Winding device and winding method

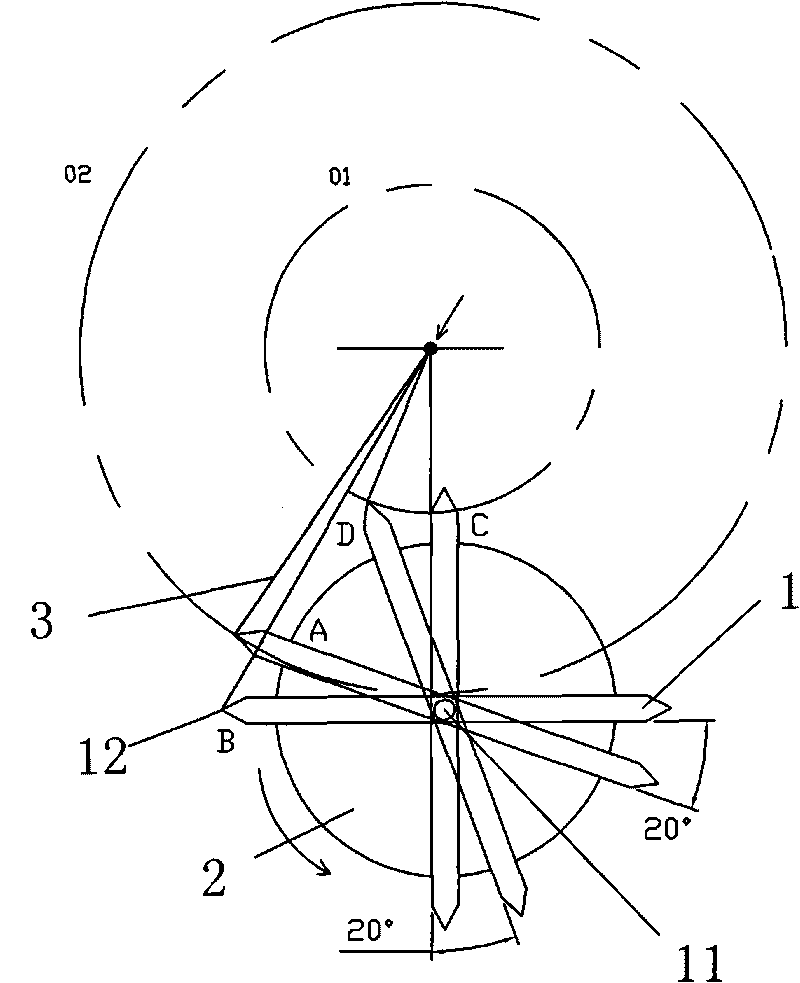

A winding device and winding head technology, applied in transportation and packaging, climate sustainability, non-aqueous electrolyte batteries, etc., can solve uneven tightness, deformation of battery cells, and difficulty in ensuring the regular shape of lithium-ion batteries, etc. problems, to achieve the effect of balancing the degree of tightness, preventing deformation, and maintaining stable winding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

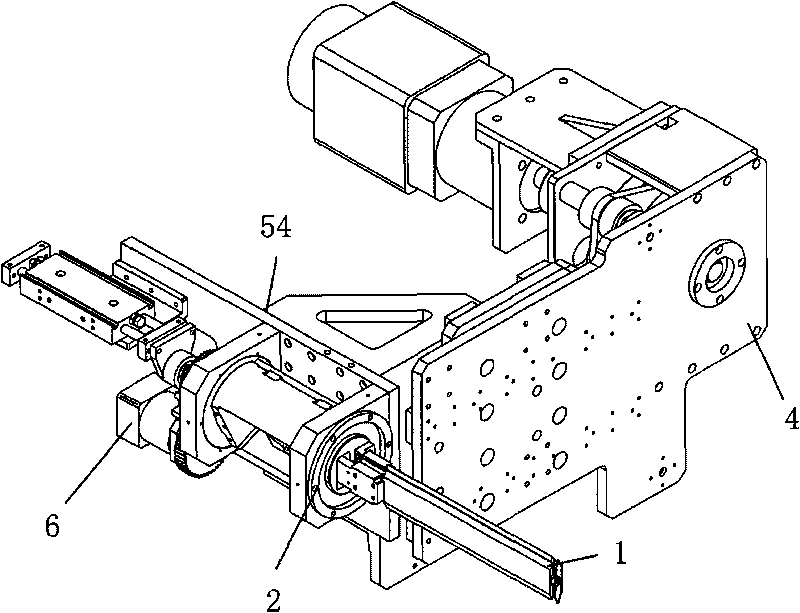

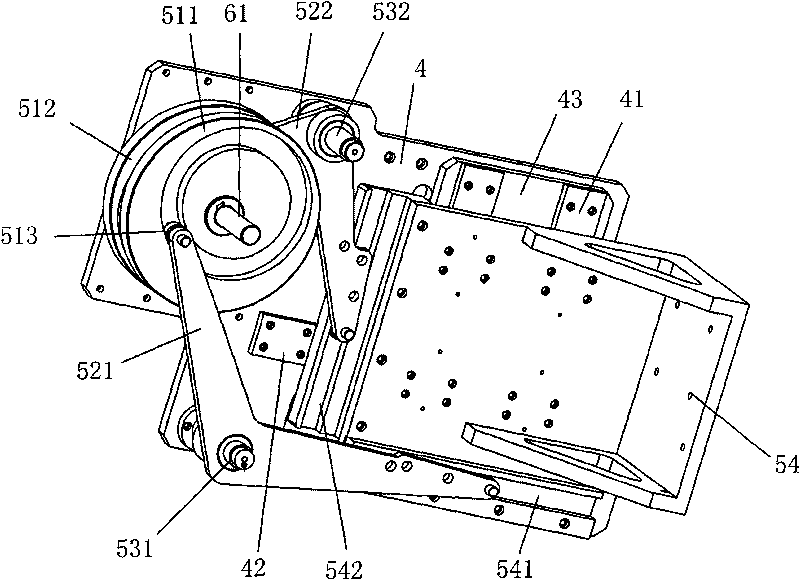

[0044] Such as image 3 and Figure 5 As shown, similarly, the base 4 can also form a lateral movement pair with the winding head mounting part 54. For example, the base 4 includes a second guide rail 42 arranged laterally, and the winding head mounting part 54 can also be left and right along the second guide rail 42. move. In order to smoothly realize the winding head mounting part 54 to slide longitudinally and laterally along the first guide rail 41 and the second guide rail 42 respectively, a cross displacement plate 43 can also be added on the base 4, for example, the first guide rail 41 can be arranged on on the cross displacement plate 43 , and the cross displacement plate 43 and the second guide rail 42 form a lateral movement pair.

[0045] The driving mechanism 51 in this embodiment further includes a second driving mechanism 512 , the swing rod further includes a second swing rod 522 , and the bearing seat 53 further includes a second bearing seat 532 . The midd...

no. 3 Embodiment approach

[0050] Such as Figure 8 In the embodiment shown, the compensation control member that controls the strip material 3 to carry out linear velocity compensation motion includes a strip control lever 55 for controlling the strip material 3 to perform transverse linear velocity compensation movement, and one end of the strip control lever 55 is connected to the swing rod. 52 is hinged, and the other end forms a lateral movement pair with the base plate 4. Specifically, the base plate 4 also includes a third guide rail 43 arranged laterally, and the strip material control lever 55 also includes a third slider, which can slide laterally along the third guide rail 43 and simultaneously control the left and right swing of the strip material 3 to realize lateral movement. Line speed compensation.

[0051] For example, when the driving mechanism 51 rotated along the direction of the arc arrow, the end of the fork 52 connected to the tape control rod 55 moved to the right, and the tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com