Conveyor and manufacture method thereof

A manufacturing method and conveyor technology, which is applied in the field of conveyors, can solve problems such as difficulty in forming, achieve the effect of suppressing torsion, and improve the effect of suppressing torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

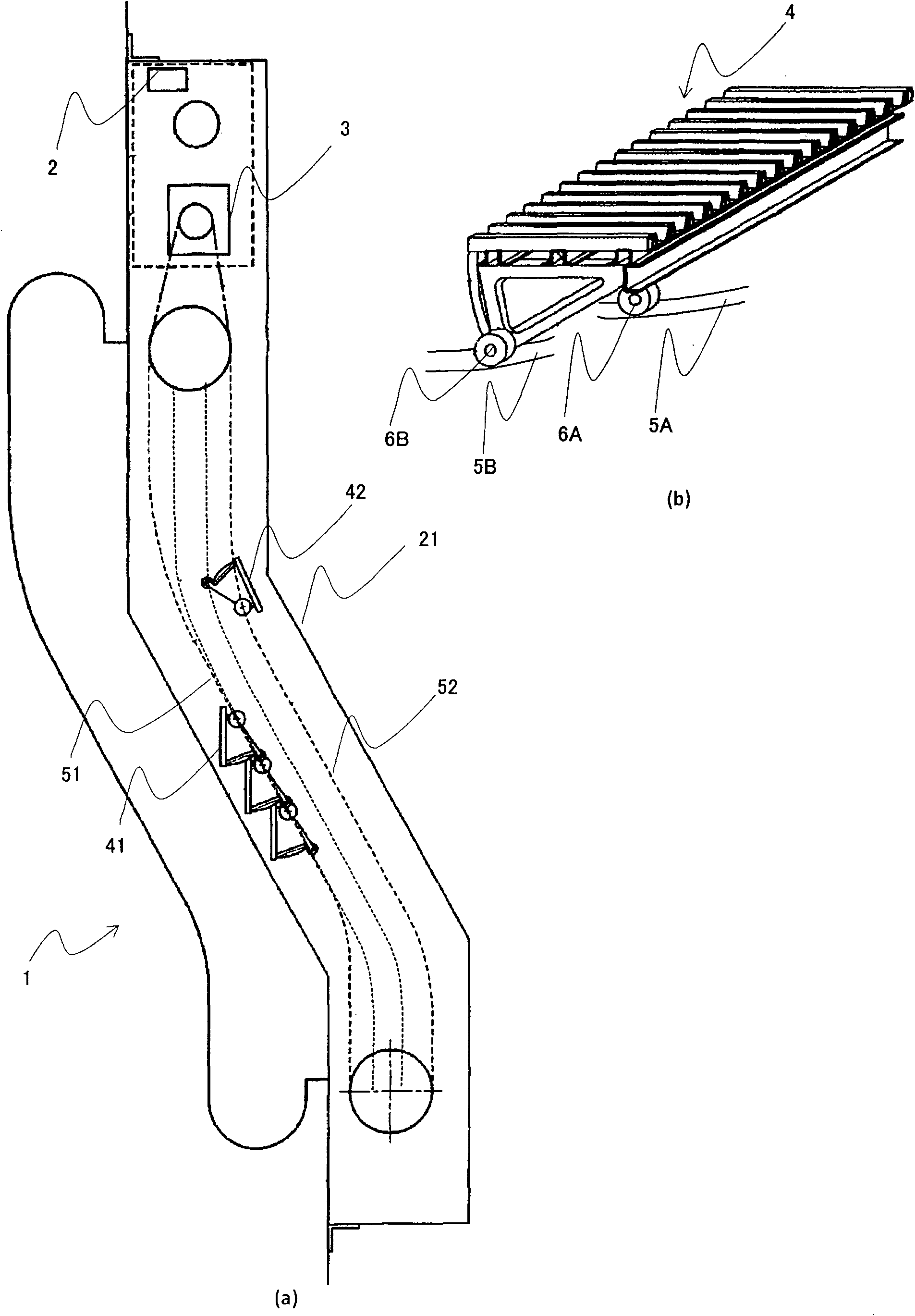

[0051] Hereinafter, the embodiment of the conveyor of this invention and its manufacturing method is demonstrated in detail based on drawing. figure 1 The structure of the usual escalator 1 is shown. exist figure 1 Among them, (a) is a diagram showing the overall structure, and (b) is an enlarged diagram of a part of (a), that is, a staircase.

[0052] exist figure 1 Among them, as shown in (a), along the escalator 1, there is a large framework called a frame 21 supporting the structure of the escalator 1. When using the electric power supplied from the control panel 2 to drive the motor (not shown), then by The drive gear 3 rotated by the motor pulls the steps 4 to make the steps 4 run on the step running track 5 . The stair running track 5 is arranged circularly along the escalator 1 , so the steps 4 circulate because they run on the stair running track 5 . The structure of the ladder running track 5 includes: the outbound side track 51 on which the stairs 41 on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com