Patents

Literature

118results about How to "Reduce bending force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

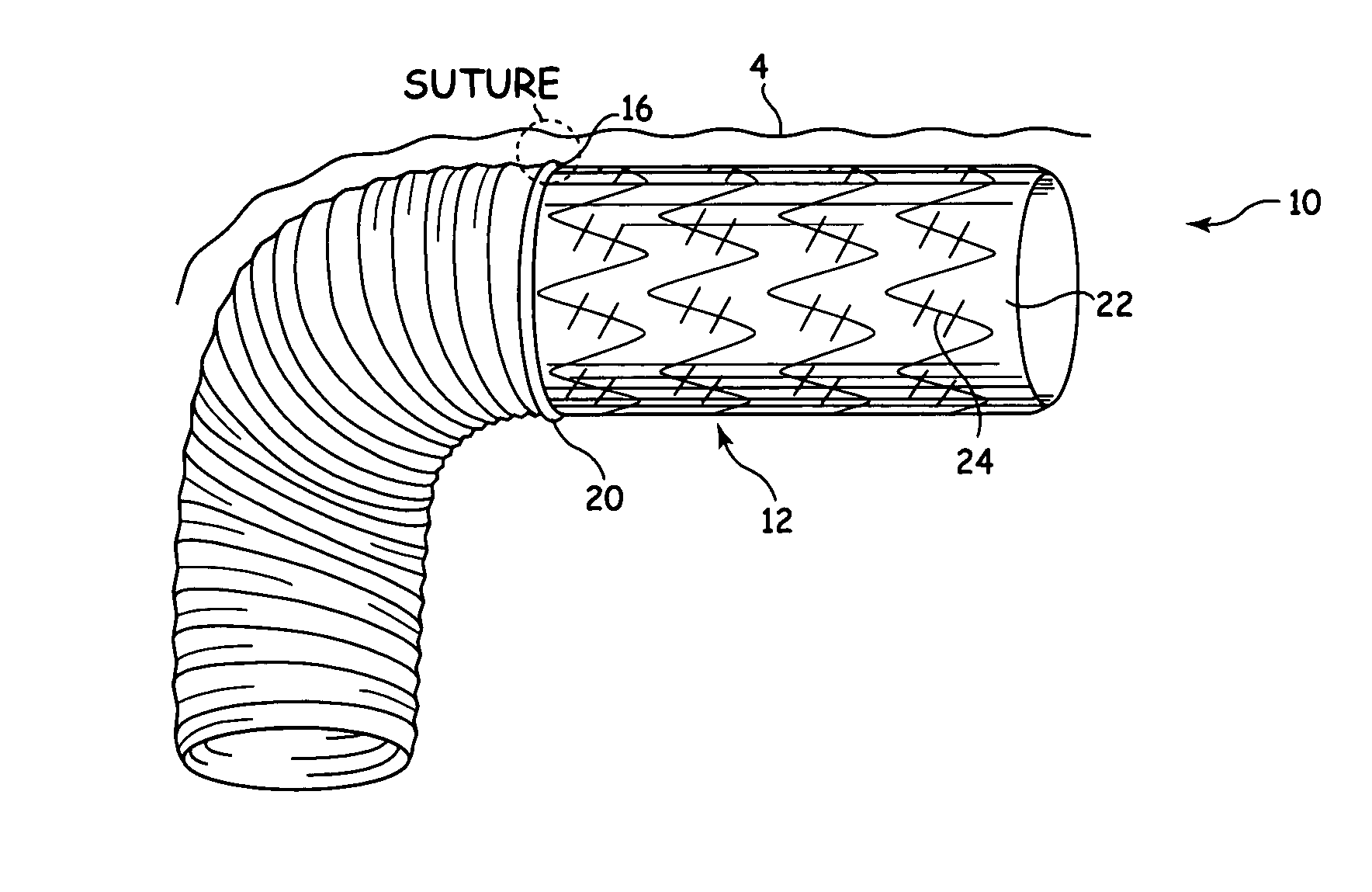

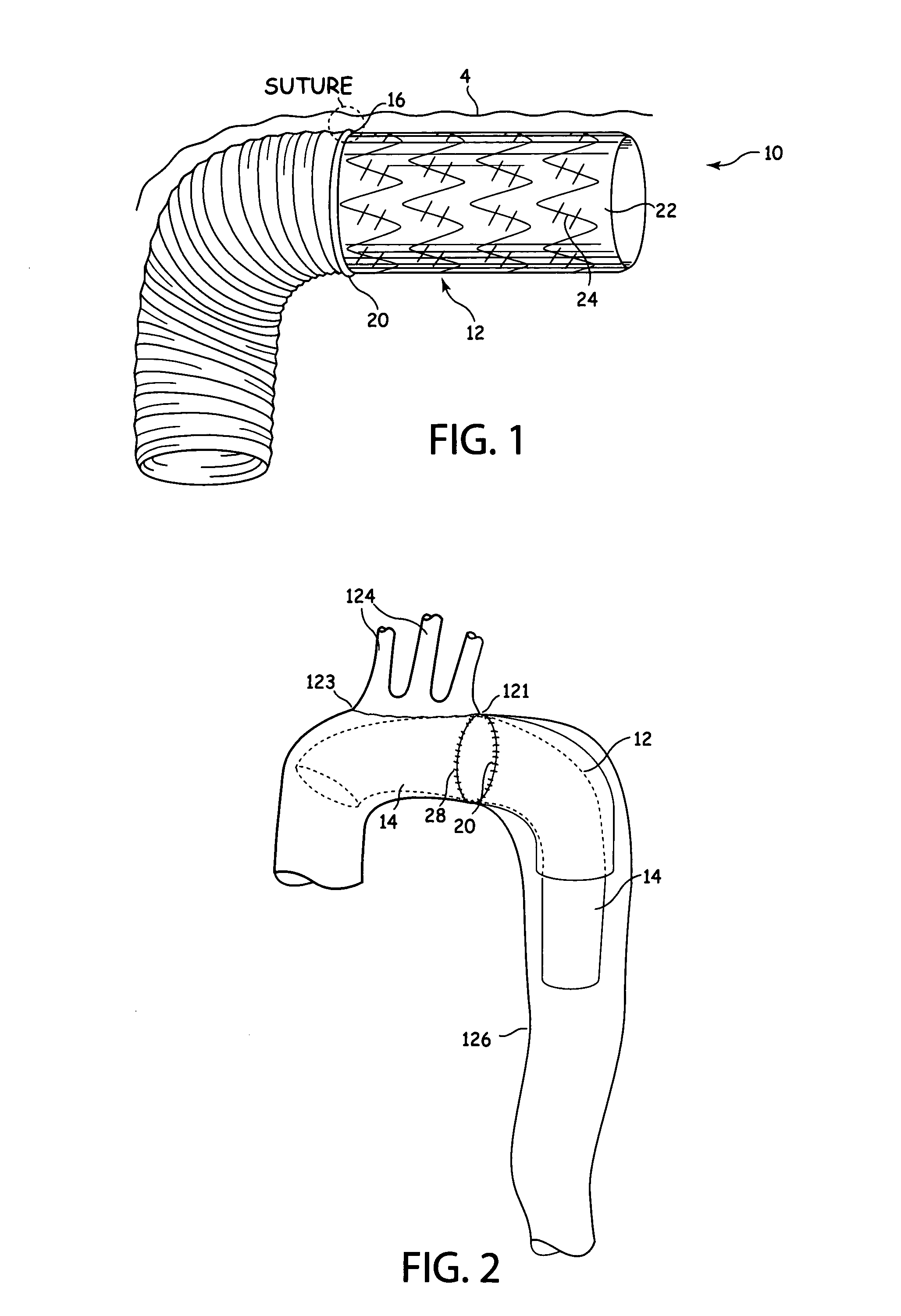

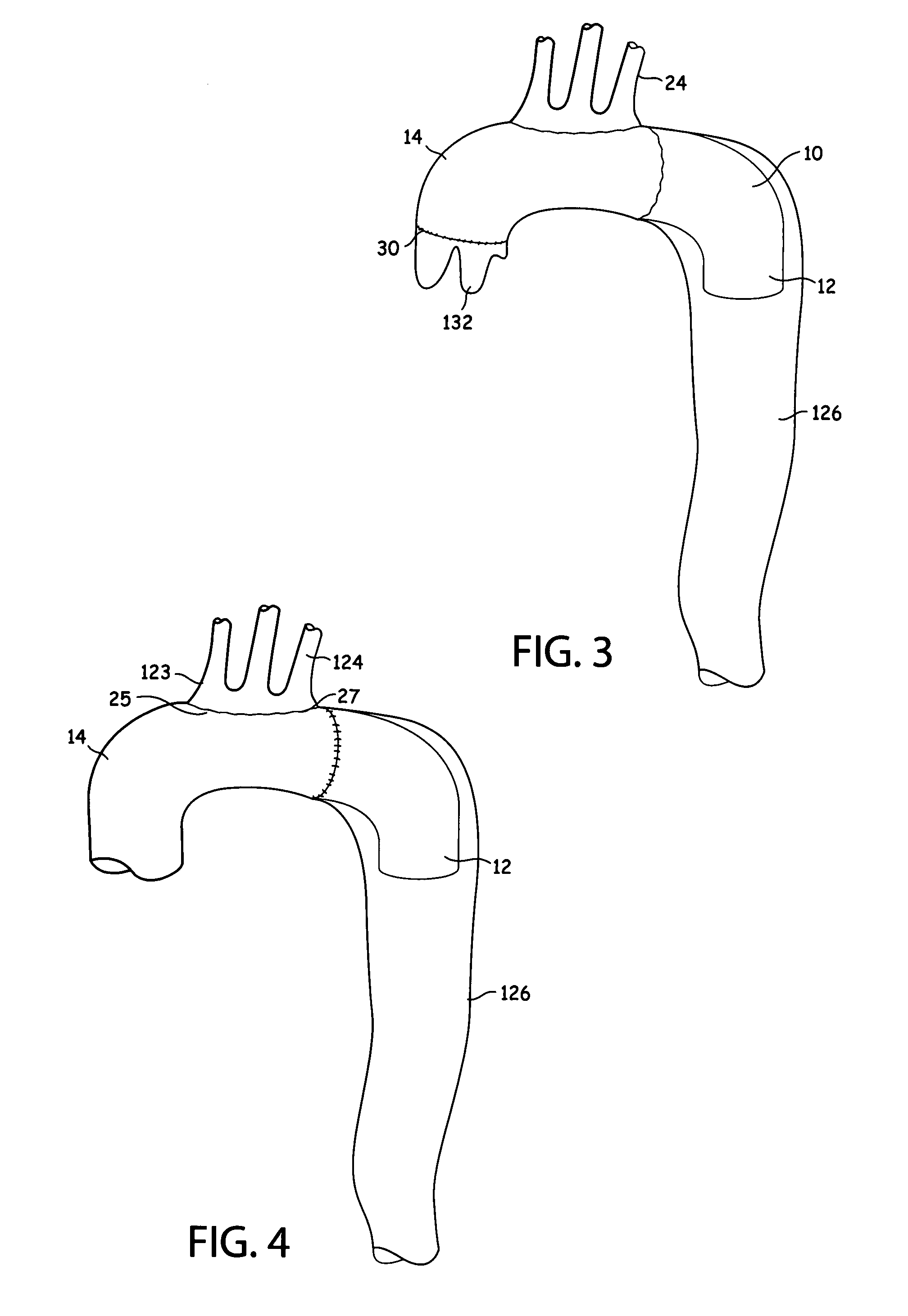

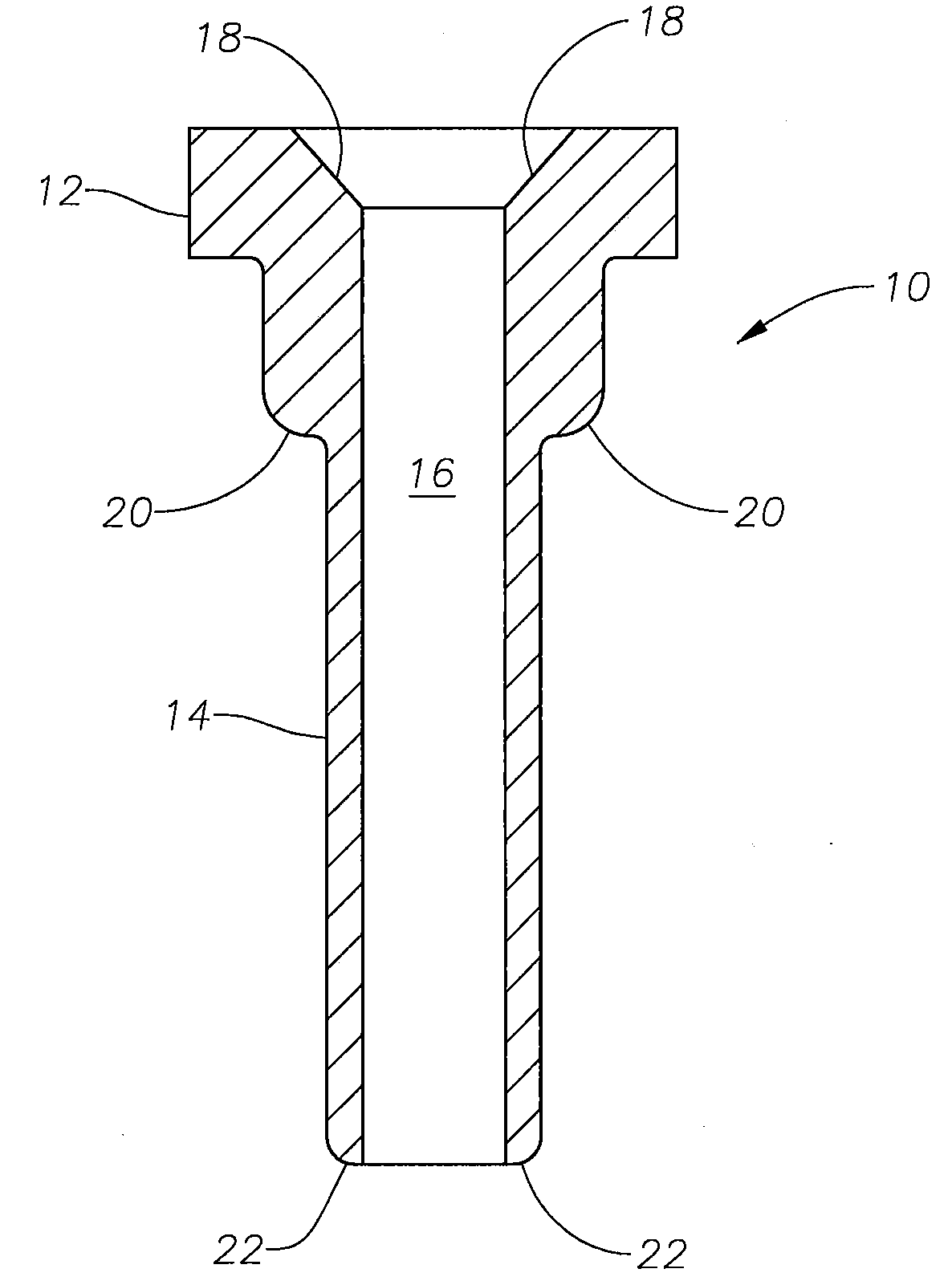

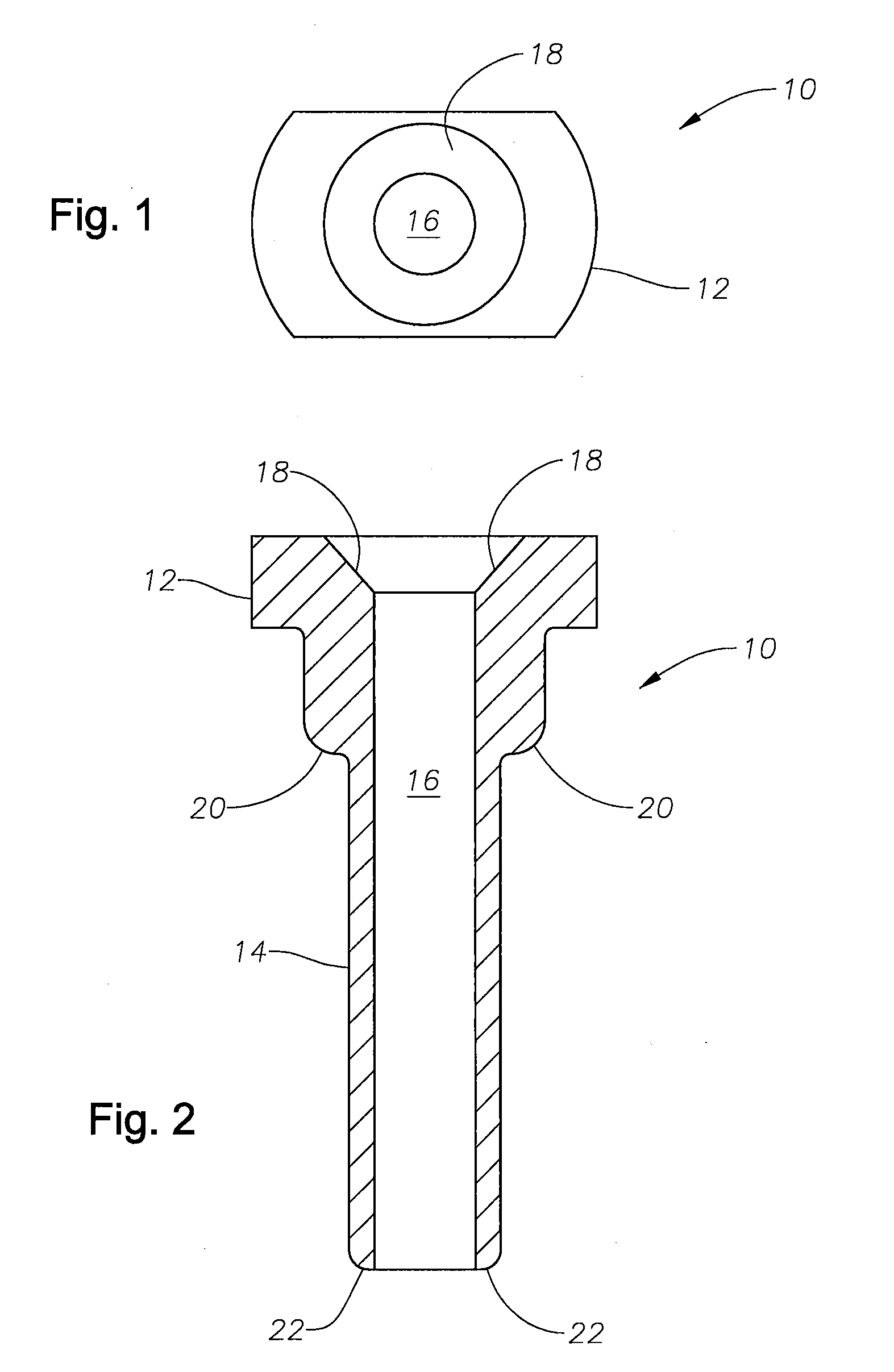

Aortic graft design

An aortic graft device ( 10 ) is provided with a graft portion ( 12 ) integrally fixed to a corrugated trunk portion ( 14 ). A fixing ring ( 16 ) is provided between the graft and trunk portions. The trunk portion ( 14 ) can be everted into the graft portion, leaving the fixing ring ( 16 ) at an extremity of the device for suturing purposes. The fixing ring ( 16 ) is preferably made from a relatively stiff material such as a compressed foam or rubber like material, which provides a relatively solid component for a surgeon to hold during suturing and which can provide a strong support for sutures.

Owner:COOK MEDICAL TECH LLC

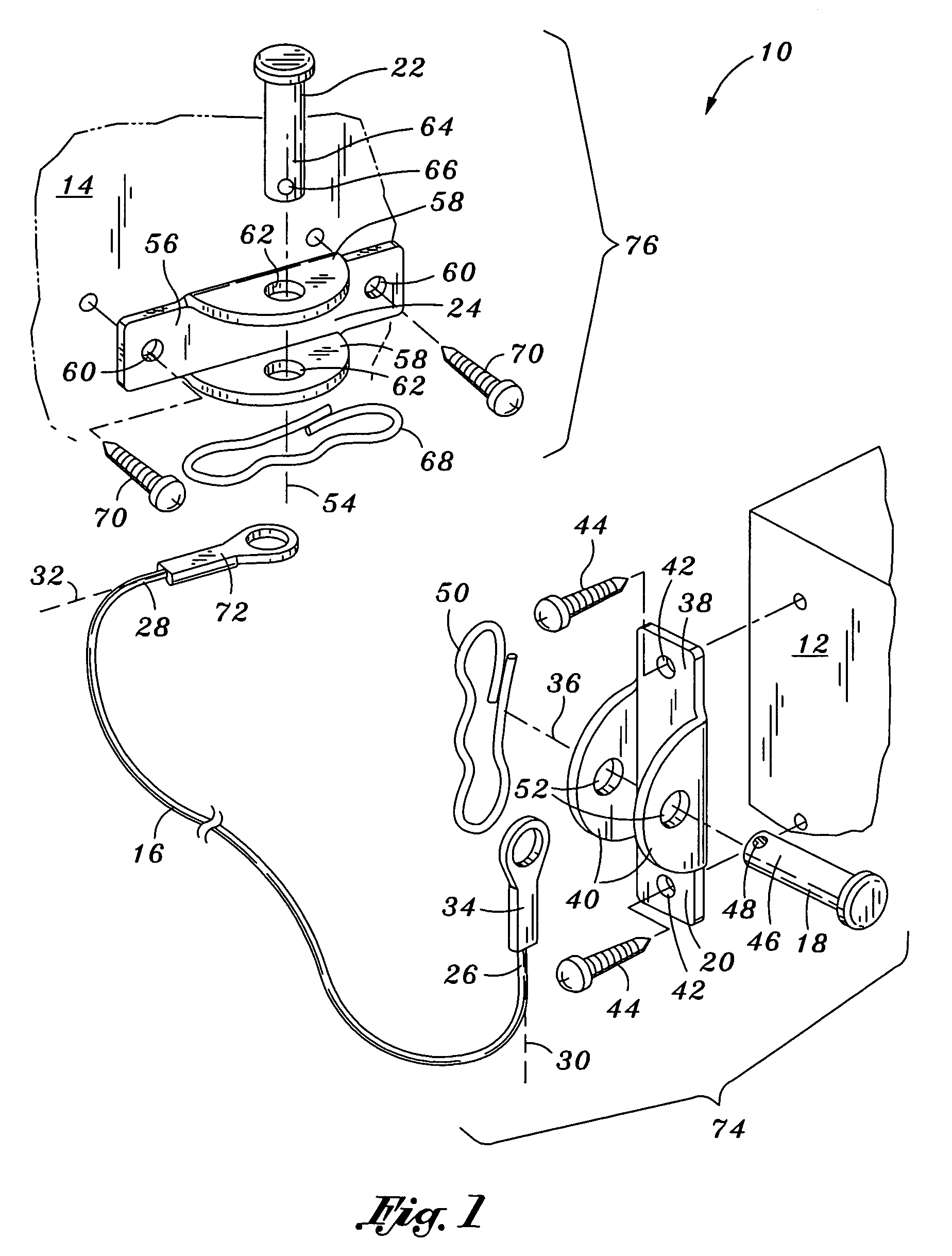

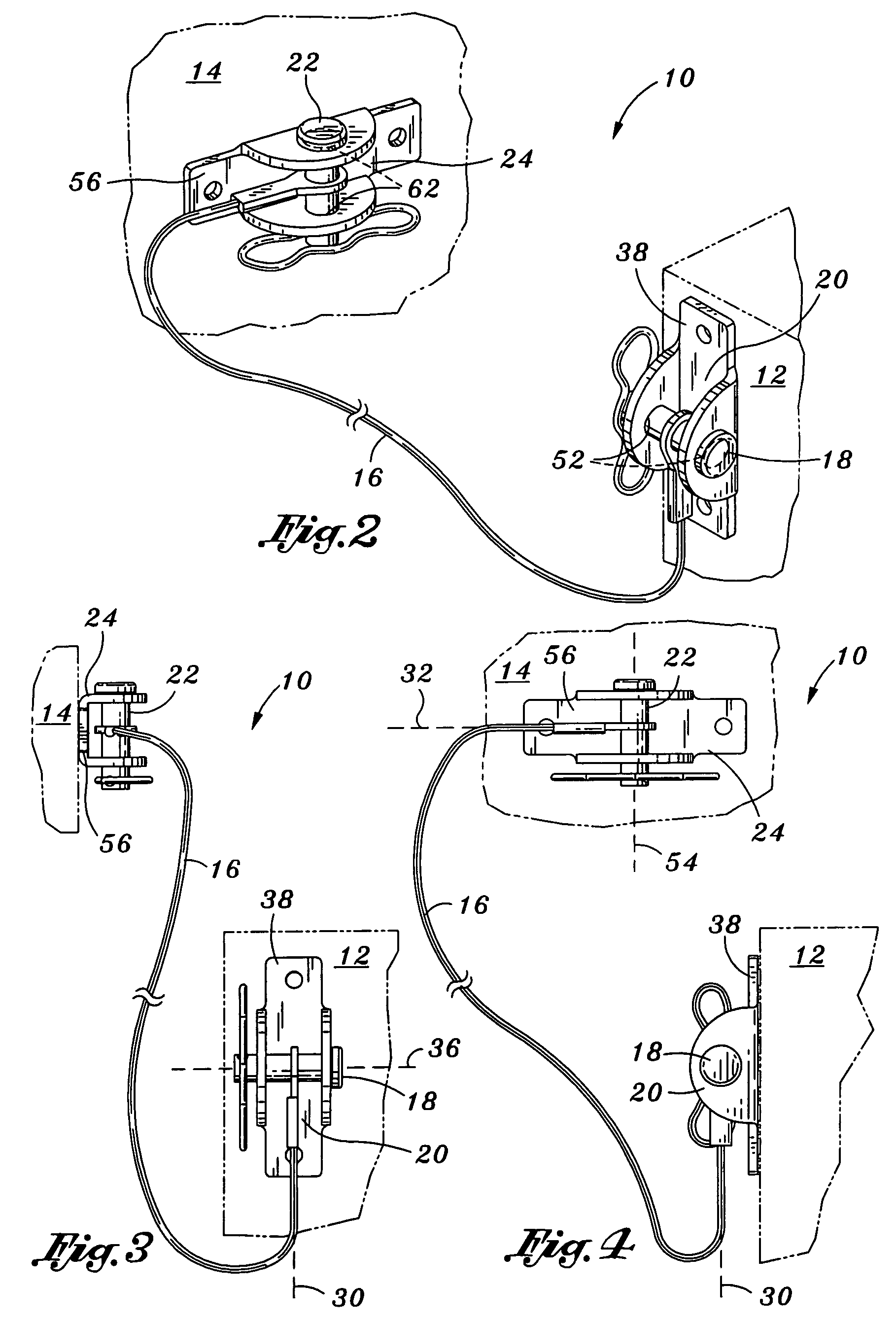

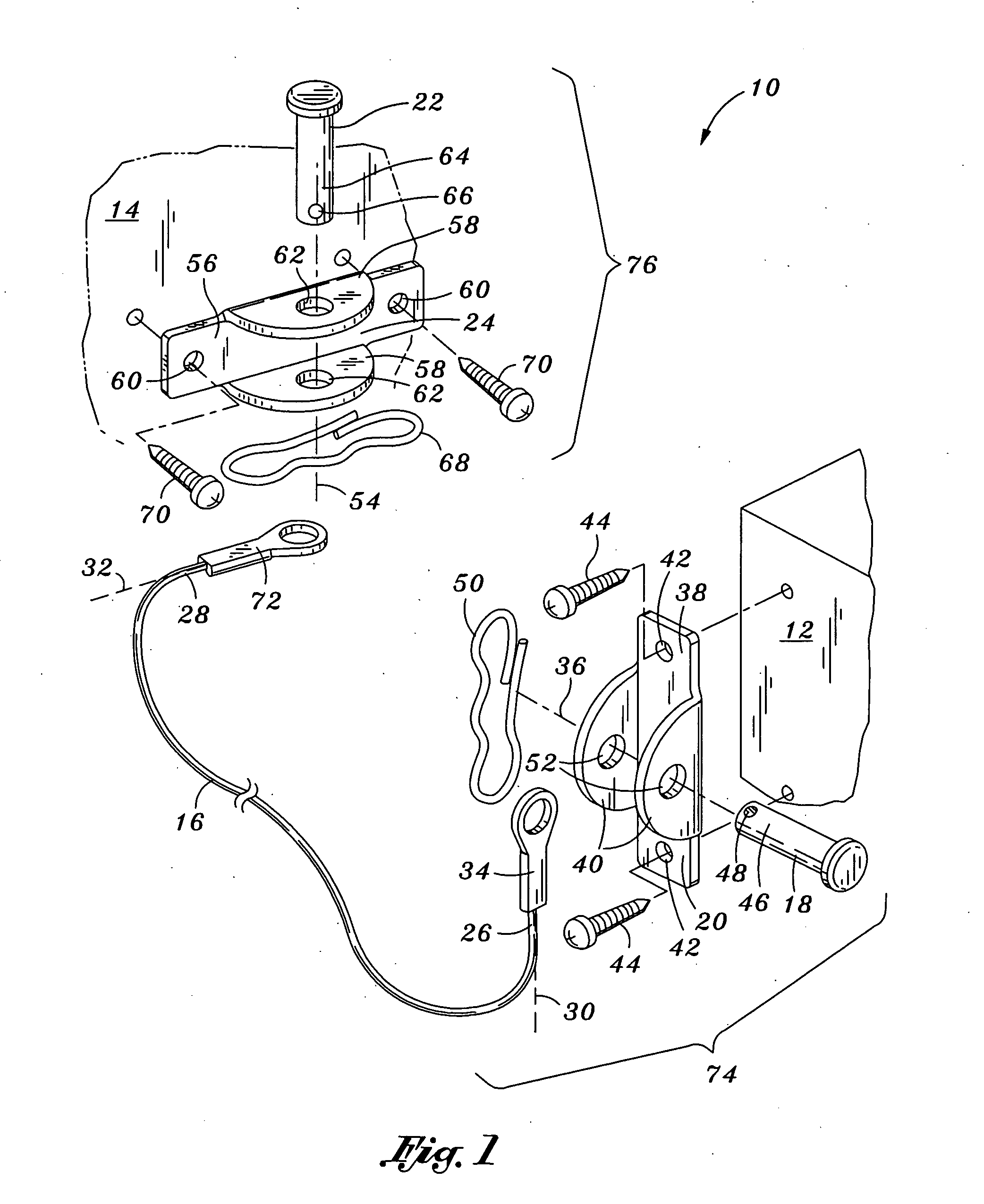

Anti-tipover device

ActiveUS7175149B2Reduce generationEqually distributedWing fastenersFlexible elementsRotational axisElectric cables

Owner:HANGMAN PRODS

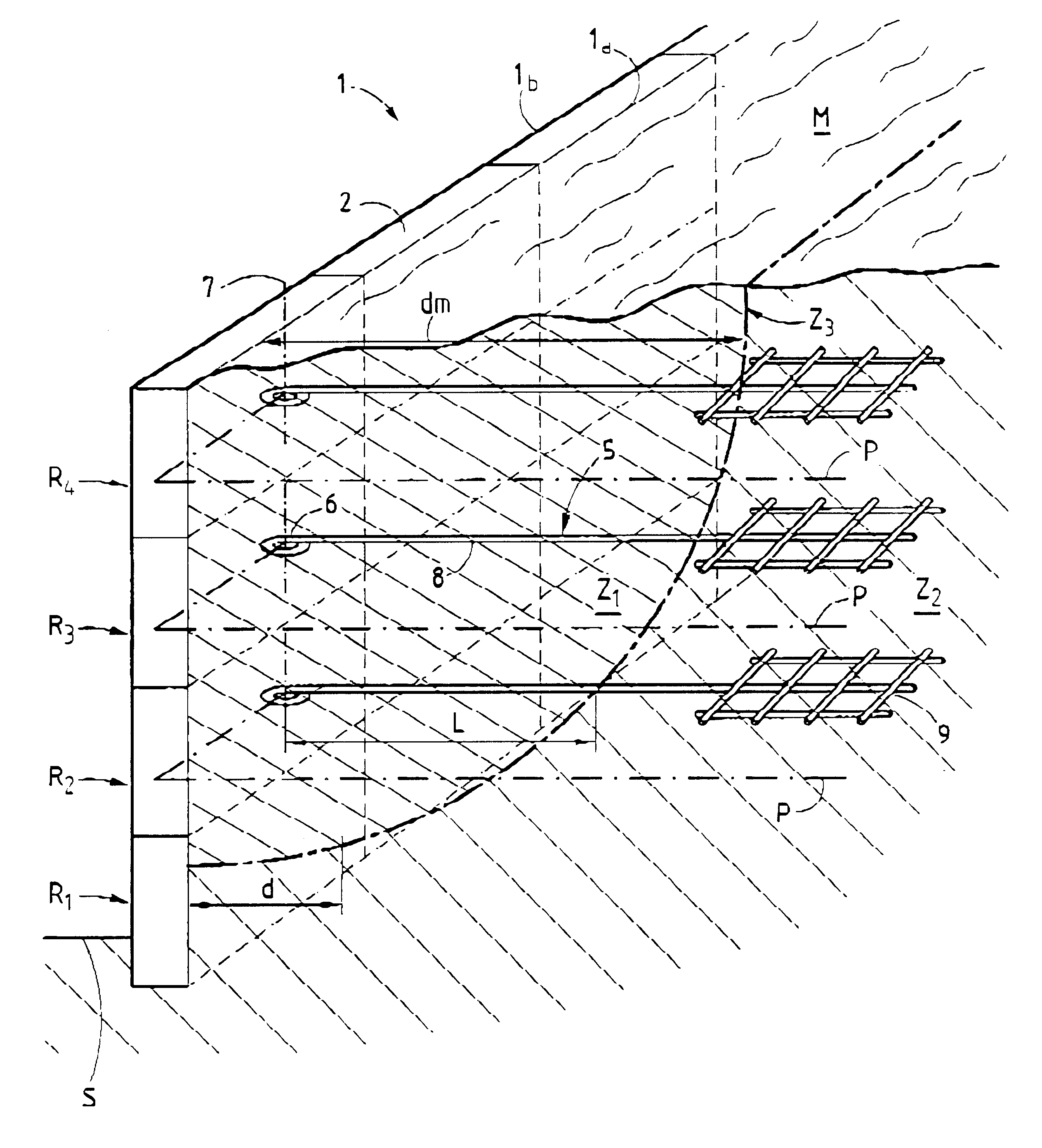

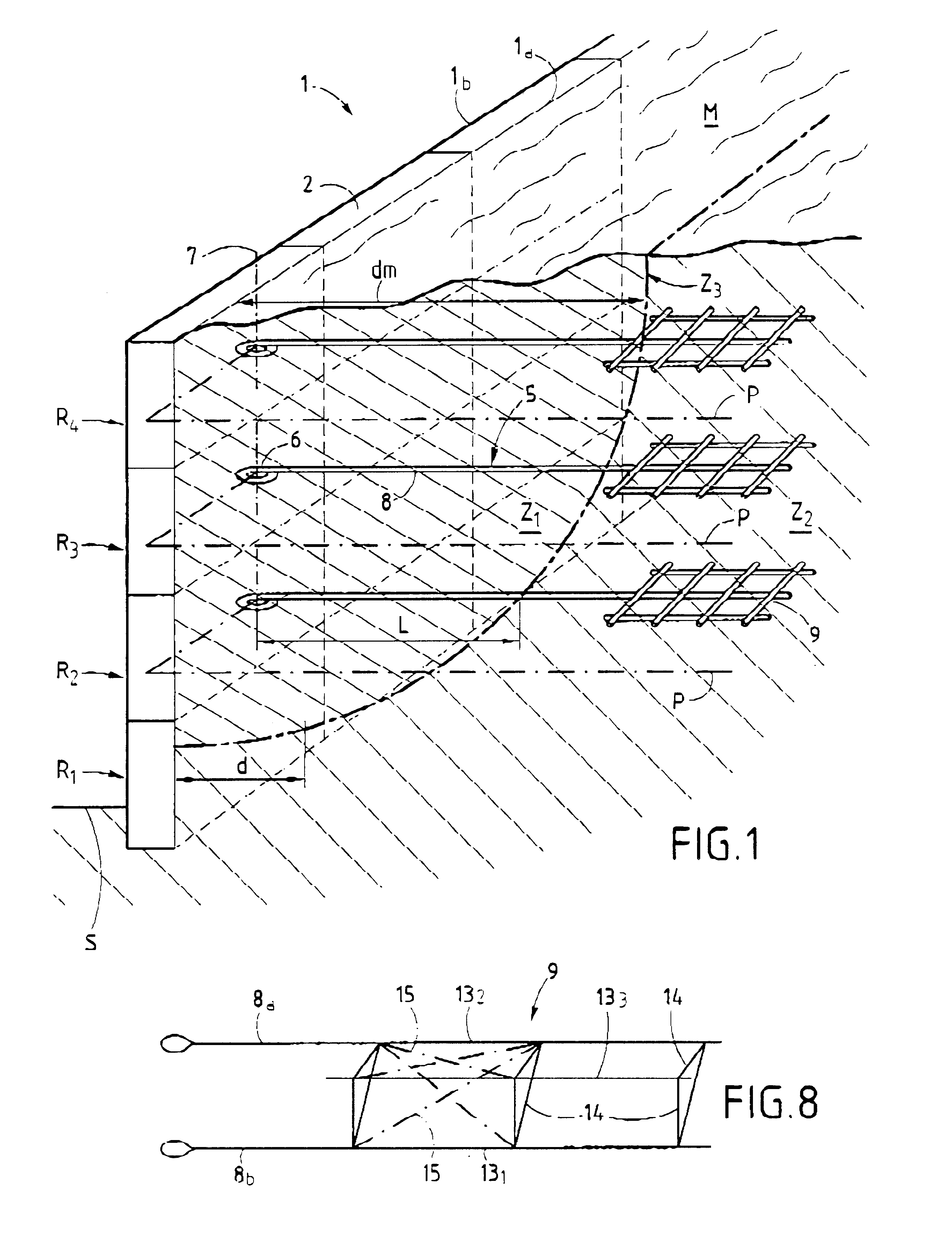

Method for forming a head wall from an anchor pile and reinforcing member for said anchor pile structure

InactiveUS6675547B1Function increaseIncrease anchoring forceArtificial islandsConstruction materialMechanical engineeringRetaining wall

Owner:GOLCHEH JOSEPH

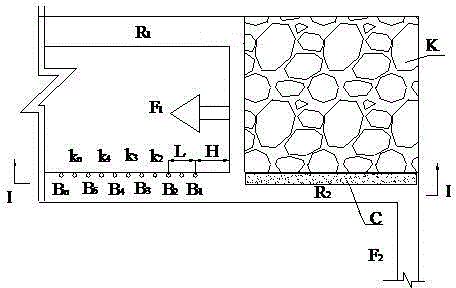

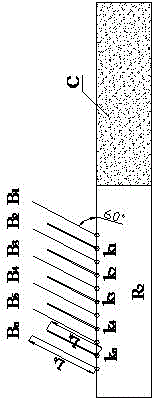

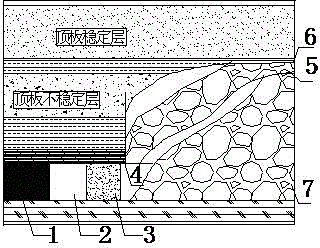

Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

InactiveCN104790954ARelieve pressureEliminate problems such as support difficultiesUnderground miningSurface miningStructural engineeringDeep hole

The invention discloses a roadside packing gob-side entry retaining top-cutting explosion pressure relief method which comprises the following four steps: I, confirming a top-cutting method, the drilling construction time and a drilling construction site; II, confirming top-cutting pressure relief explosion drilling parameters; III, drilling deep-hole explosion holes and explosive filling and sealing holes; IV, performing explosion top-cutting pressure relief. The roadside packing gob-side entry retaining top-cutting explosion pressure relief method is applied to roadside packing gob-side entry retaining top-cutting explosion pressure relief.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

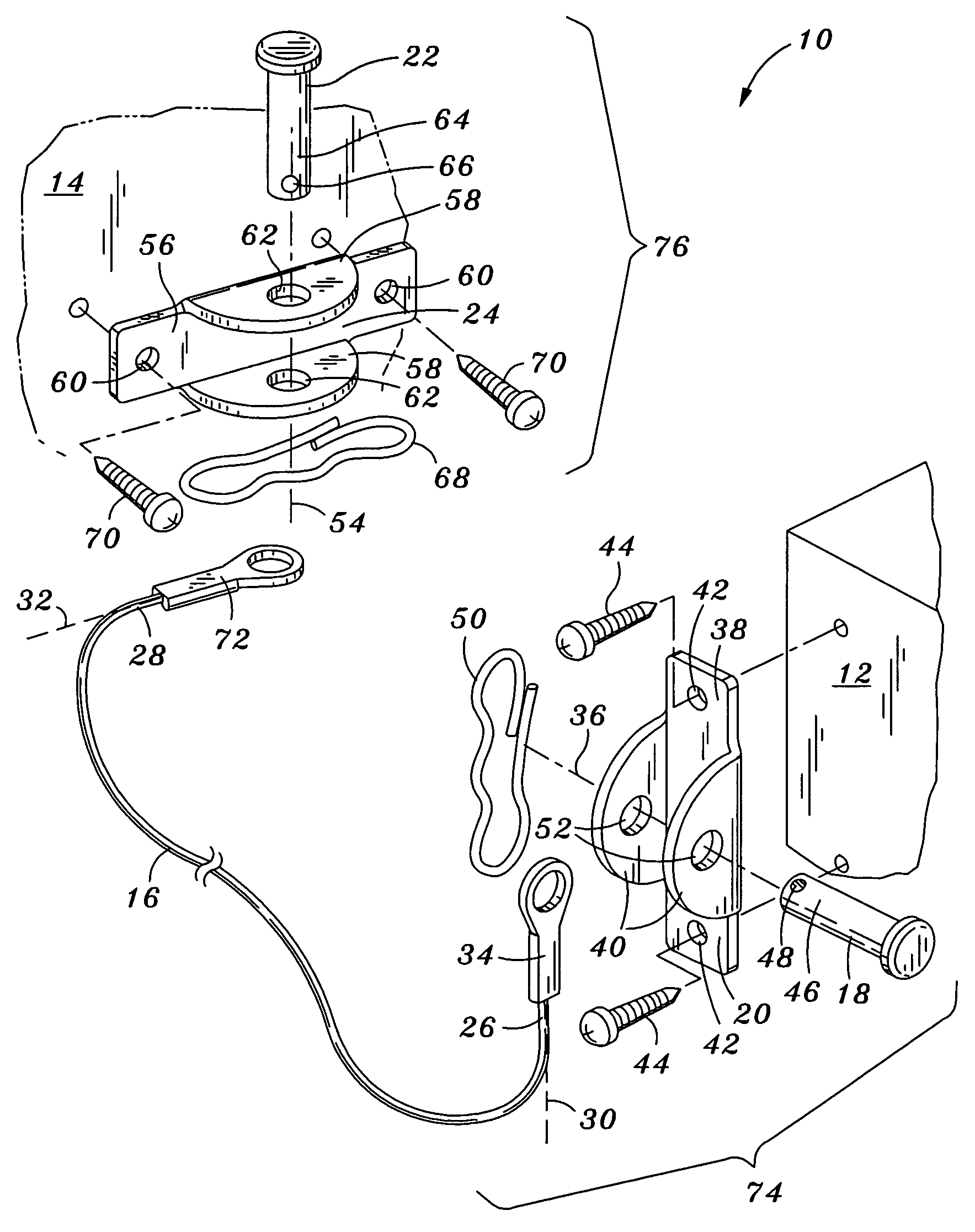

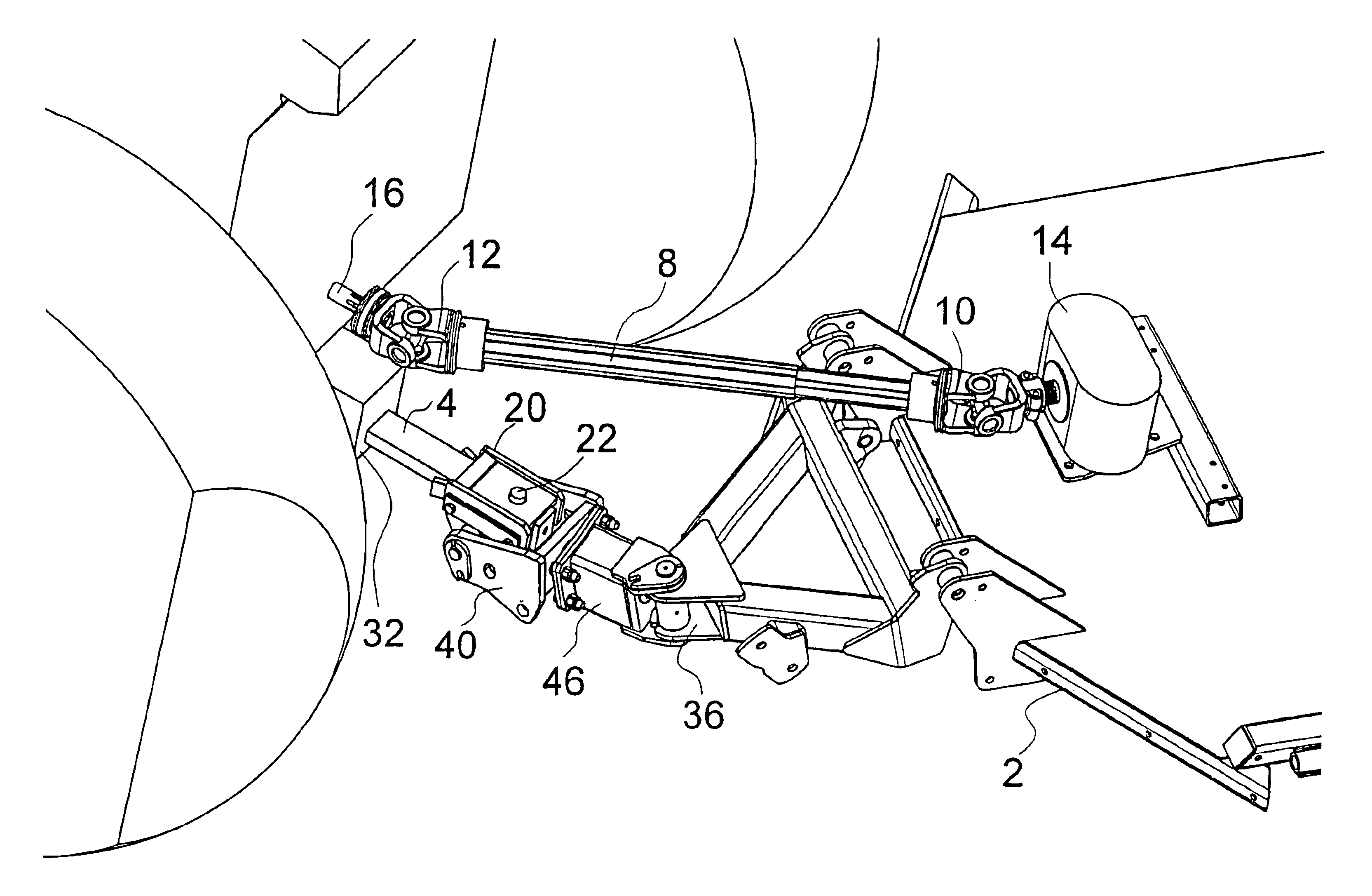

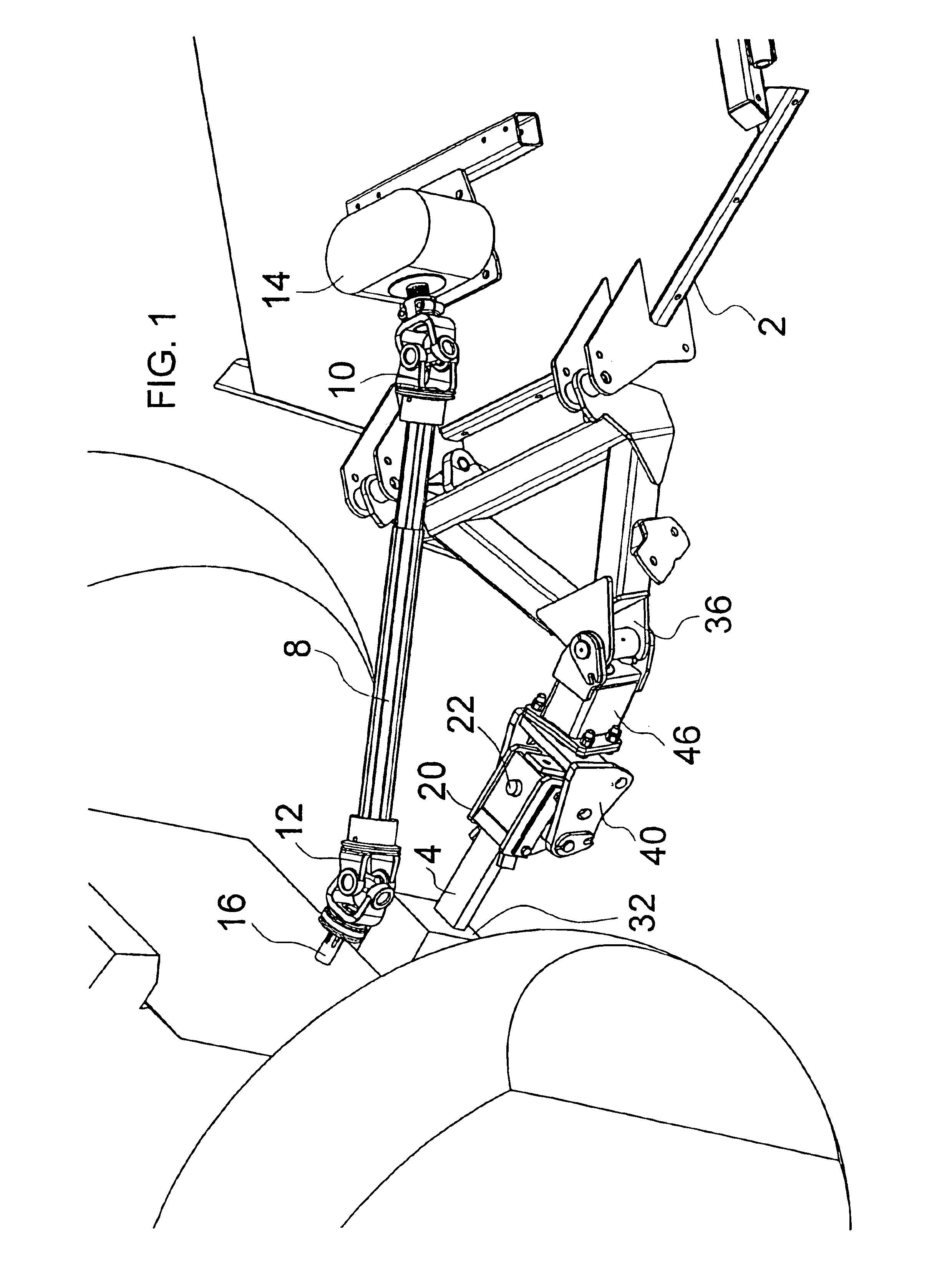

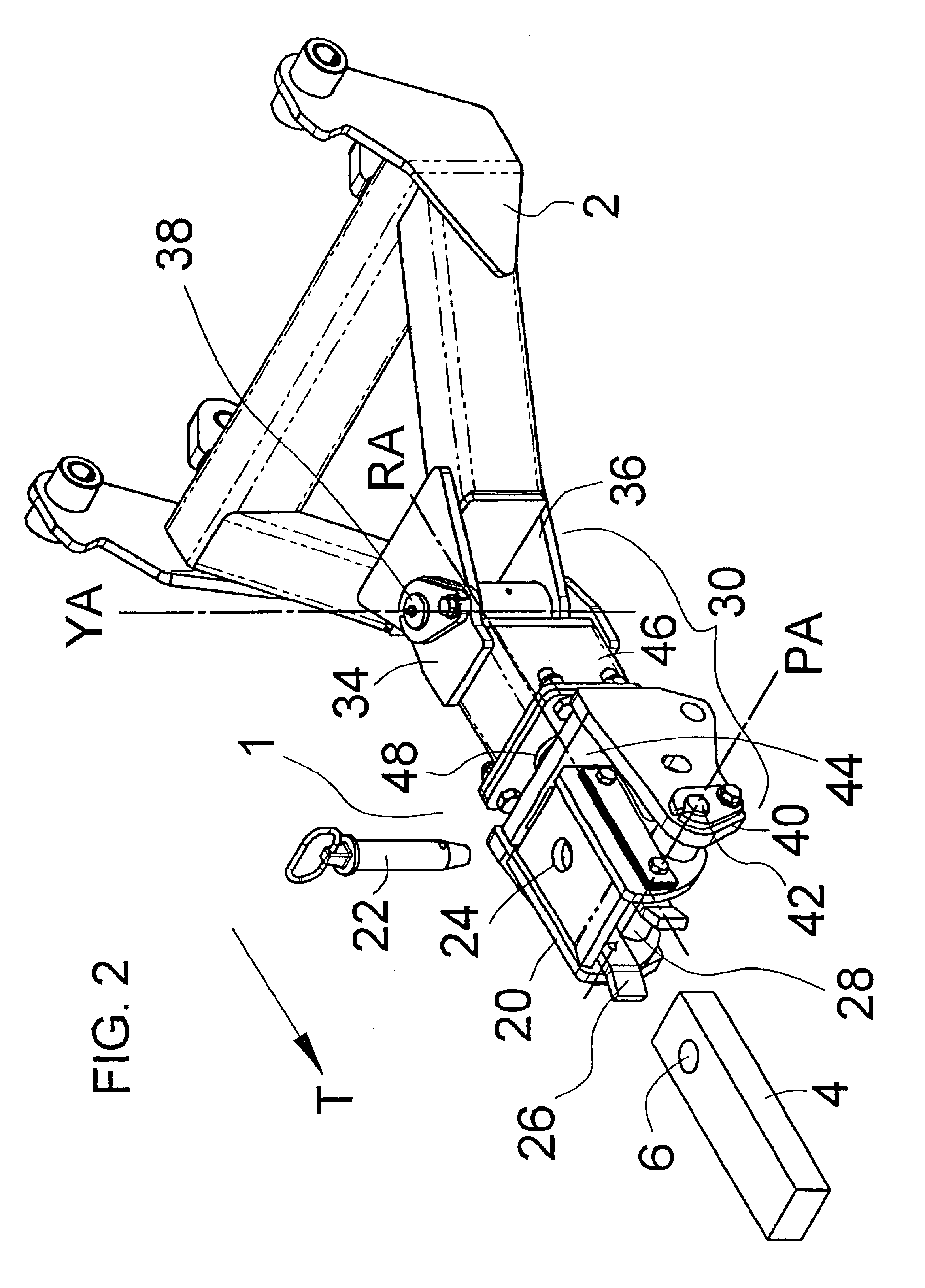

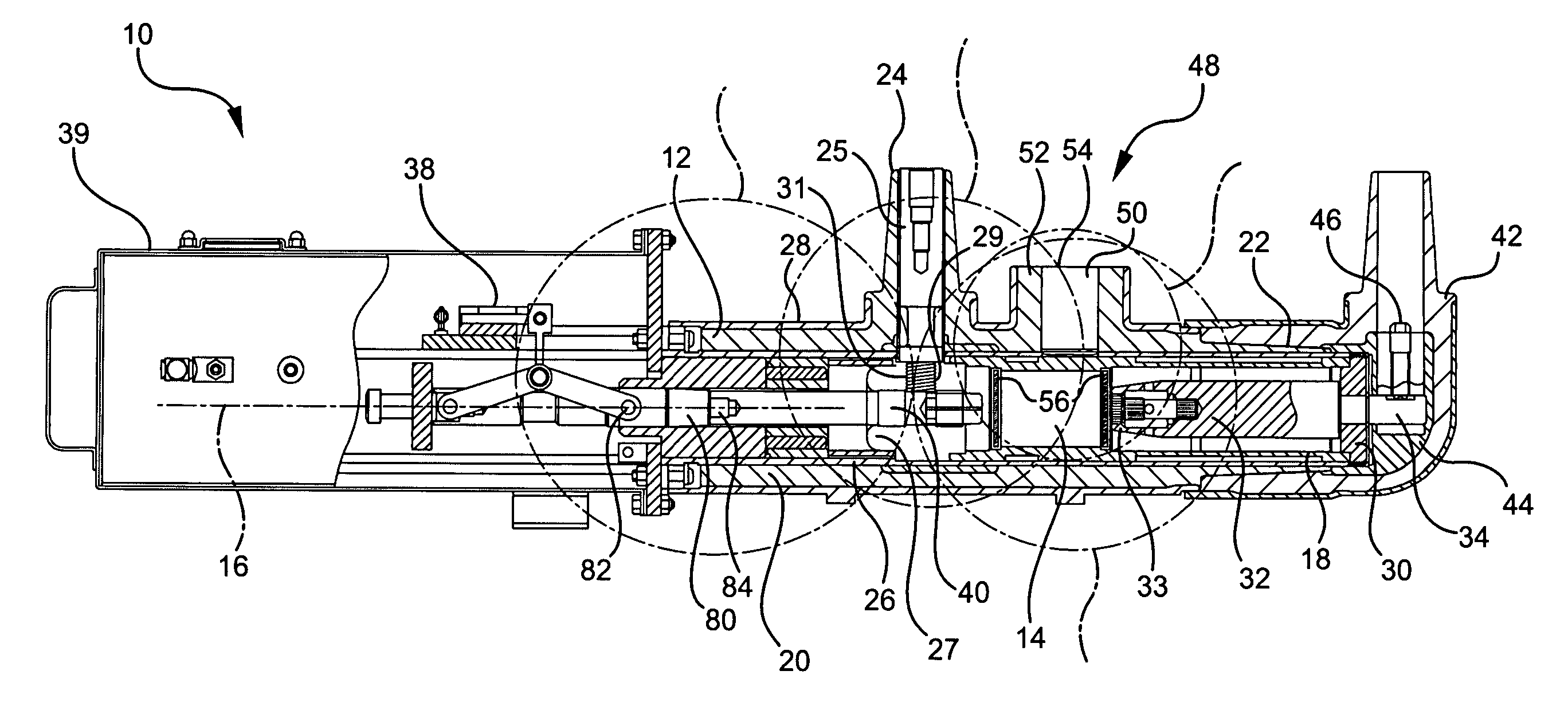

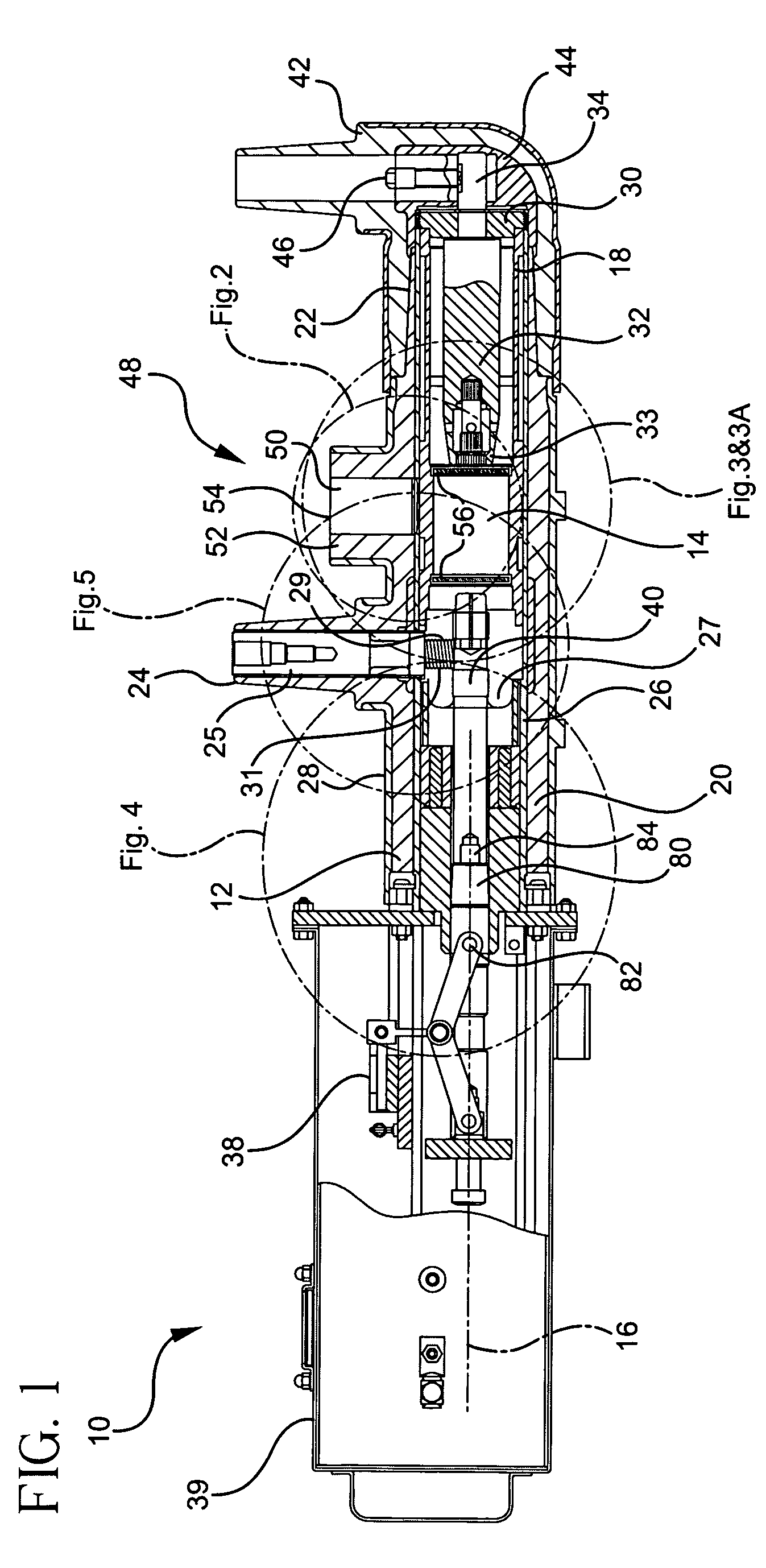

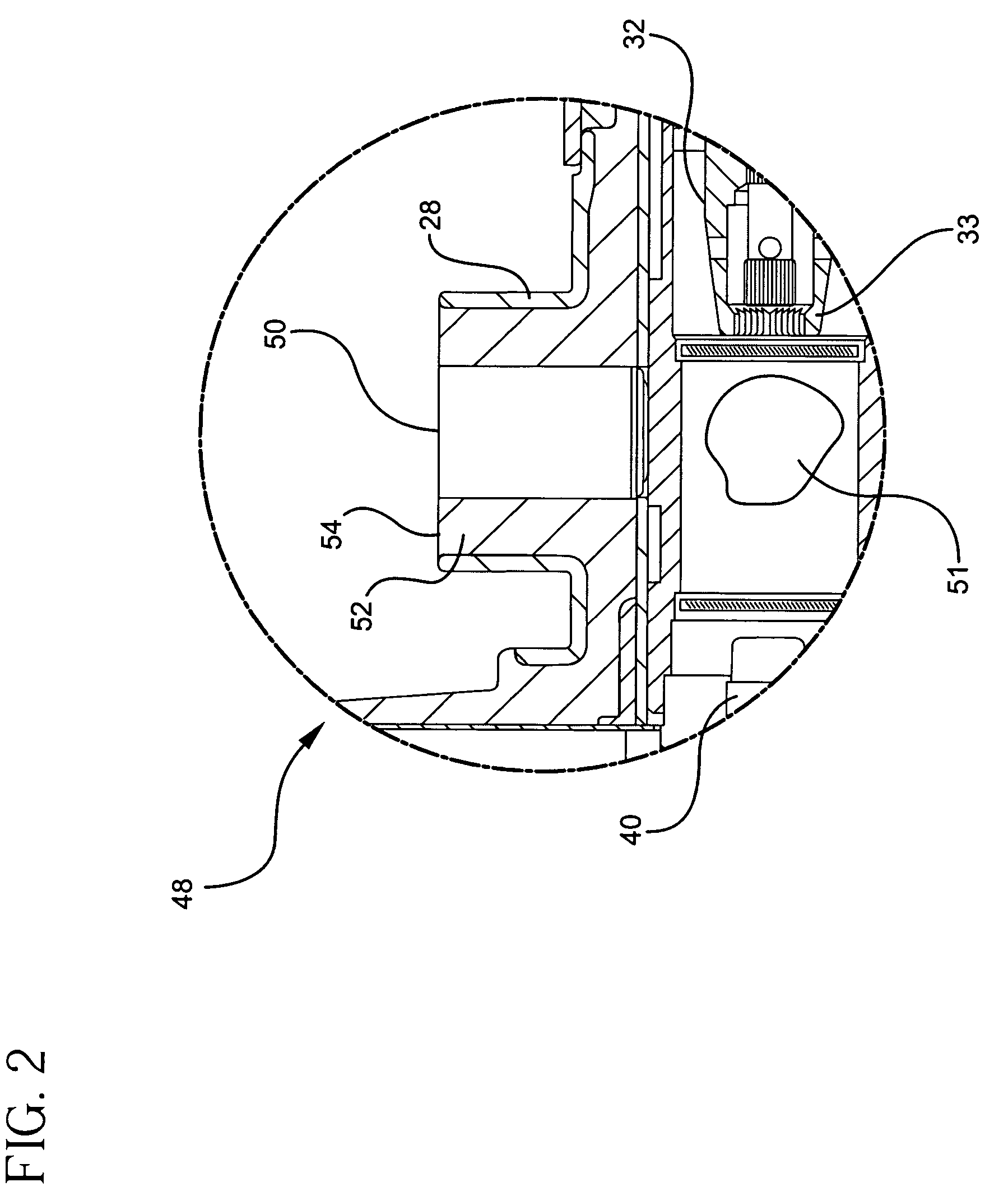

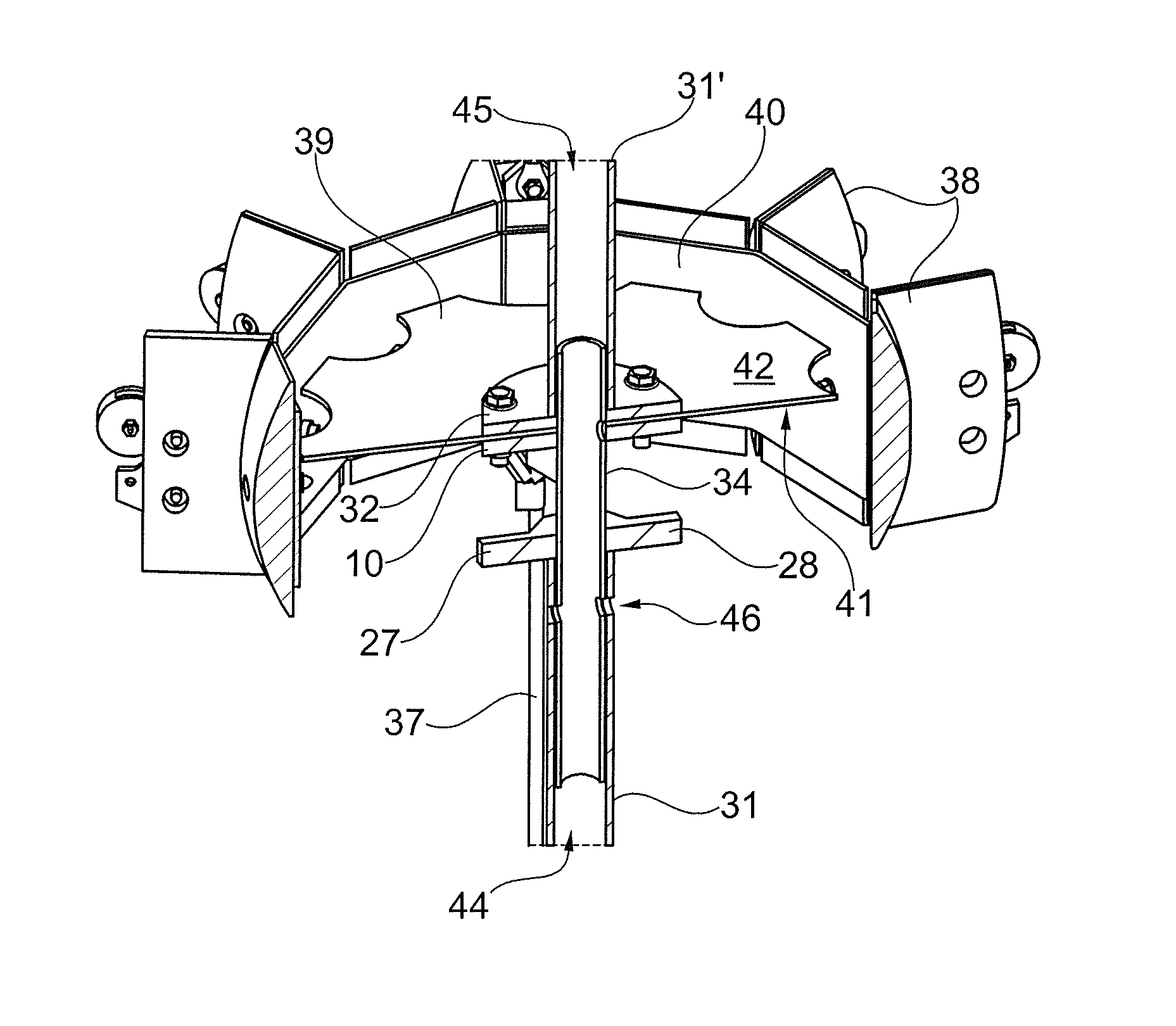

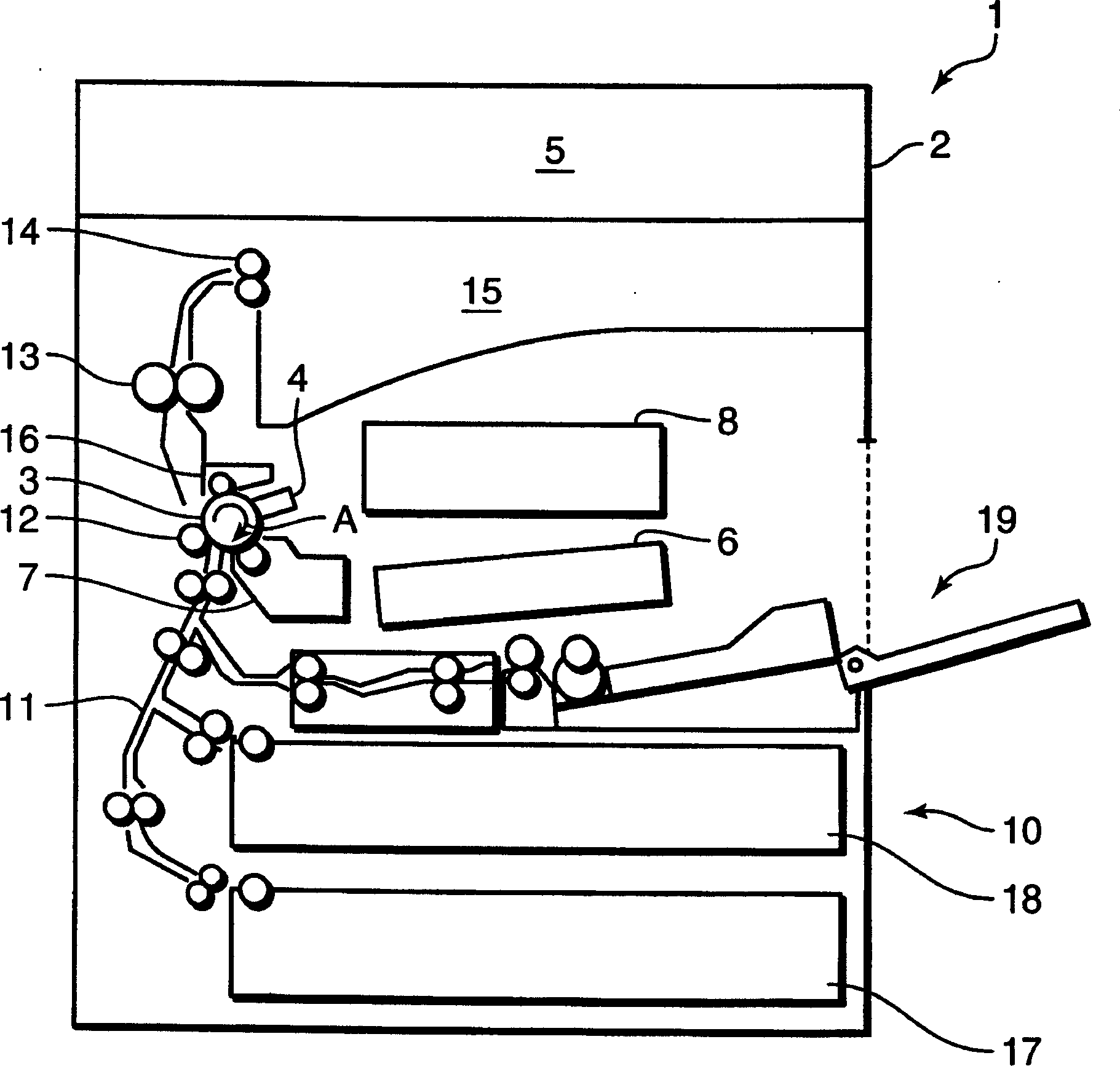

Pivoting implement hitch extension

InactiveUS6877758B2Reduce bending forceReduce vibrationAgricultural machinesTractor-trailer combinationsUniversal jointDrive shaft

A hitch extension apparatus for attaching an implement with a pto driven drive shaft having front and rear universal joints to a tractor drawbar. The apparatus comprises a first member adapted for attachment to the tractor drawbar by insertion of a drawbar pin through the drawbar such that the first member is fixed with respect to the drawbar. An extension member is pivotally attached to the first member about a horizontal pitch axis oriented perpendicular to the travel direction, and about a horizontal roll axis oriented parallel to the operating travel direction. The extension member defines a pivotal attachment location rearward of the draw pin hole adapted for pivotal attachment of the implement about a vertical yaw axis located equidistant from the front and rear universal joints when the drive shaft is connected to the tractor power take off. The pitch axis can be located forward of the yaw axis, and forward of the draw pin hole in order to reduce bending forces on the drawbar.

Owner:SCHULTE INDS

Anti-tipover device

ActiveUS20060097123A1Reduce generationMitigating generation of torqueWing fastenersFlexible elementsRotational axisElectrical and Electronics engineering

Owner:HANGMAN PRODS

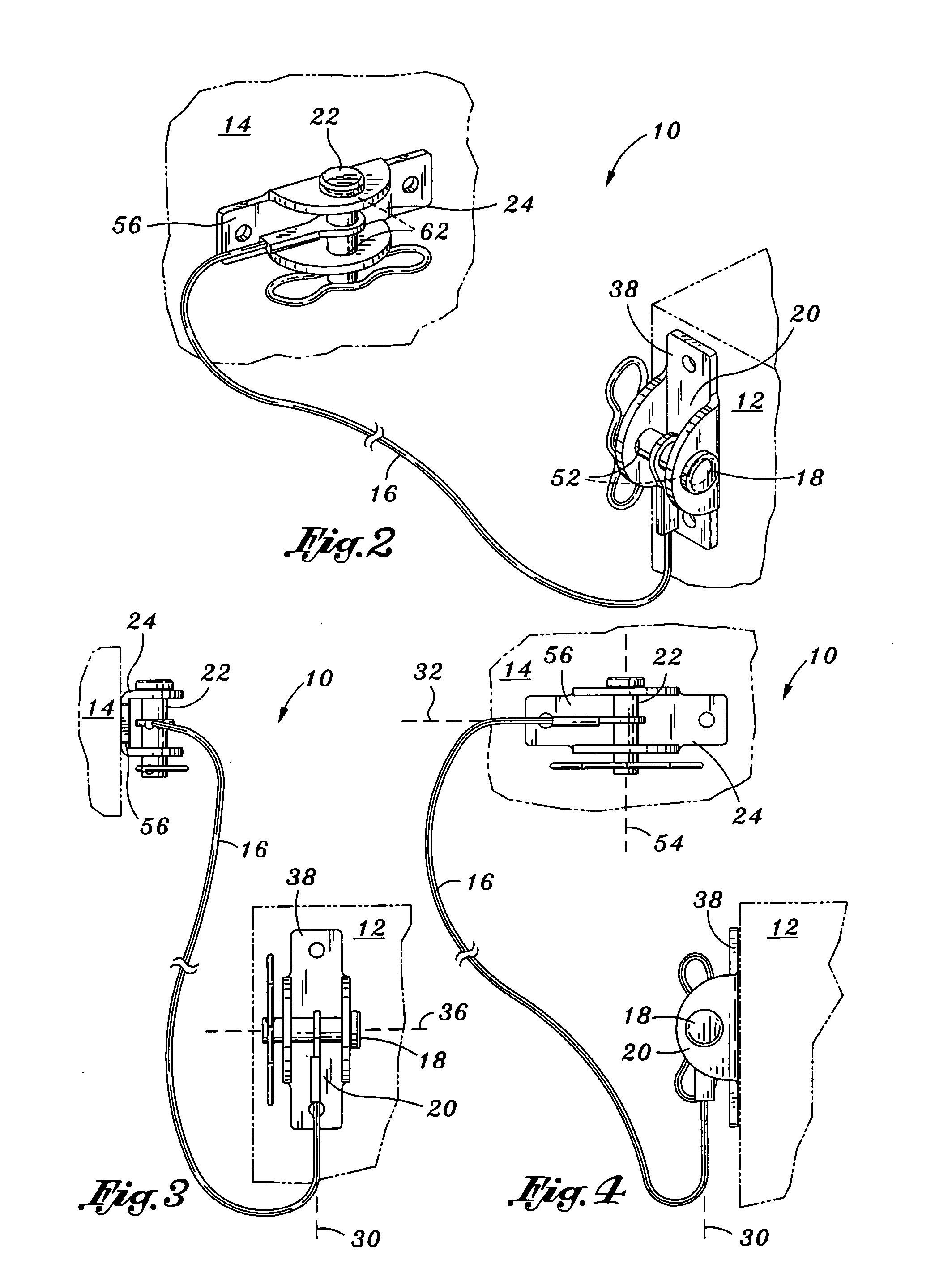

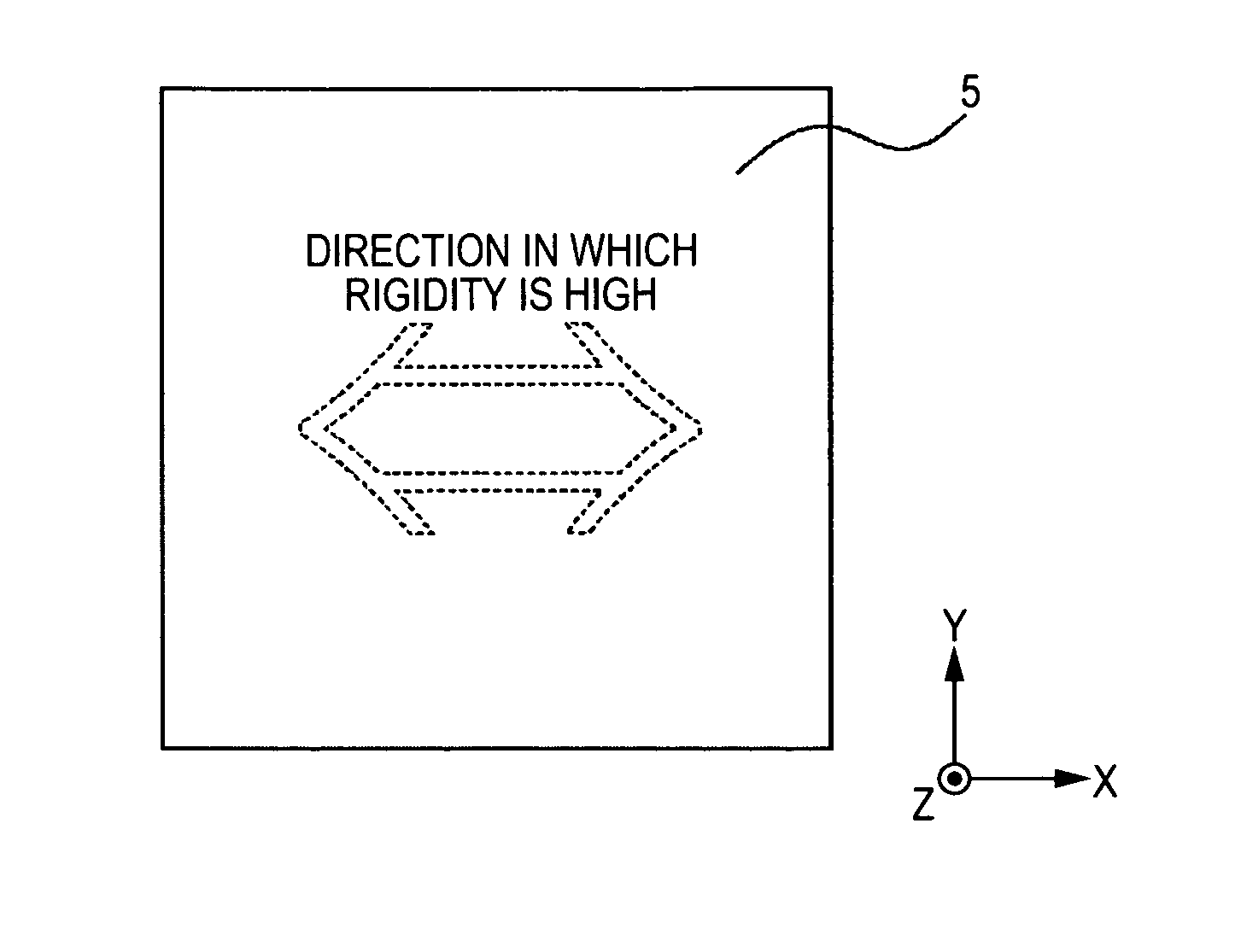

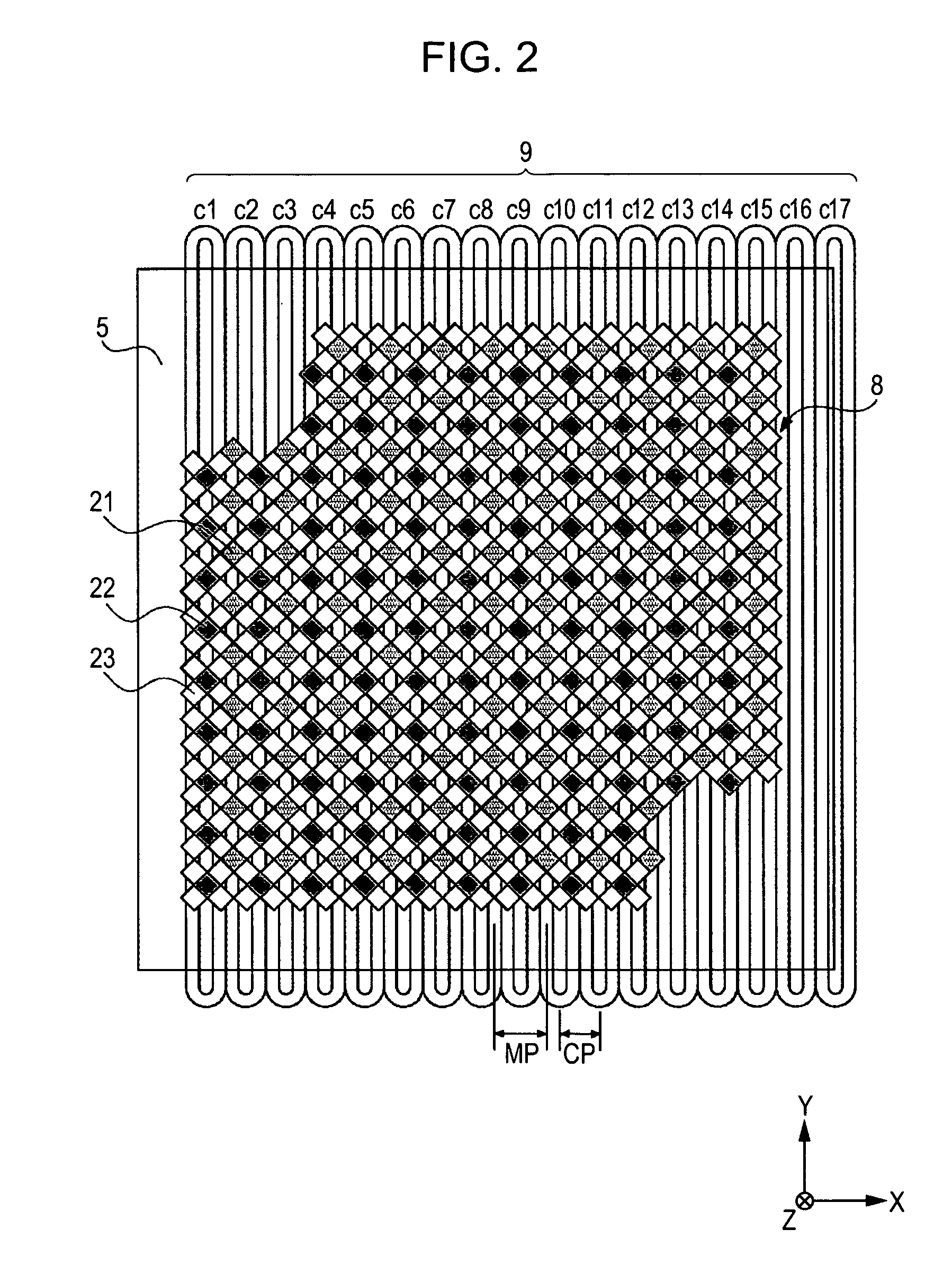

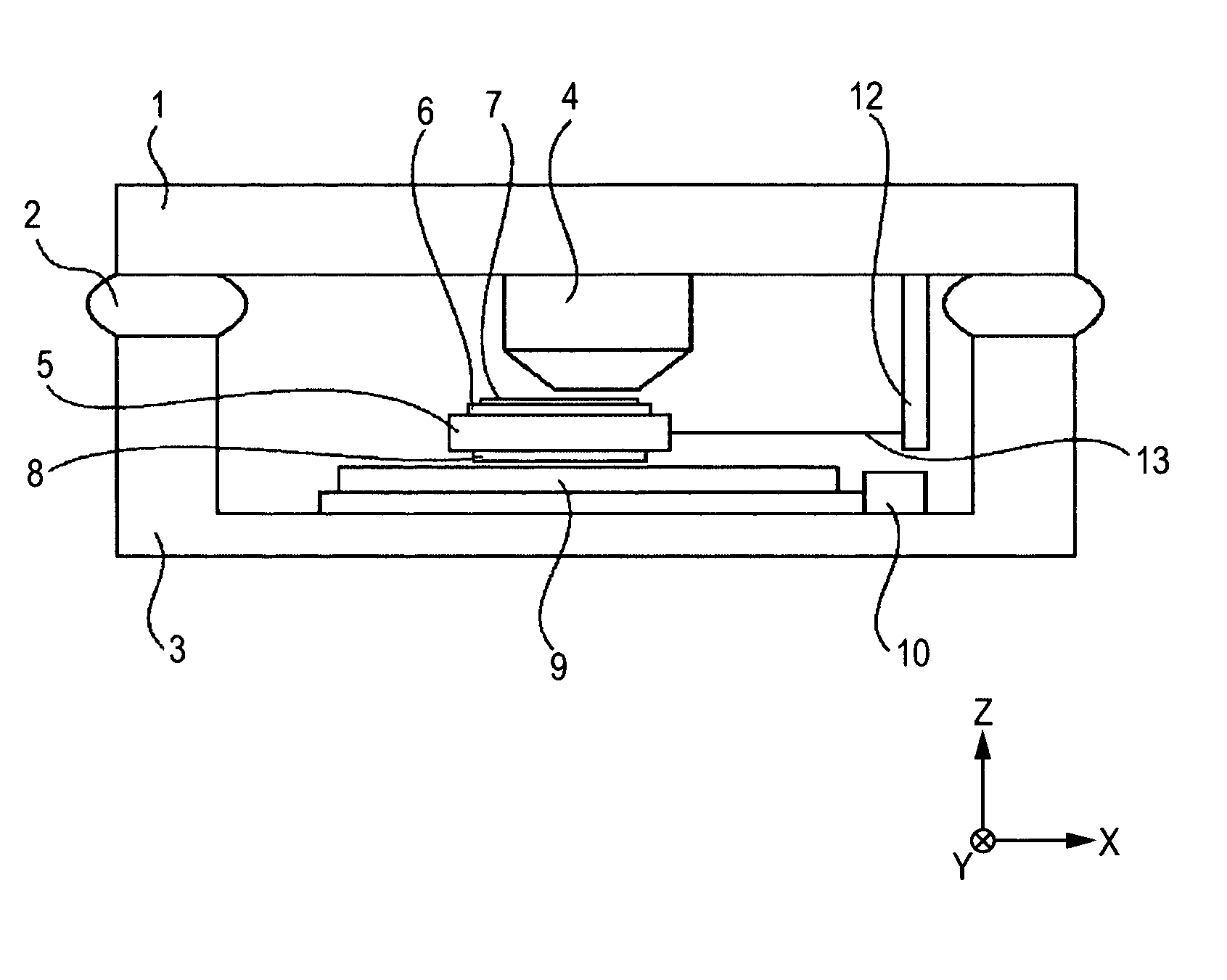

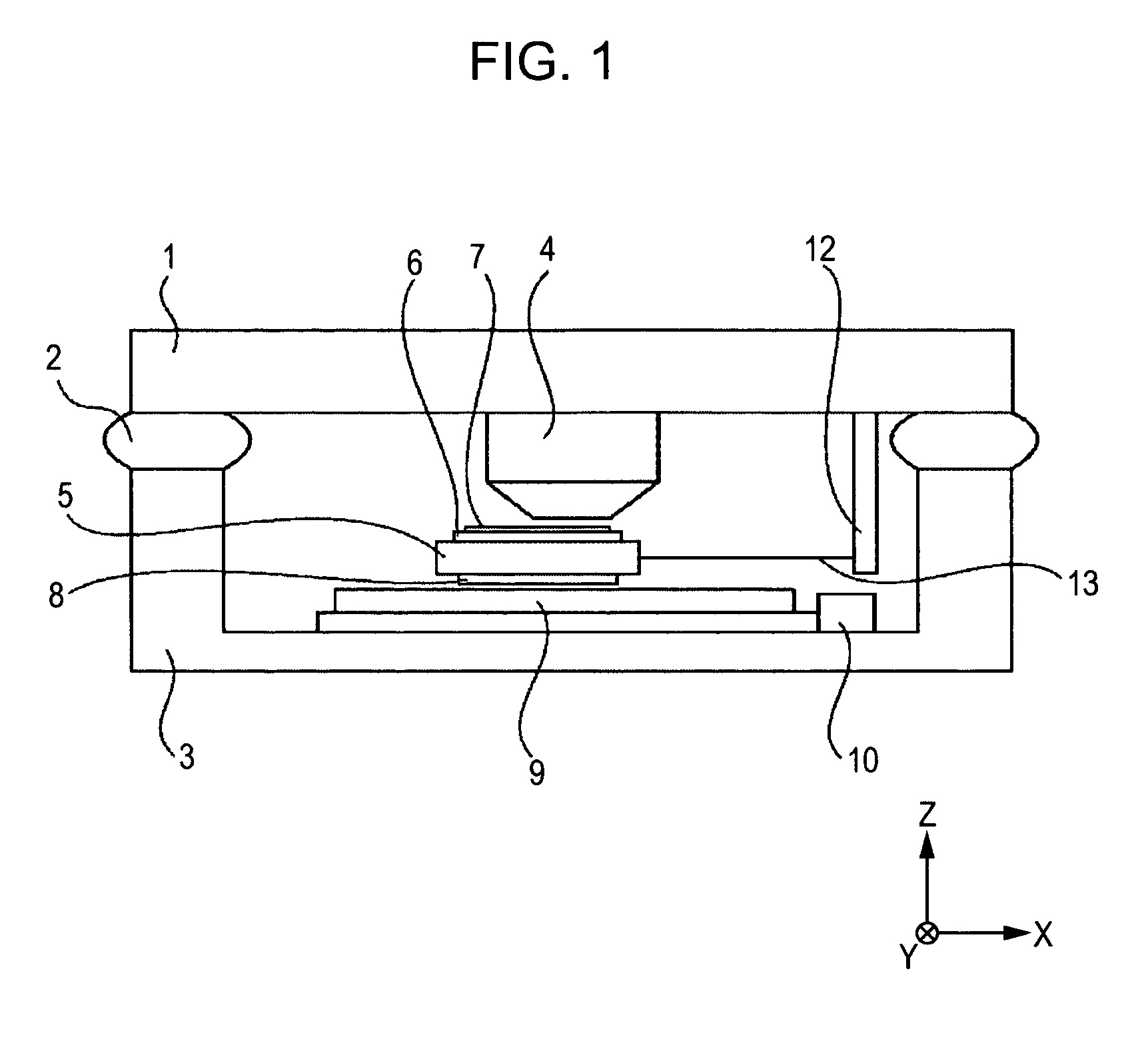

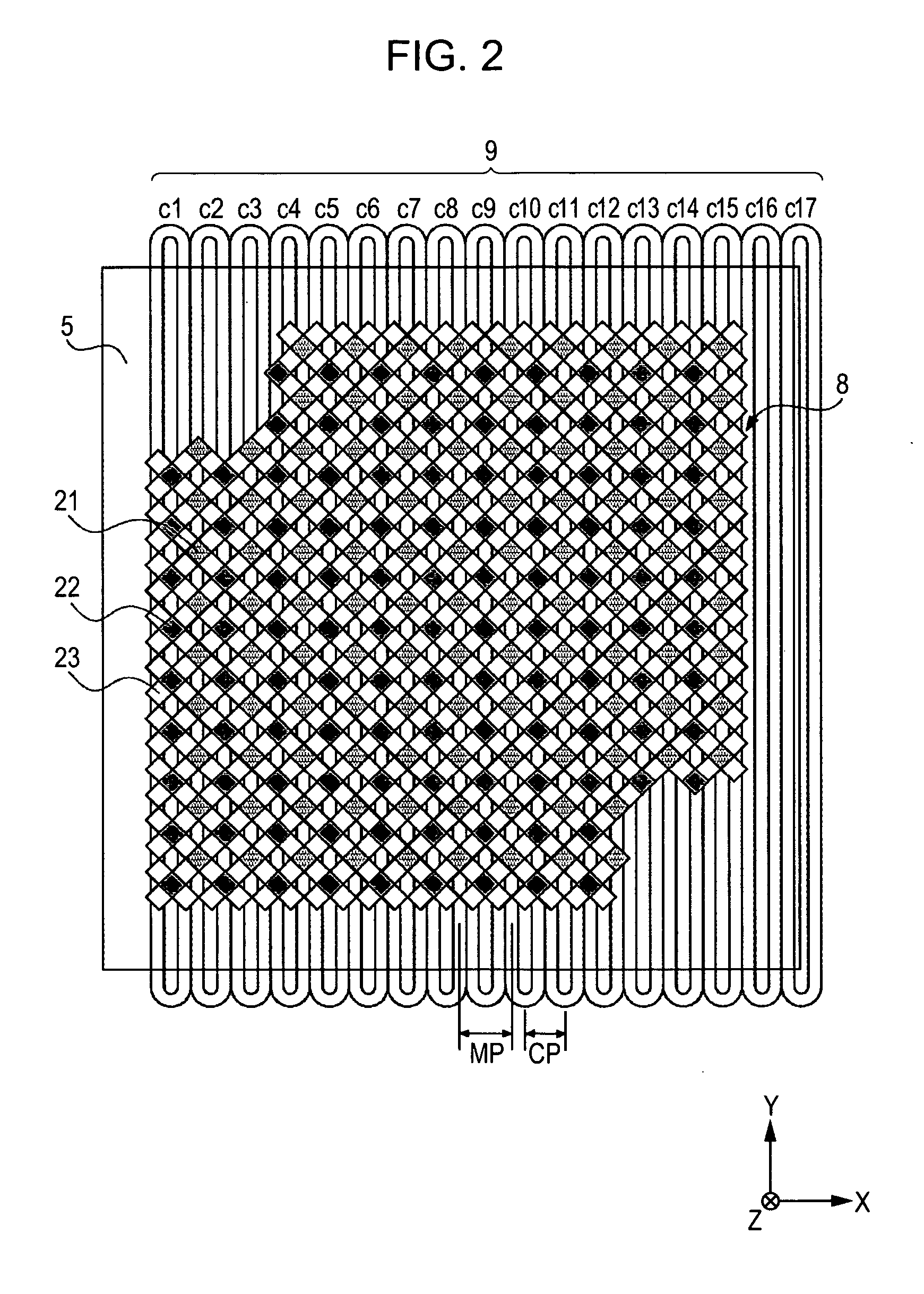

Positioning apparatus

InactiveUS8031328B2Reduce bending forceReduce impactMagnetic circuitPhotomechanical apparatusActuatorLocation Equipment

A positioning apparatus includes a moving member, an actuator, and a controller. The moving member can move in at least a first direction. The actuator is provided along the first direction. The controller controls a current applied to the actuator in order to support the weight of the moving member. The bending rigidity of the moving member in the first direction is greater than the bending rigidity of the moving member in a second direction perpendicular to the first direction.

Owner:CANON KK

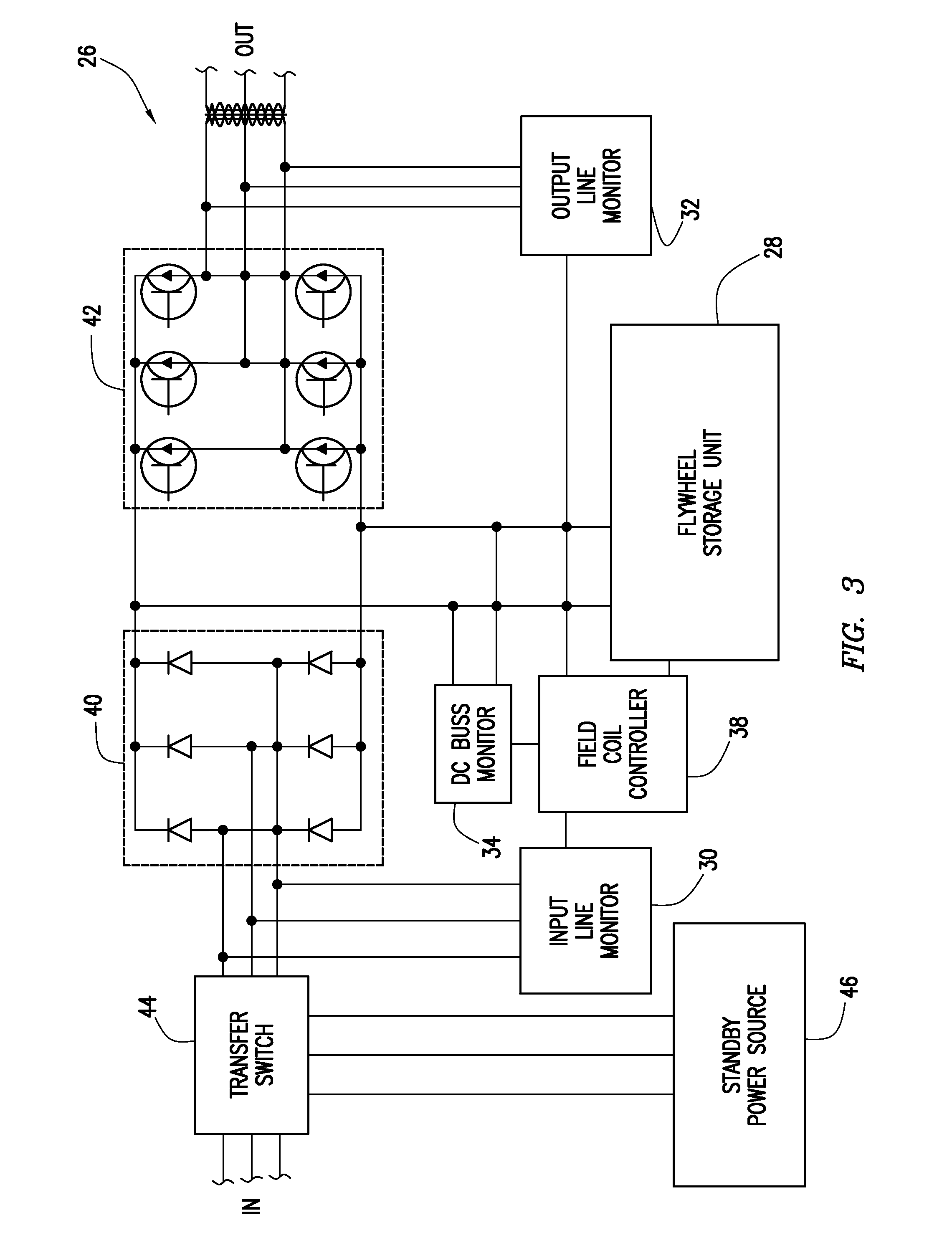

High current switch and method of operation

InactiveUS7397012B2Improve viewing effectReduce bending forceContact operating partsSwitches with movable electrical contactsEngineeringCurrent switch

Owner:THOMAS & BETTS INT INC

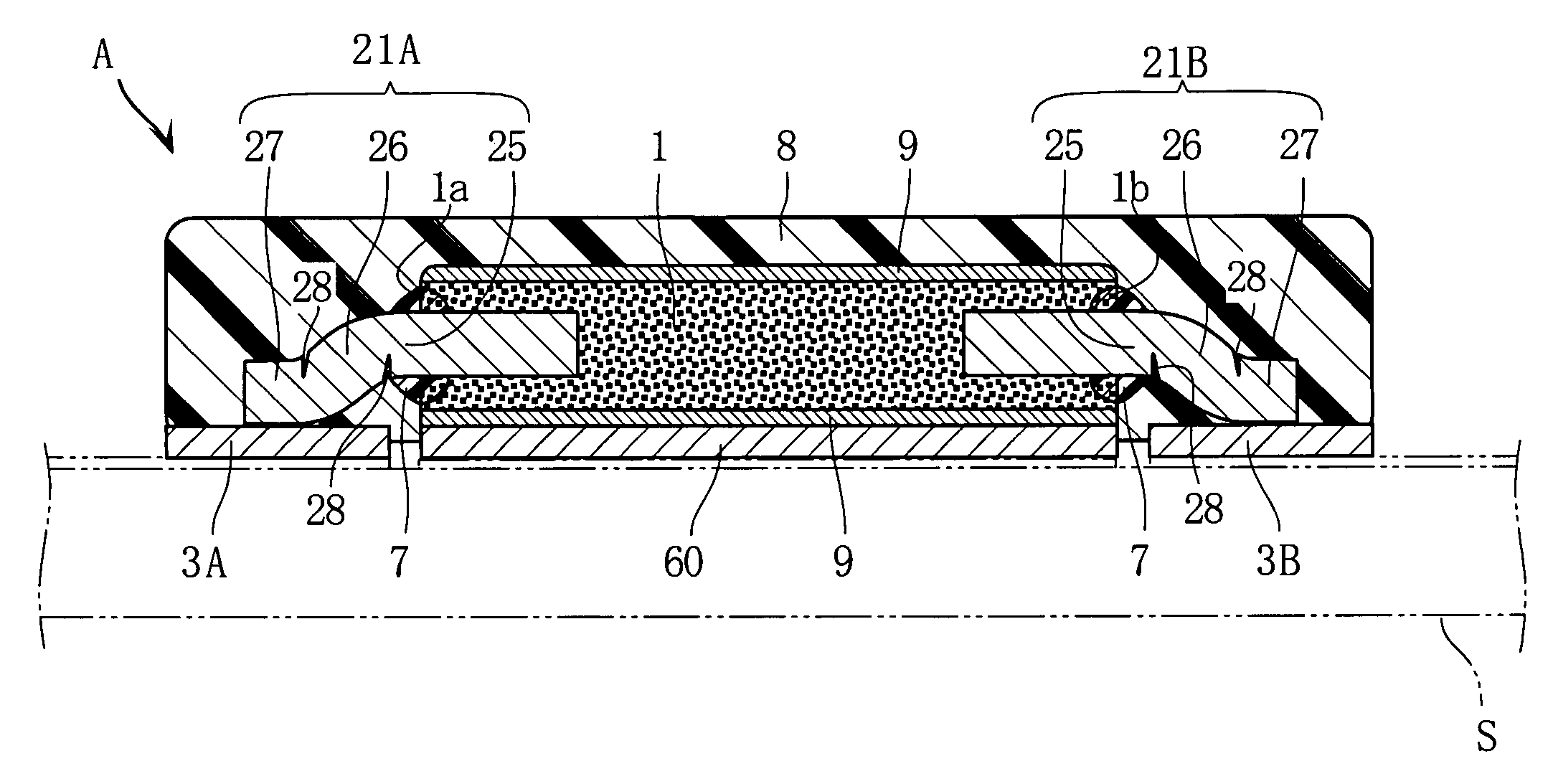

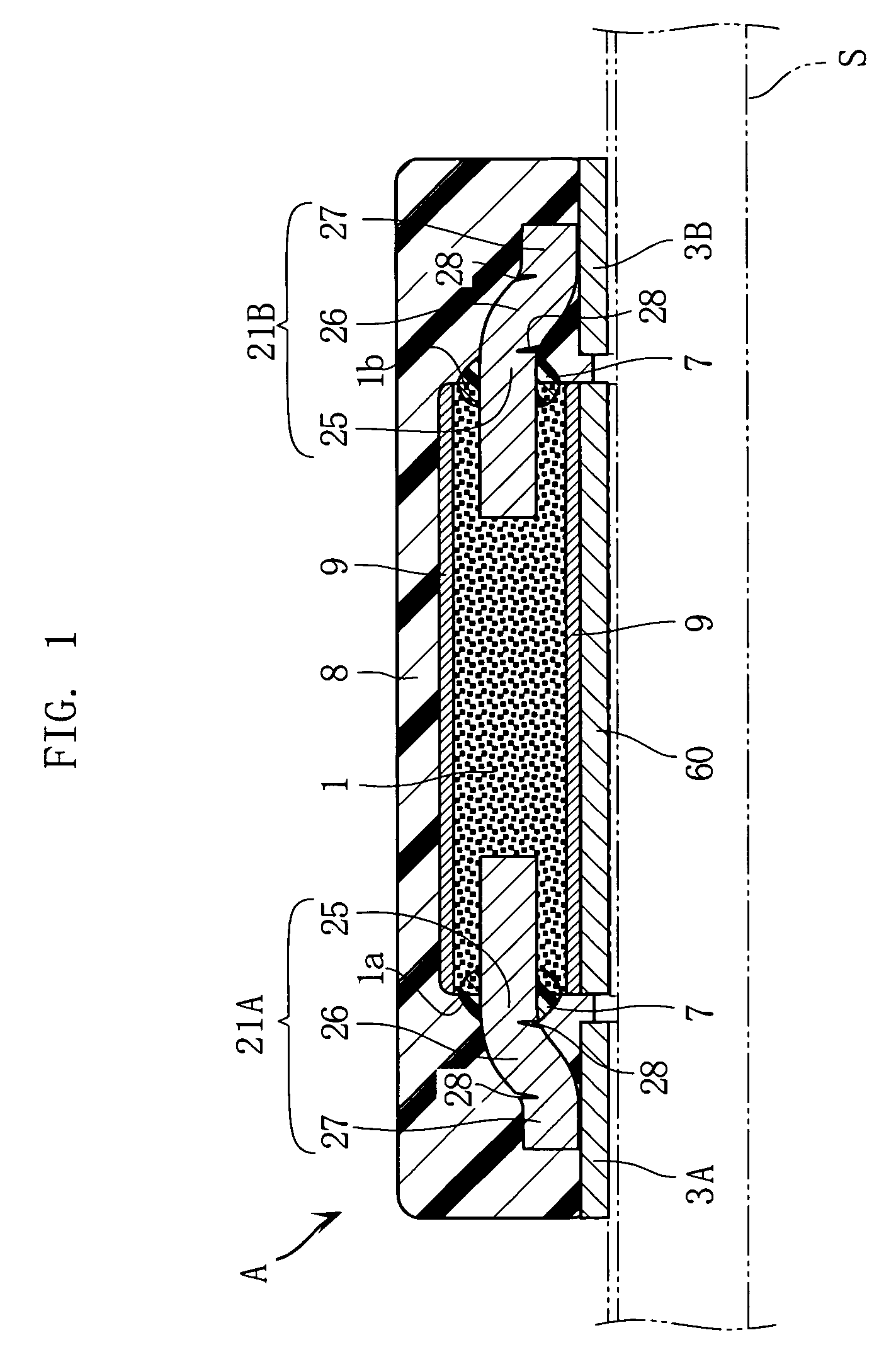

Solid electrolytic capacitor

InactiveUS7359181B2Reduce inductanceSolve the large impedanceLiquid electrolytic capacitorsCasings/cabinets/drawers detailsElectrolysisSurface mounting

A solid electrolytic capacitor includes a porous sintered body made of valve metal, and an external anode terminal used for surface-mounting. The anode terminal is offset from the center of the sintered body, as viewed in the thickness direction or first direction of the sintered body. Further, the anode terminal is spaced away from the sintered body in a second direction which is perpendicular to the first direction. Between the sintered body and the anode terminal is formed a conductive path, which is inclined with respect to both the first and the second directions. The path comes closer to the anode terminal in the first direction as it goes farther away from the sintered body in the second direction.

Owner:ROHM CO LTD

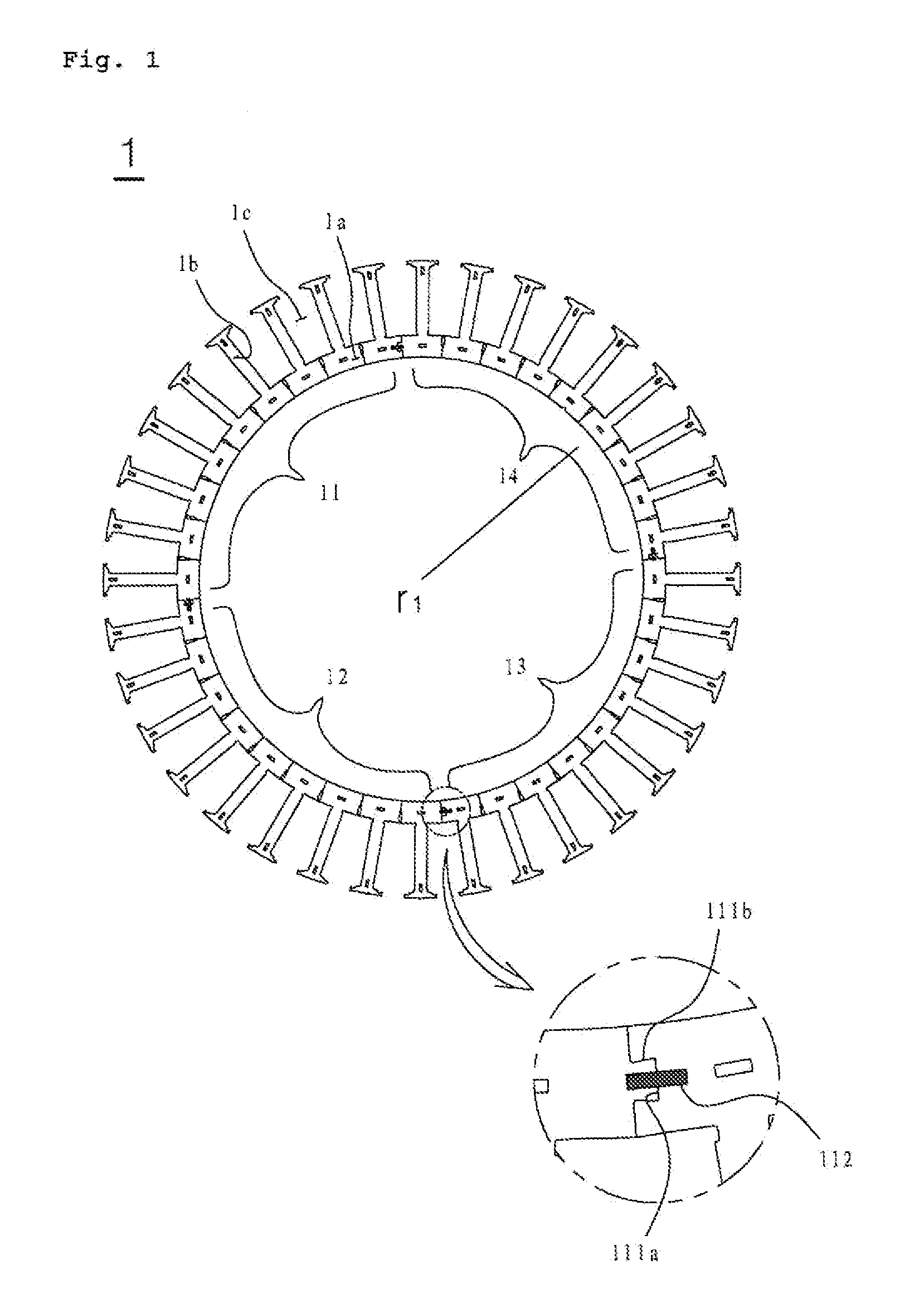

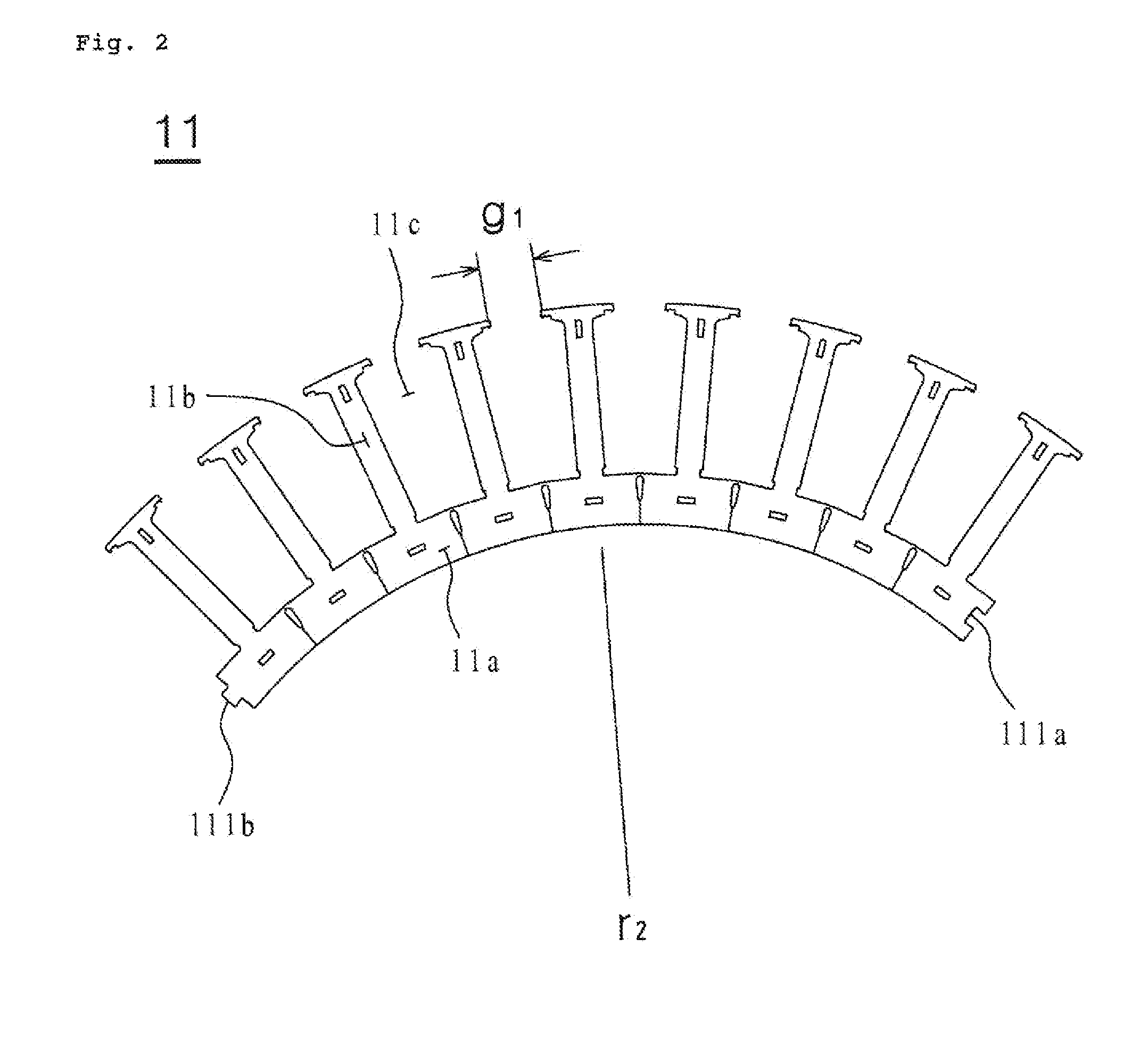

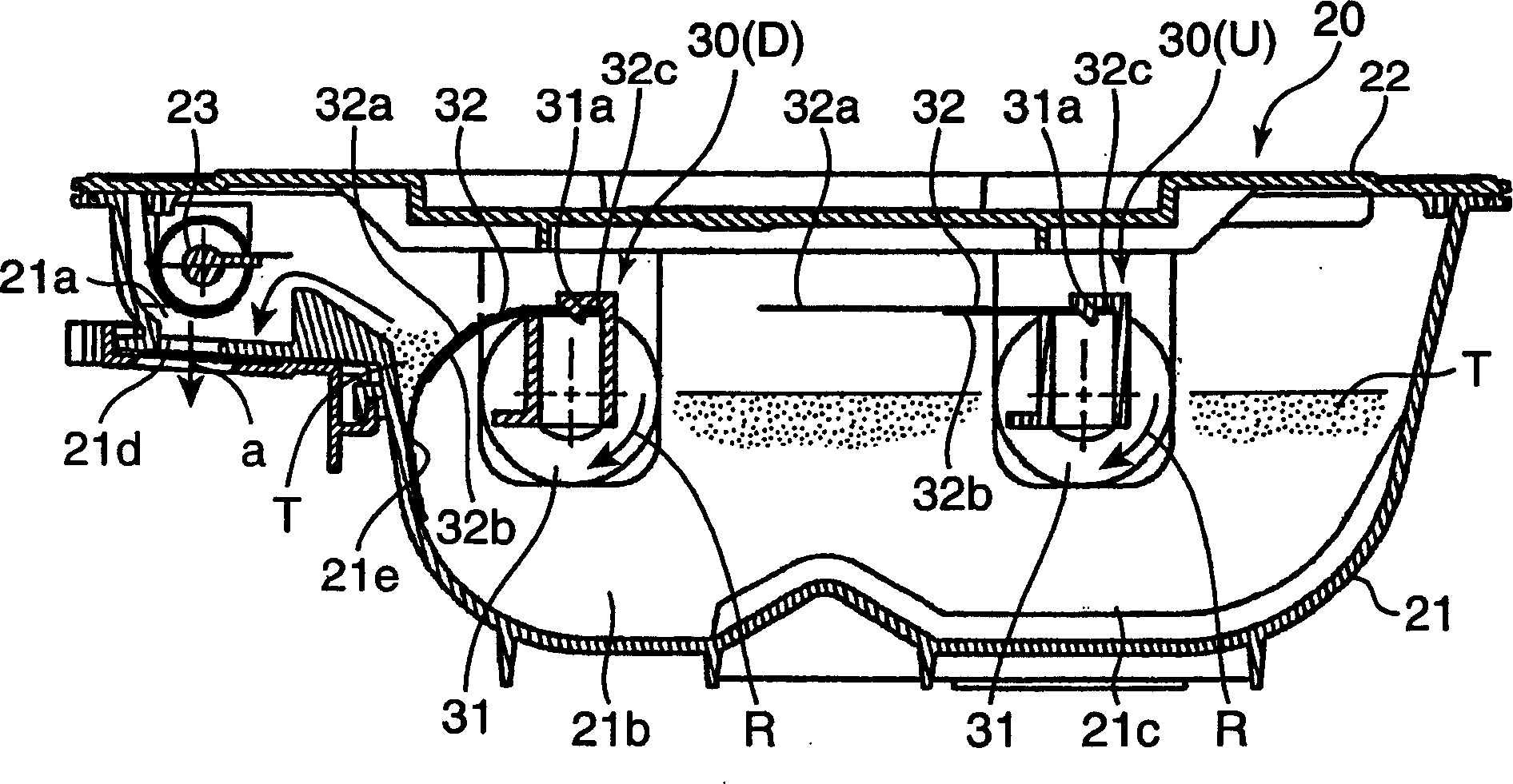

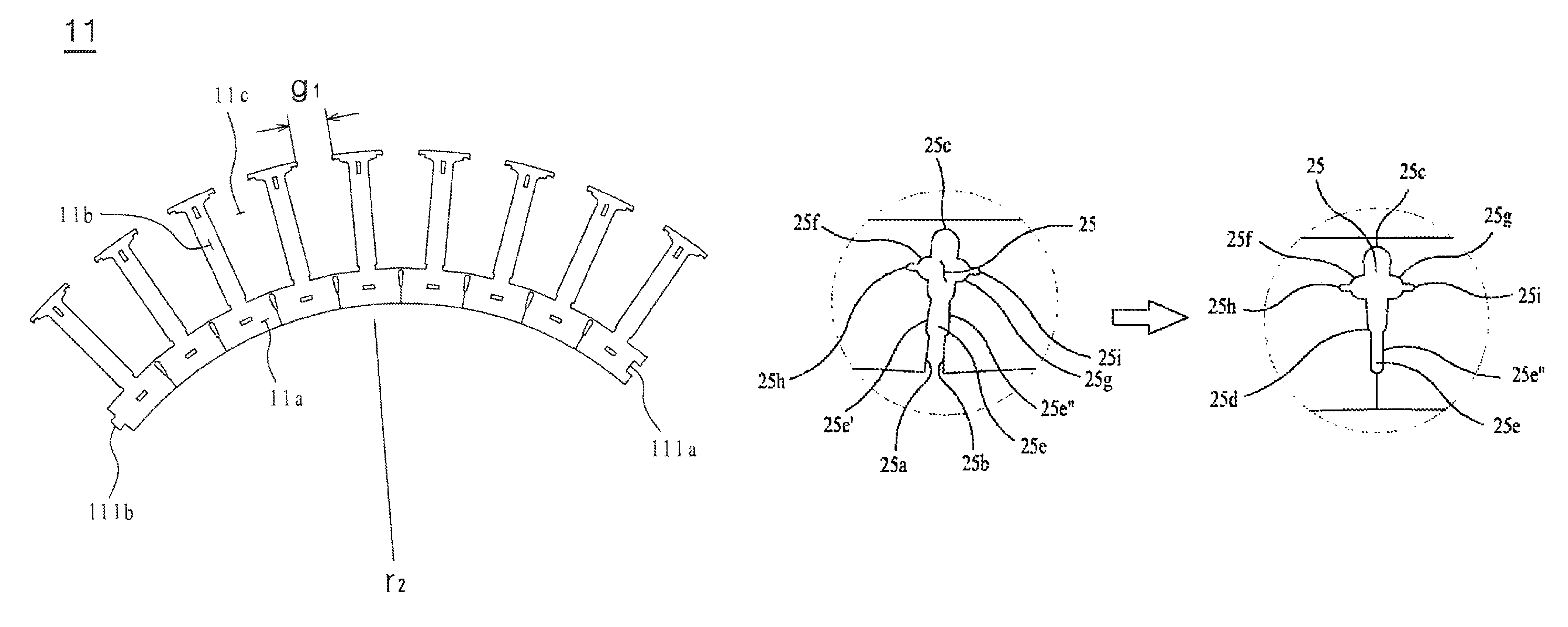

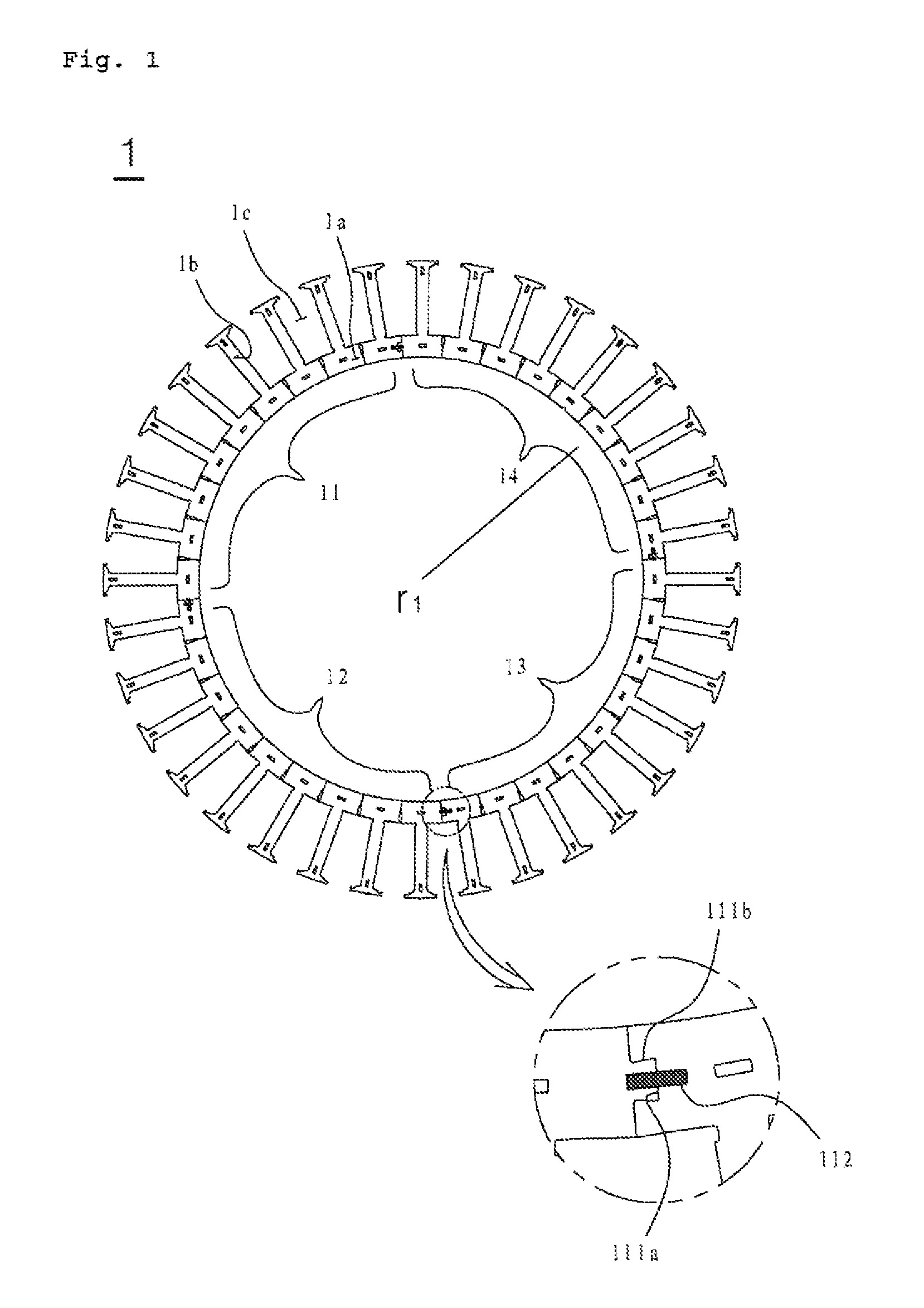

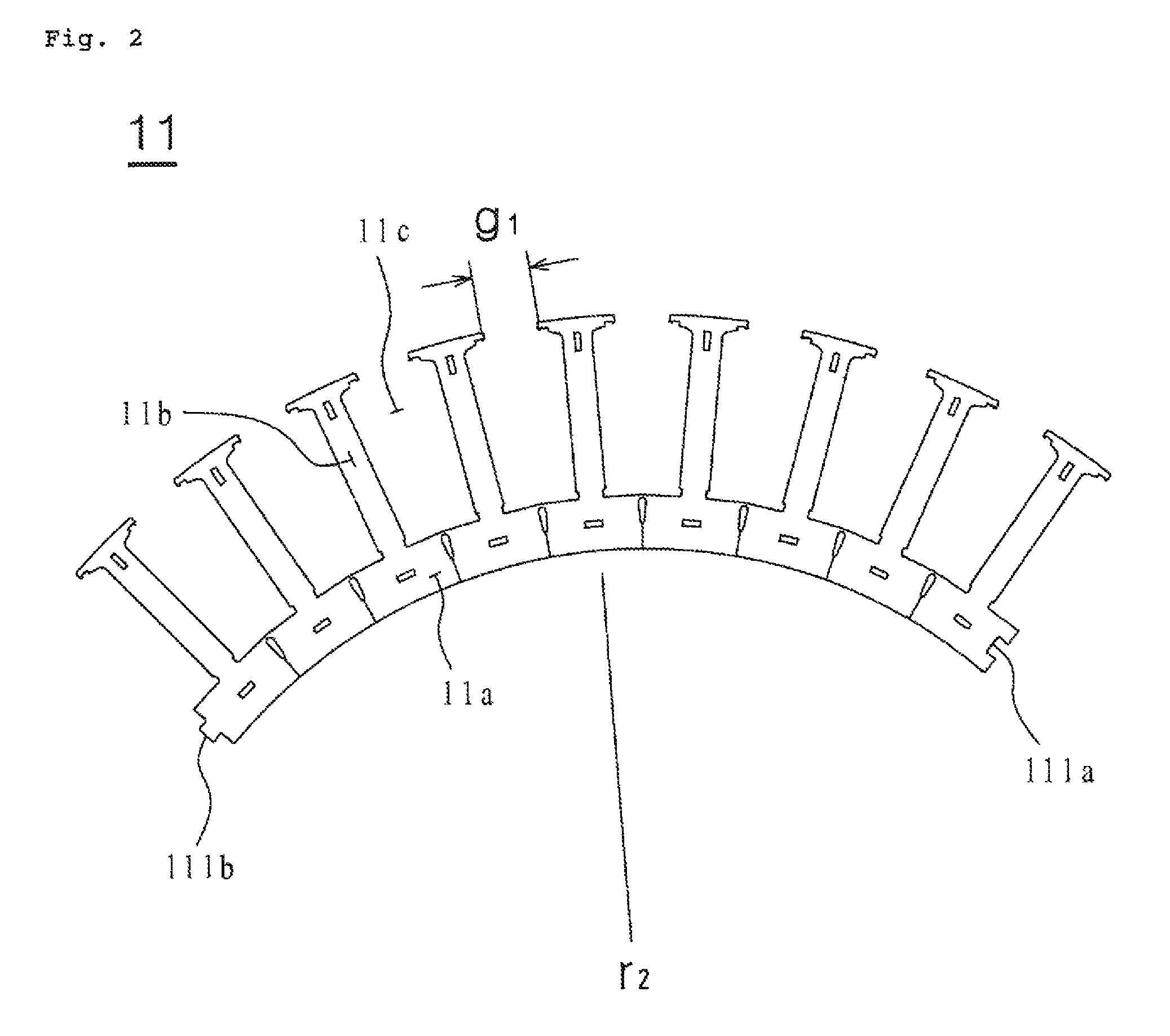

Stator core of motor for washing machine

ActiveUS20130169104A1Preventing unnecessary consumption of materialMinimize consumptionOther washing machinesMagnetic circuit stationary partsEngineeringMechanical engineering

The present invention relates to a stator core of a motor for a washing machine that is formed by connecting a plurality of arc-shaped core pieces to each other, each of the core pieces being formed by stacking core piece steel plates on top of each other and by bending the stacked core piece steel plates in such a manner that core piece teeth are disposed outward in the radial direction of a core piece yoke and the core piece yoke has the same curvature as a yoke of a stator core, the core piece yoke on each core piece steel plate having a plurality of incised portions for bending formed partially incised thereon between the respective neighboring core piece teeth on the opposite side to the side on which the core piece teeth are formed.

Owner:NEW MOTECH

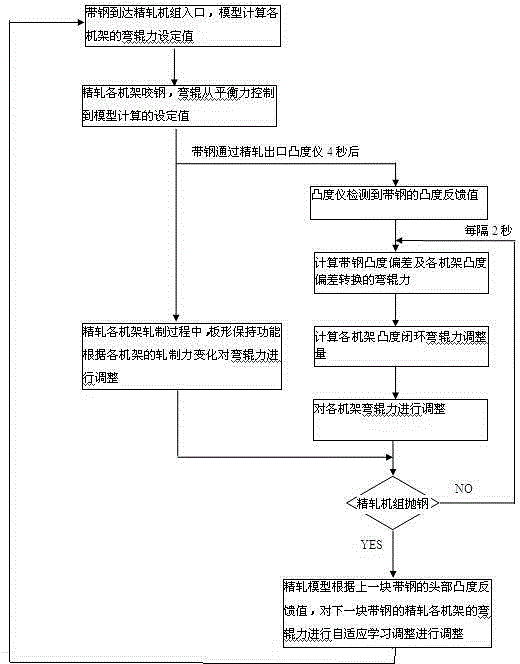

Hot rolled strip convexity on-line closed loop control method

ActiveCN105268747ARealize closed-loop controlImprove crown control accuracyProfile control deviceLoop controlStructural engineering

The invention relates to a hot rolled strip convexity on-line closed loop control method. The method is characterized by comprising the following steps that (1) strip steel reaches an inlet of a finishing rolling unit, the required roll bending force set value of each rack of the finishing rolling unit is worked out through a finish rolling model according to temperature, thickness, width and materials of the strip steel and real-time roll shape of the rolls; (2) after each rack of the finishing rolling unit bites steel, the roll bending force of each rack is switched from balance force to the roll bending set value worked out through the finish rolling model; (3) during rolling of the finishing rolling unit, certain adjustment for the roll bending force is conducted according to change of the rolling force of each rack by means of the strip shape keeping function; and (4) the closed-loop control over strip steel convexity is added, during rolling of the finishing rolling unit, the adjustment value of the required roll bending force of each rack is worked out by means of a convexity-to-roll bending force conversion algorithm according to the deviation between the set value and a strip steel convexity feedback value real-timely detected by a finish rolling outlet profile gauge, the roll bending force of each rack of the finishing rolling unit is real-timely adjusted, and the closed-loop control over the strip steel convexity is achieved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Positioning apparatus

ActiveUS20060175910A1Reduce bending forceReduce impactMagnetic circuitPhotomechanical apparatusActuatorControl theory

A positioning apparatus includes a moving member, an actuator, and a controller. The moving member can move in at least a first direction. The actuator is provided along the first direction. The controller controls a current applied to the actuator in order to support the weight of the moving member. The bending rigidity of the moving member in the first direction is greater than the bending rigidity of the moving member in a second direction perpendicular to the first direction.

Owner:CANON KK

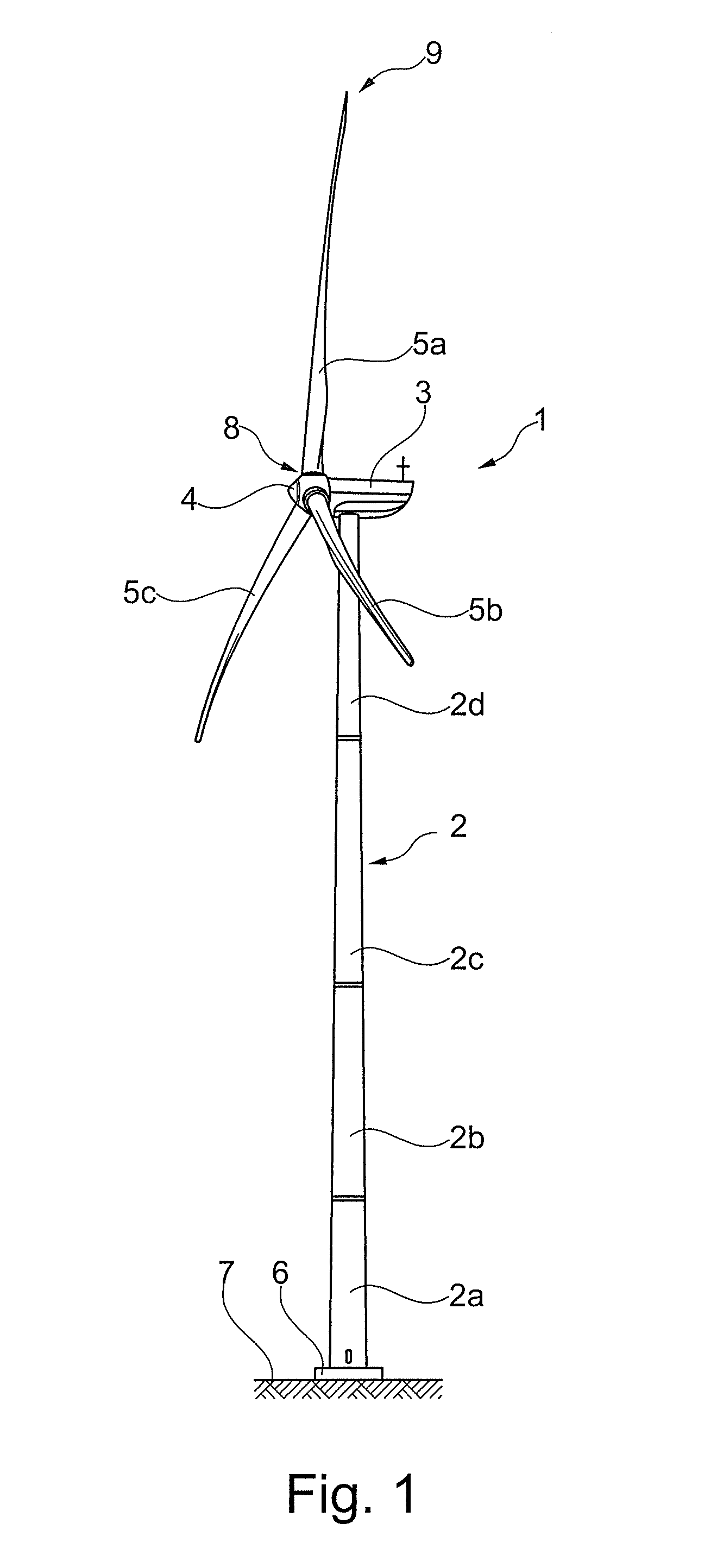

Unit for rotating cable spacing plates in a wind turbine tower

InactiveUS20140286778A1Stress minimizationRelieve pressurePropellersPump componentsNacelleTurbine blade

A wind turbine having a wind turbine tower with a nacelle provided on the top to which a rotor hub with one or more wind turbine blades is rotatable mounted. A cable twisting system is arranged inside the wind turbine tower and suspended from the bottom of the nacelle. The cable twisting system comprises a number of cable spacing plates having a number of guiding means for guiding the electrical cables from the nacelle to the bottom of the wind turbine tower. A first and second element having engaging fingers configured to be brought into contact with each other are coupled to two adjacent cable spacing plates. The first element rotates relative to the second element when the nacelle is yawing, bringing the fingers into contact with each other. The two elements then rotate together as the nacelle continues to yaw in the same direction.

Owner:ENVISION ENERGY DENMARK

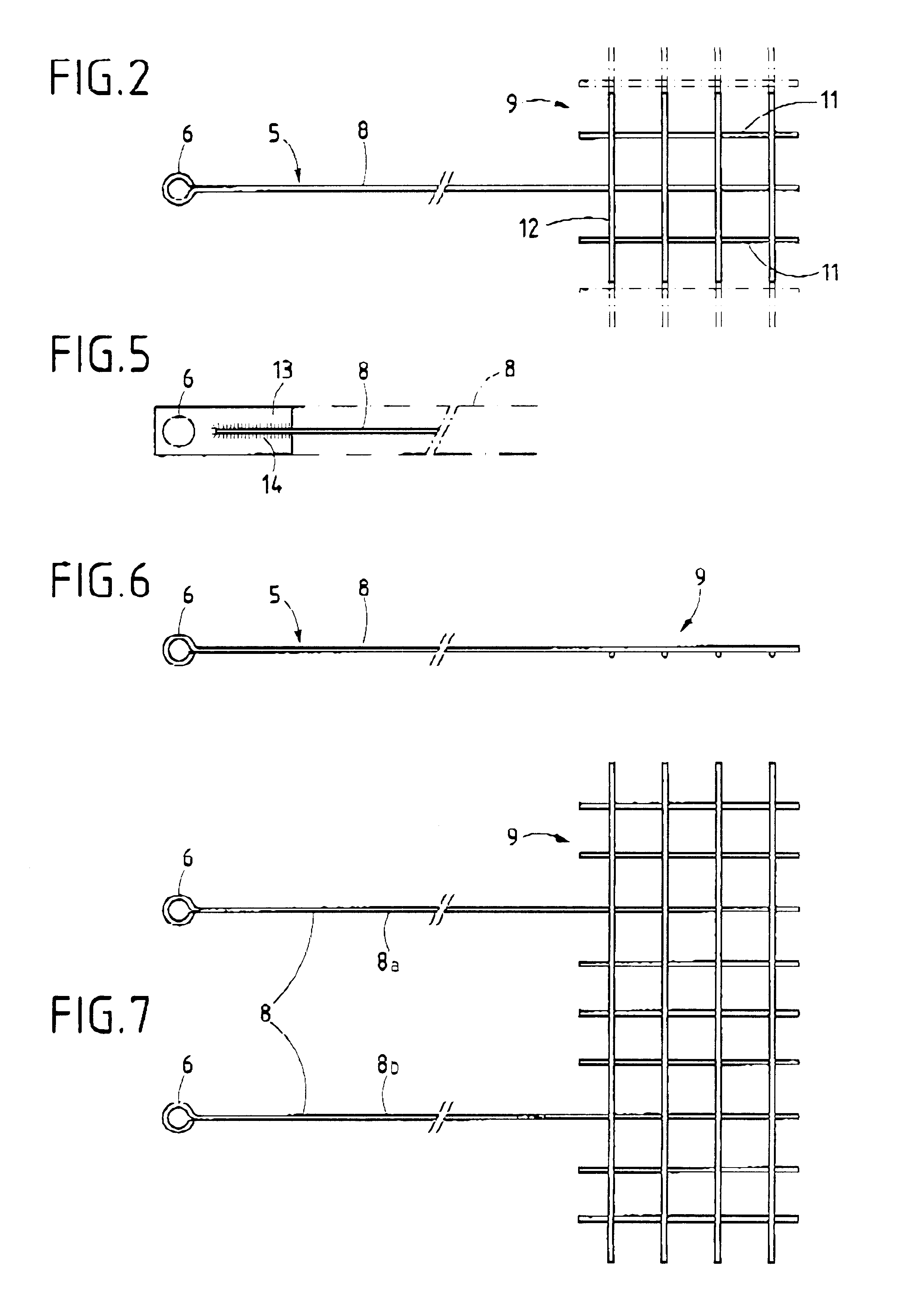

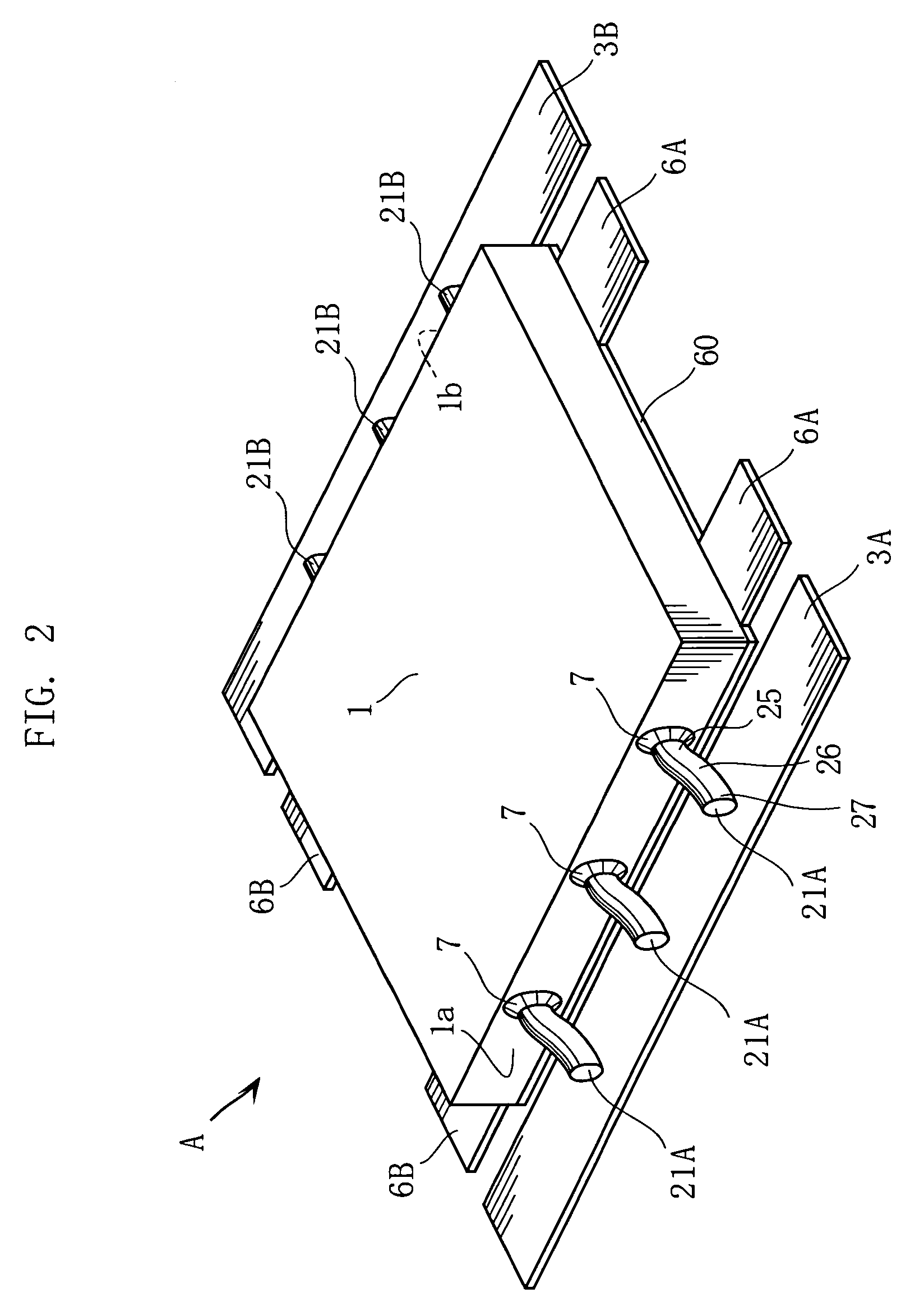

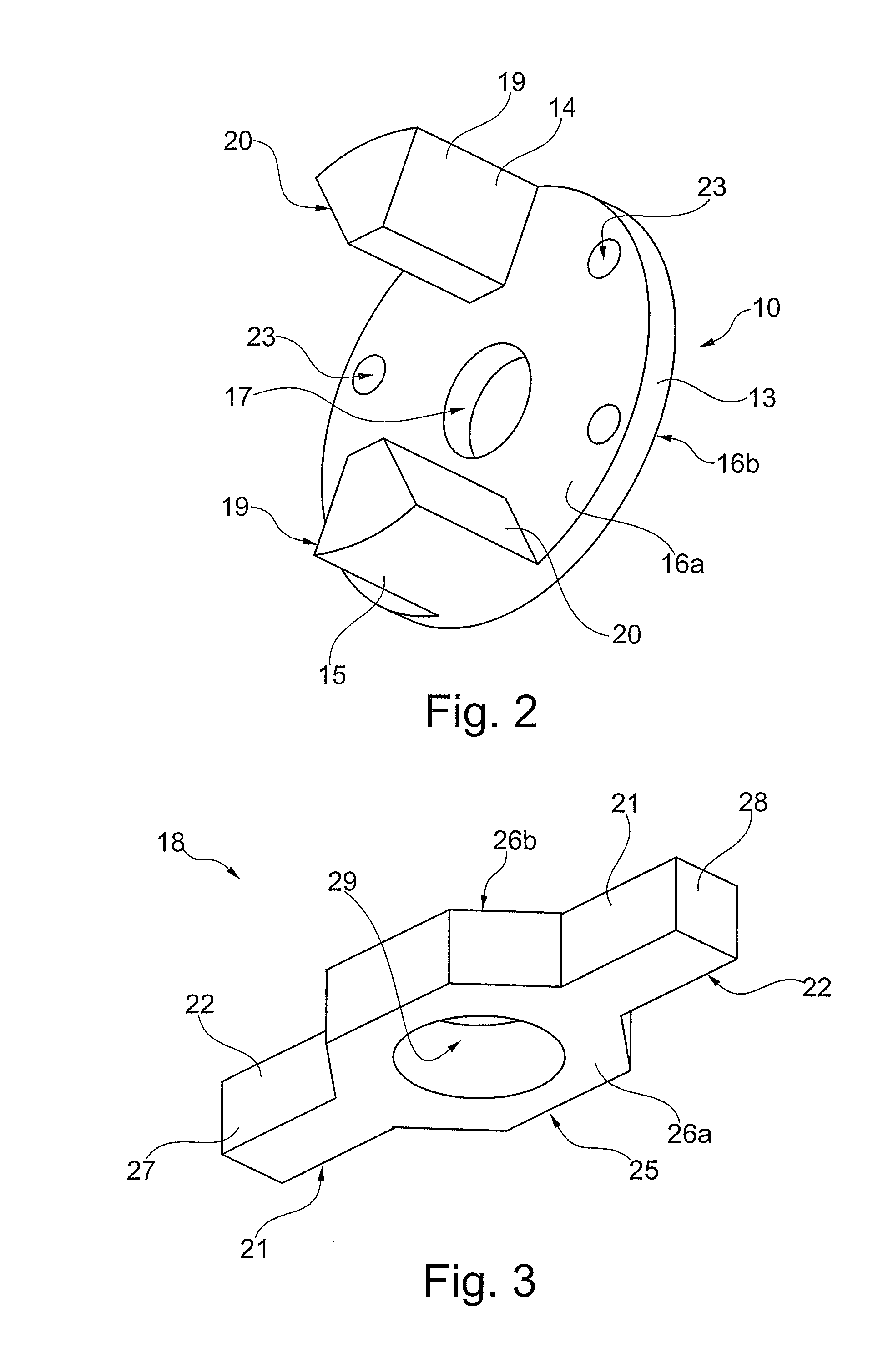

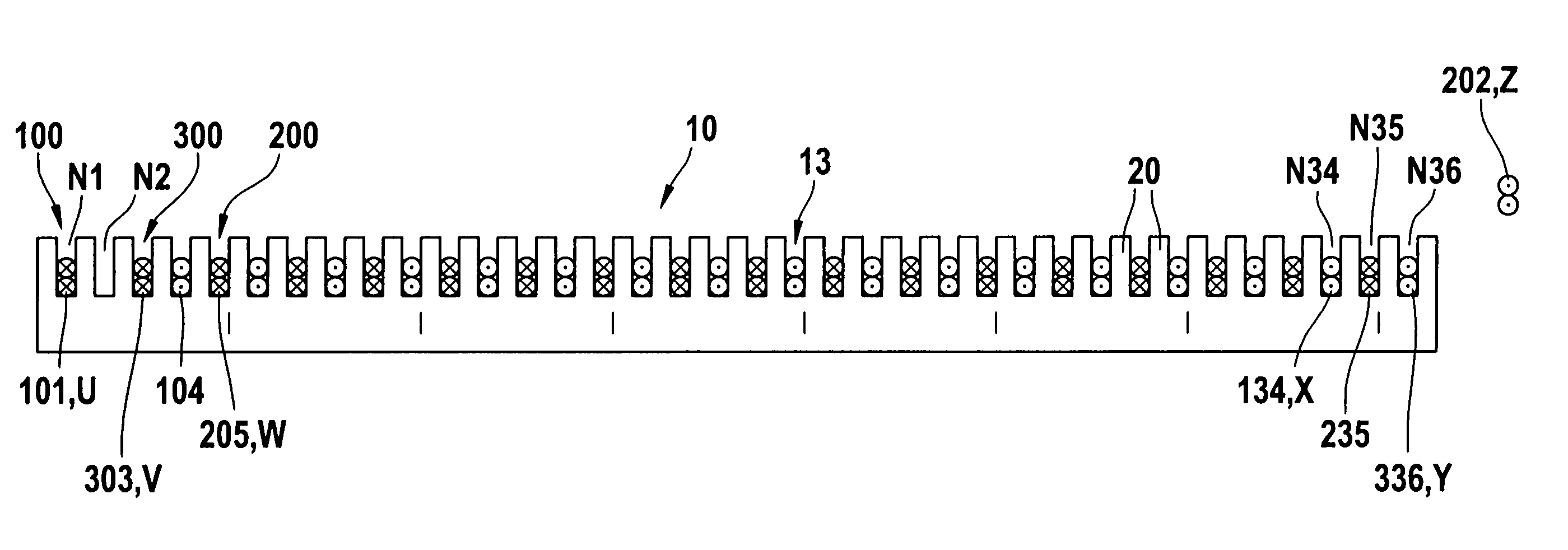

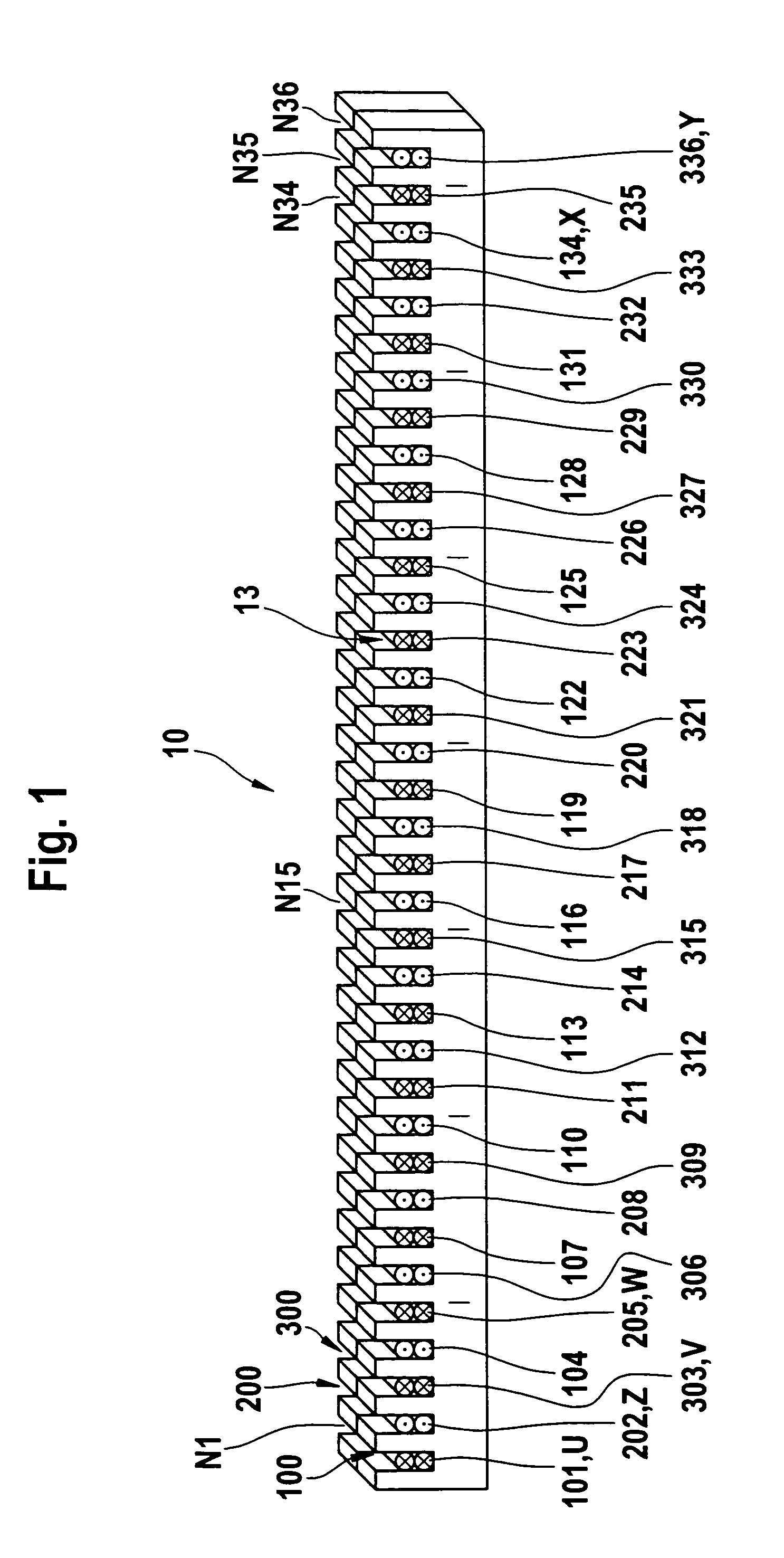

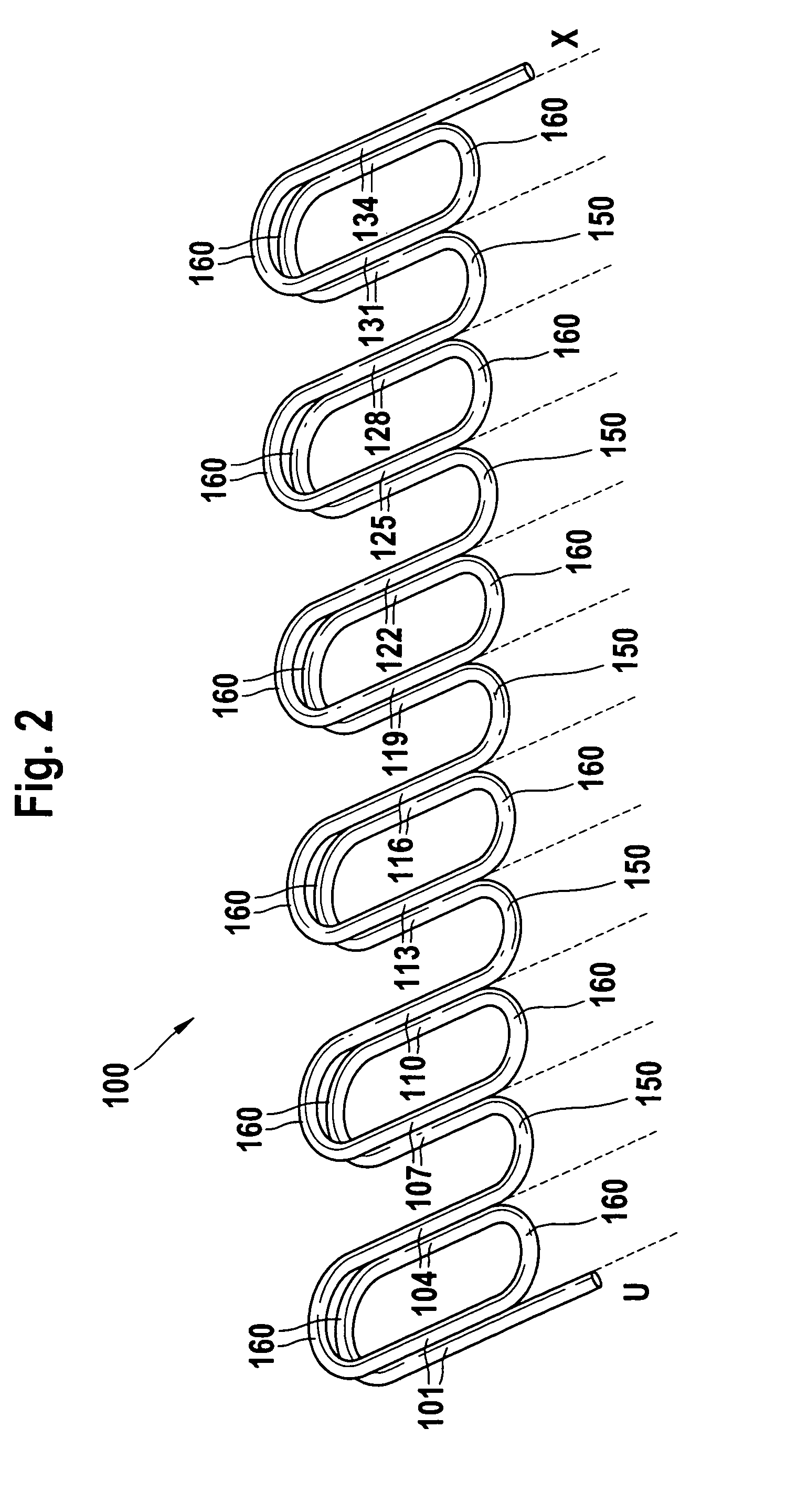

Method for making an electromagnetically excitable core of an electrical machine with a multiphase winding

InactiveUS7726005B2Simple manufacturing processReduce bending forceMagnetic circuitOther manufacturing equipments/toolsElectric machineEngineering

The method of making an electromagnetically excitable core of an electrical machine with a multiphase winding (13) includes preparing a core (10) having a substantially parallelepiped shape, which is provided with a plurality of parallel grooves (N1 to N36; N1 to N48) in one side in a first step. In at least one subsequent step at least three phase windings (100, 200, 300) are laid in these grooves in such a manner that only one winding overhang is outside of the core.

Owner:SEG AUTOMOTIVE GERMANY GMBH

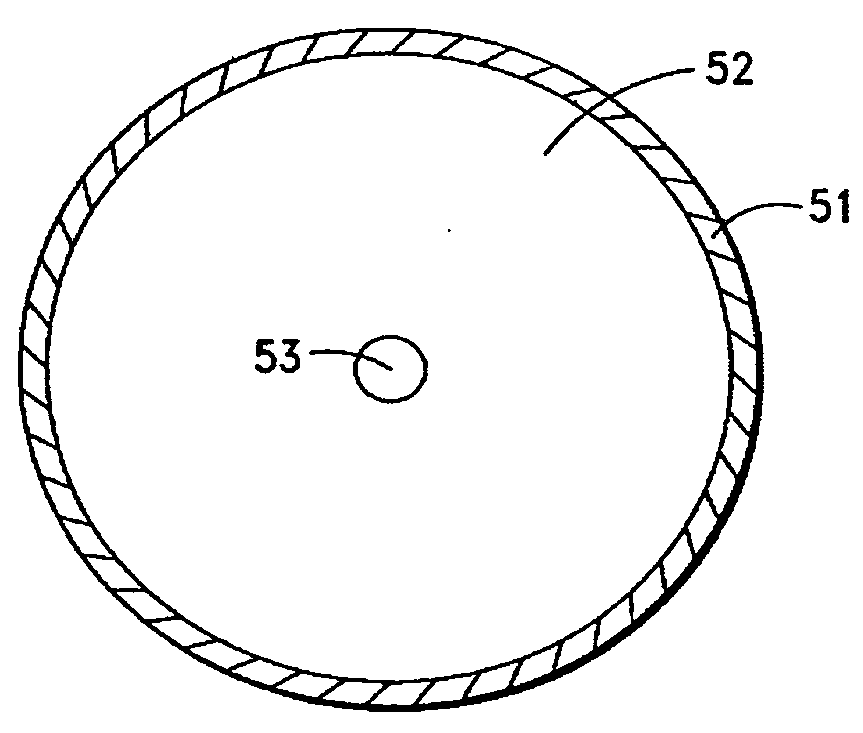

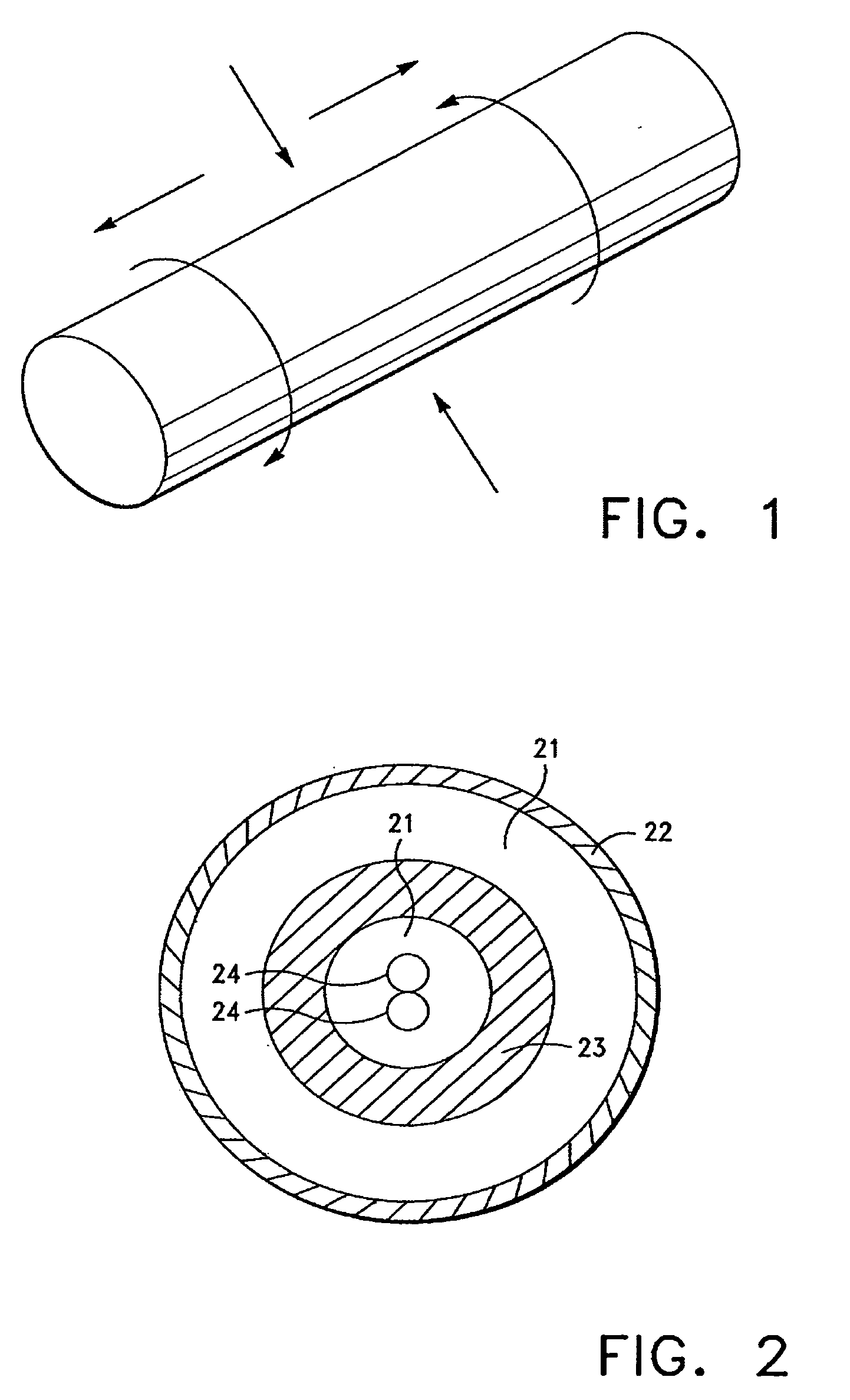

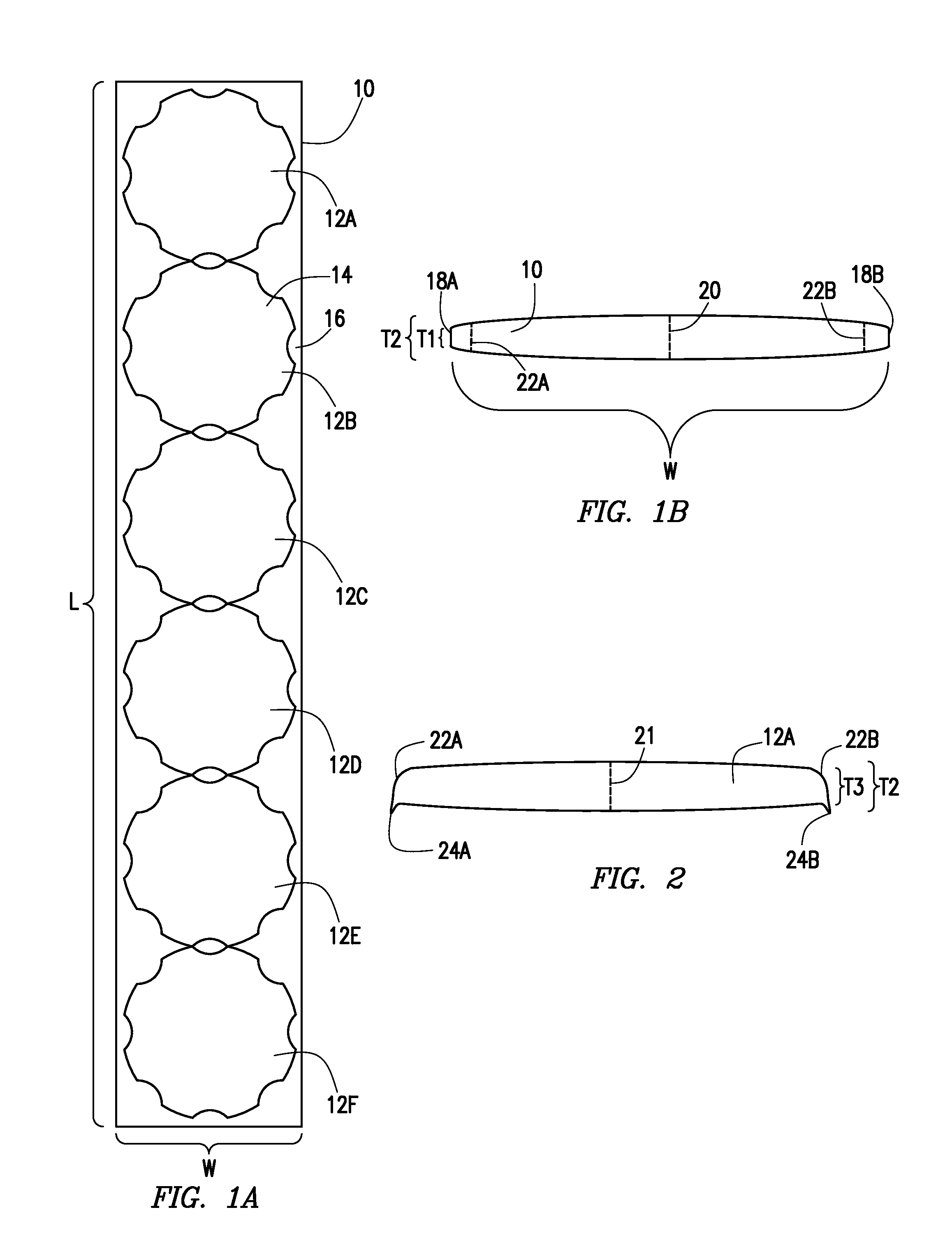

Electrically conductive buoyant cable

InactiveUS20080296040A1Increase buoyancyGreat resistance to tensile stressFloating cablesInsulated conductorsElectrical conductorFilling materials

Disclosed herein is an electrically conductive buoyant cable. The cable includes an electrical conductor member having at least one electrical conductor. The cable also includes a filler layer that consists of buoyant materials with relative density lower than 1. The filler layer surrounds and encloses the electrical conductor member. The invention includes a jacket, which, in one embodiment, contains a small quantity of filler material or no filler material. The jacket surrounds the filler layer. In one embodiment, the filler layer and the jacket are made of the same material.

Owner:SMARTPOOL

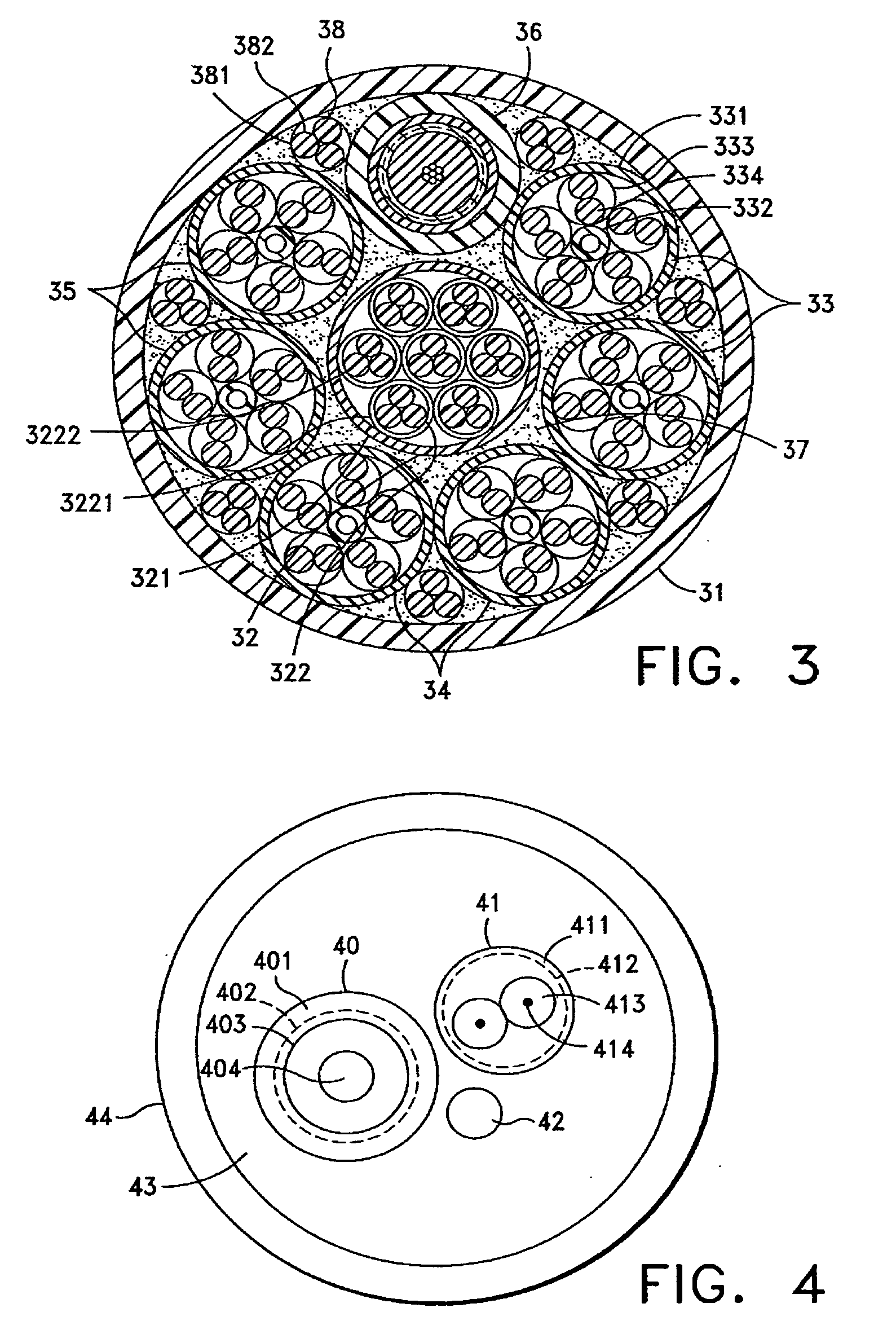

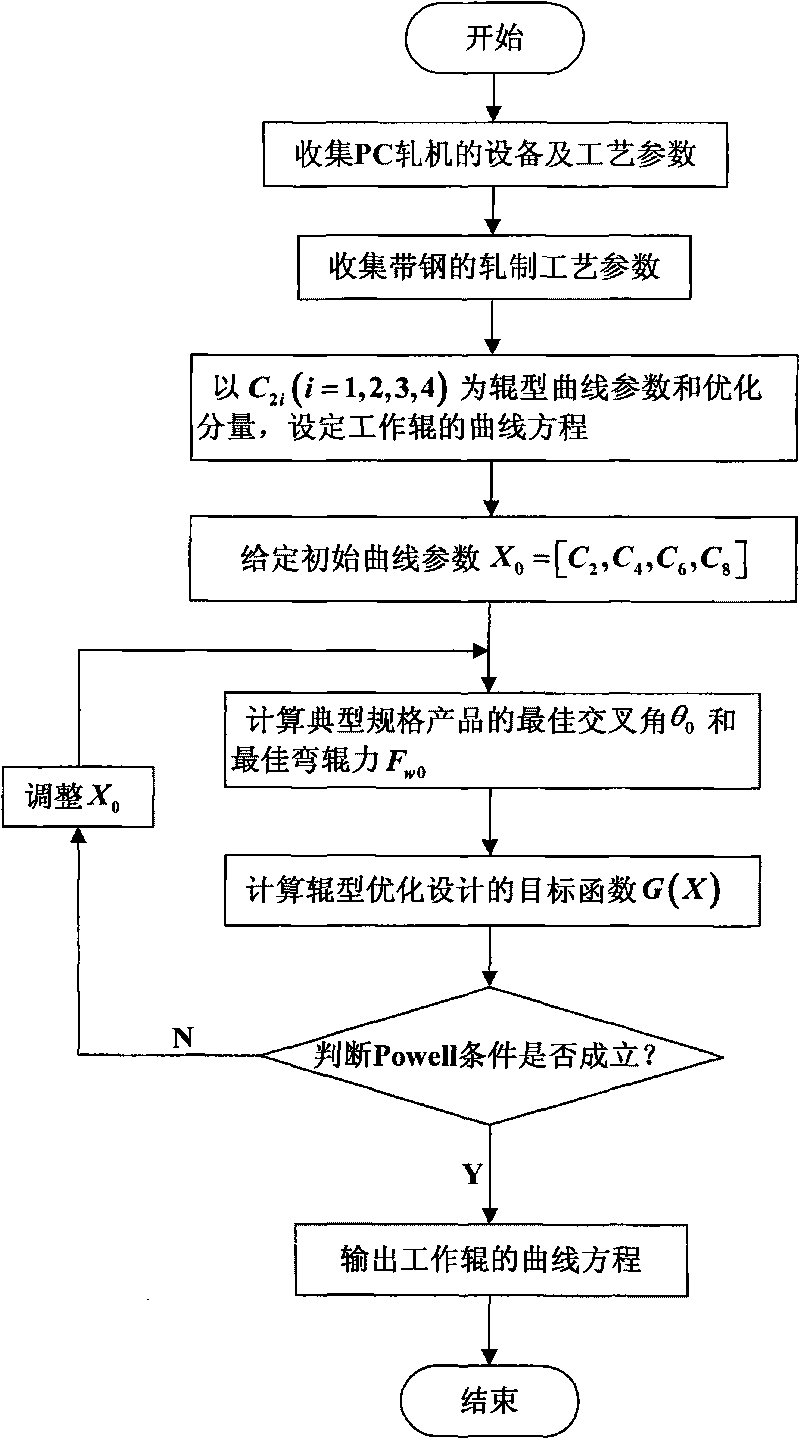

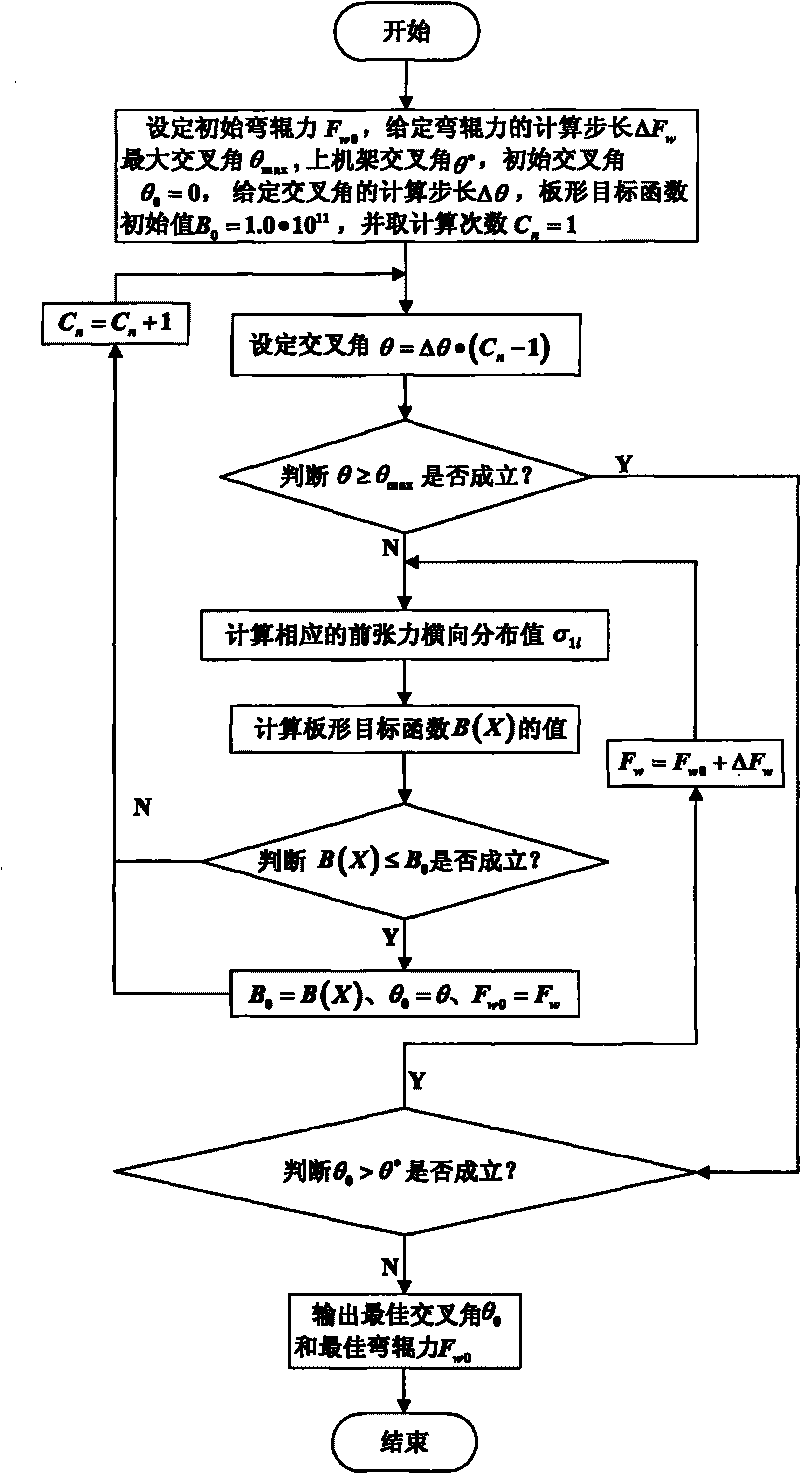

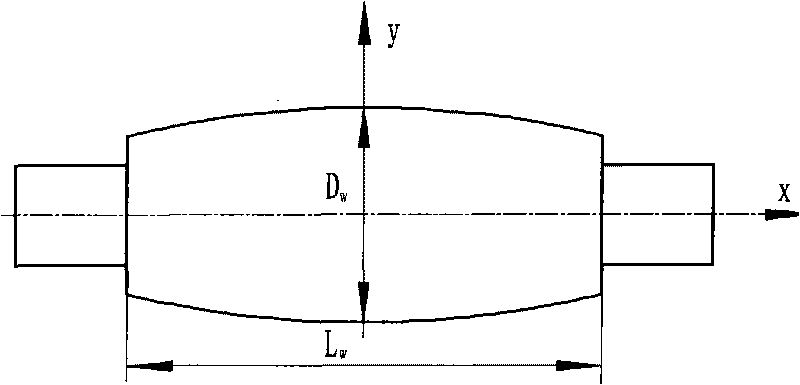

Crossing angle and roll bending force reduction based roll shape design method of work roll of PC rolling mill

InactiveCN101714177AImprove plate crown control abilityImprove stabilityRollsSpecial data processing applicationsWork rollStrip mill

The invention provides a crossing angle and roll bending force reduction based roll shape design method of a work roll of a PC rolling mill, aiming at the rolling characteristics of the PC rolling mill. The roll shape design method comprises the following steps of: (a) collecting equipment parameters and process parameters of the PC rolling mill; (b) collecting rolling process parameters of typical band steel; (c) setting a curve equation of the work roll; (d) optimally computing curve parameters of a roll shape; and (e) substituting the curve parameters of the roll shape into the roll shape curve equation of the work roll so as to obtain an optimized roll shape curve equation of the work roll. The invention enhances the stability of the PC rolling mill because a roll shape curve of the work roll reduces the crossing angle and the roll bending force, prolongs the service life of the work roll, enhances the convexity control capacity of the PC rolling mill, not only ensures the qualityrequirement of a profile shape, but also meets the requirement for industrial application precision, and can also be used for the roll shape curve design of the work roll of any rack according to actual field situation.

Owner:YANSHAN UNIV

Sectional bending mould for machining heavy forging

InactiveCN101585066AImprove the state of stressQuality improvementShaping toolsDraw-gearEngineeringBack pressure

The invention discloses a sectional bending mould for machining heavy forging, includes a inclined concave mould, and a convex mould and a back pressure mould matching with the concave groove, wherein, upper surface of the inclined concave mould has a concave groove cavity with both sides end face of inner-low and outer-high inclined surface, lower surface of the convex mould has a concave plate matching with the concave groove cavity, appearance of lower surface of the convex plate is matching with shape of inner surface of middle of the forging, the back pressure mould is disposed inside the concave groove cavity with its contour of upper surface matching with shape of non-bending area of outer side of middle of the forging, the lower surface is provided with a elastic mechanism to connect with bottom of the concave groove cavity, the elastic mechanism can push the back pressure mould to upper surface of the inclined concave mould without external force. The invention can be used for machining bending of heavy forging, and has advantages of low cost and good quality.

Owner:CHONGQING JIEXIN LIANZHONG MECHANICAL & MFR

Toner supply device

InactiveCN1841230AImprove rigidityReduce rigidityElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

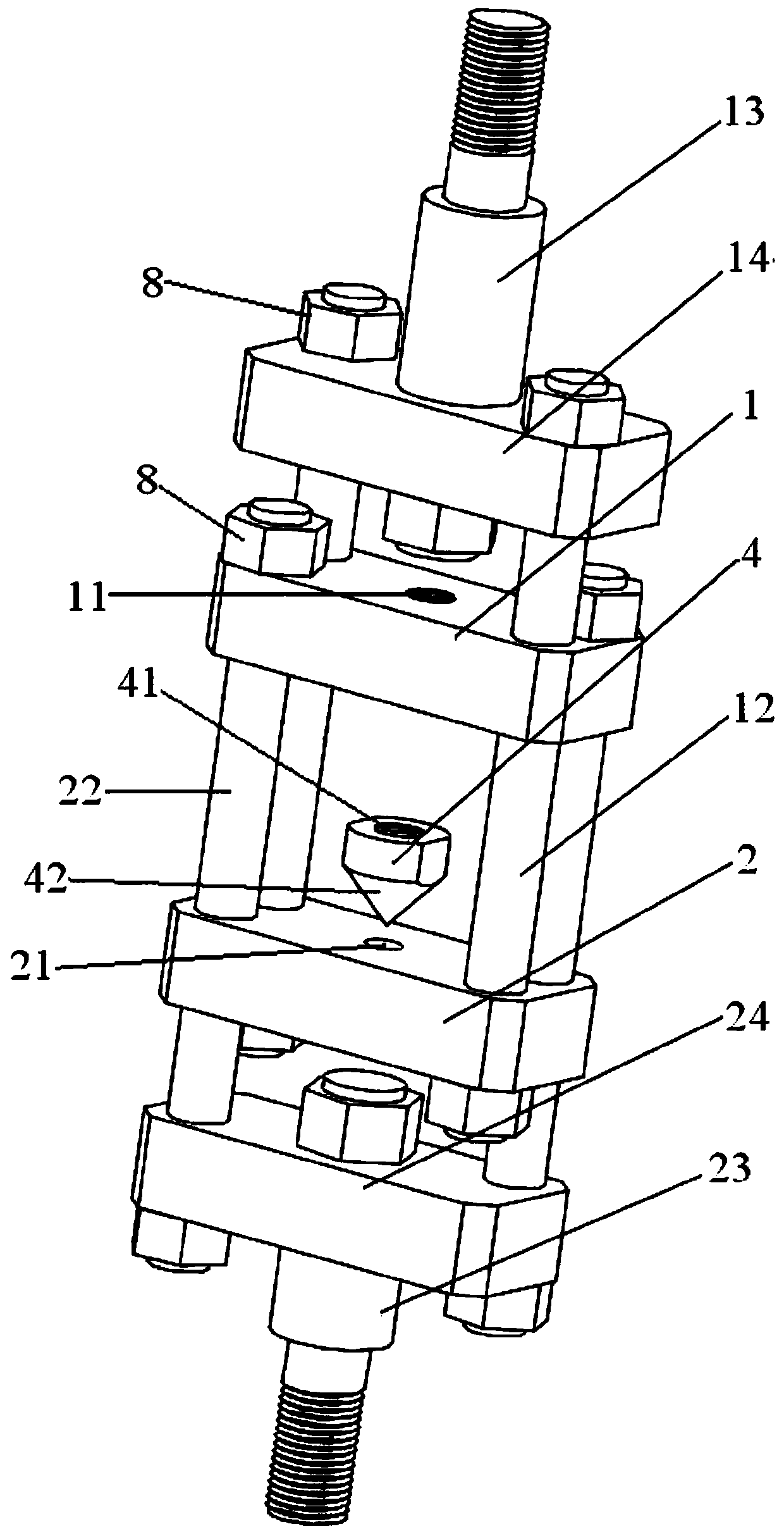

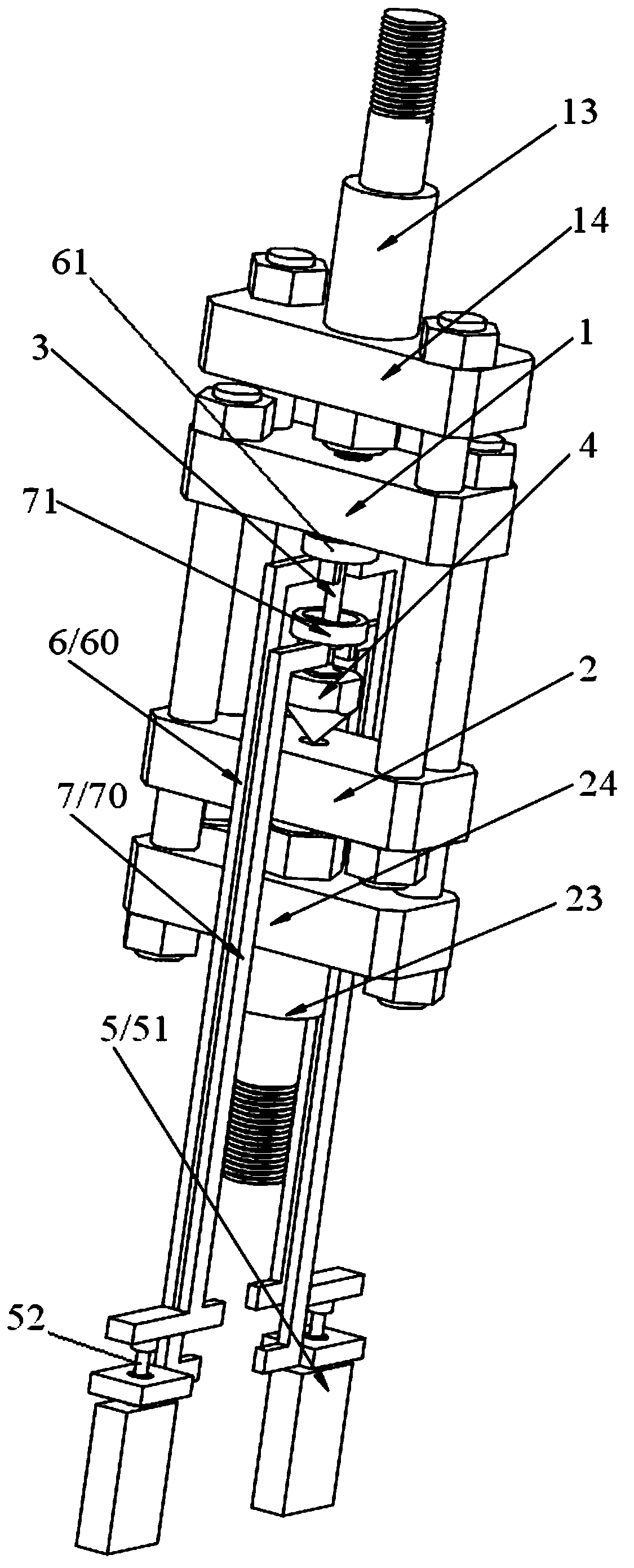

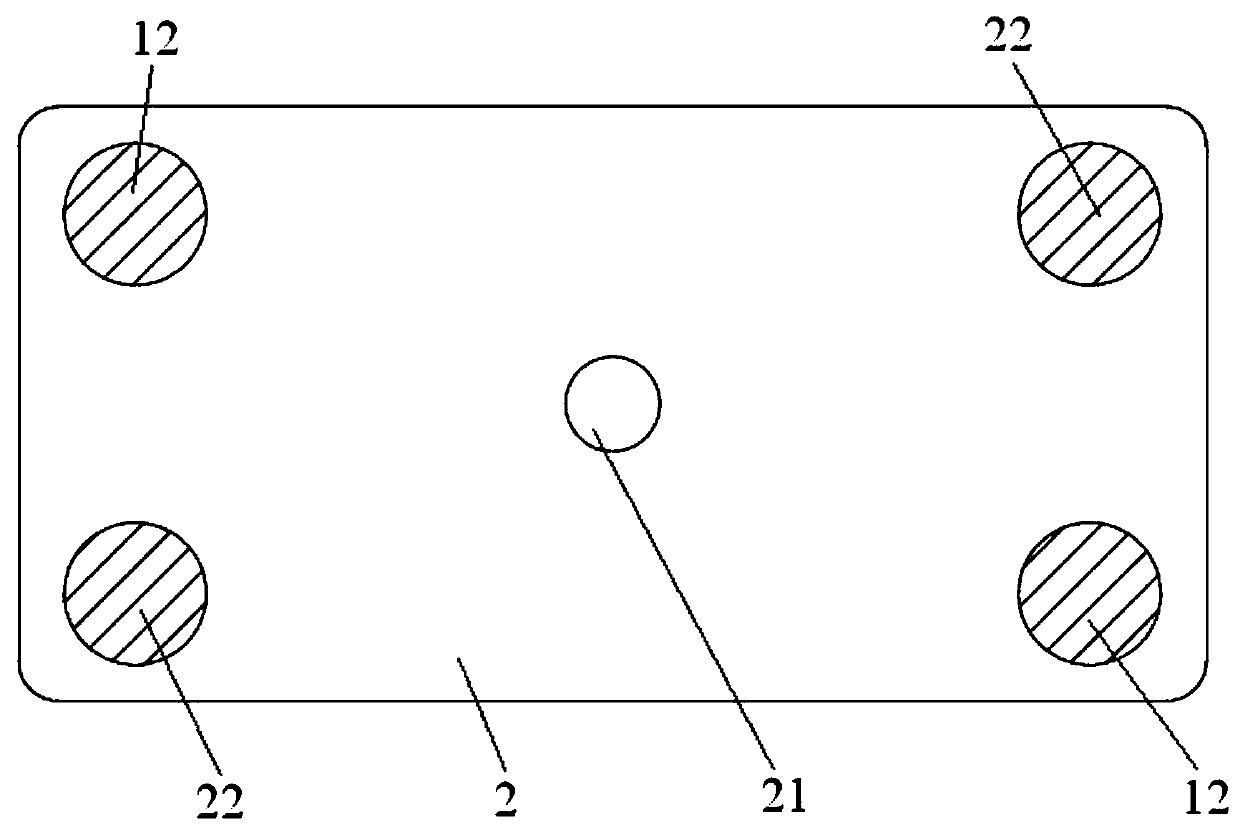

Creep compression experimental apparatus

ActiveCN109870371ANeutral goodReduce risk of damageInvestigating material ductilityNuclear energy generationUniaxial compressionTest sample

The invention provides a creep compression experimental apparatus. The creep compression experimental apparatus comprises an installation frame connected between an upper stretching rod and a lower stretching rod of a creep test machine, wherein the installation frame comprises an upper pressure block and a lower pressure block, the upper pressure block is provided with a threaded hole A, the lower pressure is provided with a conical hole coaxial with the threaded hole A, one end of a test sample is fixed in the threaded hole A, the other end is located in the conical hole by virtue of a conical head of a conical positioning device, and when the conical head is matched with the conical hole, the threaded hole A, the conical head, the conical hole and the test sample are coaxial. The auto-positioning function is realized by virtue of a conical surface contact of the conical positioning device, so that the test sample can be well centralized in the single-axis compression process, and the instability bending possibility of the test sample can be reduced. By virtue of the reversely-arranged extension rod, the rebound displacement of a precompressed sensor measuring head in the reset process is taken as the compression creep deformation of a sample, so that the occurrence of overstroke of the sensor measuring head and damage to the displacement sensor can be effectively avoided.

Owner:CENT SOUTH UNIV

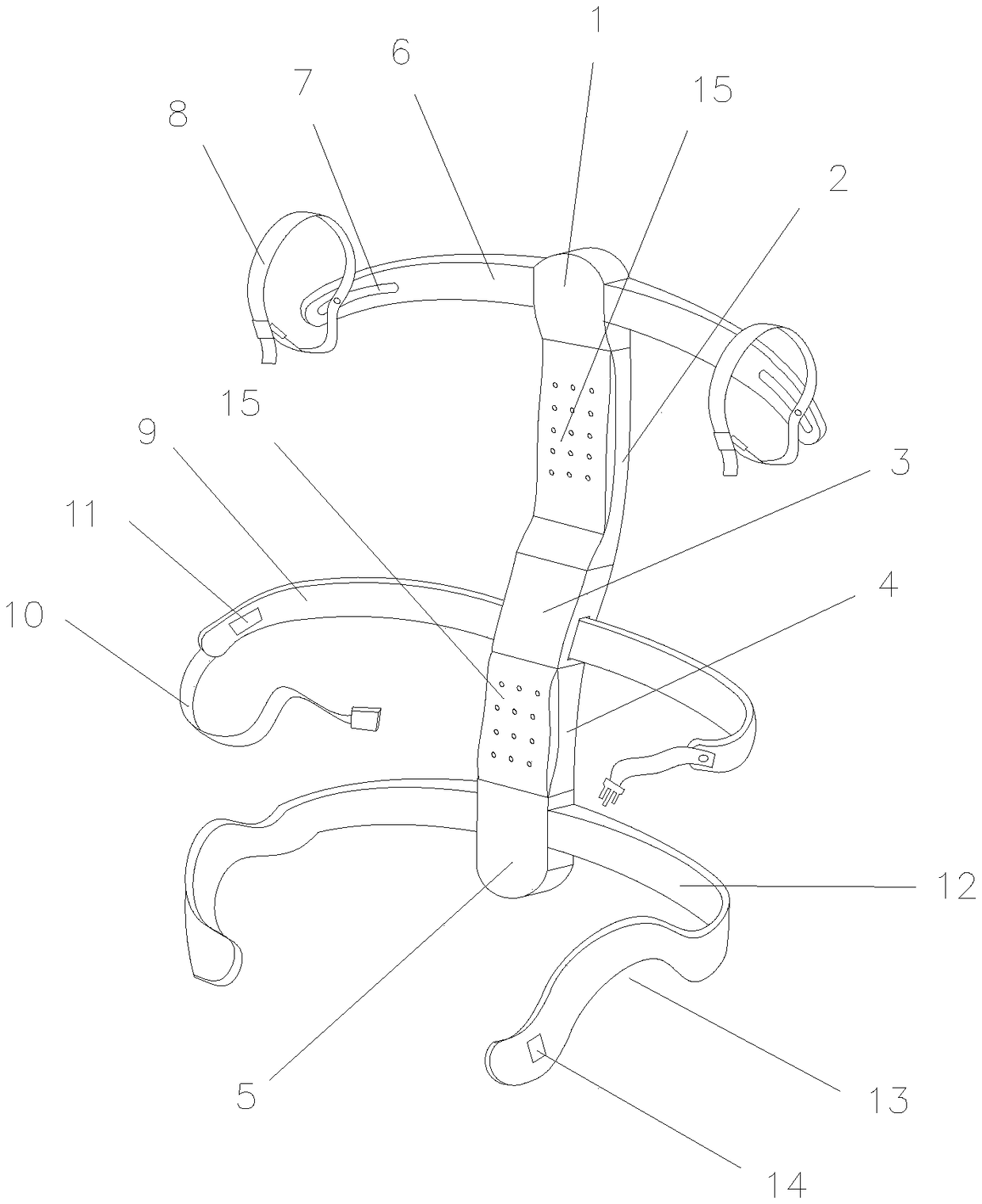

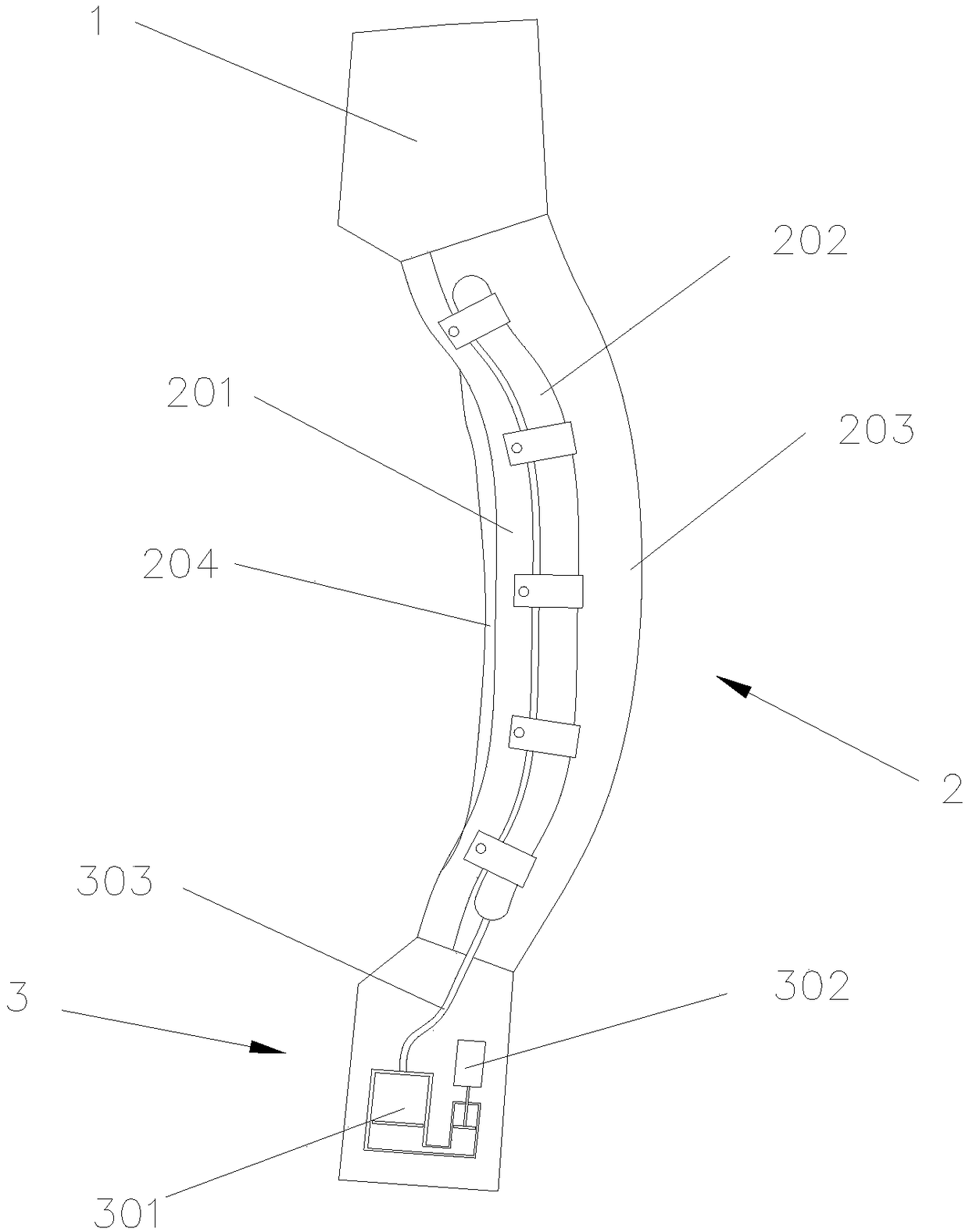

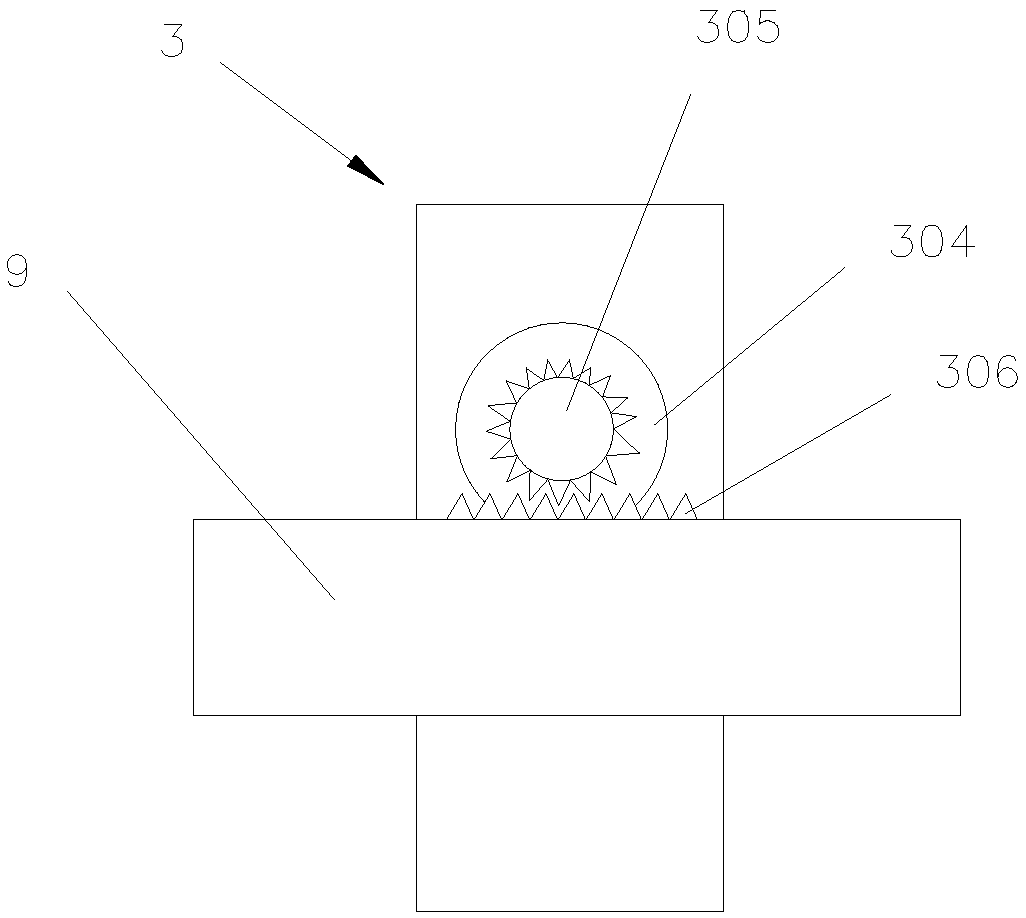

Spinal anesthesia postoperative auxiliary rehabilitation device

PendingCN108742966AReduce volumeImprove portabilityMedical devicesNon-surgical orthopedic devicesSpinal anesthesiaPhysical medicine and rehabilitation

The invention discloses a spinal anesthesia postoperative auxiliary rehabilitation device. The spinal anesthesia postoperative auxiliary rehabilitation device comprises an upper connecting portion, afirst elastic portion, a middle connecting portion, a second elastic portion and a lower connecting portion, wherein a shoulder supporting beam with a shoulder bandage is fixed on the upper connectingportion; an abdomen supporting beam with an abdomen bandage is arranged at the middle connecting portion; a waist supporting beam is fixed on the lower connecting portion; a body side portion of thewaist supporting beam is a hook portion while the front portion of the waist supporting beam is an inclined bent waist portion; and the supporting beam is an elastic beam body. The device has a wearable structure, is small in size and portable, and can be used at any time in any places; the device has a multi-point stabilizing effect on the spine of a patient in a vertical direction, the bending range of the spine of the patient is limited, the curvature of the spine of the patient is reduced, and recovery of the spine and other wounds is facilitated; and moreover, the elasticity of the elastic portion of the device can be adjusted, the movement range of the spine of the patient can be controlled by himself, the spine can be protected, furthermore, the amount of exercising can be adjustedto adapt to different rehabilitation periods, and high-quality body recovery is facilitated.

Owner:常州朝旭企业服务有限公司

Bending forming method of railway van coupler yoke forge piece

The invention discloses a bending forming method of railway van coupler yoke forge pieces. The method is realized by an incline female die, and a male die which is matched with the female die and a back pressure die. The method comprises the steps of:preheating a forge piece rough part, carrying out primary bending by taking the highest point of the incline of the incline female die as a first supporting point, and carrying out secondary bending by taking the lowest point of the incline of the incline female die as a second supporting point. The method has the advantages of low cost and good processing quality.

Owner:CHONGQING UNIV

Stator core of motor for washing machine

ActiveUS8674579B2Preventing unnecessary consumption of materialMinimize consumptionOther washing machinesMagnetic circuit stationary partsMechanical engineeringSteel plates

The present invention relates to a stator core of a motor for a washing machine that is formed by connecting a plurality of arc-shaped core pieces to each other, each of the core pieces being formed by stacking core piece steel plates on top of each other and by bending the stacked core piece steel plates in such a manner that core piece teeth are disposed outward in the radial direction of a core piece yoke and the core piece yoke has the same curvature as a yoke of a stator core, the core piece yoke on each core piece steel plate having a plurality of incised portions for bending formed partially incised thereon between the respective neighboring core piece teeth on the opposite side to the side on which the core piece teeth are formed.

Owner:NEW MOTECH

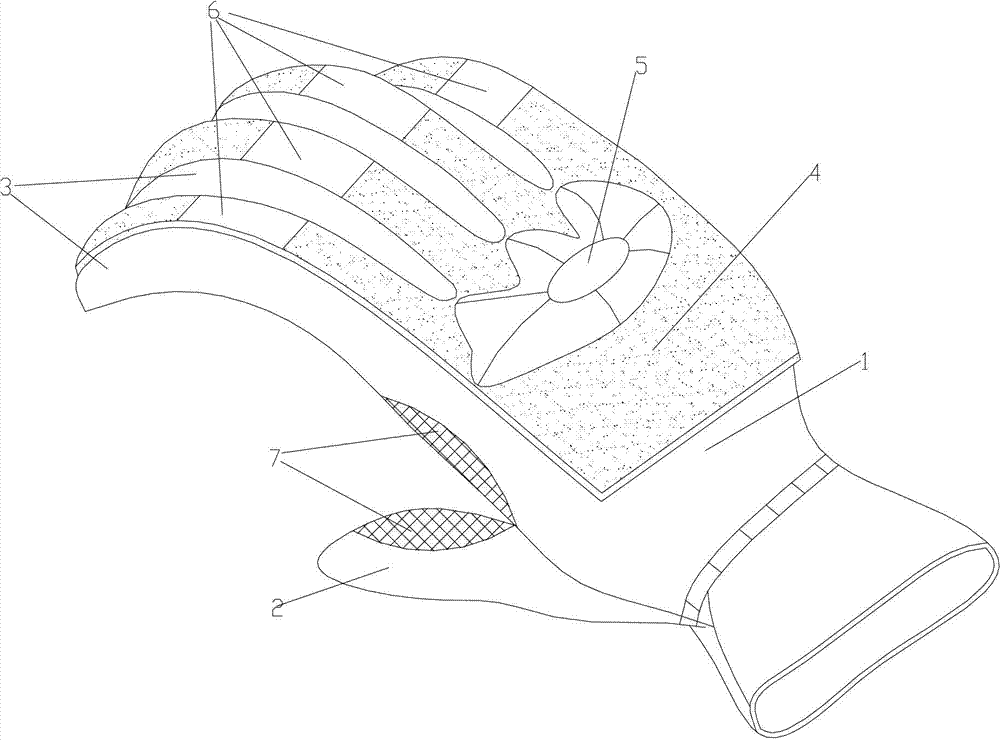

Shock resistant motorcycle gloves

InactiveCN102960879AReduce hand fatigueImprove cushioning performanceProtective garmentHand partsEngineering

The invention discloses a pair of shock resistant motorcycle gloves, comprising hand parts, wherein each hand part comprises a hand back part and a four-finger part, and a sponge rubber layer with an integrated structure is arranged on the hand back part and the four-finger part; the four-finger part is bent; the thickness of the sponge rubber layer is 35-40 mm; an impact buffering body is arranged on the sponge rubber layer of the hand back part; the impact buffering body is made of foam plastic; and reflective strips are arranged on the sponge rubber layer of the four-finger part. According to the shock resistant motorcycle gloves, the four-finger part adopts the bent structural design, when a user wears the gloves, four fingers of each hand of the user can naturally bend in the gloves, the gloves fit with the hands perfectly, when the user holds a handlebar, the force on bending the four-finger part of each glove is reduced, and the hand fatigue is accordingly reduced; the sponge rubber layer is arranged on the hand back part and the four-finger part of each glove, so that the buffering performance is increased, and the hands are protected from impact and friction and other accidental injury in accidental circumstances.

Owner:SUZHOU LONGXIN GLOVES

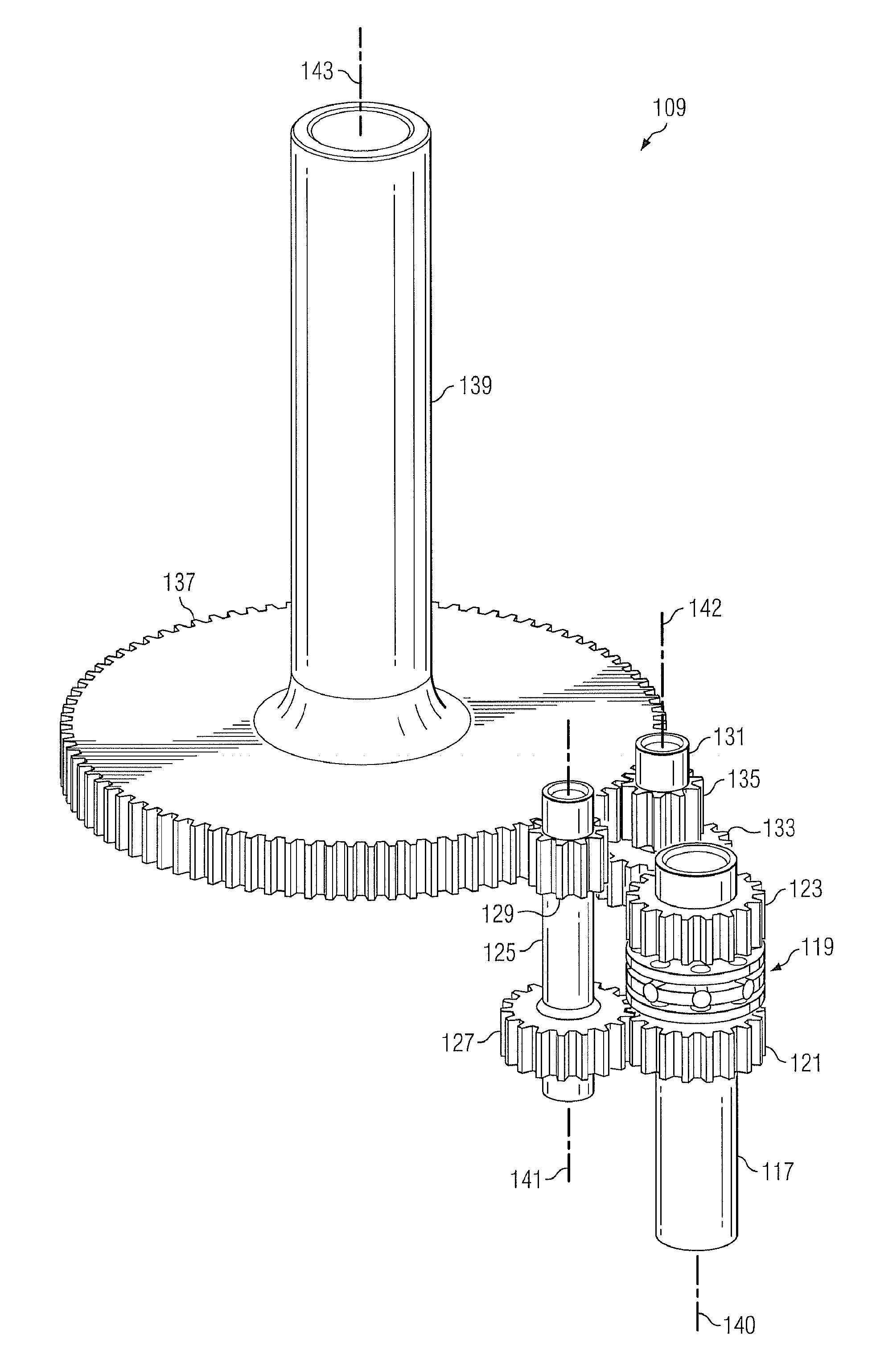

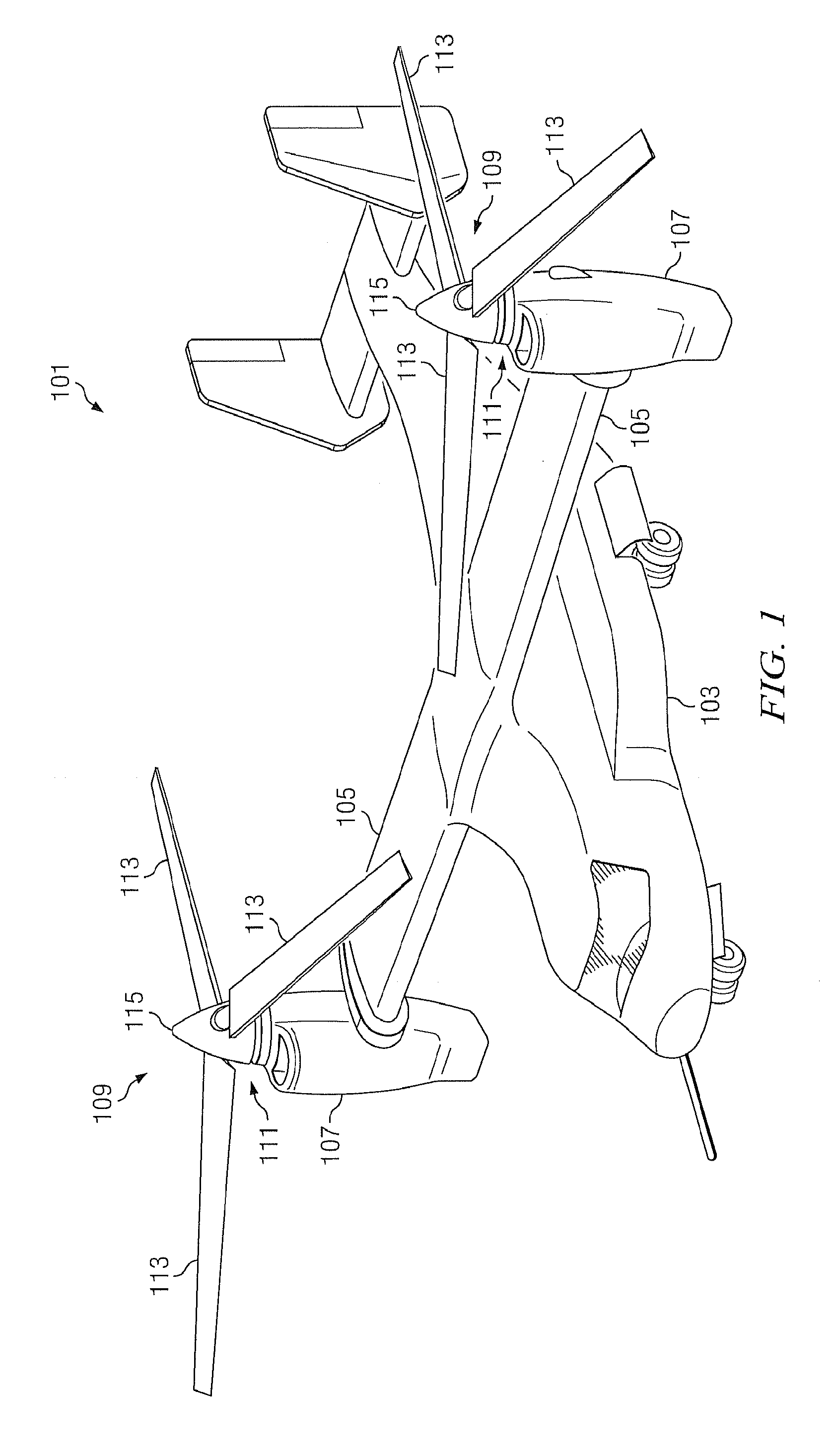

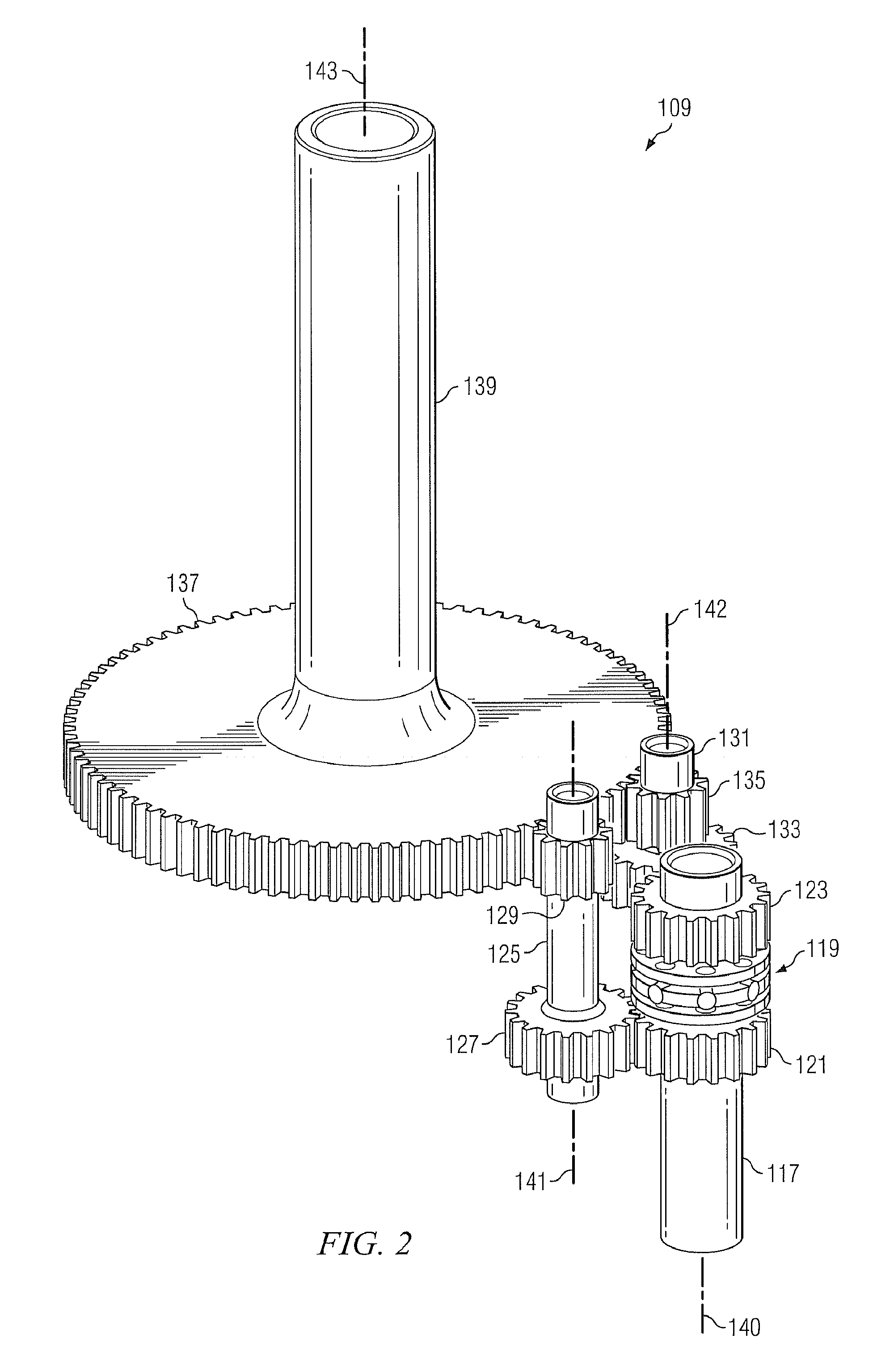

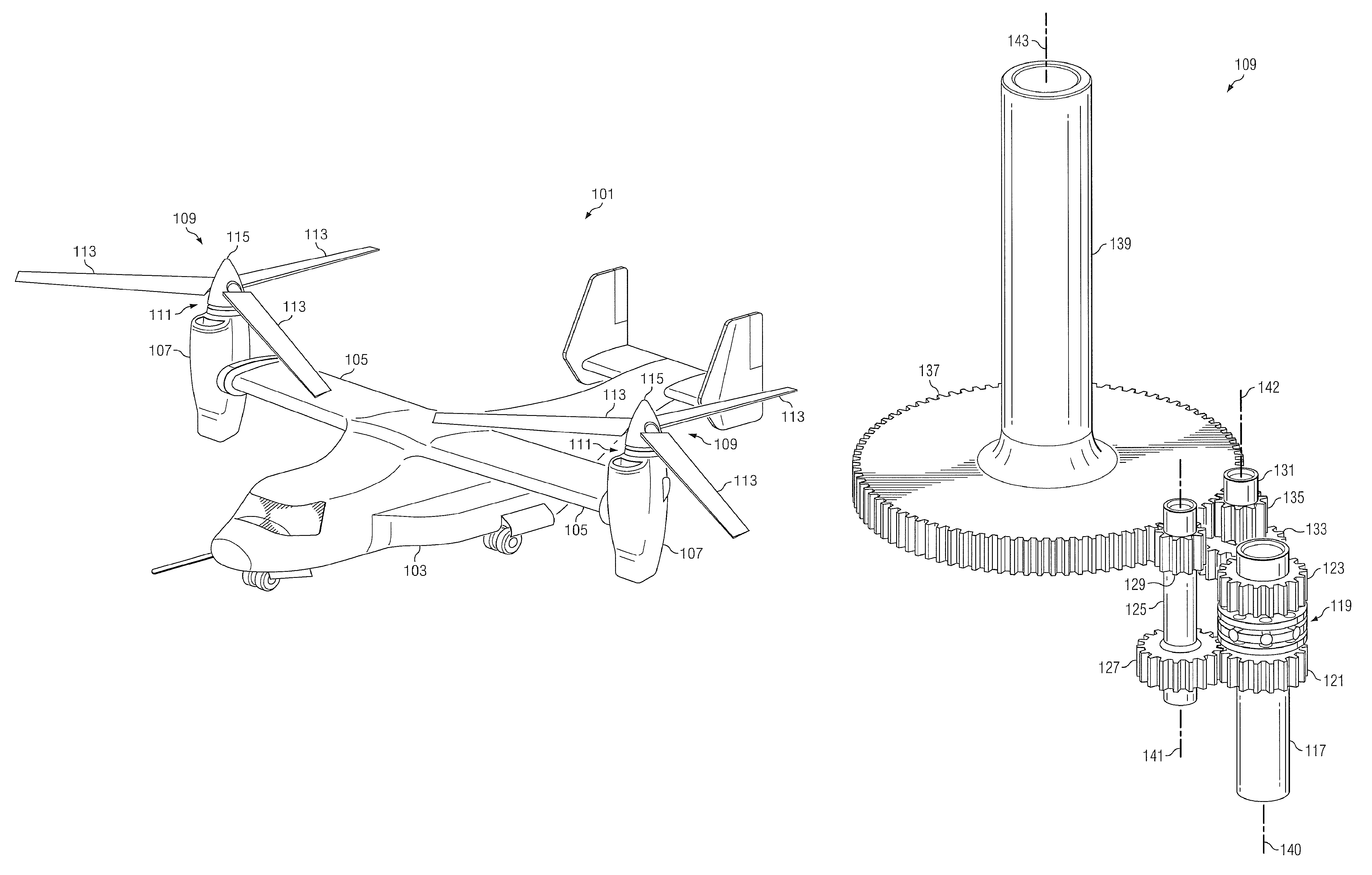

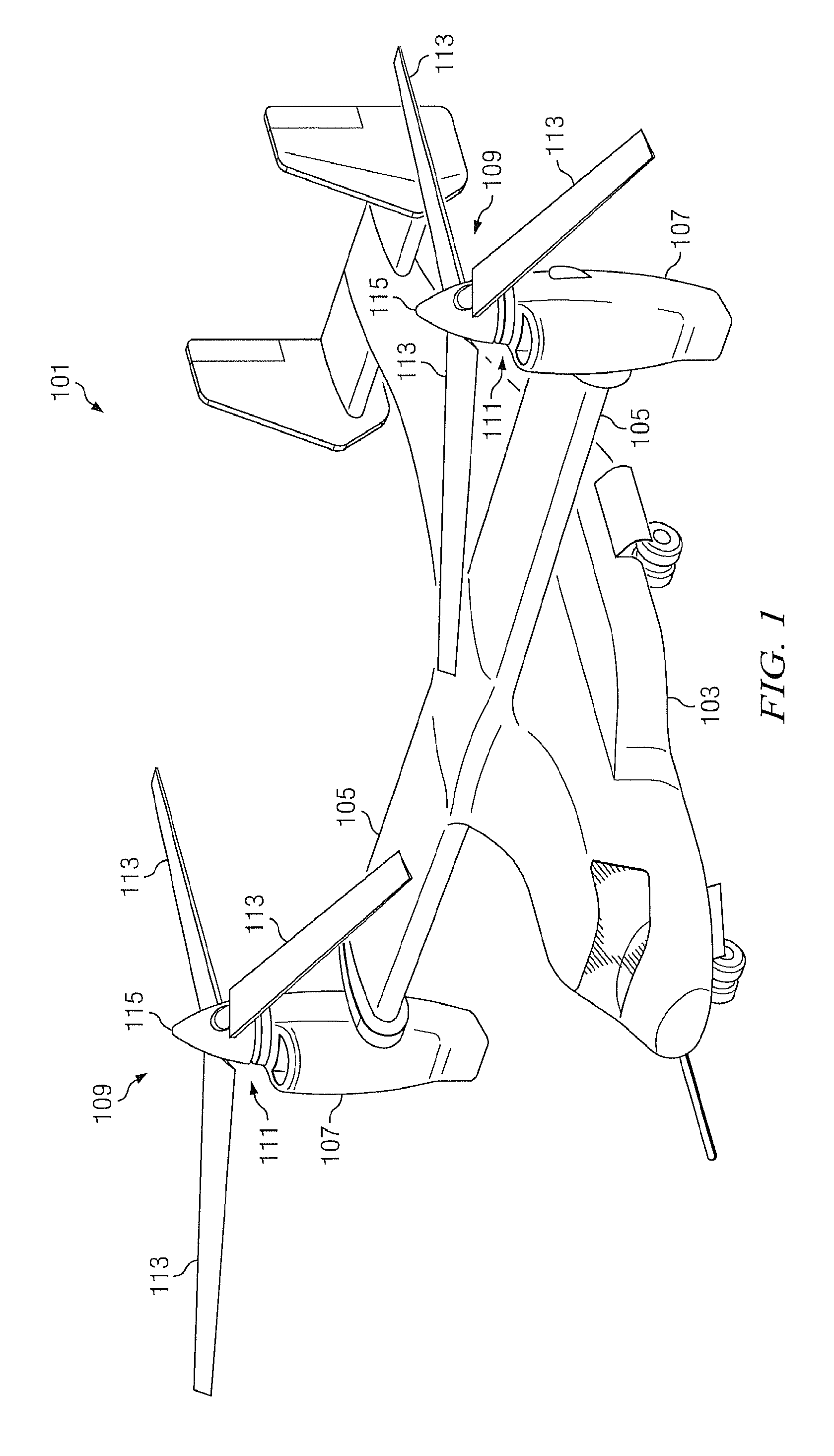

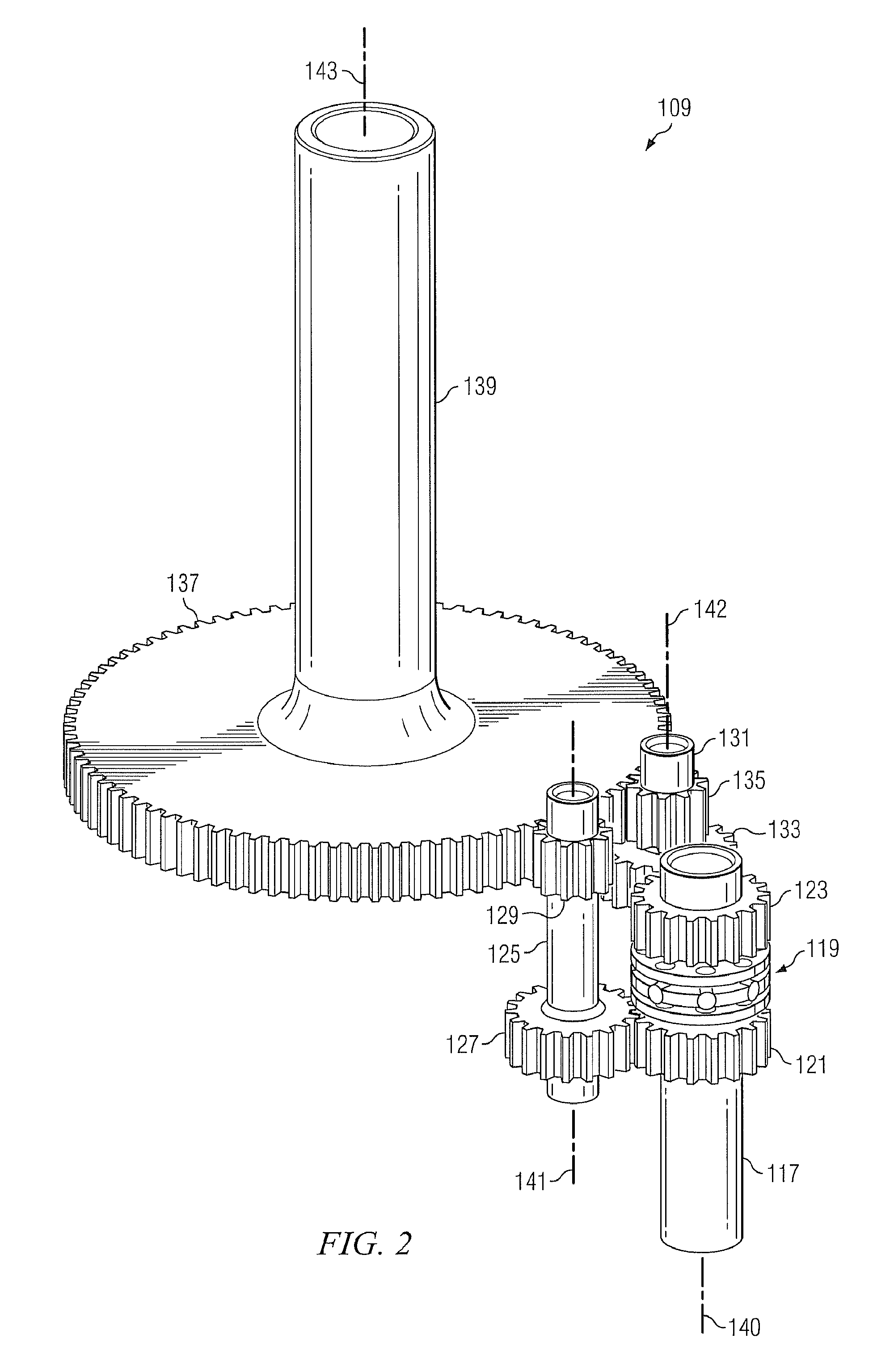

Multiple Drive-Path Transmission with Torque-Splitting Differential Mechanism

ActiveUS20100314492A1Small sizeReduce weightToothed gearingsDifferential gearingsEngineeringRotary wing

Owner:TEXTRON INNOVATIONS

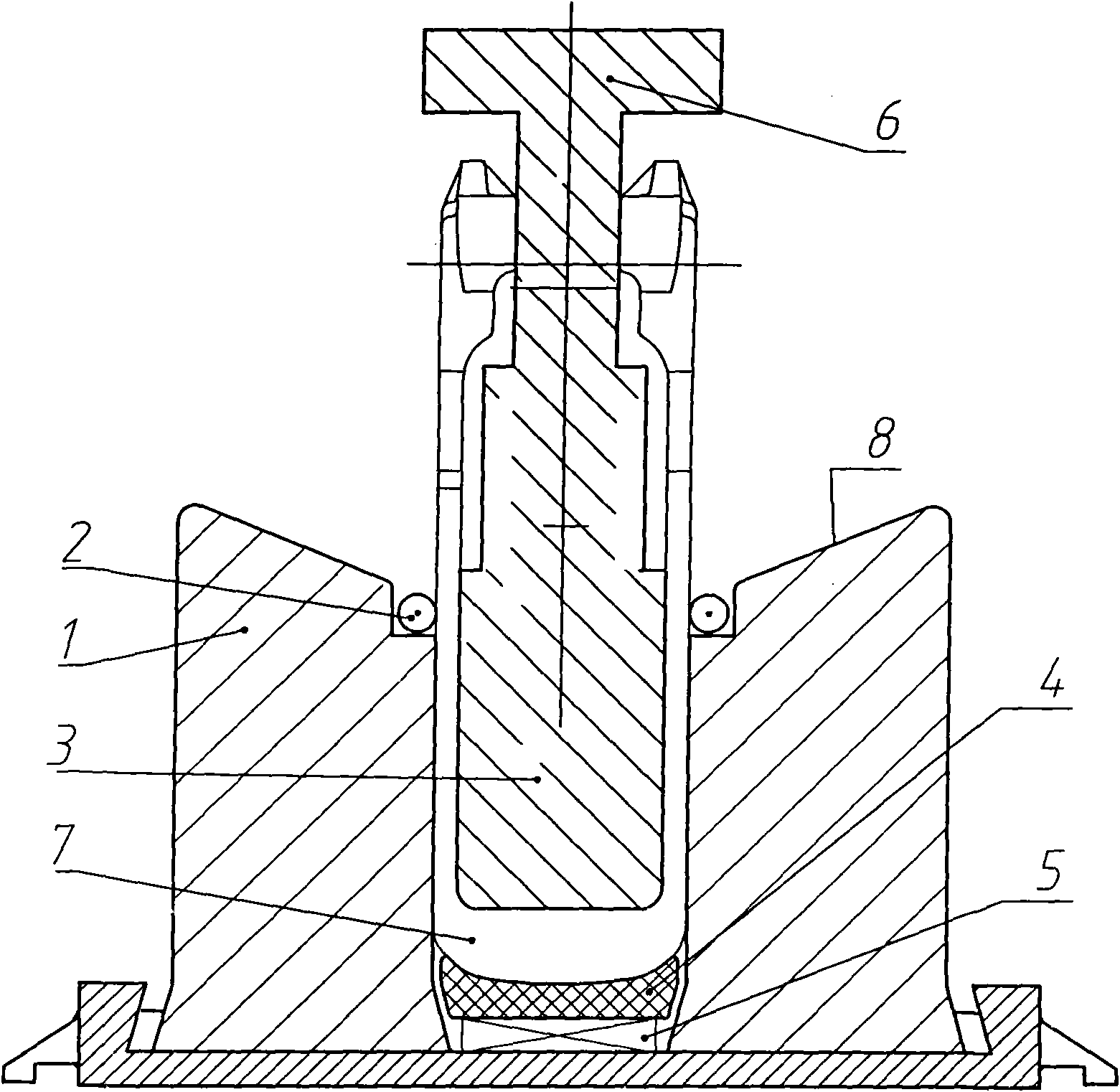

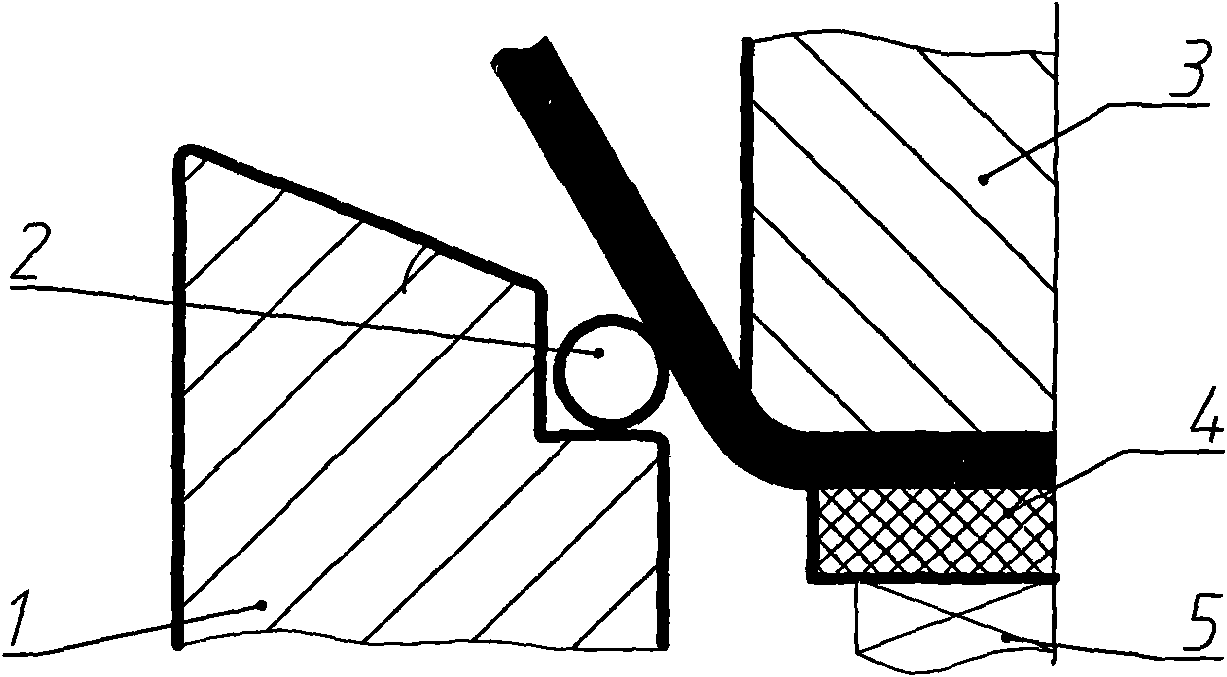

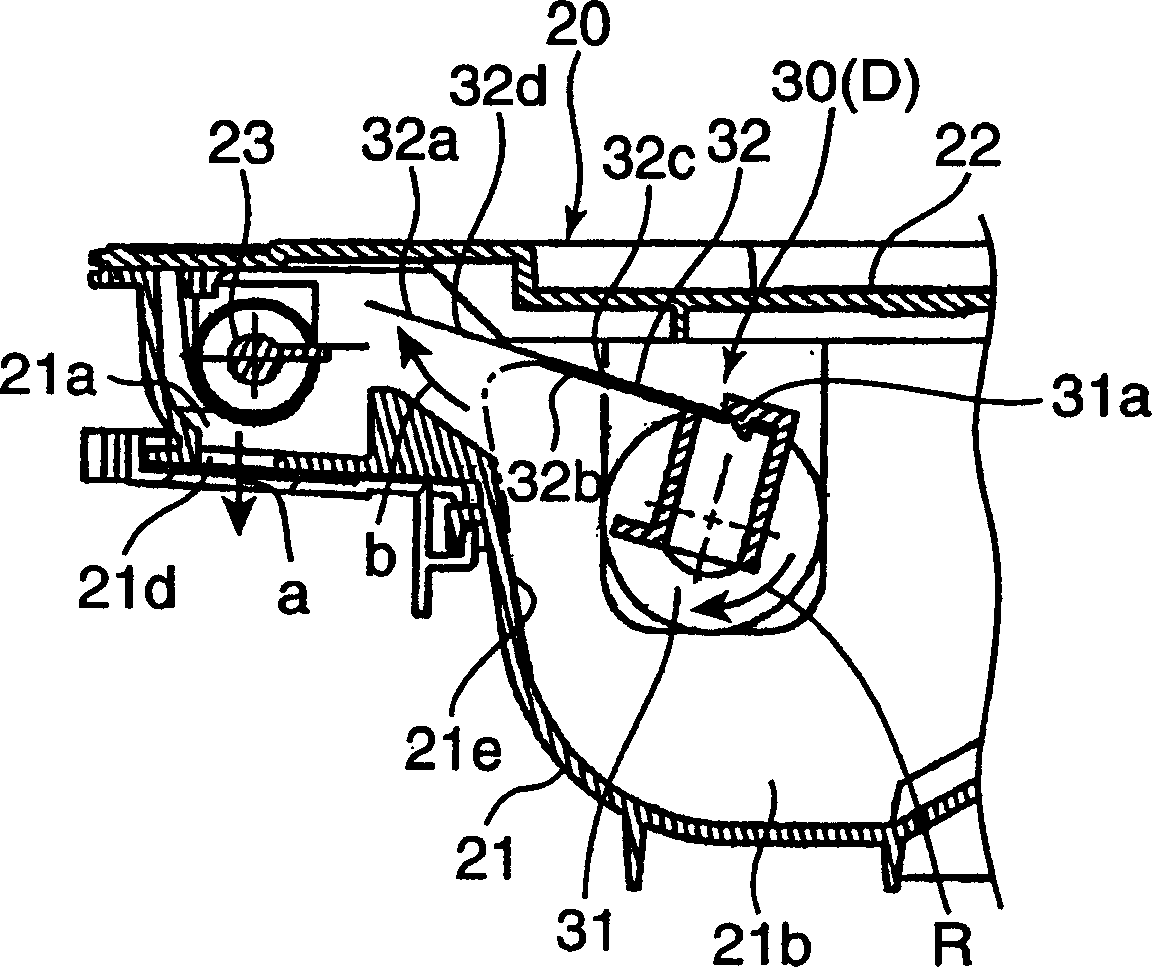

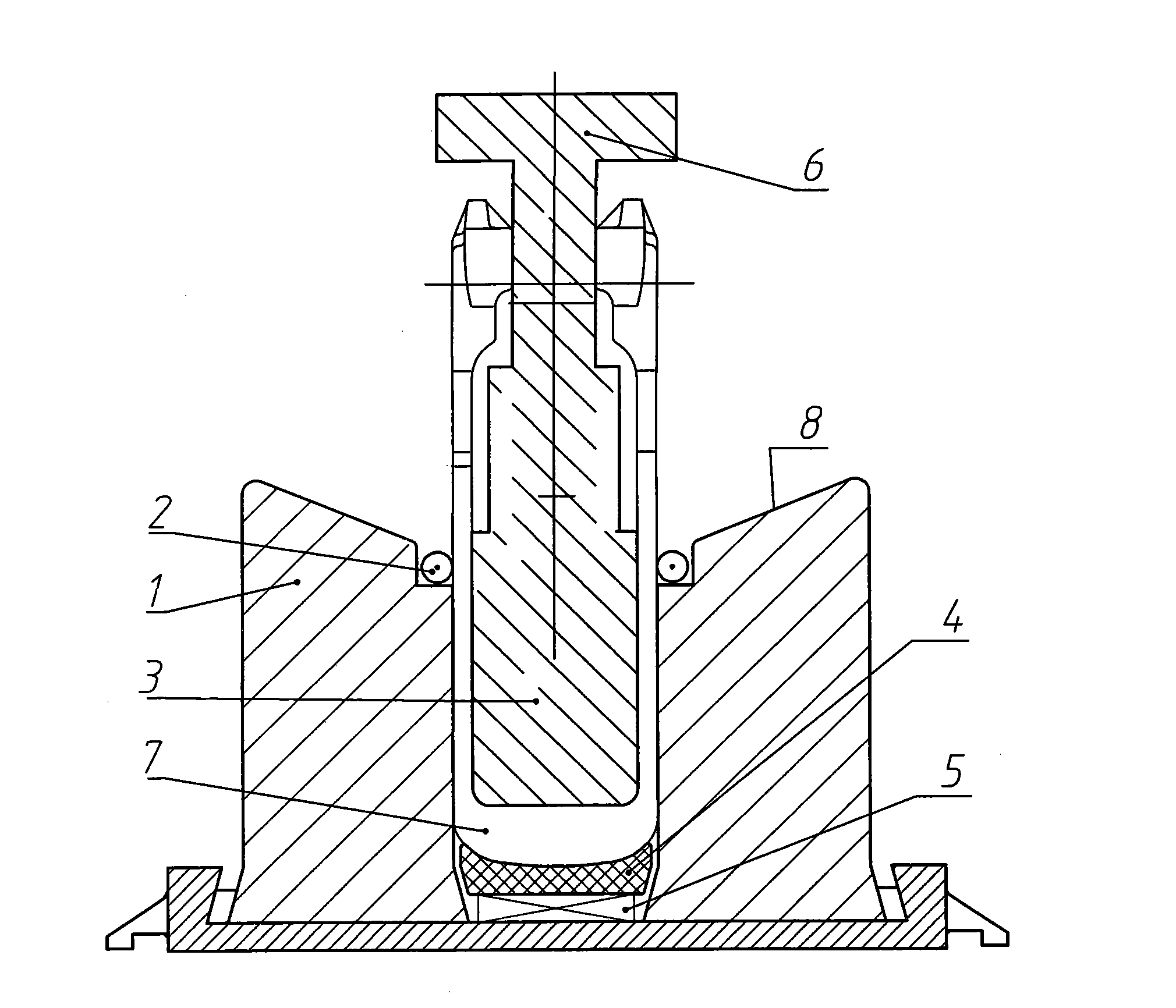

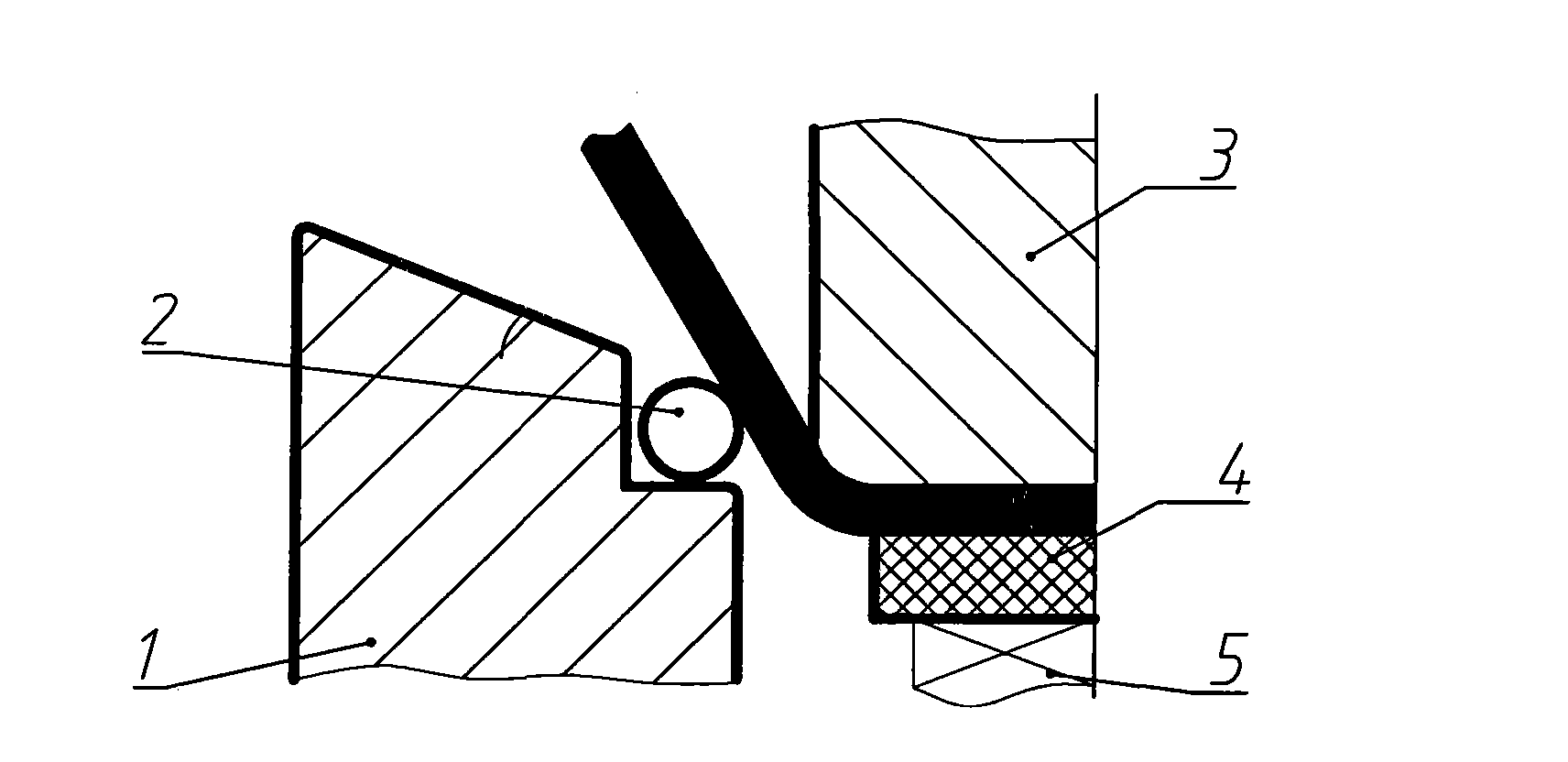

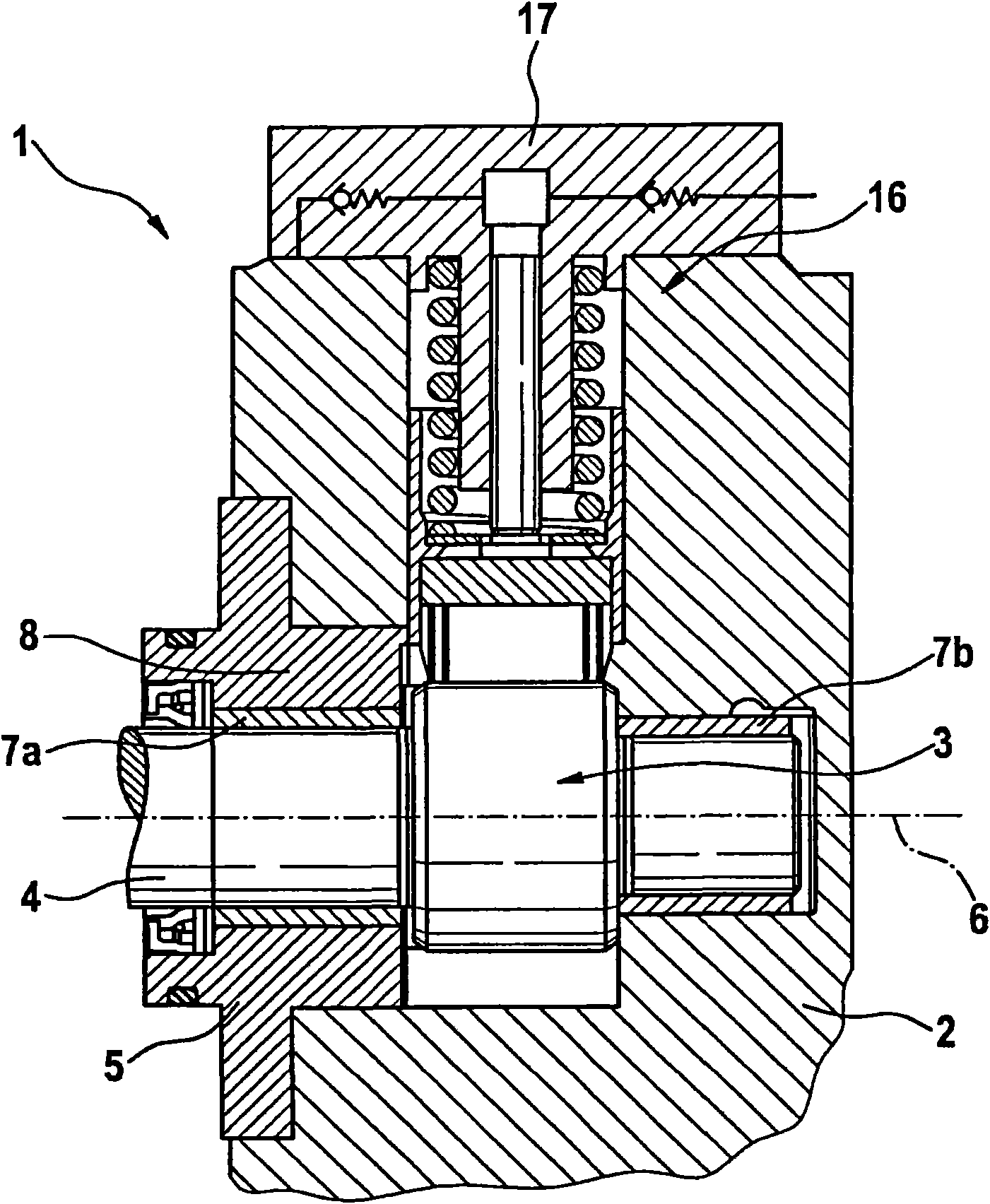

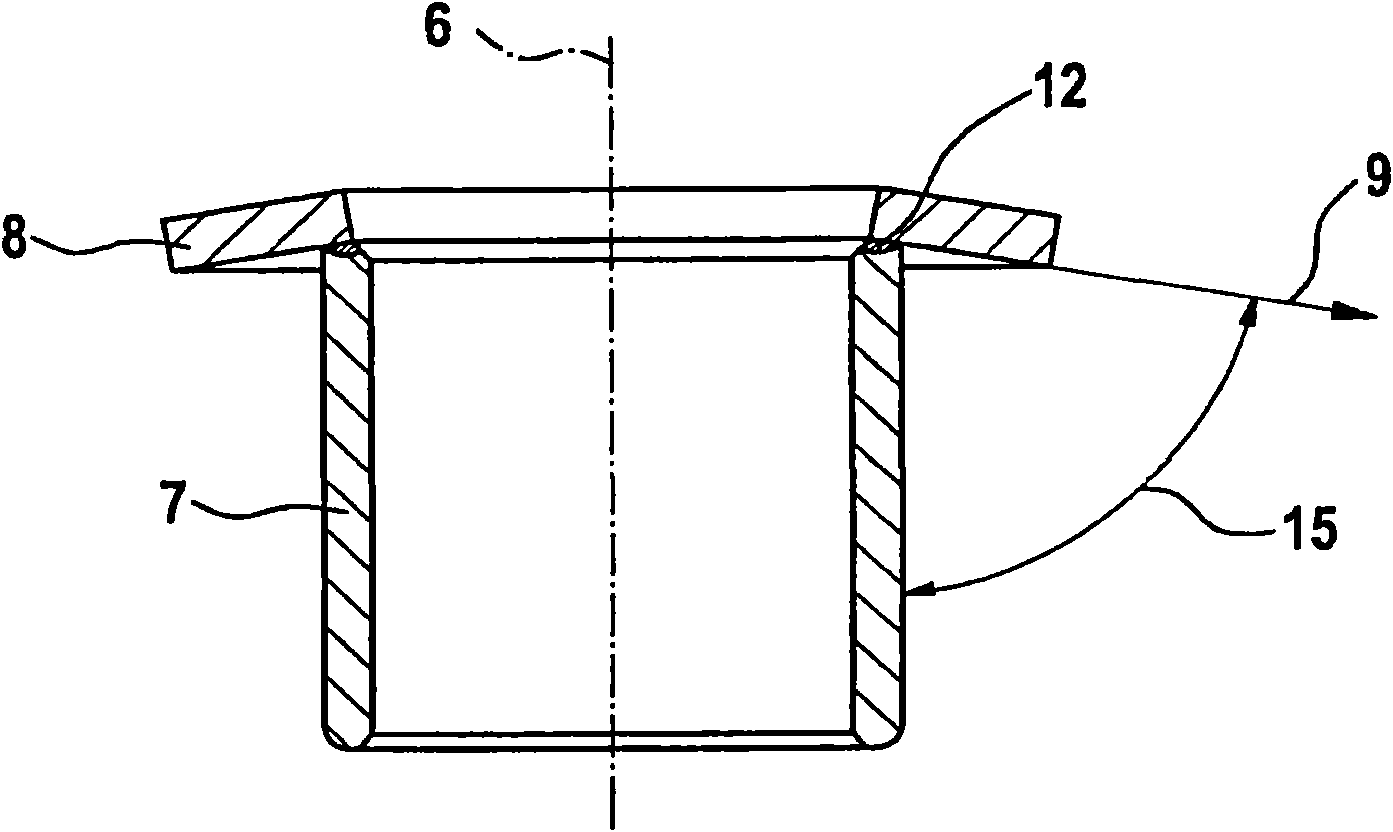

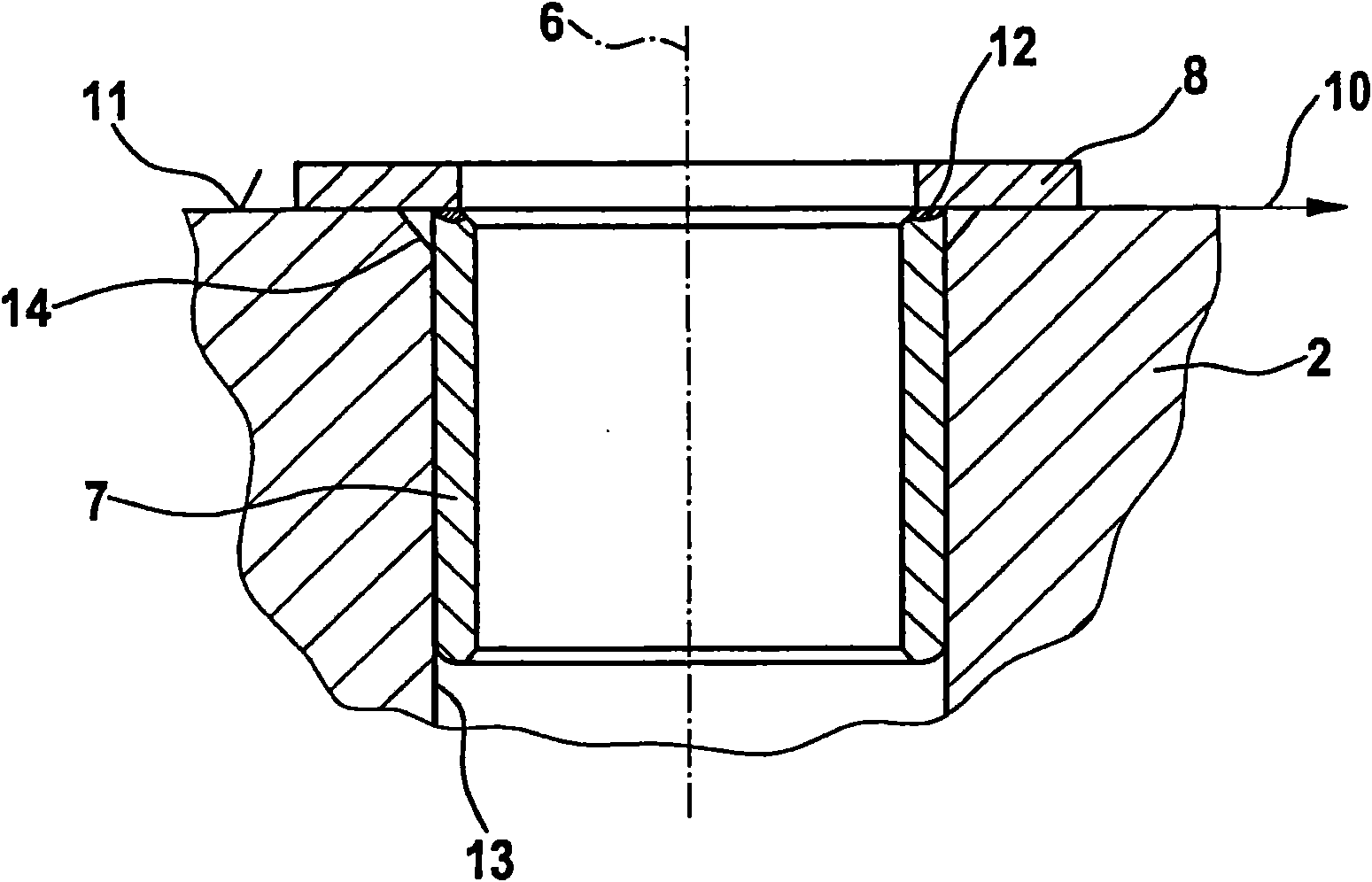

High-pressure pump for delivering fuel with an improved design of the bearing arrangement for the support of the cam shaft

InactiveCN101646860ANo breakageAvoid breakingFuel injecting pumpsPositive-displacement liquid enginesCommon railEngineering

The present invention relates to a high-pressure pump (1), particularly for delivering fuel for a common rail fuel injection system, comprising a pump body (2), in which at least one cam drive (3) having a cam shaft (4) is received, wherein said cam shaft is pivotally supported about a cam shaft axis (6) in the pump body (2) and / or in a flange body (5) by means of at least one bearing arrangement,and wherein the bearing arrangement comprises a radial bearing bush (7) extending in the direction of the cam shaft axis (6), and an axial bearing disk (8), which is integrally formed on the radial bearing bush (7) on an end, and / or is connected to the same, wherein the axial bearing disk (8) extends in a radial extension direction (9) of <90 DEG relative to the cam shaft axis (6) in the non-installed state, wherein the radial extension direction (9) is directed toward the radial bearing bush (7) and can be brought into an axial bearing plane (10) extending at an angle of 90 to the cam shaft axis (6) in the installed state by means of elastic deformation of the axial bearing disk (8).

Owner:ROBERT BOSCH GMBH

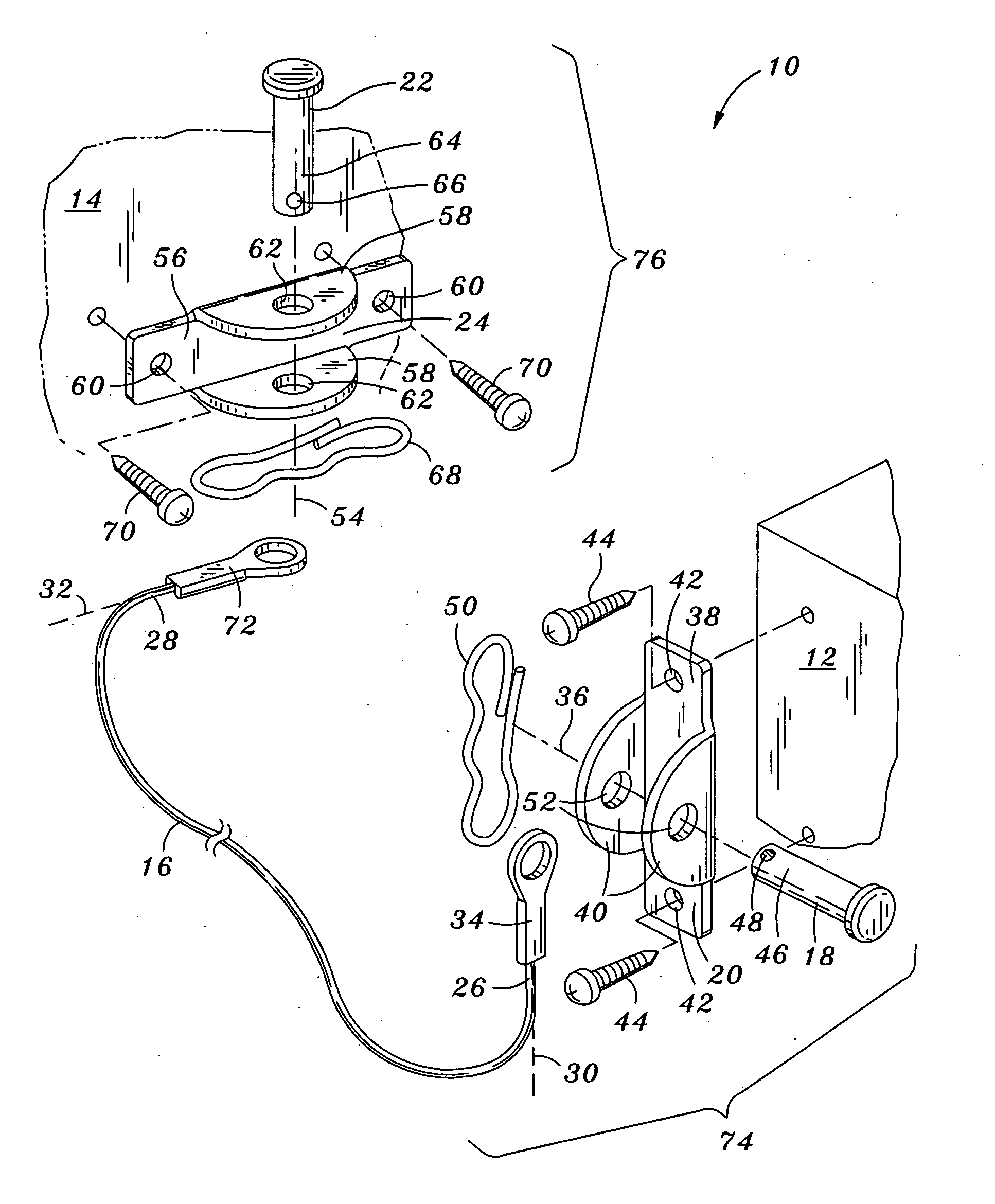

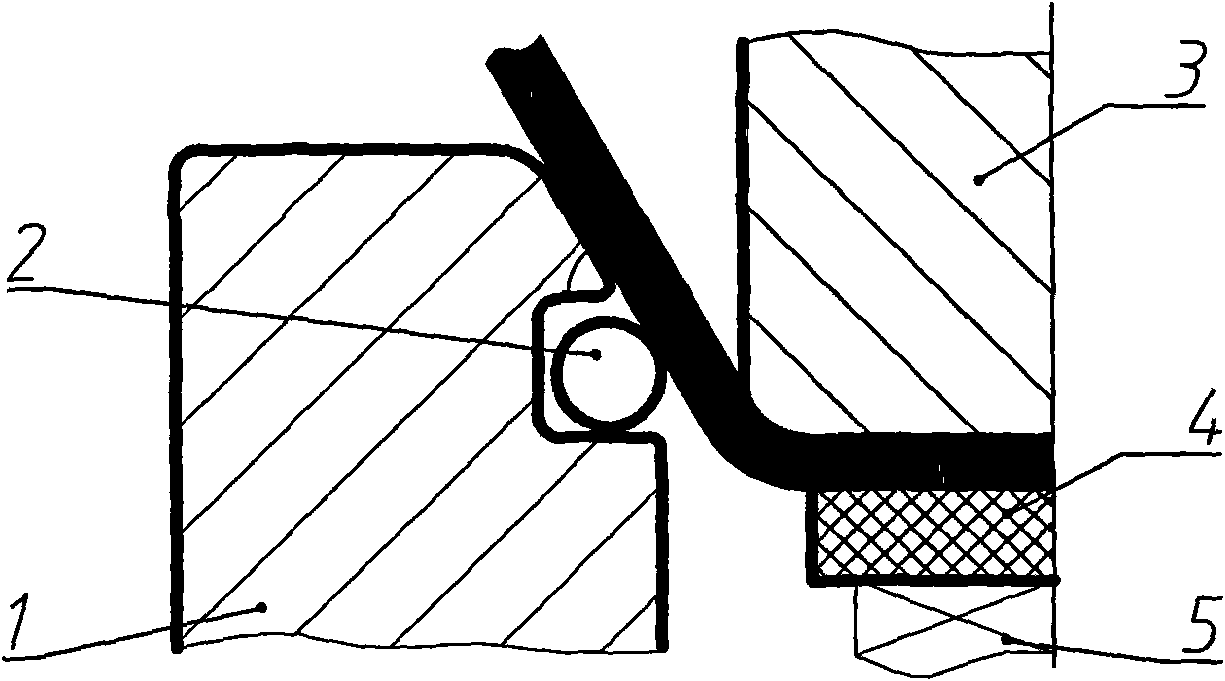

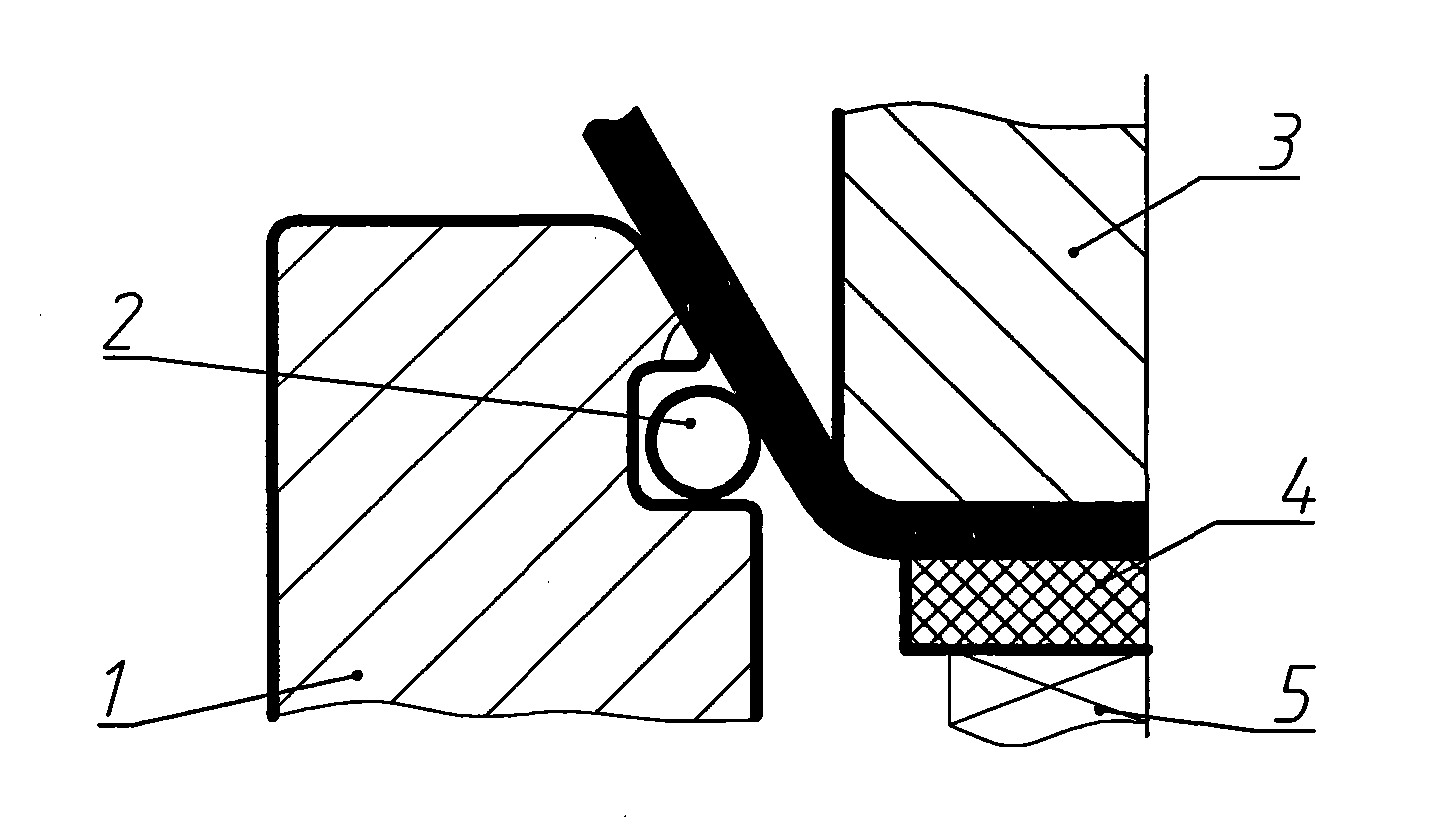

Sclerotomy adapter

A thin walled, hubbed cannula with an exterior diameter of approximately that of a 20 gauge surgical instrument and in interior bore having a diameter that is slightly larger than a 23 gauge or 25 gauge surgical instrument. The scleral contact surface of the hub of the adapter also can be rounded to provide a pivot point for the surgical instrument shaft, thereby reducing bending forces on the relatively thin shaft of the instrument.

Owner:ALCON INC

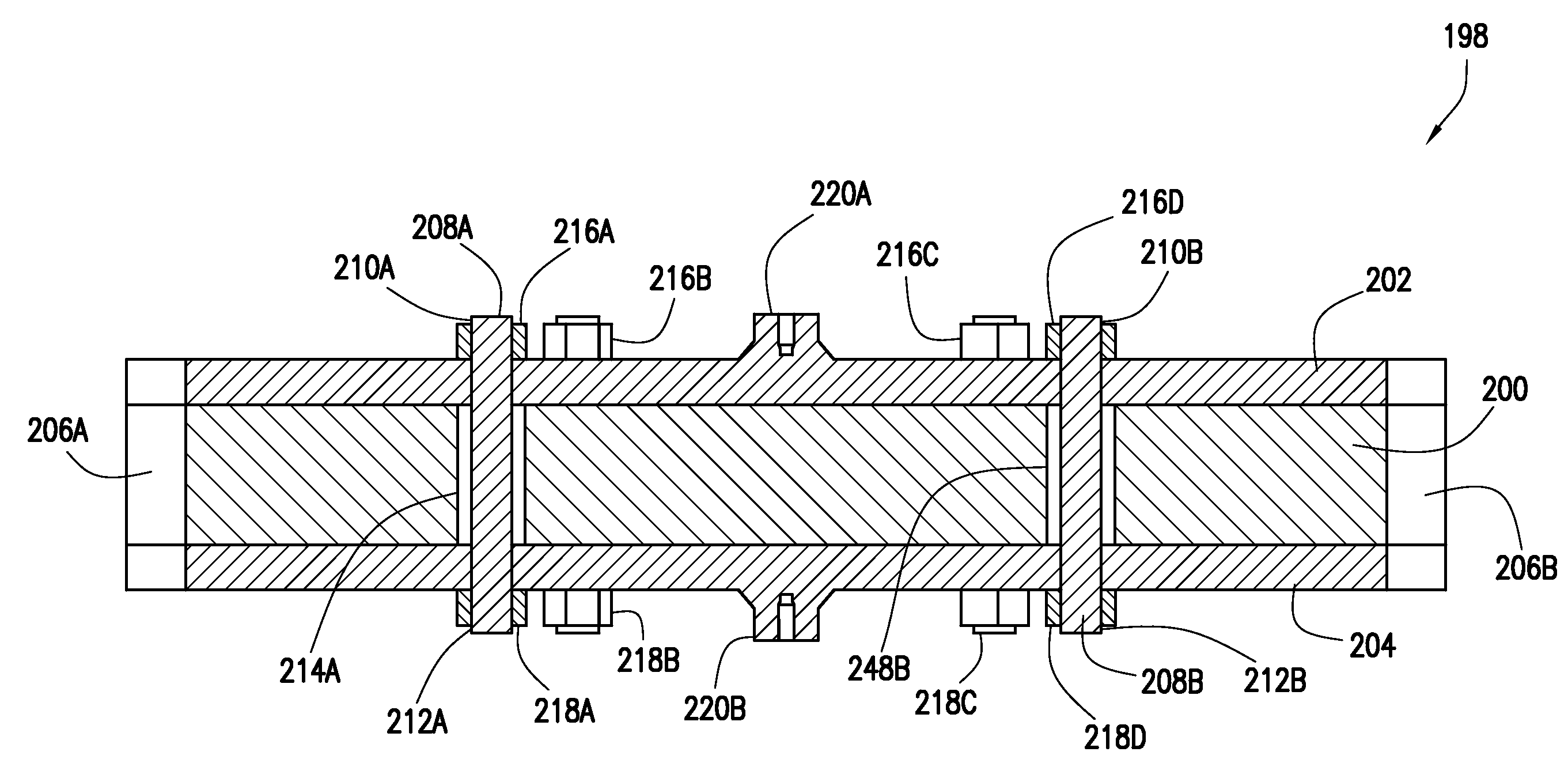

Systems and methods for securing a rotor apparatus

InactiveUS20140165777A1Good orientationReduce exposureMechanical apparatusManufacturing stator/rotor bodiesEngineeringBending force

Rotors apparatus usable in energy storage devices and power systems include a plurality of laminations having a center and at least one orifice spaced a distance from the center, and at least one fastener extending through the orifice. The one or more fasteners, the one or more orifices, or combinations thereof are sized to reduce contact between the fasteners and the laminations during rotation of the rotor apparatus. The fasteners and orifices can define an envelope, corresponding to the maximum space able to be occupied by a fastener to reduce contact between the fastener and the laminations, and one or more fasteners can have a volume of material less than the volume of the envelope to reduce bending forces on the fastener.

Owner:PILLER USA INC

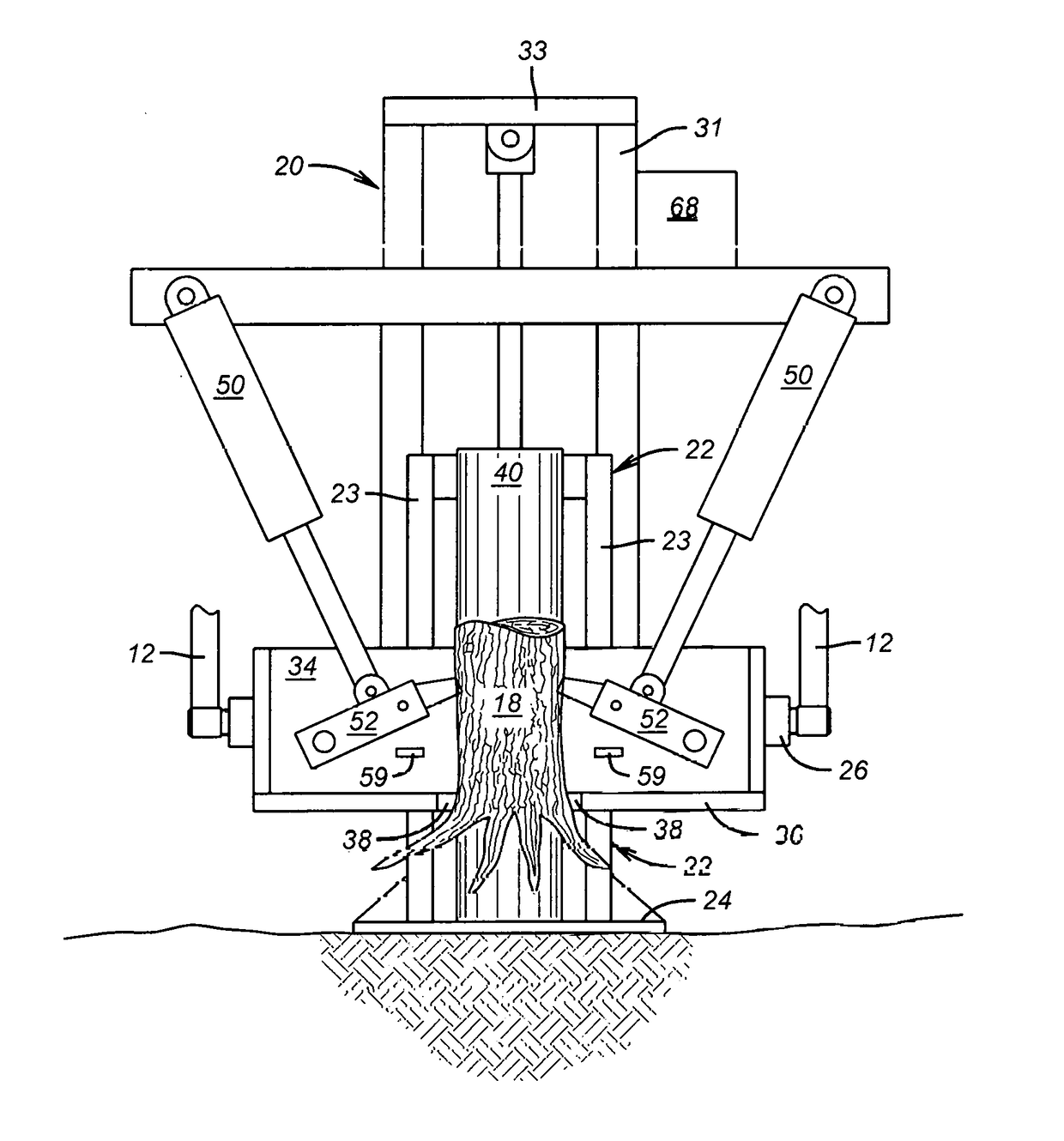

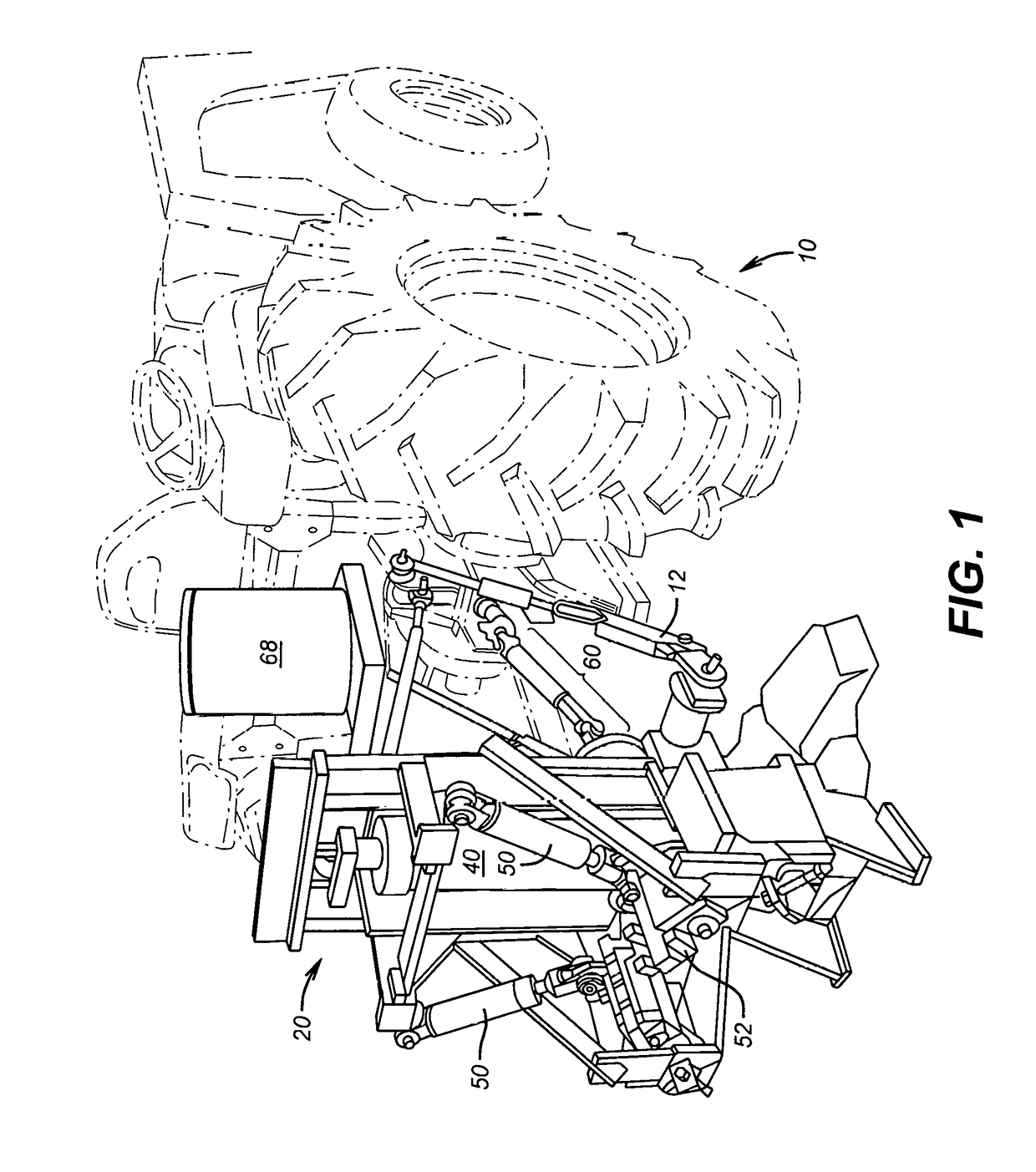

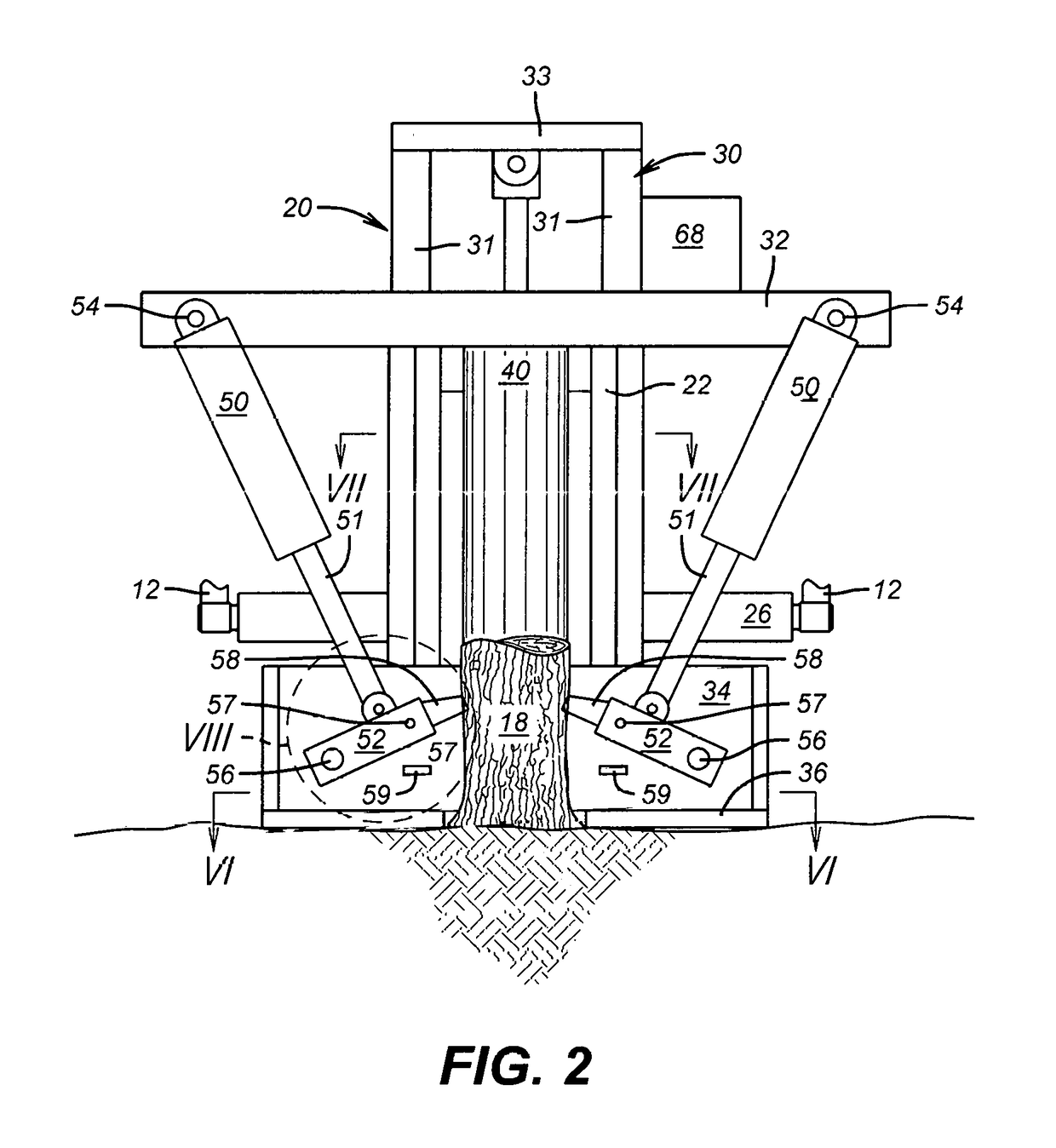

Tree, stump and post puller

ActiveUS20180049377A1Constant pressure maintenancePrevent slight movementForestryEngineeringLinear motor

An apparatus for extracting trees, stumps, posts and similar structures from the ground is attached to a 3-point hitch tractor accessory. The apparatus comprises a base frame and a lifting frame. The base frame includes a pair of vertical guides for confining a corresponding pair of vertical rails on the lift frame. A piston / cylinder type of linear motor is connected between the base frame and lifting frame to translate the lifting frame relative to the base frame. A pair of independently controlled gripping cylinders that are connected to respective gripping cams are mounted on the lifting frame. A tree is extracted by engaging the gripping cams against the tree and translating the lifting frame.

Owner:MAXWELL CHRISTIAN LANE

Multiple drive-path transmission with torque-splitting differential mechanism

ActiveUS8141812B2Reduce weight and sizeReduce bending forceToothed gearingsRotocraftGear wheelEngineering

Owner:TEXTRON INNOVATIONS

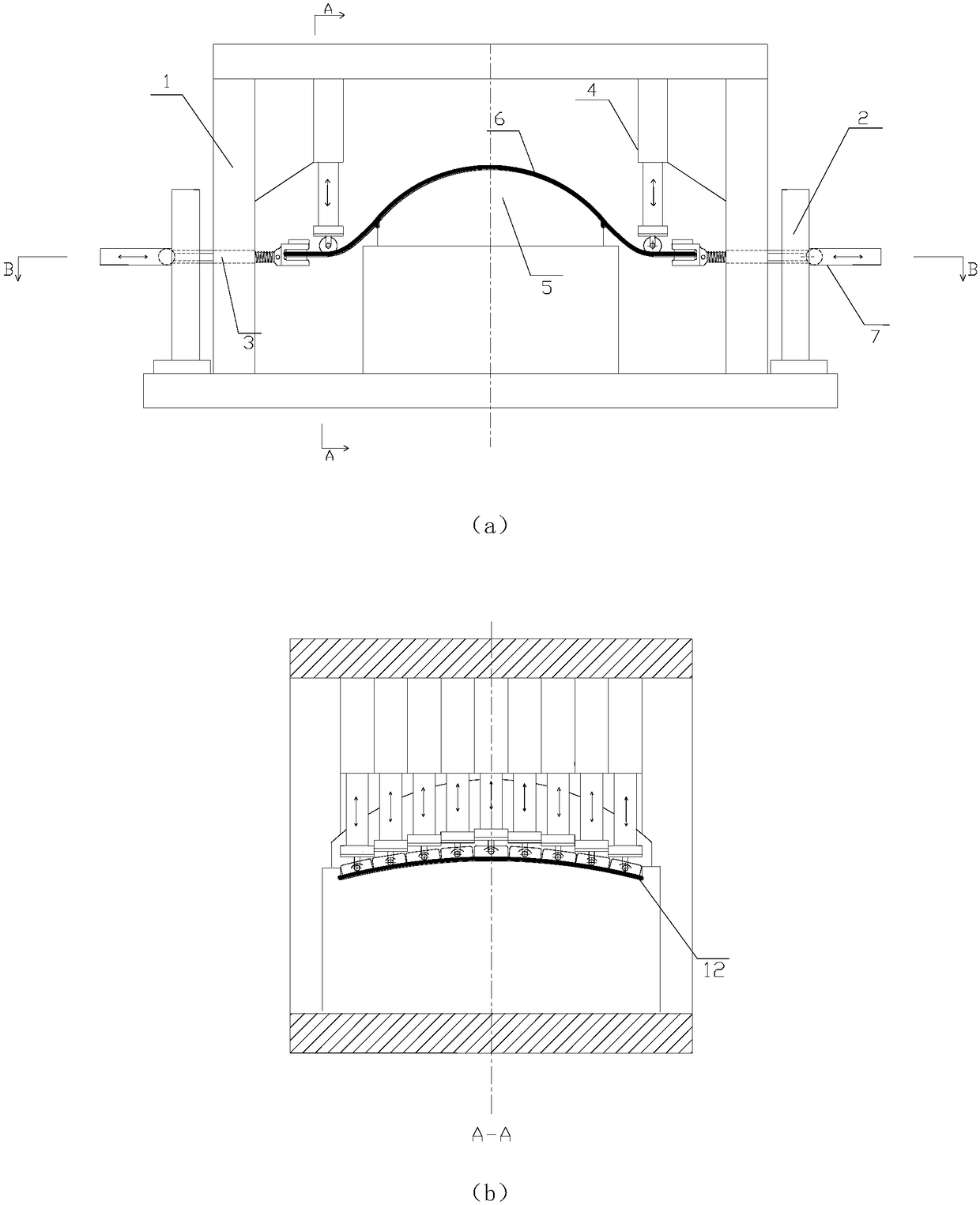

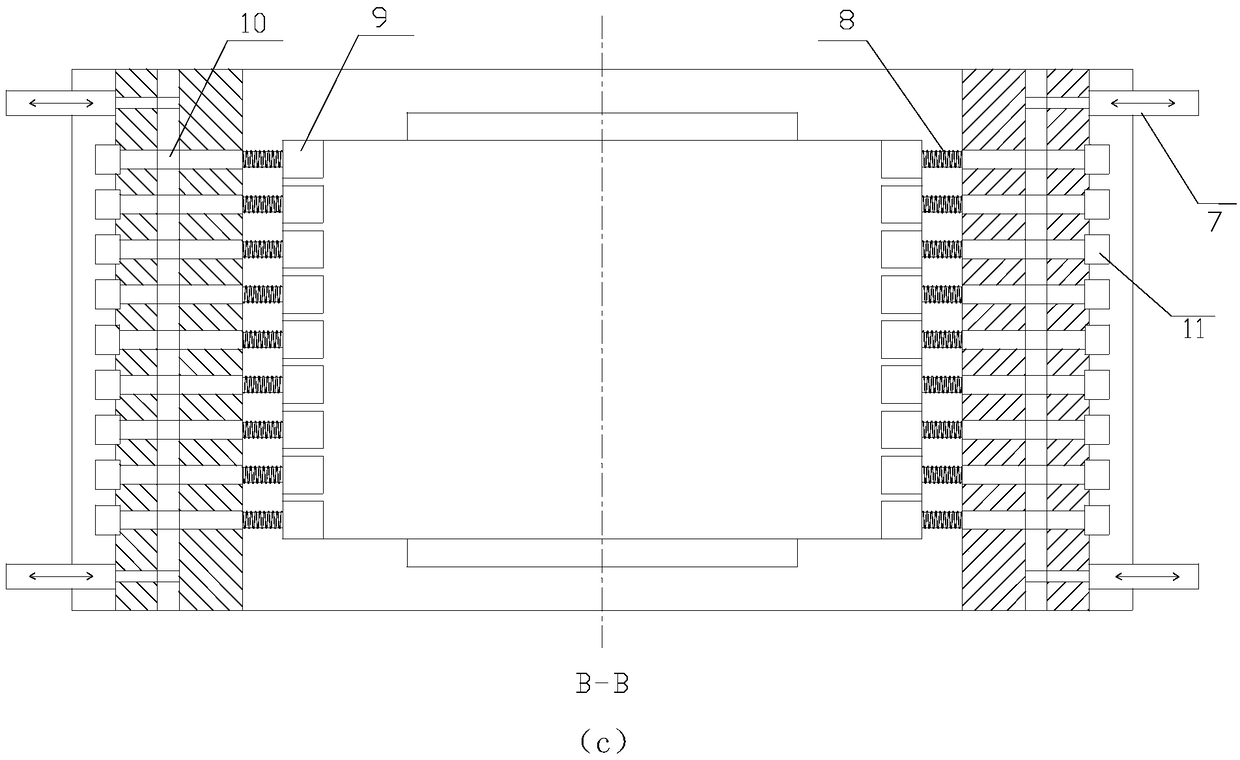

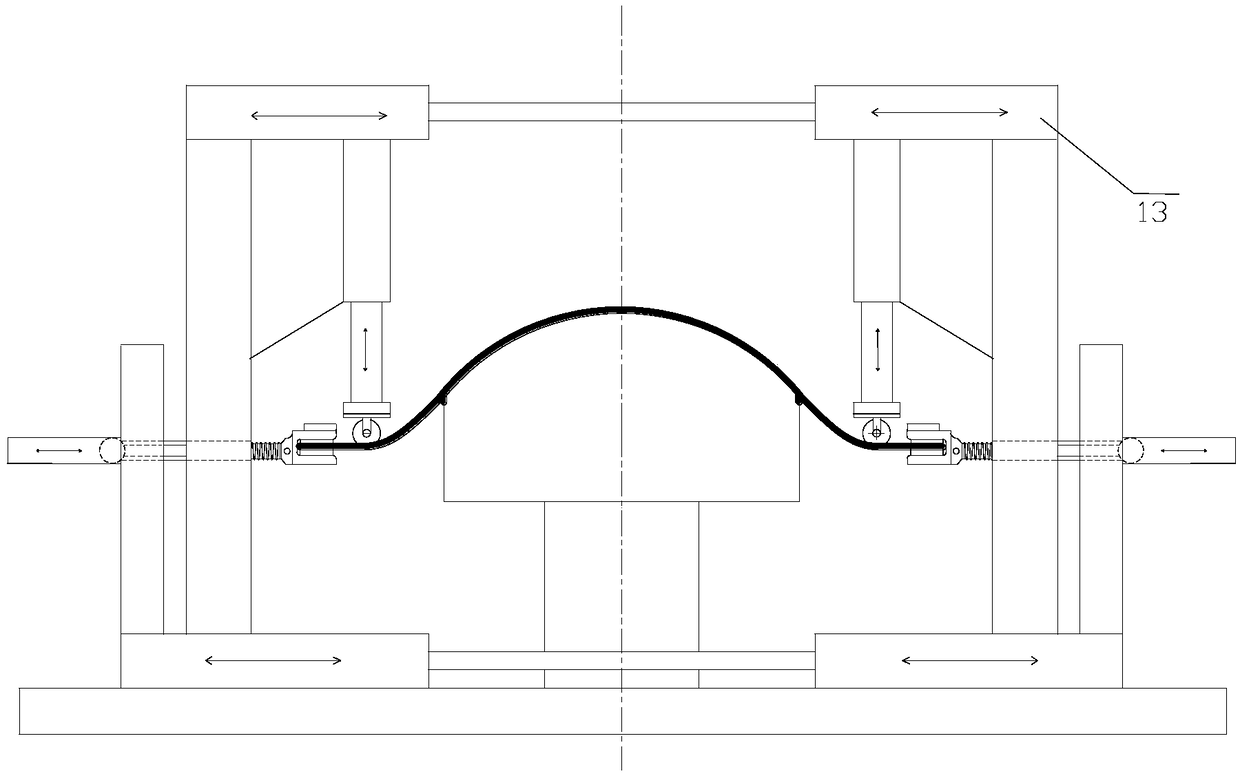

Stretching and pressing combined type plate stretch forming machine

ActiveCN108746332ASimplification of hydraulic control system and electrical control systemEasy to operate and maintainAircraft componentsMetal-working feeding devicesElectrical controlBending force

The invention discloses a stretching and pressing combined type plate stretch forming machine which is plastic working equipment for stretch forming of a plate type three-dimensional curved surface piece, and belongs to the field of mechanical engineering. A first object of the invention is to simplify hydraulic pressure of equipment and an electrical control system to lower the manufacturing cost; and a second object is to eliminate bending force on a plate when a vertical oil cylinder on a previous clamping device is loaded, so that pulling stress and strain of the stretch forming piece aredistributed more uniformly, and the shape stability and material utilization of the formed piece are improved. The stretch forming machine mainly consists of a rack, guide devices, downward pressing devices, clamping devices and horizontal prestretching devices (as shown in figures); the rack and the guide devices support the downward pressing devices, the clamping devices and the horizontal prestretching devices on the two sides; each clamping device consists of a plurality of clamping mechanisms; the downward pressing devices consists of a plurality of downward pushing mechanisms; the clamping mechanisms are arranged on the two sides of a mould in a row correspondingly; the downward pushing mechanisms are arranged on the two sides of the mould in a row correspondingly; and the horizontalprestretching devices consist of four hydraulic oil cylinders and universal joints and are arranged on the guide devices on the two sides.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com