Pneumatic radial tire for use on passenger car

A technology for radial tires and passenger cars, applied in the reinforcement layers of pneumatic tires, tire parts, vehicle parts, etc., to achieve the effect of expanding the actual interval, improving durability, and reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

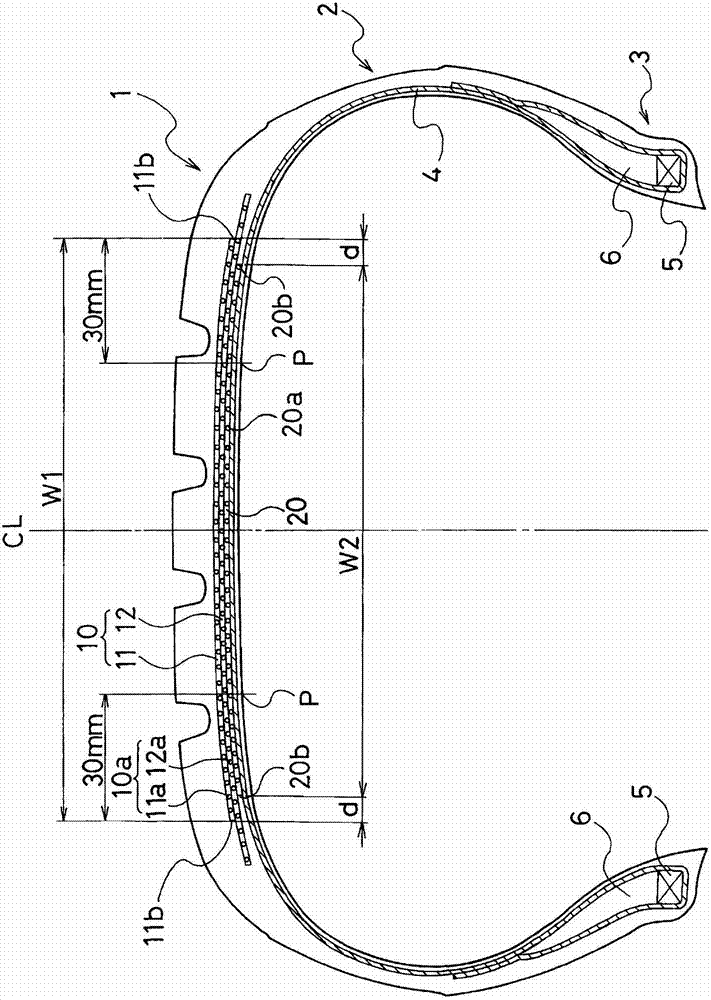

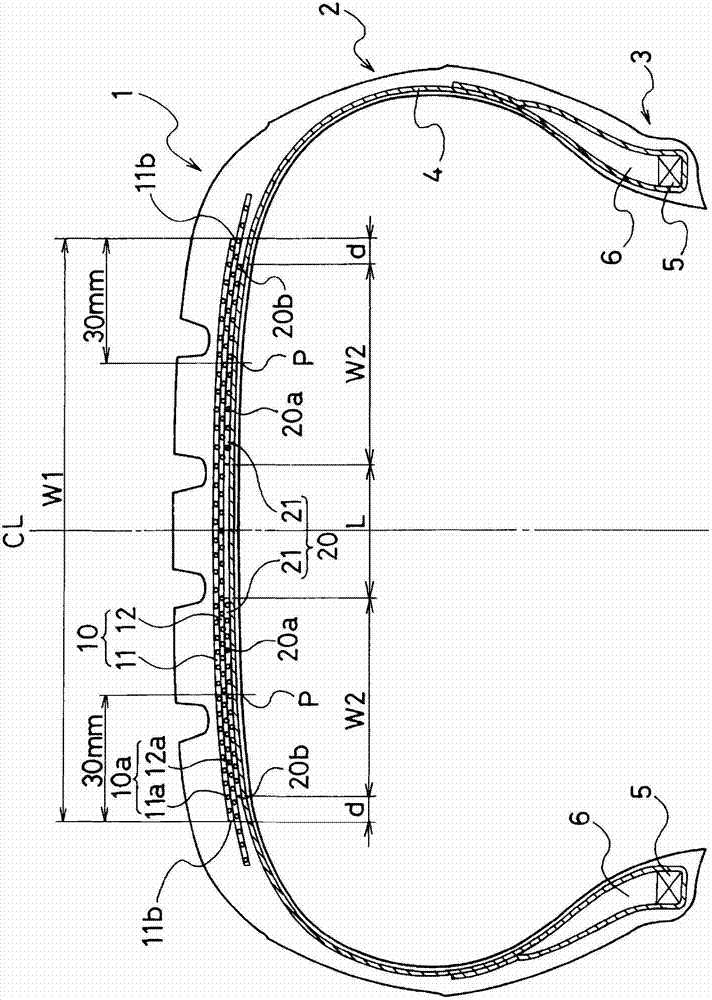

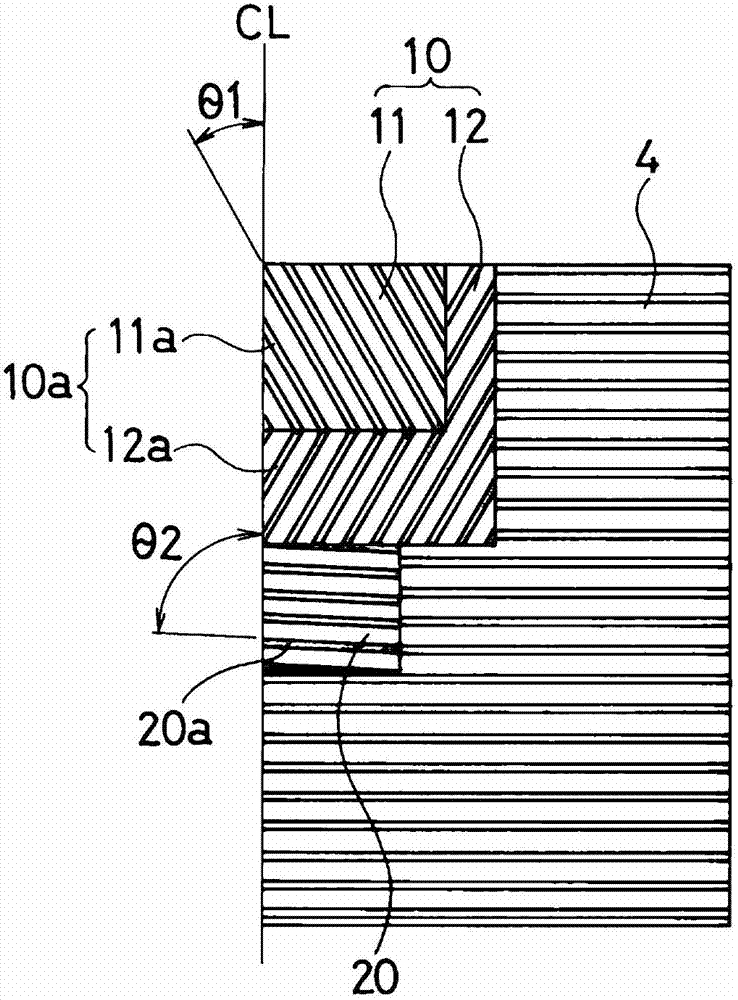

[0053] In a pneumatic tire with a tire size of 195 / 65R15, in terms of the belt layer, the number of layers of the belt layer, the arrangement of the belt cords, the structure, the strength, the amount of embedding, the number of embedding wires, and the diameter, in 20 The dynamic elastic modulus E' at ℃ and the setting of tanδ at 60℃ are shown in Tables 1 to 3, respectively. In terms of the belt auxiliary layer, the presence or absence of the belt auxiliary layer, the arrangement, and the belt auxiliary cord The structure, angle, arrangement form of the belt auxiliary layer, layer width, whether it overlaps with the position P, and the setting of the embedded number of belt auxiliary layer cords are shown in Tables 1 to 3, and thus manufactured Conventional Examples 1-2, Comparative Examples 1-4, and Examples 1-18 total 22 kinds of test tires.

[0054] Here, Conventional Examples 1 and 2 are tires without a belt auxiliary layer, the belt layer of Conventional Example 1 is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com