Garment print tunnel drying equipment adopting infrared heat treatment

A drying equipment, infrared technology, applied in the direction of lighting and heating equipment, drying, drying machine, etc., can solve the problems of non-adjustable, no cooling system, poor effect of hot air system, etc., to increase buffer performance and heat distribution Uniform, productivity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

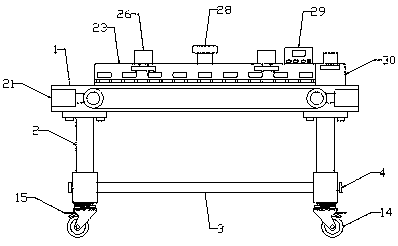

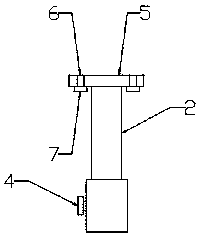

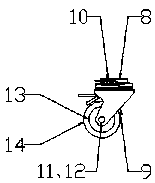

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, an infrared heat treatment clothing printing tunnel drying equipment includes a frame 1, which is characterized in that the bottom of the frame 1 is provided with a telescopic support frame device, and the telescopic support frame device is located around the bottom of the frame 1 and The telescopic support frame 2 fixedly installed around the bottom of the frame 1, the cross bar 3 between the adjacent two telescopic support frames 2 and the cross bar 3 fixedly installed between the adjacent two telescopic support frames 2, the telescopic support frame 2- The side is provided with a positioning button 4, a fixed block 5 positioned at the top of the telescopic support frame 2 and fixedly installed on the top of the telescopic support frame 2, a circular through hole 6 located around the surface of the fixed block 5 and evenly opened around the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com