Patents

Literature

62results about How to "Buckling suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-Pneumatic Tire

ActiveUS20100132858A1High compressive rigidityImprove performanceNon-inflatable tyresHigh resiliency wheelsEngineeringCoupling

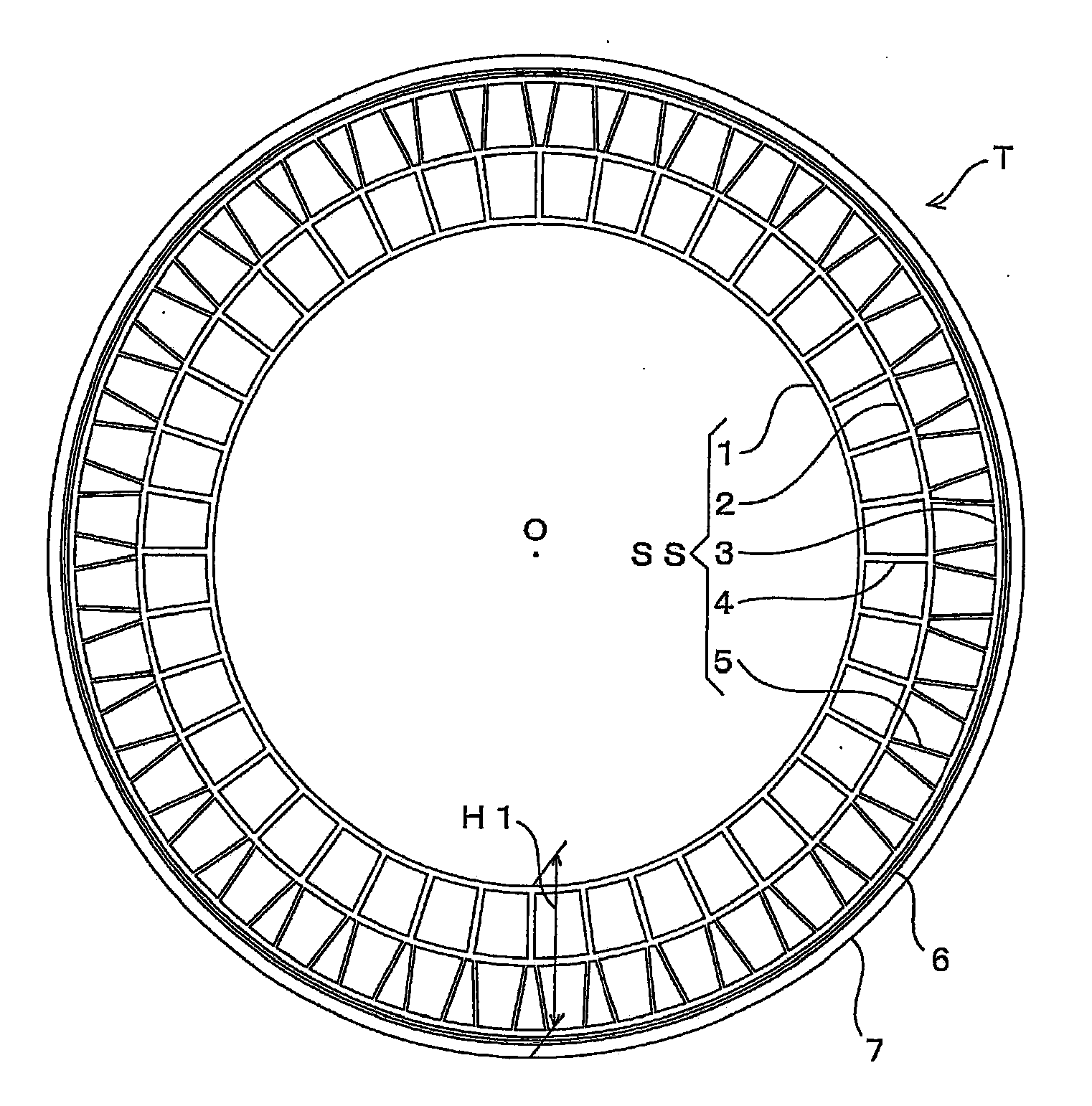

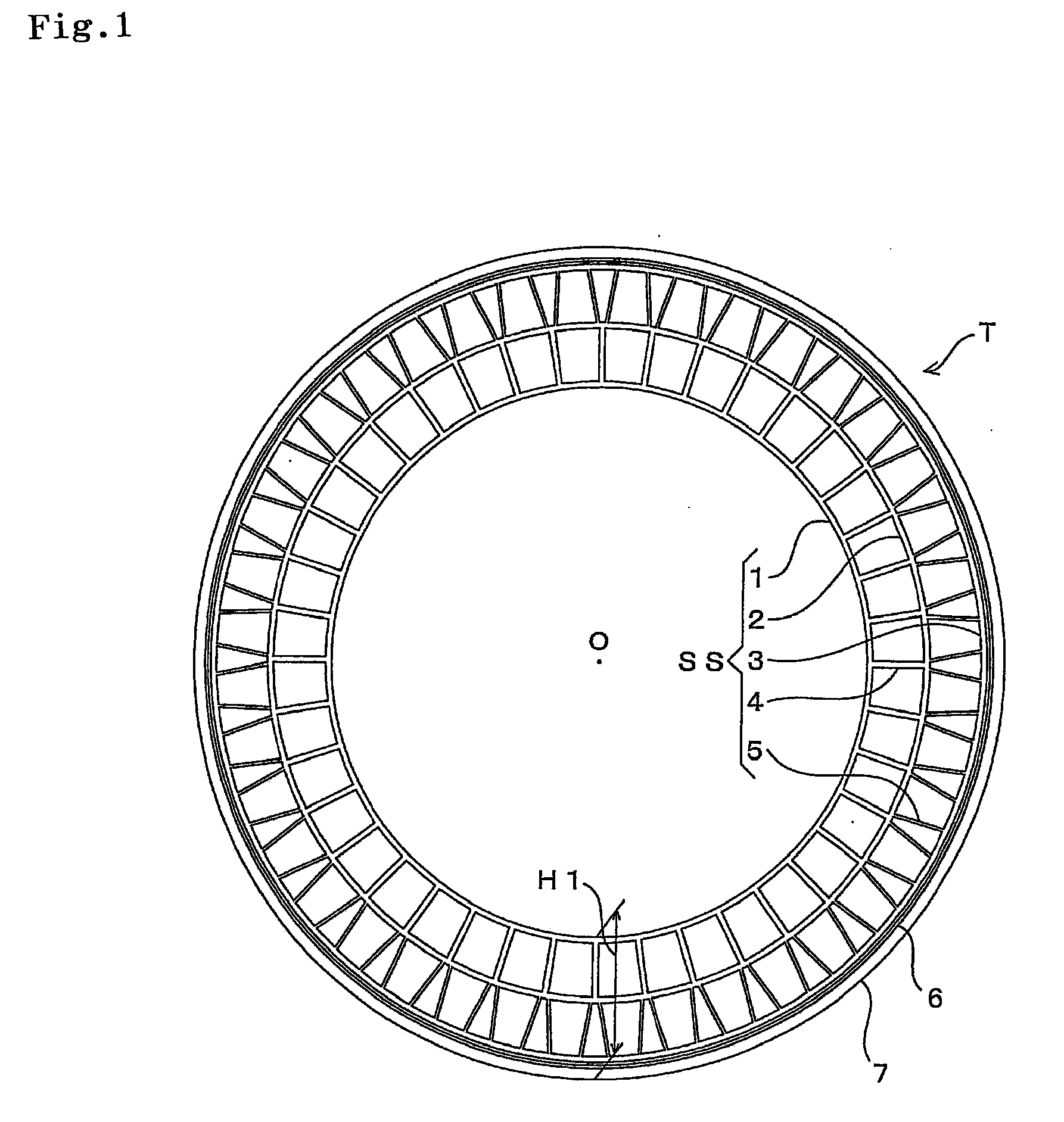

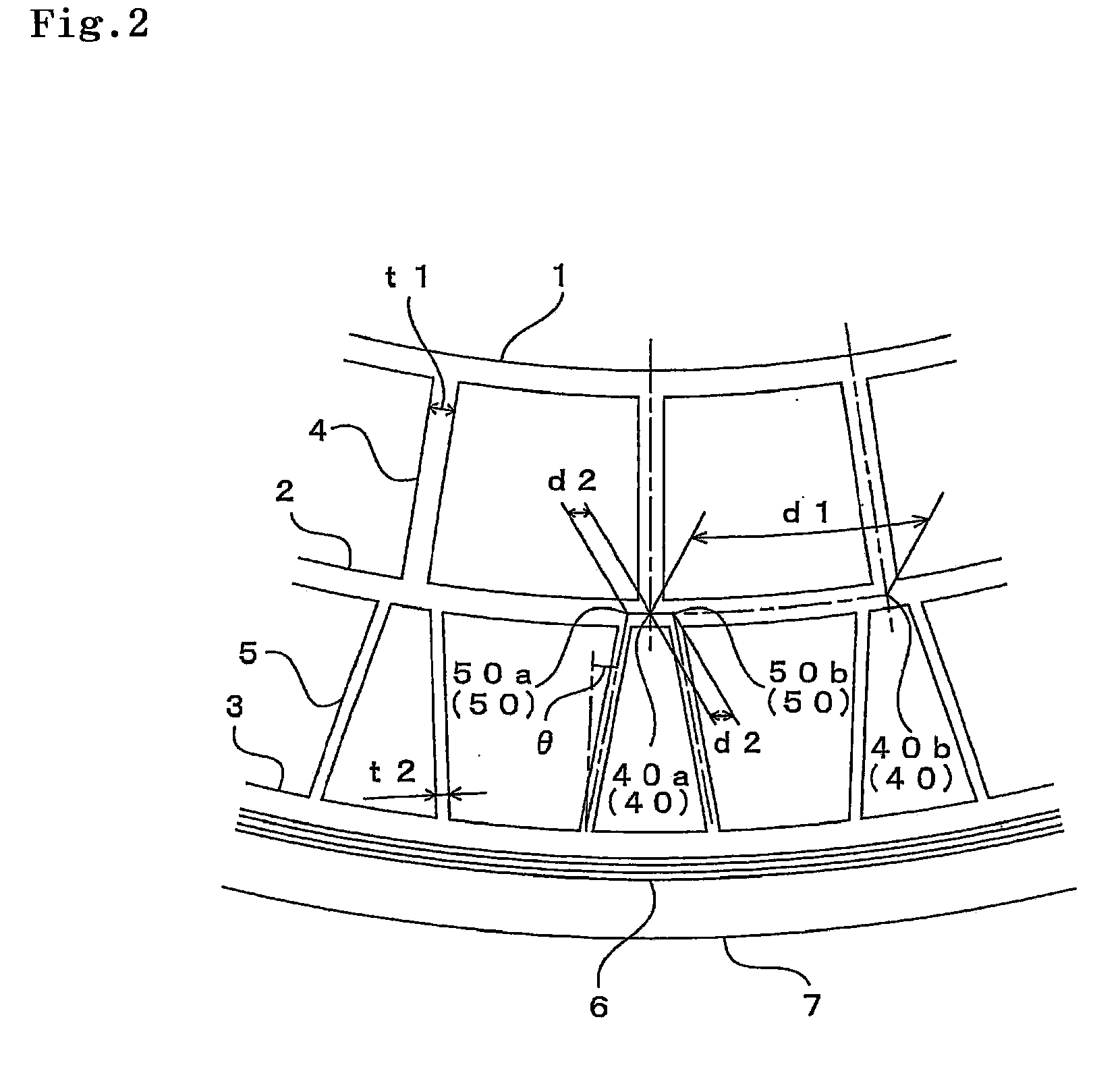

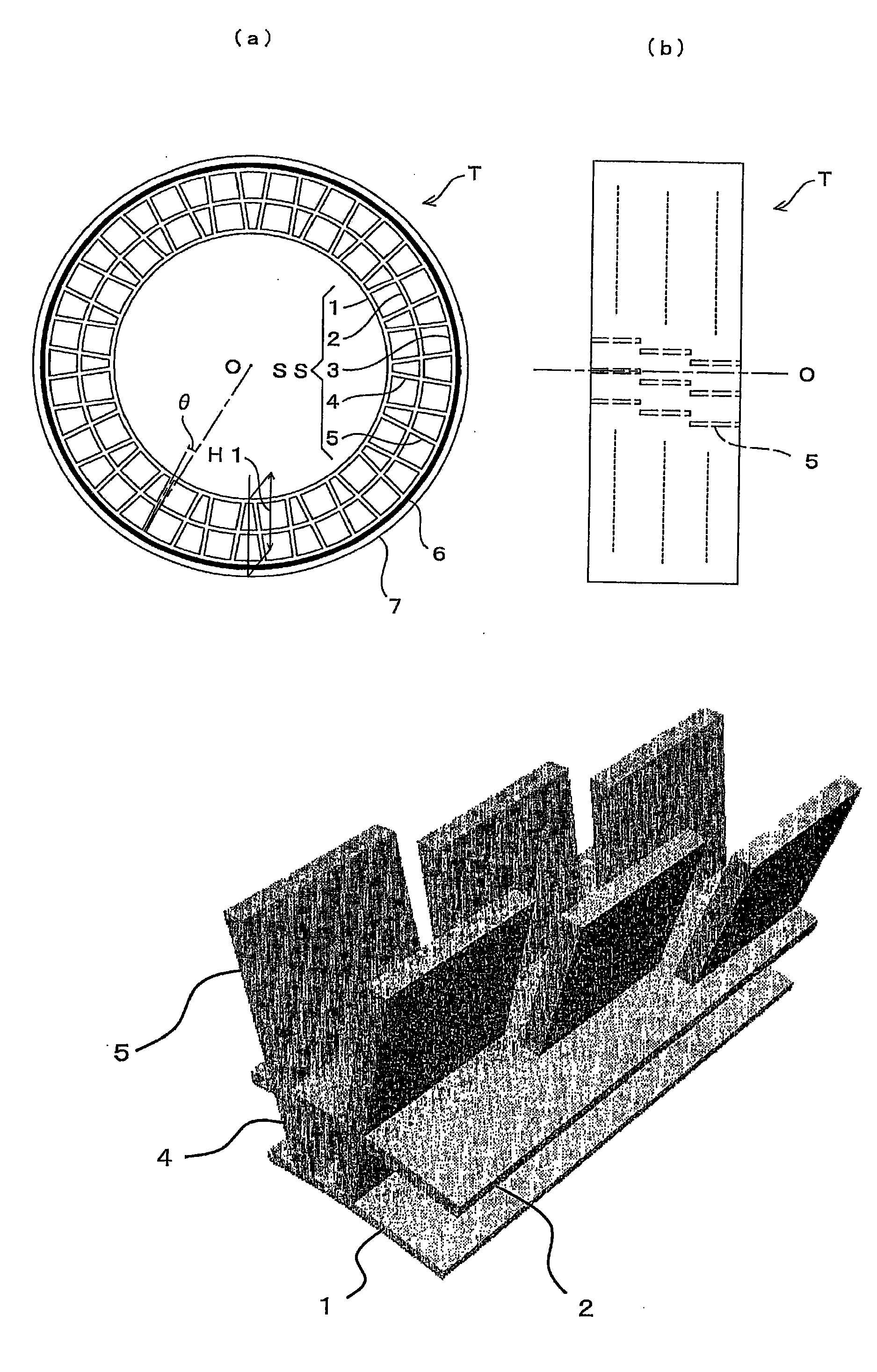

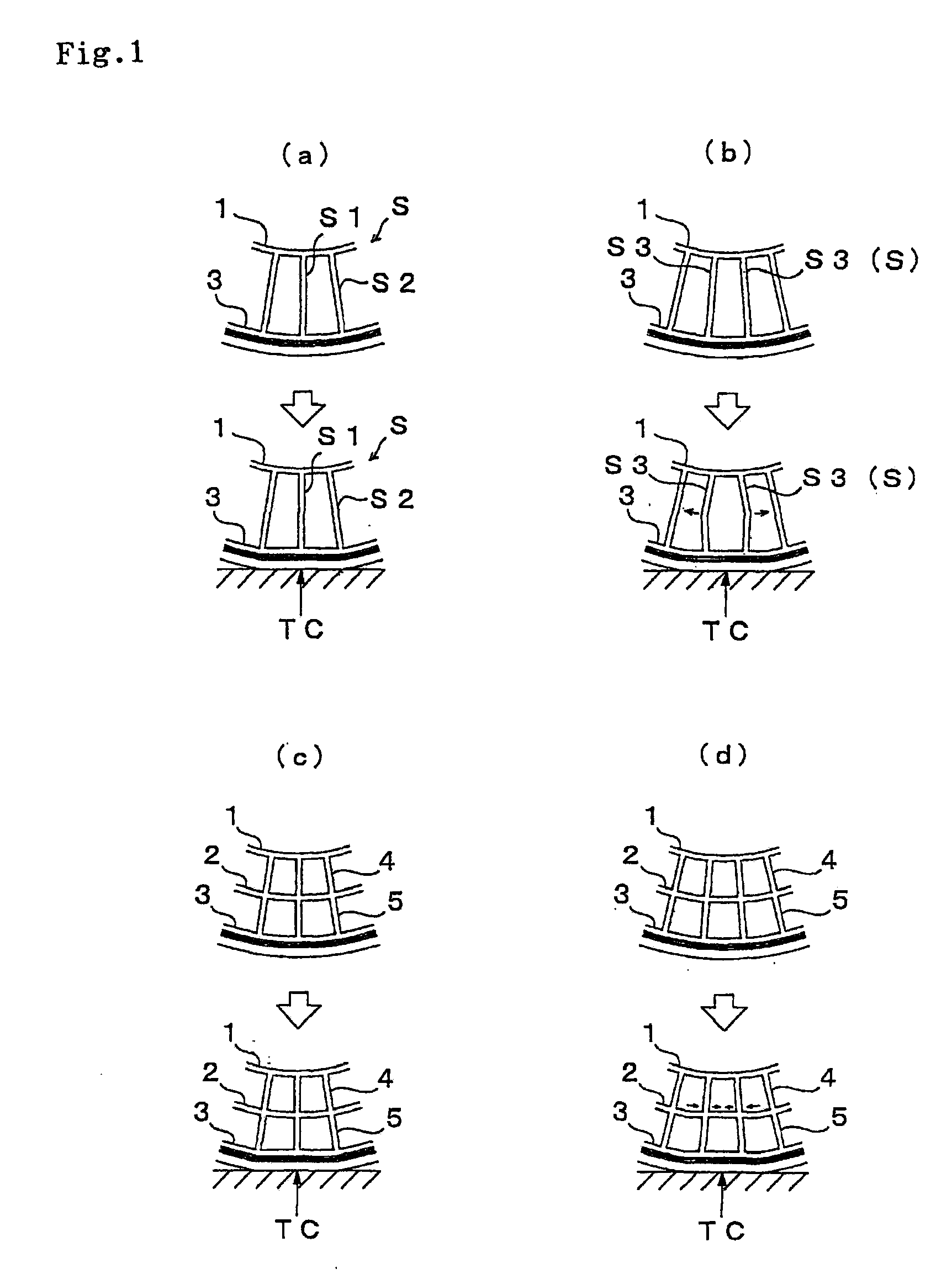

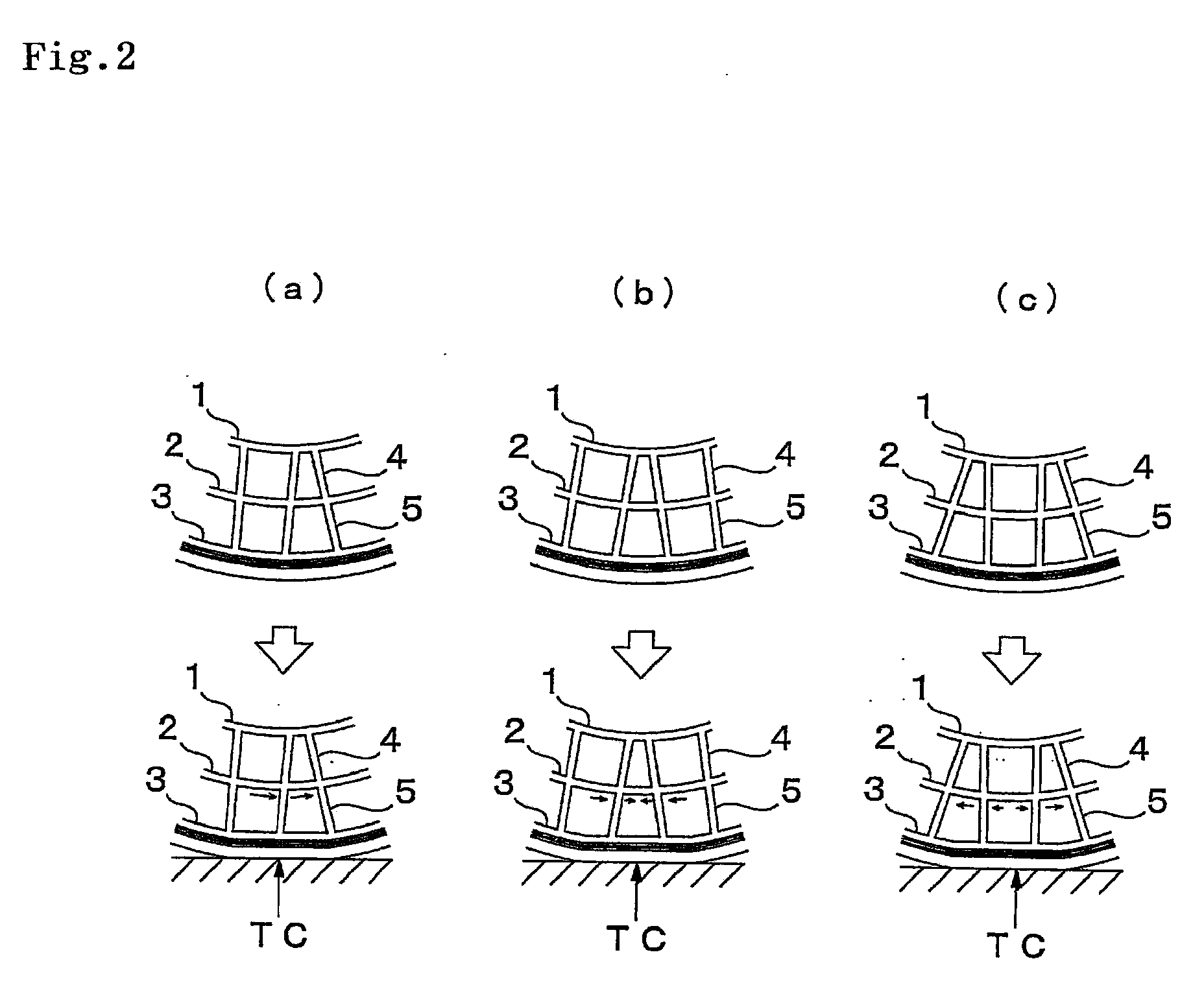

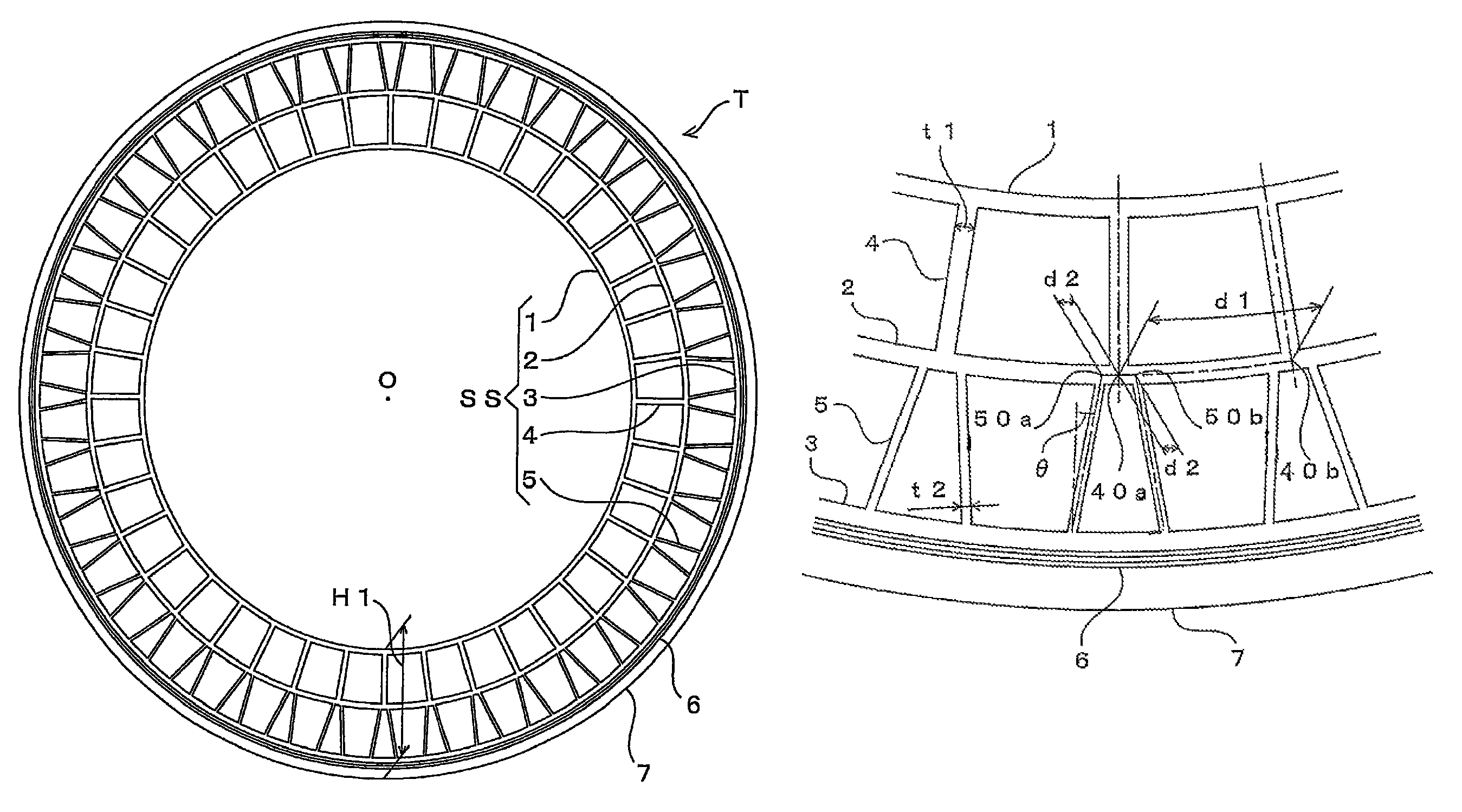

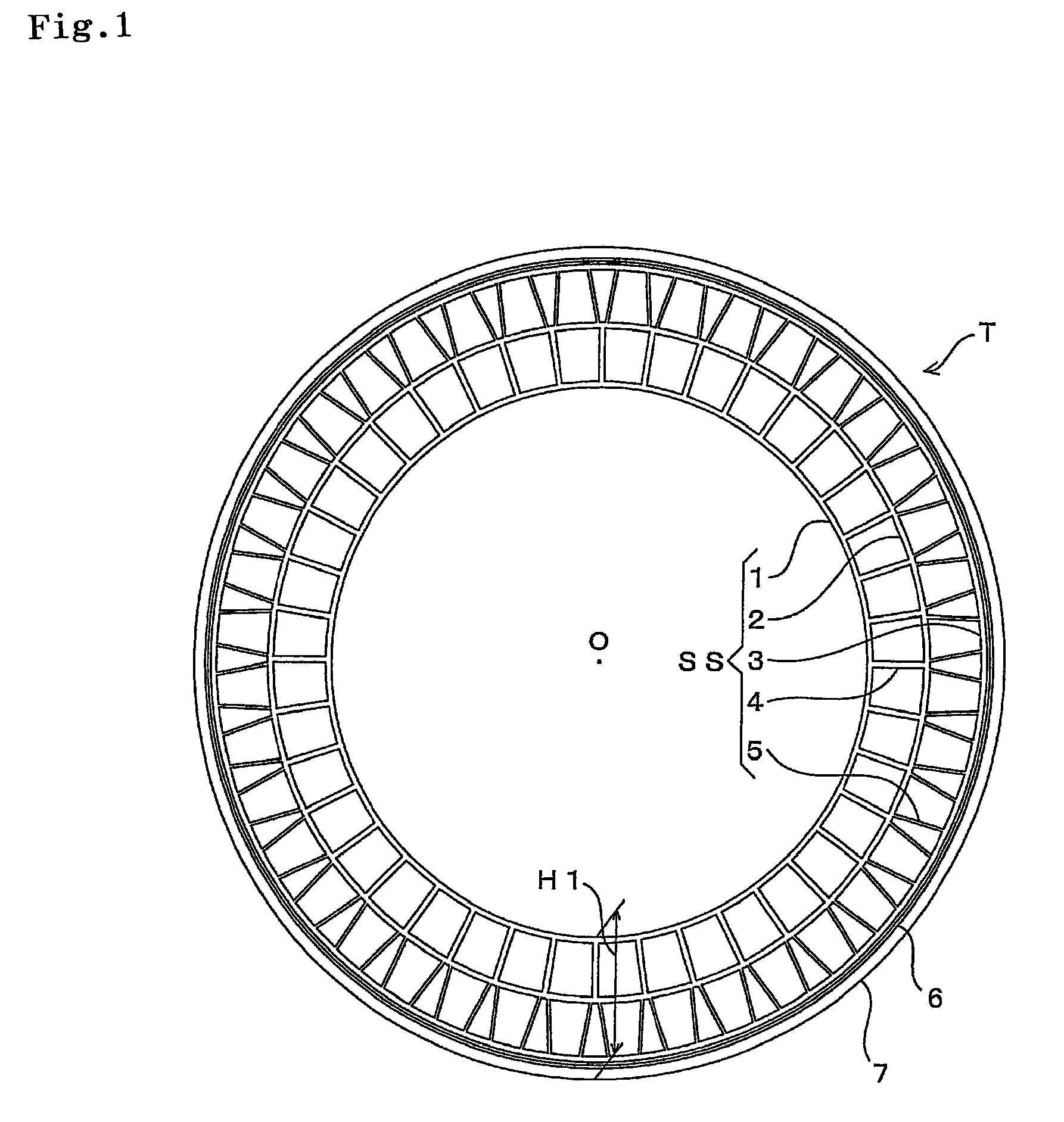

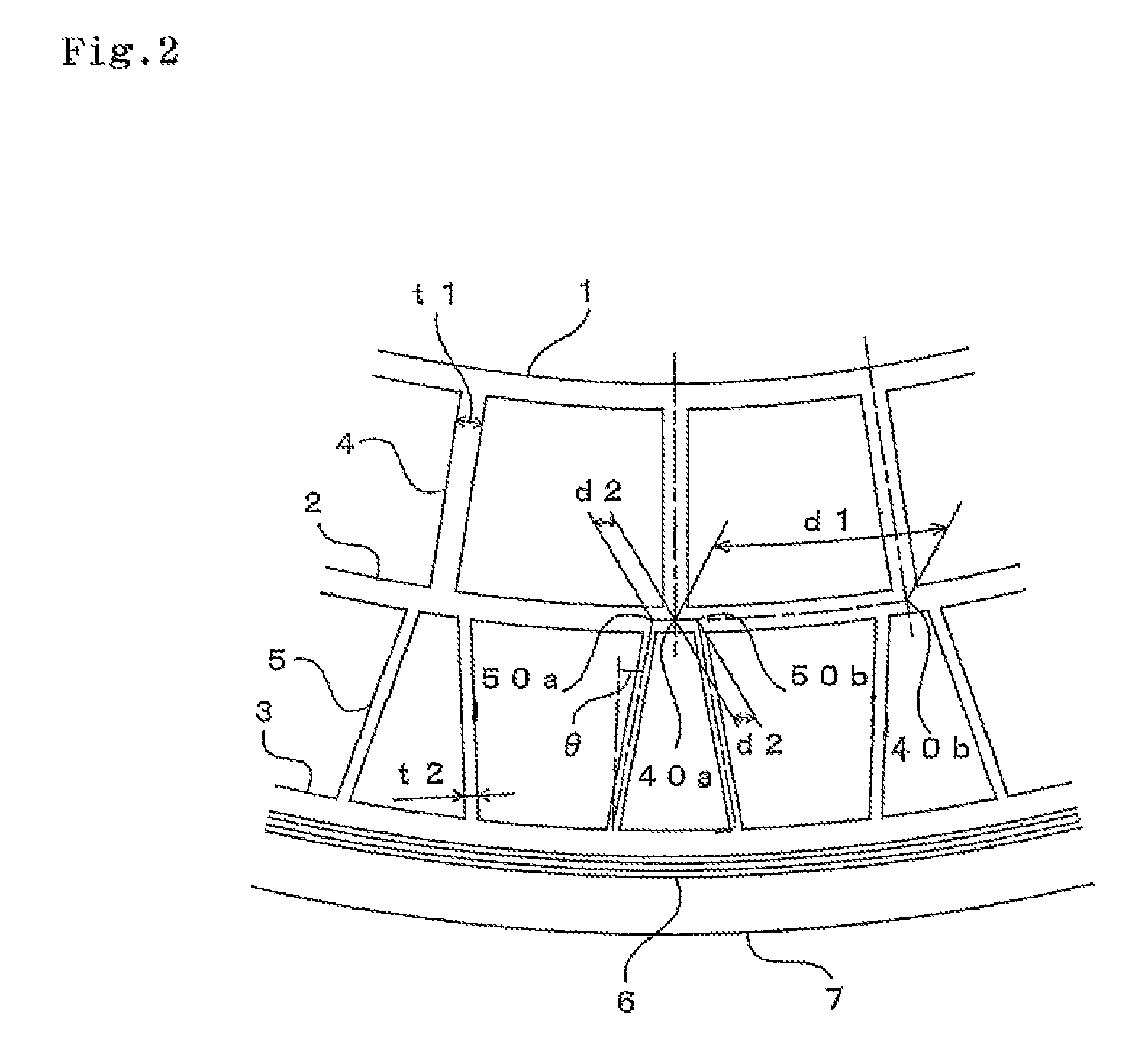

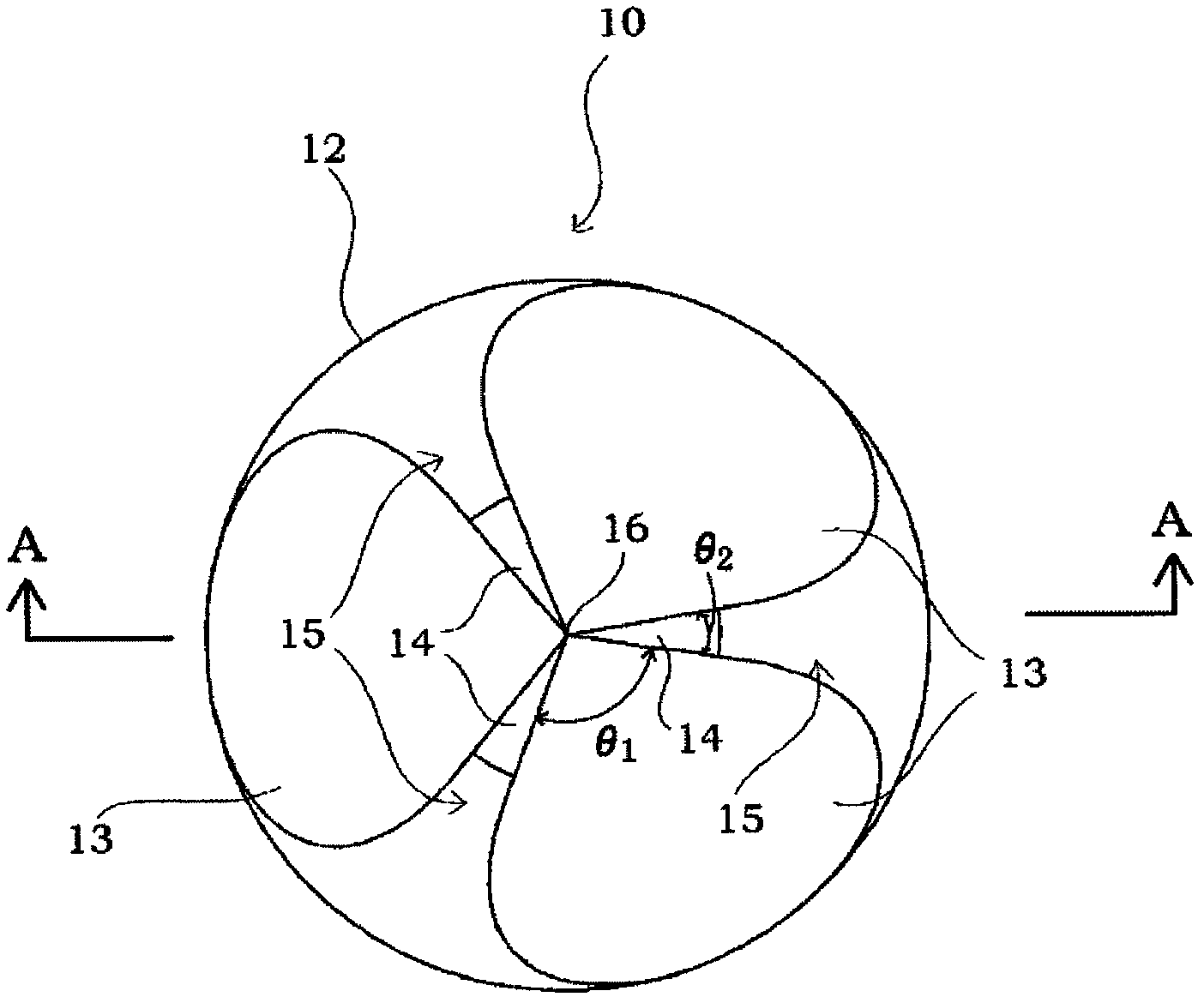

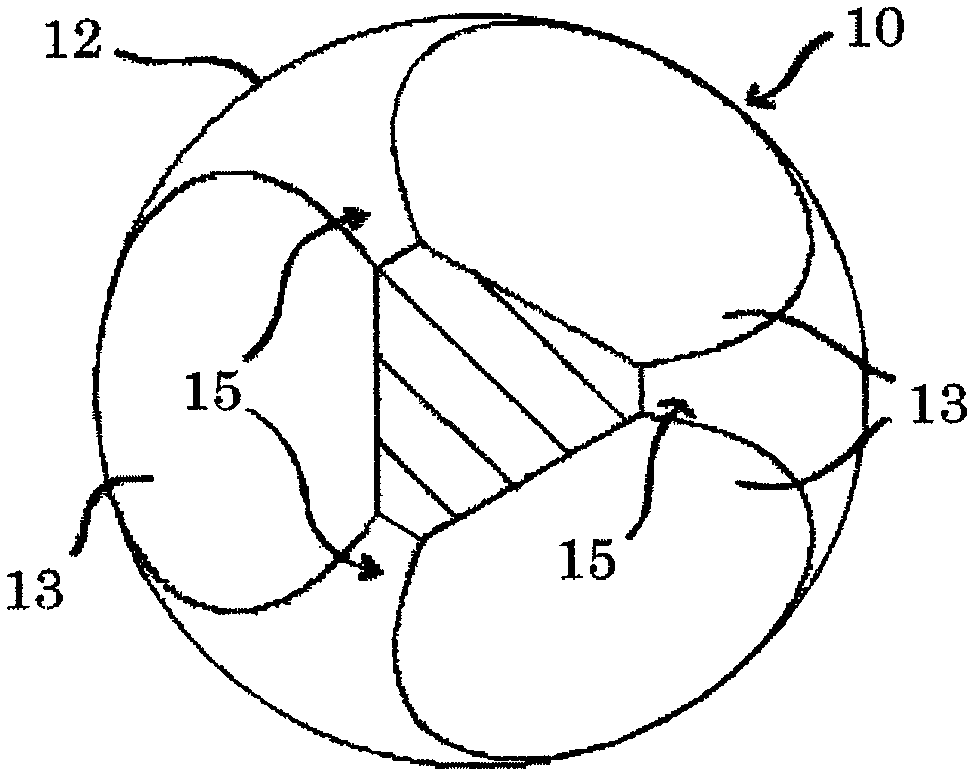

The invention provides a non-pneumatic tire which can improve a riding quality, a noise performance and the like while improving a durability, and can further sufficiently suppress a buckling of a ground portion between spokes, because a circumferential fluctuation of a tire rigidity is hard to be generated due to a positional relationship between a spoke position and a center position of the ground surface, and a strain can be dispersed into each of portions of a support structure body. In a non-pneumatic tire T comprising a support structure body SS supporting a load from a vehicle, the support structure body SS includes an inner annular portion 1, an intermediate annular portion 2 concentrically provided in an outer side of the inner annular portion 1, an outer annular portion 3 concentrically provided in an outer side of the intermediate annular portion 2, a plurality of inner coupling portions 4 coupling the inner annular portion 1 and the intermediate annular portion 2, and a plurality of outer coupling portions 5 coupling the outer annular portion 3 and the intermediate annular portion 2, and the number of the outer coupling portions 5 is larger than the number of the inner coupling portions 4.

Owner:TOYO TIRE & RUBBER CO LTD

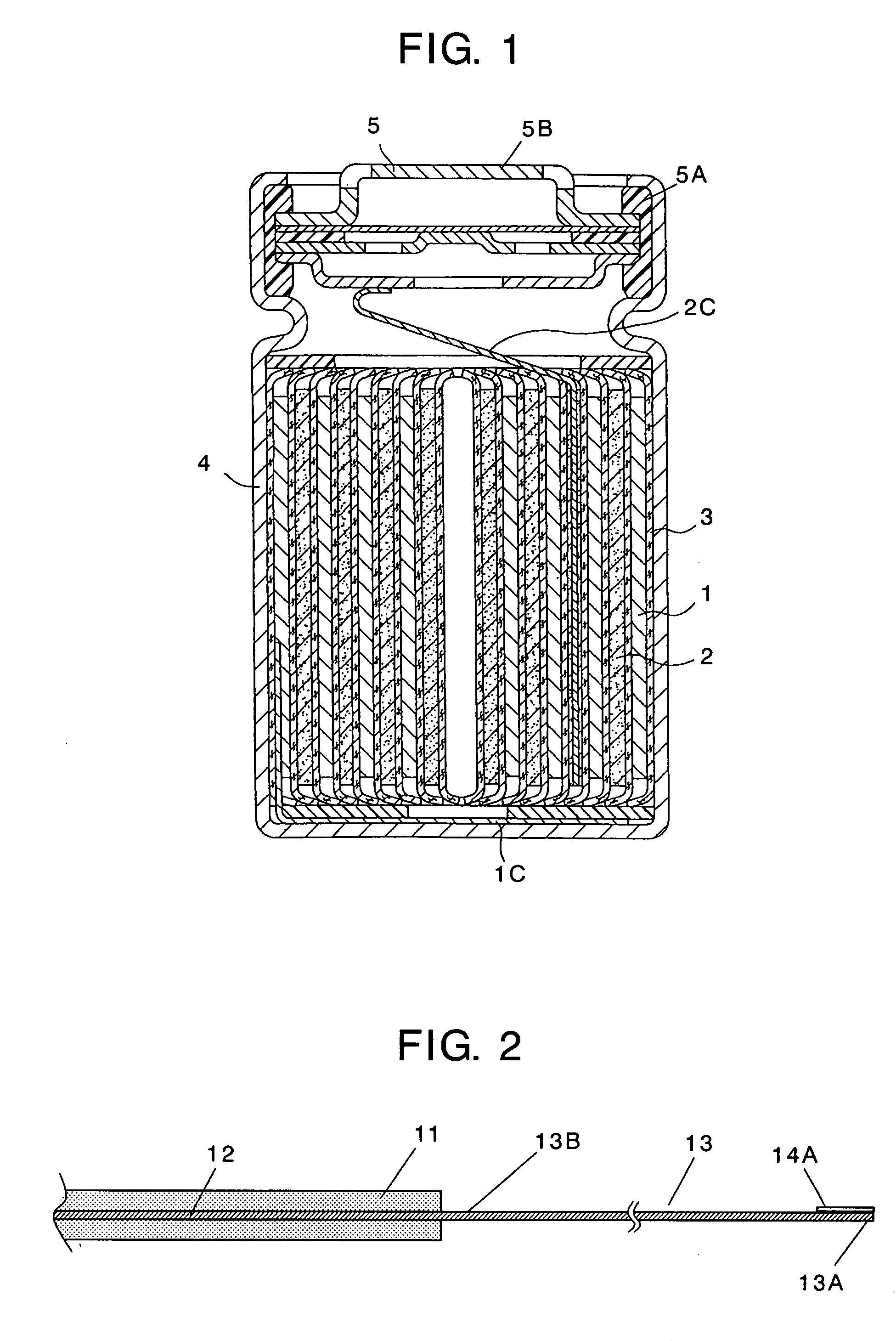

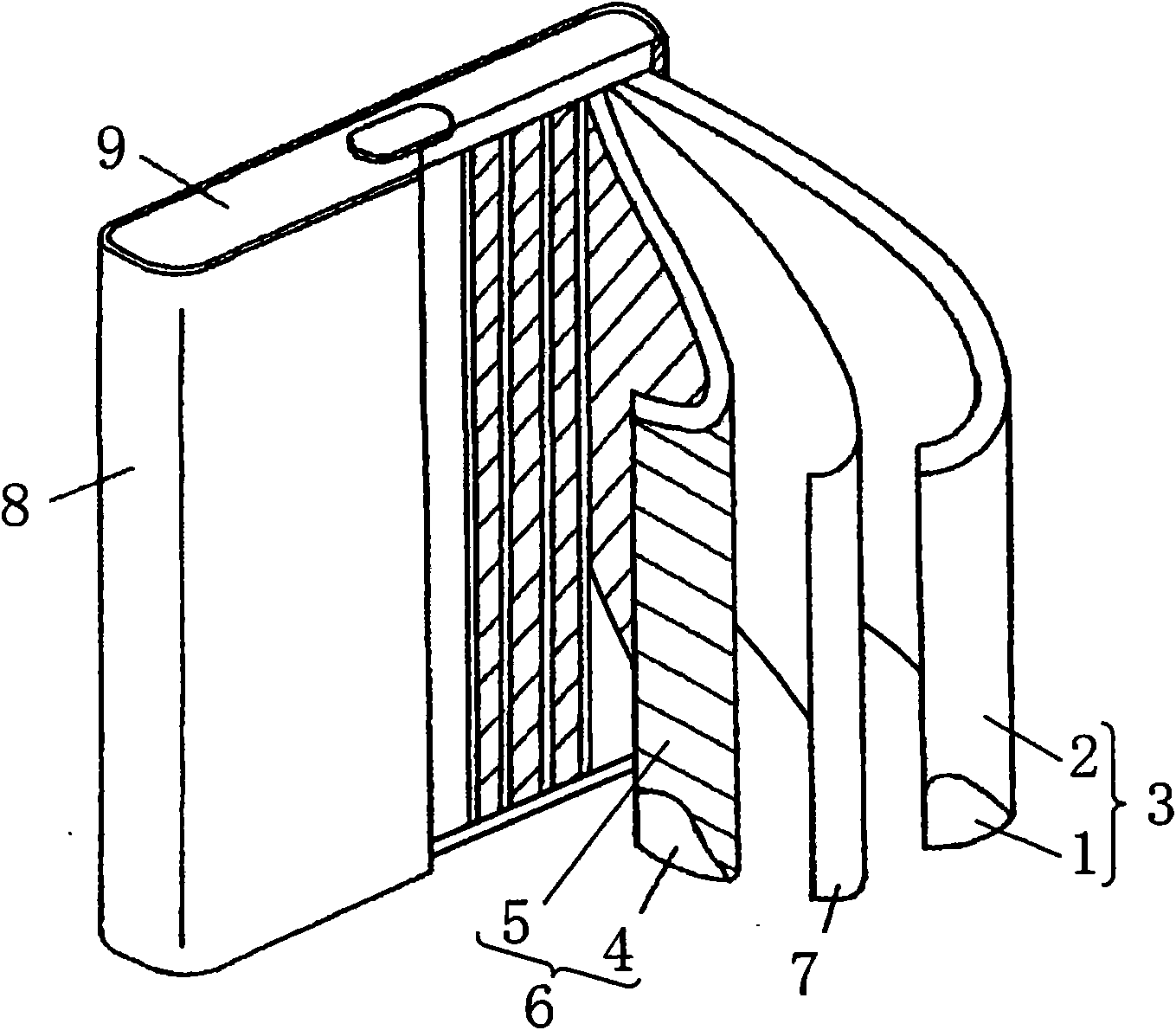

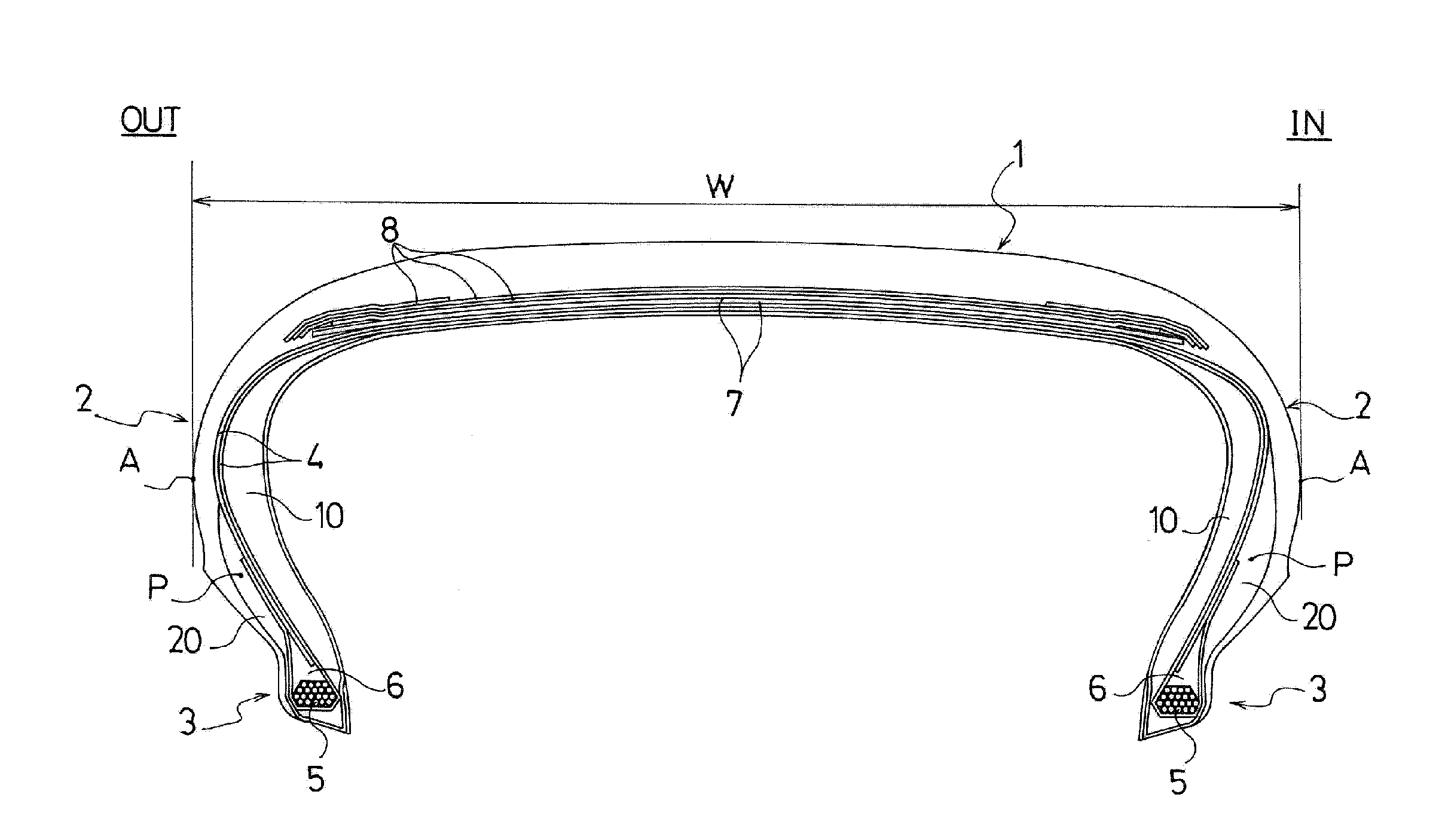

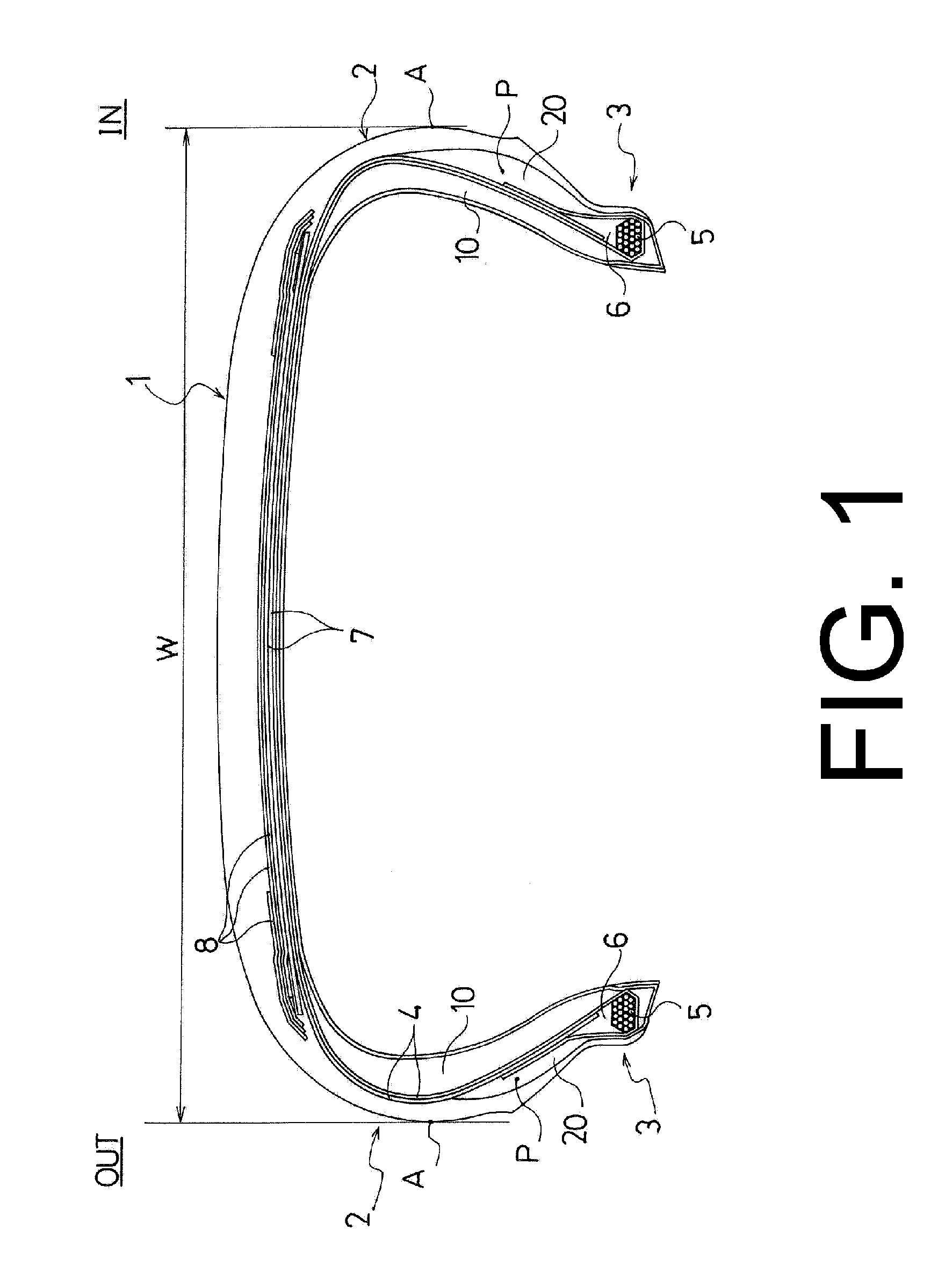

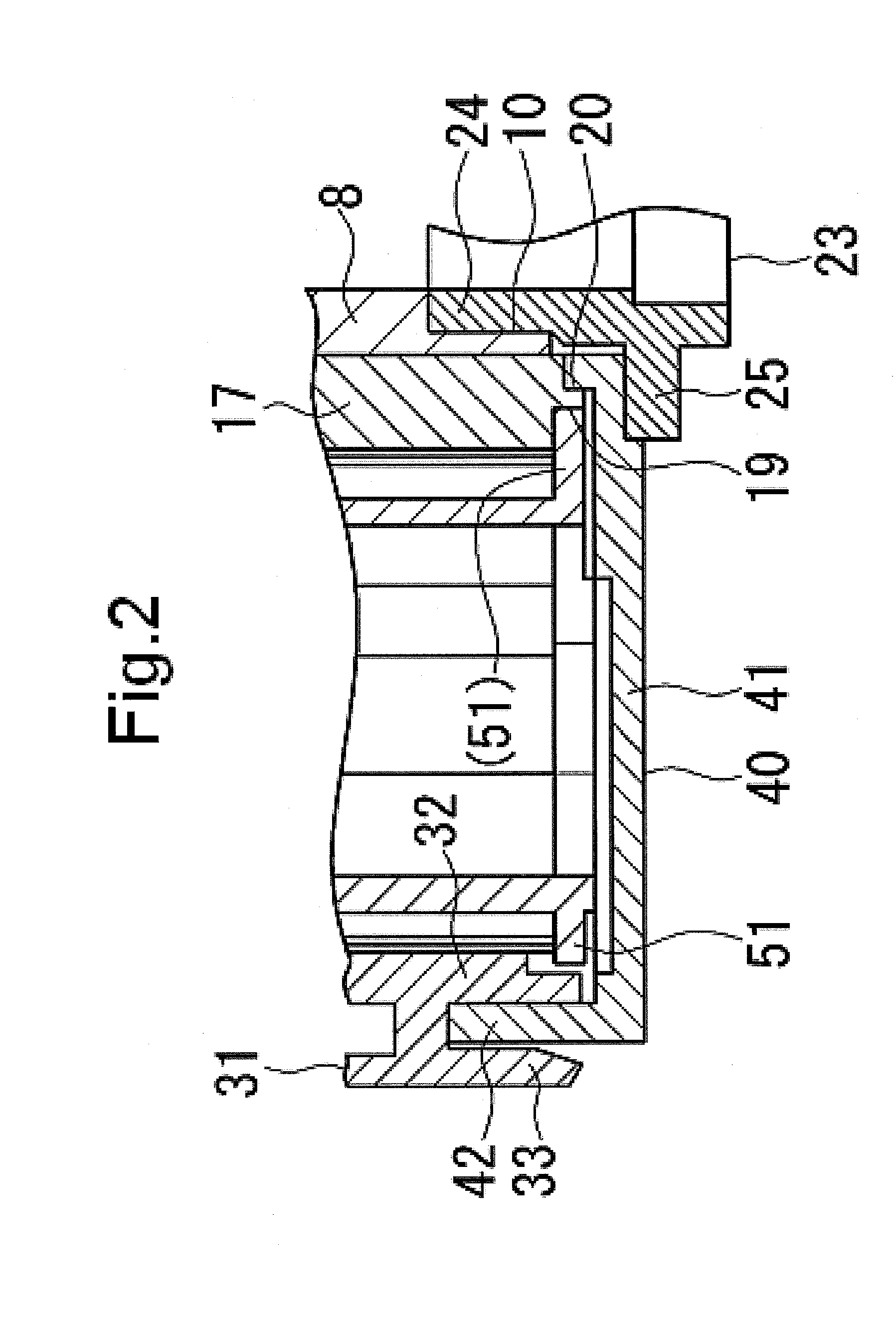

Non-Pneumatic Tire

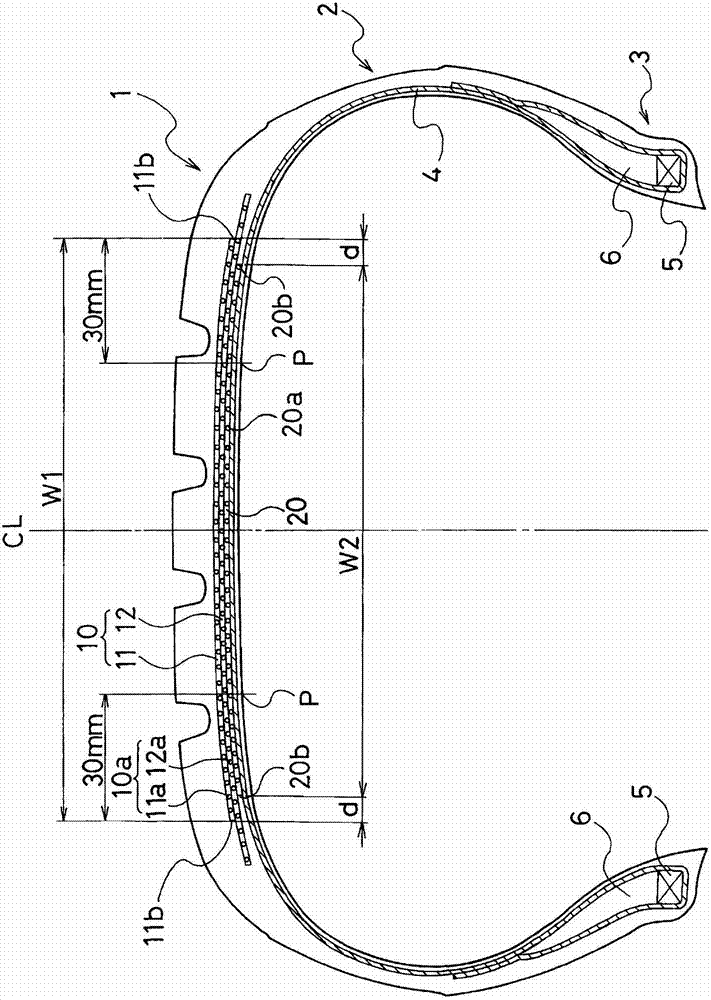

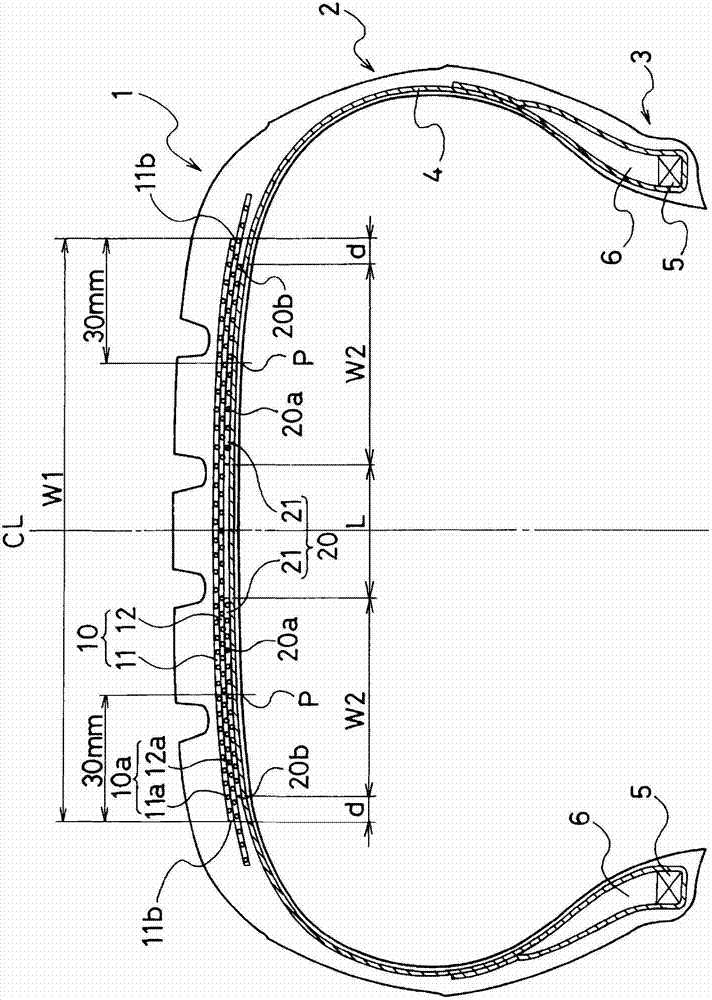

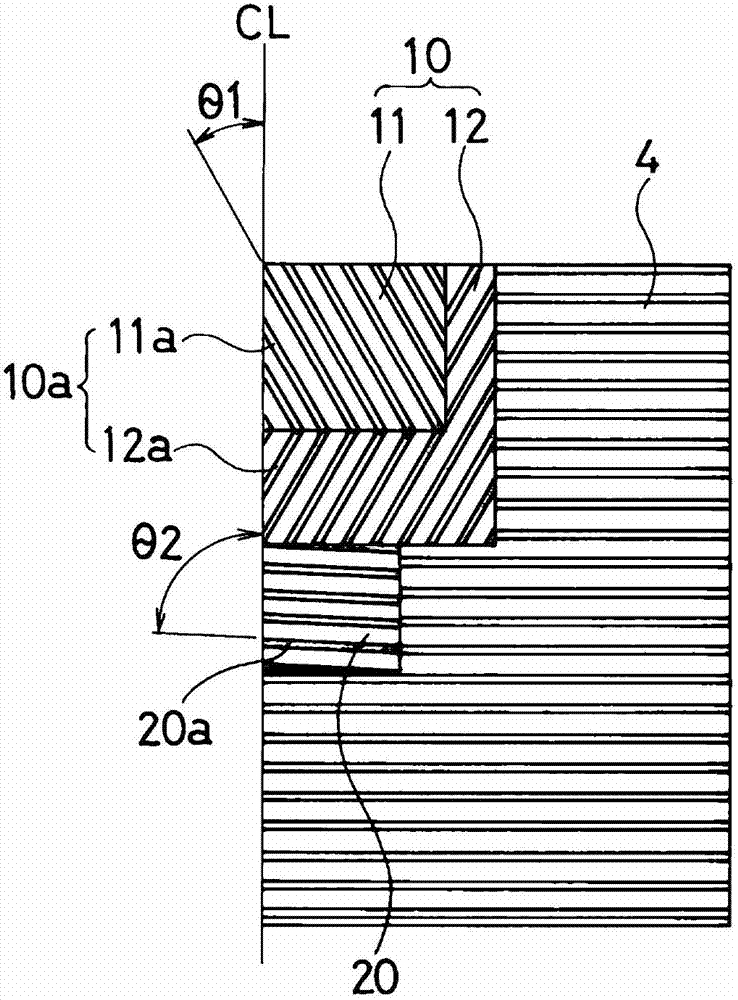

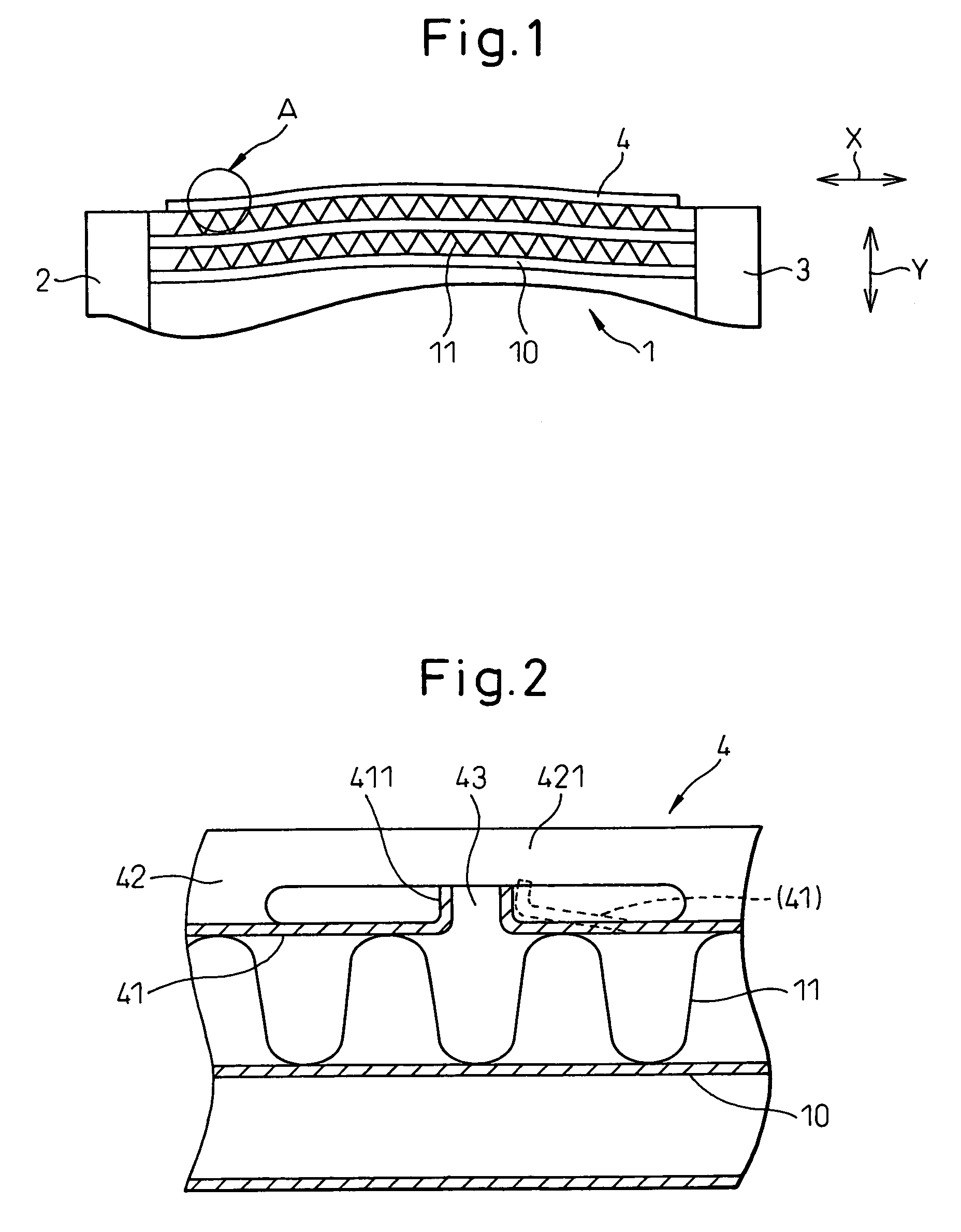

InactiveUS20100132865A1Buckling of a ground portionBuckling suppressionNon-inflatable tyresWheelsCouplingEngineering

The invention provides a non-pneumatic tire in which a fluctuation in a circumferential direction of tire rigidity is hard to be generated by a positional relationship between a spoke position and a center position of a ground surface, and a buckling of a ground portion between the spokes can be sufficiently suppressed. In a non-pneumatic tire T comprising a support structure body SS supporting a load from a vehicle, the support structure body SS includes an inner annular portion 1, an intermediate annular portion 2 concentrically provided in an outer side of the inner annular portion 1, an outer annular portion 3 concentrically provided in an outer side of the intermediate annular portion 2, a plurality of inner coupling portions 4 coupling the inner annular portion 1 and the intermediate annular portion 2, and a plurality of outer coupling portions 5 coupling the outer annular portion 3 and the intermediate annular portion 2, wherein the inner coupling portions 4 and the outer coupling portions 5 are divided in a tire width direction, are independent in a tire circumferential direction, and are provided so as to be shifted from each other in the tire circumferential direction per zones which are divided in the tire width direction.

Owner:TOYO TIRE & RUBBER CO LTD

Non-pneumatic tire

ActiveUS8113253B2Improve performanceQuality improvementNon-inflatable tyresHigh resiliency wheelsCouplingEngineering

Owner:TOYO TIRE & RUBBER CO LTD

Cantilever and inspecting apparatus

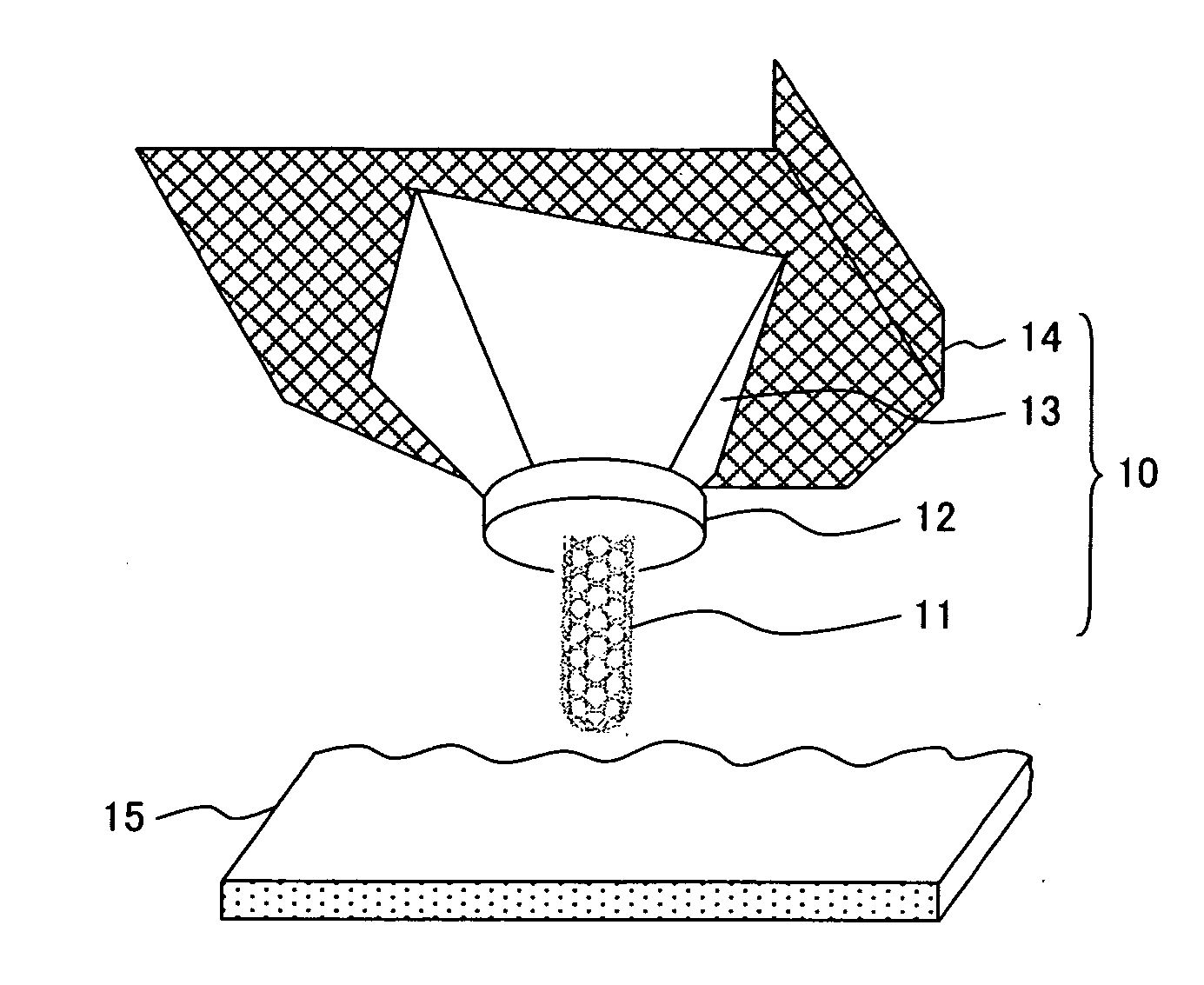

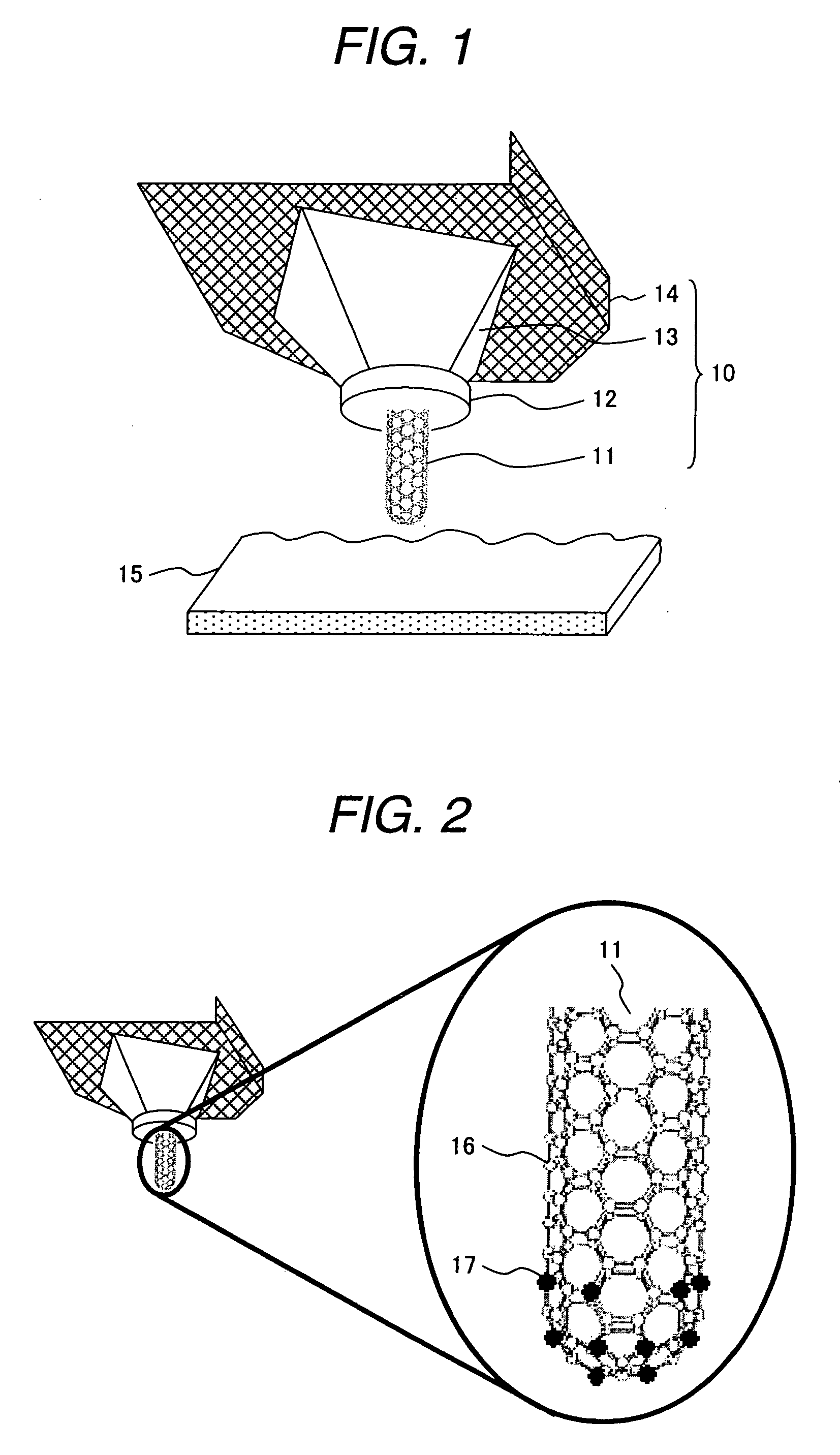

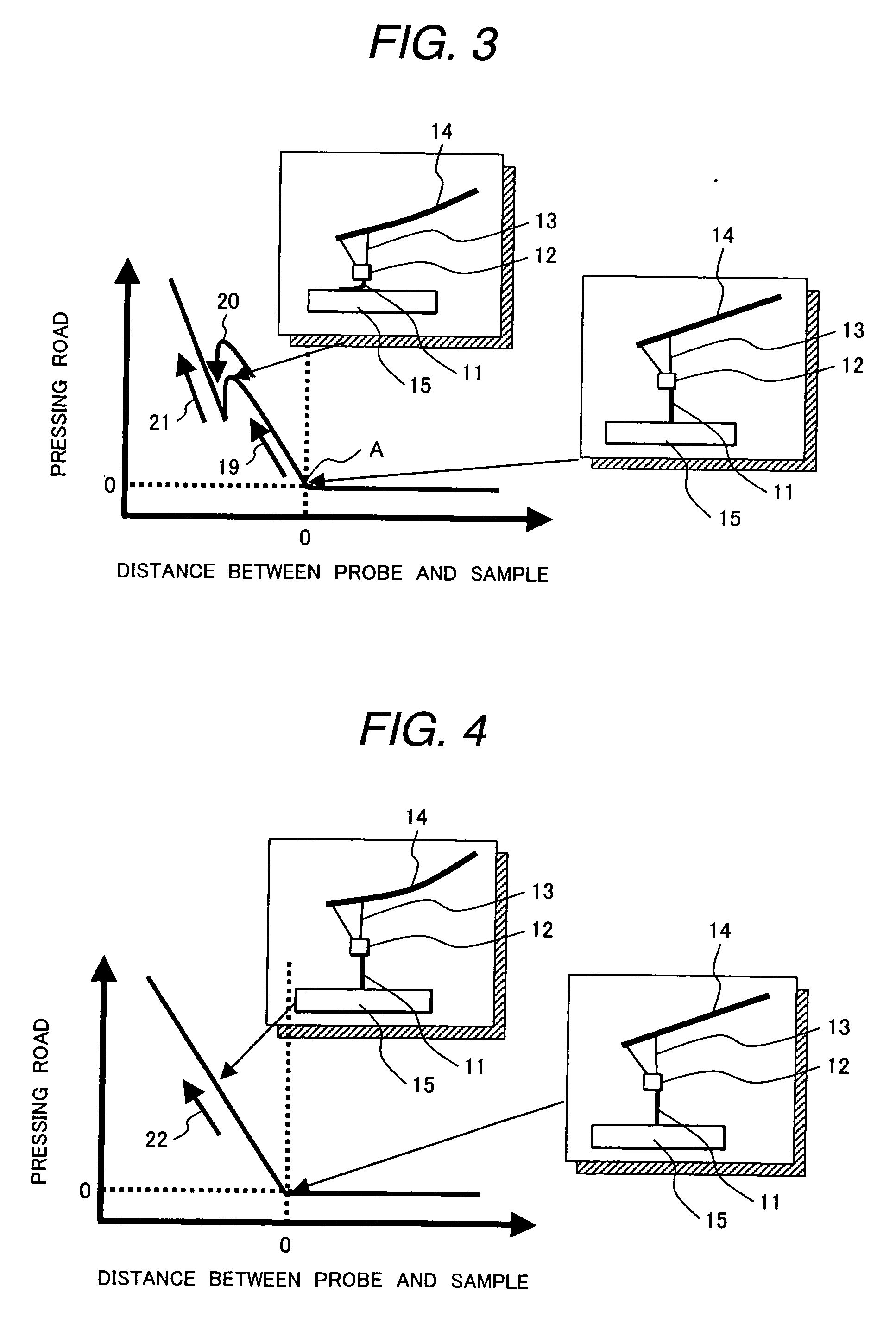

InactiveUS20070051887A1Stable AFM-based measurementIncrease stiffnessMaterial analysis using wave/particle radiationNanosensorsCantilevered beamCarbon nanotube

The present invention provides a cantilever having a base fixed to an inspecting apparatus, a beam protruding from the base, and a probe fixed to an end of the beam, wherein: the probe is formed by use of a carbon nanotube; and the probe is fixed by metal layers from at least two directions when the cantilever is operated, the probe protrudes in a direction in which a sample is fixed. It is possible to prevent the probe from warping and suppress image failures during observation of a sample.

Owner:HITACHI KENKI FINE TECH CO LTD +1

Pneumatic radial tire for use on passenger car

InactiveCN102815172AReduce thicknessIncreased durabilityPneumatic tyre reinforcementsRolling resistanceEngineering

Owner:THE YOKOHAMA RUBBER CO LTD

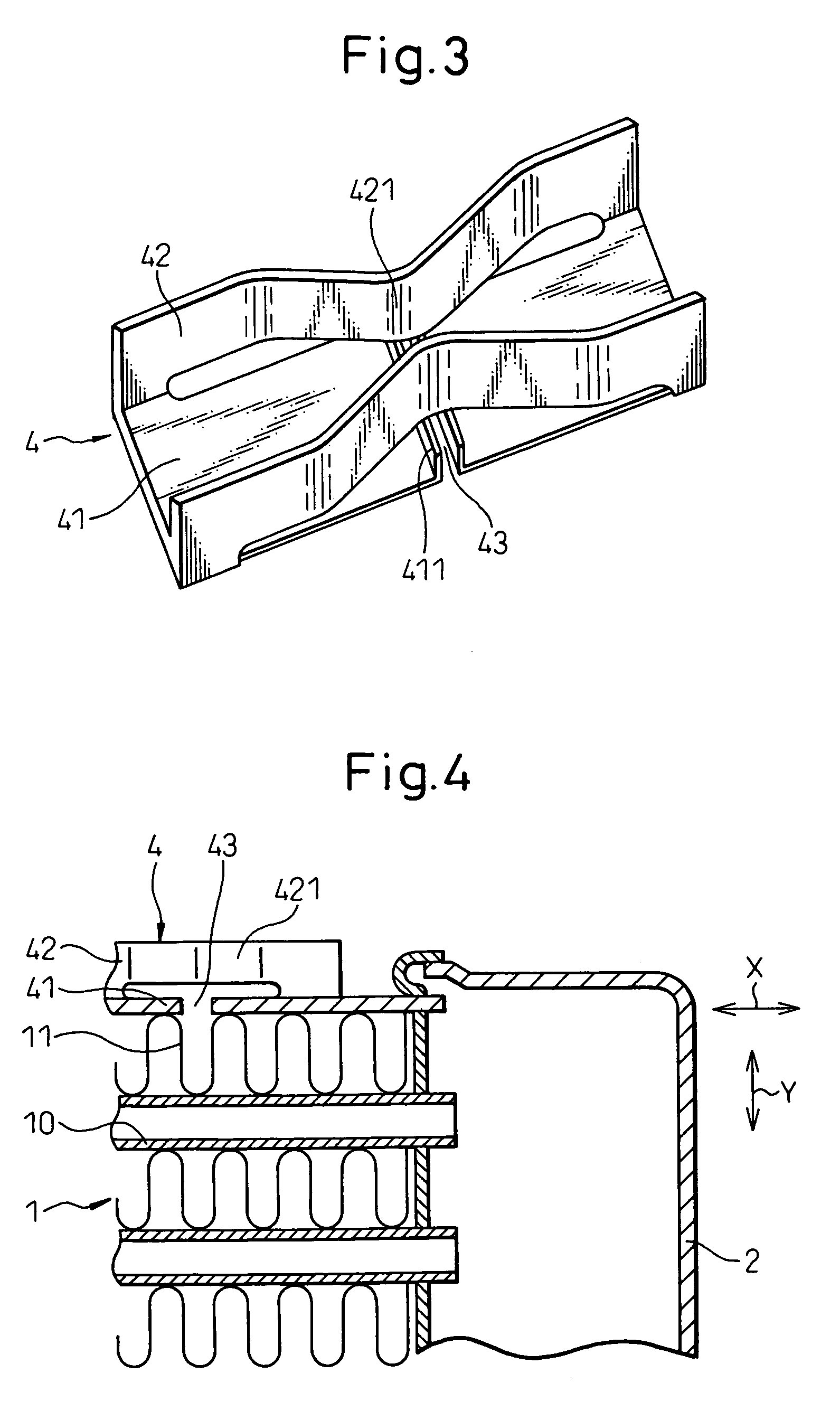

Displacement prevention device for the side plate of a heat exchanger

InactiveUS7389810B2Buckling suppressionSuppress or prevent the displacement of the base portion and the twisting of the side platesSafety devices for heat exchange apparatusStationary conduit assembliesPlate heat exchangerEngineering

Owner:DENSO CORP

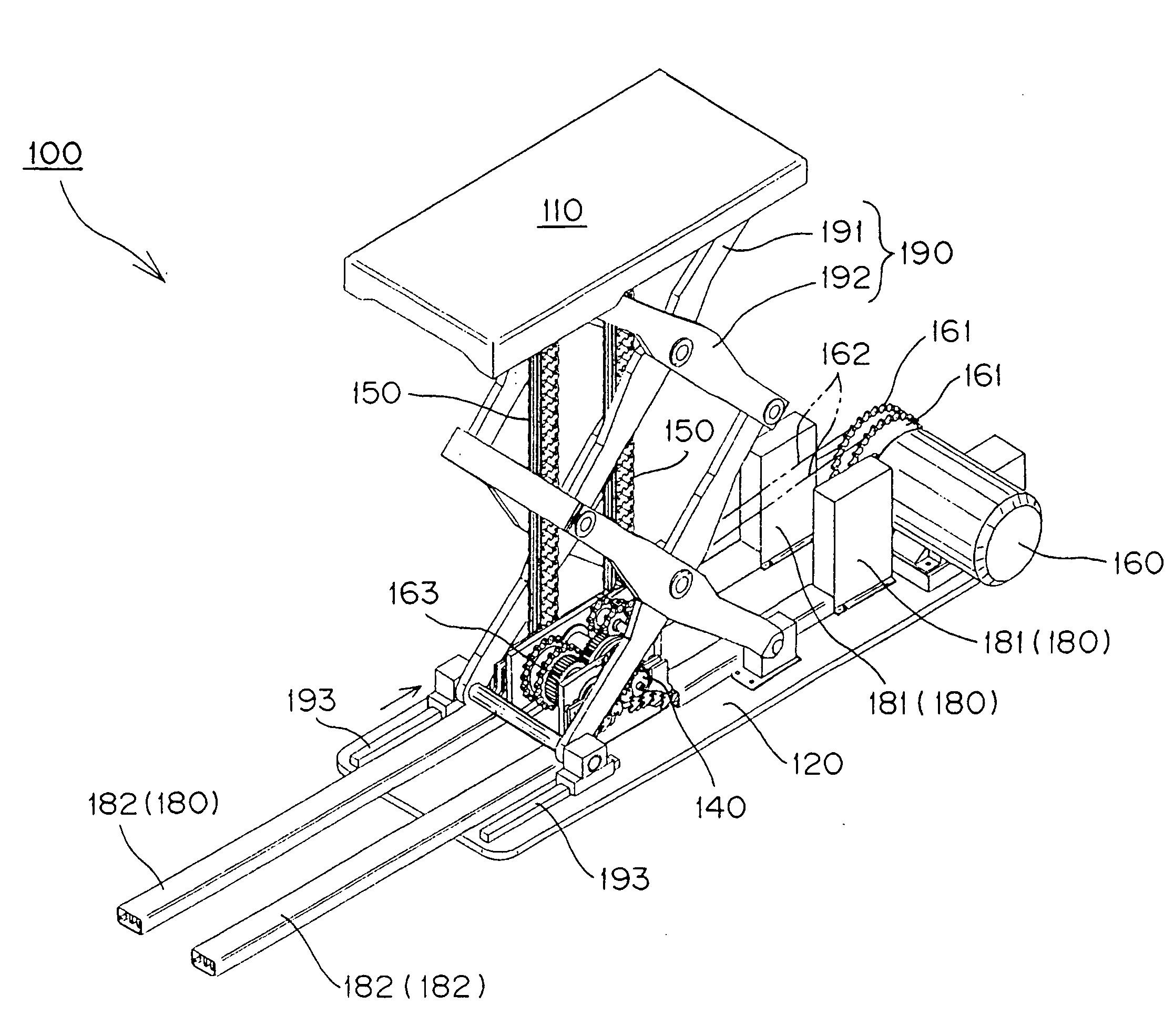

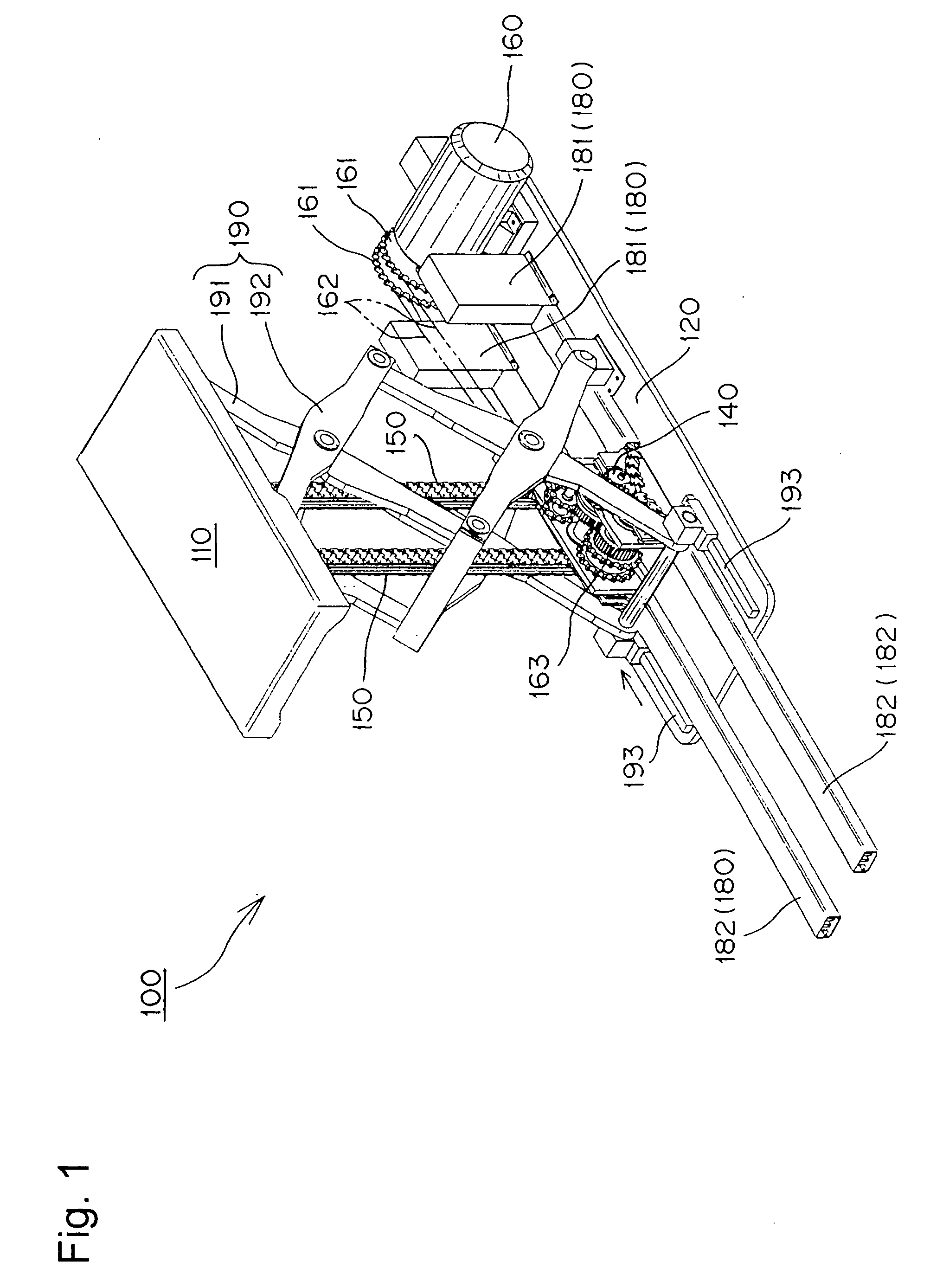

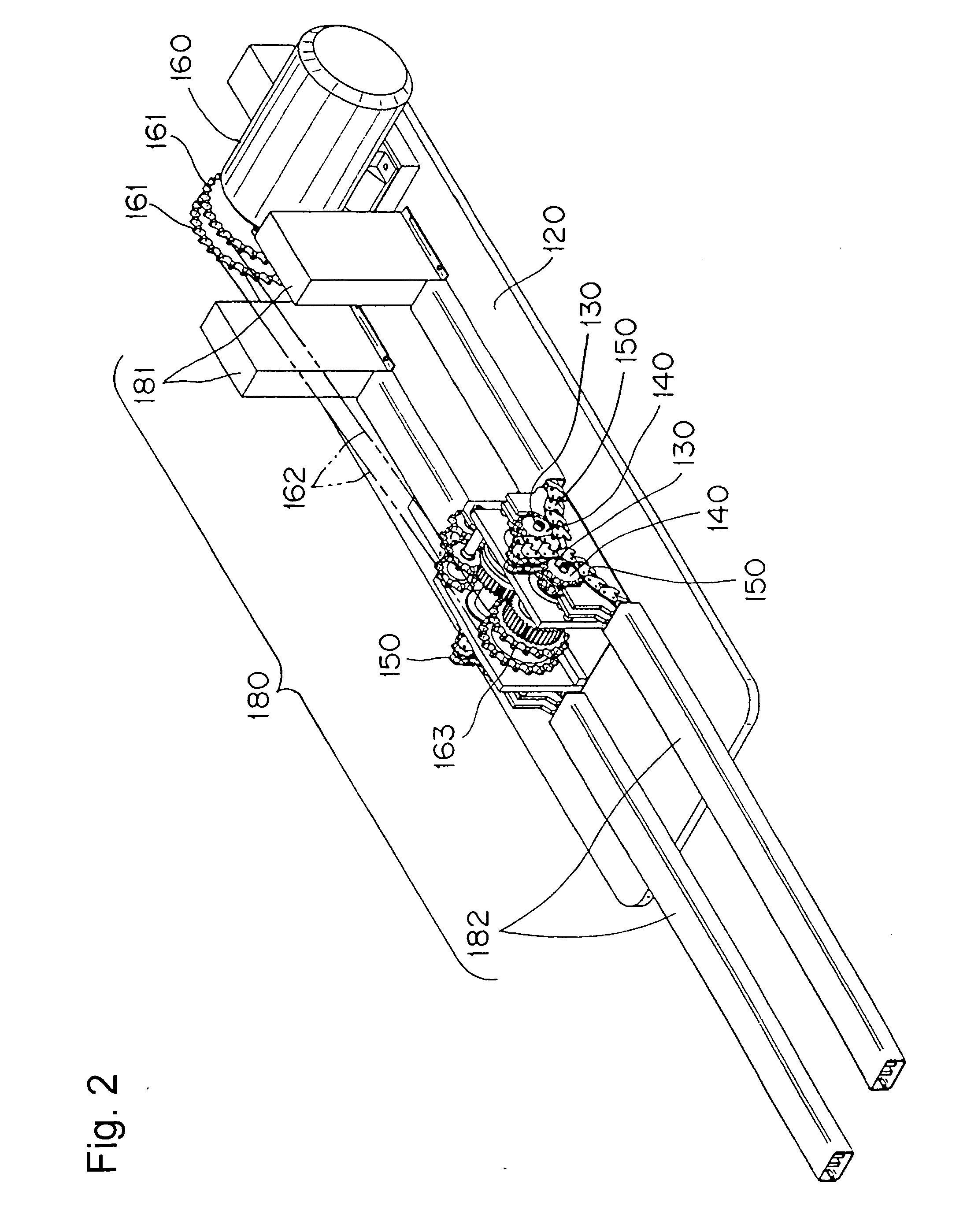

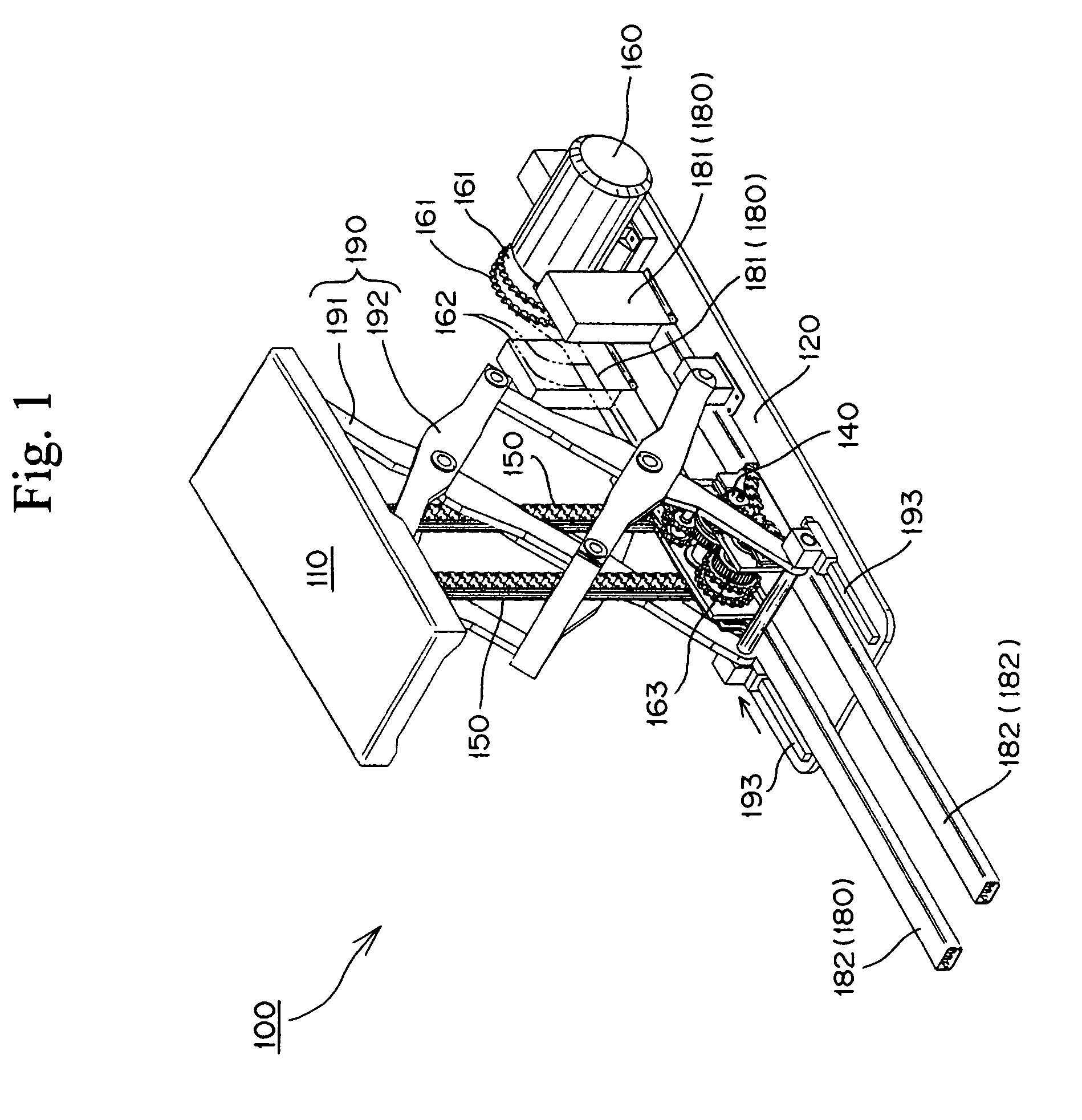

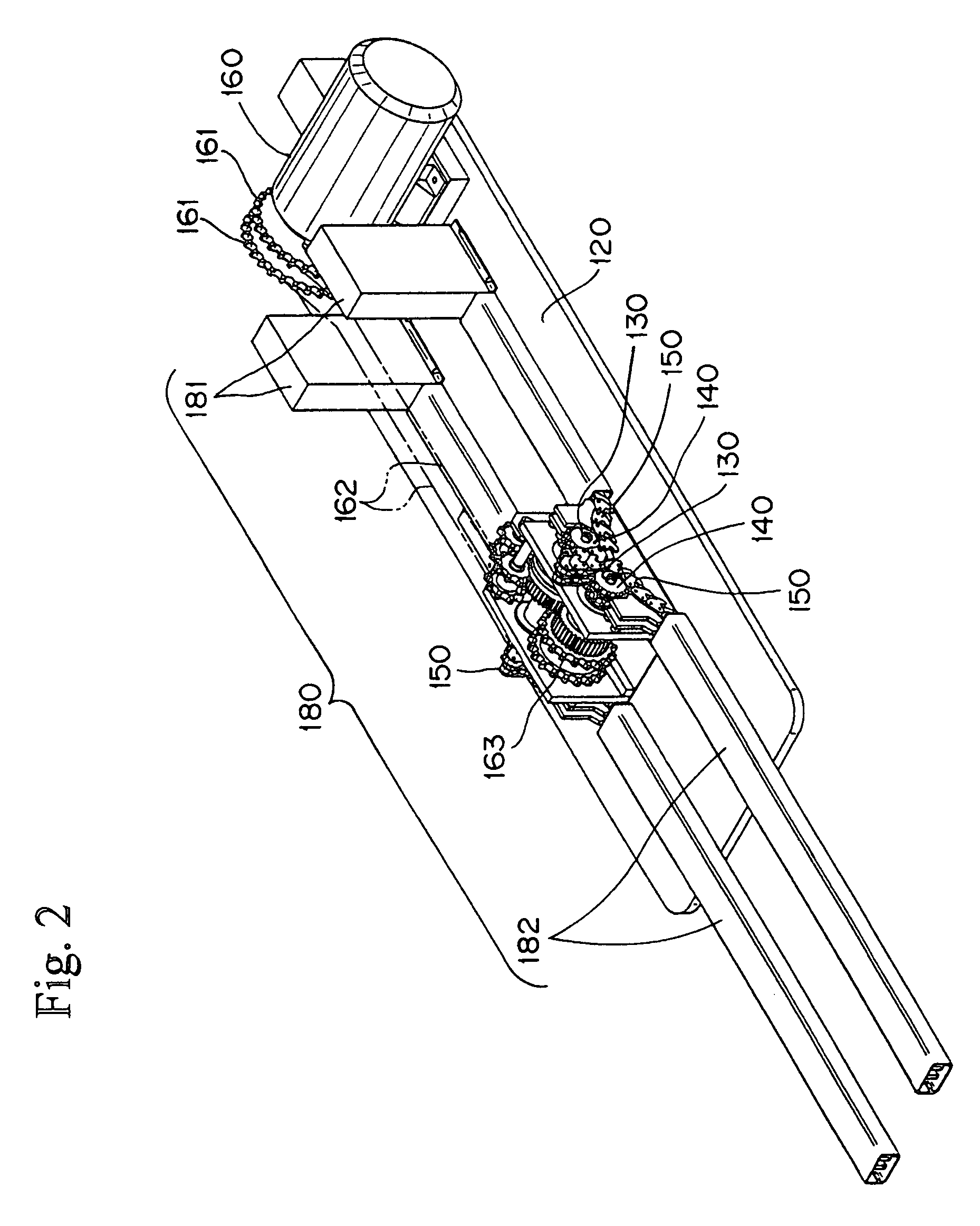

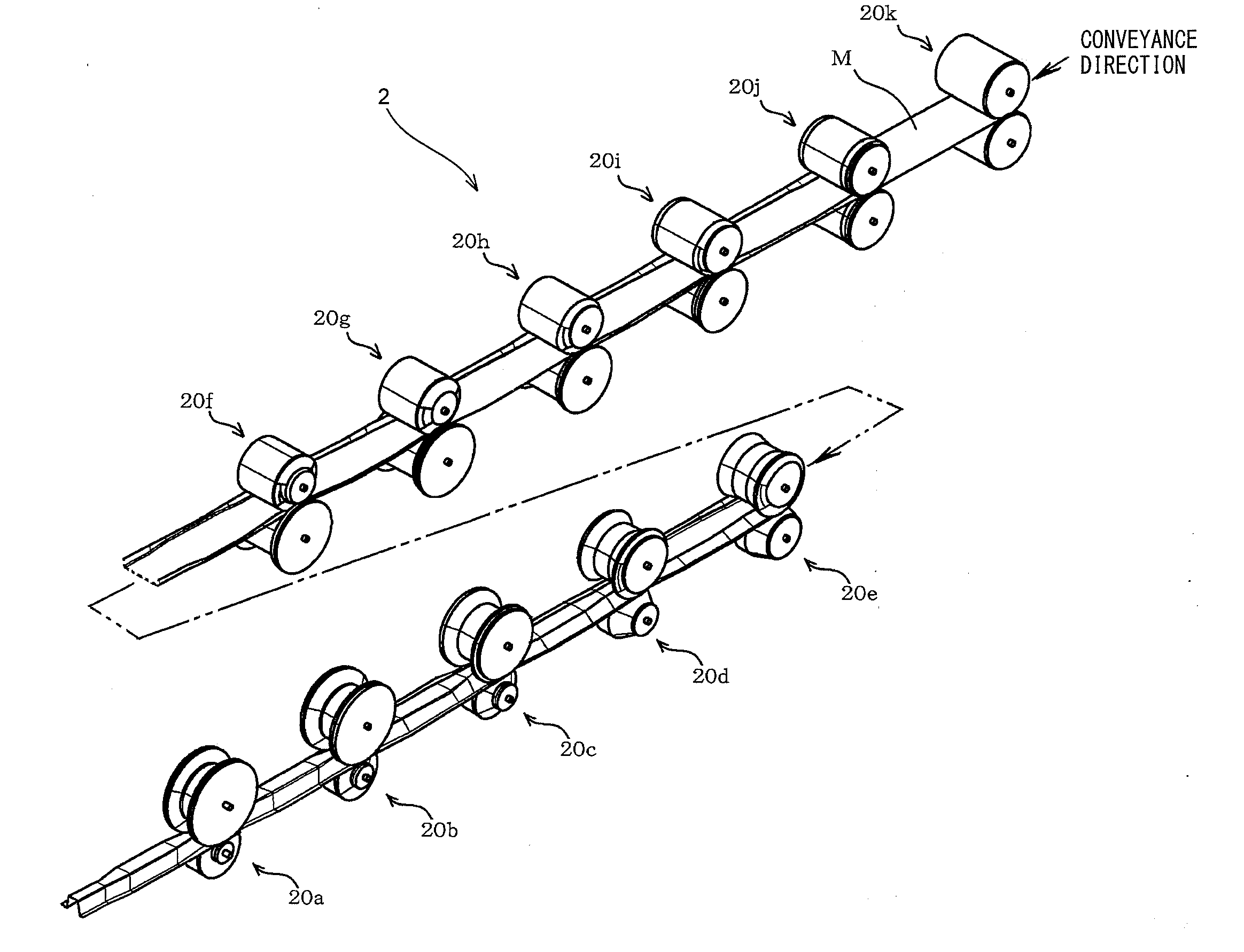

Engagement chain type hoisting and lowering device

InactiveUS20080315168A1Improve design flexibilitySignificant comprehensive benefitsPortable liftingLifting framesChain typeSprocket

An engagement chain type hoisting and lowering device is disclosed, having a hoisting and lowering table attached to the upper end of two or more pairs of hoisting and lowering driving engagement chains. A driving motor drives two pairs of hoisting and lowering sprockets which, in turn, raise or lower two pairs of hoisting and lowering driving engagement chains. By arranging two pairs of hoisting and lowering driving engagement chains on two opposed sides of the hoisting and lowering table, buckling of the hoisting and lowering driving engagement chains is suppressed, resulting in stable hoisting and lowering operations without slippage of articles on the hoisting and lowering table, and chain endurance is improved. The device is designed so that the lowest position of the hoisting and lowering table can be lower than the height of the peripherally located driving motor, for ease and safety of operation and maintenance.

Owner:TSUBAKIMOTO CHAIN CO

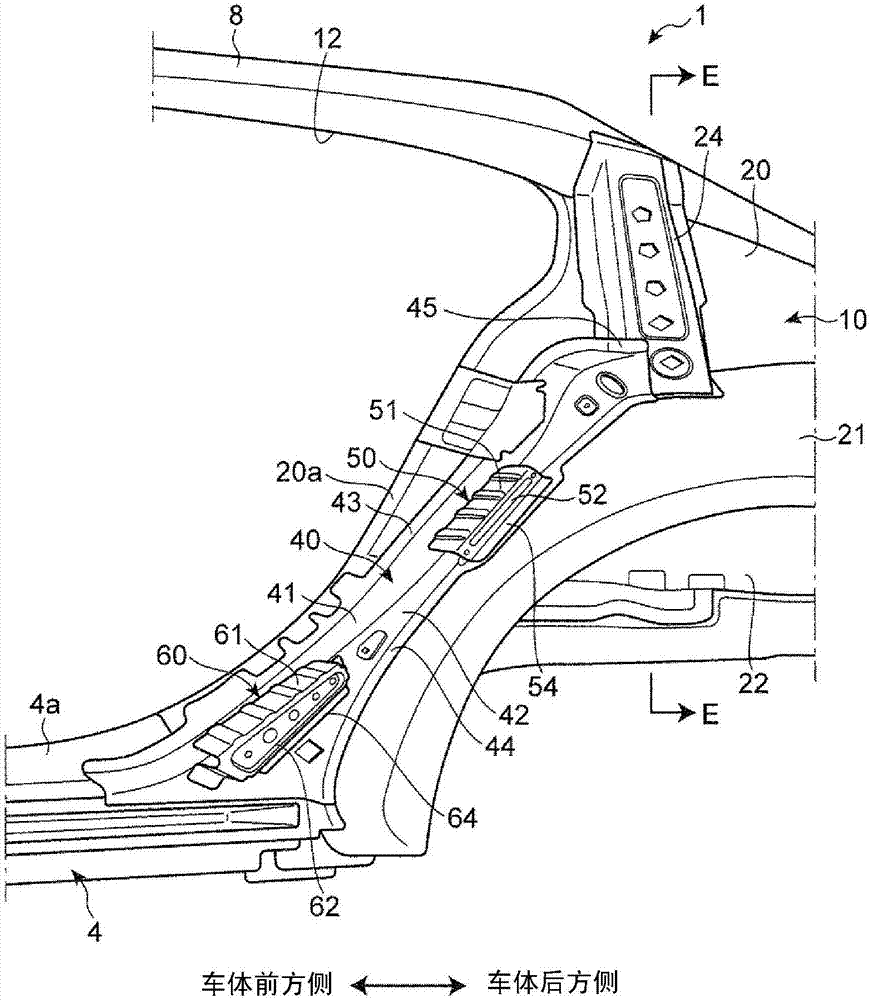

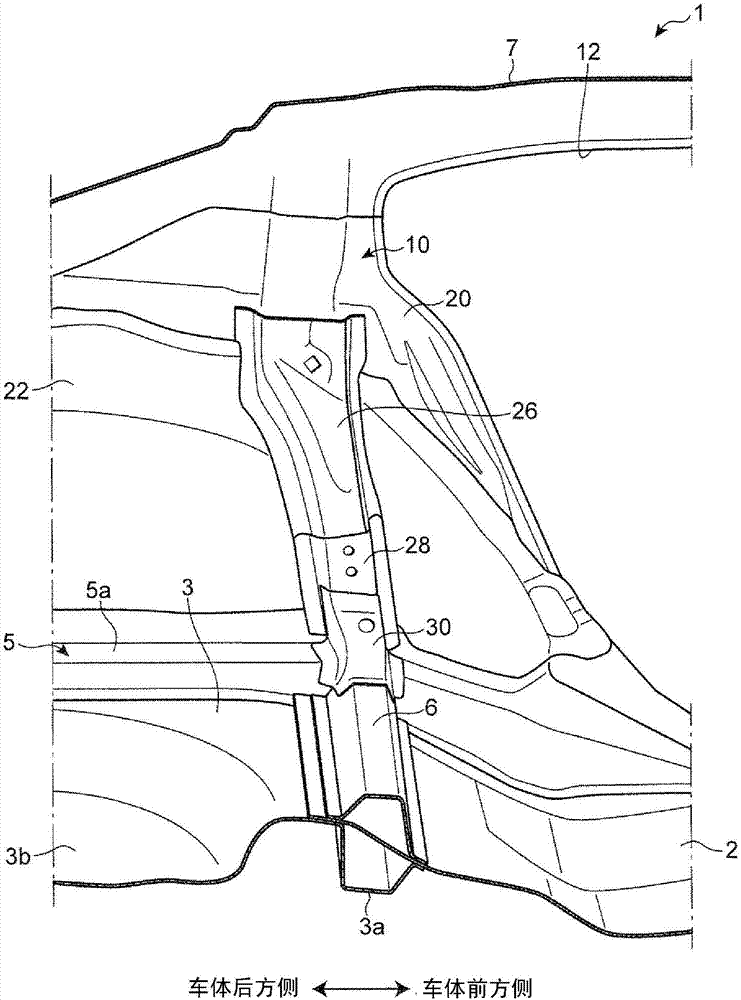

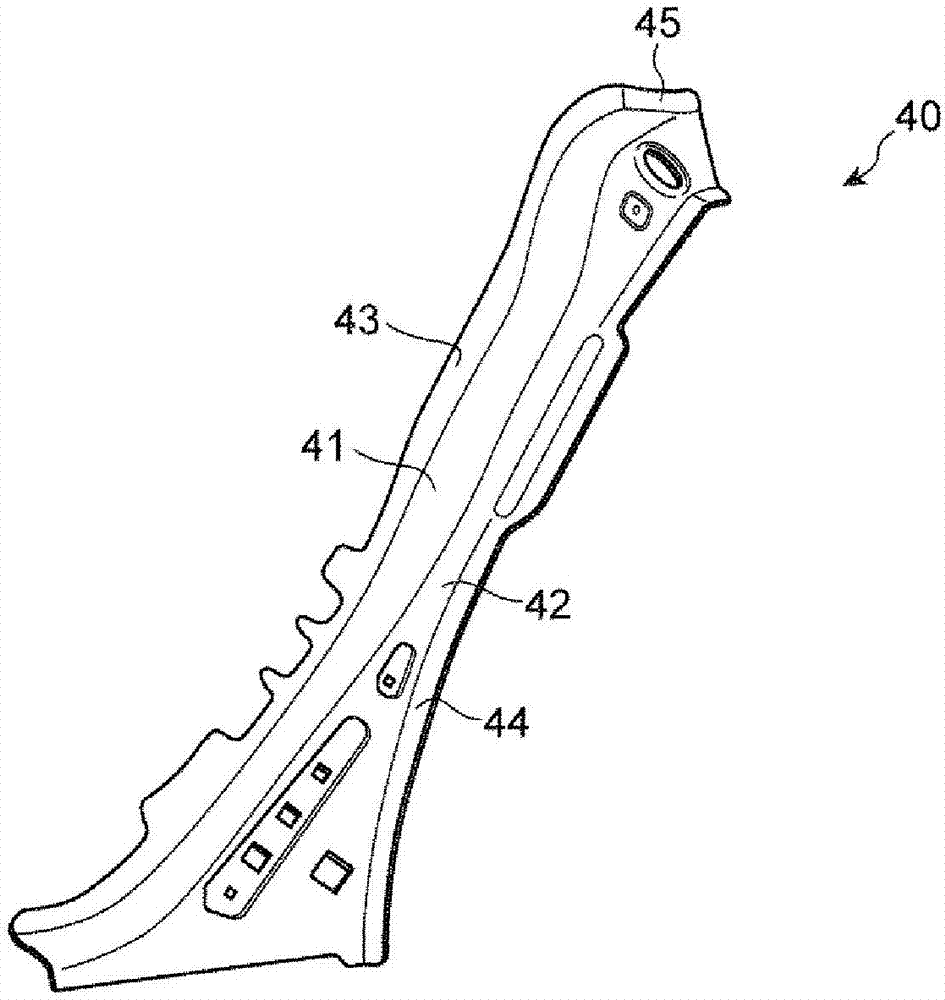

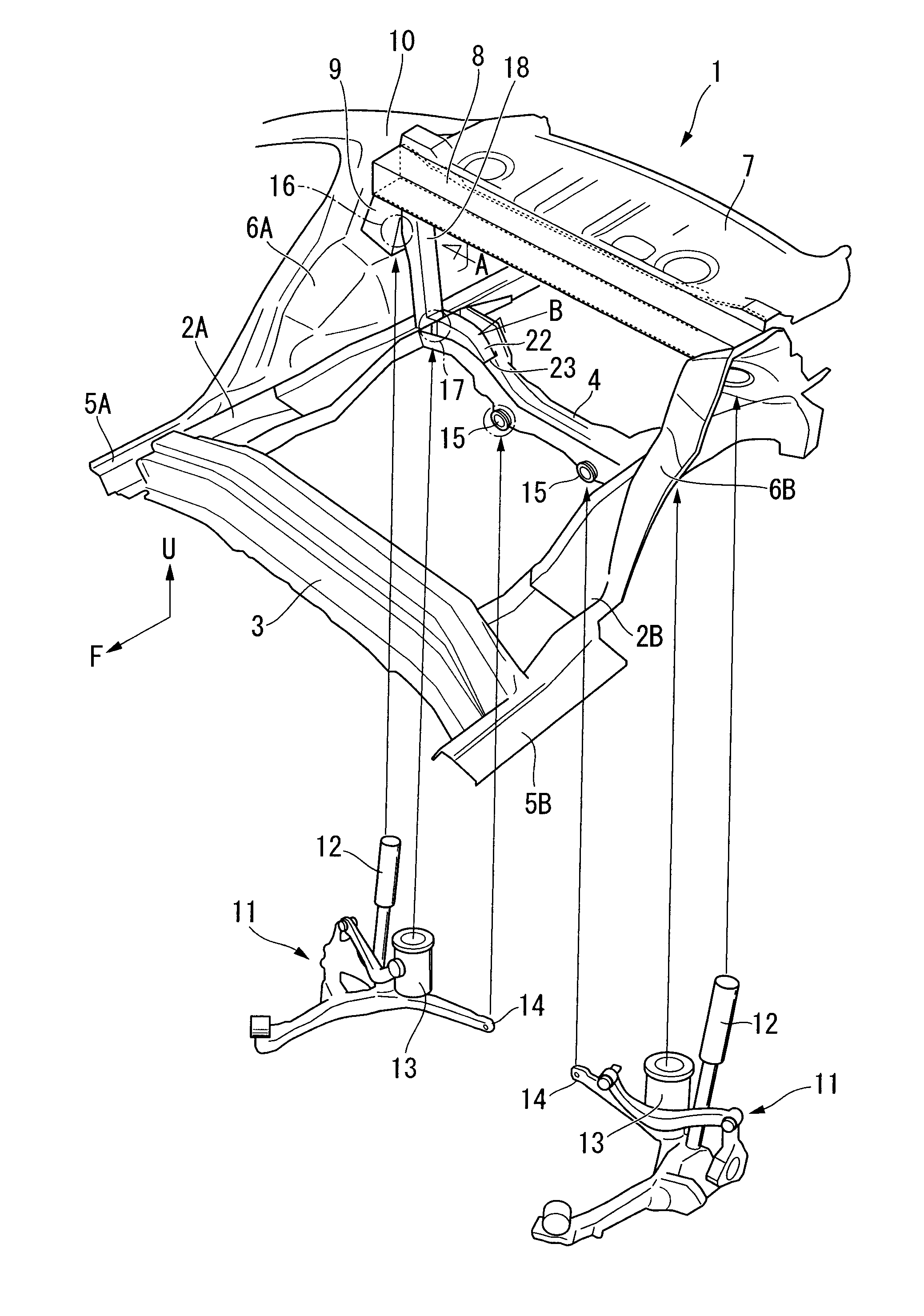

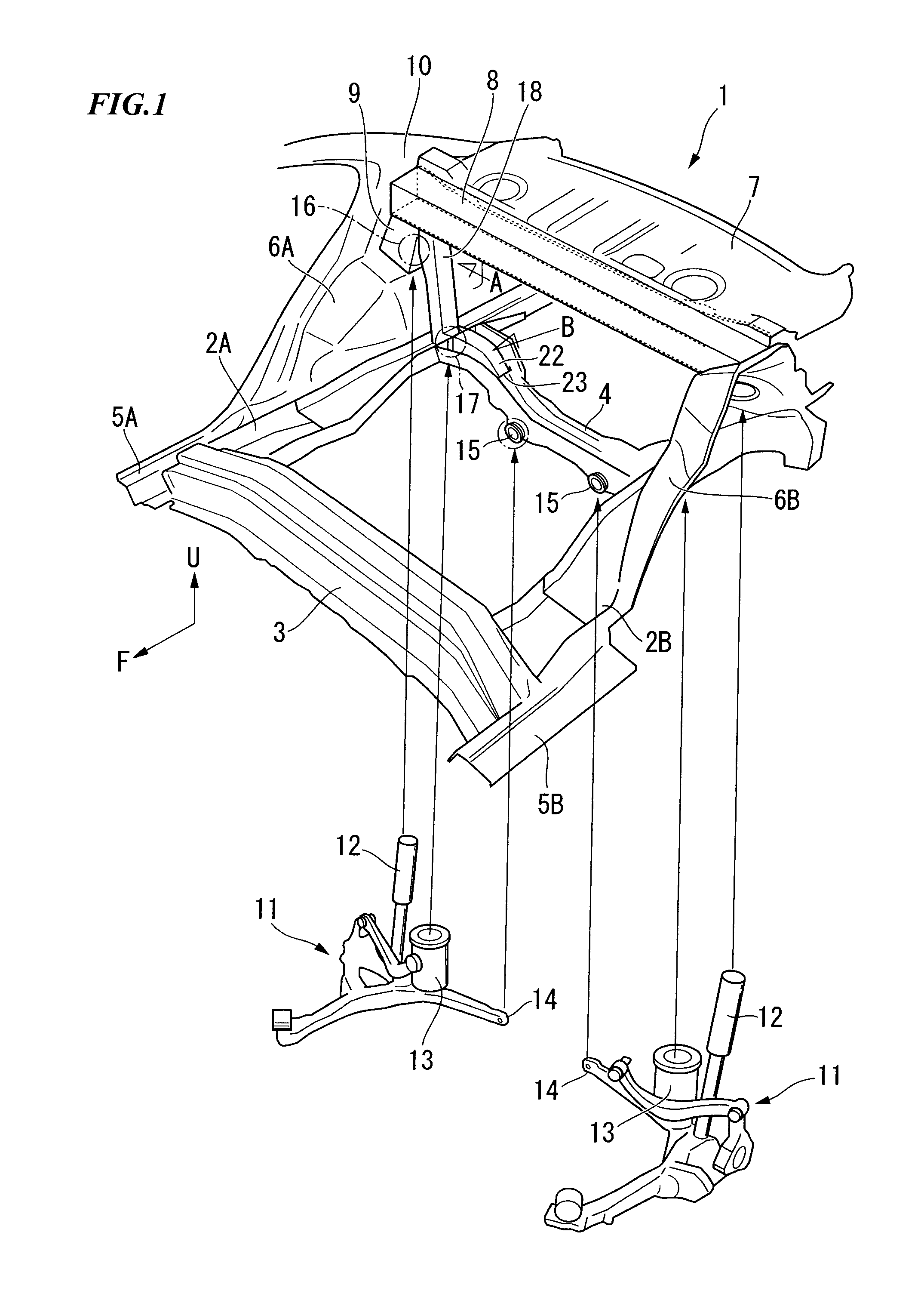

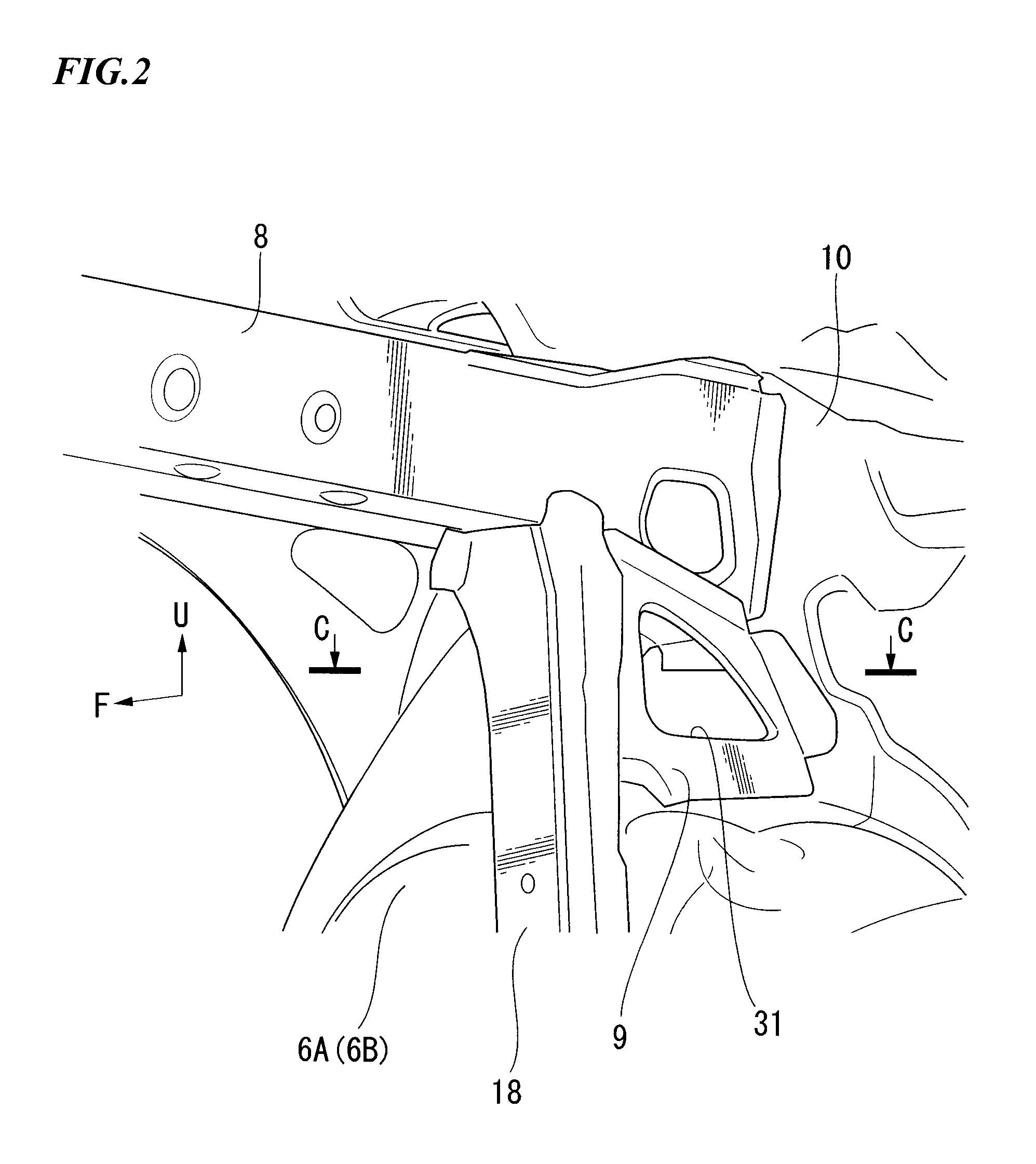

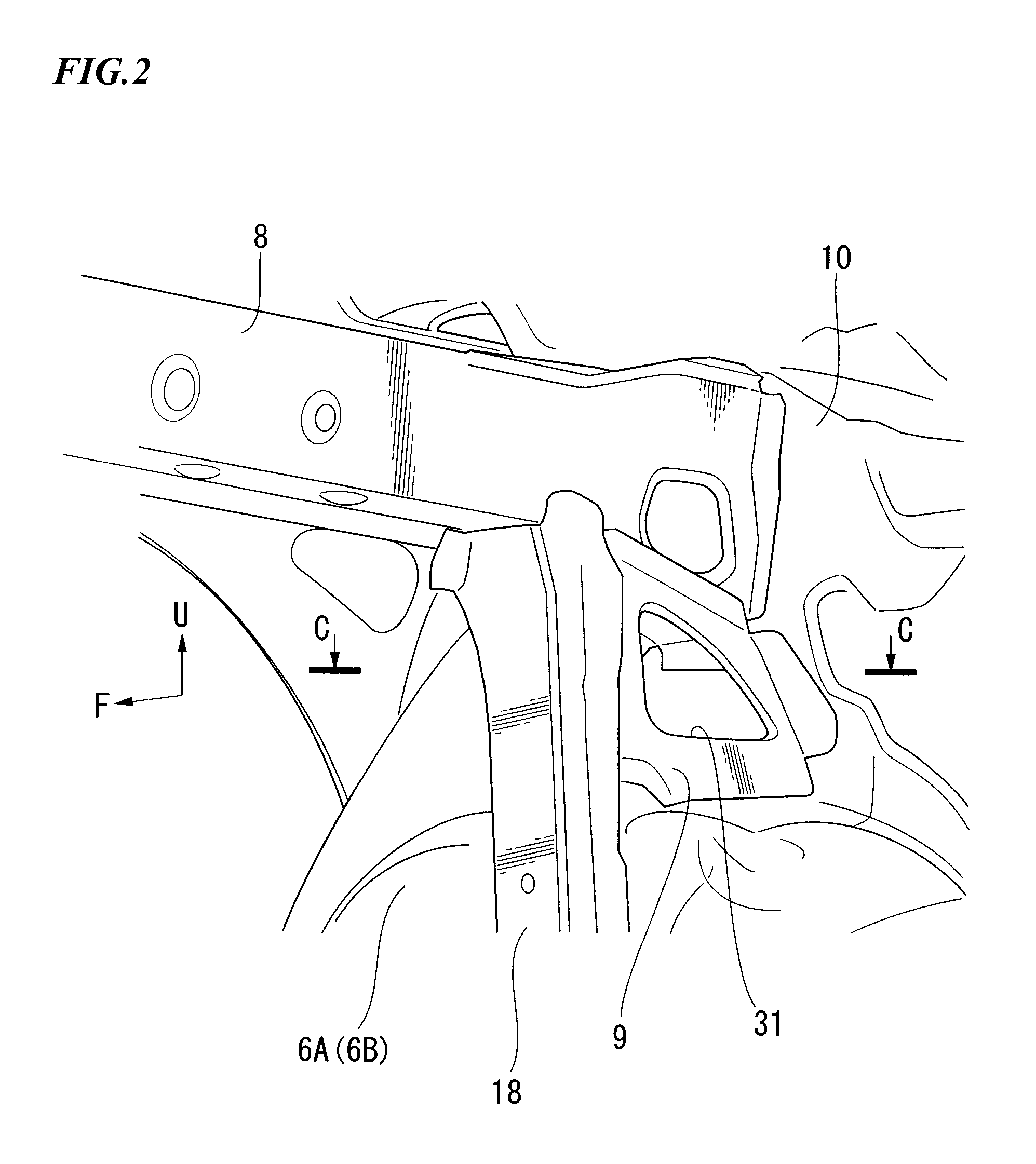

Side vehicle-body structure of automotive vehicle

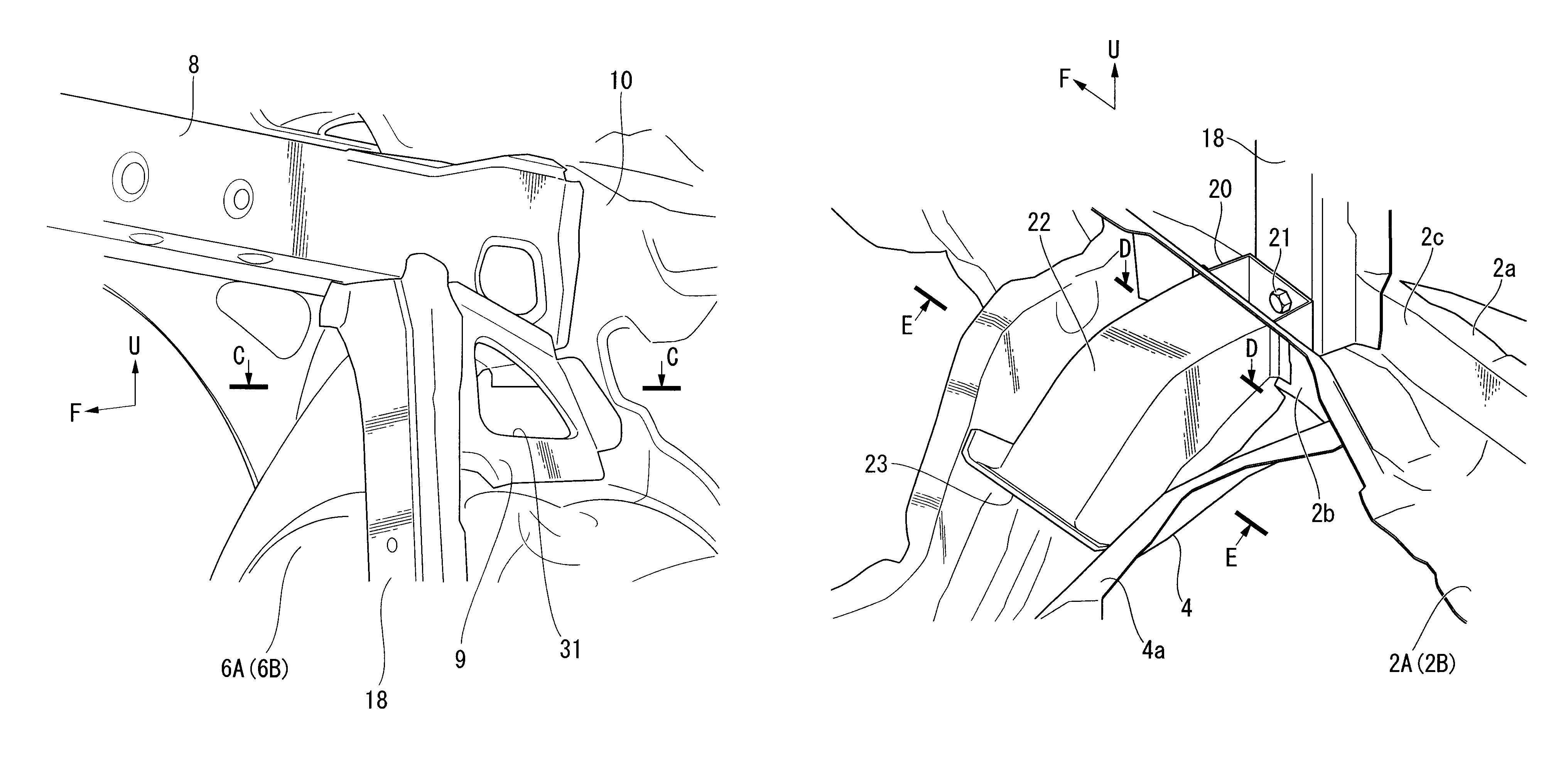

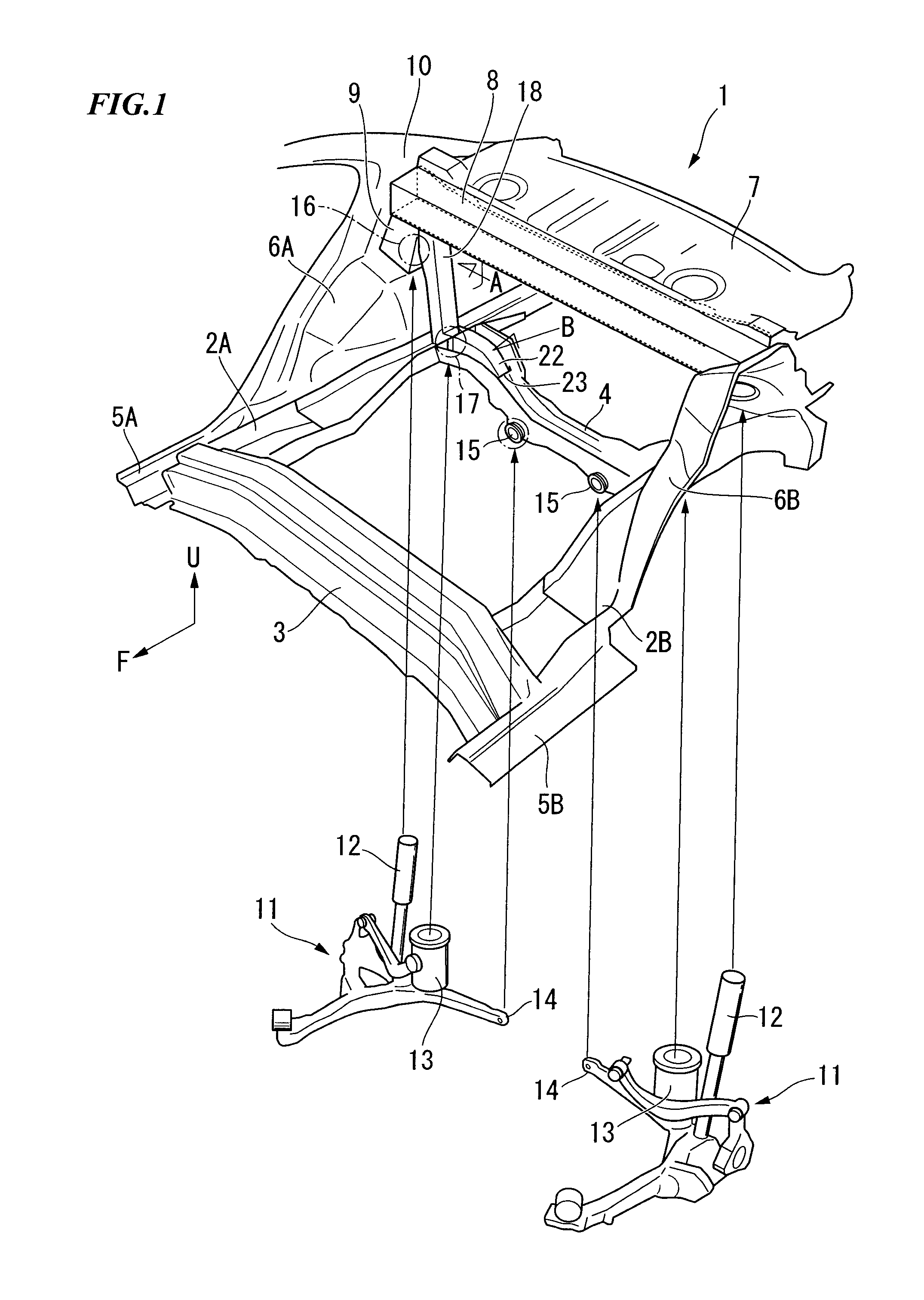

ActiveCN107031731AReduce the size of the vehicle width directionInhibition of local bucklingUnderstructuresSuperstructure subunitsControl theoryMechanical engineering

The invention provides a side vehicle-body structure of an automotive vehicle. The side vehicle-body structure can increase the effects of impact absorption when an impact load is input to a side door from a vehicle body side and the effects of load diffusion to each part of the vehicle body. The side vehicle-body structure includes: a side door which is formed on a side surface part of the vehicle body and opens and closes an opening part for getting on and off from a rear seat; an anti-collision pole which is disposed on the side door in a manner that the anti-collision pole extends along the front and rear direction of the vehicle body; a side plate internal side member which constitutes a vehicle side part which includes a peripheral part on vehicle body rear side of the opening part for getting on and off; a first reinforcing part which extends along the peripheral part on the vehicle body rear side of the opening part for getting on and off and engages the outside of a compartment of the side plate internal side member so as to form a first closed cross section with the side plate internal side member; a second reinforcing member which is configured such that the second reinforcing member is partly overlapped with the anti-collision pole when the side door is closed if viewed from the vehicle body side and the second reinforcing member engages the outside of the compartment of the first reinforcing member so as to form a second closed cross section with the first reinforcing member.

Owner:MAZDA MOTOR CORP

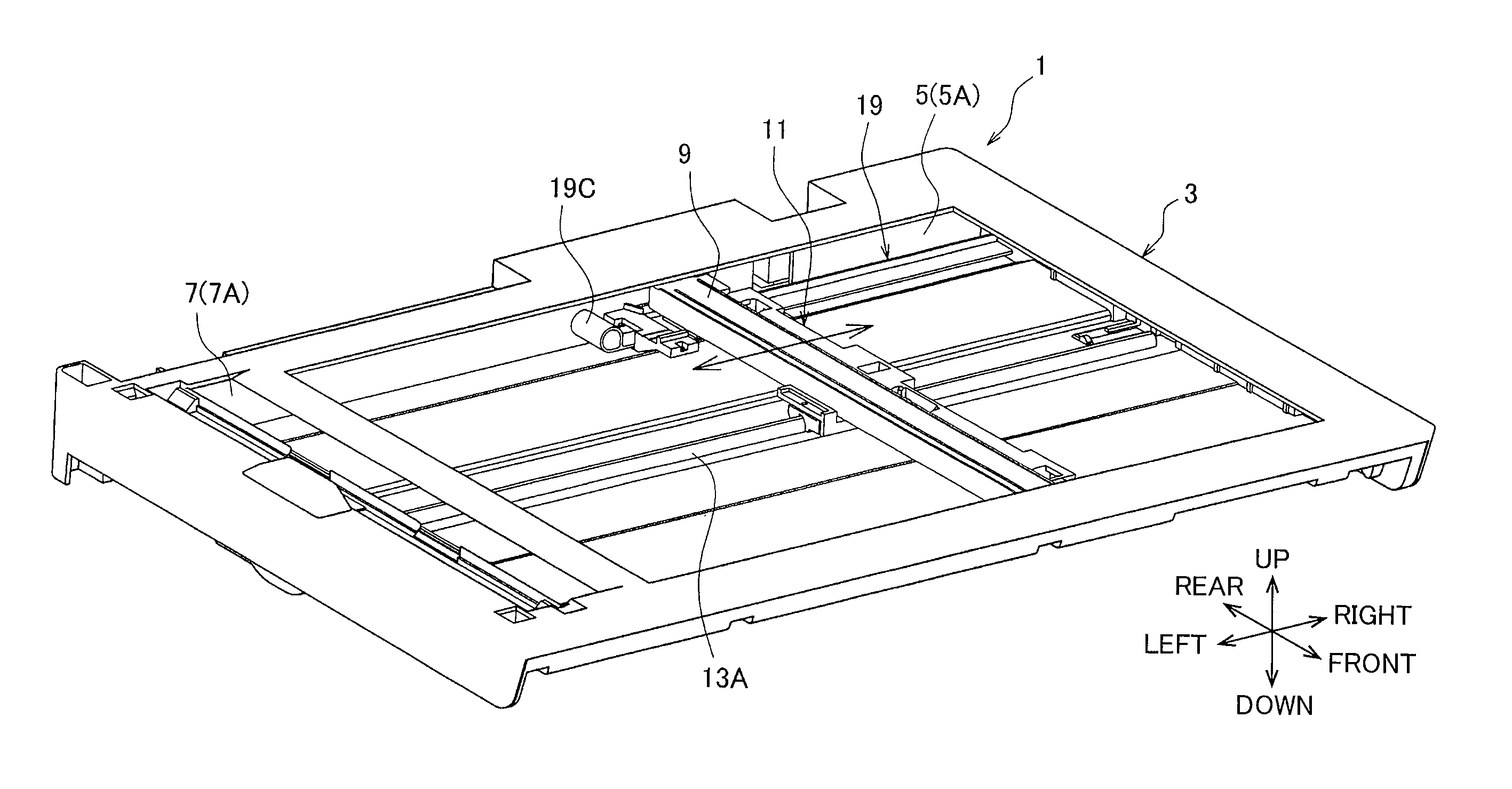

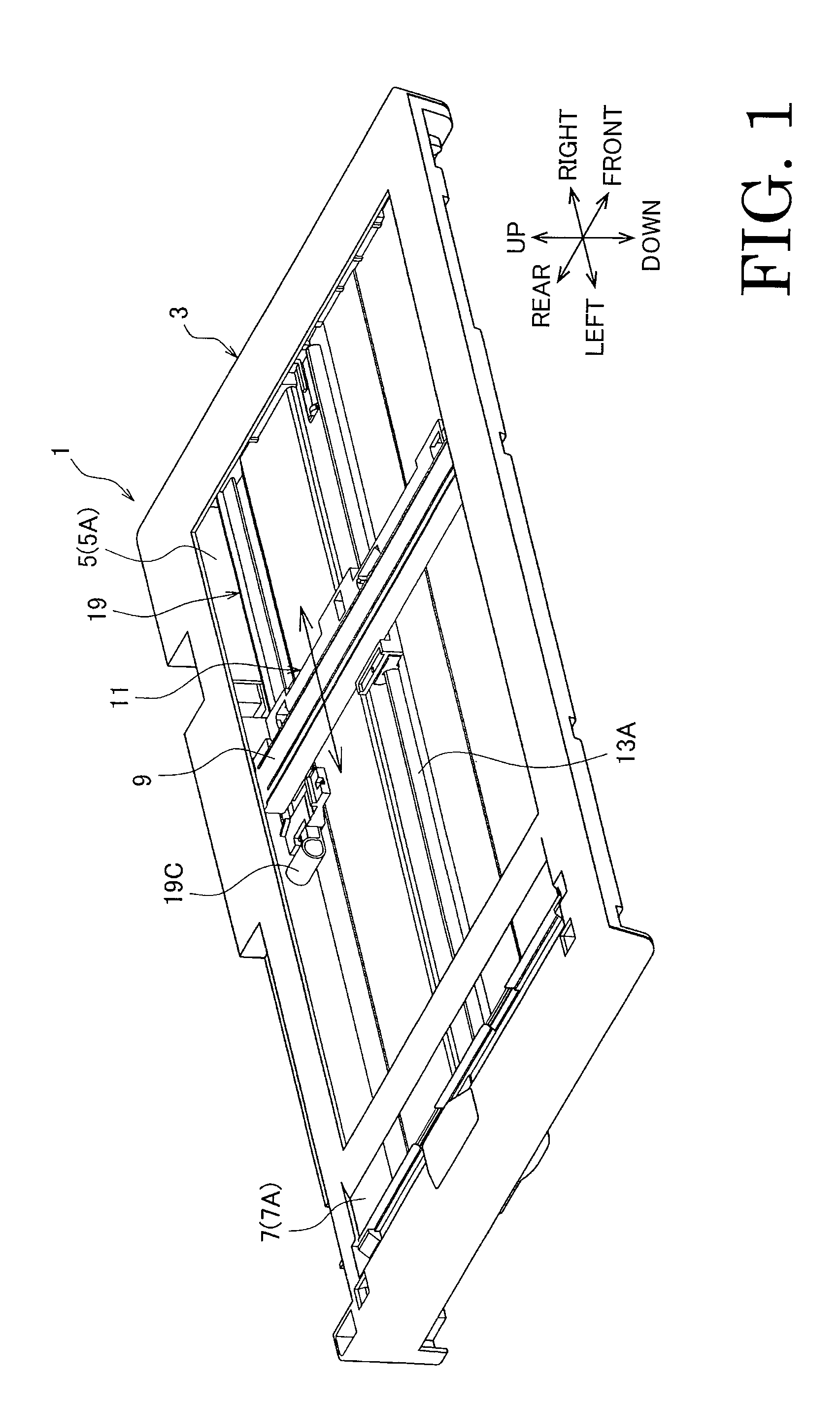

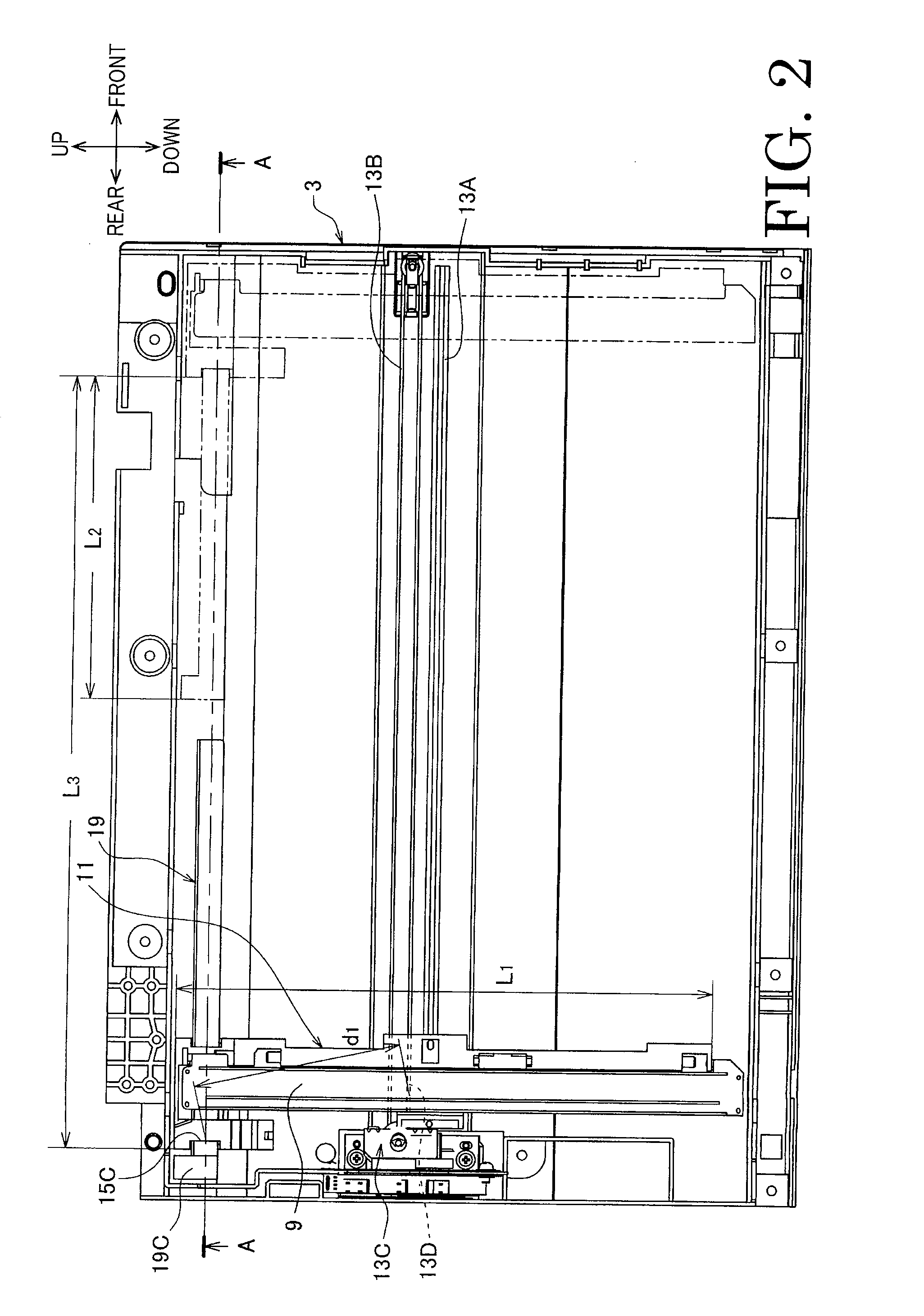

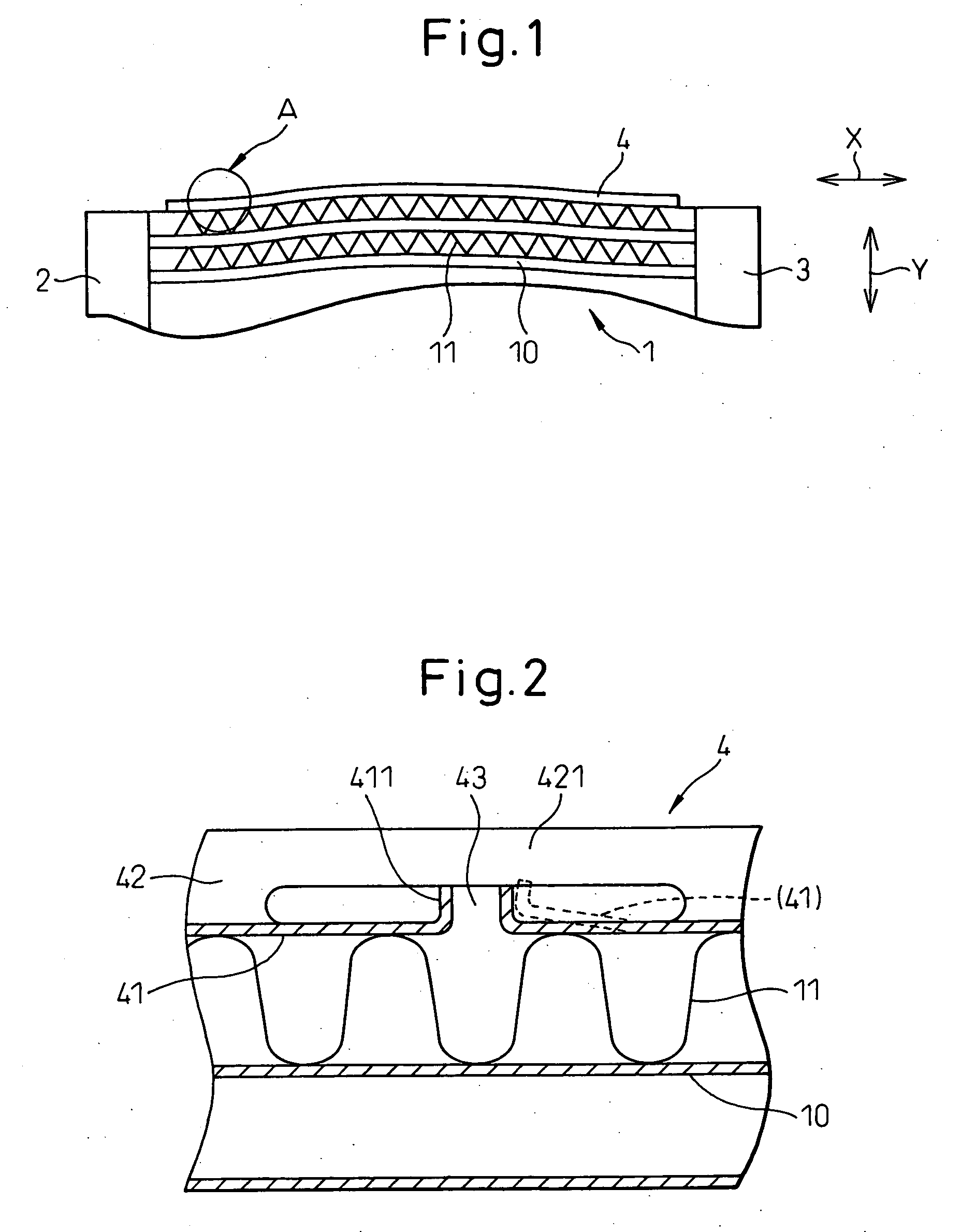

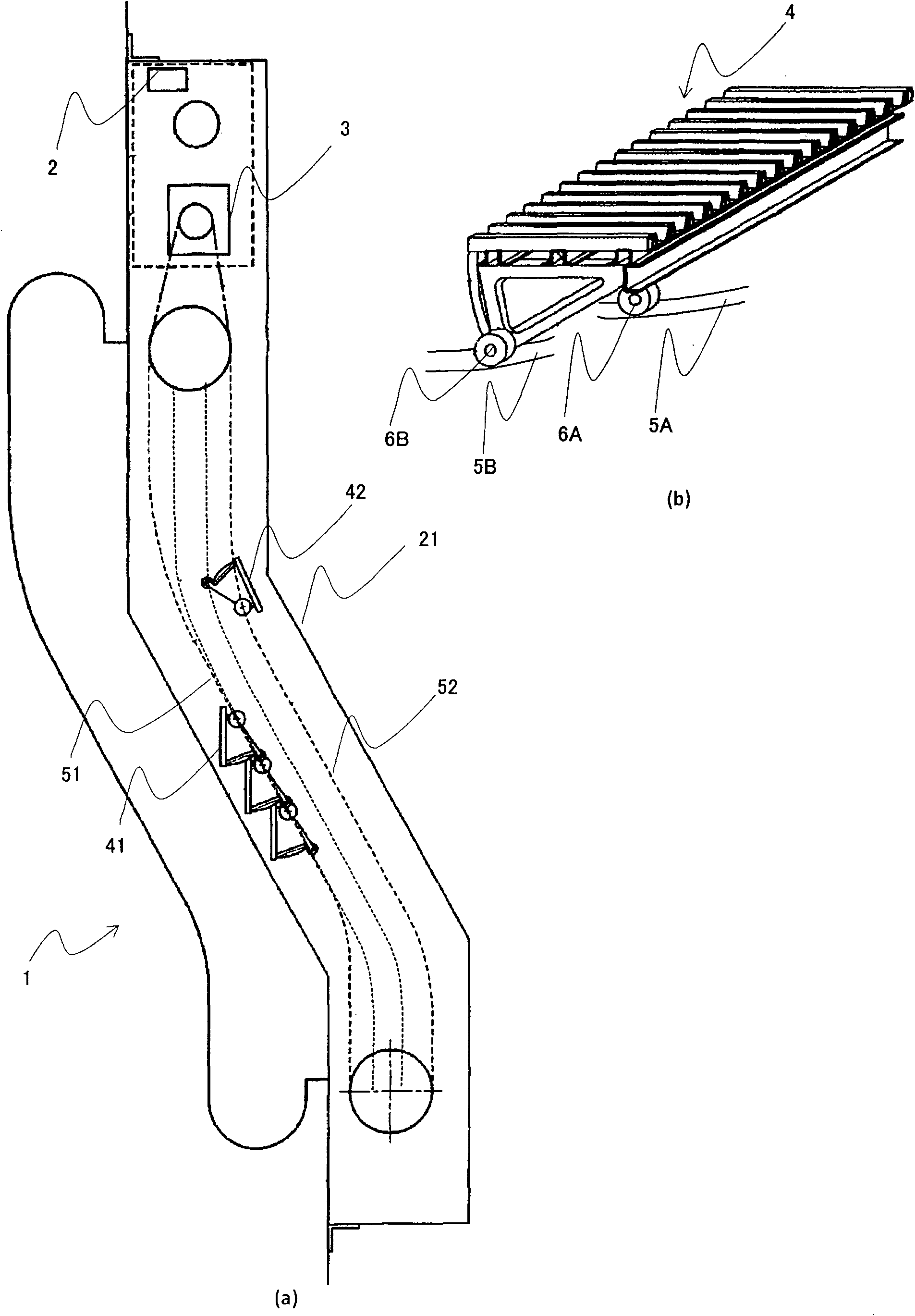

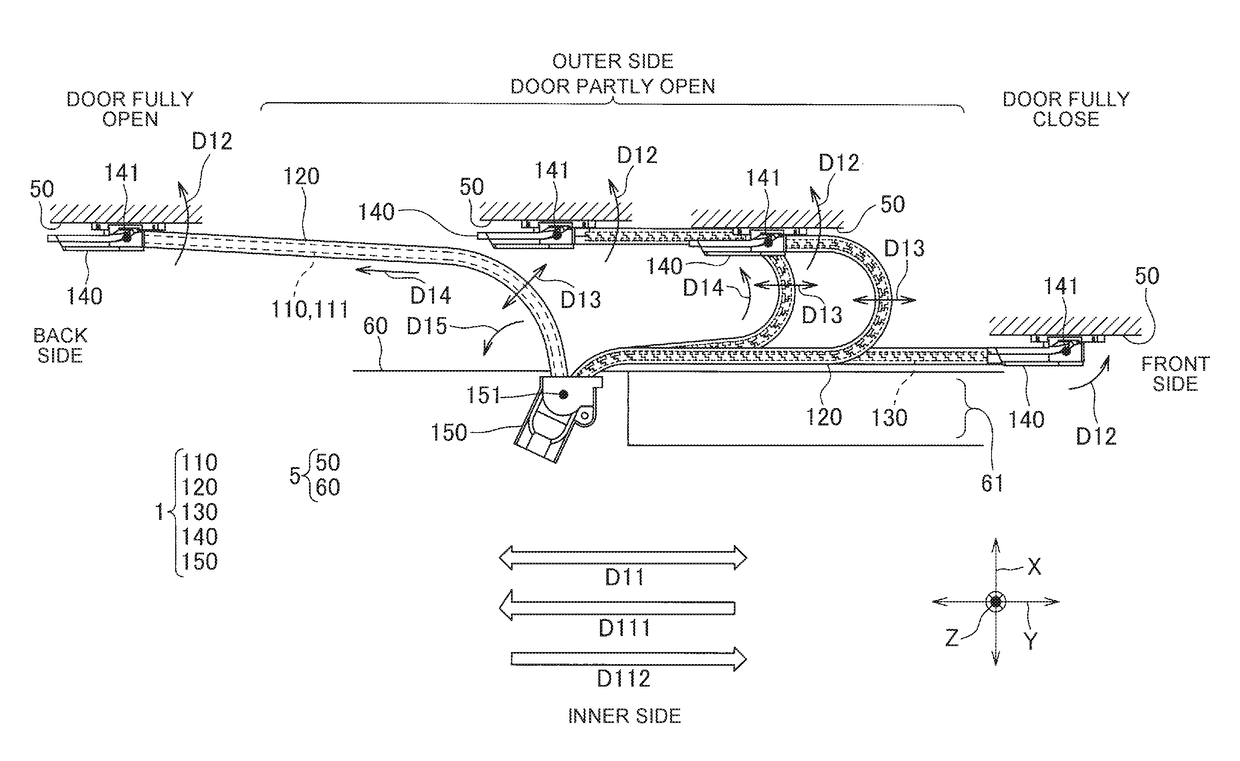

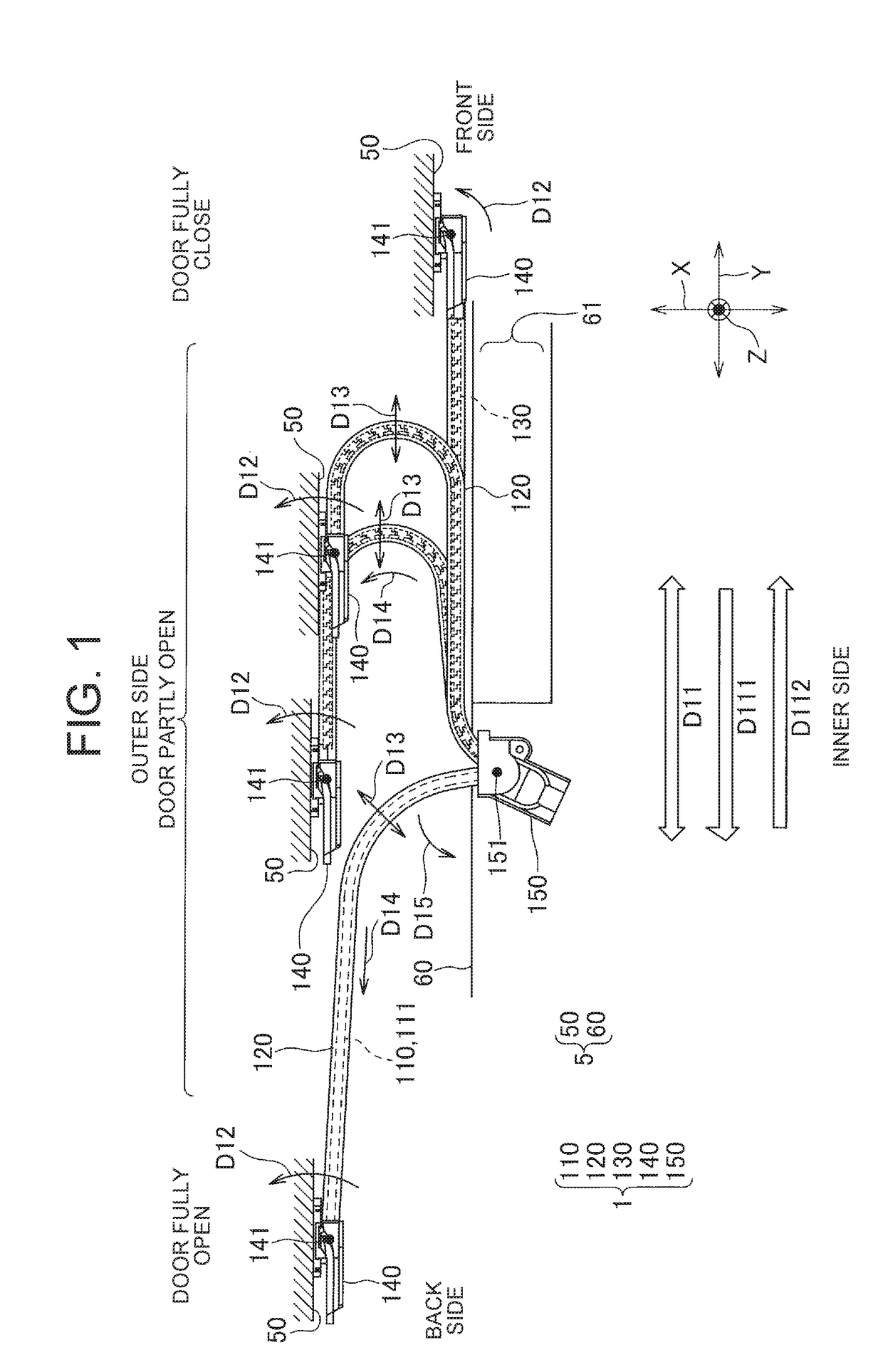

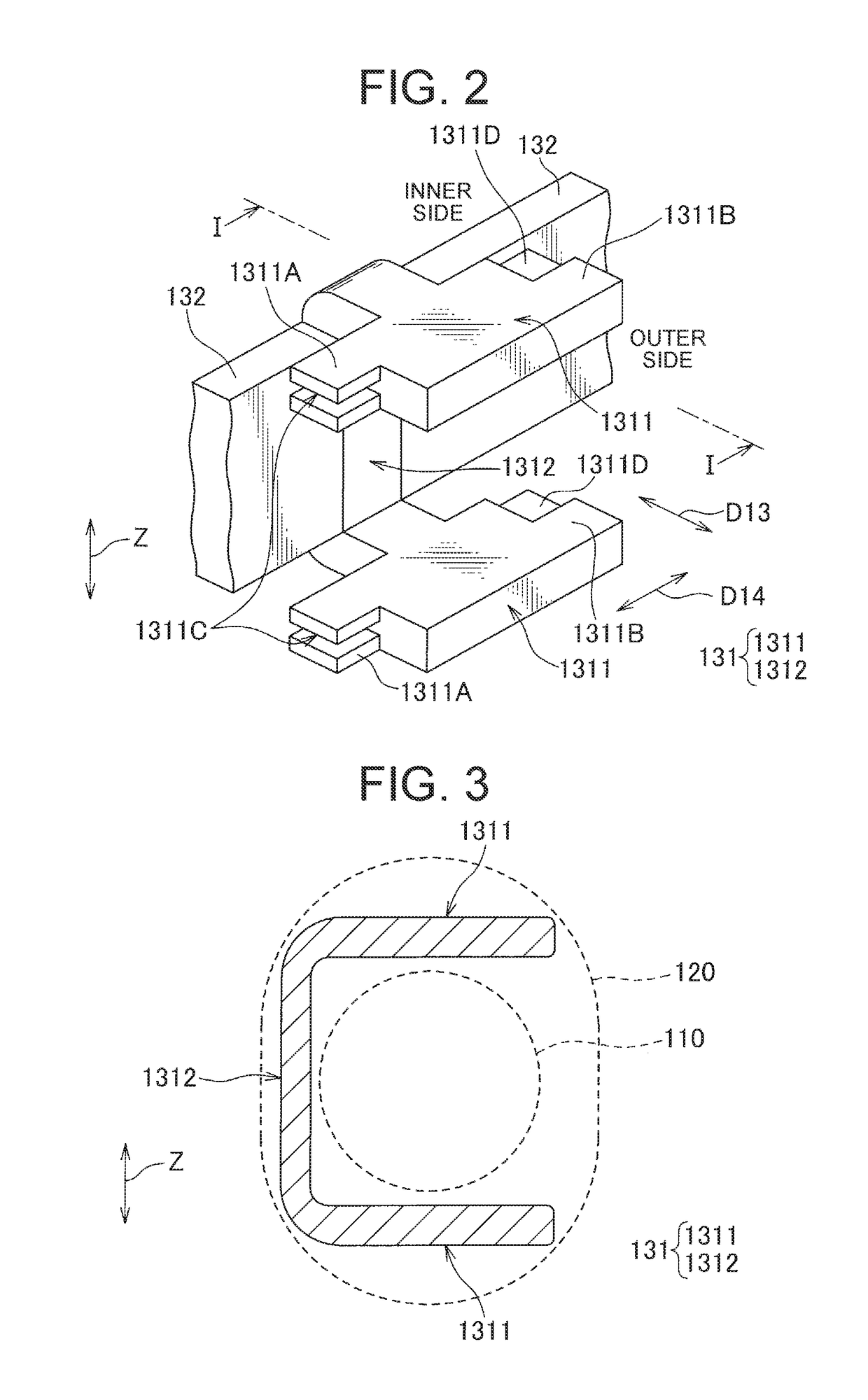

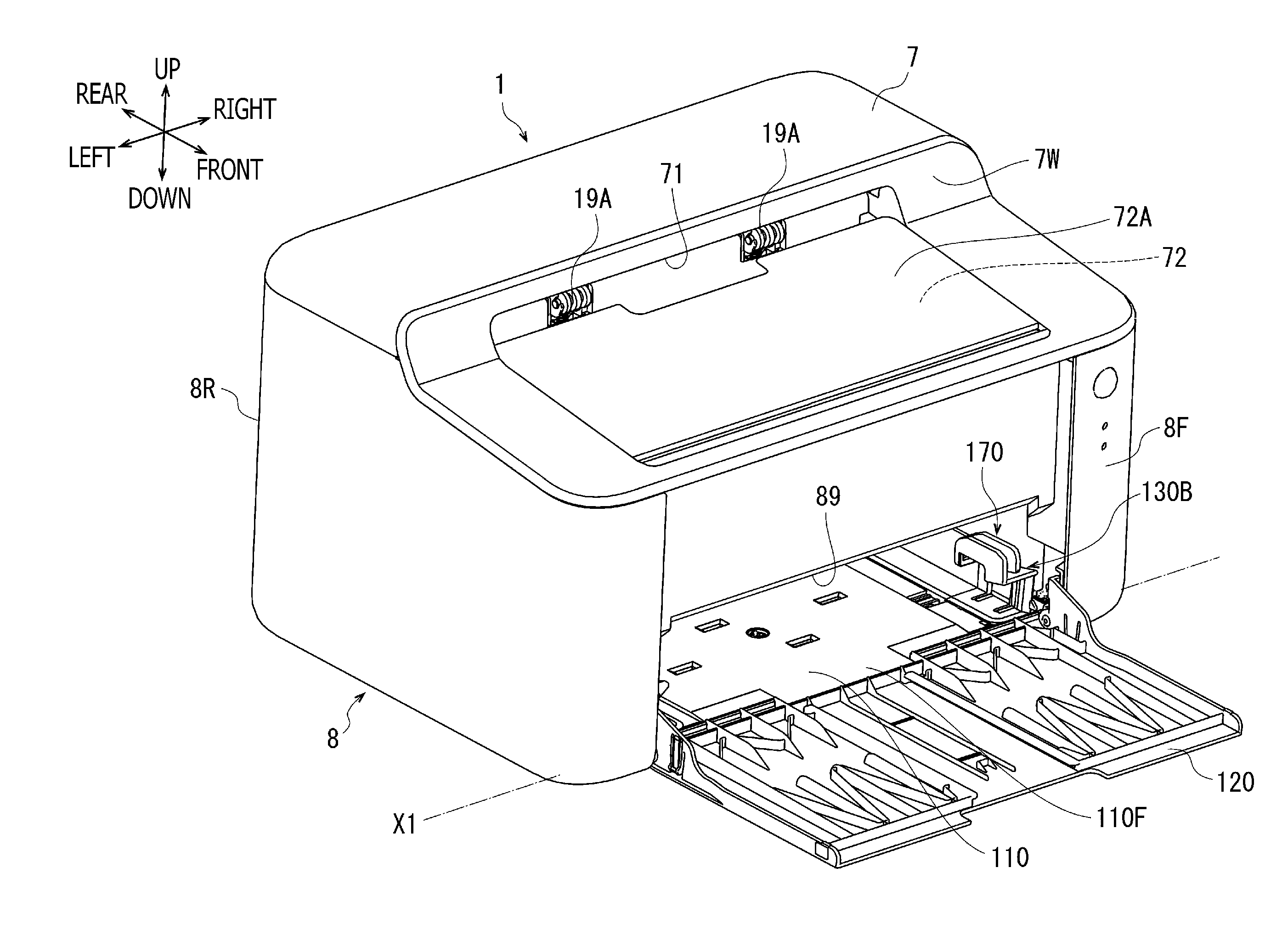

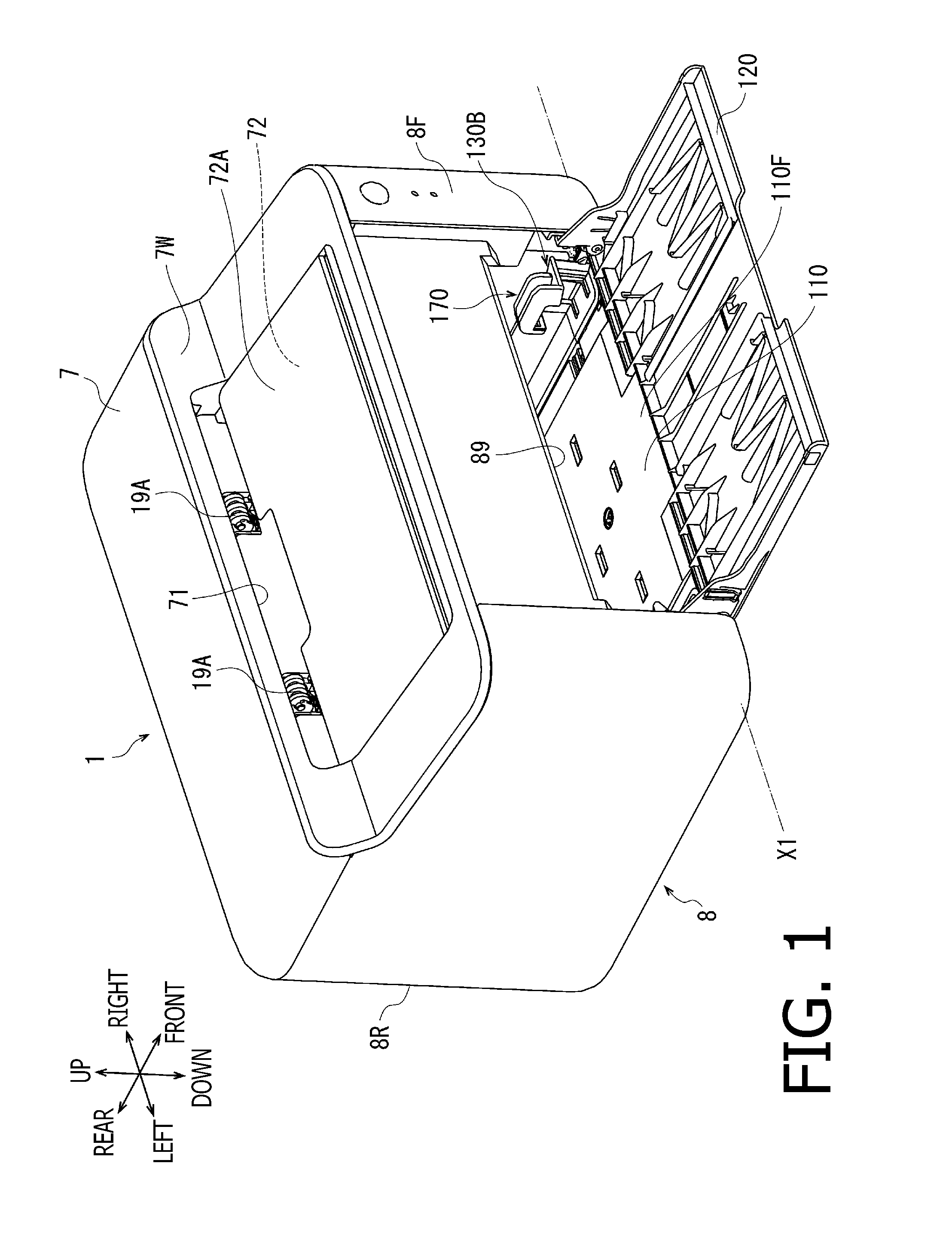

Cable Arrangement Structure and Image Scanner Employing the Same

ActiveUS20110211234A1Buckling suppressionCable arrangements between relatively-moving partsArticle feedersEngineeringFlexible cable

A cable arrangement structure is provided with a movable body configured to reciprocally move relative to a base member, and a flexible cable transmitting electrical signals. One end of the flexible cable is fixedly connected to the base member, and another end is connected to the movable body. The flexible cable has a curved portion, and both ends of the flexible cable being located on a same side with respect to the curved portion. A tension applying unit configured to contact the curved portion of the flexible cable from an inner side of a curvature of the curved portion to apply tension to the flexible cable when the curved portion is located on a front direction of the movable body as moved. Application of the tension to the flexible cable is controlled in mechanical association with movement of the movable body.

Owner:BROTHER KOGYO KK

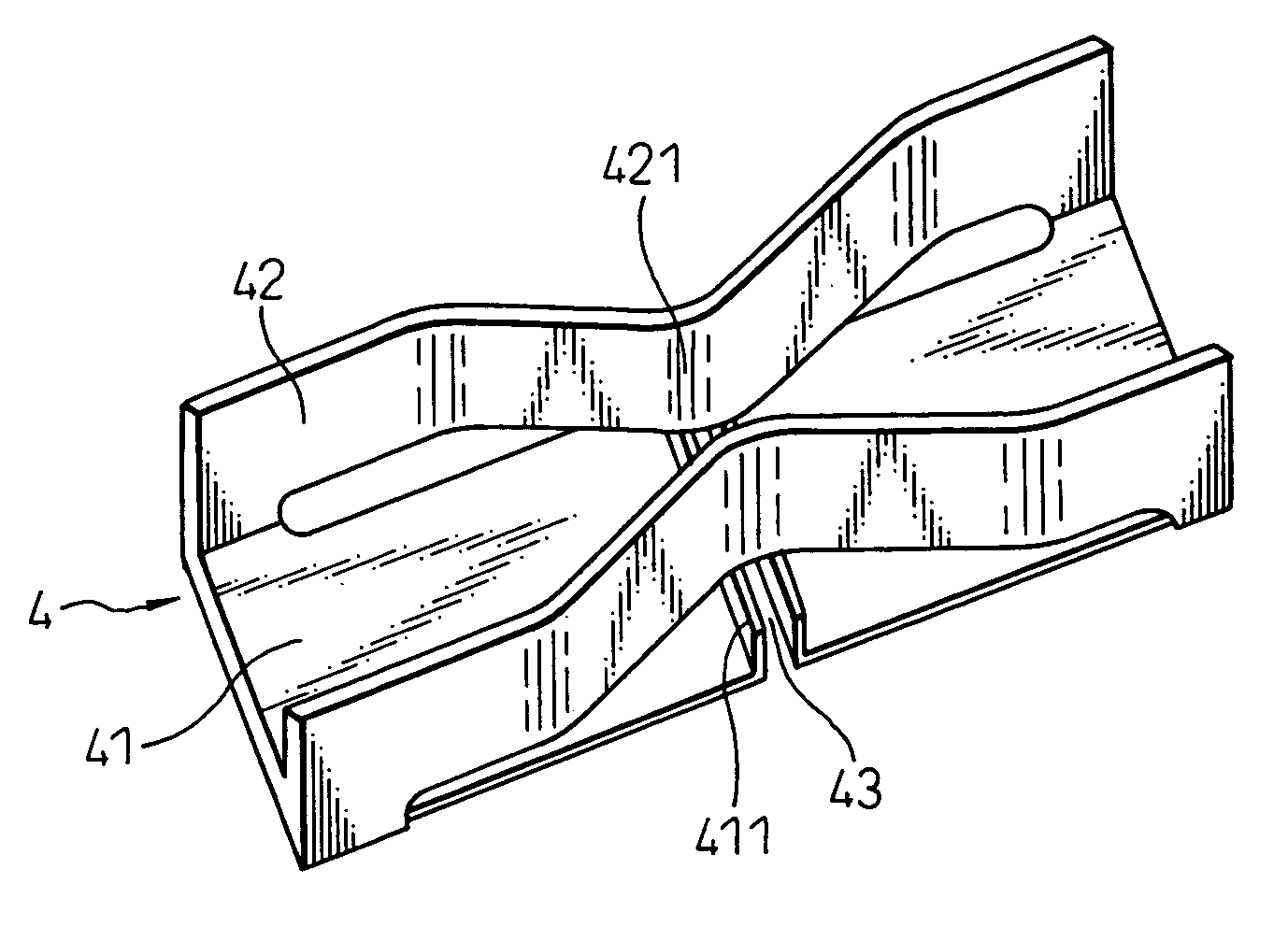

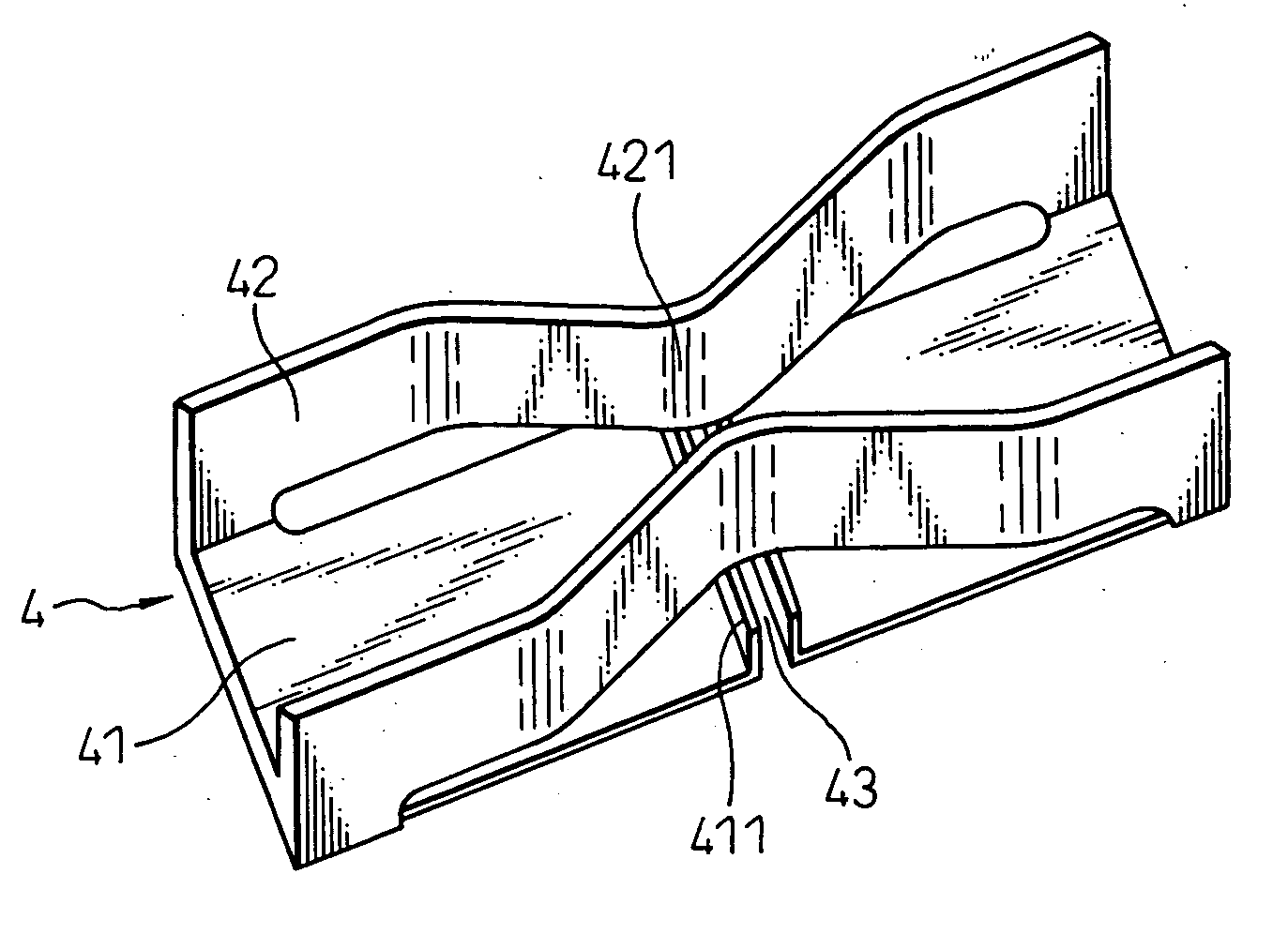

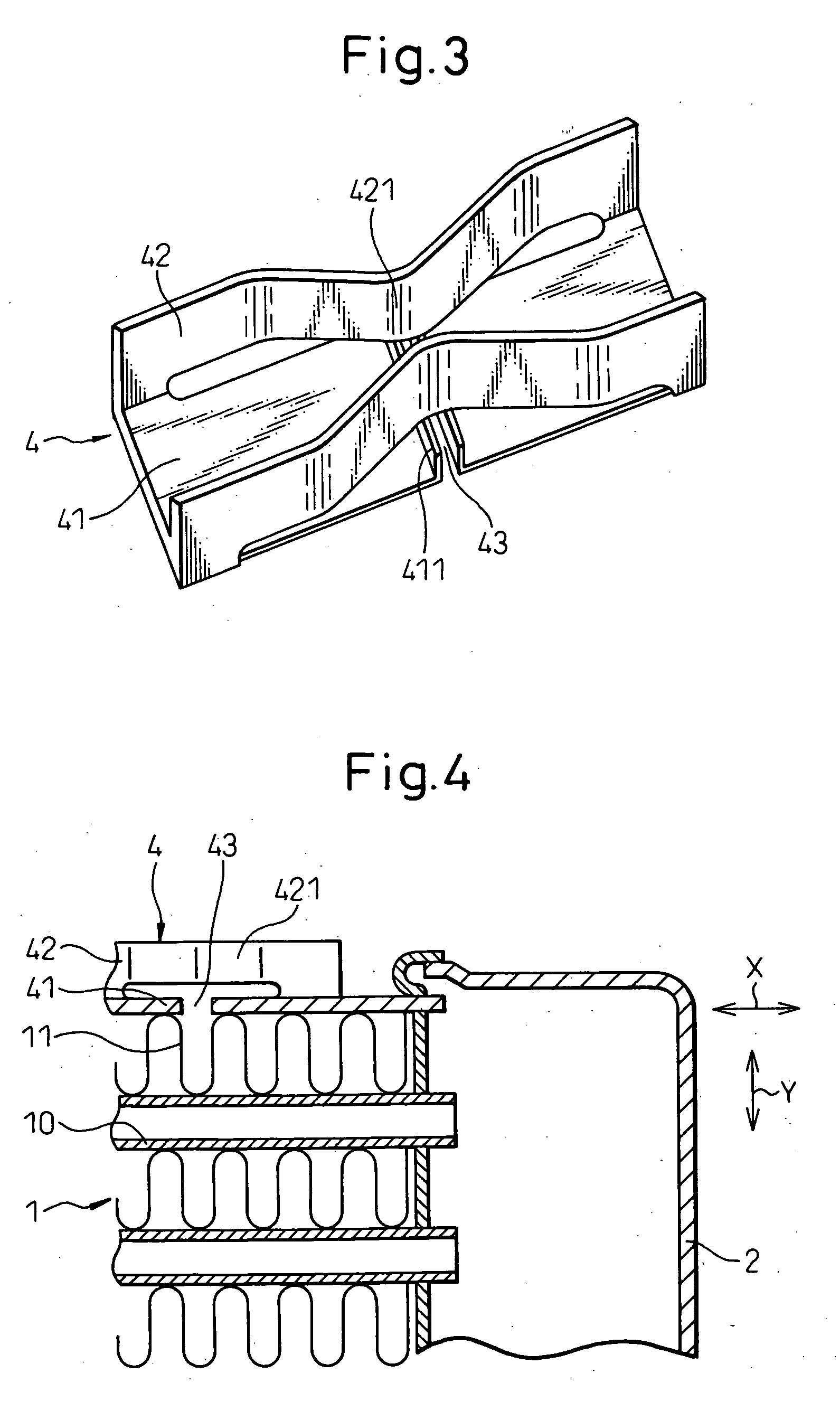

Heat exchanger

InactiveUS20060185824A1Buckling suppressionSuppress or prevent the displacement of the base portion and the twisting of the side platesSafety devices for heat exchange apparatusStationary conduit assembliesEngineeringMechanical engineering

A heat exchanger is disclosed. Side plates (4) each include a base portion (41), in contact with fins (11), and side wall portions (42) extending from the base portion (41) in the direction Y in which tubes (10) are stacked. The side wall portions (42) are formed with a bent deforming portion (421) to facilitate extension / shrinkage, of the side wall portions (42), in the longitudinal direction (X) of the tubes (10). The base portion (41) is formed with a pair of hooks (411) extending toward the surface of the bent deforming portion (421) in opposed relation to the base portion (41). In the case where the base portion (41) tends to be displaced, the hooks (411) come into contact with the bent deforming portion (421) to thereby suppress or prevent the displacement of the base portion (41).

Owner:DENSO CORP

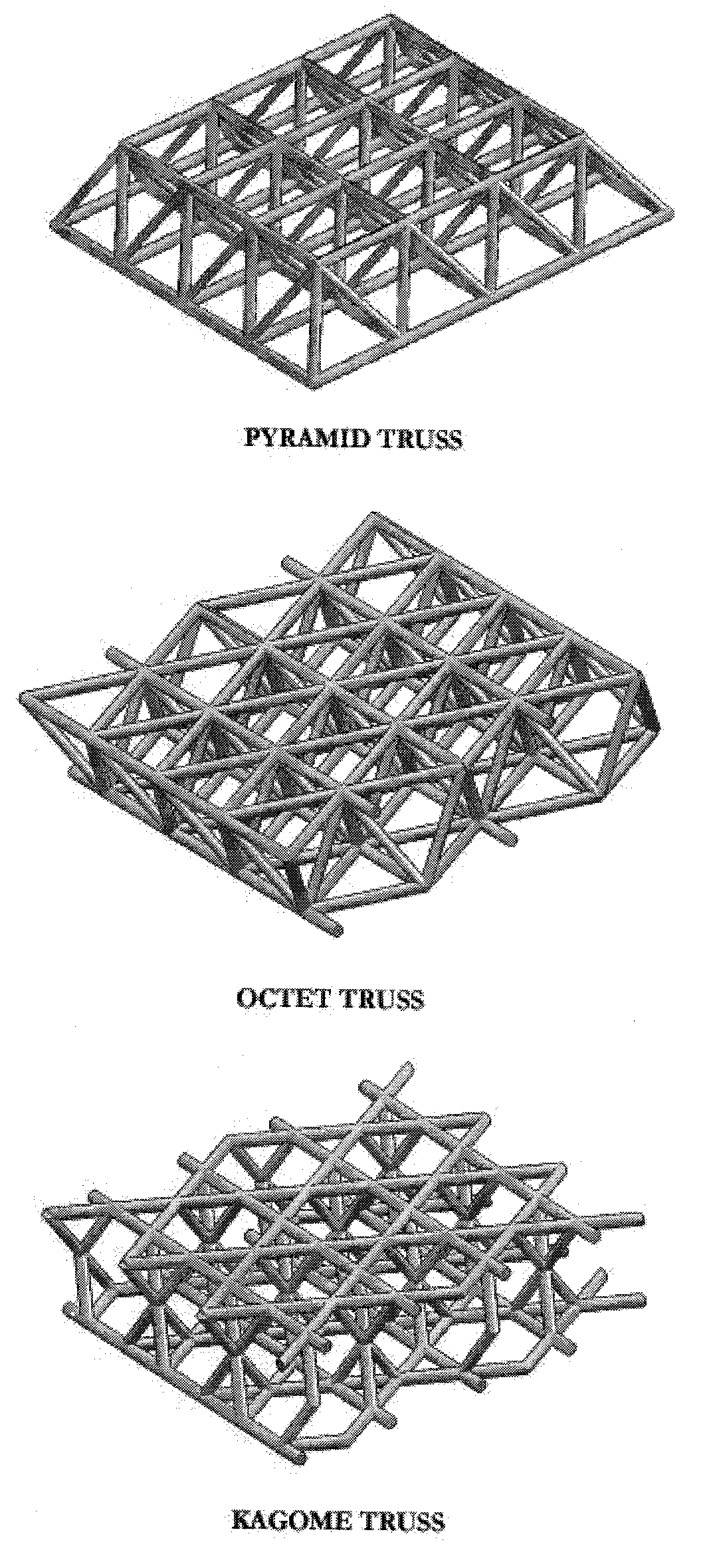

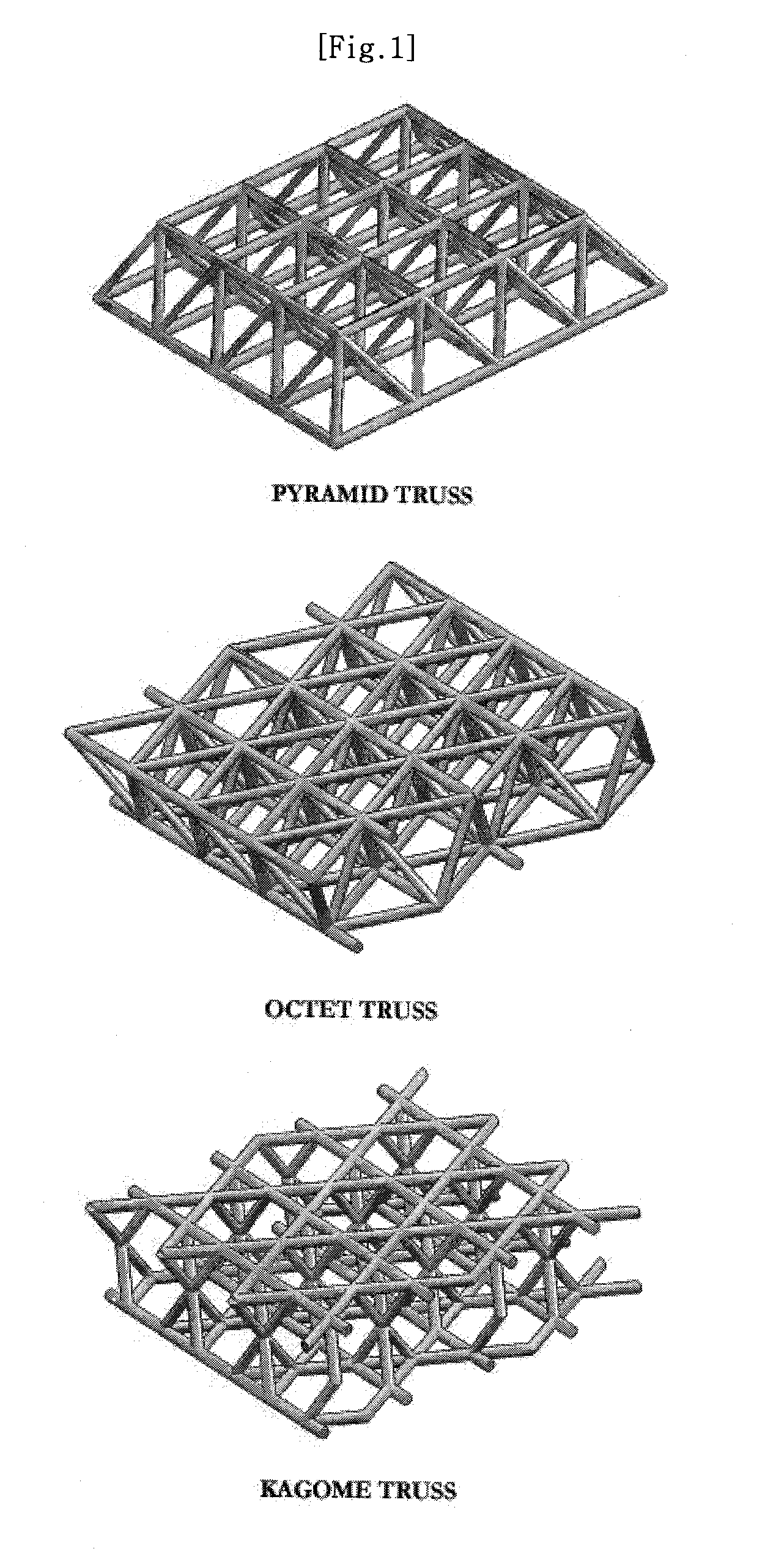

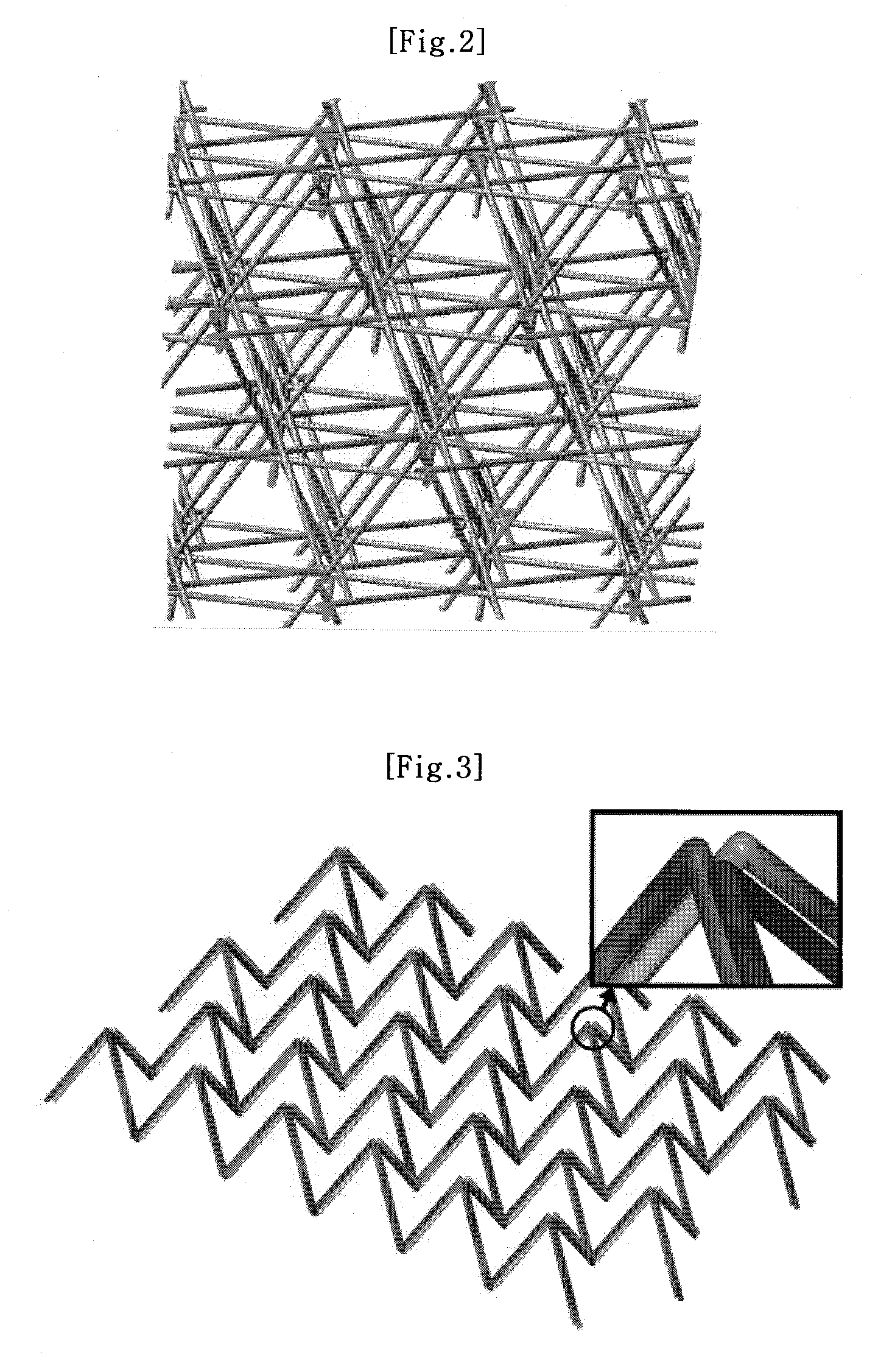

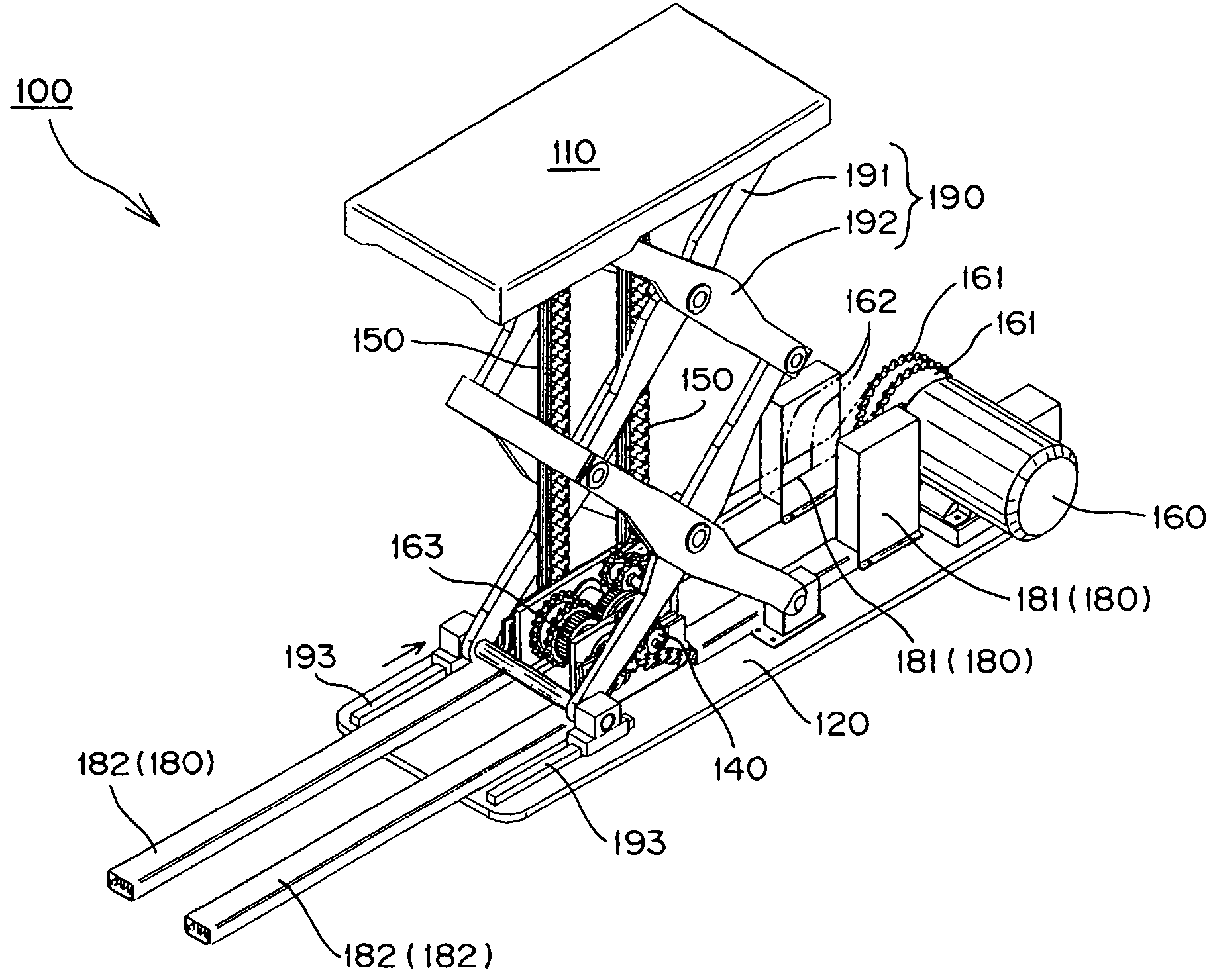

Truss type periodic cellular materials having internal cells, some of which are filled with solid materials

InactiveUS20110117315A1Buckling suppressionImprove stabilityLayered productsWire networkUltimate tensile strengthSynthetic resin

Provided are three-dimensional truss type periodic cellular materials, wherein a plurality of internal cells are formed periodically and part of the internal cells are filled with solid material like as metal, ceramic, synthetic resin, or composite materials for the purpose of preventing buckling of the truss elements when external compressive or shear loads is applied to the truss structure. By filling only parts of internal cells provided in the truss with appropriate solid materials, the buckling of truss elements can be suppressed maximally and effectively, and even if the buckling accidentally occurs, the sharp decline of strength can be prevented so as to ensure sufficient structural stability of the truss type periodic cellular materials.

Owner:IND FOUND OF CHONNAM NAT UNIV

Hoisting and lowering device having engagement chains

InactiveUS7819389B2Improve staminaMaintenance is safe and simplePortable liftingLifting framesControl engineeringElectric machinery

An engagement chain type hoisting and lowering device is disclosed, having a hoisting and lowering table attached to the upper end of two or more pairs of hoisting and lowering driving engagement chains. A driving motor drives two pairs of hoisting and lowering sprockets which, in turn, raise or lower two pairs of hoisting and lowering driving engagement chains. By arranging two pairs of hoisting and lowering driving engagement chains on two opposed sides of the hoisting and lowering table, buckling of the hoisting and lowering driving engagement chains is suppressed, resulting in stable hoisting and lowering operations without slippage of articles on the hoisting and lowering table, and chain endurance is improved. The device is designed so that the lowest position of the hoisting and lowering table can be lower than the height of the peripherally located driving motor, for ease and safety of operation and maintenance.

Owner:TSUBAKIMOTO CHAIN CO

Vehicle rear portion structure

InactiveUS20080277970A1Reduce weightImprove usabilityVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

A vehicle rear portion structure including: a pair of rear frames that extend substantially in a vehicle longitudinal direction; a rear cross member that extends in a vehicle width direction and that connects both of the two rear frames; a pair of rear wheel houses that are provided with damper supporting portions; a parcel frame that extends along the vehicle width direction above the rear wheel houses; and a pair of reinforcing frames that connect both end portions of the rear cross member and both end portions of the parcel frame, wherein the reinforcing frames are placed along a side wall of respective the rear wheel houses, the side wall being adjacent to respective the damper supporting portions, and a toroidal skeleton frame is formed with the parcel frame, the reinforcing frames, and the rear cross member so as to follow a plurality of rear suspension mounting points.

Owner:HONDA MOTOR CO LTD

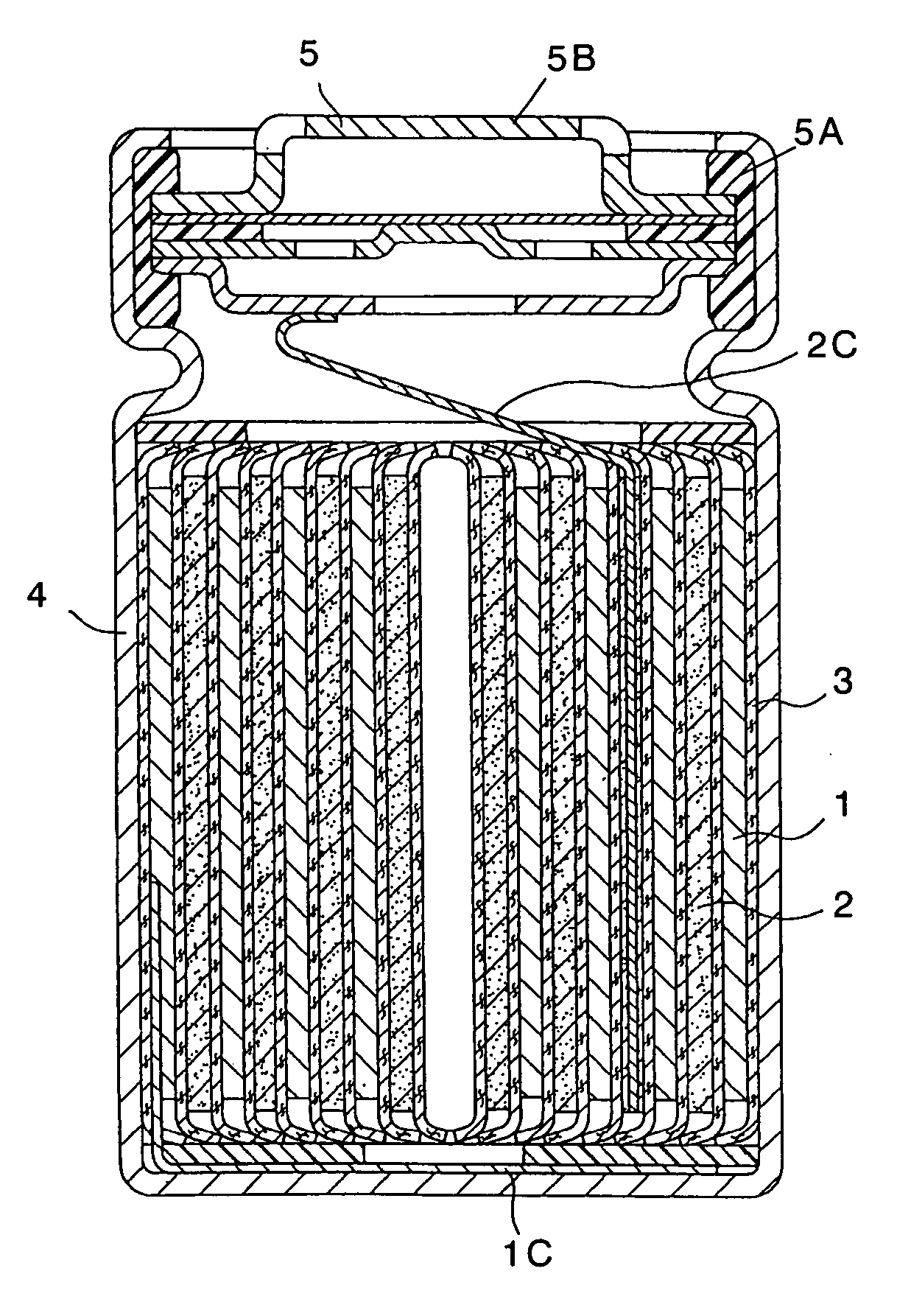

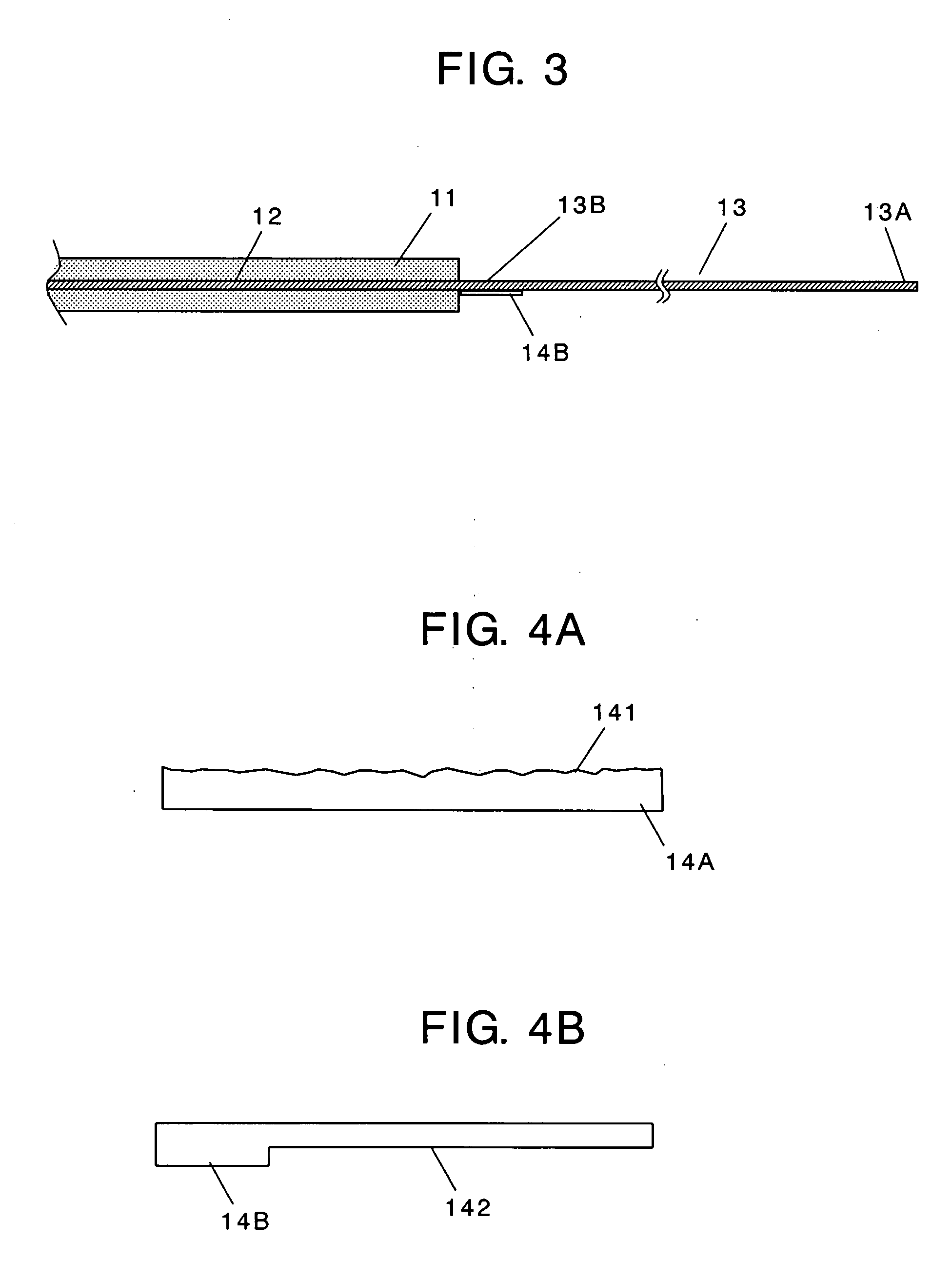

Non-aqueous electrolyte secondary battery and manufacturing method of the same

InactiveUS20080102353A1Avoid unwindingBuckling suppressionFinal product manufactureElectrode carriers/collectorsMetallic lithiumConductor Coil

In a method for manufacturing a non-aqueous electrolyte secondary battery, a negative electrode having a current collector exposed portion in a portion corresponding to an outer winding end of an electrode body, metallic lithium piece is allowed to precipitate or be deposited on this current collector exposed portion, and this metallic lithium piece is joined to the other portion of the current collector exposed portion or one metallic lithium piece is joined to the other metallic lithium piece so as to fix two points of the negative electrode.

Owner:PANASONIC CORP

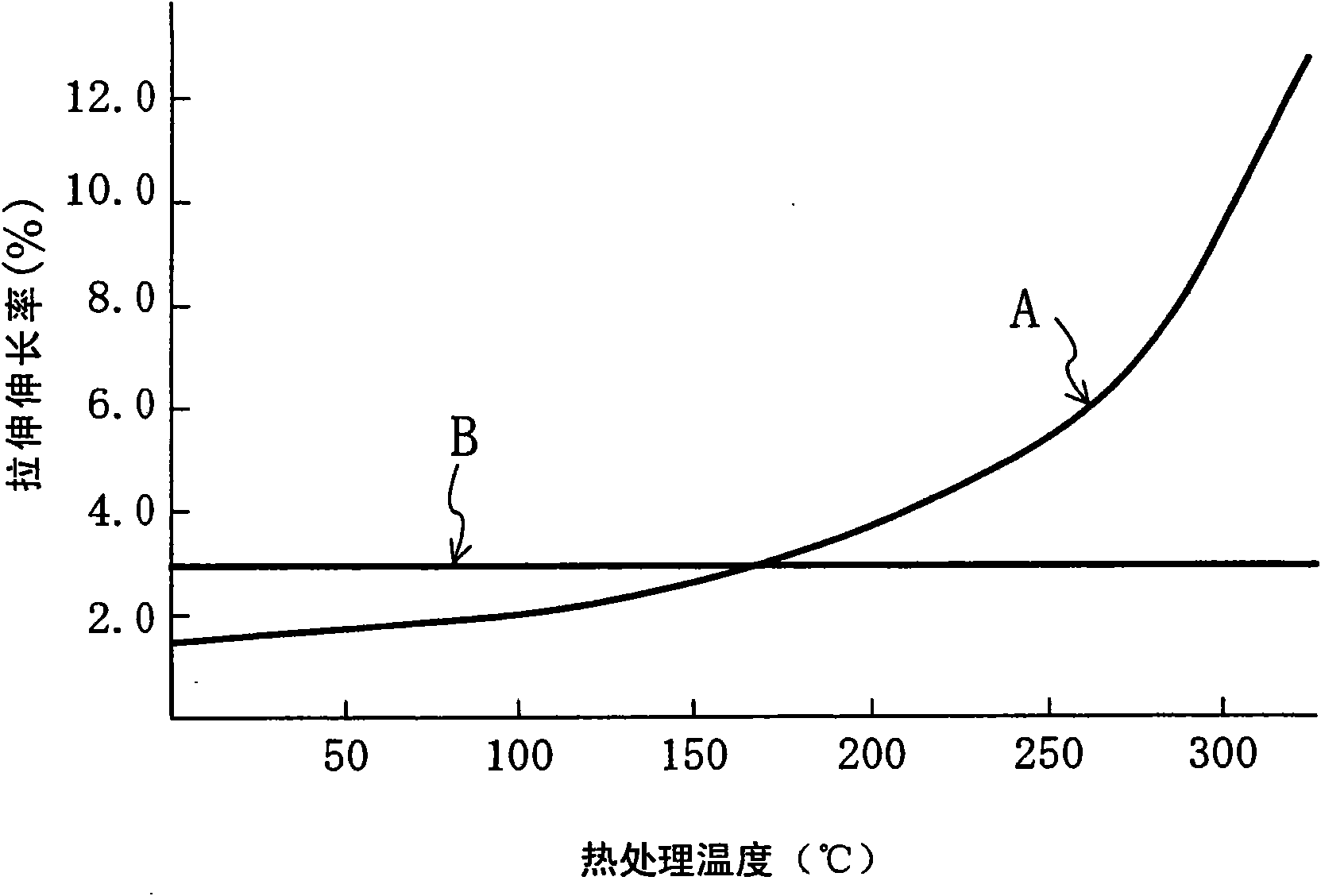

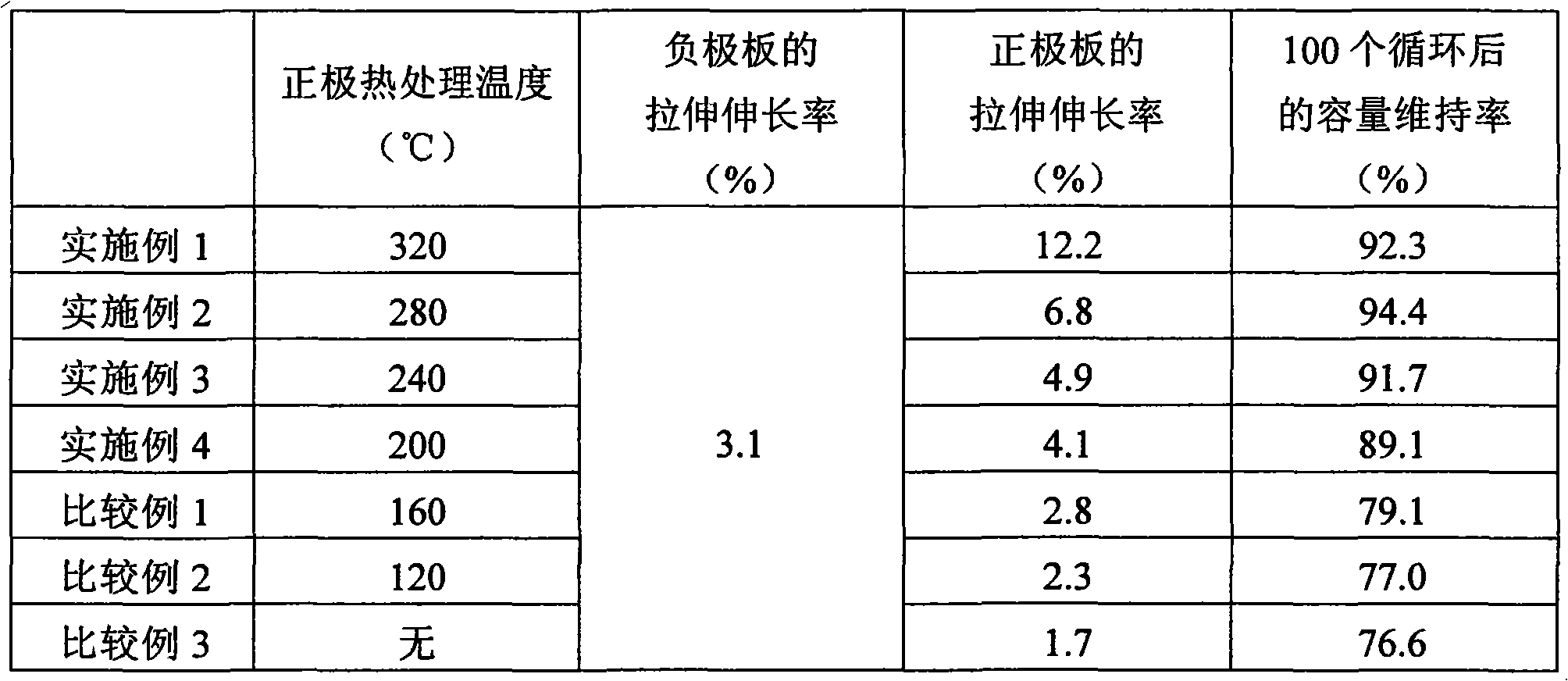

Nonaqueous electrolyte secondary battery and method for producing the same

InactiveCN101572330ABuckling suppressionImproved cycle life characteristicsFinal product manufactureActive material electrodesEngineeringCurrent collector

The present invention provides a negative active material which can also inhibit the buckling cuased by expansion and shrinkage of the negative active material, in a nonaqueous electrolyte secondary battery with flat electrode group by winding, even the negative active material uses high content material, a nonaqueous electrolyte secondary battery with good long service life property, and a method for manufacturing thereof. The nonaqureous electrolyte secondary battery includes an electrode group in which a positive electrode plate (3) including a positive electrode active material (2) formed on a positive electrode current collector (1) and a negative electrode plate (6) including a negative electrode active material (5) formed on a negative electrode current collector (4) are wound with a separator interposed therebetween, and a tensile elongation rate of the positive electrode plate (3) is larger than a tensile elongation rate of the negative electrode plate (6).

Owner:PANASONIC CORP

Pneumatic Run Flat Tire

InactiveUS20130075003A1Comfortable rideRun-flat durability can be enhancedSpecial tyresPneumatic tyre reinforcementsReinforced rubberEngineering

A pneumatic run flat tire includes an inner side reinforcing rubber layer having a falcated cross-section and an outer side reinforcing rubber layer having a center of gravity position in a meridian cross-section that is positioned inward in a tire radial direction of a tire maximum width position disposed in a side wall portion. Volumes of the inner side reinforcing rubber layer and the outer side reinforcing rubber layer are each different on a vehicle inner side and a vehicle outer side when mounted on a vehicle.

Owner:YOKOHAMA RUBBER CO LTD

Load Bearing Frame

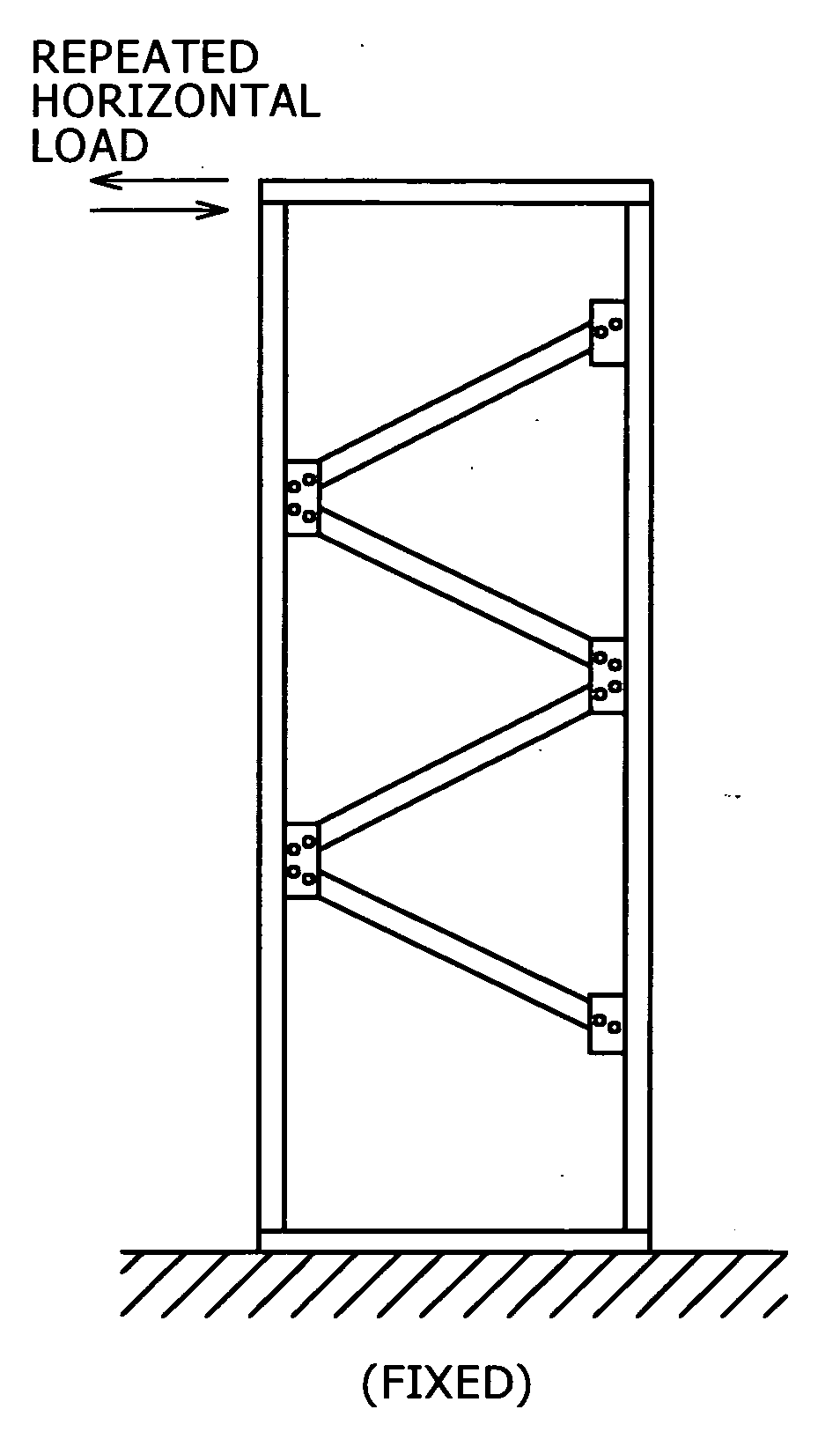

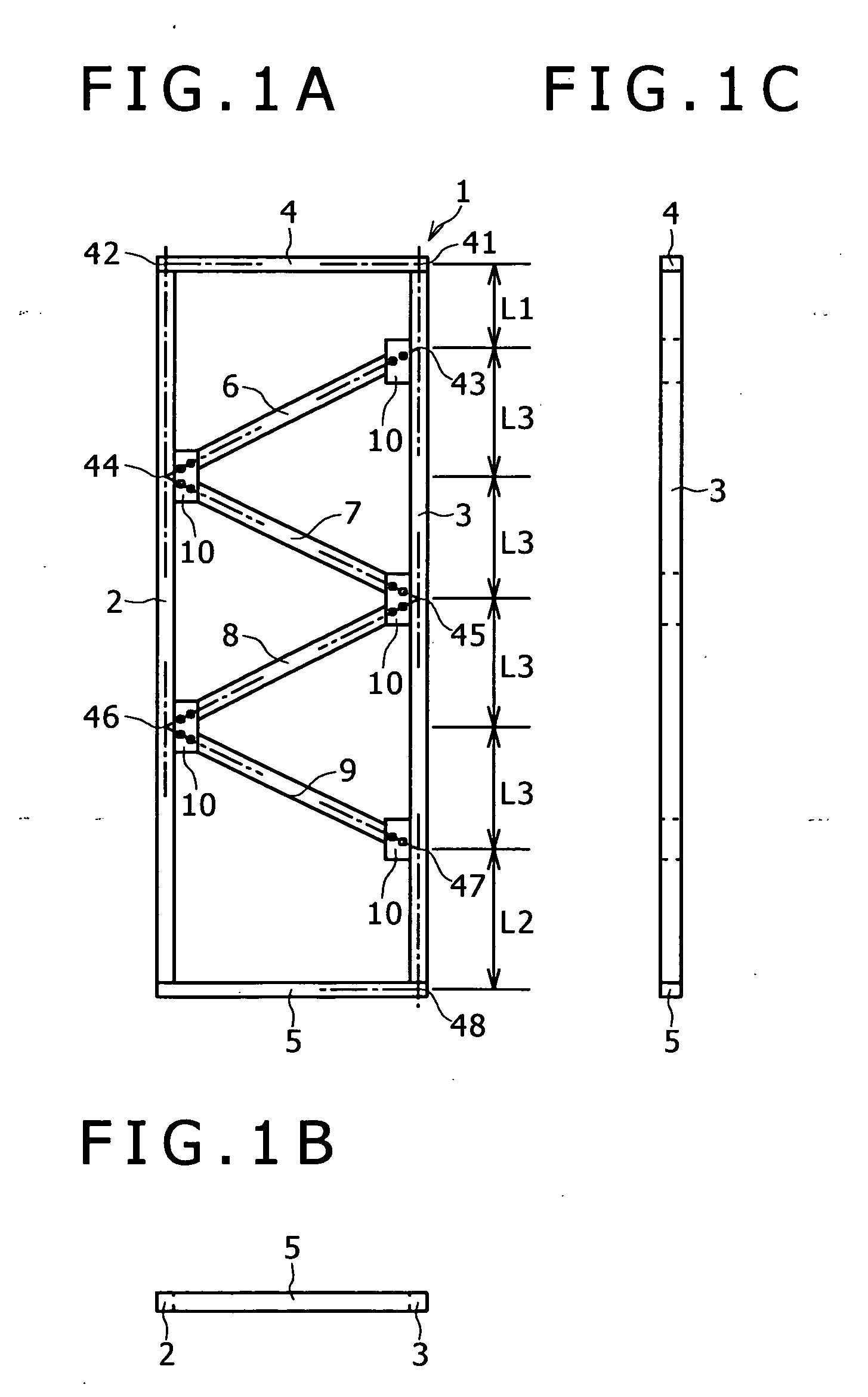

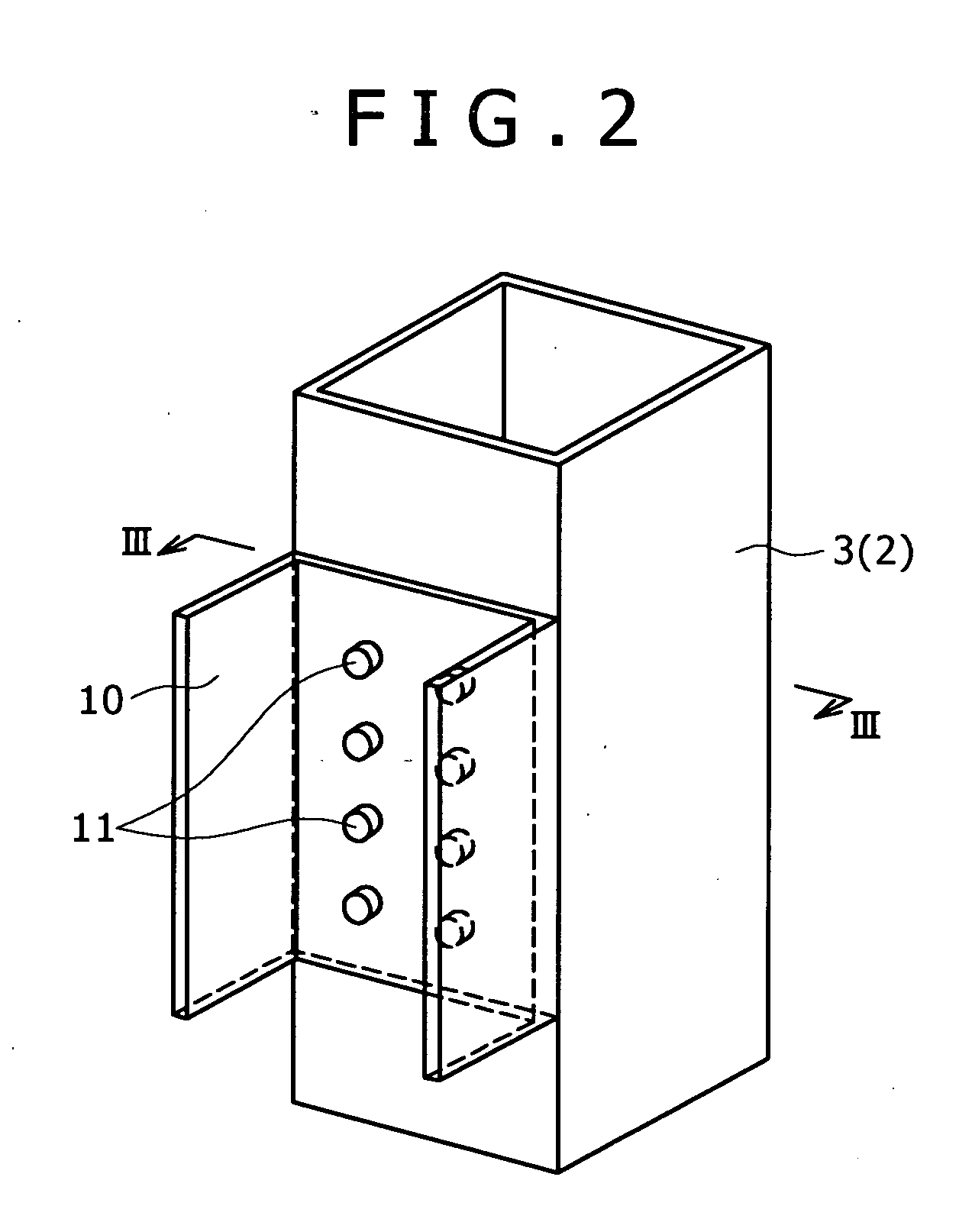

InactiveUS20100031600A1Improve carrying capacityBuckling suppressionWallsTowersEngineeringLoad bearing

The present invention is to provide a load bearing frame for suppressing generation of buckling of diagonal materials and breakage of connection parts and having high deformability.A load bearing frame 1 has two pillar materials 2 and 3, two frame materials 4 and 5 and four diagonal materials 6 to 9. A connection point 41 between the pillar material 3 and the frame material 4 is apart from a connection point 43 between the diagonal material 6 arranged on the uppermost side and the pillar material 3 by a distance L1. A connection point 48 between the pillar material 3 and the frame material 5 is apart from a connection point 47 between the diagonal material 9 arranged on the lowermost side and the pillar material 3 by a distance L2.

Owner:KOBE STEEL LTD

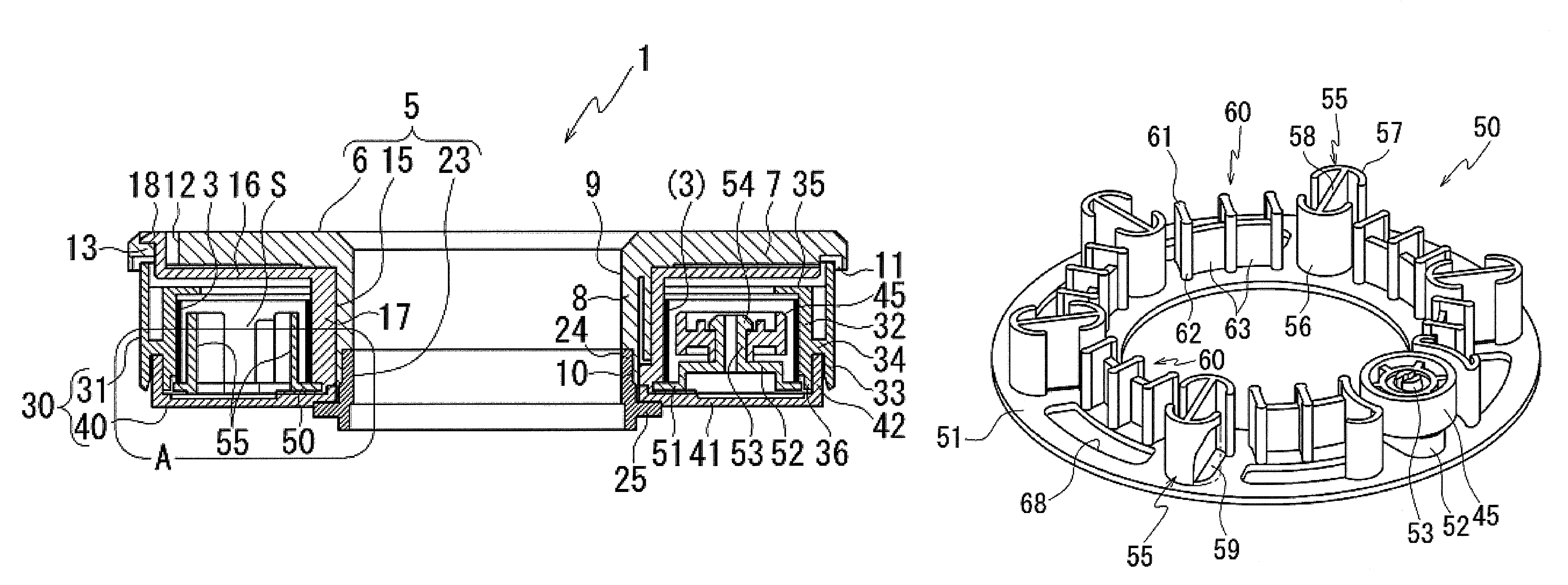

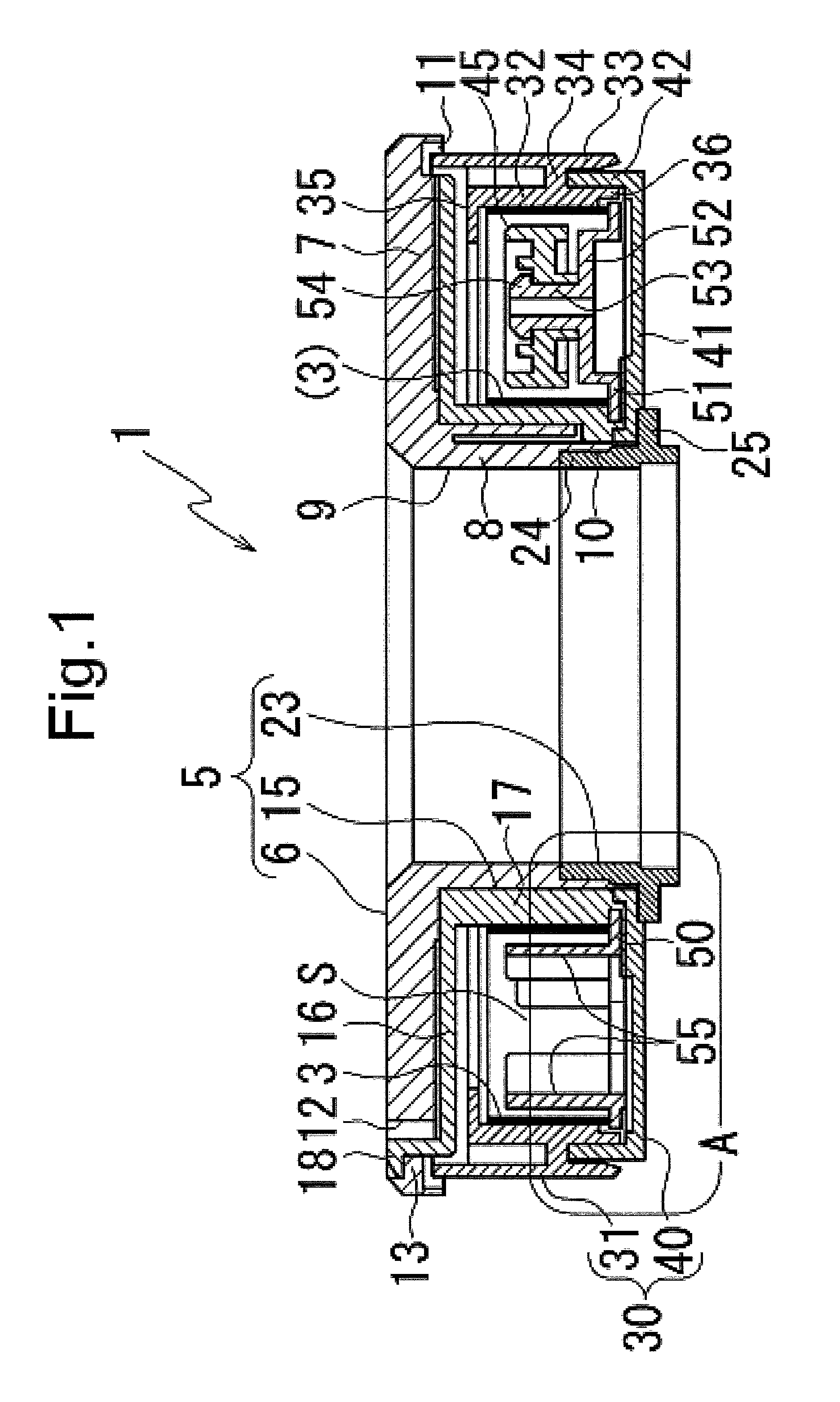

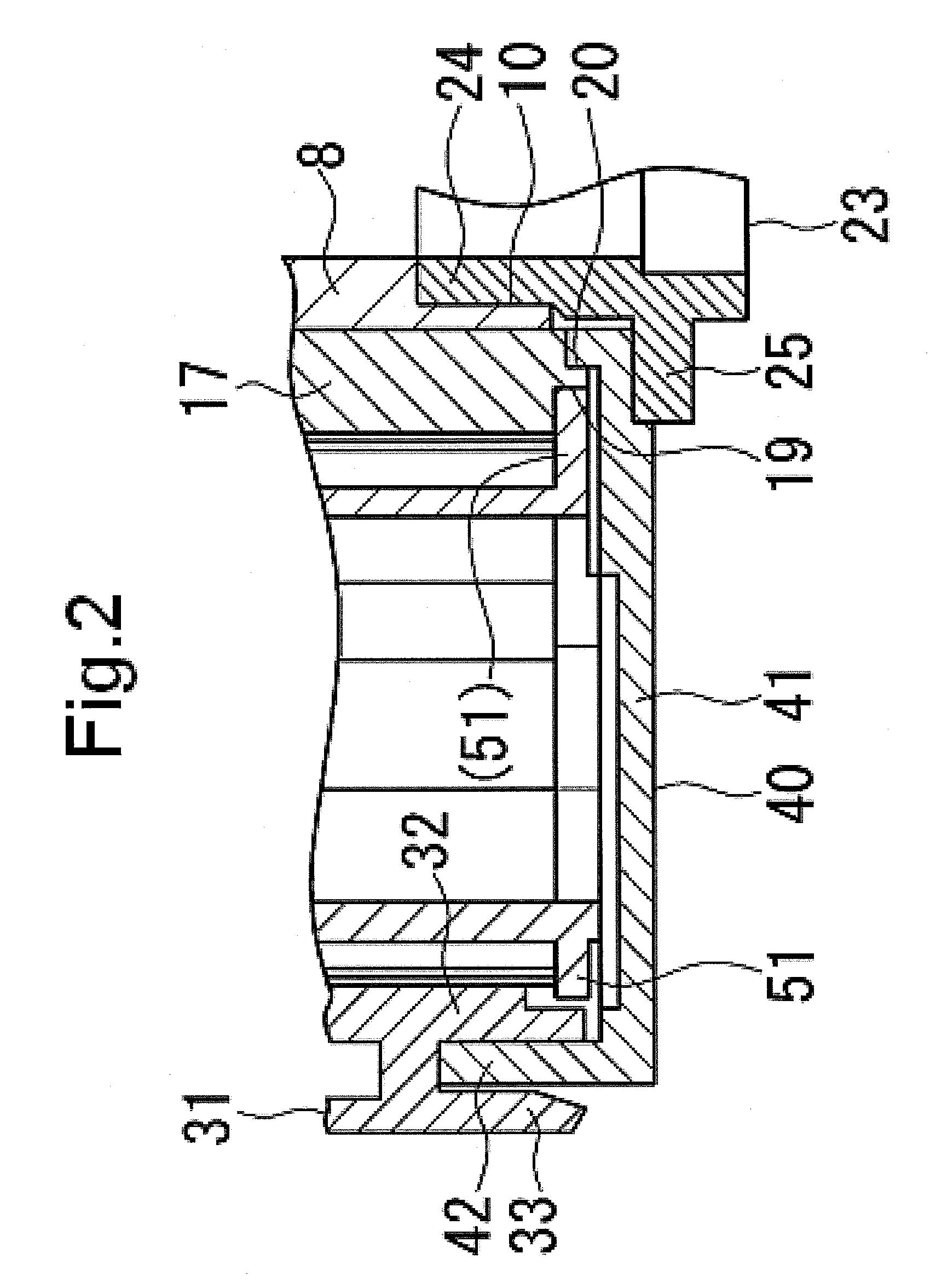

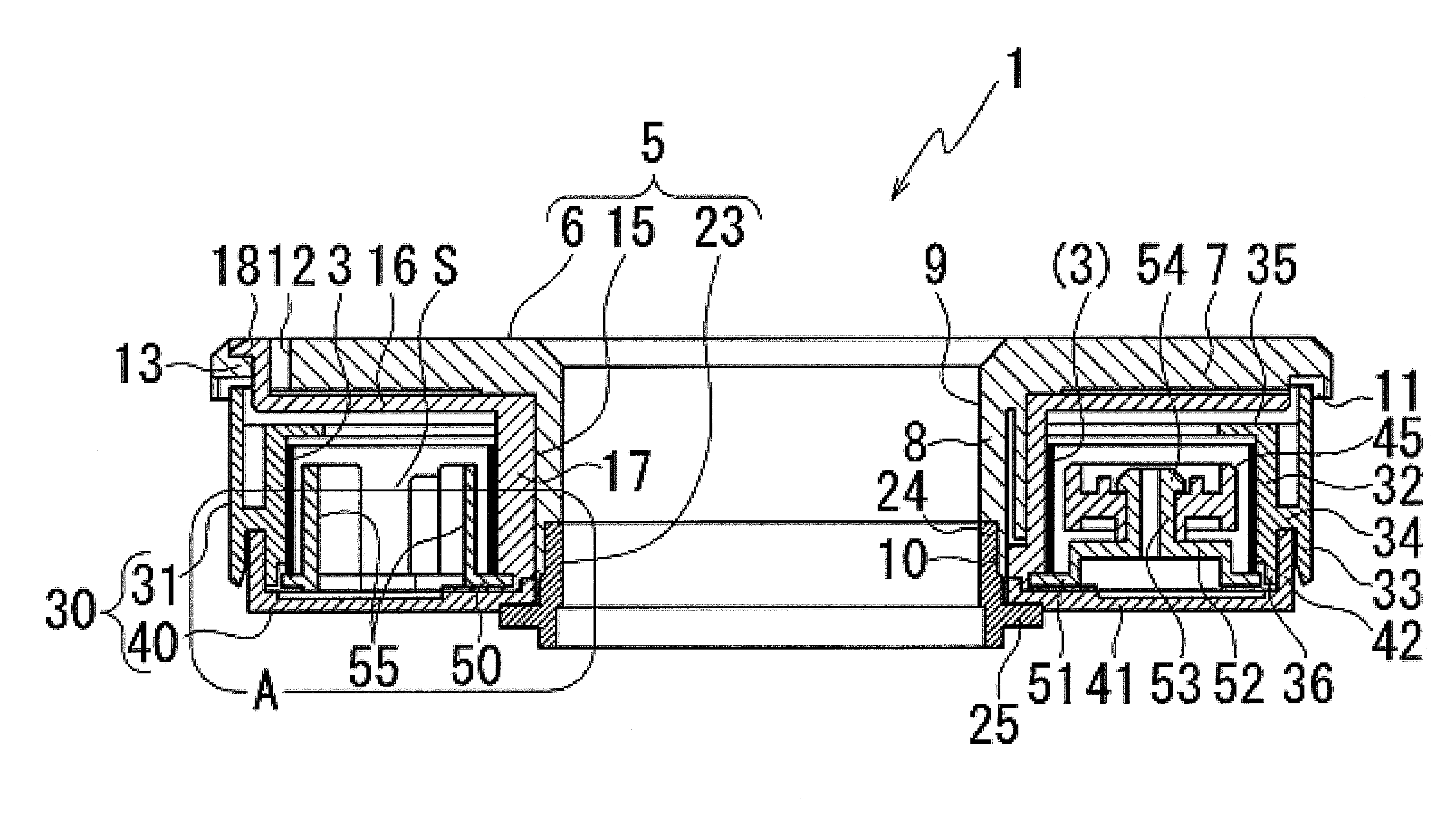

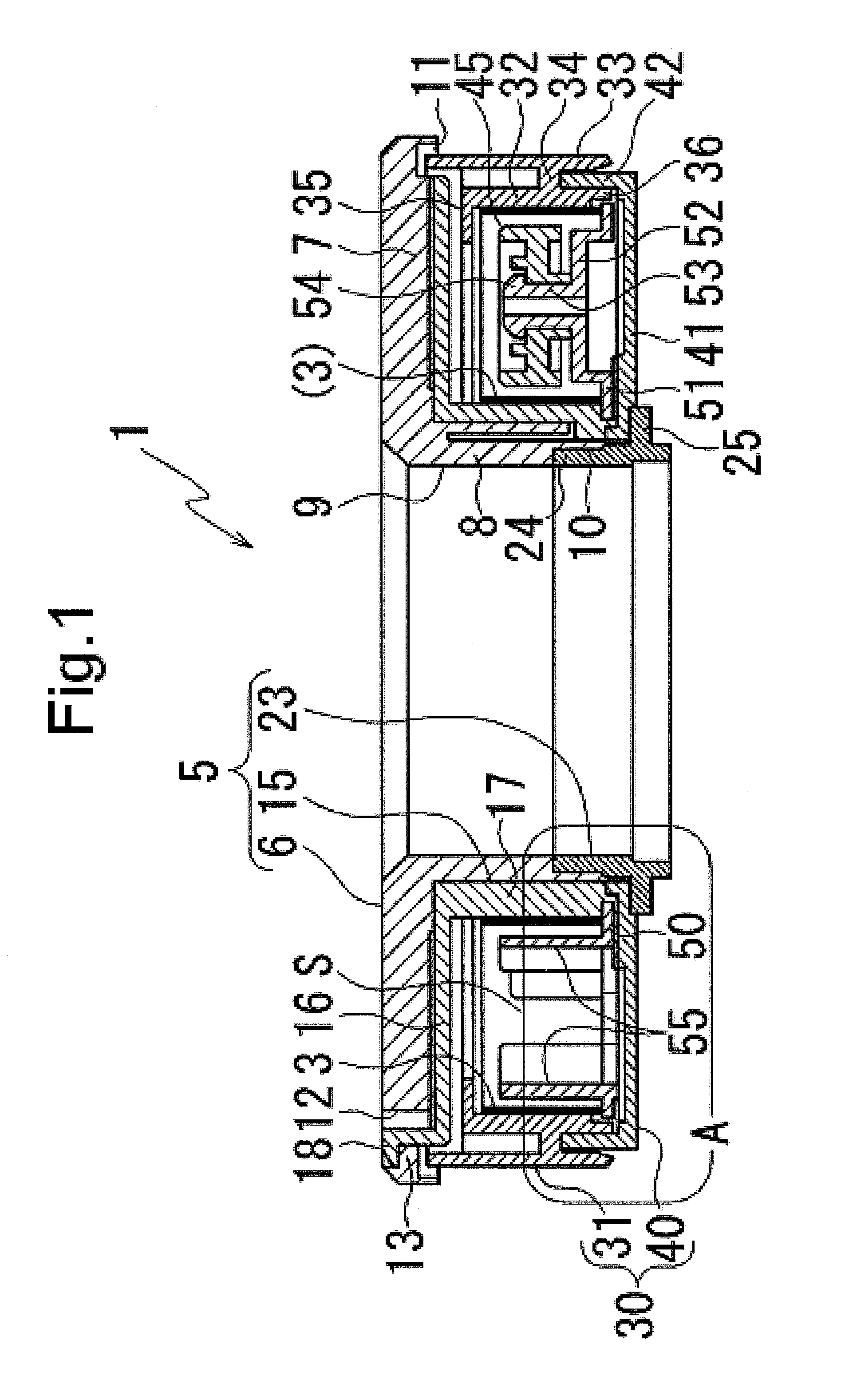

Rotational connector device including a spacer disposed in an annular space formed between a rotor and a stator

InactiveUS8740626B2Prevent bucklingLight weightRotary current collectorCable arrangements between relatively-moving partsParallel plateEngineering

A spacer arranged in an annular space between a rotor and a stator for supporting a roller reversing a winding direction of a flat cable is made of plastic having high lubricating properties. First guide portions on an annular plate portion are spaced by equal intervals from each other. The first guide portion includes an inner guide rib having a semicircle cross section projecting inward, an outer guide rib having a semicircle cross section projecting outward, and a tension wall connecting the inner guide rib and the outer guide rib. A second guide portion is provided between the first guide portions, and includes three parallel plate ribs extending from an inner peripheral side to an outer peripheral side of the annular plate portion, and circumferential connecting walls connecting the three parallel plate ribs.

Owner:VALEO JAPAN CO LTD

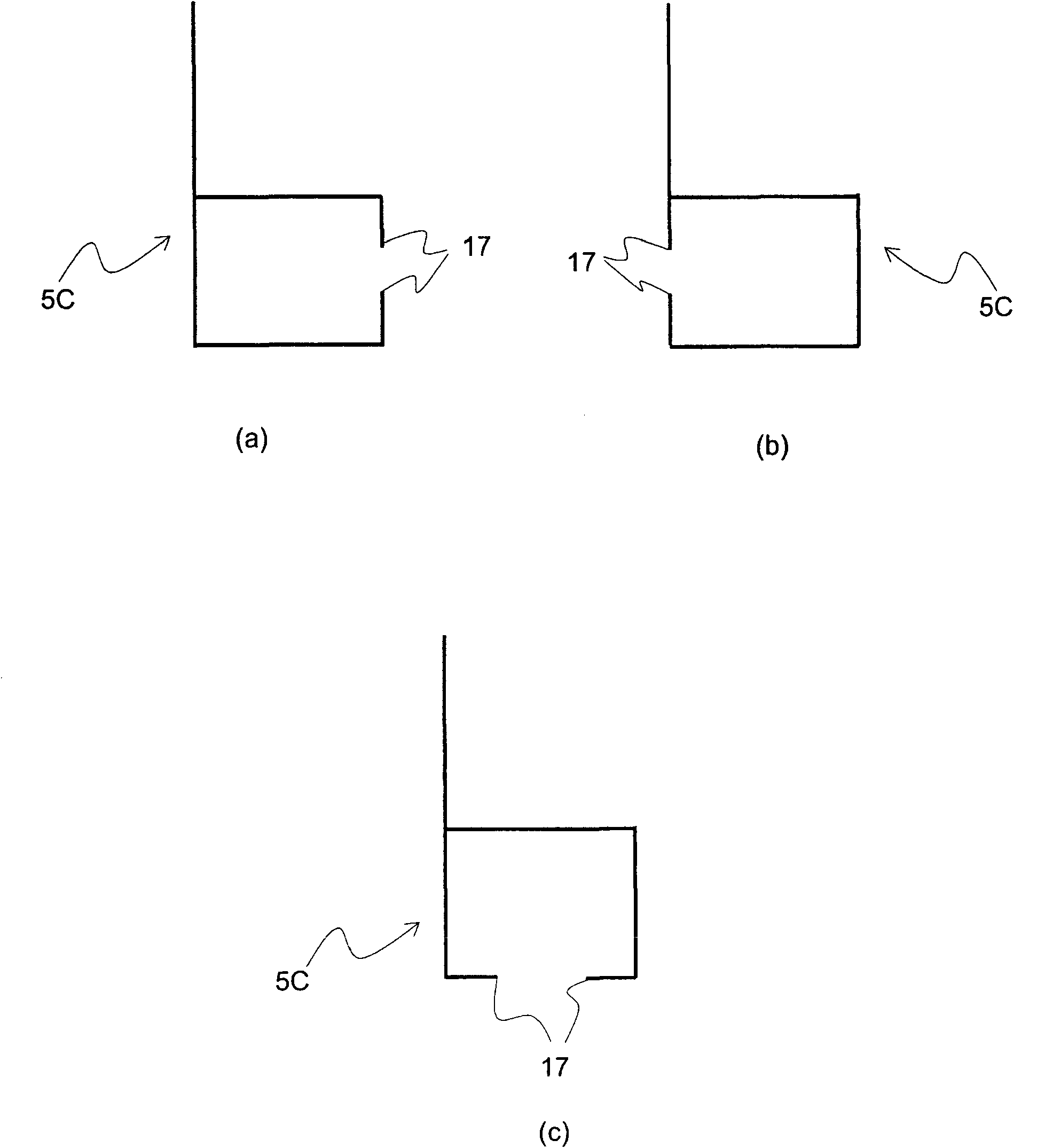

Conveyor and manufacture method thereof

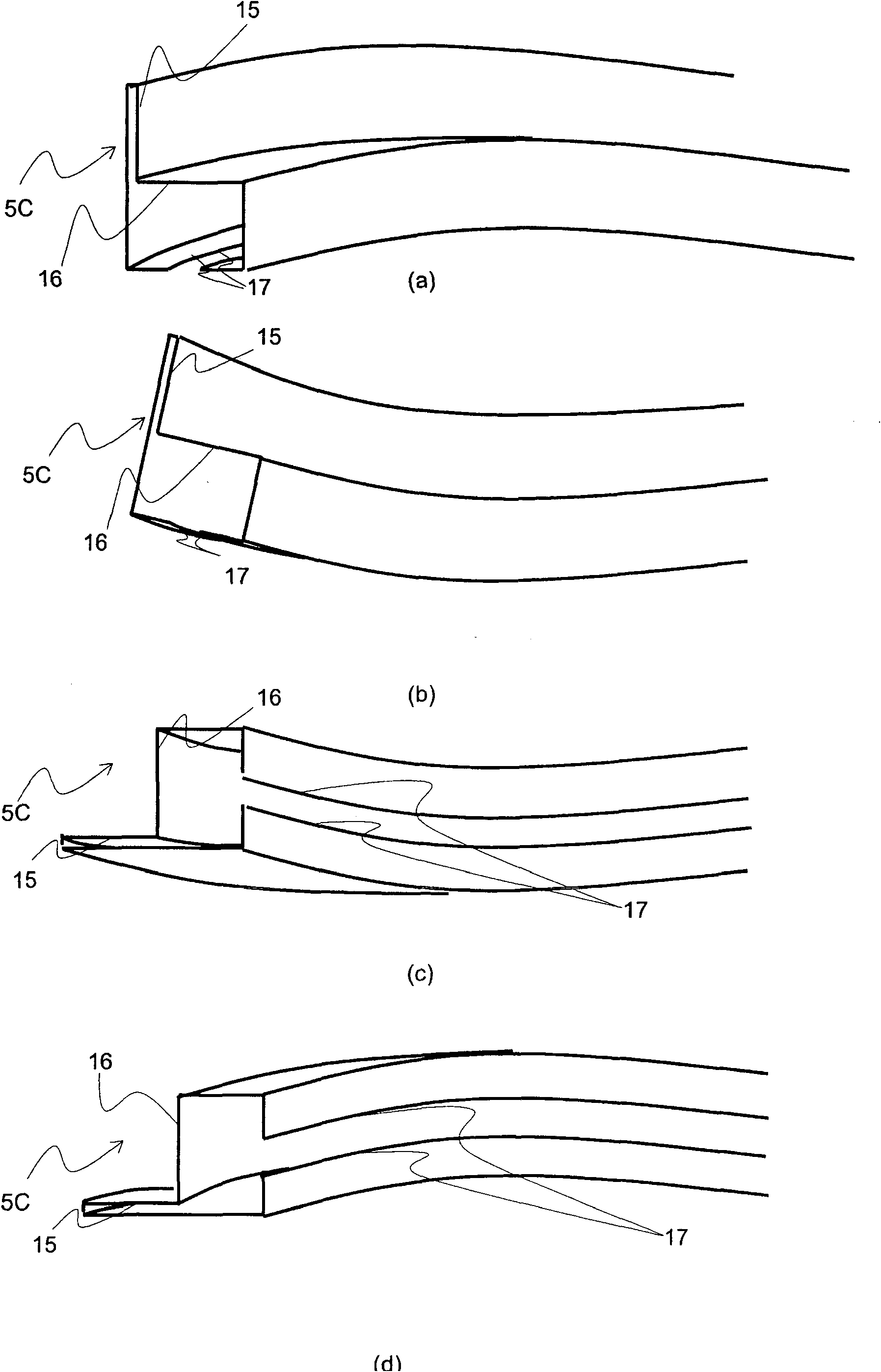

The invention provides a conveyor and a manufacture method thereof, so that soft roll forming is realized, the bending machining with restraints only from the outer side is achieved without generation of torsion, in-plane corrugation and in-plane buckling, and therefore a curve part of a stepped operating track for a conveyor is small in weight and highly precise in shape. The curve part of the stepped operating track is formed by a stepped operating track (5C) with at least one of a short side and a long side having a hollow structure, thereby realizing that the weight of the conveyor is small. The wall of the hollow structure is provided with an opening part (17), which is mounted to a frame (21) via through bolts (22) at appropriate intervals. A roller for preparing the curve part of the stepped operating track with the hollow structure is made in such a shape as to prohibit the deformation which is caused by concentration of stress generated by corners of the stepped operation track during the bending machining.

Owner:HITACHI LTD

Curvature regulating member and power supply device

InactiveUS20180141505A1Improve rigidityAvoid displacementElectric/fluid circuitArrangements using extensible carrierEngineeringCable harness

Owner:YAZAKI CORP

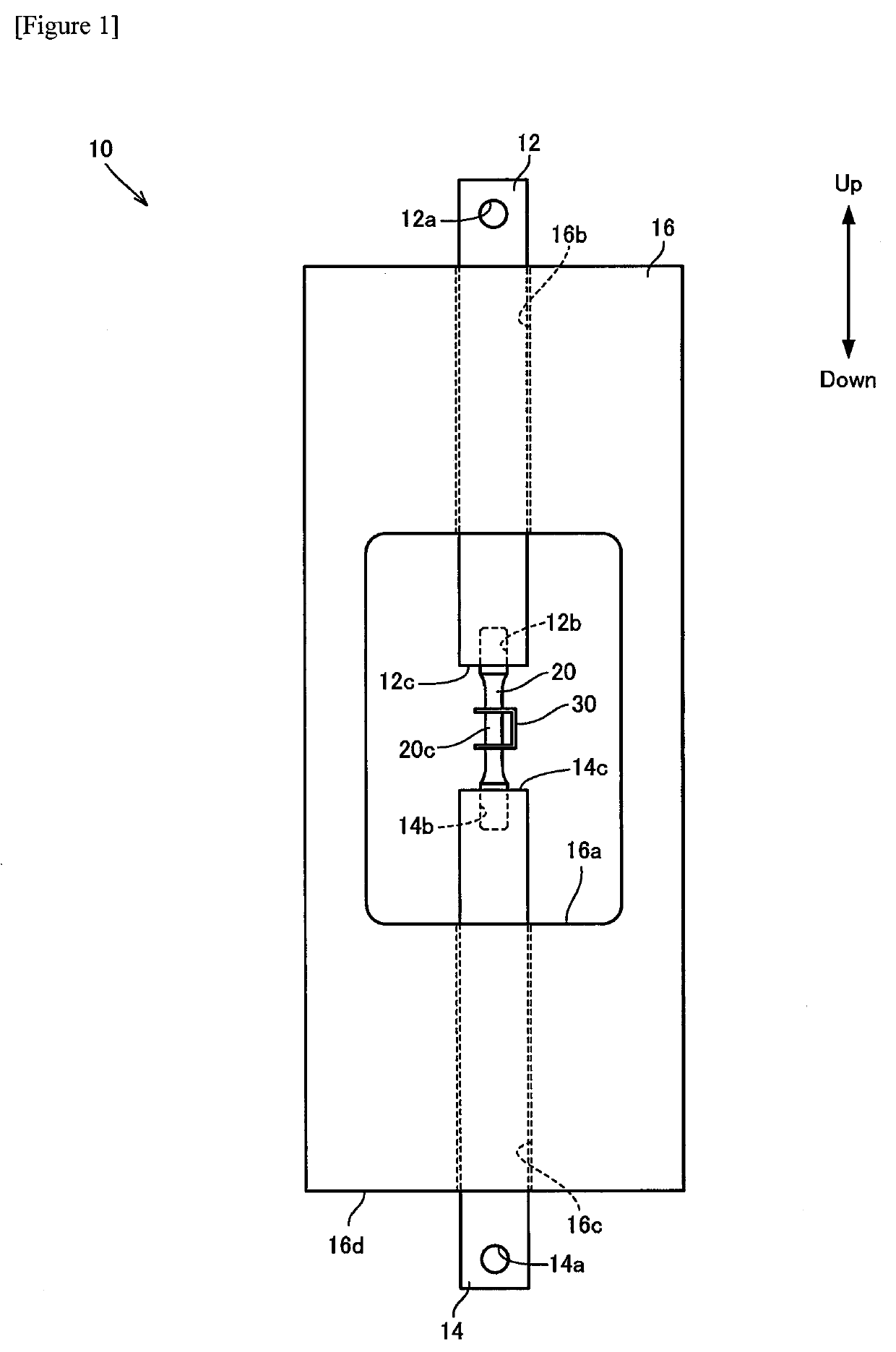

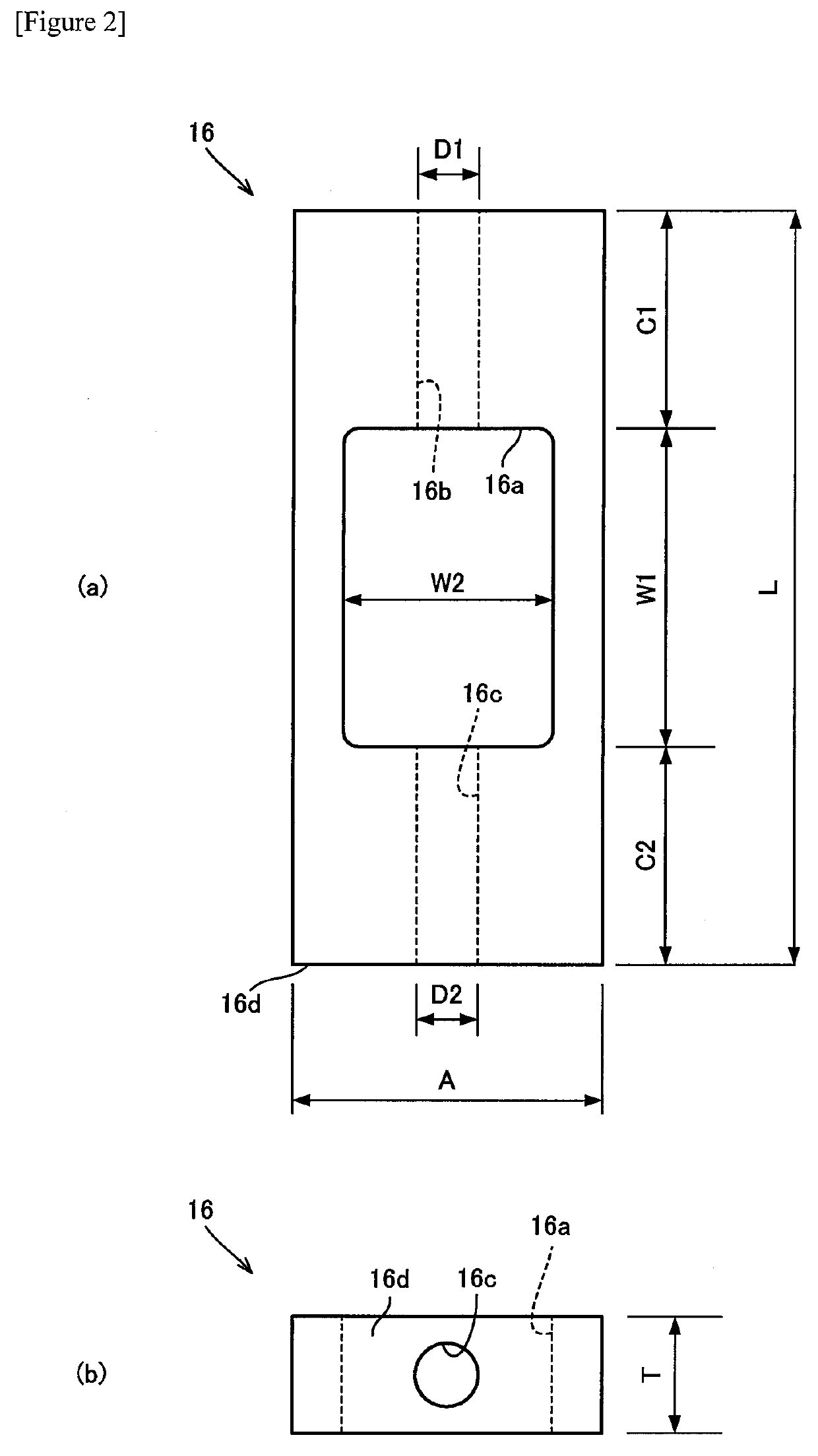

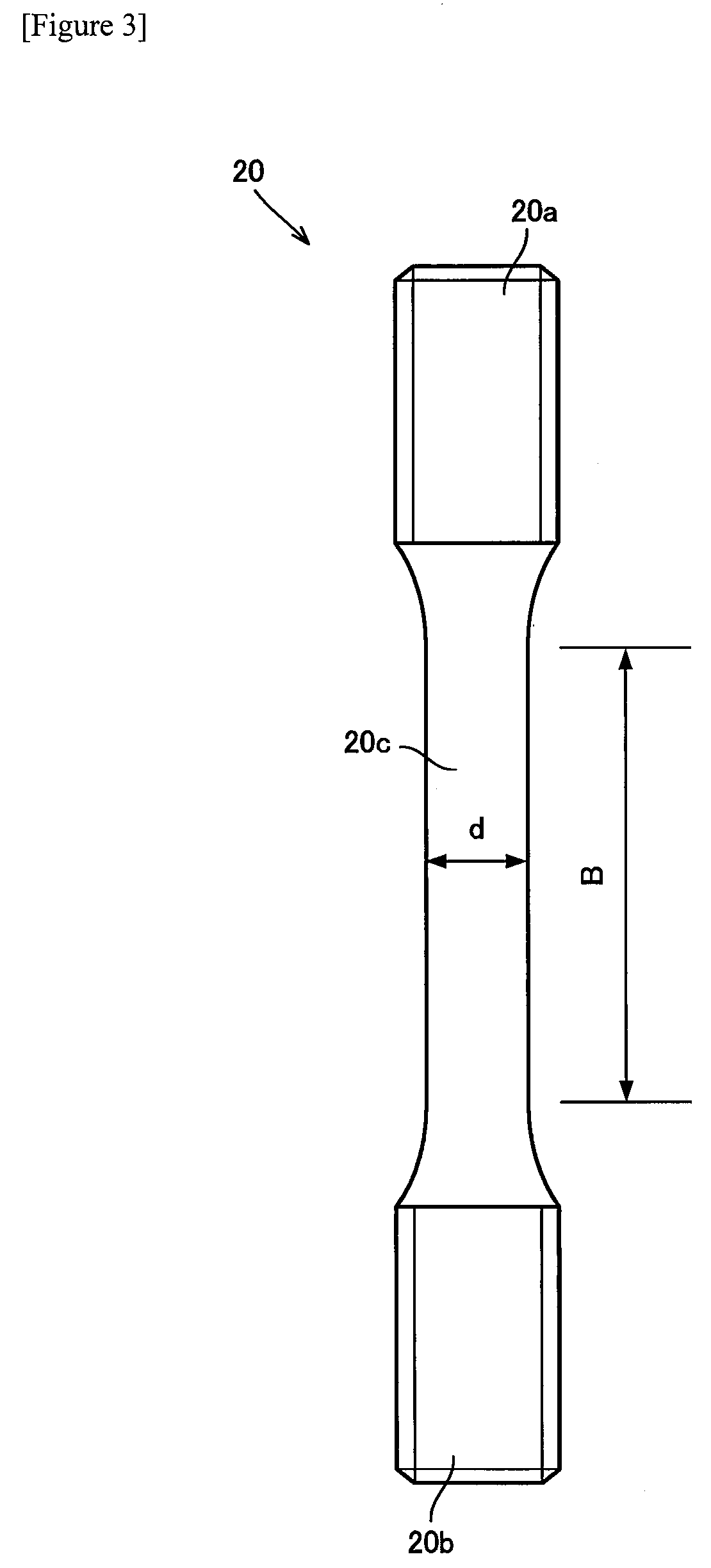

Stress Test Jig and Stress Test Method

ActiveUS20190242799A1Buckling suppressionAccurate assessmentMaterial strength using tensile/compressive forcesEngineering

Owner:NIPPON STEEL CORP

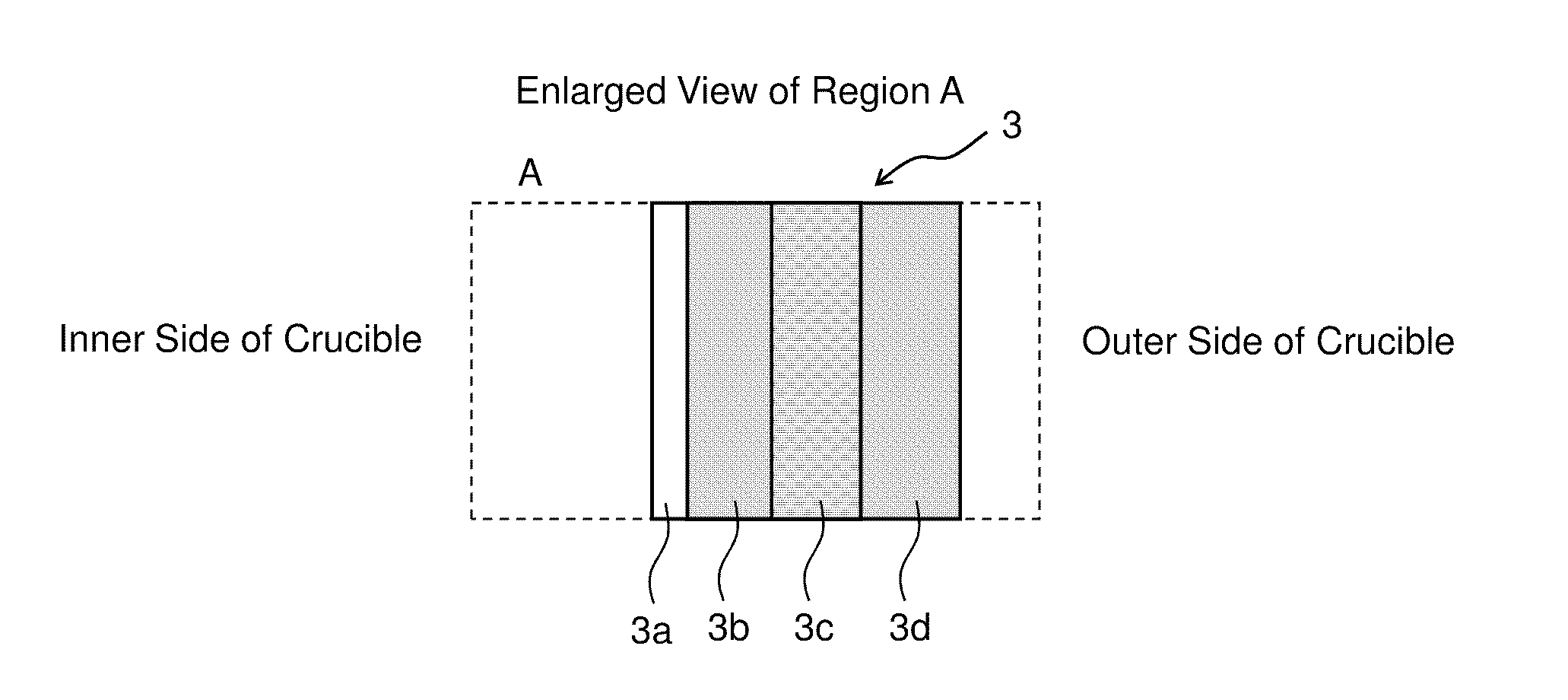

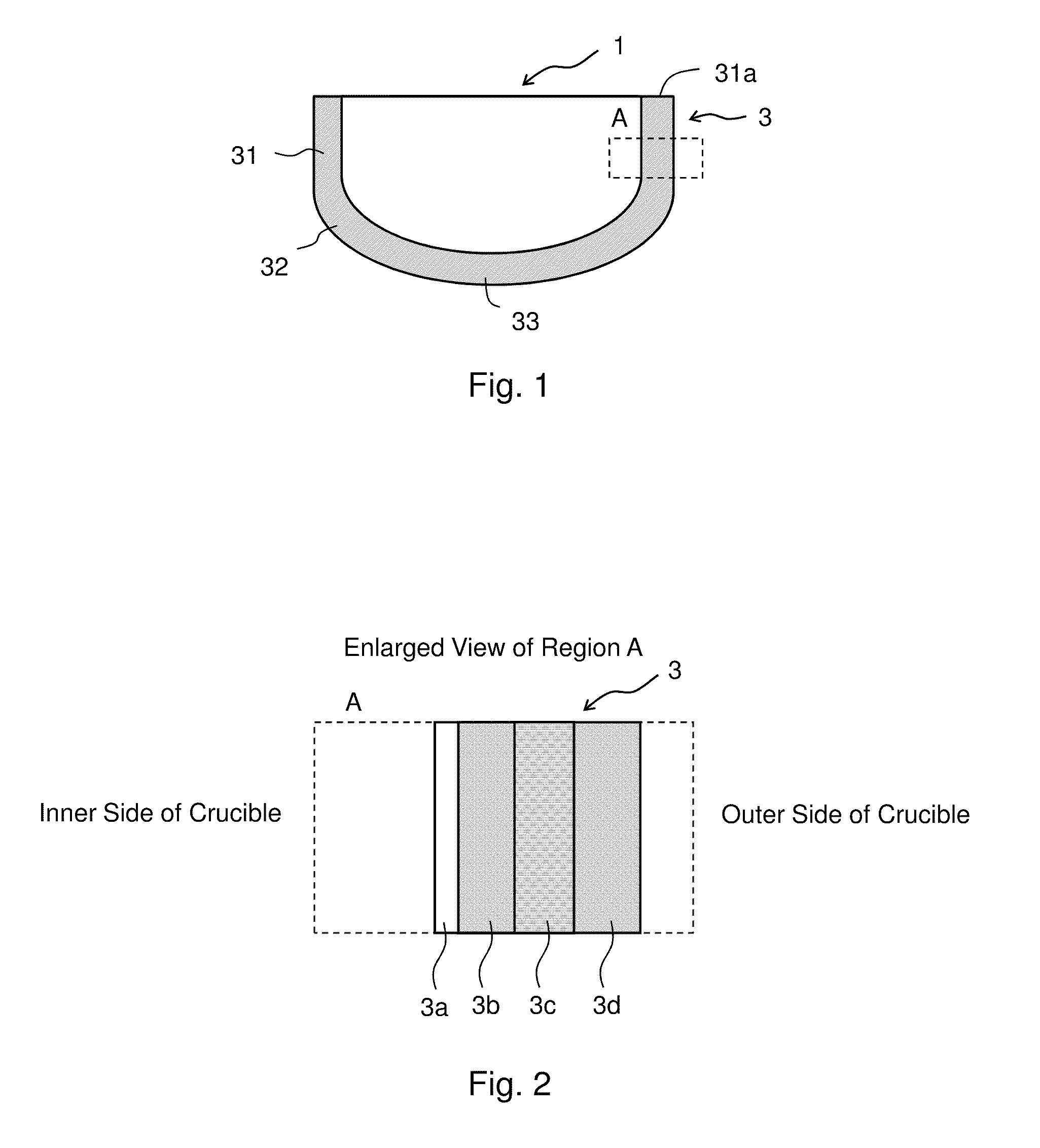

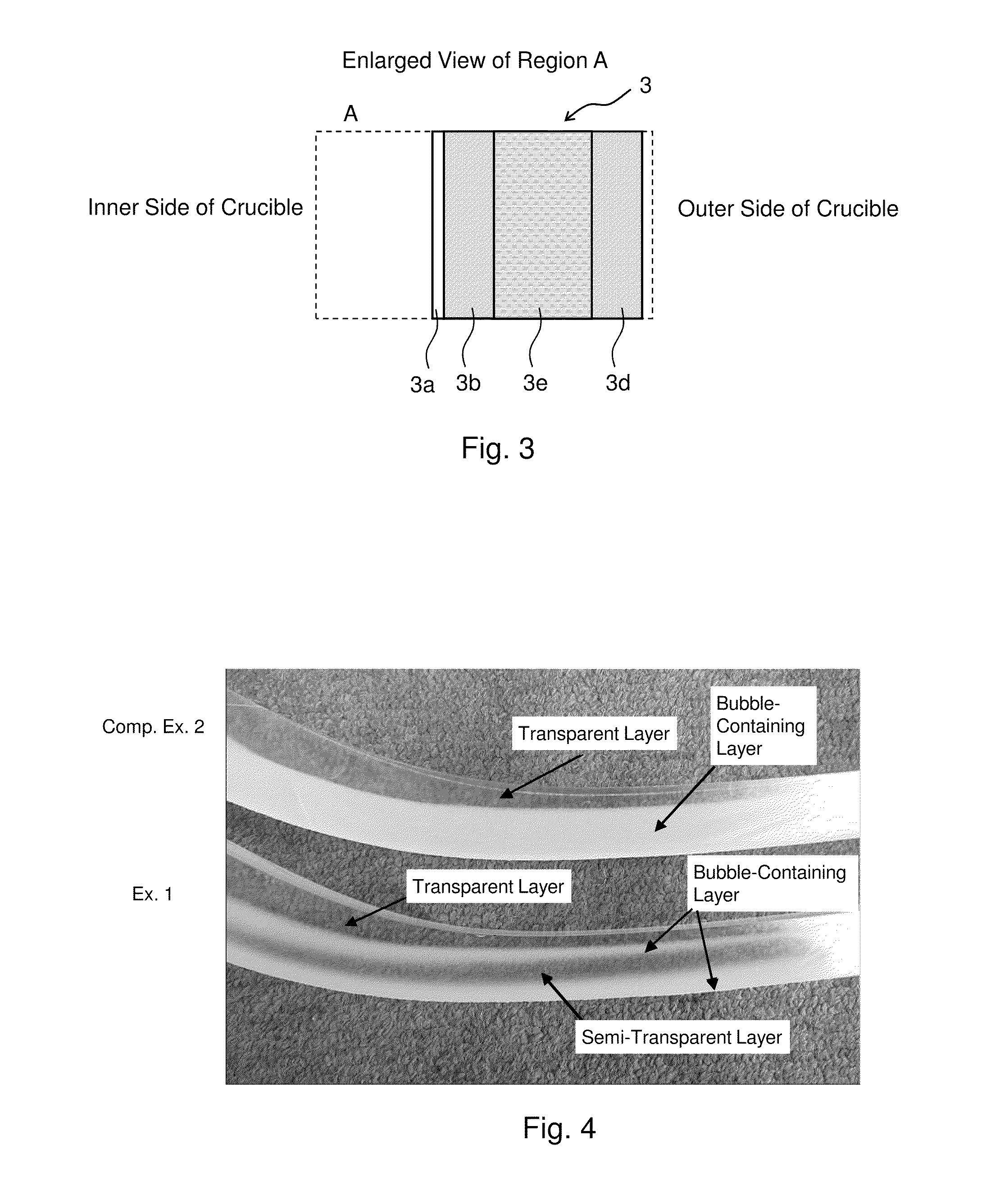

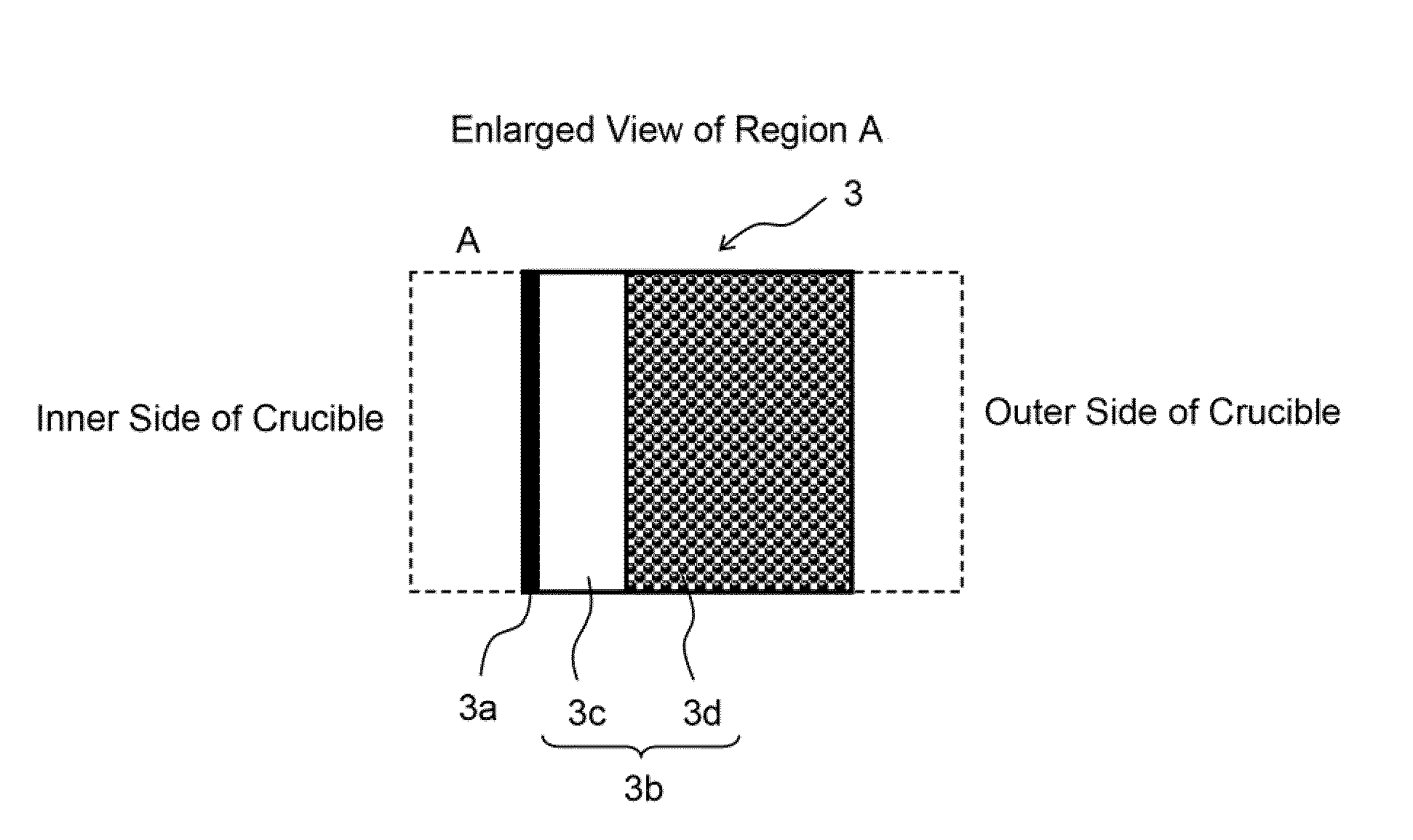

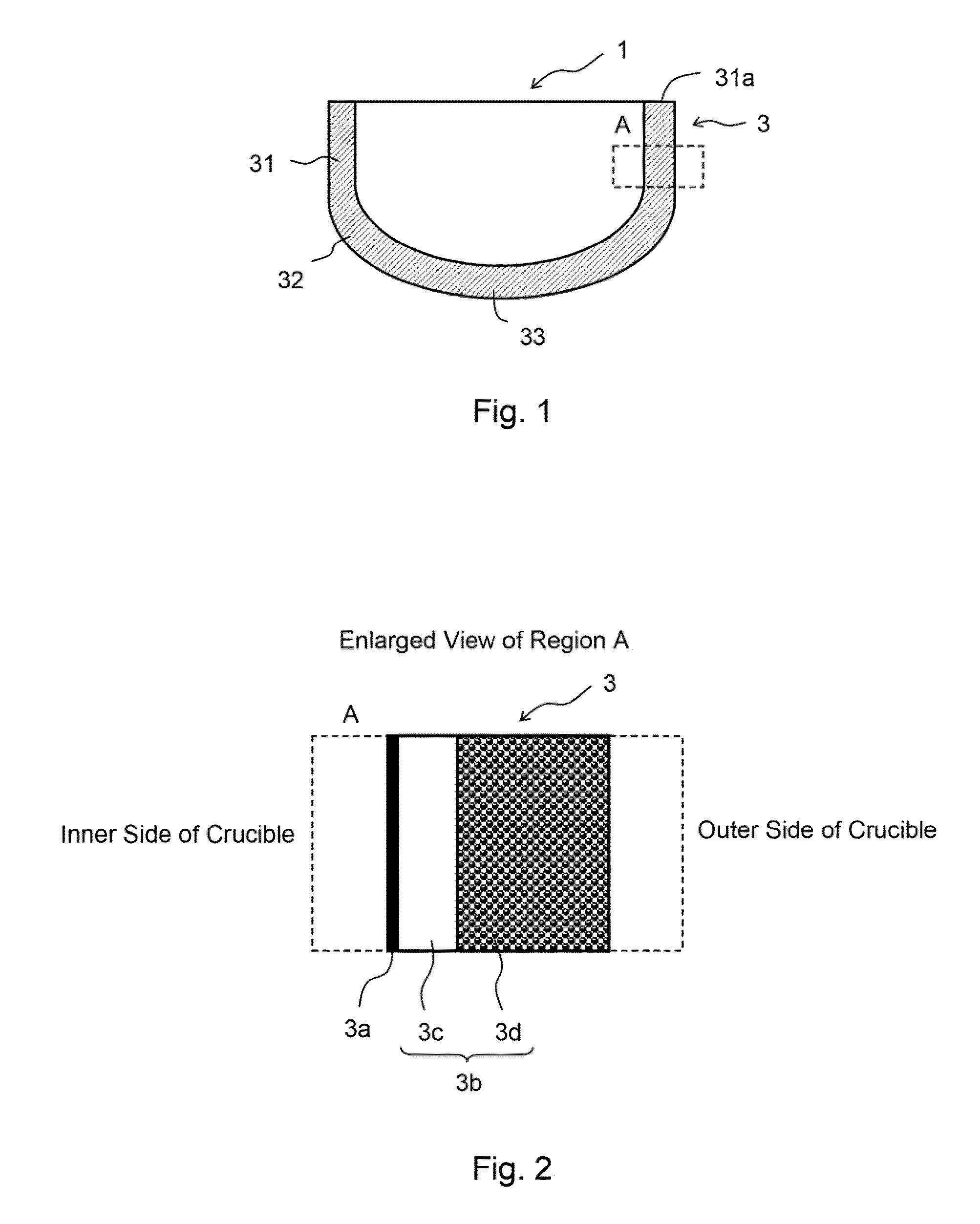

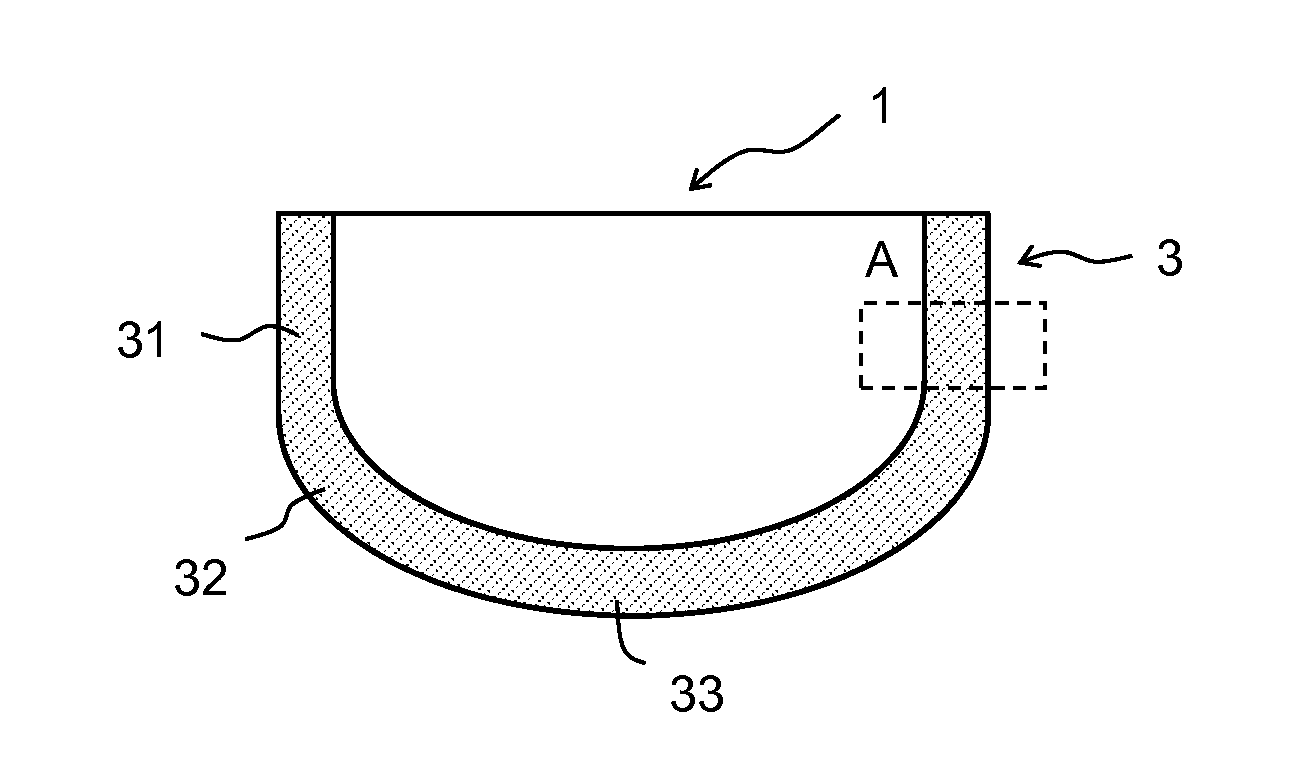

Vitreous silica crucible and method of manufacturing the same, and method of manufacturing silicon ingot

ActiveUS20110315072A1Suppress inward saggingBuckling suppressionAfter-treatment apparatusPolycrystalline material growthCrucibleIngot

Provided is a vitreous silica crucible which can suppress inward sagging and buckling of the sidewall effectively even when time for pulling silicon ingots is extremely long. According to the present invention, provided is a vitreous silica crucible for pulling a silicon single crystal, wherein the crucible has a wall comprising, from an inner surface toward an outer surface of the crucible, a transparent vitreous silica layer having a bubble content rate of less than 0.5%, a bubble-containing vitreous silica layer having a bubble content rate of 1% or more and less than 50%, a semi-transparent vitreous silica layer having a bubble content rate of 0.5% or more and less than 1.0% and having an OH group concentration of 35 ppm or more and less than 300 ppm.

Owner:SUMCO CORP

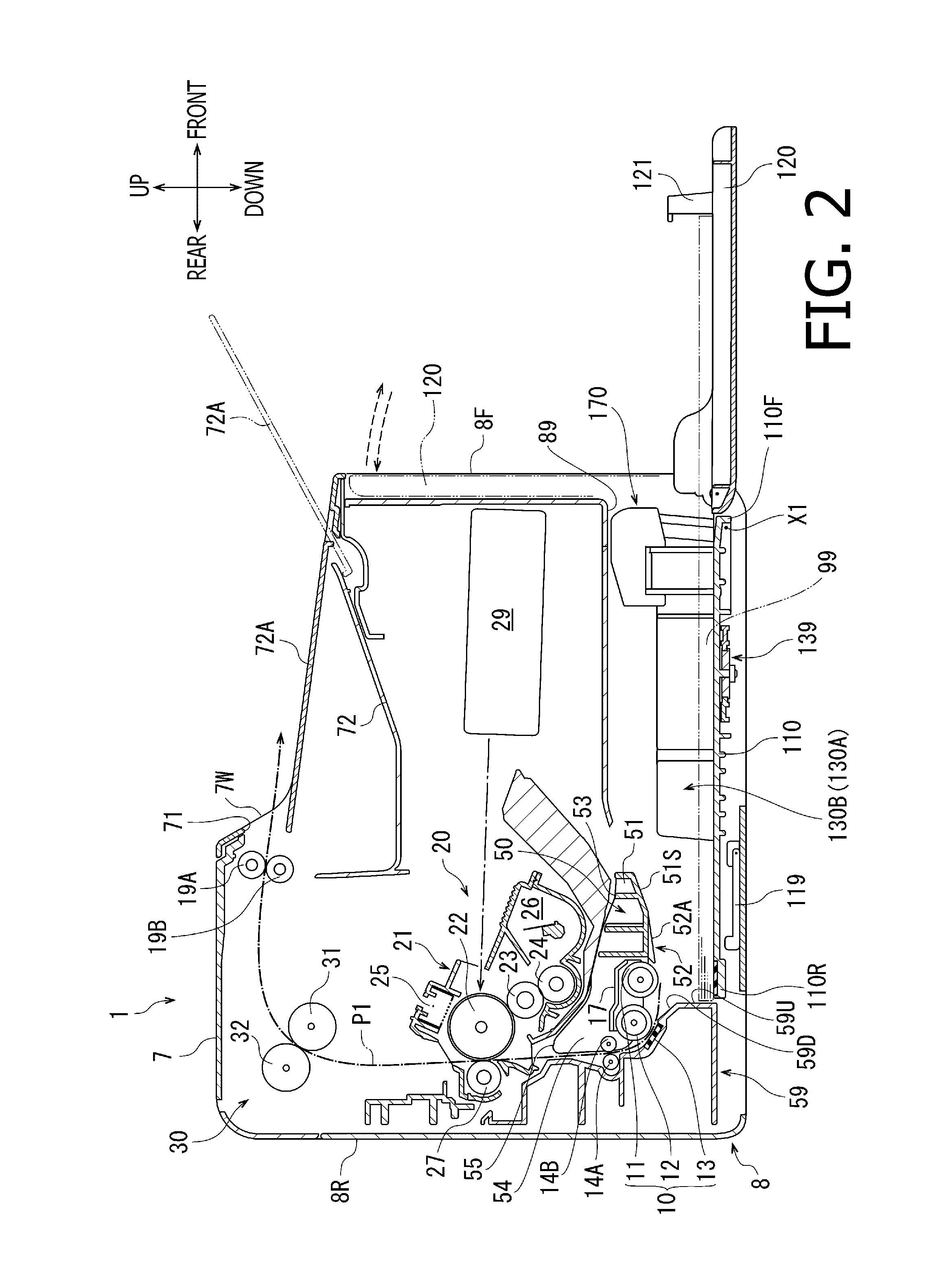

Image Forming Apparatus

ActiveUS20140091513A1Buckling suppressionElectrographic process apparatusPile receiversImage formationEngineering

Owner:BROTHER KOGYO KK

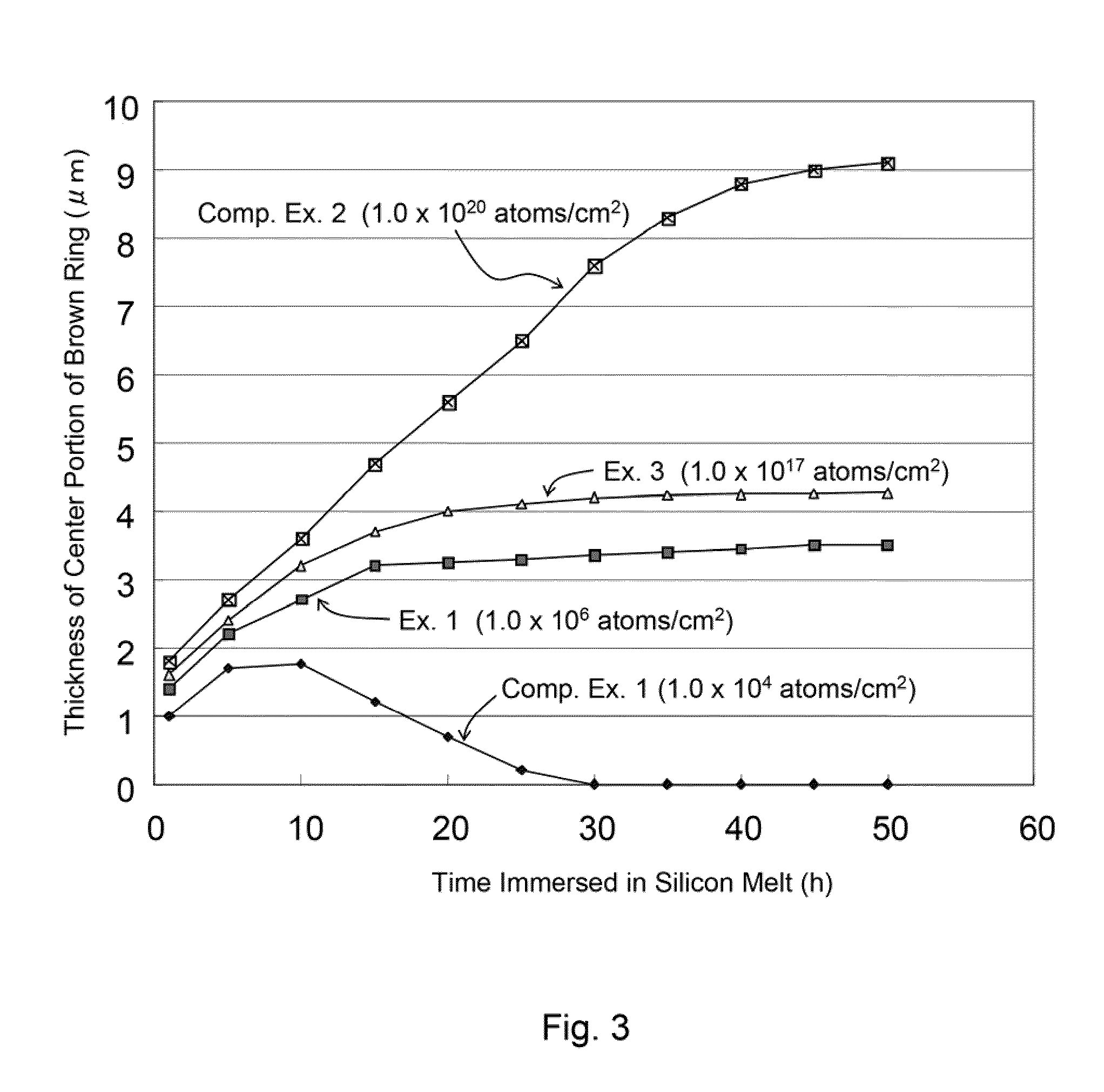

Vitreous silica crucible and method of manufacturing silicon ingot

ActiveUS20120017824A1Buckling suppressionPromote crystallizationPolycrystalline material growthBy pulling from meltCrucibleSingle crystal

The present invention provides a vitreous silica crucible which can suppress buckling and sidewall lowering of the crucible in multi-pulling. According to the present invention, provided is a vitreous silica crucible for pulling a silicon single crystal, comprising a mineralizer on an inner surface of the crucible, wherein the mineralizer contains at least one atoms selected from the group consisting of Ca, Sr, Ba, Ra, Ti, Zr, Cr, Mo, Fe, Co, Ni, Cu, and Ag, and the concentration of the mineralizer on the inner surface is 1.0×105 to 1.0×1017 atoms / cm2.

Owner:SUMCO CORP

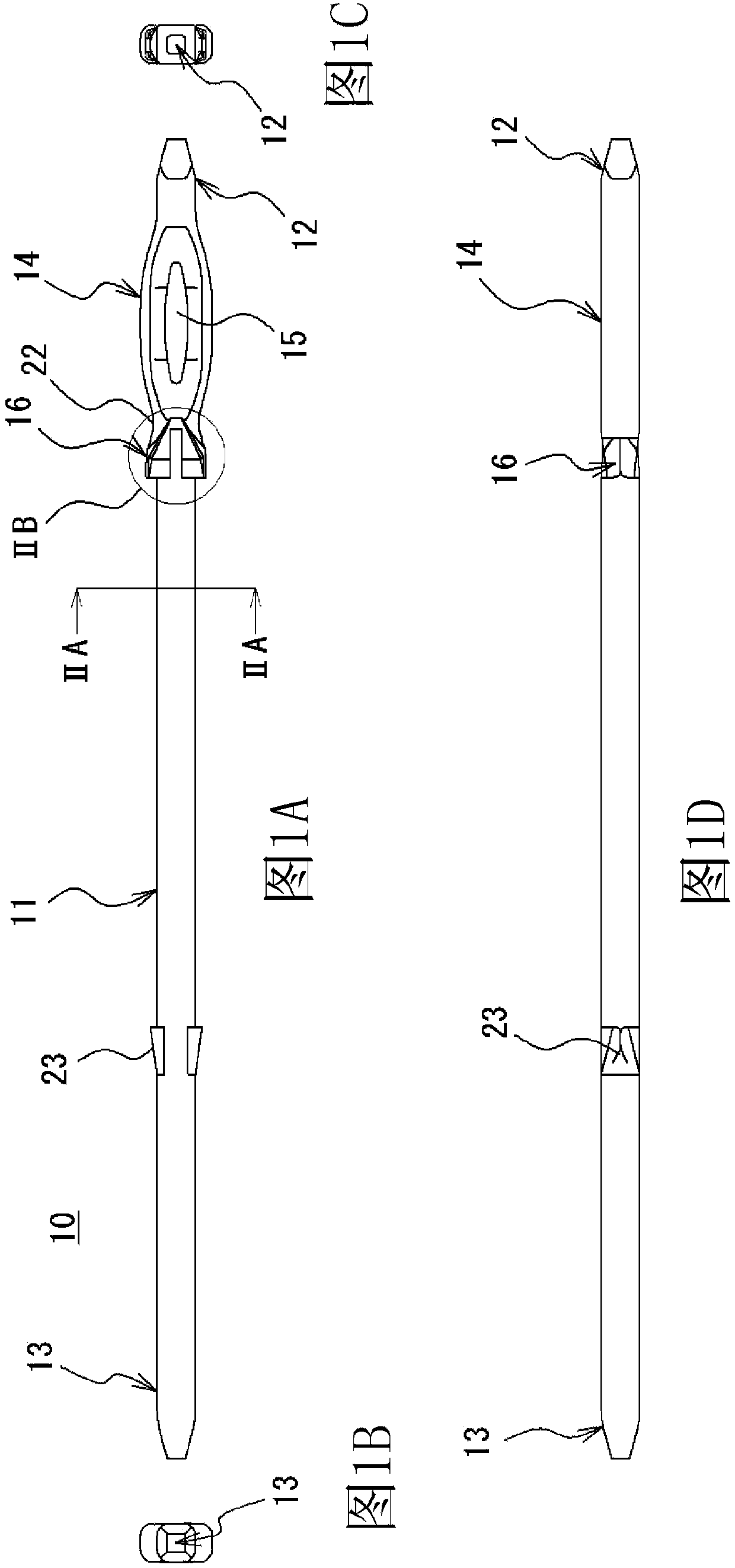

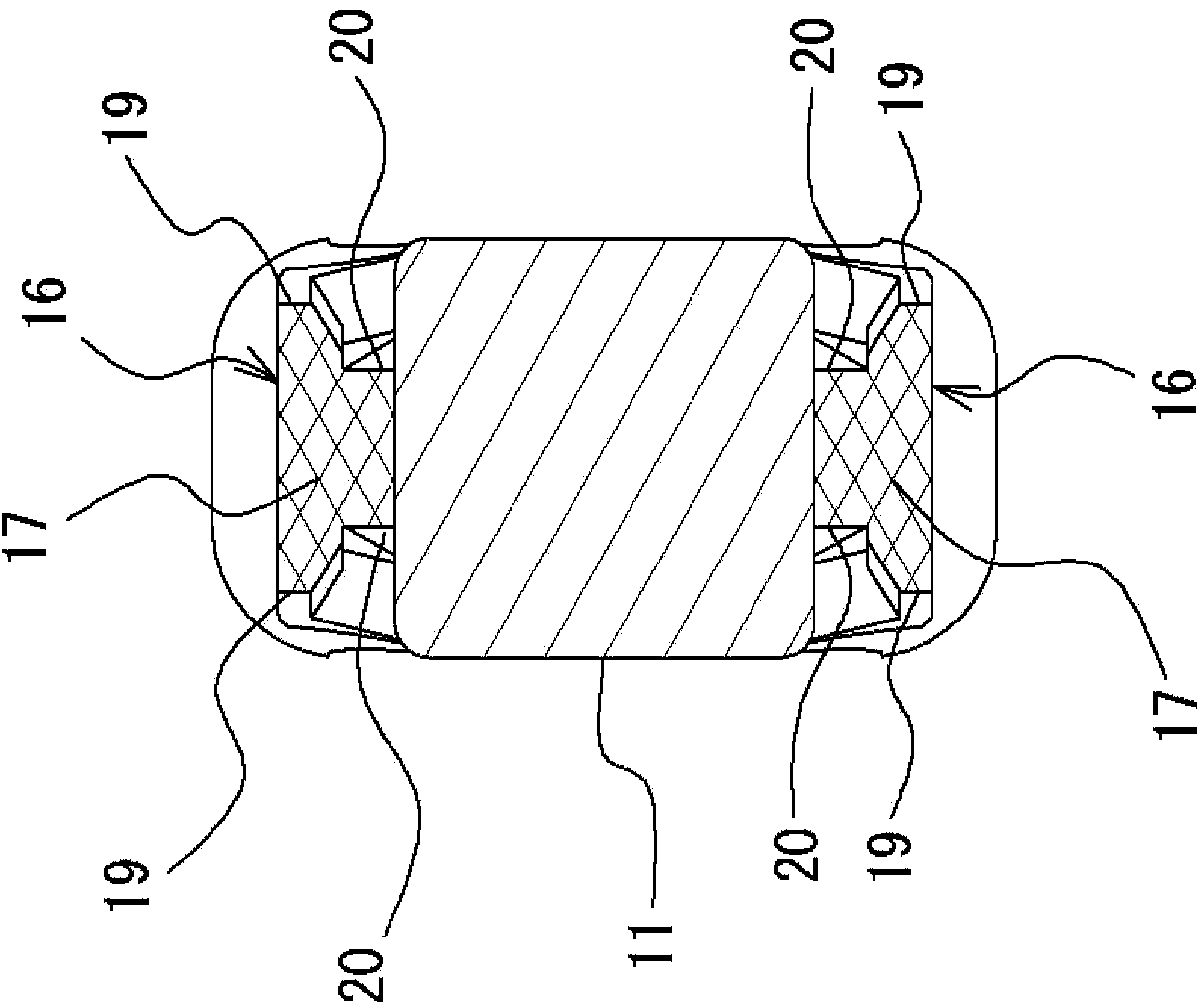

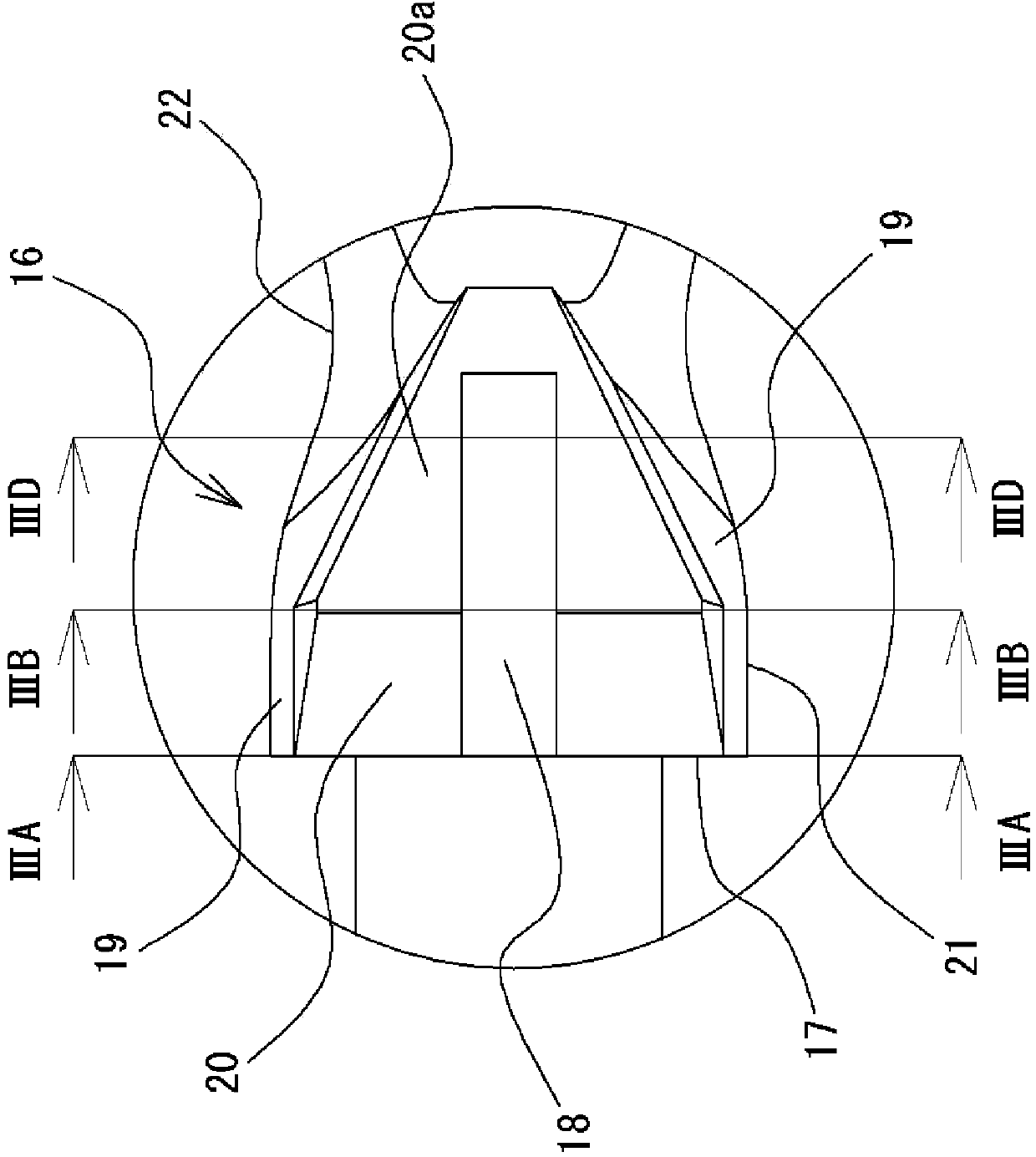

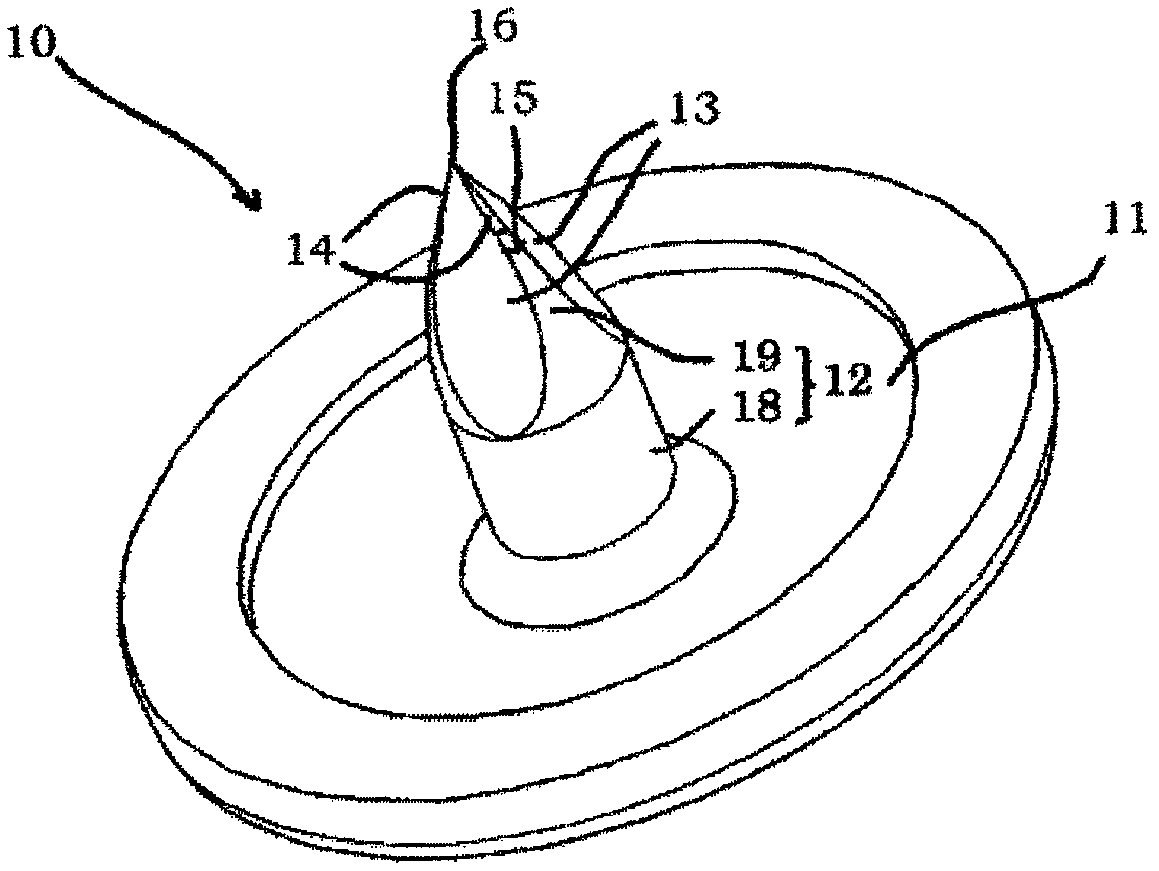

Press-fit terminal, connector and press-fit connector continuous body employing same, and wound press-fit connector continuous body

ActiveCN104011940AAvoid damageReduce distanceContact member manufacturingSecuring/insulating coupling contact membersMechanical engineeringEngineering

Provided are a press-fit terminal and a connector whereby damage to the substrate and breakage of contacts can be minimized, and consistent insertion force and retaining force can be attained. The press-fit terminal (10) comprises a wire material (11) of predetermined length. At a first end of wire material (11) is formed a distal end part (12) for insertion into a substrate, and at the other end is formed a connecting part (13) for connection to a corresponding terminal. A press-fit part (14) for pressure fitting into the substrate is formed at the distal end part (12) side of the wire material (11), and a shoulder part (16) is formed to the connecting part (13) side from the press-fit part (14).

Owner:JST MFG CO LTD

Button mounting member

A button mounting member (10) is equipped with a base (11, 71) and a columnar post (12, 52, 62, 72) formed to stand upright on the surface of the base (11, 71). The columnar post (12, 52, 62, 72) is equipped with a post barrel part (18, 58, 68, 78) extending from the surface of the base (11, 71) and a triangular cone-shaped post top part (19, 59, 69, 79) extending from the post barrel part (18, 58, 68, 78). The post top part (19, 59, 69, 79) is provided with three first inclined surfaces (13, 53, 63, 73) that form the three side surfaces of the triangular cone, and second inclined surfaces (14, 54, 64, 74) that are inclined toward the tip and are formed on ridge parts (15, 55, 65, 75) between the adjacent first inclined surfaces (13, 53, 63, 73).

Owner:YKK CORP

Vehicle rear portion structure

InactiveUS7758108B2Improve support rigidityImprove rigidityVehicle seatsSuperstructure subunitsShock absorber

A vehicle rear portion structure including: a pair of rear frames that extend substantially in a vehicle longitudinal direction; a rear cross member that extends in a vehicle width direction and that connects both of the two rear frames; a pair of rear wheel houses that are provided with damper supporting portions; a parcel frame that extends along the vehicle width direction above the rear wheel houses; and a pair of reinforcing frames that connect both end portions of the rear cross member and both end portions of the parcel frame, wherein the reinforcing frames are placed along a side wall of respective the rear wheel houses, the side wall being adjacent to respective the damper supporting portions, and a toroidal skeleton frame is formed with the parcel frame, the reinforcing frames, and the rear cross member so as to follow a plurality of rear suspension mounting points.

Owner:HONDA MOTOR CO LTD

Vitreous silica crucible

ActiveUS20120132133A1Improved strengthSuppress bucklingPolycrystalline material growthBy pulling from meltCrucibleSingle crystal

The present invention provides a vitreous silica crucible which can suppress buckling and sidewall lowering of the crucible without fear of mixing of impurities into silicon melt. According to the present invention, provided is a vitreous silica crucible for pulling a silicon single crystal, wherein a ratio I2 / I1 is 0.67 to 1.17, where I1 and I2 are area intensities of the peaks at 492 cm−1 and 606 cm−1, respectively, in Raman spectrum of vitreous silica of the region having a thickness of 2 mm from an outer surface to an inner surface of a wall of the crucible.

Owner:SUMCO CORP

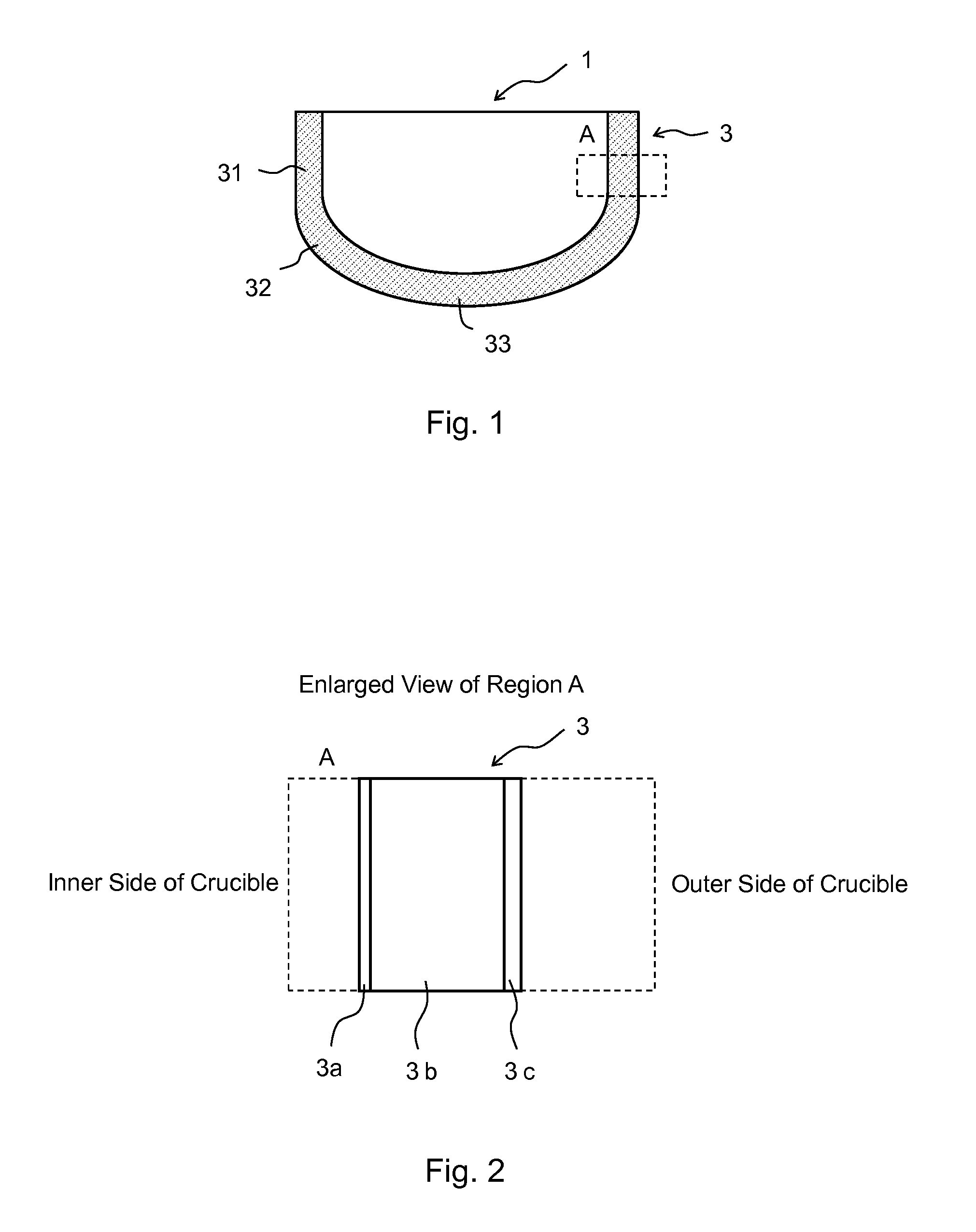

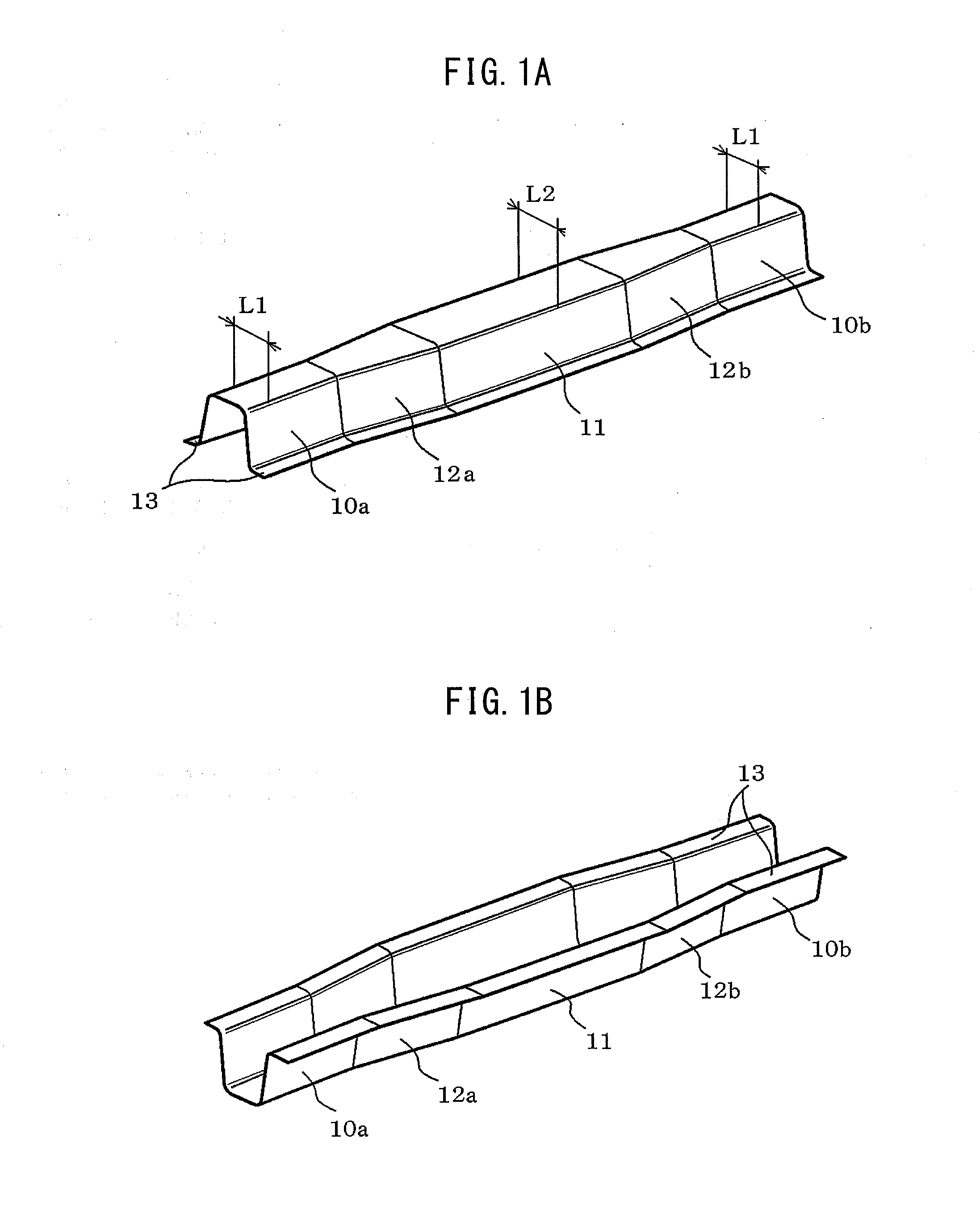

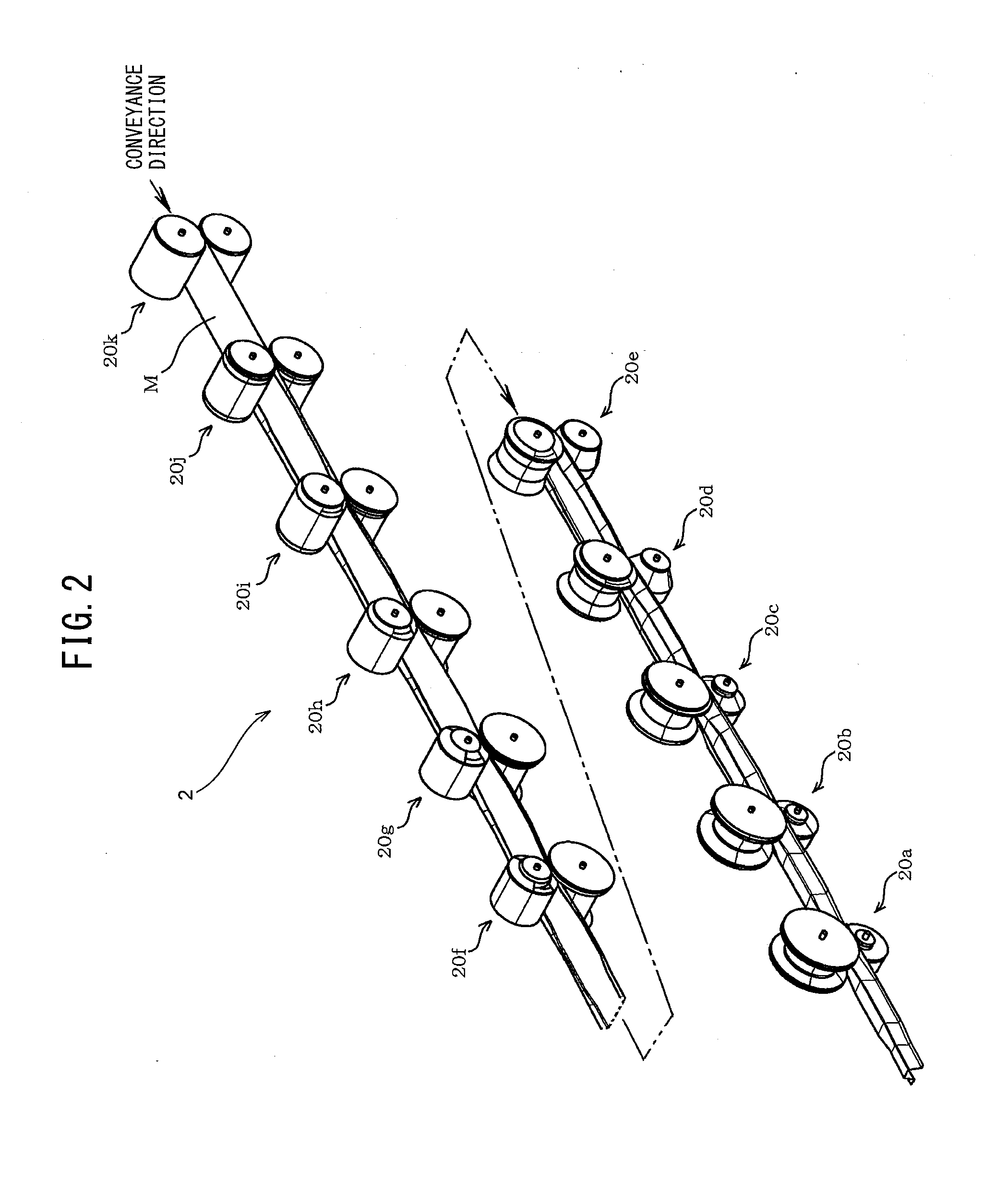

Method of producing shaped steel changing in cross-sectional shape in longitudinal direction and roll forming apparatus for same

A roll forming apparatus for roll forming for producing from a sheet material a shaped steel which varies in cross-sectional shape in a longitudinal direction comprises a first rolling die which has an annular ridge part which varies in cross-sectional shape in a circumferential direction; a second rolling die which has an annular groove part which varies in cross-sectional shape in a circumferential direction; and a drive device for the first rolling die and the second rolling die. At least transition parts of the side surfaces of the annular ridge part of the first rolling die are provided with relief so that the gap with respect to the side surfaces of the annular groove part of the second rolling die becomes broader inward in the radial direction.

Owner:PEKING UNIV FOUNDER GRP CO LTD +3

Rotational connector device

InactiveUS20130014975A1Prevent bucklingLight weightCable arrangements between relatively-moving partsInsulated cablesParallel plateMechanical engineering

A spacer arranged in an annular space between a rotor and a stator for supporting a roller reversing a winding direction of a flat cable is made of plastic having high lubricating properties. First guide portions on an annular plate portion are spaced by equal intervals from each other. The first guide portion includes an inner guide rib having a semicircle cross section projecting inward, an outer guide rib having a semicircle cross section projecting outward, and a tension wall connecting the inner guide rib and the outer guide rib. A second guide portion is provided between the first guide portions, and includes three parallel plate ribs extending from an inner peripheral side to an outer peripheral side of the annular plate portion, and circumferential connecting walls connecting the three parallel plate ribs.

Owner:VALEO JAPAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com