Box type limit engine suspension assembly

An engine mounting and assembly technology, which is applied to power units, jet propulsion units, internal combustion propulsion units, etc., can solve the problems of poor impact resistance and short service life, and achieve good buffer performance, long service life, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

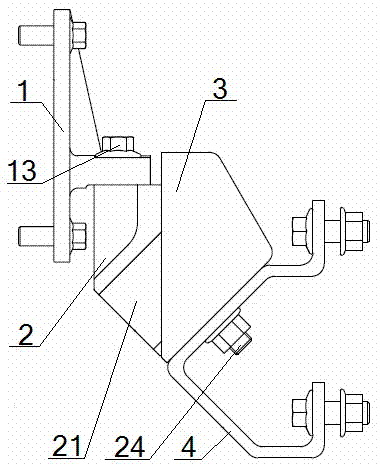

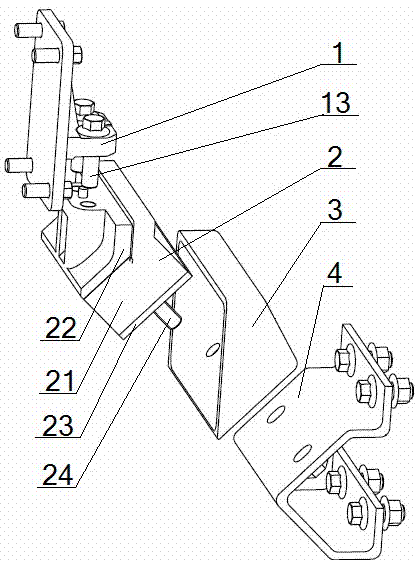

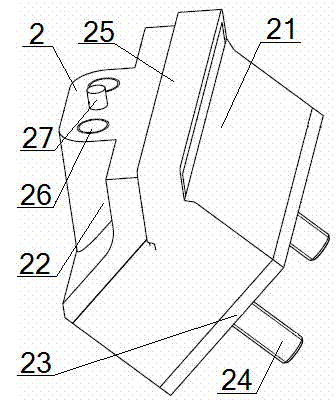

[0044] see figure 1 – Figure 7 , a box-type limit engine suspension assembly, including a suspension cushion vulcanization assembly 2 and a suspension bracket 4 connected to each other, the suspension cushion vulcanization assembly 2 includes vulcanization rubber 21, an upper frame 22, The lower frame 23 and the lower frame bolts 24, the upper frame 22 is vulcanized with the lower frame 23 and the lower frame bolts 24 through vulcanized rubber 21; the engine suspension assembly also includes a limit box 3, and the suspension cushion The vulcanization assembly 2 is arranged inside the limit box 3, and the suspension cushion vulcanization assembly 2 is fixedly connected with the suspension bracket 4 through the limit box 3, and the limit box 3 includes a bottom plate 33 and a back plate 34, The rear end of the base plate 33 is fixedly connected to the rear end of the upper limit plate 31 through the back plate 34, and the two sides of the upper limit plate 31 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com