Ceramic filter with CTE compensation

A ceramic filter and filter technology, which is applied in the field of communication, can solve the problems of increased cost of use, poor buffer performance, and high cost increase, and achieve the effects of reduced cost of use, excellent buffer performance, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

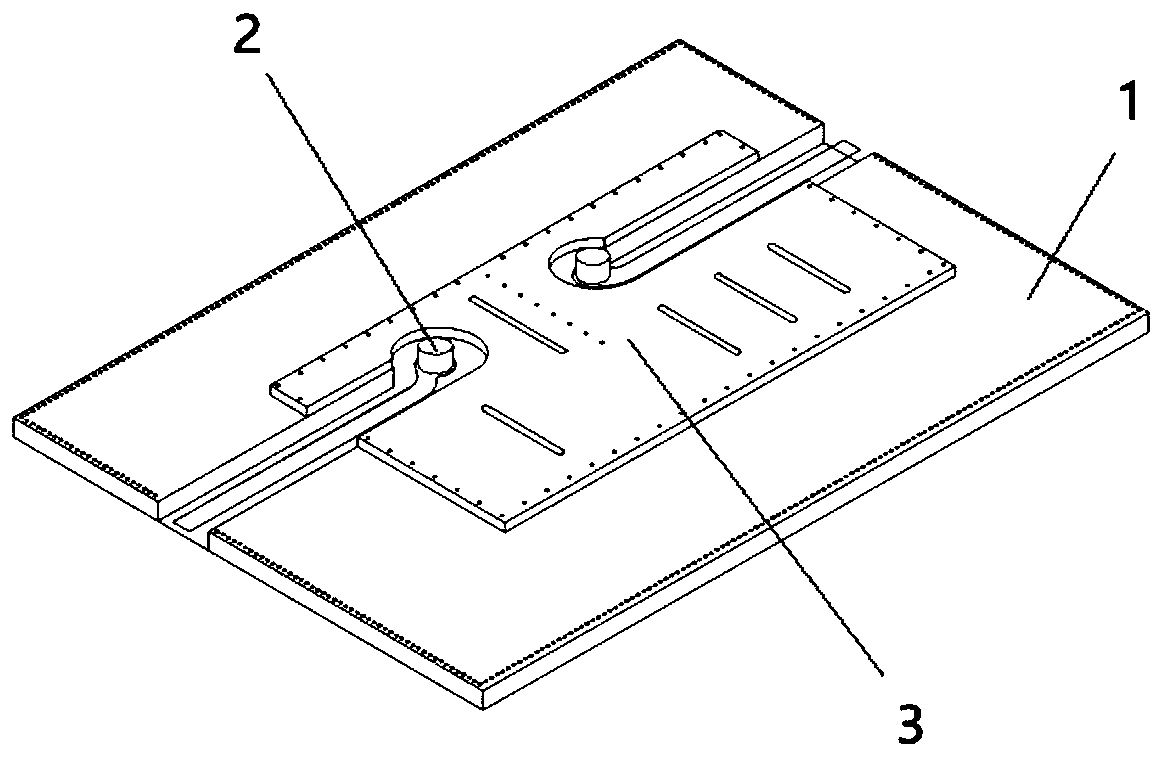

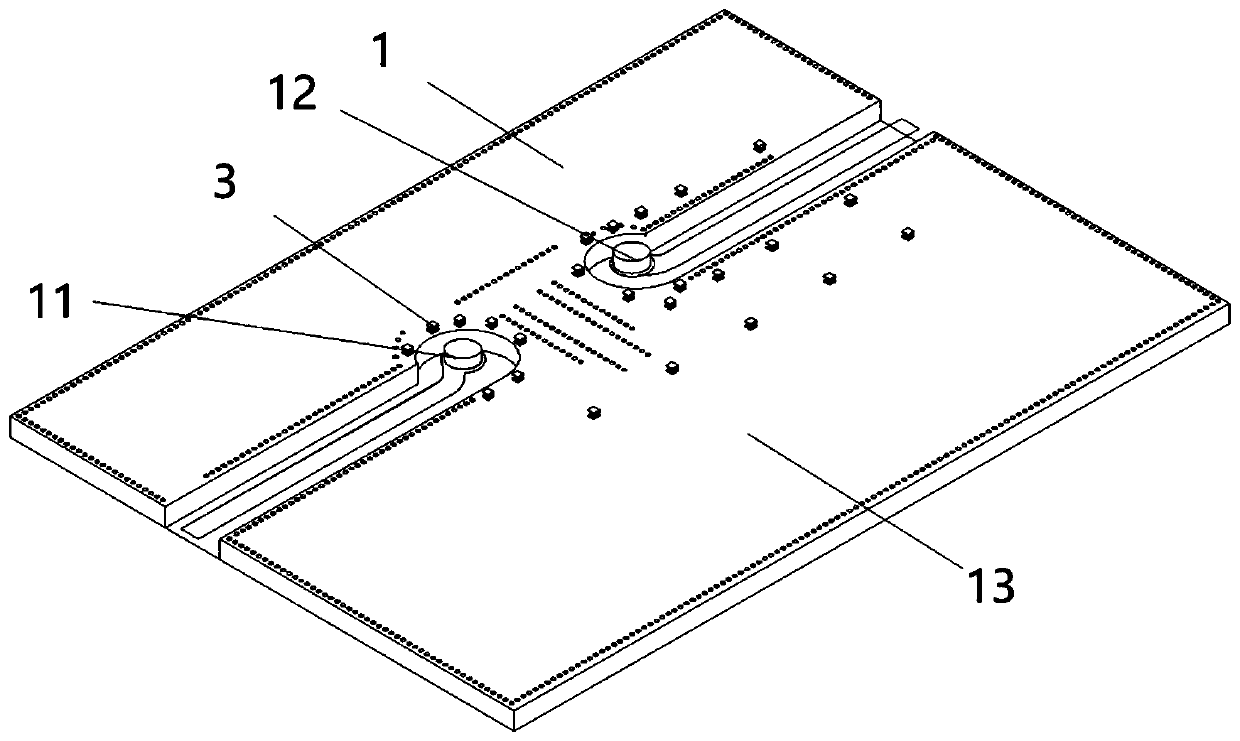

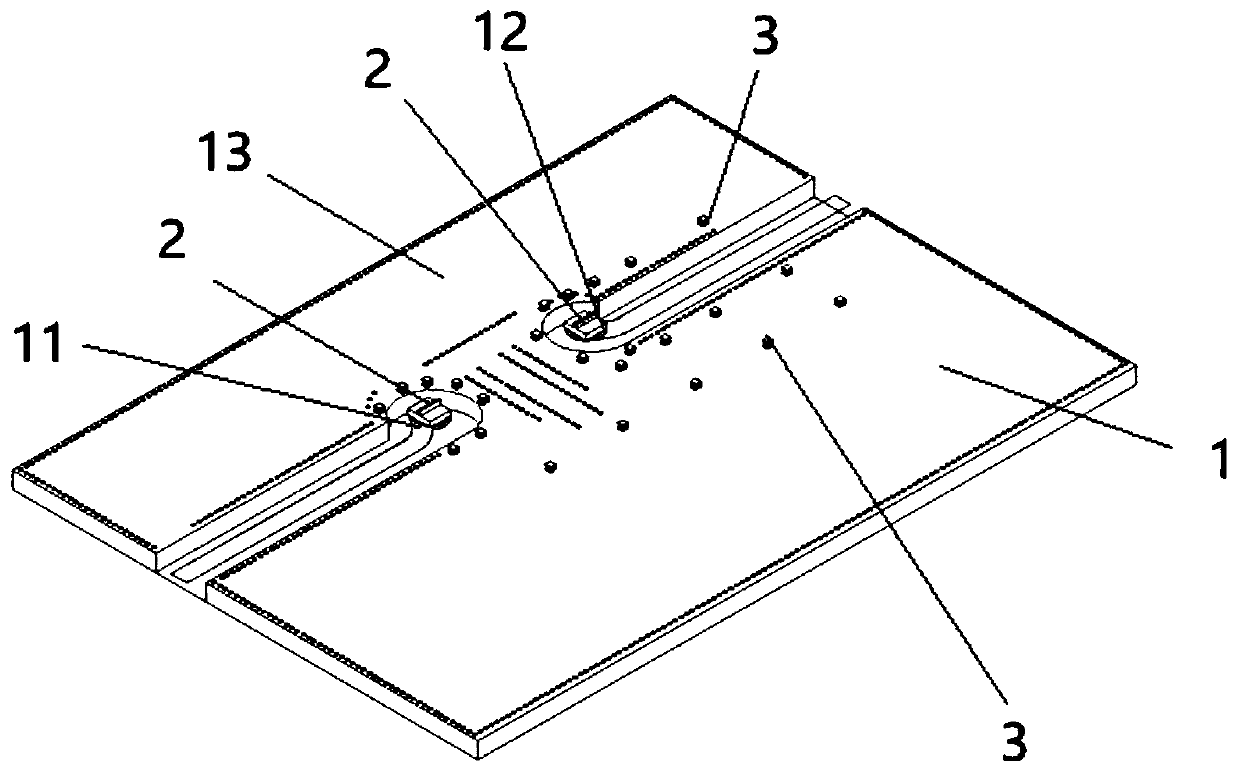

[0045] Such as figure 2 and Figure 6 Shown is the first embodiment of the ceramic filter with CTE compensation according to the present invention, including a filter body 1, and an input end 11 and an output end 12 are provided on the signal transmission surface 13 of the filter body 1 , in order to eliminate the need to connect the PCB board, effectively reduce the cost of use, it can also improve the buffer performance when connecting with the communication system board, and can also retain the ability to support the filter, connect the signal to the ground, and the CTE of the ceramic and the communication system board when using the PCB board Inconsistent compensation function, the ceramic filter with CTE compensation according to the present invention also includes several first elastic metal pads 3 for connecting the communication system board; the first elastic metal pads 3 are discretely arranged on the The signal transmission surface 13 is staggered with the input e...

Embodiment 2

[0051] Figure 7 Shown is the second embodiment of the ceramic filter with CTE compensation according to the present invention, the only difference between it and the first embodiment above is that the cross section of the first elastic sheet structure is bent The arc structure 37 of 36, so that the signal line can be routed from the cutout part of the first shrapnel structure, and the electrical effect is better. However, compared with the first elastic sheet structure with a rectangular structure 35 with a bend 34 in the longitudinal section, the first elastic sheet structure with an arc-shaped structure 37 with a bend 34 in the cross section has slightly poorer elasticity, so the effect of buffering stress is relatively low. Poor, but the installation stability with the communication system board is relatively high. In this embodiment, the arc-shaped structure is a superior arc-shaped structure, and the arc length of the superior arc-shaped structure is 3 / 4 of a circle. Spe...

Embodiment 3

[0053] image 3 Shown is the third embodiment of the ceramic filter with CTE compensation described in the present invention, the only difference between it and the above first embodiment is: the input end 11 and the output end 12 are also provided with The second elastic metal pad 2; the coefficient of thermal expansion of the second elastic metal pad 2 is equivalent to that of the PCB board.

[0054] The input end 11 and output end 12 on the filter body 1 are provided with second elastic metal pads 2 instead of the existing copper pins as the signal transmission end, which is more elastic, so the buffer performance is better when connected to the communication system board.

[0055] As a further improvement of this embodiment, such as Figure 5 As shown, the second elastic metal pad 2 is a second elastic sheet structure. The second elastic sheet structure includes a third welding portion 21 for connecting the input end 11 and the output end 12, a fourth welding portion 22 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com