A gray-based polyurethane sound-absorbing and noise-reducing material for biomass power plants

A technology of polyurethane and biomass, which is applied in the direction of sound-generating devices and instruments, can solve the problems of resource waste and environmental pollution, and achieve the effects of fast molding, improved sound absorption performance, and simple processing and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

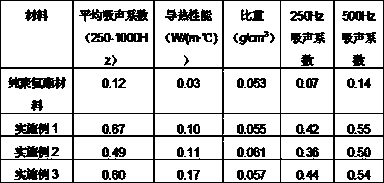

Examples

Embodiment 1

[0031] The proportion of polyurethane black and white materials is 1:1, 43% each, expanded perlite accounts for 4% of the total material, and rice husk ash accounts for 10%.

[0032] The polyurethane black and white material is (XY) n-type linear block copolymer.

[0033] The rice husk ash is the rice husk ash of the power plant, which is ground by a ball mill for 30 minutes to make the fineness meet the specification requirements, not higher than 80 μm, and the treated rice husk ash has higher volcanic activity.

[0034] The specific process is:

[0035] (1) For preparation, apply engine oil evenly in the mold for standby;

[0036] (2) Put polyurethane black and white material, expanded perlite, and rice husk ash in a beaker in turn according to the ratio, and stir for 6 seconds with an electric stirrer at a speed of 120r / min to make a polyurethane foam prepolymer containing inorganic particles;

[0037] (3) Pour the prepolymer into the mold quickly and gently, and use a sh...

Embodiment 2

[0041] The proportion of polyurethane black and white materials is 1:1, 40% each, expanded perlite accounts for 10% of the total material, and rice husk ash accounts for 10%.

[0042] The polyurethane black and white material is (XY) n-type linear block copolymer.

[0043] The rice husk ash is the rice husk ash of the power plant, which is ground by a ball mill for 30 minutes to make the fineness meet the specification requirements, not higher than 80 μm, and the treated rice husk ash has higher volcanic activity.

[0044] The specific process is:

[0045] (1) For preparation, apply engine oil evenly in the mold for standby;

[0046] (2) Put polyurethane black and white material, expanded perlite, and rice husk ash in a beaker in turn according to the ratio, and stir for 6 seconds with an electric stirrer at a speed of 120r / min to make a polyurethane foam prepolymer containing inorganic particles;

[0047] (3) Pour the prepolymer into the mold quickly and gently, and use a s...

Embodiment 3

[0051] The proportion of polyurethane black and white materials is 1:1, 40% each, expanded perlite accounts for 5% of the total material, and rice husk ash accounts for 15%.

[0052] The polyurethane black and white material is (XY) n-type linear block copolymer.

[0053] The rice husk ash is rice husk ash from a power plant, which is ground by a ball mill for 30 minutes to make the fineness meet the specification requirements, not higher than 80 μm, and the treated rice husk ash has higher volcanic activity.

[0054] The specific process is:

[0055] (1) For preparation, apply engine oil evenly in the mold for standby;

[0056] (2) Put polyurethane black and white material, expanded perlite, and rice husk ash in a beaker in turn according to the proportion, and stir for 6 seconds with an electric stirrer at a speed of 120r / min to make a polyurethane foam prepolymer containing inorganic particles;

[0057] (3) Pour the prepolymer into the mold quickly and gently, and use a sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com