Patents

Literature

41results about How to "Improve cushioning performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

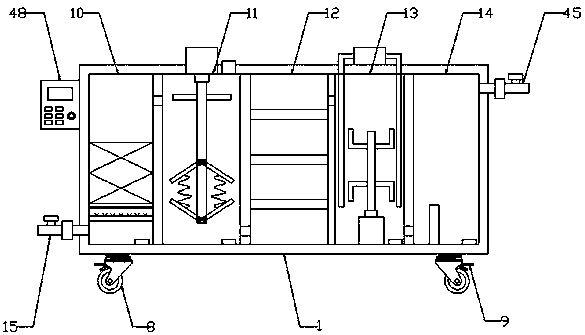

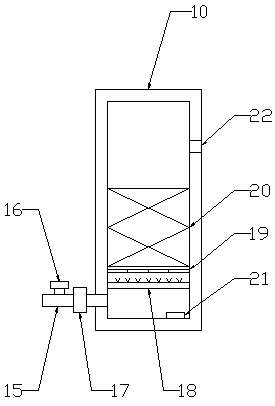

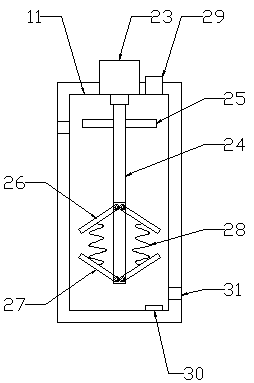

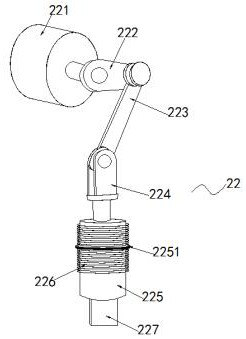

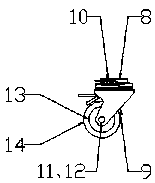

Movable multistage effective sewage treatment device

InactiveCN108033656AImprove cushioning performanceImprove safety performanceWater treatment parameter controlTreatment using aerobic processesPrecipitationSewage treatment

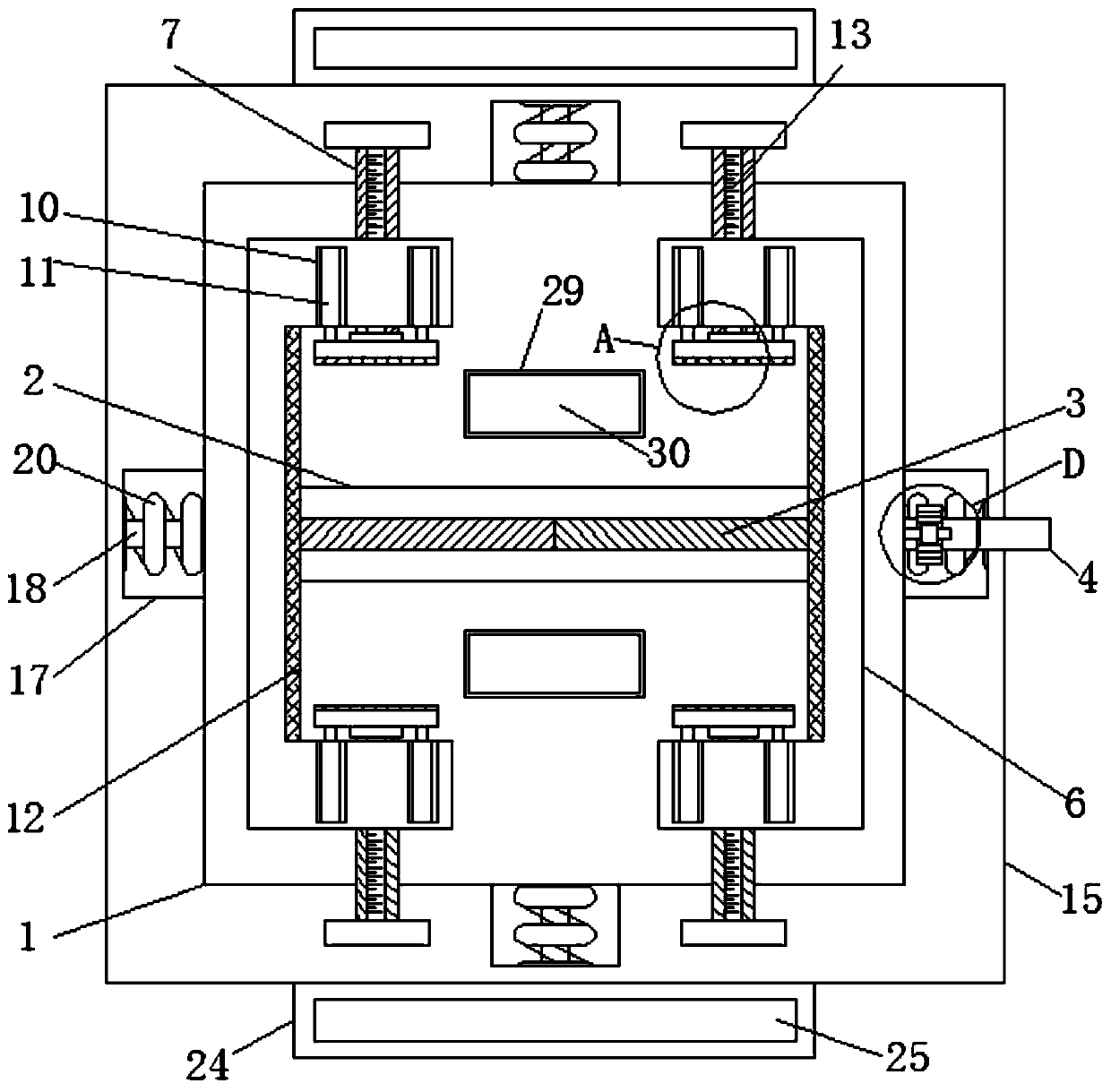

The invention discloses a movable multistage effective sewage treatment device, comprising a shell; the shell is in a rectangular shape; a damping universal wheel device is arranged at the bottom of the shell; the shell is internally and sequentially provided with an oxidation tank, a flocculating tank, a filter tank, a disinfection tank and a precipitation tank in the length direction; a waste water inlet pipe, fixedly connected with the oxidation tank, is arranged under one side of the shell; the oxidation tank is internally provided with an oxidation device; the flocculating tank is internally provided with a flocculating device; the filter tank is internally provided with a filtering device; the disinfection tank is internally provided with a disinfection device; the precipitation tankis internally provided with a precipitating device; a water outlet pipe, fixedly connected with the precipitation tank, is arranged above the right side of the shell; a controller is arranged outsidethe shell; the controller is respectively and electrically connected with the oxidation device, the flocculating device, the filtering device, the disinfection device and the precipitating device. The movable multistage effective sewage treatment device has the beneficial effects of being simple in structure and high in practicality.

Owner:赵风元

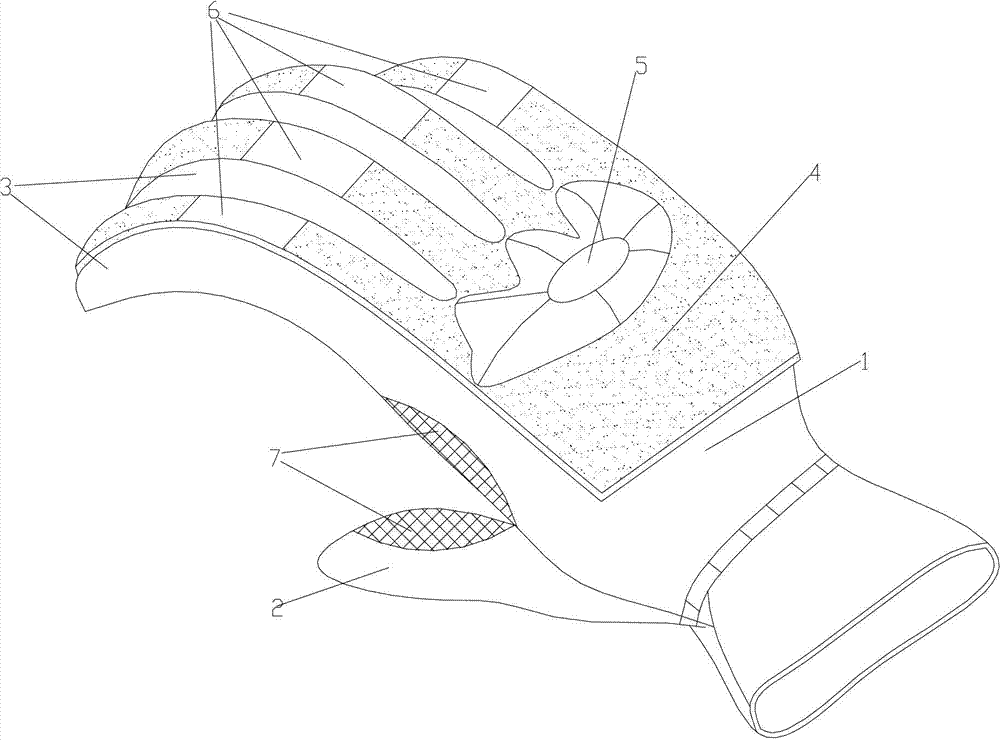

Shock resistant motorcycle gloves

InactiveCN102960879AReduce hand fatigueImprove cushioning performanceProtective garmentHand partsEngineering

The invention discloses a pair of shock resistant motorcycle gloves, comprising hand parts, wherein each hand part comprises a hand back part and a four-finger part, and a sponge rubber layer with an integrated structure is arranged on the hand back part and the four-finger part; the four-finger part is bent; the thickness of the sponge rubber layer is 35-40 mm; an impact buffering body is arranged on the sponge rubber layer of the hand back part; the impact buffering body is made of foam plastic; and reflective strips are arranged on the sponge rubber layer of the four-finger part. According to the shock resistant motorcycle gloves, the four-finger part adopts the bent structural design, when a user wears the gloves, four fingers of each hand of the user can naturally bend in the gloves, the gloves fit with the hands perfectly, when the user holds a handlebar, the force on bending the four-finger part of each glove is reduced, and the hand fatigue is accordingly reduced; the sponge rubber layer is arranged on the hand back part and the four-finger part of each glove, so that the buffering performance is increased, and the hands are protected from impact and friction and other accidental injury in accidental circumstances.

Owner:SUZHOU LONGXIN GLOVES

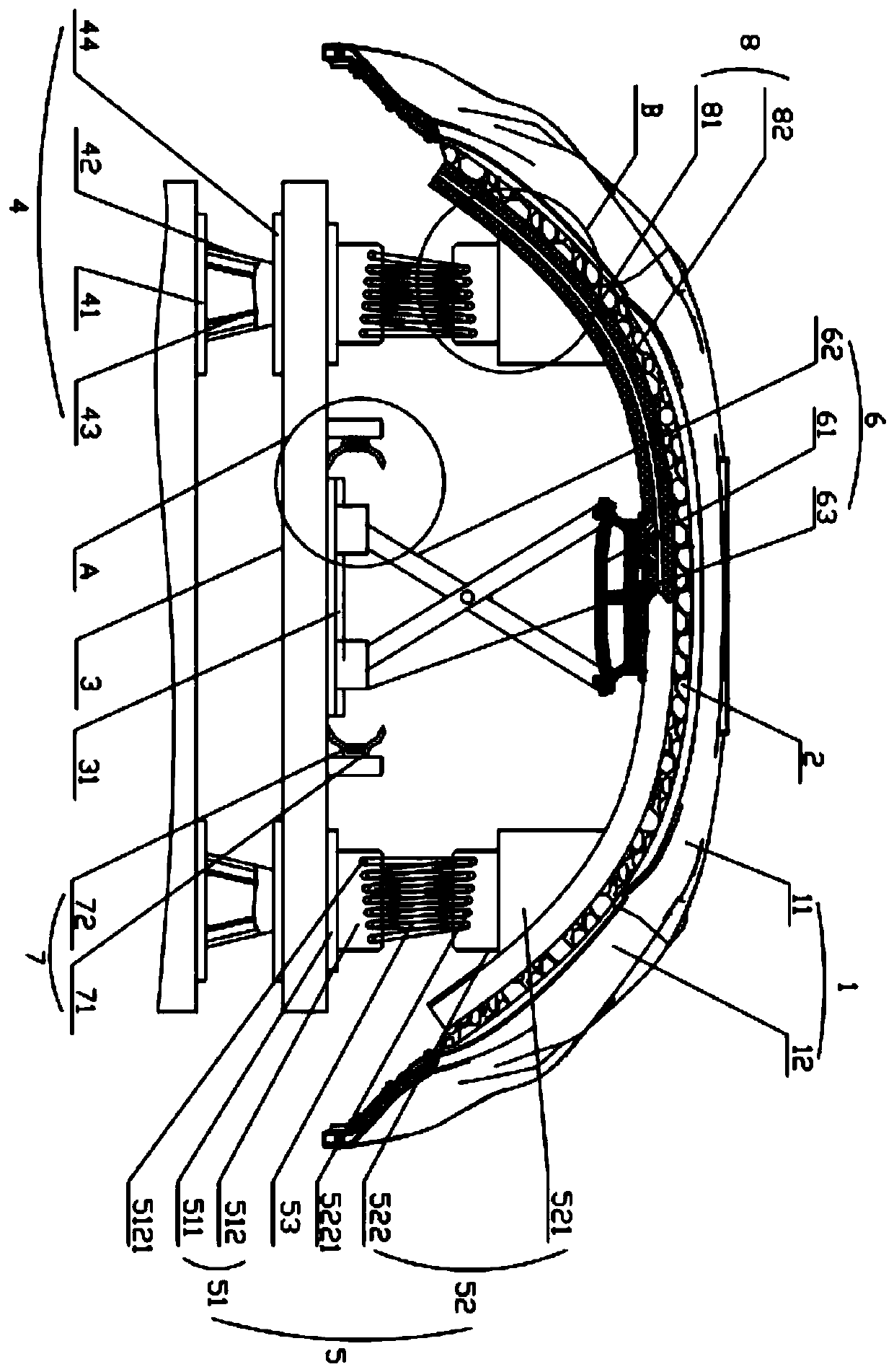

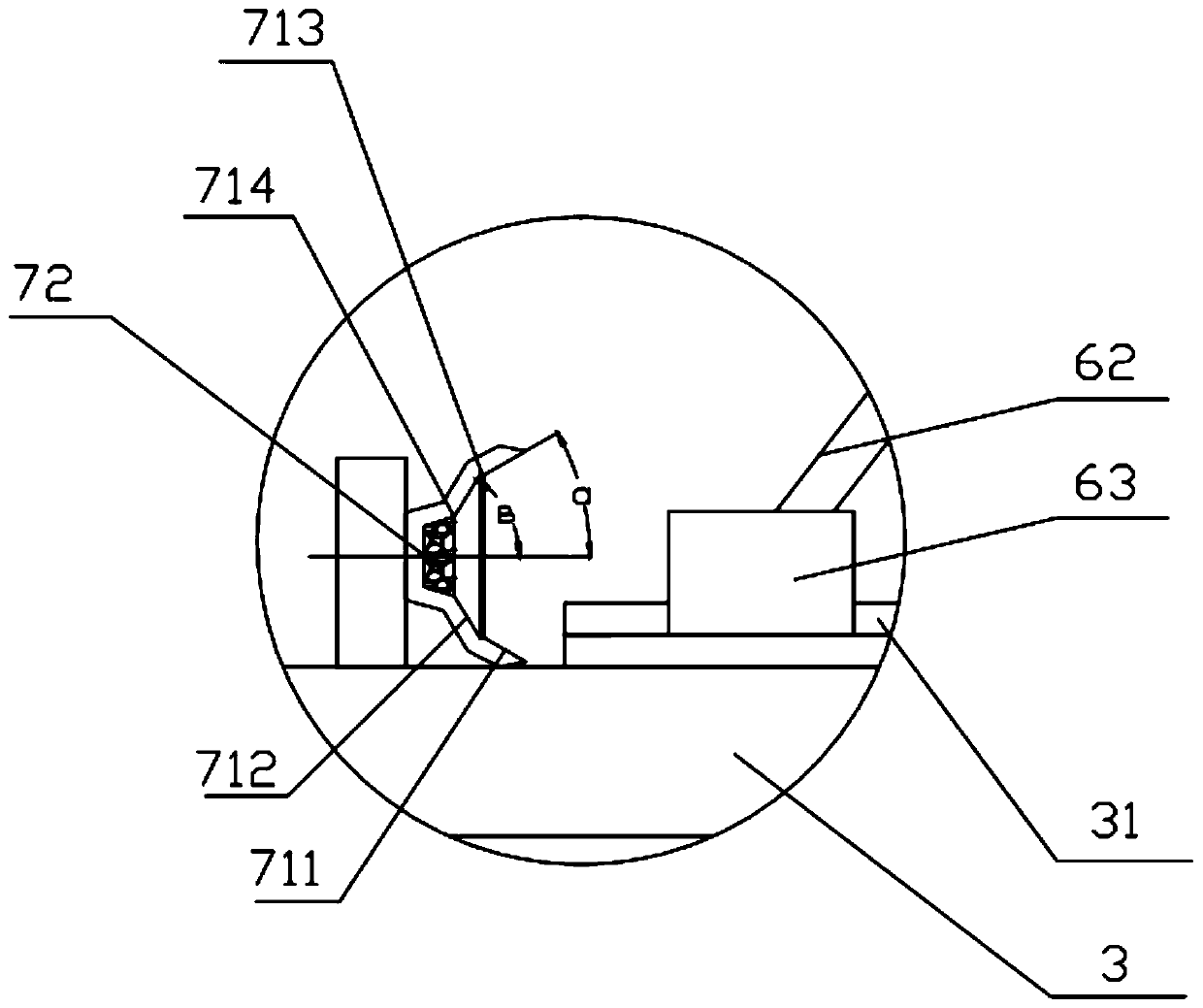

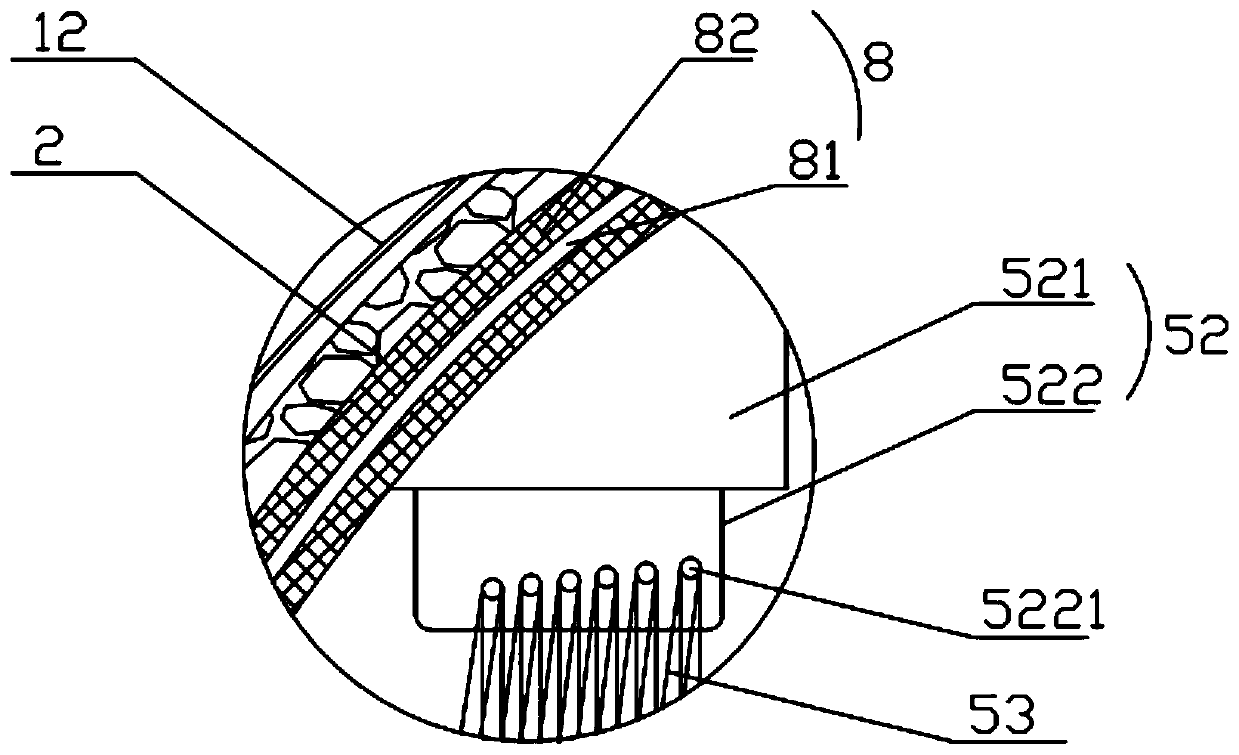

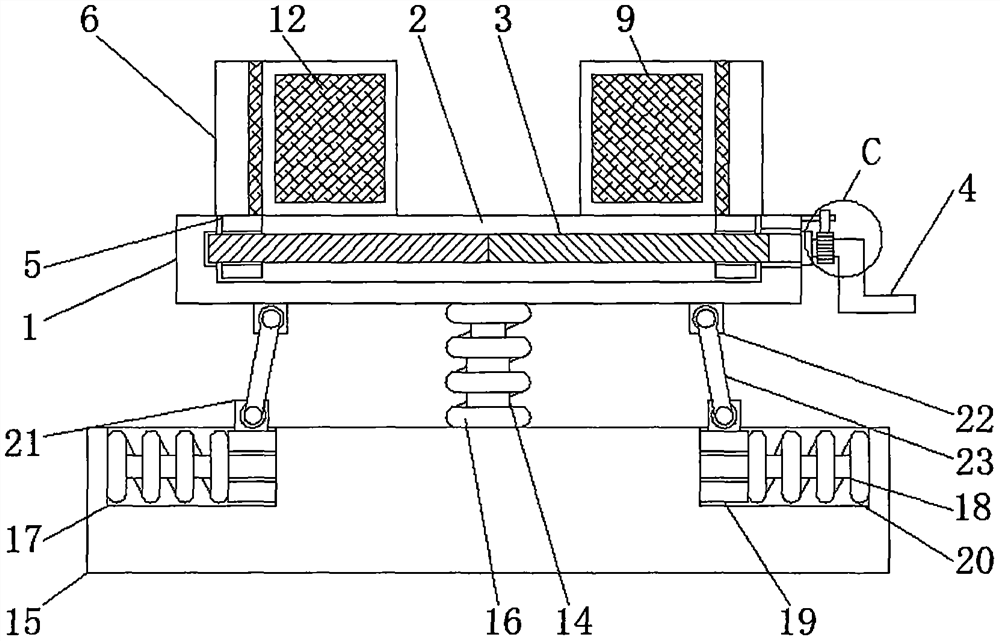

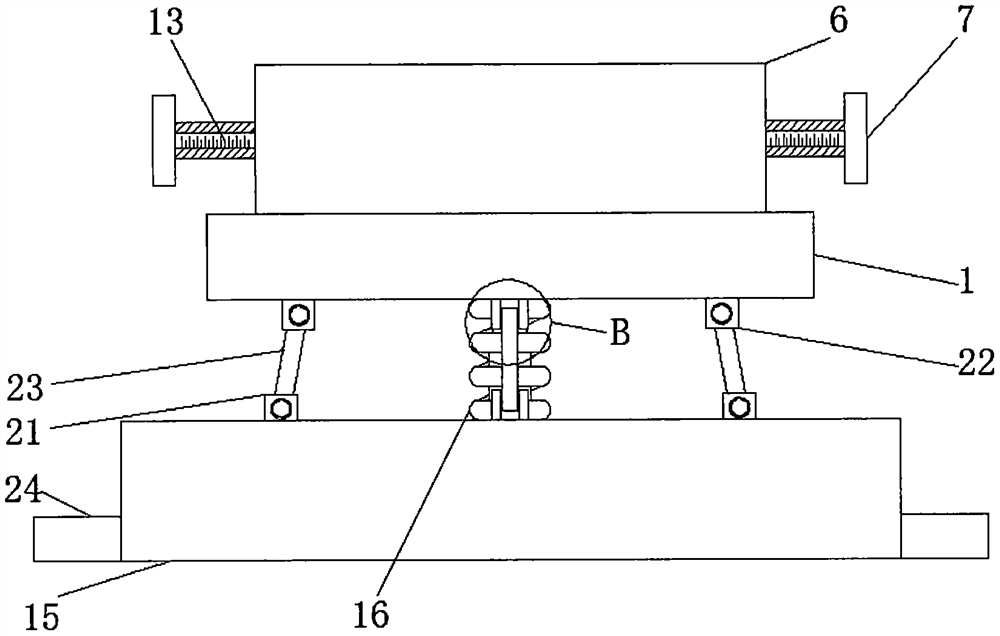

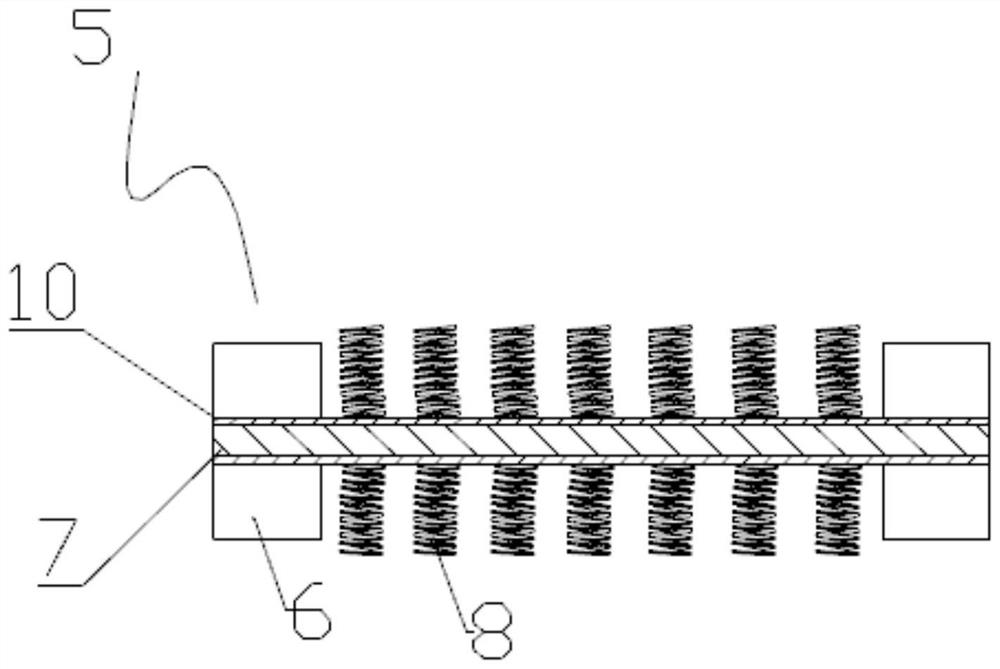

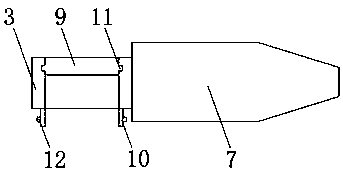

Telescopic step-by-step layered buffering vehicle bumper

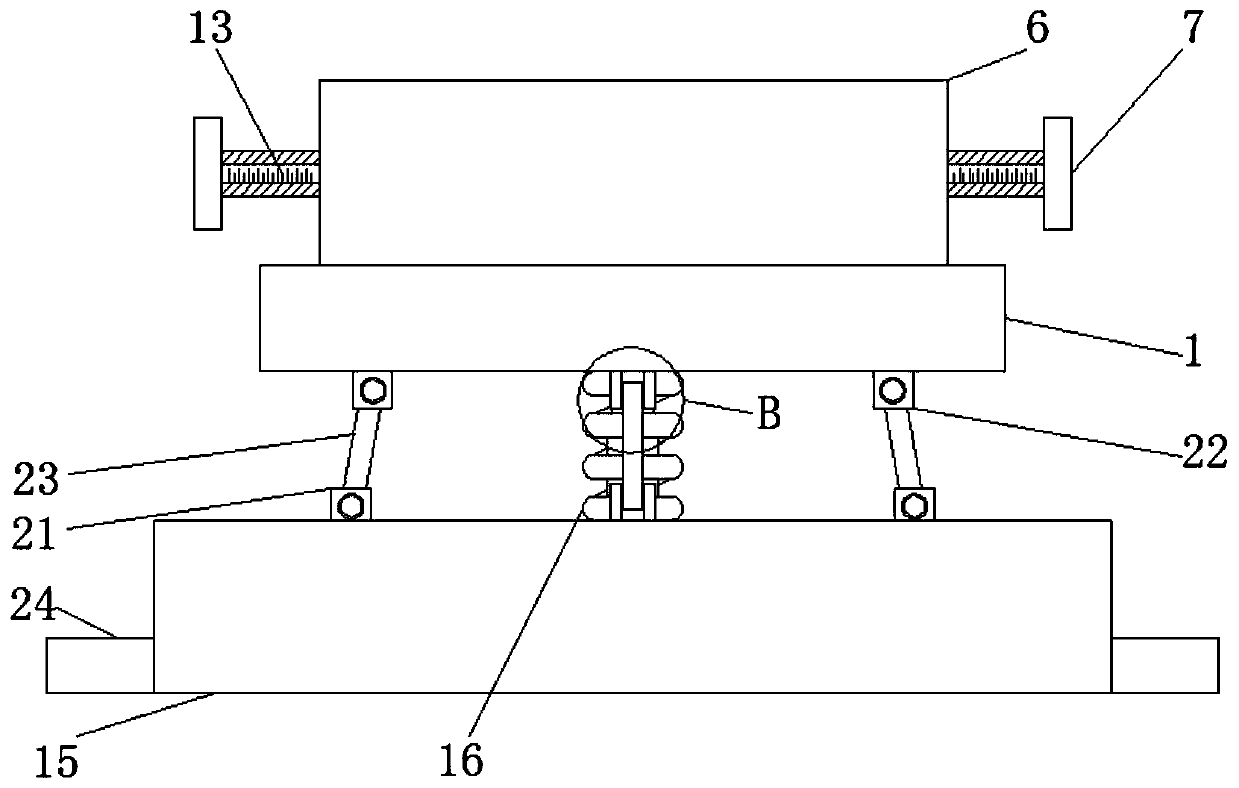

ActiveCN111002934AImprove cushioning performanceAvoid secondary collisionBumpersAutomotive engineeringCoil spring

The invention discloses a telescopic step-by-step layered buffering vehicle bumper, and belongs to the field of vehicle bumpers. The bumper comprises a bumper shell assembly, an energy absorption block, a bumper beam, a bumper support, a first-stage buffer mechanism, a second-stage buffer mechanism, a valve base assembly and a bearing plate. The primary buffer mechanism comprises a first support,a second support and a plurality of spiral springs; the first-stage buffer mechanism can ensure that the bumper absorbs energy during torsional vibration rotation. Therefore, overlarge torsional vibration and impact amplitude in impact are attenuated; a common amplitude value of a resonance region in impact is inhibited and a large torque is transmitted; even if the collision direction of the external force is uncertain, when the vehicle bumper is collided, multi-stage buffering can be carried out through the two-stage buffering mechanism, that is to say, the two-stage buffer mechanism can convert the vertical impact load into the horizontal transverse impact load, and can buffer the horizontal transverse impact load to play an important role in improving the impact energy absorption effect, improving the vehicle collision safety and protecting pedestrians.

Owner:南昌华翔汽车内外饰件有限公司

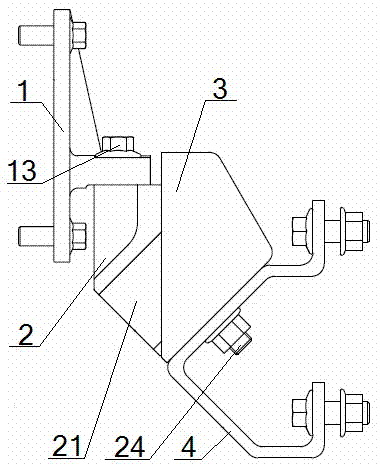

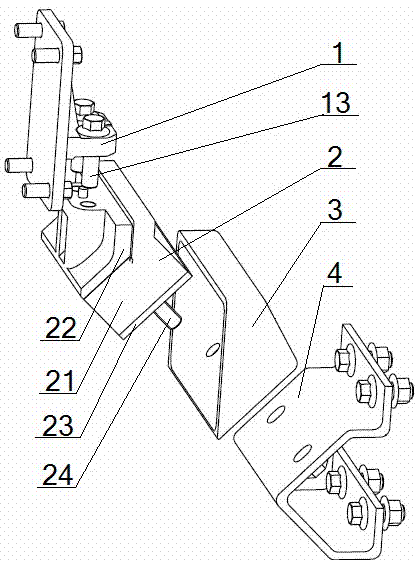

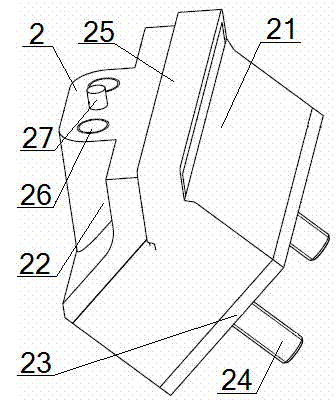

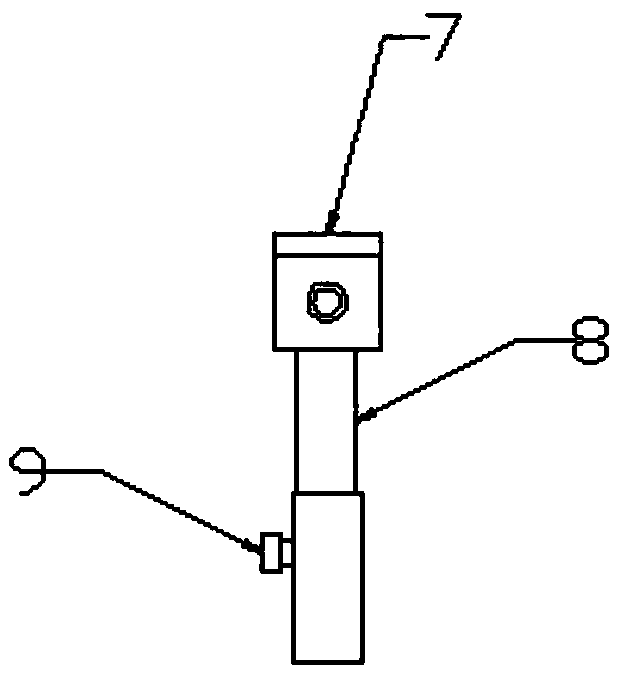

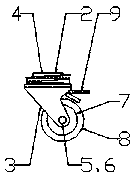

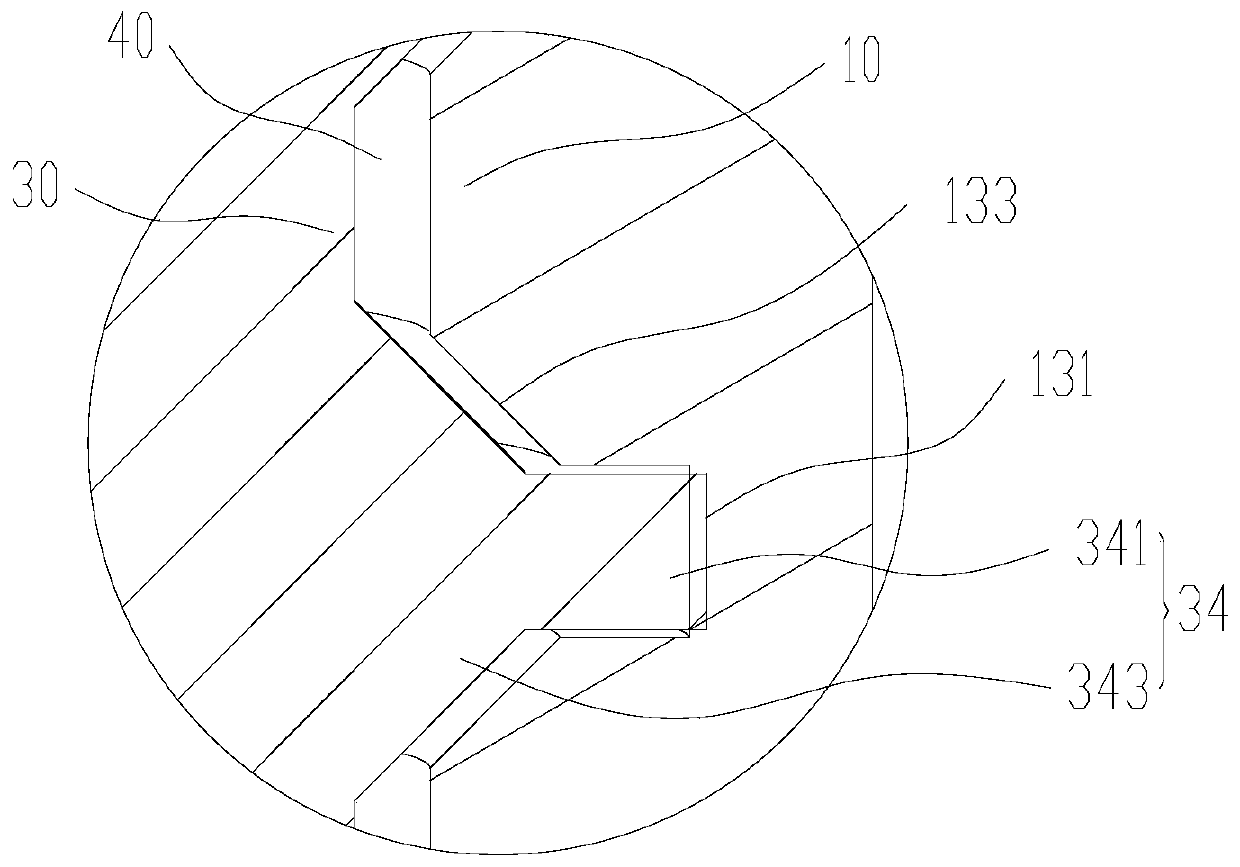

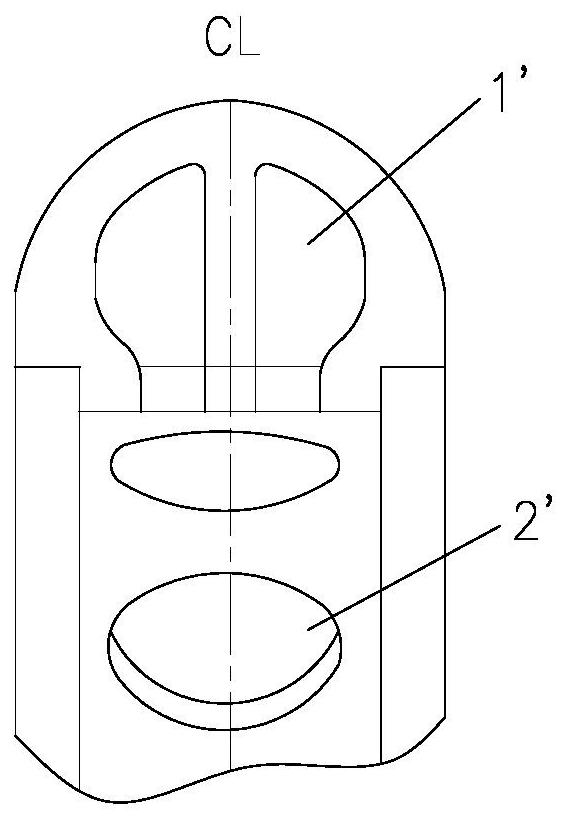

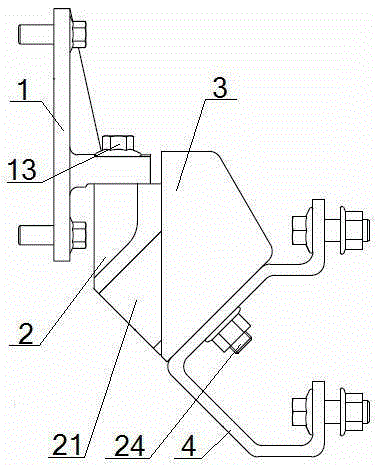

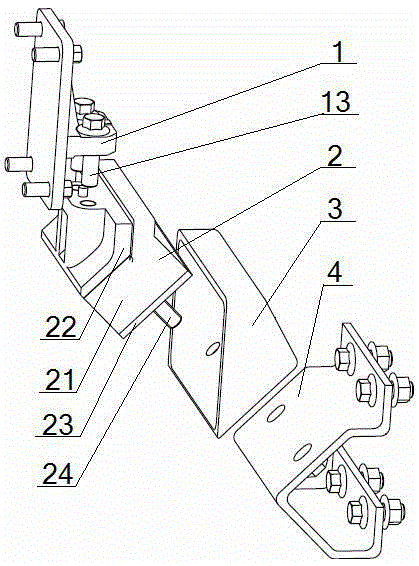

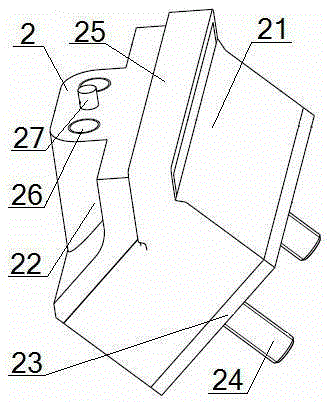

Box type limit engine suspension assembly

ActiveCN103568806AAvoid tearingExtended service lifeNon-rotating vibration suppressionJet propulsion mountingVulcanizationUltimate tensile strength

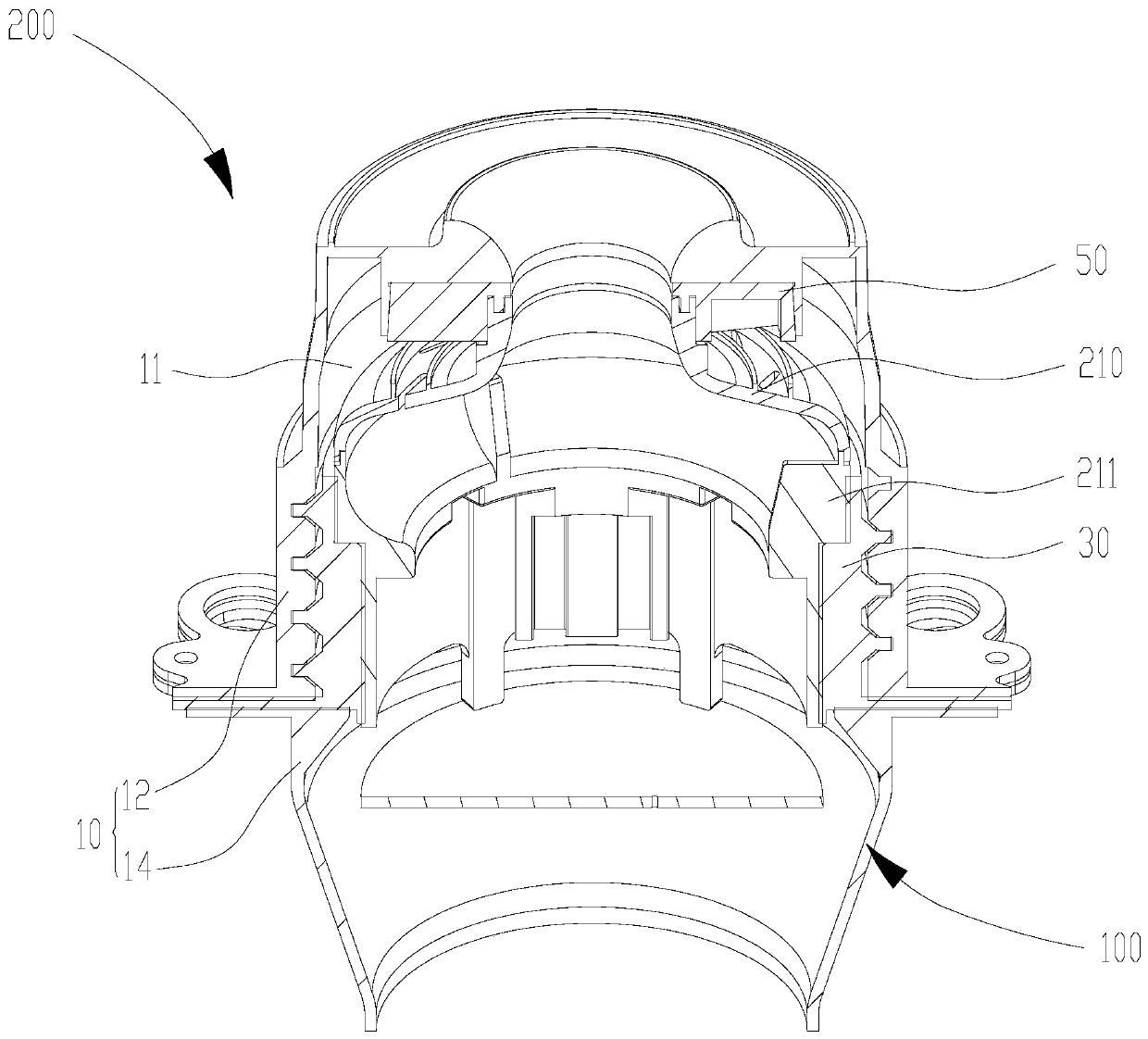

A box type limit engine suspension assembly comprises a suspension cushion vulcanization assembly and a suspension bracket which are mutually connected, wherein the suspension cushion vulcanization assembly comprises vulcanized rubber, an upper framework, a lower framework and a lower framework bolt, and the upper framework is integrally vulcanized with the lower framework and the lower framework bolt through the vulcanized rubber; and the engine suspension assembly further comprises a limit box, the suspension cushion vulcanization assembly is arranged in the limit box, and the suspension cushion vulcanization assembly is fixedly connected with the suspension bracket through the limit box. With the adoption of the design, the box type limit engine suspension assembly is convenient to mount, high in mechanical strength, good in buffer performance and long in service life, and can be suitable for heavy vehicles such as a commercial vehicle and the like.

Owner:DONGFENG COMML VEHICLE CO LTD

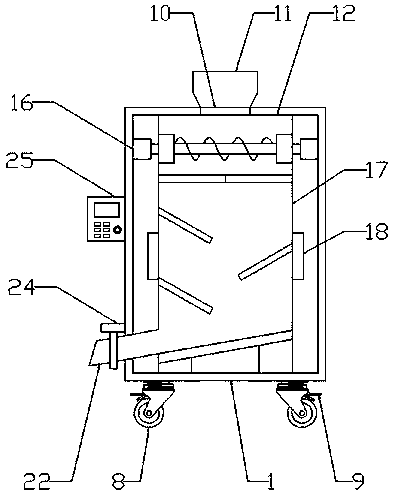

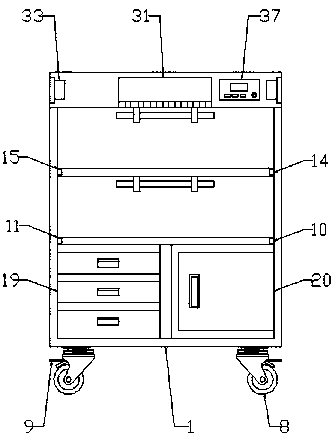

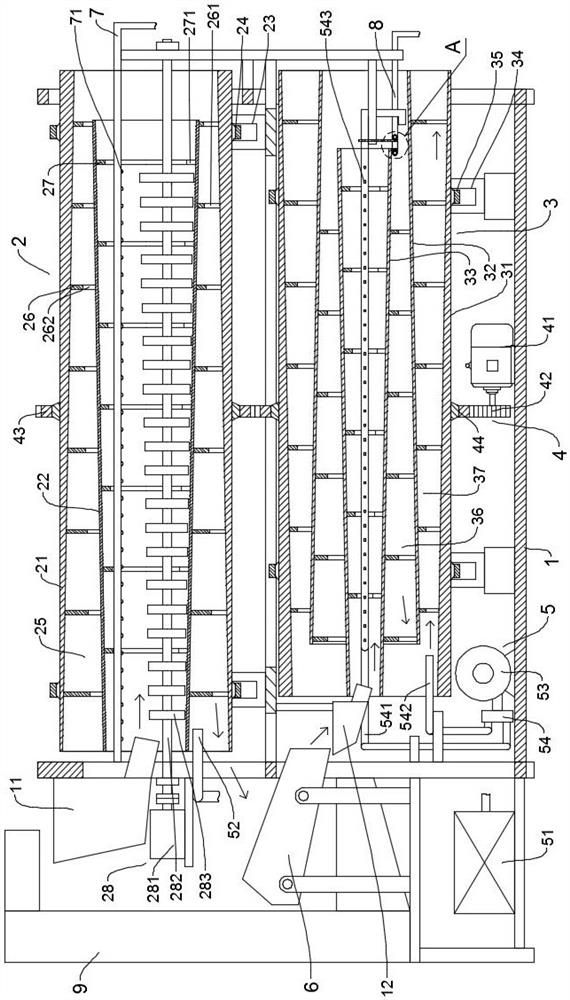

High-precision Chinese medicinal material dispensing and sub-packaging system

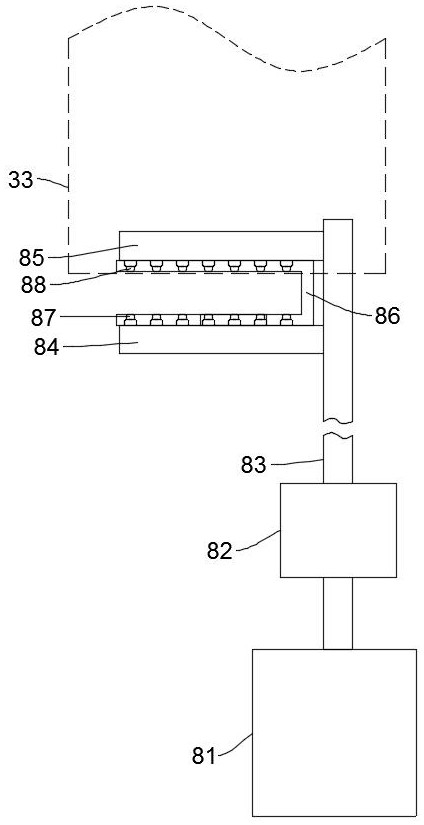

InactiveCN108248939AImprove cushioning performanceImprove safety performanceRotary stirring mixersNon-rotating vibration suppressionEngineeringPackaging machine

The invention discloses a high-precision Chinese medicinal material dispensing and sub-packaging system. The system comprises a sub-packaging machine body, wherein the sub-packaging machine body is ina rectangular shape; a damping universal wheel device is arranged at the bottom of the sub-packaging machine body; a feeding device is arranged above the sub-packaging machine body; a stirring deviceis arranged in a Chinese medicinal material stirring box; an automatic weighing device is arranged in a Chinese medicinal material weighing box; a controller is arranged on one side of the sub-packaging machine body; and the controller is respectively and electrically connected with the feeding device, the stirring device and the automatic weighing device. The high-precision Chinese medicinal material dispensing and sub-packaging system disclosed by the invention has the beneficial effects of simple structure and strong practicability.

Owner:李桂英

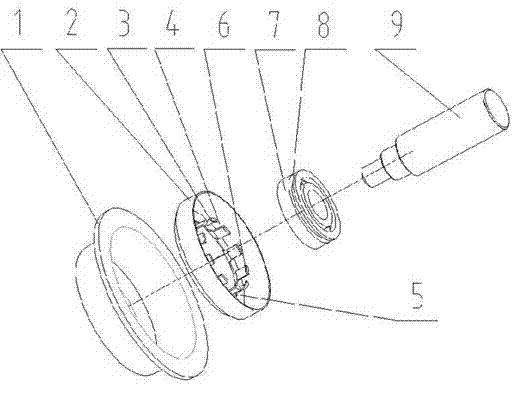

Radial rolling bearing seat assembly structure with good vibration absorption

InactiveCN102252020AImprove cushioning performanceReasonable elastic coefficientVibration suppression adjustmentsElastic bearingsPhysicsCentre of rotation

The invention relates to a radial rolling bearing seat assembly structure with good vibration absorption. The structure comprises a bearing seat and a radial rolling bearing, wherein the radial rolling bearing consists of an inner ring, an outer ring, a rolling body and a retainer and is provided with an axial stop groove; the inner ring is matched with a shaft and rotates together with the shaft; the structure also comprises a metallic vibration absorption ring, wherein the vibration absorption ring is arranged between the bearing seat and the outer ring of the radial rolling bearing, the outer side and the bottom of the vibration absorption ring consist of a U-shaped outer edge and a bottom edge in a mode of rotating by using the central line of the shaft as a rotating center, and the inner side of the vibration absorption ring consists of a U-shaped inner edge in a mode of continuously rotating around the rotating center in equal clearance, so that the petal-like and roughly rotary vibration absorption ring, the inner side of which is provided with an equal central angle gap, is formed; the outer side of the vibration absorption ring is matched with and fastened to the bearing seat; and the protrusion on the petal-like body of the vibration absorption ring is embedded and limited in the axial stop groove of the radial rolling bearing. The structure has the advantages of good vibration absorption, low working noise and long service life of the bearing.

Owner:张华林

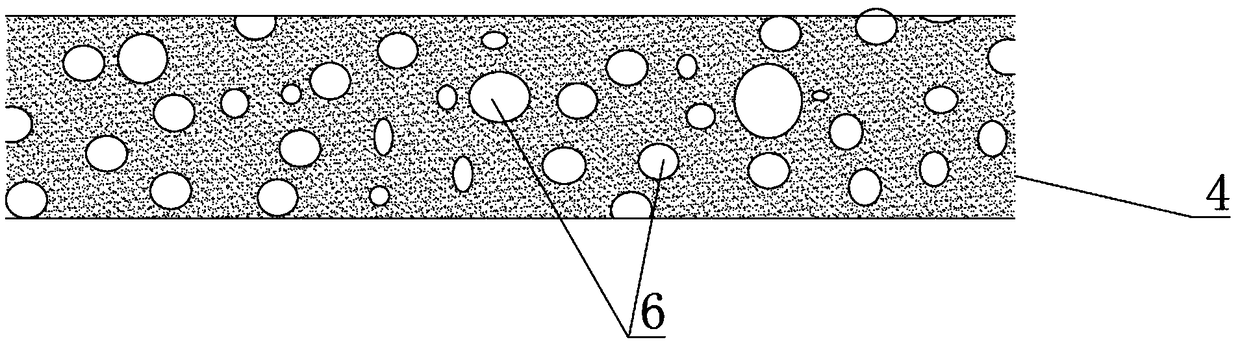

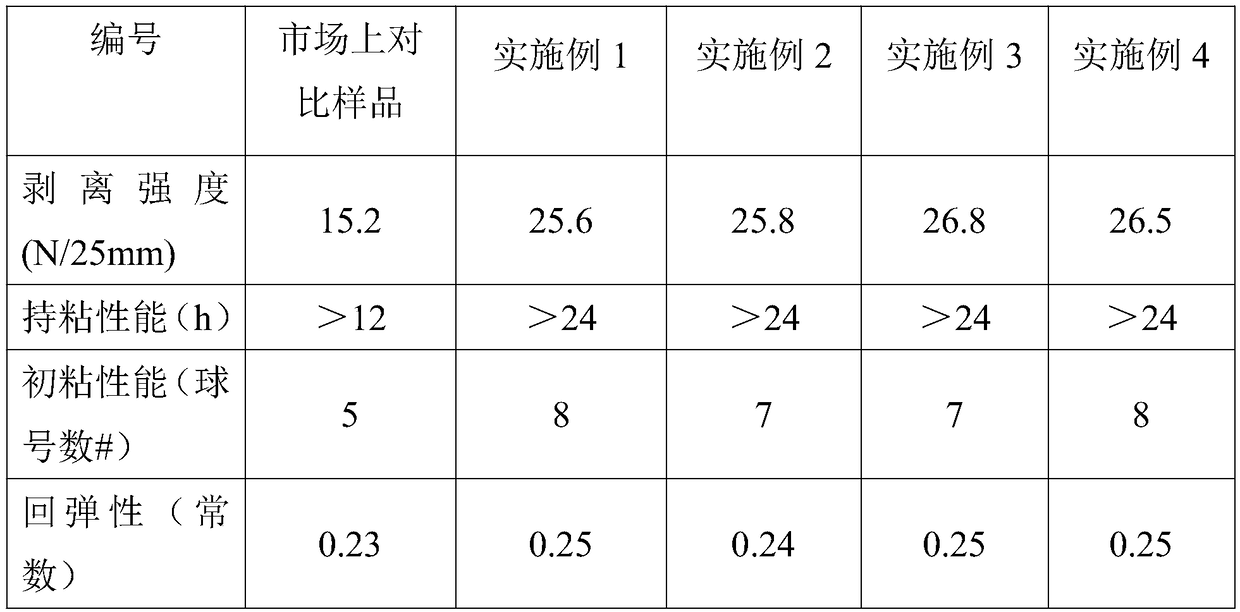

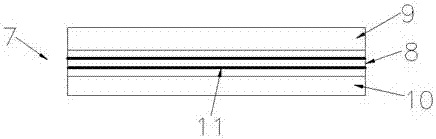

Polystyrene foam tape for automobiles

PendingCN109504306AImprove cushioning performanceEasy to Die Cut to ShapeNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryPolystyrene

The invention discloses a polystyrene foam tape for automobiles. The polystyrene foam tape comprises a first release layer, a first polystyrene foam layer, a substrate layer, a second polystyrene foamlayer and a second release layer which are adhered in sequence from top to bottom, wherein the substrate layer is of a double-layer structure and comprises a fiber layer and a foam layer; the first polystyrene foam layer and the second polystyrene foam are pressure sensitive adhesives or polyacrylic ester polystyrene foam with micropore structures, and are made from the following raw materials inparts by weight: 70-80 parts of a soft monomer, 20-30 parts of a hard monomer, 5-10 parts of an elastomer, 0.5-1 part of an emulsifier, 0.2-0.5 part of a buffer agent, 0.5-1 part of a foaming agent and 5-10 parts of a cross-linking agent. Due to adoption of a substrate of a double-layer structure of a fiber layer and a foam layer, and the polystyrene foam as an adhesive layer, the buffering property is improved while strength is ensured, and die cutting molding can be easily implemented; the acrylic adhesive is environmental-friendly in preparation process and good in temperature resistance and can be widely applied to automobile trim adhesion and electronic instrument fixation.

Owner:SHENZHEN NIKTO TAPE NEW MATERIAL CO LTD

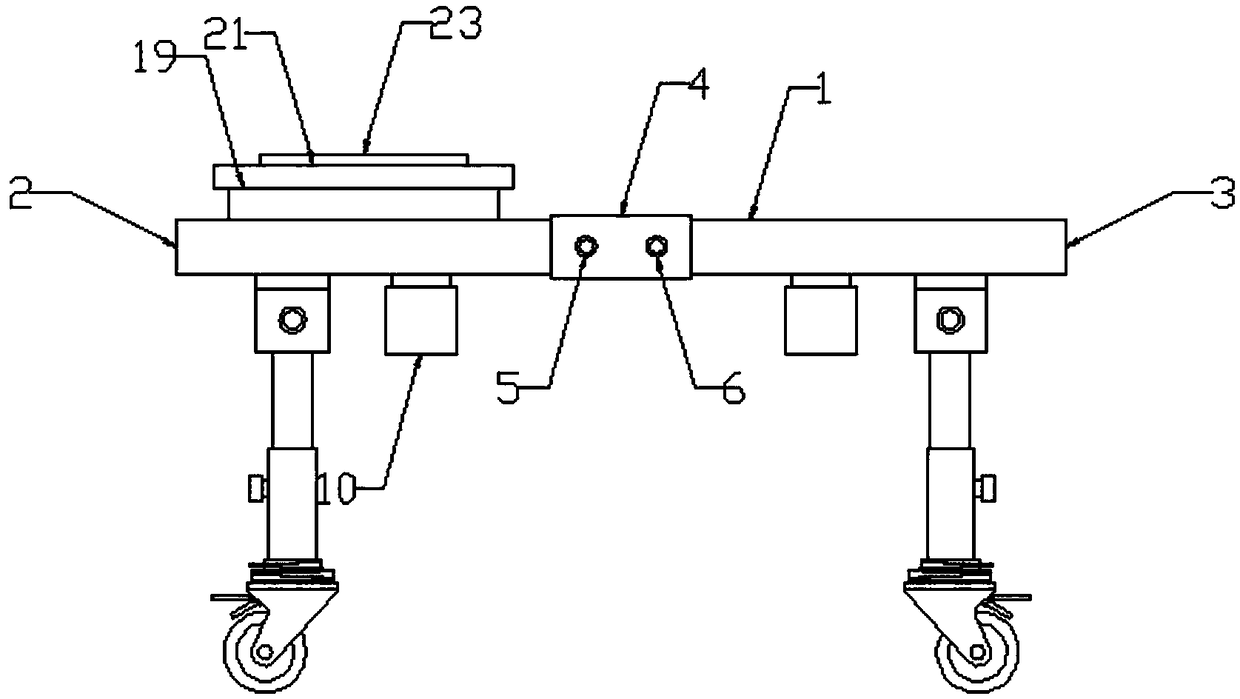

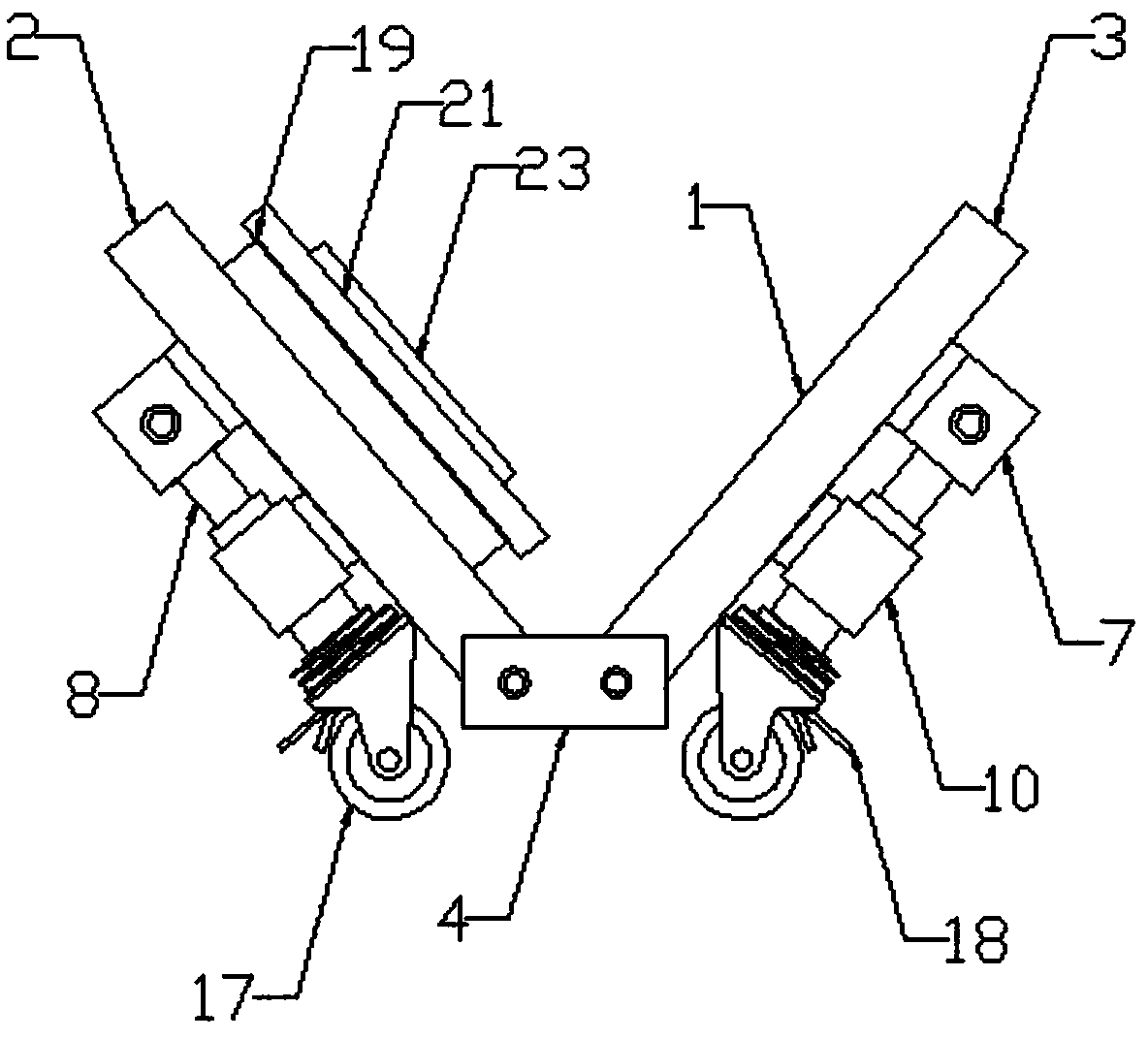

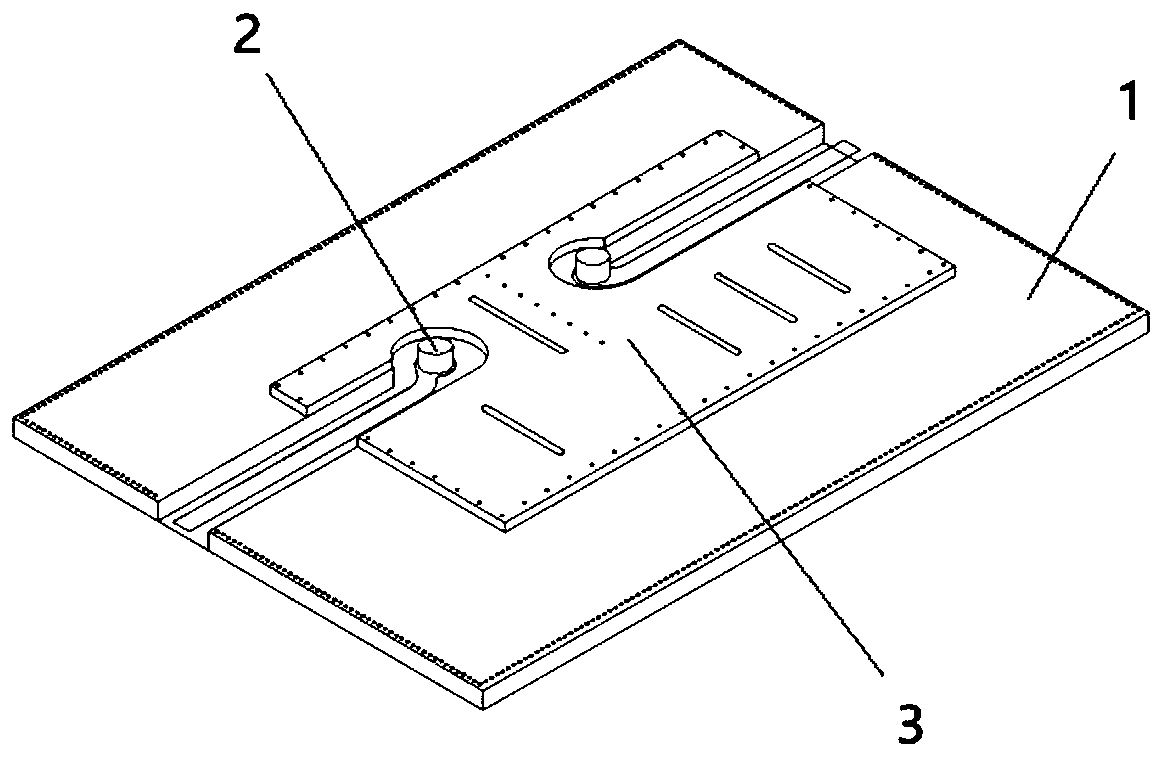

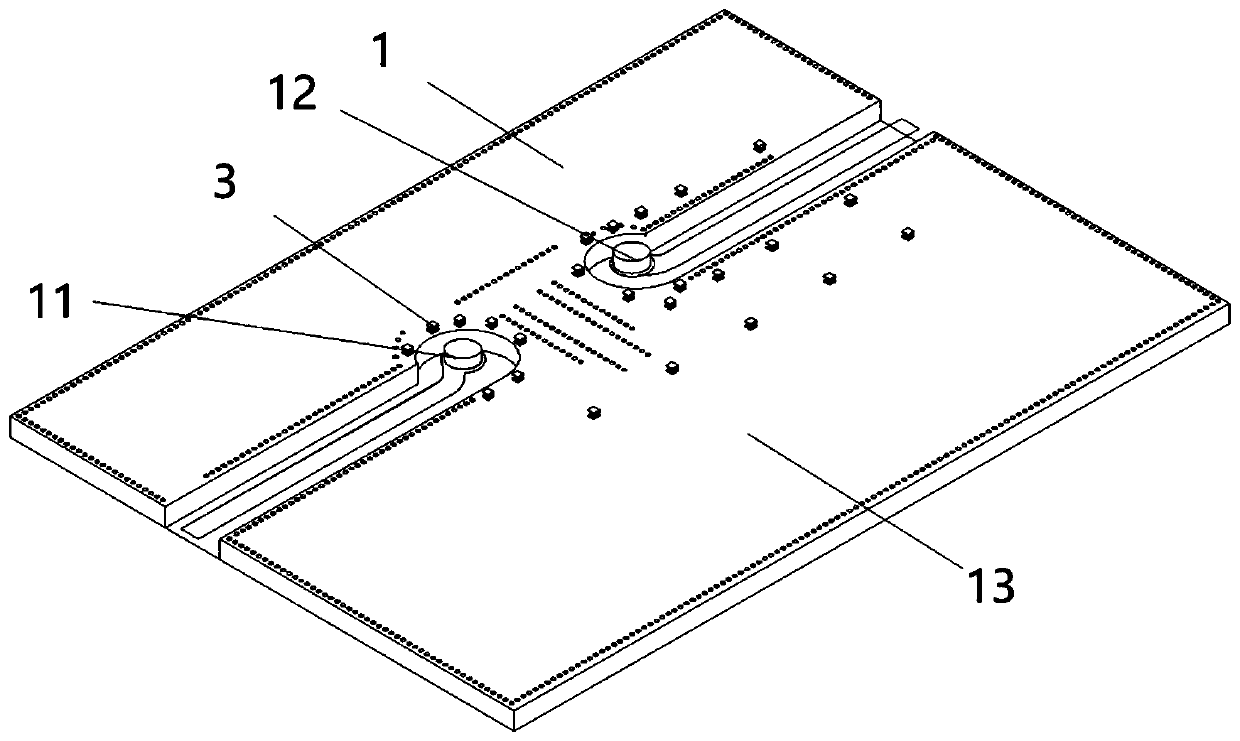

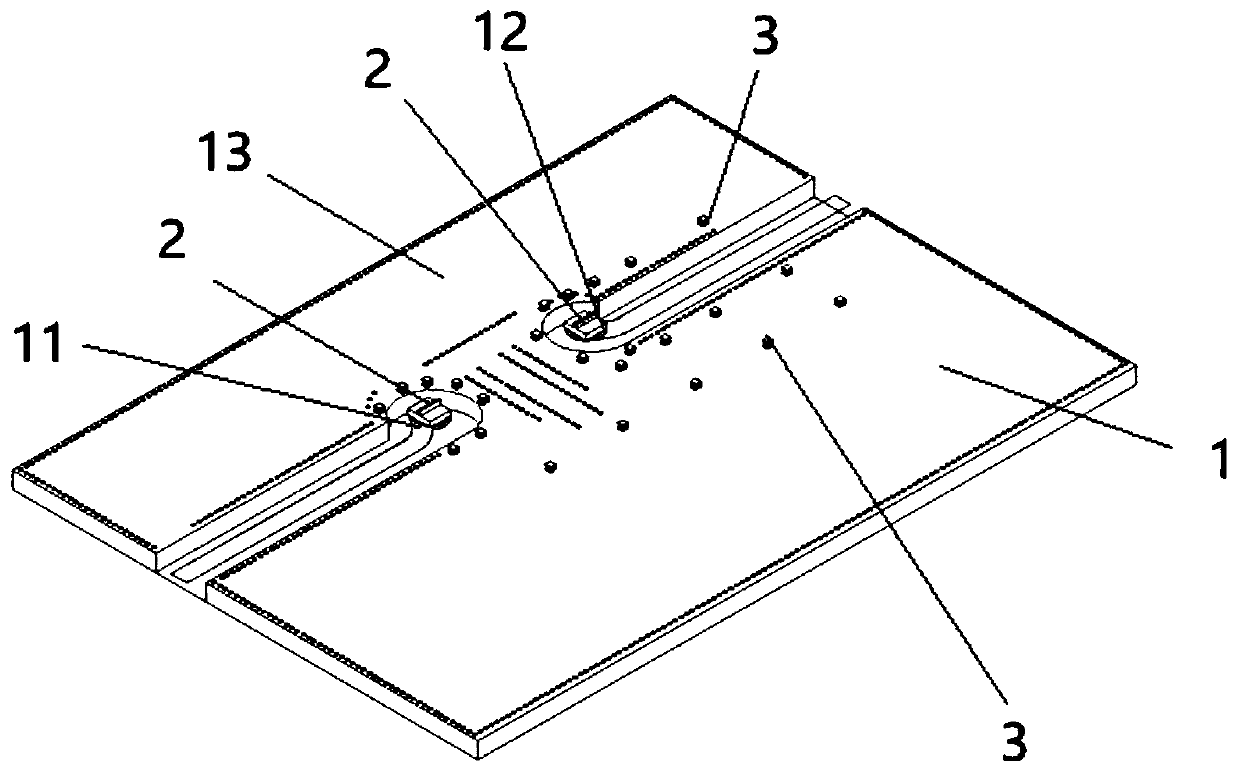

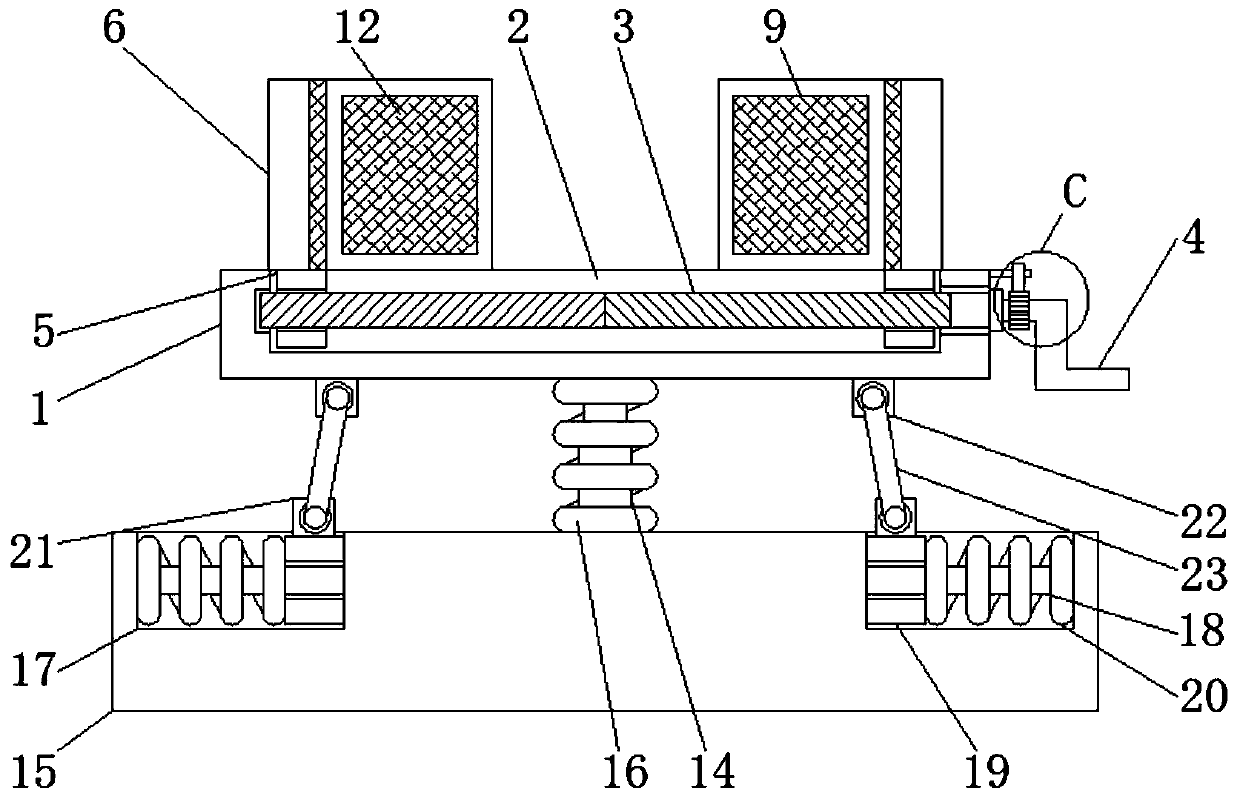

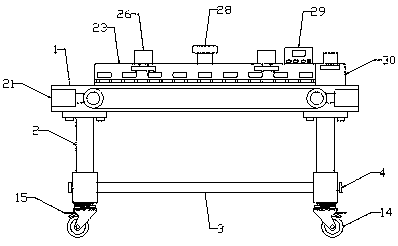

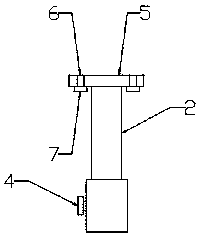

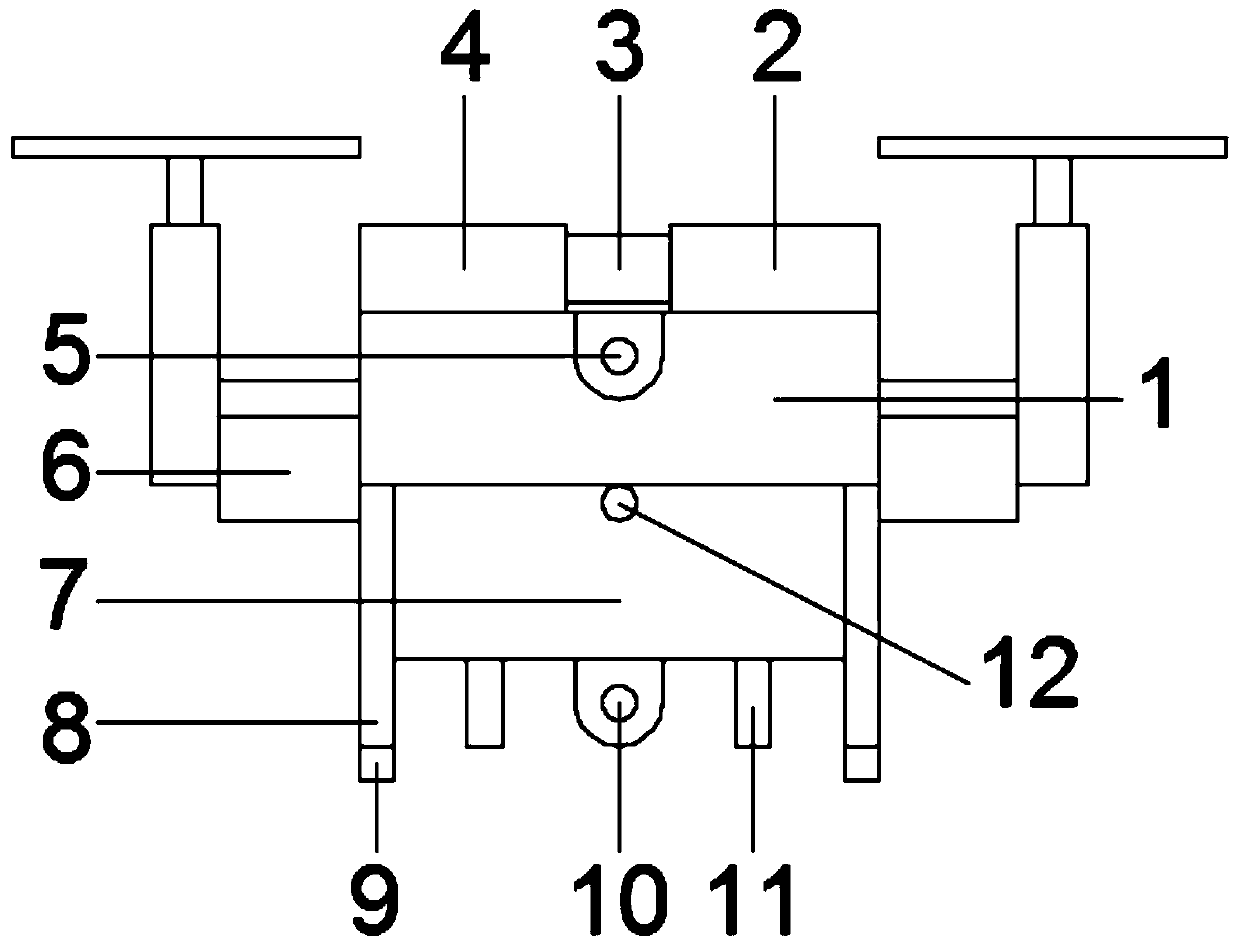

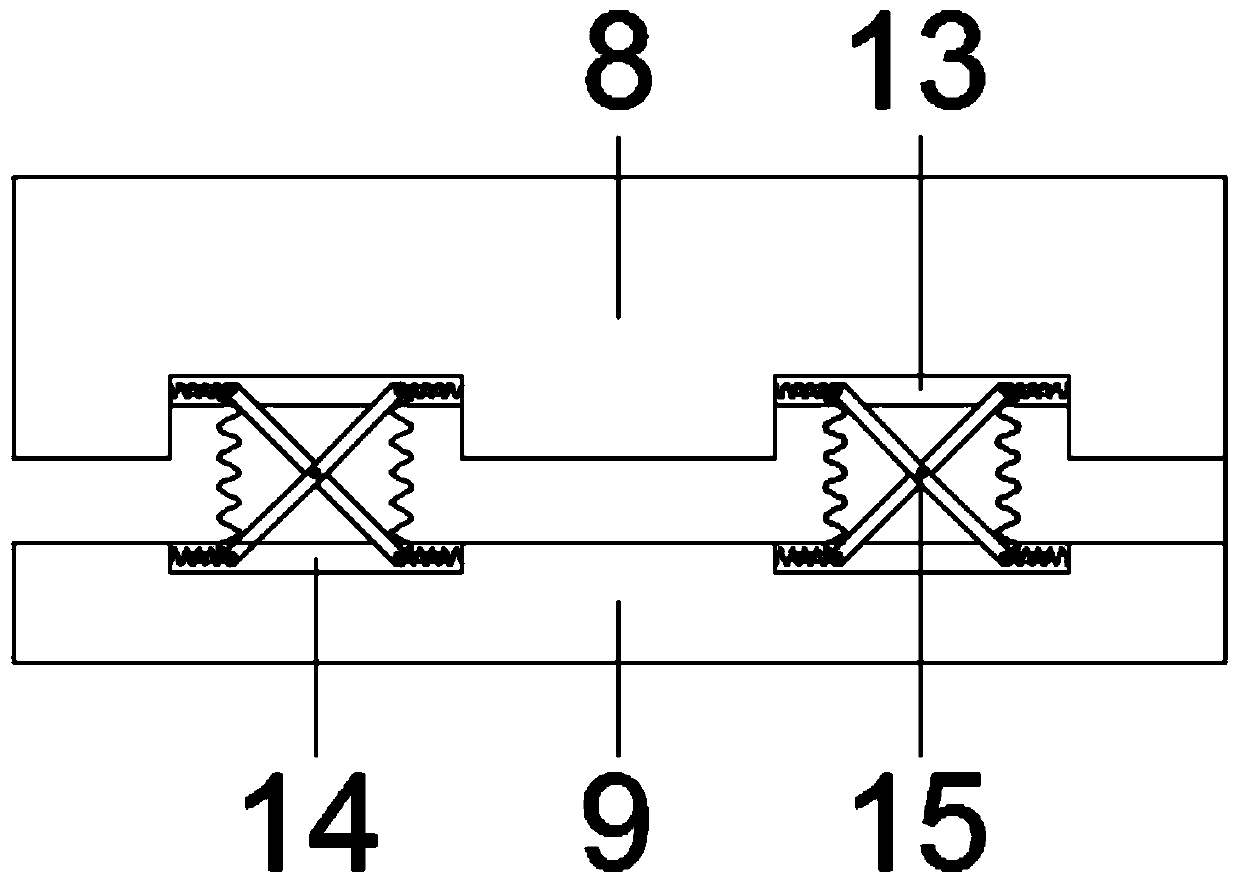

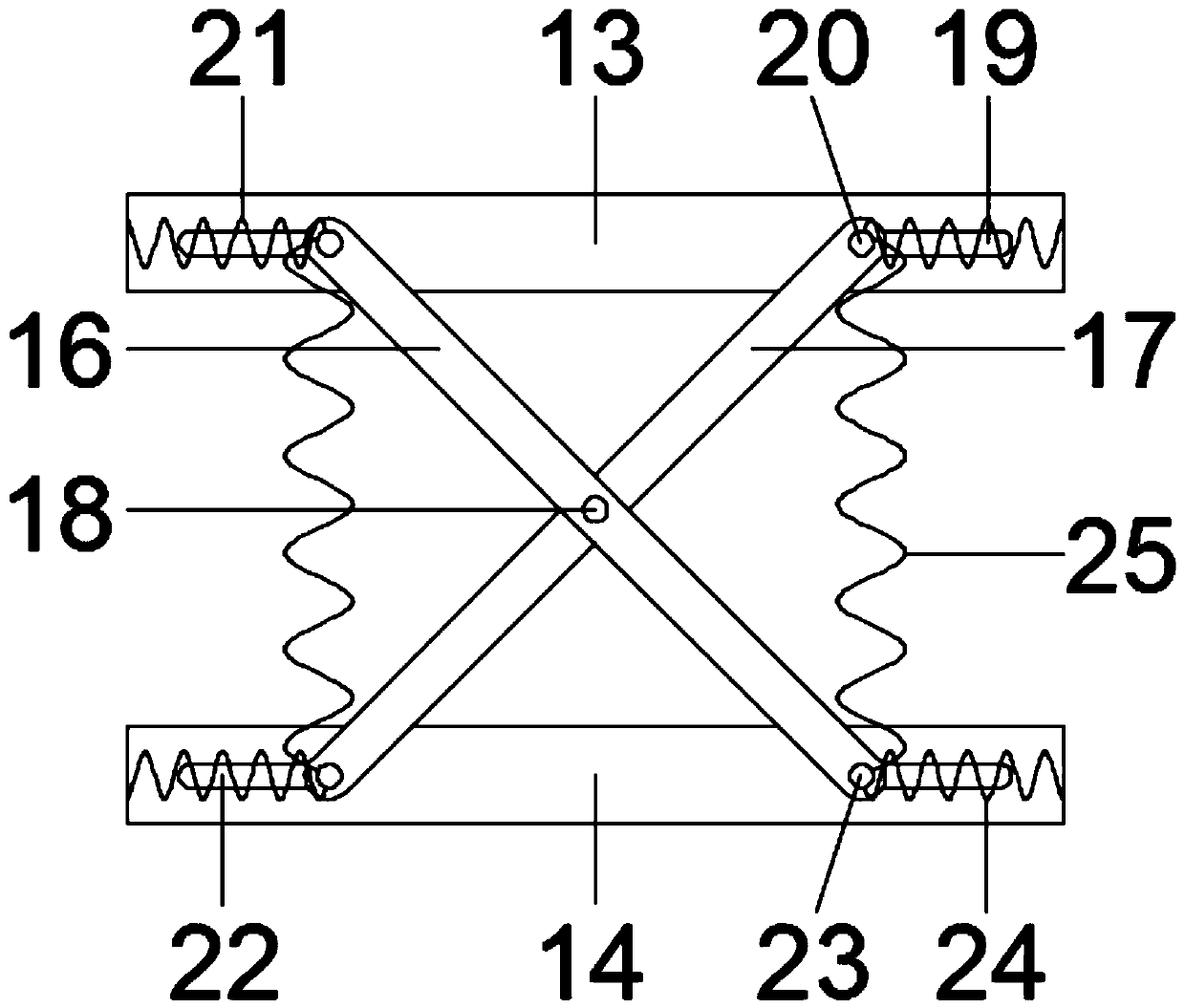

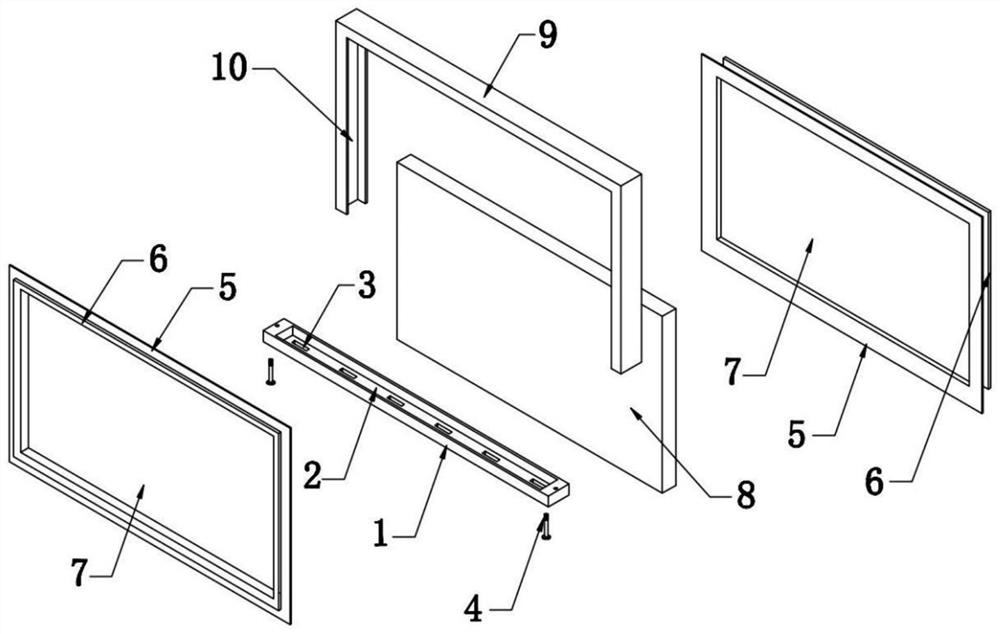

Portable foldable multifunctional computer desk

InactiveCN109380874AImprove cushioning performanceImprove safety performanceOffice tablesDigital data processing detailsMultiple functionComputer engineering

The invention discloses a portable foldable multifunctional computer desk. The computer desk comprises a computer desk plate. The computer desk plate is composed of a first computer desk plate and a second computer desk plate jointly. The first computer desk plate and the second computer desk plate are movably hinged through a connecting shaft. The bottoms of the first computer desk plate and thesecond computer desk plate are each provided with a foldable stretchable supporting leg device. A damping universal wheel device is arranged at the bottom of each stretchable supporting leg. A foldingheat dissipation support device is arranged above the first computer desk plate, and a clamping groove is formed in the upper portion of the surface of the second computer desk plate. The desk has the advantages of being simple in structure and high in practicability.

Owner:东营鲁知信息科技有限公司

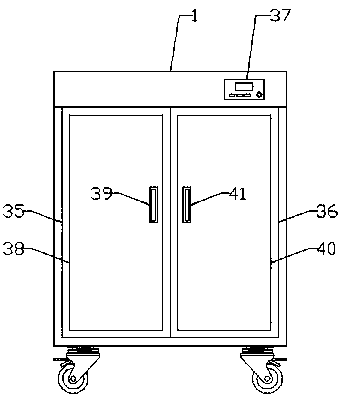

Instrument sterilization cabinet used in radiology department

InactiveCN108434477AImprove cushioning performanceImprove safety performanceLavatory sanitoryChemicalsHOLDING CHAMBERBiomedical engineering

The invention discloses an instrument sterilization cabinet used in a radiology department. The instrument sterilization cabinet comprises a sterilization cabinet body, wherein the sterilization cabinet body takes the shape of a rectangle; damping universal wheel devices are arranged at the bottom of the sterilization cabinet body; an ultraviolet sterilization device is arranged at the upper partinside the sterilization cabinet body; the lower part inside the sterilization cabinet is divided into a medicine holding chamber and a refrigeration cabinet through a vertical partition plate; an ozone generation device is arranged at the upper part of the sterilization cabinet body; a first gate and a second gate are moveably hinged on the sterilization cabinet body; a controller is arranged onthe sterilization cabinet body; the controller is electrically connected with the ultraviolet sterilization device, an infrared intelligent thrusting device and the ozone generation device. The instrument sterilization cabinet has the beneficial effects of being simple in structure and good in practicability.

Owner:张永凯

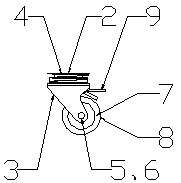

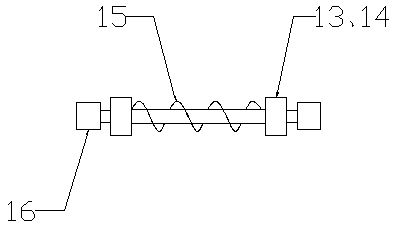

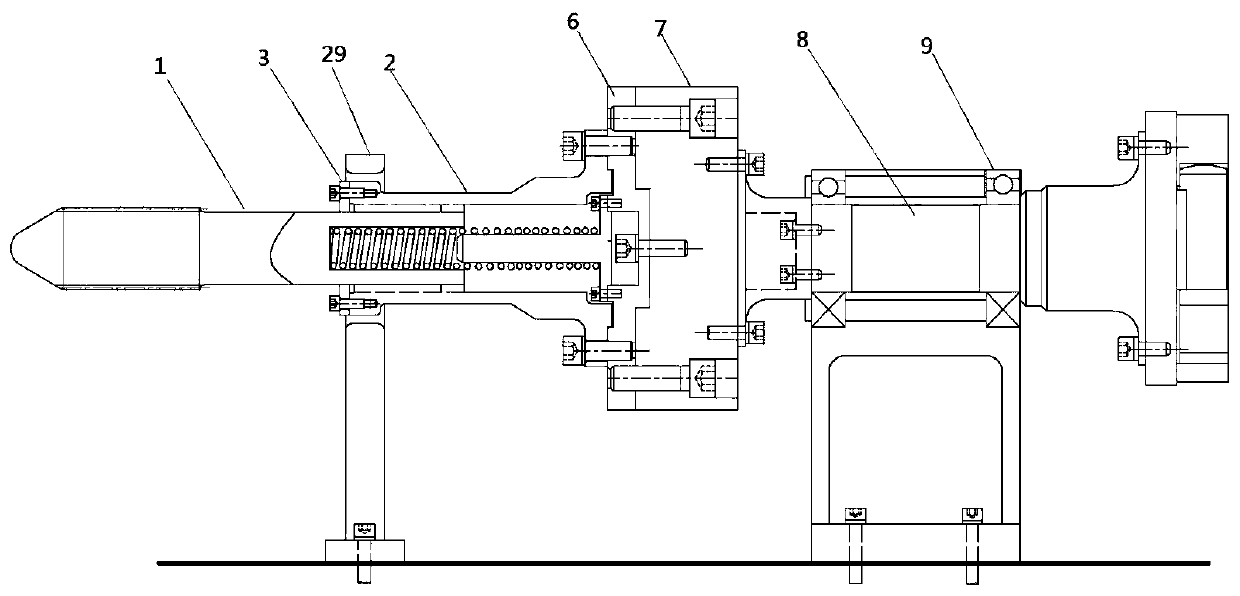

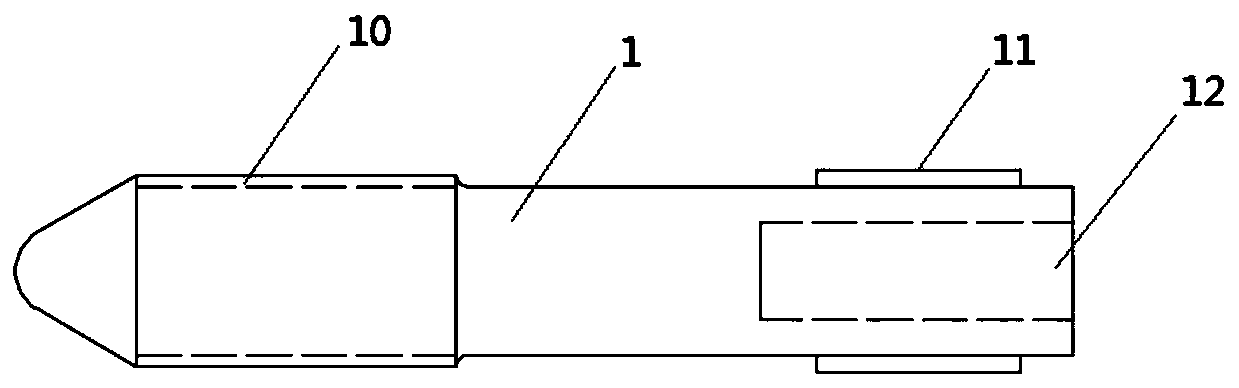

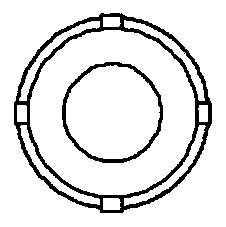

High torsion-resistance connecting device capable of quickly connecting with engine to rotate

PendingCN109991009AImprove torsional performanceImprove cushioning performanceEngine testingDynamometerAgricultural engineering

The invention discloses a high torsion-resistance connecting device capable of quickly connecting with an engine to rotate. The device comprises a connecting shaft, a shaft sleeve, a lock plate, a spring, a spring positioning shaft, a connecting disk, a connector, a middle shaft and a middle shaft permanent seat, wherein the left part of the connecting shaft is provided with a spline, and four bosses are evenly distributed on the right part of the connecting shaft; the right end of the connecting shaft is provided with a spring spacing hole; the spring is distributed between the connecting shaft and the spring positioning shaft; the spring positioning shaft is connected with the connecting disk; the middle shaft permanent seat is connected with the middle shaft; and the lock plate, the shaft sleeve, the connecting disk, a connector and the middle shaft are connected in sequence. By use of the device, the engine and a dynamometer can guarantee to be quickly connected, meanwhile, the accuracy of measurement data can be guaranteed, and production efficiency is obviously improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

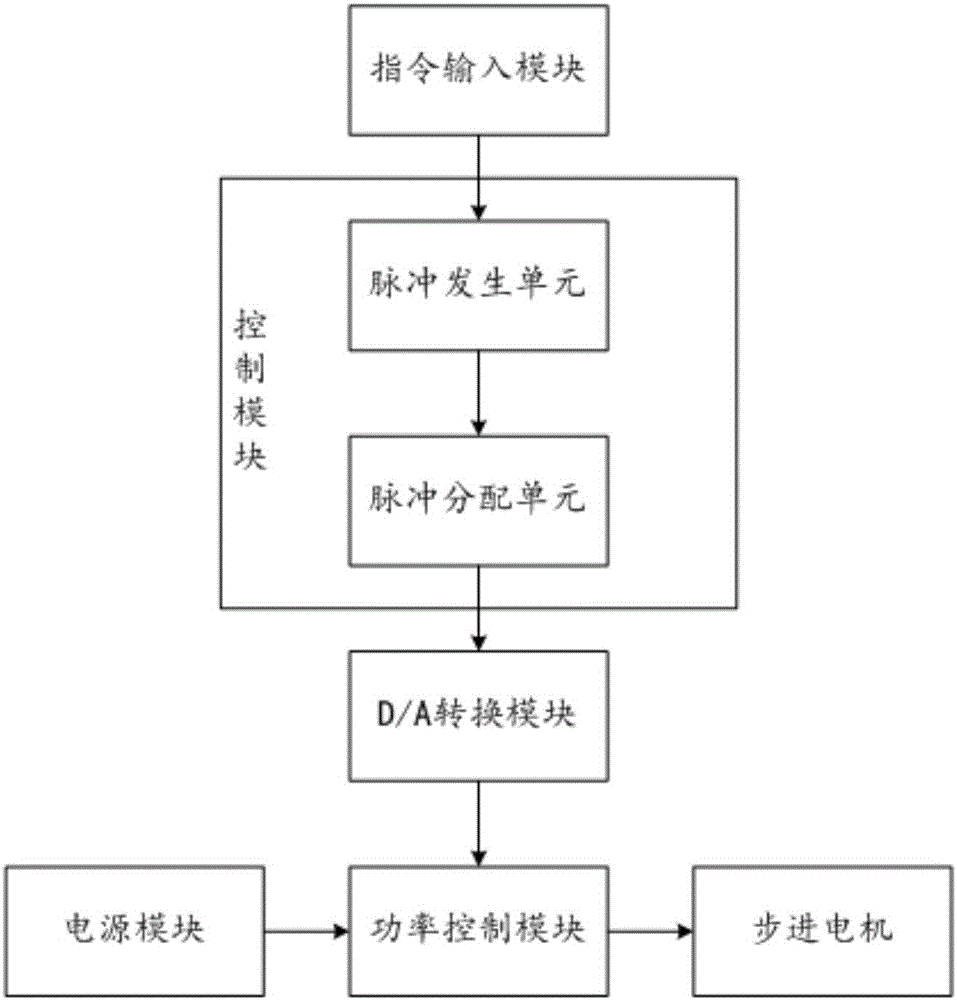

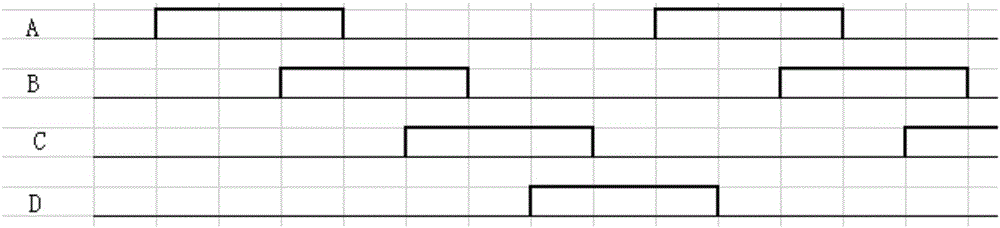

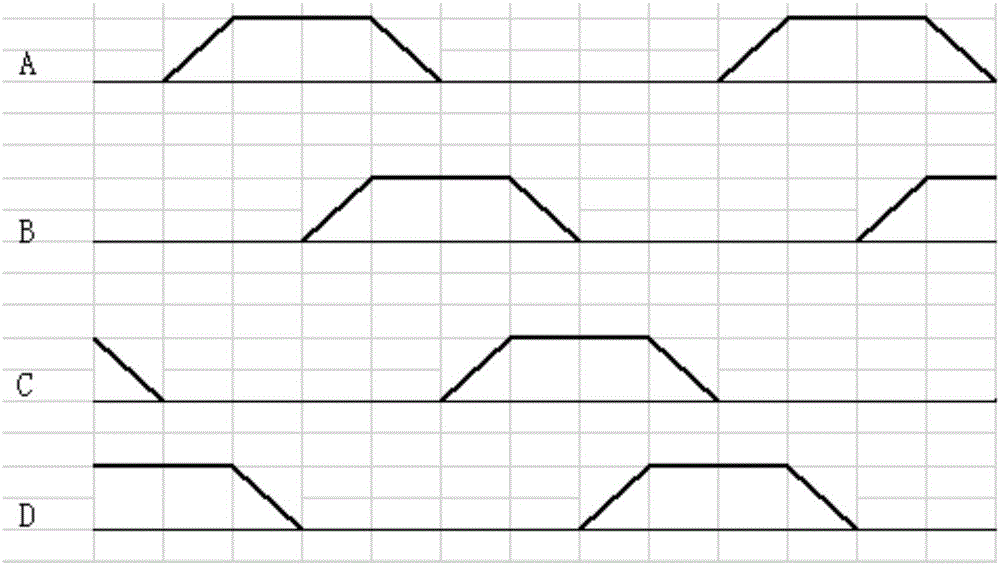

Control method of pulse stepping motor

ActiveCN106301120AImprove cushioning performanceHigh precisionDynamo-electric converter controlTriangular wavePower control

The invention relates to the technical field of control of a pulse stepping motor, and in particular to a control method of the pulse stepping motor. The control method comprises the following steps according to a signal processing flow: (1) inputting a running instruction by an instruction input module; (2) converting the running instruction to a time sequence pulse signal with an integral waveform being a triangular wave or a trapezoidal wave by a control module, wherein a rising edge and a falling edge of the time sequence pulse signal are stepped waves; and (3) controlling a power supply module to supply power to a winding of the stepping motor according to a certain mode by a power control module according to the time sequence pulse signal. By the method, excellent positioning accuracy and positioning precision can be acquired.

Owner:杭州大精机械制造有限公司

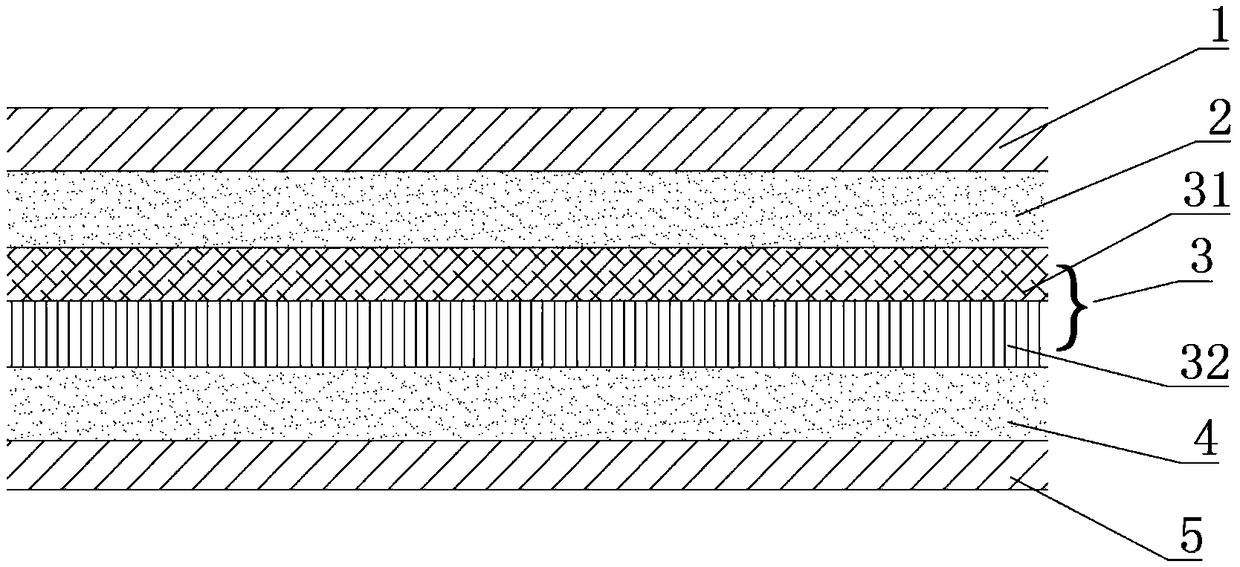

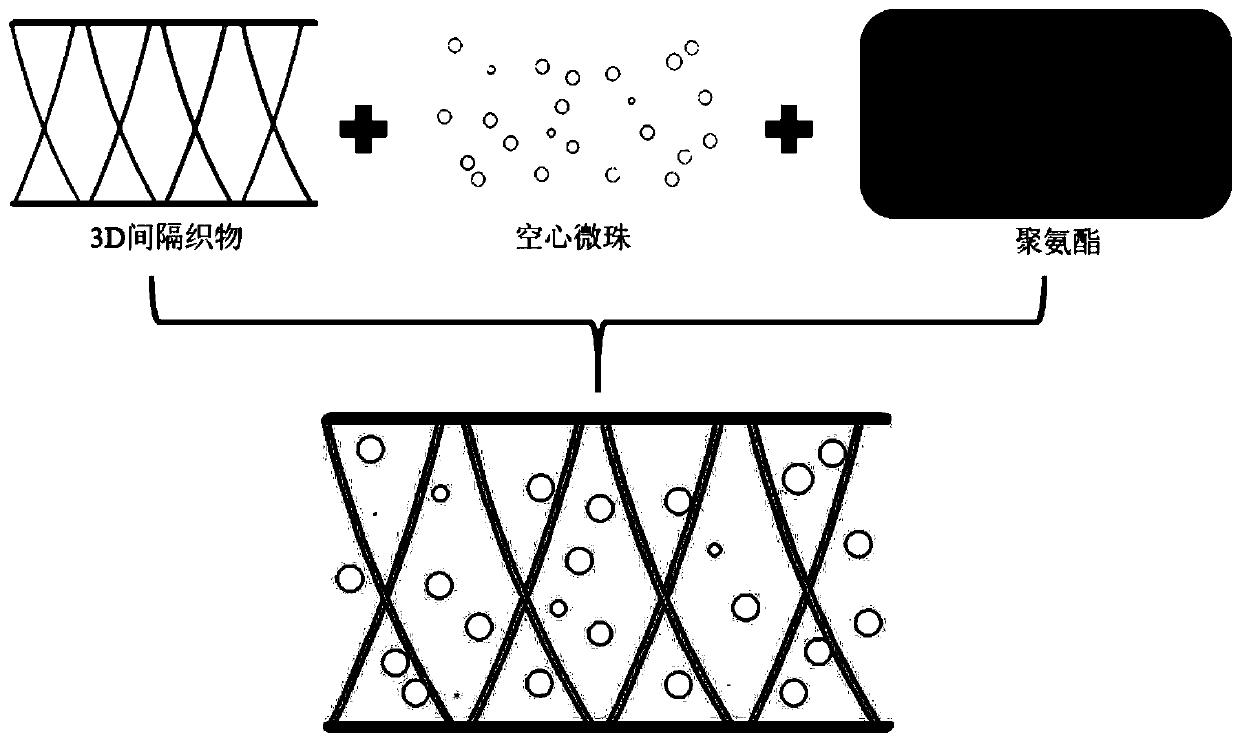

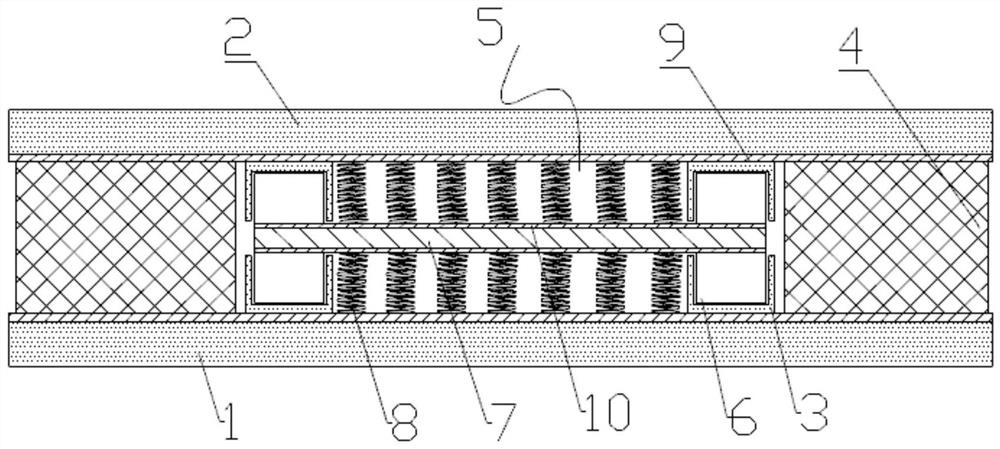

Three-phase composite structure sound absorption material and preparation method and application thereof

PendingCN110534083AImprove the sound absorption performance of low and medium frequencyImprove cushioning performanceSound producing devicesComposite structureCavity resonance

The invention discloses a three-phase composite structure sound absorption material and a preparation method and application thereof, and belongs to the technical field of sound absorption materials.The preparation method includes a step of compounding the polyurethane matrix filled with the hollow microspheres with the 3D spacer fabric; so that the obtained sound absorption material with the three-phase composite structure has the characteristics of a cavity resonance sound absorption material and a particle filling sound absorption material; meanwhile, the 3D spacer fabric is added into thematerial to form micro-perforated holes with the hole diameters being the diameters of the spacer wires and filled with the spacer wires, so that the low and medium frequency sound absorption performance of the material is further improved, and the mechanical property of the material can be obviously improved due to the good buffering performance of the 3D spacer fabric. The sound absorption material can be used as a building sound absorption material and an underwater sound absorption material, and is wide in application range and good in market prospect. The preparation method is simple inprocess, mild in reaction condition, short in preparation period and suitable for industrial production.

Owner:XI'AN POLYTECHNIC UNIVERSITY

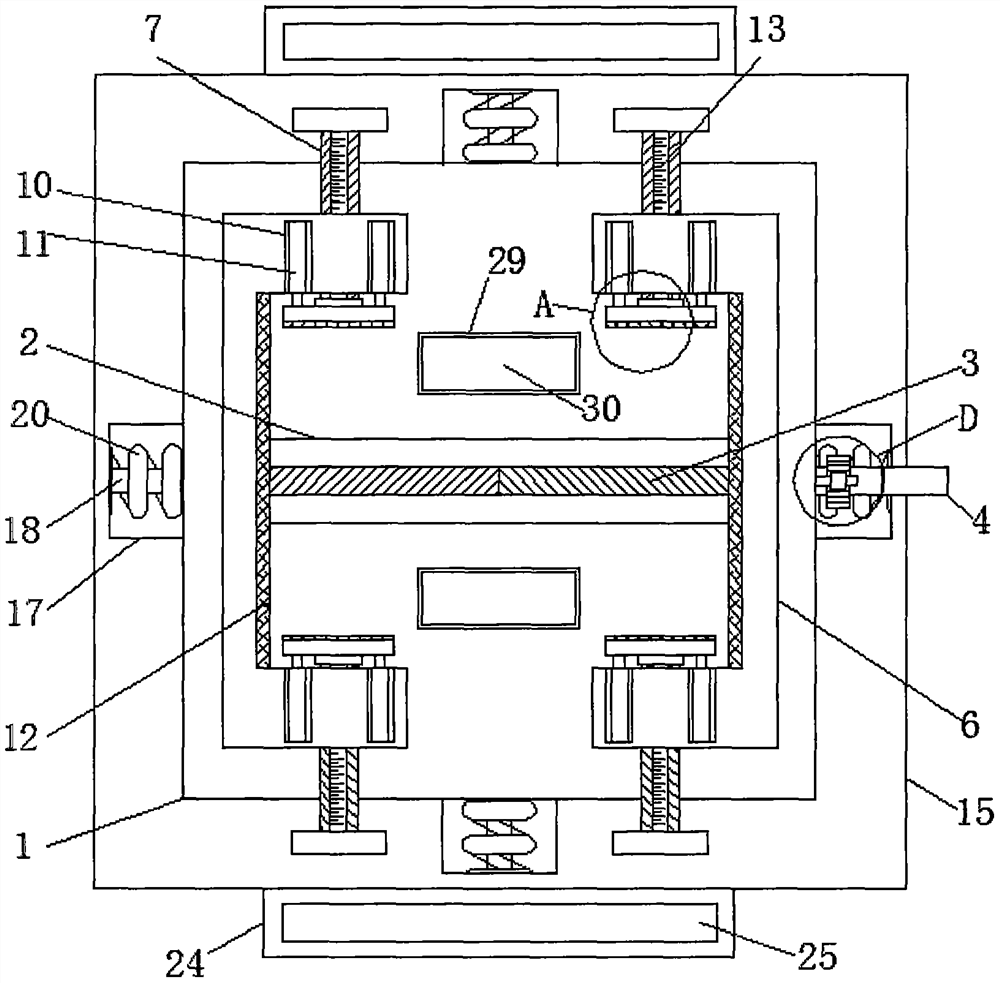

Adjustable fixing device for bionic micro-nano flexible tactile sensors

PendingCN112013209AImprove protectionPrevent tiltingStands/trestlesVibration suppression adjustmentsPhysicsHeat sink

The invention relates to the technical field of fixing devices, in particular to an adjustable fixing device for bionic micro-nano flexible tactile sensors. The adjustable fixing device comprises a bottom plate, a groove is transversely formed in the middle of the top end of the bottom plate, a rotating rod is transversely and movably inserted into the groove in a penetrating manner, the right endof the rotating rod penetrates through the bottom plate and extends out of the bottom plate to be fixedly provided with a handle, threads in opposite directions are arranged at the left side and theright side of the rotating rod, and the left side and the right side of the rotating rod are movably sleeved with threaded sliding blocks correspondingly. The adjustable fixing device is simple in structure, fixation of the bionic micro-nano flexible tactile sensors of different sizes can be met, the bionic micro-nano flexible tactile sensors can be fixed more firmly by clamping and fixing the four sides of the bionic micro-nano flexible tactile sensors, the self buffer performance is good, the bionic micro-nano flexible tactile sensors can be well protected, the bionic micro-nano flexible tactile sensors can dissipate heat through the arrangement of cooling fins to prevent the bionic micro-nano flexible tactile sensors from being burnt due to overheating, and the adjustable fixing deviceis worthy of application and popularization.

Owner:JILIN TEACHERS INST OF ENG & TECH

Smashing device for kitchen

InactiveCN112741476AImprove cushioning performanceEasy to use and safeStrainersEngineeringStructural engineering

Owner:马鞍山蒹葭电子科技有限公司

Red wine packing box

InactiveCN108216824ASave transportation and storage spaceImprove cushioning performanceRigid containersAerospace engineeringPlastic foam

The invention discloses a red wine packing box. The red wine packing box comprises a front wall, a right wall, a rear wall, a left wall, a box cover and a box bottom. The box cover and the box bottomare formed by folding and clamping a front wing, a rear wing, a left wing and a right wing. The left wing and the right wing are of the same structure. The front wing and the rear wing are of the samestructure. A first folding edge is arranged on the front wing. The first folding edge divides the front wing into a locking piece and a supporting piece which are connected with each other. A secondfolding edge is arranged on the right wing. The second folding edge divides the right wing into a closing piece and a vertical inserting piece which are connected with each other. The red wine packingbox is formed by mutually folding and clamping a piece of board. When the red wine packing box is transported and stored, the red wine packing box can be unfolded into a plane, and thus the transportation and storage space is saved; and a clamping body is formed inside the packing box, the buffering performance of the packing box is improved without filling of plastic foam between the packing boxand a bottle body, and thus the packing is easy, convenient and fast, and the packing time is shortened.

Owner:SHANGHAI KUNZHIXIANG PAPER IND CO LTD

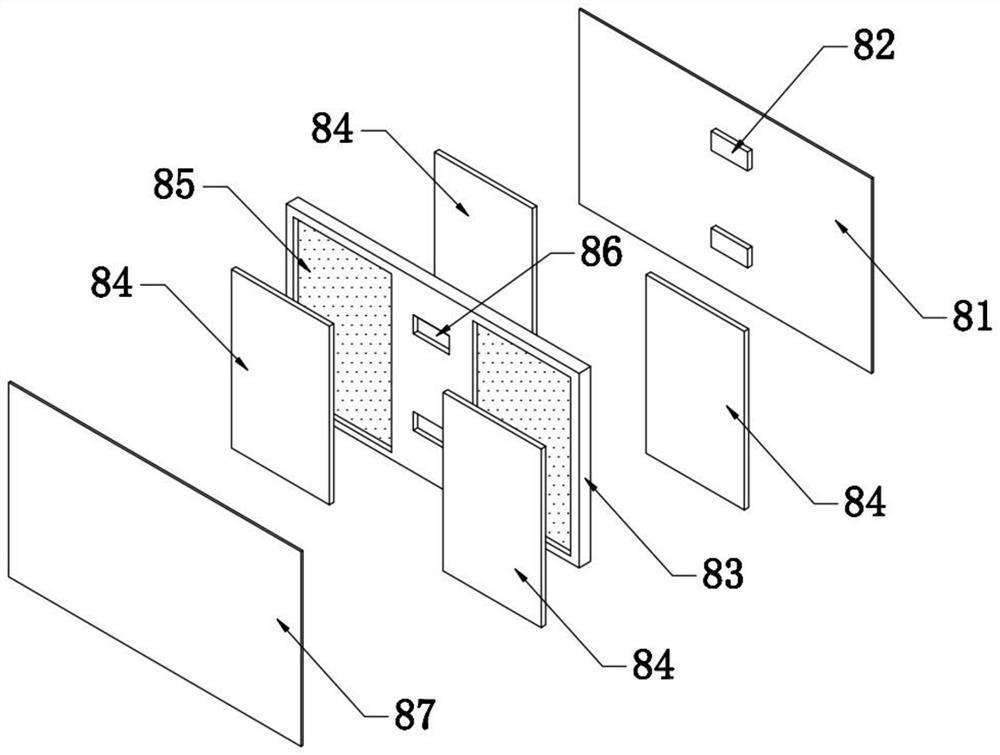

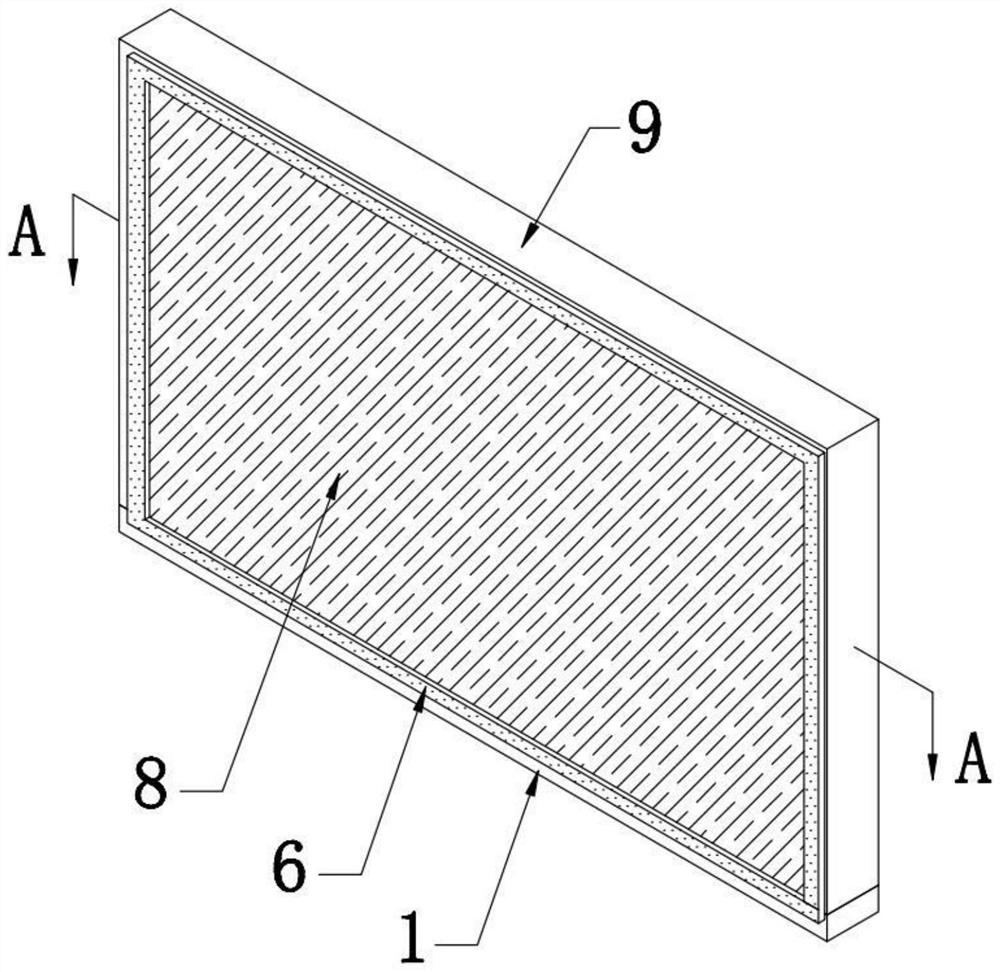

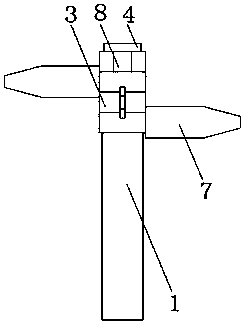

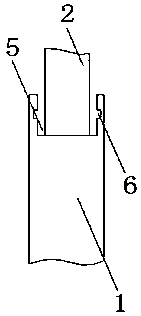

Ceramic filter with CTE compensation

PendingCN111293387AImprove cushioning performanceReduce use costWaveguide type devicesComposite materialEngineering

The invention discloses a ceramic filter with CTE compensation. The ceramic filter comprises a filter body. The signal transmission surface of the filter body is provided with an input end and an output end. The ceramic filter is free of a connecting PCB, can effectively reduce use cost, can improve the buffer performance during connection with a communication system board and can reserve the functions of supporting the filter, connecting signals to the ground and compensating CTE inconsistency of the ceramic and the communication system board when the PCB is used; the ceramic filter with CTEcompensation further comprises a plurality of first elastic metal bonding pads used for being connected with the communication system board; the first elastic metal bonding pads are discretely arranged on the signal transmission surface and are staggered with the input end and the output end; and the thermal expansion coefficient of the first elastic metal bonding pad is equivalent to the thermalexpansion coefficient of the PCB.

Owner:SHENZHEN SUNLORD ELECTRONICS

Adjustable fixing device for bionic micro-nano flexible tactile sensor

PendingCN110823266AImprove protectionPrevent tiltingMeasurement apparatus componentsTactile sensorHeat sink

The invention relates to the technical field of fixing devices, in particular to an adjustable fixing device for a bionic micro-nano flexible tactile sensor. The device comprises a bottom plate, and agroove is transversely formed in the middle of the top end of the bottom plate. A rotating rod is transversely and movably inserted into the groove in a penetrating manner; the right end of the rotating rod penetrates through the bottom plate and extends out of the bottom plate to be fixedly provided with a handle; threads in opposite directions are arranged at the left side and the right side ofthe rotating rod; the left side and the right side of the rotating rod are movably sleeved with threaded sliding blocks correspondingly. The device is simple in structure, and meet the requirements of the fixation of bionic micro-nano flexible tactile sensors in different sizes; the bionic micro-nano flexible tactile sensor can be fixed more firmly by clamping and fixing the four sides of the bionic micro-nano flexible tactile sensor; the buffering performance is good and the device can well protect the bionic micro-nano flexible tactile sensor, can dissipate heat of the bionic micro-nano flexible tactile sensor through cooling fins to prevent the bionic micro-nano flexible tactile sensor from being burnt due to overheating, and is worthy of application and popularization.

Owner:JILIN TEACHERS INST OF ENG & TECH

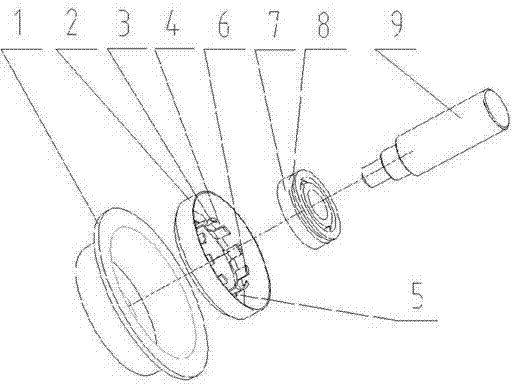

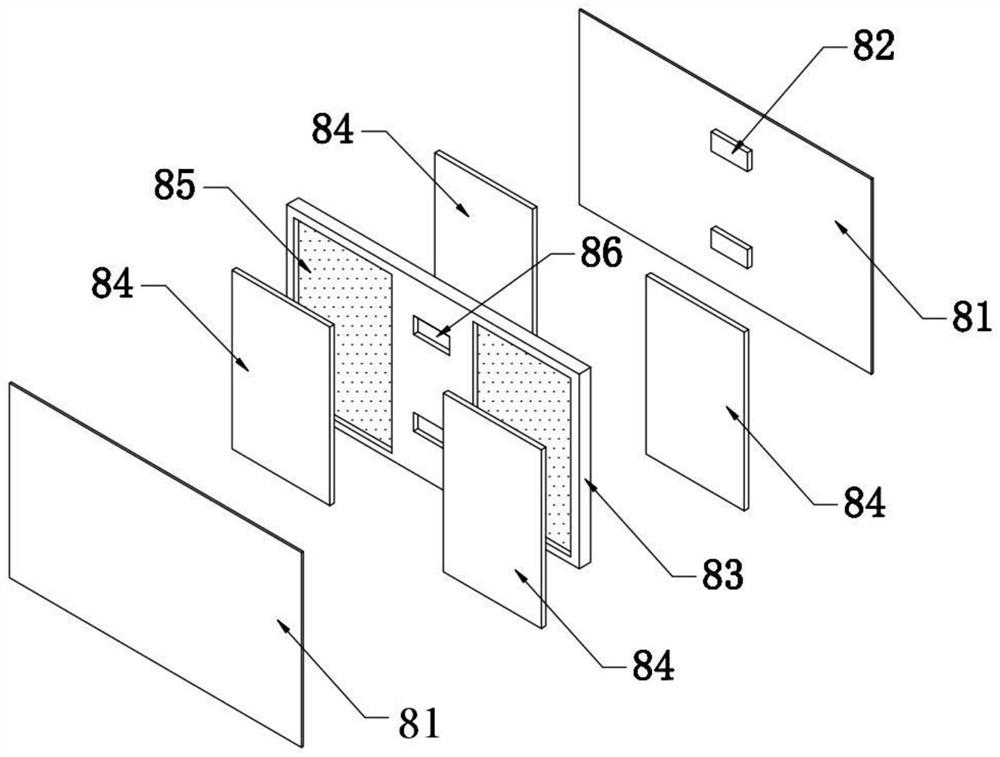

Motor cover, motor assembly and dust collector

PendingCN110876584AImprove cushioning performanceElectric equipment installationMotor shaftEngineering

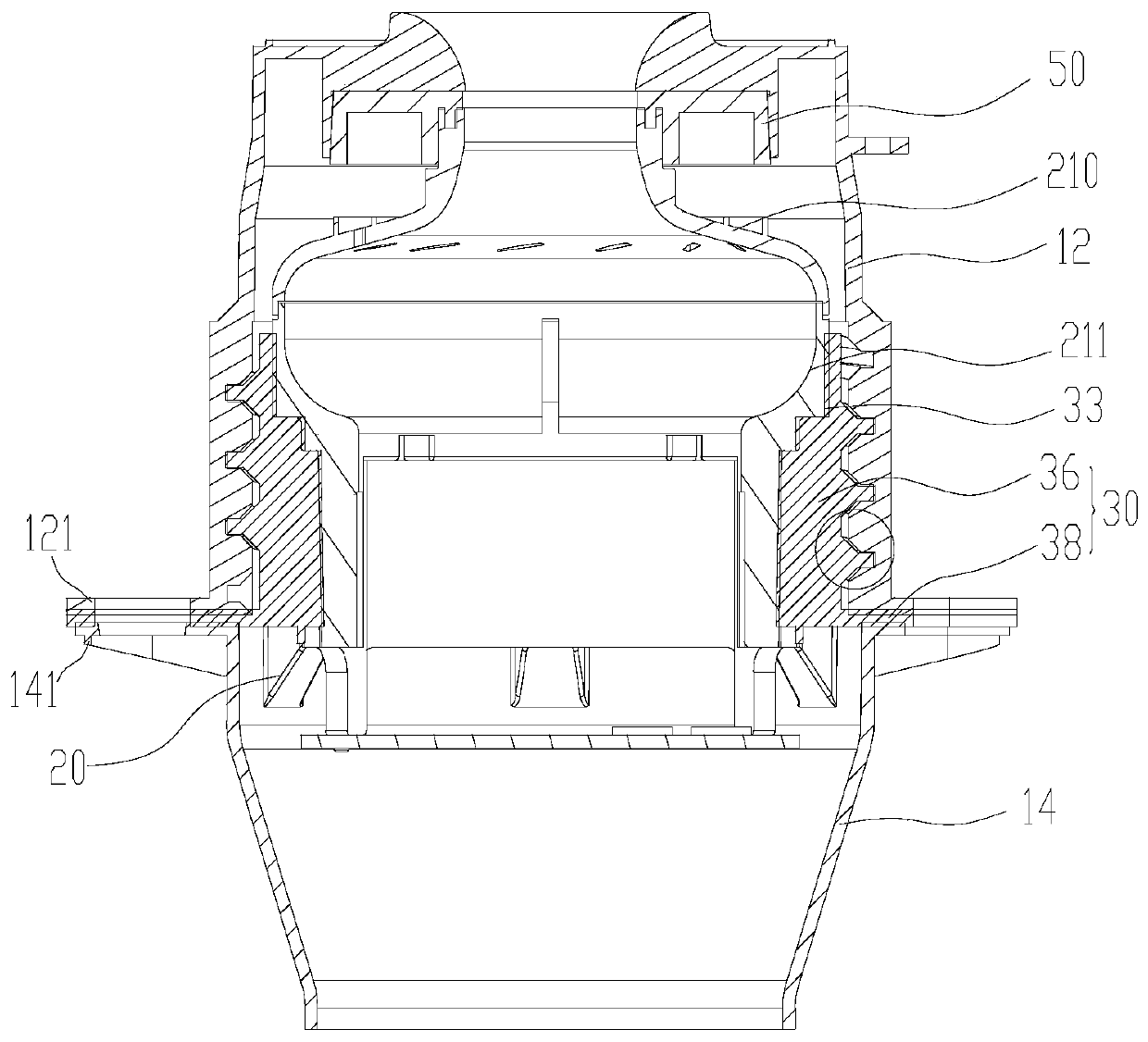

The invention relates to a motor cover, a motor assembly and a dust collector, and the motor cover comprises: a cover body which is provided with an accommodation cavity; an elastic sleeve, wherein atleast part of the elastic sleeve extends into the containing cavity and is connected with the inner wall of the containing cavity in a matched mode,a mounting hole is formed in the elastic sleeve inthe axial direction of the elastic sleeve in a penetrating mode, he elastic sleeve sleeves the motor through the mounting hole, a groove is formed in the inner wall of the mounting hole in a sunken mode and extends in the circumferential direction of the elastic sleeve, and the bottom wall of the groove supports a shaft shoulder of the motor. The elastic sleeve is sleeved outside the motor to provide certain buffer for the motor, protect the motor and absorb the vibration of the motor. Furthermore, a shaft shoulder of the motor is matched with a groove in the inner wall of the elastic sleeve;the groove extends in the circumferential direction of the elastic sleeve, the shaft shoulder can be supported in the whole circumferential direction of the motor through the bottom wall of the groove, the shaft shoulder of the motor can completely make contact with the bottom wall of the groove extending in the circumferential direction in the elastic sleeve in the circumferential direction, theelastic sleeve provides uniform buffering force for the motor from all positions in the circumferential direction, and the buffering performance of the elastic sleeve is improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Garment print tunnel drying equipment adopting infrared heat treatment

InactiveCN108507329AImprove cushioning performanceImprove safety performanceDrying chambers/containersDrying machines with progressive movementsInfraredEngineering

The invention discloses garment print tunnel drying equipment adopting infrared heat treatment. The garment print tunnel drying equipment comprises a rack. A telescopic supporting frame device is arranged at the bottom of the rack, and damping universal wheel devices are arranged at the bottoms of telescopic supporting frames. A through groove in the length direction of the rack is formed in the internal surface of the rack and internally provided with a conveying device. A drying tunnel is arranged on the upper portion of the rack, and the two sides of the drying tunnel are each of a closed structure. An infrared heat treatment device and a fan cooling device are sequentially arranged on the upper portion of the drying tunnel in the length direction of the drying tunnel. A controller is arranged on one side on an infrared heat treatment box body and electrically connected with the conveying device, the infrared heat treatment device and the fan cooling device. The garment print tunneldrying equipment adopting infrared heat treatment has the beneficial effects of simple structure and high practicability.

Owner:张炳辉

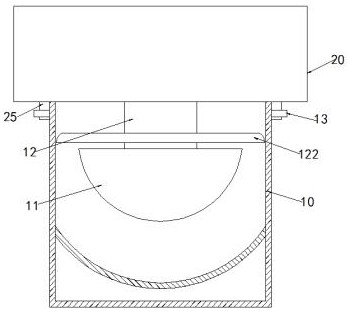

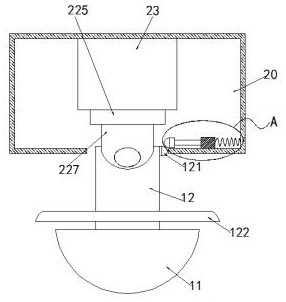

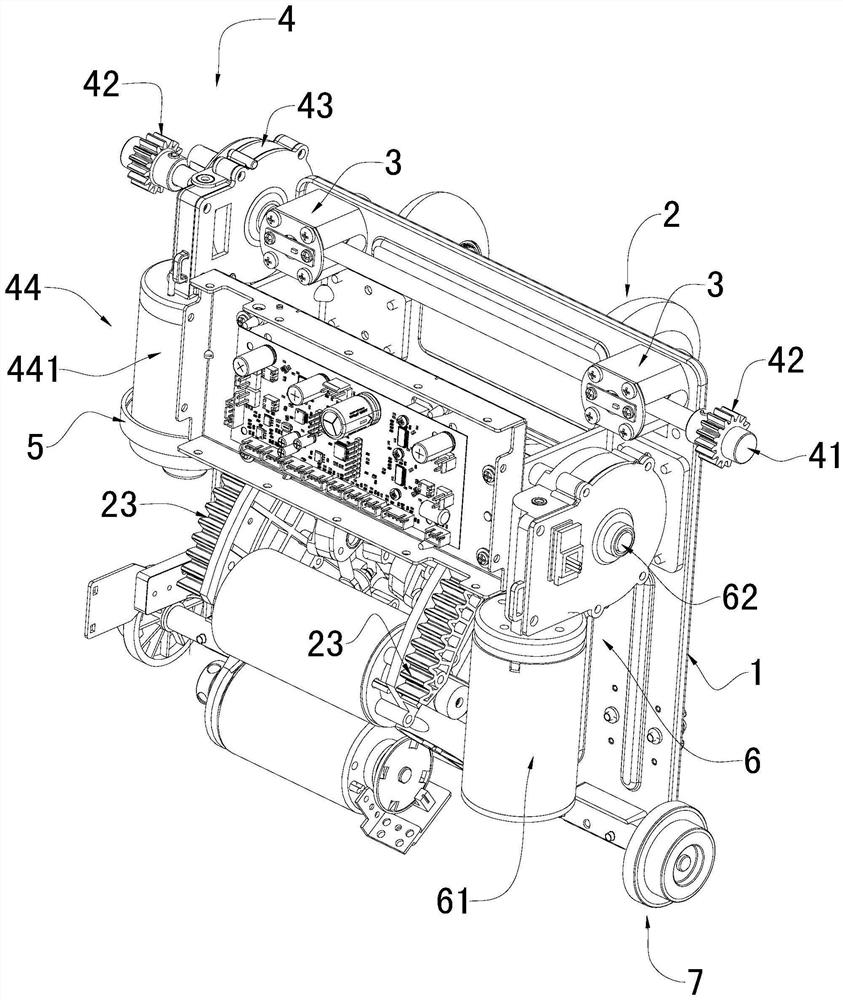

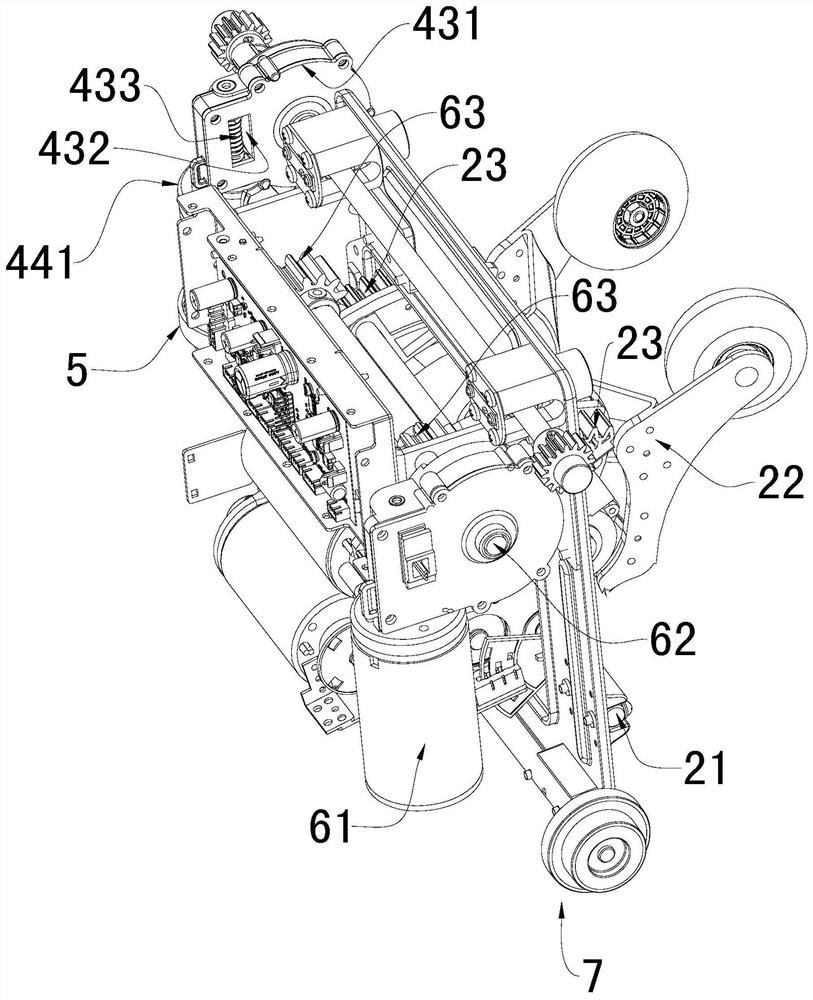

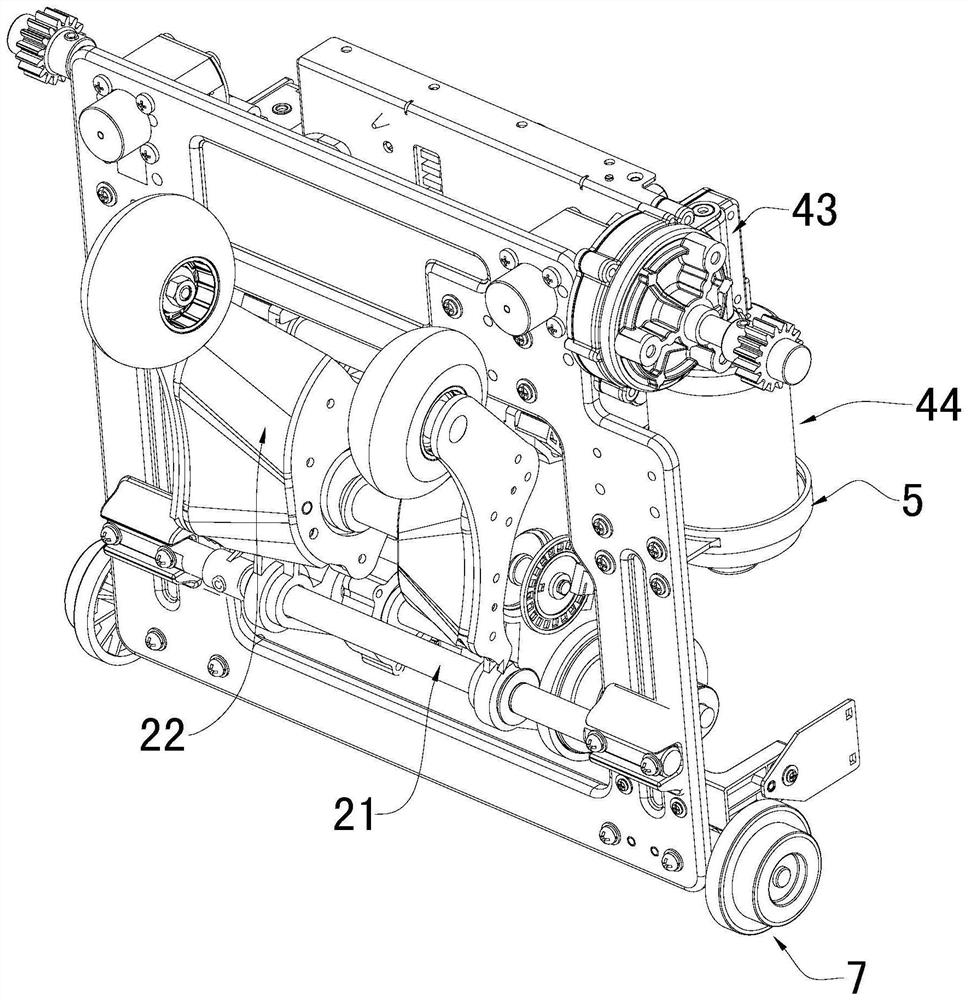

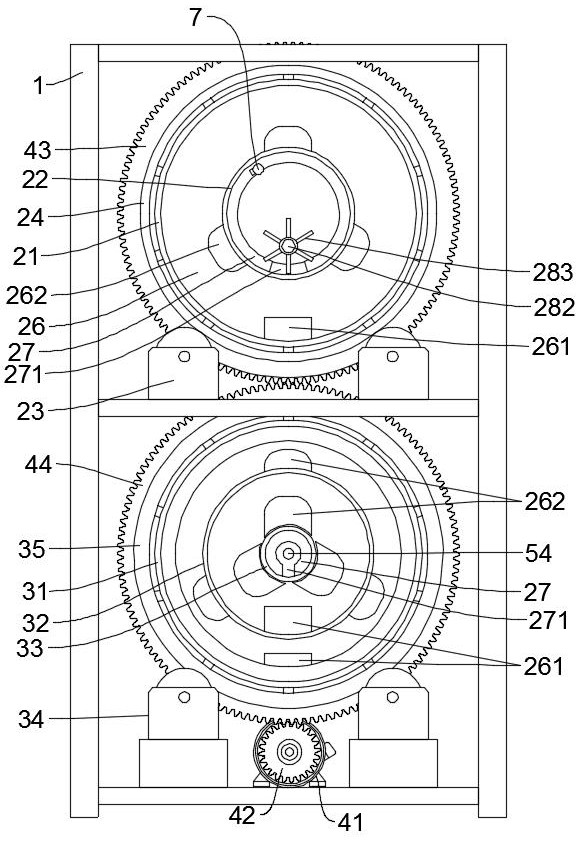

Intelligent massage machine core with massage force measurement and control function and massage chair

PendingCN111773053AImprove cushioning performanceImprove massage comfortSuction-kneading massageMassage - actionEngineering

The invention provides an intelligent massage machine core with a massage force measurement and control function and a massage chair. The intelligent massage machine core comprises a rack, a massage mechanism used for massaging a user, a force measuring device used for detecting massage force of the massage mechanism on the user, a driving walking mechanism and a constraint part, wherein the driving walking mechanism comprises a driving wheel shaft, a driving walking wheel, a transmission mechanism and a power device; the driving wheel shaft is rotationally arranged on the force measuring device in a penetrating mode and is arranged in a resettable floating mode relative to the rack due to the change of counter-acting force of the user on the massage mechanism; the power device is in transmission connection with the driving wheel shaft through the transmission mechanism; and the constraint part is arranged on the rack and movably limits the power device on one side of the rack. The force measuring device can be arranged between the driving walking mechanism and the rack, so that power transmission between the power device and the driving wheel shaft is not affected, the massage force of the massage mechanism on the user is detected, and the buffer performance of the massage mechanism during massage of the user is improved.

Owner:SHANGHAI RONGTAI FITNESS TECH DEV CO LTD

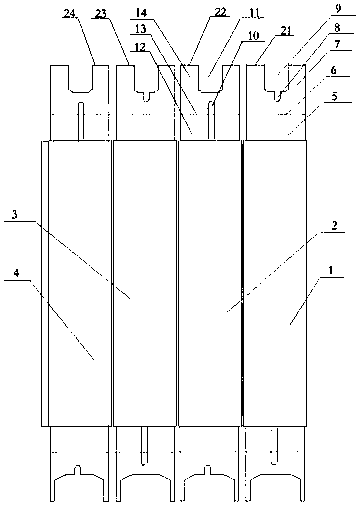

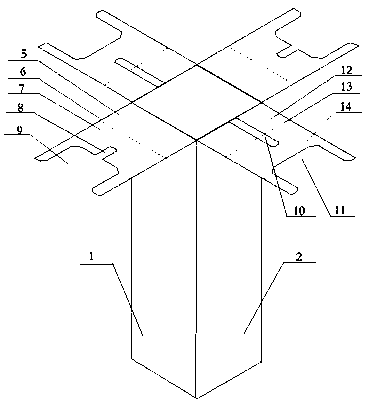

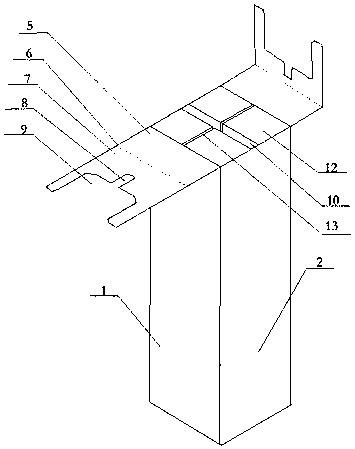

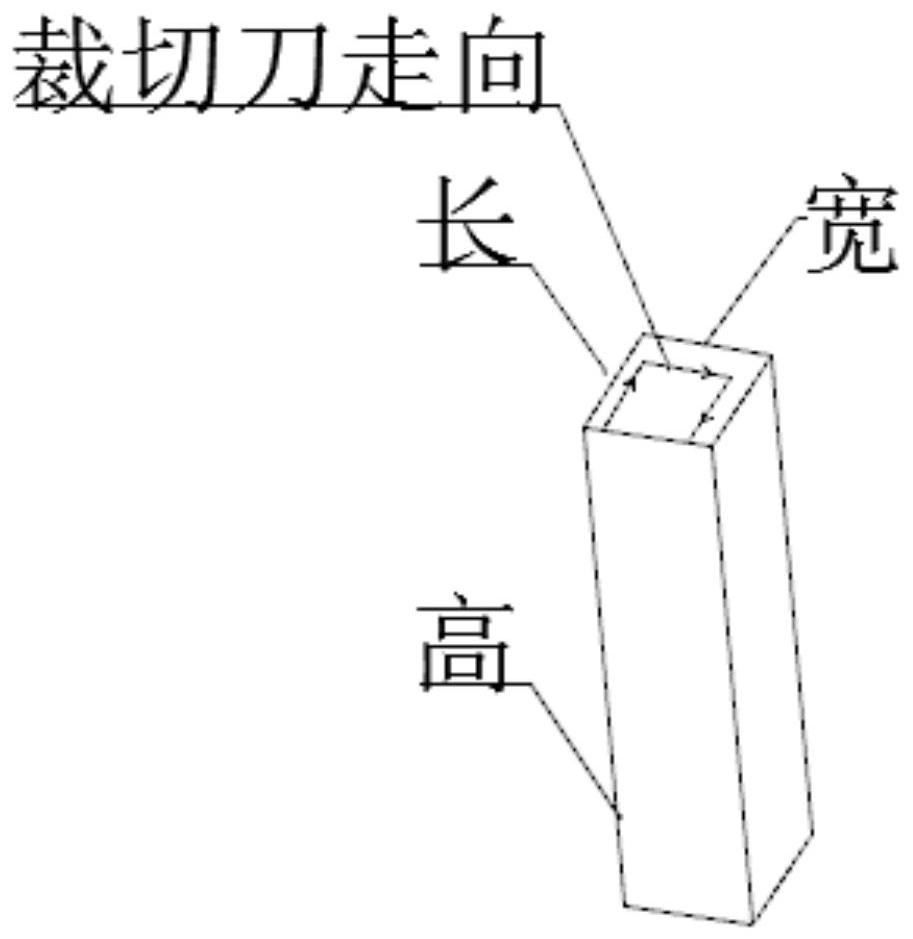

Production process of honeycomb plate for household appliance packaging

InactiveCN111873604AImprove cushioning performanceReduce damageFlexible coversWrappersHoneycombManufacturing engineering

The invention discloses a production process of a honeycomb plate for household appliance packaging, and relates to the field of honeycomb plate processing. The process comprises the steps of cutting,feeding, gluing, surface paper compounding, rubber spring core manufacturing, assembling and drying warehousing. A rubber spring core and a honeycomb core are used, so that the buffer performance ofthe product in the household appliance transportation process is improved; the spring of the rubber spring core has a reset effect so that when the rubber spring core is extruded by a household appliance , damage to the honeycomb board is reduced due to the reaction of force, the service lifetime is prolonged, and the cost is saved. Four paper clamping grooves, four clamping strips and one supporting strip form the rubber spring core which is similar to a beam structure, so that the structural stability of the rubber spring core is enhanced, the structural strength is improved, and protectionon household appliances is improved. In a manufacturing process, a cutting device is used, the paper clamping grooves and the clamping strips in the rubber spring core are manufactured at the same time, the steps are simple, the efficiency is high, two auxiliary materials do not need to be additionally manufactured, and paper waste is reduced.

Owner:安徽祥欣新材料科技有限公司

Saline-alkali soil conditioner rich in salt-tolerant microorganisms and preparation method and device thereof

PendingCN114854422AImprove micro-ecological environmentImprove cushioning performanceMaterial granulation and coatingAgriculture tools and machinesHumic acidEnvironmental chemistry

The invention discloses a saline-alkali soil conditioner rich in salt-tolerant microorganisms and a preparation method and device thereof, the conditioner comprises salt-tolerant bacteria, a sulfur-containing substance, potassium humate, decomposed livestock and poultry manure and decomposed straw, through the cooperation of multiple salt-tolerant bacteria microorganisms, the micro-ecological environment of soil can be improved, and the buffer performance of the soil is improved; according to the preparation device, the integrated layout of modifier production is achieved, the occupied space can be saved, the drying efficiency of organic particles is improved, during preparation, the granulation step and the strain inoculation step are carried out separately, high-temperature rapid drying is carried out after wet granulation, and the production efficiency is improved. The bacterial liquid is uniformly sprayed on the organic particles dried and cooled at high temperature through the bacterial liquid opposite spraying mechanism, so that the bacterial content of the modifier is ensured, and then the modifier is dried in a normal-temperature rapid air-drying manner, so that the activity of strains is ensured, and the production efficiency is improved.

Owner:HEBEI UNIV OF ENG

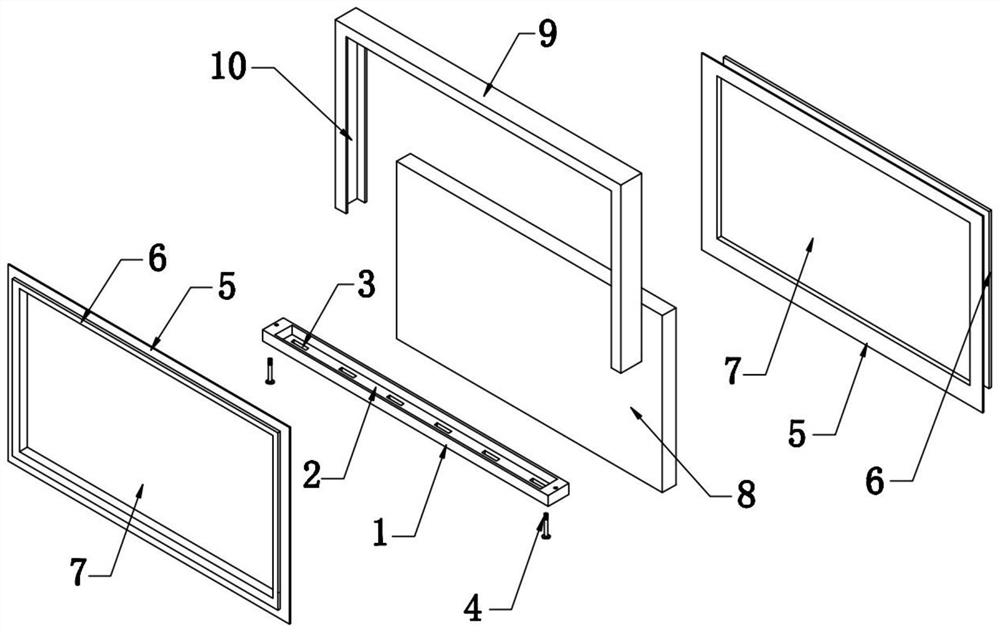

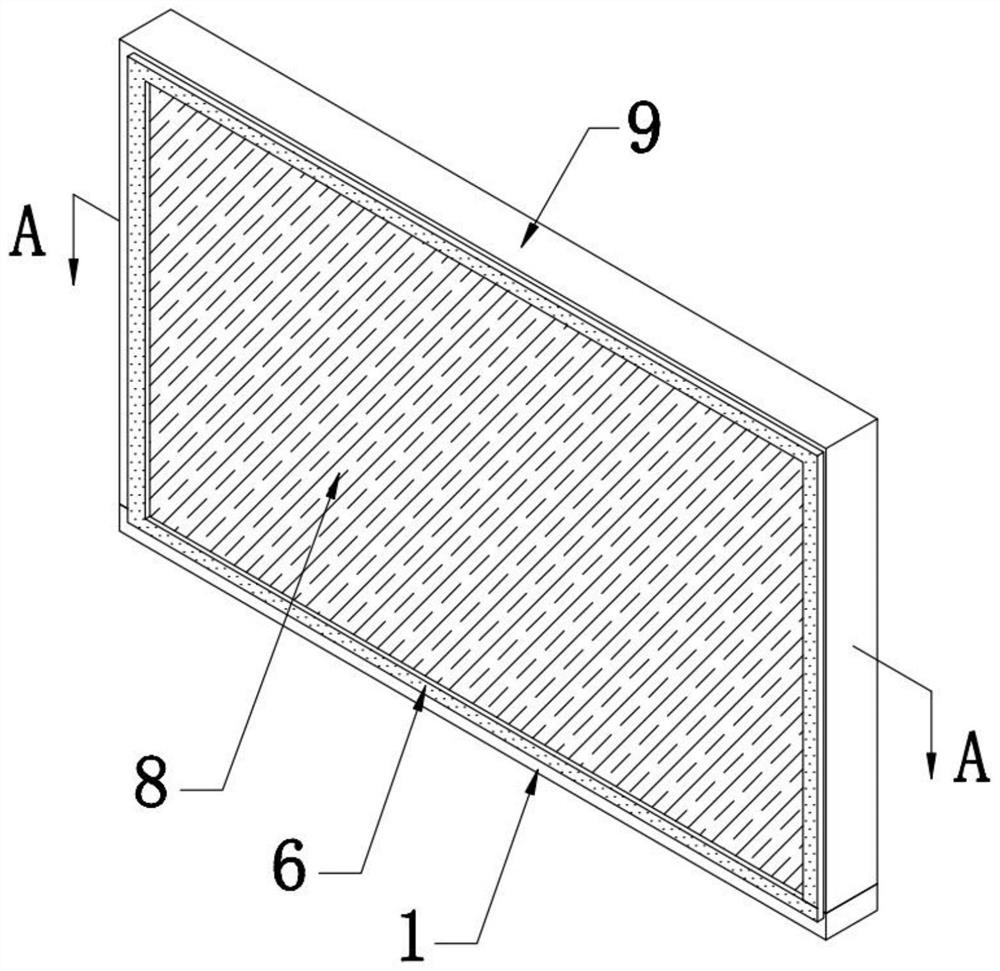

Manufacturing process of artificial decorative plate with good waterproof effect

ActiveCN113320326APlay a sealing rolePlay a protective effectEngine sealsLamination ancillary operationsEngineeringHigh stress

The invention discloses a manufacturing process of an artificial decorative plate with a good waterproof effect. The process comprises the following steps: S1, uniformly spraying a release agent into a mold, and uniformly distributing a mixture in a stock bin of a material distributor into the mold; S2, laying the mold flat and moving the same to a position below a pressing machine, conducting static pressure for 20 seconds through a high-pressure hydraulic machine, to form a blank material; S3, maintaining the blank material, and cutting the blank material into a decorative panel and a main body plate with required thicknesses to obtain a decorative plate main body; S4, clamping the left ends, the right ends and the upper ends of the pressing frame and the decorative plate body into side edge clamping grooves in the inner side of the upper frame; and S5, installing a base at the lower end of the upper frame through sunk screws, and clamping the lower ends of the pressing frame and the decorative plate body into a bottom clamping groove in the base. By arranging sealing rings, the sealing performance of the connecting positions of the decorative plate body, the upper frame and the base is achieved. The pressing frame can further play a sealing role to prevent water from entering.

Owner:江苏仙野建材有限公司

Oil-electricity hybrid multifunctional unmanned aerial vehicle

PendingCN111056007AImprove cushioning performanceGood protectionAlighting gearPower plant typeAutomotive engineeringElectric generator

The invention relates to an oil-electricity hybrid multifunctional unmanned aerial vehicle, and belongs to the technical field of unmanned aerial vehicles. The vehicle comprises an unmanned aerial vehicle body, an engine and a generator are fixedly mounted at the upper end of the unmanned aerial vehicle body; the generator is connected with the engine through a coupler, a first camera and a floating plate are fixedly installed on the side face of the unmanned aerial vehicle body, supporting legs are fixedly installed at the bottom of the unmanned aerial vehicle body, damping bases are installed at the bottoms of the supporting legs, and the damping bases are connected with the supporting legs through damping mechanisms. By arranging the damping mechanism, the buffering performance of the unmanned aerial vehicle during landing is greatly improved, the protection effect is good, meanwhile, the water tank and the underwater camera are arranged to be matched with the floating plate, underwater and water surface shooting can be conducted through the unmanned aerial vehicle, the effects of water source collection and higher irrigation can be achieved, the functions are rich, and the practicability is high.

Owner:北京致媒科技有限公司

A manufacturing process of artificial decorative board with good waterproof effect

ActiveCN113320326BPlay a sealing rolePlay a protective effectEngine sealsLamination ancillary operationsHigh stressIndustrial engineering

The invention discloses a manufacturing process of an artificial decorative board with a good waterproof effect, comprising the following steps: S1, spraying a release agent evenly into a mold, and evenly distributing the mixture in the feed bin of a distributing machine into the mold; S2 1. Lay the mold flat and move the mold under the press, and use a high-pressure hydraulic press to press statically for 20 seconds to form a blank; S3. Carry out maintenance on the blank, and cut it into decorative panels and main panels of required thickness to obtain the main body of the decorative panel ; S4, press the left and right ends of the frame and the main body of the decorative panel and the upper end into the side slot on the inner side of the upper frame; S5, then use countersunk screws to install the base on the lower end of the upper frame, and make the frame and The lower end of the main body of the decorative plate can be snapped into the bottom slot on the base. In the present invention, the arrangement of the sealing ring can seal the connection between the main body of the decorative plate and the upper frame and the base; pressing the frame can further play a sealing role to prevent water ingress.

Owner:江苏仙野建材有限公司

A road indicator and a mounting method thereof

InactiveCN109024345AImprove cushioning performanceHigh strengthTraffic signalsRoad signsEngineeringUltimate tensile strength

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

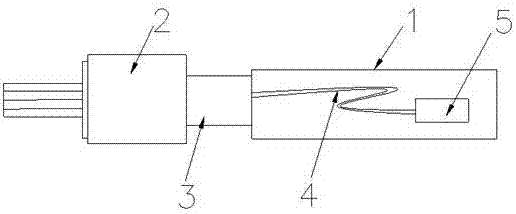

Novel temperature measurement thermal resistor

InactiveCN106918401ASimple structureImprove cushioning performanceThermometers using electric/magnetic elementsUsing electrical meansTemperature measurementEngineering

The invention discloses a novel temperature measurement thermal resistor, including a metal protective tube, a junction box and an elastic connection column. One end of the metal protective tube is connected with one end of the junction box through the elastic connection column, the metal protective tube is internally provided with a leading-out wire and a temperature measurement element, one end of the leading-out wire is connected with the temperature measurement element, the other end stretches out of the junction box, the outer side end of the junction box is fixedly provided with a sealing gasket, and the leading-out wire in the metal protective tube is of an S-shaped structure. The novel temperature measurement thermal resistor provided by the invention is simple in structure, adopts the S-shaped leading-out wire, can enhance buffering performance, improve measurement accuracy, and prolong the service life of the temperature measurement element; and in addition, the adopted sealing gasket can reduce heat loss, thereby further improving a temperature measurement effect.

Owner:MAANSHAN RUNQI NEW MATERIAL SCI & TECH

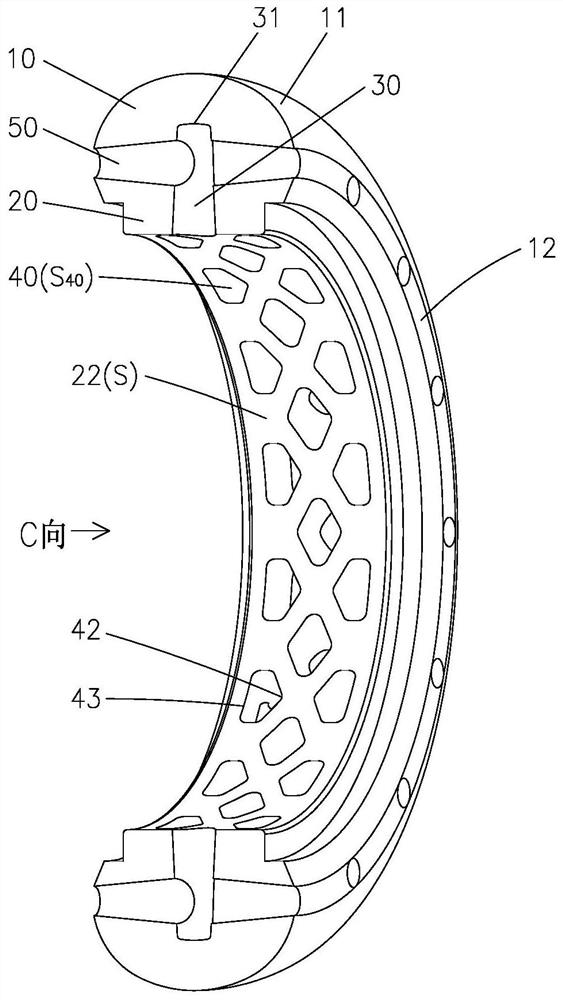

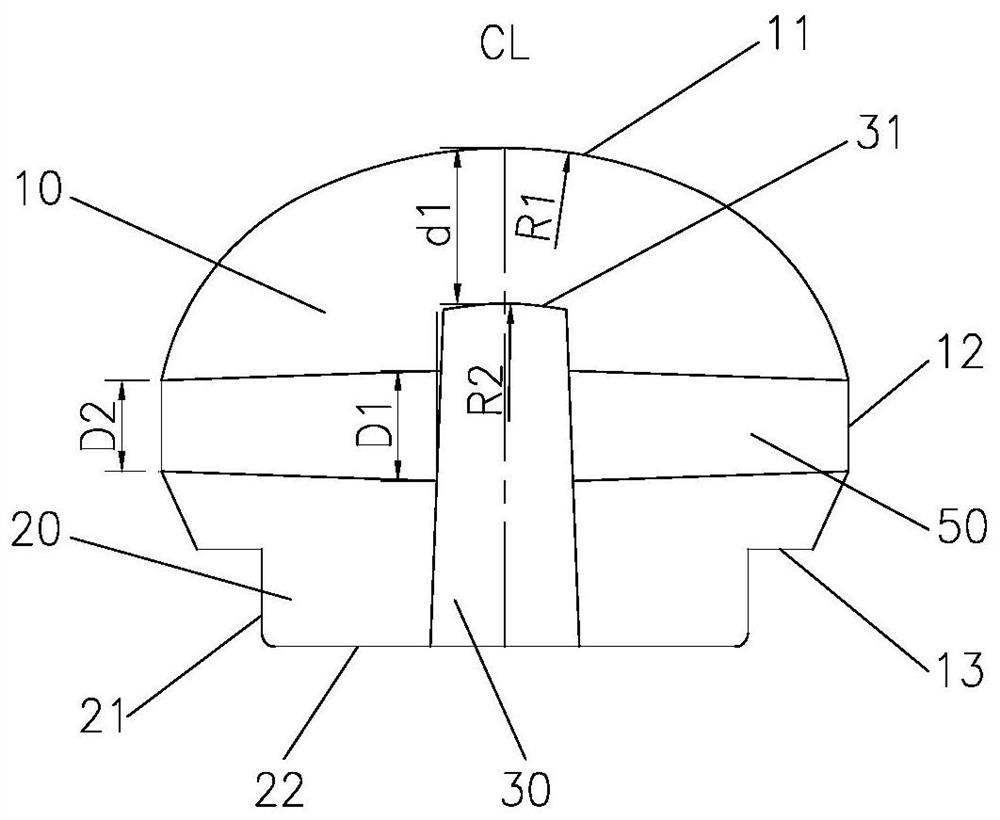

Tire body structure and non-pneumatic tire

PendingCN112477522AGuaranteed reasonablenessImprove cushioning performanceNon-inflatable tyresAutomotive engineeringNeck parts

Owner:CHENG SHIN RUBBER XIAMEN IND

A box type limit engine mount assembly

ActiveCN103568806BAvoid tearingExtended service lifeNon-rotating vibration suppressionJet propulsion mountingVulcanizationEngineering

A box type limit engine suspension assembly comprises a suspension cushion vulcanization assembly and a suspension bracket which are mutually connected, wherein the suspension cushion vulcanization assembly comprises vulcanized rubber, an upper framework, a lower framework and a lower framework bolt, and the upper framework is integrally vulcanized with the lower framework and the lower framework bolt through the vulcanized rubber; and the engine suspension assembly further comprises a limit box, the suspension cushion vulcanization assembly is arranged in the limit box, and the suspension cushion vulcanization assembly is fixedly connected with the suspension bracket through the limit box. With the adoption of the design, the box type limit engine suspension assembly is convenient to mount, high in mechanical strength, good in buffer performance and long in service life, and can be suitable for heavy vehicles such as a commercial vehicle and the like.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com