System and method for reinforcing structures

a technology of structure and reinforcement, applied in the field of building methods, can solve the problems of not allowing time for a person, framed wall not having good resistance to forces, and conventional wooden frameworks that do not have much resistance to lateral forces, etc., and achieve the effect of strengthening the structure and increasing the ductility of the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

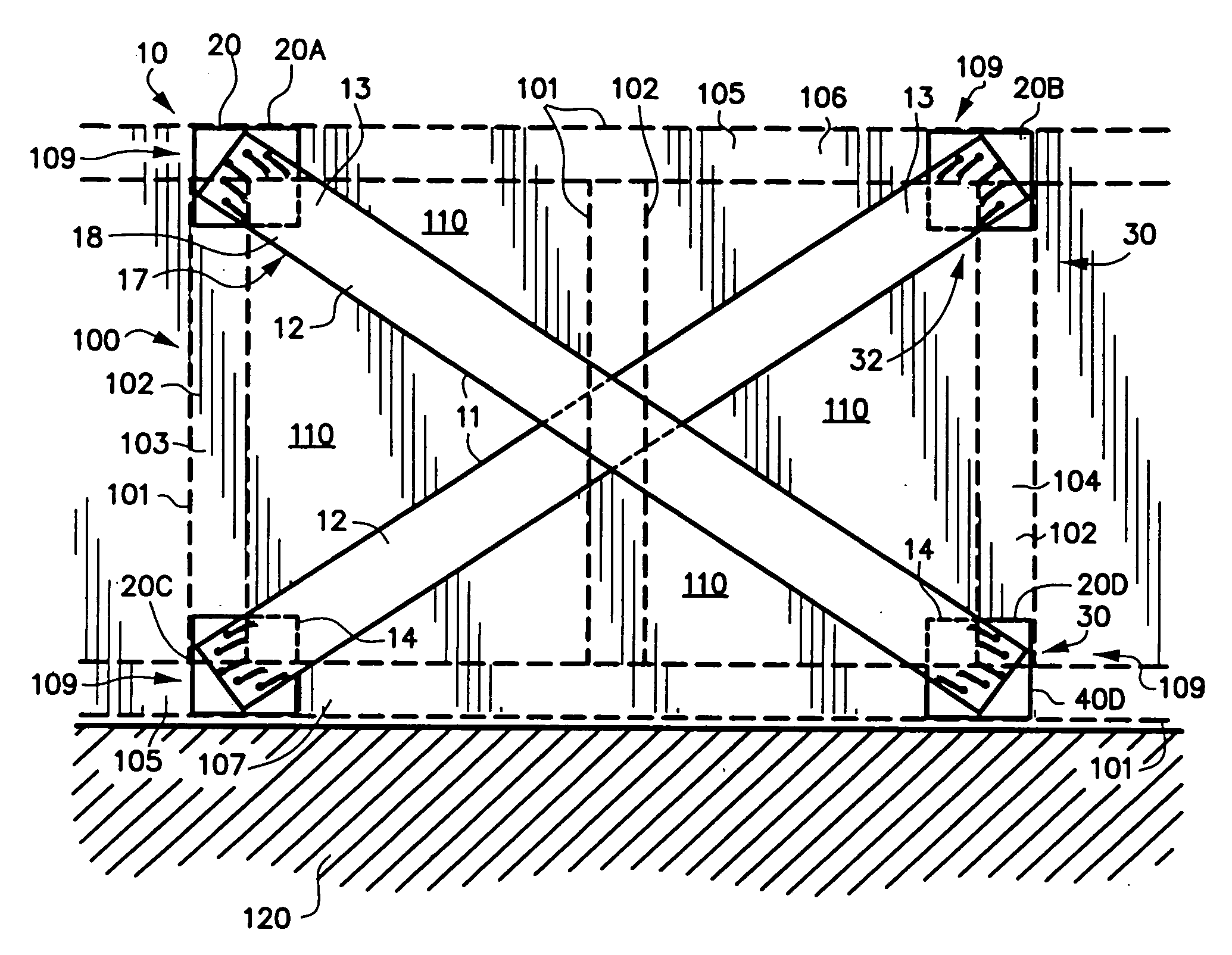

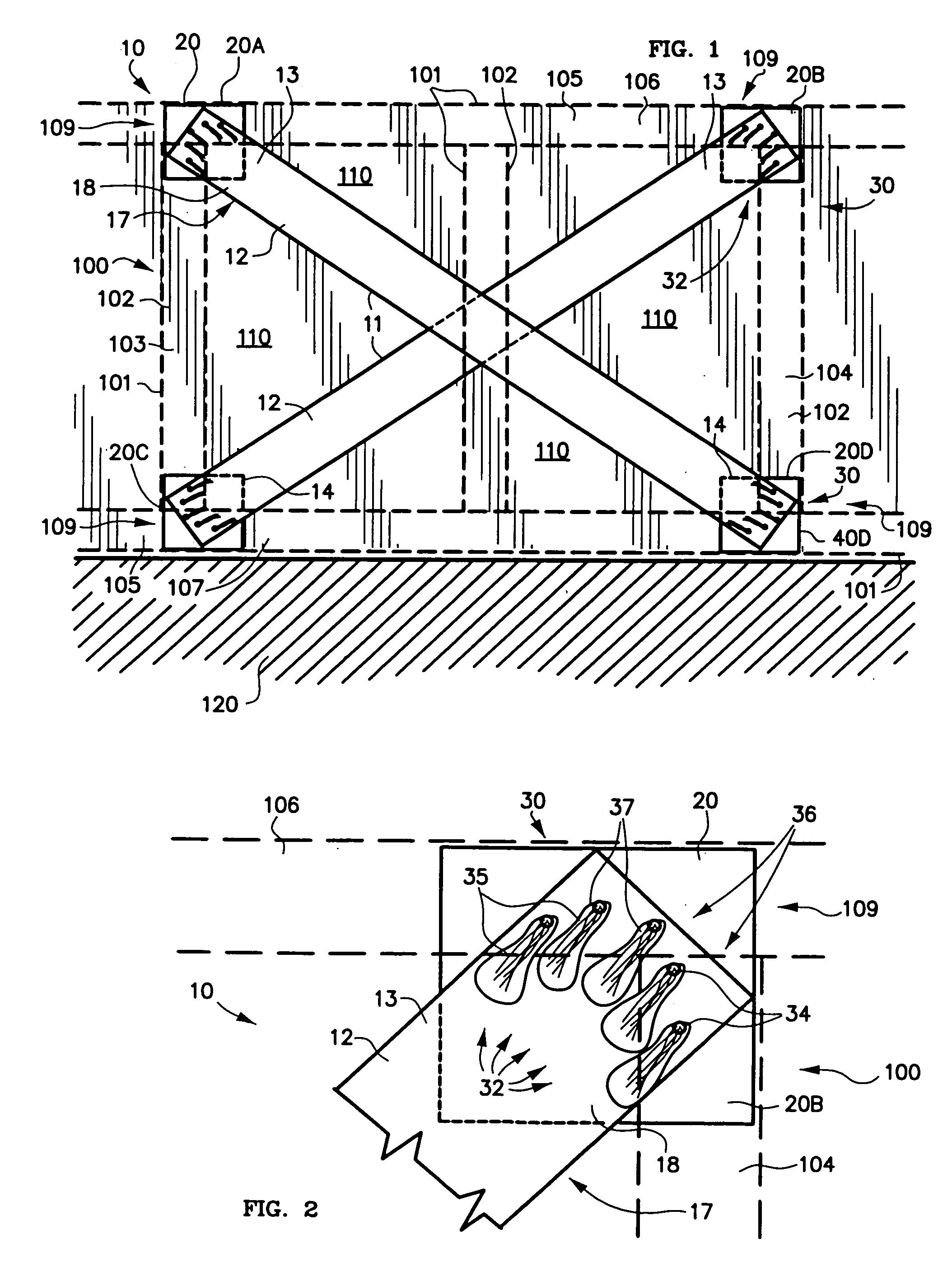

[0029]FIG. 1 is an environmental front elevation view of reinforcement system 10 of the present invention, attached to a conventional framed wall 100. Framed wall 100 consists generally of frame members 101 (shown in phantom) and wall sheathing 110 for covering frame members 101.

[0030]Frame members 101 typically include vertical support members 102, such as first vertical support member 103 and second vertical support member 104. First and second vertical support members 103,104 for a single family house are typically “studs” of soft wood that are nominally 2 inches by 4 inches cross-section and of any needed length, frequently 8 feet.

[0031]Support members 103,104 are parallel and spaced apart from one another. The maximum spacing is usually specified by relevant building code for the region and the type of structure. FIG. 1 indicates an additional support member 102 between first support member 103 and second support member 104.

[0032]Vertical support members 102 must have sufficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com