Multi-core warp resistance medium voltage rubber jacketed flexible cable for wind power generation

A twist-resistant, flexible cable technology, used in bendable cables, power cables with shielding/conductive layers, insulated cables, etc., can solve the problems of low radial force of twist-resistant cables and increase the torsion-resistant performance. , Improve the effect of the overall force and force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

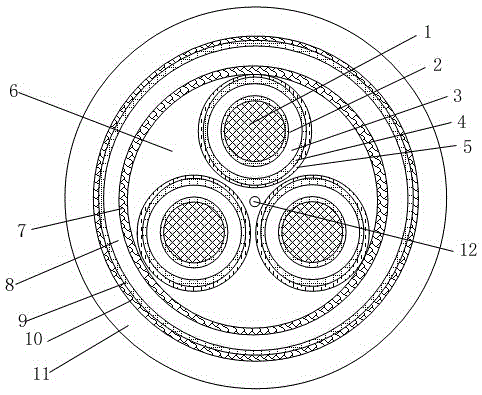

[0016] Such as figure 1 A twist-resistant rubber-sheathed flexible cable for multi-core medium-voltage wind power generation is shown, including a cable core and a star bar 6 located in the cable core. The cable core is twisted in parallel by three insulated cores. The twisting direction of the cable core is the same as that of the conductor; the first butyl glue layer 7 is coated on the outside of the cable core, and the first butyl glue layer 7 is extruded Inner sheath 8, then weaving reinforcing core aramid yarn 9 outside the inner sheath 8, coating the second butyl glue layer 10 outside the reinforcing core aramid yarn 9, and finally extruding outer sheath 11 on the outermost layer of the cable The cable is also provided with a reinforced aramid rope 12 at the center of the cable core; wherein, the insulated wire core is composed of a central conductor 1 and a conductor shielding layer 2 extruded outside the conductor 1 in a three-layer co-extruded manner. , an ethylene-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com