Bending forming method of railway van coupler yoke forge piece

A railway freight car and bending forming technology is applied in the field of bending forming of forgings of yoke stern frame of railway freight cars, which can solve the problems of thinning of the bending root of forgings, poor quality of formed products, excessive height of frame arms, etc. Improve production efficiency and improve the effect of stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

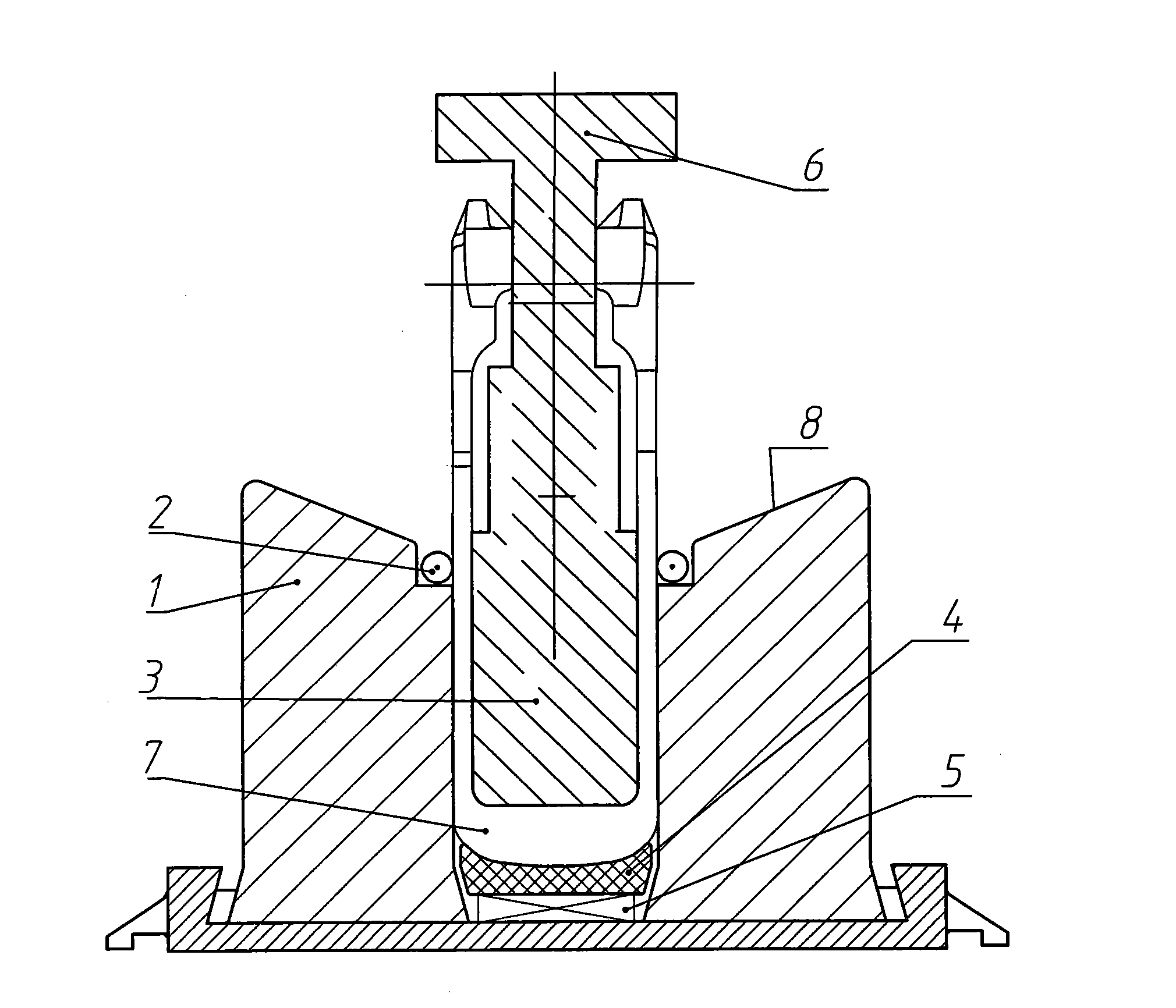

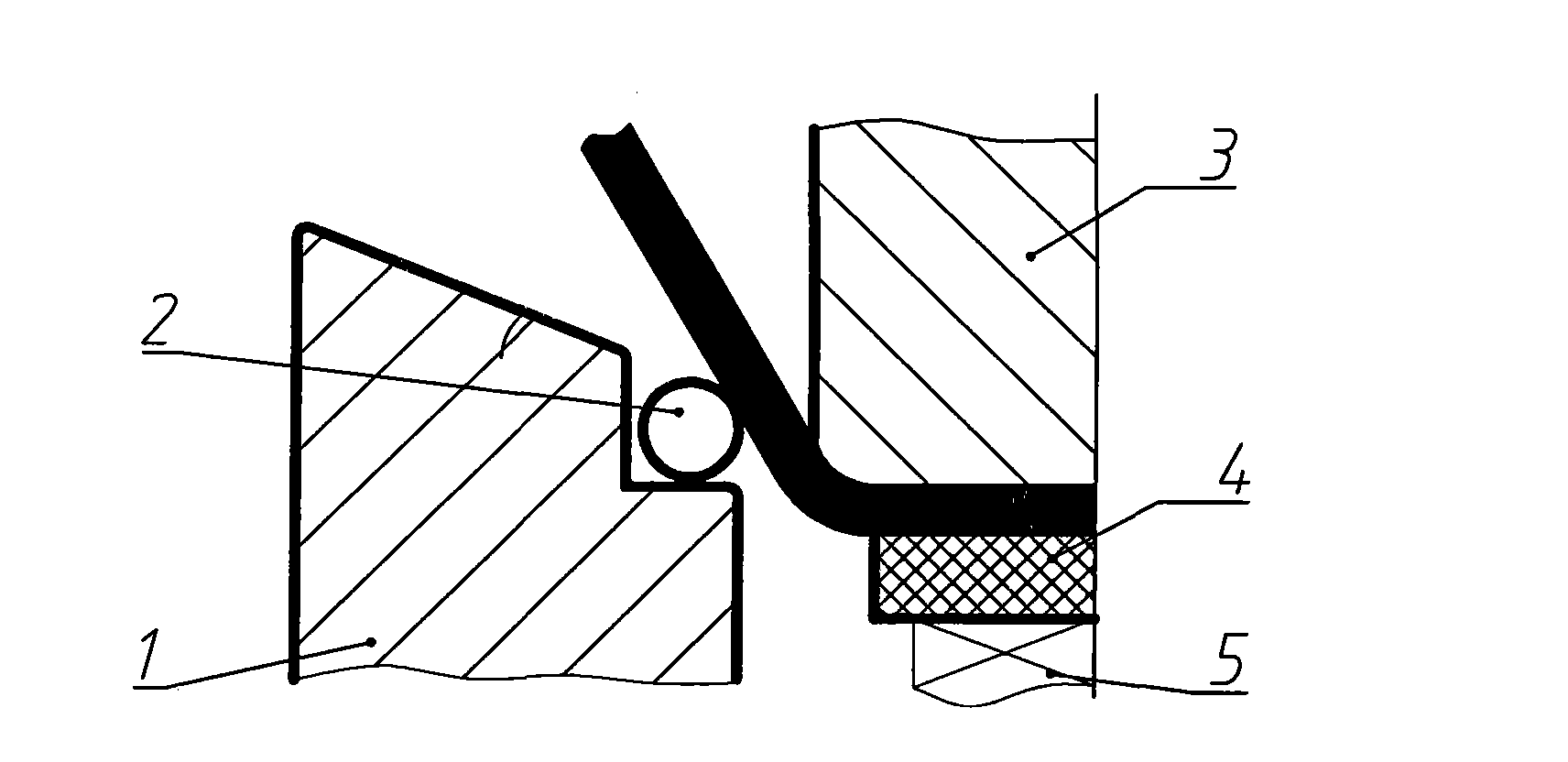

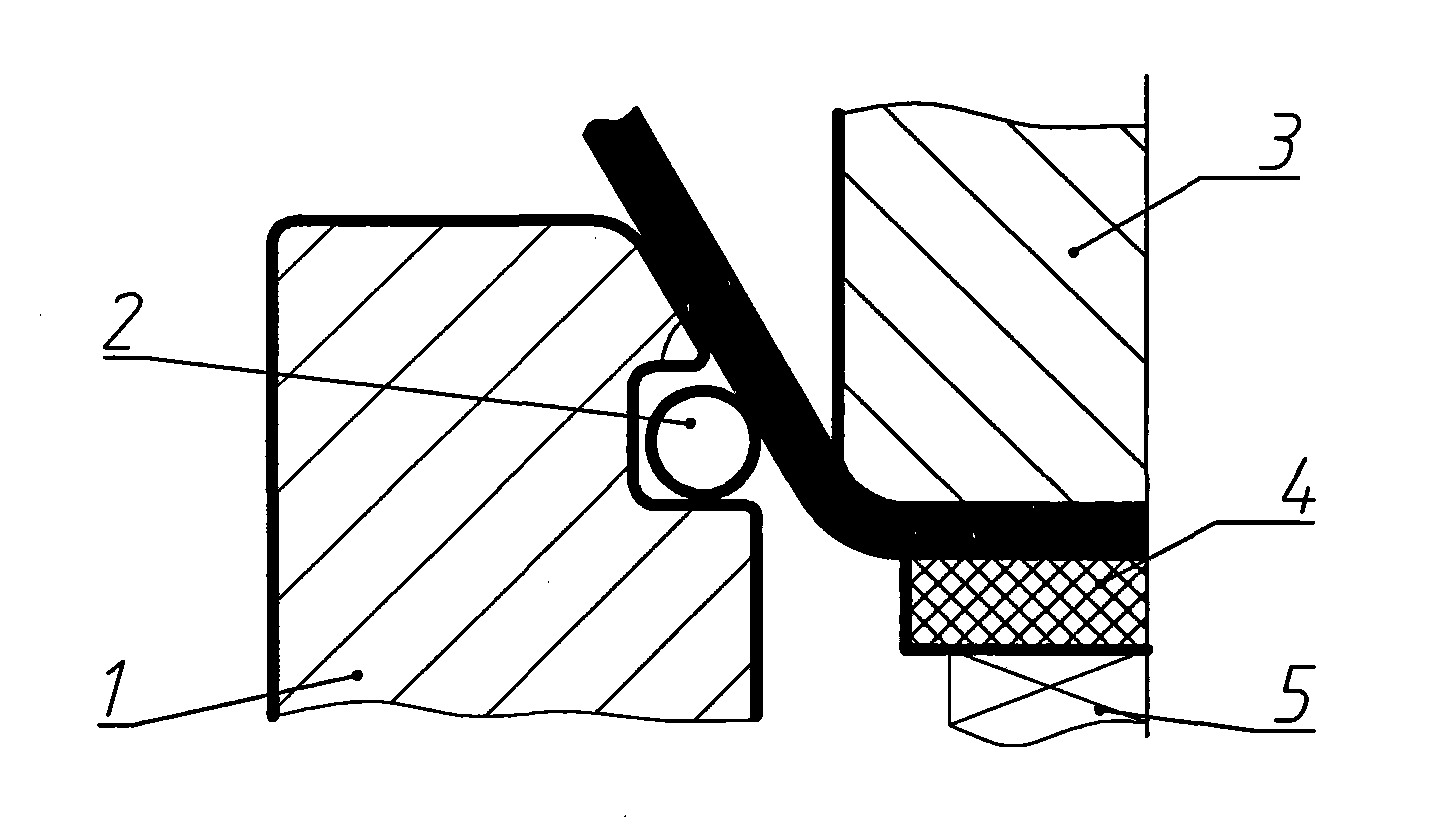

[0024] When this method is actually implemented, through such as figure 1 The shown structural device realizes the bending forming of the forging of the coupler frame of a railway freight car, and its structure is as follows: it includes an inclined-plane die 1, and a matching punch 6 and back pressure die 4 are realized, wherein the inclined-plane die 1 is shown on the upper surface There is a groove cavity 7, and the end faces on both sides of the groove cavity 7 are slopes 8 that are low on the inside and high on the outside. The lowest point of the slope 8 is provided with a roller 2. The lower surface of the punch 6 has a The boss 3 matching the cavity 7, the shape of the lower end surface of the boss 3 matches the shape of the inner surface of the middle part of the coupler frame forging, the back pressure die 4 is set inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com