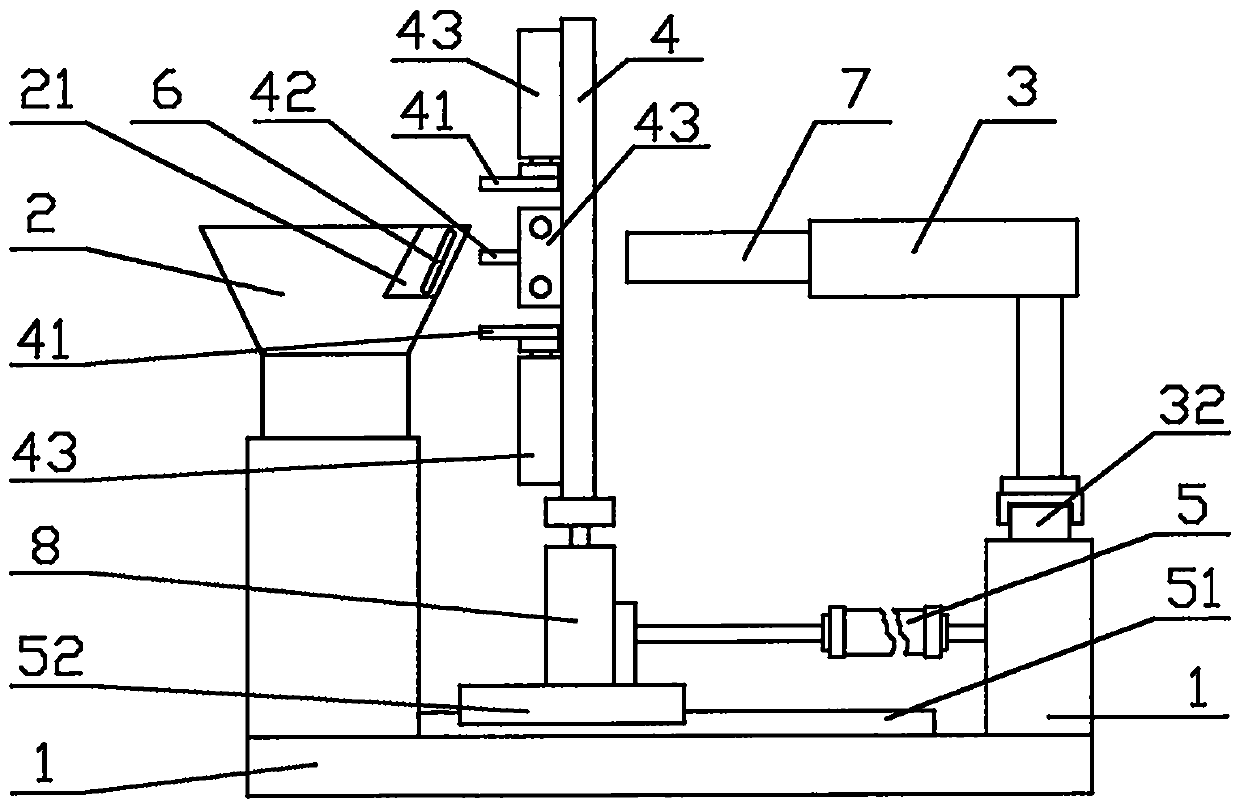

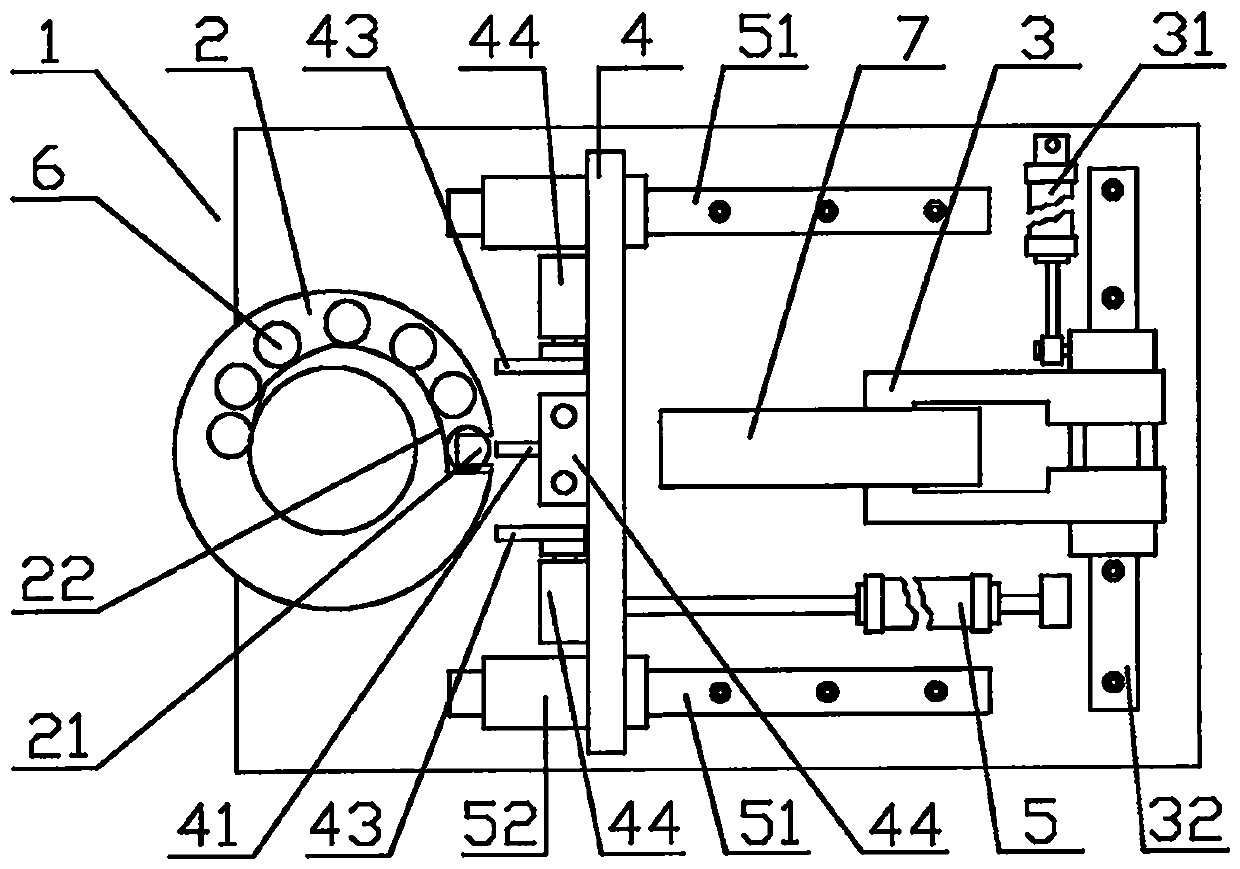

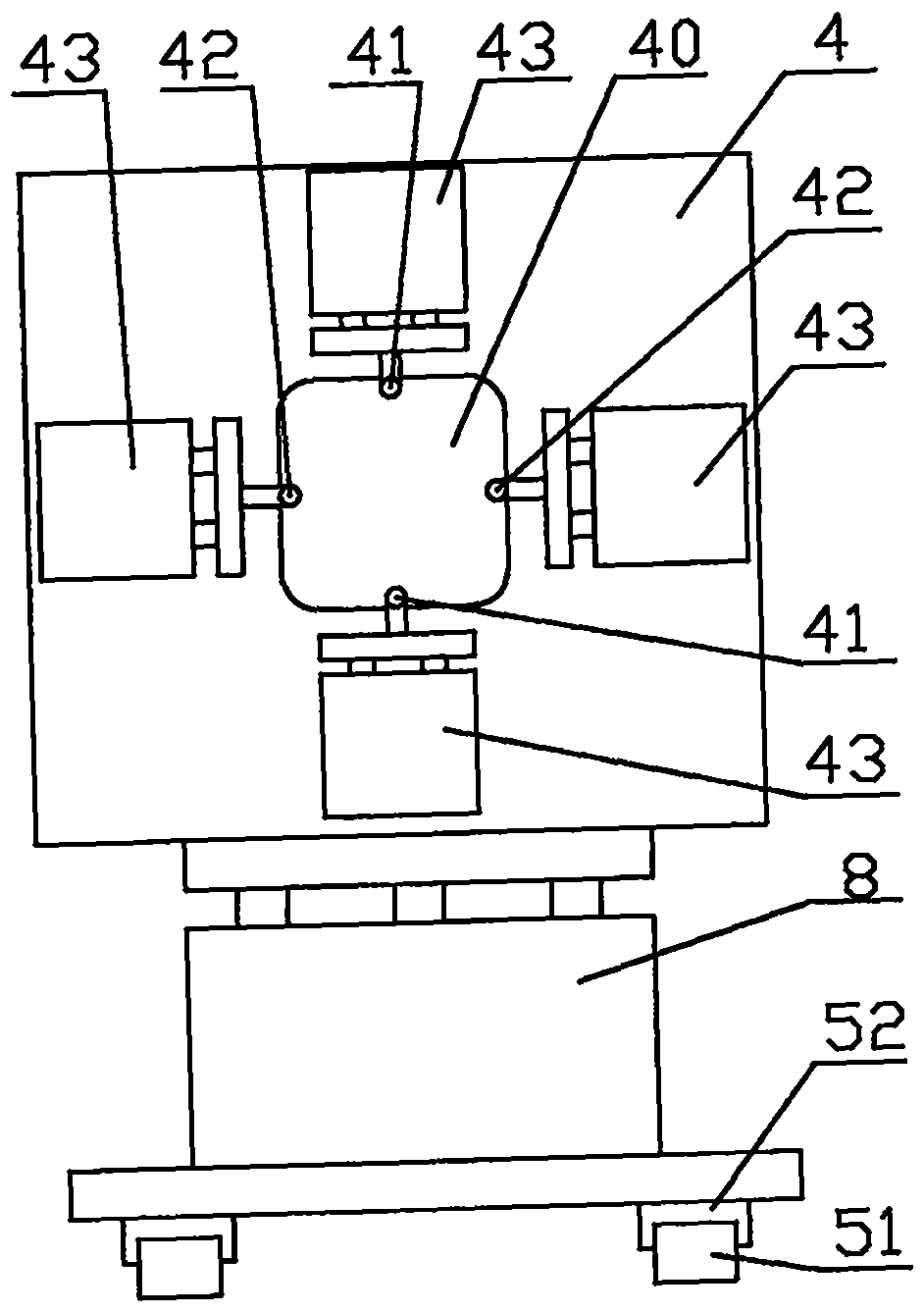

The invention discloses a binding machine by means of an annular rubber band. The annular rubber band is used for binding plastic bags which are folded into strips. The binding machine mainly comprises a machine frame, a vibration disc device and a plastic bag conveying device; and the binding machine is characterized in that a U-shaped notch is further formed in the vibration disk device, and a rubber band stretching device is further arranged at the position, corresponding to the U-shaped notch; the rubber band stretching device mainly comprises a support, an opening-direction supporting rod, two side supporting rods, an opening-direction movement mechanism and an inserting movement mechanism; and the inserting movement mechanism firstly drives the supporting rod to be inserted into theannular rubber band at the U-shaped notch, the opening-direction movement mechanism moves the annular rubber band out of the vibration disc device and then stretches the annular rubber band to carry out the binding function. According to the binding machine, a mechanical arm rubber band transferring device in the prior art is omitted, mechanisms such as a rib removing plate and a blocking ring areomitted, so that the working links are reduced, the work is stable, the structure is simple and compact, and the yield of the binding is high.

Owner:王秀来

Plastic bag strapping machine

InactiveCN109733657AStable jobWork compactBinding material applicationBundling machine detailsEngineeringTransfer mechanism

The invention discloses a plastic bag strapping machine. The plastic bag strapping machine comprises a machine frame, a vibration disc device and a plastic bag conveying device. The plastic bag strapping machine is characterized in that a U-shaped notch is arranged on the vibration disc device; a rubber band expansion device is arranged at the position corresponding to the U-shaped notch; the rubber band expansion device comprises a bracket; the bracket is provided with an upper side supporting rod, a bottom side supporting rod, two side supporting rods and an expansion cylinder; an insertionmoving mechanism is connected between the bracket and the machine frame; and the plurality of supporting rods penetrate through the U-shaped notch to be inserted into an inner hole of a rubber band under driving of the insertion moving mechanism, so that the rubber band is expanded in one direction and taken out from the U-shaped notch after being narrowed, and then stretched again. Compared withthe prior art, the plastic bag strapping machine omits a rubber band transfer mechanism and a driving device thereof, so that the whole machine is compact in structure, the working procedure is simplified, and the grasping and expansion work of the rubber band is reliable and stable.

Owner:王秀来

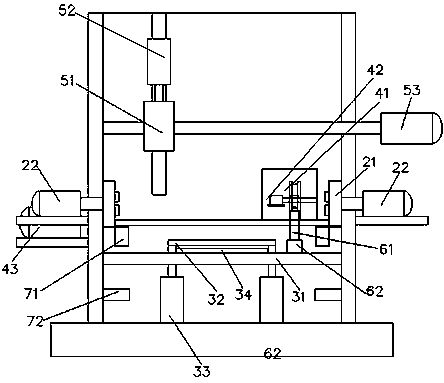

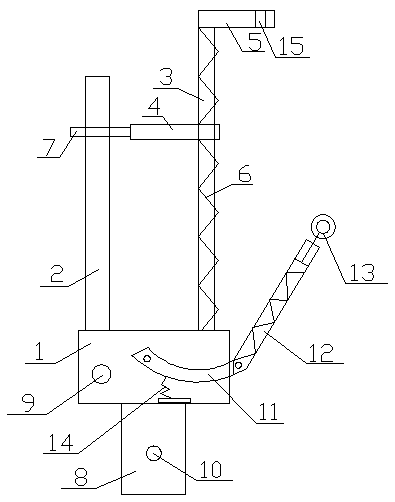

Canvas tightening machine of painting frame

InactiveCN105946436AImprove tightnessUniform tightnessSpecial ornamental structuresAtmospheric pressureUpper floor

The invention relates to a processing device of a painting frame, in particular to a canvas tightening machine of a painting frame. A rack comprises an upper-layer rack body and a lower-layer rack body. Feeding sliding ways are arranged on the lower-layer rack body and provided with a feeding tray moving along the feeding sliding ways. The positions, on the two sides of the feeding sliding ways, of the lower-layer rack body are each provided with a nail gun sliding way. A nail gun frame moving along the nail gun sliding ways is arranged on the nail gun sliding ways. The nail gun frame is connected with a moving pneumatic cylinder. Nailing guns are arranged and mounted on the nail gun frame and connected with nailing pneumatic cylinders. The upper portions of the positions, corresponding to the two sides of the painting frame, of the upper-layer rack body are each provided with a clamp plate for clamping a canvas. Two clamping plates of each clamp plate are connected with clamping pneumatic cylinders. Tightening pneumatic cylinders are connected between the two clamp plates. According to the canvas tightening machine of the painting frame, operations of tightening, clamping and automatic nailing of the canvas and the painting frame can be achieved at a time, the tightness degree of the canvas is increased and is uniform, and the ideal requirement of a painter can be met; and production cost and manual input are greatly reduced, production efficiency is improved, and operation is easy and fast.

Owner:河北凯强文教用品有限公司

Preparation method of Nb3Al superconducting precursor wire rod based on layer-by-layer stacking

ActiveCN108878054ASmall size deviationUniform tightnessSuperconductors/hyperconductorsReduction of cables/conductors sizeCorrosionCopper

The invention relates to a preparation method of an Nb3Al superconducting precursor wire rod based on layer-by-layer stacking. The preparation method mainly comprises the steps of A, preparation of anNb-Al composite sheath: enabling an Nb foil and an Al foil to be alternately stacked in a tubular Nb box rectangular groove from the bottom up, covering an upper cover, sleeving in a Cu pipe and performing welding and sealing; B, preparation of an Nb-Al single-core rod: performing static liquid extrusion, repeated drawing and pulling for many times and corrosion and copper removal on the Nb-Al composite sheath to obtain the Nb-Al single-core rod; and C, preparation of the Nb3Al superconducting precursor wire rod: enabling multiple Nb-Al single-core rods to be assembled into a Cu or Cu alloy sheath, and carrying out electron beam sealing and welding, static liquid extrusion, and repeatedly drawing and pulling and processing for multiple times to obtain a multi-core wire rod; and carrying out corrosion and copper removal. The method is simple to operate, the assembly filling rate of the foil materials is high, and the compactness of each layer of foil materials is uniform and consistent. The finally prepared superconducting wire rod prepared by the method is high in performance, high in consistency and high in percent of pass. The method is especially suitable for preparation of superconducting long wire rods.

Owner:SOUTHWEST JIAOTONG UNIV

A fully integrated nucleic acid detection microfluidic chip and its use method

ActiveCN107129930BEasy to handleWith testing conditionsBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid detectionBiology

The invention relates to a fully-integrated nucleic acid detection microfluidic chip and a use method thereof. The fully-integrated nucleic acid detection microfluidic chip comprises a cover plate, a substrate, a bottom plate, a sample box and bubble caps, wherein the cover plate and the bottom plate are respectively stuck to two sides of the substrate; the substrate is provided with a sample outlet, a channel, a sample box groove, at least one bubble cap groove and at least one reaction tank, wherein the channel is communicated with the sample box groove, all the bubble cap grooves and all the reaction tanks, and all the reaction tanks are respectively connected with the sample outlet; the sample box is arranged on the sample box groove; the sample box groove is connected with the at least one reaction tank; the bubble caps are arranged on the bubble cap grooves; the bubble caps are internally filled with a reagent; the bubble cap grooves are respectively connected with the sample box groove and the at least one reaction tank. The invention also provides the use method of the fully-integrated nucleic acid detection microfluidic chip. The fully-integrated nucleic acid detection microfluidic chip can be used for treating a complex sample in an integrated way, and is good in airtight property and simple in structure.

Owner:BEIJING BAIKANGXIN BIOLOGICAL SCI & TECH

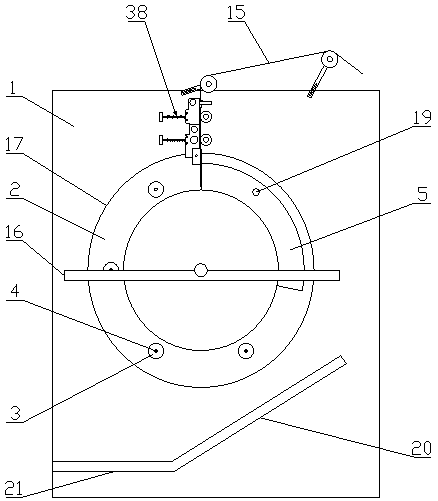

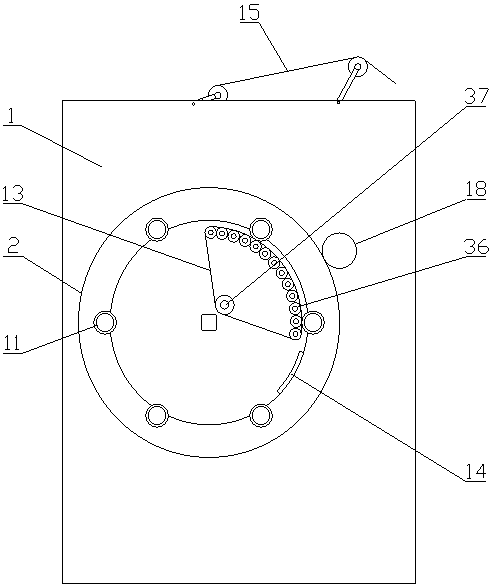

Production system of round cotton balls and method for preparing cotton balls by using same

PendingCN110141767AReduce volumeSave spaceMedical devicesMedical applicatorsEngineeringSpherical form

The invention discloses a production system of round cotton balls and a method for preparing cotton balls by using the same, and belongs to the technical field of medical dressing. The production system comprises a processing table, a cotton sliver fixed-length conveying device, a ball rolling device and a cotton ball collecting device, wherein the ball rolling device comprises a round turntable,a plurality of winding heads and winding needles thereon, a rounding passage and a needle withdrawing structure; the winding needles are coaxially arranged at the front ends of spindles and can project out of sleeves into the rounding passage and retract into the sleeves; the needle withdrawing structure comprises a needle withdrawing disk and a driving belt; and the needle withdrawing disk is provided with a needle withdrawing bevel surface for retracting the winding needles. The system adopts a vertical structure and is smaller in volume and space-saving. The cotton sliver is rounded in therounding passage through the winding needles, and the obtained round cotton ball has a regular spherical shape, uniform tightness and good product quality.

Owner:稳健医疗(嘉鱼)有限公司

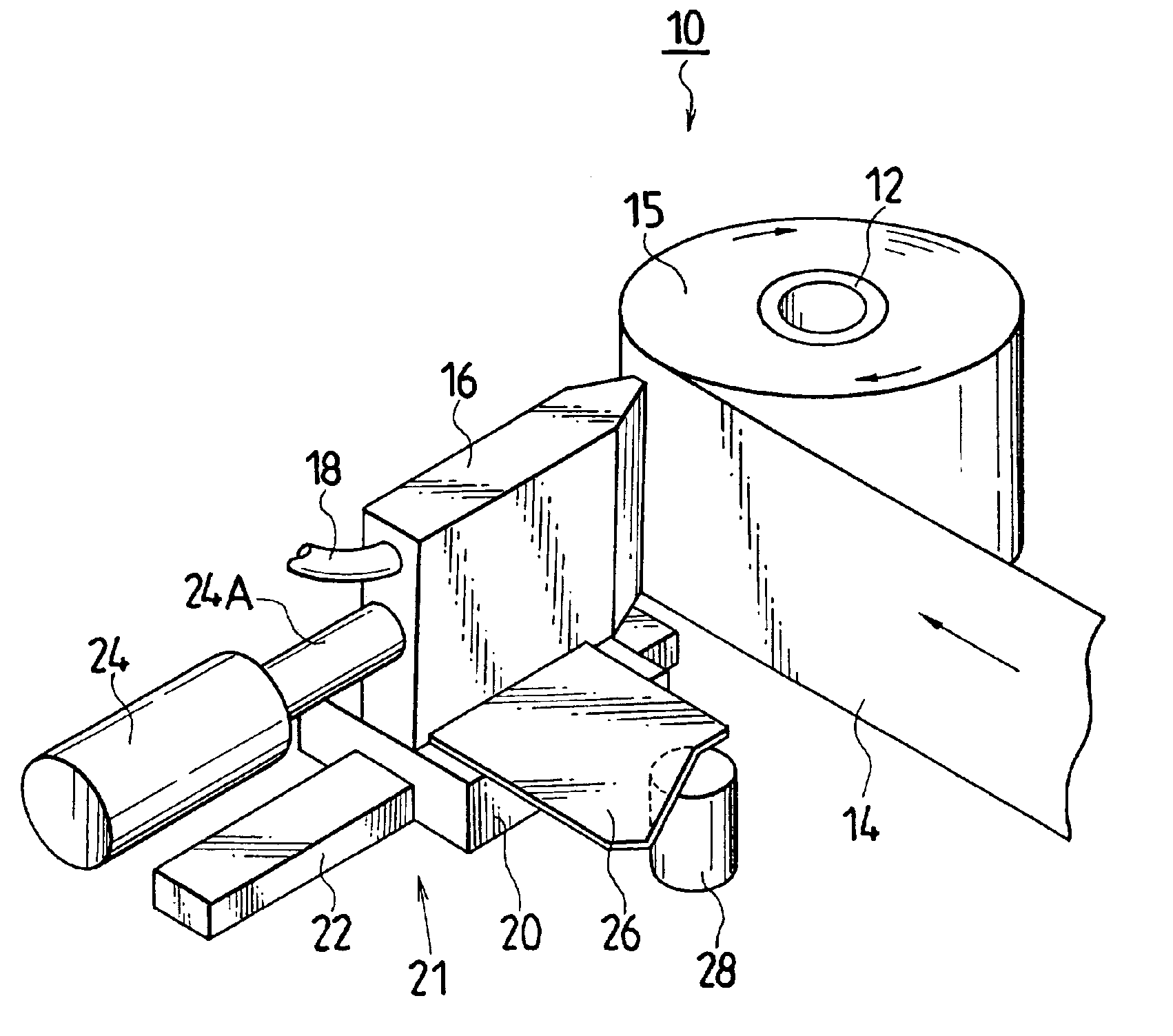

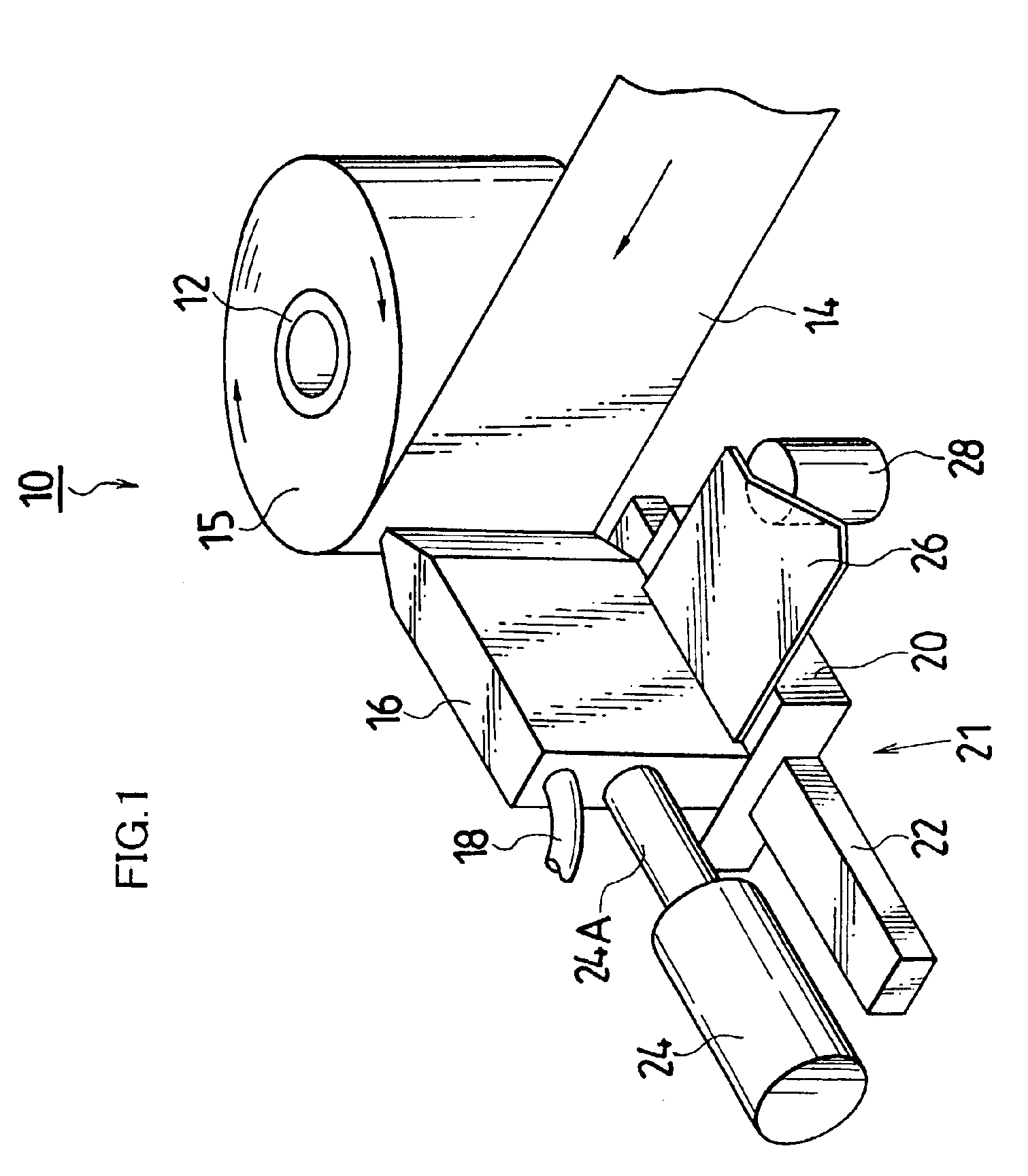

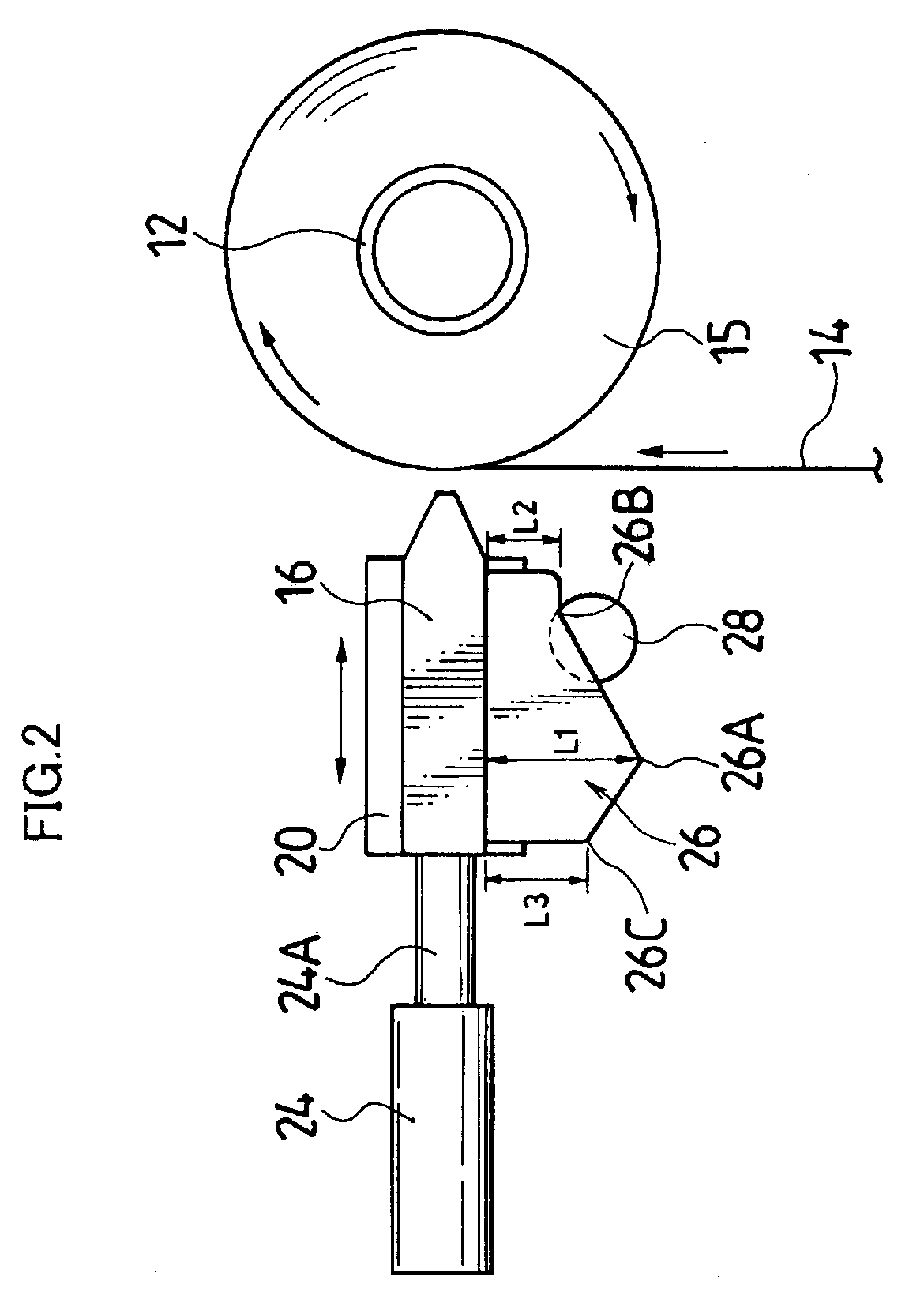

Tape winder

In the tape winder for winding a tape on a reel to form a tape roll, a nozzle which blows a gas toward an outer peripheral surface of the tape roll at a winding time of the tape is fixed on a slider, which is slidably supported on a rail. In this way, the nozzle is supported movably forward and backward with respect to the tape roll. Moreover, the nozzle is pressed toward the tape roll by an air cylinder with a constant pressing force. Thus, the nozzle is allowed to accurately follow an outer peripheral surface of the tape roll, and a constant pressure can be applied to the outer peripheral surface of the tape roll. Consequently, the tape can be wound with an adequate winding tightness.

Owner:FUJIFILM CORP +1

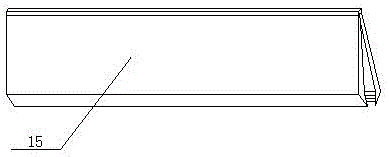

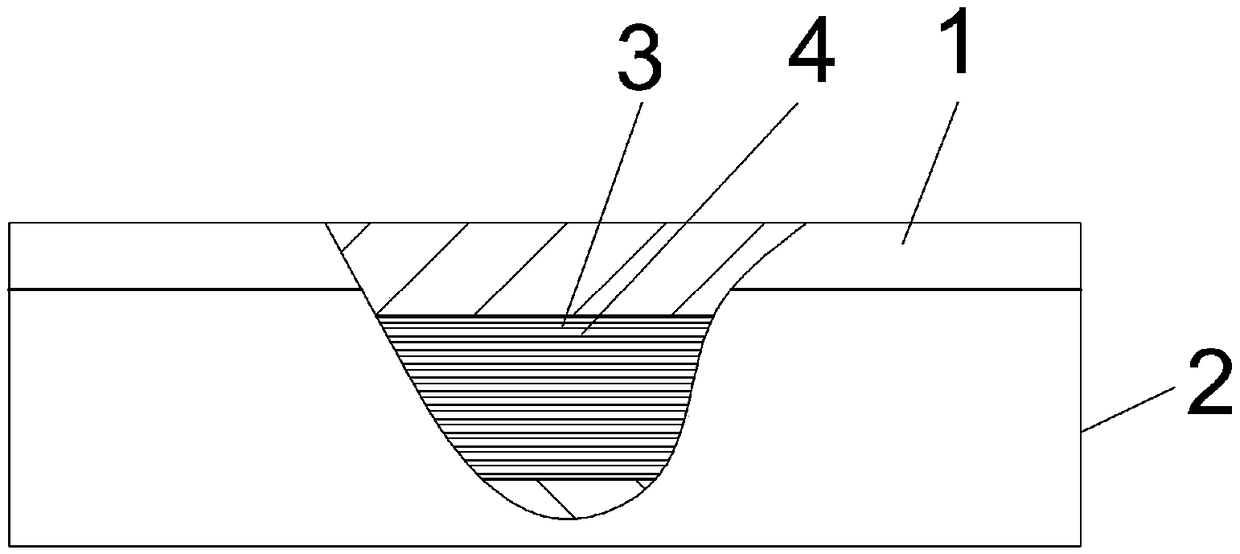

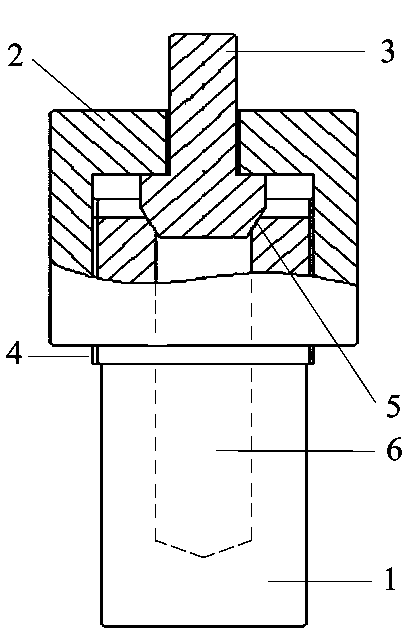

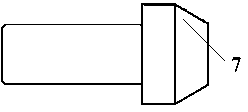

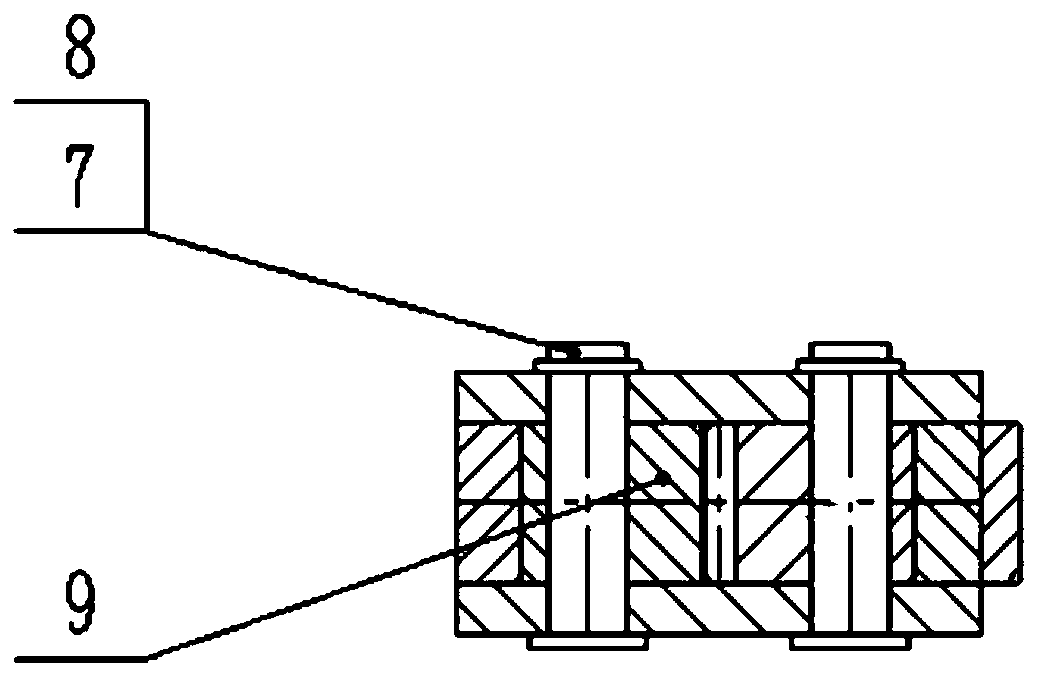

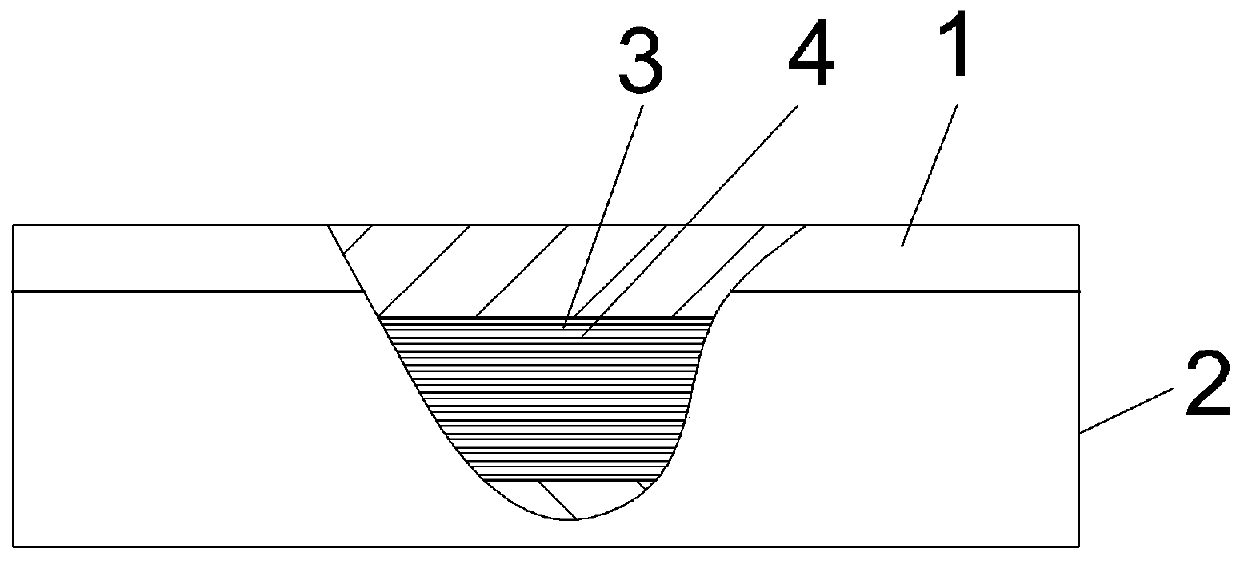

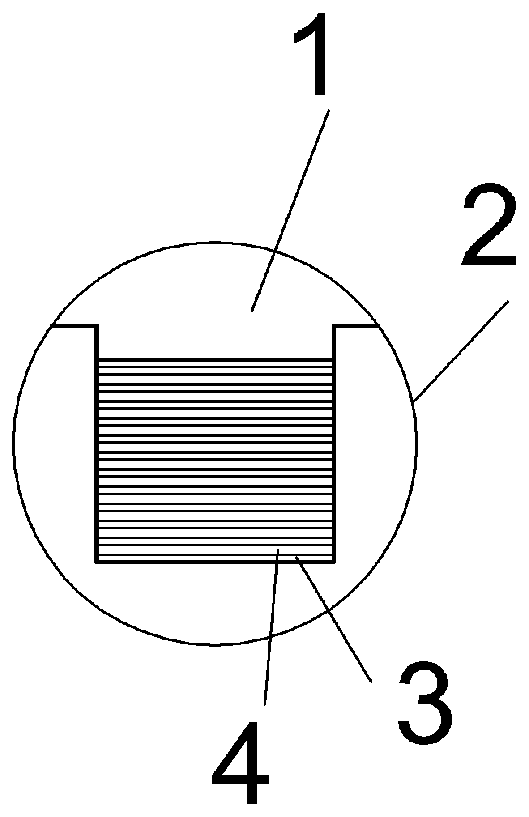

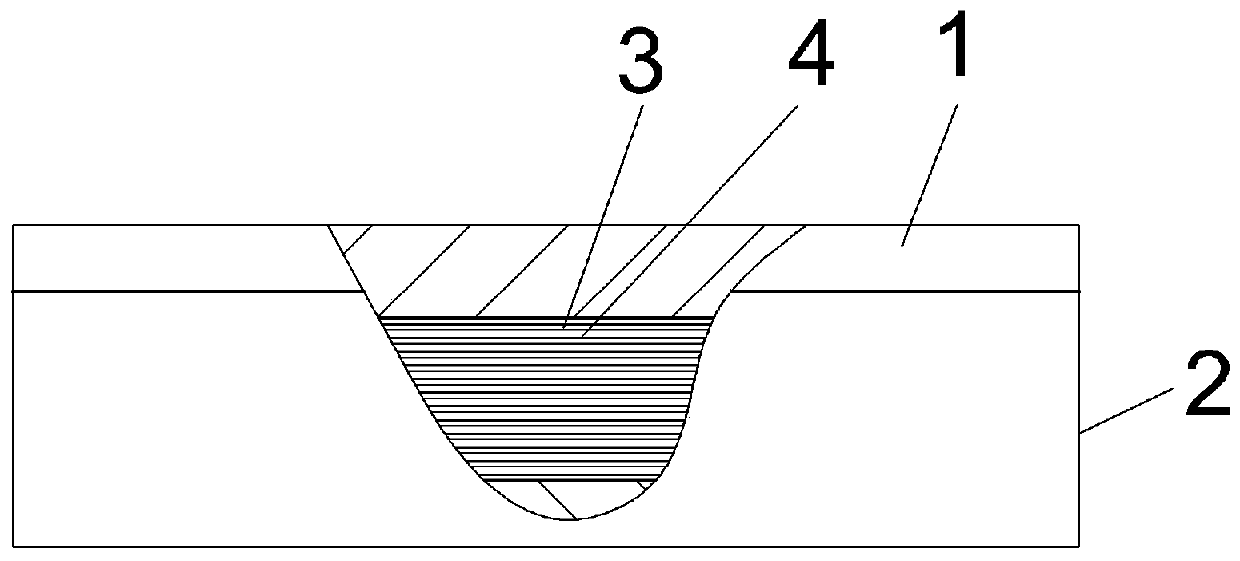

Safety high-temperature and high-pressure reaction vessel sealing structure for solvothermal synthesis

InactiveCN103949186ACompact structure designSimple structure designPressure/vacuum vesselsPressure vessels for chemical processVessel sealingMetallic materials

The invention relates to a safety high-temperature and high-pressure reaction vessel sealing structure for solvothermal synthesis, belongs to the field of solvothermal synthesis application and aims at solving the technical problem of providing the solvothermal high-temperature and high-pressure reaction vessel sealing structure capable of relatively well integrating the sealing property and the safety. According to the technical scheme, the safety high-temperature and high-pressure reaction vessel sealing structure for the solvothermal synthesis comprises a vessel body 1, a vessel cover 2 and a sealing pin 3; the vessel body 1 and the vessel cover 2 are connected and fastened by threads, the sealing pin 3 is compacted by the vessel cover so as to realize the conical sealing between the sealing pin 3 and the vessel body 1. The safety high-temperature and high-pressure reaction vessel sealing structure for the solvothermal synthesis is mainly used as a safety high-temperature and high-pressure solvothermal synthesis reaction container applied in the field of the solvothermal synthesis of a nanomaterial and other materials under the high-temperature and high-pressure conditions, and also can be used as a digestion tank appiled in the fields of quality testing, drug testing and food testing under the high-temperature and high-pressure conditions. The safety high-temperature and high-pressure reaction vessel sealing structure for the solvothermal synthesis has the beneficial effects of being capable of guaranteeing the safety of the high-pressure reaction vessel for the solvothermal synthesis, avoiding extreme accidents of explosion and the like as the pressure in the high-pressure reaction vessel exceeds the pressure-proof safety value in a metal material, and solving the safety and sealing problems.

Owner:ANHUI CHINTEK INSTUMENT & EQUIP CO TD

Pony roll cutter

InactiveCN101850558BFlat surfaceUniform tightnessMetal working apparatusBobbinPulp and paper industry

The invention relates to a pony roll cutter, which comprises a paper placing frame and a rewinding frame. A paper placing swinging arm, a paper placing motor, an unwinding top, and an unwinding lift cylinder are arranged on the paper placing frame; a middle trolley frame is arranged on the left of the paper placing frame; and an offset adjusting roller, a buffer roller and a non-return roller arearranged on the middle trolley frame. The rewinding frame is arranged on the left of the middle trolley frame; a pressure roller, an upper slitter, a lower slitter, a paper guiding roller, a paper guiding roller, and a paper unfolding roller are arranged on the rewinding frame respectively; a rewinding motor and a motor for driving the pressure roller are arranged on the rear part of the rewinding frame; a rotating arm shaft, a rewinding swinging arm, and a rewinding shaft are arranged on the upper part of the rewinding frame; and a paper discharging trolley is arranged on the left of the rewinding frame. The pony roll cutter has the advantages of realizing automatic discharge and bobbin splitting, labor conservation, improvement of working efficiency, flat rewound bobbin surface, uniformcompactness, and high-speed slitting and rewinding.

Owner:苏州市乾丰造纸机械制造有限公司

Binding machine for binding plastic bag with rubber band

InactiveCN109911290ACompact structureReduce work linksPaper article packagingBundling machine detailsTransfer mechanismPlastic bag

The invention discloses a binding machine for binding a plastic bag with a rubber band. The binding machine comprises a machine frame, a vibration disc device and a plastic bag feeding mechanism, andis characterized in that a material taking opening is further formed in the vibration disc device; a rubber band opening device is further arranged at a position corresponding to the material taking opening and comprises a first opening rod, a swing opening rod and a bottom side opening rod; the first opening rod and the swing opening rod are connected with opening air cylinders; and the machine frame is further provided with an inserting movement mechanism. The binding machine has the beneficial effects that compared with the prior art, a rubber band transferring mechanism and a rib removingmechanism can be omitted, so that the structure of the whole machine is simple and compact; the working procedure of the rubber band opening device is simplified; and the binding work is stable and reliable.

Owner:王秀来

Plastic bag bundling machine and bundling method thereof

InactiveCN109515802AUniform tightnessReduce the chance of work errorsBinding material applicationBundling machine detailsEngineeringManipulator

The invention discloses a plastic bag bundling machine and a bundling method of the plastic bag bundling machine. An annular rubber band is adopted for bundling a plastic bag which is folded into a strip shape. The plastic bag bundling machine mainly comprises a machine frame, a vibration disc device and a plastic bag conveying device, and is characterized in that a U-type notch is further formedin the vibration disc device, and a rubber band opening device is further arranged at the position corresponding to the U-type notch and mainly comprises a support, a first sub-expanding rod, a bottom-side expanding rod and two side expanding rods. Firstly, the annular rubber band is expanded by the first sub-expanding rod to form a rectangle, and the longer and narrowing annular rubber band can be easily moved out of the U-type notch, and then the annular rubber band is expanded by the bottom-side expanding rod and the two side expanding rods into a square or a rhombus correspondingly. By means of the plastic bag bundling machine and the bundling method, mechanical arm rubber band transferring devices in the prior art are omitted, so that working procedures are simplified, the work is stable, the structure is simple and compact, the tightness degree of the expanded rubber band is uniform, and the finished product rate is high.

Owner:王秀来

Full-automatic mechanical-type book bagging machine and bagging method thereof

InactiveCN101575015BReduce working noiseImprove working environmentWrapping material feeding apparatusWrapper folding/bending apparatusAdhesiveAutomaton

Owner:XIAN UNIV OF TECH

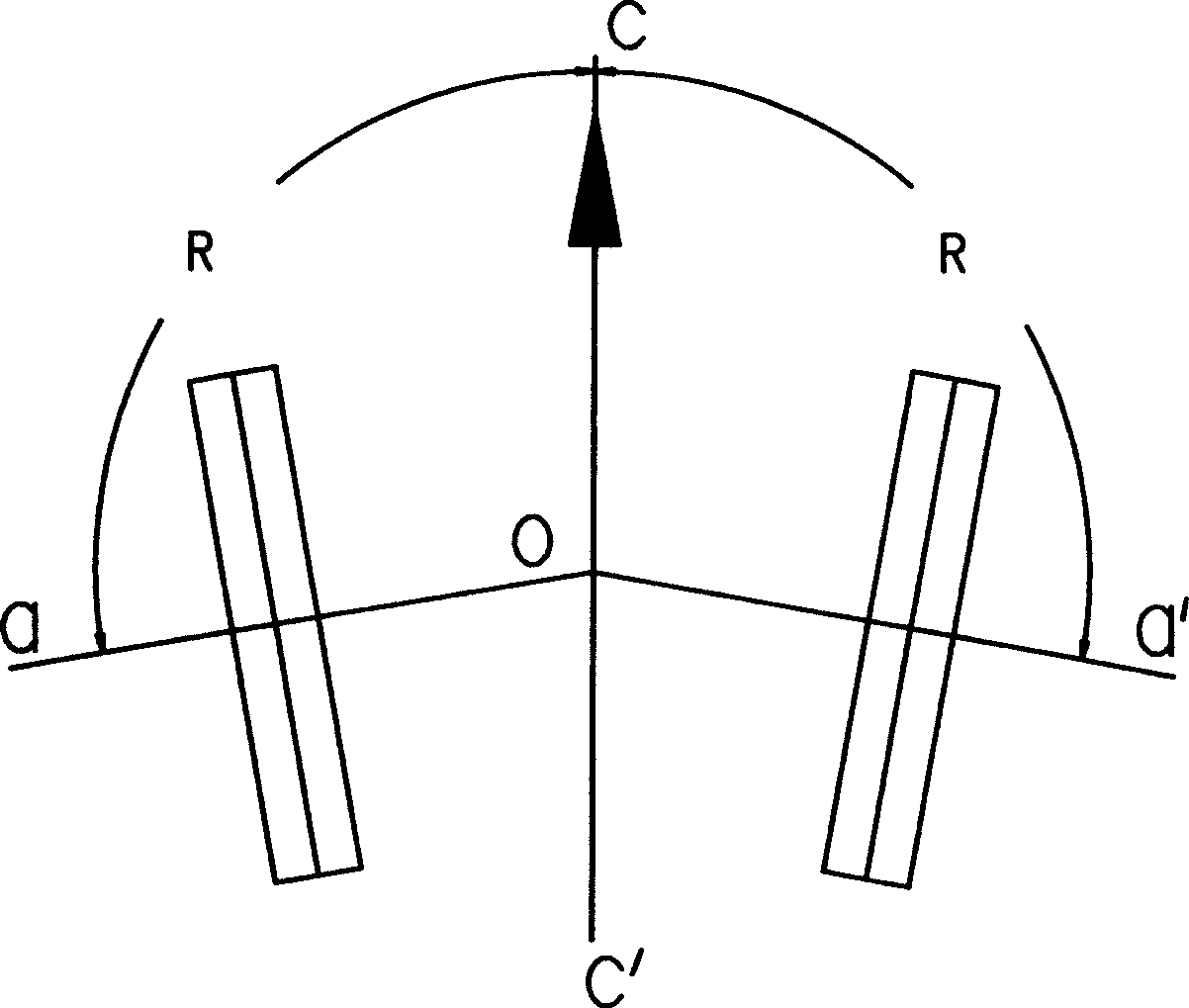

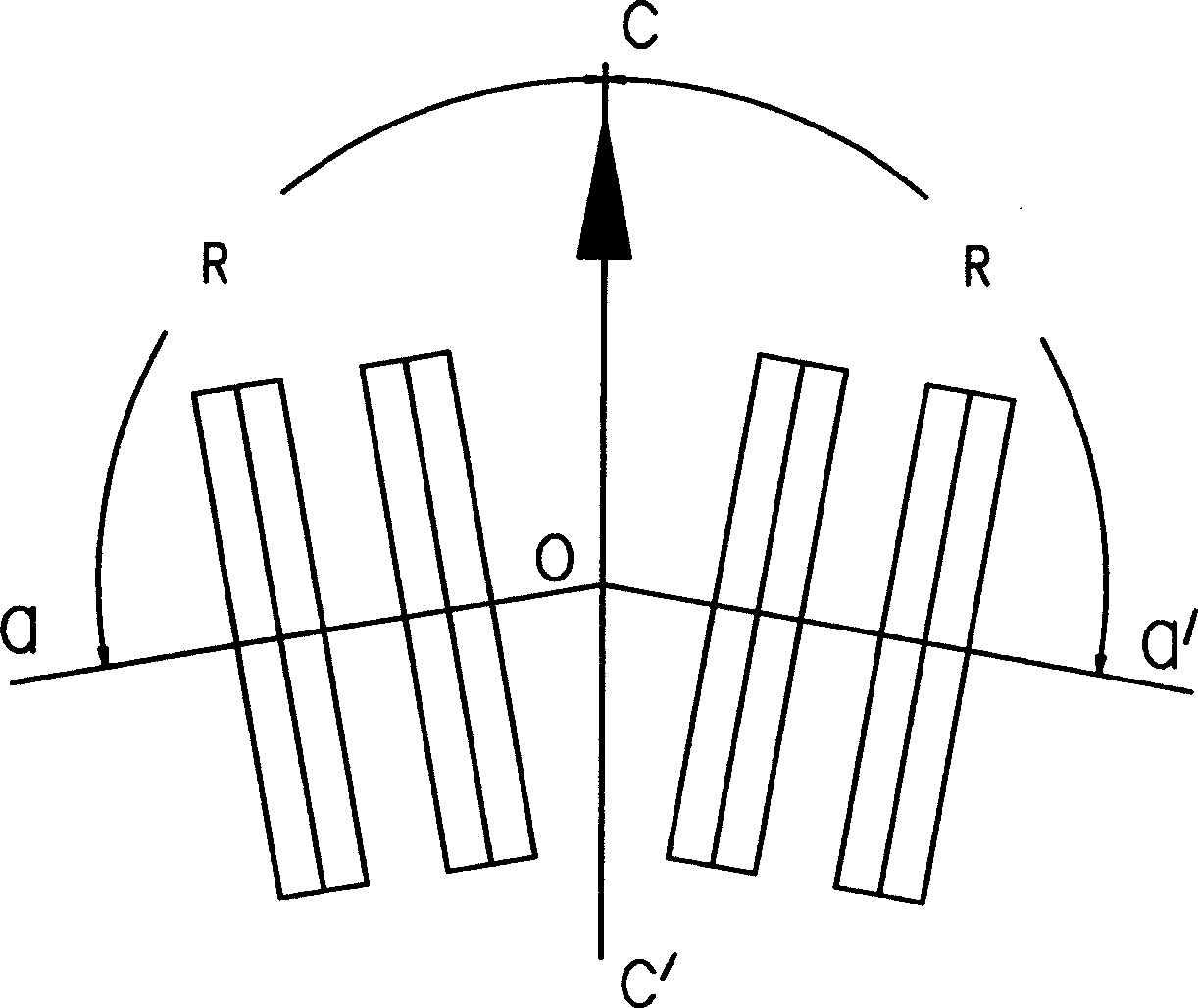

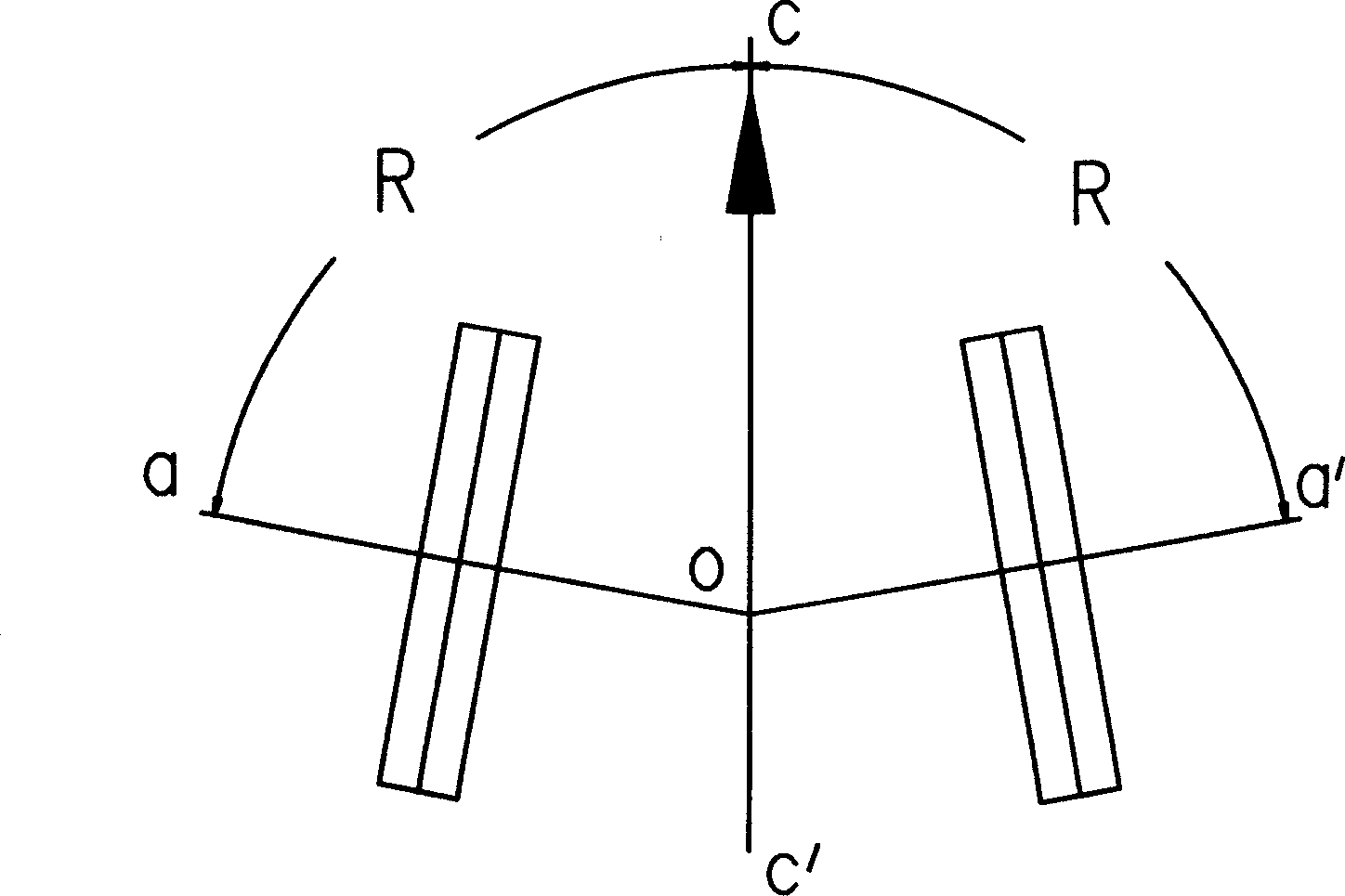

Non-stick earth pack roller

InactiveCN1729737ASolve sticking soil problemsUniform tightnessAgricultural rollersEngineeringAgricultural machinery

The invention relates to agricultural machine, which in detail to a roller for the compacting and consolidating of the soil after sowing. The roller concludes a roller holder and a number of cylinders, which equipped in the two sides 0f the longitudinal axis symmetrically, the angle between the axial cord and longitudinal axis along the direction of roller traveling is 81-89 or 91-99. The invention can effectively solve the problem of adhesion between roller and soil, and the tightness of rolled soil is uniform and the surface of soil is smooth.

Owner:JILIN UNIV

Oil well pump plunger assembler and assembling method thereof

ActiveCN104653450AExtended service lifeEven by forcePositive displacement pump componentsLiquid fuel engine componentsPumpjackOil well

The invention discloses an oil well pump plunger assembler which comprises a platform and a low-speed electric motor arranged on one side of the platform. Platform supporting legs are arranged under the platform, a hydraulic clamping head and a hydraulic clamp are arranged on the platform, the low-speed electric motor is connected with the hydraulic clamping head, a protection cover is arranged outside the hydraulic clamping head, and a straightening wheel installing plate and a straightening wheel are arranged in the middle of a connection line between the hydraulic clamping head and the hydraulic clamp. Thus, the problems of time waste, labor waste and unequal installation torque caused by installing plungers through manual tools in the prior art are solved. The invention further discloses an oil well pump plunger assembling method. An upper travelling valve and a lower travelling valve are firstly screwed to a plunger and are arranged on the hydraulic clamping head and the hydraulic clamp, the hydraulic clamping head and the hydraulic clamp tightly clamp the upper travelling valve and the lower travelling valve, the low-speed electric motor drives the hydraulic clamping head to rotate to fasten threads among the upper travelling valve, the plunger and the lower travelling valve, the low-speed electric motor is shut down, and the hydraulic clamping head and the hydraulic clamp are released.

Owner:陕西延长石油机械装备制造有限公司

A fully automatic pneumatic book packing machine

ActiveCN103662177BSave energyImprove efficiencyWrapping material feeding apparatusWrapper folding/bending apparatusControl systemConveyor belt

The invention provides a full-automatic pneumatic type book and periodical packing machine which comprises a main machine and an auxiliary machine which are split. A cylinder forming technology and an adhesion technology are completed by the main machine. An upper corner, lower corner, front side corner and rear side corner packing technology and an adhesive tape adhesion technology are completed by the auxiliary machine. According to the sequence of the technological process, the main machine comprises a paper feeding device, a paper delivery device, a front conveyor belt device, a transverse book pushing device, a first book pressing device, a longitudinal book pushing device, a paper clamping device, a gluing device, a second book pressing device, a paper cutting device, a paper guiding device, a glue supply device and the like. According to the sequence of the technological process, the auxiliary machine comprises a rear conveyor belt device, a rear folding device, an upper folding device, a lower folding device, a forward package pushing and folding device, an adhesive tape sealing device, a package outlet station and a control system. The cylinder forming process and the processes before that are completed by the main machine. The rear side corner packaging process and the processes after that are completed by the auxiliary machine. If the two sides of a book do not need to be packed, the cylinder forming process is conducted by the main machine working independently, so that energy is saved, and efficiency is improved.

Owner:BEIJING RUNDA MACHINERY MFG

Roll paper conveying and cutting device and method

ActiveCN110000825AEasy to adjustHigh technological contentMetal working apparatusWebs handlingRolling paperEngineering

The invention discloses a roll paper conveying and cutting device. The roll paper conveying and cutting device comprises a guide shaft vertically fixed below a rack and a workbench arranged perpendicular to the guide shaft, wherein the workbench is located at the lower section of the guide shaft; the lower end of the guide shaft is fixedly provided with a cutting device; the guide shaft is provided with an opening-and-closing clamping conveyor capable of sliding up and down along the guide shaft; the opening-and-closing clamping conveyor is controlled by a synchronous pulley block to slide upand down; an upper opening device is further arranged on the workbench; a lower opening device is arranged above the cutting device; and the upper opening device and the lower opening device can control opening and closing of the opening-and-closing clamping conveyor. The invention further discloses a paper conveying and cutting method for the roll paper conveying and cutting device. Therefore, heavy manual labor is replaced with machinery, an upper feeding mode is replaced with a lower feeding mode, operation and adjustment are more convenient, and the technological content is higher and morereasonable.

Owner:XIAN UNIV OF TECH

Novel braiding machine spindle

The invention relates to a novel braiding machine spindle. The braiding machine spindle comprises a spindle base and is characterized in that a spool shaft and a spindle rest which are parallel to each other are arranged at the upper end of the spindle base, a movable sleeve sleeves the spindle rest, a transverse plate is arranged at the upper end of the spindle rest, springs are arranged betweenthe transverse plate and the movable sleeve and between the movable sleeve and the spindle base, the lateral wall of the movable sleeve is provided with a pressing ring, the pressing ring sleeves thespool shaft, the lower end of the spindle base is provided with a rotary shaft, the lateral wall of the spindle base is provided with an oil filling hole, the lateral wall of the rotary shaft is provided with an oil outlet, a channel communicating the oil filling hole and the oil outlet is arranged in the spindle base and the rotary shaft, a driving lever is arranged on the lateral side of the spindle base, the front end of the driving lever is provided with a spring tube, the front end of the spring tube is provided with a horizontal yarn guide hole, the middle of the driving lever is connected with the reset plate of the spindle base through a reset spring, and the transverse plate is provided with a vertical yarn outlet. By the arrangement, the novel braiding machine spindle is simple in structure, convenient to operate and capable of effectively preventing spool vertical movement to guarantee the uniform tightness of yarn output.

Owner:扬州市新天河绳业有限公司

Winding needle

PendingCN111613838AIncrease girthImprove deformationFinal product manufactureSecondary cellsEngineeringPole piece

A winding needle comprises an outer cover and two oppositely-arranged winding needle outer sleeve main bodies, a base material clamping space is formed between the two winding needle outer sleeve mainbodies, and each winding needle outer sleeve main body comprises a needle base groove. An outer needle seat and a clamping needle are arranged in the needle seat groove, the groove bottom of the needle seat groove extends outwards to form a forming part with a gradually reduced sectional area, and a telescopic winding needle outer sleeve auxiliary body is installed on the forming part through anadjusting assembly. Two or more plug pins are installed on the winding needle outer sleeve auxiliary body, the lower ends of the plug pins extend into plug pin holes of the forming part, and plug pinconnecting rod bodies are installed in the plug pin connecting rod holes. First inclined faces are arranged at the bottoms of the plug pins, second inclined faces corresponding to the first inclined faces are arranged on the plug pin connecting rod bodies, and a magnetic attraction piece is arranged between the winding needle outer sleeve auxiliary body and the forming part. In the winding processof the battery cell, the internal interlayer space of a winding core is increased by dynamically adjusting the overall appearance perimeter of the winding needle, so that the problem of S-shaped deformation of the battery cell caused by the tension shrinkage and pole piece expansion of a pole piece and an isolating membrane in the winding process of the battery cell can be effectively solved.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

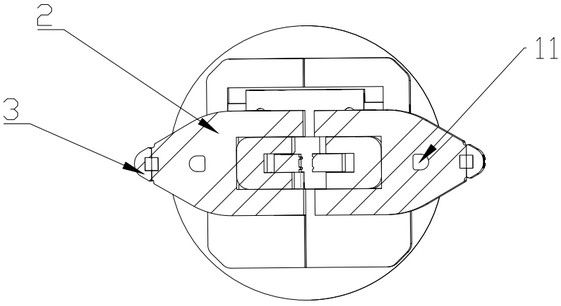

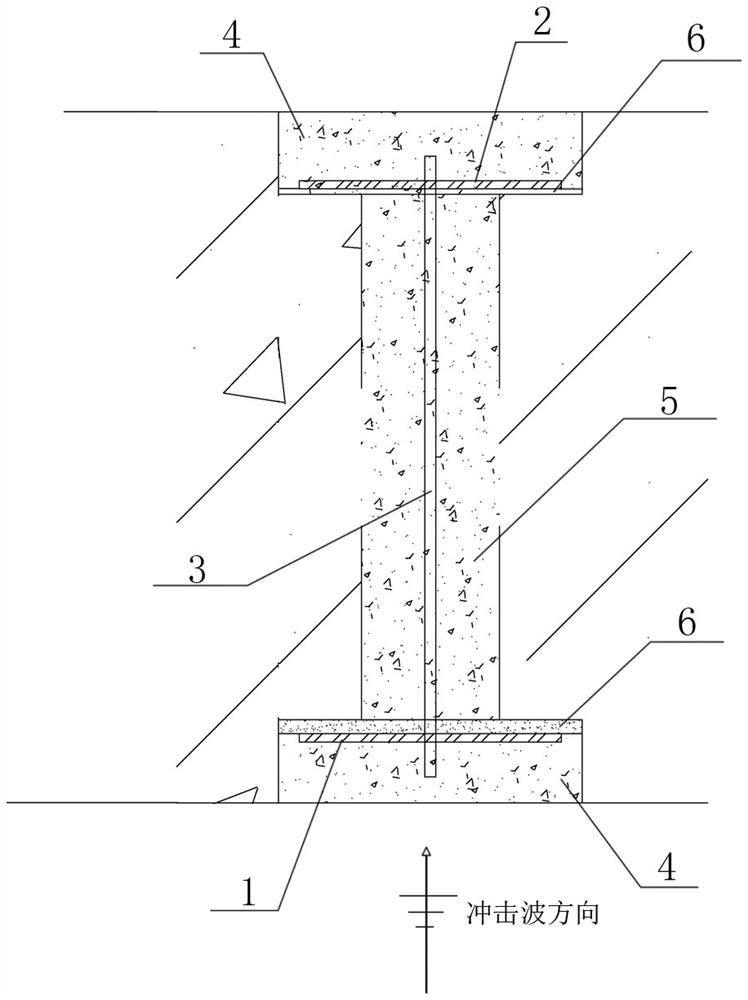

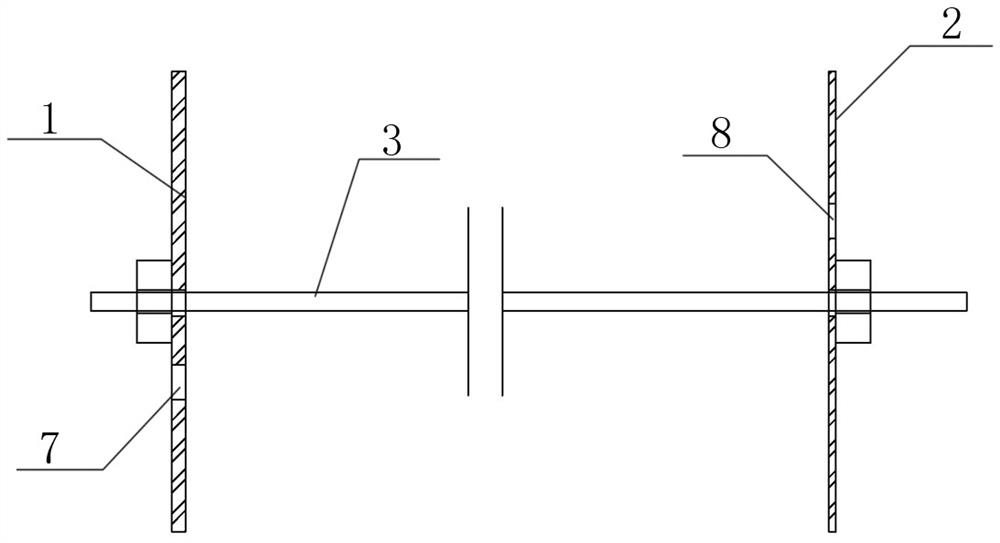

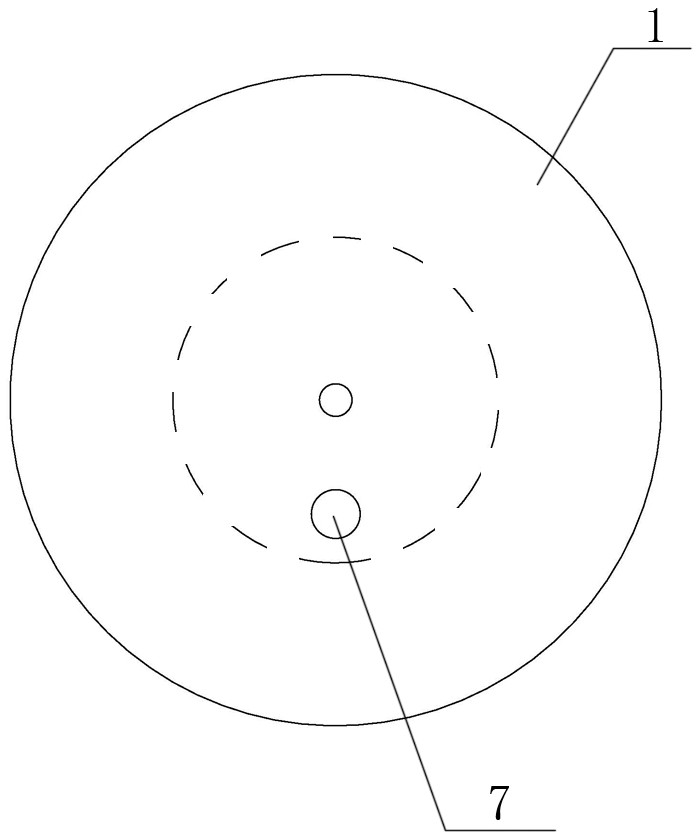

Plugging structure and plugging method for small-section deep hole in civil air defense overhead wall

ActiveCN113622702AEasy tight connectionIncrease frictionBuilding repairsArchitectural engineeringScrew thread

The invention relates to a plugging structure and plugging method for a small-section deep hole in a civil air defense overhead wall, and belongs to the field of civil air defense engineering. A resistance plate and a non-resistance plate are arranged in reaming areas at the two ends of a preformed hole in a manner of being attached to a wall body, and the resistance plate and the non-resistance plate are connected in a pulling manner through a harness cord screw rod. After the whole plugging process is finished, steel plates on the two sides of the hole and bolts are reserved in the structure and cannot be taken out, the thread concave-convex characteristic of the surface of a harness cord bolt is effectively combined with a grouting material to generate larger friction force, the holding and wrapping effect is improved, and the structure strength and plugging and sealing reliability are guaranteed. The shaving and chiseling workload on the original structure concrete in the structure treatment stage is small, and the damage influence on the original concrete structure is small. Grouting plugging operation is simple and convenient, and plugging work of corresponding requirements can be completed at a time. After the plugging measures are completed, the surface treatment traces of the structure are not obvious, and later decoration work is facilitated.

Owner:BEIJING NO 3 CONSTR ENG +1

nb based on layer-by-layer stacking 3 Al superconducting precursor wire preparation method

ActiveCN108878054BSmall size deviationUniform tightnessSuperconductors/hyperconductorsReduction of cables/conductors sizeWire rodAlloy

A Nb based on layer-by-layer stacking 3 The preparation method of Al superconducting precursor wire mainly includes: A. Preparation of Nb-Al composite sheath: Nb foil and Al foil are alternately stacked in the rectangular groove of the tubular Nb box from bottom to top, and the upper cover is covered , in the Cu tube, welded and sealed; B. Preparation of Nb-Al single mandrel: the Nb-Al composite sheath is hydrostatically extruded, repeatedly drawn, and then corroded to remove the copper to obtain the Nb-Al single mandrel. Mandrel; C, Nb 3 Preparation of Al superconducting precursor wires: multiple Nb‑Al single mandrels are packed closely into Cu or Cu alloy sheaths, and multi-cores are obtained by electron beam sealing welding, hydrostatic extrusion, and repeated drawing. Wire rod; then corrode to remove copper. The method is simple to operate, the assembly filling rate of the foil material is high, and the compactness of each layer of foil material is uniform. The final superconducting wire prepared by it has good performance, strong consistency and high qualified rate. It is especially suitable for the preparation of long superconducting wires.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com