Patents

Literature

107results about "Nanobatteries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

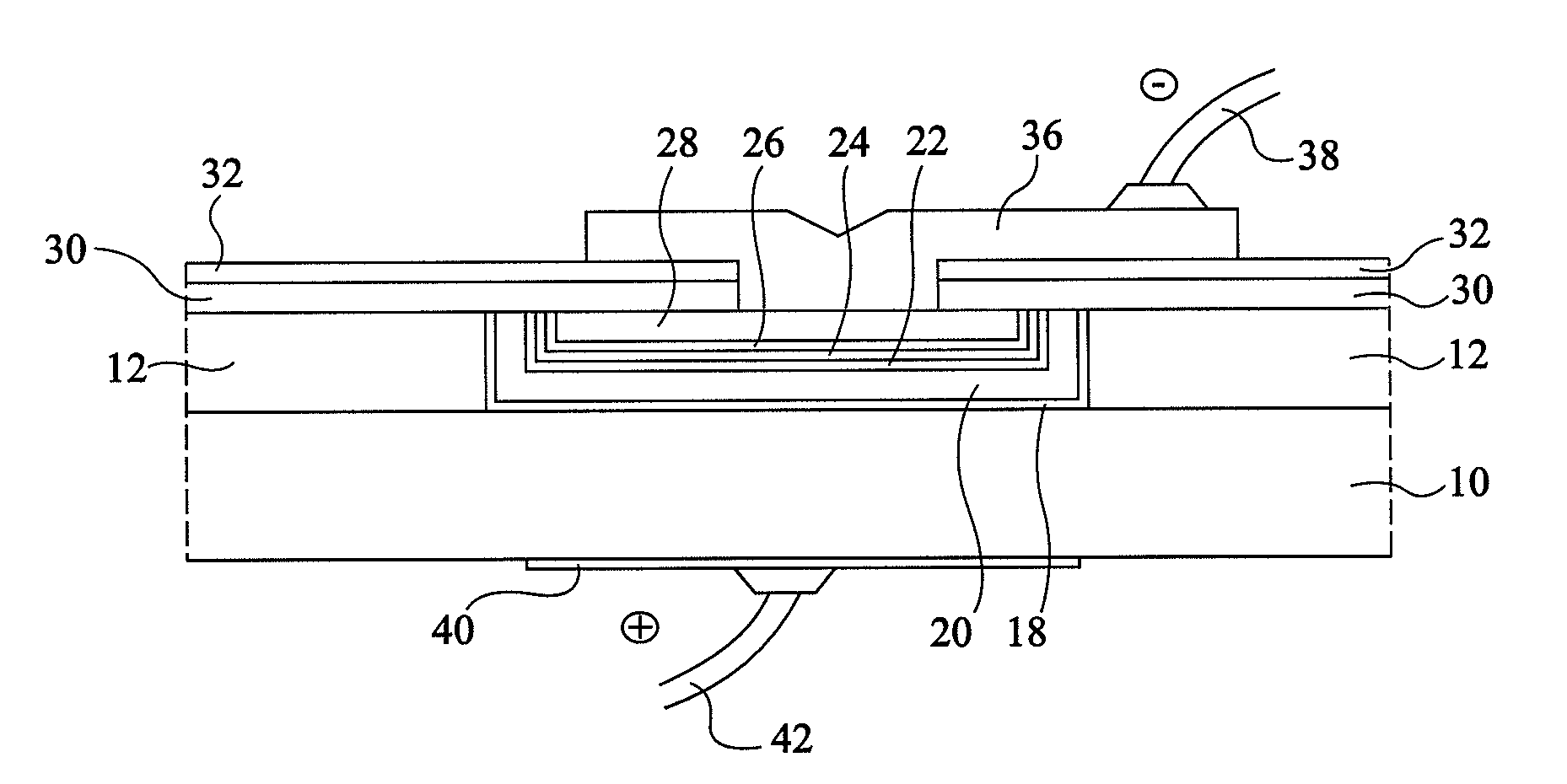

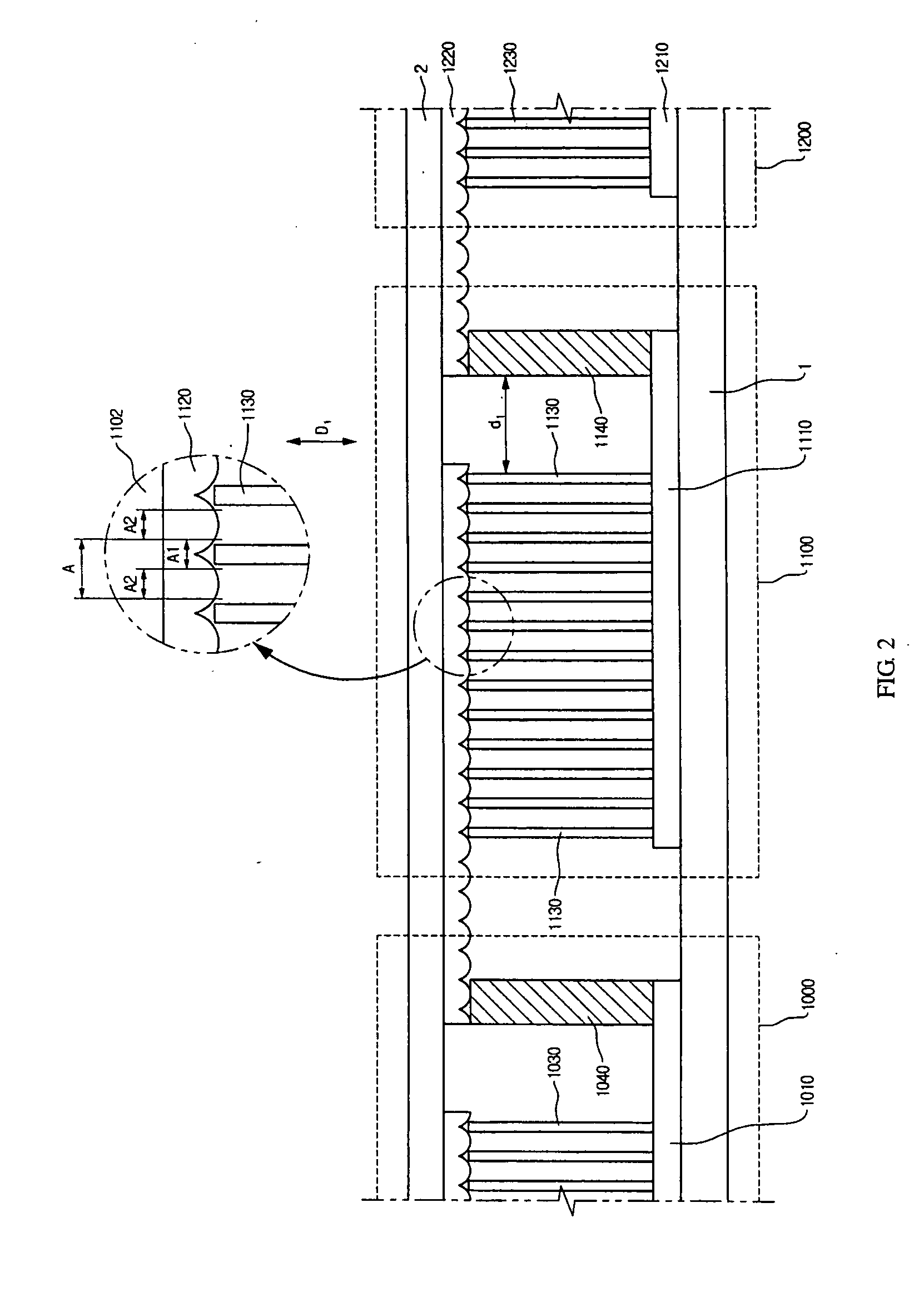

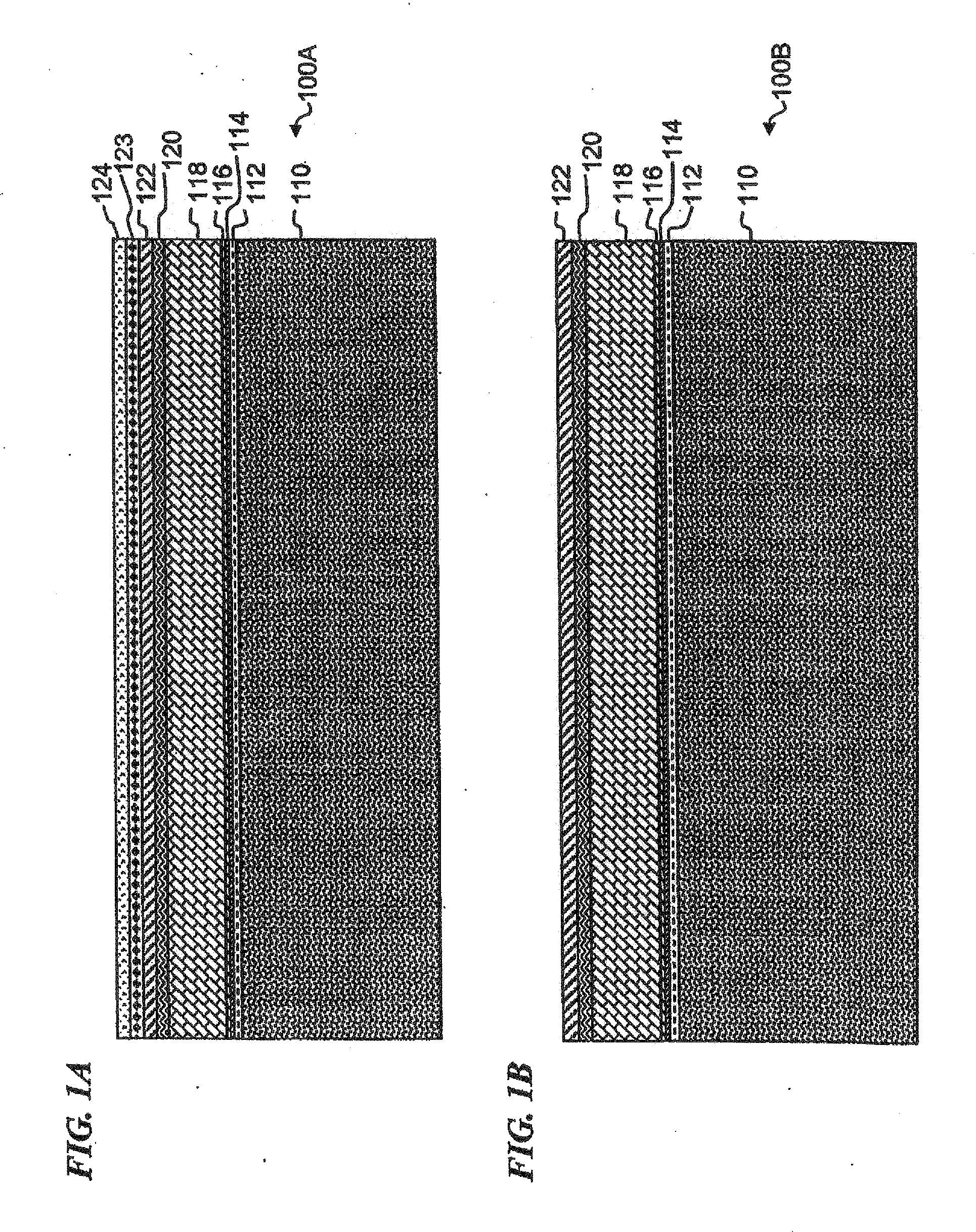

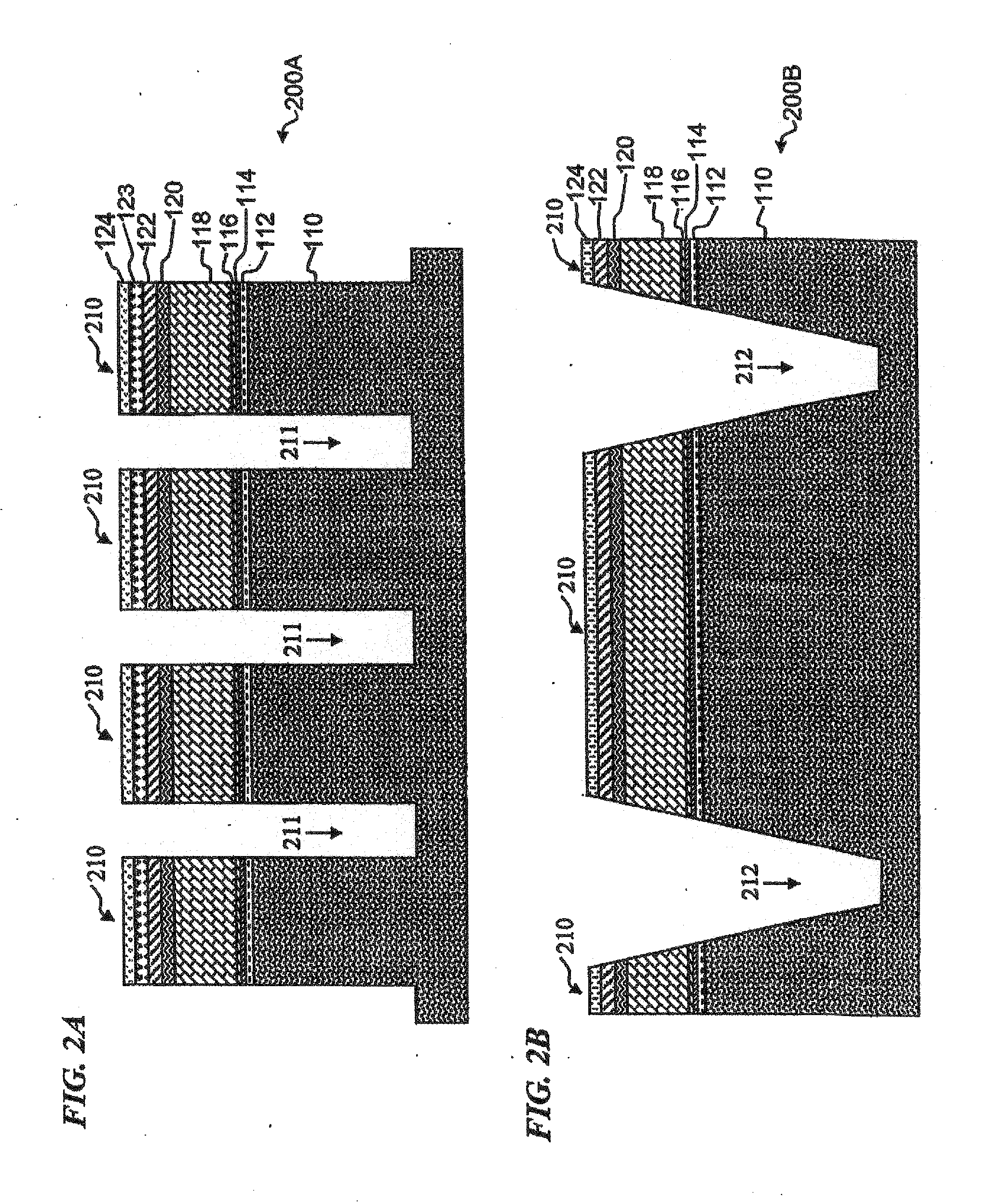

Micro electrochemical energy storage cells

InactiveUS6197450B1Improve performanceIncrease capacityPrimary cell to battery groupingFinal product manufactureThin layerOptoelectronics

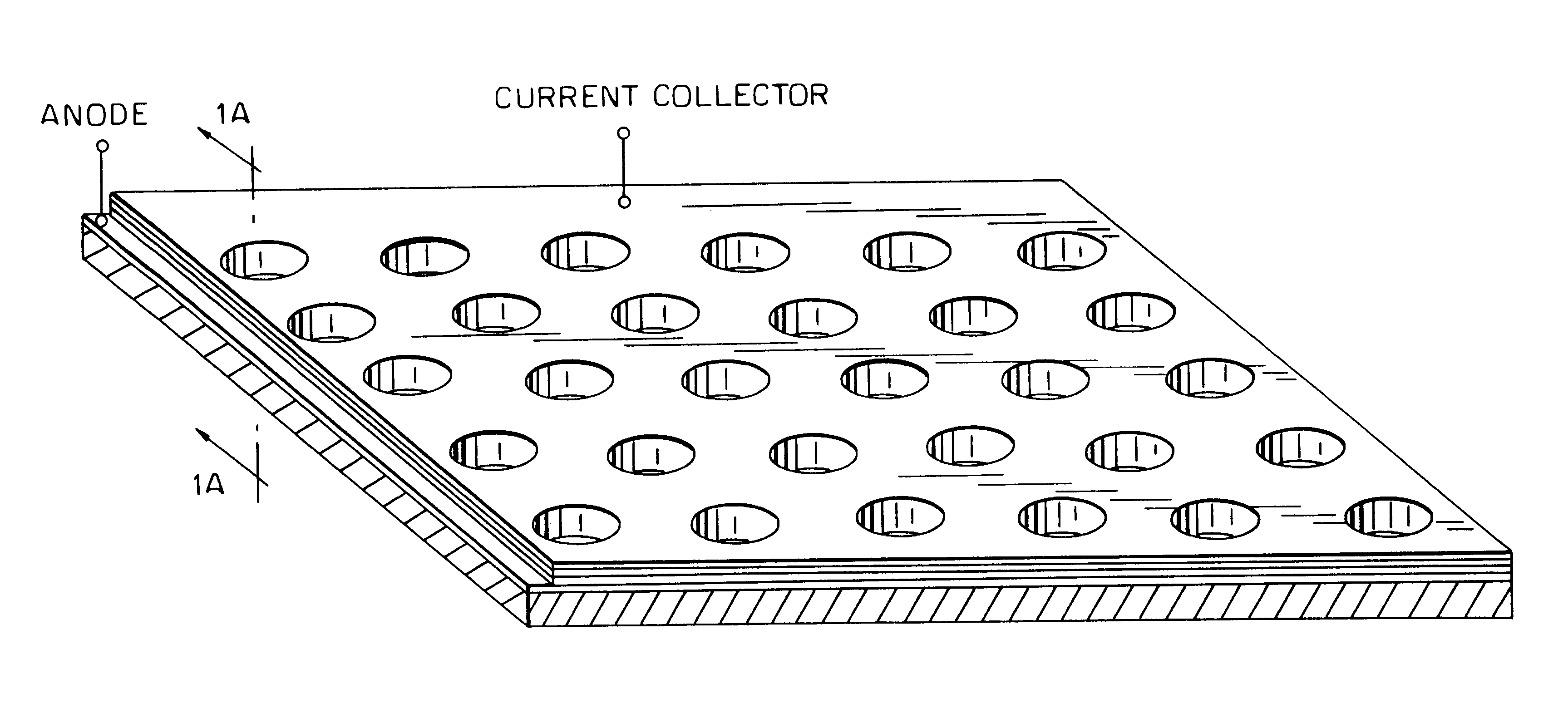

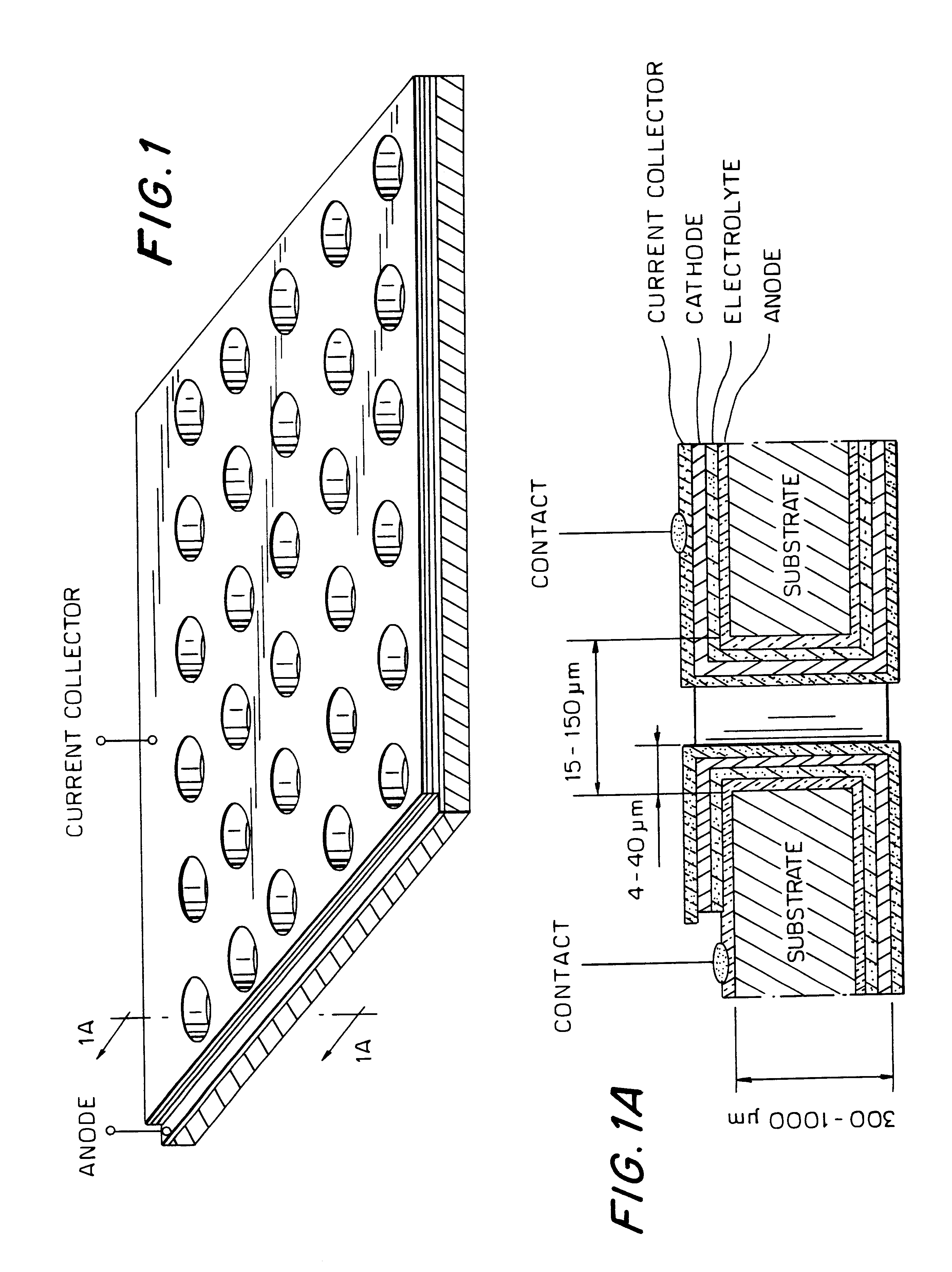

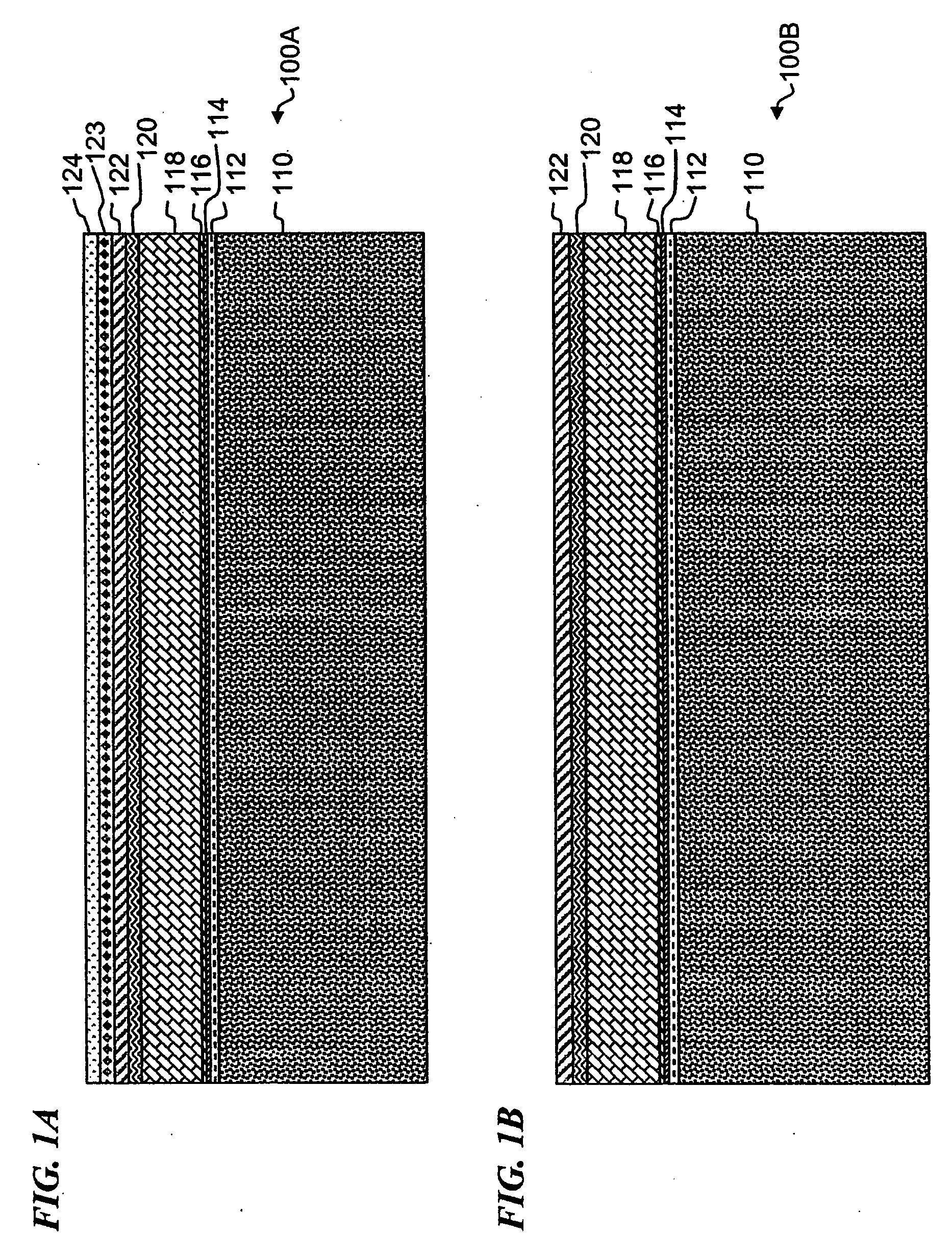

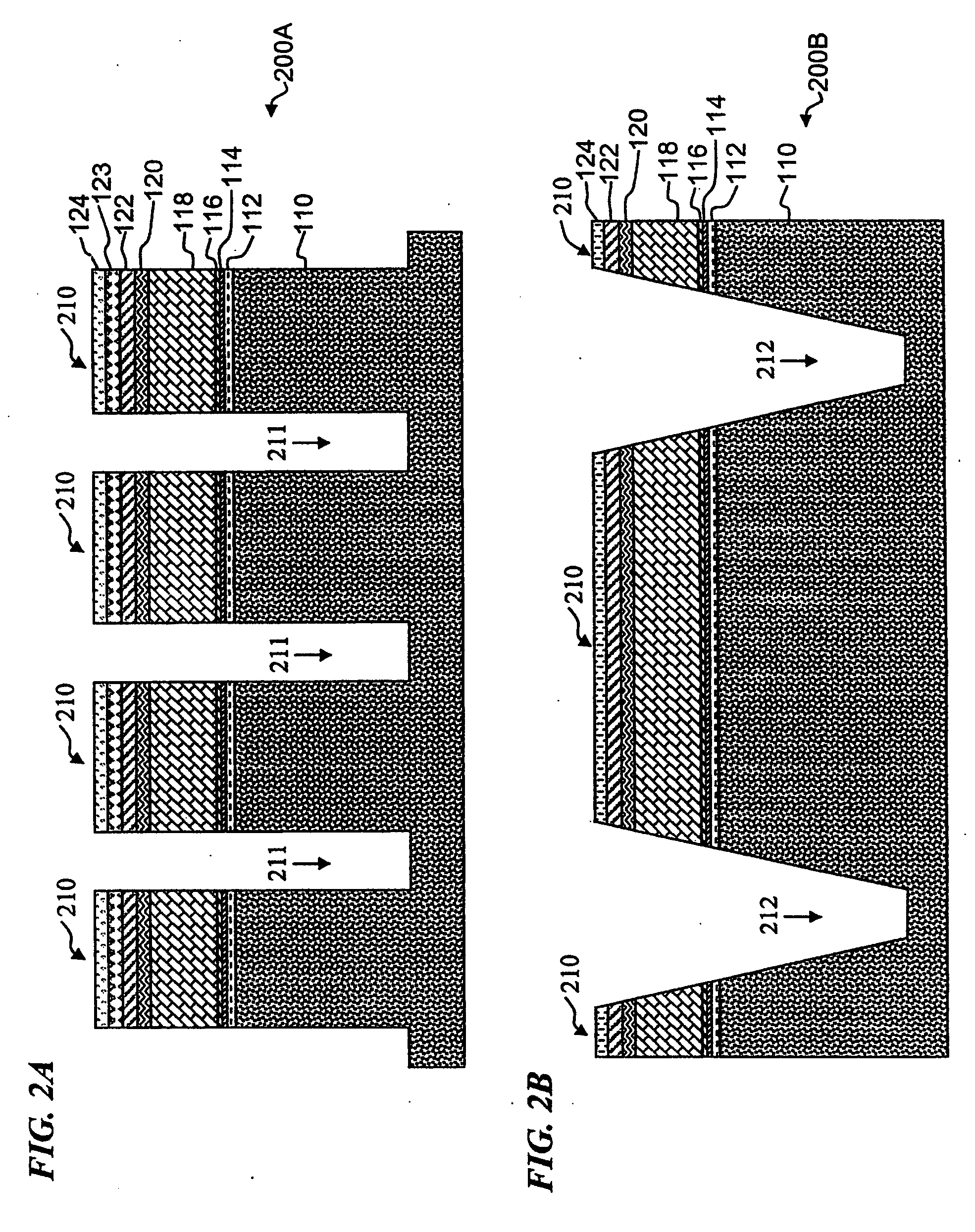

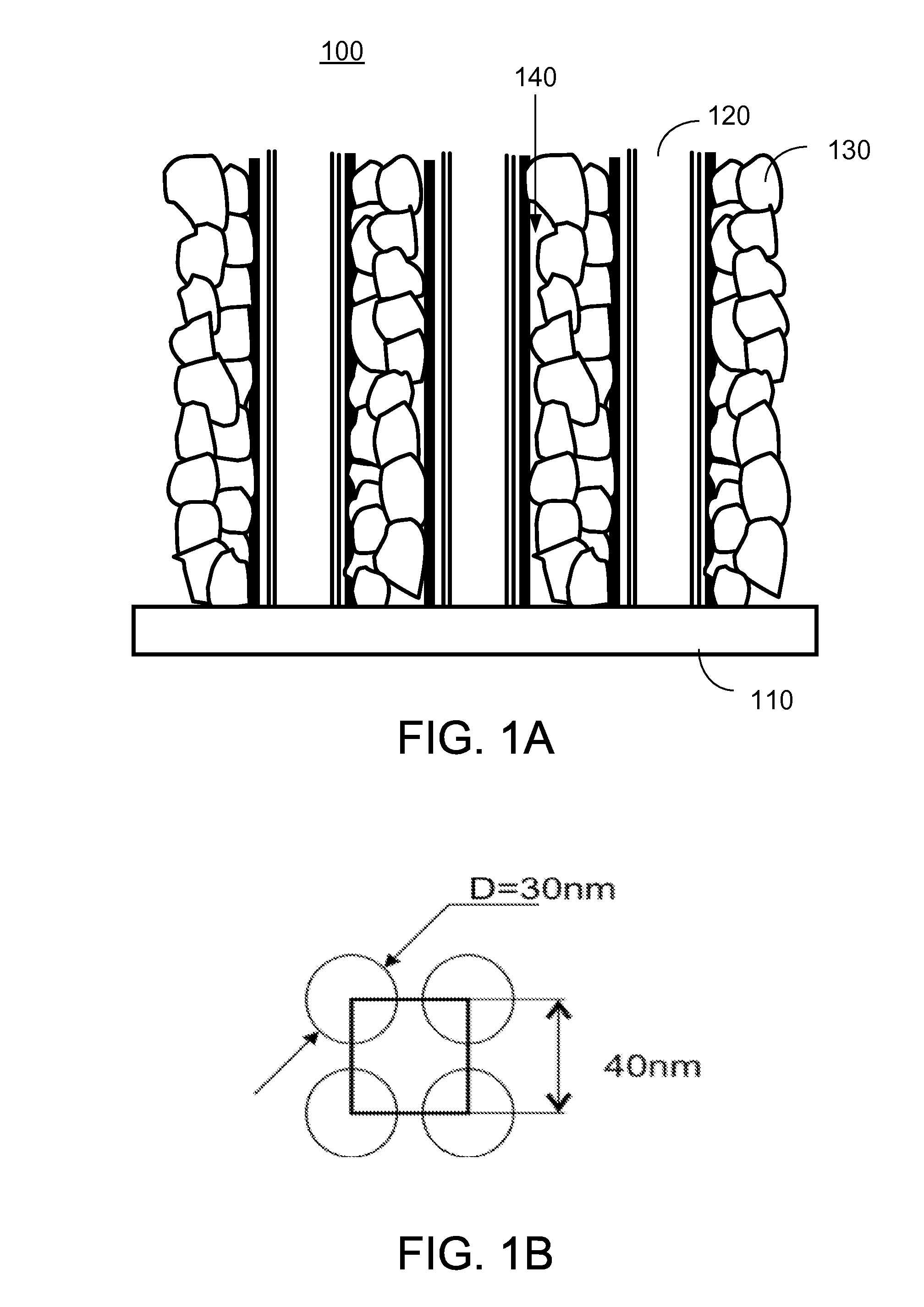

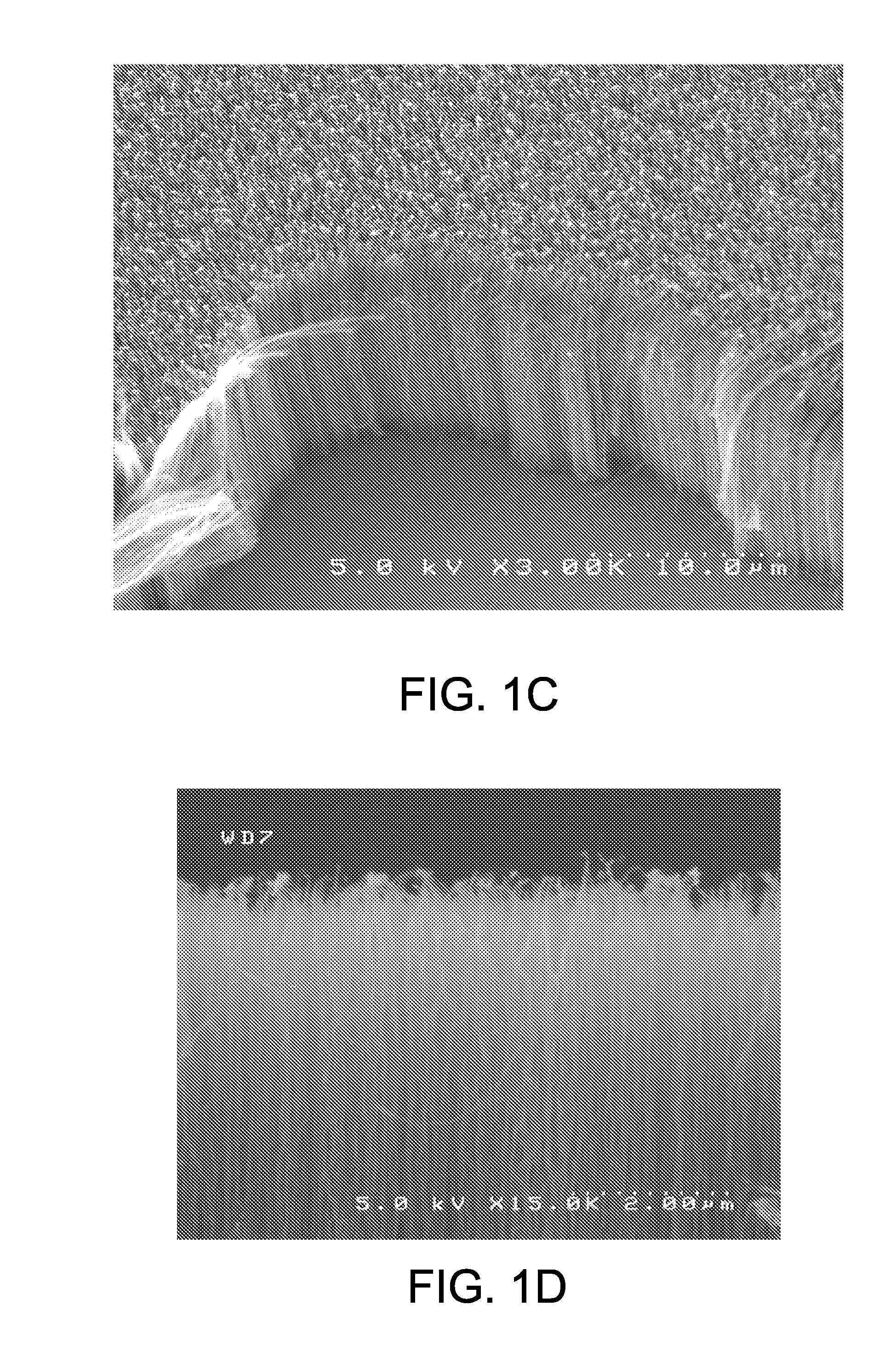

Thin-film micro-electrochemical energy storage cells (MEESC) such as microbatteries and double-layer capacitors (DLC) are provided. The MEESC comprises two thin layer electrodes, an intermediate thin layer of a solid electrolyte and optionally, a fourth thin current collector layer; said layers being deposited in sequence on a surface of a substrate. The MEESC is characterized in that the substrate is provided with a plurality of through cavities of arbitrary shape, with high aspect ratio. By using the substrate volume, an increase in the total electrode area per volume is accomplished.

Owner:TEL AVIV UNIV FUTURE TECH DEVMENT

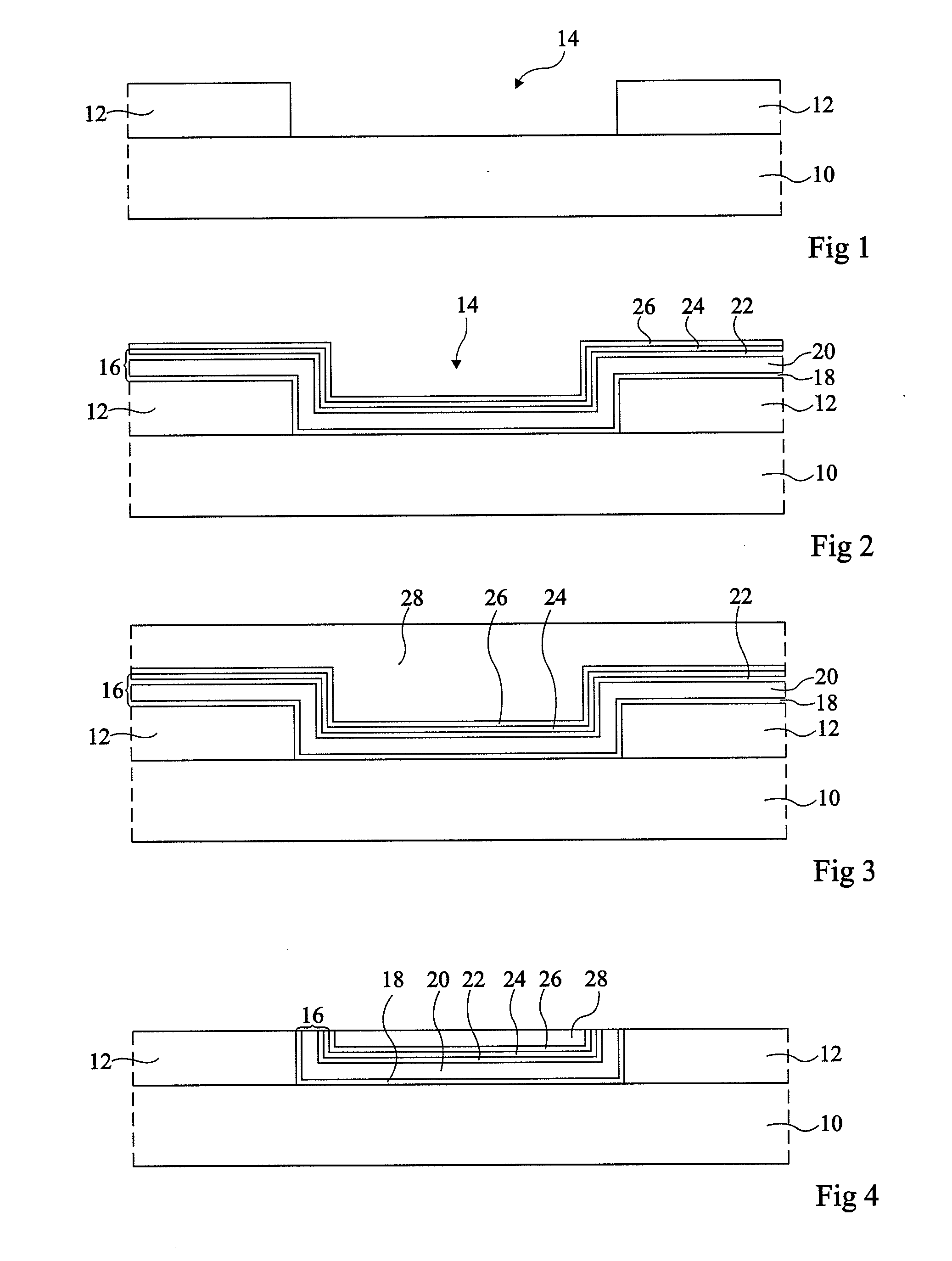

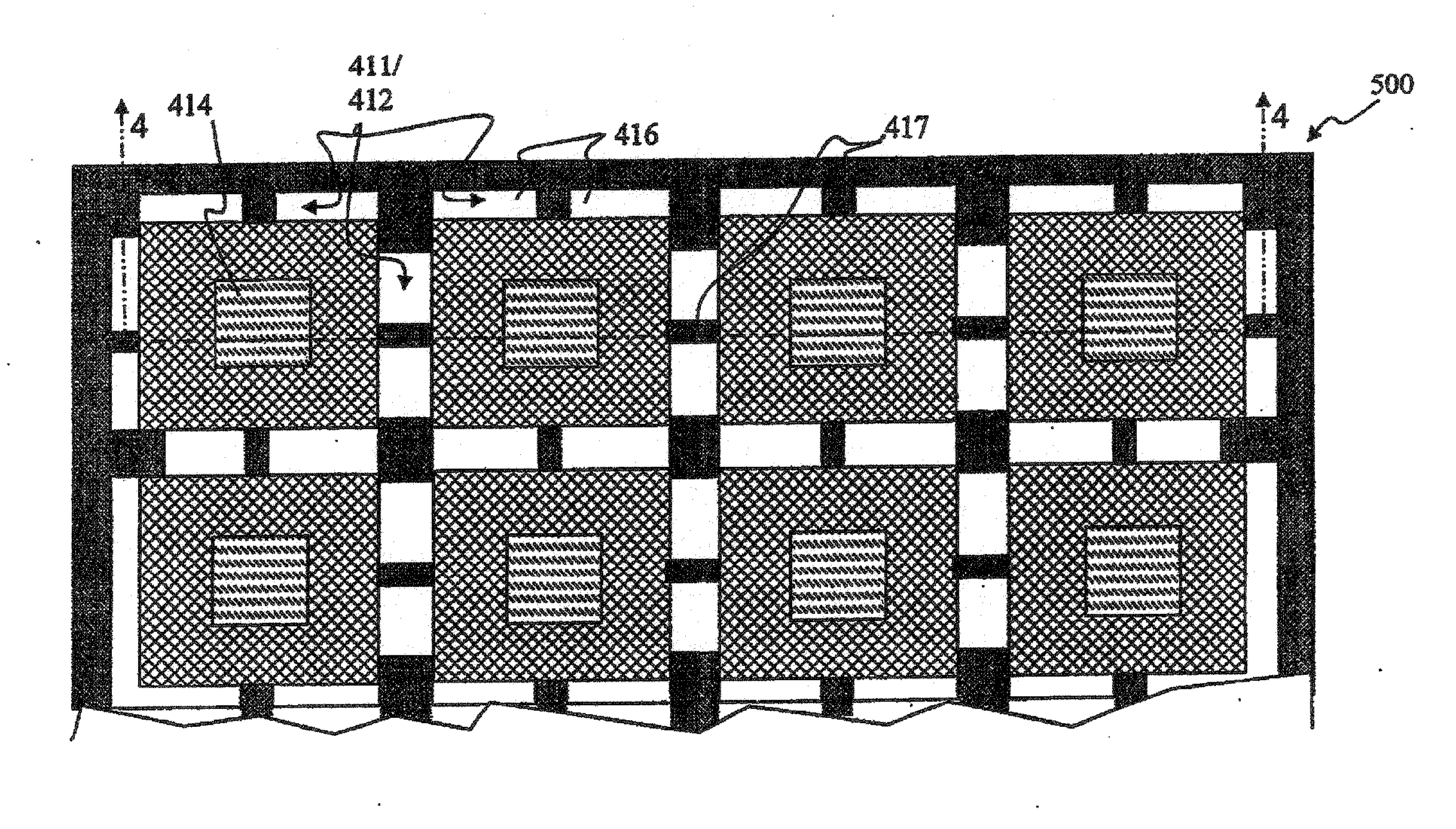

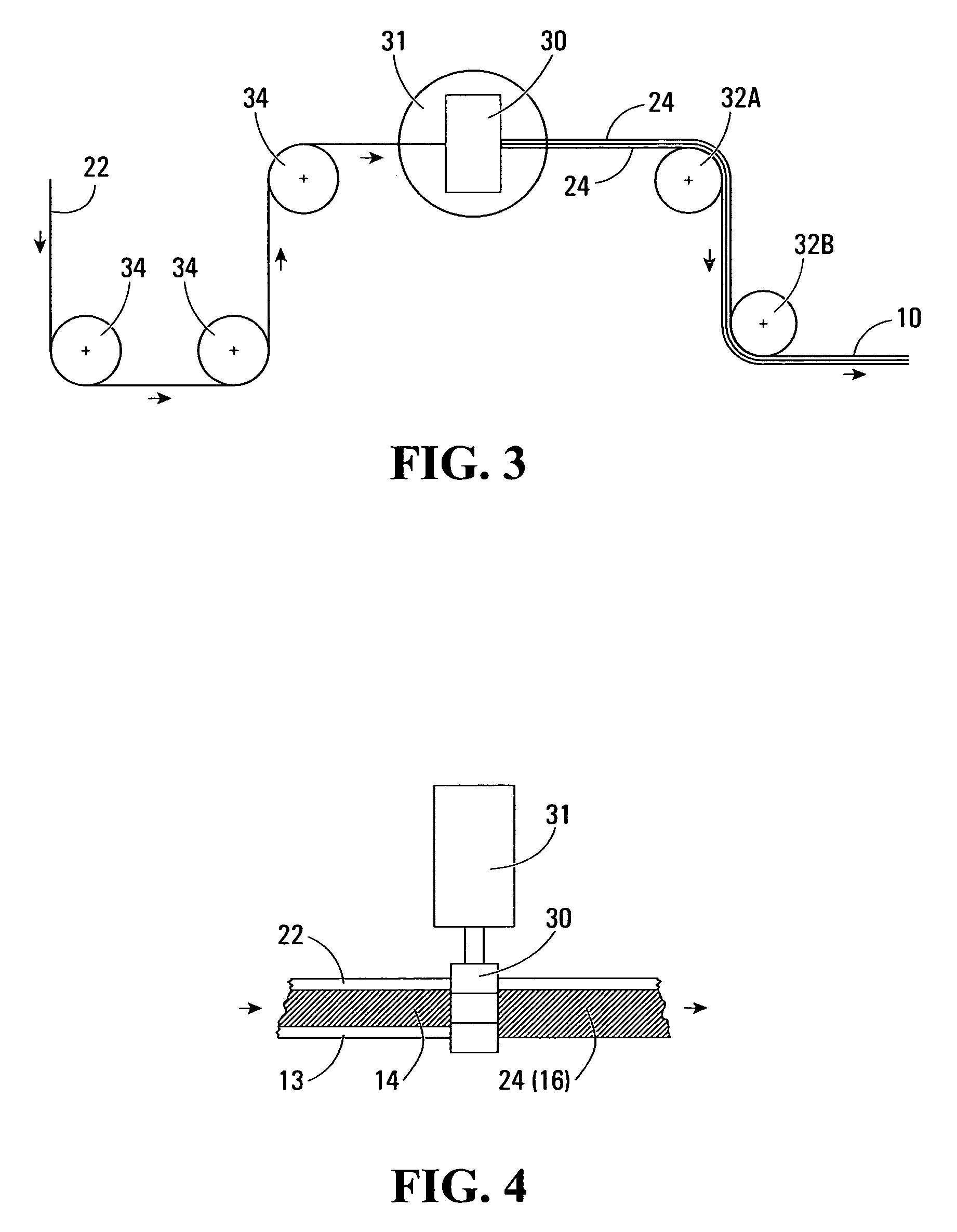

Method and apparatus for solid-state microbattery photolithographic manufacture, singulation and passivation

InactiveUS20080032236A1Efficient and economical manufactureReduced number of stepSolid electrolytesDecorative surface effectsChemical treatmentPhotoresist

A method for producing a thin film lithium battery is provided, comprising applying a cathode current collector, a cathode material, an anode current collector, and an electrolyte layer separating the cathode material from the anode current collector to a substrate, wherein at least one of the layers contains lithiated compounds that is patterned at least in part by a photolithography operation comprising removal of a photoresist material from the layer containing lithiated compounds by a process including a wet chemical treatment. Additionally, a method and apparatus for making lithium batteries by providing a first sheet that includes a substrate having a cathode material, an anode material, and a LiPON barrier / electrolyte layer separating the cathode material from the anode material; and removing a subset of first material to separate a plurality of cells from the first sheet. In some embodiments, the method further includes depositing second material on the sheet to cover the plurality of cells; and removing a subset of second material to separate a plurality of cells from the first sheet.

Owner:CYMBET CORP

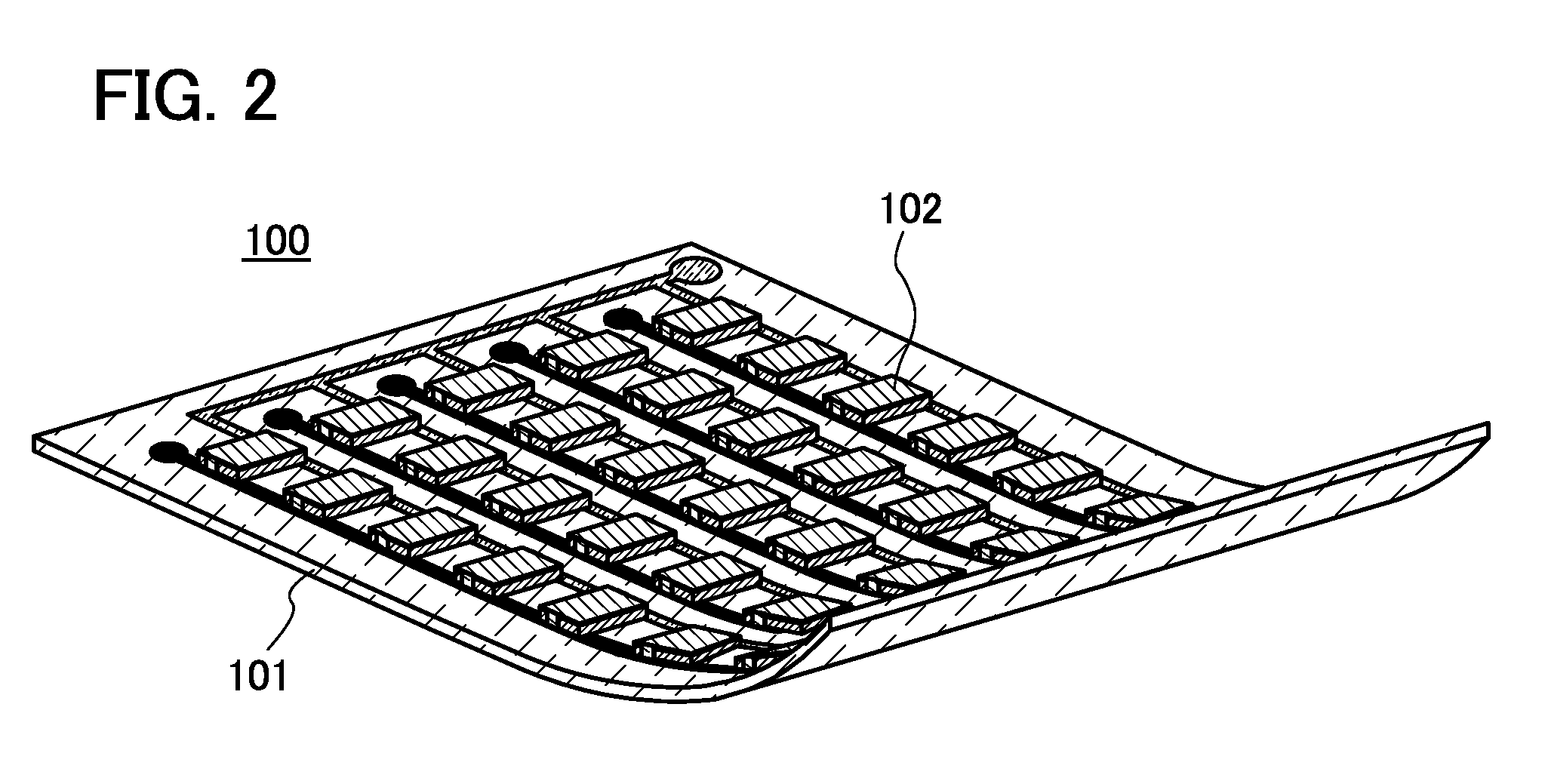

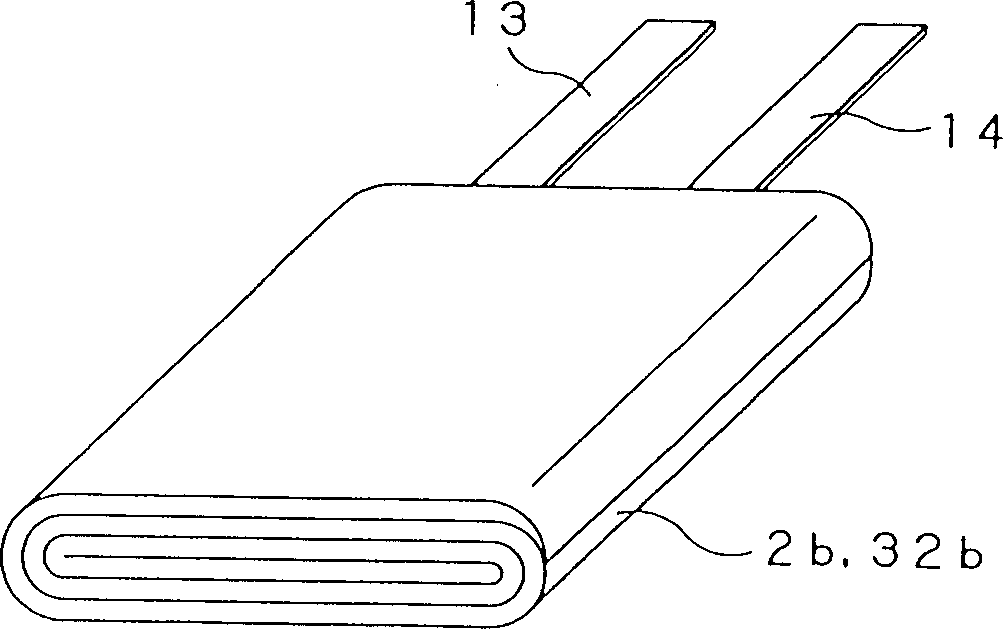

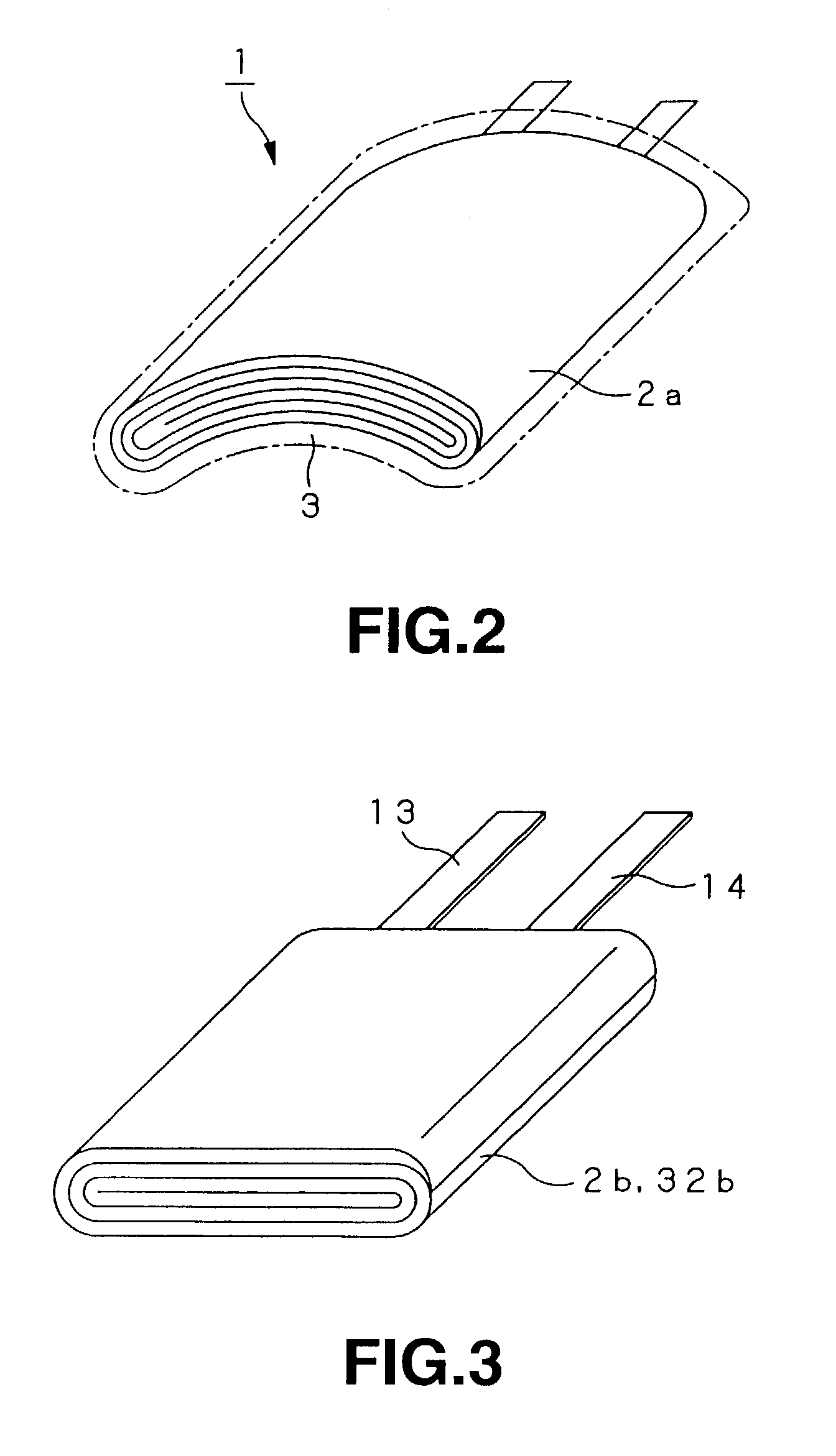

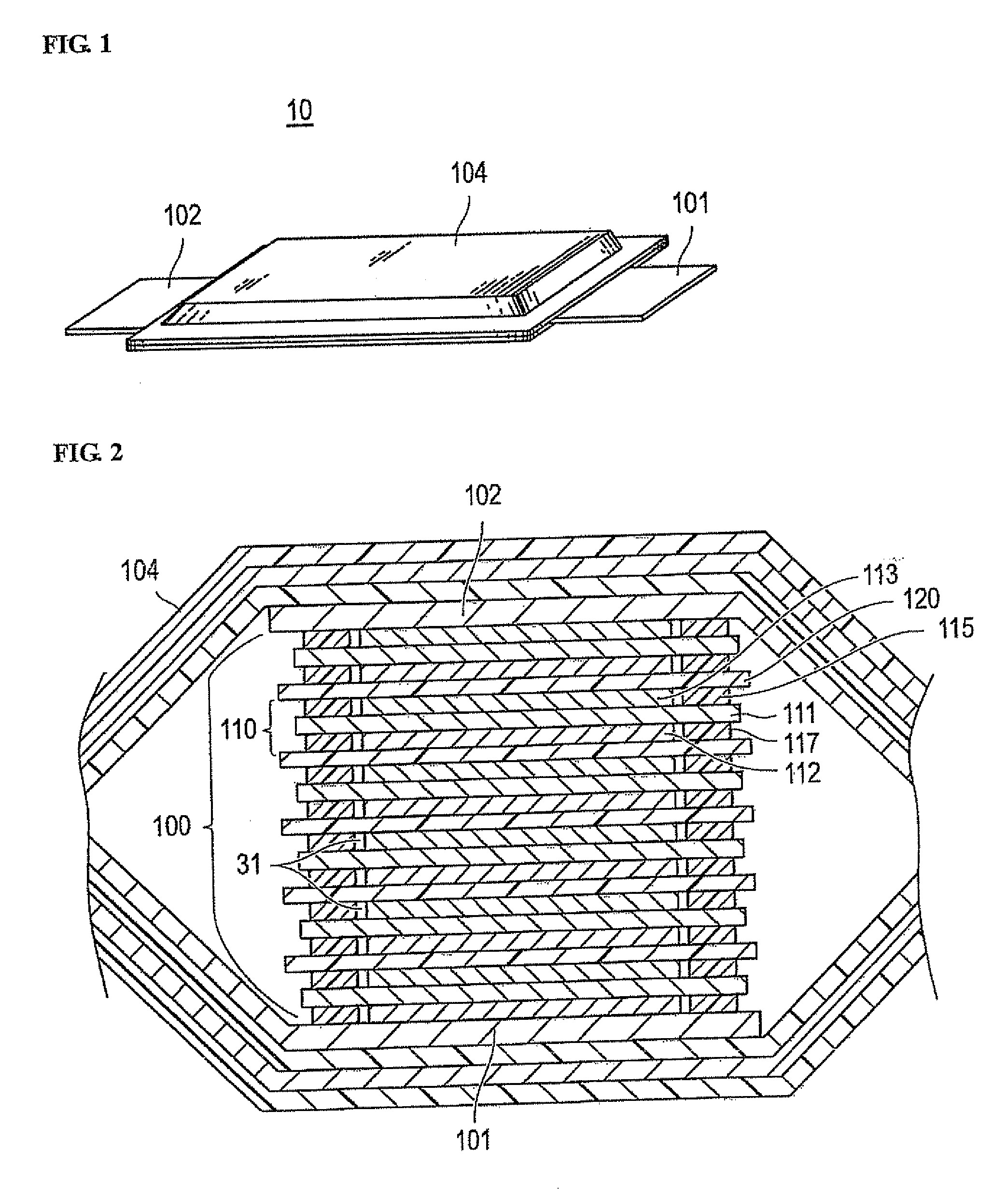

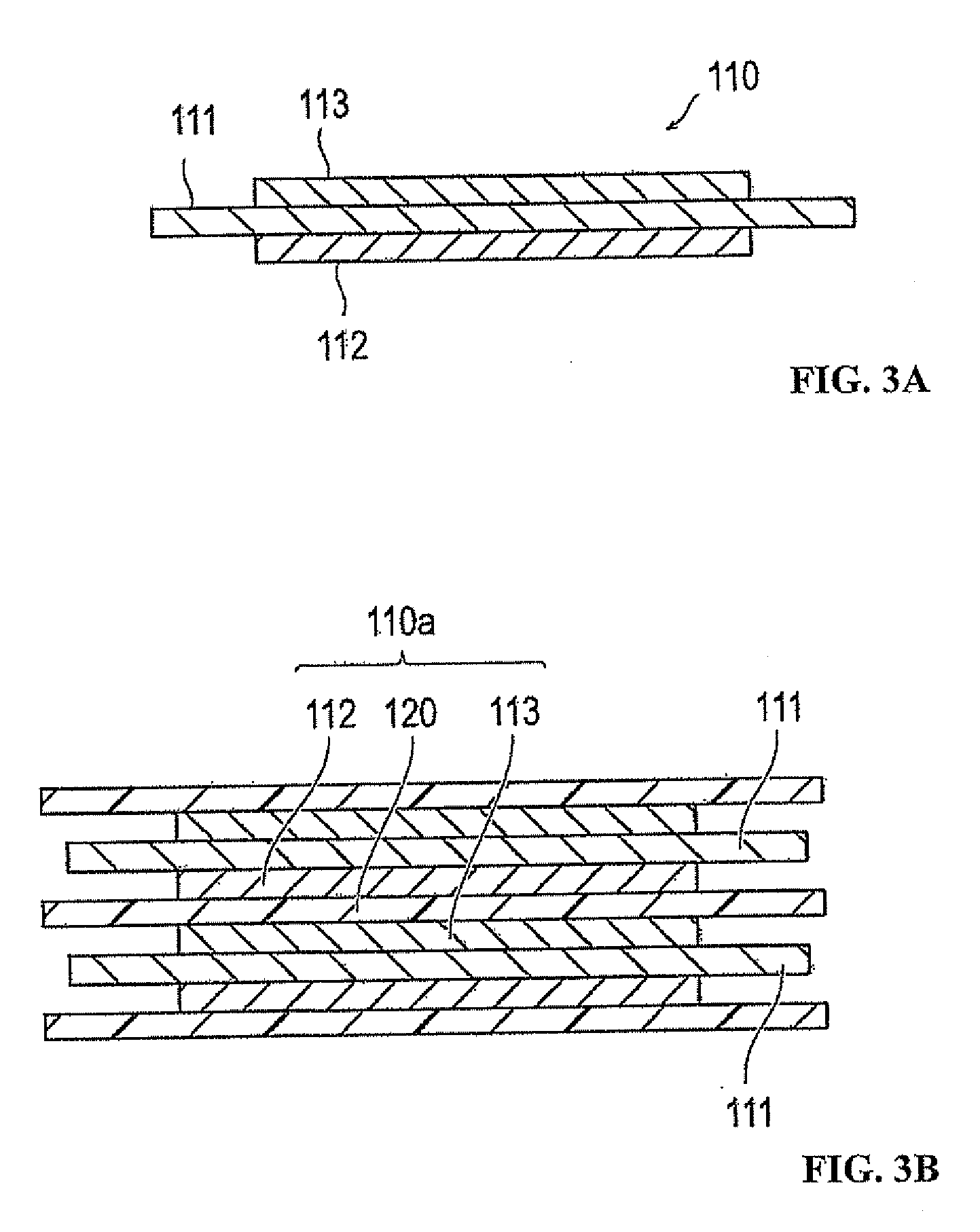

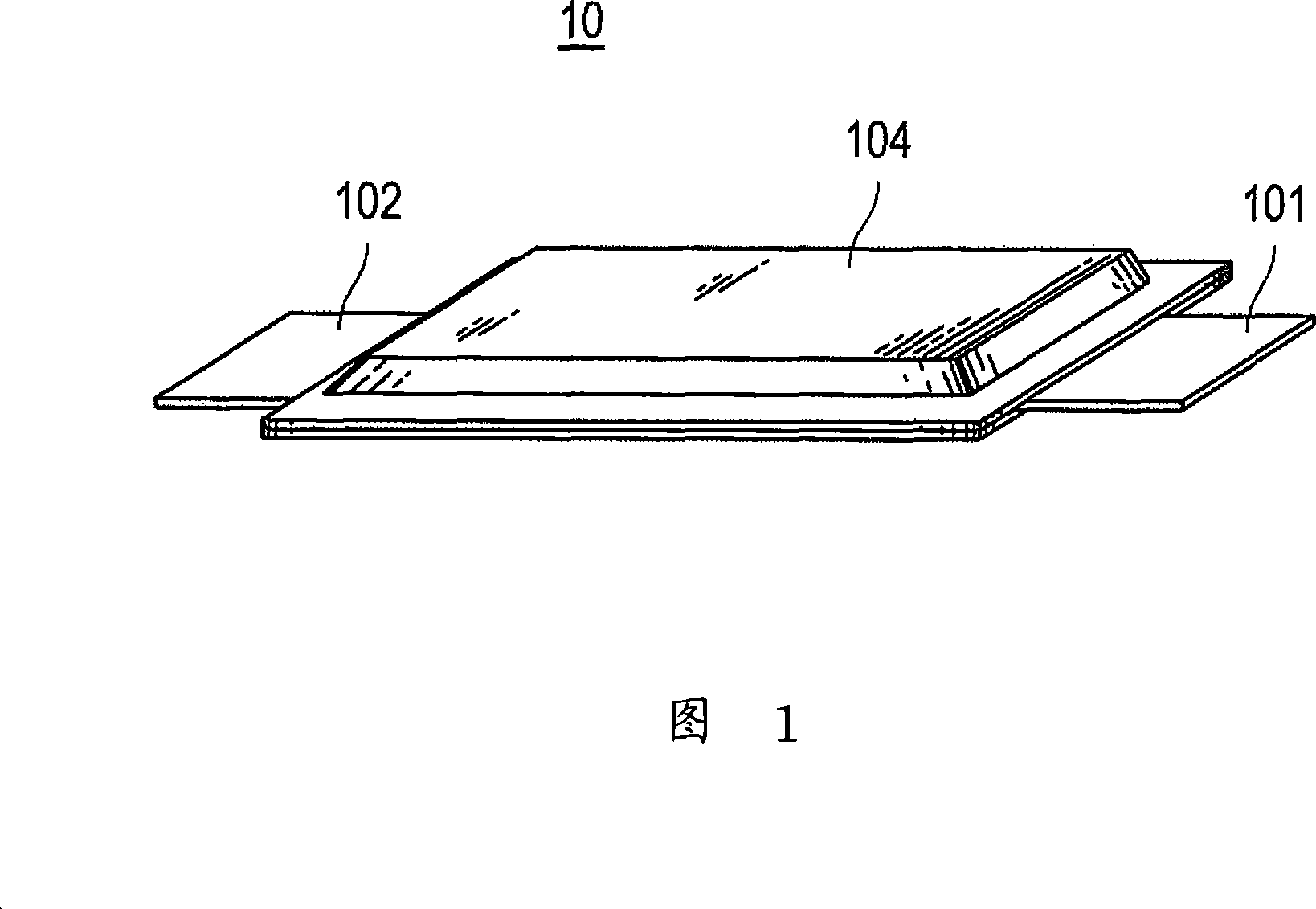

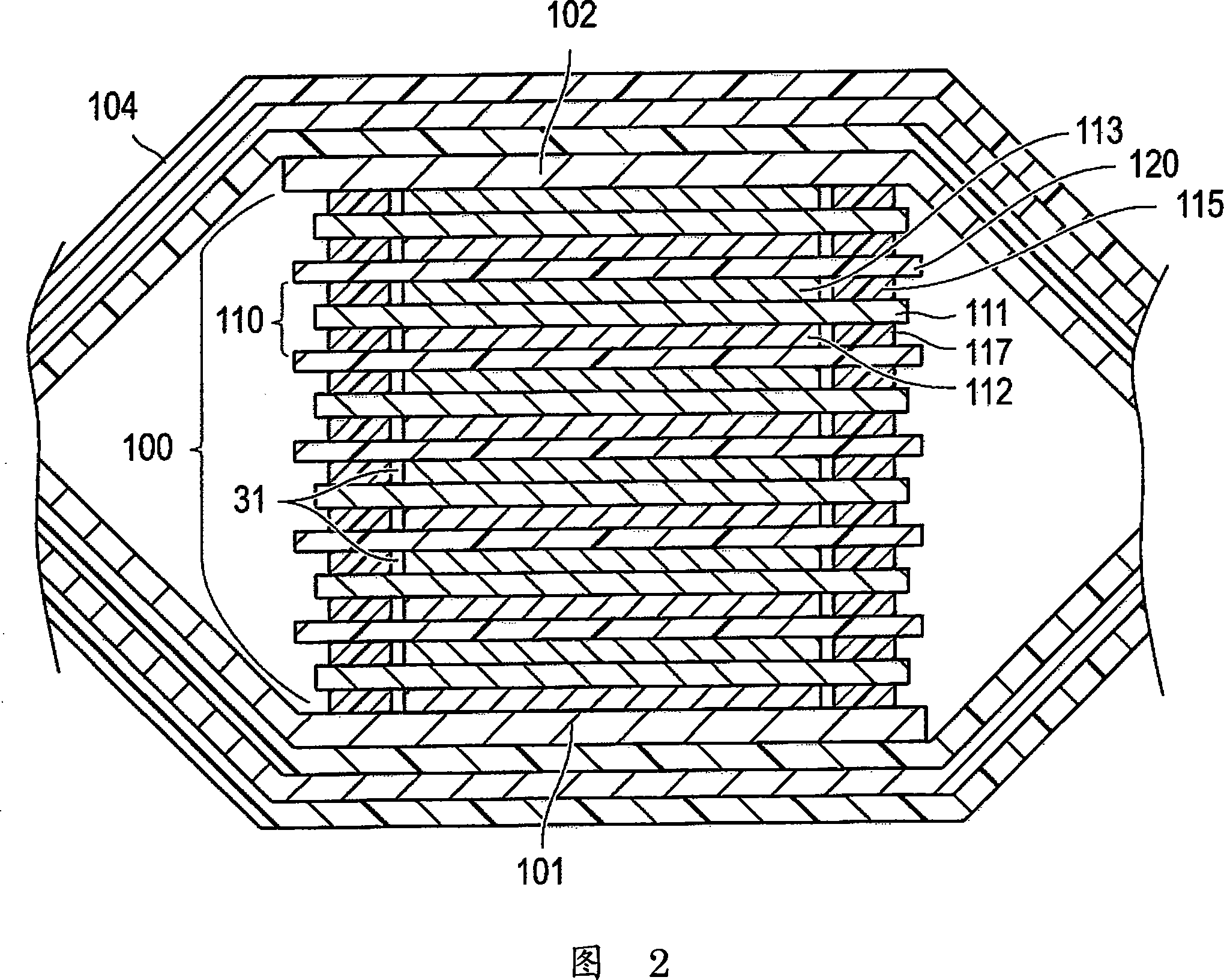

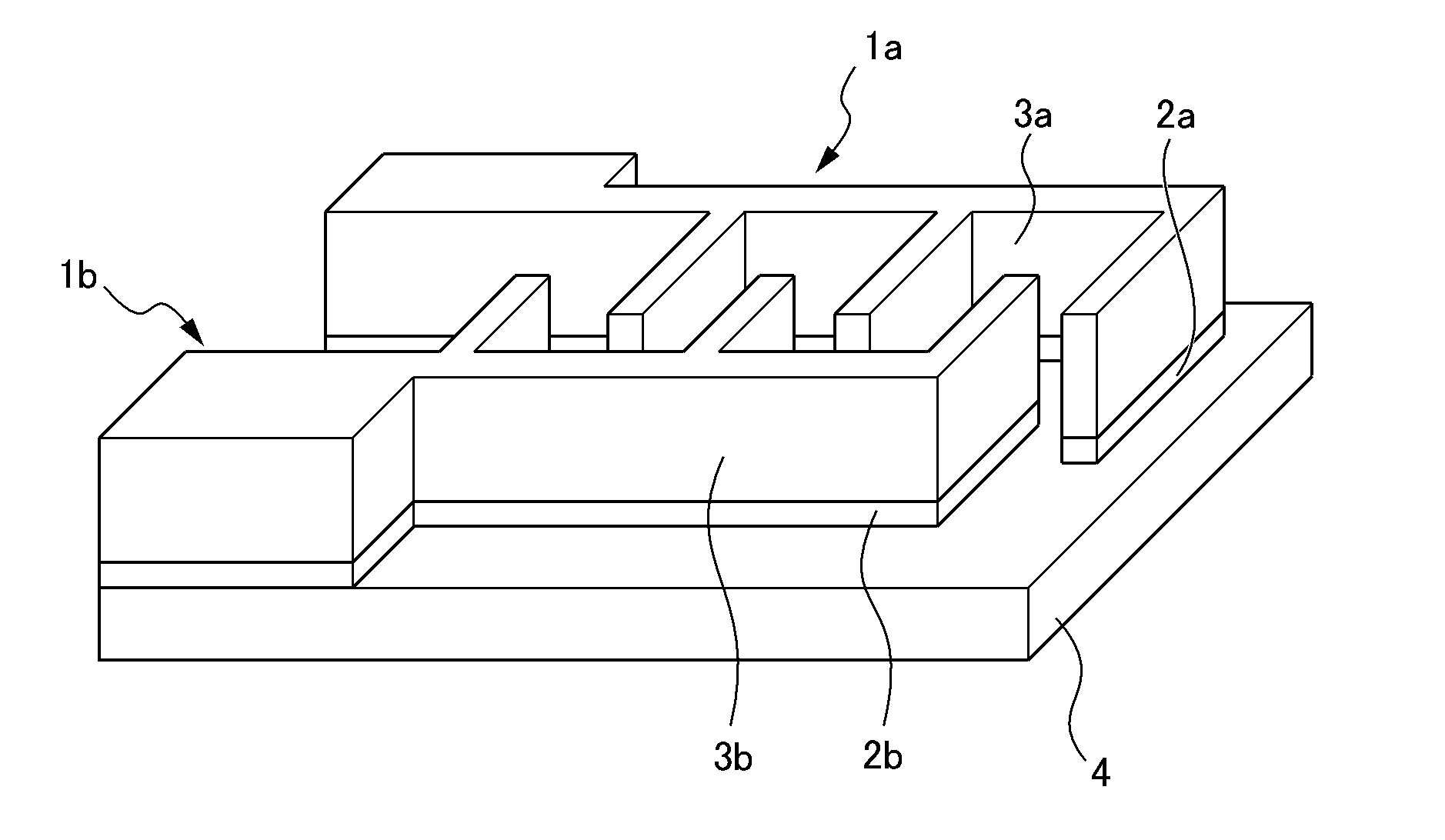

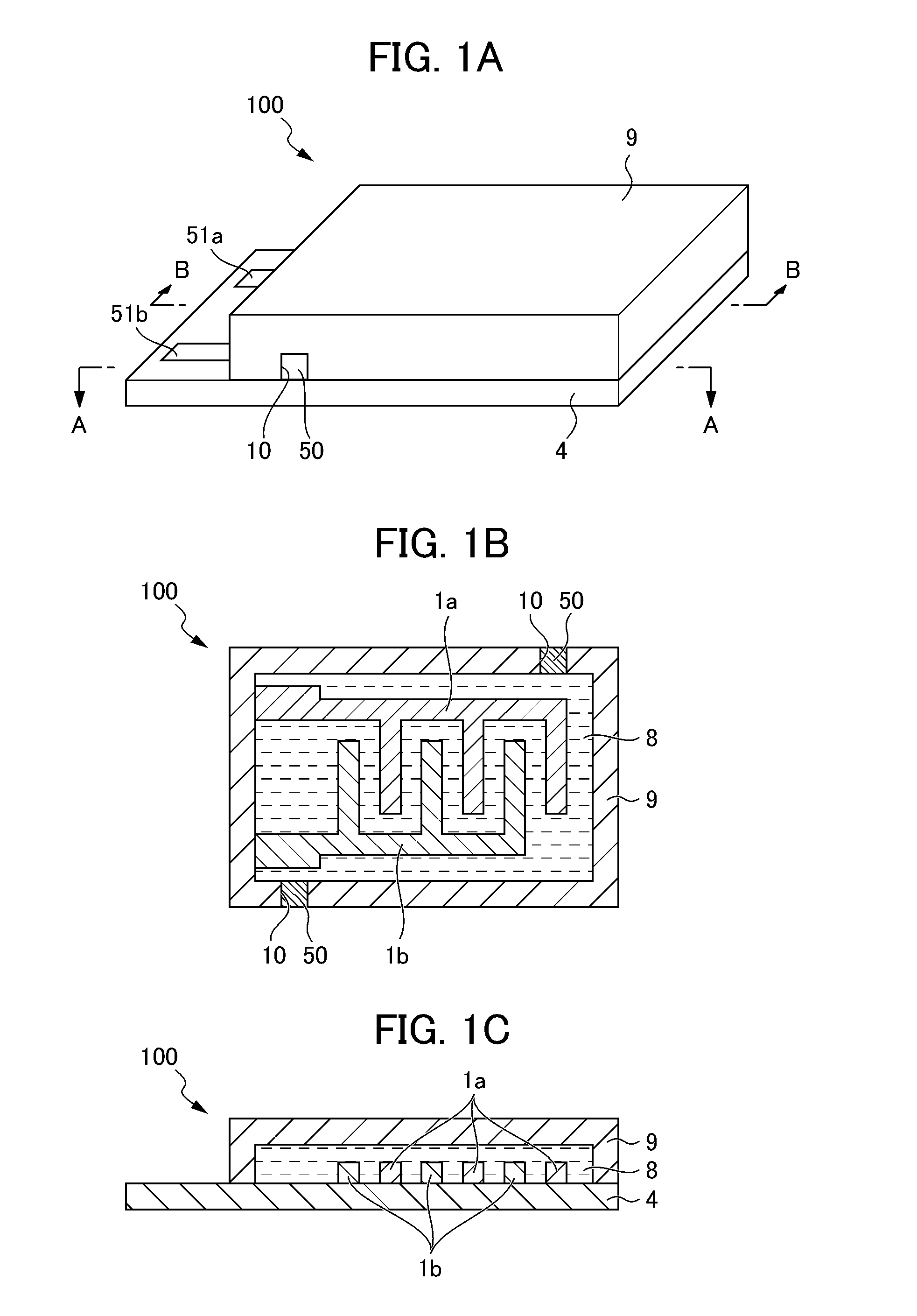

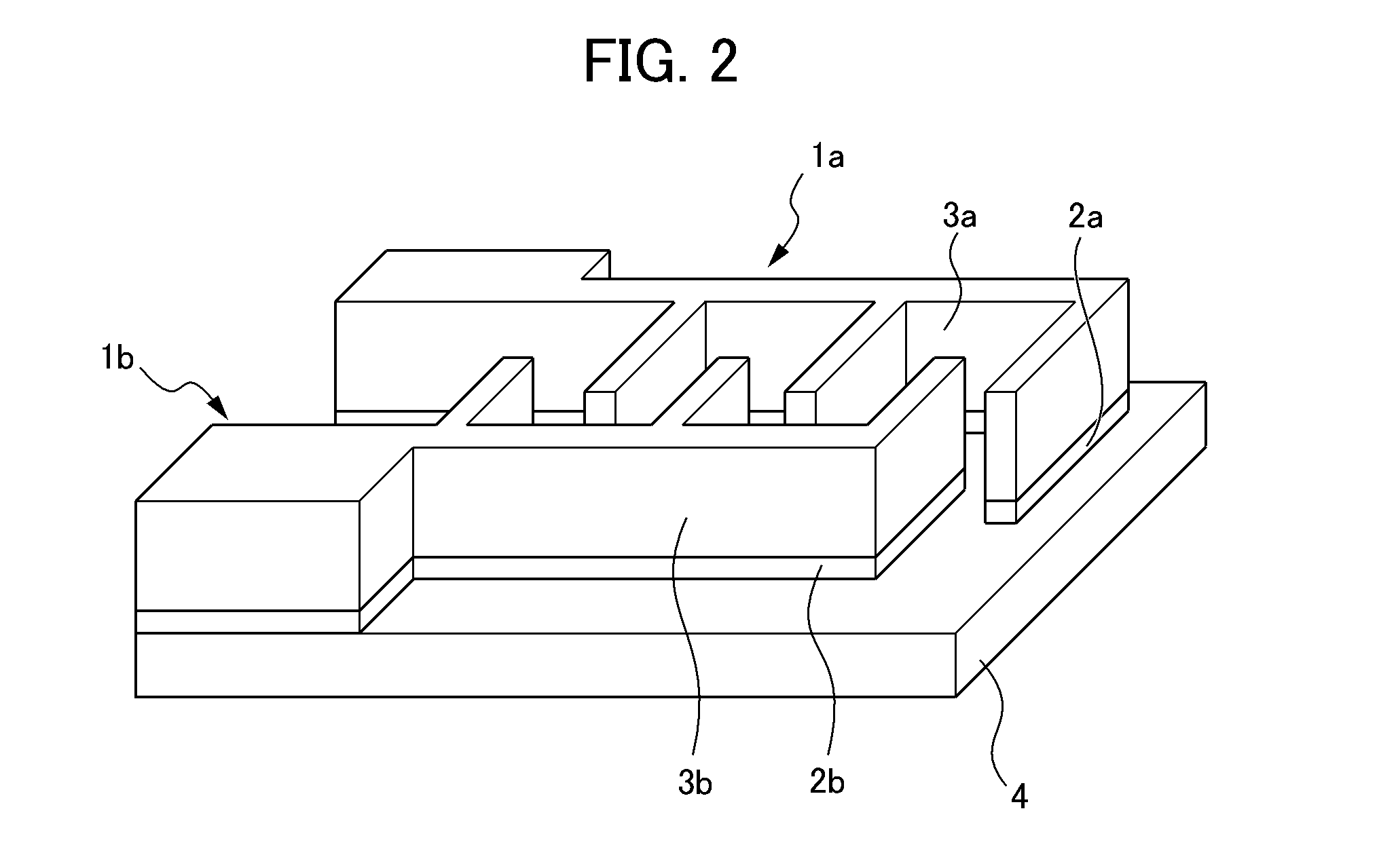

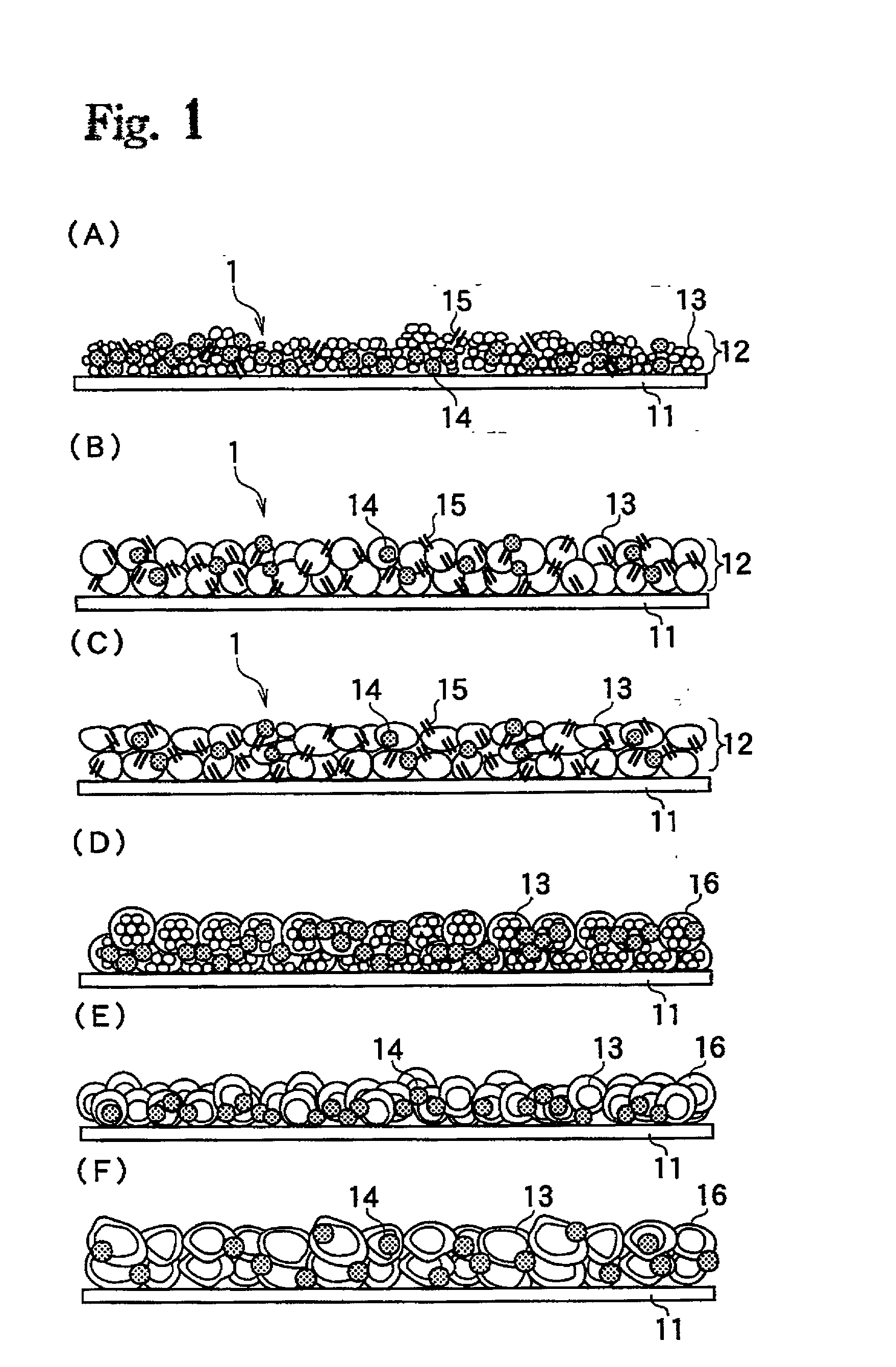

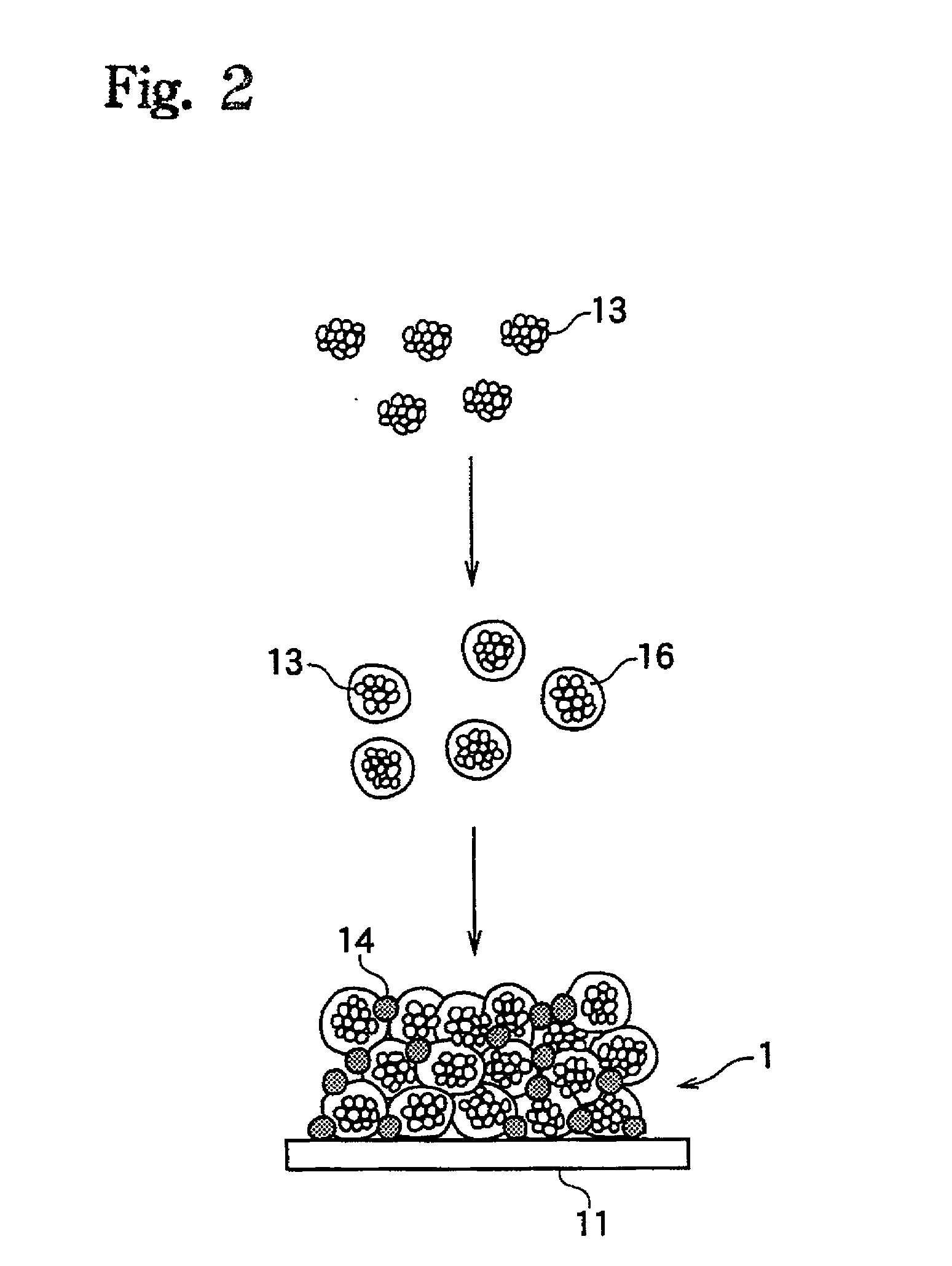

Power storage device and method for manufacturing the same

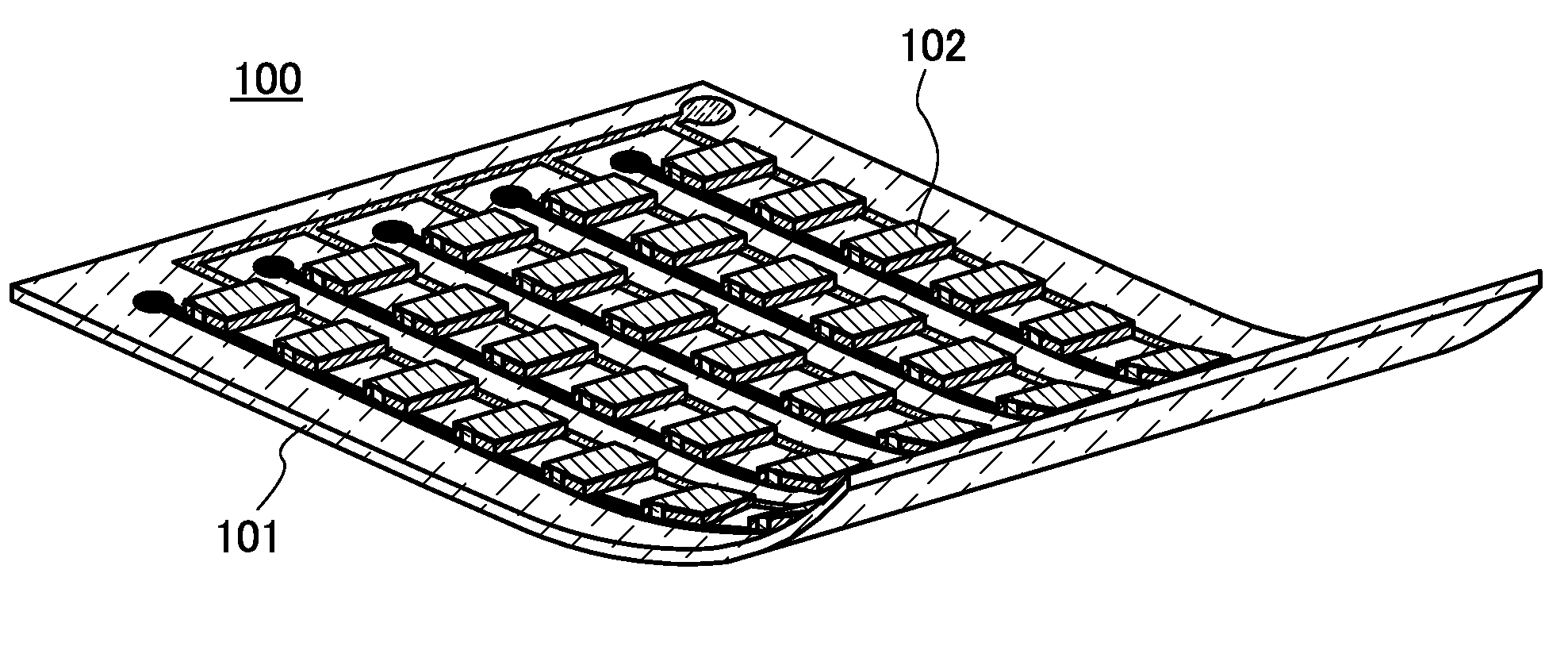

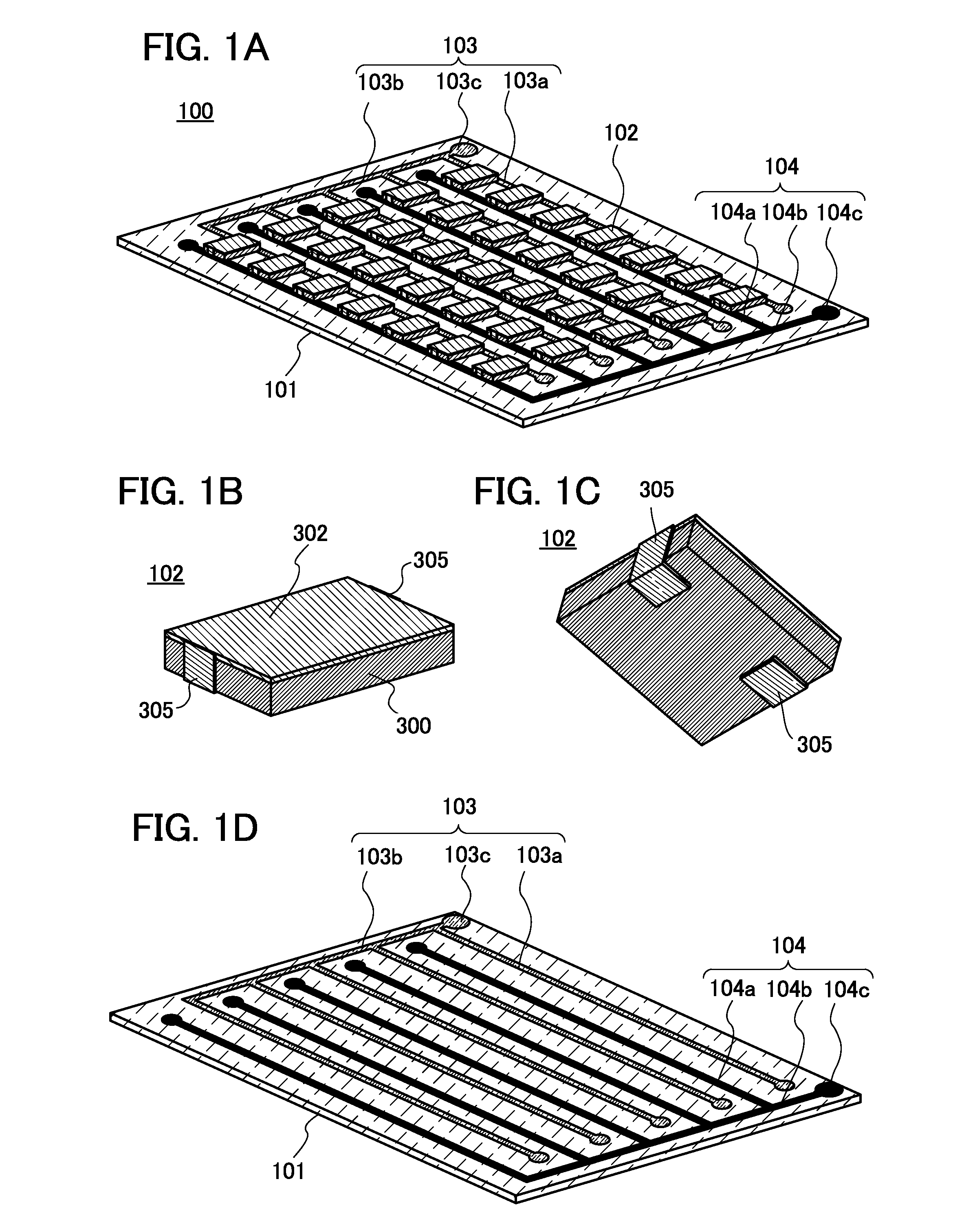

ActiveUS20130273405A1Improve reliabilityIncrease resistanceSolid electrolytesFinal product manufactureElectrolyteElectrical and Electronics engineering

To provide a flexible, highly reliable, and sheet-like power storage device. The power storage device including a flexible substrate; a positive electrode lead and a negative electrode lead over the flexible substrate; and a plurality of power storage elements over the flexible substrate. The plurality of power storage elements each includes a stack body including a sheet-like positive electrode; a sheet-like negative electrode; and an electrolyte therebetween in an exterior body. An edge portion of the sheet-like positive electrode which extends to the outside of the exterior body is electrically connected to the positive electrode lead through a positive electrode tab provided for the exterior body. An edge portion of the sheet-like negative electrode which extends to the outside of the exterior body is electrically connected to the negative electrode lead through a negative electrode tab provided for the exterior body.

Owner:SEMICON ENERGY LAB CO LTD

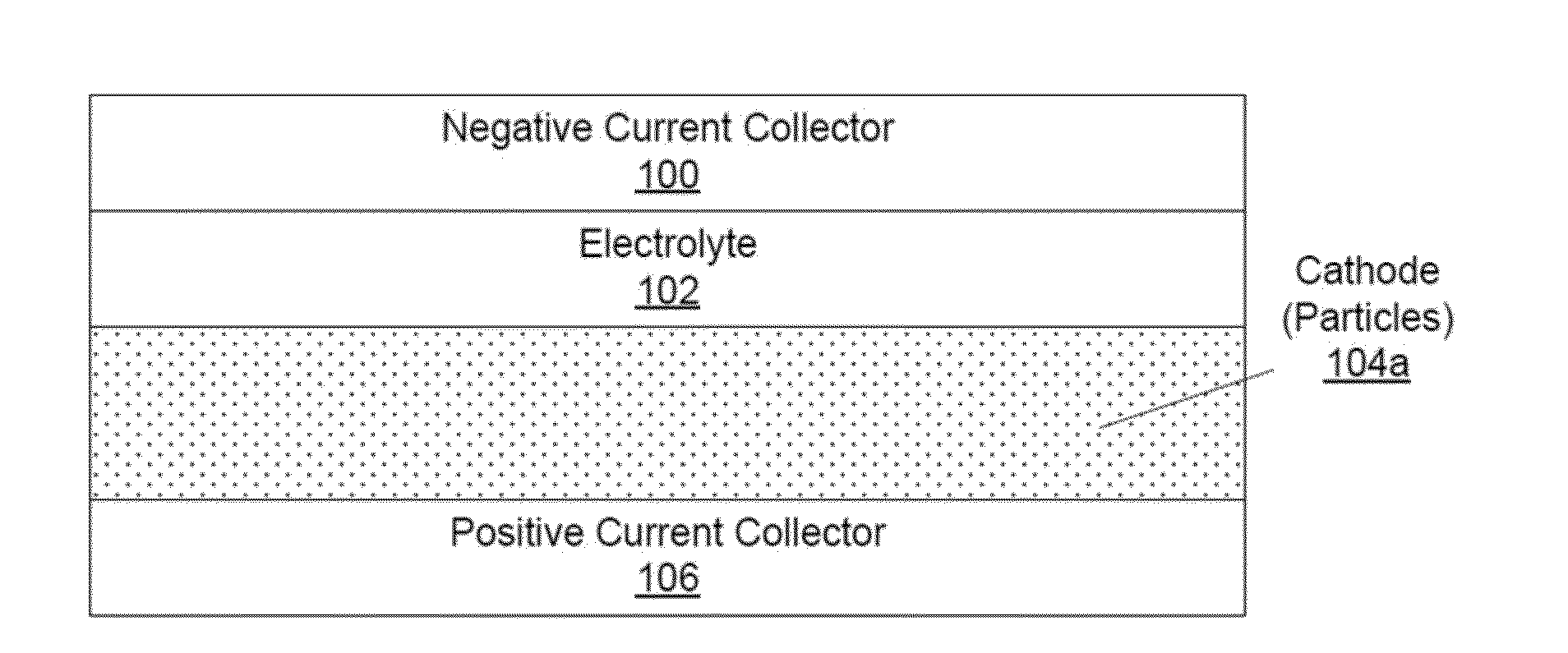

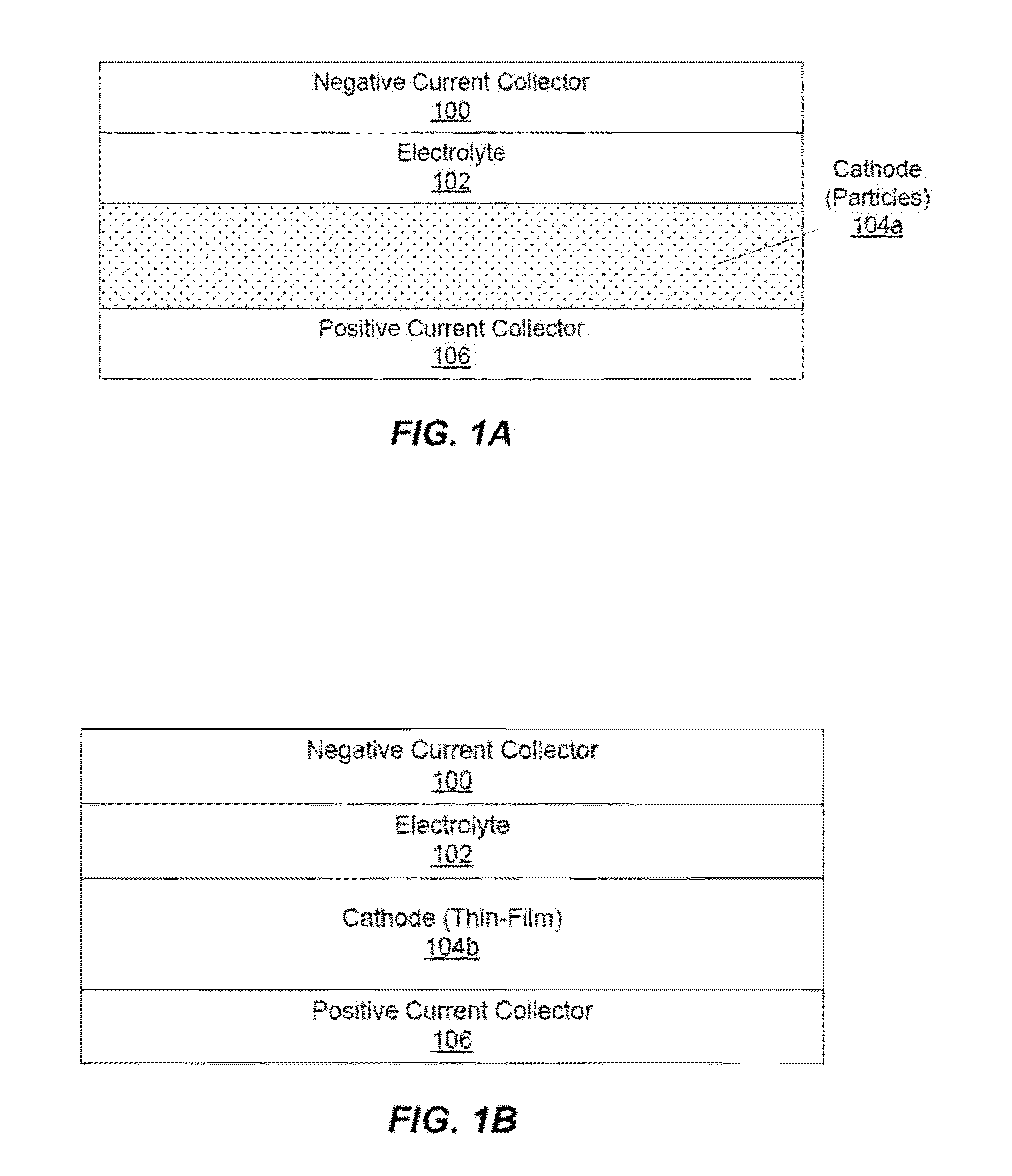

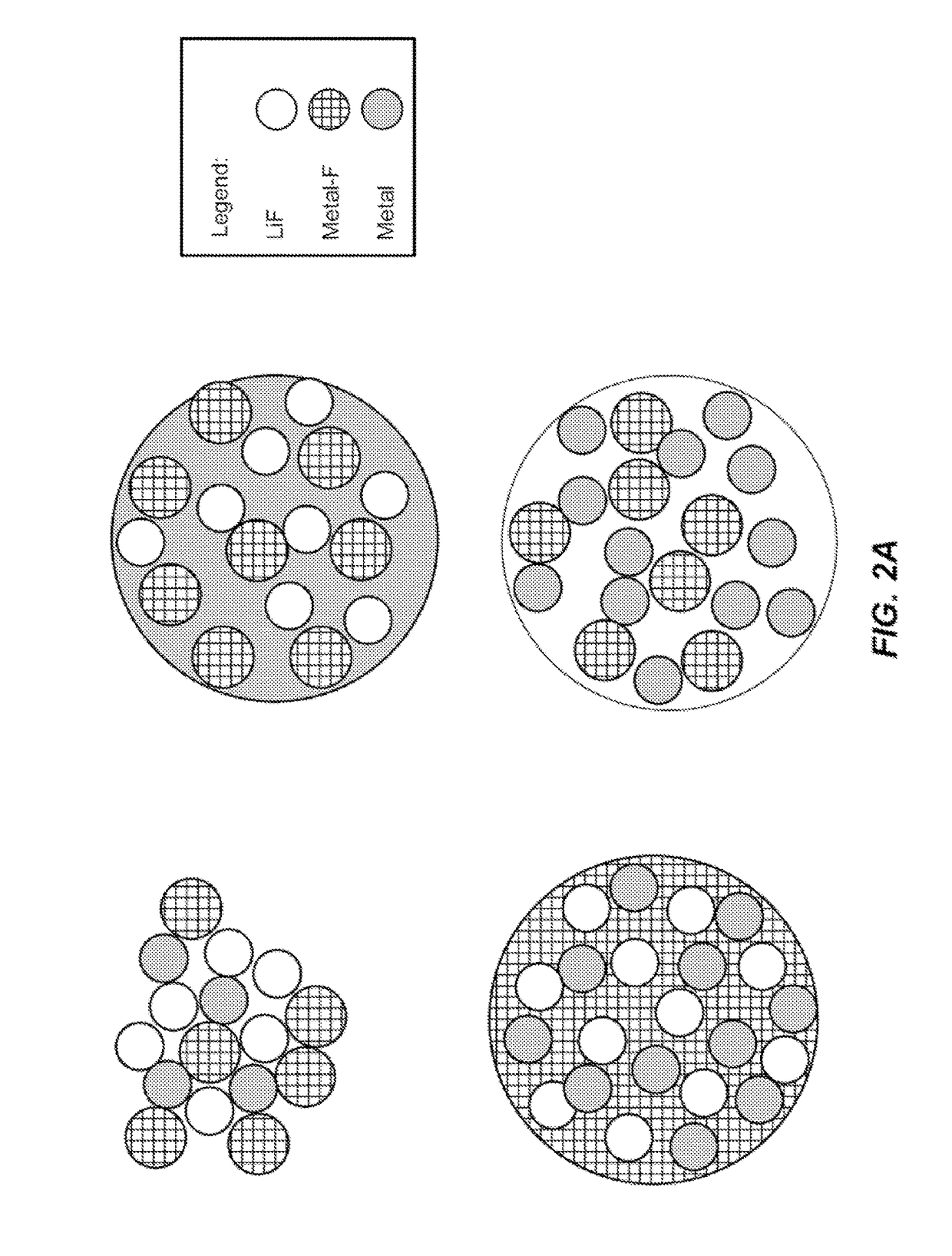

Protective coatings for conversion material cathodes

Battery systems using coated conversion materials as the active material in battery cathodes are provided herein. Protective coatings may be an oxide, phosphate, or fluoride, and may be lithiated. The coating may selectively isolate the conversion material from the electrolyte. Methods for fabricating batteries and battery systems with coated conversion material are also provided herein.

Owner:QUANTUMSCAPE BATTERY INC

Protective coatings for conversion material cathodes

Battery systems using coated conversion materials as the active material in battery cathodes are provided herein. Protective coatings may be an oxide, phosphate, or fluoride, and may be lithiated. The coating may selectively isolate the conversion material from the electrolyte. Methods for fabricating batteries and battery systems with coated conversion material are also provided herein.

Owner:QUANTUMSCAPE CORP

Method for forming a thin-film lithium-ion battery

InactiveUS20110076567A1Low costFinal product manufactureVacuum evaporation coatingLithiumOptoelectronics

A method for forming a lithium-ion type battery including the steps of forming, over an at least locally conductive substrate, an insulating layer having a through opening; successively and conformally depositing a stack comprising a cathode collector layer, a cathode layer, an electrolyte layer, and an anode layer, this stack having a thickness smaller than the thickness of the insulating layer; forming, over the structure, an anode collector layer filling the space remaining in the opening; and planarizing the structure to expose the upper surface of the insulating layer.

Owner:STMICROELECTRONICS (TOURS) SAS

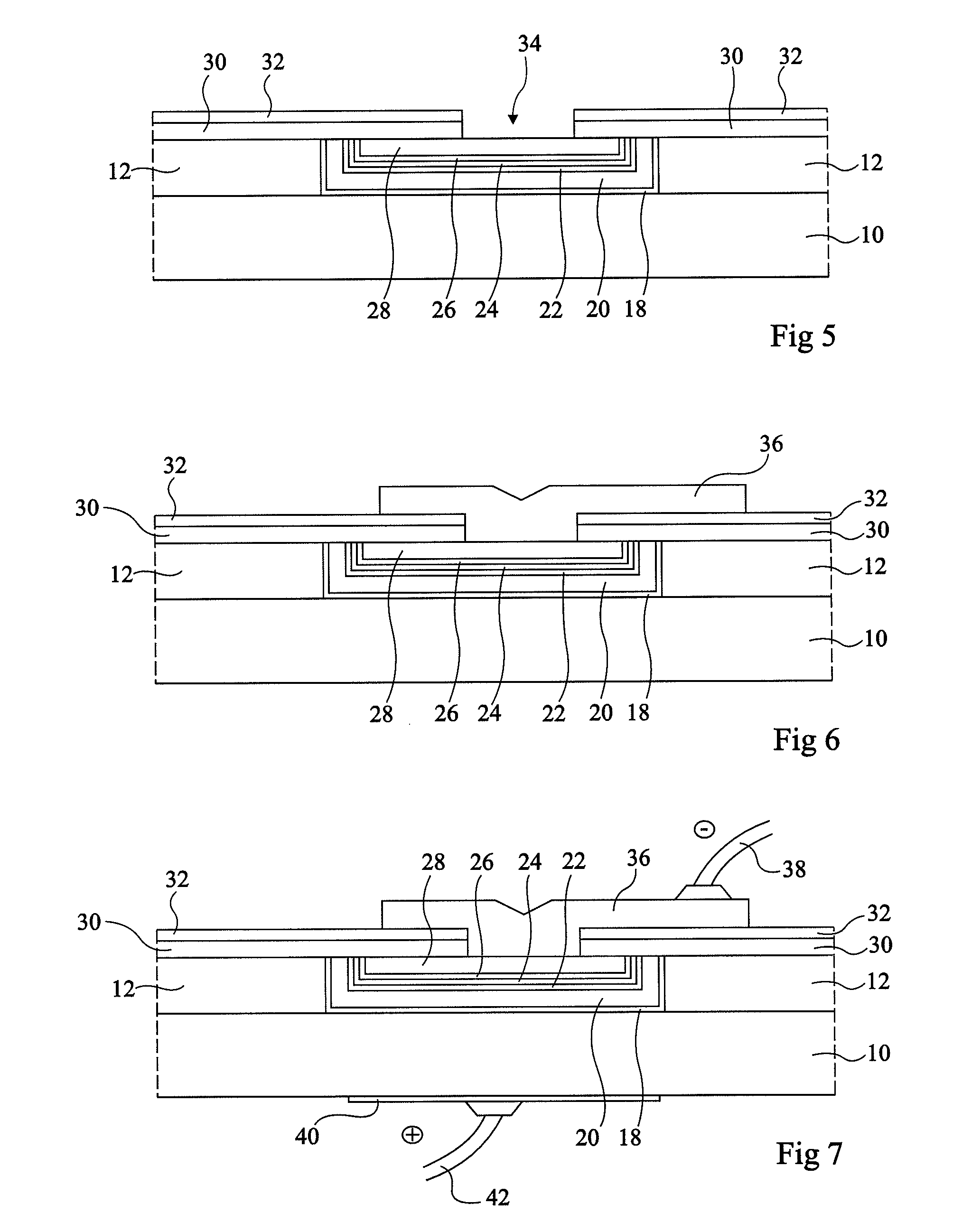

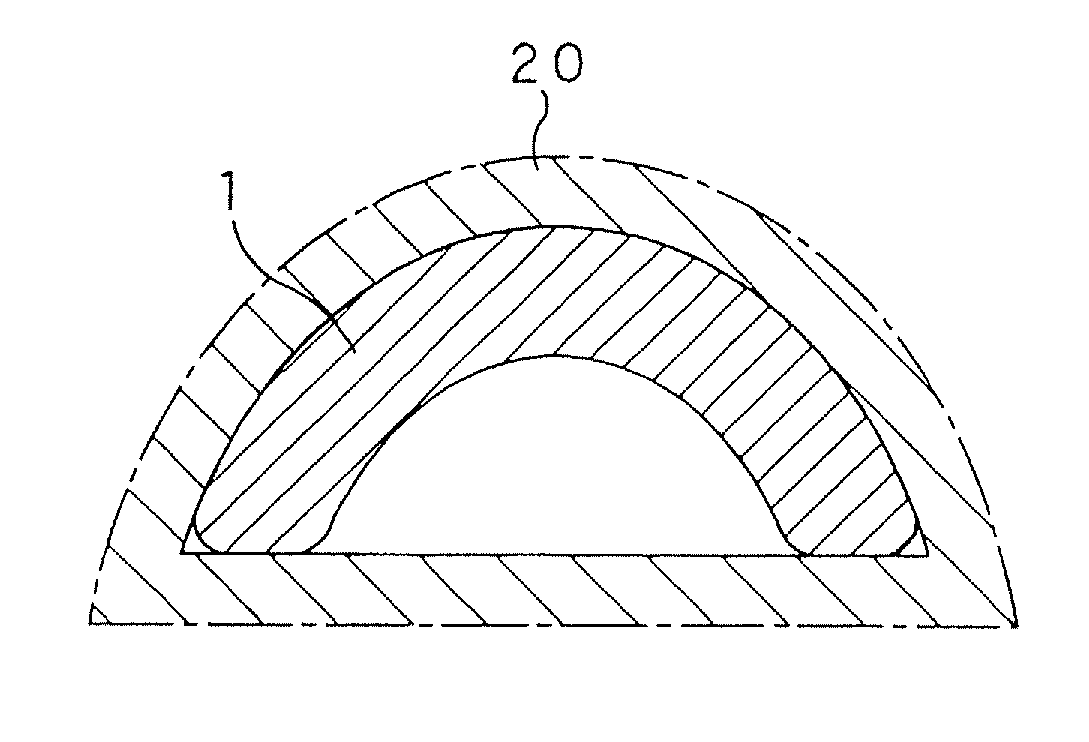

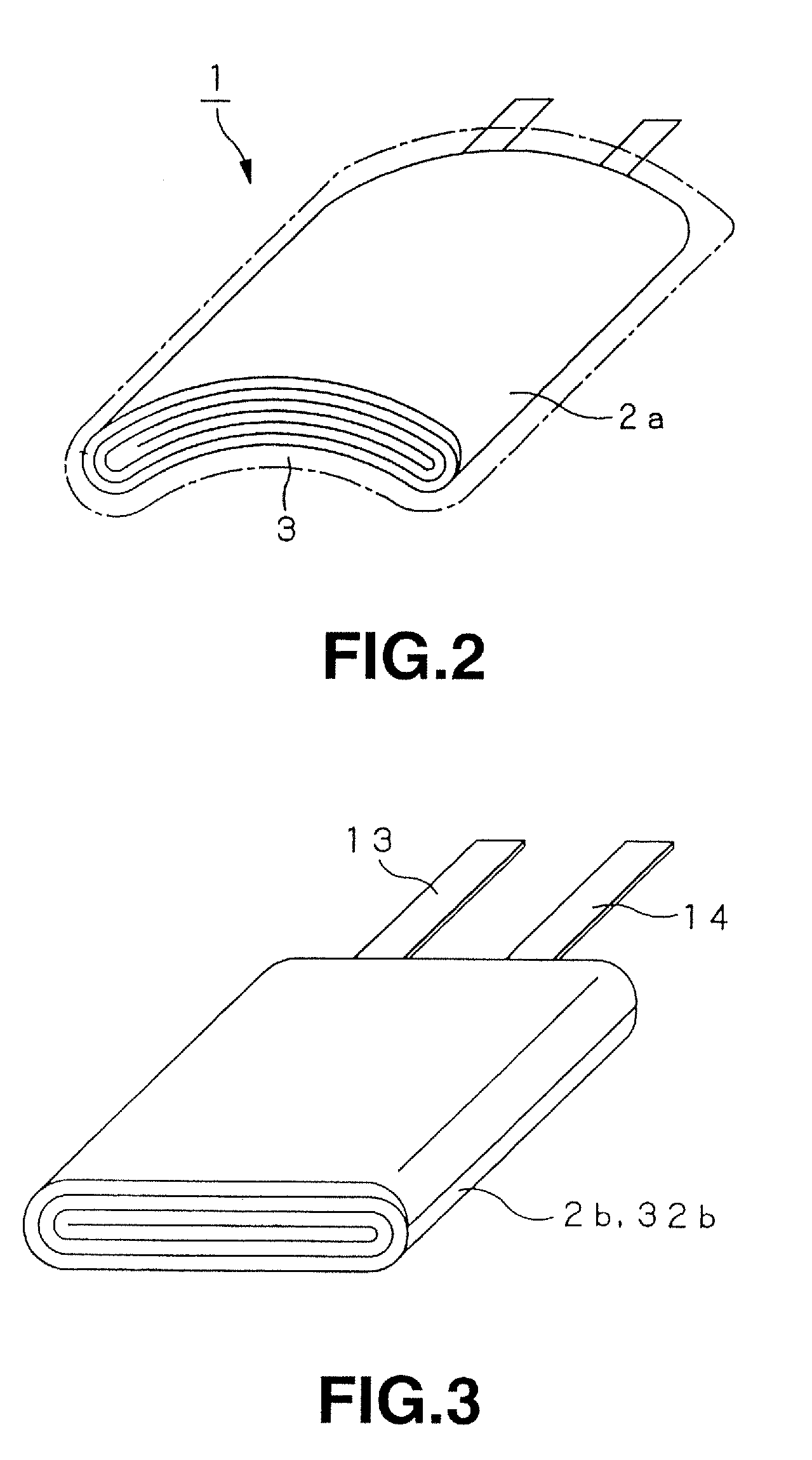

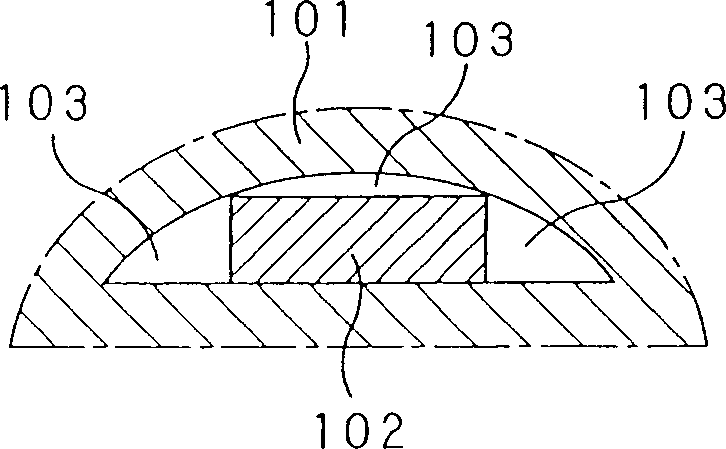

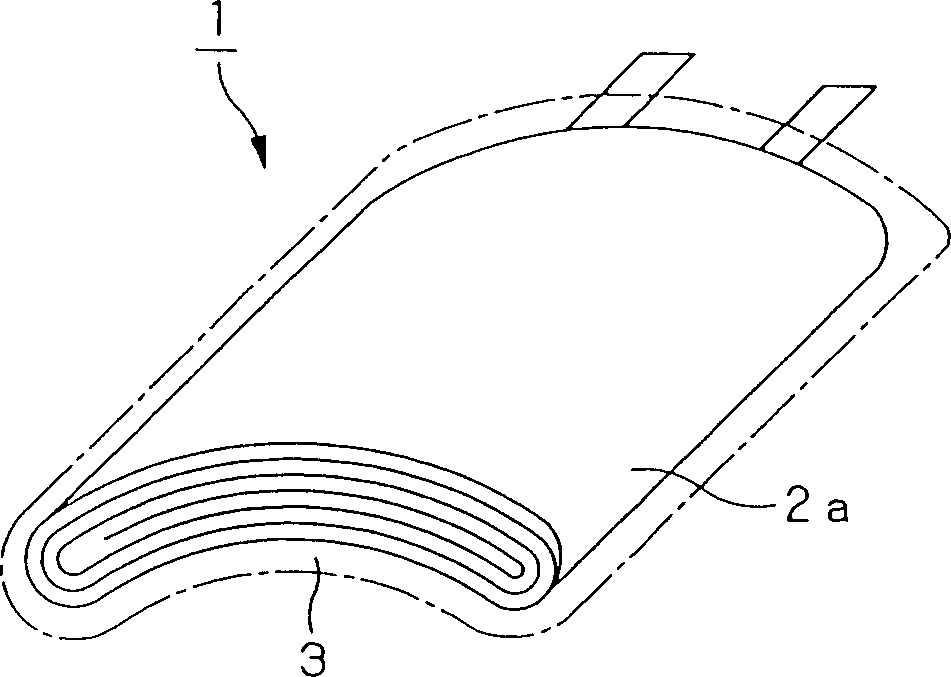

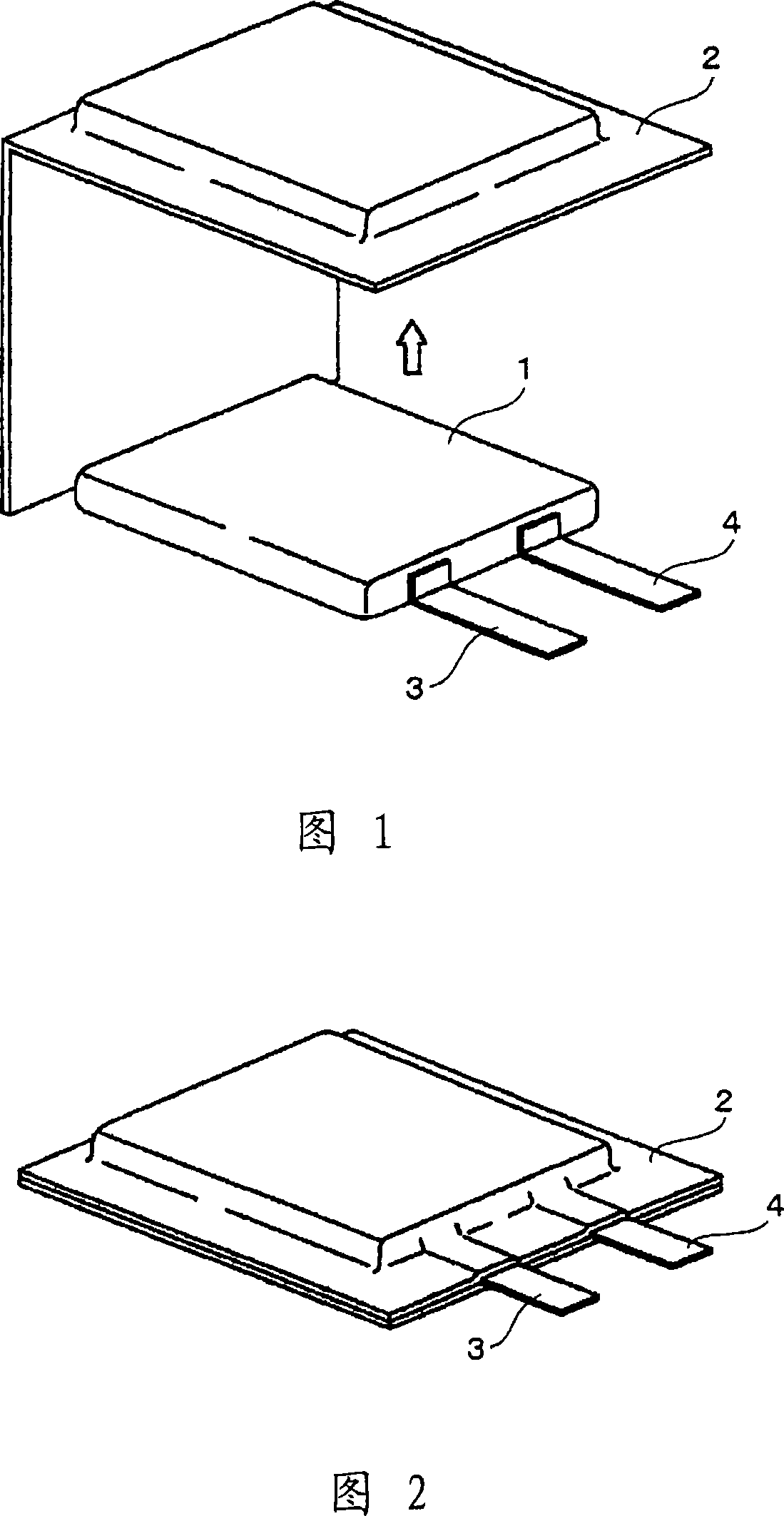

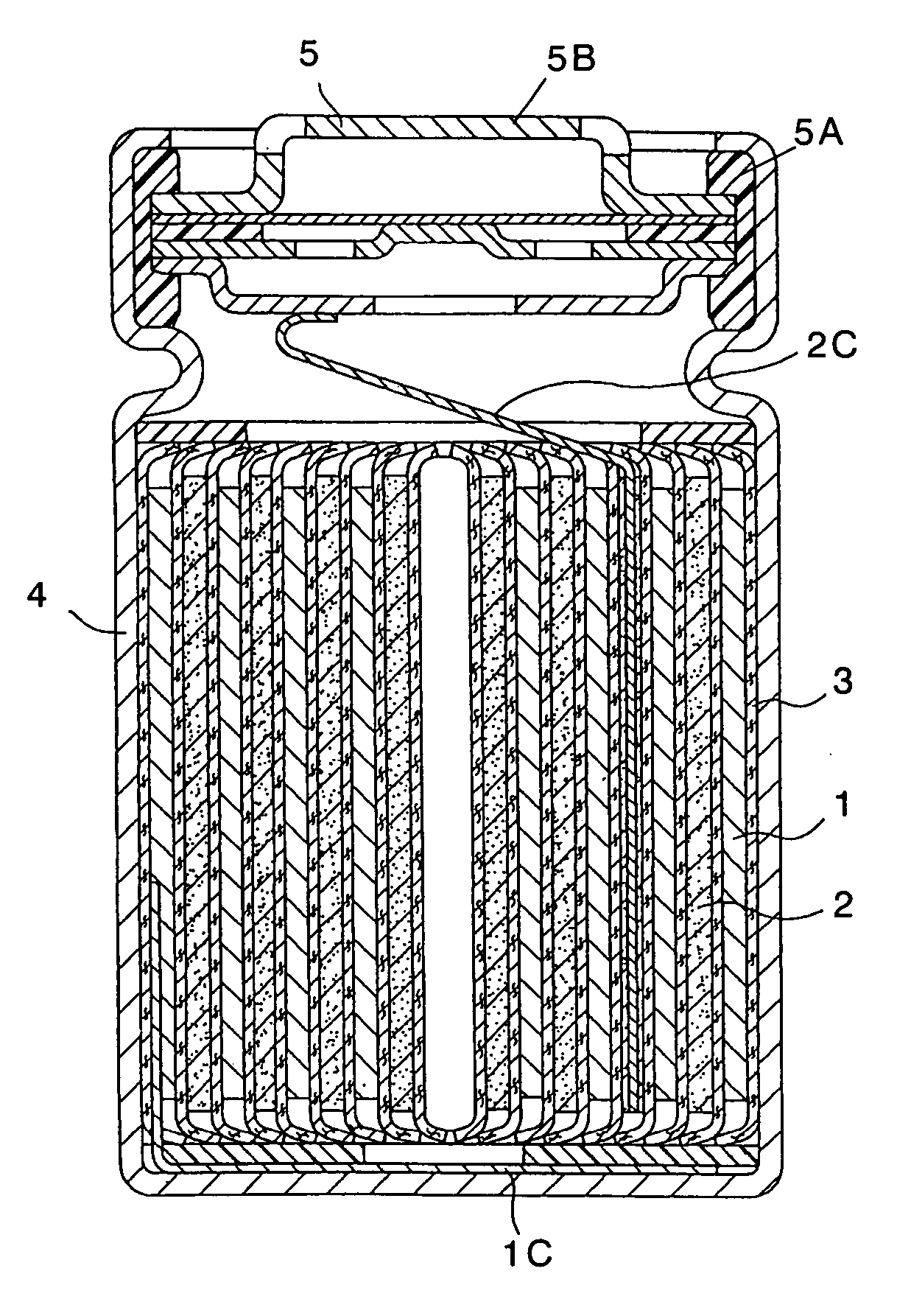

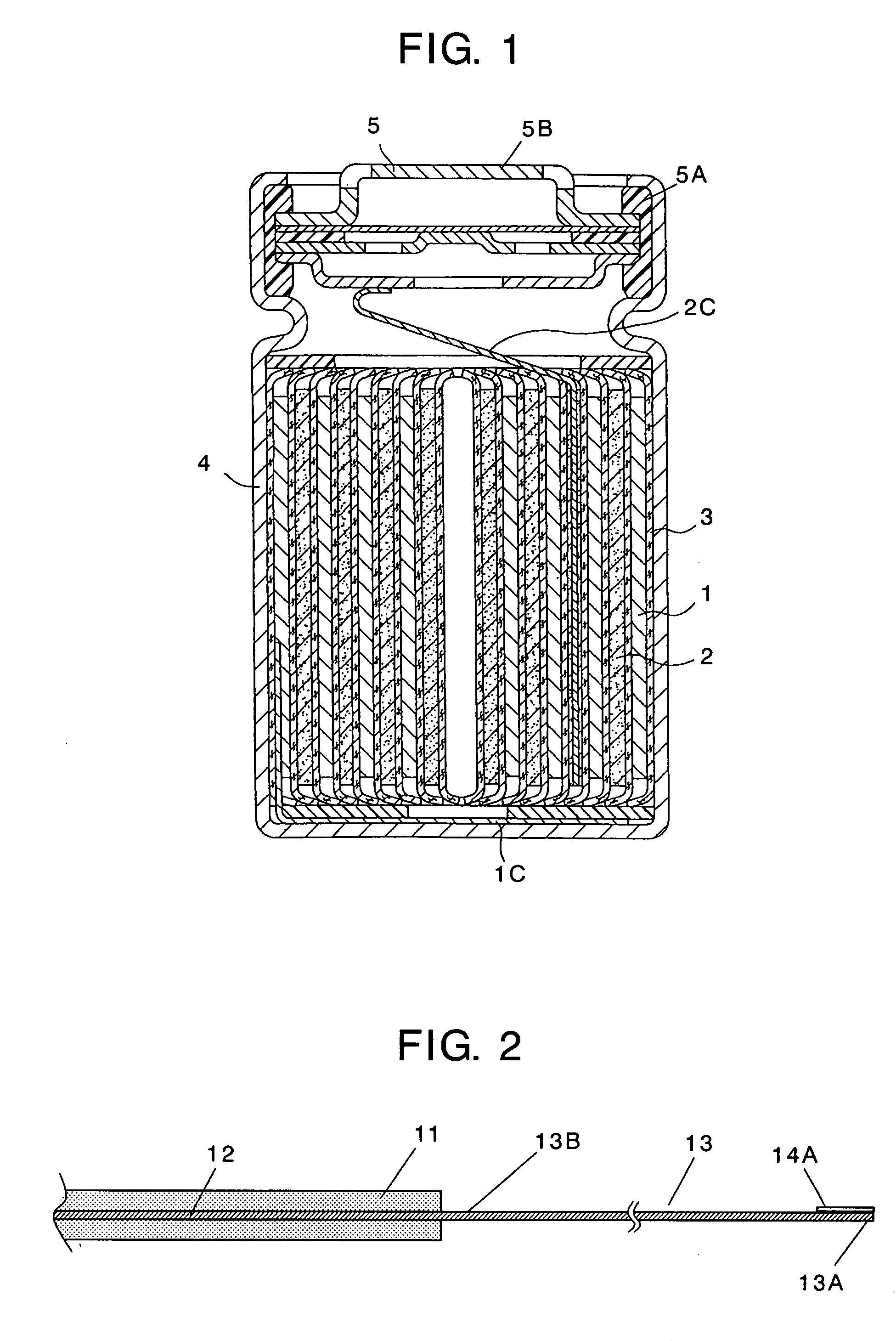

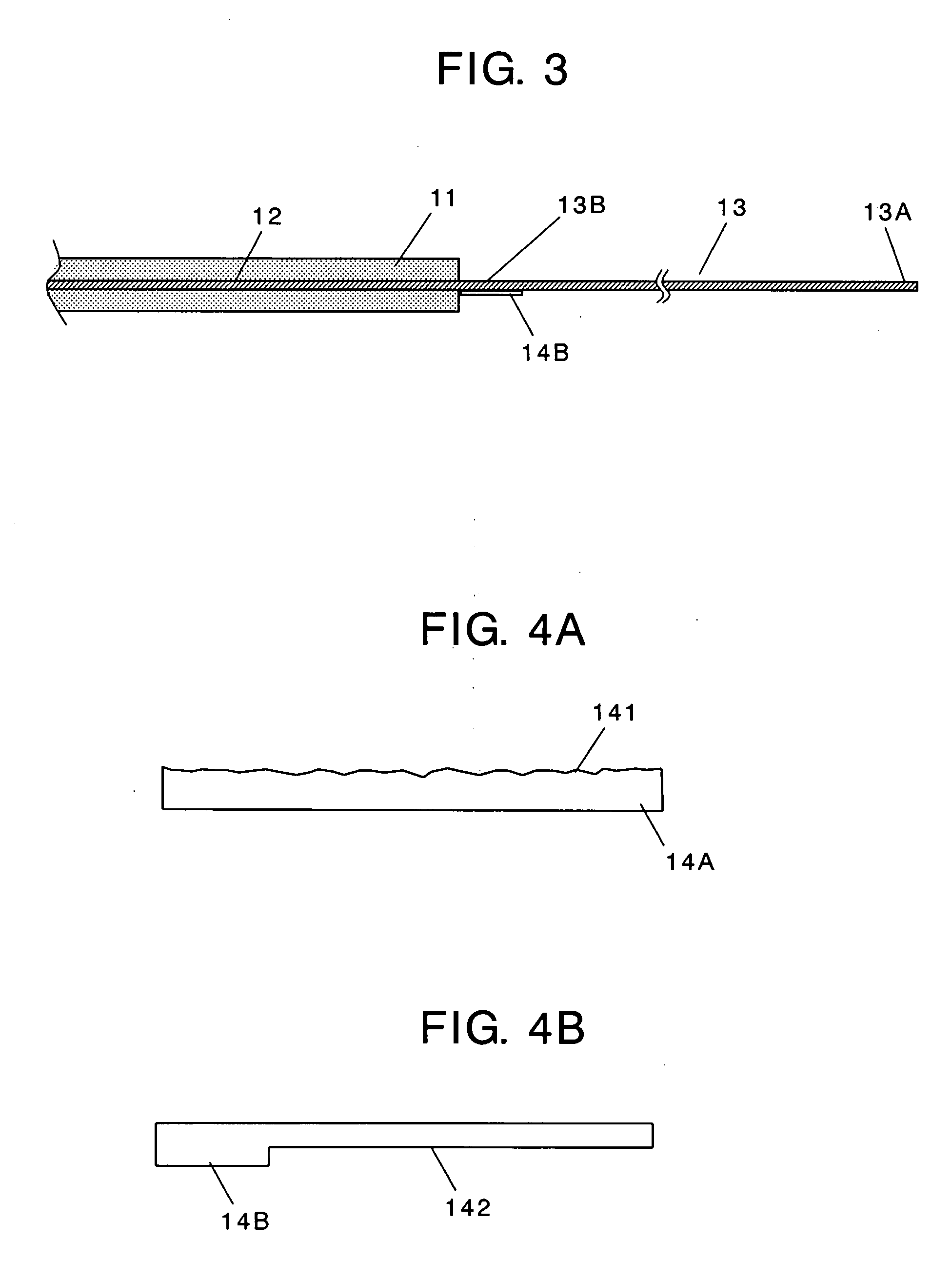

Polymer Electrolyte Battery and Method for Manufacturing Same

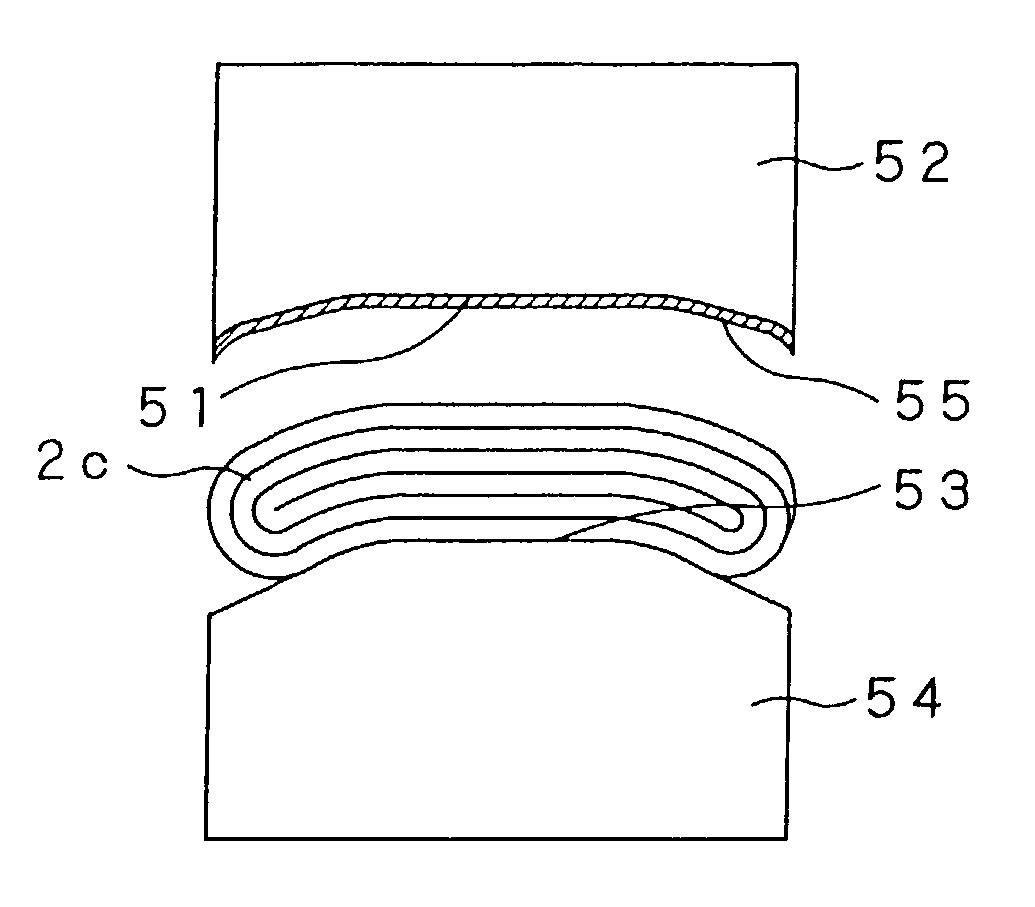

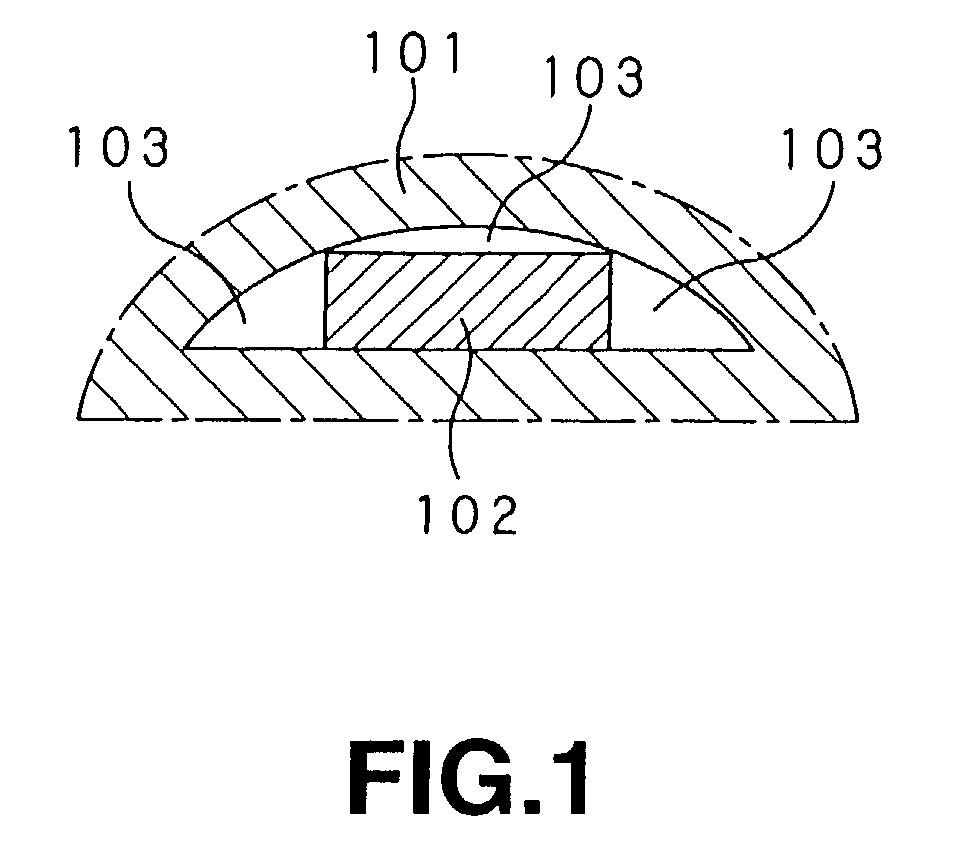

InactiveUS20070059595A1Improve featuresReduce the possibilityFinal product manufactureConductive materialPolymer electrolytesEngineering

In a polymer electrolyte battery including a battery element having a cathode and an anode coiled through a polymer electrolyte, a section of the battery element perpendicular to the coiling axis has a curved form. As compared with a polymer electrolyte battery having a flat plate type battery element curved, the former battery has an extremely low possibility of short-circuit at the end of an electrode and excellent battery characteristics.

Owner:MURATA MFG CO LTD

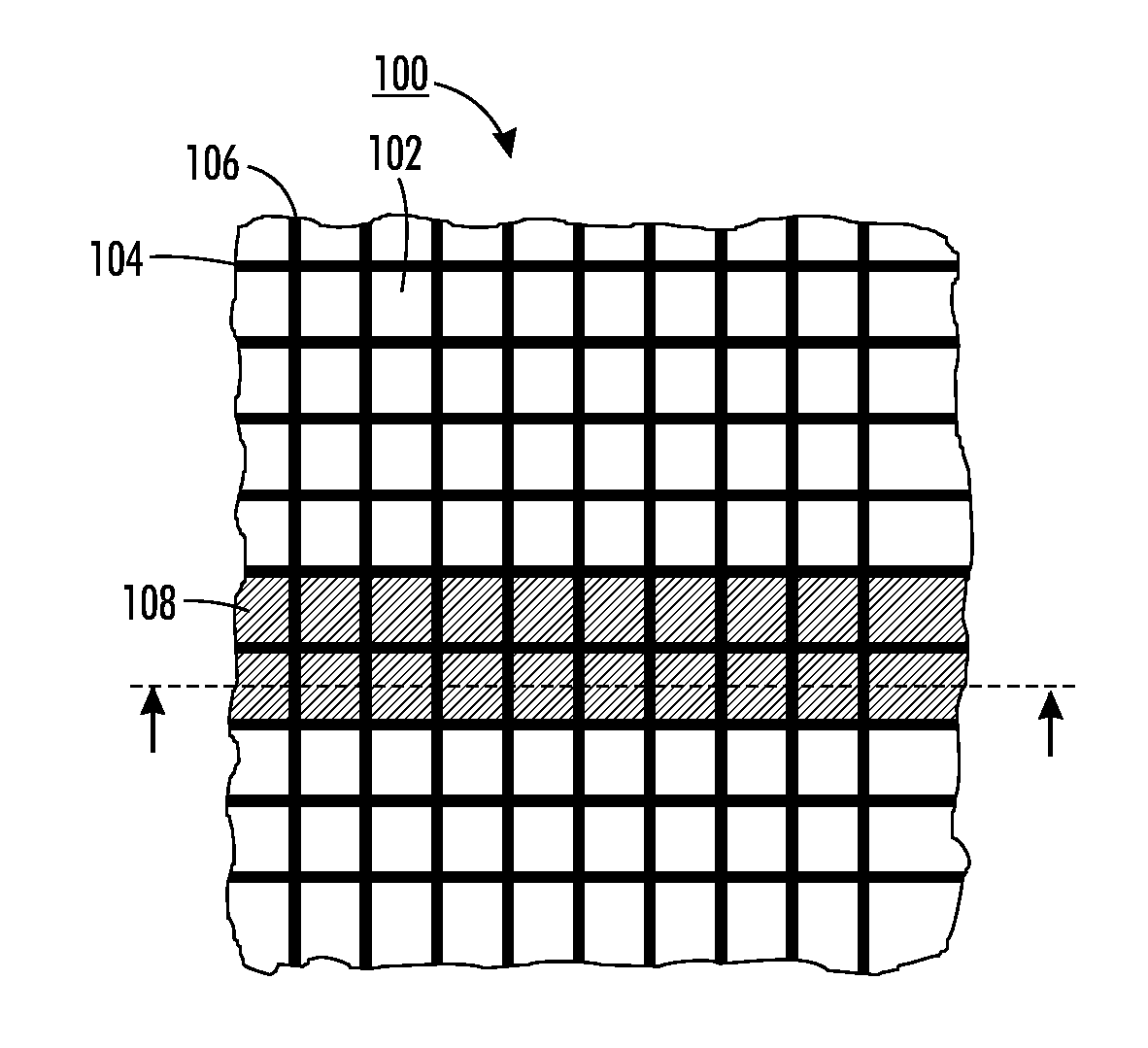

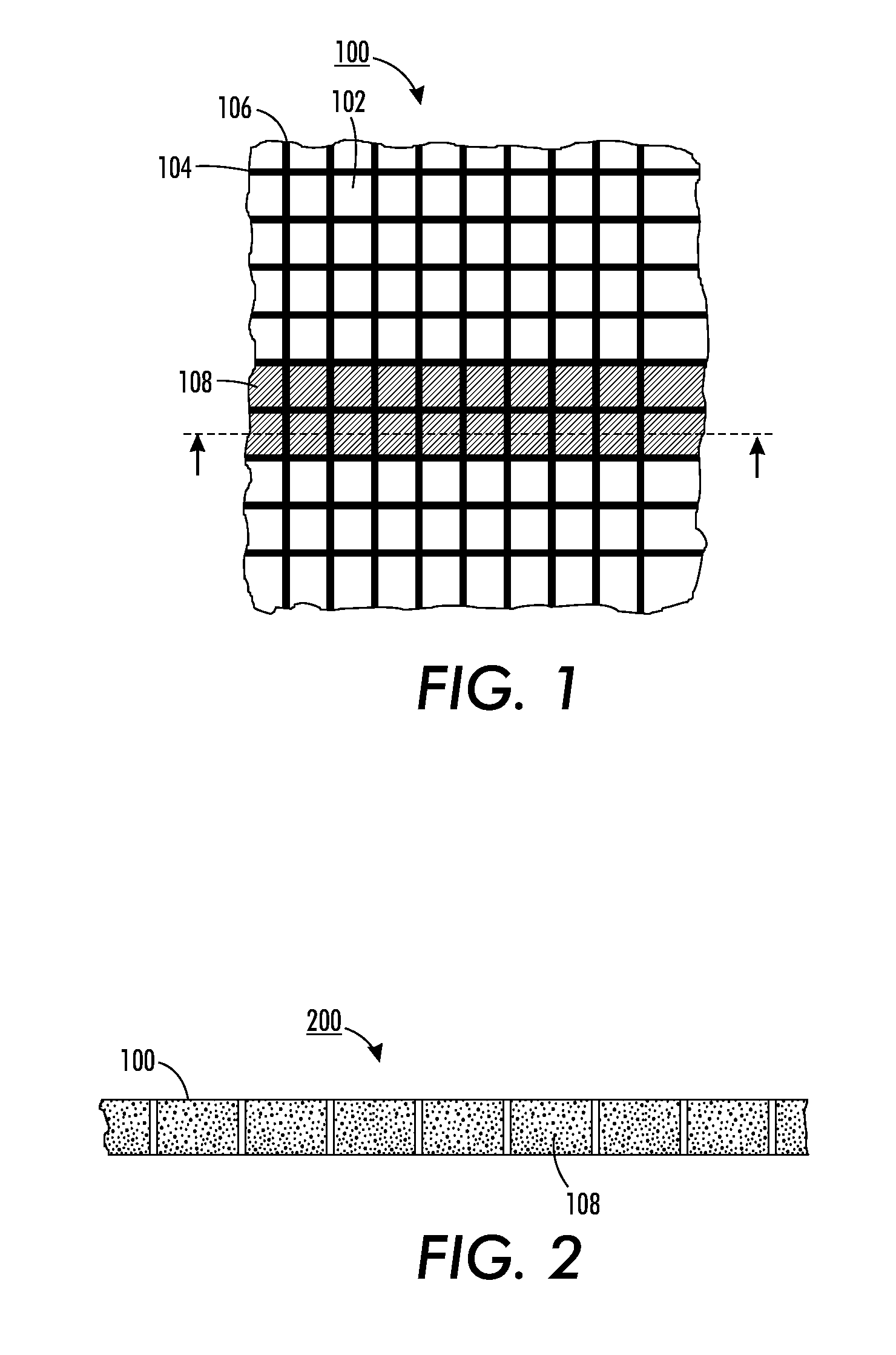

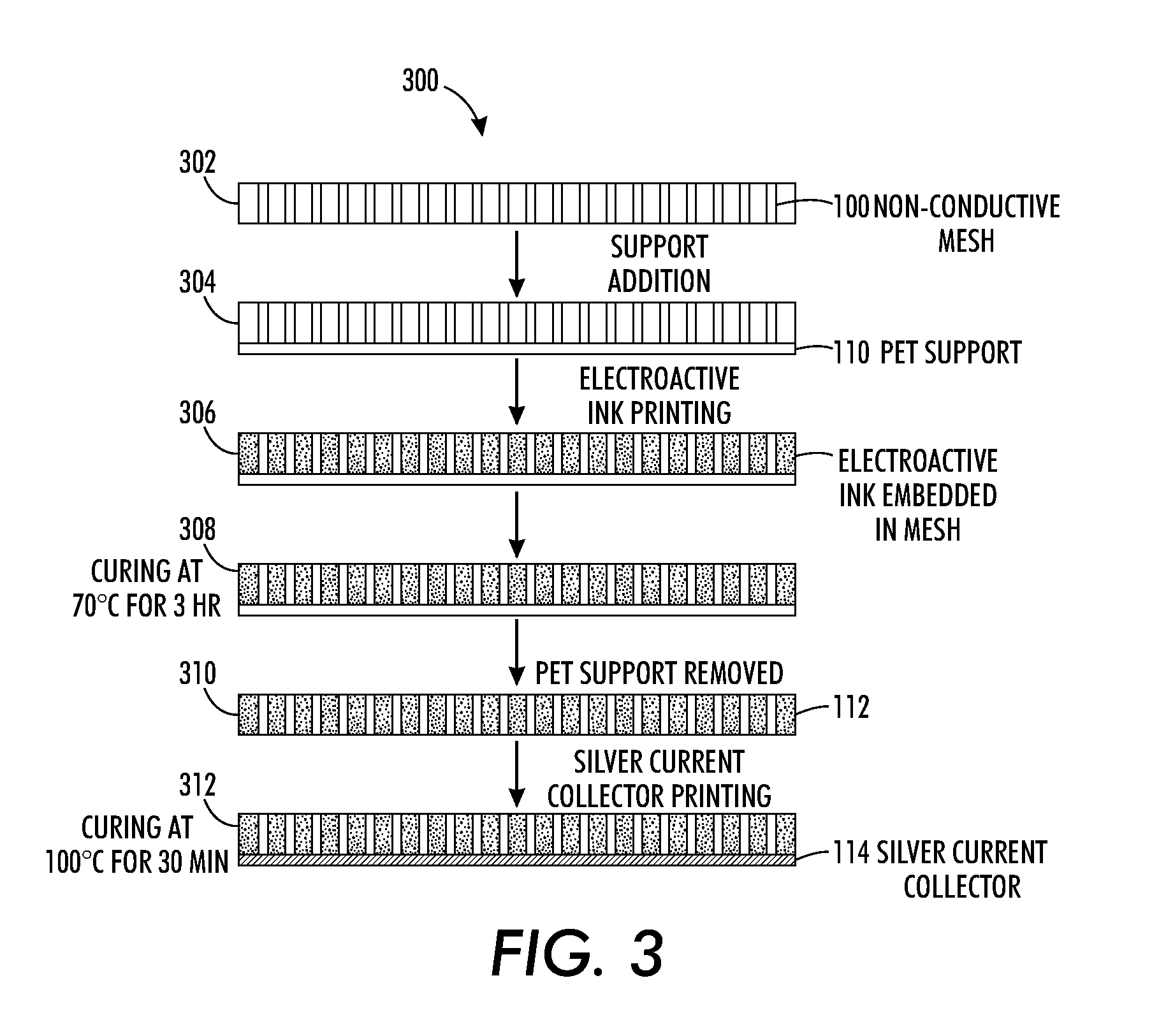

Highly flexible printed alkaline batteries based on mesh embedded electrodes

InactiveUS20120276434A1Final product manufactureElectrode carriers/collectorsMetallurgyFlexible battery

A flexible battery and a method to form the flexible battery include forming an anode by embedding an anode type electro-active material within a mesh material and associating an anode current collector with the anode. Similarly a cathode is formed by embedding a cathode type electro-active material within a mesh material and a cathode current collector is associated with the cathode. An electrolyte is located between the anode and cathode, and the arrangement is sealed.

Owner:PALO ALTO RES CENT INC

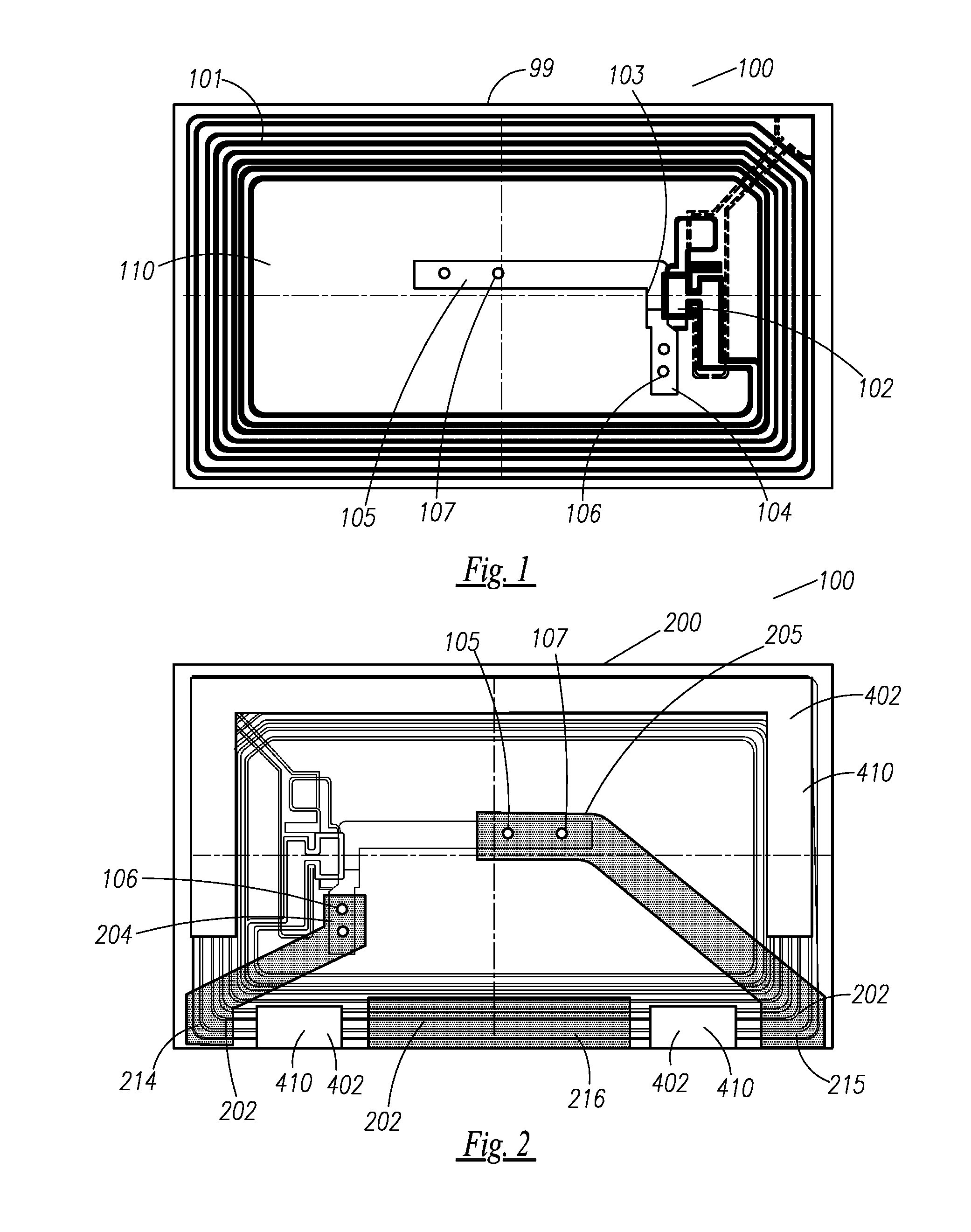

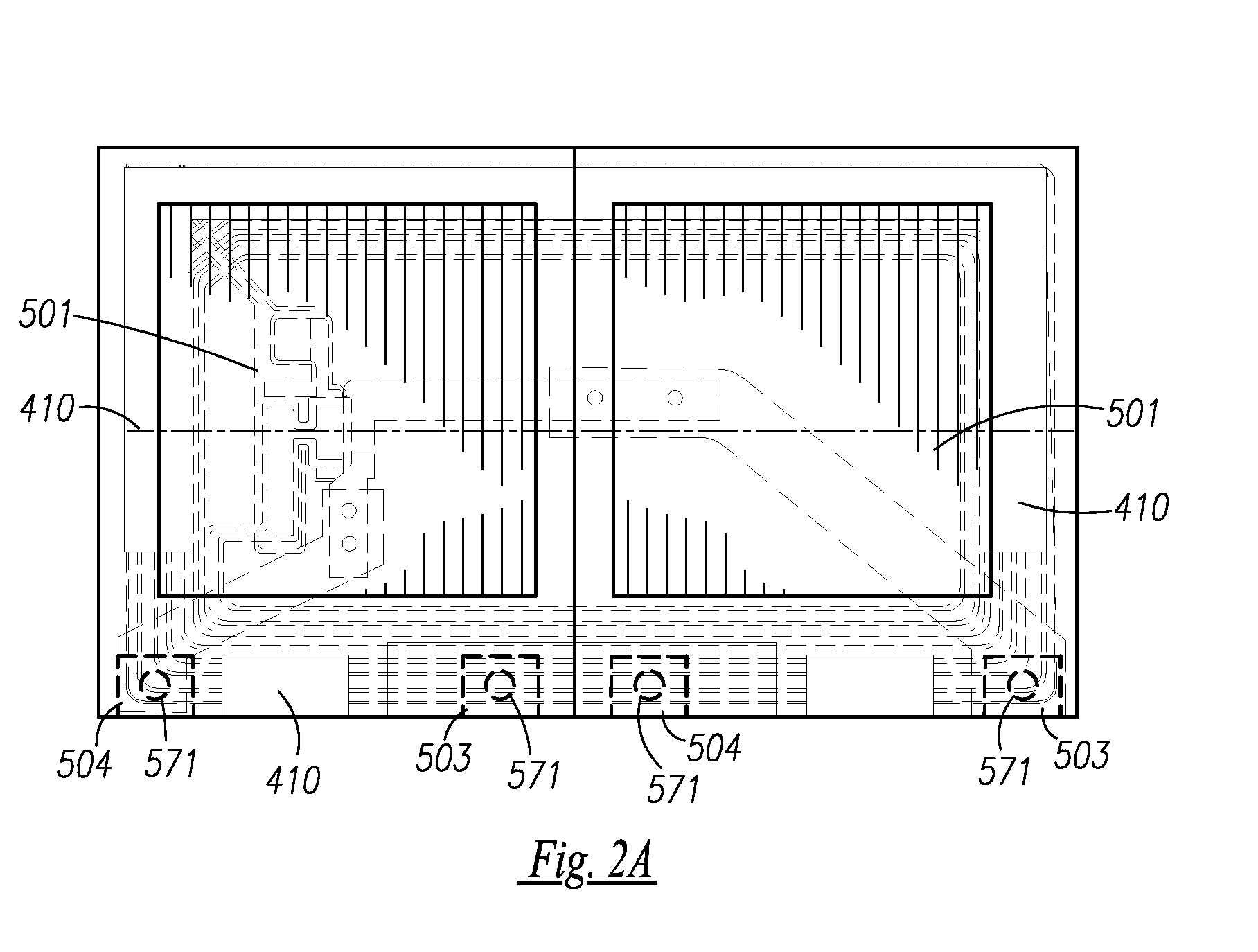

RFID antenna-battery assembly and the method to make the same

ActiveUS20090038746A1Decorative surface effectsPrinted electric component incorporationEngineeringElectronic assemblies

Printed electronics are increasingly becoming an important industry, thus innovations to integrate the various components and processes would be very useful to expand this industry. Disclosed are innovational concepts that would be very useful to accelerate this industry. Webs of printed electronics, antennas, power sources (cells / batteries), and assembly substrates can be merged together to form a completed electronic assembly that could be, for example, in label form or in a stand alone electronic device.

Owner:BLUE SPARK INNOVATIONS LLC

Polymer electrolyte battery and method of producing same

InactiveCN1395750AReduces the possibility of short circuitsImprove performanceFinal product manufactureElectrode carriers/collectorsPolymer electrolytesEngineering

In a polymer electrolyte battery including a battery element having a cathode and an anode coiled through a polymer electrolyte, a section of the battery element perpendicular to the coiling axis has a curved form. As compared with a polymer electrolyte battery having a flat plate type battery element curved, the former battery has an extremely low possibility of short-circuit at the end of an electrode and excellent battery characteristics.

Owner:MURATA MFG CO LTD

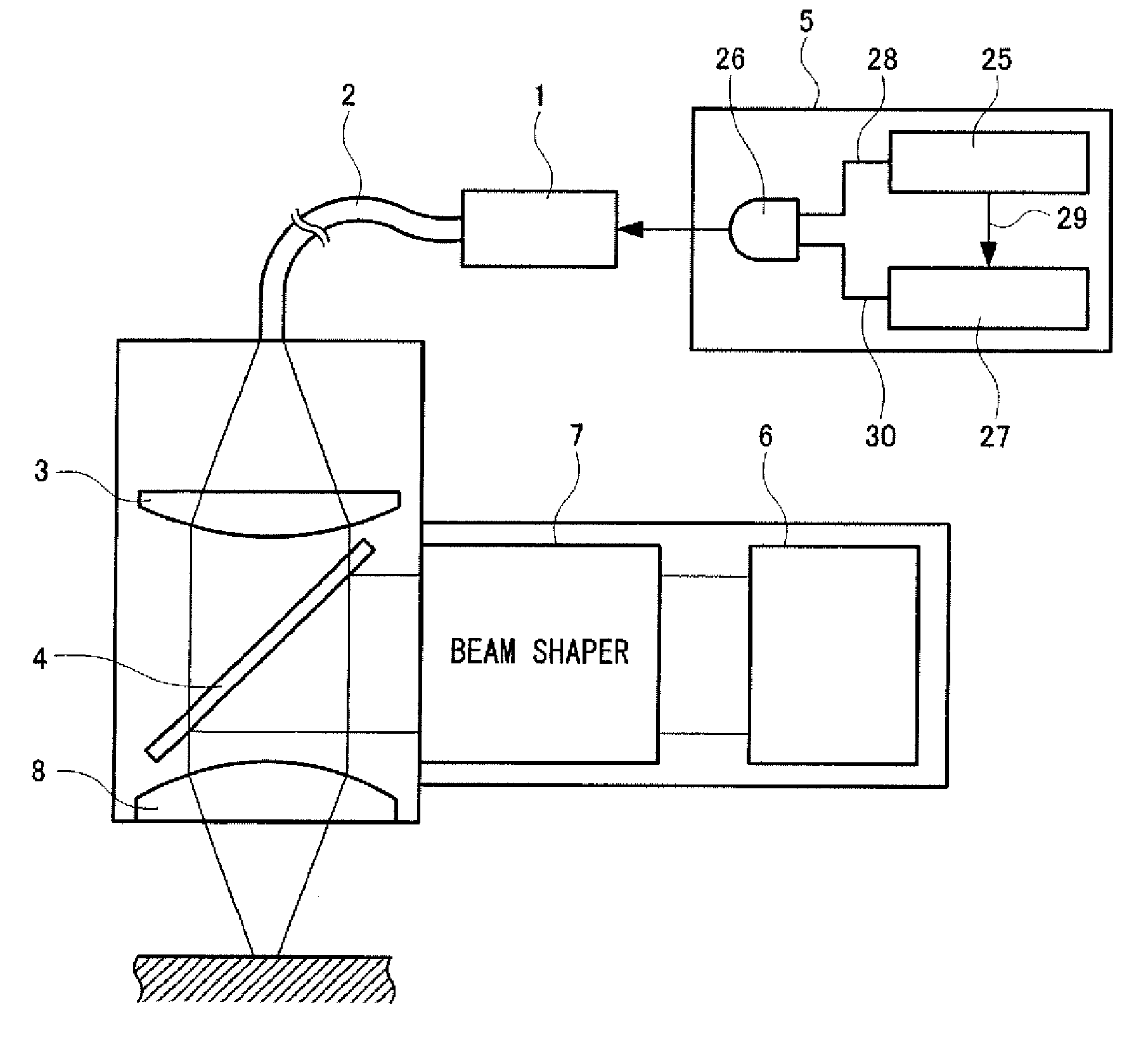

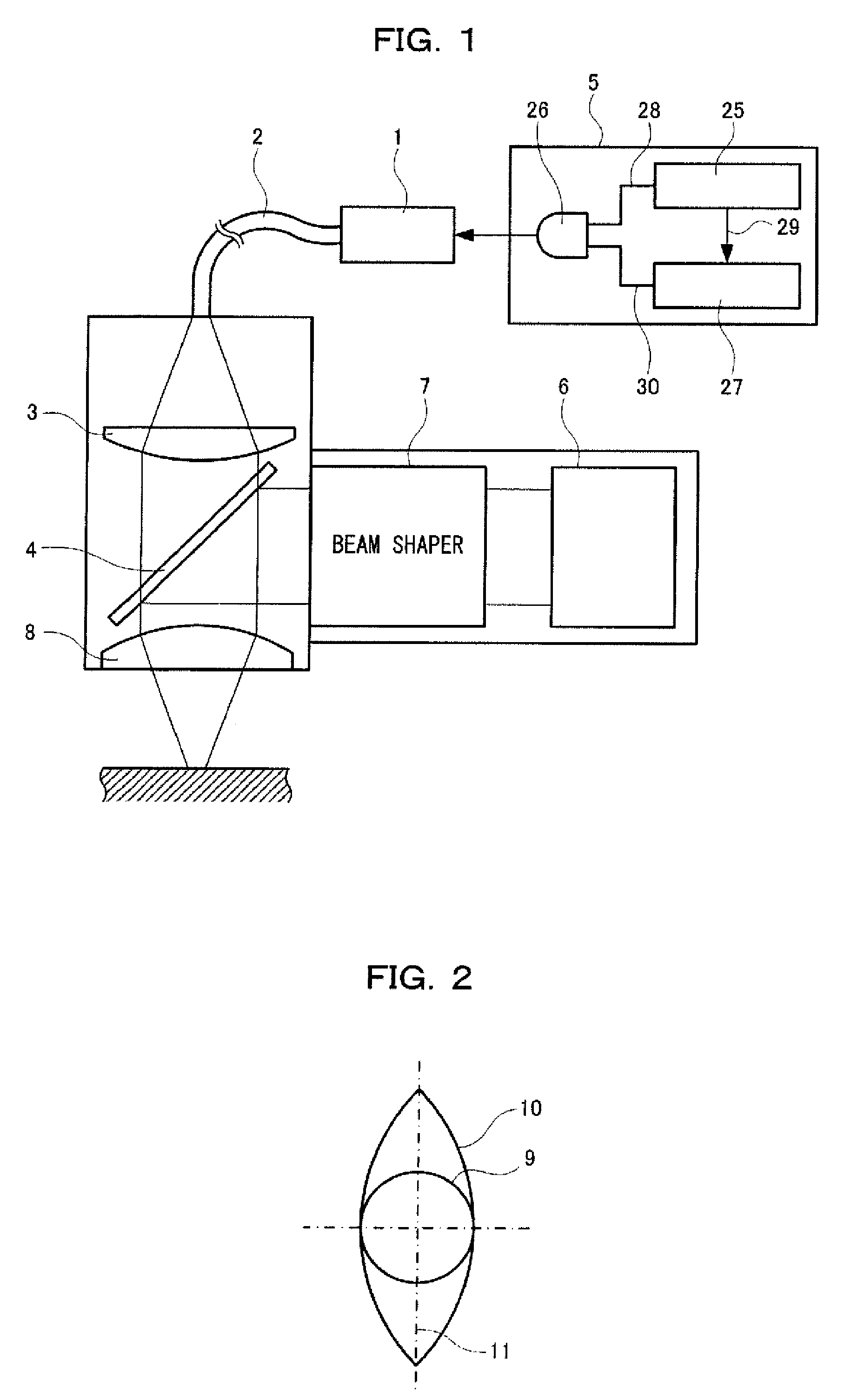

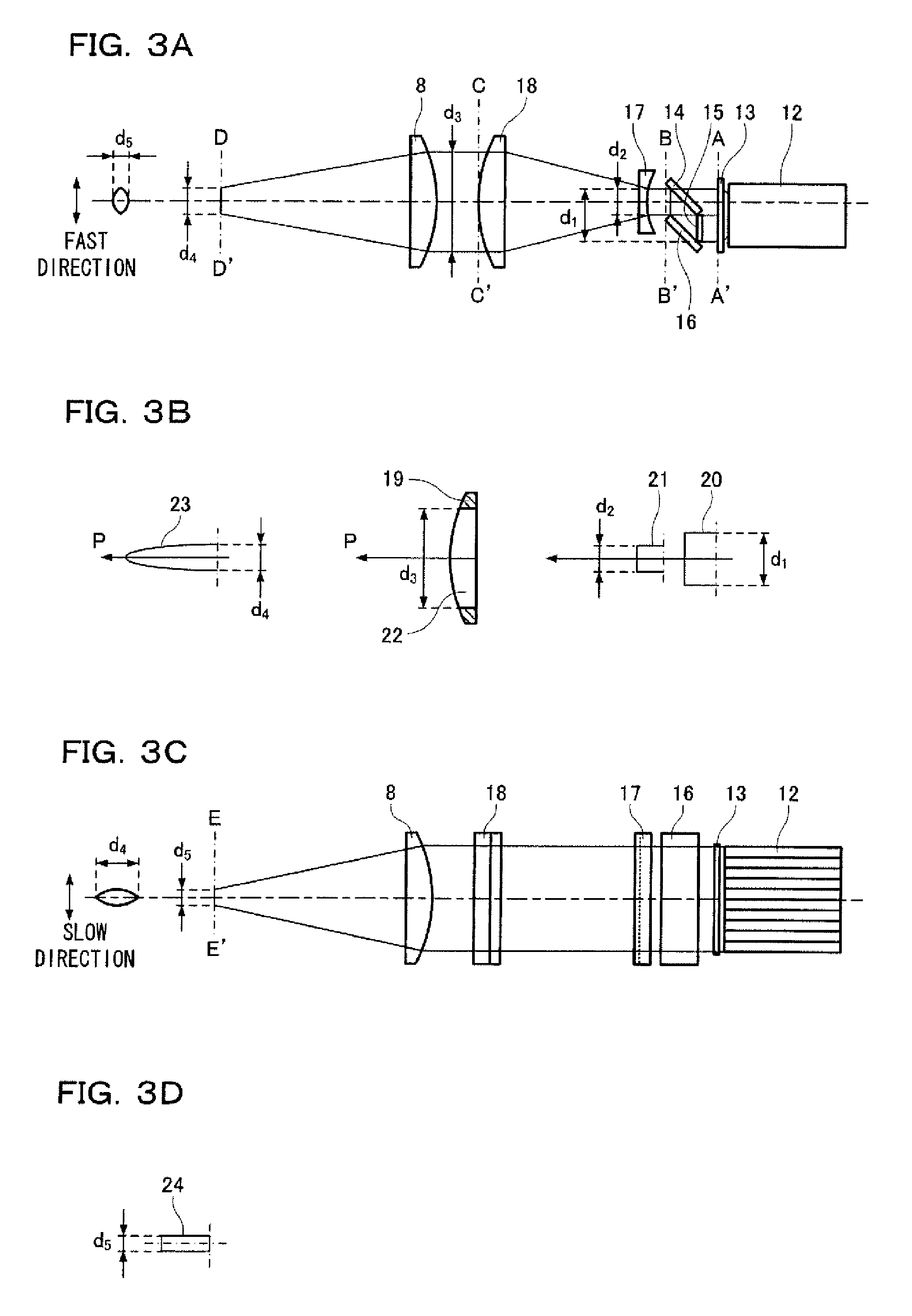

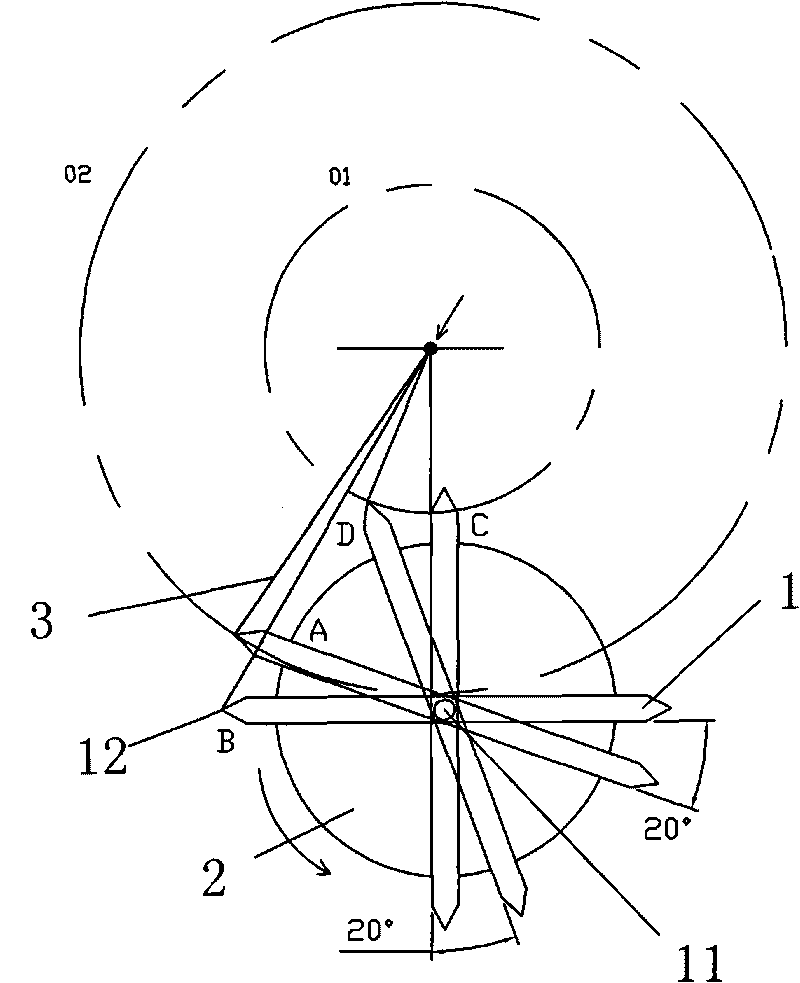

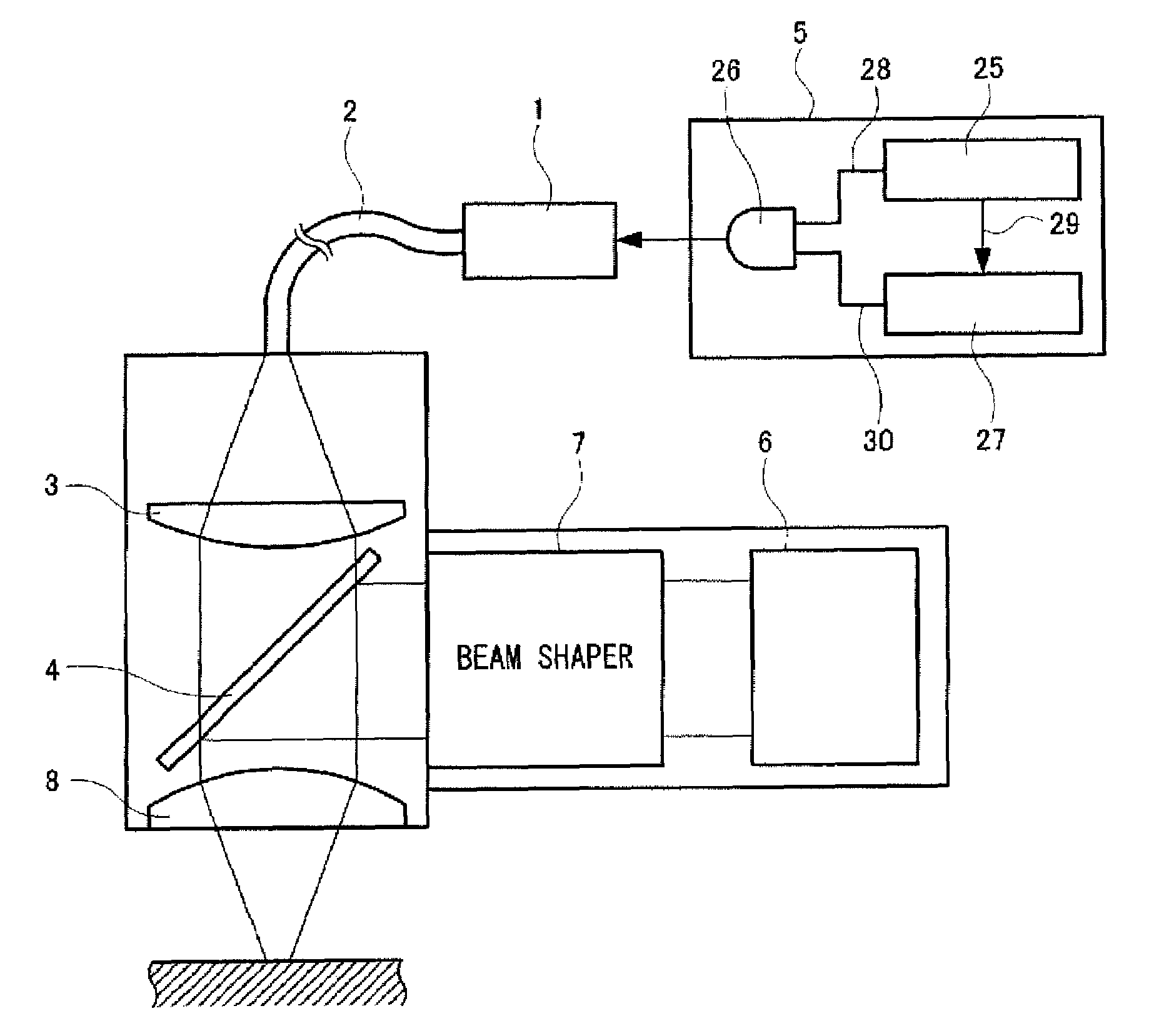

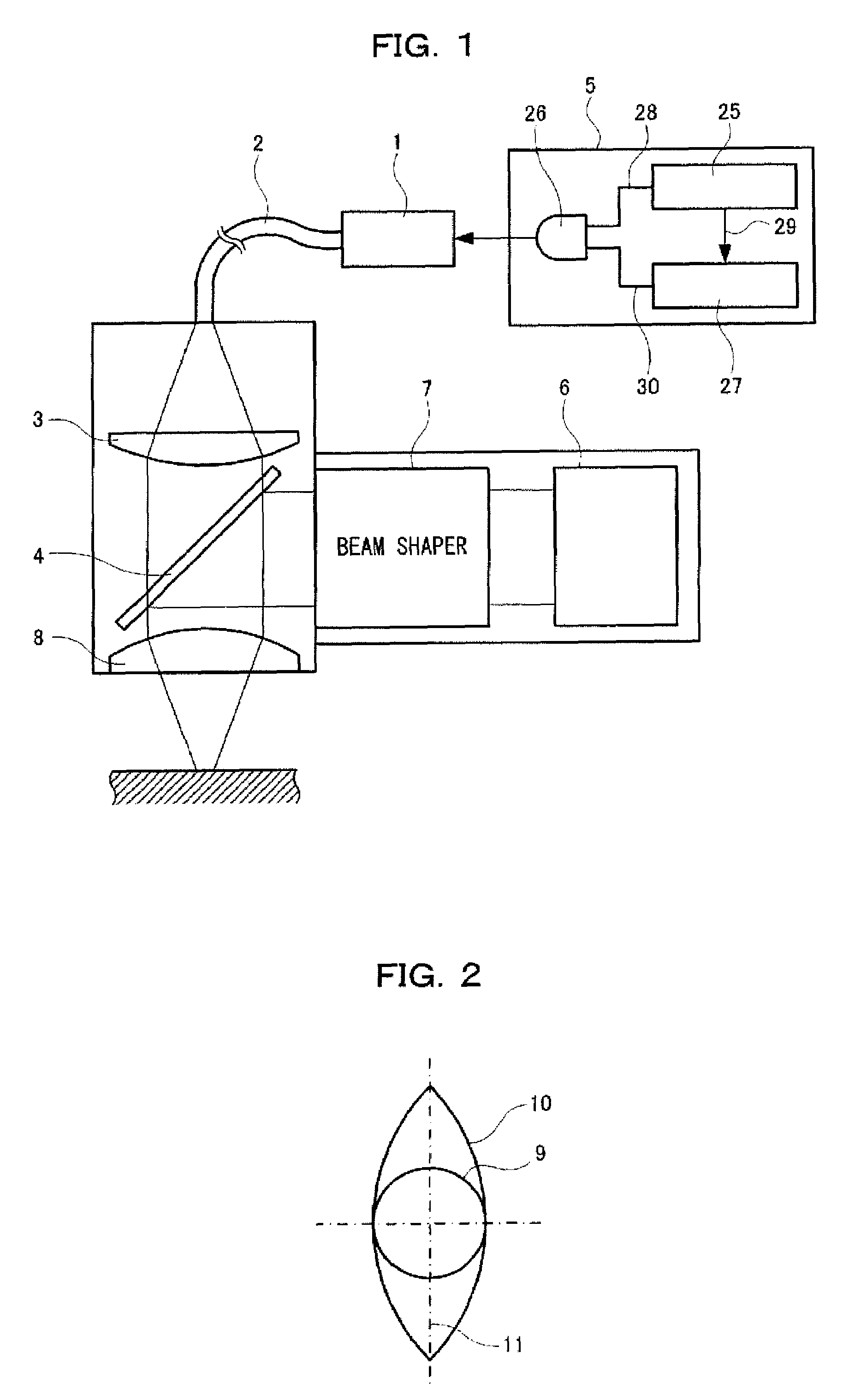

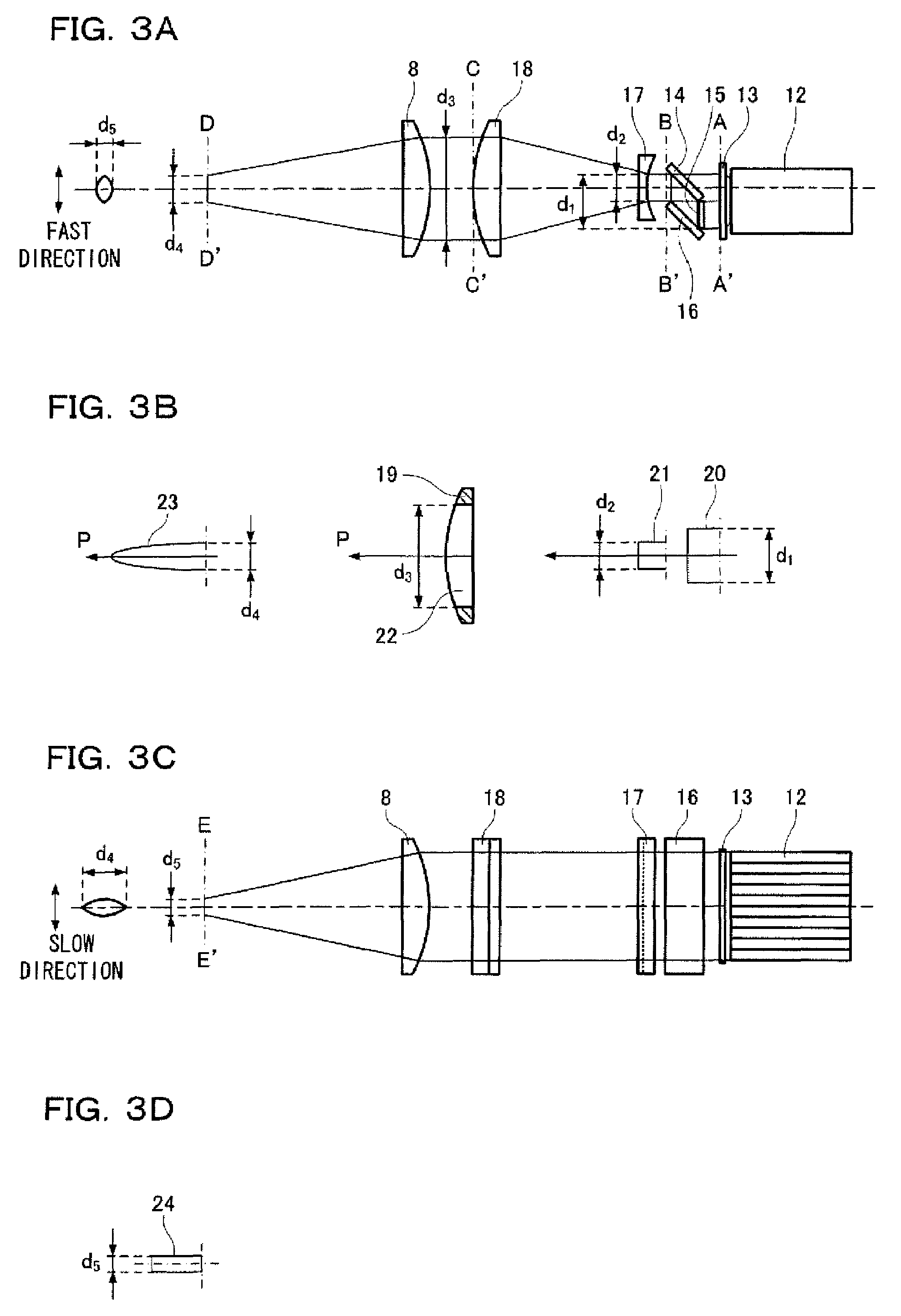

Laser apparatus and manufacturing method of a battery

InactiveUS20080253410A1Reduced stabilityReduction in welding speedLaser detailsNanobatteriesMetallic materialsOptoelectronics

A laser apparatus is provided which is capable of achieving deep penetration into an aluminum-like metal material without causing welding defects such as spatters or cracks and performing high-speed pulse seam welding. The laser apparatus includes a pulse power source that generates a current signal and a mask signal for masking a fluctuation component included in the current signal, and which supplies a current signal in which a fluctuation component has been masked by the mask signal to a YAG pulsed laser oscillator. In addition, the laser apparatus sets the spot shape of a CW laser light oscillated by a CW laser oscillator to a rhombic streamlined shape, and causes a focus spot of the CW laser light to include a circular focus spot of a pulsed laser light.

Owner:PANASONIC CORP

Lead sealant film and non-aqueous electrolyte battery

A lead sealant film and a non-aqueous electrolyte battery are provided. The lead sealant film includes a laminated structure composed of an inner layer, an intermediate layer, and an outer layer. The intermediate layer includes a first acid-modified polypropylene having a high melting-point, and each of the inner layer and the outer layer includes a second acid-modified polypropylene having a lowmelting-point. A difference between the melting point of the first acid-modified polypropylene and the melting point of the second acid-modified polypropylene is from 20 DEG C. to 25 DEG C.

Owner:MURATA MFG CO LTD

Polymer electrolyte battery and method of producing same

InactiveUS7163762B2Improve featuresReduce the possibilityFinal product manufactureElectrode carriers/collectorsPolymer electrolytesEngineering

In a polymer electrolyte battery including a battery element having a cathode and an anode coiled through a polymer electrolyte, a section of the battery element perpendicular to the coiling axis has a curved form. As compared with a polymer electrolyte battery having a flat plate type battery element curved, the former battery has an extremely low possibility of short-circuit at the end of an electrode and excellent battery characteristics.

Owner:MURATA MFG CO LTD

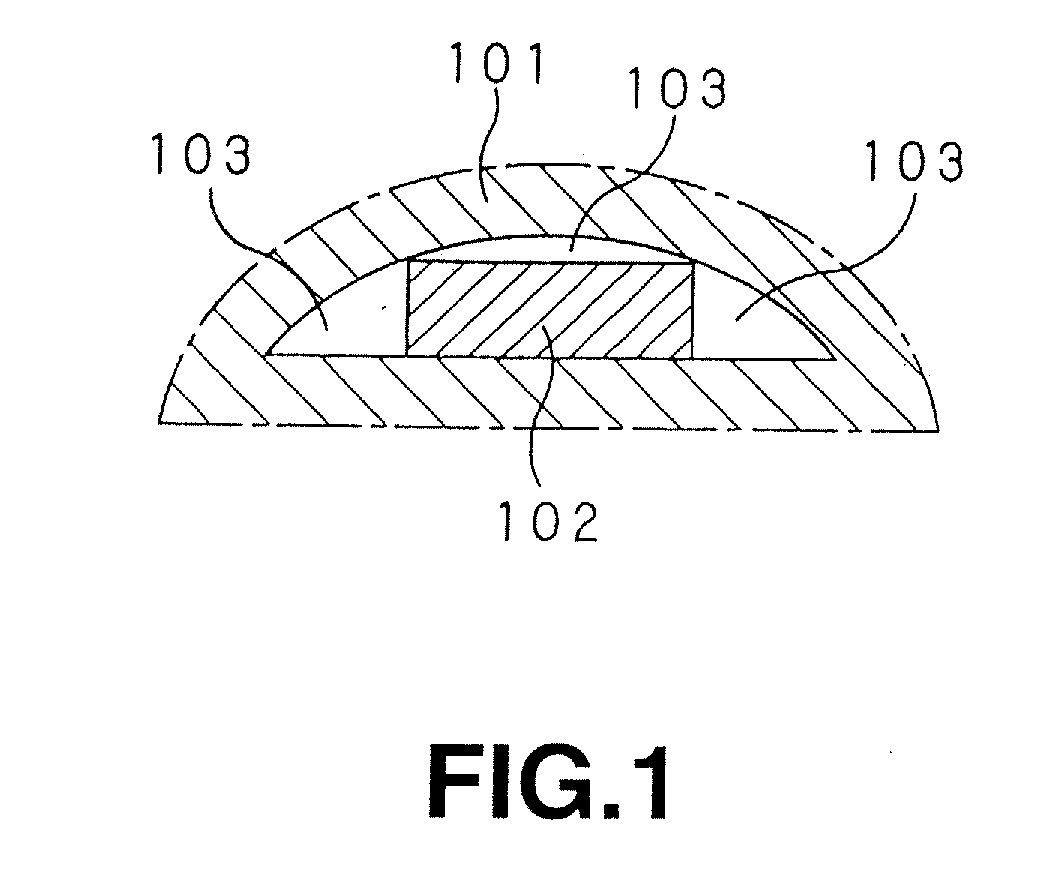

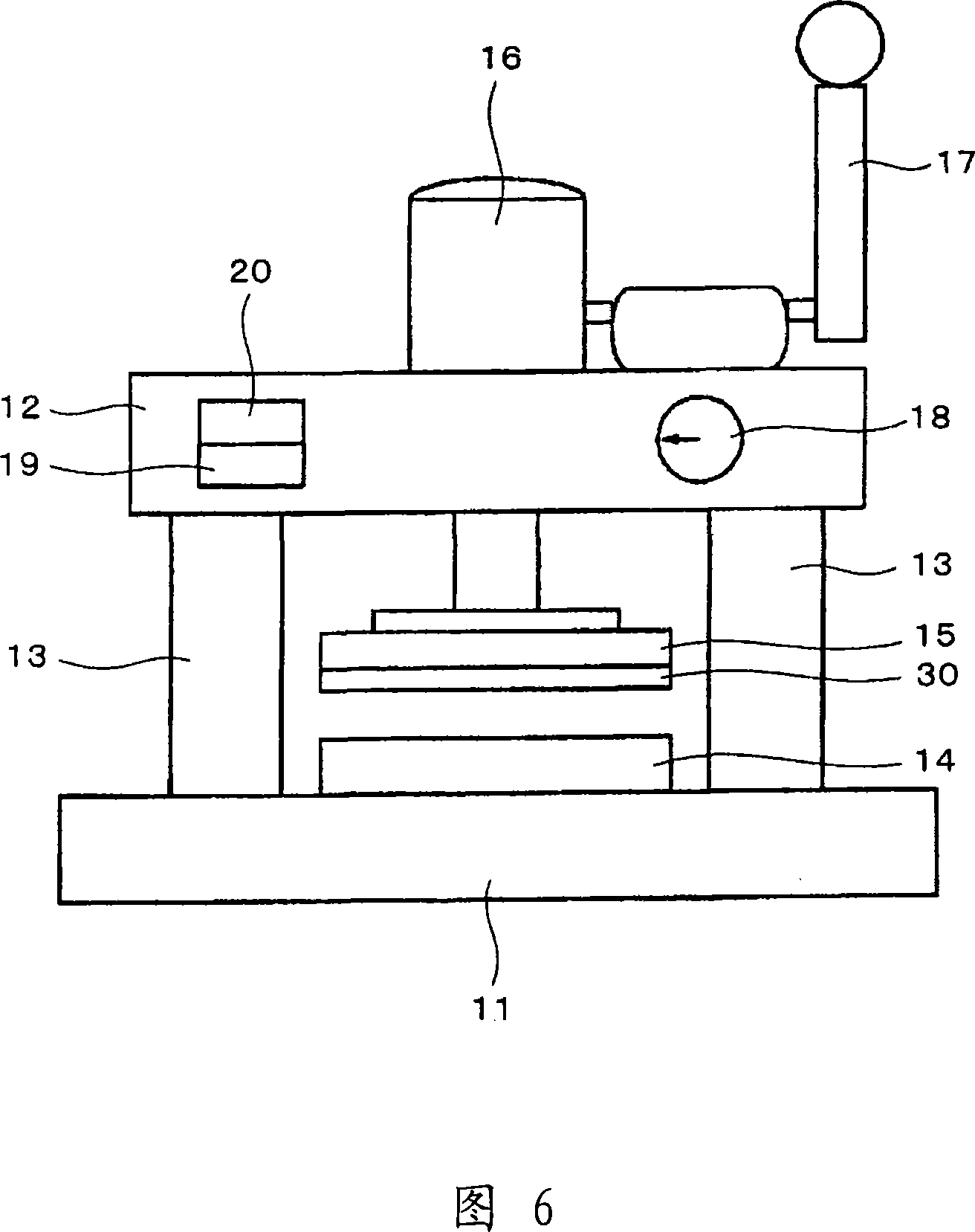

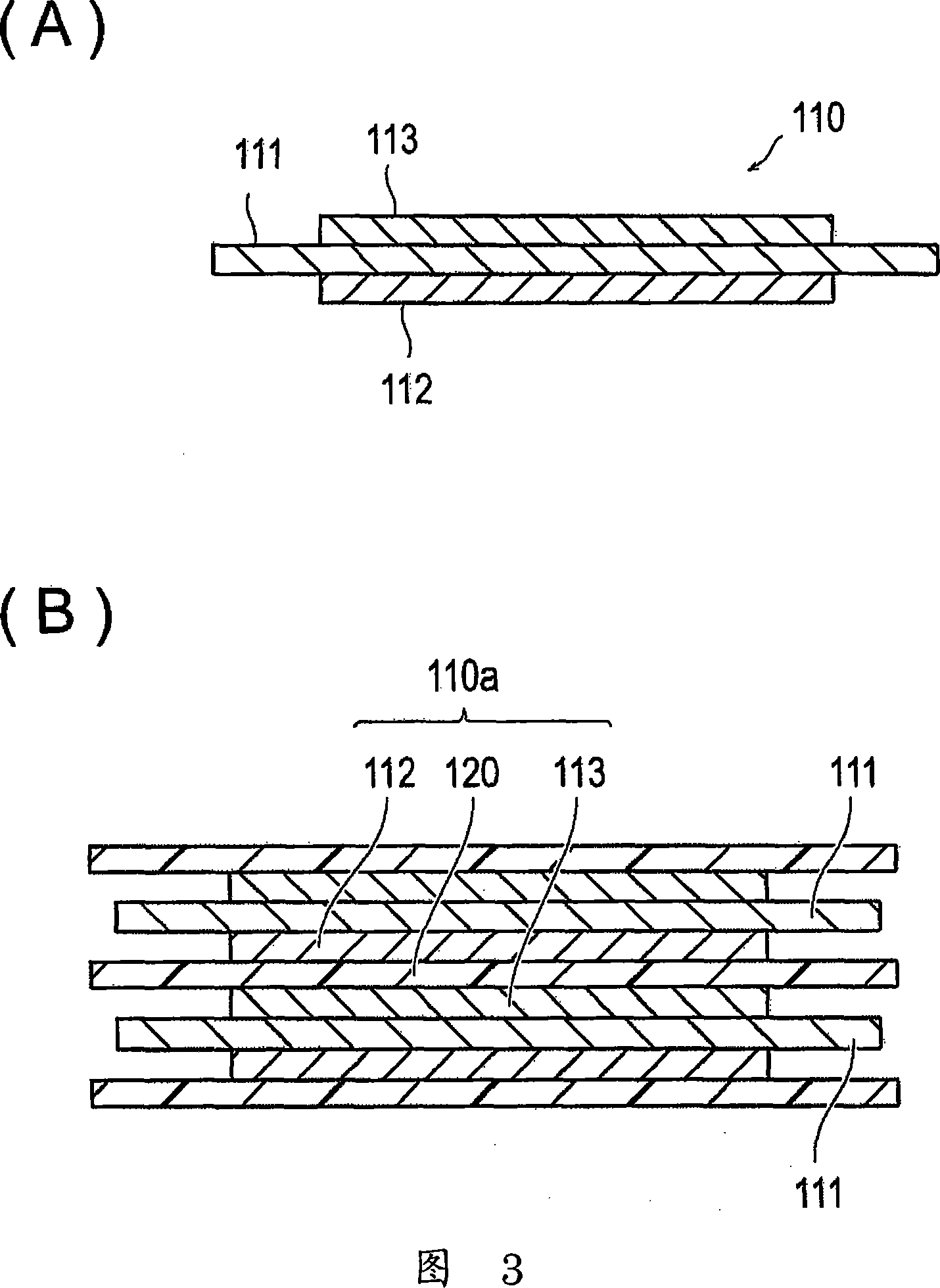

Bipolar battery and method of manufacturing the same

ActiveUS20080138706A1Improve battery performanceLarge-sized flat cells/batteriesFinal product manufactureEngineeringGas bubble

Disclosed are a bipolar battery, a bipolar battery component and a method of manufacturing the same. The bipolar battery minimizes the occurrence of gas bubbles to provide superior battery performance. A battery element has a plurality of bipolar electrodes stacked upon one another while interposing separators therebetween. The bipolar electrode includes a collector formed with a cathode on one surface and an anode on the other surface. The component is a charging part with charging material disposed between collectors and separators to surround at least a periphery of the cathode and a periphery of the anode. An exhaust part is mounted to the charging part to exhaust a residual gas bubble from an inner space to outside of the inner space when stacking the bipolar electrodes.

Owner:NISSAN MOTOR CO LTD

Bipolar battery and method of manufacturing the same

InactiveCN101202365ASuppress mix-inImprove performanceLarge-sized flat cells/batteriesFinal product manufactureFilling materialsAir bubble

The present invention provides a bipolar battery which can restrain intermingle of the air bubble and has excellent battery performance and the manufacturing method thereof. The bipolar battery comprises a battery element, a filling part (20) and an air discharging part (32); the battery element is formed by stacking a plurality of bipolar electrodes separating with the electrolyte layer, the bipolar electrode is formed with a positive pole at one surface of the current collector (111) and is formed with a negative pole at the other surface; the filling part (20) is arranged with filling material (114) in the mutual space of the adjacent current collector thereby that the filling material at least surrounds the circumference of the positive pole and the circumference of the negative pole;the air discharging part (32) is arranged on the filling part to discharge the air residual in the inner space surrounded by the current collector, the electrolyte layer and the filling material to the outside of the inner space when stacking the bipolar electrodes.

Owner:NISSAN MOTOR CO LTD

Nonaqueous secondary battery, manufacturing method thereof and electrolyte

InactiveUS20160294016A1Reduce thicknessAvoid performanceFinal product manufactureSmall-sized flat cells/batteriesEngineeringFluid electrolytes

A nonaqueous secondary battery, a manufacturing method thereof, and an electrolyte. The battery includes a positive electrode, a negative electrode, a substrate and an electrolyte, in which respective end surfaces of the positive electrode and the negative electrode face each other at a distance, the positive electrode and the negative electrode are arranged in substantially the same plane, the substrate fixingly supports the positive electrode and the negative electrode, the electrolyte is present between the facing end surfaces of the positive electrode and the negative electrode, the electrolyte is involved in a battery reaction between the positive electrode and the negative electrode, and the electrolyte contains ion conductive inorganic solid electrolyte particles and a liquid electrolyte component.

Owner:TOKYO OHKA KOGYO CO LTD +1

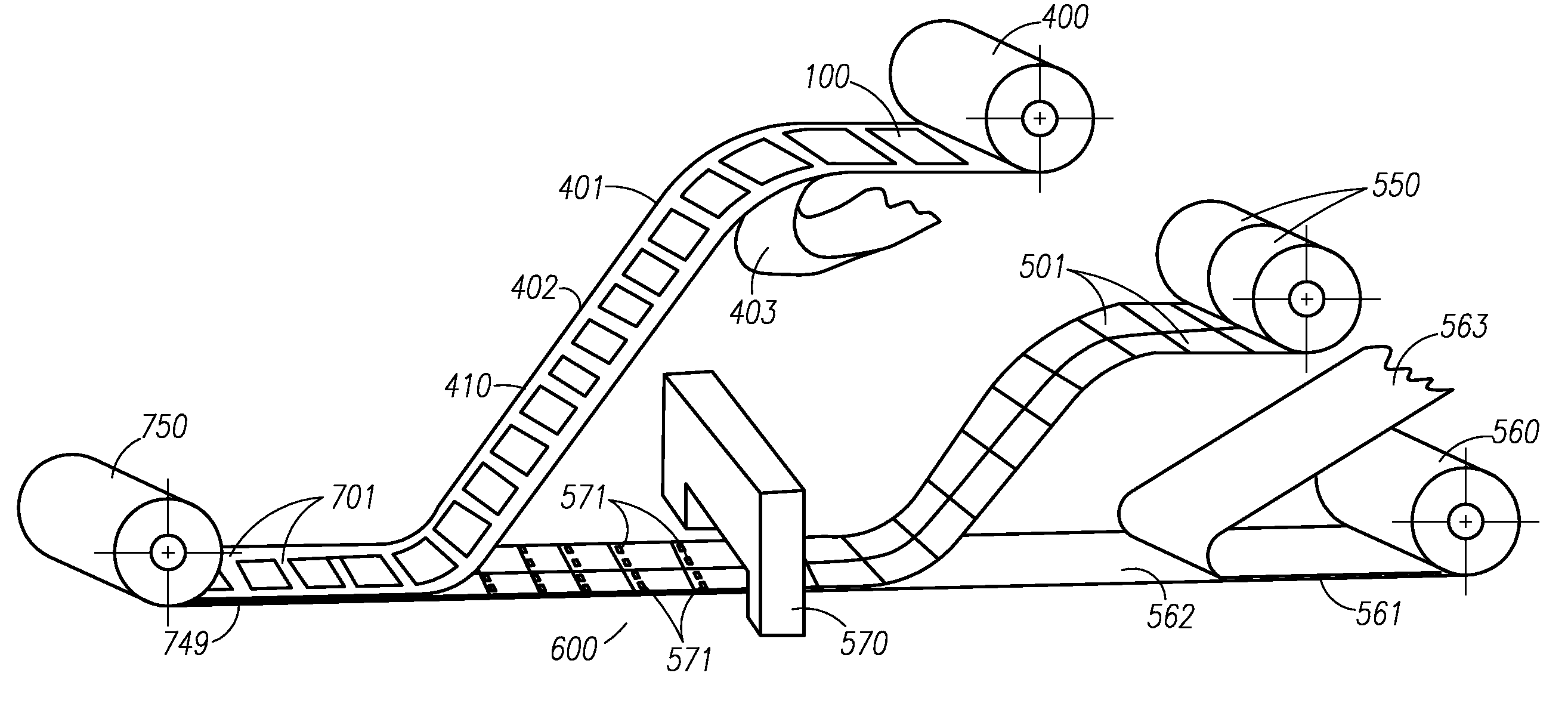

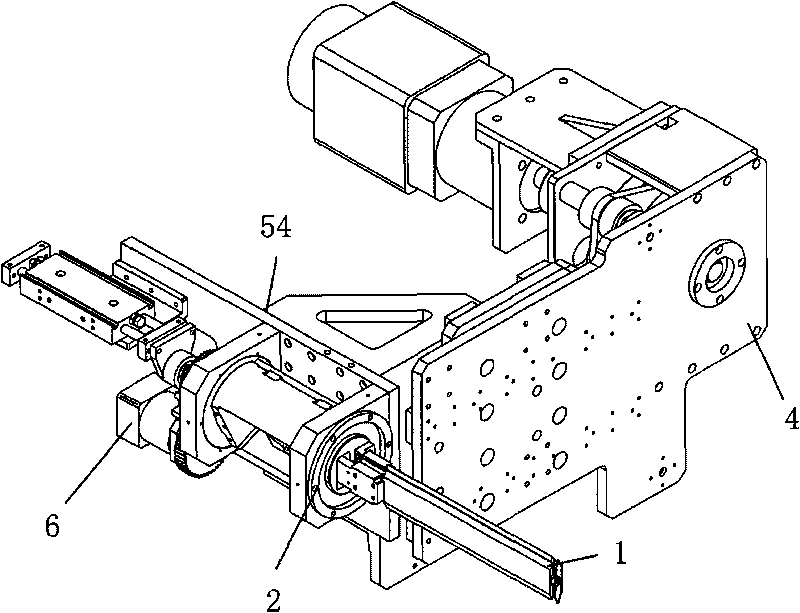

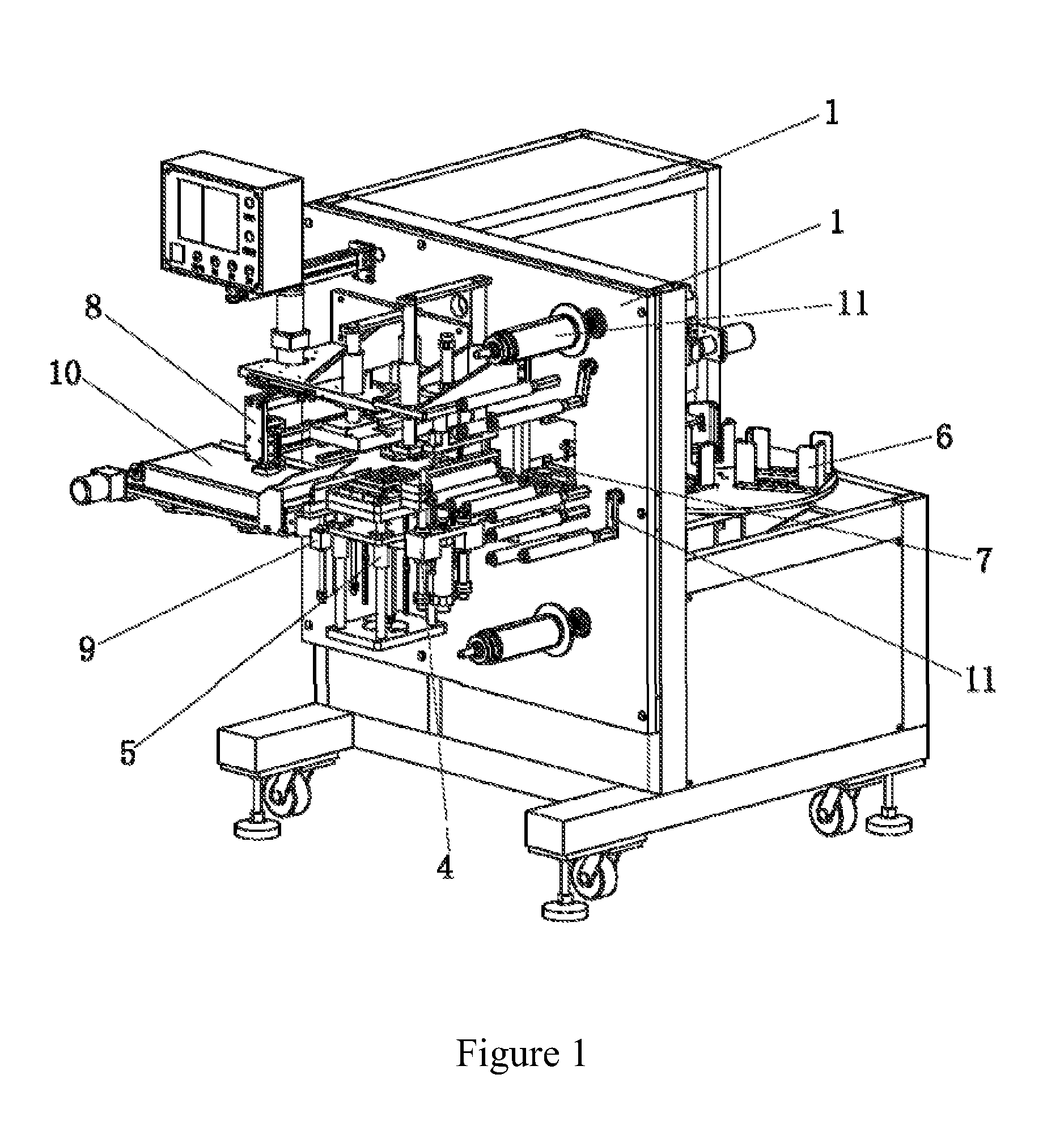

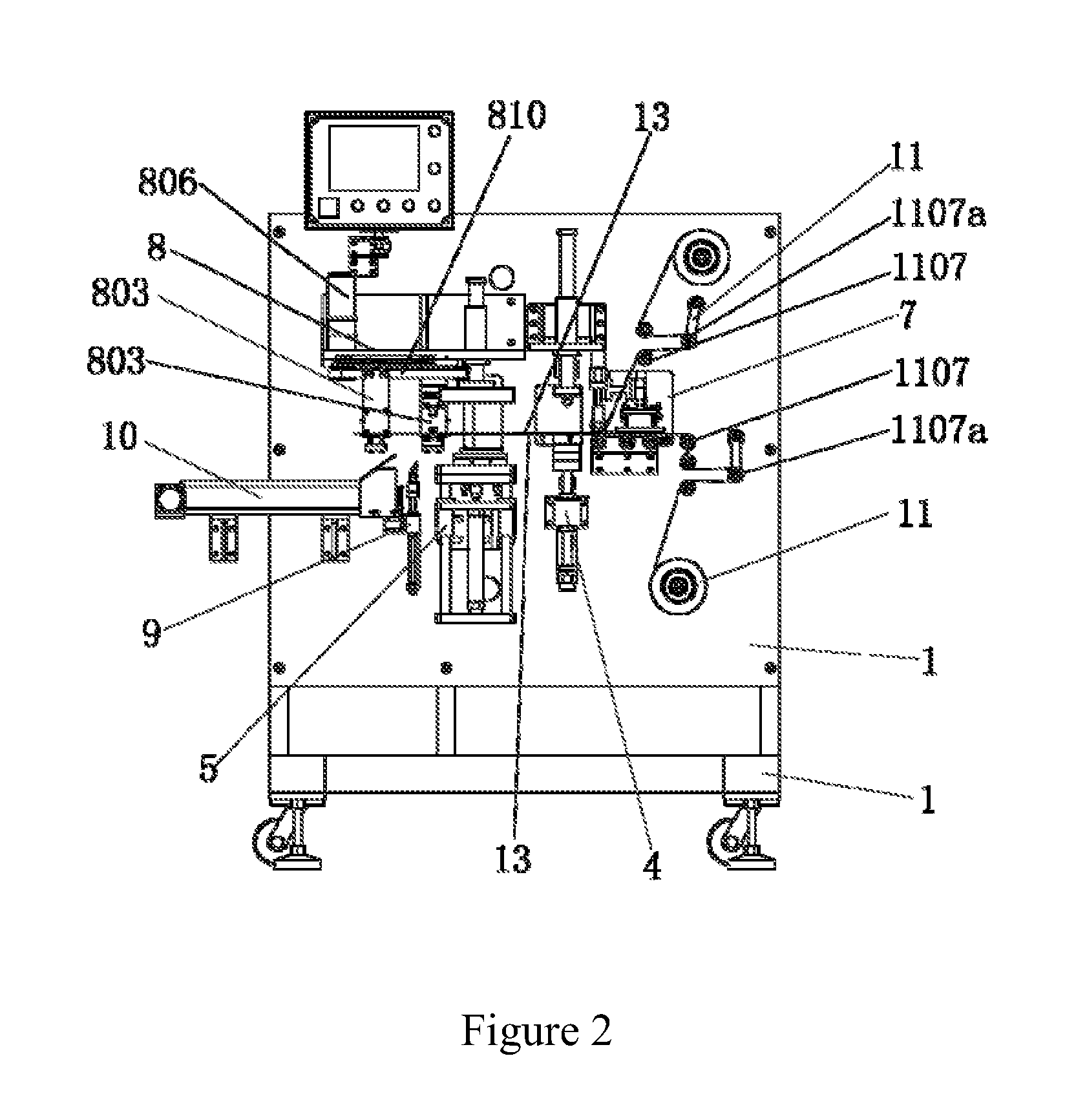

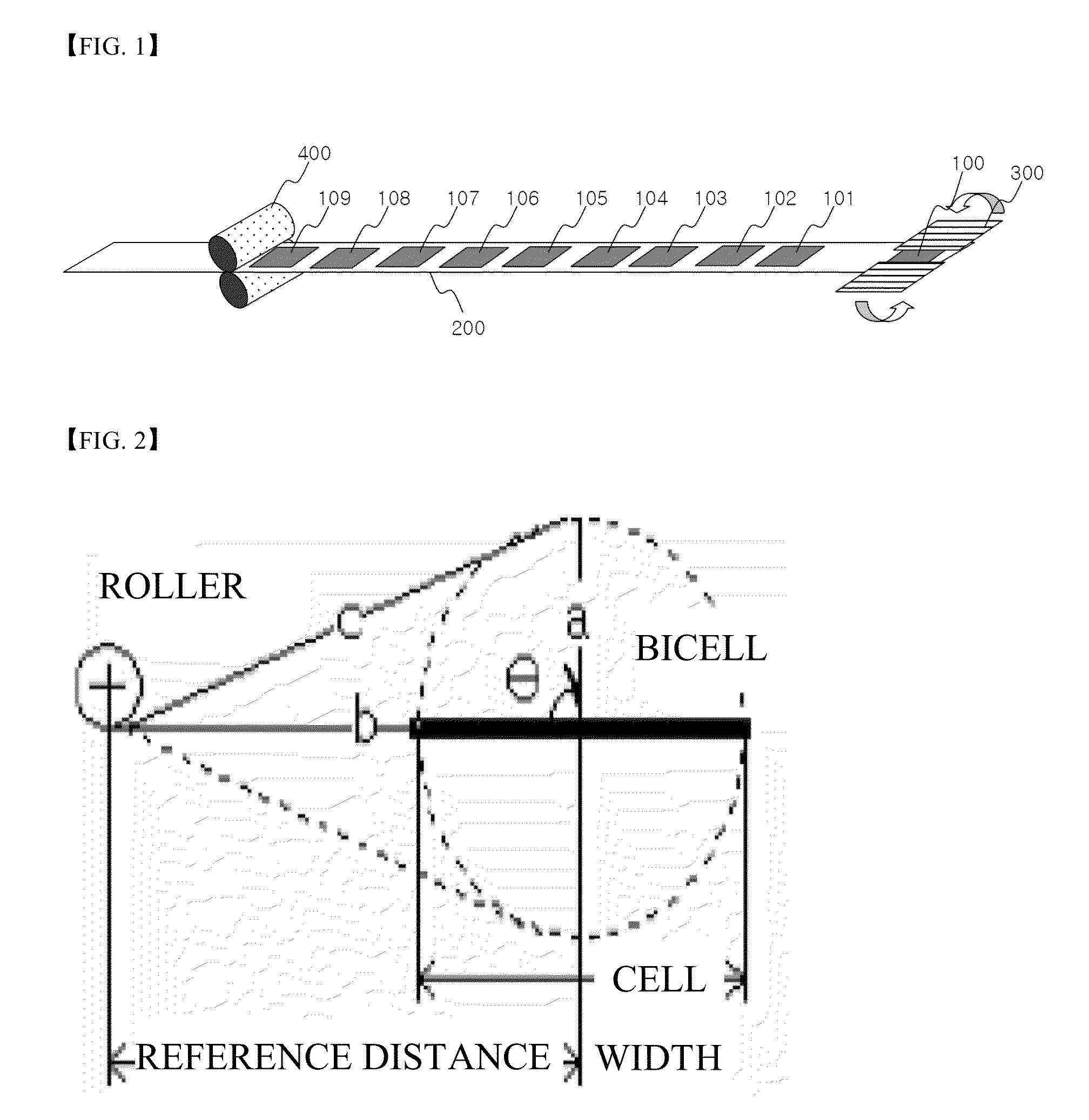

Winding device and winding method

ActiveCN101719561AStable winding tensionAvoid deformationFinal product manufactureFilament handlingEngineeringConductor Coil

Owner:GEESUN AUTOMATION TECH

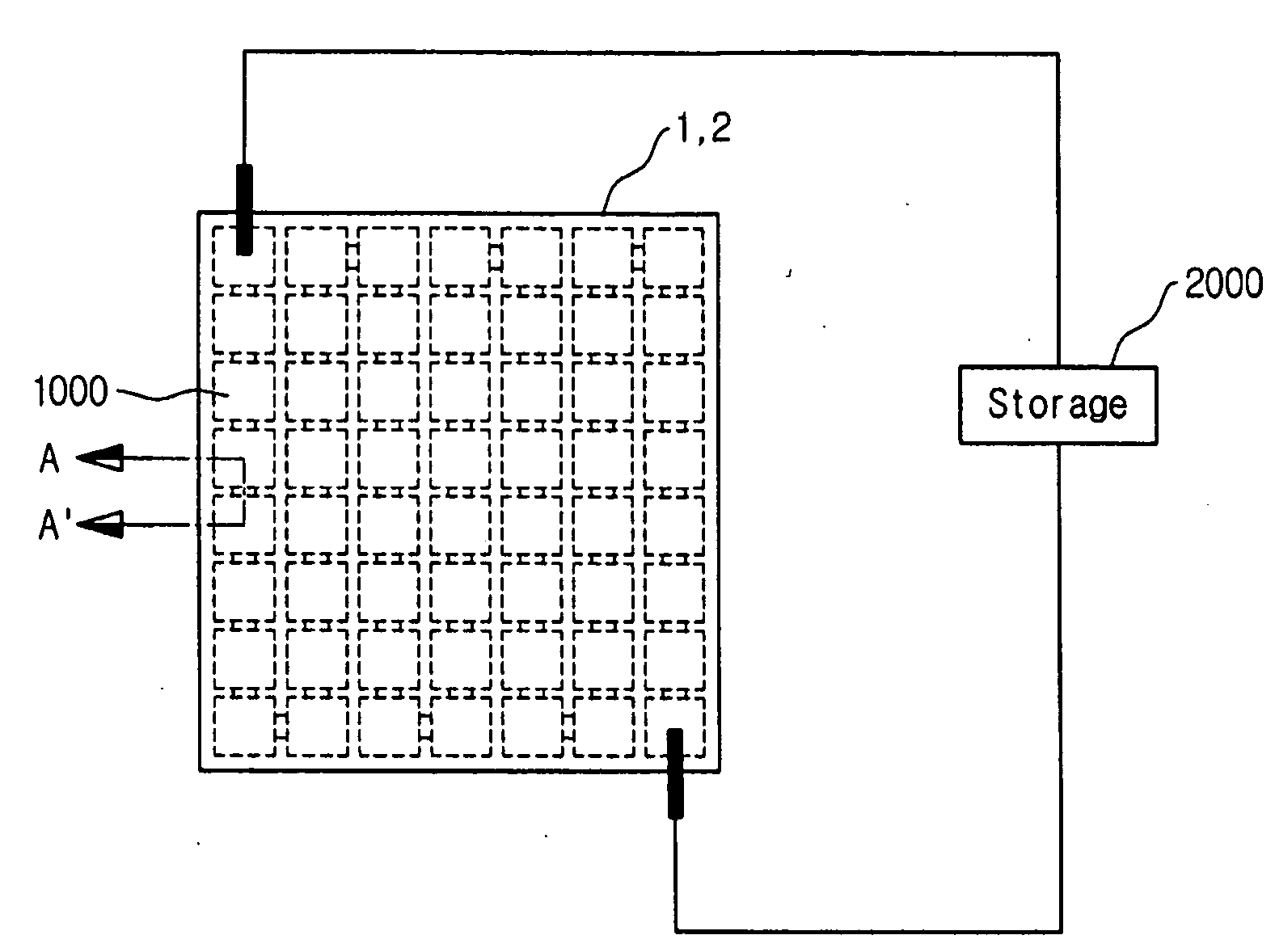

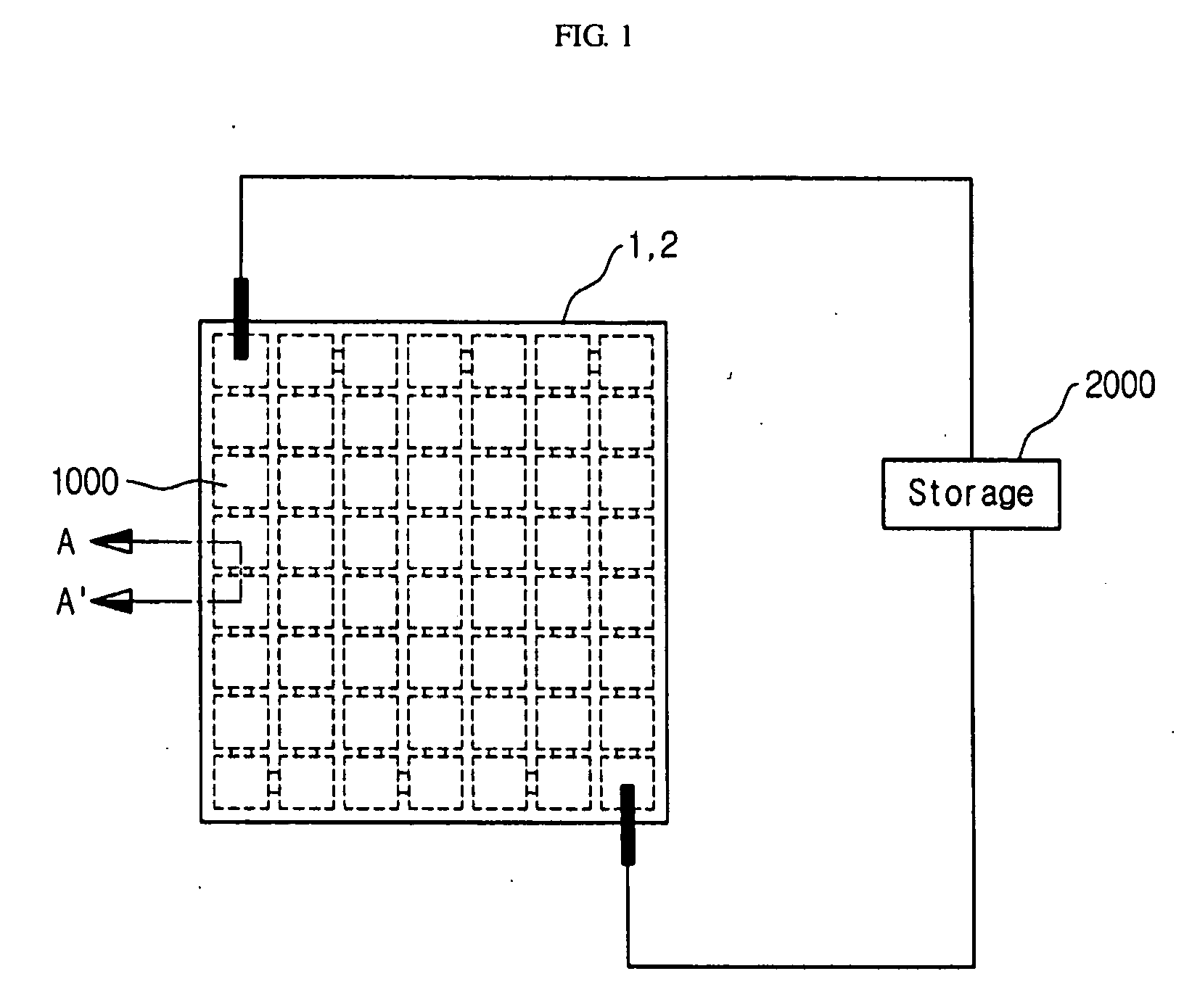

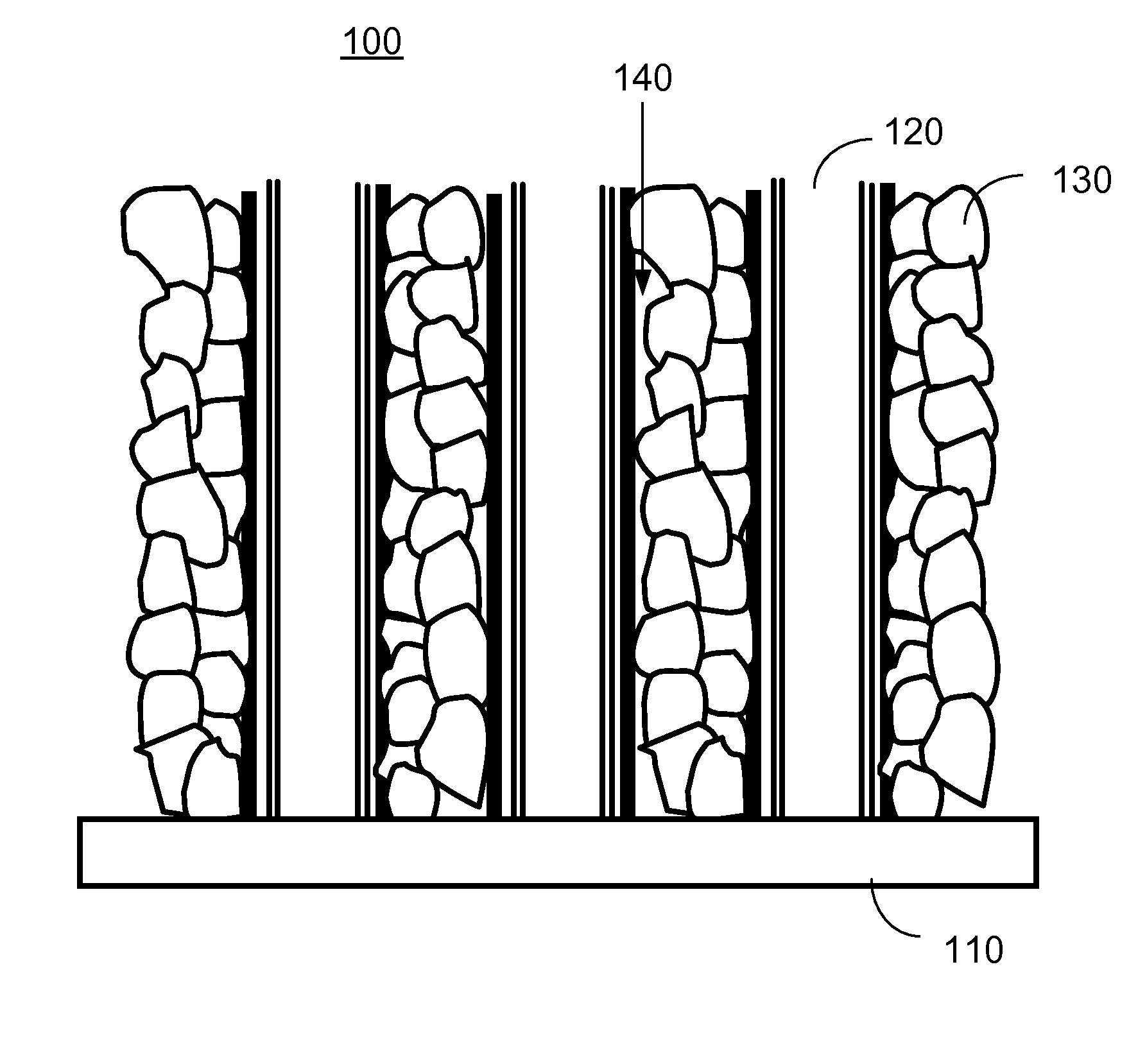

Apparatus for storing energy and method for manufacturing the same

An apparatus for storing energy may include: a plurality of nanowire cells electrically connected to each other; and a storage for storing electrical energy generated from the nanowire cells. Each of the plurality of nanowire cells may include: first and second electrodes disposed at an interval; and a nanowire, which is disposed between the first and the second electrodes and made of a piezoelectric material. The plurality of nanowire cells may be electrically connected, so that voltage or current may be increased. Therefore, wireless recharging of the storage connected to the nanowire cells with electrical energy may be enabled.

Owner:SAMSUNG ELECTRONICS CO LTD +1

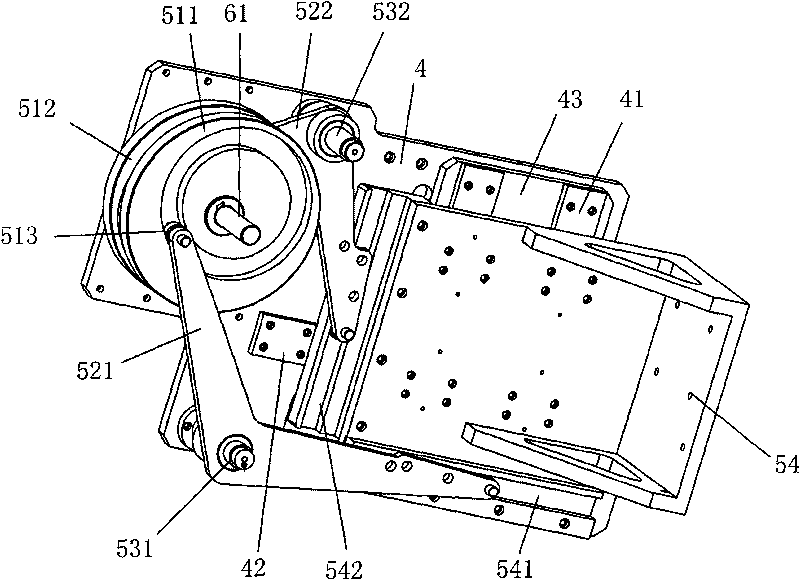

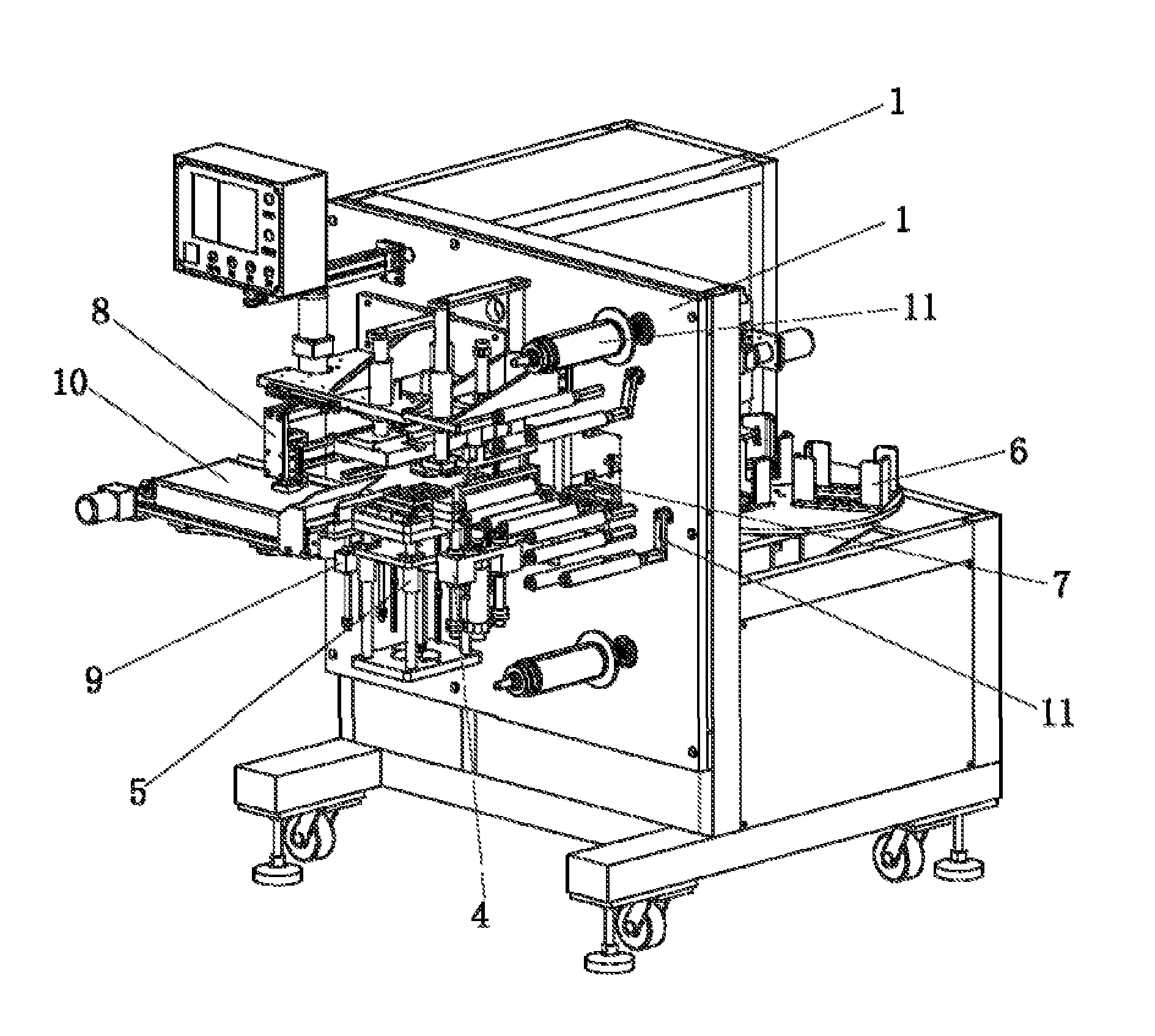

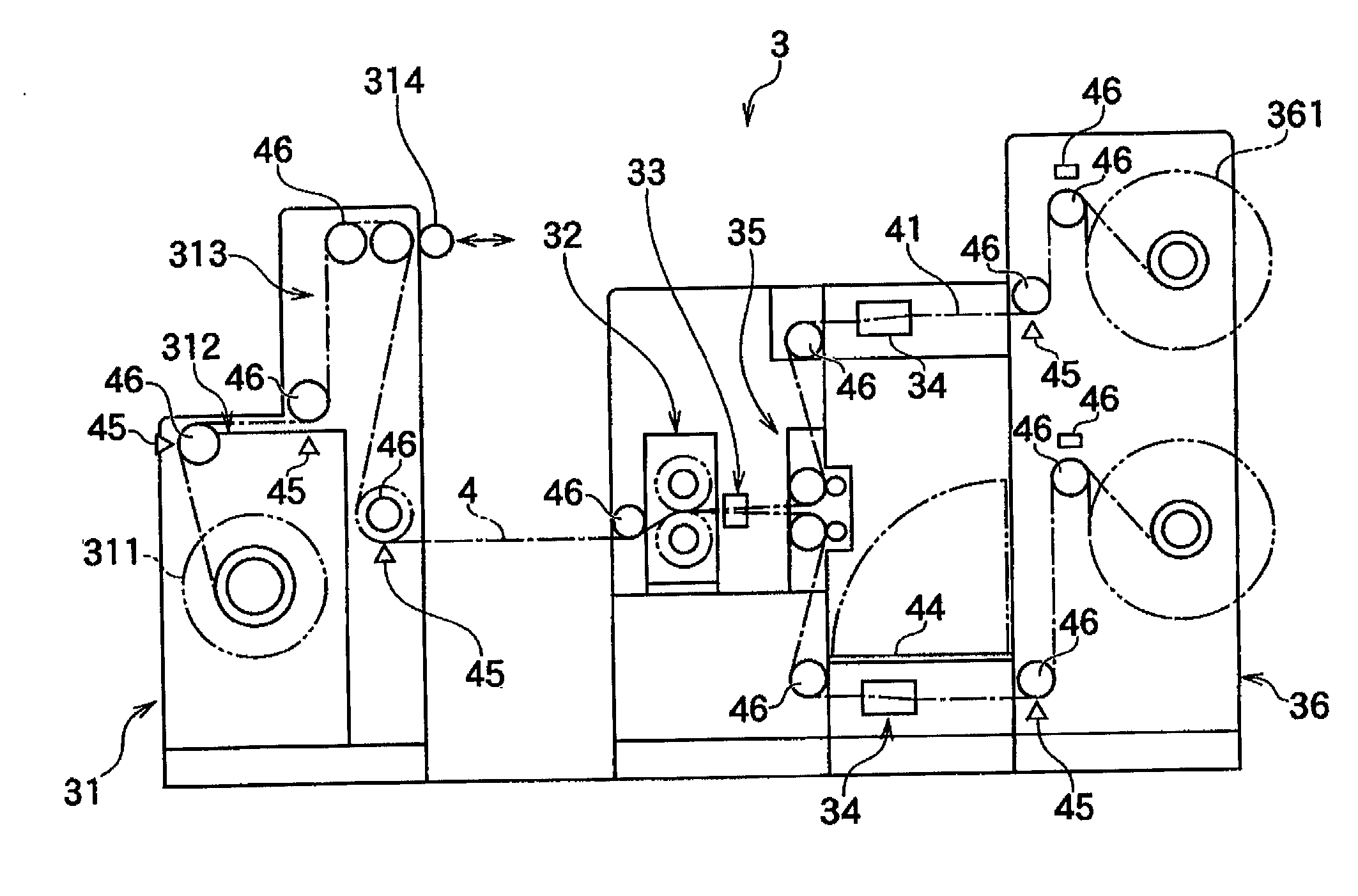

Apparatus For Manufacturing Pole-Piece Pockets

ActiveUS20110214401A1Quality improvementReduce riskElectrode manufacturing processesLamination ancillary operationsEngineeringWelding joint

Disclosed is a apparatus for manufacturing pole-piece pockets, comprising a framework, an pole-piece supplying assembly, an pole-piece transporting and regulating assembly, a vertically thermal-welding assembly, a transversely thermal-welding assembly, a film clamping and drawing assembly, and a film cutting assembly for cutting the films. The vertically thermal-welding assembly comprises a press welding cutter having two blades for simultaneously welding the two lateral edges of the pole-piece pocket. The transversely thermal-welding assembly comprises a first thermal welding cutter for welding the base of the pole-piece pocket and a second thermal welding cutter for welding the opening of the pole-piece pocket. The press welding cutter has two blades so that the two lateral edges of a pole-piece pocket can be welded in just one welding operation. Thus, the parallelity and welding consistency of the welding joints can be ensured. Moreover, the welding efficiency and quality are increased, and the risk of malfunction is decreased.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

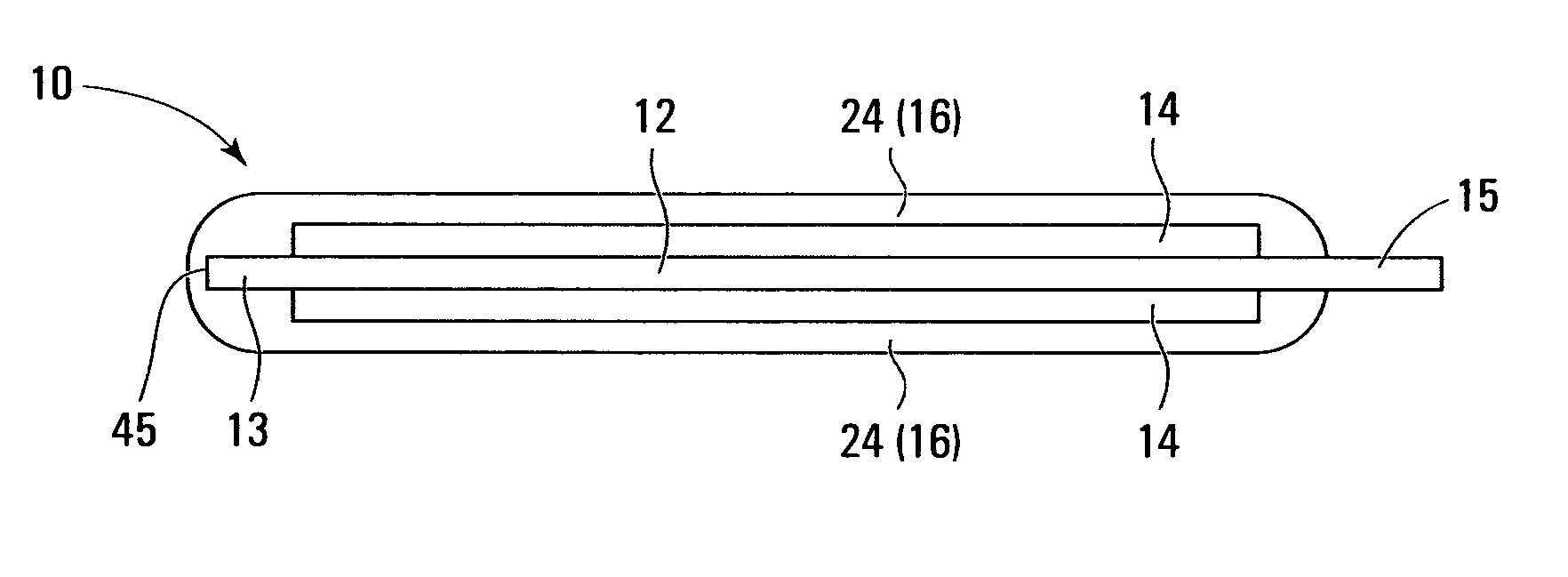

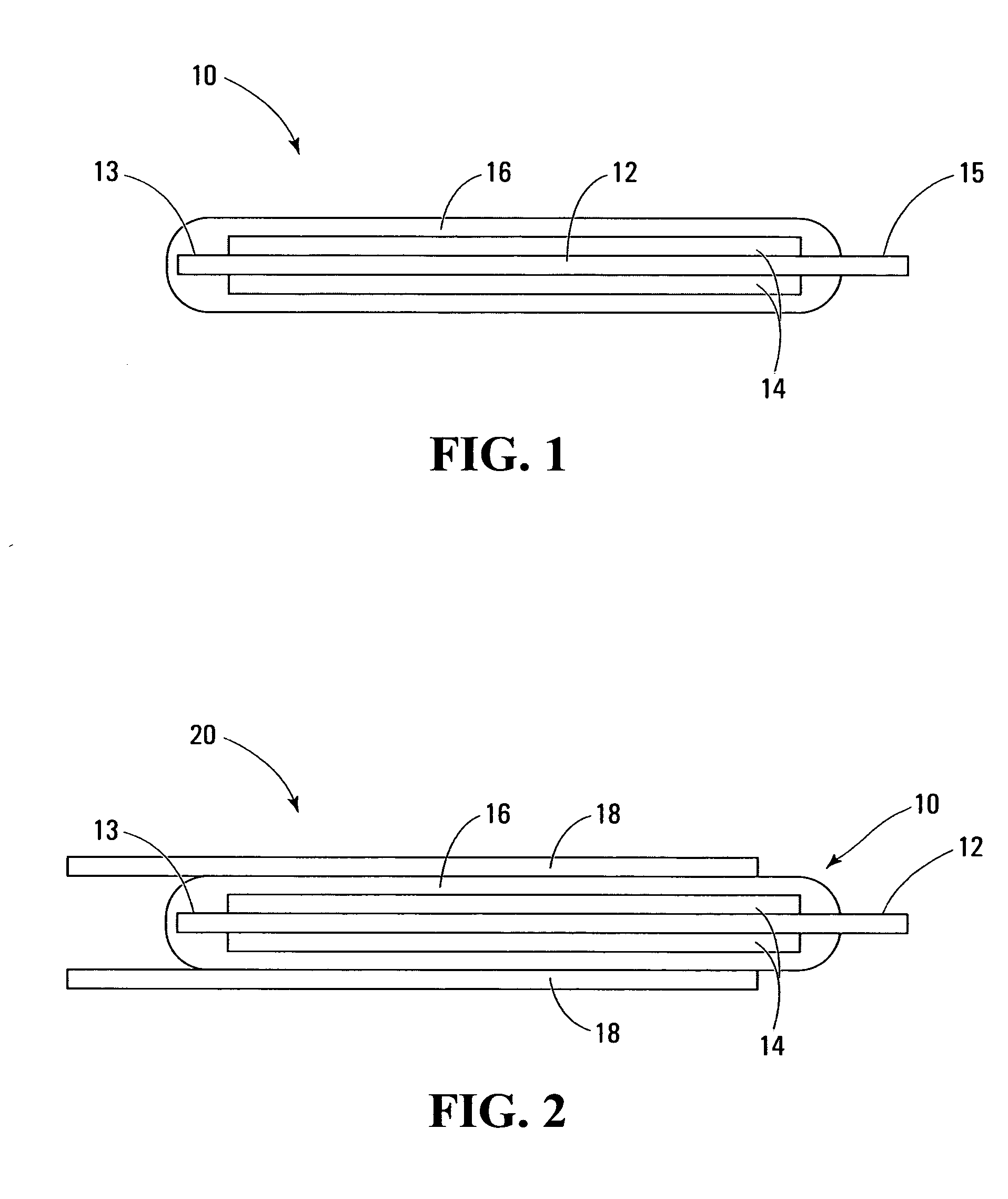

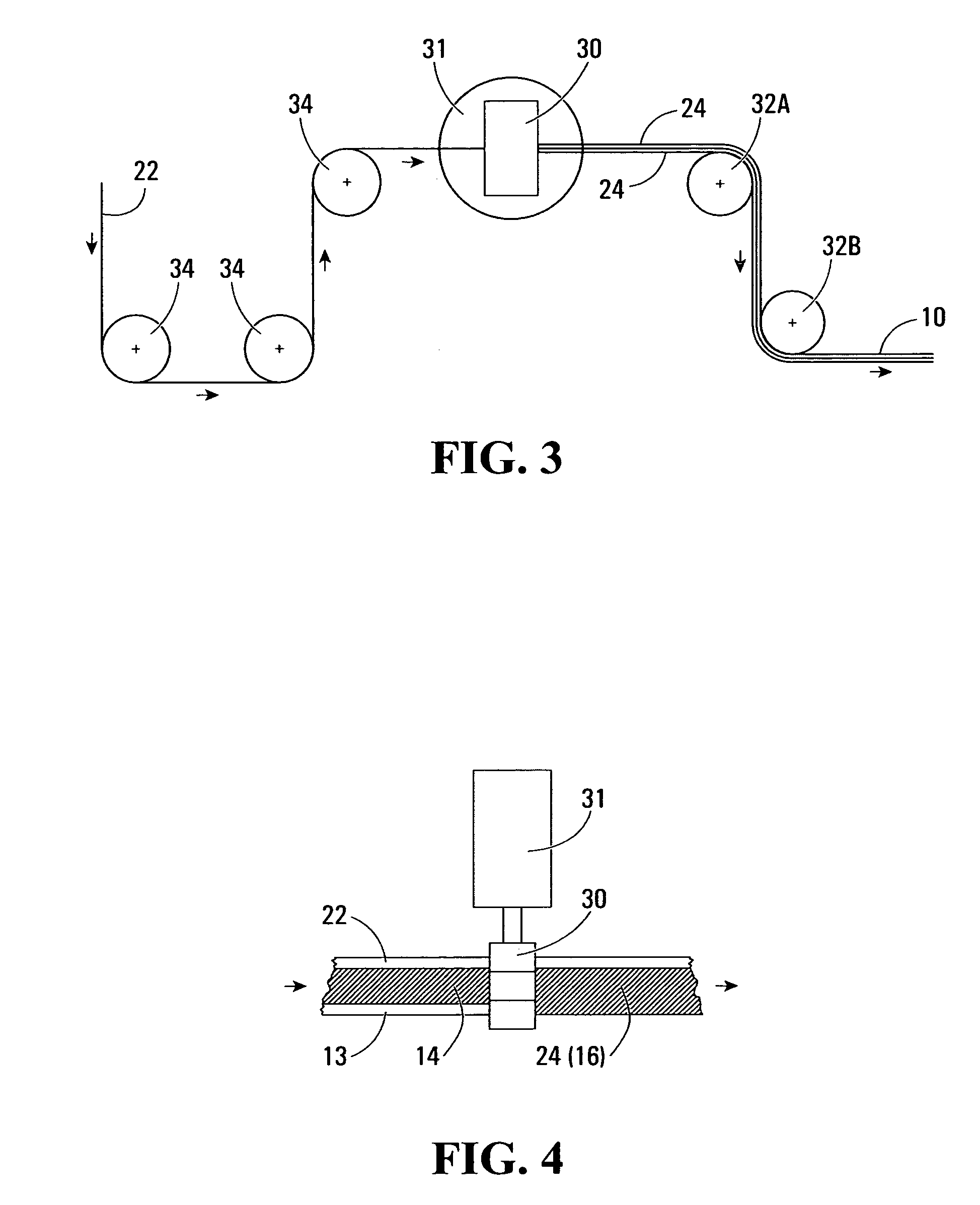

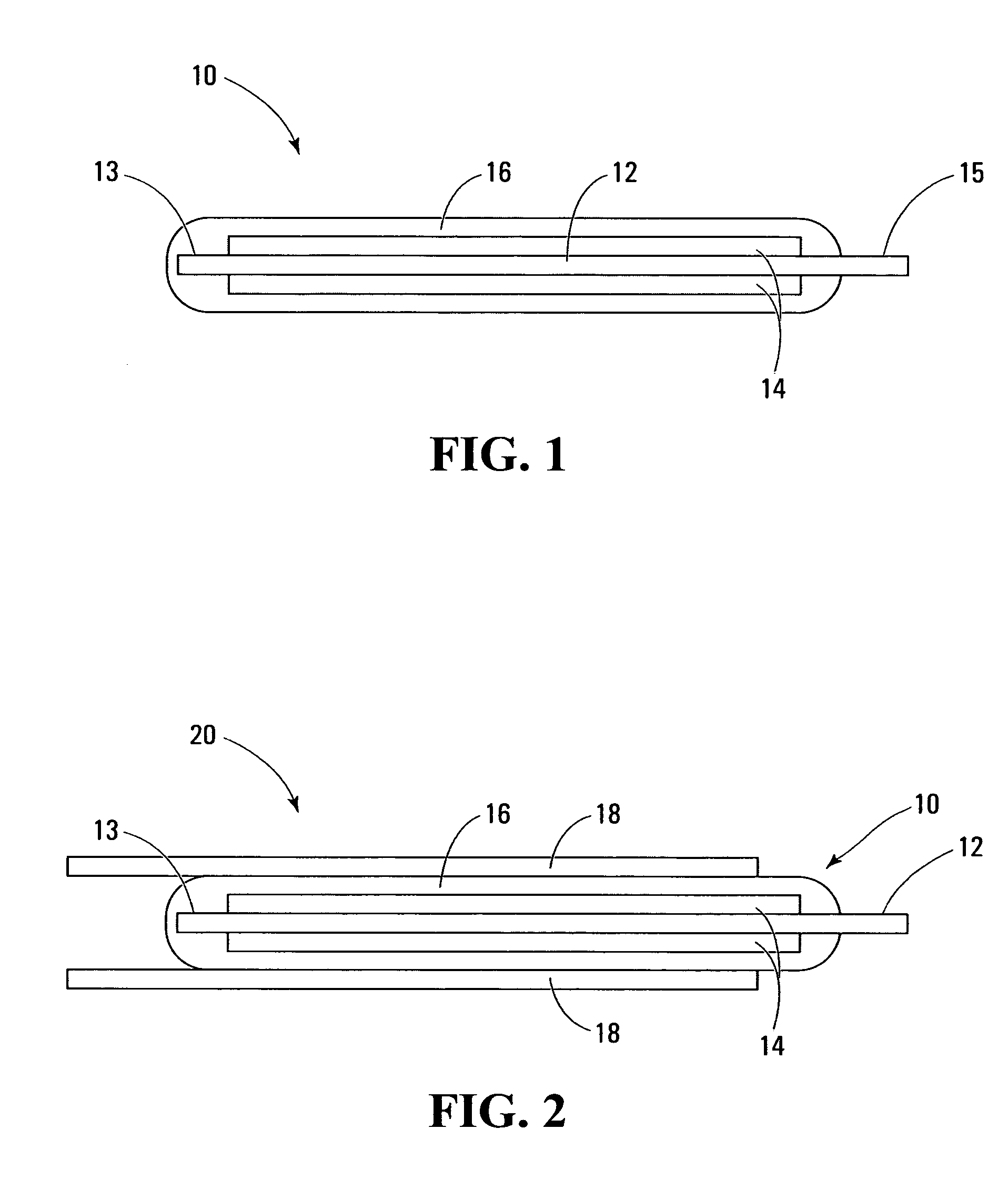

Thin film electrochemical cell for lithium polymer batteries and manufacturing method therefor

ActiveUS20060085972A1Prevents inadvertent short circuitsPrevent inadvertent short circuitsFinal product manufactureElectrode carriers/collectorsPolymer electrolytesEngineering

An electrochemical cell sub-assembly and a method for manufacturing same. The electrochemical cell sub-assembly includes a current collector sheet having a pair of opposite surfaces and a pair of opposite edges, each surface being coated with a respective layer of electrode material. A layer of polymer electrolyte envelopes both layers of electrode material and one of the pair of edges of the current collector sheet, thereby encapsulating the one edge of the current collector sheet white leaving exposed the other edge of the current collector sheet.

Owner:BATHIUM CANADA

Method and apparatus for solid-state microbattery photolithographic manufacture, singulation and passivation

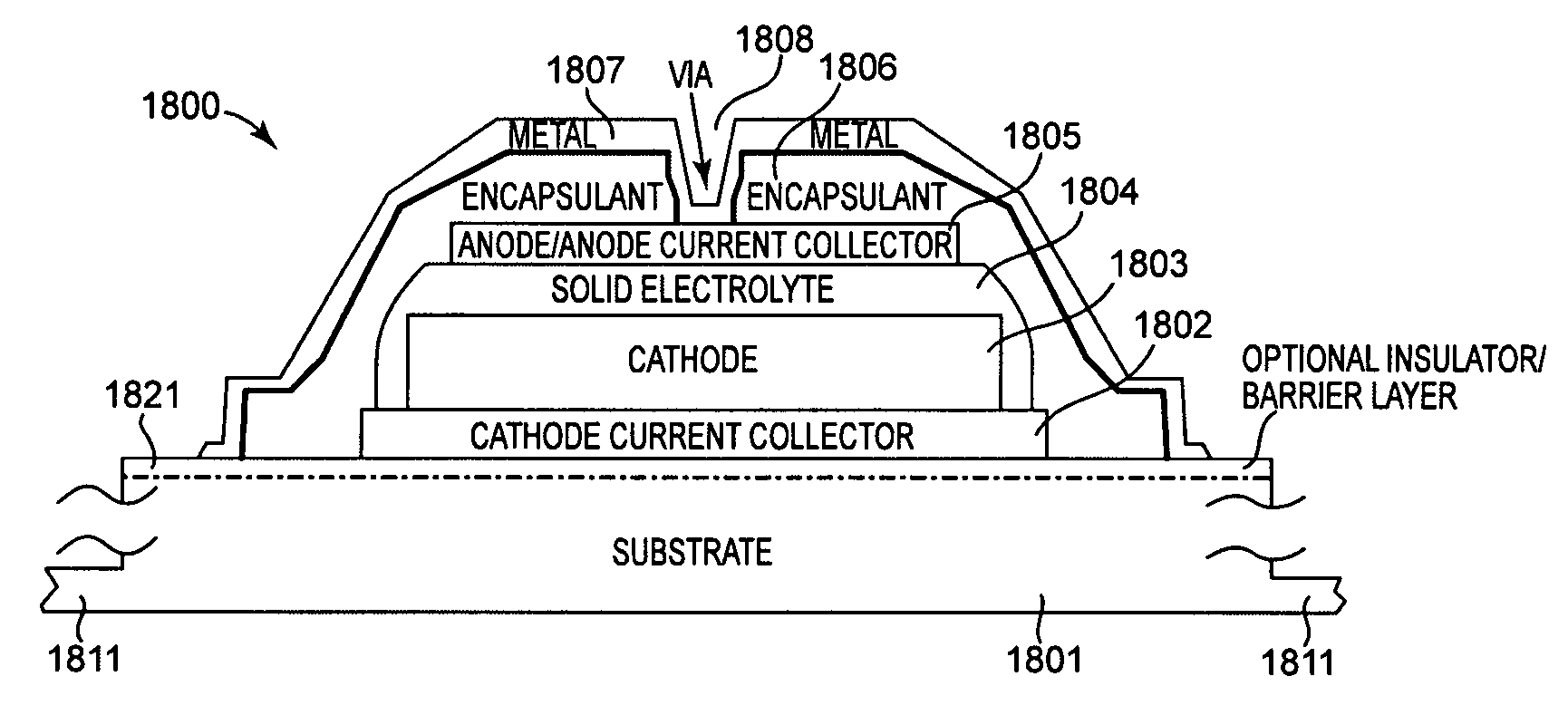

InactiveUS20130230646A1Efficient and economical manufactureReduced number of stepSolid electrolytesFinal product manufactureChemical treatmentPhotolithography

A method for producing a thin film lithium battery is provided, comprising applying a cathode current collector, a cathode material, an anode current collector, and an electrolyte layer separating the cathode material from the anode current collector to a substrate, wherein at least one of the layers contains lithiated compounds that is patterned at least in part by a photolithography operation comprising removal of a photoresist material from the layer containing lithiated compounds by a process including a wet chemical treatment. Additionally, a method and apparatus for making lithium batteries by providing a first sheet that includes a substrate having a cathode material, an anode material, and a LiPON barrier / electrolyte layer separating the cathode material from the anode material; and removing a subset of first material to separate a plurality of cells from the first sheet. In some embodiments, the method further includes depositing second material on the sheet to cover the plurality of cells; and removing a subset of second material to separate a plurality of cells from the first sheet.

Owner:CYMBET CORP

Slitter for an electrode raw material sheet and the slitting process

InactiveUS20020035903A1Quality improvementLess possibilityFinal product manufactureDouble layer capacitorsMaterials scienceRaw material

An electrode with an excellent quality for an electrical component, wherein an electrode raw material sheet slitter includes a slitting section to slit an electrode raw material sheet for an electrical component; a forming section to conduct smoothing of the convex portion on the slit electrode; electrode cleaning sections to remove fragments adhered on the slit electrode; and, a slitting method of electrode raw material sheet.

Owner:ITOCHU CO LTD

Laser apparatus and manufacturing method of a battery

InactiveUS7646794B2Suppress power fluctuationsShorten speedLaser detailsPrimary cellsMetallic materialsLaser light

A laser apparatus is provided which is capable of achieving deep penetration into an aluminum-like metal material without causing welding defects such as spatters or cracks and performing high-speed pulse seam welding. The laser apparatus includes a pulse power source that generates a current signal and a mask signal for masking a fluctuation component included in the current signal, and which supplies a current signal in which a fluctuation component has been masked by the mask signal to a YAG pulsed laser oscillator. In addition, the laser apparatus sets the spot shape of a CW laser light oscillated by a CW laser oscillator to a rhombic streamlined shape, and causes a focus spot of the CW laser light to include a circular focus spot of a pulsed laser light.

Owner:PANASONIC CORP

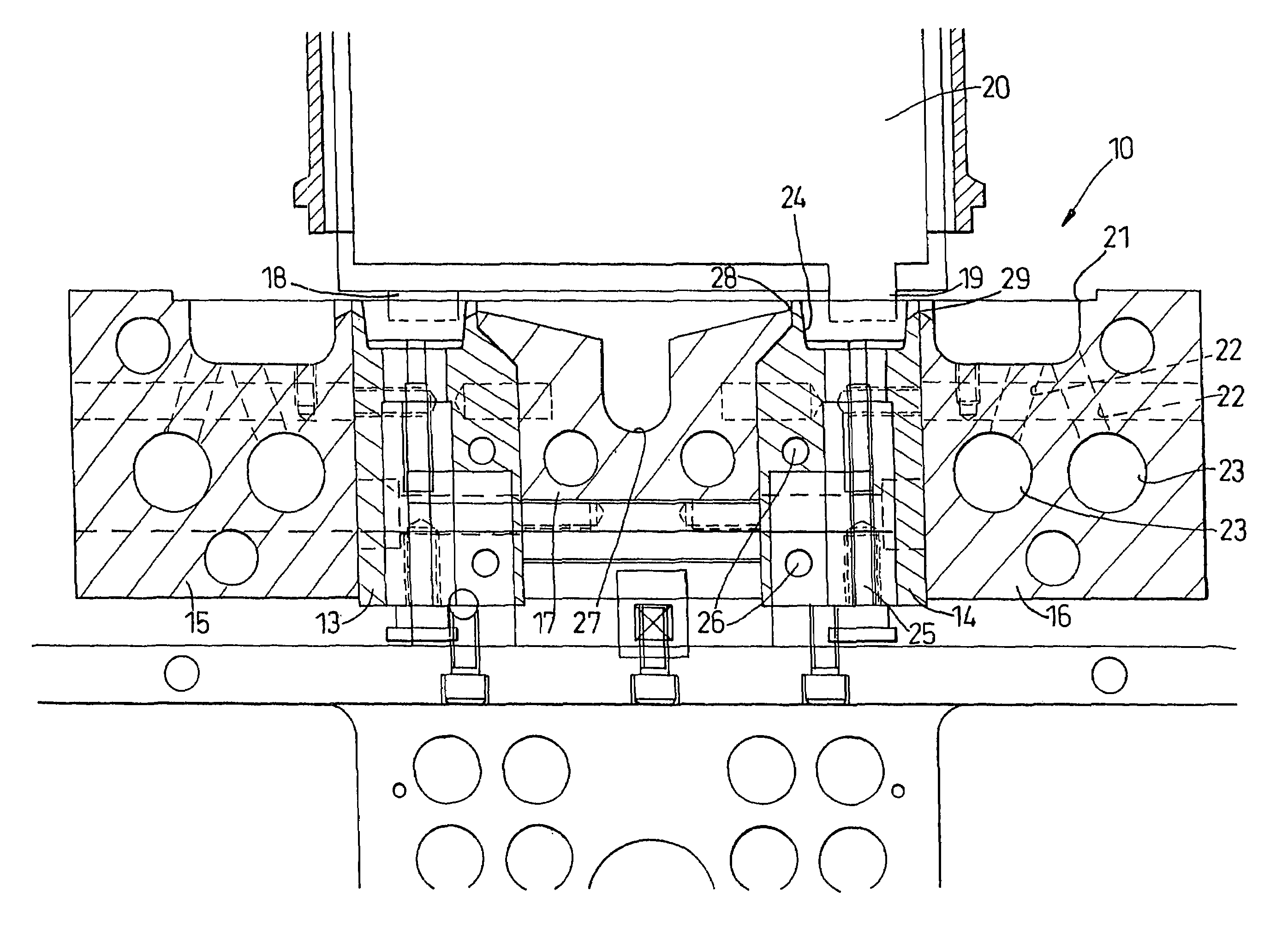

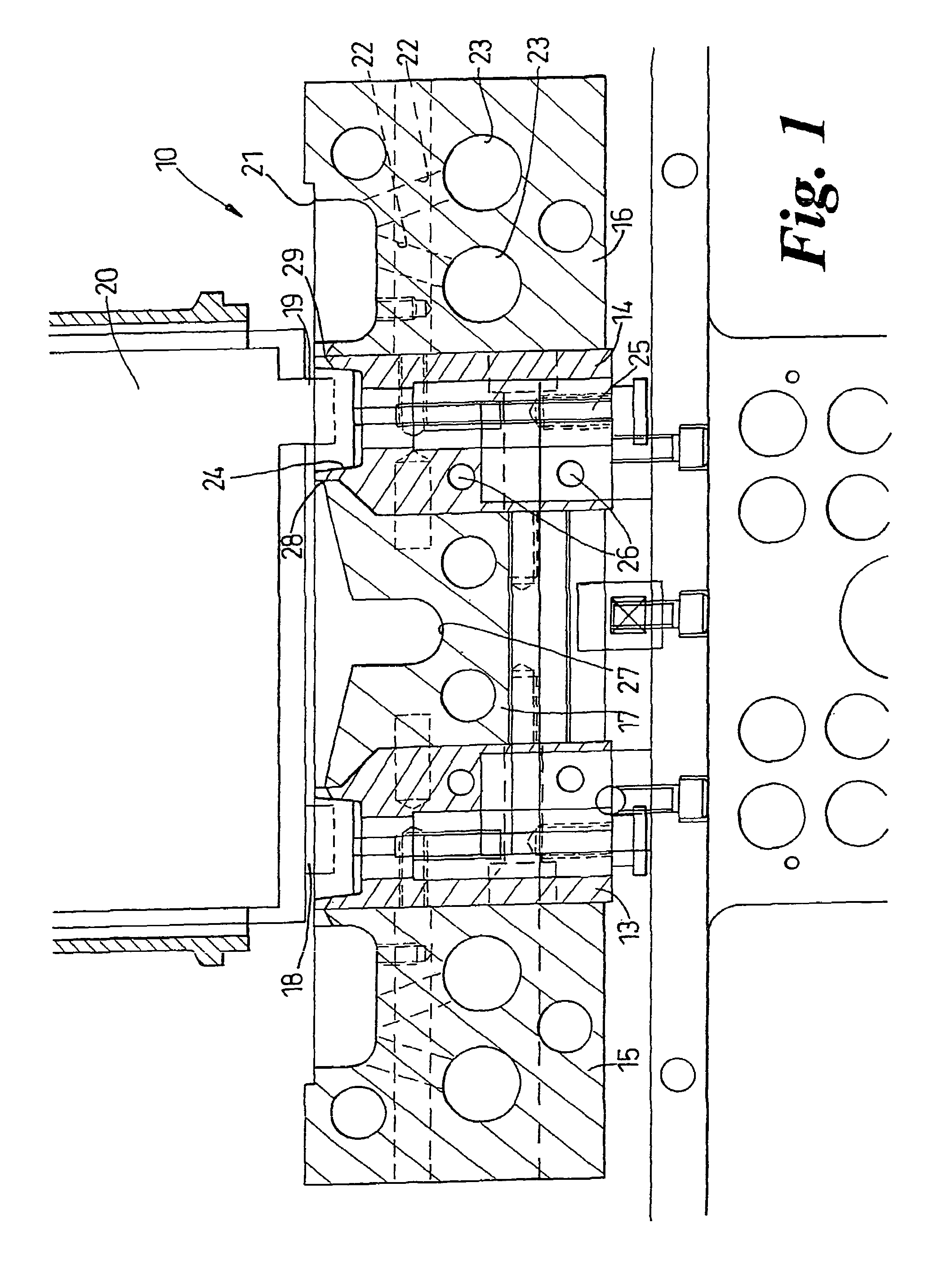

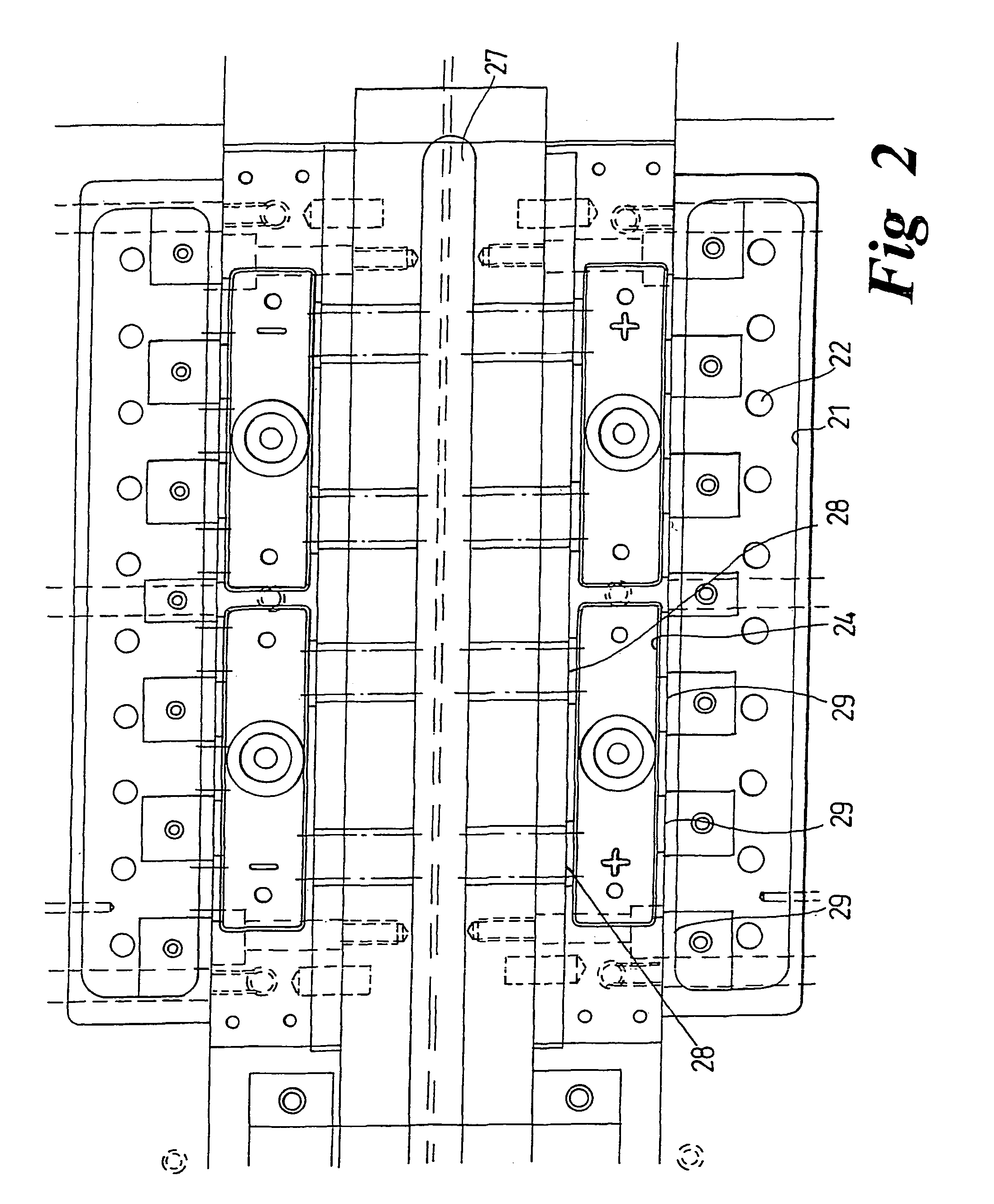

Moulding apparatus

A moulding apparatus (10) for moulding a strap on to a group of battery plates including a mould block (14) with moulds (24), each of which has an inlet weir (28) and an outlet weir (29). The ridge (30) of these weirs is effectively a knife edge but includes a thermal break. This construction allows rapid processing whilst avoiding the formation of solid tails.

Owner:TBS ENG LTD

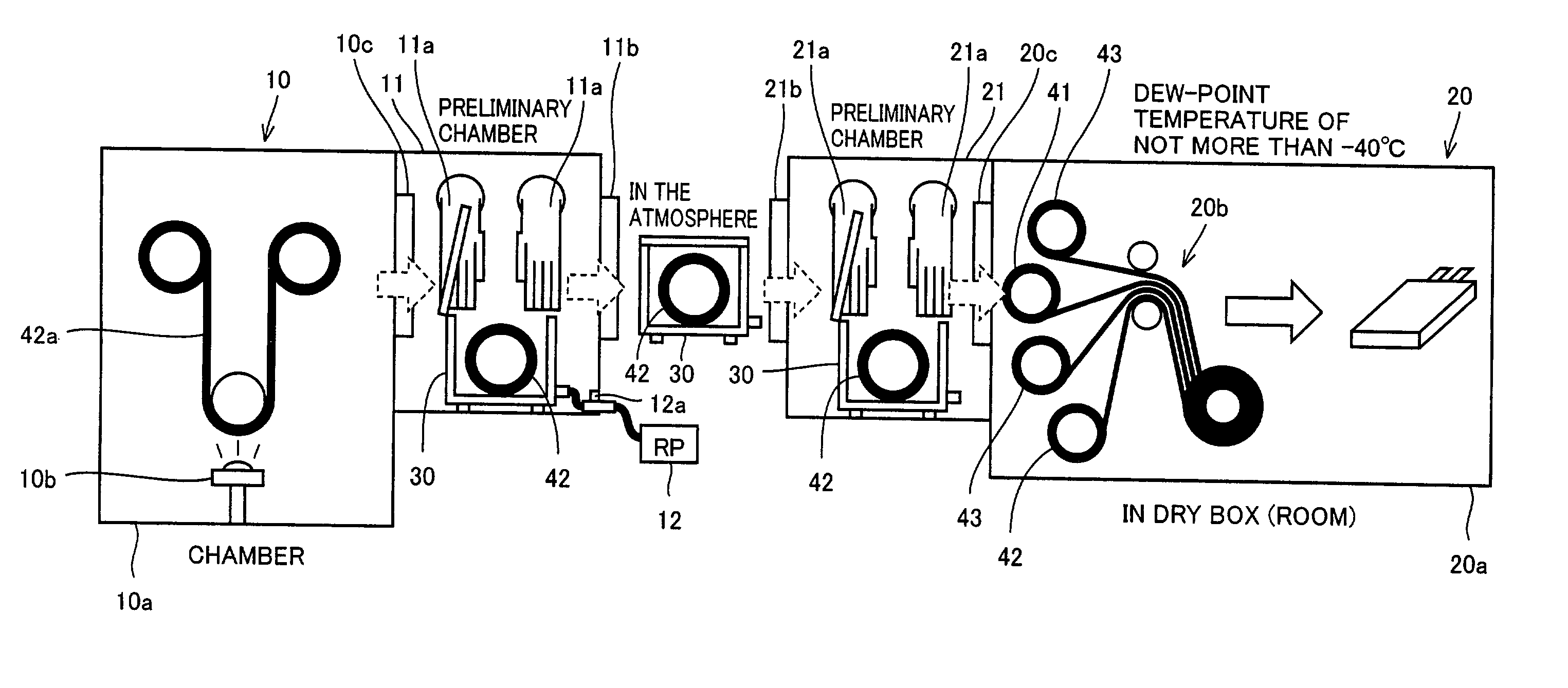

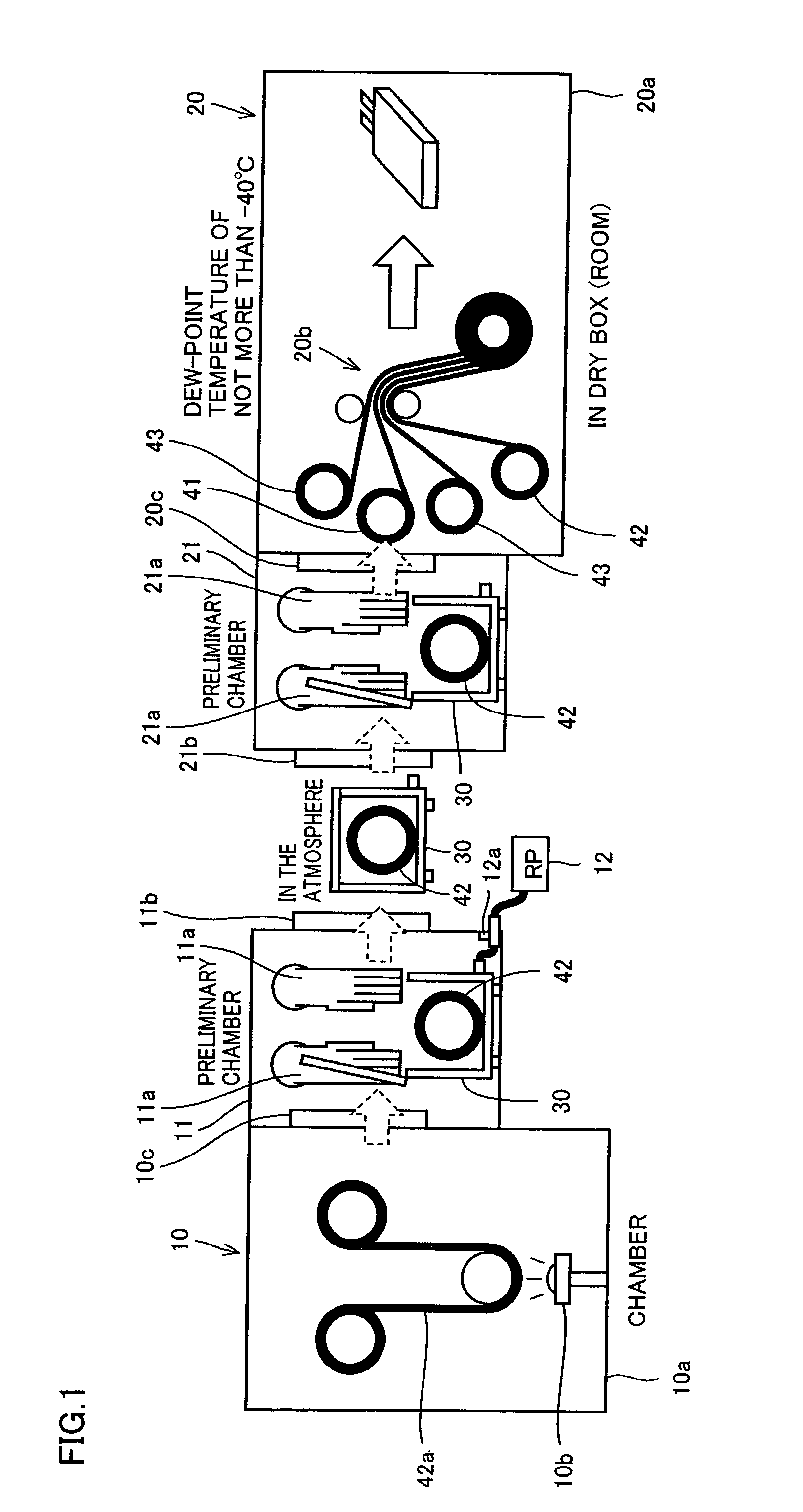

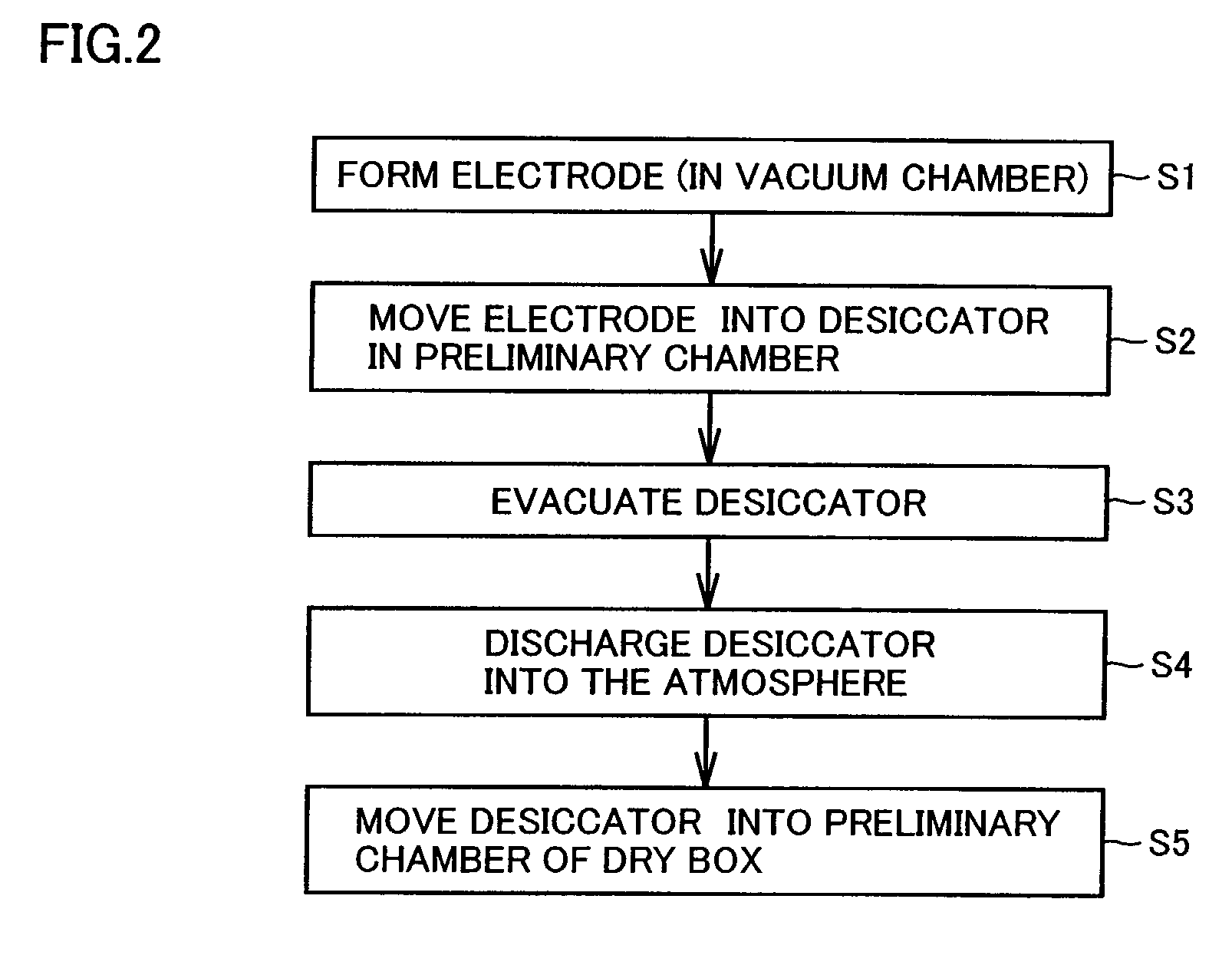

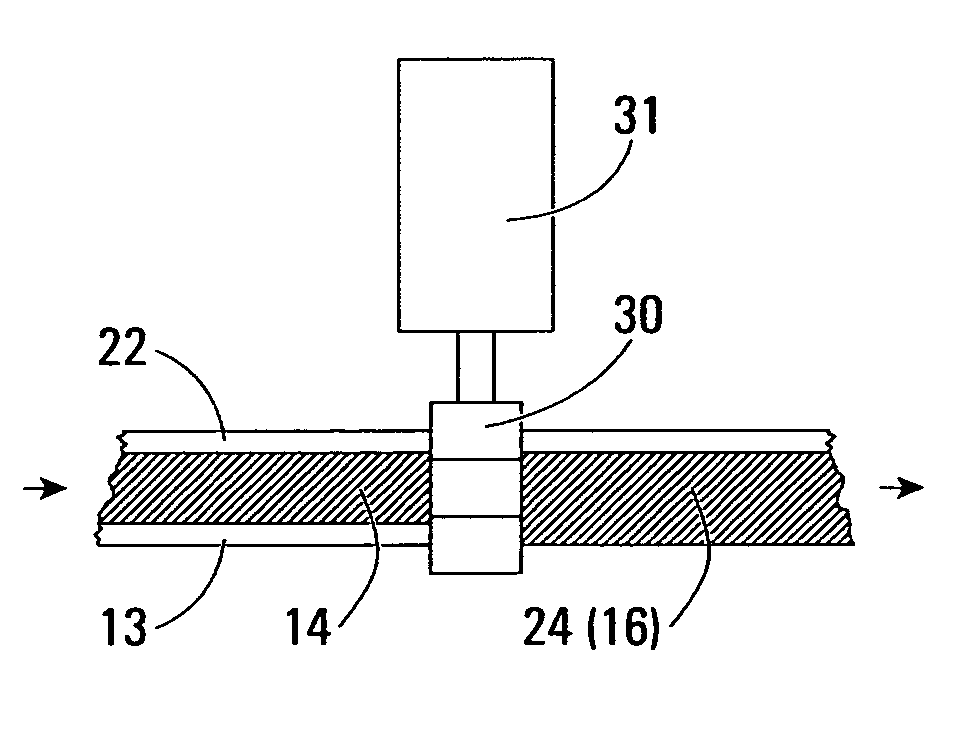

Method of and apparatus for manufacturing lithium secondary cell

InactiveUS7105253B2Avoid contactImprove featuresFinal product manufactureElectrode carriers/collectorsLithiumGas phase

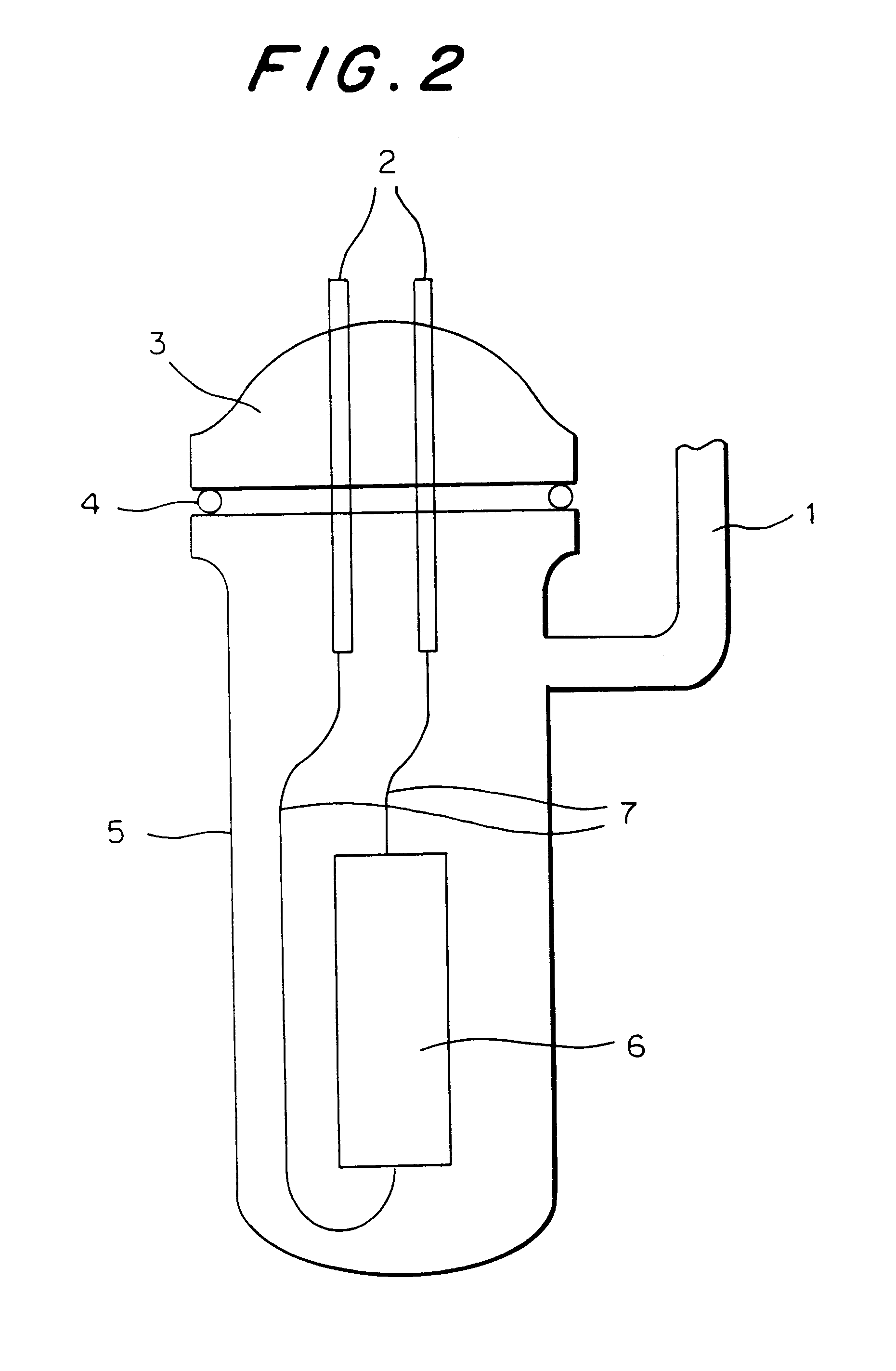

A method of manufacturing a lithium secondary cell capable of preventing an active material layer from oxidation and moisture absorption is obtained. This method of manufacturing a lithium secondary cell comprises steps of forming an active material layer on a collector by a method supplying raw material through discharge into a vapor phase and holding the collector formed with the active material layer at least under an inert atmosphere or under a vacuum atmosphere up to preparation of the cell. Thus, the collector formed with the active material layer is prevented from exposure to the atmosphere, whereby the active material layer is prevented from oxidation and moisture absorption. Consequently, a lithium secondary cell having excellent characteristics can be prepared.

Owner:SANYO ELECTRIC CO LTD

Thin film electrochemical cell for lithium polymer batteries and manufacturing method therefor

ActiveUS7531012B2Prevents inadvertent short circuitsPrevent inadvertent short circuitsFinal product manufactureElectrode carriers/collectorsPolymer electrolytesElectrical battery

An electrochemical cell sub-assembly and a method for manufacturing same. The electrochemical cell sub-assembly includes a current collector sheet having a pair of opposite surfaces and a pair of opposite edges, each surface being coated with a respective layer of electrode material. A layer of polymer electrolyte envelopes both layers of electrode material and one of the pair of edges of the current collector sheet, thereby encapsulating the one edge of the current collector sheet white leaving exposed the other edge of the current collector sheet.

Owner:BATHIUM CANADA

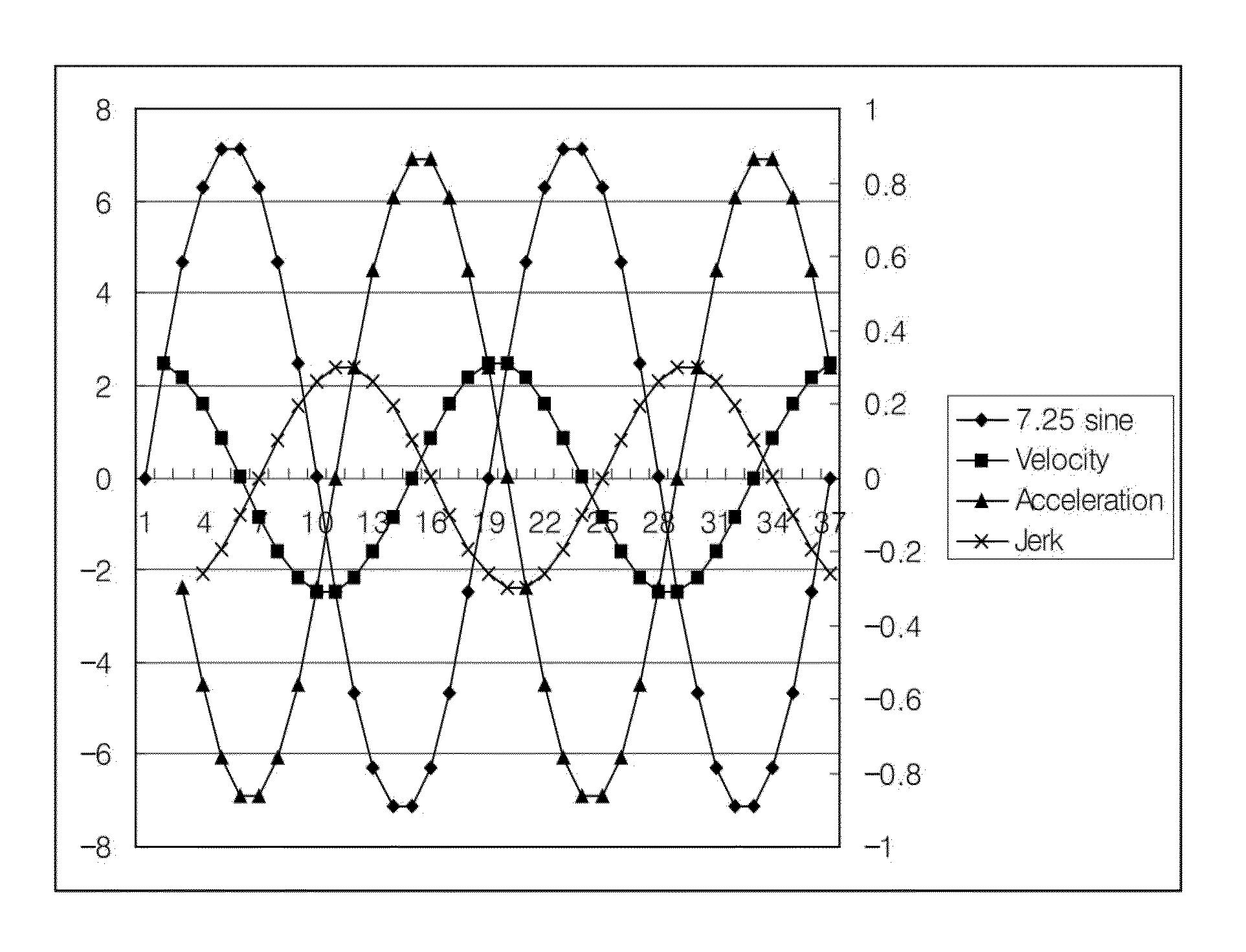

Device for folding electrode assembly

ActiveUS20130209848A1Uniformly maintaining tensionImprove processing efficiencyAssembling battery machinesCell electrodesEngineeringMechanical engineering

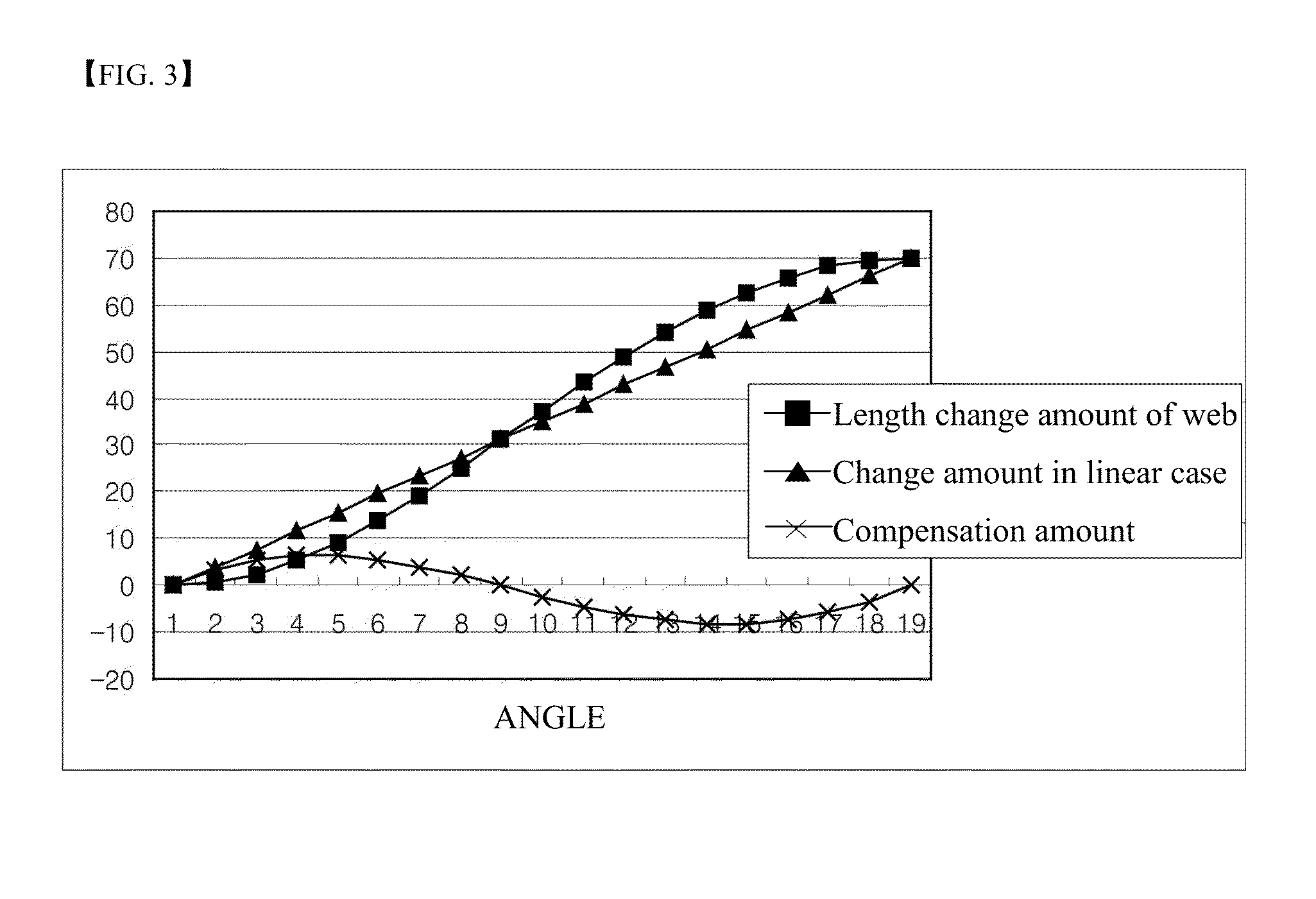

Disclosed herein is a folding device to manufacture a stacked / folded type electrode assembly having unit cells sequentially stacked in a state in which a separation film is disposed between the respective unit cells, the folding device including a web supply unit to supply a web having plate-shaped unit cells arranged at a top of a separation film at predetermined intervals, a winding jig to rotate the unit cells while holding a first one of the unit cells of the web so that the unit cells are sequentially stacked in a state in which the separation film is disposed between the respective unit cells, and a rotary shaft compensation unit to compensate for the position of a rotary shaft of the winding jig in an advancing direction of the web (X-axis direction), wherein the rotary shaft compensation unit periodically changes the position of the rotary shaft to compensate for the change in X-axis velocity (Vx) of the web caused during winding of the plate-shaped unit cells, thereby uniformly maintaining tension of the web.

Owner:LG ENERGY SOLUTION LTD

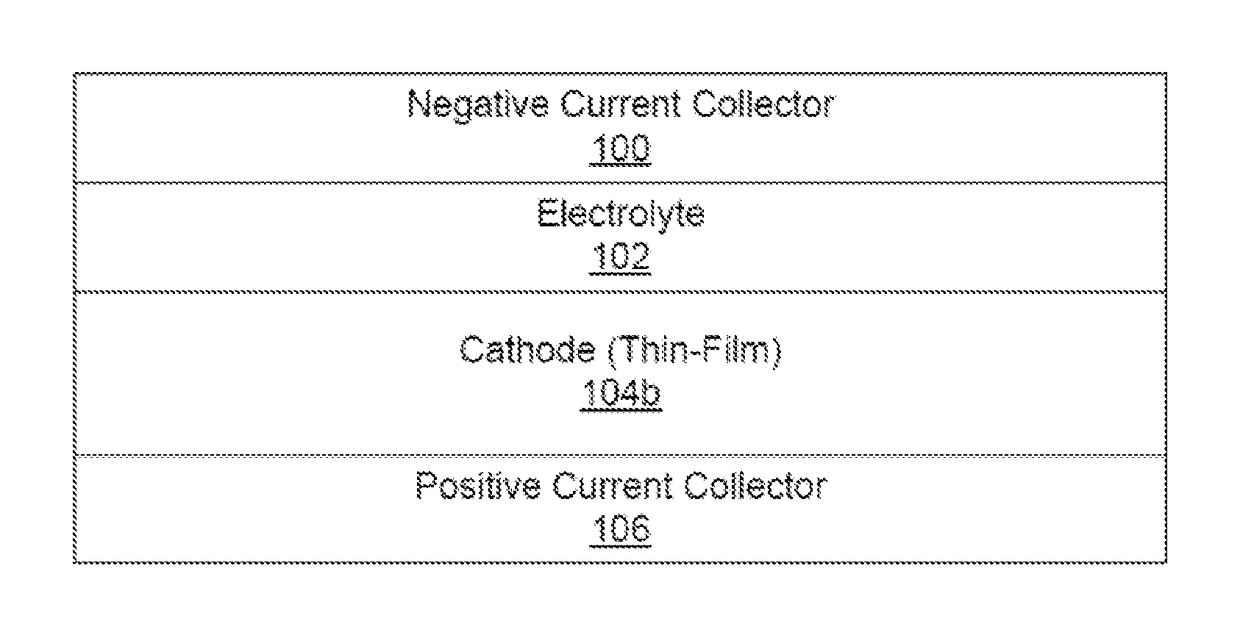

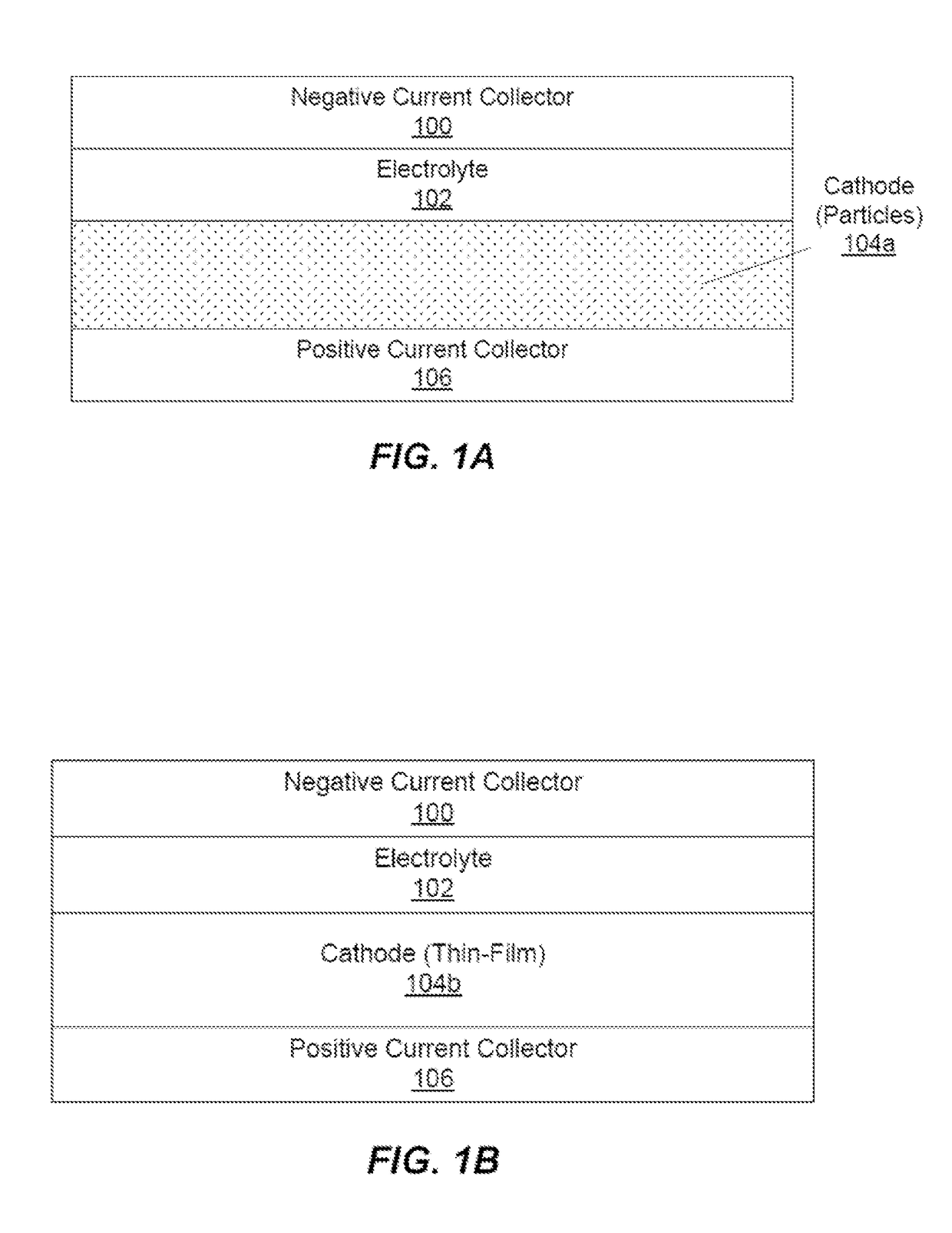

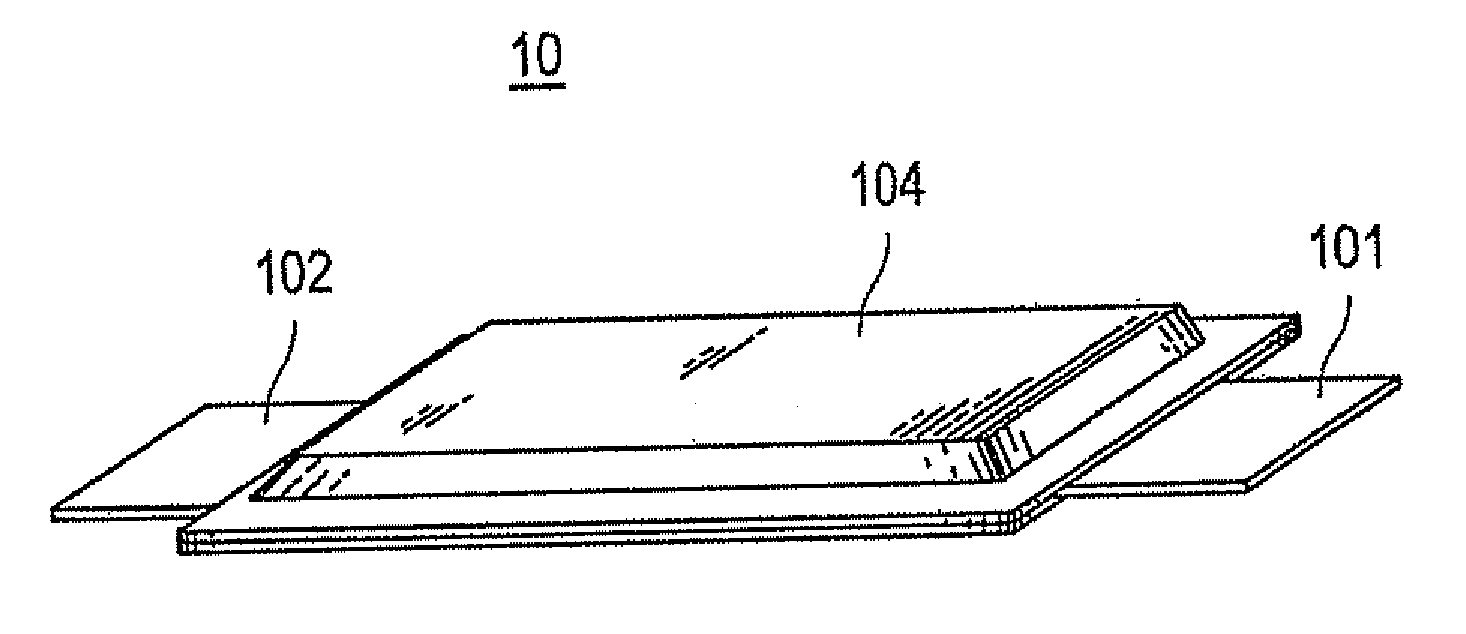

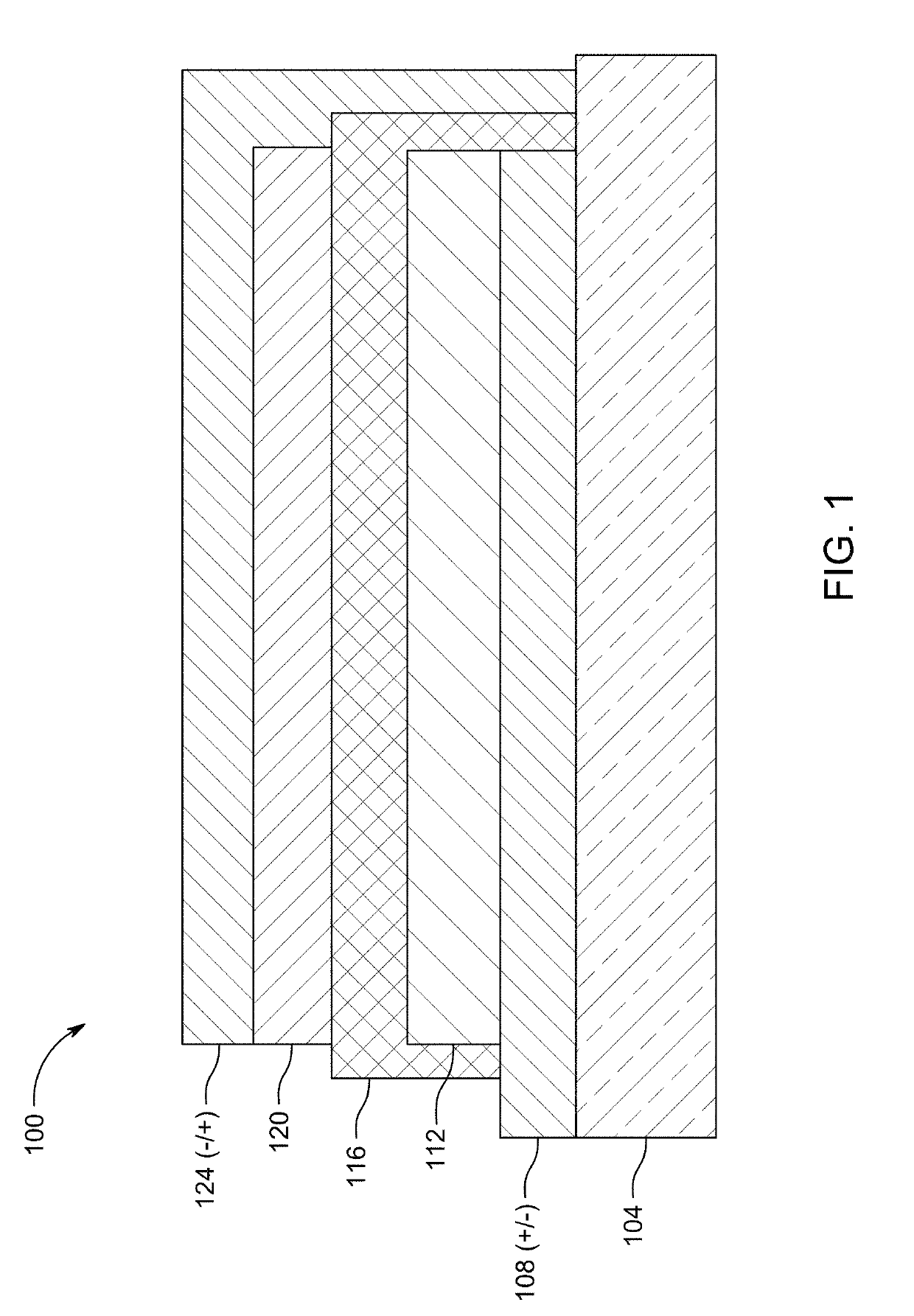

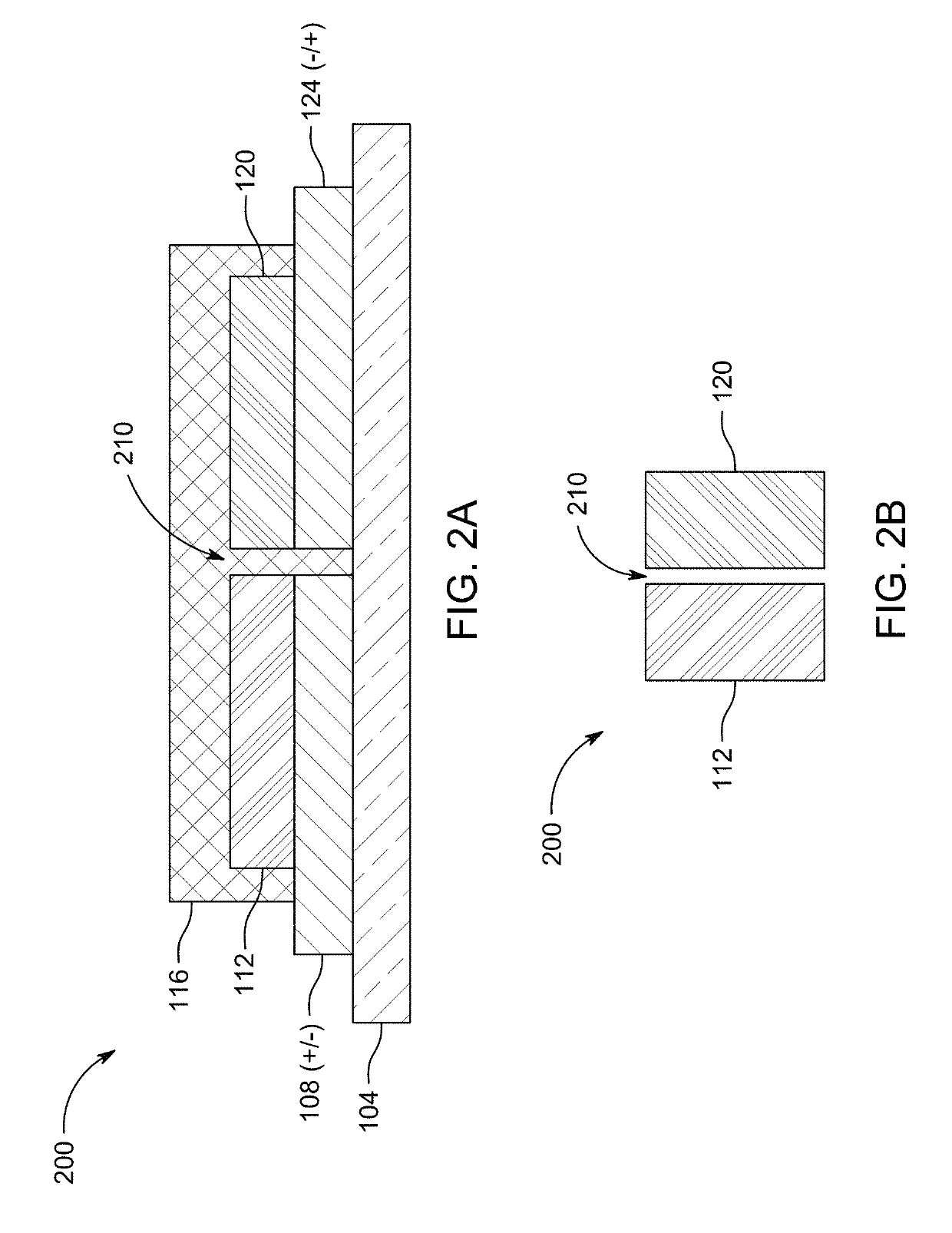

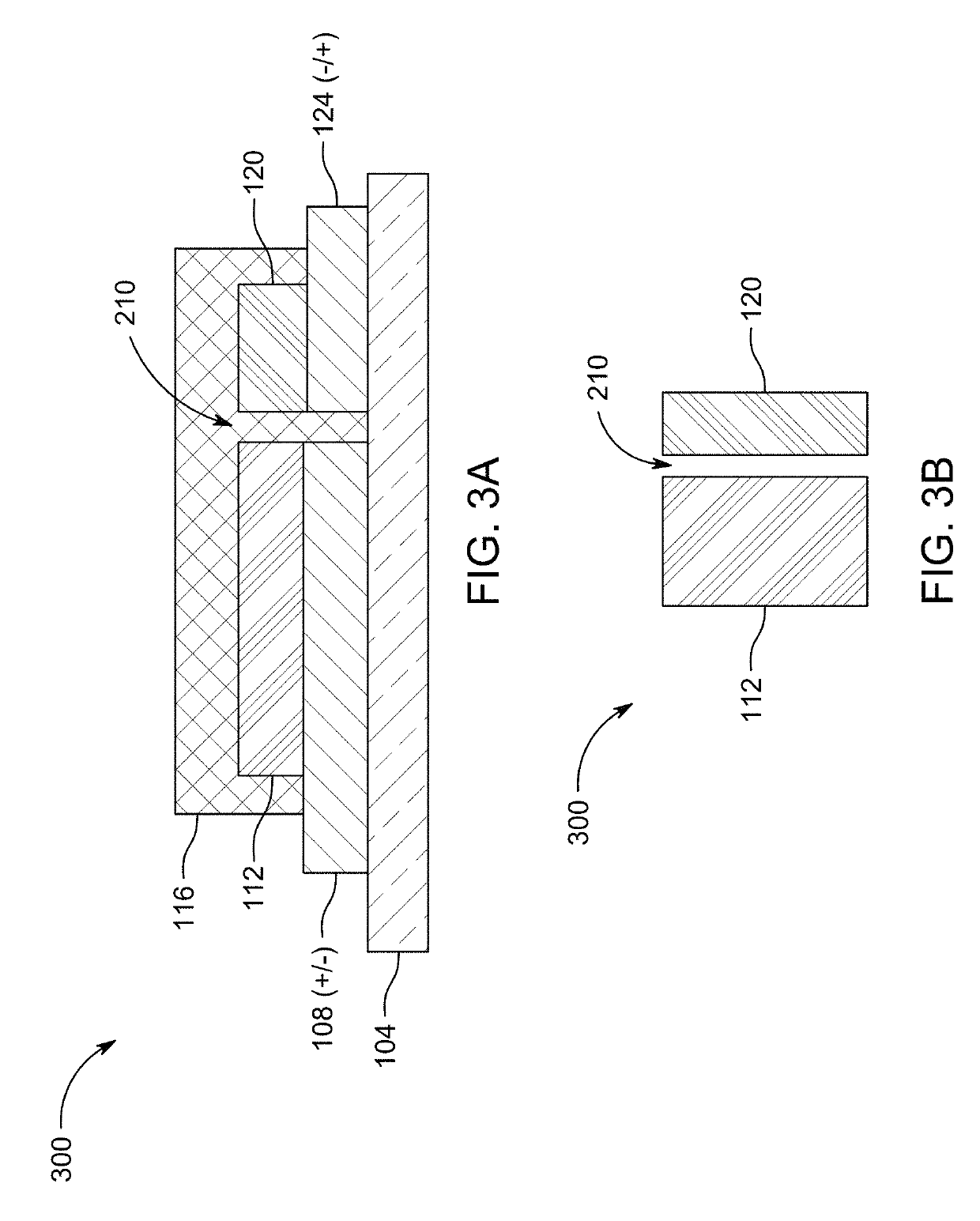

Thin film-based energy storage devices

ActiveUS20190221891A1Hybrid capacitor electrodesFinal product manufactureElectricityElectrical equipment

The disclosed technology generally relates to thin film-based energy storage devices, and more particularly to printed thin film-based energy storage devices. The thin film-based energy storage device includes a first current collector layer and a second current collector layer over an electrically insulating substrate and adjacently disposed in a lateral direction. The thin film-based energy storage device additionally includes a first electrode layer of a first type over the first current collector layer and a second electrode layer of a second type over the second current collector layer. A separator separates the first electrode layer and the second electrode layer. One or more of the first current collector layer, the first electrode layer, the separator, the second electrode layer and the second current collector layer are printed layers.

Owner:PRINTED ENERGY PTY LTD

Non-aqueous electrolyte secondary battery and manufacturing method of the same

InactiveUS20080102353A1Avoid unwindingBuckling suppressionFinal product manufactureElectrode carriers/collectorsMetallic lithiumConductor Coil

In a method for manufacturing a non-aqueous electrolyte secondary battery, a negative electrode having a current collector exposed portion in a portion corresponding to an outer winding end of an electrode body, metallic lithium piece is allowed to precipitate or be deposited on this current collector exposed portion, and this metallic lithium piece is joined to the other portion of the current collector exposed portion or one metallic lithium piece is joined to the other metallic lithium piece so as to fix two points of the negative electrode.

Owner:PANASONIC CORP

Electrode useable in electrochemical cell and method of making same

InactiveUS20120301781A1Reduce environmental problemsMaterial nanotechnologyElectrode carriers/collectorsNanoparticleNanostructure

In one aspect of the present invention, an electrode useable in an electrochemical cell includes an electrically conductive substrate, nanostructured current collectors in electrical contact with the conductive substrate, and nanoparticles of a ternary orthosilicate composite coated on the nanostructured current collectors. The ternary orthosilicate composite comprises Li2MnxFeyCozSiO4, where x+y+z=1.

Owner:VANDERBILT UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com