Hot rolled strip convexity on-line closed loop control method

A closed-loop control, hot-rolled sheet technology, applied in contour control and other directions, can solve the problem of low product crown control accuracy, and achieve the effect of improving crown control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

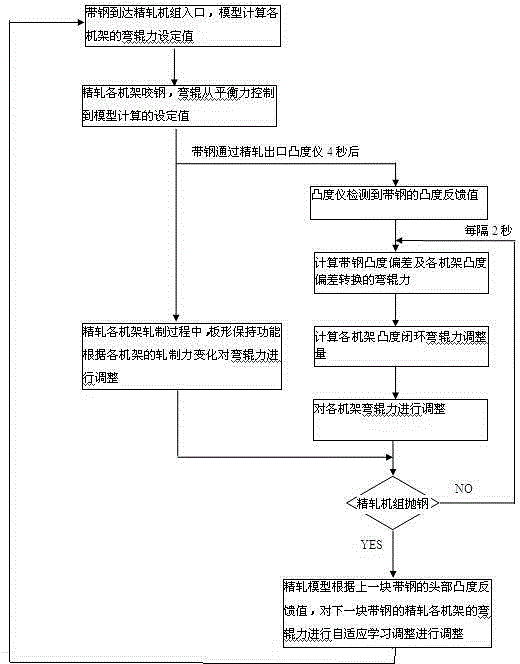

[0046] Embodiment 1: see figure 1 , an on-line closed-loop control method for hot-rolled strip crown, taking the production of strip steel with thickness Href=2.5mm and crown set value Pref=20um as an example:

[0047] 1. When the strip arrives at the entrance of the finish rolling unit, the finish rolling model calculates the set value of the roll bending force required for each stand of the finish rolling based on the temperature, thickness, width, material, and real-time roll shape of the strip steel. Bending roller setting value of F1~7 frame: 850kn, 670kn, 950kn, 540kn,, 640kn,, 720kn,, 814kn;

[0048] 2. After each frame of finish rolling bites the steel, the roll bending force of each frame is switched from the balance force to the set value of roll bending calculated by the finish rolling model;

[0049] The bending force of F1~7 frames is switched from the fixed balance force of 800kn to the bending set value, and the bending force feedback value of each frame is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com