Three-phase composite structure sound absorption material and preparation method and application thereof

A technology of sound-absorbing materials and composite structures, which is applied in the direction of sound-generating devices and instruments, can solve the problems of poor sound absorption performance at medium and low frequencies and weak mechanical properties, and achieve improved sound absorption performance at medium and low frequencies, improved cushioning performance, and improved response conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below in conjunction with accompanying drawing:

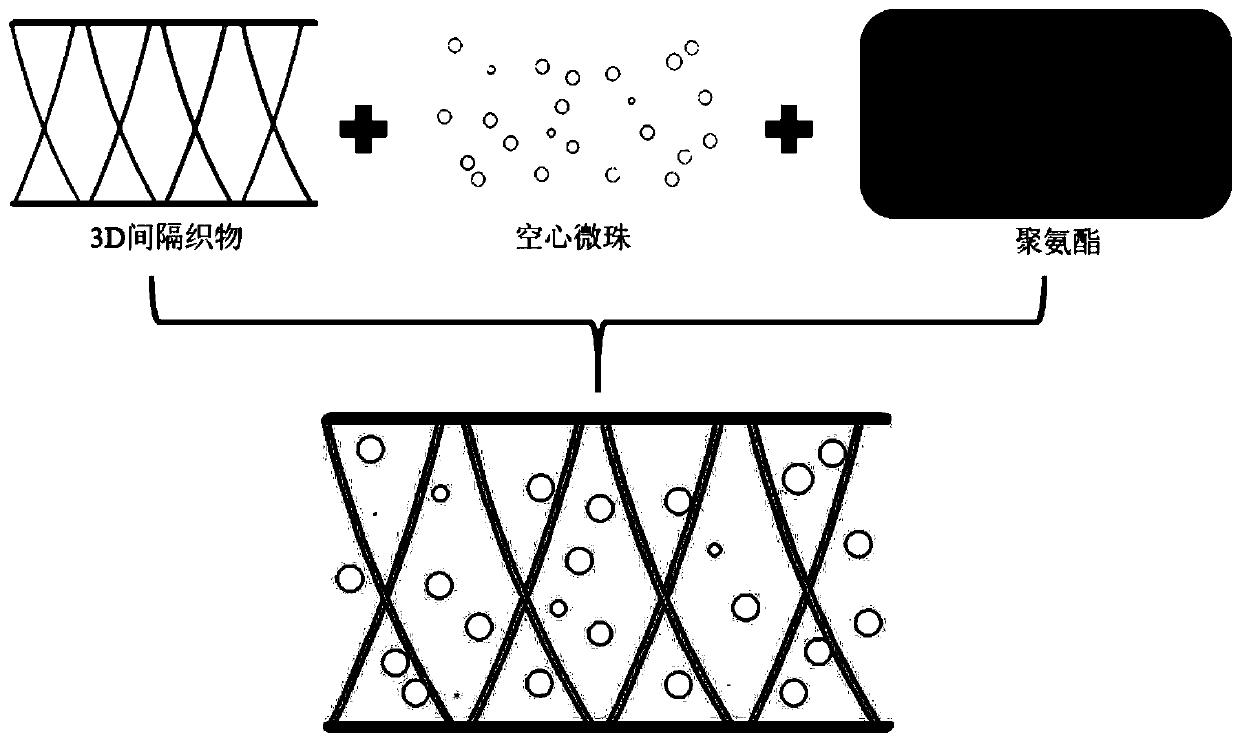

[0039] Such as figure 1 , is a three-phase composite structure sound-absorbing material of the present invention, including 3D spacer fabric 1, polyurethane matrix 2 and hollow microspheres 3; the surface layer of 3D spacer fabric 1 is a knitted fabric formed by compounding knitting chain weave and weft insertion weave. The 3D spacer fabric 1 is compounded with the polyurethane matrix 2, the volume fraction of the hollow microspheres 3 in the polyurethane matrix 2 is 20%-50%, and the hollow microspheres 3 are filled in the polyurethane matrix 2. The knitting chain yarn of the knitting chain organization can adopt polyester, and the weft insertion yarn of the weft insertion organization can adopt carbon fiber tow. The hollow microspheres 3 can be made of glass material, the particle size is less than 100 μm, and the wall thickness is 2%-10% of the particle size.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com