Saline-alkali soil conditioner rich in salt-tolerant microorganisms and preparation method and device thereof

A technology of soil improver and microorganism, which is applied to the method of granulating raw materials, fertilization equipment, transportation and packaging, etc., which can solve the problem that the material is easy to adhere to the inner wall of the drum, and it is not suitable for the bacteria improver and the activity of live bacteria. To achieve the effect of improving soil compaction, improving molding speed and molding quality, and improving absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Prepare the saline-alkali soil conditioner rich in salt-tolerant microorganisms according to the following steps:

[0045] (1) Weigh the following raw materials by weight: 1 part of salt-tolerant bacteria, 1 part of sulfur-containing substances, 13 parts of potassium humate, 15 parts of decomposed livestock and poultry manure, and 20 parts of decomposed straw;

[0046] (2) fermenting the salt-tolerant bacteria to obtain a salt-tolerant bacteria fermentation broth;

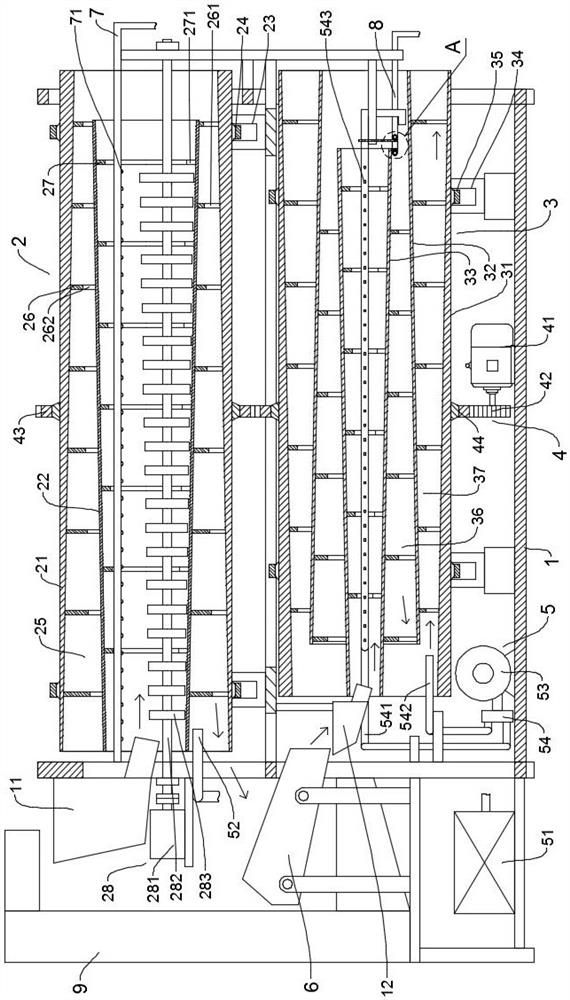

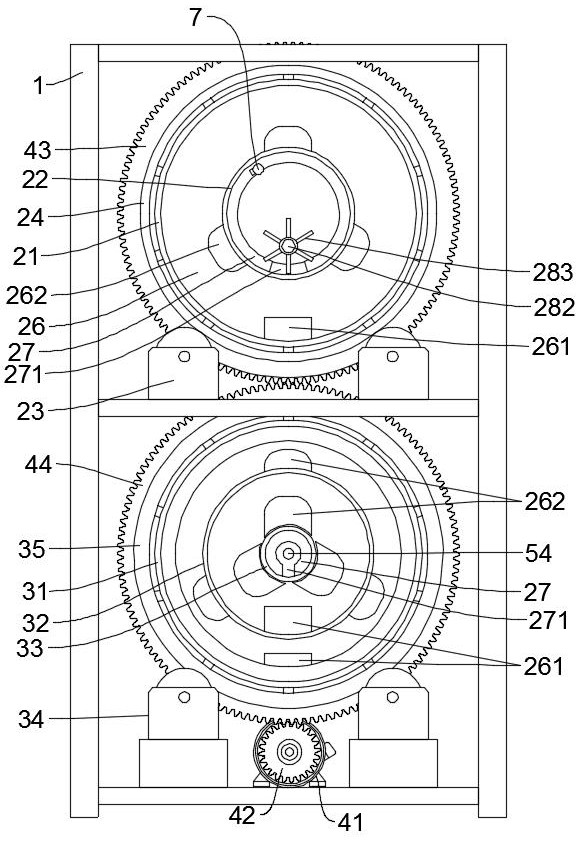

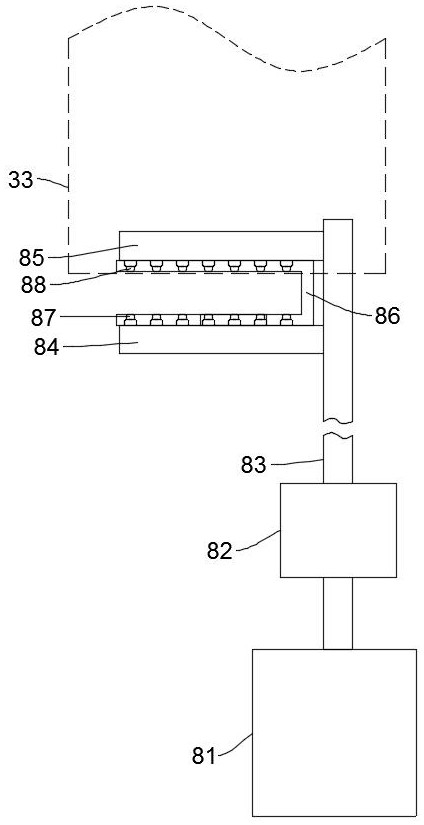

[0047] (3) After crushing and mixing the sulfur-containing substances, potassium humate, decomposed livestock and poultry manure, and decomposed straw, add it into the upper hopper 11, and introduce it into the front end of the upper inner cone 22 from the upper hopper 11, and the mixture is in the upper inner cone 22. The particles are rolled and extruded into particles, which are discharged from the rear end of the upper inner cone 22 and fall into the upper outer cylinder 21. After being dried by high tem...

Embodiment 2

[0053] This embodiment is roughly the same as Embodiment 1, except that:

[0054] The saline-alkali soil conditioner rich in salt-tolerant microorganisms includes the following raw materials in parts by weight: 2 parts of salt-tolerant bacteria, 2 parts of sulfur-containing substances, 13 parts of potassium humate, 15 parts of decomposed livestock and poultry manure, and 18 parts of decomposed straw.

Embodiment 3

[0056] This embodiment is roughly the same as Embodiment 1, except that:

[0057] The saline-alkali soil conditioner rich in salt-tolerant microorganisms includes the following raw materials in parts by weight: 3 parts of salt-tolerant bacteria, 3 parts of sulfur-containing substances, 13 parts of potassium humate, 13 parts of decomposed livestock and poultry manure, and 18 parts of decomposed straw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com