Patents

Literature

75results about How to "Improve torsional performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

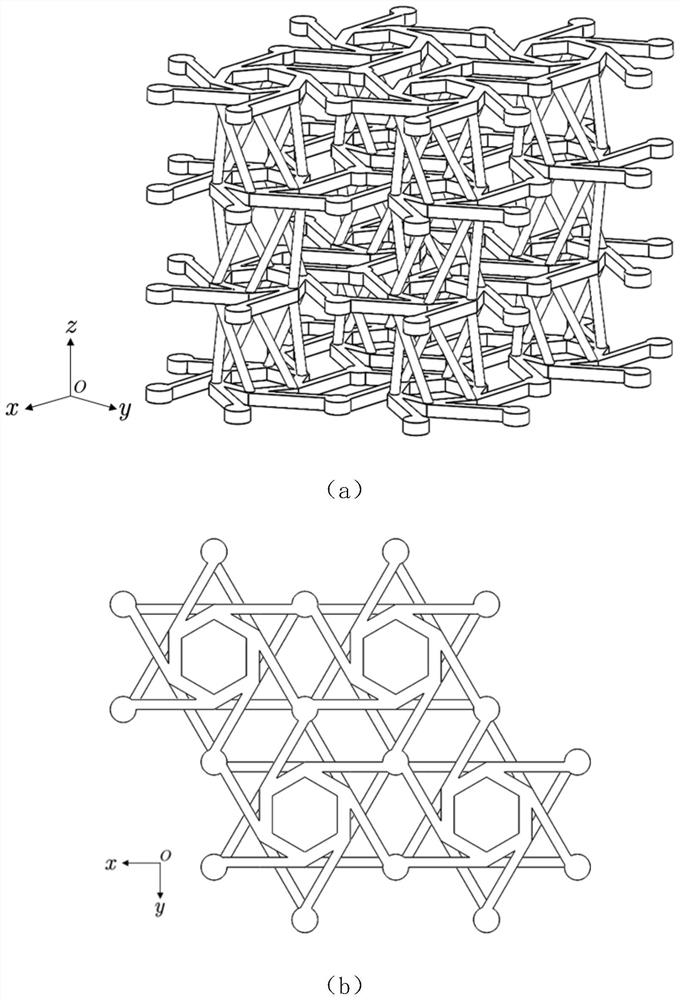

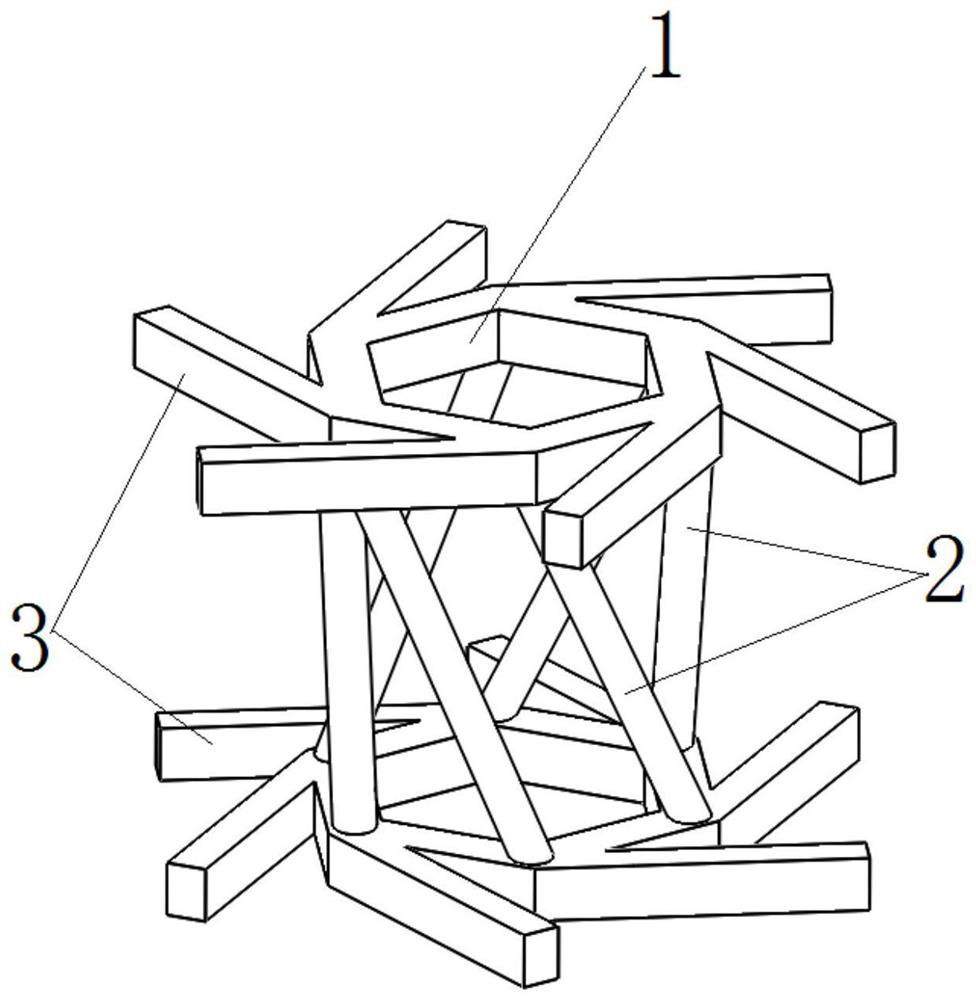

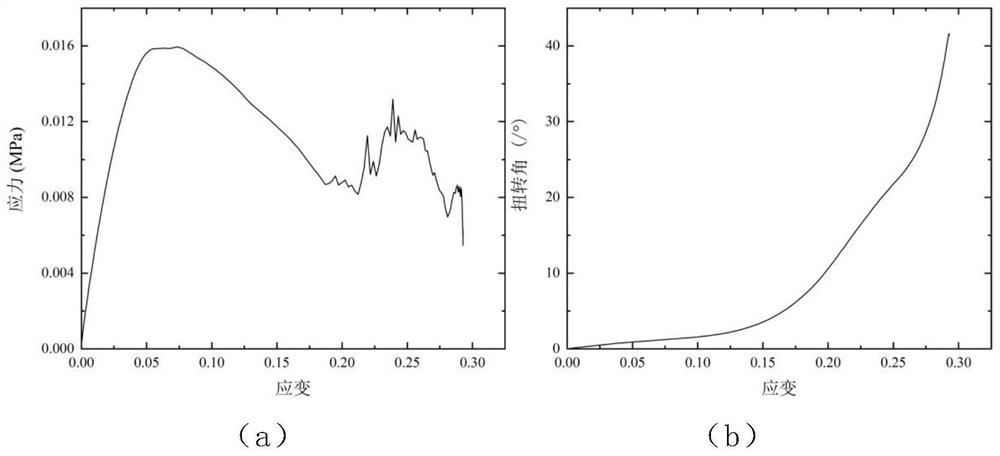

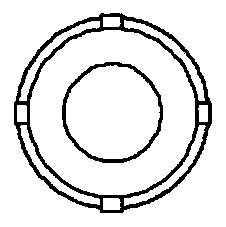

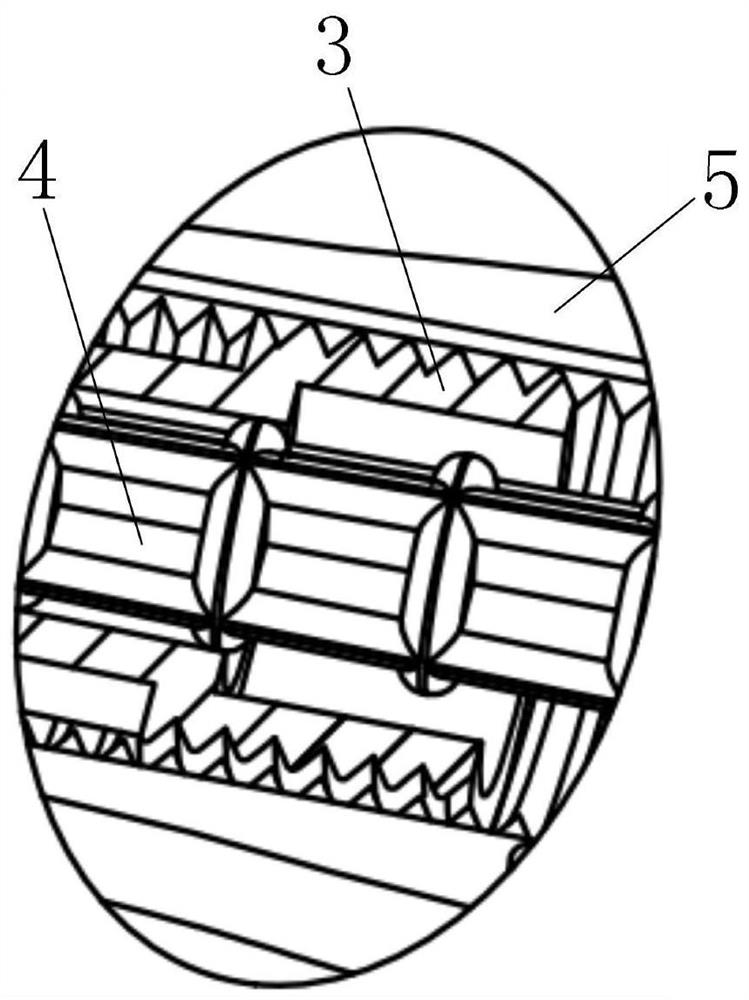

Chiral auxetic metamaterial structure with tension-torsion coupling characteristics and preparation method thereof

ActiveCN112049886AWith tension torsion coupling characteristicsImprove carrying capacityAdditive manufacturing apparatusIncreasing energy efficiencyStructural engineeringMechanical engineering

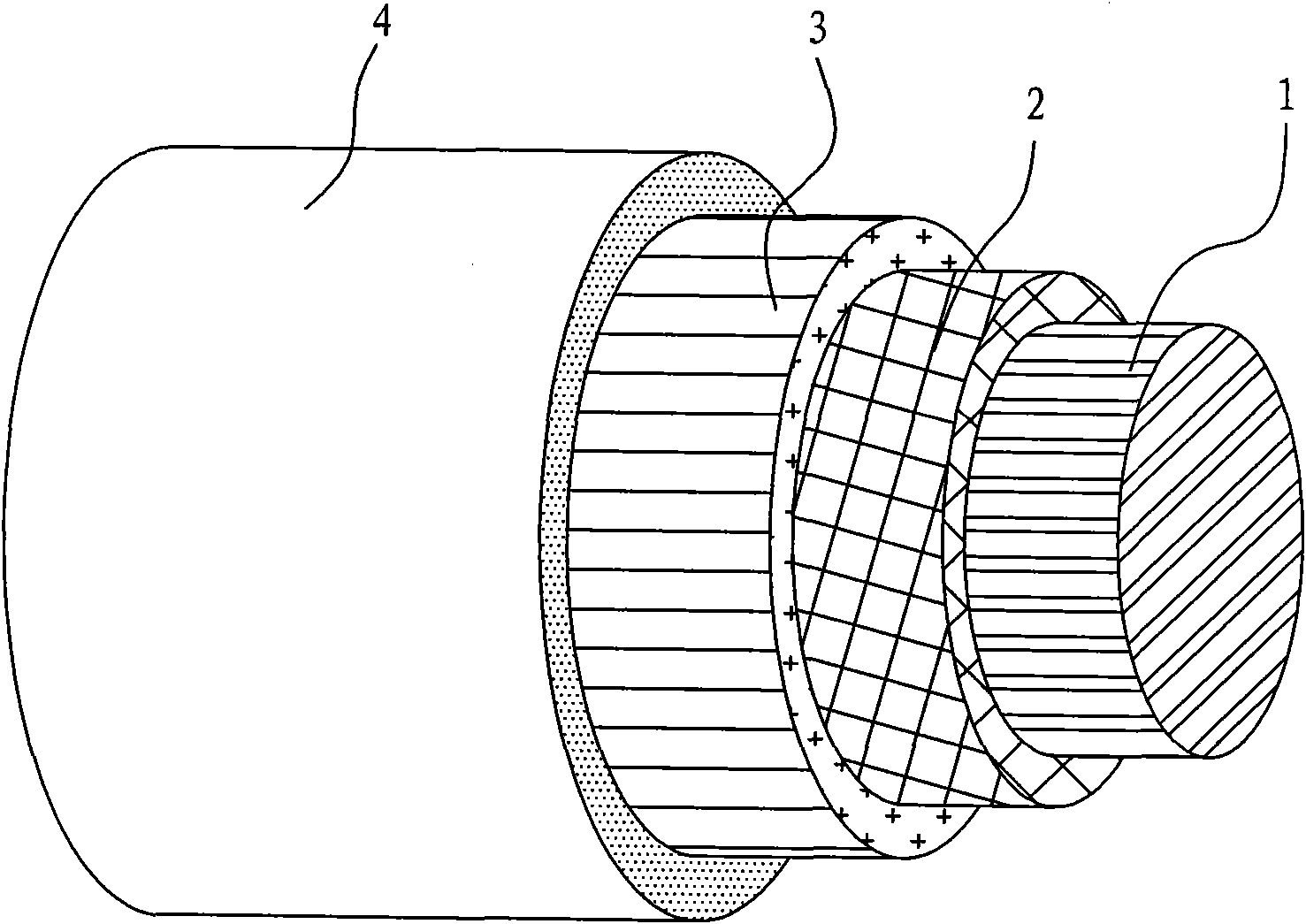

The invention discloses a chiral auxetic metamaterial structure with tension-torsion coupling characteristics and a preparation method thereof. The chiral auxetic metamaterial structure comprises a plurality of three-dimensional unit cell structures, each three-dimensional unit cell structure comprises two polygonal annular structures arranged up and down, and the vertexes of the upper and lower polygonal annular structures are connected through correspondingly-arranged inclined cylinders; a plurality of inclined cylinders are arranged in a staggered mode in the same direction, connecting rodsused for being connected with the adjacent three-dimensional unit cell structures are arranged at the vertexes of the two polygonal annular structures respectively, the plurality of three-dimensionalunit cell structures are arranged in a spatial array mode, and the chiral auxetic metamaterial structure with the tension-torsion coupling characteristics is formed by connecting the corresponding connecting rods.

Owner:XI AN JIAOTONG UNIV +1

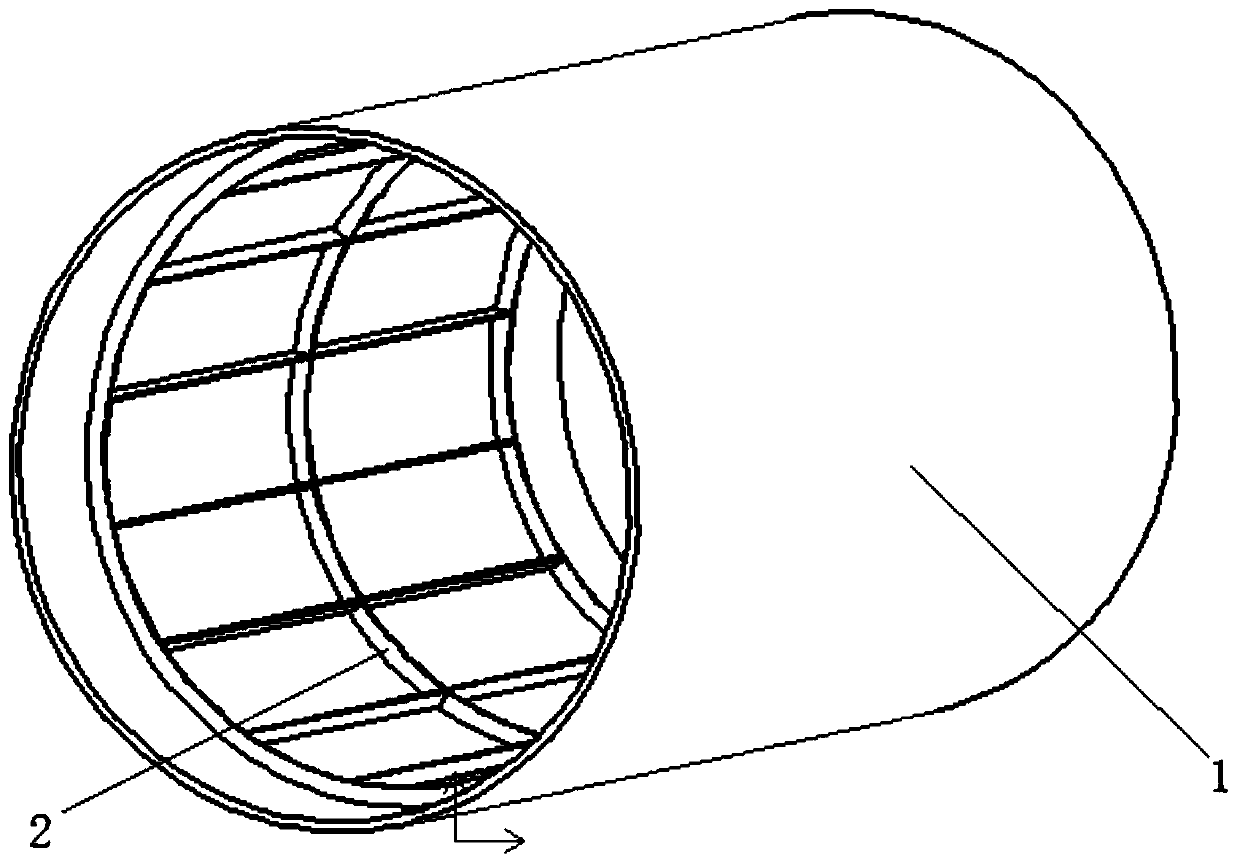

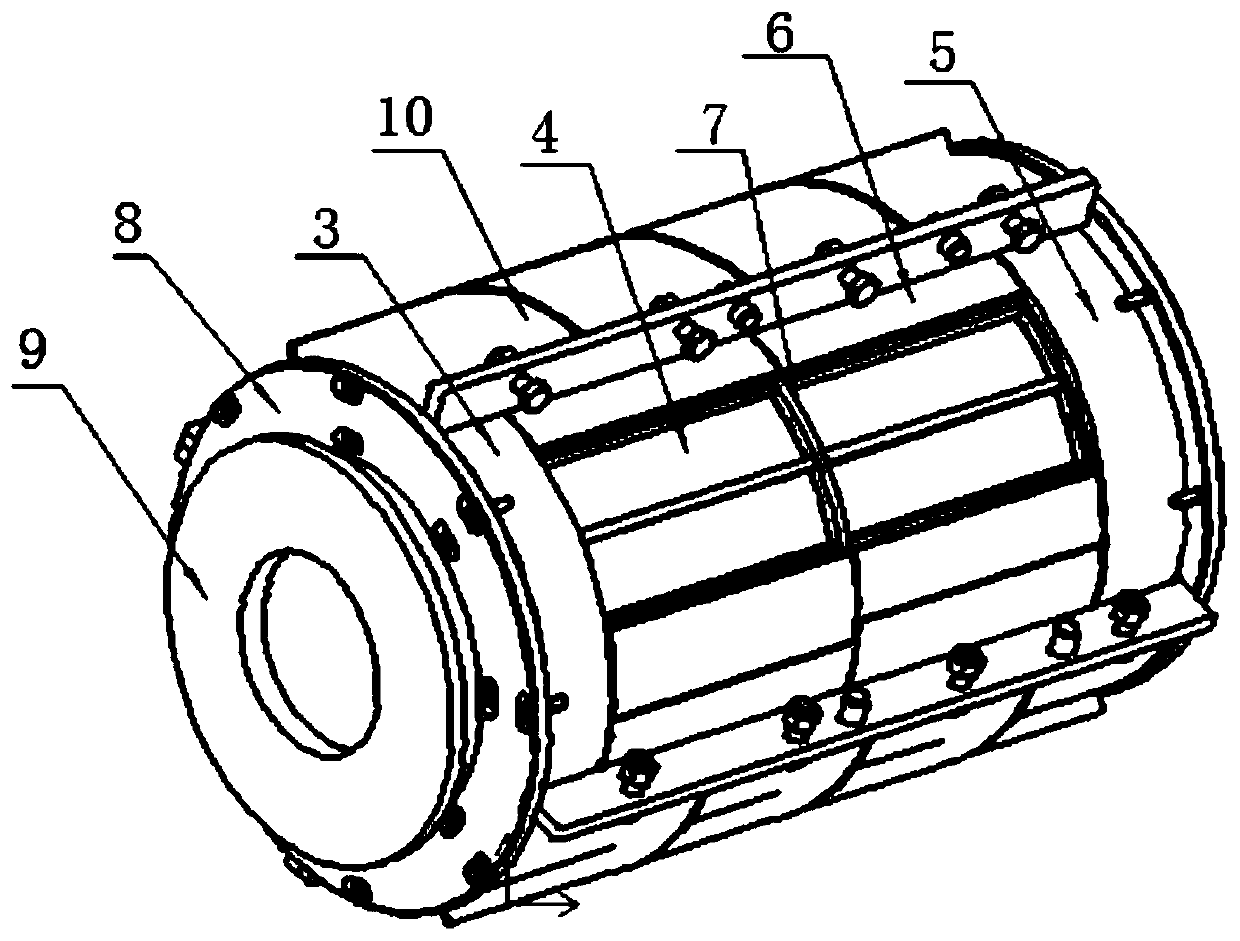

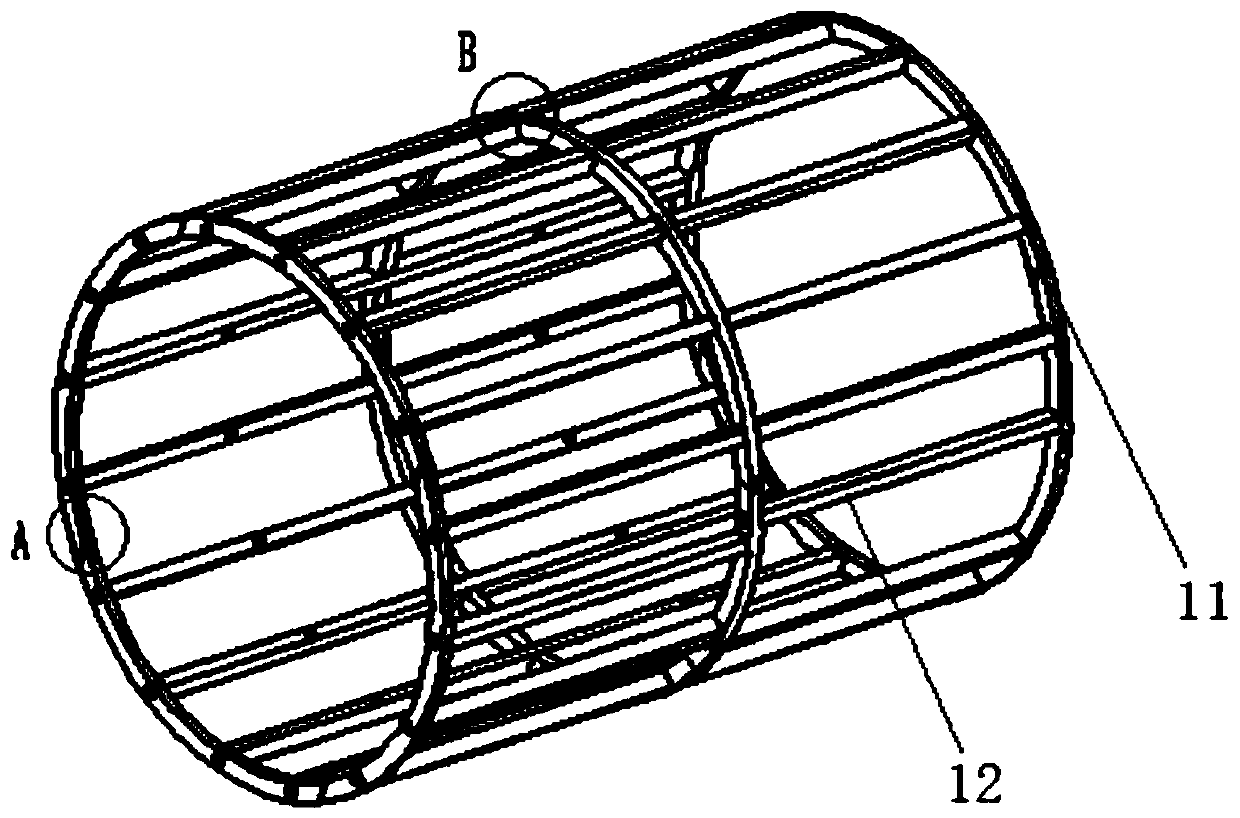

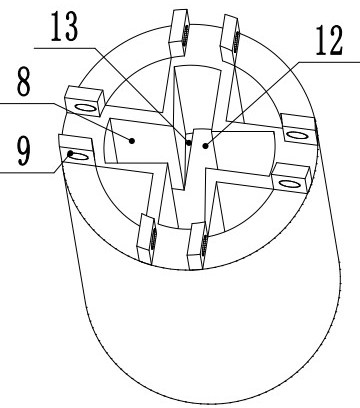

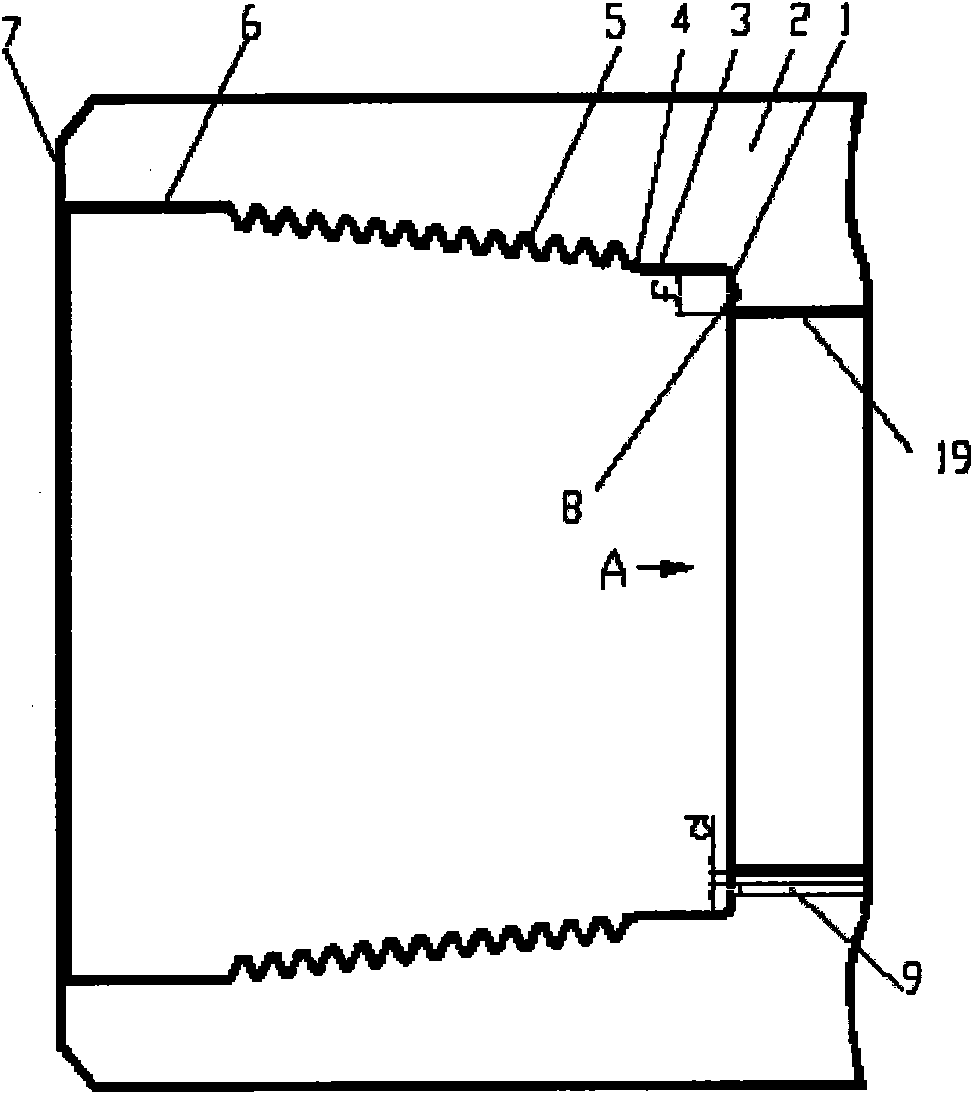

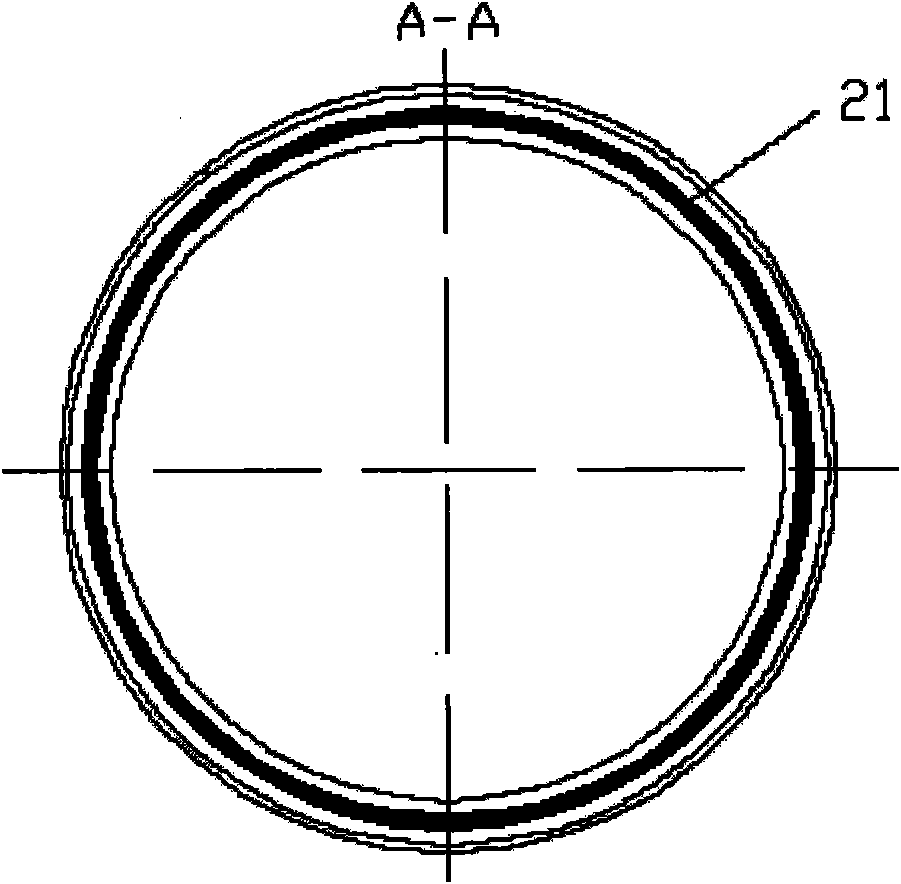

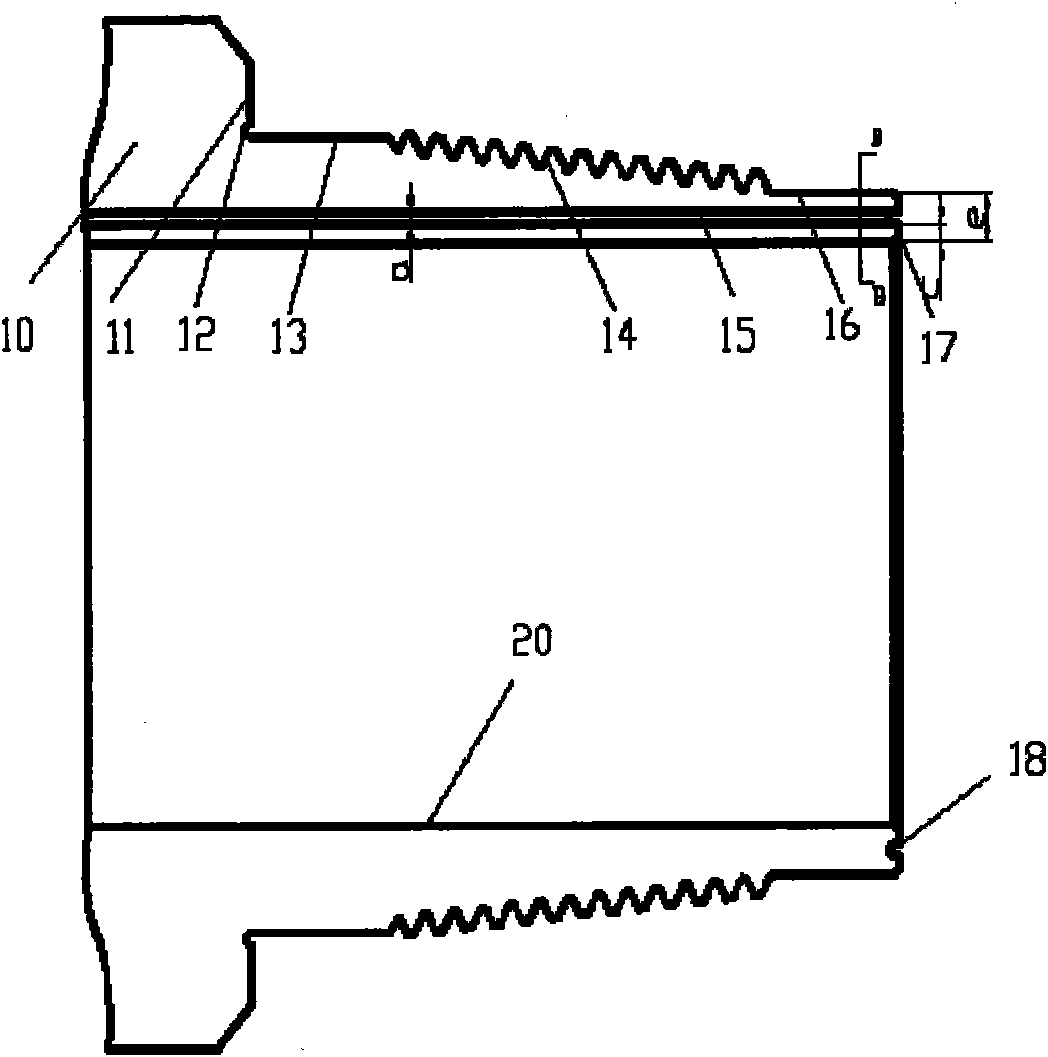

Mold for integral molding and manufacturing of carbon fiber grid bearing cylinder and molding method

InactiveCN110948903ASolve the problem of reduced torsional performanceIncrease productivityFiberCarbon fibers

The invention provides a mold for integral molding and manufacturing of a carbon fiber grid bearing cylinder and a forming method. The molding mold comprises a metal molding mold body and a silicon rubber core mold body, wherein the metal molding mold boby comprises a first core mold, a second core mold, a third core mold, a fixed support, a split outer mold, cover plates and stripper plates, thesecond core mold is arranged inside the fixed support, the first core mold and the third core mold are arranged on the two sides of the fixed support, the cover plates are arranged on the two sides ofthe first core mold and the two sides of the third core mold, the stripper plates are arranged on the outer sides of the cover plates, the silicon rubber core mold is arranged on the fixed support and is located on the outer side of the second core mold, and the split outer mold is arranged on the periphery of the fixed support, the periphery of the first core mold and the periphery of the thirdcore mold. According to the mold, the problem that a reinforcing rib built-in bearing cylinder is complex in integral molding and large in stripping difficulty is solved. Compared with a post-gluing molding mode, a continuous fiber layer of the reinforcing ribs and a cylinder body is reserved to the greatest extent, so that the torsion performance is improved, and the risk caused by the quality defects of the gluing surface is avoided.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

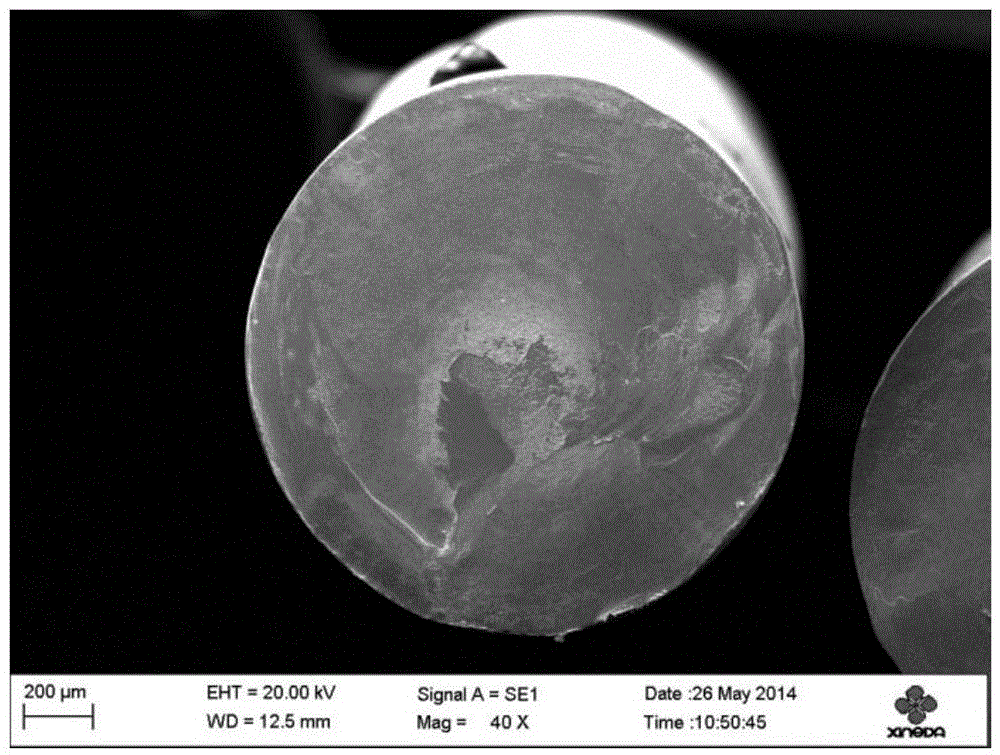

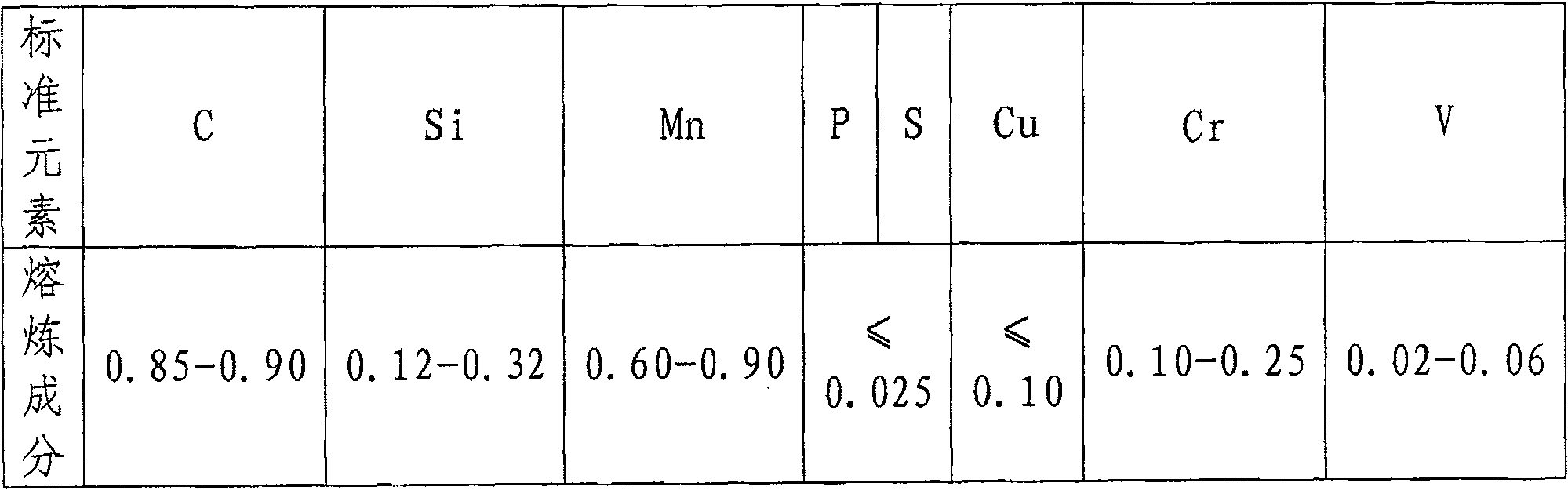

Method for preparing phi7.0mm1770MPa high-strength low-relaxation zinc-coated wire

ActiveCN101085454AHigh strengthImprove torsional performanceDrawing diesFurnace typesHigh intensityCurrent technology

The Phi 7.0mm1770MPa zinc plated steel wire is made through coiling inspection, surface preparation, wiredrawing, hot galvanizing, stable treatment and inspection. It adds a radius limit mold for steel wire surface friction, smoothening, limiting of the wire diameter, preventing the wire deformation, proceeding low temperature tempering and surface smoothening treatment, with the generation of zinc plated steel wire having high strength, low looseness, higher flexible and ductility and high torque feature, effectively getting over the difficulty of current technology being unable to cover the high strength low looseness, producing wire conforming to technical index.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

Ultrahigh strength steel wire dip-coated with Zn-Al-Mg-Si alloy coating, preparation method thereof and application thereof

InactiveCN105331918AHigh strengthImprove toughnessHot-dipping/immersion processesHigh intensityAlloy coating

The invention relates to an ultrahigh strength coating steel wire dip-coated with a Zn-Al-Mg-Si alloy coating, a preparation method thereof and an application thereof. The alloy coating consists of the following components in percentage by mass: 30-97% of Zn, 5-80% of Al, 0.02-11% of Mg, and 0.05-5.0% of Si, based on 100% in total. The preparation method comprises the following steps: inspecting performances of an original coil rod; carrying out surface treatment; carrying out wire drawing; preparing a hot dipping Zn-Al-Mg-Si alloy coating; and carrying out stabilization treatment. The ultrahigh strength coating steel wire with the Zn-Al-Mg-Si alloy coating provided by the invention has corrosion resistance and mechanical performance superior to those of a current high-strength zinc-coated steel wire; the preparation method is easy to implement, meets needs of special environments such as a marine corrosion environment and the like on a bridge steel wire, and has a wide market prospect.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

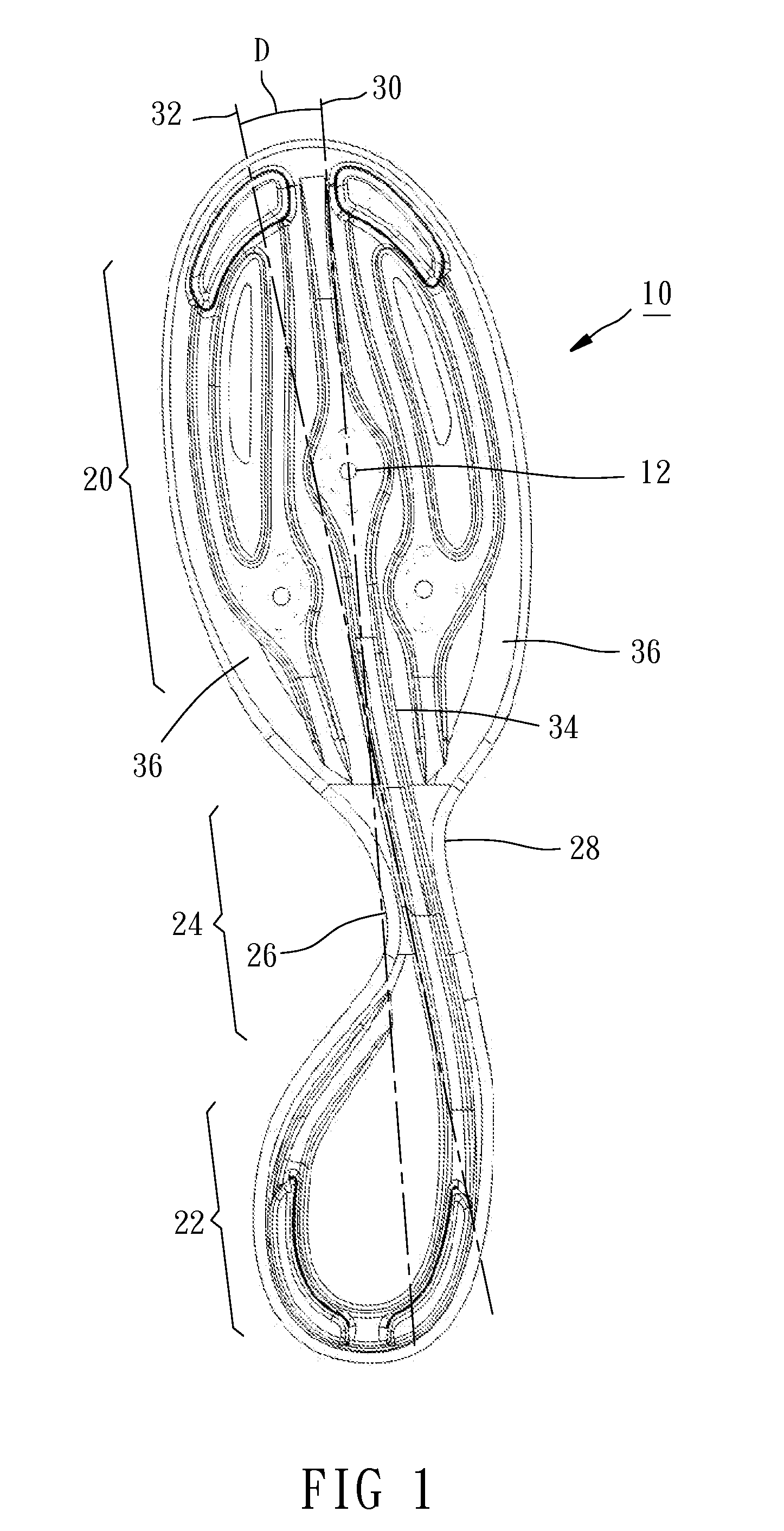

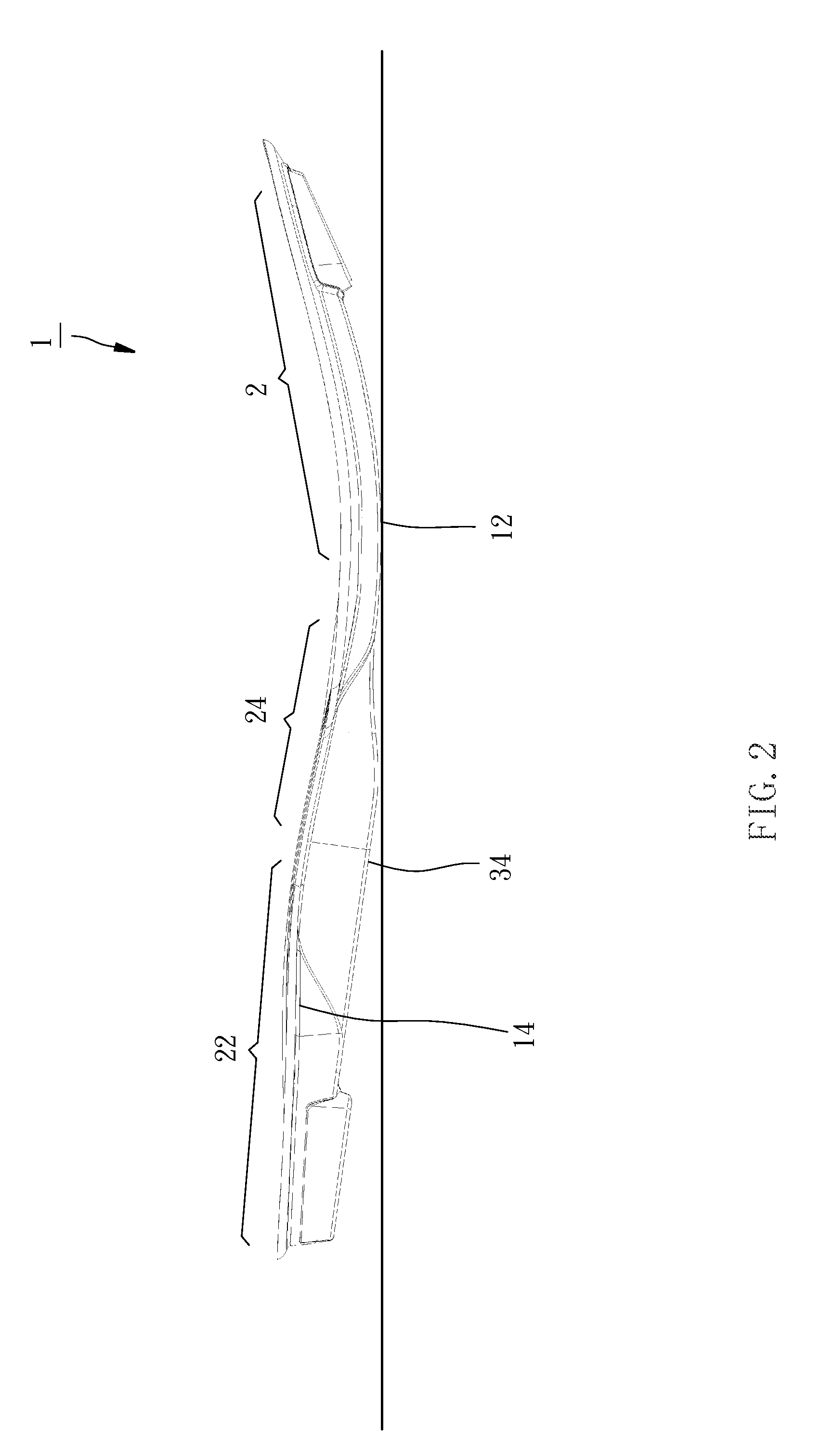

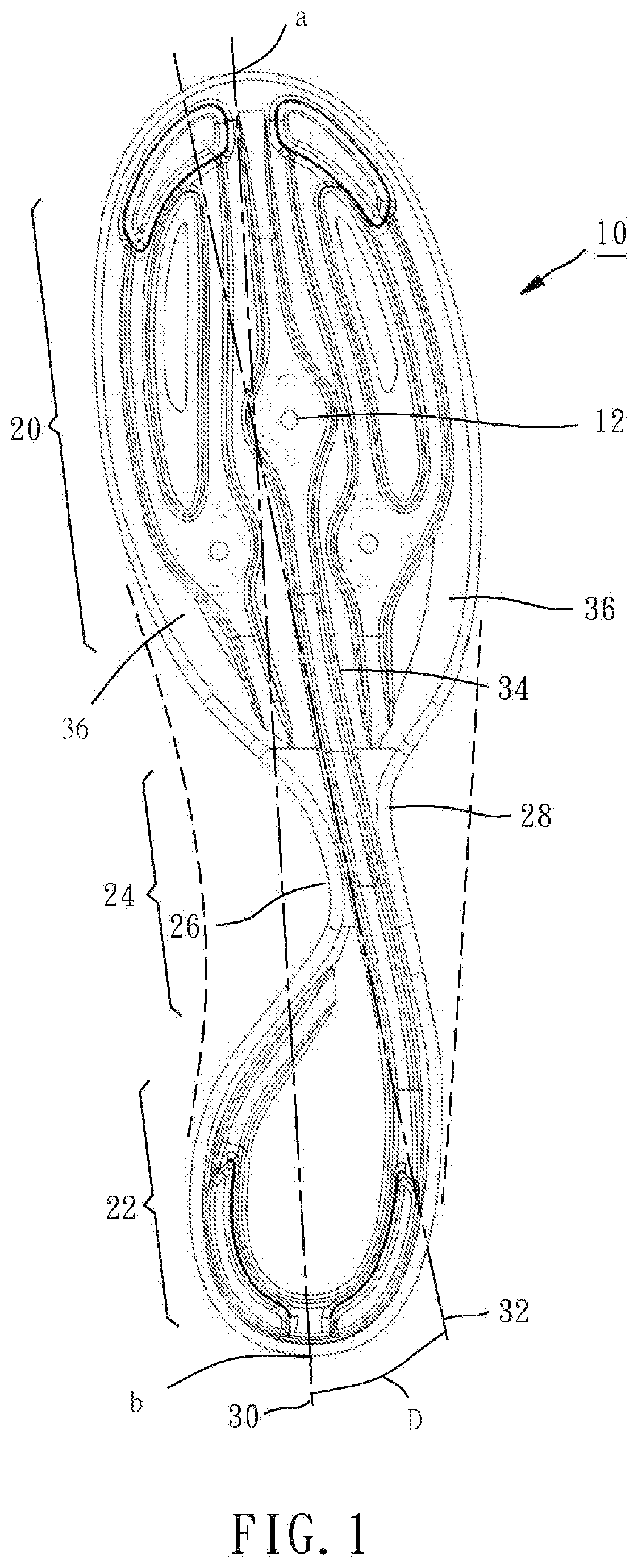

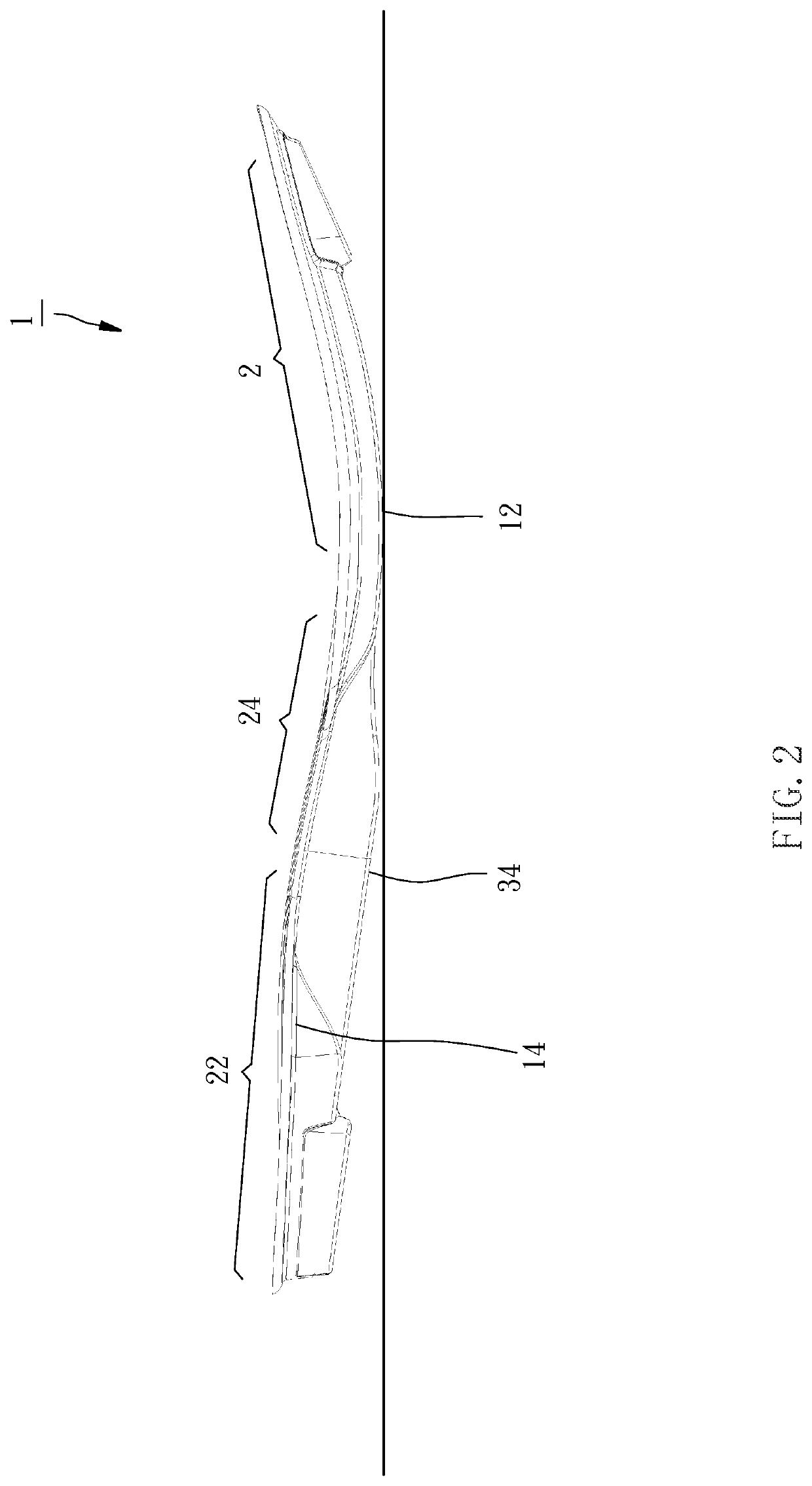

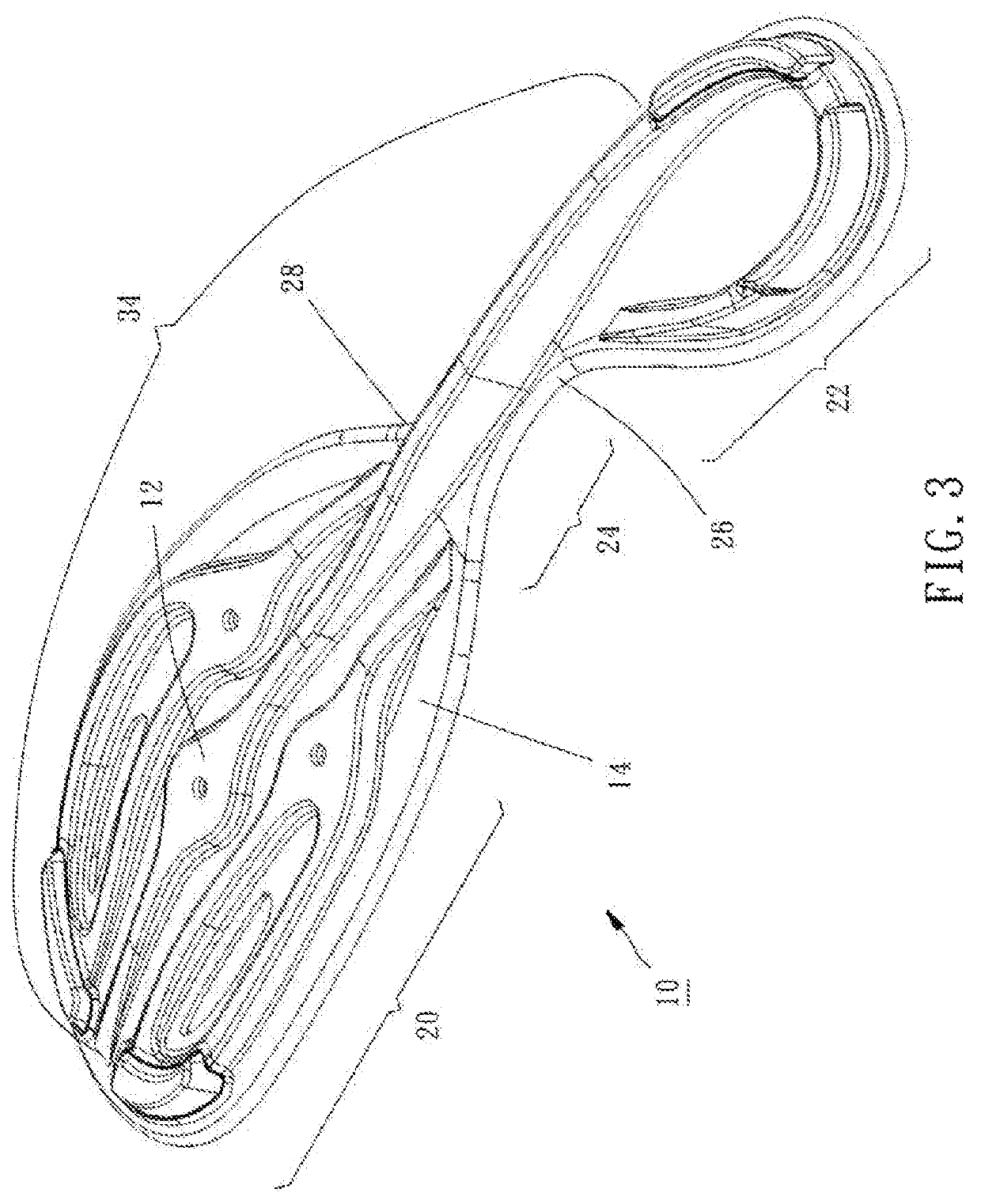

Sole for cycling shoe

A sole for cycling shoe includes a forefoot section, a heel section and an arch section connected between the forefoot section and the heel section, a longitudinal axis and a tilting axis defined between the forefoot section and the heel section, a deviation angle defined between the tilting axis and the longitudinal axis, a middle part extending through the forefoot section, the arch section and the heel section, and two side wing portions defined at two opposite sides relative to the middle part. The rigidity of the middle part is higher than the two side wing portions. The middle part extends in the arch section along the tilting axis. Based on the above-described technical features, the overall structure of the sole has sufficient rigidity with enhanced torsionability on the rear end thereof, making the cycling shoe more comfort.

Owner:GIANT MFG

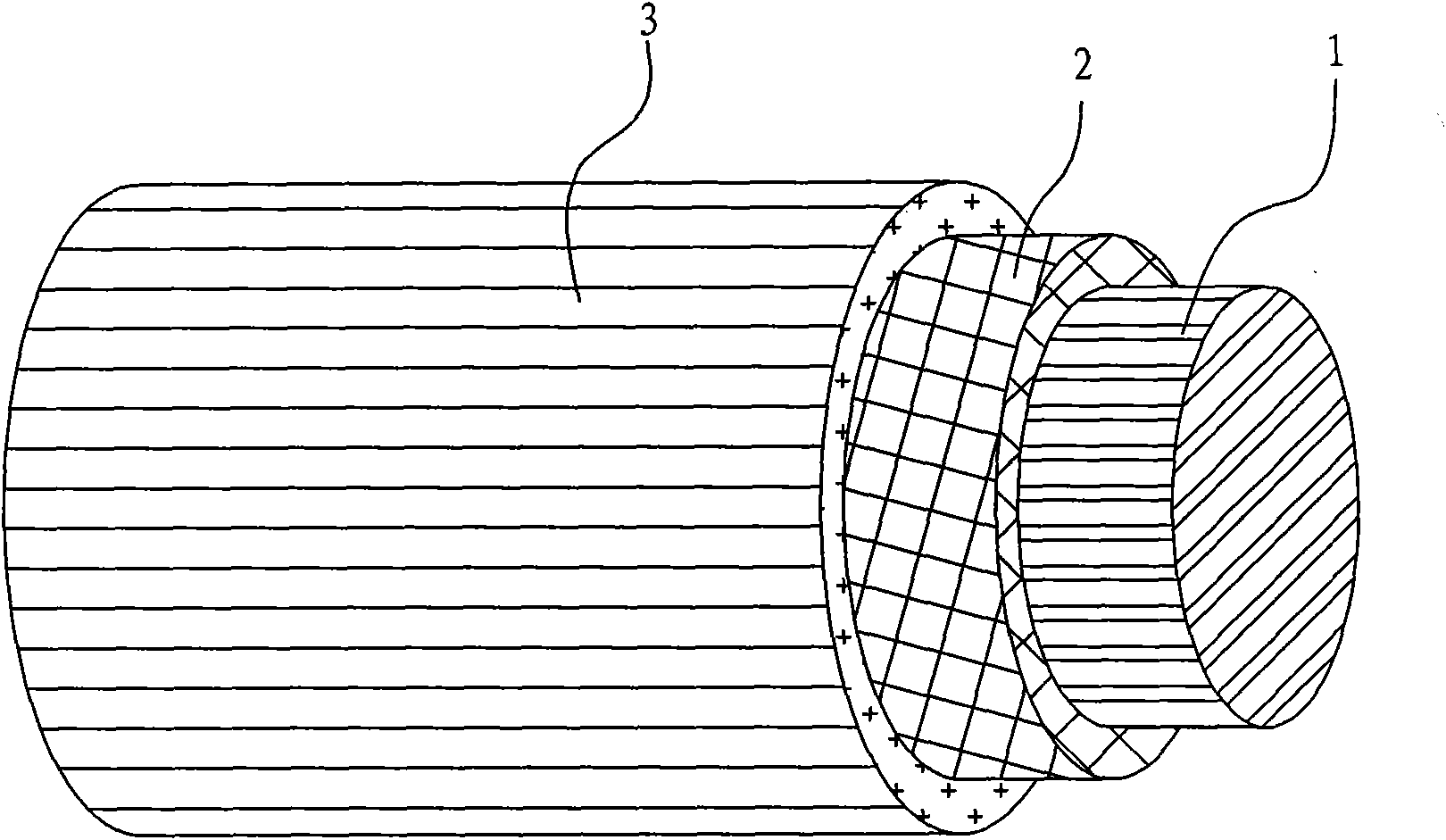

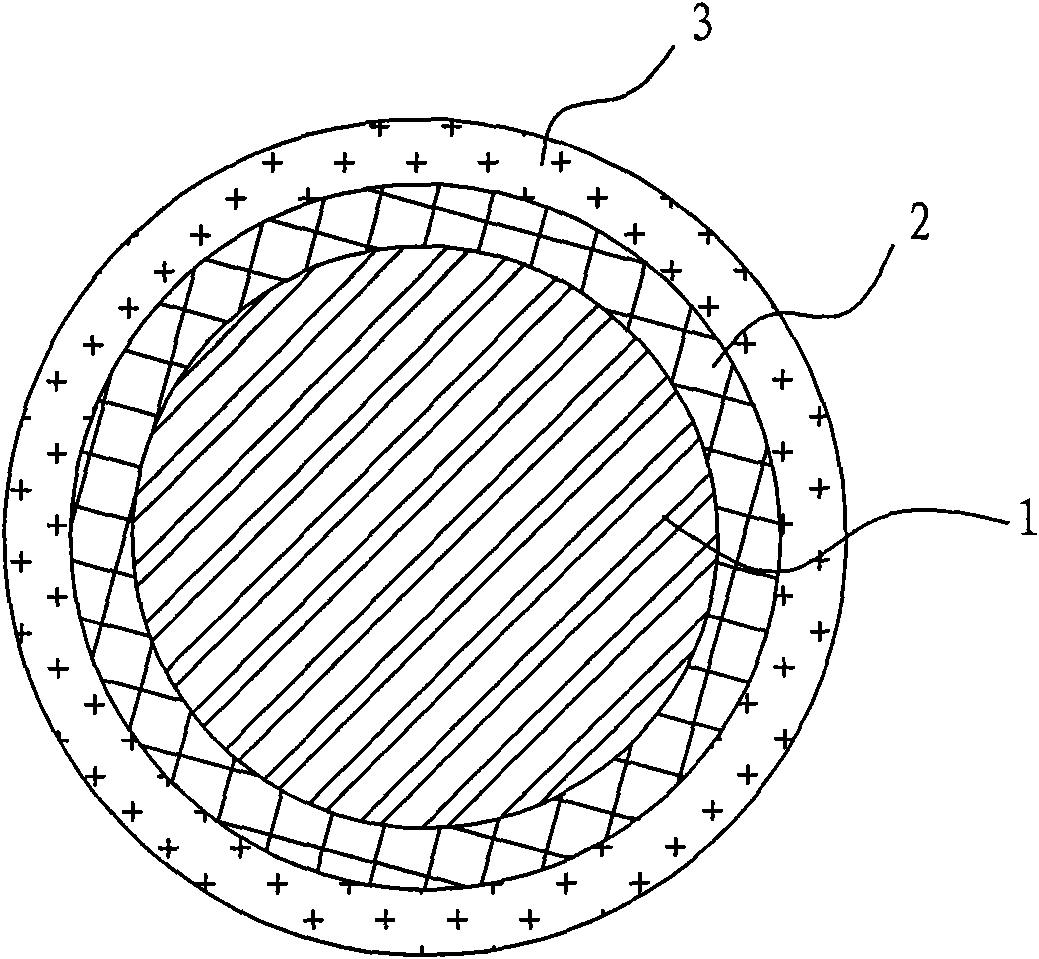

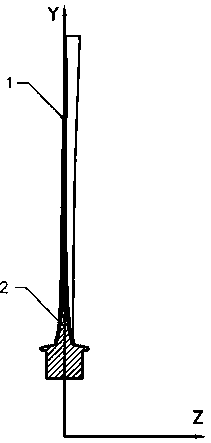

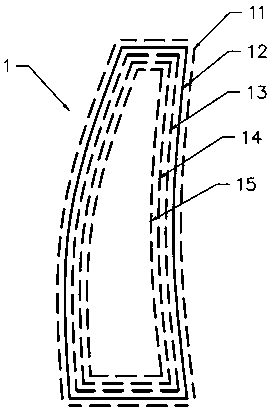

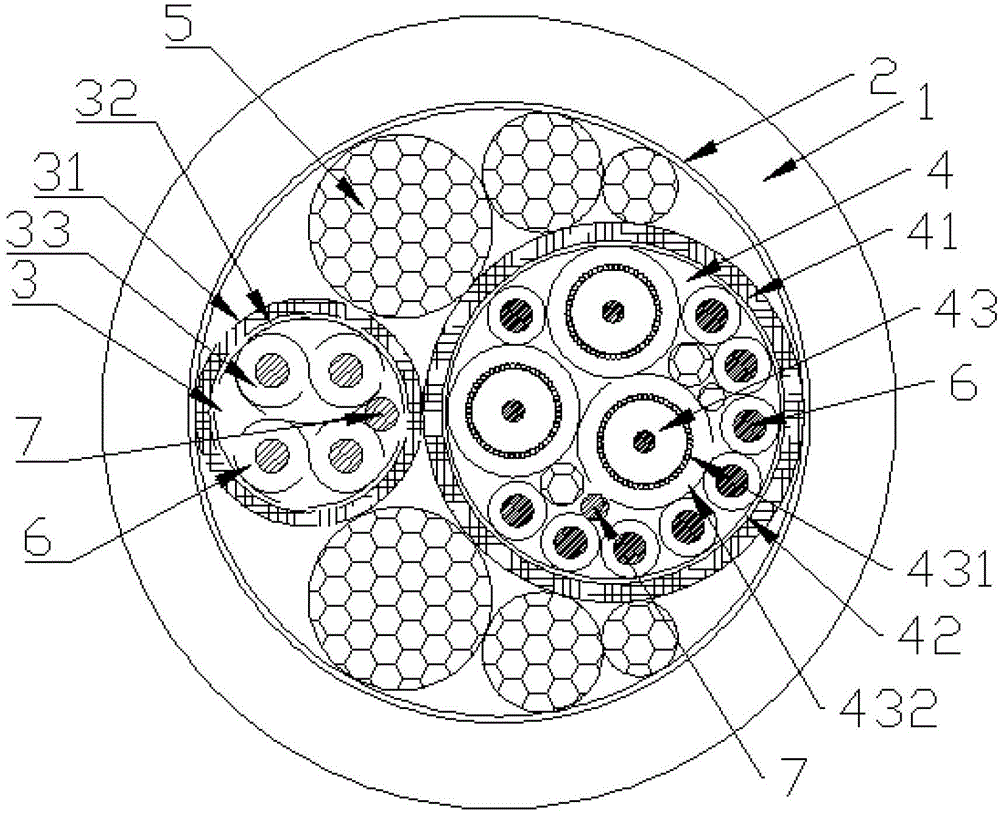

Composite core used for reinforced cable and reinforced cable

InactiveCN102110491AExtended syncNot easy to fall offNon-insulated conductorsInsulated cablesOptoelectronicsFiber

The invention relates to a composite core used for a reinforced cable. The composite core comprises an inner core, a structural layer and an outer layer, wherein the inner core comprises fibers and thermosetting resins; the structural layer comprises a fiber sleeving and the thermosetting resins; the fiber sleeving is formed by braiding a plurality of fibers or spirally winding the fibers along the axial direction of the inner core; and the outer layer comprises fibers arranged along the length direction of the composite core and the thermosetting resins. The composite core provided by the invention has the following beneficial effects: the outer layer is added outside the structural layer and the continuous fibers arranged along the length direction of the composite core are added to theouter layer; and the added outer layer wholly covers the structural layer 2 and provides protection to the fiber sleeving in the structural layer 2, under the condition that the composite core is subjected to great tension, the stretch and extension rates of the outer layer 3 and the inner core 1 are basically the same and the extension quantities of the outer layer 3 and the inner core 1 are synchronous, and the structural layer is tightly squeezed by the inner core and the outer layer so that the structural layer in the middle is not easy to drop or separate, thus effectively overcoming thedefect that the composite core adopts the fiber sleeving structure.

Owner:JIANGSU JIATAI TECH MATERIAL

Designing and manufacturing method of composite blade and composite blade

The invention provides a designing and manufacturing method of a composite blade. Pre-forming sheets are paved on the two sides of a metal framework, and the composite blade of a sandwich structure isformed after curing compounding of curing equipment. Through the manner of manufacturing the composite blade through a composite of the pre-forming sheets, the manufacturing process can be simplified, cost can be reduced, and good integrity and bonding strength are achieved. The invention further relates to the composite blade. The composite blade comprises the composite and the metal framework.The metal framework is pre-manufactured to be in a blade shape, the pre-forming sheets formed by multiple layers of prepreg fiber cloth are paved outside the metal framework, through holes are formedin the metal framework, carbon fiber wiring harnesses used for fixing the metal framework and the pre-forming sheets on the two sides are wound in the through holes, and the composite blade is obtained through curing of the curing equipment. The composite blade has the advantage that the composite blade cannot be screwed or twisted or bent under the limiting condition, weather resistance is good,certain impact resistance is achieved, and the special requirements of aviation and ships can be met.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Novel computer embroidery thread processing method

ActiveCN103388247AHigh strengthEasy to bendFibre treatmentLiquid/gas/vapor yarns/filaments treatmentComputer architectureSoftware engineering

The invention relates to a novel computer embroidery thread processing method, which belongs to the technical field of textile processing. The processing method is characterized in that two long filament yarns unwound from a bobbin are exported by a bobbin creel, and the exported filament yarns enter a cladding device containing water-soluble polyurethane solution to be treated, then are treated by a drying device and finally are wound on the bobbin. The novel computer embroidery thread processing method has the beneficial effects that the surfaces of the two long filament yarns are tangent and are in a parallel arrangement state, a cladding layer is formed on the surfaces of the two long filament yarns, the strength of a computer embroidery thread is improved, the bending property and the torsional property are improved, a core thread is protected while the wear resistance of the computer embroidery thread is improved, and the method is suitable for high-speed embroidery, is convenient in operation and has a little influence on the operation of a knitter.

Owner:WUHAN TEXTILE UNIV

Production process of clad steel wire rod with steel core wire of dual phase structure

InactiveCN101992224AHigh strengthHigh elongationFurnace typesIncreasing energy efficiencyManganeseCopper

The invention relates to a production process of a clad steel wire rod with a steel core wire of a dual phase structure, which comprises the following steps: carrying out pretreatment on a copper belt and a steel core wire rod; cladding and wielding; drawing, wherein the steel core wire rod is made of low carbon steel the carbon content of which is less than or equal to 0.2%, or made of low carbon steel the contents of manganese and vanadium of which are respectively less than or equal to 0.2%, and less than or equal to 0.12%; carrying out double phase heat treatment on drawn wire rod, wherein the double phase heat treatment is carried out on the drawn wire rod, and enables the temperature of the drawn wire rod to be 740-950DEG C; and then rapidly cooling so as to enable the steel core wire rod to obtain the double phase structure of ferrite and martensite. The clad steel wire rod has high strengthen, tensile strength which can be 600-1000MPa, and good elongation percentage which can be over 15%, and when in pretreatment, the process has low production cost and high efficiency, is easy to operate and can produce the clad steel wire rod the diameter of which can be 6mm, and expand the using range of the wire rod.

Owner:大连通大设备技术开发有限公司

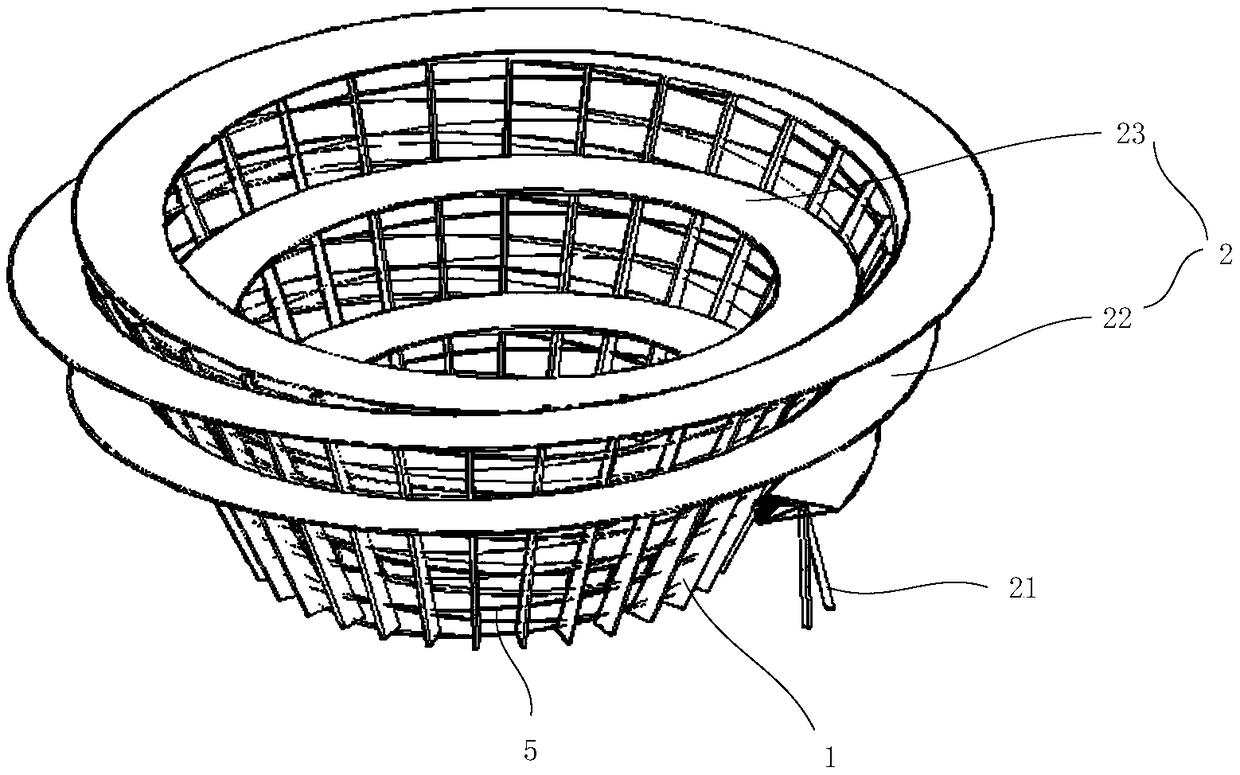

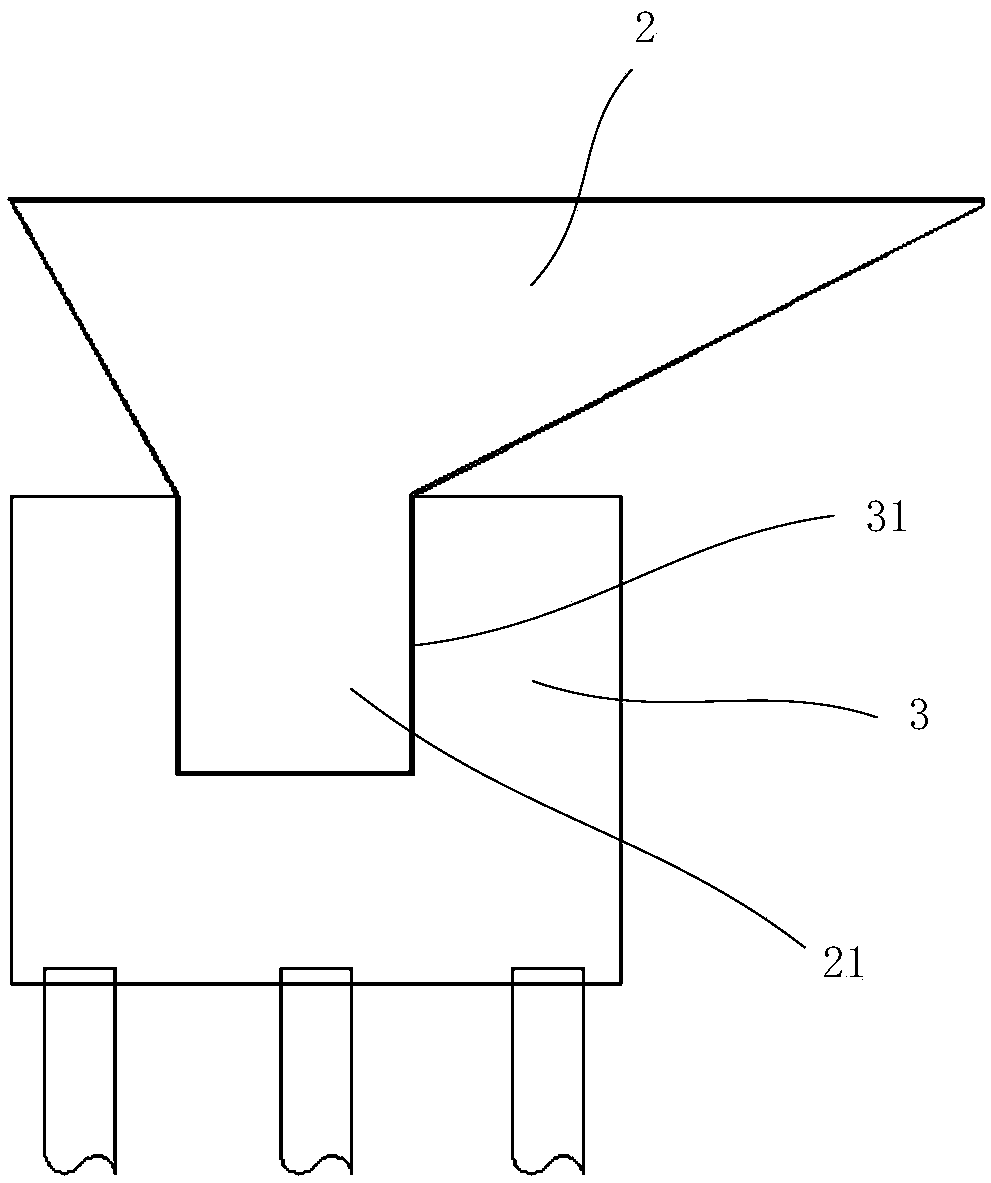

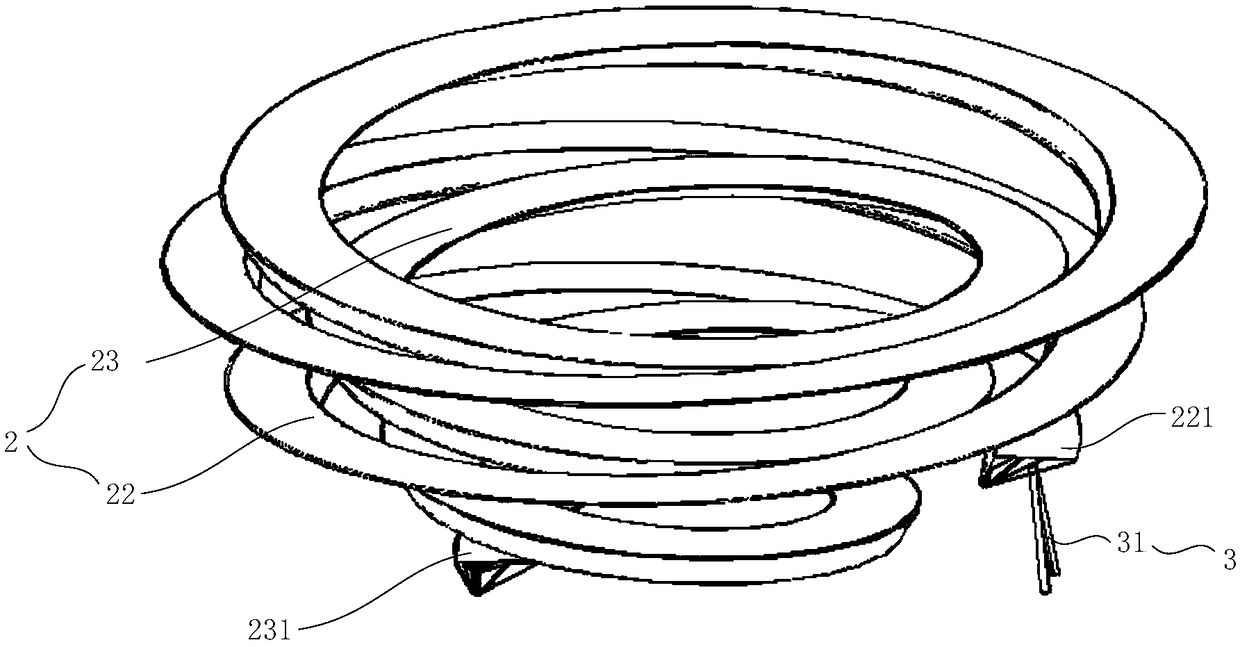

Inverted cone spiral building structure with high torsional resistance

PendingCN108824646AImprove torsional performanceImprove structural torsional performanceExtraordinary structuresRampsEngineeringCivil/structural engineers

The invention discloses an inverted cone spiral building structure with high torsional resistance, and relates to the technical field of structural engineering. According to the inverted cone spiral building structure, without affecting the appearance and expressiveness of a building, torsional resistance performance of the structure can be improved, and good economical efficiency is provided. Theinverted cone spiral building structure with high torsional resistance comprises a plurality of oblique columns which are arranged obliquely at a certain angle to a horizontal plane and are fixed onthe ground. The oblique columns are enclosed to form an inverted cone shape. A spiral annular path is arranged in the circumference direction of the oblique columns in a spiral mode, the spiral annular path is fixedly connected with the oblique columns, and the bottom end of the spiral annular path is fixed to the ground through a fixing member. The inverted cone spiral building structure with high torsional resistance is used for the construction of buildings.

Owner:CCDI INT SHENZHEN DESIGN CONSULTANTS

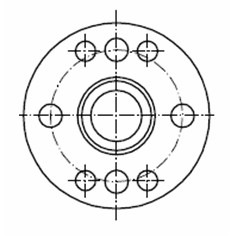

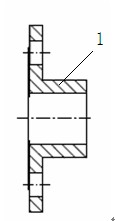

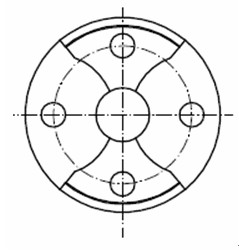

Manufacturing method for planetary support of electric power tool gear box

InactiveCN102003522AImprove torsional performanceHigh hardnessGearing detailsPower toolPowder metallurgy

The invention discloses a manufacturing method for a planetary support of an electric power tool gear box. The method comprises the following steps: respectively extruding to form an upper cover with a flange and a lower cover with a support section; respectively presintering the upper cover and the lower cover; then primarily jointing the upper cover and the lower cover by a locating pin; integrally welding through sintering; carrying out heat treatment and then releasing the locating pin; and using a specific jig to press a planetary gear and a functional pin. In the invention, the planetary support of the electric power tool gear box is decomposed into two independent powder metallurgy parts, and after being subject to extrusion forming, the two metallurgy parts are subject to welding assembly. As extrusion forming is carried out respectively, the density of each support leg part is up to 6.9-7.0g / cm<3>, the anti-torsion of products can be improved, and crackles on the root part of each support leg are avoided. Two major parts are respectively manufactured, thereby being more convenient for ensuring the accuracy of the products. In the invention, products with complex structures can be processed featuring low cost, high accuracy and high efficiency.

Owner:扬州保来得科技实业有限公司

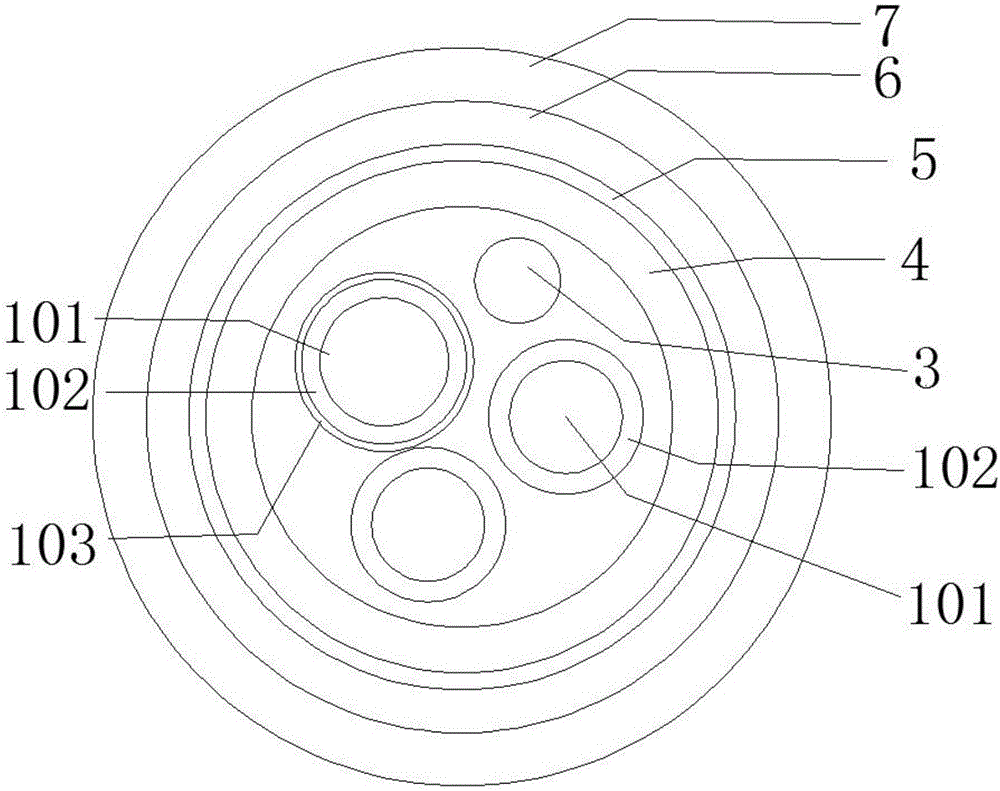

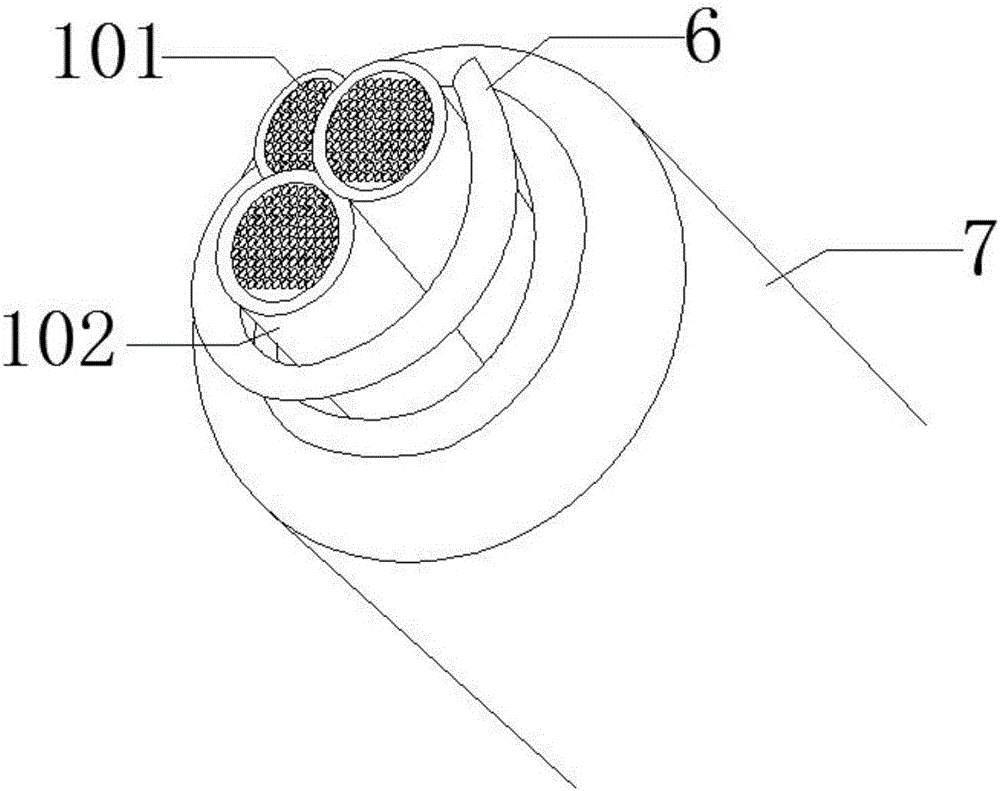

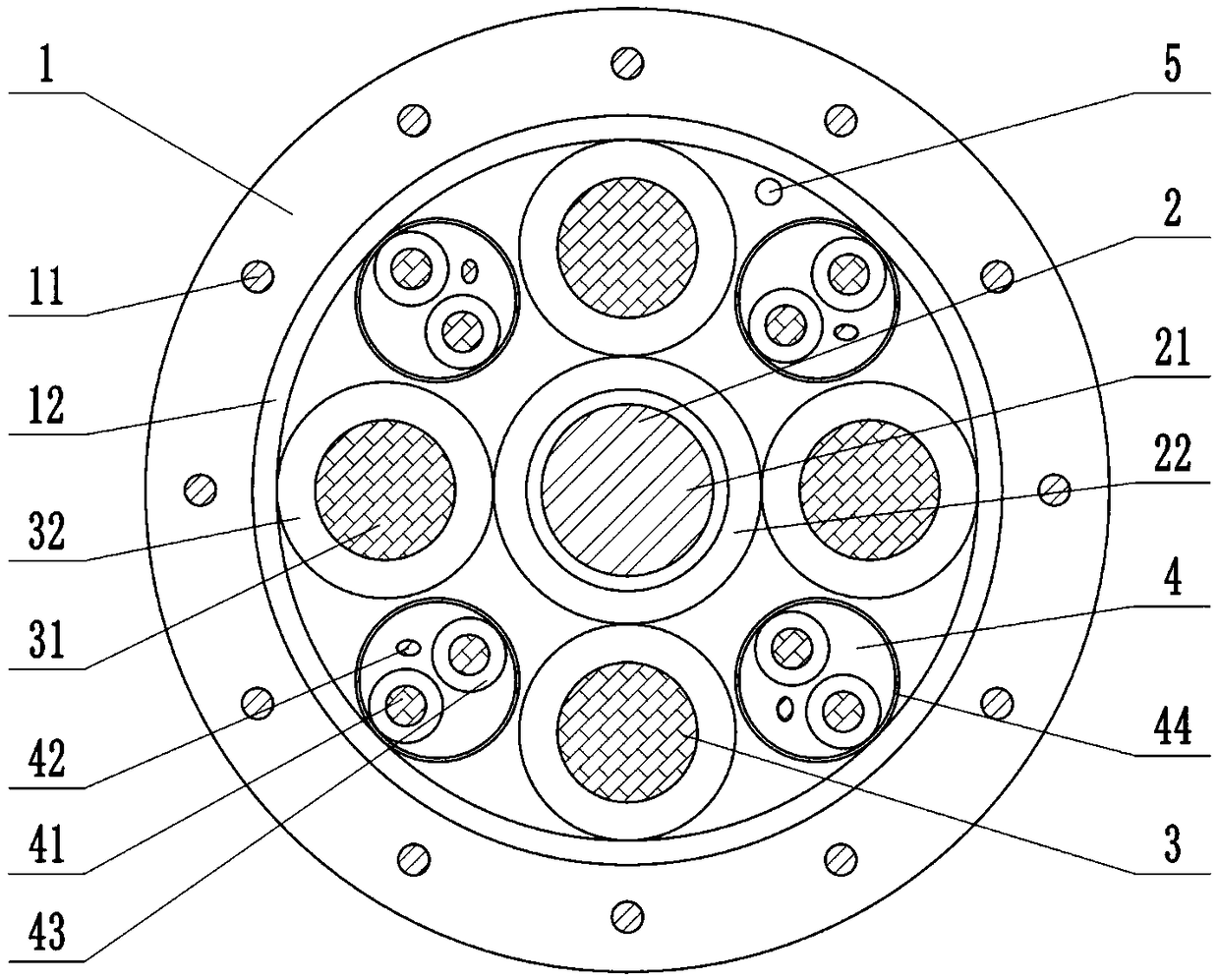

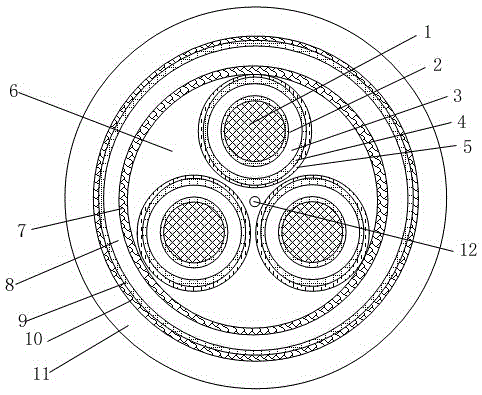

Cold-proof, oil-proof and halogen-free signal cable

ActiveCN102982865AImprove cold and oil resistanceImprove the effect of low-smoke and halogen-freeInsulated cablesInsulated conductorsElectrical conductorTransmitted power

The invention discloses a cold-proof, oil-proof and halogen-free signal cable which comprises an outer sheath and an outer wrapping layer, wherein the outer wrapping layer is internally provided with a USB (universal serial bus) transmission line and an RGB (red green blue) coaxial transmission line; the USB transmission line comprises a first weaving layer and a first inner wrapping layer; the first inner wrapping layer is internally provided with first signal lines and power lines; the RGB coaxial transmission line comprises a second weaving layer and a second inner wrapping layer; the second inner wrapping layer is internally provided with three second signal lines and power lines; the power lines consist of power line insulating layers and power line conductors; the first signal lines consist of first insulating layers and first conductors; the second signal lines consist of second conductors, inner insulating layers, oblique cladding layers and inner sheaths; the first insulating layers and the power line insulating layers are made of cold-proof, oil-proof, antiflaming and halogen-free materials; the inner sheaths are made of cold-proof and oil-proof thermoplastic materials; and the outer sheath is made of an oil-proof, halogen-free, antiflaming and low-temperature-resistant XLPE (cross linked polyethylene) material. The cable has high-antiflaming and low-smoke effects, can transmit power and signals, and is good in physical property, corrosion-resistant, and low-temperature-resistant.

Owner:南通信昌线缆有限公司

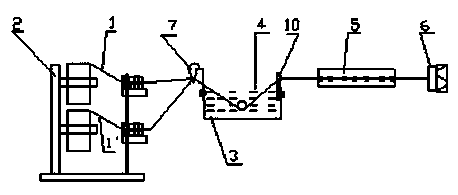

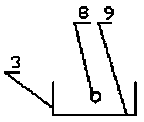

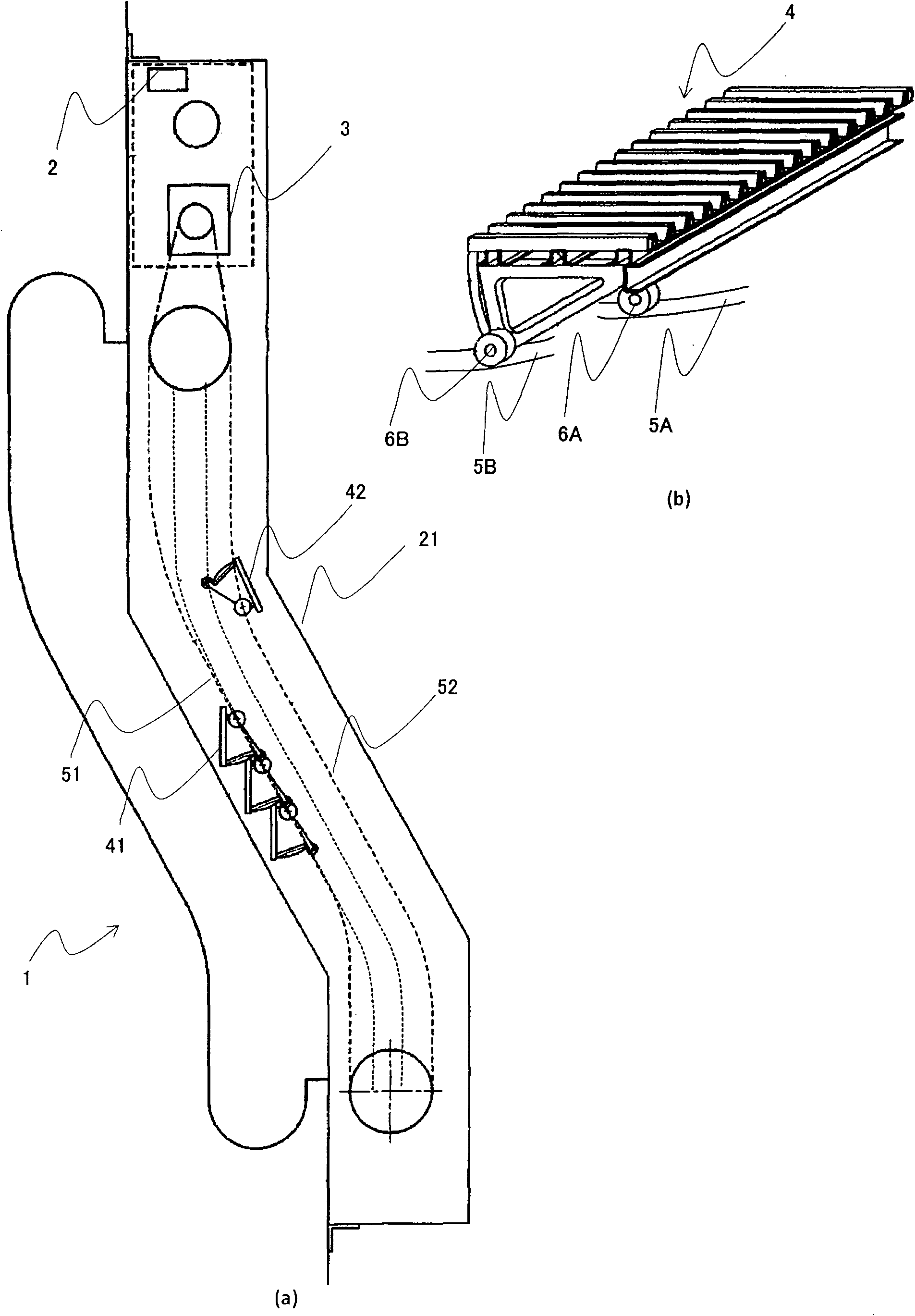

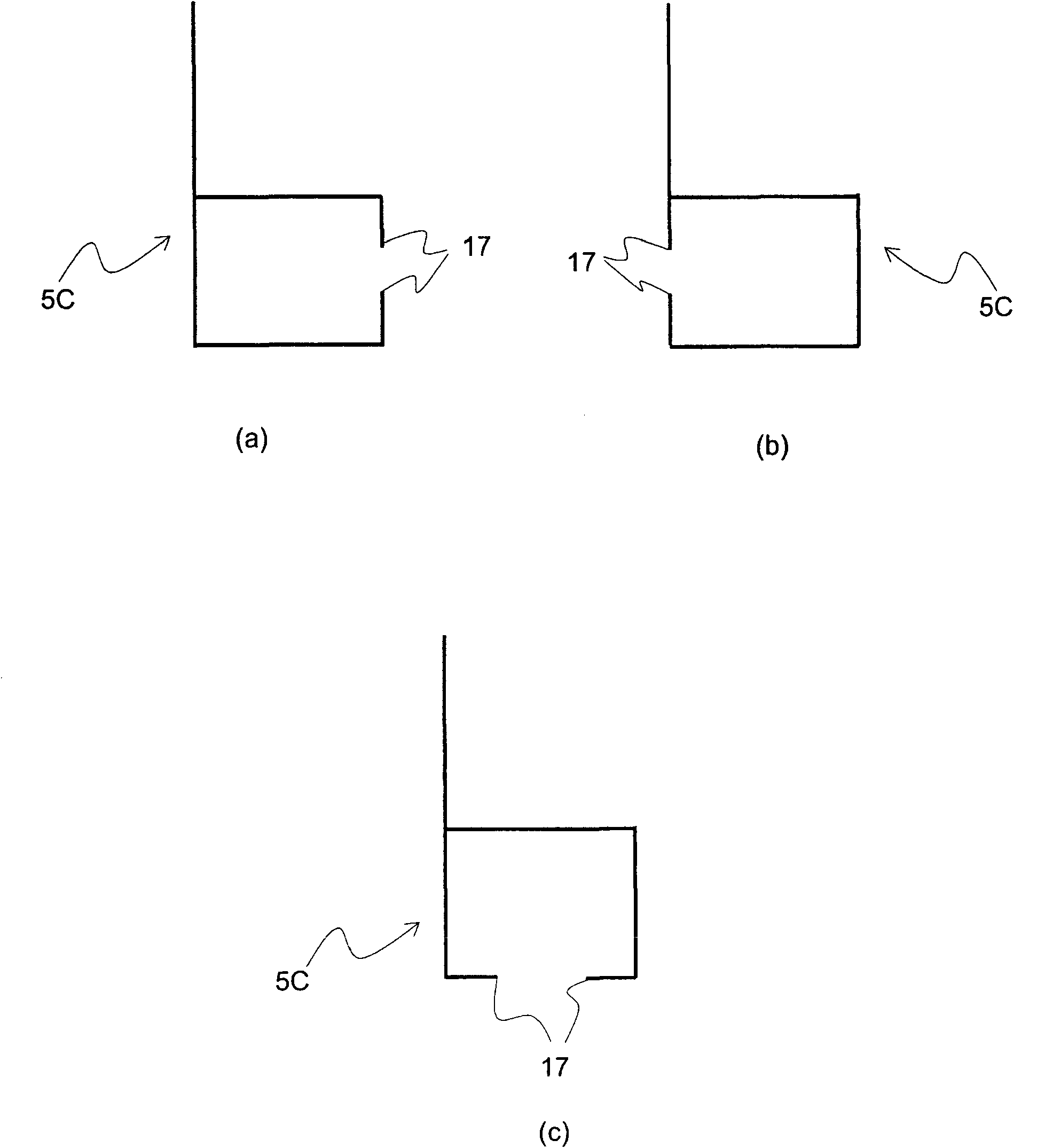

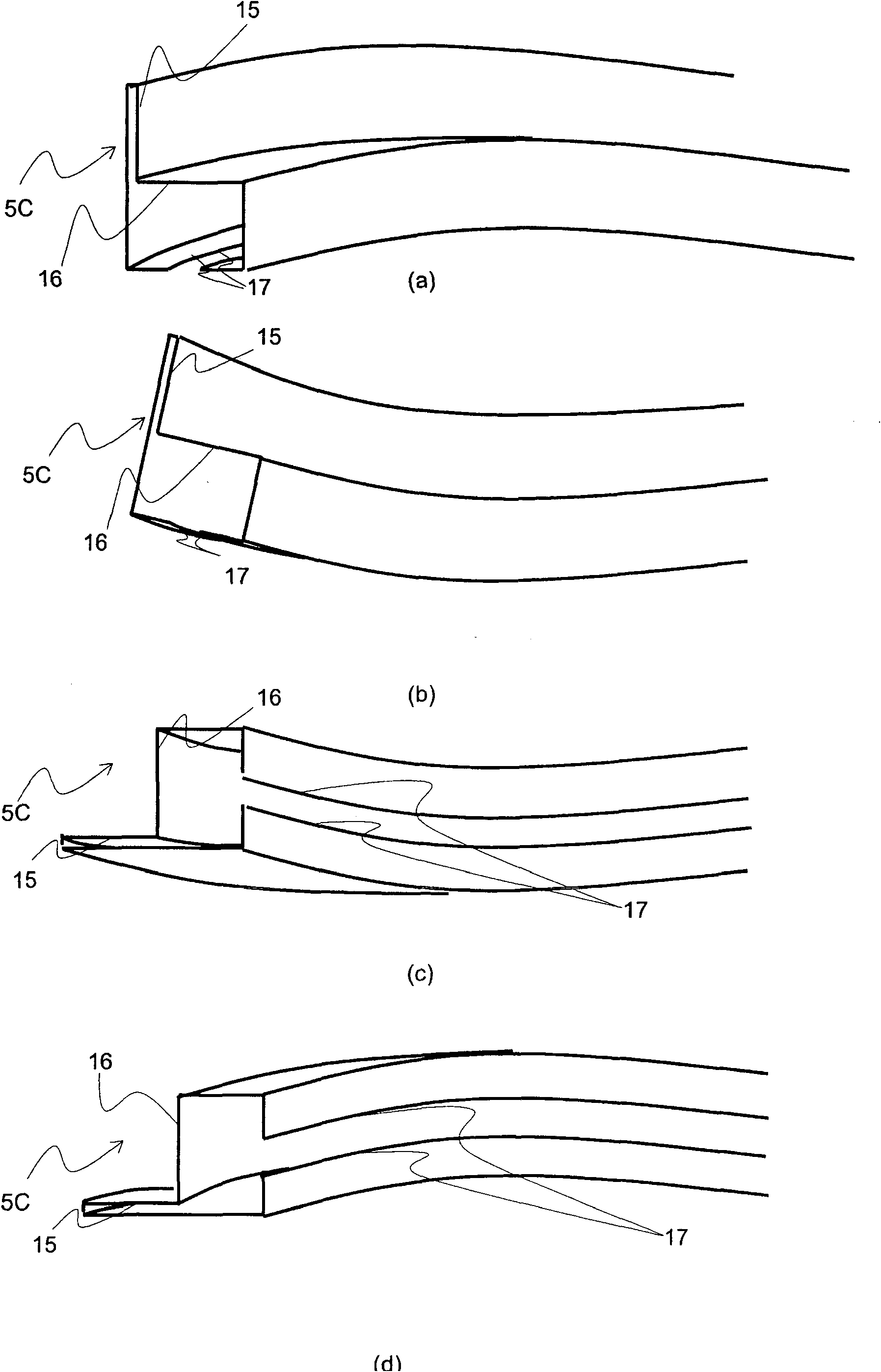

Conveyor and manufacture method thereof

The invention provides a conveyor and a manufacture method thereof, so that soft roll forming is realized, the bending machining with restraints only from the outer side is achieved without generation of torsion, in-plane corrugation and in-plane buckling, and therefore a curve part of a stepped operating track for a conveyor is small in weight and highly precise in shape. The curve part of the stepped operating track is formed by a stepped operating track (5C) with at least one of a short side and a long side having a hollow structure, thereby realizing that the weight of the conveyor is small. The wall of the hollow structure is provided with an opening part (17), which is mounted to a frame (21) via through bolts (22) at appropriate intervals. A roller for preparing the curve part of the stepped operating track with the hollow structure is made in such a shape as to prohibit the deformation which is caused by concentration of stress generated by corners of the stepped operation track during the bending machining.

Owner:HITACHI LTD

Cable for conduction charge system of electric vehicle

InactiveCN106448843AImprove tensile propertiesImprove anti-sway performanceFlexible cablesMetal/alloy conductorsElectrical conductorInterference resistance

The invention discloses a cable for a conduction charge system of an electric vehicle. The cable for the conduction charge system of the electric vehicle is characterized by comprising at least two conductor cores, a signal core, an inner sheath layer, a shielding layer, a spring and an outer sheath layer. The cable has the functions of improvement of tension resistance and swinging resistance and the beneficial effects of improvement of the roundness of the cable, control on mechanism movement and component positions, buffering and shock absorption, the deformation of the cable can be alleviated under the action of external force, the cable can be rebounded to an original state after the external force is eliminated, and thus the interference resistance and the reciprocation bending property of the wire cable can be improved; and the mechanical property of the cable is improved, and thus the cable is relatively good in vehicle crushing resistance.

Owner:张大明

Lock cylinder fixing structure of a baseball-type automobile steering wheel lock

InactiveCN102287077AReasonable fixed structureAvoid breakingBuilding locksAnti-theft devicesSteering wheelRetaining ring

The invention discloses a lock cylinder fixing structure of a baseball type automobile steering wheel lock, which comprises a lock body, a fixing ring arranged at one end of the lock body, a lock cylinder arranged on the fixing ring, a lock body arranged on the lock body and covered on the lock cylinder Lock core cover; the fixed ring is provided with a bayonet and a screw hole, and the surface of the lock core is provided with circumferential steps and positioning blocks, and the lock core is installed in the fixed ring by using its steps to cooperate with the inner ring of the fixed ring Axial limit, use its positioning block to cooperate with the bayonet on the fixed ring to limit the circumferential limit; the inner side of the lock core cover is provided with a screw hole corresponding to the screw hole on the fix ring, and the lock core cover is fixed with the screw. ring connection. The invention has the advantages of reasonable lock core fixing structure, unbreakable lock core, good anti-theft performance and the like.

Owner:雷先鸣

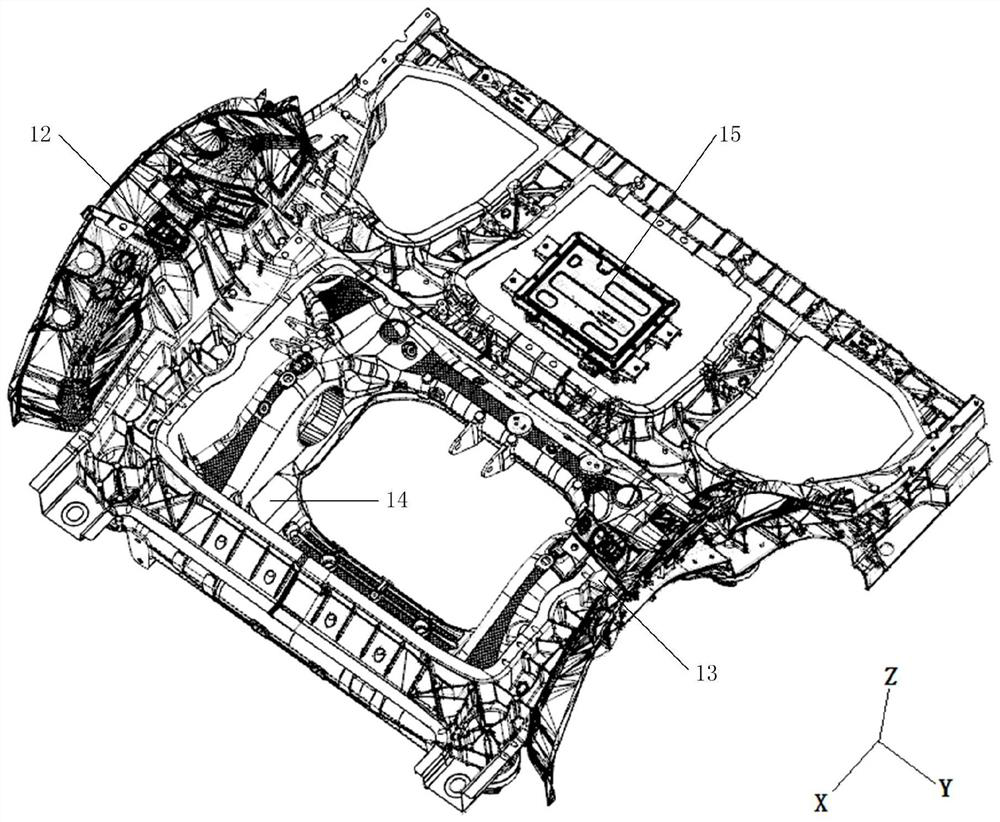

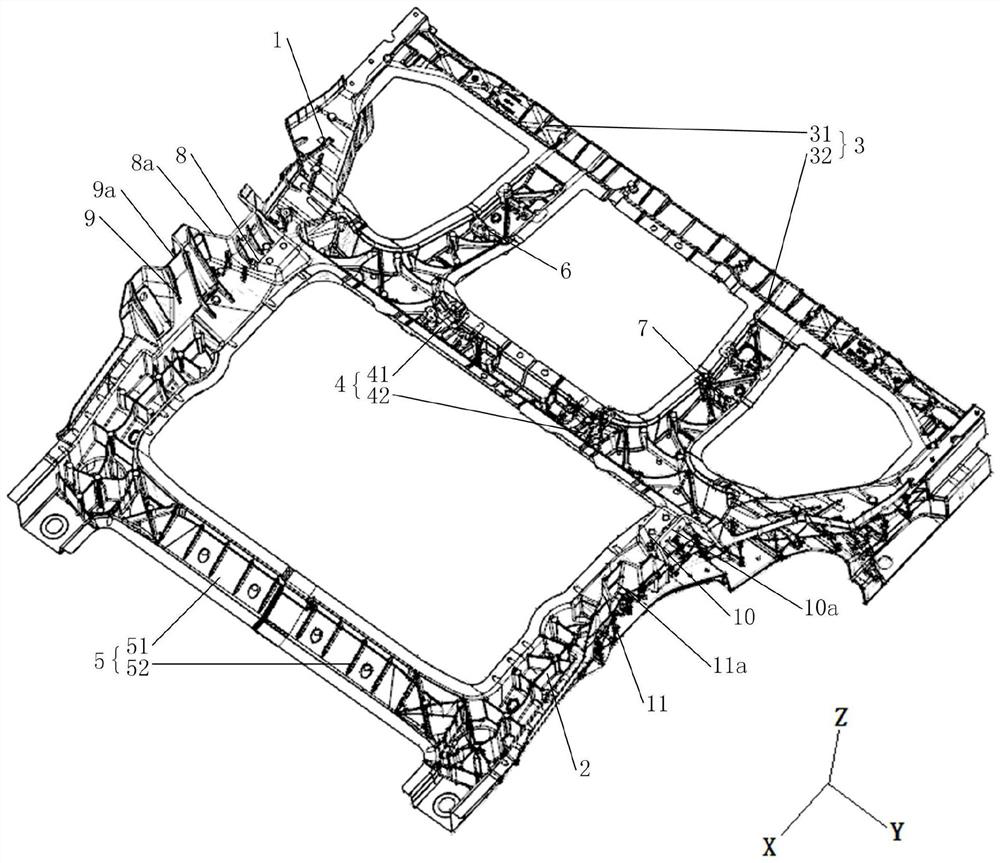

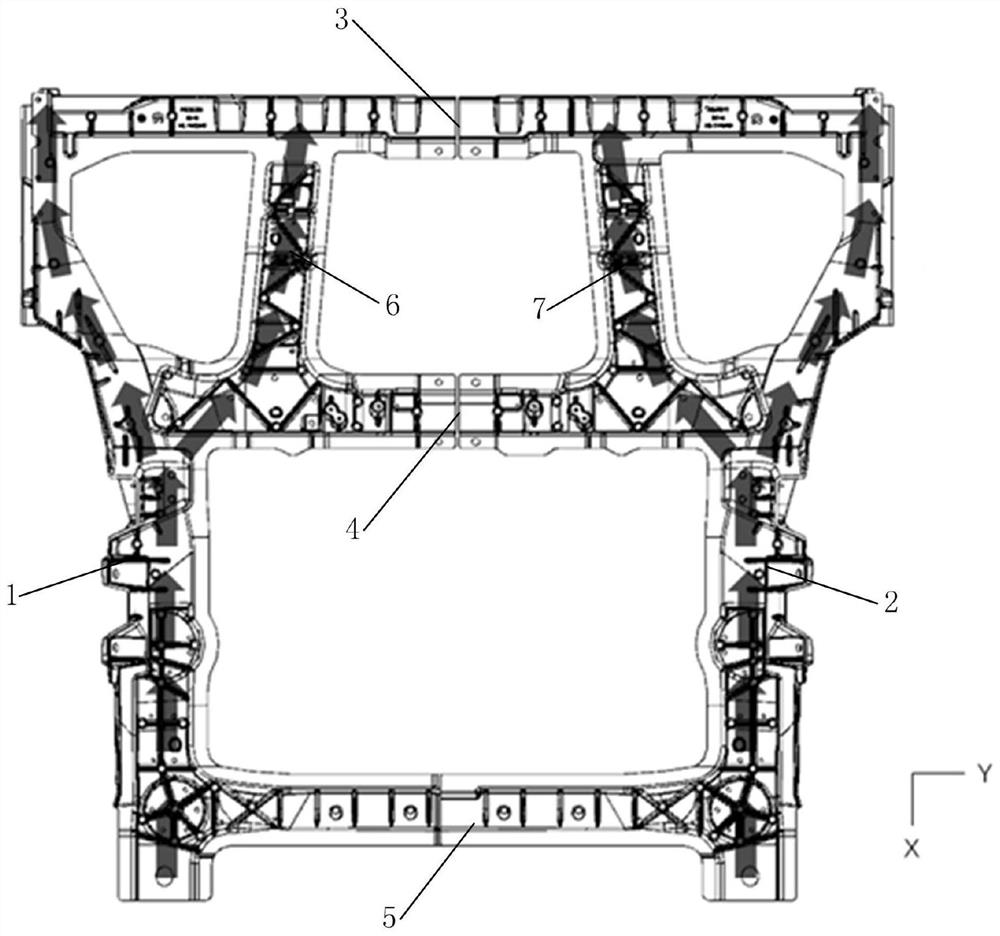

Automobile and rear floor framework assembly thereof

PendingCN113998009ASolve the rear high and low speed collision problemImprove strength and durabilitySuperstructure subunitsLow speedStructural engineering

The invention relates to the technical field of automobiles, in particular to an automobile and a rear floor framework assembly thereof, and aims to solve the problems that an existing automobile rear floor framework assembly cannot meet the rear high-low speed collision requirement of the automobile, and the strength, durability and torsional rigidity need to be improved. In order to achieve the purpose, the rear floor framework assembly comprises a left longitudinal beam structure, a right longitudinal beam structure, a front cross beam, a middle cross beam, a rear cross beam, a middle left longitudinal beam structure and a middle right longitudinal beam structure, and a left Y-shaped force transmission structure and a right Y-shaped force transmission structure are formed. A first left reinforcing structure and a second left reinforcing structure which extend upwards and are arranged side by side are arranged on the left longitudinal beam structure, and a first right reinforcing structure and a second right reinforcing structure which extend upwards and are arranged side by side are arranged on the right longitudinal beam structure. The problem of rear collision of the automobile can be solved, personnel safety in the rear collision process of the automobile is effectively protected, the strength, durability and torsion performance of the automobile are improved, and the automobile body structure is simplified.

Owner:NIO TECH ANHUI CO LTD

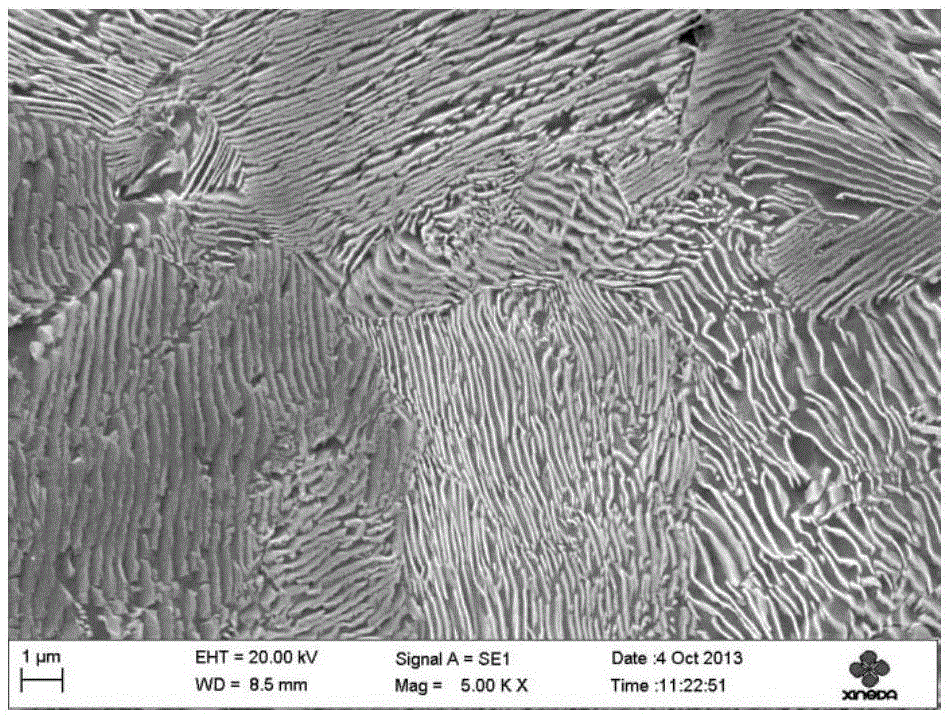

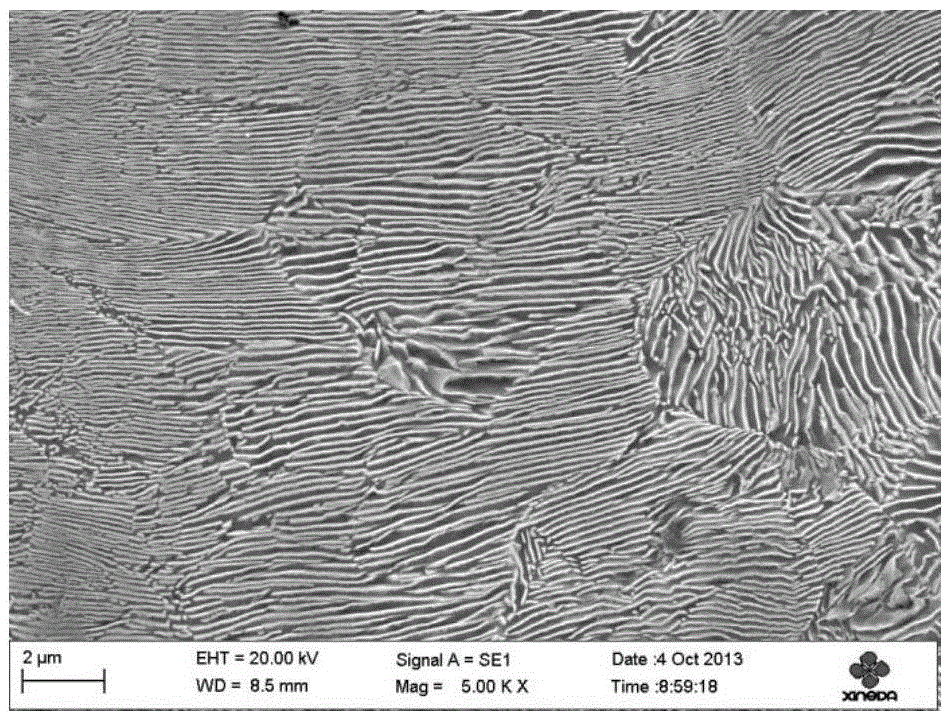

Reinforcing method for high-strength tire bead steel wire material and preparation method for tire bead steel wires

The invention provides a reinforcing method for high-strength tire bead steel wire material. According to the reinforcing method, on the condition of not changing the tensile strength and the carbon equivalent (Ceq) of the material, the content of carbon atoms is lowered to 0.74-0.78 wt% from 0.80-0.84 wt%, and the content of chromium atoms is increased to 0.20-0.30 wt% from 0.008 wt%. Thus, by lowering the content of carbon in raw material and adding chromium capable of refining pearlite lamellas, on the condition of the same carbon equivalent, the work hardening rate is increased, cementite dissolution in the cold-drawing process is restrained, and the twisting and layering problem of tire bead steel wires with the dependent variable epsilon being greater than or equal to 2.3 but smaller than or equal to 3.0 is solved; the mechanical property and the torsion property of the tire bead steel wires made of the material are improved, the cold-drawing limit is improved, the intermediate heat treatment process can be eliminated for partial thin-size and high-strength tire bead steel wires, and the production cost of the steel wires is greatly lowered.

Owner:JIANGSU XINGDA STEEL TYPE CORD

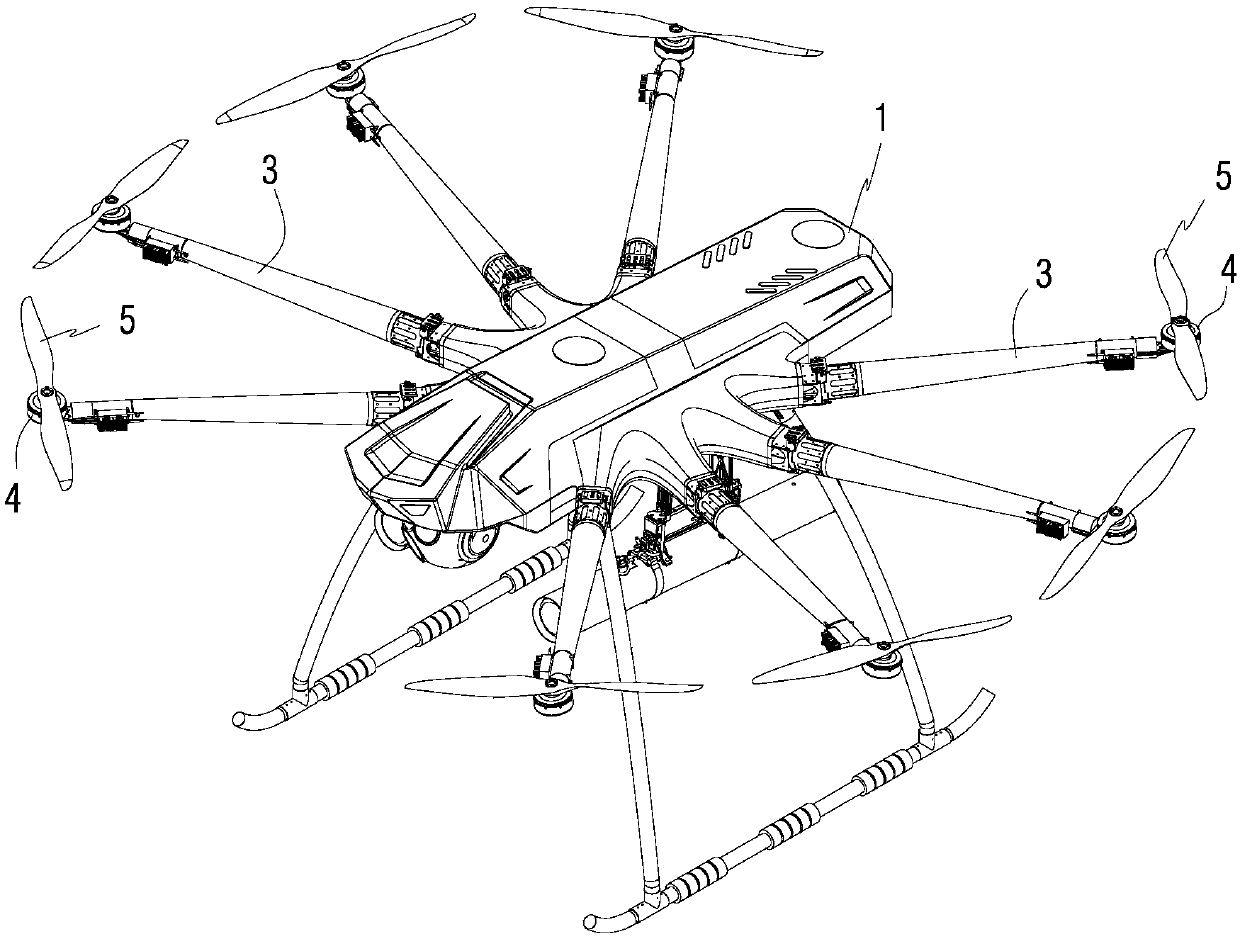

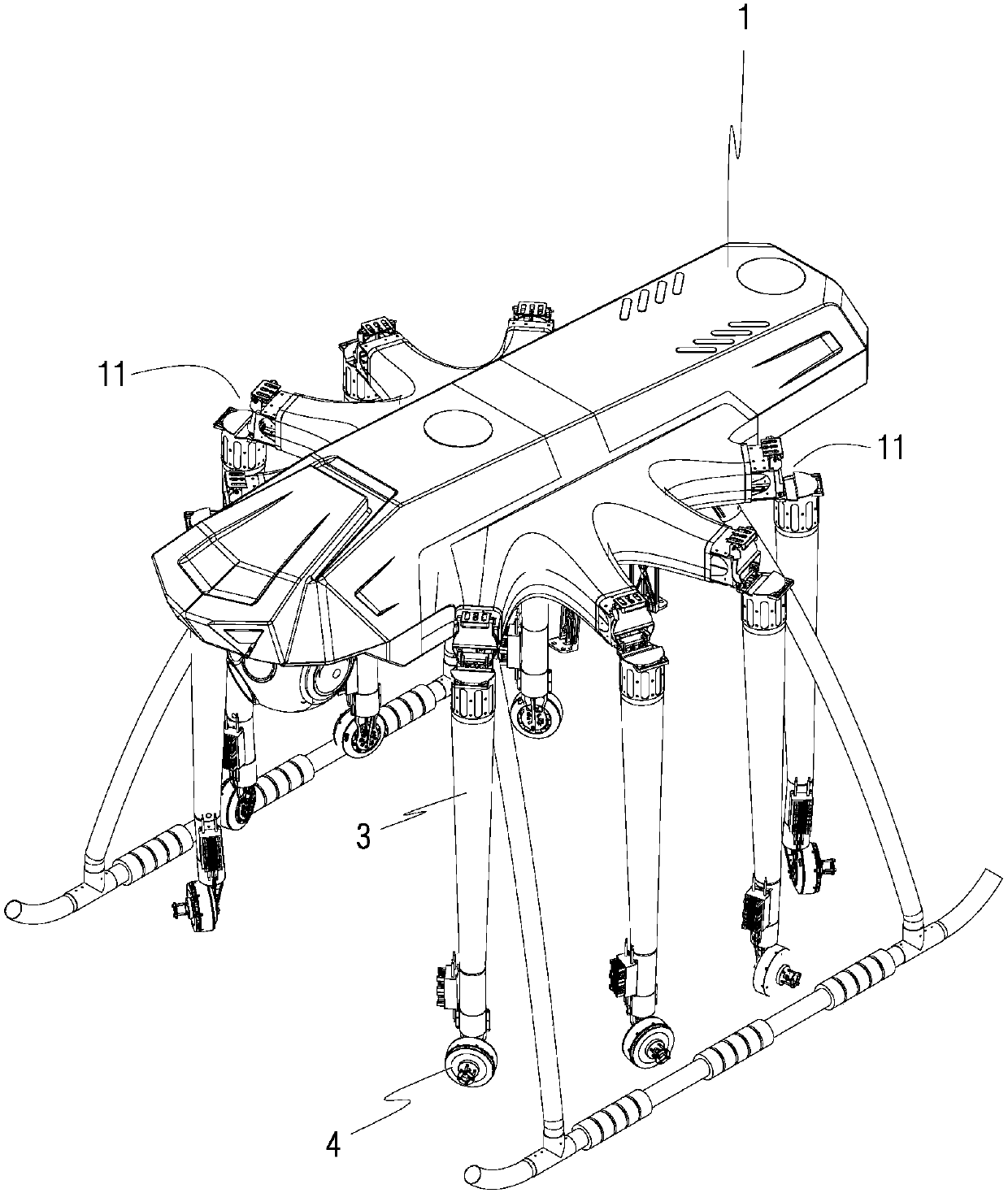

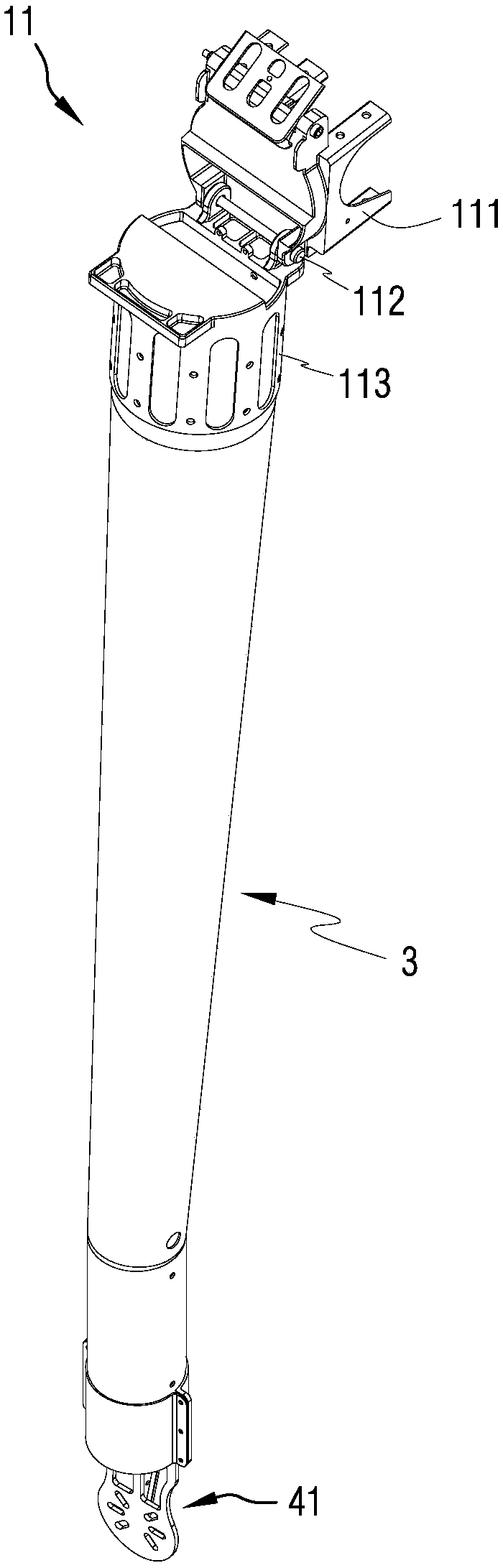

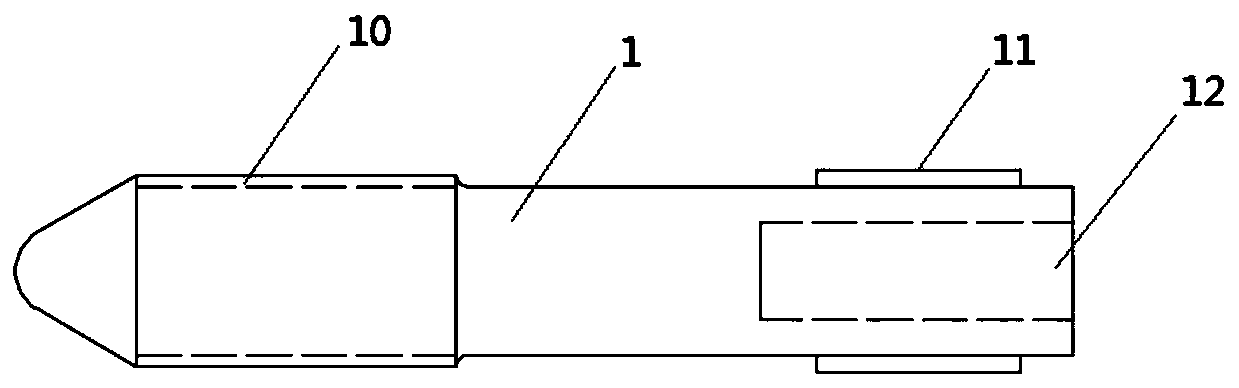

Cantilever of electric unmanned aerial vehicle

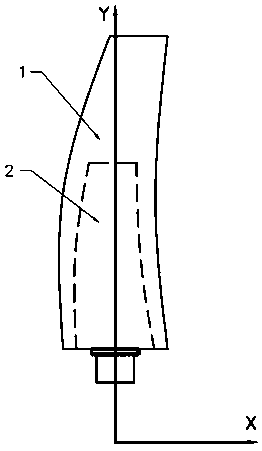

PendingCN107600386AReduce weightImprove torsional performanceFuselage framesAir-flow influencersEngineeringStrength design

The invention provides a cantilever of an electric unmanned aerial vehicle. The cantilever of the electric unmanned aerial vehicle is used for being connected to a vehicle body of the electric unmanned aerial vehicle to support a motor, and the cantilever comprises a first end part connected with the vehicle body, a second end part supporting the motor and a middle section located between the first end part and the second end part. The first end part is composed of a cylinder with the diameter being the same in the length direction. The second end part is composed of a cylinder with the diameter being the same in the length direction as well. The middle section is of a tapered cylindrical structure. The cantilever of the electric unmanned aerial vehicle is integrally of a hollow cylindrical structure, is lower in weight under the same strength situation, and can obtain a larger torsional property. The two ends of the cantilever are designed to be the cylinders with the diameters beingthe same so that cylindrical connection structures can be conveniently inserted in and firm connection can be achieved. The middle section is designed to be of the tapered cylindrical structure, thusequal strength design can be formed, and the lightening effect is better.

Owner:沈阳旋飞航空技术有限公司

Halogen-free super-soft distortion-resistant cable and preparation method thereof

PendingCN109411117AReduce stress concentrationNo crackFlexible cablesCable/conductor manufactureCopper conductorStress concentration

The invention discloses a halogen-free super-soft distortion-resistant cable and a preparation method thereof. The cable comprises an outer sheath, wherein the outer sheath is provided with a plurality of reinforced aramid yarns; and a steel wire rope, a power line, a twist pair shielding transmission signal wire and a winding nylon yarn, which are stranded together, are coated in the outer sheath. The preparation method comprises the following specific steps of: preparing a super-soft copper conductor by using a high-speed bunching machine; preparing a power insulating layer and a signal insulating layer by using an extruder; stranding the power line and the twist pair shielding transmission signal wire at the periphery of a spiral support by using a cable former; braiding a cotton yarn braid layer outside an industrial control cable core by using a braider; and carrying out double-layer co-extrusion on anti-flaming ethylene propylene rubber to prepare the halogen-free super-soft distortion-resistant cable. The halogen-free super-soft distortion-resistant cable is capable of effectively eliminating the stress concentration phenomenon of cables in the using environment, transmitting control electronic signals and synchronously providing electric energy for mechanisms of equipment, and the overall structural design has high flexing resistance and high torsion performance so thatnormal work can be carried out under three-dimensional and + / - 360-degree reciprocating torsion.

Owner:TIANJIN YXT TECH

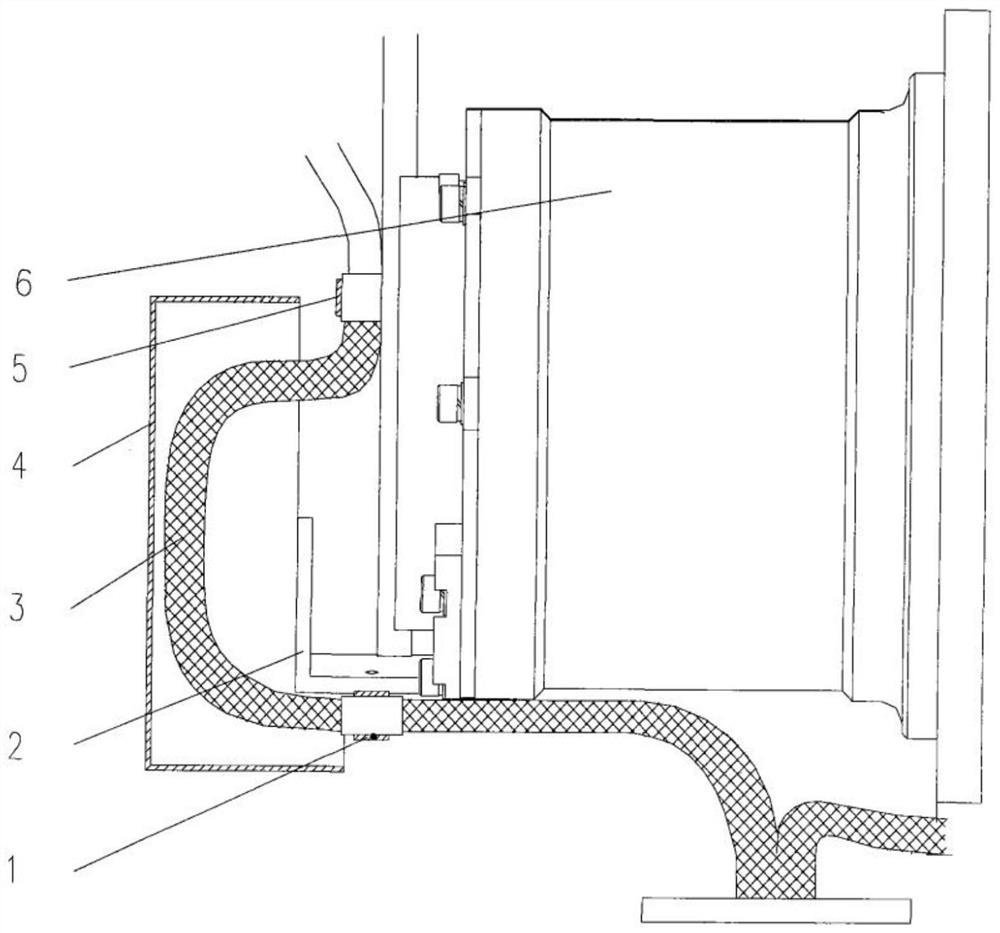

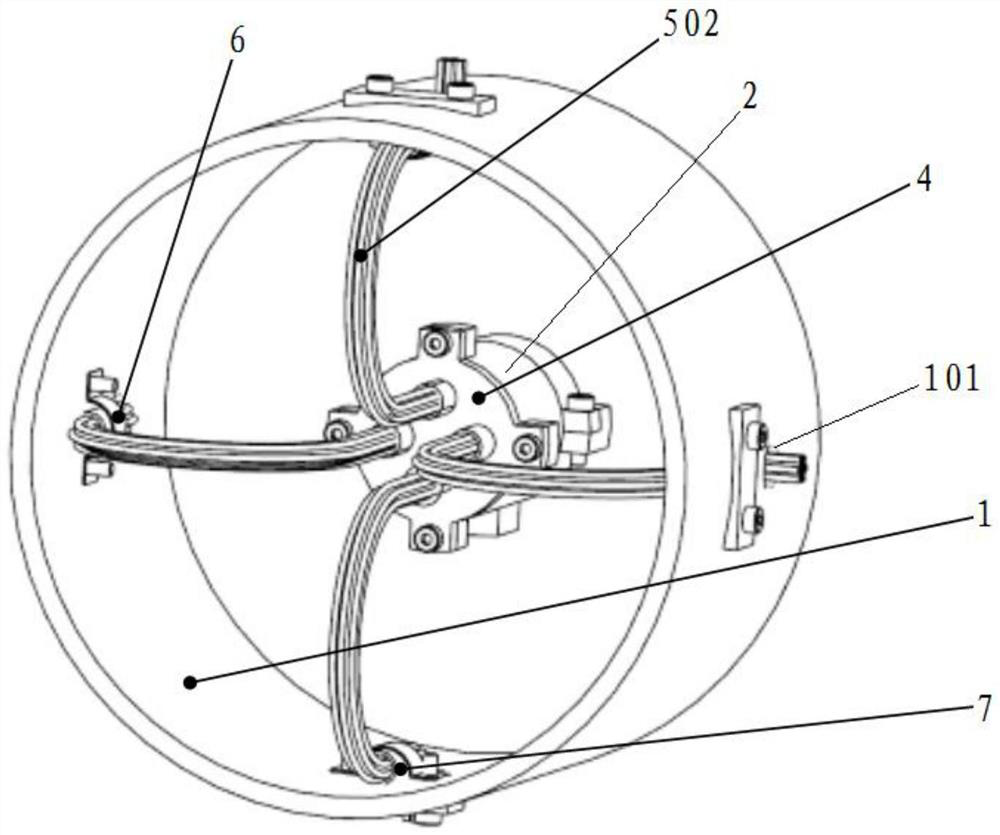

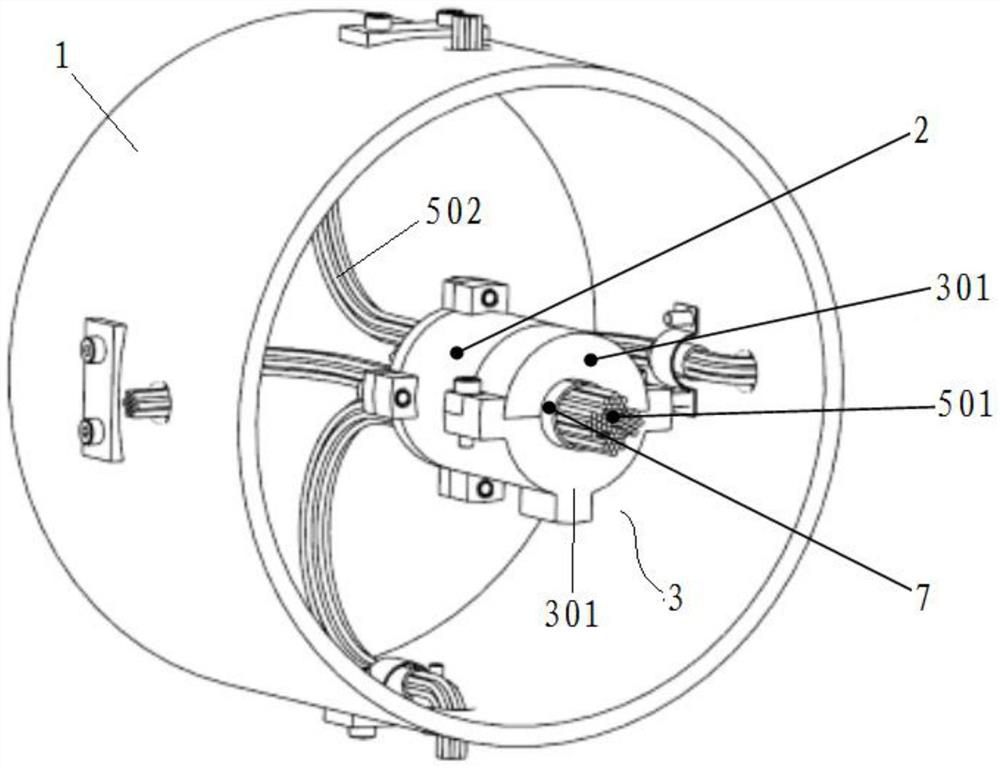

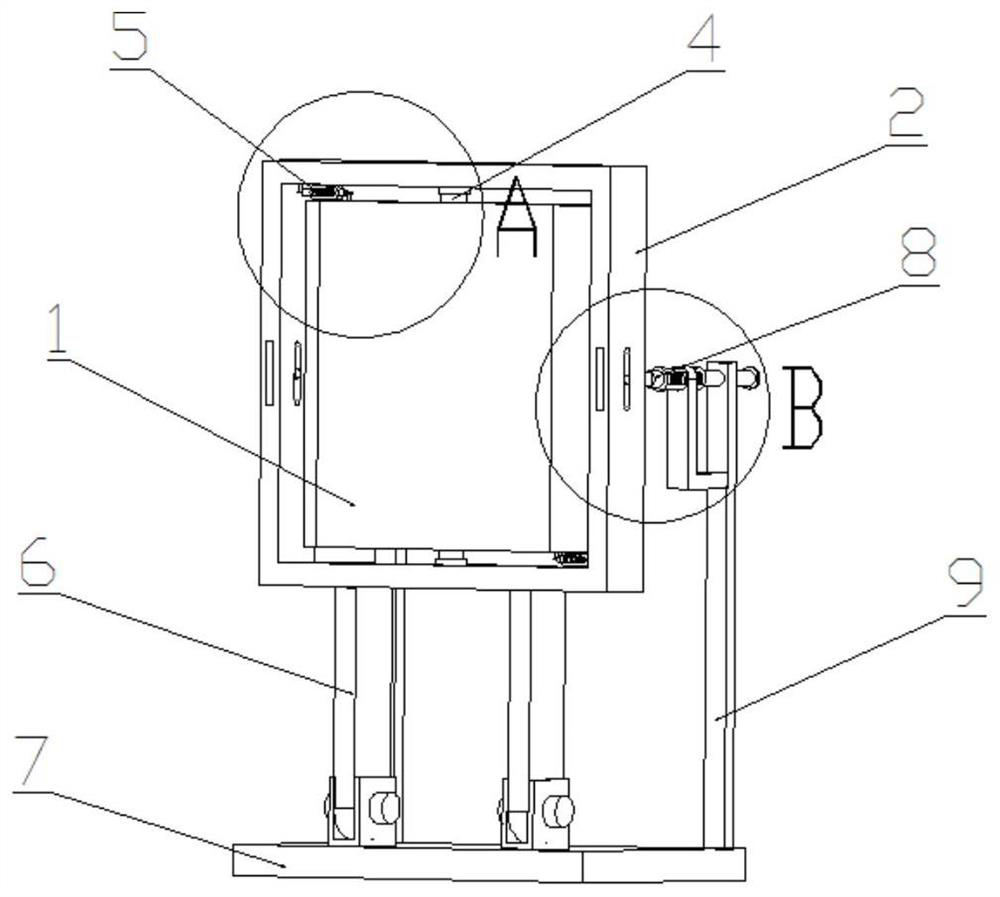

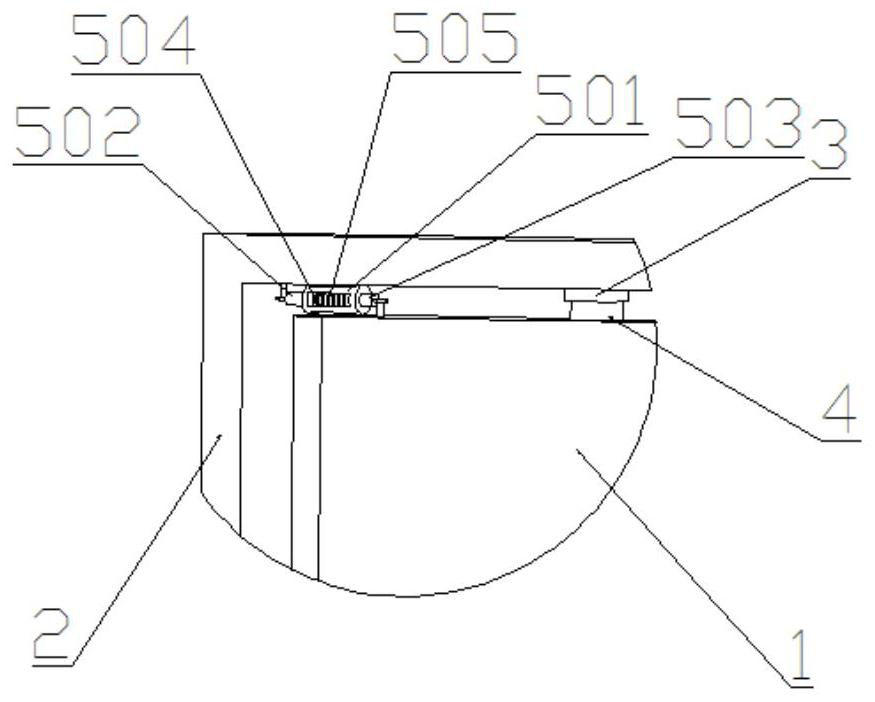

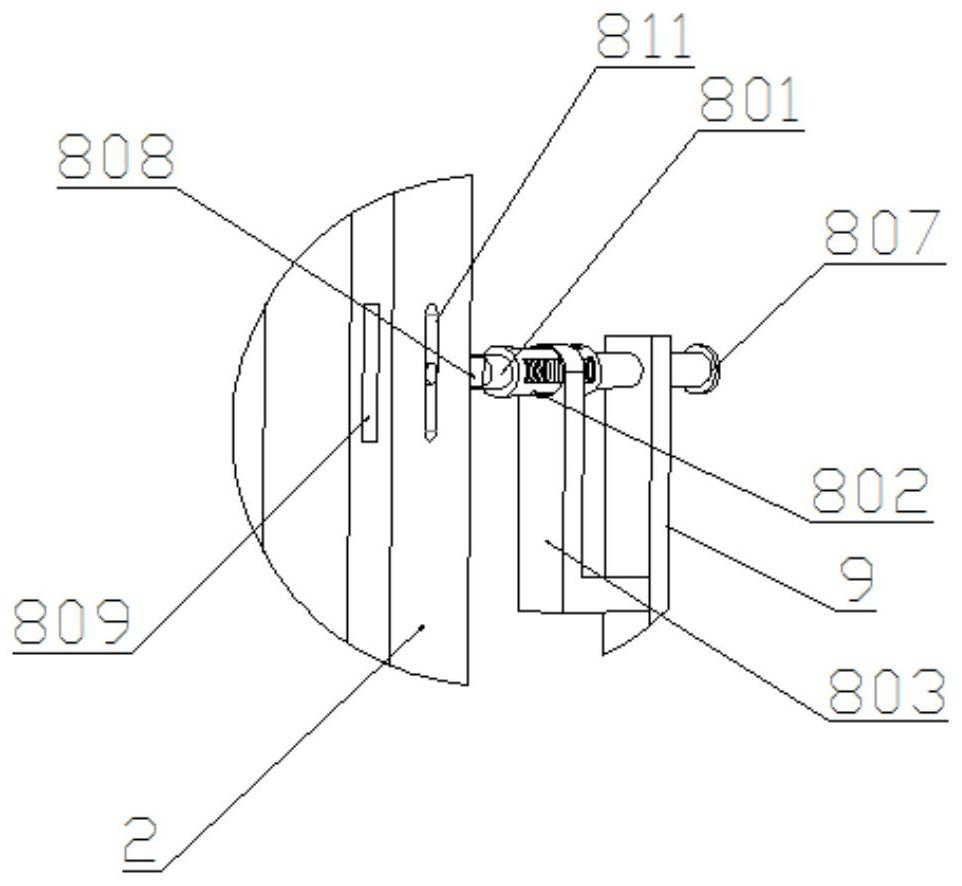

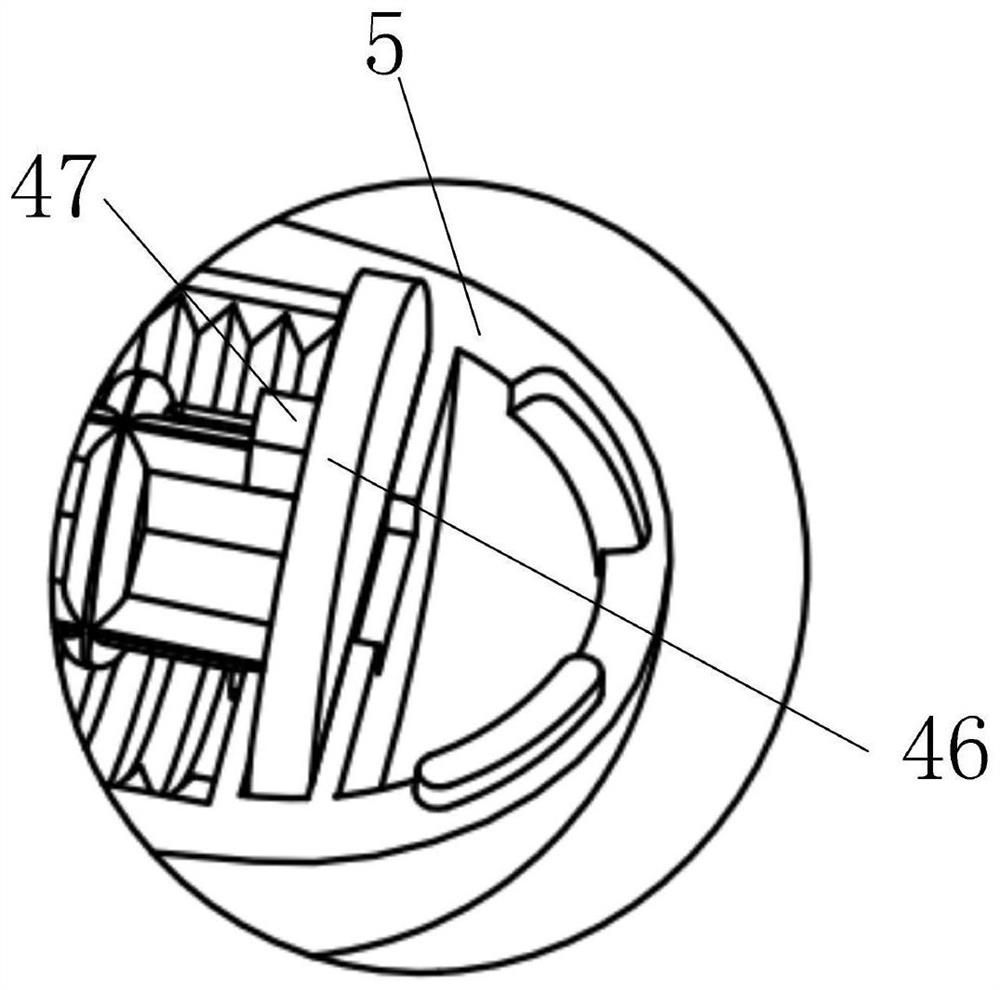

Wire harness management device for slip ring-free solar wing driving mechanism

ActiveCN112688254AReduce bloatReduce drag torqueElectrical apparatusEnergy efficient board measuresEngineeringStructural engineering

The invention discloses a wire harness management device for a slip ring-free solar wing driving mechanism. The wire harness management device comprises a box body and a wire harness fixing sleeve integrated in an accommodating cavity of the box body, the matching position of the wire harness and one end of a wire harness pressing sleeve is configured to be a whole wire harness, and the whole wire harness of the wire harness is divided into four strands of branch wire harnesses through a deconcentrator; branch wire harness leading-out holes are distributed in the box body in the circumferential direction of the box body. Part of the branch wire harness is contained in the accommodating cavity, and the far end of the branch wire harness is led out of the branch wire harness lead-out hole. According to the device, the whole wire harness is divided into four strands of branch wire harnesses, the bloating property of the wire harness is greatly reduced, the resistance moment corresponding to a single strand of wire harness is greatly reduced due to the fact that the wire harness is thinned, the requirement for the pressing force of the wire harness fixing sleeve is also reduced, and therefore the risk that a cable at the fixed end of the wire harness is damaged is reduced; in addition, the torsion property of the wire harness can be improved, so that the rotation angle of the wire harness management device is increased, and the applicability of the wire harness management device to different wire harness management requirements is improved.

Owner:CHANGGUANG SATELLITE TECH CO LTD

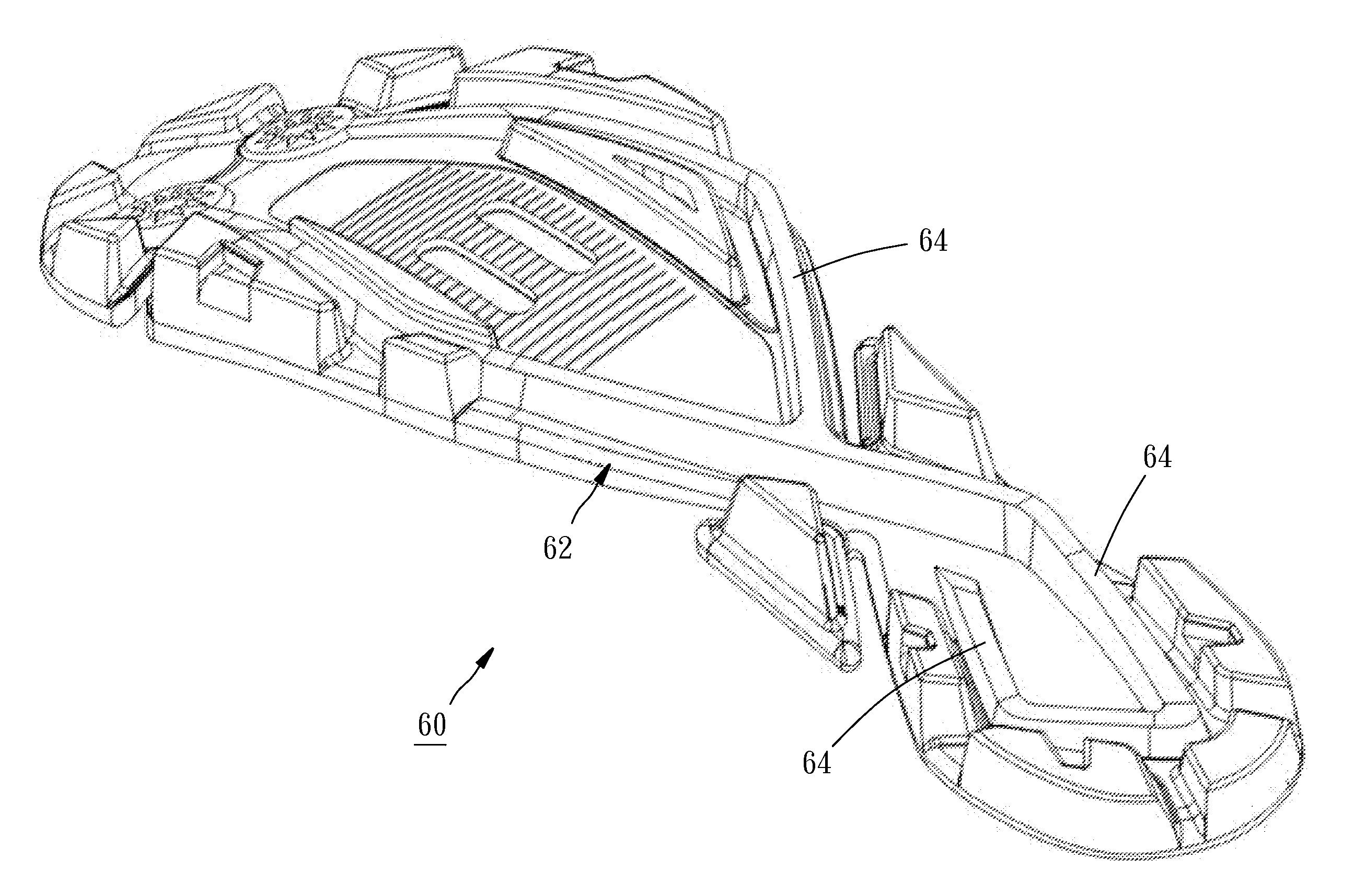

Sole for cycling shoe

ActiveUS11311073B2More comfortableEnhances transverse torsionabilitySolesEngineeringStructural engineering

A sole for cycling shoe includes a forefoot section, a heel section and an arch section connected between the forefoot section and the heel section, a longitudinal axis and a tilting axis defined between the forefoot section and the heel section, a deviation angle defined between the tilting axis and the longitudinal axis, a middle part extending through the forefoot section, the arch section and the heel section, and two side wing portions defined at two opposite sides relative to the middle part. The rigidity of the middle part is higher than the two side wing portions. The middle part extends in the arch section along the tilting axis. Based on the above-described technical features, the overall structure of the sole has sufficient rigidity with enhanced torsionability on the rear end thereof, making the cycling shoe more comfort.

Owner:GIANT MFG

Mechanical windproof advertising board

ActiveCN112002271AAvoid damageReduce the windward areaBoardsStructural engineeringMechanical engineering

Owner:湖南精雕细琢广告标识有限公司

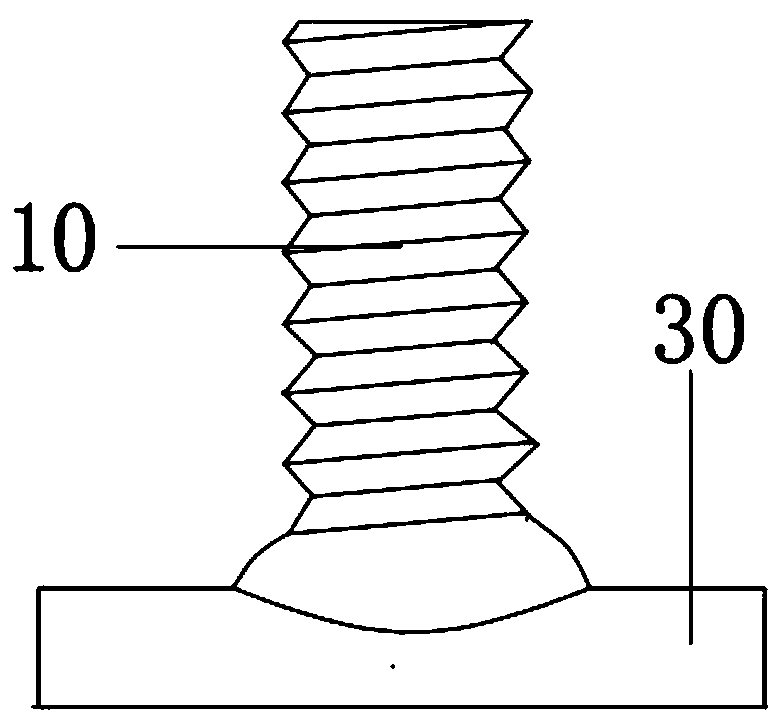

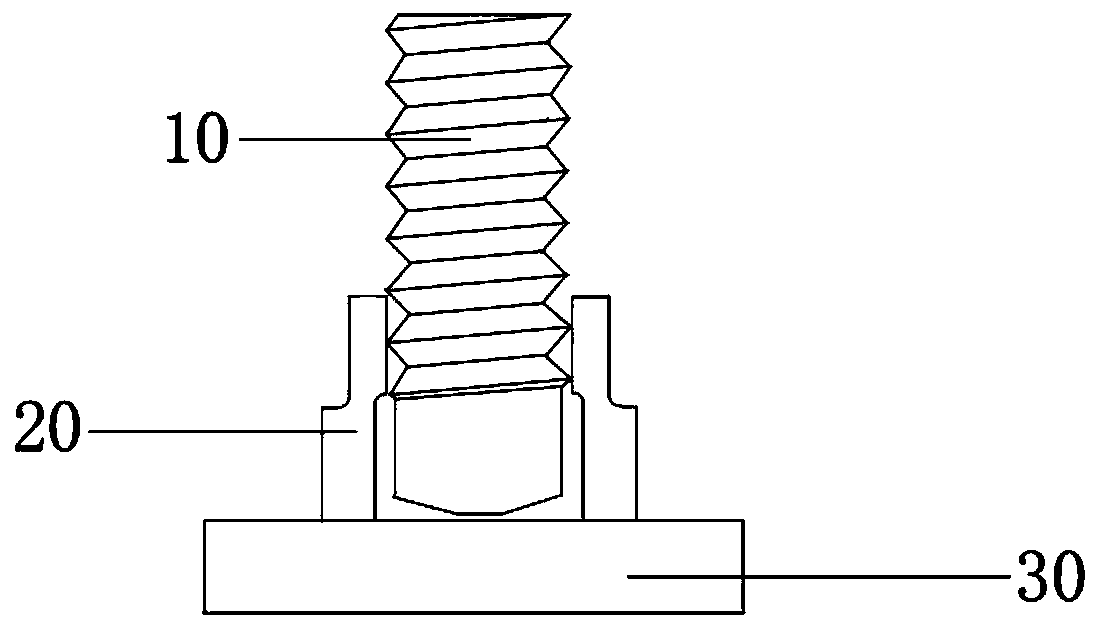

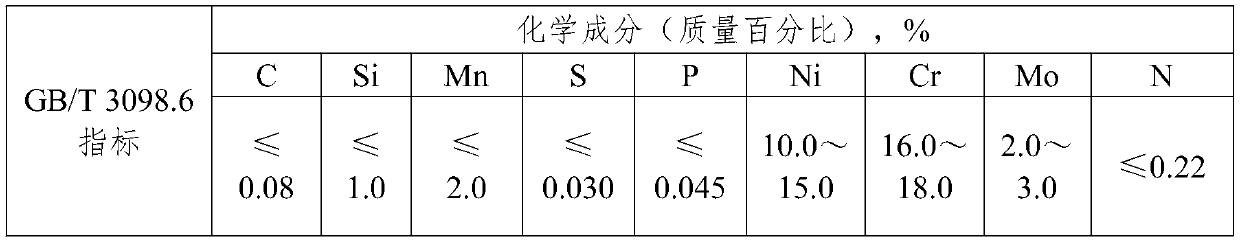

Method of welding between stainless steel stud and steel plate

InactiveCN111069750AThe welding method hasPrevent oxidationWelding accessoriesEngineeringStud welding

The invention discloses a method of welding between a stainless steel stud and a steel plate. A hole is drilled in an end of the steel stud, and is filled with an aluminum agent. Because optimal designing is carried out on the form of the steel stud, and a magnetic ring is adopted for protection on the stainless steel stud, it is effectively avoided that a stainless steel stud is oxidized in the welding process, and the welding quality is guaranteed. Because the stainless steel stud is used instead of a Q235 carbon steel stud, the corrosion resistance of a welding joint of the stainless steelstud is improved, the situation that the stud becomes rusty in the service process of a product is effectively avoided, and service safety of the product is guaranteed; and the welding technology of the stainless steel stud is optimized, the technological parameters such as the welding current, the arc discharge length and the lifting height at the horizontal gesture, the vertical gesture and theposition of facing upward are determined, hot cracks during welding are avoided, the bending performance and the torsion performance of the welding point of the stud are improved, the hardness of thewelding point is reduced, and the comprehensive performance of the welding point is improved.

Owner:WUHAN WUCHUAN MEASUREMENT & TEST

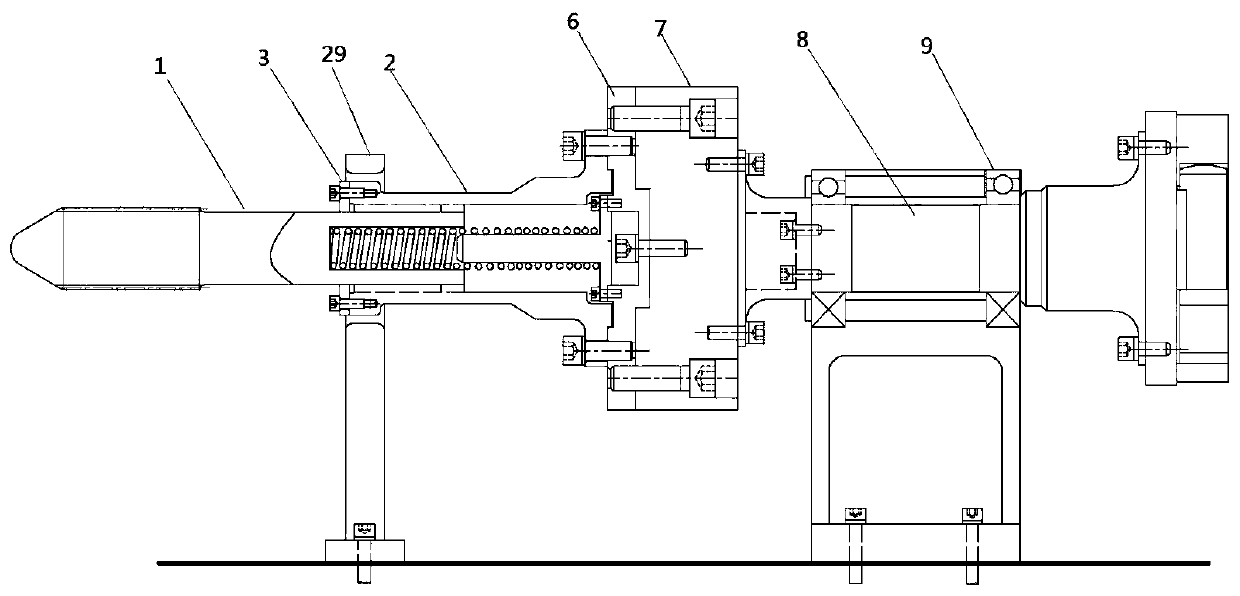

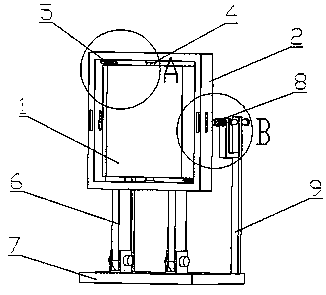

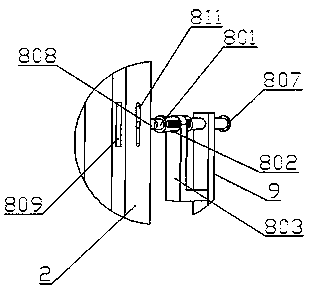

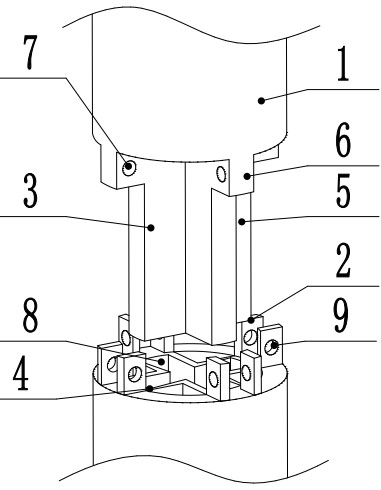

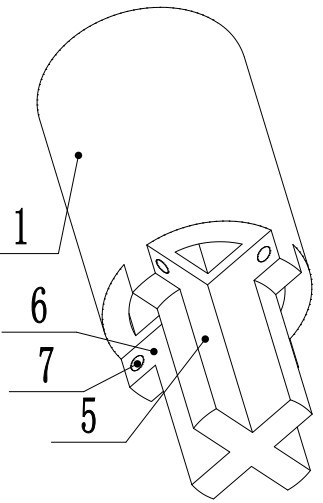

High torsion-resistance connecting device capable of quickly connecting with engine to rotate

PendingCN109991009AImprove torsional performanceImprove cushioning performanceEngine testingDynamometerAgricultural engineering

The invention discloses a high torsion-resistance connecting device capable of quickly connecting with an engine to rotate. The device comprises a connecting shaft, a shaft sleeve, a lock plate, a spring, a spring positioning shaft, a connecting disk, a connector, a middle shaft and a middle shaft permanent seat, wherein the left part of the connecting shaft is provided with a spline, and four bosses are evenly distributed on the right part of the connecting shaft; the right end of the connecting shaft is provided with a spring spacing hole; the spring is distributed between the connecting shaft and the spring positioning shaft; the spring positioning shaft is connected with the connecting disk; the middle shaft permanent seat is connected with the middle shaft; and the lock plate, the shaft sleeve, the connecting disk, a connector and the middle shaft are connected in sequence. By use of the device, the engine and a dynamometer can guarantee to be quickly connected, meanwhile, the accuracy of measurement data can be guaranteed, and production efficiency is obviously improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Windproof billboard for advertisement media

The invention discloses a windproof billboard for advertisement media, and belongs to the technical field of billboards. According to the technical scheme, the billboard comprises an advertisement board and a frame arranged around the advertisement board, wherein the advertisement board is provided with a first torsion mechanism, the first torsion mechanism is hinged with the frame and the advertisement board, the first torsion mechanism drives the advertisement board to twist under the action of wind force, and drives the advertisement board to recover to the initial position when the wind isweakened or disappears, a supporting column is arranged below the frame, the supporting column is hinged with a base, the base is arranged on the ground, two sides of the frame are respectively provided with a second torsion mechanism, the second torsion mechanisms are in sliding connection with the frame and a supporting rod, the other end of the supporting rod is connected with the base. According to the technical scheme, the device has the advantages that the structure is simple, the design is unique, the use is convenient, and under the condition that the wind power is large, the billboard can be automatically changed, the wind-receiving area is reduced, so that the influence of the wind power on the billboard is reduced, and damage to the billboard is avoided.

Owner:南通东晨服饰有限公司

Method for preparing phi7.0mm1770MPa high-strength low-relaxation zinc-coated wire

ActiveCN100534657CHigh strengthImprove torsional performanceDrawing diesFurnace typesHigh torqueSizing

The invention relates to a manufacturing method of φ7.0mm1770MPa high-strength and low-relaxation galvanized steel wire. The technological process is: wire rod re-inspection→surface preparation→wire drawing→hot-dip galvanizing→stabilization treatment→inspection. Due to absorbing the advantages of the two traditional processes of "die drawing" and "double tensioning", by adding a "double tensioning" production line to the production line to wipe and smooth the surface of the steel wire and limit the diameter of the steel wire. The "diameter limiting die" that does not cause deformation of the steel wire as a whole, performs low-temperature tempering and surface smoothing treatment on the steel wire while applying tension to the steel wire, so that the steel wire has a smooth surface while obtaining low relaxation performance, and the production A high-strength, low-relaxation galvanized steel wire with high strength, low relaxation, high toughness and plasticity and high torsional performance is produced, which effectively overcomes the drawbacks of the existing technology that cannot simultaneously take into account high strength, low relaxation and high torsional performance, enabling production It has become a reality to produce galvanized steel wires for stay cables that fully meet the requirements of technical indicators.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

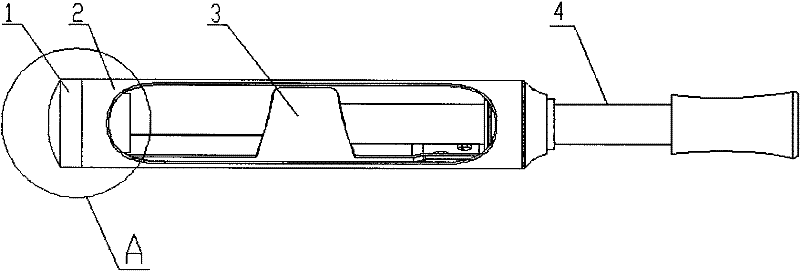

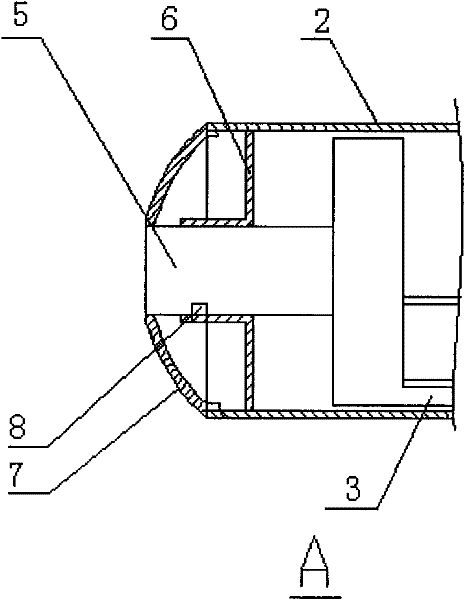

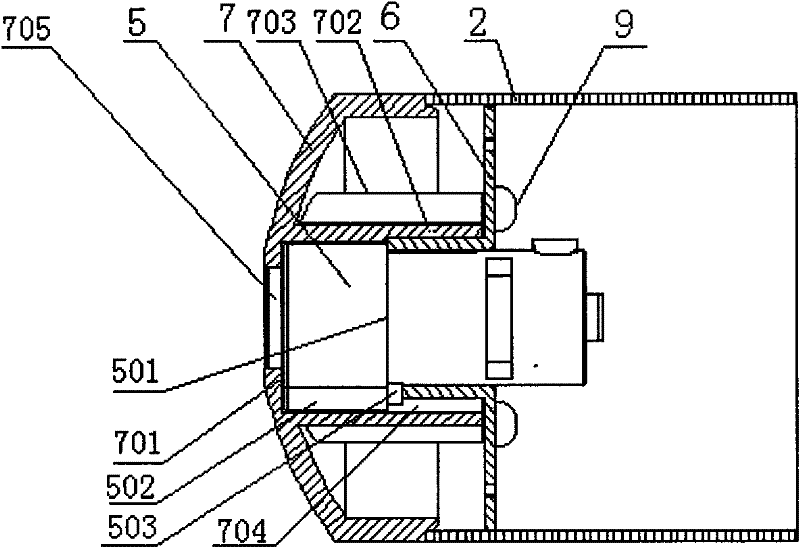

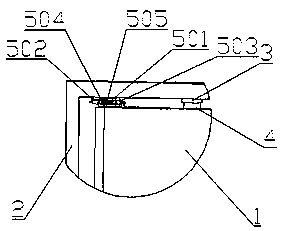

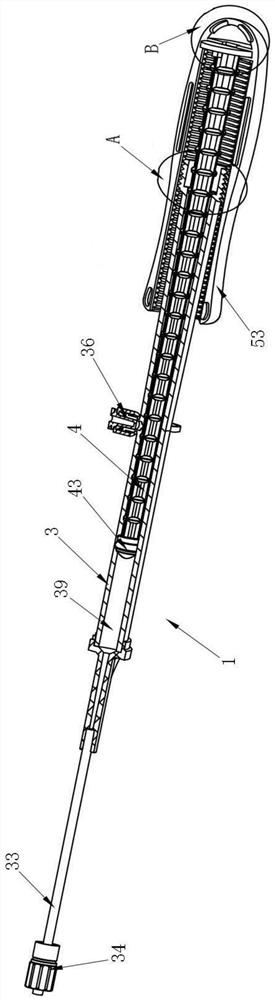

Injection device and exchange system comprising injection device

ActiveCN111789701AImprove torsional performanceAvoid deformationAnnuloplasty ringsEngineeringHigh torque

The invention discloses an injection device and an exchange system comprising the injection device, and solves the technical problem that a high-pressure medium exchange process is blocked due to thefact that a plunger rod is easily subjected to relatively high torque and deformed when high-pressure medium exchange is carried out in the prior art. The injection device comprises a syringe, a plunger rod and a plunger; the plunger rod and the plunger are matched with the syringe; the injection device further comprises a torque driving part connected with the near rend of the plunger rod; the plunger rod comprises an output propulsion section and an expansion section connected with the output propulsion section; the expansion section extends to the near end of the plunger rod; and the section area of the near end of the expansion section is greater than the section area of the far end. The exchange system comprises the injection device and a collection device matched with the injection device and used for collecting exchanged mediums. According to the injection device in the invention, the diameter of the section of the force application section of the plunger rod is gradually increased; therefore, the torsion resistance capability of the plunger rod is improved; deformation of the plunger rod due to relatively high torsion is prevented; and thus, smooth exchange of the high-pressure medium is effectively ensured.

Owner:CHENGDU SILARA MEDTECH INC

Multi-core warp resistance medium voltage rubber jacketed flexible cable for wind power generation

InactiveCN105006280AImprove torsional performanceStable structurePower cables with screens/conductive layersFlexible cablesYarnElectrical conductor

The invention discloses a multi-core warp resistance medium voltage rubber jacketed flexible cable for wind power generation. The flexible cable comprises a cable core and a star shaped bar inside the cable core. The cable core is formed in such a manner as three insulation cores are twisted in parallel inside the star shaped bar. The twisting direction of the core is identical to that of conductors. The core is coated with a first butyl rubber water layer; an inner protection sheath is wrapped around the first butyl rubber water layer through extrusion; a reinforcing aramid yarn is woven outside the inner protection sheath. The reinforcing aramid yarn is coated with a second butyl rubber water layer. Finally, an outer protection sheath is arranged through extrusion as the outermost layer of the cable. The uttermost center of the cable core is further provided with a reinforced aramid fiber rope. The introduction of a new structure into the cable enables the cable to possess a strong warp resisting ability. In comparison with the prior art, the service lifetime of cable can be extended so that the cable renewal cycle of a wind power generator is shortened. The cable is also energy-saving, possesses the feature of reducing emissions and plays an important role in saving resources.

Owner:JIANGSU ZHONGMEI CABLE

Hard rock drill rod

ActiveCN112112579AImprove torsional performanceExtended service lifeDrilling rodsDrilling casingsStructural engineeringDrill pipe

The invention relates to the technical field of drill rods, in particular to a hard rock drill rod. The hard rock drill rod comprises a drill rod body and a connecting mechanism arranged on the drillrod body, the connecting mechanism comprises a first connecting assembly and a second connecting assembly, the first connecting assembly and the second connecting assembly are arranged at the two endsof the drill rod body respectively, the first connecting assembly comprises a connecting block and a locking block arranged at the upper end of the connecting block, a locking hole is formed in the locking block, the second connecting assembly comprises a connecting groove, a locking pin hole formed in the top of the connecting groove and a buffering wedge block arranged in the connecting groove,and a buffering assembly is arranged in the buffering wedge block. The hard rock drill rod is simple in structure and convenient to connect, the drill rod body can be efficiently connected, the torsion resistance of the hard rock drill rod in the drilling process can be effectively improved, and the service life of the drill rod body is prolonged.

Owner:ZOUCHENG YANKUANG TAIDE IND & TRADE CO LTD

High-performance tool joint for transmitting electric power and relevant signals

InactiveCN101881140AImprove torsional performanceHighly Intelligent Drilling and Production RequirementsDrilling rodsDrilling casingsEngineeringPerformance tool

The invention relates to a high-performance tool joint for transmitting electric power and relevant signals. The high-performance tool joint consists of an internally threaded part and an externally threaded part, wherein the internally threaded part comprises a first external circular bead surface, a first cylindrical hole, an internal thread, a conical hole, a second cylindrical hole and an internal circular bead surface; the first external circular bead surface is positioned at the top end of the internally threaded part; the first cylindrical hole, the internal thread, the conical hole, the second cylindrical hole and the internal circular bead surface are arranged on the inner wall of the internally threaded part sequentially from the first external circular bead surface backward; the internal circular bead surface is annularly provided with a first signal transmission channel; one side of the internal circular bead surface is through provided with a first joint pipe transmission channel communicated with the first signal transmission channel; the externally threaded part comprises a second external circular bead surface, a first cylindrical surface, an external thread, a second cylindrical surface and a third external circular bead surface; the second external circular bead surface is positioned at the top end of the externally threaded part; the first cylindrical surface, the external thread, the second cylindrical surface and the third external circular bead surface are arranged on the outer wall of the externally threaded part sequentially from the second external circular bead surface backward; the second external circular bead surface is annularly provided with a second signal transmission channel; and one side of the internal circular bead surface is axially through provided with a second joint pipe transmission channel communicated with the second signal transmission channel. The high-performance tool joint solves the technical problems.

Owner:上海海隆石油钻具有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com