Sectional bending mould for machining heavy forging

A technology for bending processing and large forgings, which is applied in the field of segmented bending processing molds for large forgings, can solve the problems of difficulty in achieving one-time precise bending, idle general forging equipment, and thinning of the bending roots of forgings, so as to reduce abnormal bending problems and restrain The effect of side wall displacement and reduction of bending force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

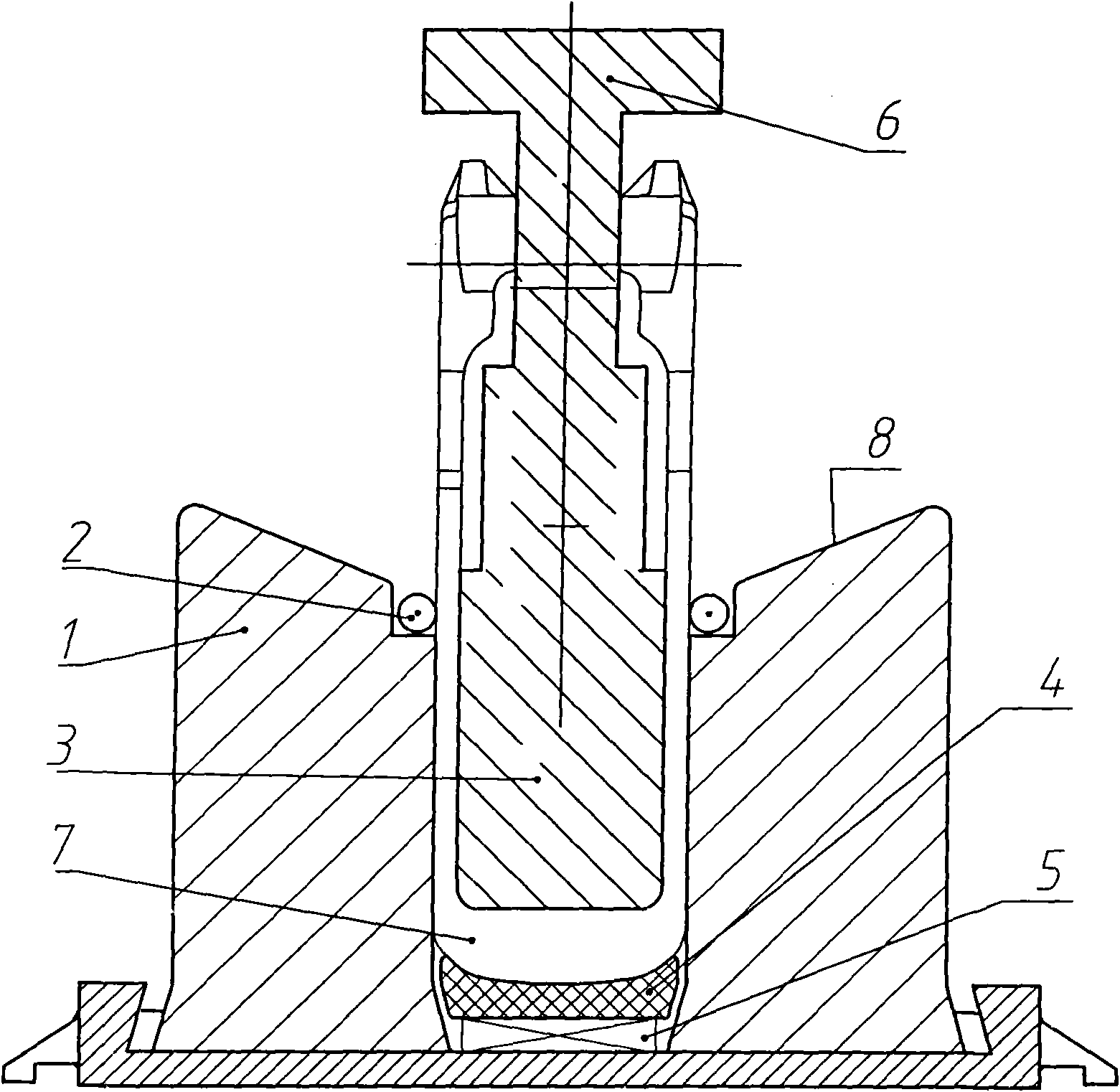

[0019] In order to illustrate the shape and structure of the present invention more clearly, the forging of the coupler frame of a railway freight car is used as an example forging below, and the present invention will be further described in detail in conjunction with the accompanying drawings.

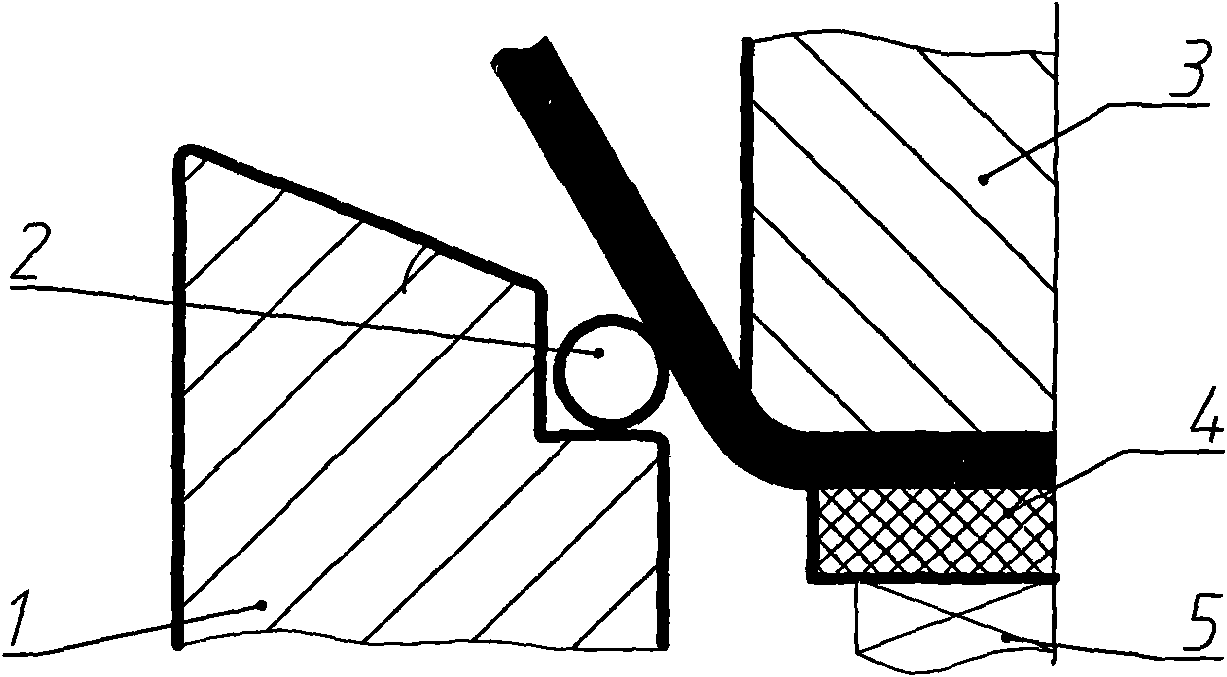

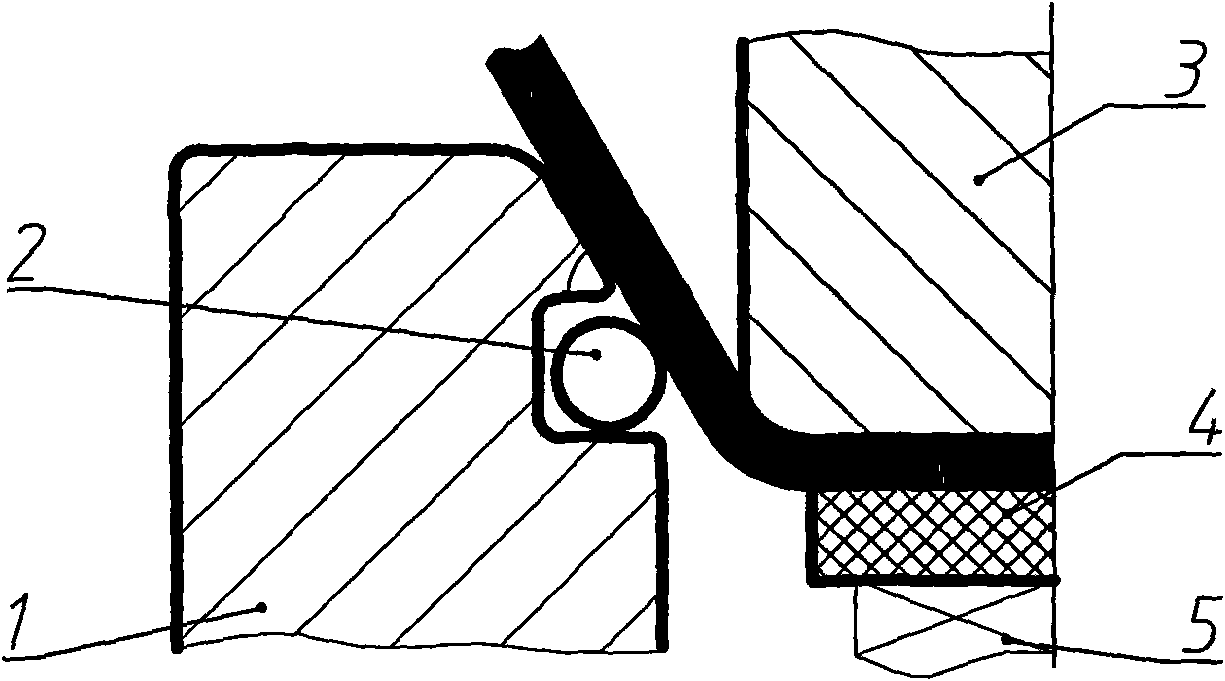

[0020] Such as figure 1 , figure 2 As shown, a segmented bending die for large forgings includes a beveled die 1, a matching punch 6 and a back pressure die 4, wherein the upper surface of the beveled die 1 has a groove cavity 7. The end surfaces on both sides of the groove cavity 7 are slopes 8 that are low inside and high outside. The highest point of the slope 8 is the fulcrum of the first bending process, and the lowest point of the slope 8 is the fulcrum of the second bending process. A roller 2 is arranged at the point, and the lower surface of the punch 6 has a boss 3 that matches the groove cavity 7, and the shape of the lower end surface of the boss 3 matches the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com