Halogen-free super-soft distortion-resistant cable and preparation method thereof

A super flexible and durable cable technology, applied in bendable cables, cable/conductor manufacturing, insulated cables, etc., to achieve the effect of optimized design structure, high torsion, and elimination of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a halogen-free ultra-flexible twist-resistant cable, the specific steps are as follows:

[0037] Step 1: Prepare ultra-flexible copper conductors with a high-speed wire bundle machine, with a stranding pitch of 8-10mm and a speed of 30m / min; ten copper wires with a diameter of 0.06mm are wound around the nylon wire by a wire winding machine , the signal composite conductor 41 was obtained; nineteen copper wires with a diameter of 0.10 mm were twisted and twisted to the left to obtain the power line conductor 31;

[0038] Step 2, using a ¢50 extruder to prepare the power insulating layer 32 and the signal insulating layer 43, the temperature of the extrusion head is 210 degrees Celsius, and the extruded thicknesses of the power insulating layer 32 and the signal insulating layer 43 are 0.25 mm and 0.5 mm, respectively. Power frequency AC voltage 4000V, extrusion speed 150-200m / min;

[0039] Step 3: Wrap every two signal composite conductors 41 cov...

Embodiment 1

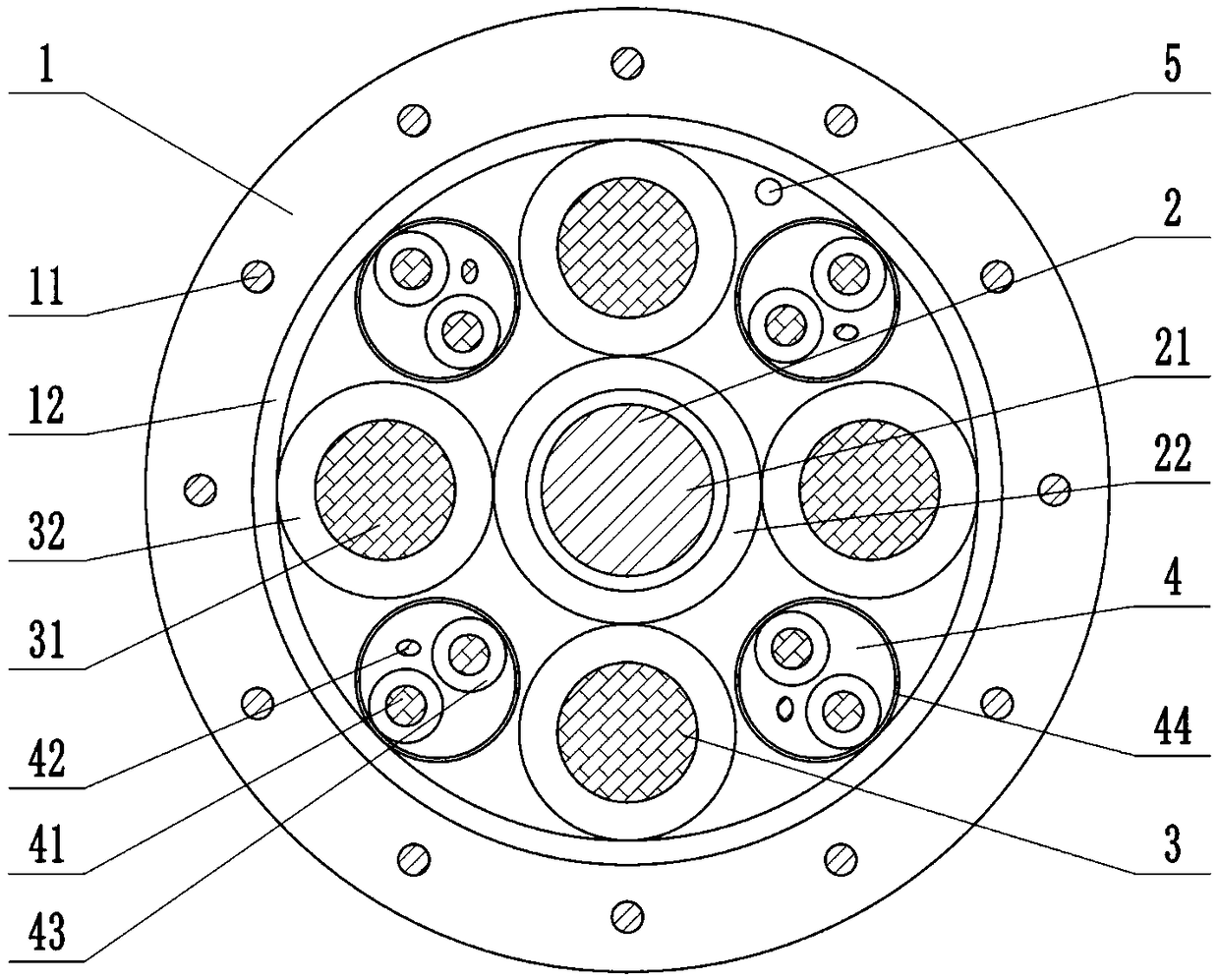

[0050] A halogen-free ultra-flexible twist-resistant cable, comprising an outer sheath 1, a number of reinforced aramid fibers 11 are arranged in the side wall of the outer sheath 1, a cotton yarn braided layer 12 is fixed on the inner wall of the outer sheath 1, and the cotton yarn braided layer 12 is covered with a steel wire rope 2, four power wires 3, four twisted pair shielded transmission signal wires 4 and a twisted nylon wire 5, the power wire 3 and the twisted pair shielded transmission signal wire 4 are twisted around the steel wire rope 2 at intervals ,

[0051] The steel wire rope 2 includes a stress-relieving regular stranded steel wire rope 21, and the stress-relieving regular stranded steel wire rope 21 is provided with a spiral support 22. The power line 3 includes a power line conductor 31, and the power line conductor 31 is covered with a power insulation layer 32, and the twisted pair is shielded. The transmission signal line 4 includes two signal composite ...

Embodiment 2

[0070] A halogen-free ultra-flexible twist-resistant cable, comprising an outer sheath 1, a number of reinforced aramid fibers 11 are arranged in the side wall of the outer sheath 1, a cotton yarn braided layer 12 is fixed on the inner wall of the outer sheath 1, and the cotton yarn braided layer 12 is covered with a steel wire rope 2, four power wires 3, four twisted pair shielded transmission signal wires 4 and a twisted nylon wire 5, the power wire 3 and the twisted pair shielded transmission signal wire 4 are twisted around the steel wire rope 2 at intervals ,

[0071] The steel wire rope 2 includes a stress-relieving regular stranded steel wire rope 21, and the stress-relieving regular stranded steel wire rope 21 is provided with a spiral support 22. The power line 3 includes a power line conductor 31, and the power line conductor 31 is covered with a power insulation layer 32, and the twisted pair is shielded. The transmission signal line 4 includes two signal composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com